• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

AMENDMENTS AND ALTERATIONS TO THIS PUBLICATION ARE NOT SUBJECT TO NOTIFICATION. CATERPILLAR RESERVES ALL RIGHTS TO THIS PUBLICATION. ITS CONTENT IS PROTECTED BY COPYRIGHT LAWS. NO PART OF THIS PUBLICATION MAY BE REPRODUCED OR TRANSFERRED IN ANY WAY OR FORM WITHOUT THE PRIOR WRITTEN APPROVAL OF CATERPILLAR. CATERPILLAR DECLINES ANY LIABILITY FOR DIRECT OR INDIRECT CONSEQUENCES OF PRINTING ERRORS. WE RESERVE THE RIGHT TO INTRDUCE MODIFICATIONS AS A RESULT OF TECHNICAL DEVELOPMENTS WITHOUT PREVIOUS NOTICE.

CAT, CATERPILLAR, THEIR RESPECTIVE LOGOS, ”CATERPILLAR YELLOW“ AND THE “POWER EDGE” TRADEDRESS, AS WELL AS CORPORATE AND PRODUCT IDENTITY USED HEREIN, ARE TRADEMARKS OF CATERPILLAR AND MAY NOT BE USED WITHOUT PERMISSION.

© 2021 CATERPILLAR ALL RIGHTS RESERVED

© 2021 CATERPILLAR ALL RIGHTS RESERVED

1

About this manual

This chapter contains important information that makes it easier for you to use this manual. You will also get information about the structure of the manual and the symbols, characters and abbreviations used and frequently used terms.

application This operating manual belongs to the control of a support with system components of the PMC® system.

PMC® PMC® is a system of devices and associated hardware intended for safe control of machines under extreme conditions. The designation PMC® is legally protected and is the property of Caterpillar Global Mining Europe GmbH, Lünen. For the purpose of improved legibility, the registered trademark symbol ® will henceforth not be used in this operating manual.

applicable operating manual If you use an operating manual that is not intended for your hardware or software, you are endangering yourself, other people and items of equipment. A list of parameters belongs to this operating manual.

category according to ATEX directive The system components of the PMC system meet the European directive 2014/34/EU, device group I, category M2, in compliance with EN 50014-1997 + Revisions 1 and 2 Intrinsic safety "i" EN 50020-2002.

new operating manual Request a new operating manual immediately if the current operating manual is no longer complete or has become illegible.

target group The operating manual is intended for those persons who set up the PMC system, work with it, make settings and perform troubleshooting.

All persons working on the face, at the edge of the face or in the entry must read this operating manual. This includes persons who: are in charge of transport, perform installation/removal work, correct malfunctions, perform daily routine work on the face, carry out maintenance work, carry out repair work.

Supervisory personnel who: initiate the activities mentioned above and/or supervise them.

efficiency This operating manual is intended to help you work efficiently and safely with our product. It contains important information on all activities relating to the product.

Take the time to read this operating manual in its entirety. Pay particular attention to the respective safety instructions. Familiarize yourself well with the appearance and meaning of the safety and information symbols.

The operating manual is to be stored within reach of the PMC system and to be kept readily accessible for operating and maintenance personnel. It must be passed along to all owners or users of the PMC system. Every supplement received must be inserted into the operating manual.

safety Carefully read through the chapter "Safety". This chapter contains important information indicating possible hazards.

Observe the information given and follow the instructions.

liability exclusion Caterpillar Global Mining Europe GmbH assumes no liability for damage or operating malfunctions resulting from non-compliance with this operating manual. The warranty provided by Caterpillar Global Mining Europe GmbH becomes void in the event of non-compliance with this operating manual.

service partner Please contact your service partner for spare part requests or for the clarification of technical questions.

1.1 Signs and symbols

DANGER

The combination of the signal word DANGER and a corresponding symbol warns you of an immediate danger with a high personal risk!

If not observed, you or your coworkers will be seriously injured or killed. Follow the described instructions!

WARNING

The combination of the signal word WARNING and a corresponding symbol warns you of a potential danger with a moderate personal risk!

If not observed, you or your co-workers might be seriously injured or killed. Follow the described instructions!

CAUTION

The combination of the signal word CAUTION and a corresponding symbol indicates a potential personal risk!

If not observed, you or your co-workers could suffer minor to moderate injuries. Follow the described instructions!

NOTICE

The combination of the signal word NOTICE and the adjacent symbol indicates a potential risk of damage to the machine!

If not observed, material damage might occur on the machine. Follow the described instructions!

Tip

The signal word TIP indicates useful tips and information! This information will help you become more familiar with the machine and allow you to prepare your work more exactly. Observe the provided tips and information!

Important information

The combination of the signal words IMPORTANT INFORMATION and the adjacent symbol indicates important information or other operating manuals which must be observed at this place. Observe the information and read the specified operating manuals.

1.2 Terms and representations

lists Lists are marked by triangular, yellow eye-catching symbols at the beginning of the line. Sublists are marked with gray eye-catching symbols.

Example:

Columns with error messages follow for each value: Sensor not configured!

Short circuit!

instructions Instructions begin with the prerequisites. The prerequisites must be met prior to proceeding with the instruction. Prerequisites are identified by a checkmark. The individual instruction steps then follow as a numbered list. Intermediate results (if specified) are marked within the individual steps as non-numbered lists with an arrow. The end of an instruction is followed by the result of the action. Results are indicated by checkmarks on a gray circle. Follow the instructions step by step. Proceed with the instructions steps only if the required prerequisites are met.

Structure:

Prerequisite that must be met prior to the instruction

1. First step

2. Second step

ð Intermediate result

3. Last step Result after completing instructions

Example: A PC is to be switched off. No external application has access to the PC.

1. Save all files you worked on last.

2. Close all running programs.

ð All programs (applications) are closed.

3. Shut down the PC.

The PC is off.

links [ 3]

At various locations you will find a reference to another section of text, a table or a figure. In a printed document, you can turn to the indicated page. In a PDF document, the cursor appears in the form of a hand on the reference ( ). The reference text always has square brackets with a gray arrow head ( ) and a page number. Left-clicking on the reference link takes you to the indicated page in the document. To facilitate returning easily to the starting point from this location, you should place the appropriate buttons permanently in the toolbar of the software you use to read PDF documents. In Acrobat Reader, you can make the following settings: "View" - "Show/Hide" - "Toolbar Items" - "Page Navigation" - "Show All Page Navigation Tools".

The key combination [Alt + ←] also returns you to the starting point. The following example is not a genuine reference, but shows its appearance. ... see "Table of Contents" [ 3].

LEFT/RIGHT

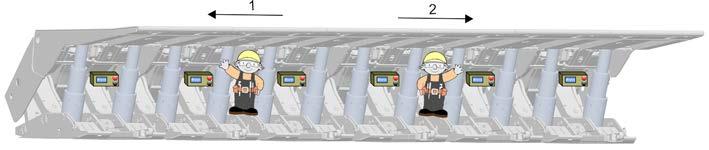

In this operating manual, if the directions LEFT and RIGHT are written in capital letters then the miner's understanding of direction is meant. For example, the left shield is always the shield which is to the left when looking at the coal face, in whatever direction you are currently looking.

parameters

You can affect control by means of parameters. When you have the appropriate authorizations, you can set and change the content of parameters. Typical parameters include min/max values (e.g. pressures). When they are reached, the control initiates an action (e.g. message or shutdown). Using parameters, you can also determine whether a default state exists (e.g. automatic mode active or inactive).

2 Safety

This chapter provides you with important information about your safety. Pay special attention to this chapter. The safety instructions and rules of conduct are intended to help you avoid hazardous situations and perform the necessary work as safely as possible.

2.1 General safety instructions

state of the art technology

The system components are state of the art and have been manufactured in accordance with approved safety regulations.

You and others can nevertheless be exposed to dangerous situations, e.g. as a result of environmental influences, machine damage or operator errors. Do not make any modifications or changes. The devices may only be opened and worked on by the manufacturer or persons specially trained by the manufacturer.

use within the EU The European directives/standards which appear in this operating manual must be applied if the devices and system components are used within the European Union.

use outside the EU If the device is used outside the EU, the directives and standards which apply in the respective countries must be observed.

accident prevention regulations

In addition to this operating manual, make sure you also observe the legal provisions and regulations for accident prevention in your country.

Observe the safety and accident prevention regulations of the: Mining company

Mines inspectorate

Employers' liability insurance association for mining.

additional operating manuals Also read the operating manuals of the components required to operate the face, such as electric motors as well as any other neighboring machines which may be affected by the control device. Clarify any questions before starting work.

personal protective equipment

Always wear your personal protective equipment. This also includes ear protectors as the noise emitted by the system may at times exceed 85 dB(A), (e.g. when the conveyor is being emptied).

orderliness and cleanliness Keep the machine as clean as possible. Ensure that the operating symbols and other information signs are recognizable. Säubern Clean the control elements at regular intervals.

Maintain the signal and lighting systems in working condition.

Pay special attention to the system's acoustic and optical start-up warnings. Only start the machine if it is in perfect technical condition and all safety equipment, e.g. EMERGENCY STOP devices, cover plates etc., is installed. Never reach into or enter areas between machine components which can move.

2.2 Operating conditions

2.2.1 Intended use

The PMC system was developed and manufactured for controlling underground systems. This PMC system is configured for the control of support frames. Use the PMC system components only as intended.

2.2.2 Unauthorized use Use

that is not described in this document, that is not expressly listed as intended, constitutes unauthorized use and must not be performed with the PMC system. Caterpillar Global Mining Europe GmbH cannot be held liable for damage caused by unauthorized use.

2.2.3 Ambient conditions

Suitable measures must be taken by the operator to mitigate explosion hazards due to firedamp and the ignition of dust which might occur in a mine. That includes:

adequate and consistent ventilation water spraying system

If the firedamp concentration in the free cross-section of the parts of the face which are continuously ventilated reaches a percentage of the lower explosion limit (LEL) defined by applicable national legislation, the M2 device must be switched off. The limit values can be found in your national laws.

DANGER Explosion hazard

The power to the supply cable and control system cable must be switched off if the local gas concentration in the mining equipment areas exceeds the permissible parameters given in the safety regulations for coal mines.

It may only be restarted by an authorized person.

The atmosphere in the mine should be monitored at hazardous points to allow the power supply of all devices to be switched off, except those which are relevant for safety and suitable for use in explosive atmospheres.

The M2 equipment must be stopped immediately and secured against restarting if the firedamp protection systems are found to be damaged.

The control and peripheral equipment of the MMC system with appropriate explosion protection marking are intrinsically safe and manufactured according to the approved technical regulations.

The use of components with appropriate explosion protection marking has no effect on the safety regulations and the regulations concerning firedamp protection at the mining company.

You may only open live control units in an environment which is not potentially explosive, even if there is no voltage. Observe the instructions on the device housings.

2.2.4 Prerequisites for operation

The entire PMC system must not be put into service until it has been determined by an appropriately trained and authorized person that the machine controlled by the system complies with European Directive 2014/34/EU and the DIN EN1710 standard.

Since the control system delivered is only part of an overall system, the operator must meet the safety requirements required for the devices/components not included with this system/those necessary for operation or install the required safety equipment. This must be labeled according to the legal provisions applicable at the time of its placement on the market.

safety requirements according to DIN EN 1552

M2 equipment may only be operated once the safety requirements according to DIN EN 1552 have been met. This includes: equipment for preventing unauthorized startup, startup warning systems, safe shutdown command systems, emergency-stop systems, dust extraction equipment, noise protection, Warnings

All electrical equipment required to operate the face must be designated according to the legal provisions applicable at the time when it is placed on the market.

2.3 Personnel

The machine may only be operated by skilled or trained personnel.

As a fundamental rule, installation and repair work may only be carried out by personnel who have been adequately trained for these particular requirements. Repair work on the system components may be performed only by service personnel of the manufacturer, or a company authorized by the manufacturer.

qualification A skilled worker is someone who, based on his special training and experience, has sufficient knowledge and is familiar with the relevant regulations. A skilled worker can carry out the work assigned to him. He can recognize potential hazards and take the necessary measures to eliminate them. He also has the required repair and installation knowledge.

An instructed person is someone who has been instructed with regard to the tasks assigned to him and the potential hazards which arise due to improper behavior, and, if applicable, has been trained/instructed concerning the necessary safety equipment and protective measures. The instructed person is able to work while looking ahead, recognize hazards and act accordingly.

2.4 Operator requirements

Operators are responsible for ensuring that the machine is always in a technically serviceable condition. This includes for example:

Regularly maintenance and checking the machine in accordance with the provided schedule

Ensuring sufficient supplies for operation such as electricity, water or hydraulic fluid

Regularly checking all safety equipment (document the test results). If any irregularities are noticed during operation, investigate them immediately and shut down the machine until any problems have been rectified

Make sure that all of the signage on the machine is legible.

2.5 Work on and with the machines

Always work with great concentration and familiarize yourself with your working environment.

Inform your colleagues about: where your exact site is, the work you are carrying out, how much time you will probably need

EMERGENCY STOP

Make yourself familiar with the EMERGENCY STOP equipment on the face. Press the EMERGENCY STOP switch immediately in the event of faults or irregularities in operation. Notify your supervisor of any peculiarity, so that necessary action can be taken immediately.

Actuate the EMERGENCY STOP SWITCH also if safety equipment, such as firedamp protection systems, breaks down.

support locking

For your own safety and that of other persons, the shield locking switch is to be actuated for the shield support in question when working in the shield support, driving through narrow passages or when two or more people meet.

Installation and commissioning

storage/transport of parts Do not store any materials or components in the travel way or in your working area.

inform involved persons Inform the persons involved about the planned transport route and the expected duration of the transport.

transport safety devices Make sure the transport safety devices/packaging are fitted properly. Never walk or stay under unsecured components or suspended loads.

use system brackets Only use retaining strips from the PMC system as brackets. Do not damage any connector insertions or other fitting surfaces.

inclined face On inclined faces, secure all components by chains, e.g., to the supports. environmental protection When working with oils, greases, and other chemical substances, observe the safety regulations that apply to the product.

Always dispose of materials contaminated with oil, grease, or other chemical substances in an environmentally acceptable manner. Inform the supervising personnel and the face crew about any maintenance and repair work required. Provide them with information on the intended work and its probable duration.

safety Cordon off your working area over a wide range to avoid endangering other persons. Secure the devices against unauthorized and unintentional restarting before all work.

replacing components Stop and lock out the devices to secure them against restarting before replacing any defective components.

Remove any defective components from the face immediately to avoid hindering the face crew. This measure also helps to prevent the unintentional re-installation of these defective components elsewhere.

Pass on these components for servicing without delay.

On inclined faces, secure the replacement parts with chains or lifting tackle, for example.

replacement parts Only use replacement parts that meet the technical requirements. This is only guaranteed if using genuine spare parts from Caterpillar Global Mining Europe GmbH. Please refer to the spare parts lists for the order numbers.

protective devices Refit any removed protective devices immediately after completing work, and check that they are working properly.

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.