Portfolio

1

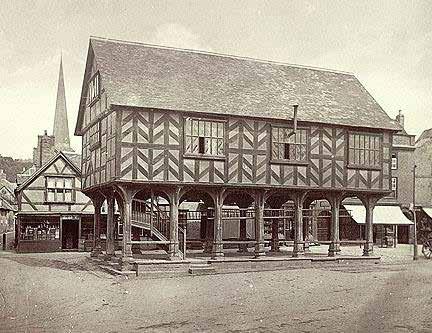

Figure 0.1 Harrison Laurie - 21143857 16.12.2022

Praxis - Technical

Coal Drops Yard by Heatherwick Studio

Task 1 - Introduction to Practise Introduction to Practise

Task 2 - Design Opportunities Constraints

Task 3 - Health and Safety Moving Vehicles and Machinery Working at Height Airborne Pollutants

Task 4 - Fire Safety Introduction Horizontal Means of Escape & Travel Distances Alternative Escape Routes and Angles Vertical Means of Escape and the Provision of Refuges Horizontal and Vertical Escape Widths

Task 5 - Accessibility Access to the Building Access Into the Building Horizontal Circulation Vertical Circulation

Task 6 - Project Costs Gross Internal Floor Area BCIS and Spon’s

References List of Figures

3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

2

Contents Figure 0.2

Intoduction to Practice

Heatherwick Studio Limited is an architecture firm on 55 Argyle St, London WC1H 8EE.

The team is made up of just over 200 people.

It is a private limited company that was founded by Thomas Heatherwick and incorporated on the 1st of March 2001. The registered nature of their business includes architectural activities, urban planning and landscape architectural activities and technical testing and analysis.

Thomas Heatherwick is a ‘person of significant control’ of the company, owning 75% of company shares and voting rights. (Companies House, n.d.)

Thomas Heatherwick has been ‘immersed in materials and making’ all his life. This is demonstrated in the studio’s work by how they express materiality and construction processes within their projects. The team at Heatherwick’ Studio class themselves as problem-solvers who focus on implementing a positive social impact and ‘design soulful and interesting places which embrace and celebrate the complexities of the real world.’ (Heatherwick Studio, n.d.)

Heatherwick Studio works on large scale projects in cities all over the world and they have won more than 100 international awards for design excellence, including the Prix Versailles and the RIBA National Award.

They create buildings, master-plans, infrastructure, spaces and sculptural pieces. Below are three examples demonstrating their work.

Figure 1.1

Figure 1.2

Google King’s Cross

Heatherwick Studio collaborated with Bjark Ingels Group to design Google’s new London Headquarters in Kings Cross. They drew upon they extensive knowledge of the area to draw upon industrial influences and implement reusability into the building’s design. (Heatherwick Studio, n.d.)

Figure 1.3

Guy’s Hospital

Guy’s Hospital has seen many alterations in it’s lifetime but they have been purely practical and neglected user experience. Heatherwick Studio designed a sculptural tile panel cladding system that made of undulating stainless steel mesh that help create a focal point on the main entrance and make the movement into the building more intuitive. The system is also highly practical as it prolongs the structure of the existing facade by shielding it from the elements but allowing ventilation. (Heatherwick Studio, n.d.)

Figure 1.4

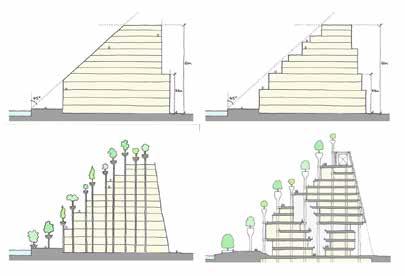

1000 Trees

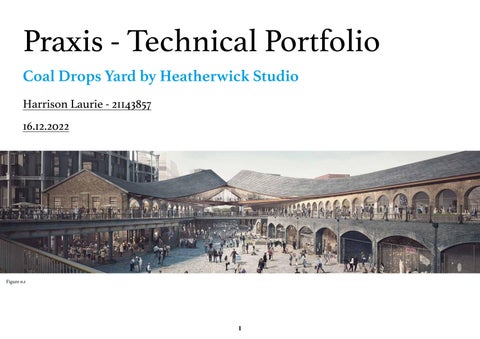

1000 Trees is a multi-use complex next to Shanghai’s art district. The studio aimed to design a building that would connect to the park on its boundary, while also achieving the density required by the client. Their design solution was to turn the structural columns into a feature by extruding them above the roof line and sculpting them to produce tree planters. (Heatherwick Studio, n.d.)

3 Task 1:

Design

Opportunities

1. Heritage

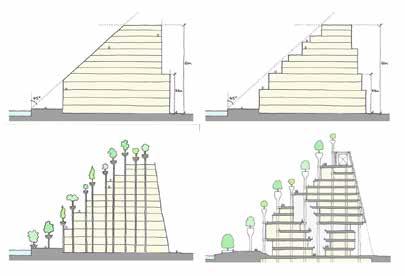

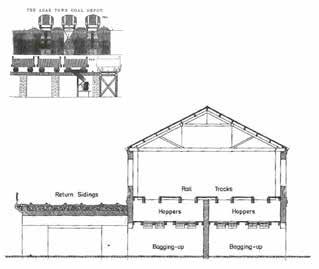

The original structures were built in 1850 to receive coal trains from the north of England (Figure 7). The site played an important role in England’s growing Victorian 2.1conomy but was also a place of poor working conditions. The renovation of this site presented the design team with the opportunity to create a high-end retail development and a new public space. This can be seen as a homage to the people who worked here, as the profits they brought to London is now being used to create a safe and enjoyable space for people to use.

3. Mixed Use Development

The ability to design a mixed-use development of retail, hospitality and services presented Heatherwick Studio the opportunity to bring together a community through their design. As the studio is located within the community, the design team understood the importance of creating a new public space that people treat as an integral part of the city as well as a retail destination. It was important to facilitate movement into and through the site, so many routes have been designed intersecting the site, allowing Londoners and tourists to pass through and experience the architecture and interact with businesses.

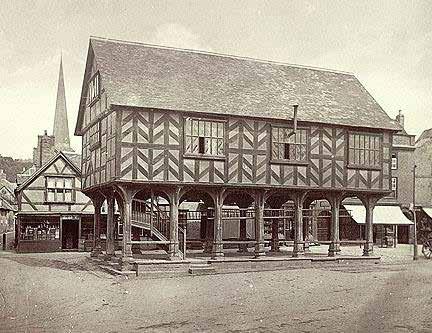

Thomas Heatherwick was inspired by raised buildings in historic market squares (Figure 2.2) that form the architectural heart of the

2. Contemporary Design

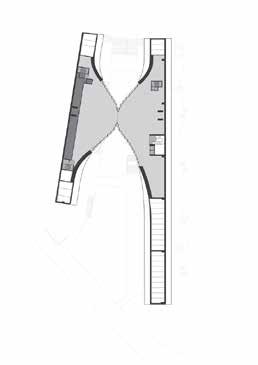

Heatherwick’s client, Argent LLP, requested that the two coal drop buildings be linked. The immediate solution would be to connect them with a single-storey extension or an elevated footbridge but the design team found these solutions clashed with the Victorian design. The design solution came when they ‘merged the language of the old with the new’ and a new space ’emerged from the existing forms’. (Finlay, 2018) (Figure 2.3 & 2.4)

Coal Drops Yard achieved the Prix Versailles and the RIBA National Award in 2019 as a result of this design strategy.

The structures were built from Victorian bricks and cast iron which, when accentuated, can become beautiful material features in a project. Thomas Heatherwick’s personal touch can be seen in the way the design celebrates the materiality and structure of the original buildings.

Figure 2.1

market. This led to a design that ‘fused the roofs together as if it healed into a heart’ (Heatherwick, 2018) creating a raised footbridge with a double-height sheltered space beneath that can be used for concerts and performances. (Heatherwick Studio, n.d.)

As locals, the design team also appreciated the importance of facilitating local business and cultural growth. The spaces were therefore designed for a mixture of known brands and smaller boutique shops and restaurants, along with spaces designed for students of the adjacent University of the Arts London campus to display and sell their work.

Figure 2.2

Figure 2.4

4 Figure 2.3 Task 2:

Design

Constraints

1. Grade II Listed Building

As one of the the original buildings is grade II listed, the design team had to be sensitive to the site’s history when designing the renovation. The facades of the original structures legally had to be preserved, however they had been vacant for over 15 years so had fallen into a state of disrepair.

The design team decided to embrace the site’s heritage and in collaboration with heritage consultant, Giles Quarme & Associates, undertook a sensitive restoration of the Victorian structures and cobbled yard (Figure 2.5). This included the use of materials and techniques that would have been used in their original construction in 1850. The new roof even uses slate from the same location as the original slate was sourced.

Due to the listing and the structural capabilities of the original buildings, the footbridge and roof extension had to be designed to not add any additional weight to the original structure. The steel structure was designed to ‘thread through the existing building’. (Finlay, 2018)

2. Design for Manufacture and Assembly

The complexity of the proposed roof structure required extensive structural analysis and precise construction. Heatherwick Studio collaborated with structural engineer ARUP to develop a strategy to prefabricate the new roof and deliver it to site in sections. (Figure 2.6)

This allowed for increased precision during construction as the majority of the assembly was done under the controlled conditions of a factory. It also increased safety on site and reduced construction time.

Figure 2.5

Figure 2.6

5 Task 2:

Health and Safety

The Health and Safety Executive outlines a hierarchy of controls to be implemented when carrying out a risk analysis.

1. Elimination – physically remove the hazard

2. Substitution – replace the hazard

3. Engineering controls – isolate people from the hazard

4. Administrative controls – change the way people work

5. PPE – protect the worker with equipment’ (Health and Safety Executive, n.d.)

A. Moving Vehicles and Machinery

The Provision and Use of Work Equipment Regulations (PUWER) place a duty on employers to ensure the work equipment they own, operate, and have control over is safe to use at all times.

1. Elimination

A project of this scale required heavy machinery to be present. This presented a hazard that could not reasonably be eliminated.

2. Substitution

Tasks that required machinery could not be carried out safely in any other way.

3. Engineering controls

Moving vehicles and machinery was only used in designated areas. Pedestrian walkways were installed and ‘moving vehicle’ signs were installed around the site.

4. Administrative controls

All work equipment was maintained and had an up-to-date maintenance log. Anyone who used machinery was trained to do so and kept below the site speed limit.

5. Personal Protective Equipment

All personnel on site were provided with steel capped boots, hard hats and high-visibility jackets.

Building Use and Maintenance

The use of vehicles and machinery are restricted in and around the building. Designated access points are used for deliveries and emergency access. Maintenence is only to be undertaken by trained proffessionals and with the appropriate use of PPE. They are to adhere to health and safety guidelines regarding using vehicles and machinery.

6 Task 3:

Figure 3.1

Health and Safety

B. Working at Height

The Work at Heights Regulations of 2005 state that work at height should be avoided when reasonably practicable and if not, falls should be prevented and consequences minimised using the appropriate collective, or personal protective equipment.

1. Elimination

The risk of working from height could not be entirely eliminated for Coal Drops Yard, however the design of the low-rise structure with balconies and mezzanines slightly reduced the heights of potential falls.

2. Substitution

By designing the roof structure for manufacture and assembly, the risk of working at height was reduced because the majority of the structural work was undertaken at ground level in a factory.

3. Engineering Controls

Where there was still a risk falling from height, it was isolated using engineering controls. This was done by installing guard rails, kick-boards and netting on scaffolding to prevent of people, materials or tools from falling off. Working at height presented a risk of objects falling as well as people. Therefore people walking beneath those working at height were still at risk including pedestrians and cars passing the site so engineering controls were used to protect them too. When tasks required access to difficult locations, engineering controls were implemented including using mechanically elevated platforms or mobile cranes.

4. Administrative Controls

Where risks were still present, administrative controls were implemented. These included the provision of training and clear information and instructions to all personnel at risk. This was carried out by holding health and safety briefings with the construction operatives, using appropriate health and safety signage around the site and ensuring the site foreperson communicates effectively with operatives.

5. Personal Protective Equipment

PPE should be a last resort, however it is useful to reduce risks when all previous steps have been followed. PPE for working at height includes harnesses, hard-hats and steel-capped boots.

Building Use and Maintenance

Areas that present a risk of falling are restricted to building users as far as reasonably practical. Where this could not be applied, for instance on balconies or stairs, engineering controls such as barriers and handrails were installed.

Building maintenance is only carried out by trained professionals. Walkways and handrails have been provided to them where possible. PPE must be worn when undertaking maintenance work

7 Task 3:

Figure 3.2

Health and Safety

C. Airborne Pollutants

An environmental assessment of the site would have found contamination in the soil and in and around the buildings. There would also likely be poor air quality and high levels of dust in the air due to the previous function of the Coal Drops building. This would present a significant hazard to all personal on and around the site.

1. Elimination

Unfortunately the hazard could not be eliminated, as any work on the site would result in disturbance of the soil and building fabric, releasing coal dust and other pollutants.

2. Substitution

By implementing off-site manufacturing and component assembly, less work was carried out on-site which reduced exposure to pollutants.

3. Engineering controls

Some tasks were carried out from within the air-conditioned cab of site machinery such as diggers and cranes. These operatives were protected from pollutants by the vehicle’s air filtration system. In cases where this was not feasible, mechanical ventilation systems were installed to remove air pollution from the area where operatives were working.

4. Administrative controls

Site operatives were informed of the risks associated with air pollutants and trained to protect themselves and others from harm. Controlled practices included dry-sweeping which was substituted for the use of industrial vacuum cleaners. Operatives and other site personnel with respiratory health problems were identified before construction and individual risk assessments were carried out for them.

5. Personal Protective Equipment

In cases where airborne pollutants were still present, PPE including industry certified respirators and eye masks were provided.

Building Use and Maintenance

The site was adequately cleaned after completion, preventing coal dust and other pollutants from affecting building users. The building is also installed with a mechanical ventilation system which prevents the build up of pollutants. Maintenence is only to be undertaken by trained proffessionals and with the appropriate use of PPE.

8 Task 3:

Figure 3.3

Fire Safety

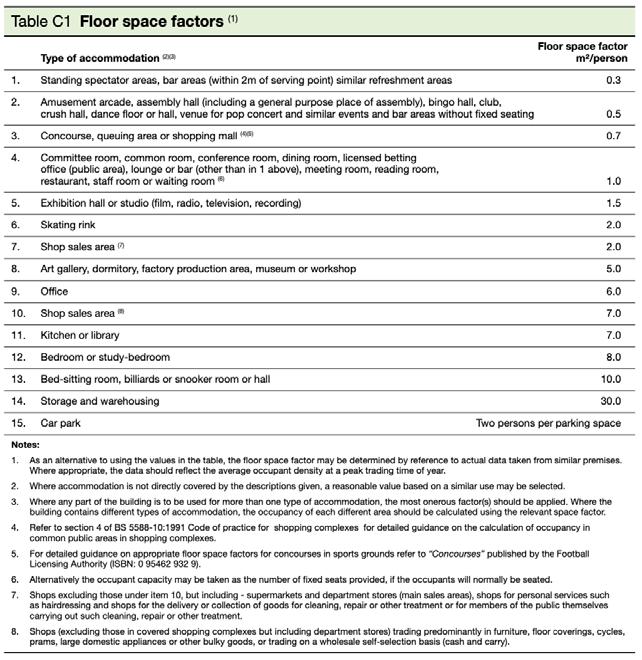

UK Building Regulations Part B set out the requirements for fire safety in buildings.

Approved Document Part B Volume 2 is concerned with all buildings other than dwellings, so therefore contains appropriate guidance for Coal Drops Yard.

This document will analyse how the design of Coal Drops Yard complies with three regulations found under requirement B1: Means of warning and escape, Section 2 and 3.

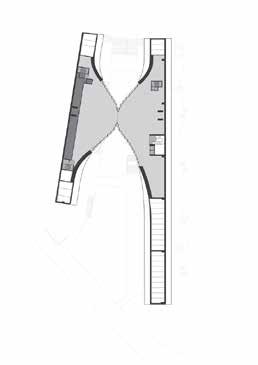

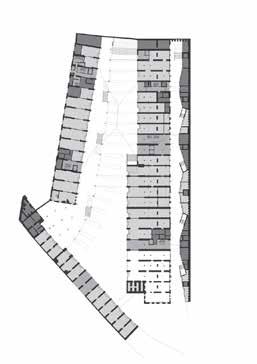

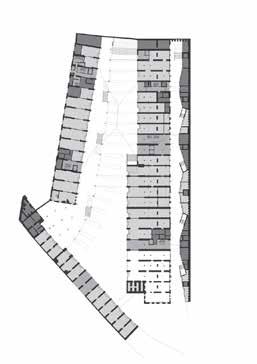

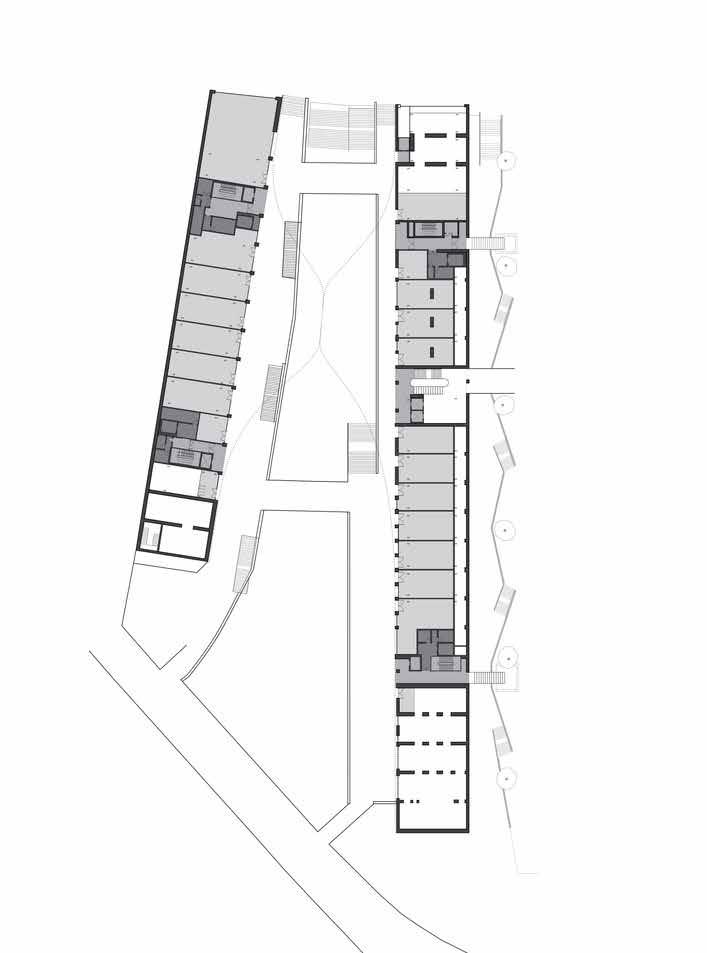

Gross Internal Floor Area (GIFA) (see task 6)

Floor 0: 4016 m²

Floor 1: 2873 m² Floor 2: 2224 m²

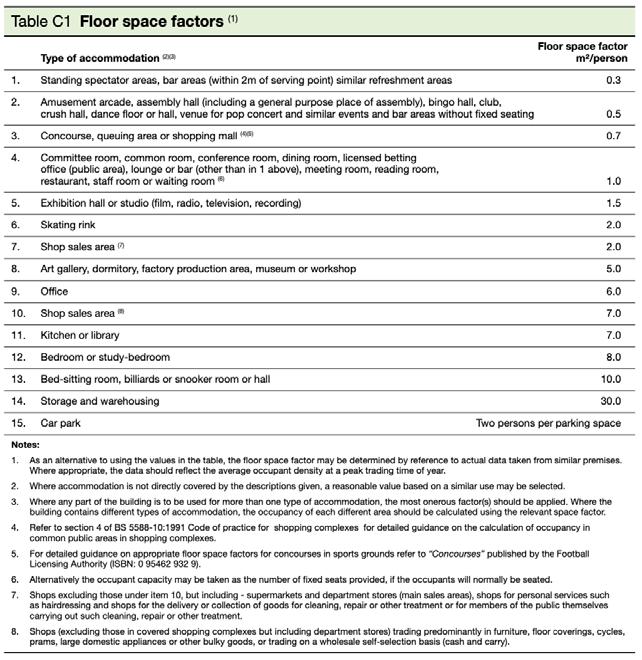

Maximum Capacity: GIFA / 2.0

These are:

1. Horizontal means of escape

2. Travels distances

3. Vertical means of escape Floor 0 Yard Level Floor 1 Viaduct Level Floor 2 Upper Level

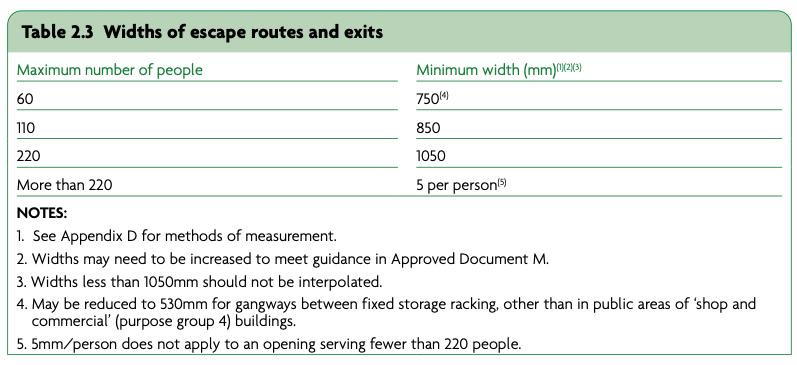

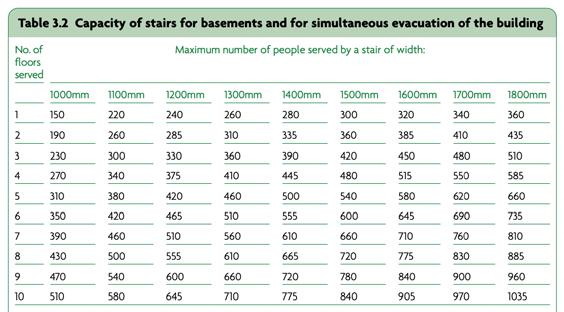

Floor 0: 2008 people Floor 1: 1436 people Floor 2: 1112 people Table C1 p.153 Approved Document B Vol. 2 (2006 edition with 2019 ammendments) Figure 4.5 Figure

9 Task 4:

10m 0 10m

10m

0

0

4.1 Figure 4.2 Figure 4.4

Fire Safety

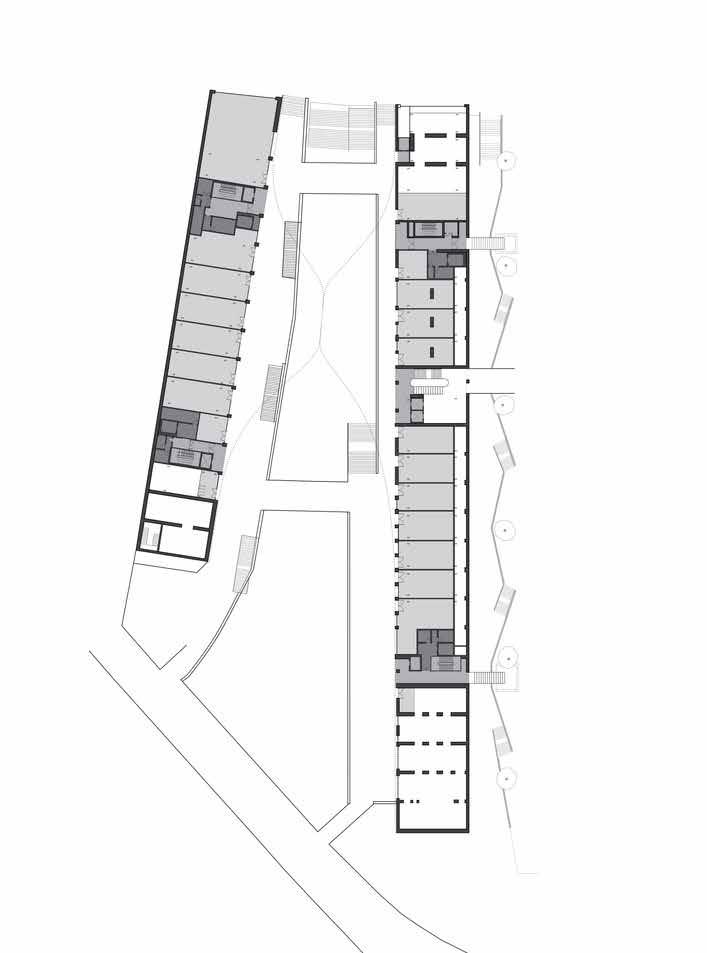

Horizontal Means of Escape & Travel Distances

Floor 0 - Yard Level

0 10m

Scale 1:1000 at A3

Fire exit

Longest horizontal escape route where travel is possible in only one direction (15.6m)

Longest horizontal escape route where travel is possible in more than one direction (43.3m)

Fire protected corridor, staircases or lift shaft

Emergency vehicle access Regulatory Compliance

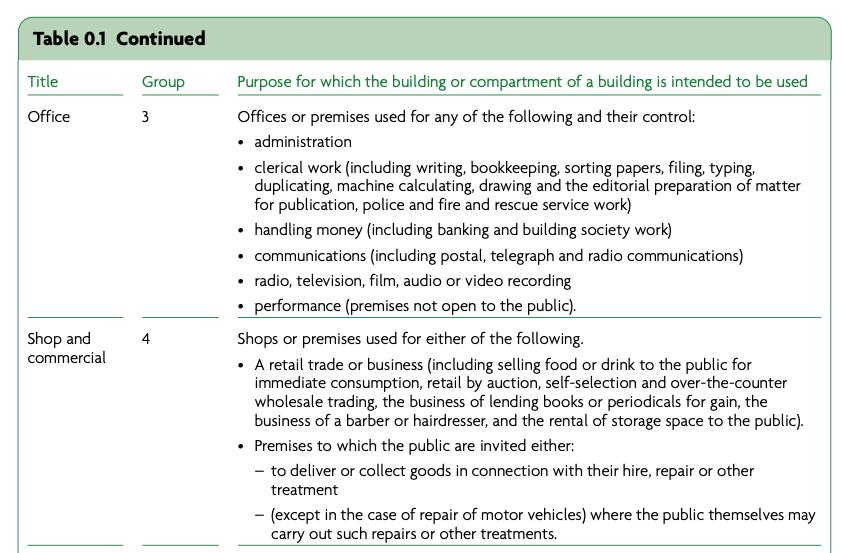

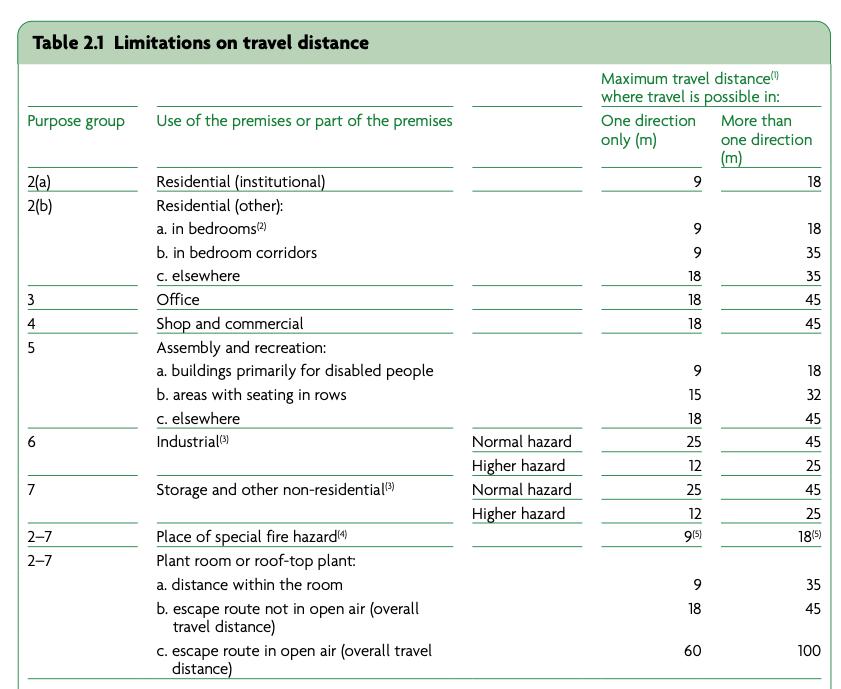

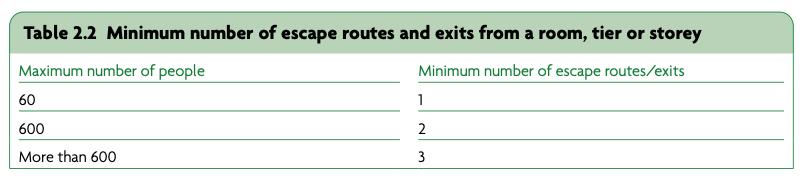

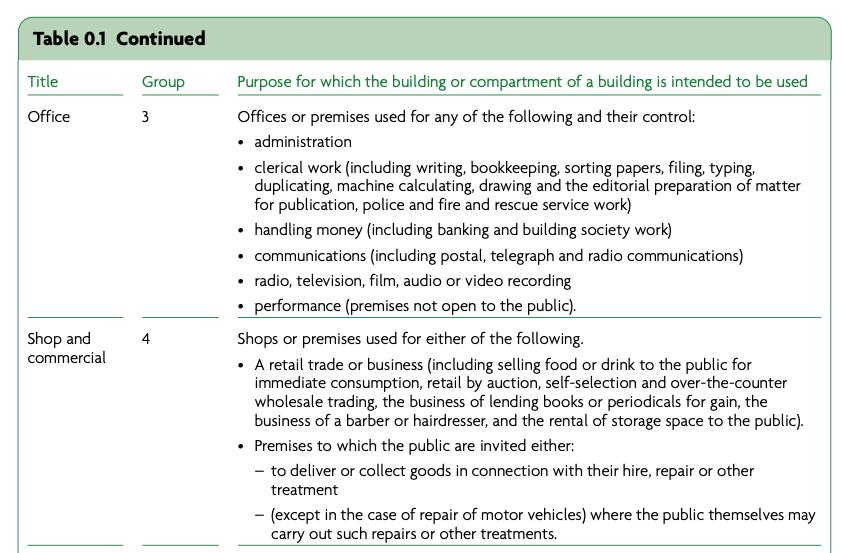

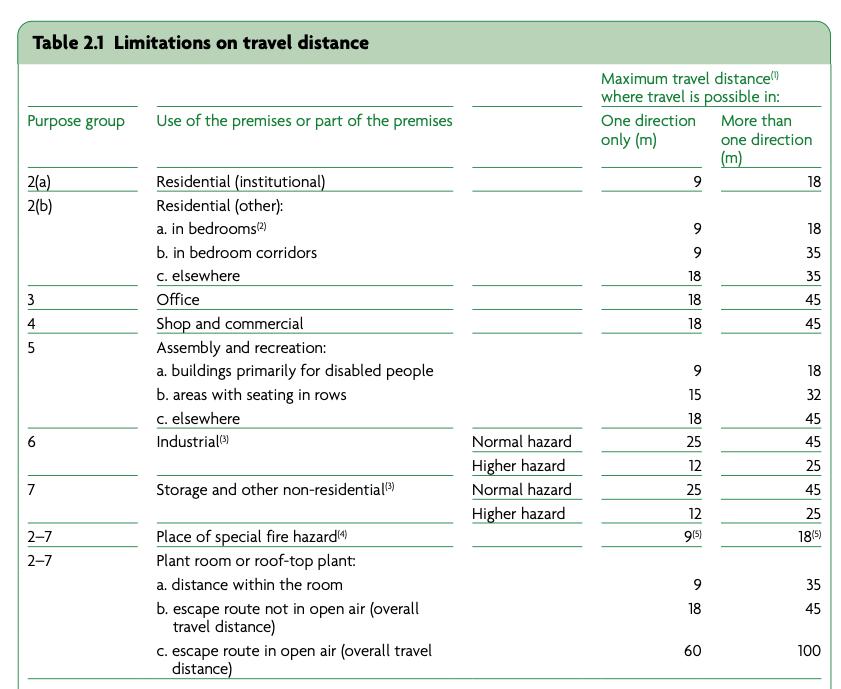

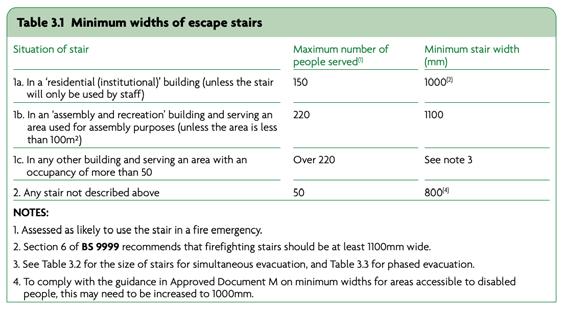

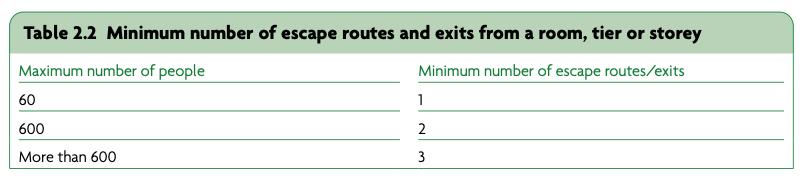

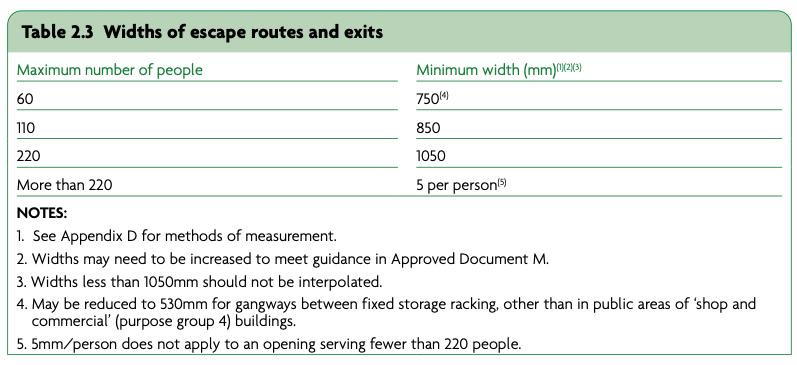

Coal Drops Yard can be classed as ‘Shop and commercial’ or ‘group 4’ under table 0.1.

Therefore, as stated in table 2.1, the maximum longest horizontal escape route where travel is possible in only one direction is 18m. On floor 0 this number is 15.6m showing regulatory complience.

The maximum longest horizontal escape route where travel is possible in more than one direction is 45m. On floor 0 this number is 43.3m showing regulatory complience.

Figure 4.6

Figure 4.7

10 Task 4:

Figure 4.1

Fire Safety

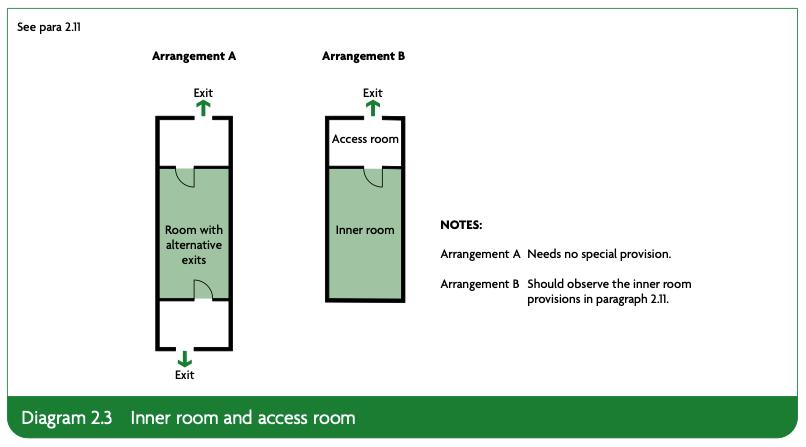

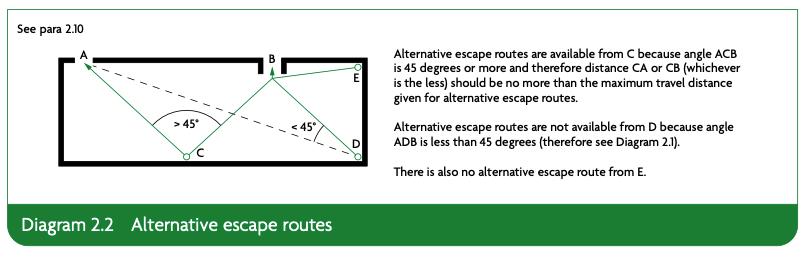

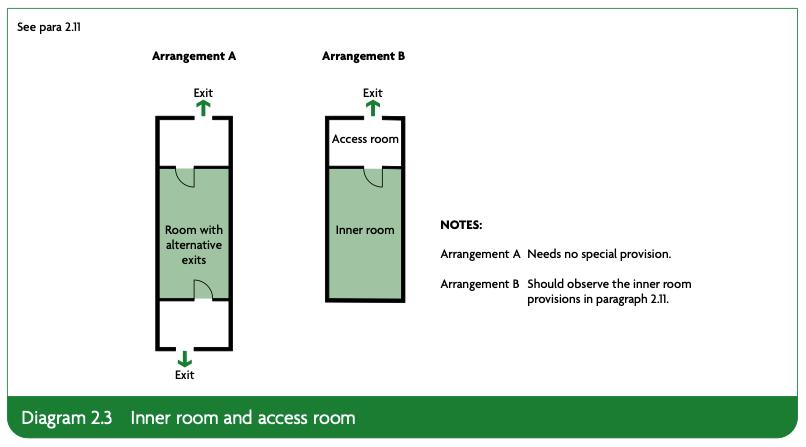

Alternative Escape Routes and Angles

Floor 1 - Viaduct Level

Scale 1:1000 at A3

Fire exit

Longest horizontal escape route where travel is possible in only one direction (17.7m) which is under the maximum distance of 18m.

Longest horizontal escape route where travel is possible in more than one direction (27.6m) which is under the maximum distance of 45m.

Fire protected corridor, staircases or lift shaft Regulatory Compliance

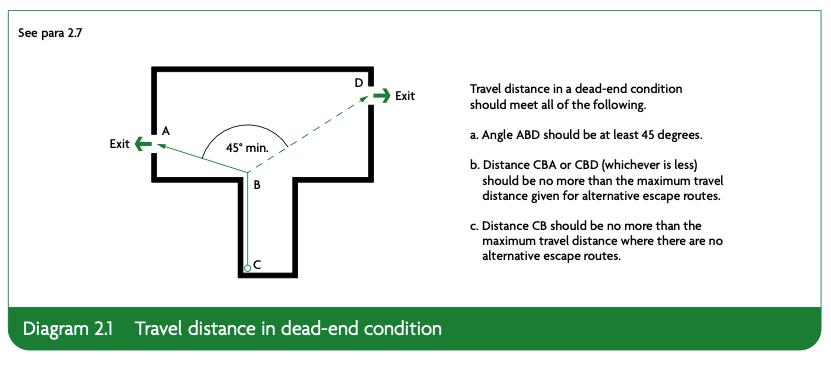

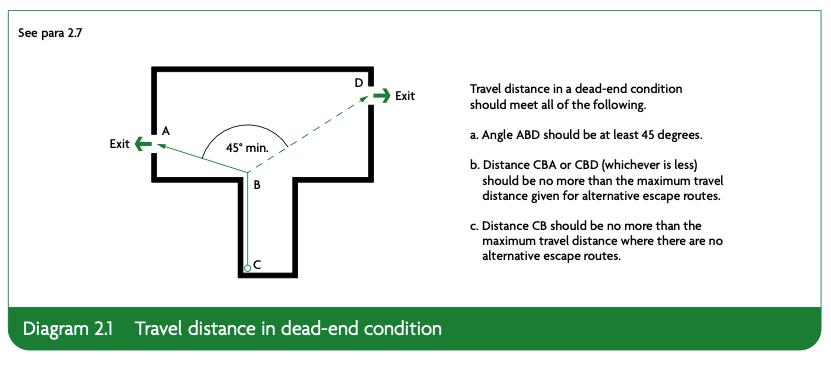

47°

In cases where an alternative escape route is provided, said escape route must be at a 45° angle or more from the original escape route. In this case it is 47°. All alternative escape routes in Coal Drops Yard are 45° or more from the original route.

Figure 4.8

Figure 4.9

11 Task 4:

0 10m

Figure 4.2

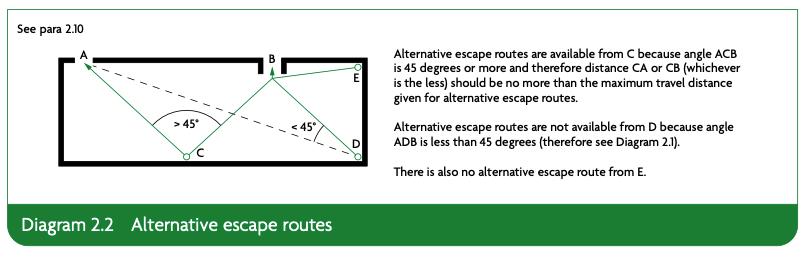

Fire Safety

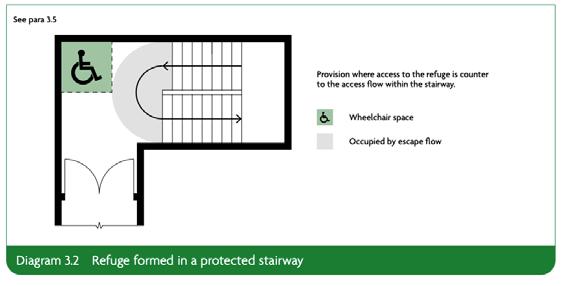

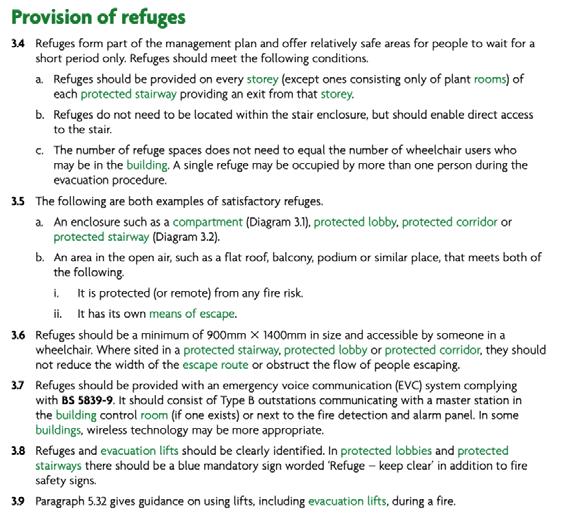

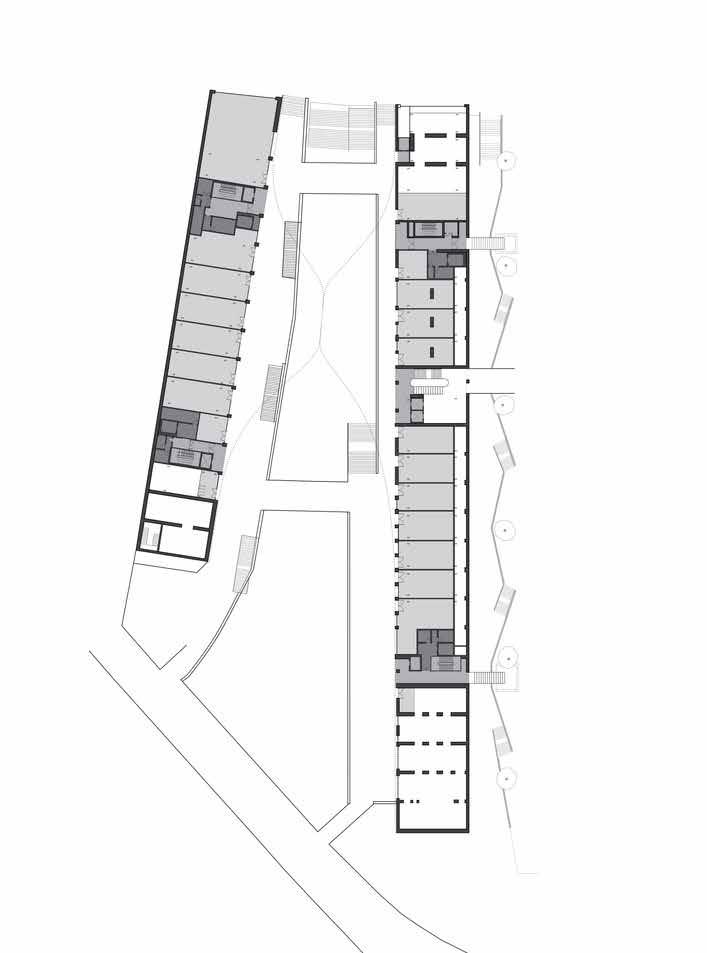

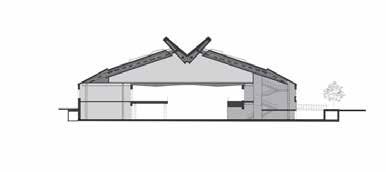

Vertical Means of Escape and the Provision of Refuges Section Looking North

Floor 1 - Viaduct Level

Figure 4.10

Centre Section Looking North

Figure 4.11

External escape stairs

Refuge in fire protected corridor or stairway

Escape route 0 10m

Scale 1:1000 at A3

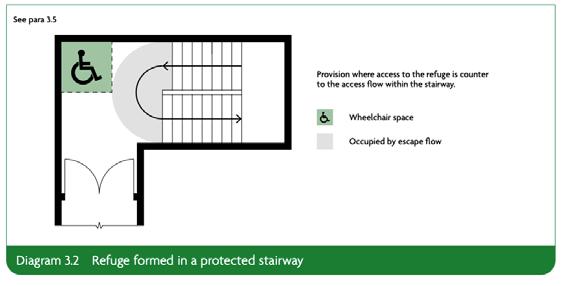

Regulatory Compliance

People with disabilities can struggle with vertical escape routes so refuge points are put in place so they can wait for rescue.

Coal Drops Yard provides 4 refuges on each storey in accordance with the regulatory minimum of one. They take the form of protected corridors and protected stairways. These also function as protected escape routes.

Figure 4.12

Figure 4.13

12 Task 4:

Figure 4.3

Fire Safety

Horizontal and Vertical Escape Widths

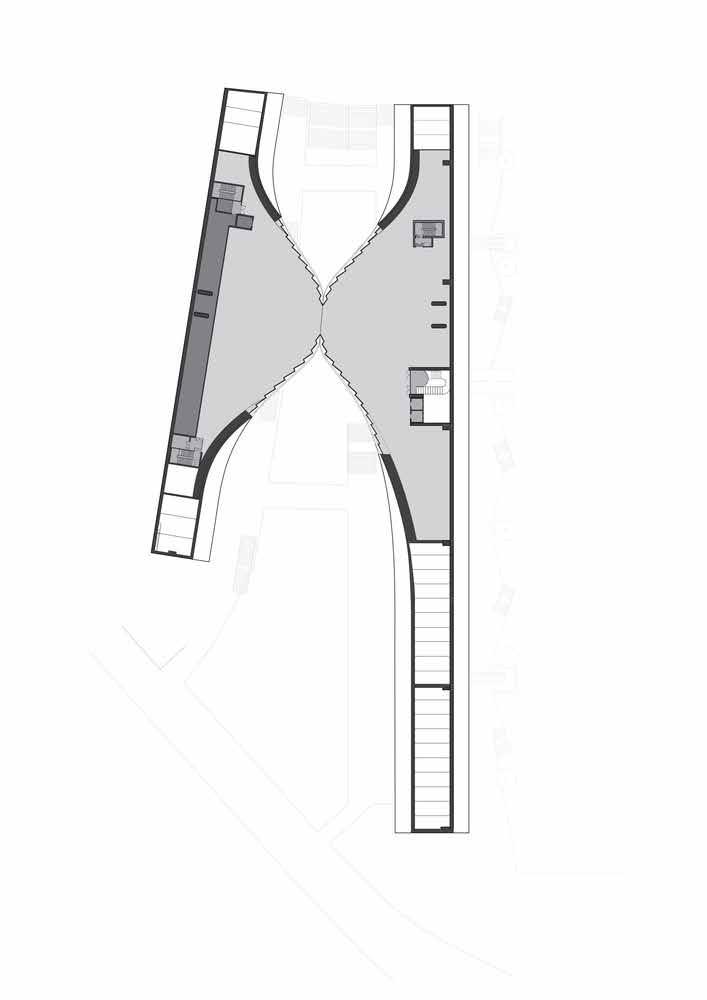

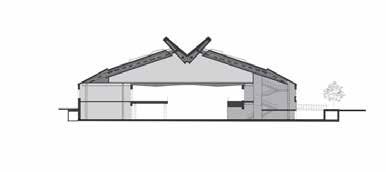

Floor 3 - Upper Level

Scale 1:1000 at A3

Gross Internal Floor Area (GIFA) (see task 6)

Floor 0: 4016 m²

Floor 1: 2873 m² Floor 2: 2224 m²

Maximum Capacity: GIFA / 2.0

Floor 0: 2008 people Floor 1: 1436 people Floor 2: 1112 people

Figure 4.14

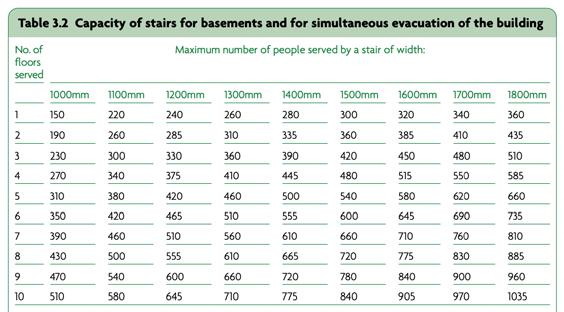

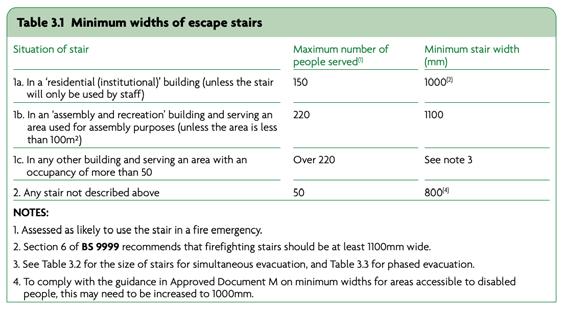

Regulatory Compliance

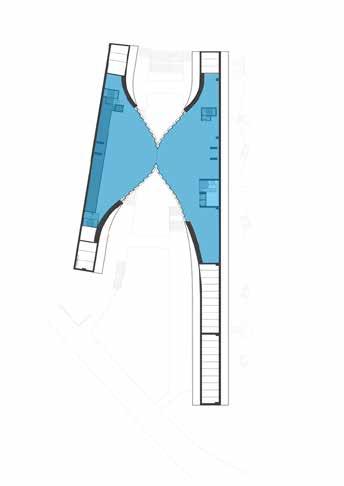

The maximum capacity on this floor is 1112 so there should be a minimum of 3 escape routes. There are 4; via the fire protected stairwells.

The maximum number of people using each exit is caluculated by dividing the maximum capacity by the number of exits. 1112/4 is 278.

As this is more than 220, the minimum width of the escape routes therefore is calculated by multiplying the number of people using the route by 5mm, giving us 1390mm.

The escape routes provided are all 1400mm wide. This exceeds the minimum requirements.

The width of the stairs in the escape route are 1200mm which also exceeds the minimum requirements and therefore demonstrates regulatory compliance.

Figure 4.15

Figure 4.16

Figure 4.17

13 Task

4:

0 10m

Figure 4.4

Accessibility

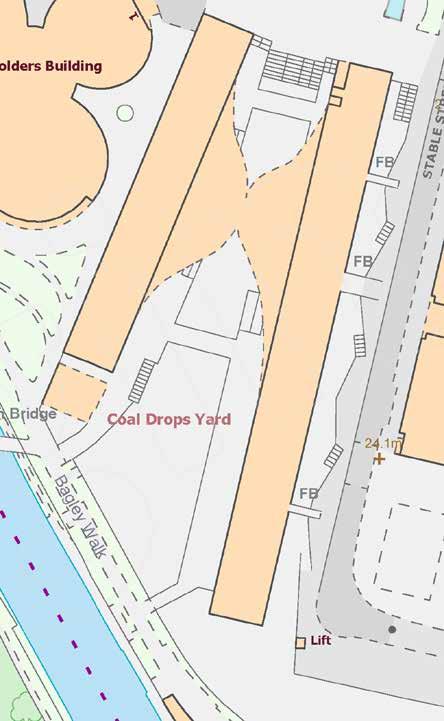

Access to the Building

Figure 4.11

Figure 5.2

Access on the north side of the site is only via stairs.

Figure 5.3

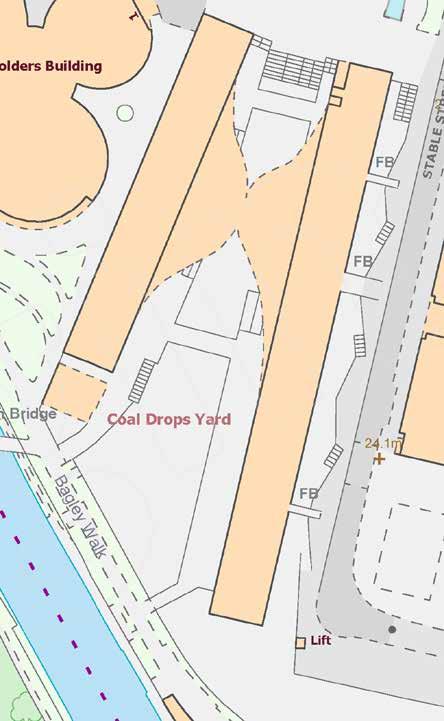

A ramp is located on the eastern side of the site leading direcly onto level 1 of the building.

Figure 5.4

Level 0 (Yard Level) can be accessed directly from the towpath via an underpass under Bagley Walk.

Figure 5.5

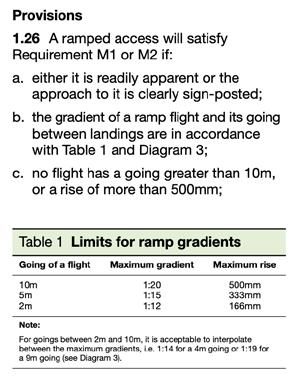

Regulatory Compliance

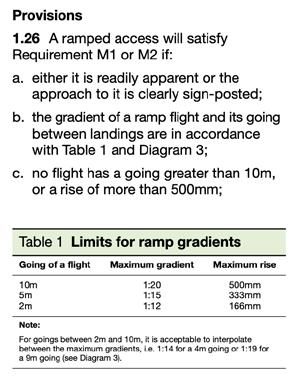

The eastern ramp shown in figure 5.3 and 4.11 has a going of 7m and a rise of 200mm. 7000/200=35. The gradient is therefore 1:35 which is less steep than the regulatory 1:20 gradient that is required for a slope of this length.

A lift is located at the south east of the site to assist those with accessibility needs to move between street level (level 1) and yard level (level 0).

Figure 5.1

Figure 5.5

14 Task 5:

Accessibility

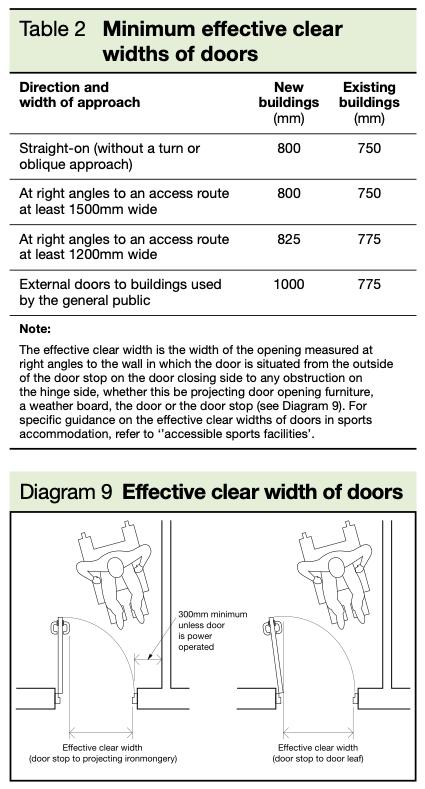

Access into the Building

Regulatory Compliance

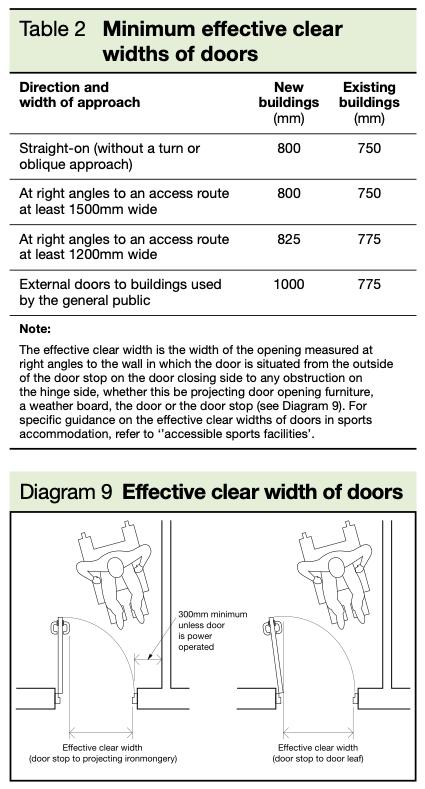

All external doors to Coal Drops Yard that are used by the general public are double doors with an effective clear width of 1800mm. This exceeds the minimum width of 775mm.

Internal and maintenance doors are single doors with an effective clear width of 800mm. This exceeds the minimum width of 775mm.

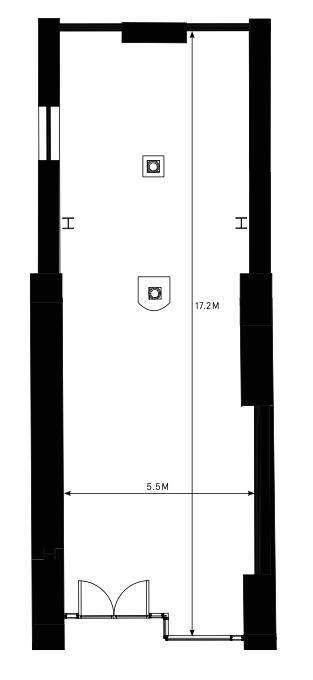

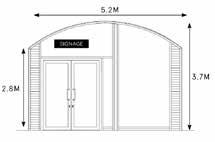

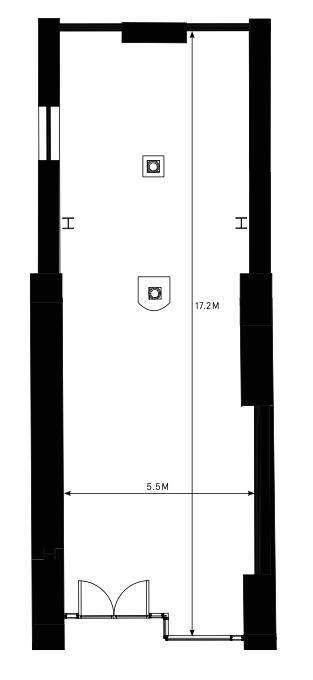

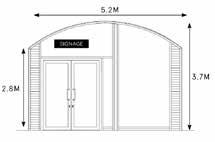

The plan and elevation of a typical retail unit at Coal Drops Yard (Figure 5.6 and 5.7) show the location and size of the double doors.

Figure 5.6 Not to scale

Figure 5.7 Not to scale Figure 5.8

15 Task 5:

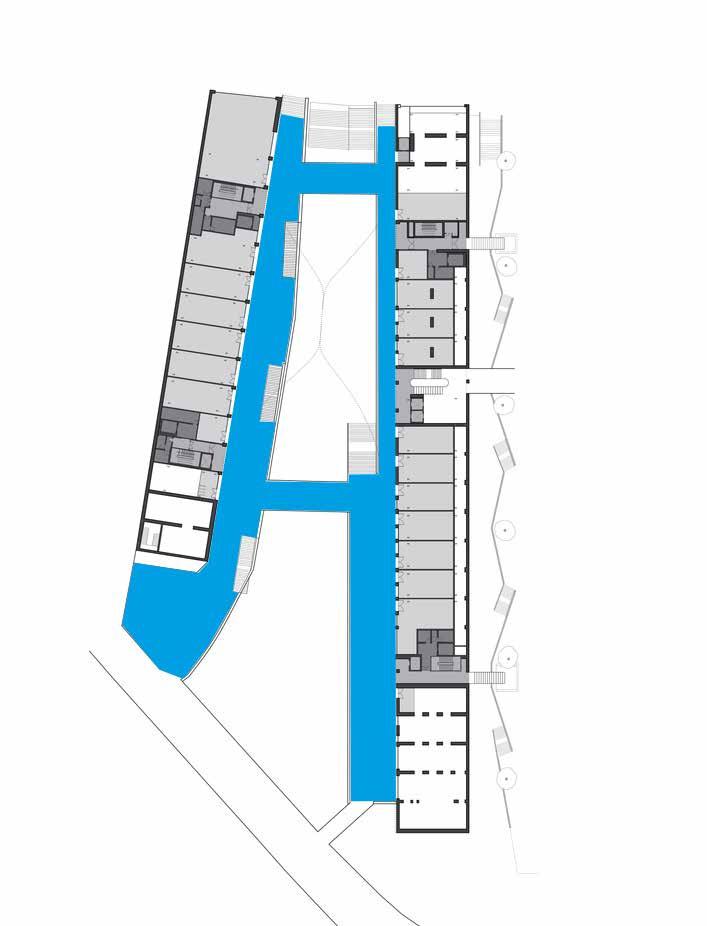

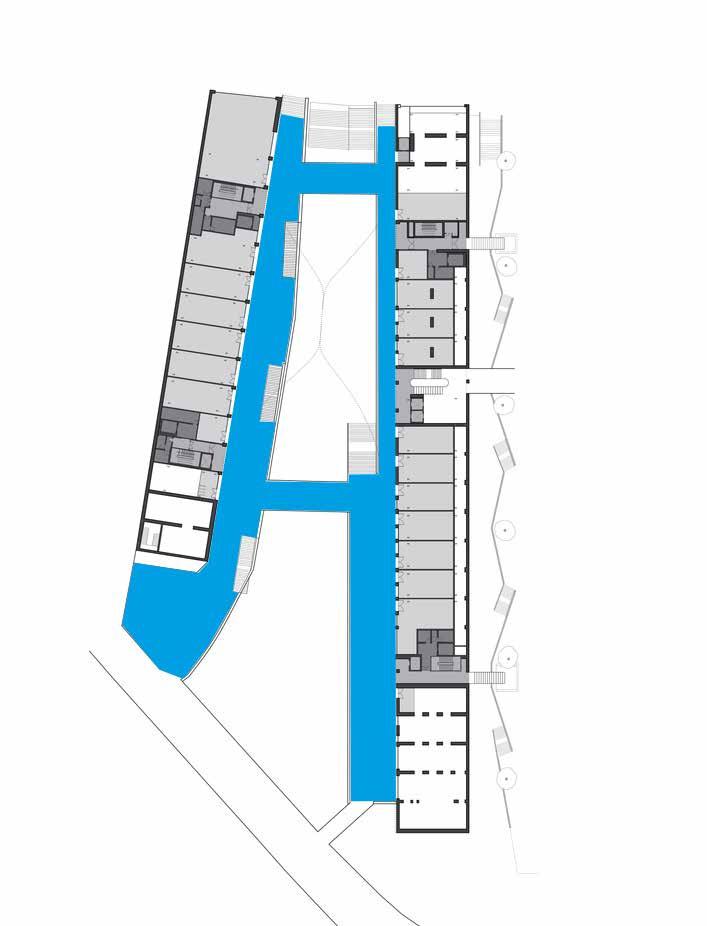

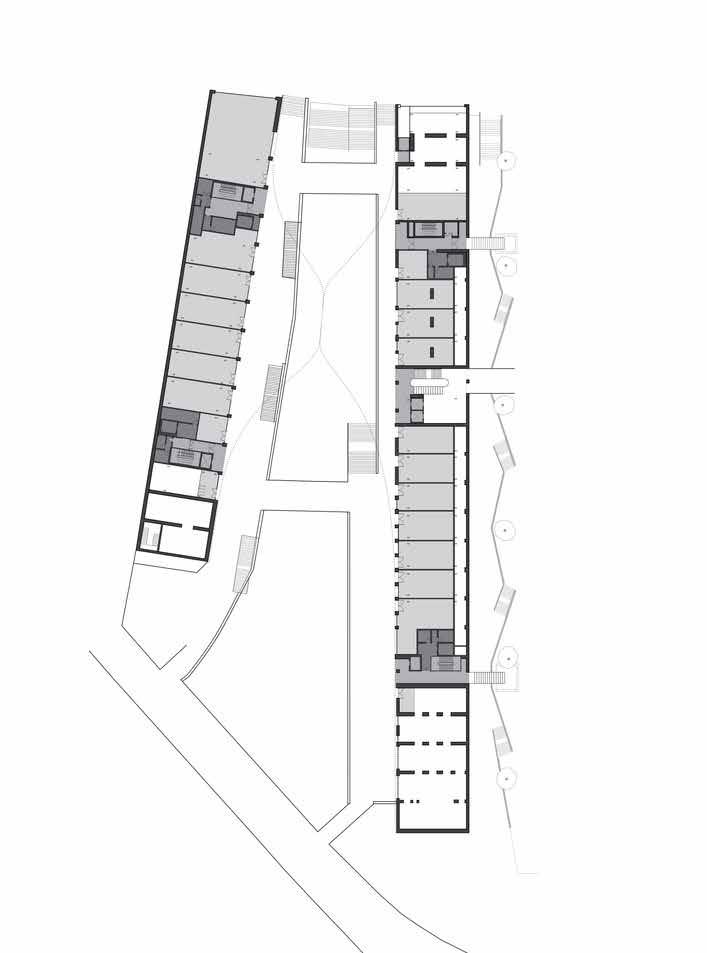

0 10m Scale 1:1000 at A3 Figure 4.1

Accessibility

Horizontal Circulation

Corridor/passageway

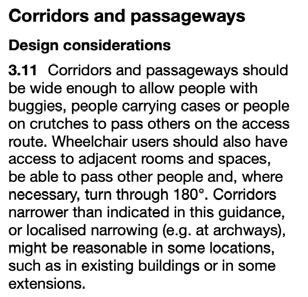

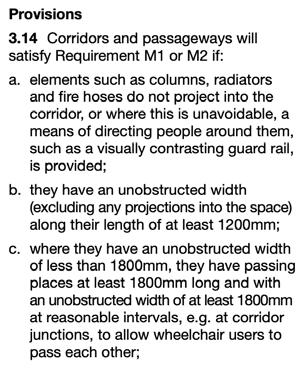

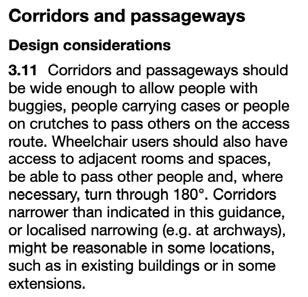

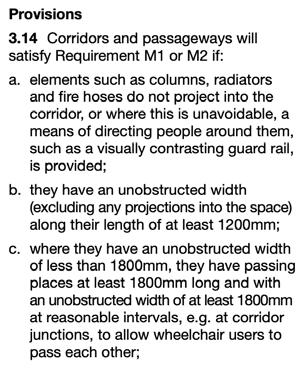

Regulatory Compliance

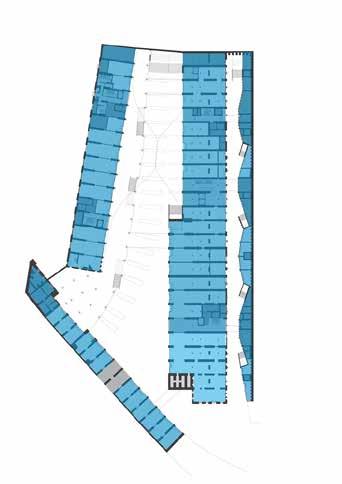

Horizontal circulation around Coal Drops Yard is provided via external walkways. The narrowest point is 3000mm which exceeds the minimum width of 18oomm and allows wheelchirs to pass eachother and perform 180° turns.

There are no columns or other extruding projections along the walkways.

Because the walkways are part of major access routes and emergency escape routes, all doors used by the general public open away from it to prevent obstuctions when open. The only doors that open into the walkways are those used for minor utility functions and are kept locked in accordance with provision 3.14 g.

16 Task 5:

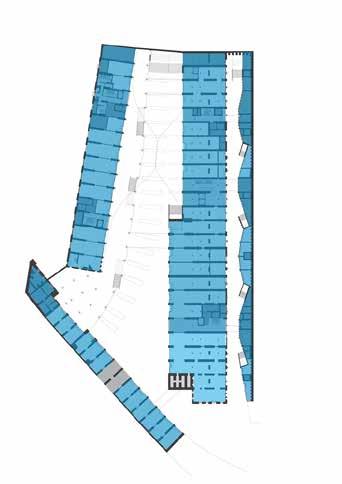

0 10m Scale 1:1000 at A3 Figure 4.3

Figure 5.9

Accessibility

Vertical

Passenger lift

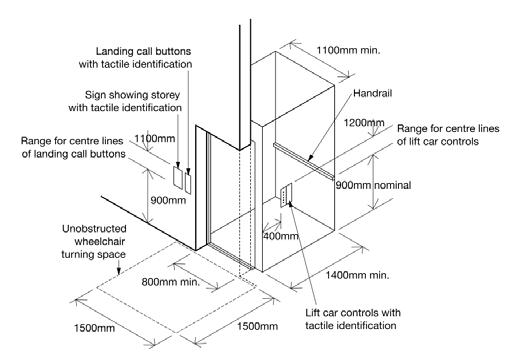

Regulatory Compliance

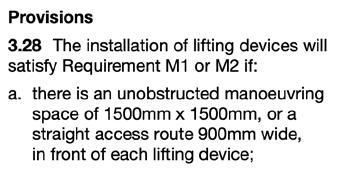

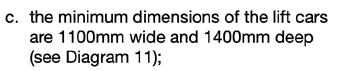

In addition to the external lift mentioned under ‘Accessibility: access to the building’ (p.14) Coal Drops Yard has 5 passenger lifts.

Approved Document M Volume 2 states that ‘a passenger lift is the most suitable means of vertical access and should be provided wherever possible.’ (2020)

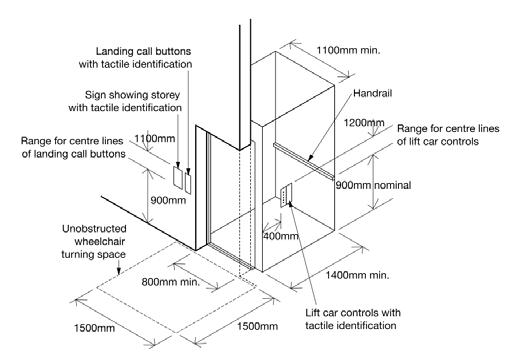

As per provision 3.28 a, there is an unobstructed manouvering space of 1500mm x 1500mm in front of each lift.

All lift cars conform with Lift Regulations 1997, SI 1997/831 and have a minimum width of 1100mm and depth of 1400mm.

Figure 5.9

Figure 5.10

17 Task 5:

Figure 4.3

Circulation 0 10m Scale 1:1000 at A3

Cost Estimate

A cost estimate is required during stages 2, 3 and 4 of the Riba Plan of Works. There are three main methods of estimating costs;

1. Preliminary estimate - cost per square meter multiplied by the gross internal floor area.

2. Working estimate - cost per functional unit multiplied by the number of functional units required.

3. Accurate estimate - elemental breakdown; the sum of the cost of each building element.

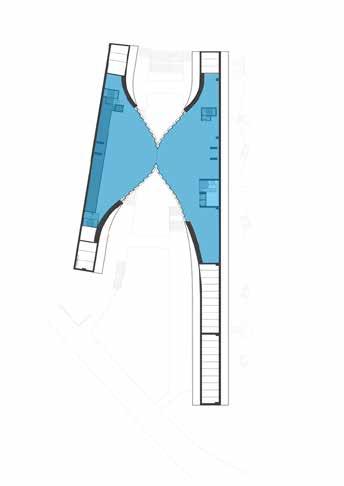

Unlike Net Internal Floor Area, GIFA includes circulation and storage spaces. It is measured from the inside of the external walls, including space taken up by any internal walls or stair wells. Building elements that are excluded include atriums, inaccessible basements and balconies. For this reason, the balconies serving as circulation space in Coal Drops Yard are not included in this calculation.

GIFA Floor 0: 4016 m² Floor 1: 2873 m² Floor 2: 2224 m² GIFA: 9113 m²

Floor 0 Yard Level Floor 1 Viaduct Level Floor 2 Upper Level 0 10m 0 10m 0 10m Figure 4.1 Figure 4.2 Figure 4.4

18 Task 6:

Gross Internal Floor Area (GIFA)

Cost Estimate

BCIS & Spon’s

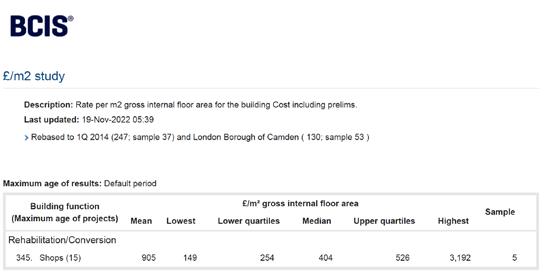

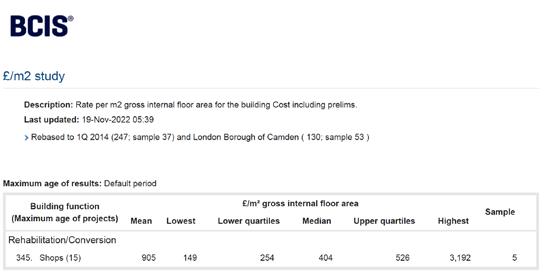

The Building Cost Information Service (BCIS)

The BCIS is a provider of independent cost data regarding the built environment in the UK.

The BCIS website includes a calculator that can be used to calculate the area cost of a project in £/ m².

Inputs include;

1. Building function

2. Site location

3. Economic quarter

The outputs can be seen in Figure 6.1

The upper quarterly data (due to the high end nature of the project) would provide an estimated construction cost of;

£526 x 9113 m² = £4 793 438 (rebased to Q1 2014)

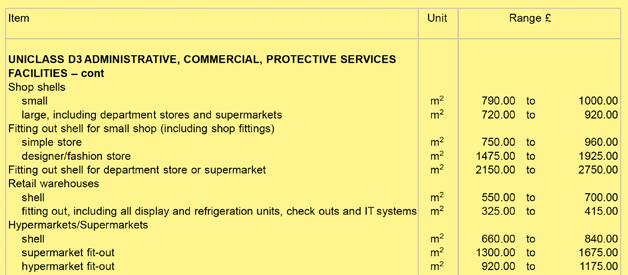

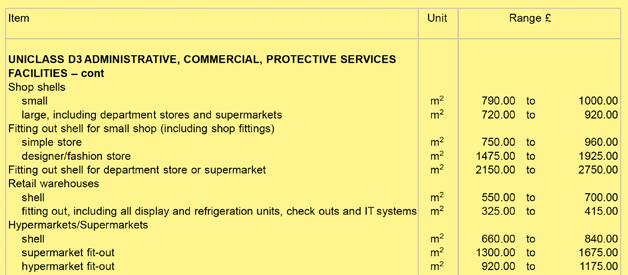

Spon’s

Spon’s is a range of construction cost estimating books for architects and builders. It includes accurate and detailed price information for a wide range of project types.

Choosing the The 2021 edition gives a estimates a cost of £750 to £960 per m² to fit out the retail units in Coal Drops Yard.

This data would provide an estimated range of; £750 x 9113 m² = £6 834 750 to £960 x 9113 m² = £8 748 480

Note: Estimated costs exclude: - Land Acquisition - Site works and landscaping - Professional fees - Local Authority Fees - VAT

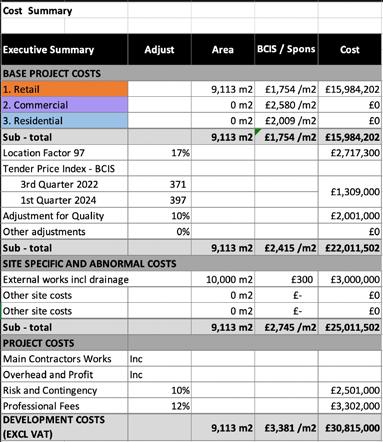

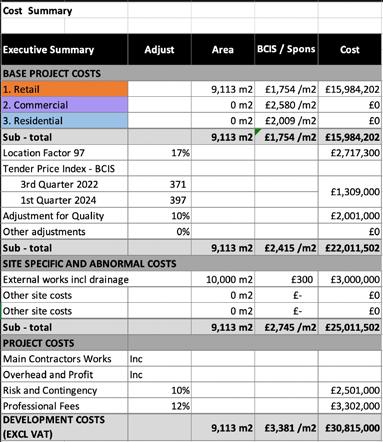

Executive Summary

To achieve a more acurate estimate the BCIS and Spons data can be combined into a table with additional variables including;

1. Location factor

2. Tender price index

3. Adjustment for quality

4. External works cost

5. Contingencies

6. Professional fees

The output after inputting this data is a more acurate project cost estimate of £30 815 000

19 Task 6:

Figure 6.1 Figure 6.2

ReferencesArchDaily. (2018) Coal Drops Yard / Heatherwick Studio. Available at: https://www.archdaily.com/904676/ coal-drops-yard-heatherwick-studio [Accessed 9th October 2022]

Companies House (n.d.) Heatherwick Studio Limited. Available at: https://find-and-update.companyinformation.service.gov.uk/company/04170748 [Accessed 4th October 2022]

Dezeen. Finlay, L. Heatherwick, T. (2018) Thomas Heatherwick explains design of Coal Drops Yard. Available at: https://www.youtube.com/watch?v=iLUGxPP0iNw [Accessed 9th October 2022]

Heatherwick, (n.d.). Studio. Available at: https://www.heatherwick.com/studio/about/ Accessed: [Accessed 4th October 2022]

Health and Safety Executive. Using personal protective equipment (PPE) to control risks at work. (n.d.) Available at: https://www.hse.gov.uk/ppe/managing-risk-using-ppe.htm [Accessed 2nd November 2022]

Heatherwick, (n.d.). Coal Drops Yard. Available at: https://www.heatherwick.com/projects/buildings/coaldrops-yard/ [Accessed 9th October 2022]

Heatherwick, (n.d.). Google Kings Cross. Available at: https://www.heatherwick.com/projects/buildings/ google-kings-cross/ [Accessed 4th October 2022]

Heatherwick, (n.d.). 1000 Trees. Available at: https://www.heatherwick.com/projects/spaces/1000trees/ [Accessed 4th October 2022]

Heatherwick, (n.d.). Guy’s Hospital. Available at: https://www.heatherwick.com/projects/objects/guyshospital/ [Accessed 4th October 2022]

HM Government. (2022) Approved Document B Volume 2, 2019 edition with 2022 amendments. Available at: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/1121266/ Approved_Document_B__fire_safety__volume_2_-_Buildings_other_than_dwellings__2019_edition_ incorporating_2020_and_2022_amendments.pdf [Accessed 16th November 2022]

HM Government (2019) Approved Document B Volume 2, 2006 edition with 2019 amendments. Available at: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/806711/ Approved_Document_B__fire_safety__volume_2_buildings_other_than_dwellinghouses.pdf [Accessed 16th November 2022]

HM Government. (2020) Approved Document M Volume 2, 2015 edition incorporating 2020 amendments. Available at: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/ file/990362/Approved_Document_M_vol_2.pdf [Accessed 16th November 2022]

RIBA (n.d.) Coal Drops Yard. Available at: https://www.architecture.com/awards-and-competitions-landingpage/awards/riba-regional-awards/riba-london-award-winners/2019/coal-drops-yard [Accessed 9th October 2022]

20

List of Figures

Figure 0.1. Luxury London. (2018) Coal Drops Yard: London’s New Retail & Dining Destination. Available at: https://luxurylondon.co.uk/taste/food/coal-drops-yard-kings-cross-london/[Accessed 4th October 2022]

Figure 0.2. Howarth, F. (n.d.) Coal Drops Yard in Kings Cross by Heatherwick Studio. Available at: https:// www.fredhowarth.com/coal-drops-yard [Accessed 4th October 2022]

Figure 1.1. Architects’ Journal. (2021) Astragal: Wanted – multi-tasking Heatherwick gofer. Available at: https://www.architectsjournal.co.uk/news/astragal-wanted-multi-tasking-heatherwick-gofer [Accessed 4th October 2022]

Figure 1.2. Heatherwick, (n.d.). Google Kings Cross. Available at: https://www.heatherwick.com/projects/ buildings/google-kings-cross/ [Accessed 4th October 2022]

Figure 1.3. Heatherwick, (n.d.). Guy’s Hospital. Available at: https://www.heatherwick.com/projects/objects/ guys-hospital/ [Accessed 4th October 2022]

Figure 1.4. Heatherwick, (n.d.). 1000 Trees. Available at: https://www.heatherwick.com/projects/ spaces/1000trees/ [Accessed 4th October 2022]

Figure 2.1. Heatherwick, (n.d.). Coal Drops Yard. Available at: https://www.heatherwick.com/projects/ buildings/coal-drops-yard/ [Accessed 9th October 2022]

Figure 2.2. ShowMe. (n.d.). Market House, Ledbury, Herefordshire, England. Available at: https:// showmeengland.co.uk/ledbury/tourism/market-house-ledbury-herefordshire-england/ Accessed: [Accessed 9th October 2022]

Figure 2.3. Heatherwick, (n.d.). Coal Drops Yard. Available at: https://www.heatherwick.com/projects/ buildings/coal-drops-yard/ [Accessed 9th October 2022]

Figure 2.4. Heatherwick, (n.d.). Coal Drops Yard. Available at: https://www.heatherwick.com/projects/ buildings/coal-drops-yard/ [Accessed 9th October 2022]

Figure 2.5. Heatherwick, (n.d.). Coal Drops Yard. Available at: https://www.heatherwick.com/projects/ buildings/coal-drops-yard/ [Accessed 9th October 2022]

Figure 2.6. Heatherwick, (n.d.). Coal Drops Yard. Available at: https://www.heatherwick.com/projects/ buildings/coal-drops-yard/ [Accessed 9th October 2022]

Figure 3.1. For Construction Pros. (2020) Remote and Autonomous Construction Equipment Technologies Increase Safety and Productivity. Available at: https://www.forconstructionpros.com/constructiontechnology/machine-grade-control-gps-laser-other/article/21134012/built-robotics-remote-and-autonomousconstruction-equipment-technologies-increase-safety-and-productivity [Accessed 2nd November 2022]

Figure 3.2. Faset (n.d.) FASET – WORKING TOWARDS ELIMINATING ACCIDENTS AT HEIGHT.

Available at: https://www.faset.org.uk/news/faset-working-towards-eliminating-accidents-at-height/ [Accessed 2nd November 2022]

Figure 3.3. Aval Consulting Group. (n.d.) Occupational Health and Safety/ Workplace Exposure. Available at: https://www.aval-group.co.uk/occupational-health-and-safety-assessment/ [Accessed 2nd November 2022]

Figure 4.1, 4.2, 4.3, 4.4, 4.10, 4.11. ArchDaily. (2018) Coal Drops Yard / Heatherwick Studio. Available at: https://www.archdaily.com/904676/coal-drops-yard-heatherwick-studio[Accessed 16th November 2022]

Figure 4.5. HM Government (2019) Approved Document B Volume 2, 2006 edition incorporating 2019 amendments. Available at: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/ attachment_data/file/806711/Approved_Document_B__fire_safety__volume_2_buildings_other_than_ dwellinghouses.pdf [Accessed 16th November 2022]

Figure 4.6 - 4.17 (exc. 4.10, 4.11). HM Government. (2022) Approved Document B Volume 2, 2019 edition incorporating 2022 amendments. Available at: https://assets.publishing.service.gov.uk/government/uploads/ system/uploads/attachment_data/file/1121266/Approved_Document_B__fire_safety__volume_2_-_Buildings_ other_than_dwellings__2019_edition_incorporating_2020_and_2022_amendments.pdf [Accessed 16th November 2022]

Figure 5.1. Ordnance Survey. (2022). Map of Coal Drops Yard [Online], 1:750, OS VectorMap® Local. Available from: https://digimap.edina.ac.uk/roam/map/os [Accessed 16th November 2022]

Figure 5.2, 5.3, 5.4, 5.5. Google (2022). Google maps street view. Available at: https://www.google.co.uk/maps/ place/Coal+Drops+Yard/@51.5358763,-0.1286432,17z/data=!3m2!4b1!5s0x48761b17d562d595:0x6240f16e618038d c!4m5!3m4!1s0x48761b17d4bbb45d:0x612712282880100b!8m2!3d51.5358763!4d-0.1264545?hl=en [Accessed 16th November 2022]

Figure 5.6, 5.7, 5.8, 5.9, 5.10. HM Government. (2020) Approved Document M Volume 2, 2015 edition incorporating 2020 amendments. Available at: https://assets.publishing.service.gov.uk/government/uploads/ system/uploads/attachment_data/file/990362/Approved_Document_M_vol_2.pdf [Accessed 16th November 2022]

21