Editor TOM HENMAN

Group Editor

KIERAN NEE

Digital Manager

KELLY NEWSTEAD

Group Manager

ROBERT GILHAM

Senior Account Manager

ALEX DILLEIGH

Design

ADEEL QADRI

Group Production Manager

CAROL PADGETT

Production Assistant

KERRI SMITH

Professional Motor Factor is an essential business magazine for those with decision-making responsibilities within motor factors.

To be removed from this magazine’s circulation, please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Stephens & George Ltd

Published by HAMERVILLE MEDIA GROUP

Regal House, Regal Way; Watford, Herts; WD24 4YF

Tel: (01923) 237799

Copyright © 2025

Professional Motor Factor:

Certificate of Average Net Circulation for the 11 issues distributed between July 2023 and June 2024

Net total: 3,159

United Kingdom: 3,159

The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication.

©tashatuvango/AdobeStock (Pg 16)

©Dilok/AdobeStock (Pg 19)

©Laura Rocandio/AdobeStock (Pg 31)

I’ve just returned from a fabulous week away with my family; the timing of it probably could’ve been better with Automechanika Birmingham a week later and the June issue to put to bed simultaneously, but cool heads prevailed, communication and planning were completed works in advance, and the support of a great team meant the wonderful memories of a holiday weren’t forgotten!

In this issue, our regular HR columnist, Amy Blick, reveals what are the most frequent questions asked of her with summer approaching – page 14 – what can businesses do to best prepare for, what she describes, as ‘annual leave season’?

She began: “Summer means annual leave season is undeniably upon us. The magical time when Out of Offices are set, rotas are blocked out and employees forget all about work for a week. Meanwhile, you are covering gaps, juggling low-staffed rotas and calculating holiday entitlements. In a nutshell, holiday season brings joy and chaos.

“I have noticed that my clients have similar frequently asked questions, particularly when summer is upon us and holiday is requested at short notice. I have gathered the questions I have been asked over the past three months and answered them…”

I’ll let you flick to the article to see what questions she’s forever asked, but maybe take a punt before you get there? Perhaps you’ve got your own way of doing things, or you’ll take inspiration from Amy’s insights and say goodbye to holiday headaches.

Of course, while I was fortunate to take time away and return refreshed, the reality is that not everyone has the same opportunity – or even feels able – to fully disconnect from work. For many, the pressure doesn’t pause for summer. That contrast has been brought into sharp focus by some sobering findings in Ben’s latest health and wellbeing report.

After polling more than 1,000 automotive workers, the survey uncovered that almost all respondents were personally affected by a health and wellbeing issue during the previous year – with stress (57%), poor sleep (52%), anxiety (44%), low mood (41%) and not taking time out (to rest or relax) (43%) in the top five.

Poor work-life balance has increased by 6% to 38%, and, according to Ben, this issue is most common for those working in showrooms, parts departments and garages. Long hours, low staffing levels and high workloads are also growing concerns.

The survey also revealed that almost one in four automotive workers are considering leaving the industry and, of these people, one in two are considering doing this due to poor mental health.

BEN CEO, Rachel Clift, said: “Stress remains the biggest issue for our automotive family, with many people citing they don’t feel they have enough time to switch off from work to rest and relax, as well as raising concerns over access to support. Money worries are also clearly continuing to impact on people’s lives, adding to these stresses. Unsurprisingly, the challenges we’re seeing are taking a toll on people’s mental health which is a continuing trend for our industry.

“Following these results, we want to ensure that everyone who works, or has worked, in the automotive industry knows we’re there for them, so please get in touch if you’re struggling by visiting www.rdr.link/FAR001. We also work closely with employers to support employees – you can read more in our full report, or by visiting www.rdr.link/FAR002.”

Enjoy the issue.

‘FOLLOW US HERE’ pmfmag.co.uk

Professional Motor Factor Magazine @PMFMag @ProMotorFactor

Tom Henman Editor

A new report by Ben has revealed the escalating health and wellbeing challenges faced by workers across the automotive sector.

Based on responses from over 1,000 industry professionals, the 2025 Health and Wellbeing Report identifies stress, poor sleep, anxiety, low mood and lack of rest as the top five concerns impacting the trade.

e annual survey, now in its eighth year, reveals that almost all respondents were affected by at least one health or wellbeing issue in the past year. Stress was the most commonly reported concern (57%), followed by poor sleep (52%) and anxiety (44%).

Poor work-life balance emerged as a growing problem, increasing by 6% to affect 38% of workers, particularly those in showrooms, parts departments and workshops. Long hours, staffing shortages and high workloads were also highlighted as

contributing factors to the industry’s wellbeing struggles.

Mental health appears to be deteriorating, with the report indicating a decline in overall mental health scores over the past year. Workers are calling for greater support from employers, with one in nine respondents citing a lack of workplace mental health support.

e findings also revealed that nearly one in four automotive workers are considering leaving the industry, with half of them pointing to poor mental health as the reason. Financial pressures continue to weigh heavily on workers as well, with one in six admitting to skipping meals and one in five reporting issues with debt.

and is facing health or wellbeing challenges to seek help through their support services at www.rdr.link/FAR003. Employers can also access resources and support for their teams via www.rdr.link/FAR004

Ben is encouraging anyone working or who has worked in the automotive industry

To access the full report and explore detailed findings by industry sub-sector, visit www.rdr.link/FAR005

UKS Distribution Limited, formerly Optimal Distribution Limited, went into administration on Friday 28th March 2025, PMF can reveal.

In a statement sent to PMF from administrators RSM UK Restructuring Advisory, it was confirmed that “following a period of trading and cashflow challenges and reducing liquidity”, UKS Distribution’s director made the “difficult decision” to

appoint administrators.

RSM UK also revealed that unsuccessful efforts were made to avoid administration, including diversification of services and a search for external investment.

RSM UK Joint Administrator and Restructuring Advisory Director, Chris Lewis, said: “Following our appointment by the director in order to protect the company’s assets, unfortunately the

business has ceased to trade.

administrators are liaising with several parties interested in the company’s assets as we look to maximise realisations for the benefit of creditors.”

Based in Halesowen in the West Midlands, UKS Distribution had been trading for 15 years and employed nine staff.

GSF Car Parts has unveiled the second of 11 new branches set to open in 2025.

e branch is located on the St Austell Bay Business Park and will act as a regional distribution centre. It will supply independent garages in Cornwall, supporting existing GSF branches in Camborne, Penryn and Newquay.

GSF opened 15 branches in 2024, as well as a 500,000sq national distribution centre in Wolverhampton. is next phase will see it introduce seven new branches

and four smaller satellite sites to the network by the end of 2025.

is latest branch is a 5,300sq unit on the St Austell Bay Business Park, featuring a shopfront, office and stock storage, and its opening has created 17 jobs.

GSF St Austell Branch Manager, Jim Medlin, said: “We’re setting up here in St Austell to bring a customer-first service to garages and motorists in the area. Every GSF branch operates to provide fast service, expert advice and a huge catalogue of parts to the local community.”

NTN Europe has taken a significant step in expanding its footprint in the shock absorber market by announcing the acquisition of a 35% stake in LTM, the shock absorber subsidiary of the Mecatech Group.

The move follows the launch of NTN Europe’s shock absorber range under the SNR brand in December 2023. It also marks a milestone in the company’s efforts to establish itself as a leading manufacturer in the trade.

“is acquisition of a 35% stake is a concrete expression of the work we have been doing for nearly two years,” said a representative from NTN Europe. “Buoyed by the excellent industrial and commercial

dynamic that has emerged from this partnership, we now want to go further and take new steps to develop our joint shock absorber production business.”

e strategic investment will enable LTM to expand its industrial capacity and increase production volumes, directly supporting NTN Europe’s ambition to become a manufacturer and key partner in the shock absorber segment. e partnership builds on the companies’

collaboration that began in late 2023, focusing on technical development, data sharing and logistics coordination.

REPXPERT, Schaeffler’s brand that delivers support and knowhow to industry professionals, has begun its ‘Driven by REPXPERT’ tour.

Following last year's ‘Road Trip’ campaign, Schaeffler’s latest journey is taking its experts to workshops around the country – delivering knowledge, product insights and giveaways to REPXPERT members that maximise the platform – and will conclude in September.

Schaeffler has confirmed that nonmembers will also be visited, emphasising its commitment to the trade as a whole.

Schaeffler Marketing and Sales Director, Matt Selby said: “We’re not just dropping in with freebies, we’re here to support garage owners, front of house staff and vehicle technicians, face to face, where they work. is tour is about celebrating independent workshops, empowering them with the

latest knowhow and saying thank you for the amazing work they do.”

Duckhams Oils has confirmed that Zuber Issa CBE, the billionaire entrepreneur that co-led the acquisition of Asda in 2021 and the CEO of EG On e Move, has invested in “revitalising and expanding” the legacy of Duckhams.

Duckhams, established by Alexander Duckham in 1899, is confident that the new investment will “propel it into a new era of innovation and growth”.

Zuber said: “Duckhams is a brand with an extraordinary legacy and immense potential for growth. I am confident the

brand will resonate with customers both in the UK and globally, given car manufacturers are producing more efficient vehicles that need premium grade oils and fuels.

“By investing in innovation, sustainability and strategic market expansion, we can ensure Duckhams can establish itself to be a leader in the lubricant sector for years to come.”

Mike Bewsey, Duckhams’ global CEO, added: “Zuber’s equity investment signals strong confidence in the Duckhams brand, its leadership and its long-term vision.

“Zuber is a very successful entrepreneur with a proven track record and strategic insights that will be invaluable as we scale our business both in the UK and globally. is partnership opens exciting new possibilities for Duckhams.”

Brett Ward has become the first back-to-back champion of DENSO’s annual karting challenge, mastering the grand final challenge set by the Whilton Mill circuit.

Following its now familiar pattern, the regional heats took place in late 2024 and early 2025 at venues across the UK and Ireland, giving as many DENSO customers and technicians who use the OEM’s products a chance to compete for the overall title.

For the second year in succession, the weather was unseasonably warm and sunny, so the circuit was dry, making the conditions perfect for the finale. To help the finalists hone their skills before the lights turned green, the DENSO Stig was on hand to provide some extra advice and inside knowledge to encourage them to maximise their performance.

At the end of the 10-lap race, nothing could prevent Brett from again showing his karting prowess, as he took the chequered flag and with it the 2025 DENSO Go Karting trophy, to sit proudly on his mantlepiece alongside the one he won the year previous.

DENSO UK and Eire Sales Manager, Kevin Peacocke, said: “e final once again lived up to its billing and, just like last year, Brett showed his class and was a worthy winner.

“However, we can’t forget both Robbie Mackenzie and Jake Postans who finished second and third, both of whom pushed

Brett all the way. So, congratulations to the top three and well done to everyone who made it to the grand final!”

As well as the honour of being crowned the 2025 champion, Brett was awarded additional prizes worth almost £2,000, which included an LG65” LED TV, a PS5, an iPad and an Apple Watch.

Niterra UK has announced that it has continued its support for British racing driver, Max Coates, as he competes in the Porsche Carrera Cup GB in 2025.

This is the sixth season that Max has partnered with Niterra UK, and this year he has moved up into Porsche’s premier UK racing series, having finished runner-up in the 2024 Porsche Sprint Challenge.

Max is already getting to grips with his new Porsche Carrera 992 GT3 Cup car whilst continuing for a fih season with the Graves Motorsport team. A new title

partnership has helped to enable Max’s progression, and he now dons the iconic blue and yellow Duckhams Yuasa Racing livery this season.

Fresh from a recent race win at Snetterton, Max is confident that his move into the Carrera Cup will be an exciting and rewarding new challenge.

He said: “At this stage in my career, I feel ready to take on the toughest and most competitive championship in onemake racing. Having Niterra by my side on this journey has meant a lot to me –they’ve had my back from the early

days and have supported me through the ups and downs in MINIs to now driving in the fastest class of Porsche racing in the UK.”

PMF introduces this month’s movers and shakers as they begin a new stage of their career in the UK aftermarket.

BM Catalysts has bolstered its marketing team with the appointment of Joe O’Neill as marketing executive.

Joe will help shape and deliver marketing strategies that promote BM Catalysts’ range of hot end emissions products, its service offering and brand.

His responsibilities will involve both strategic and operational tasks, from campaign execution and content development to performance monitoring and collaboration across departments.

The new recruit will also play a major part in event planning, helping to enhance the company’s presence across key industry exhibitions and trade shows.

Joe said: “When I saw the role, I knew it was the ideal opportunity to take the next step in my career. BM Catalysts’ attention to detail and eagerness to exceed expectations within the automotive industry is clear to see.

“I’m excited to play a part in pushing the business forward as it embraces the opportunities brought about by the ageing vehicle parc by continuing to be Europe’s leading provider of hot end emissions solutions. I also really enjoy the variety of work within the marketing team – every day is different, and that’s what makes it so engaging.”

Brake Engineering, a ZF Aftermarket brand, has appointed Fabio Di Nino as its new regional product manager. He brings “international experience” in product category management to the team, as well as a “passion for innovation, technical precision and customer collaboration”.

Fabio’s appointment shows ZF’s commitment to promoting from within too, as he was previously based in South Africa – in the same role – for ZF Services. There, he was responsible for the passenger car aftermarket product range, including TRW, SACHS and Lemförder.

Now based in the UK, Fabio believes the role is the “perfect opportunity” to continue his ZF journey while moving closer to his family: “ZF consists of great, multi-functional teams that allow for ideas to be shared, executed and implemented, and I’m excited to take on this new challenge and contribute to a respected brand, like Brake Engineering. I’m looking forward to growing the brand’s market presence and introducing meaningful, environmentally responsible product development.”

Frasle Mobility has strengthened its team with the appointment of Bryan Donaghy as business development manager for Northern Ireland, as the company looks to grow its presence and enhance service levels across the region.

Bryan boasts experience in the automotive aftermarket, having worked in the industry from a young age through his family’s motor factor business, which he later went on to manage.

Frasle Mobility believes his hands-on knowledge of the trade and understanding of customer needs make him a valuable addition to the team – and he is already well acquainted with the company’s product portfolio, having previously worked closely with Juratek, a Frasle Mobility braking brand.

Bryan said: “When I saw the opportunity, I knew Frasle Mobility was the right company for me. It’s straightforward to deal with and offers high-quality products at competitive prices. Even in my short time here, I’ve already seen the strong relationships we have with customers, which speaks volumes about the culture and values of the business.”

MTell us what you think via #PMFCounterView on LinkedIn or e-mail pmf@hamerville. co.uk

arketing in the independent garage sector has changed dramatically in the last two decades. What used to be about a decent sign outside and a listing in the Yellow Pages has evolved into a complex, digital-first operation. At Oldfields, we’ve always tried to be ahead of the curve, not just because it looks good, but because it's what modern customers expect. I studied marketing in my degree so understand the importance.

We introduced online booking 17 years ago – a novelty back then. It was a simple system, but times change. Today, that system is fully integrated into our live schedule, giving customers real-time access to our availability. It’s seamless, quick and has improved our efficiency. It’s not just tech for tech’s sake – it makes the customer journey smoother and gives us better control of our workflow.

Despite the benefits, there’s still a divide in the trade: some garages continue to treat marketing as an afterthought, or, worse, a luxury. There’s a mindset that if the ramp’s full, there’s no need to market. That might work for now, but it’s a risky bet long-term. The reality is that today’s consumer expects an experience: convenience, clarity and confidence from the first Google search to the final invoice.

At Oldfields, marketing isn’t about being flashy; it’s about being clear and consistent. We invest where it matters: a professional website, genuine customer reviews, useful social media content and clear communications. But we’re cautious not to overspend or chase trends that don't convert. Too much effort, without direction, can be just as damaging as no effort at all. One thing we’ve embraced is sponsorship, giving back to the area and keeping our profile in the area it matters most: our hometown and surrounding villages.

There’s a lot of noise out there about what garages should be doing – not all of it is helpful – but what’s non-negotiable is the need to understand how people find us. AI is already reshaping how search works, changing how customers ask questions and expect answers. If we don’t adapt to how people search, we risk being invisible, no matter how good our service is.

Marketing isn’t a bolt-on; it’s part of the job when you run a business. Just like diagnostics or customer service, it needs training, attention and strategy. Get it right, and it pays dividends. Get it wrong – or ignore it – and garages might find themselves busy today but struggling tomorrow.

While digital marketing has become a major focus for many industries, at Car Spares Factors, we’ve found that our customers still respond best to traditional, hands-on approaches. Face-to-face visits from our experienced sales team, printed promotional materials and well-timed, targeted campaigns continue to deliver the strongest results. That said, we’ve also recognised the importance of supporting these efforts with a consistent, well-rounded marketing strategy that blends the best of traditional and digital methods.

A few years ago, we undertook a full brand refresh, setting the stage for a modernised, forward-thinking identity. This wasn’t just a cosmetic update; it was the beginning of a more strategic, long-term marketing focus. A milestone in this journey was the update of our website, which has delivered a significant increase in monthly visitors and strengthened our online presence in an increasingly competitive market.

We’ve also built a consistent marketing rhythm that keeps our audience engaged and informed. This includes regular email campaigns, quarterly newsletters and seasonal promotions that align with customer needs throughout the year. Our monthly Bargain Deals is a favourite with trade customers looking for top-value parts at bargain prices. We have a printed brochure and a recently created consumables catalogue showcasing over 1,000 products.

But it’s not just about selling… We’ve also worked to build trust and reputation by encouraging and increasing our Google reviews, while our proactive and consistent outreach on LinkedIn helps us connect with both suppliers and the trade community on a personal level.

This holistic, integrated approach to marketing has helped to drive real business growth. We have seen real growth over the last 24 months, and whilst it is an accumulation of many different activities, marketing has definitely been at the forefront.

Crucially, we recognised the value in bringing in outside expertise to elevate our efforts. Outsourcing our marketing has been a costeffective solution, and the results achieved working alongside our agency have been phenomenal.

Of course, not every business in our sector views marketing with the same importance. There is still a divide – some firms are all-in, while others see it as an afterthought. Some worry too much time or budget goes into it. But at CSF, we’ve found the opposite: smart, consistent marketing amplifies everything else we do for the benefit of our loyal customer base.

The magical time when Out of Offices are set, rotas are blocked out and employees forget all about work for a week. Meanwhile, you are covering gaps, juggling low-staffed rotas and calculating holiday entitlements. In a nutshell, holiday season brings joy and chaos.

I have noticed that my clients have similar frequently asked questions, particularly when summer is upon us and holiday is requested at short notice. I have gathered the questions I have been asked over the past three months and answered them here:

Can employers refuse a holiday request during peak trading periods?

This article of Agony Amy comes with the reality that half of the year has already sped past us. Getting away to enjoy some downtime and wonderful weather is inevitable, but what if you’re the one handling holiday request forms? What can you do to best prepare for ‘annual leave season’? A Q A Q A Q

Yes. However, this comes with the caveat that holiday is a right, and this means you must think about your trading year strategically. Whilst it seems laborious, an Annual Leave Policy is paramount to ensuring your expectations are clear and you have the ability to refuse holiday if needed.

Consideration points for an Annual Leave Policy from my archives: Periods of peak business operations – this might be summer, Christmas or even half-term breaks. Considering first-come-first-served as a holiday booking rule is a good start. Also considering ‘blackouts’ in the year where holiday simply cannot be booked, as well as if you would like to shut between Christmas and New Year.

Are there legal limits on how much holiday an employee can carry over into the next year?

The statutory minimum is four weeks for basic annual leave under the Working Time Regulations, unless there is a reason the employee couldn’t take the holiday. An example of this would be long-term sickness or parental leave. If your holiday entitlement is set at the minimum requirement – at four weeks – then under normal circumstances, you cannot approve annual leave being carried over.

However, if you have enhanced your entitlement then the difference can be carried over. I have a motor factor client who has their standard annual leave set at 25 days plus statutory Bank Holidays. They allow five days of annual leave carryover that has to be used by March the following year – this is fairly standard.

What’s the best practice for handling last-minute time-off requests?

Have a clear and consistent process. Having an approach to holiday requests that is ‘ask, don’t assume’ will pay you in dividends alongside a minimum notice period for requesting leave – I usually say at least two weeks’ notice and no more than two weeks off without director-level authorisation.

Emergencies happen, and no-one can plan for these, but make sure you don’t treat every request as urgent and you have allowed enough cover for just in case something pops up! Be consistent, be transparent and be fair.

Can employers require staff to take holiday during quiet periods or shutdowns?

Yes, and this is often a smart approach. Make sure you give double the notice of the time you are asking them to take off, so two weeks’ notice for one week of annual leave. Shutdowns between Christmas and New Year or a predictable slow spell? Legal and a good use of staff planning. Make sure it is in writing, make sure you give plenty of notice and make sure it is fair for everyone.

What happens if a worker calls in sick during pre-booked annual leave?

A Q A Q A Q

They can reclaim the holiday, but only if your sickness policy has been followed and they have reported the sickness. It cannot be backdated three months after the holiday – I have seen this before!

If it is genuine sickness, make sure you treat it as such, log it properly and make sure you get evidence if appropriate.

How can small teams stay fair and consistent with holiday approval?

A must and a non-negotiable: you must be transparent. Having a clear first-come, first-served process is essential – unless there is a business priority of course!

So, whether you are battling last minute annual leave requests, juggling peak period cover, or fed up with a three-week holiday request during your busiest month, please remember this: clear policies, fair processes and consistent communication are your best defence.

If your current policy is to cross your fingers and hope for the best, then it is time to get more strategic and book in an exhilHRate power hour. In just 60 minutes, we can get your holiday watertight, your team aligned and your business process ready and prepared –no more out-of-office panic!

● Use a shared calendar

● Write a clear policy

● Stick to your own rules

● Being consistent doesn’t mean saying yes to everyone!

The WhatsApp Business Platform is opening up “major opportunities” for both workshops and motor factors, according to the founder of Stitch AI, a Meta tech provider that aims to help the trade use the WhatsApp Business Platform to improve customer communication.

Paul Gandar is the person behind Stitch AI, and he believes that in workshops around the country, phone calls are being ignored, and e-mails are going unread. He argues that the ‘modern technician’ wants answers fast, on-the-go, and on a platform that fits into their working day – for the vast majority, he says, that is WhatsApp.

And while many factors are using WhatsApp to message customers – maybe you are one of them? – Paul believes that most of them are using it incorrectly, namely personal phones or the free WhatsApp app, and that’s a real problem.

Paul said: “The current setup is broken. Staff are messaging customers from

personal mobiles or shared work phones, but those chats are isolated, untracked and completely outside the business’s control. It’s not compliant, it’s not professional, and it’s not scalable.”

Although WhatsApp is widely used, Paul argues the free app – including the downloadable WhatsApp Business version – isn’t designed for team use. He said it is limited to one user on one device, with no way to link up with CRMs, no order tracking, no reporting and no way for multiple staff members to view or manage conversations together. Paulcompares the free version of WhatsApp to like running

X No visibility: If someone’s off sick or leaves the business, their chat history and customer conversations go with them.

X No compliance: Messages sent through personal phones sit outside GDPR control, putting the business at legal risk.

X No consistency: Without integration into order systems or CRMs, there’s no record of what’s been said or promised — making it hard to follow up or pick up where someone else left off.

“customer service out of someone’s back pocket: risky, inefficient and nearimpossible to scale”.

Paul revealed that the WhatsApp Business Platform is specifically designed for professionals. Available via API, it enables companies to use WhatsApp in a centralised, secure way that fully complies with GDPR and integrates with internal processes.

Paul continued: “This is a huge opportunity for motor factors to finally modernise how they engage with workshops. No more missed calls, no more chasing quotes by email — technicians just want to fire off a quick message and get a fast, helpful response. WhatsApp, done properly, makes that possible.”

Paul is confident that workshops and technicians are already using the platform during their working day – messaging

customers about repairs or sharing images of issues – and while some “progressive factors” have started to make the shift, there are plenty that haven’t.

He added: “By adopting the WhatsApp Business Platform, motor factors are giving their teams modern tools to improve service, reduce order turnaround times, and respond faster — all while staying fully compliant and keeping communications visible across the business.”

Because the WhatsApp Business Platform is API-only, it can’t be downloaded as an app. Businesses either need to build their own custom tools to connect to it — or work with an official Meta tech provider that can implement it.

Companies, like Stitch AI, are helping businesses do just that — getting teams up and running quickly with shared inboxes, automation and integration with backoffice systems.

Paul concluded: “This isn’t just a messaging upgrade! It’s a way for parts

✔ Shared access for teams, so messages don’t get lost or siloed

✔ Integration with CRMs and order systems to keep context and customer records complete

✔ Full data visibility and storage to support compliance

✔ Message templates and automation to handle FAQs or send instant updates

✔ Web-based access — no need for staff to use personal mobiles

WhatsApp chat buttons that can be added to websites, letting workshops start a conversation as easily as picking up the phone!

suppliers to finally fix the communication gap with workshops. It saves time, cuts admin and delivers the kind of responsive, joined-up service workshops want.”

For more information about Stitch AI, www.rdr.link/FAR010

For those looking to take the next step in their aftermarket career – perhaps you’re one of them? – finding the right recruiter can make a huge difference in a job search, argues recruiter, Glen Callum Associates (GCA). Here, it provides a bestpractice guide to help candidates understand what to expect from a recruiter.

This handy checklist, penned by Kerrie Richards, director at GCA, offers guidance on how candidates can ensure they are working with a recruiter that prioritises their career goals, while dispelling common misconceptions:

1.Firstly, we encourage candidates to consider whether the recruiter understands their unique needs. A quality recruiter will take time to understand the candidate’s experience, skills and long-term career goals. Instead of pushing roles that don’t align, they focus on matching candidates with opportunities that suit them best.

2.Next, we advise candidates to check if the recruiter offers career advice. A good recruiter should be a valuable career resource, providing guidance on CV improvements, interview techniques and market insights. At GCA, we go beyond job listings, offering one-on-one CV reviews, interview coaching and career development advice to help candidates stand out.

3.Choosing a recruitment agency that has strong networks is also key, reasoning that the best recruiters are well connected and hold established relationships with top employers and industry bodies.

4.Rather than rushing to fill vacancies, we believe that true recruitment success lies in creating lasting, well-aligned placements that focus on finding the best match, not only for the role but also for the candidate.

5. Ethics and integrity also sit at the heart of best-practice recruitment. A reputable recruiter should always act with transparency, discretion and professionalism, and be affiliated with recognised industry bodies.

6. Honest and clear communication is another vital factor; it’s about ensuring candidates are kept updated at every

stage, offered honest feedback and clear details about salary, expectations and company culture. We don’t leave candidates in the dark. We’re here to guide and support them through every step.

7.Having access to the best opportunities should be a given. When it comes to job opportunities, our reputation opens doors to roles that often aren’t publicly advertised.

8.Beyond job matching, a great recruiter provides genuine support, which includes personalised notes submitted with applications to boost CVs, direct engagement with decision-makers, tailored interview prep and even postplacement follow-up to ensure a smooth transition. Our job isn’t done when a CV is sent. We stay involved and invested in the outcome.

9.Recruiters should also be equipped to offer advice on packages and support salary and contract discussions, helping candidates understand total package value, from benefits and flexibility to longer-term prospects, and advise on negotiations, ensuring informed and confident decisions.

10. Specialist industry knowledge is another defining factor. As a dedicated automotive aftermarket recruiter and IAAF member, we bring insider knowledge and real-time market insight, helping candidates explore areas of growth and identify career opportunities that suit their long-term ambitions.

11.And finally, reputation matters! Before choosing a recruiter, it’s worth checking reviews and testimonials from other candidates and employers.

A recruiter with a strong track record and proven success is far more likely to provide a positive experience. We have built long-standing relationships across the industry and are proud to be consistently rated highly by both job seekers and hiring businesses. Candidates can explore our testimonials and Google reviews for realworld reassurance of the quality service we provide.

And while choosing the right recruiter is essential, we are keen to clear up one of the biggest myths in the job-hunting process: candidates don’t pay for recruitment support. Our services are funded by the employer, meaning job seekers benefit from advice, coaching and guidance at no cost.

We want to reassure candidates that this process is for them. We’re here to offer honest advice, confidential support and access to fantastic roles, all without any fees.

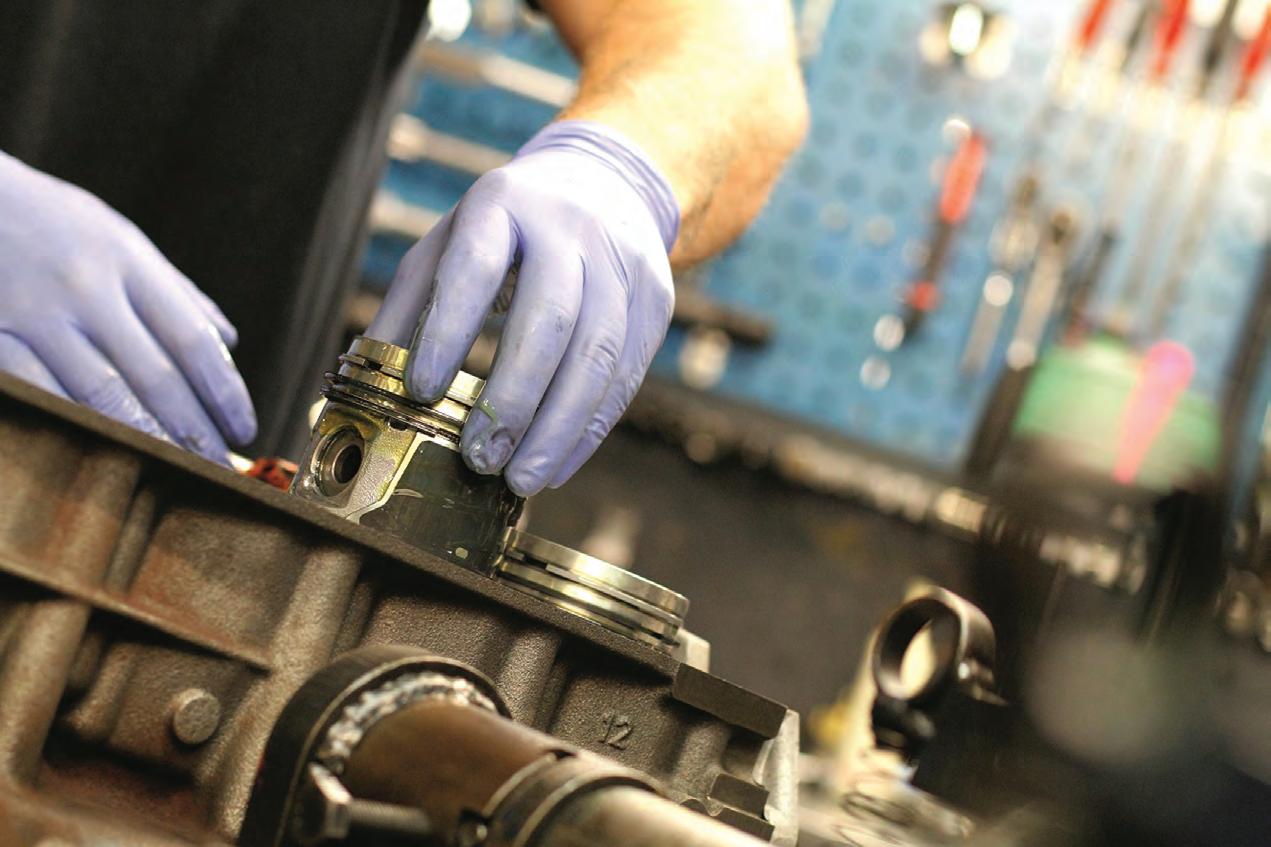

Ivor Searle has added the 1.5L DV5 diesel engine to its all-makes range, covering 26 Ford, Peugeot, Citroën and Vauxhall applications, and over 90% of the UK vehicle parc.

Delivering a power output of 75120PS, the four-cylinder engine covers a number of Ford and Stellantis cars and vans produced from 2017-onwards. Vehicles include the Ford Focus, EcoSport, Puma, Kuga and Transit Connect and Courier, as well as the Peugeot 208, 308 and 508, the 2008, 3008 and 5008 SUVs, plus the Partner, Rifter, Expert and Traveller vans.

For Citroën, the unit covers C3, C4 and C5 applications, as well as the Berlingo, Dispatch and Space Tourer LCVs. For

Vauxhall, the engine covers the Corsa supermini and Grandland SUV, as well as Combo and Vivaro van models.

Costing up to 40% less than OE, claimed Ivor Searle, it also stated that its engines are remanufactured to exceed the BS AU257:2002 Code of Practice for remanufacturing engines. All Ivor Searle engines are covered by a 12-month unlimited mileage parts and labour warranty. Customers are also offered free next day UK mainland delivery for stock items ordered before 3.30pm.

QUICK-FIRE Q&A: IVOR SEARLE COMMERCIAL DIRECTOR, DAVID ESZENYI

What factors led Ivor Searle to prioritise the DV5 engine for inclusion in its remanufactured range?

A range development is a continuing process, and the DV5 diesel unit has been added in response to high demand.

A Q A Q

How does Ivor Searle ensure consistent quality and compliance with BS AU257:2002 across high-demand units, like the DV5? It is ensured through a quality management process certified to ISO9001:2015.

A Q

What support or guidance is available for motor factors and workshops fitting the remanufactured DV5 engine?

All of our remanufactured engines are supplied with preinstallation guidelines and model specific instructions, if required. Our expert customer service team is also on hand to support factors and workshops.

A Q

Are there any trends in demand for remanufactured diesel engines among motor factors or workshops?

The LCV segment is particularly active in terms of demand for diesel engines, driven by the high proportion of diesel vans serving the home delivery market and previous delays in new vehicle supply. This has led to fleets and owner operators extending vehicle lifecycles, increasing the probability of major component failure.

For more information about Ivor Searle, www.rdr.link/FAR012

With many vintage car owners and enthusiasts preferring to restore original components back to OE specification, we can guarantee an exact fit and function, one that maintains authenticity, performance and, crucially, aids resale value.

At Autoelectro, our remanufactured starter motors and alternators are tested individually to meet – or exceed – OE specification. This is achieved thanks to the latest OE specification test equipment available in the market.

The alternative is a mass-produced copy version that, while often

readily available, may not offer the same level of precision or compatibility required for classic vehicles. By choosing remanufactured OE units, enthusiasts can be assured of both authenticity and dependable performance, preserving the vehicle’s heritage and long-term value.

Autoelectro believes its ‘reman and return’ service is more important than ever with classic car season well and truly underway! But what does it entail?

Here’s Harnek Bhogal to explain.

It is a myth that classic cars are tougher to fix than today’s modern vehicles; in fact, as starter motor and alternator technology is much less complex than newer units, such as an iStARS (integrated Starter-Alternator Reversible System) or BSG (Belted Starter Generator), technicians should feel confident about fitting them.

Worn bearings are a common sight on older alternators; they allow the rotor inside the unit to spin, so if one is worn, it can lead to excessive noise –comparable to a grinding or whining noise – and reduced charging efficiency. Corroded or loose wiring is also prevalent; this can lead to intermittent charging issues.

Switching to starter motors, a bad earth – which can lead to weak cranking – and worn bushes – that can wear down over time and lead to starting issues – are two of the most typical faults associated with vintage units.

If you are searching for a particular part number, you can utilise our business WhatsApp service. By sending images of units to our base in Bradford, a member of the engineering team can identify that unit and offer a solution.

For any classic car owner looking to maintain authenticity, reliability and performance, working with a skilled and experienced remanufacturer – not to mention passionate classic car enthusiast – we can give old units a new lease of life, without compromising its heritage.

“IT IS A MYTH THAT CLASSIC CARS ARE TOUGHER TO FIX THAN TODAY’S MODERN VEHICLES; IN FACT, AS STARTER MOTOR AND ALTERNATOR TECHNOLOGY IS MUCH LESS COMPLEX THAN NEWER UNITS, SUCH AS AN ISTARS (INTEGRATED STARTER-ALTERNATOR REVERSIBLE SYSTEM) OR BSG (BELTED STARTER GENERATOR), TECHNICIANS SHOULD FEEL CONFIDENT ABOUT FITTING THEM.”

We have more than 5,000 unique part numbers in stock – from fastmoving, technologically modern to specialist, traditional units. This is possible because of our engineers and technicians’ ability to source core, disassemble, inspect, assemble and test units.

Standout, timeless units include an alternator for an Aston Martin Lagonda 5.3 V8 petrol (1990onwards), starter motor for a Talbot Express 2.5 diesel (1989-onwards), water-cooled alternator for a Bentley Arnage 6.7 V8 petrol (2000-onwards) and starter motor for a Suzuki Alto 0.8 petrol (1985-onwards).

For more information about Autoelectro, www.rdr.link/FAR013

AS-PL Production Director, Michał Czarzasty, looks at both the ecological and economic benefits of remanufacturing.

In a world where sustainability is no longer optional but essential, remanufacturing is emerging as a powerful solution that balances ecological responsibility with economic sense.

At its core, remanufacturing is the process of giving a second life to used products –alternators, starter motors and other essential automotive components – making it an

From an environmental standpoint, the benefits of remanufacturing are clear: the process minimises waste by salvaging as many components as possible from each core, drastically reducing the volume of usable parts that would otherwise end up in landfills. On average, our premium line of remanufactured products retain more than 80% of original components. By extending the lifecycle of these parts, we’re helping conserve valuable natural resources, including raw materials, energy and water –the result? A significant reduction in environmental impact without sacrificing performance or quality.

innovative alternative to purchasing new parts, which often come at a high cost.

At our advanced production facility in Poland, this process is executed with precision, using advanced equipment and adhering to rigorous EU quality standards. Every component begins its journey as a ‘core’ –used parts sourced from specialised partners. These cores undergo detailed analysis and, if

From an economic perspective, remanufacturing offers a high-value, cost-effective alternative to new components. Optimised processes and early-stage testing of cores allow us to reduce operational costs, streamline labour and improve efficiency.

Moreover, each remanufactured product undergoes comprehensive testing, significantly reducing the risk of future defects and minimising the likelihood of customer complaints. This commitment to quality assurance boosts both customer confidence and protects the reputation of the factors and technicians that rely on our products.

they meet our strict criteria, are disassembled and subjected to a thorough inspection. Parts that pass this evaluation are then sent to dedicated stations for cleaning, refinement and refurbishment. Components that don’t meet our expectations are excluded early on, optimising time, labour and machine resources. The successful parts are reassembled, tested repeatedly throughout the process, and then subjected to a final inspection. Only after passing this last hurdle is the remanufactured product approved, accompanied by a detailed test report that certifies its performance to be on par with OEM standards.

Our dedication to refining the remanufacturing process showcases how innovation and sustainability can go hand in hand. By blending technological excellence with a deep sense of environmental and economic responsibility, remanufacturing is a practical alternative for the future of the automotive aftermarket.

Modern engine technology demands precision — and fuel filtration is no exception. As engines become more sophisticated, their fuel systems are built with components engineered to tolerances of less than two microns and subjected to extreme pressures. This makes clean fuel essential, especially in diesel engines, where the fuel doubles as a lubricant for high-pressure pumps and injectors. Here’s Charles Figgins, product and technical information manager, for Blue Print.

Unfortunately, fuel purity can't always be guaranteed. Contaminants from fuel station refills or corrosion inside metal tanks are common and pose serious risks. Even microscopic particles can damage injector pintles, distorting spray patterns and impacting combustion efficiency, fuel economy, idle stability and emissions. Maintaining proper fuel flow is critical: while some contaminants may seem insignificant, poor filtration can result in restricted flow, reduced performance and long-term engine damage.

WHY DIESEL NEEDS MORE THAN JUST FILTRATION

While both petrol and diesel fuels require protection against abrasive contaminants, diesel engines face additional challenges. Water contamination is one of the most significant. Condensation within the tank, as well as water suspended or emulsified in diesel fuel, can lead to corrosion in

sensitive fuel system components.

At Blue Print, our diesel fuel filters are engineered to address this issue directly. They utilise a hydrophobic coalescing material that allows fuel to pass through while trapping water. The separated water collects in the base of the filter canister and can be drained during regular maintenance — a vital step in protecting fuel system longevity.

“DIESEL IS NOT ONLY UNSTABLE, BUT IT’S ALSO ORGANIC — AND THIS MAKES IT AN IDEAL BREEDING GROUND FOR CERTAIN FUNGI, SUCH AS CLADOSPORIUM RESINAE. SPORES NATURALLY PRESENT IN THE AIR CAN CONTAMINATE FUEL, PARTICULARLY IN SYSTEMS WHERE DIESEL AND WATER MEET UNDER WARM CONDITIONS. SINCE MANY MODERN DIESEL SYSTEMS CONTINUOUSLY CIRCULATE AND WARM THE FUEL, THE TANK BECOMES AN IDEAL ENVIRONMENT FOR MICROBIAL GROWTH.”

Diesel is not only unstable, but it’s also organic — and this makes it an ideal breeding ground for certain fungi, such as Cladosporium resinae. Spores naturally present in the air can contaminate fuel, particularly in systems where diesel and water meet under warm conditions. Since many modern diesel systems continuously circulate and warm the fuel, the tank becomes an ideal environment for microbial growth.

The byproducts of fungal activity can clog fuel lines and degrade system performance. This is another reason why regular filter maintenance — and the use of high-quality filters that remove water effectively — is essential.

These petrol and diesel fuel filters are manufactured to meet or exceed OE specifications. This ensures proper fuel flow, maximum engine protection and long-term reliability. To reinforce this commitment to quality, we offer a three-year manufacturer guarantee on all replacement parts.

Do filters get the credit and attention that they deserve? To find out, MANN+HUMMEL Product and Marketing Manager – Aftermarket, Gary Winslow, gives a candid opinion and takes you through the importance of each filter.

Filtration is often overlooked on a vehicle. To many, filters can be a consumable, throw-away item that is out of sight, out of mind. Subsequently, claims of OE

First, the oil filter. This filters the oil in an average car sump approximately 240 times an hour – for context, on a 200-mile trip, circa 5,000 litres of oil is filtered! At modern service intervals, upwards of 300,000 litres of oil can be cleaned by the filter. That’s a lot of oil for a small filter.

Fuel filters: As fuel is recirculated by modern injection systems, a 50-60L tank of fuel is cleaned around twice per hour. This equates to the fuel filter cleaning approximately 12 times more fuel than the engine is consuming. With

specification are often banded about, irrespective of any actual credentials to back this up. ‘Fit and forget’ is often a very apt opinion of filters by some technicians.

injection systems now very fine and increasingly sensitive to water in the fuel, many OE quality fuel filters will also double-up and filter water from the fuel and contaminant. Twice the work for this filter.

Air filters are often the poor relation and not replaced at ‘interim’ services but can ‘breathe’ in around 2,500 litres of air per minute. For context this is around 40 litres of air a second, and over a 200mile journey around two million litres of air! Coupled with wet winter conditions, and air-flow meters becoming very

Sure, filters can be relatively inexpensive as part of the whole engine service, but they can be a real deal-breaker – and engine breaker! – if low-cost, low-

sensitive to any disruption in airflow, the air filter is critical.

And lastly, cabin filters. Since COVID, many VMs are now seeing this filter as the main, key filter – why? It protects the driver and the passengers, the most important operating part of the whole car, lorry or machine. With a modern, high-specification cabin filter now not just filtering pollen but also harmful gases – nitrogen oxide, sulphur dioxide, ozone – and now stopping allergens and bacteria from entering the cabin, the modern cabin filter is a must-fit.

“Sure, filters can be relatively inexpensive as part of the whole engine service, but they can be a real deal-breaker – and engine breaker! – if lowcost, low-quality items are used to cut corners.”

quality items are used to cut corners.

Once the vehicle, be it a car, lorry or tractor leaves the workshop, it can be hard to justify spending a little more on a proven, OE quality product. But when something goes wrong…the whole vehicle comes to a grinding halt, often with very expensive repercussions and possible loss of reputation to the workshop and technician.

So, is the filter really fit and forget ?

Imagine selling a filter without the manufacturing expertise from the likes of MANN-FILTER, for example… Oil loss, blown engine? Fuel starvation, stalled car? Low power, error codes? Misted windows, stale, stuffy air in the cabin? Not worth it, or the reputational damage.

then:probably the hardest working component of the engine – but not that you can see it!

For more information about MANN-FILTER, www.rdr.link/FAR016

Strengthening your technical knowledge will allow you to better support your workshop customers when it comes to spin-on oil filters, according to Comline. Furthermore, it should avoid needless, frustrating returns.

Still the most commonly used oil filter type in passenger vehicles, spin-on oil filters remove contaminants from the engine oil to ensure it runs smoothly and reliably. It can also help extend the engine’s lifespan. These filters – cylindrical metal canisters housing an internal filter element – screw directly onto the engine block.

As straightforward as the design may look, there are several built-in features that are essential to this filter’s performance, especially during cold starts and long service intervals, as Comline Group Product Manager for Filtration, Matthew Stanley, explained:

Anti-drainback: Found on the ‘dirty side’ of the filter, this valve prevents oil from draining back into the engine when it is switched off. This valve is particularly important for applications where the filter is installed on the side or top of the engine. Without it, oil would simply flow out of the filter and leave the engine unprotected at start-up.

Bypass: Acting as a safety feature, the bypass valve comes into play when a filter becomes blocked – whether that’s due to dense oil from cold starts or a delayed filter change. When clogging occurs, pressure builds up on the dirty side of the filter. This prompts the bypass valve to open and unfiltered oil to flow, which is preferable to starving the engine of oil altogether. Without it, the engine would be exposed to potential failure.

Anti-syphon: Located on the ‘clean side’ of the filter, this valve stops clean oil from flowing back into the engine when it is switched off. This valve also retains a small ‘reservoir’ of oil inside the filter, which means quicker lubrication after ignition. By maintaining this reservoir, the engine wear during start-up is significantly reduced, which increases the protection of critical components.

In addition to these three valves, Comline’s filters incorporate several other design features, including perforated centre tubes to help oil flow, robust housings and nitrile butadiene rubber (NBR) gaskets for flexibility and durability in harsh conditions.

By relaying the following tips to workshop technicians, you can help them avoid mistakes, repeat work, warranty issues and engine damage – all of which build trust and loyalty in both parts supply and the motorists expecting their car to be returned roadworthy and reliable over the interval period:

Overtightening: Filters should generally be hand-tightened. Once the gasket contacts the mounting surface, an additional quarter-turn is sufficient. Using a tool to tighten can risk damaging the filter, stripping threads, and causing

corrosion from compromised coatings. However, if the manufacturer provides specific instructions or requires the use of a special tool to tighten the filter to a designated torque, those guidelines should be followed.

Cross-threading: If the filter isn’t correctly aligned during installation, crossthreading can happen. This leads to poor sealing and potential leaks. Worse still, it can complicate removal at the next service. Comline recommends careful alignment and threading by hand to ensure a secure fit.

According to Comline, these characteristics mean that its filtration range meets OE-matching standards. Couple this with the brand’s “value promise”, Comline is confident its filters are a “compelling proposition”.

To download a technical bulletin about Comline’s spin-on filter valves, go to, www.rdr.link/FAR017

To download a technical bulletin about Comline’s oil filter fitting guidelines, visit www.rdr.link/FAR018

For more information about Comline Group, go to, www.rdr.link/FAR019

Always lubricate the gasket: A small amount of clean engine oil on the gasket ensures a secure seal and easier removal at the next change. It only takes a fingertip’s worth of oil to make a difference. Not only can you use this information over the counter or on the phone, but you can also download technical bulletins – from Comline’s website – that can be absorbed or shared with customers. Not only does the portal contain filtration content, but technical information extracted from Comline’s other product categories.

‘SMALL

As well as frequent additions to its portfolio of emissions control products, BM Catalysts also ensures that, where required, technicians have access to the accompanying mounting components, with fitting kits being launched as standard with most new-torange products. Kits can include anything from gaskets and clamps to washers and springs, as well as specialist nuts and bolts.

BM Catalysts Technical Director, James Saunders, said: “Fitting kits are a small but important factor to take into consideration when buying or fitting a replacement emissions control product. BM Catalysts recommends using a new fitting kit wherever possible, and there are several benefits to using them that are often overlooked.

“The benefits of using a new fitting kit outweigh the costs, and we encourage technicians to utilise the kits in our range to help prevent invalidating warranties and the complications that can arise from trying to reuse old or existing fittings.”

James added that, over time, gaskets can suffer wear and tear which could cause them to break. Fitting new gaskets at the time of replacing the unit itself helps eliminate this risk and creates a better, tighter seal. With manifold catalytic converters, this means that gases are less likely to leak.

He continued: “As manifold gaskets are compression gaskets, it’s unlikely even the most skilled of technicians will be able to get them in the exact same position again if they intend on reusing them.”

Much like gaskets, support rubbers can deteriorate and break over time, with rubber known to perish with age. Failure to replace worn support rubbers or hangers can allow too much movement in the exhaust, which could cause damage to the replacement unit.

Should an underfloor unit become detached and make impact with the ground, it could destroy the internal monolith, meaning a costly replacement would be in order.

Furthermore, rusty nuts and bolts can sometimes lose threads, meaning they may not be long enough to fit the new unit –something usually not discovered until the unit is about to be fitted onto the vehicle. Purchasing replacements in advance may help avoid delays or unnecessary complications when it comes to fitting, according to BM Catalysts.

Springs, they can lose their strength and so cannot hold joints together effectively, thus allowing the joints to blow.

The company also warns against the use of exhaust paste; when used in front of a catalytic converter to try and rectify fitting issues, it will invalidate the unit’s warranty.

BM Catalysts has claimed that it is important that new fittings are used when an emissions control product is replaced –and has shared some details of kit range in the process.

The company recommends using a kit designed specifically to fit the unit to the vehicle to avoid problems and possible warranty failures.

BM CATALYSTS HAS YOU COVERED

SCRs: 100% coverage

DPFs: 98%

Pipes: 90%

Catalytic converters: 87%

Also, BM Catalysts’ bestselling 100 parts are covered too!

HELLA has launched a complete braking portfolio into the trade, marking a “significant expansion” for the brand after more than a decade of “braking success” across Europe.

The lineup includes pads and discs, as well as calipers, drums and shoes, master and wheel cylinders, and wear indicators, and is complemented by HELLA electronics, such as brake-by-wire pedals and ABS sensors.

HELLA has revealed that its brake pads are engineered to OE standards, using over 200 friction material components. Constructed with powder-coated steel backplates and high-shear adhesive, they feature application-specific chamfers and noise grooves. With over 40 test vehicles covering nearly 200,000 miles annually, HELLA’s pads are engineered for safety, performance and reliability.

Discs are also built to OE standards, using high carbon content for heat dissipation and reduced brake fade where required. A water-based coating protects against corrosion and removes the need for cleaning before fitment. All discs carry ECE R90 approval.

Calipers are new units that are bench tested and ready to install, with no surcharge or core return required. Each unit includes essential mounting hardware.

Approximately 6,000 part numbers are already available, and HELLA has confirmed that number will extend to 9,000 in the future.

WWW.RDR.LINK/FAR021

Autowave has released four new YouTube videos to its channel. The latest batch of content is in response to customer demand and caters to an online community of 8,500 subscribers.

Starting with the OBDStar Key Master G3 key programming tool, it is now running the latest software that introduces a significant upgrade: it can now calculate sync data for VAG MQB vehicles in all keys lost scenarios. In the video, Autowave’s Ravi Kotecha takes viewers through the updated systems, offering a step-by-step walkthrough on how to maximise these powerful new features. Watch: www.rdr.link/FAR022

Next, continuing from the VAG MQB sync data calculation software update, the following video demonstrates live data reading from an MQB instrument cluster using the latest RH850/V850 adaptors for the OBDStar G3. The video demonstrates the full process, providing practical tips for locksmiths and technicians working on modern VAG systems. Watch: www.rdr.link/FAR023

In the ensuing hands-on demonstration – again, focusing on the OBDStar G3 – the video performs a complete all keys lost procedure on a 2018 VW Tiguan MQB. The presenter reveals each step, highlights common issues and explains how to resolve them. Watch: www.rdr.link/FAR024

Finally, addressing regular enquiries from customers, Autowave has created a tutorial covering the Peugeot 107, Citroën C1 and Toyota Aygo (up to 2014). In the clip, Ravi shows the whole process of generating a transponder using the Xhorse VVDI2 and VVDI Prog in an all keys lost situation. With plenty of these vehicles on the road, this video is a must-watch for locksmiths and technicians. Watch: www.rdr.link/FAR025

WWW.RDR.LINK/FAR026

A workshop faced a tough ask when the injectors of a 2017 model needed to be serviced – but the cylinder numbering was not visible on the vehicle’s documents – so how did the technician overcome this?

Correct cylinder numbering is essential for accurate fault diagnosis. In modern engines with common rail direct injection, each injector is individually programmed to its corresponding cylinder. Incorrect assignment can cause misfiring, rough running or power loss.

Without the correct information, the technician would likely have disconnected the injectors or dismantled them – a risk that could have exacerbated the issue to the detriment of the motorist, according to ALLDATA Europe

To quickly return the vehicle to the road, the technician contacted the ALLDATA Info Centre. An expert guided them to the correct information in ALLDATA Repair, a portal that grants independent workshop and bodyshop professionals access to genuine repair and maintenance instructions.

A targeted search for the relevant VM schematics for the engine control and glow plugs showed that one glow plug is equipped with a combustion chamber pressure sensor – a clear indication of cylinder one. With this crucial information, the technician was able to determine the correct cylinder sequence.

WWW.RDR.LINK/FAR027

Modern windscreen wiper arms can be notoriously difficult to remove due to their tapered and splined mounting, corrosion buildup and high spring tension, according to Laser Tools, and, over time, exposure to the elements can make them seize onto the spindle, turning what should be a quick job into a frustrating struggle.

Laser Tools’ new windscreen wiper lever tool (9088) is designed to make wiper arm removal fast, easy and damage-free.

This tool uses a hook and lever or hook and pull action, providing the necessary force to free stubborn arms without excessive prying or damage to surrounding bodywork – but why are wiper arms so hard to remove?

A tapered and splined fit creates a tight press-fit between components, making them resistant to removal; however, this secure connection can be further complicated by corrosion and seizure, as moisture, dirt and road salt may cause the arm to bind to the spindle.

Additionally, high spring tension, which is essential for maintaining good blade contact with the windscreen, adds to the difficulty of removing the component.

Laser Tools believe its latest tool is a “must-have” for professional technicians and DIY enthusiasts alike.

WWW.RDR.LINK/FAR028

ADVERTISEMENT INDEX

ALLDATA Europe GmbH outside back cover & bound outsert

www.rdr.link/FAR100

AS-PL Sp. Z o.o. ....................................................................page 15

www.rdr.link/FAR101

Autoelectro ............................................................................page 20

www.rdr.link/FAR102

Autowave Ltd ........................................................................page 27

www.rdr.link/FAR103

bilstein group ..........................................................................page 4

www.rdr.link/FAR104

Carwood Motor Units Ltd ....................................................page 18

www.rdr.link/FAR105

Comline Auto Parts Ltd ........................................................page 13

www.rdr.link/FAR106

Dayco Europe ........................................................................page 17

www.rdr.link/FAR107

DENSO Europe B.V ..............................................................page 31

www.rdr.link/FAR108

ELTA Automotive Ltd | VXPRO ........................inside front cover

www.rdr.link/FAR109

European Exhaust and Catalyst Ltd ................................page 24

www.rdr.link/FAR110

Ivor Searle Ltd ......................................................................page 23

www.rdr.link/FAR111

Klipboard ..................................................................................page 9

www.rdr.link/FAR112

MANN+HUMMEL (UK) Ltd ....................................................page 11

www.rdr.link/FAR113

Motul ........................................................................................page 31

www.rdr.link/FAR114

SIP Industrial Products Ltd ................................................page 29

www.rdr.link/FAR115

UFI FILTERS S.p.A. ................................................................page 29

www.rdr.link/FAR116