Turnkey fit out contracting and custom manufacturing Hospitality portfolio

DELIVERING TURNKEY FIT OUT & CUSTOM MANUFACTURING SOLUTIONS

Turnkey fit out contracting and custom manufacturing Hospitality portfolio

Company overview

Havelock One Interiors was founded as Havelock AHI. A joint venture between Havelock Europa, UK and a renowned Middle East furniture manufacturer. Today, we are one of the most important t out contractors and manufacturers in the Middle East.

Innovating with state-of-the-art machines and techniques Comprehensive interior solutions for international brands

Adopting responsible procurement measures and moving towards reducing our carbon footprint

Over 100 sta members have celebrated their 10 year work anniversary with us

25+

the year the business was founded years of evolving partnerships

671

sta members across GCC

workers across ve markets 1998

1,800+

07

us... square foot of existing manufacturing and warehouse facilities in Bahrain

520,000

8,800+ $132m

projects successfully completed average annual turnover for the past ve years o ces at locations across GCC

Havelock One covers every stage of the process, from initial design development to construction, xture installation and the provision of furnishings and equipment.

By entrusting us with your project, you can focus on your core business activities, con dent that our dedicated team will handle all aspects of creating a functional and stylish environment. This streamlined approach not only saves valuable time, but also guarantees a hassle-free experience, reinforcing our commitment to delivering excellence in interior solutions.

You will receive end-to-end project management, ensuring a seamless experience.

We use bespoke solutions to ensure we deliver your project in line with your vision and goals.

We prioritise e ciency without compromising on quality, delivering projects within agreed-upon timelines.

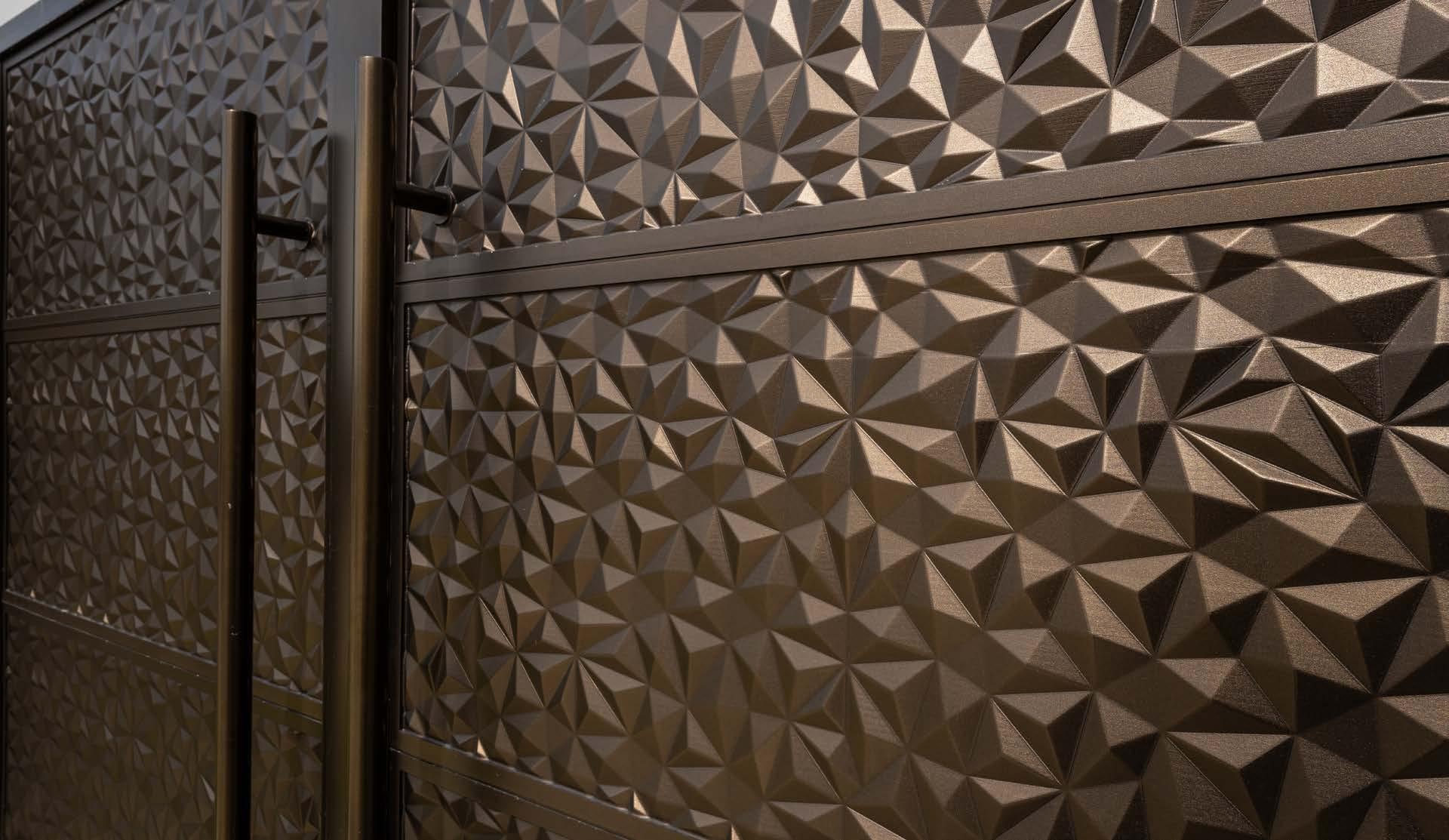

Combining cutting-edge technology with traditional cra smanship, our 520,000 sq. . factories in Bahrain delivers custom manufacturing for a wide variety of sectors.

We are motivated by four key drivers: quality control, value creation, cost reduction and continuous feedback loops.

Design development and setting out this includes material sample and drawing approvals, prototype manufacturing and value engineering.

We have one of the largest interior joinery manufacturing facilities in the region. Our team are experts in CNC router, veneer, paint, polish and assembly works.

Our experience in surface nishes and upholstery allows us to manufacture any kind of FF&E as per your desired speci cation.

Featuring a state-of-the-art metal workshop, we provide products from structural steelwork to bespoke- tting xtures.

Early contractor involvement

We will transform renders into practical detailed designs and shop drawings, speeding up the process and providing cost savings.

xtures & equipment

We will take responsibility for managing the entire process, from sourcing and manufacturing through to nal delivery.

Information technology consultancy

From the installation of cutting-edge audiovisual and video conferencing facilities, to AI-powered features, we help our clients leverage the full potential of a fast-paced digital landscape.

contract support

We will provide a one-year defects liability, ongoing client support, and a dedicated team of local professionals post-project completion.

I would like to thank Havelock One Interiors; their ability to anticipate and respond to challenges is admirable.

- Didier Jarrdin,General Manager Four Seasons Hotel, Kuwait

Great job by the Havelock One Team! The level of finishing and attention to details is one of the best I’ve seen in the region.

- Galal Mahmoud Architects Jumeirah Gulf of Bahrain

Setting-out is a fully automated department, using both AutoCAD and Inventor software, with direct links to our manufacturing CNC routers and boring machines.

Full range of services:

f Material sample approvals

• Sourcing specified materials

• Offering suitable alternatives

f Drawing approvals

• Using best practice manufacturing instructions

f Prototype manufacture and approval

f Value engineering

f Client communication

• Including initial RFIs, CPA and regular updates

With the support of a large range of modern machinery and highly experienced staff, we offer all woodworking methods, including:

f CNC Routers, nesting and drilling

• These are directly linked to our setting-out department for ease of information transfer.

f Mouldings and profiles

• With our in-house profile grinders, spindles, moulders and lathes, we can work to your specified profiles.

• Veneer preparation: we cut, stitch and bond in-house.

• Paint and polishing: our spray line and spray booths maximise our efficiency.

• Assembly: our team consists of experienced carpenters.

We're continuously investing in new technologies and machinery, to ensure we reamin at the forefront of our industry.

Material Conversion Material Machining, Shaping and Carving Veneer preparation

Resaw 5-head 4-sided moulder Fully air-conditioned

Band saws 4-head 2-sided shaper Guillotines

Panel saws Spindle moulders Veneer stitchers

Beam saws Hydraulic copy lathe

Rip and cross cuts

3 Edge banders

Multi-stage, high-speed, back knife lathe and sander

6 CNC machine centres (incl. CNC Biesse 5 Axis - 378 and Rover KFT 1836- 379)

2 through press lines

Upholstery

Industrial foam cutting band saw

Industrial sewing machines

Sanding and Preparation Latest Software Paint and Polishing Maintenance

Profile sander EPICOR ERP Custom-made paint room Profile grinders

Wide belt sanders For drilling and routing Auto spray line Circular saw grinders

Profile edge sanders 3D software for pattern and fretworks Auto moulding Straight knife grinders

Denibbing sanders

Spray equipment Center lathe

Spray booths Surface grinders

Band saw grinders

Resaw grinders

Featuring a state-of-the-art metal workshop, we provide products from structural steelwork to bespoke shop-fitting fixtures.

f Fabrication

• With many modern fabrication machines, including CNC press, laser and plasma cutting machines, we offer great expertise in fabrication.

f Metal Finishing

• Along with our spray booths and powder coating plant, we offer many individually produced finishes to meet your needs.

Metal Fabrication Machines

Machines

Equipment

CNC trumpf laser cutting machine 1.5 kw and 3 kw Double-head grinding / belt polishing machine for flat surfaces and tubes Mig welding machines

Shearing or plate / sheet cutting machines

CNC hydraulic press or press brake 150t

Power press 200T

Sheet rolling machines

V grooving machine for sharp bends on sheet metal work, up to 3m length

Pipe bending and rolling machine

Centreless grinding / belt polishing machine for round pipes Tig welding machine

buffing machine for flat surfaces and tubes Stud welding machine

Centreless buffing machine for round pipes Brasing equipment for brass and copper

High-quality dynabrade finishing equipment to achieve different finishes on metal like polished, brushed, hairline, satin etc.

Different capacity hand buffing and polishing machines

Batch-type powder coating plant with 4m and 6m drying oven

Milling machines Painting booths for metallic finishes in paint

Cold saw cutting machine

Drill machines various capacities

NC Lathe machines - 2m bed

Thread tapping machine

Different types of hand tools to facilitate mild

stainless steel, brass manufacturing

duty welding equipment for structural work

Our ability to work with many different materials in-house allows us to manufacture any kind of FF&E as per your desired specification.

f Solid surface fabrication

• We have the capability of shaping, profiling, bending and bonding to almost any requirement.

f Stone and marble

• We offer fabrication capabilities using stone and marble from our trusted partners around the world.

f Upholstery

• We work with a wide range of foams, fabrics and leathers.

• We are an experienced and technically versatile team.

f Acrylic and Glass

• We offer a broad range of acrylic products, including in-house fabrication of acrylic products, in-house fabrication with flame polisher and bending machinery.

• We can deliver in-house UV glass bonding services.

No matter the origin of materials or the destination of the final products – we ensure that you receive your products exactly when and where you need them.

f Logistics

• Our logistics department has a diverse range of experience in shipping to all Middle East regions and also continental Europe, UK, USA and the Far East.

f Packaging

• We use all modern packaging materials and cater for all types of shipping whether it be road, sea or air.

The partner of choice for the most admired projects in all of our markets.

Driving current and future relationships by consistently delivering real value and exceptional service.

To deliver exceptional work through the power of thoughtful precision. Precision detail-driven, realistic, methodical Foresight constructive, relational problem-solving Drive committed, focused proactive / responsive

Syed Kashif Akhtar

Group Managing Director

Firas Al Ayed

Group Operations Director

Nigel Wilson

Division Director – Fit Out KSA

Jihad Raad

Division Director

Hospitality Manufacturing and Fit Out Bahrain

Imtiaz Mahadiwala

Division Director - Kuwait Operations

Adrian Sellar

Division Director – Fit Out UAE

Mark Waters

Division Director – Retail Manufacturing

[Front right to le ]

Fit Out Firm of the Year

Design Middle East Awards - KSA

Specialised Manufacturer of the Year Design Middle East Awards

ICT Leadership Award

CXO Insight Middle East

Fit Out Firm of the Year

Design Middle East Awards - KSA

Fit Out Project of the Year

Empire Cinemas & IMAX

Construction Innovation Awards

CIO of the Year

CXO DX Magazine Future Workspace

Summit & Awards

CIO of the Year

CXO DX Magazine KSA Awards

Fit Out Firm of the Year

Highly Commended

Identity Design Awards

Fit Out Firm of the Year

Highly Commended

Design Middle East Awards

Fit Out Firm of the Year

Highly Commended

Construction Innovation Awards

CXO 50 Award IT Awards

HR Leader & HR Super Achiever The Middle East Leadership Awards

Fit Out Project of the Year

Highly Commended - Liberté, Grand Hyatt

Design Middle East Awards

Digital Transformation IT Leadership Awards

CXO 50 Award IT Awards

Refurbishment Project of the Year

DGDA Headquarters

Design Middle East Awards

Flocean Build Partner with Kristina Zanic Consultants

Surge for Water Sustainability Design Awards

Great Place to Work®

Certified as a ‘Great Place to Work®’ in Bahrain, Kuwait and the UAE

Retail Project of the Year

National Bank of Bahrain

Construction Business News Awards

Transformation Maestro of the Year

Enterprise Transformation Summit & Awards

Best Digital Transformation in Turnkey Fit Out Smart SMB Awards

ASKAR I BAHRAIN

Havelock One Interiors WLL PO Box 5100

Askar, Bahrain

Phone: +973 1783 2022 bahrain@havelockone.com

DUBAI I UAE

Havelock One Interiors LLC PO Box 126164

Dubai, UAE

Phone: +971 4 567 7200 uae@havelockone.com

KUWAIT CITY I KUWAIT

Havelock One Interiors WLL

PO Box 4924

Al Mirqab, Kuwait

Phone: +965 2225 1491 kuwait@havelockone.com

DOHA I QATAR

Havelock Contracting and Trading WLL

PO Box 39235, Doha, Qatar

Phone: +974 4481 4239 qatar@havelockone.com

SANABIS, MANAMA I BAHRAIN

Interior Solutions Co. WLL PO Box 21898

Sanabis, Bahrain

Phone: +973 1738 0223 interiorsolutions@havelockone.com

ABU DHABI I UAE

Havelock One Interiors LLC PO Box 30096

Abu Dhabi, UAE

Phone: +971 2 204 1000 uae@havelockone.com

RIYADH I KSA

Havelock One Interiors WLL PO Box 13214-8389

Riyadh, KSA

Phone: +966 11 4898 364 ksa@havelockone.com