NEW TESLA TRAINING FROM DELPHI

YOUR LETTERS ANSWERED

MOT GARAGE REACTIONS

LIFE IN THE PITLANE

ENTER THE CPD ZONE!

YOU COULD EARN ONE CPD CREDIT THIS MONTH BY READING THIS MAGAZINE

DIAGNOSTIC TROUBLESHOOTERS ON BMW & VAG VEHICLES

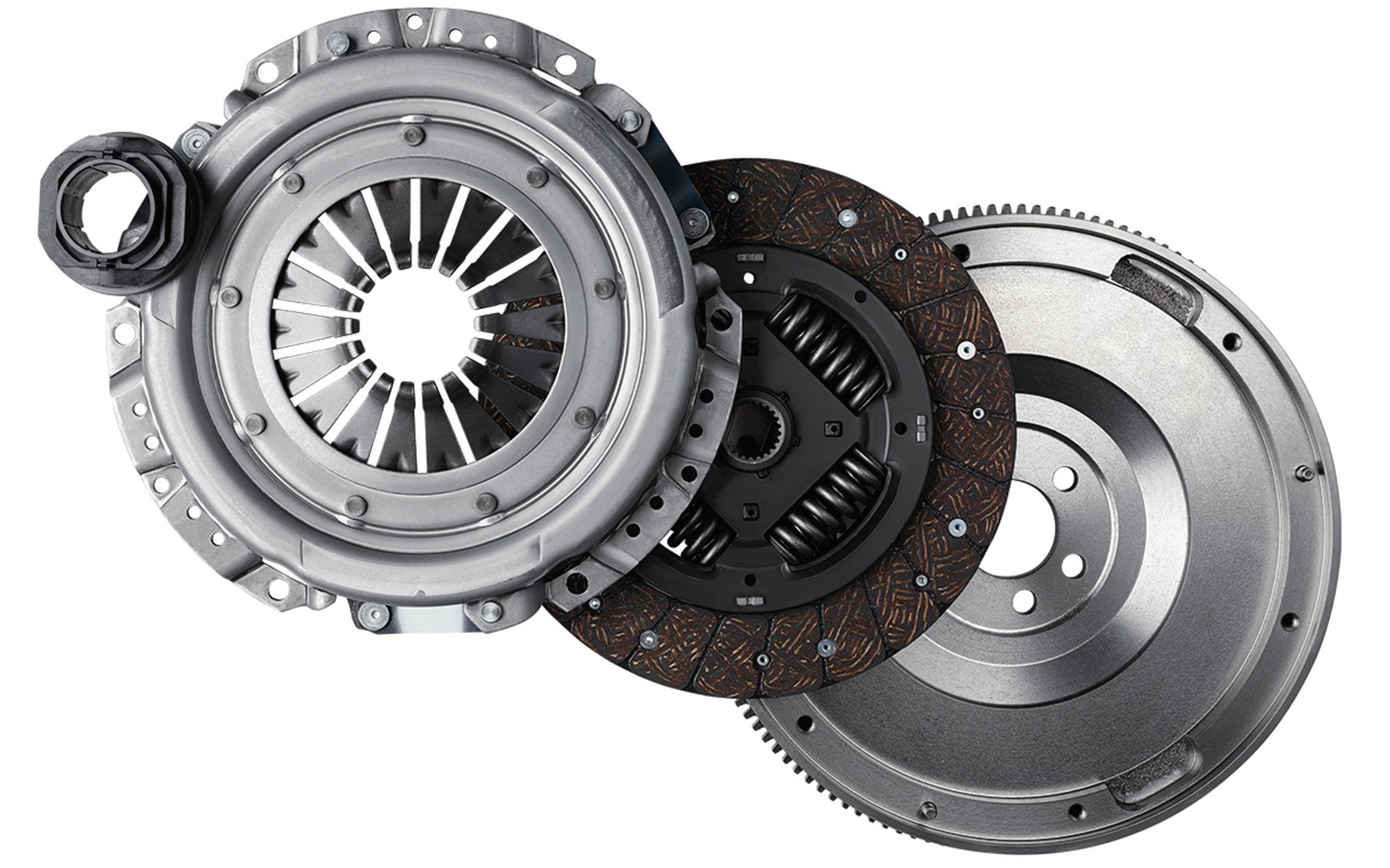

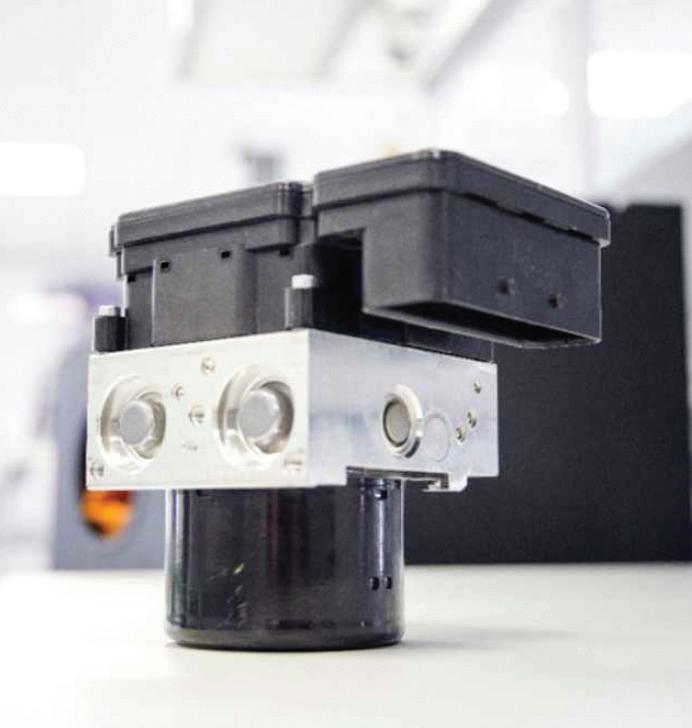

INSTALLATION TIPS ON CLUTCHES, BRAKE PADS, BELTS & ABS UNITS

CLASSIC CAR MAINTENANCE EXPLORED

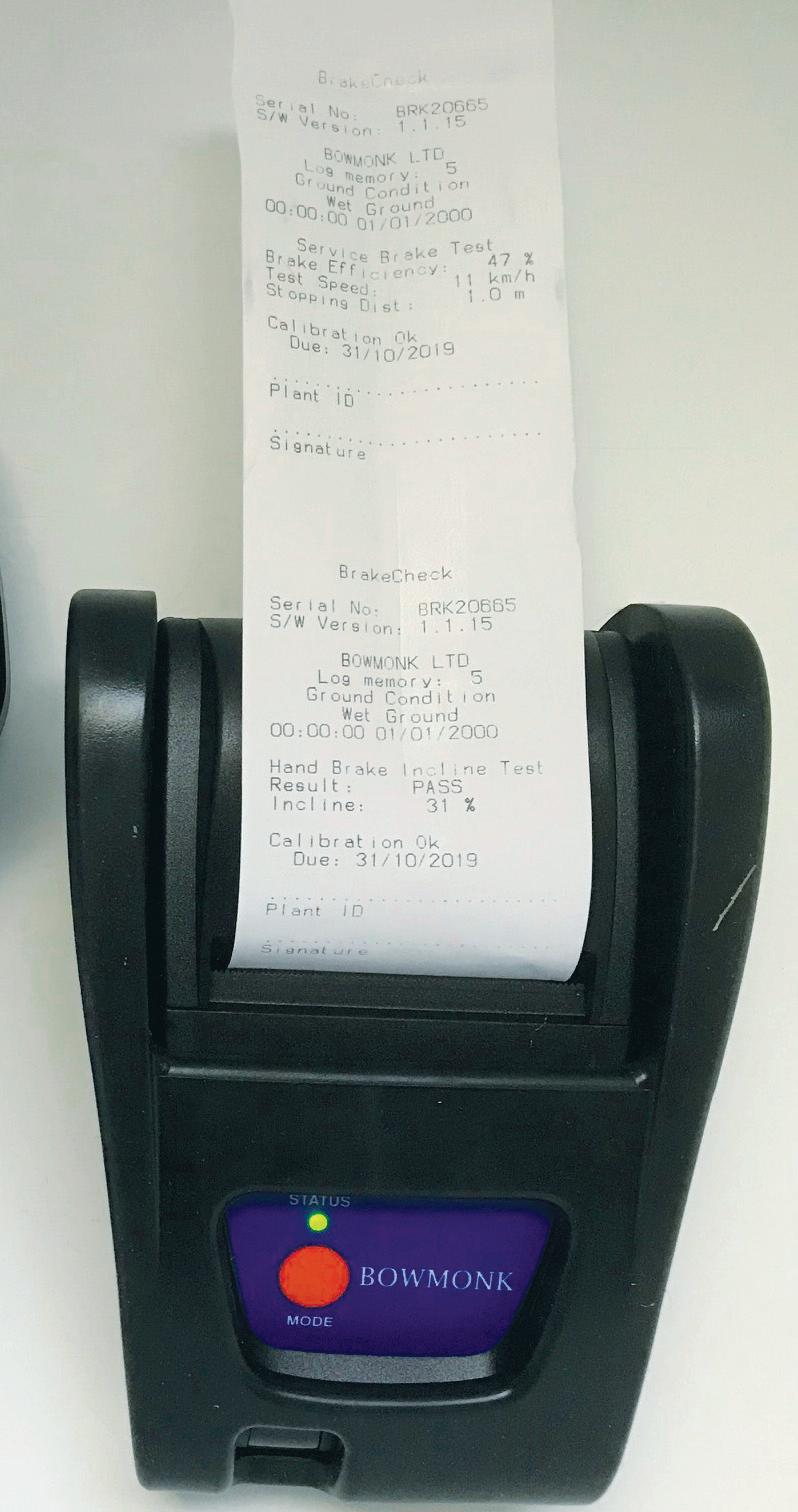

BEST PRACTICE TIPS ON BRAKE TESTING, CLUTCH CONVERSION, ADAS & FILTERS

FREE TOTHE TRADE

MAY 2023

PMM

COMMON FAULTS WITH TURBOS PROFESSIONAL M OTOR M ECHANIC

Editor’s Picks

14

TROUBLESHOOTER

Make sure to read this month’s troubleshooter where diagnostics expert Ben Johnson investigates of a headlamp failure on a BMW E60.

42 ALL ABOUT MOTS

Recently, the PMM team went out on the road to hear what you, our readers, had to say about the MOT. Find out some garages’ opinions and see if you agree.

48 TO REPLACE OR TO OVERHAUL?

ACtronics makes a case for why overhauling might be the better option when it comes to failing electronic components, as opposed to replacing the device.

54

MODERN OILS FOR CLASSIC CARS

Ever wondered how to break into the classic car market? Learn how to take advantage of this growing market thanks to Motul, here to inform PMM readers about which oils and lubricants are available for which classics.

Contents VOLUME 24 ISSUE 5 MAY 2023 Features Total Average Net Distribution 54,319 1st July 2021 – 30th June 2022 PMM MAY 2023 3 45-51 BRAKES & CLUTCHES 53-57 CLASSIC CAR Regulars 6-10 AFTERMARKET NEWS 13-30 CPD ZONE NEW 32-37 BUSINESS & TRAINING 39-42 SPECIAL REPORTS 68 PIT STOP 69 ONLINE REPORT 70-72 WHAT’S NEW? 73 MYTHBUSTERS

66-67 ADAS

59-65 FILTERS

Editor KIERAN NEE

News and Products Editor

FREYA COLEMAN

Digital Manager

KELLY NEWSTEAD

Group Manager

ROBERT GILHAM

Account Manager

ALEX DILLEIGH

Magazine Designer

GEMMA WATSON

Group Production Manager

CAROL PADGETT

Production Assistant

CLAIRE SWENDELL

Distribution Manager

KARL CLARK

Subscriptions

PROFESSIONAL MOTOR MECHANIC is a business magazine for firms and individuals involved in all aspects of the motor trade. It is published eleven times a year and is available nationally FREE to the trade through leading motor factors. It is also available through the post at a cost of £30.

EUROPE and OVERSEAS

1 year (11 issues) £50

Airmail 1 year (11 issues) £65

Printed by Walstead Peterborough

Published by HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts, WD24 4YF.

Tel: Watford (01923) 237799

Fax: (01923) 246901

E-mail: pmm@hamerville.co.uk

Sales enquiries: pmmsales@hamerville.co.uk

Website: www.pmmonline.co.uk

Facebook: /ProfessionalMotorMechanic

Twitter: @pmmmagazine

Copyright © 2023

The publishers and editor do not necessarily agree with the views expressed by contributors,nor do they accept responsibility for any errors of translation in the subject matter in this publication.

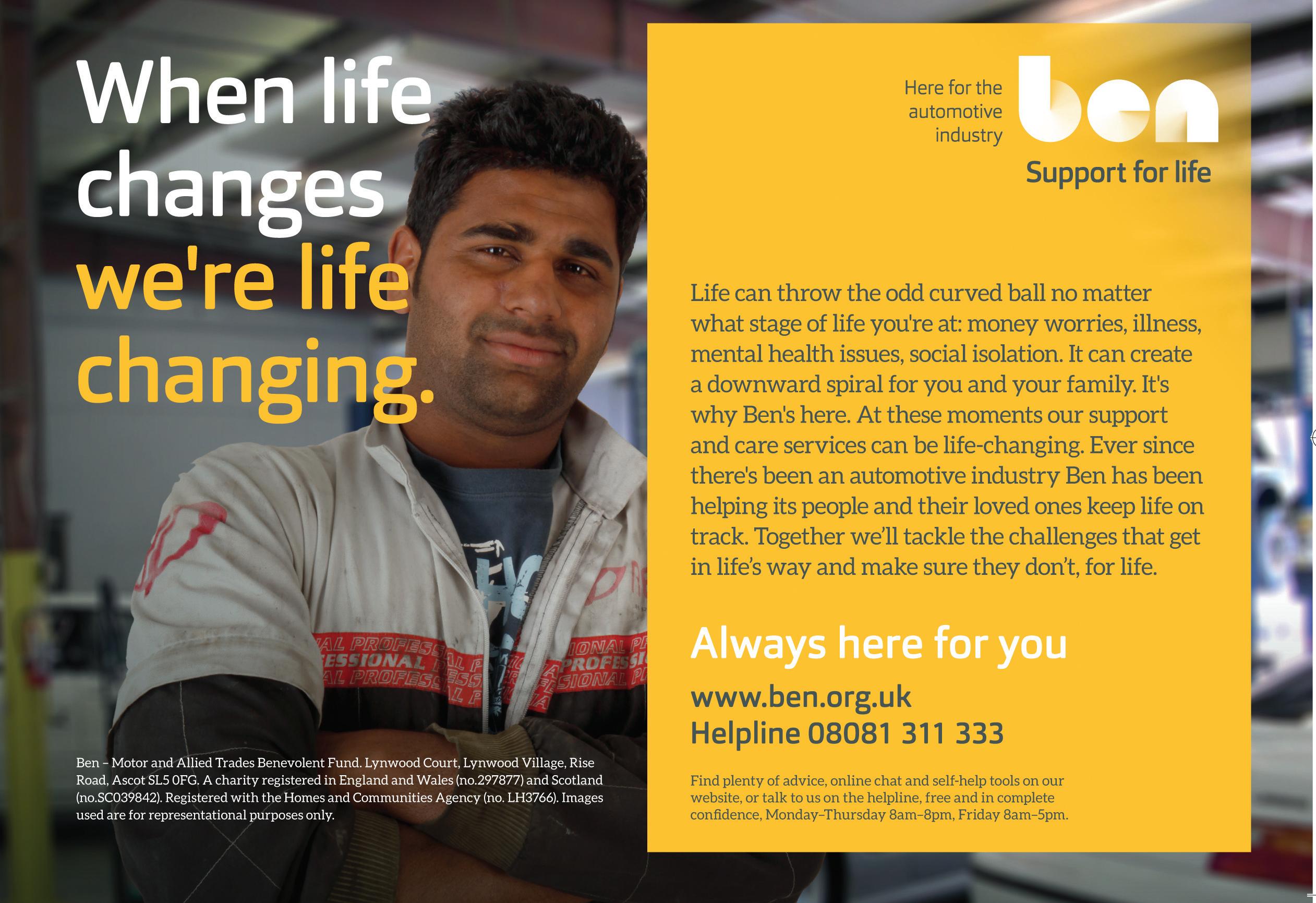

A credit to yourself

It’s finally here. After much discussion, I have finally managed to get enough ducks in a row to get PMM’s technical articles CPD accredited. So, barring any unforeseen circumstances, the Tech Tips section of the magazine will henceforth be banished –replaced by the new and shiny CPD Zone. What does this mean for you, the reader, or for the magazine, or indeed for me, the editor? Well, firstly, for me and by extension for our contributors, it has brought an already notoriously early copy deadline even earlier (for this issue it was early March) and an extra layer of process to get through each month. Secondly, for the magazine, it means that our technical content is subject to another pair of eyes scrutinising it for its neutrality, usefulness and value to the reader. Lastly, and most importantly, CPD accreditation means that you, our reader, will be able to quickly and easily add CPD points to your account, which can be put towards any professional scheme you are involved in. Does this mean the content is any different this month compared to last month? Well, surprisingly, no.

We were pleased to find that the technical content we run each month was already up to scratch in terms of technical rigour, but of course we already knew that! In fact, the reason we first approached a CPD accreditation scheme was that it was brought to my attention that the magazine was already a valid contribution towards CPD points, something which already depends largely upon self-reporting your research and learning.

What are CPD points? Well, for those of you who aren’t aware or may want to know a bit more about the scheme, CPD stands for continuous professional development. Schemes like the IMI’s TechSafe professional EV recognition scheme relies on participating technicians to take it upon themselves to top up their learning as they continue their professional careers. It’s a common gripe among industry professionals that there is a lack of official accountability and qualifications. Unless you are a part of an official trade body, there is very little to keep workshop mechanics on the straight and narrow besides their own good faith, which luckily is usually enough. Mechanics, differently from other trades such as electricians and gas engineers, aren’t beholden to an official regulatory scheme unless they are working on electric vehicles (in which case electrical regulations kick in).

However, CPD credits are open to anyone willing to do the learning and to keep on top of the latest updates. Of course, gaining access to the scheme is free of charge for readers and is easy to maintain each month – you simply need to do the reading and scan the QR code on the last page of the CPD Zone in each issue. With this new zone, we are hoping to further increase the professionalism of the aftermarket, so please make good use of it!

VIEWPOINT

Nee

Kieran

Editor

Listen on Amazon Podcasts Listen on Spotify Podcasts Listen on Apple Podcasts Associate member Find every episode at www.pmmonline.co.uk/podcasts Also available: JOIN M E EACH M ONTH ON THE

MM

P

PODCAST

PMM NEWS with

NEWSIN BRIEF

■ MILLENIALS HANDS-ON Research has found that millenials are more likely to undertake minor car repairs versus baby boomers who are more willing to put their hands in their pockets to get vehicles fixed.

■ CASTROL NEW BRANDING

According to the oils brand, the aim of this re-brand is to reflect the changing needs of its customers and its commitment to investing in the future. Evidence of this is shown by the release of EV transmission fluids and EV greases, but don’t worry, the new logo still contains the iconic red, green and white colours, making its products recognisable to technicians.

■ CAR PRODUCTION RISE SMMT

chief executive Mike Hawes says 13.1 per cent car production growth in February shows an industry on the road to recovery.

■ MG MOTOR The Motor Ombudsman has given accreditation for its motor industry code of practice for new cars to MG Motor UK. This underlines the marque’s commitment to delivering high standards of service. It also gives MG car owners access to the ombudsman’s dispute resolution service.

■ HAVE A CUPPA Airtex was welcoming workshops to its brand last month by sending them a welcome box of goodies as a ‘thank you’ for purchasing their water pump kits. The boxes included tea, coffee, a branded mug as well as snacks such as biscuits, a chocolate bar and crisps.

Freya Coleman

Government outlines zero emissions roadmap

The government has launched a consultation on its plans for a zeroemission vehicle (ZEV) mandate, which will force manufacturers to sell a certain proportion of EVs leading up to the 2030 phase-out of petrol and diesel vehicles.

The proposed minimum ZEV target trajectory for new cars being sold begins at 22 per cent in 2024, increasing to 80 per cent in 2030 and 100 per cent in 2035. If a manufacturer cannot meet these targets, the proposal suggests payments of £15,000 per non-ZEV car.

Mike Hawes, SMMT chief said: “While the proposals rightly reflect the sector’s diversity, late publication and lack of regulatory certainty make product planning near impossible, and continiued lack of

clarity as to what technologies will be permitted beyond 2030 undermines attempts to secure investment”.

The consultation is seeking views on the final proposed regulatory framework, specifically on the level of ZEV uptake, how allowances and credits could be allocated and derogations and exemptions. The consultation closes on the 24th of May.

This comes after EU restrictions relax to allow e-fuel exemptions in its 2035 combustion engine ban following pressure from Germany. Despite ministers and experts urging the UK government to follow lead, such as Sir Iain Duncan Smith telling the Telegraph the 2030 deadline is “simply not achievable”, it appears the government is unlikely to postpone.

EV tyres proving to be MOT bugbear

The Institute of the Motor Industry (IMI) has conducted in-depth analysis of MOT data, working with Garage Industry Trends, to examine root causes in current patterns of MOT failure.

The analysis provides clear evidence that extending the date for the first MOT will significantly increase road user risk. In particular, the risks surrounding electric vehicles as they are heavier than ICE vehicles and cause heavier wear to their tyres.

Evidence drawn from MOT testing records supplied to the IMI by the Department for Transport shows that comparative to petrol engine vehicles, electric vehicles are much more likely to fail their first MOT test.

EV failure rates for 2018 registered vehicles (all classes) was 11.51 per cent. This is lower than diesel (15.98 per cent) but higher than petrol (10.89 per cent). This pattern holds for 2017 and 2016 registrationyears. Given that a large proportion of EV owners in 2018 can be classed as enthusiast early adopters and would likely maintain their car better than today’s average EV driver, the IMI believes this is a significant finding.

Whether or not the government has chosen to extend the MOT to a 4-1-1 or even 4-2-2 system, it’s clear to see how tyre wear on EVs is going to pose a problem for garages and motorists in the future.

6 MAY 2023 PMM

©AdobeStock/bizoo_n

FOR UP-TO-DATE NEWS, SIGN UP FOR THE WEEKLY E-NEWSLETTER AT WWW.RDR.UK/AAX001

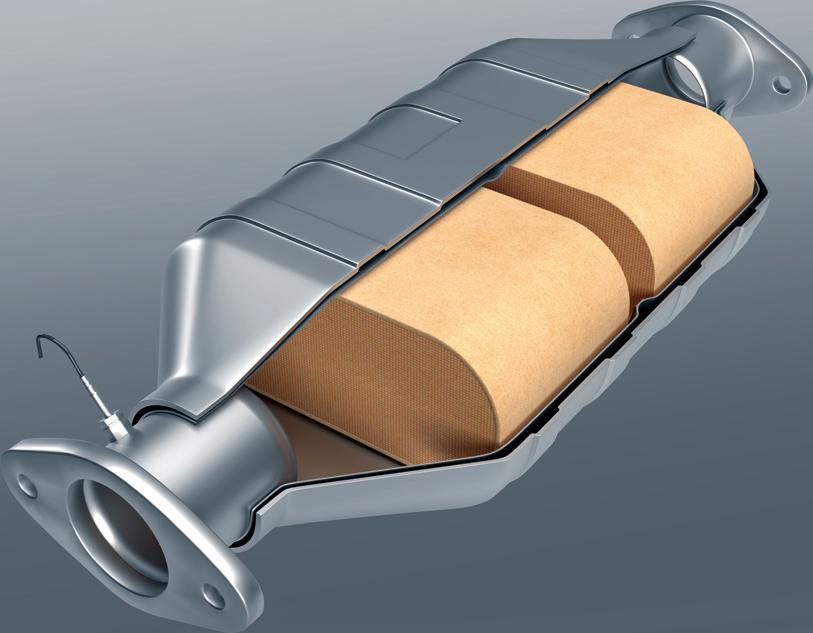

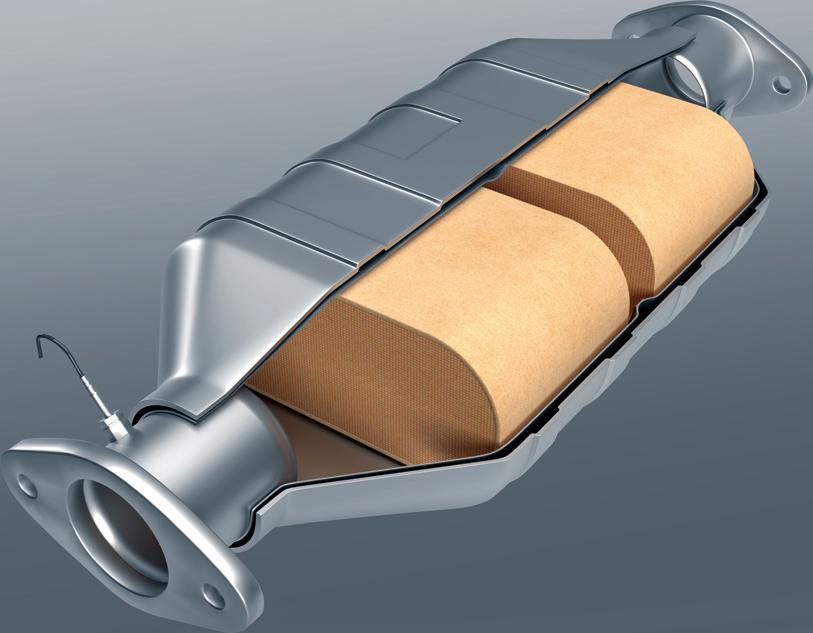

Cat burglar strikes garage owner

A Berkshire garage owner has recently had 12 catalytic converters stolen in one night. He estimates that each theft has cost him around £1,600. One of the cars affected is a sports car whose catalytic converter can only be imported from Japan. Catalytic converter theft has been branded by one MP as an “epidemic”.

Repair prices on the rise

According to a study from Intelligent Motoring, the cost of vehicle repairs rose by 40 per cent between 2018 and 2022.

NEWSIN NUMBERS

64 %

the proportion of drivers that are planning on restricting their car usage to minimise fuel bills according to BookMyGarage.com. For garages, this means motorists are also cutting back on what they will spend on their car, with 28.4 per cent saying they would put off cosmetic repairs.

300,000

the number of public chargers the Department for Transport has said it wants in operation by 2030, despite fewer than 9,000 being installed in 2022.

67 %

CEO Duncan McClure Fisher explained that repair costs started to climb after the referendum in 2016 and were made worse by the knock COVID-19 inflicted on the automotive sector. He added that the financial impact will be made worse by rising inflation and an increase in the costof-living.

However, with the rising cost of parts, the cost-of-living increase and inflation, this is no suprise. Moreover, according to leading industry experts, independent garages regularly undercharge for their work.

of UK car owners support keeping the first MOT at three years rather than extending to four according to the SMMT, saying it is not worth the 23p a week saving. This contradicts a survey from Startline that found that 89 per cent of drivers back four-year MOTs.

17 % of drivers who had scheduled MOTs for May couldn’t afford the £54.85 due to the cost-of-living crisis.

In pictures: PMM attended the IMI annual awards and dinner, seeing winners such as Thomas Morris from Bridgewater and Taunton college achieving full-time student of the year.

PMM MAY 2023 7

DATES FORTHE DIARY

■ PMM has confirmed it will be hosting a stand at this year’s Automechanika Birmingham, which will take place at the NEC in Birmingham on the 6th, 7th and 8th of June. Come and visit our stand for your chance to be featured on the PMM Podcast!

■ Garage management software Garage Hive has announced the Blend is back on the 7th of October 2023 at the Eastside Rooms in Birmingham, with tickets now on sale. It is a two-in-one event featuring a conference during the day where you can hear from industry speakers on how to run your business more efficiently, before the evening event with a threecourse meal and the chance to network.

■ The BIG Awards are back this year on Friday the 22nd of September at Leicester City Football Club. Categories include the business improvement award, the diversity equality and inclusion award and the training and development award among many others.

■ The SMMT International Automotive Summit is taking place on Tuesday 27th the of June. Speakers will include senior executives from vehicle manufacturers, policy makers and a host of content experts from automotive and aligned industries.

with Freya Coleman

DVSA apologises for MOT comments

Following a number of offensive comments from MOT records circulating on social media, the Driver and Vehicle Standards Agency (DVSA) has had to apologise.

From the original tweet, which was viewed 1.3 million times, one Twitter user responded with a link to a Facebook post with around 70 other examples of inappropriate MOT advisories.

The comments included: “beautiful owner”, “owner needs a haircut” and “number of

wotsits in the glovebox below requirements”.

The DVSA has said “We apologise for any offence caused to the vehicle owners and members of the public viewing MOT records through the ‘check MOT history service’ feature”.

The agency has also said it is investigating the misuse of its free text advisory feature, following up with any testers or garages who were found using the function inappropriately.

‘No argument for changing MOT’ according to PMM Podcast

If you’re concerned or confused about MOT proposals from the government, you need to listen to the ‘MOT madness’ episode of the PMM podcast.

“Does the MOT still need to be an annual test?” is THE big question that has been buzzing around the industry lately, especially when concerning the government’s recent consultation.

So, to get a straight answer, we spoke to Nick Lyes, head of roads policy at the RAC who said “the government’s line is that the vehicles today are completely different to those we drove round 40 years ago. I completely understand. Vehicles generally are mechanically more reliable, but when you look at some aspects of the MOT –suspensions, brakes and tyres –those things haven’t really changed.”

We also spoke to Barry Babister, managing director at MOT Juice, who doesn’t think “there’s an argument for allowing the first MOT to go to four years because I think road safety will be impacted, especially on tyres with EVs and

hybrids really, as they are that bit heavier”

The PMM team also went out on the road to talk to independent garages to get their thoughts on the MOT. “It’d be very dangerous because customers only know when there's something wrong with their car or it’s not fit for purpose for the road when they bring it for an MOT. Some customers don't even know how to change tyres, look at tyres, top wheels, that sort of stuff.” says one garage we spoke to regarding the government’s proposals.

So, join us in uncovering some myths and getting to the bottom of the governments’ proposals and the impact MOT test frequency could have in the UK.

8 MAY 2023 PMM PMM NEWS

To listen, scan the QR code

LETTERS Writetotheexperts

When readers get in touch with a query, we get PMM product tester and diagnostics expert Tony Powell on the case.

The query we heard this month was from PMM reader Ben Dobson who was looking at our website, specifically our five steps for coding injectors. He asked: “Do I need a specific code/diagnostics reader for a 2005 Ford Mondeo 2.2tdci and if each injector needs coding as I put it in or can it be done after changing all four?”

To this query, Tony Powell had the below response:

“There are so many different ‘code readers or scanners’ out there these days it's a difficult one to answer to be 100 per cent correct. Many will list the job of injector coding but when it comes down to it, they won’t or can't do it.

The only real answer to be guaranteed is the dealer tool. However, many aftermarket tools will also code them no problem and it's a case of try and fail or try and pass. You don't say what tools you have access to and I don't own them all so can't comment on them. It's probably best to go with a tool based upon recommendation from someone who has done this job on this car with this engine before. Coding injectors individually or as a whole set is again down to the individual vehicle. The other thing you need to be aware of is which way around you code them in for example English 1234 or French 4321 or firing order. Research will be your best friend here.”

If you have any queries you want to the PMM team to answer, get in touch pmm@hamerville.co.uk

Beware using latest engine oils on ageing cars says VLS chairman

Mike Bewsey, VLS chairman, is warning mechanics on the risks of using the latest engine oils in ageing customer vehicles.

Engine technology has evolved over recent years to meet government requirements for reduced emissions, but are these highly efficient lubricants suitable for ageing vehicles? Traditionally, when newer oils were developed, some were designed to be ‘backwards compatible’. However, with an increasingly complex range of industry and OEM specifications, backwards compatibility cannot be assumed.

Using the wrong oil risks accelerated wear, decreased fuel economy and damage to emission control devices. VLS strongly

recommends referring to the vehicle handbook or using an online database to identify the correct oil for every vehicle. Looking beyond the viscosity to specific ACEA and OEM standards is essential. This ensures that the lubricant is fit for purpose in that specific vehicle.

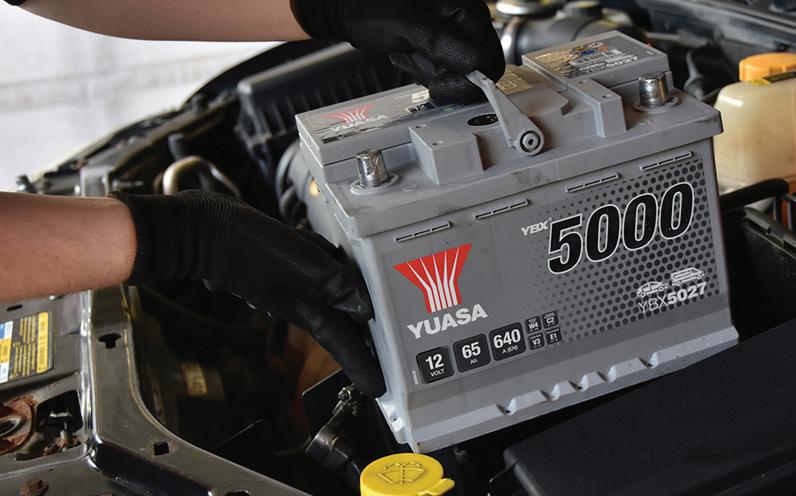

The team up between GS Yuasa and Tunnock’s is set to continue with a pack of ten Tunnock’s Tea Cakes coming with each battery purchase.

Also included is the chance for garages to win one of three £100 JustEat vouchers.

The two companies first collaborated at the end of last year to raise spiritis during winter, and are back as spring has sprung.

As well as ten tea cakes, each Tunnock’s pack includes a unique code to the prize draw for the JustEat vouchers.

10 MAY 2023 PMM Treat yourself MESSAGE ME YOUR NEWS AT FCOLEMAN@HAMERVILLE.CO.UK

In pictures: Liqui Moly signs a one-year contract with the racing series, meaning they will be sponsoring Formula 1 for the fifth consecutive year.

YOU ARE NOW ENTERING

PMM has teamed up with the CPD Group to offer you the chance to gain CPD points while you read every issue!

Continuing professional development (CPD) can be broadly defined as any type of learning you undertake which increases your knowledge, understanding and experience of a subject area and your role within it. To help professionals to better document and prove this process, our new CPD Zone features articles that have been checked, verified and accredited by a thirdparty specialist organisation.

The content within the CPD Zone will provide you with 1 CPD Credit, or 1 hour’s worth of continuous professional development.

Once you have read through the articles contained within, you will be able to scan the QR code at the end of the last article. This will provide you with a downloadable certificate, personalised to you. This can then be used as part of your ongoing CPD record, as needed to satisfy various organisations and schemes. Regular readers of PMM, therefore, could earn 11 CPD points just by reading the magazine each month.

DO NOT SCAN THE QR CODE UNLESS YOU HAVE READ ALL OF THE CONTENT WITHIN THIS SECTION!

CPD relies on self-certification, which in turn relies on professionalism and honesty from those who participate. We have great faith in the diligence and professionalism of our readers – we are called Professional Motor Mechanic, after all. It is fairly safe to assume that if you are picking up PMM each month, then you are already interested in reading and understanding technical content. Indeed, we are a lifeline for many in the industry who rely on us to spread the word on the latest changes and developments originating with the OEMs.

THIS PROCESS IS COMPLETELY FREE

Don’t worry – you won’t have to pay a penny to gain your CPD points each month. It’s on us!

All certificates are valid for one year from the issue date. If you have any issues downloading the certificate or using the system please email us at: pmm@hamerville.co.uk

NEW USERS –ACCESS YOUR BESPOKE CPD CERTIFICATE IN FIVE STEPS

Read ALL of the articles within this month’s CPD Zone

Scan the QR code or enter the RDR.Link in your web browser –both are found at the end of the last article in this section

Enter your email address

Fill out your details on the contact form

Download your certificate for use as part of your annual CPD record

PREVIOUS USERS –ACCESS YOUR CPD CERTIFICATE IN FOUR STEPS

Read ALL of the articles within this month’s CPD Zone

Scan the QR code or enter the RDR.Link in your web browser –both are found at the end of the last article in this section

Enter your name and email address

Download your certificate for use as part of your annual CPD record

PMM MAY 2023 13

CPDZONE READ ME TO REGISTER YOUR CPD POINTS

TROUBLESHOOTER

Why did the BMW E60’s headlamp fail?

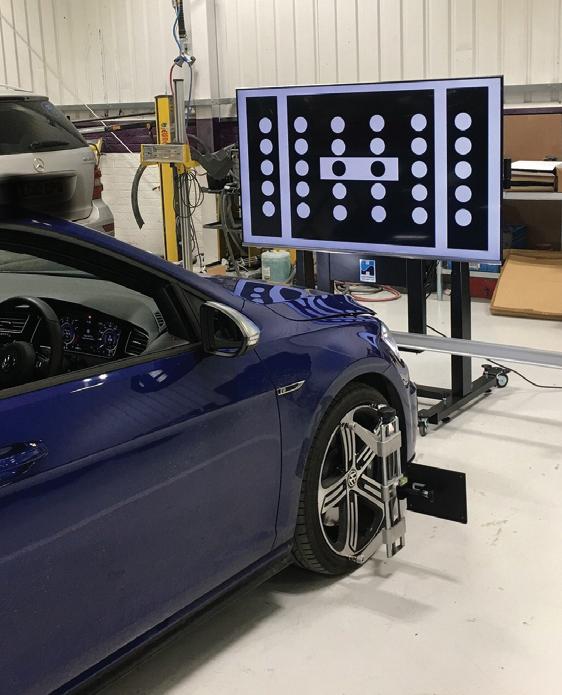

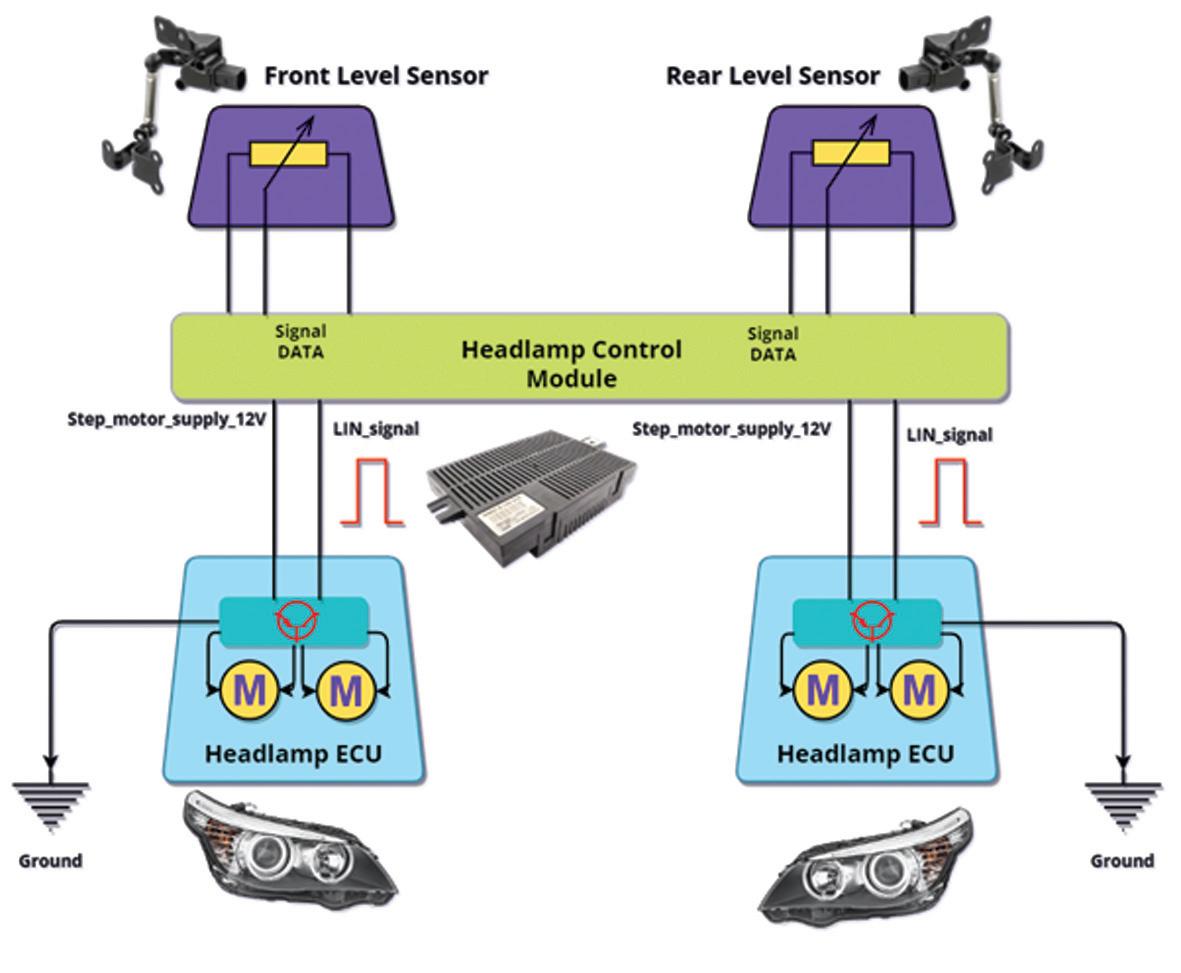

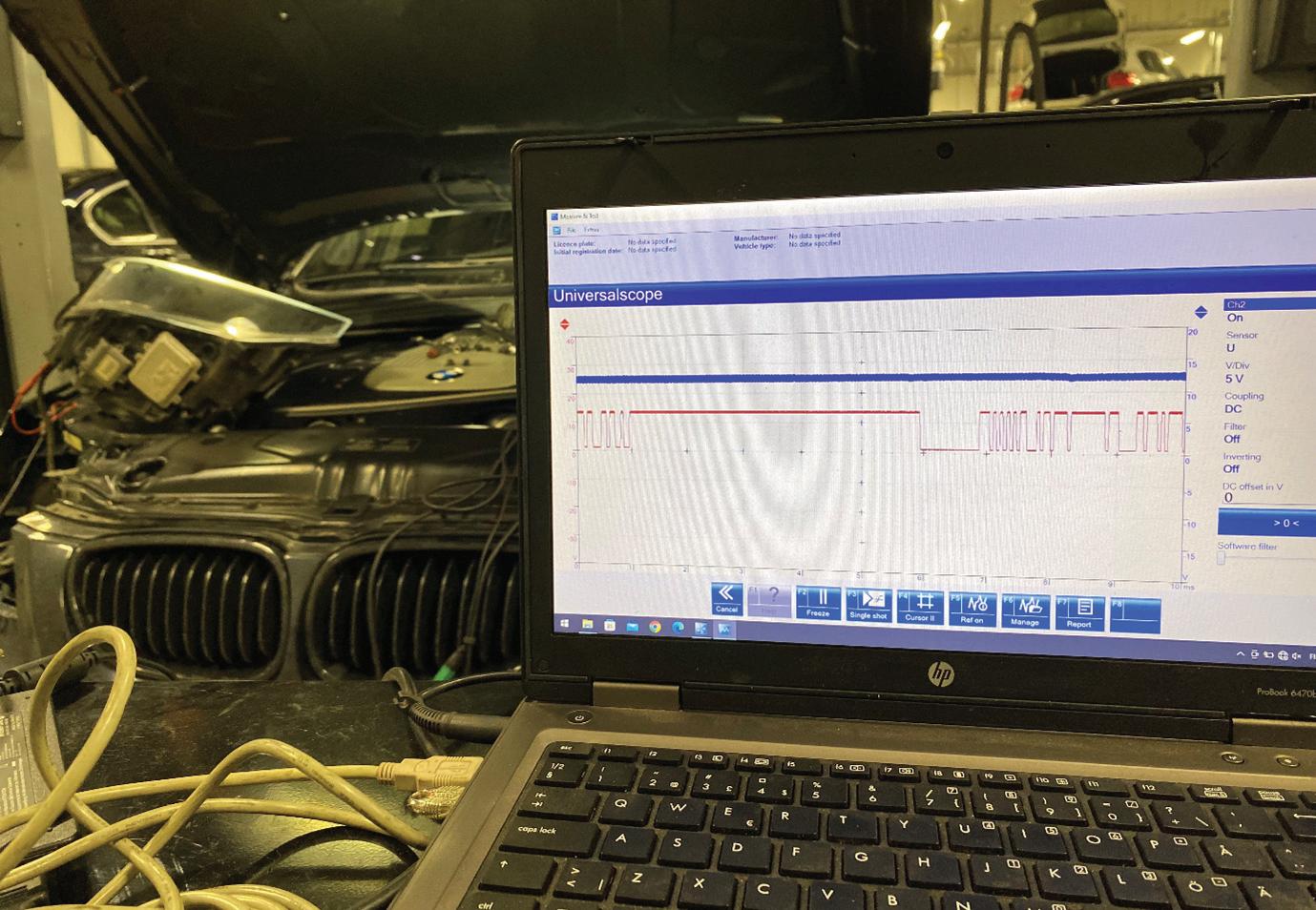

Diagnostics expert Ben Johnson investigates a recent headlamp failure on a BMW E60.

It would be fair to state that, at Schmiedmann, we tend to get our share of BMW Exx generation vehicles of which some are, by now, nearly 20 years old. Most of them have fared well during this long time with only the odd sensor failure, corrosion or part needing to be replaced. In general, they are a fairly hardy vehicle if looked after, well made and easy to work on even if, every now and then, they tend to suffer issues such as the well reported and dreaded battery drain problems that can be tricky to narrow down, even with the proprietary software, ISTA.

Confirming the fault

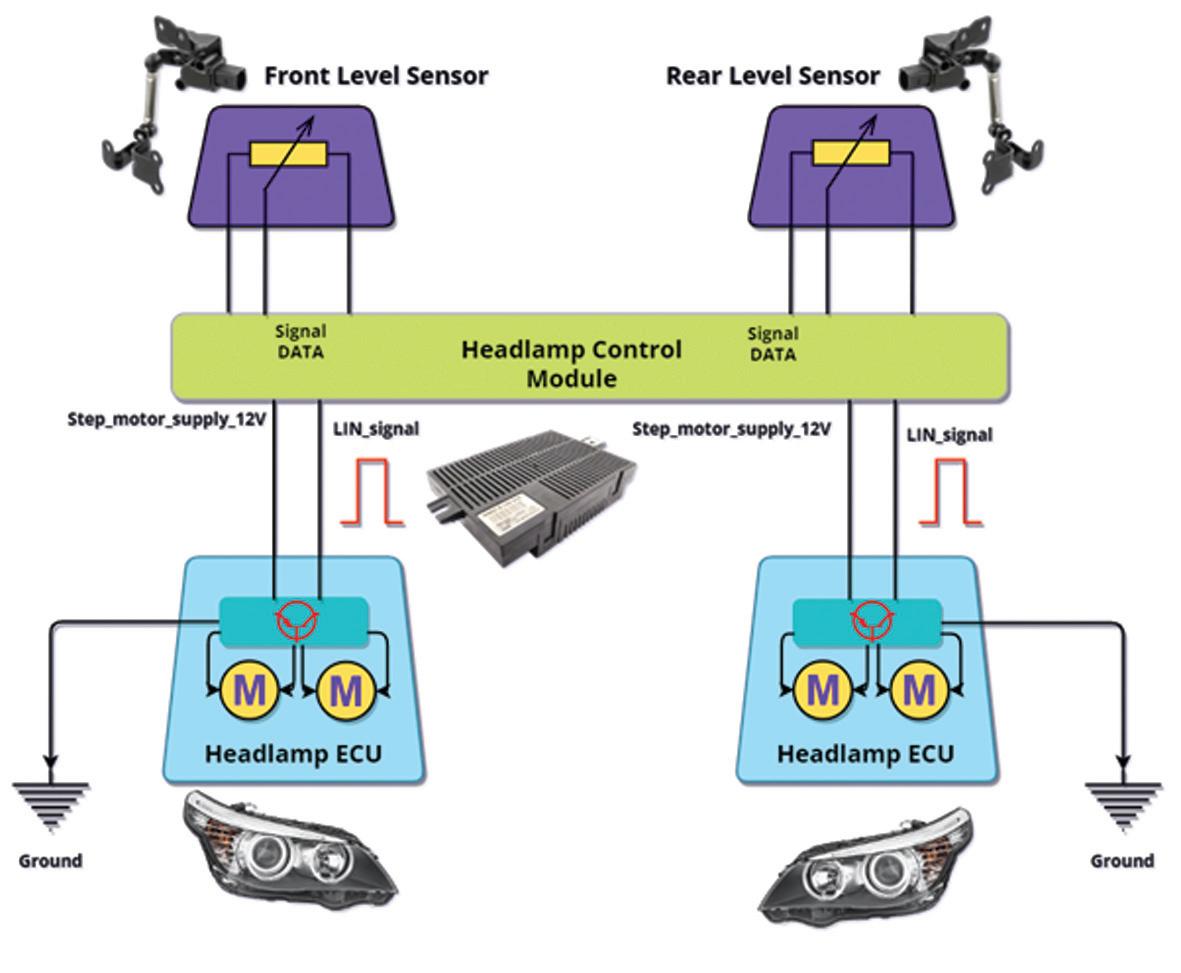

So, it was good news for me that this example came with what was assumed to be a xenon ballast module failure and not intermittent battery draining! During the customer interview he mentioned that a warning lamp illuminated with subsequent right headlamp shut down completely. The fault was confirmed both visually and by observing an active CC message (check control) that was present in both the Kombi and the CID. Kombi, for those unfamiliar with BMW terminology, refers to the instrument cluster and the CID refers to the central information display which is the screen displaying radio, menu functions and satellite navigation that sits in the centre of the dash above the radio and heater controls. This lighting design features a lighting module (LM) that utilises a 19.2 baud single wire system to communicate with an SMC module inside the headlamp. The SMC module is responsible for actuating the

stepper motors that alter the headlamp beam angle. The SMC module according to the wiring diagram is referred to as “headlamp ECU” for simplicity and the LM is referred to as “headlamp control module”

As is customary when looking at problems that need to be solved, sticking to a rigid test plan is not something that I am inclined towards as it tends to prevent the free thinking and dynamic deductive reasoning that have

become a habit of mine. After so many years fault finding, it becomes almost second nature to “feel” what is happening or, as in this case, not happening. From the stored fault codes (006140 LM: communication with SMC, right, disrupted), it was determined that the issue was possibly a noncomms event between the headlamp on the right side and the headlamp control module which is situated in the pedal box area. The SMC module in the headlamp came to mind at first since they can fill with water and corrode the circuit boards. Looking at the physical position of the right headlamp it was determined that it was pointing far too high. Sometimes the headlamp control unit can receive information via the headlamp swivel module position sensors feedback from the SMC module on the LIN if the swivel motor, for example, had failed thus leaving this headlampposition too high. In such a situation, as a result of this undesirable positioning, the headlamp module switches off the xenon lamp completely. This is done to avoid dazzling oncoming traffic. In this particular case, however, the fault code related to a loss of communication between the headlamp and the headlamp module and not of a swivel motor failure though the result was similar: Switching off the headlamp completely.

Smart beginnings

I find that it pays dividends in terms of timesaving to decide upon the best area in which to start to find some evidence as to the root cause of the fault. The headlamp control unit was clearly the smart choice as

14 MAY 2023 PMM

Figure 1: AHL headlamp schematic - BMW Exx (simplified) by the author

“I find that it pays dividends in terms of timesaving to decide upon the best area in which to start to find some evidence as to the root cause of the fault.”

READ ME TO COLLECT YOUR CPD POINT CPDZONE

Ben Johnson, diagnostics expert

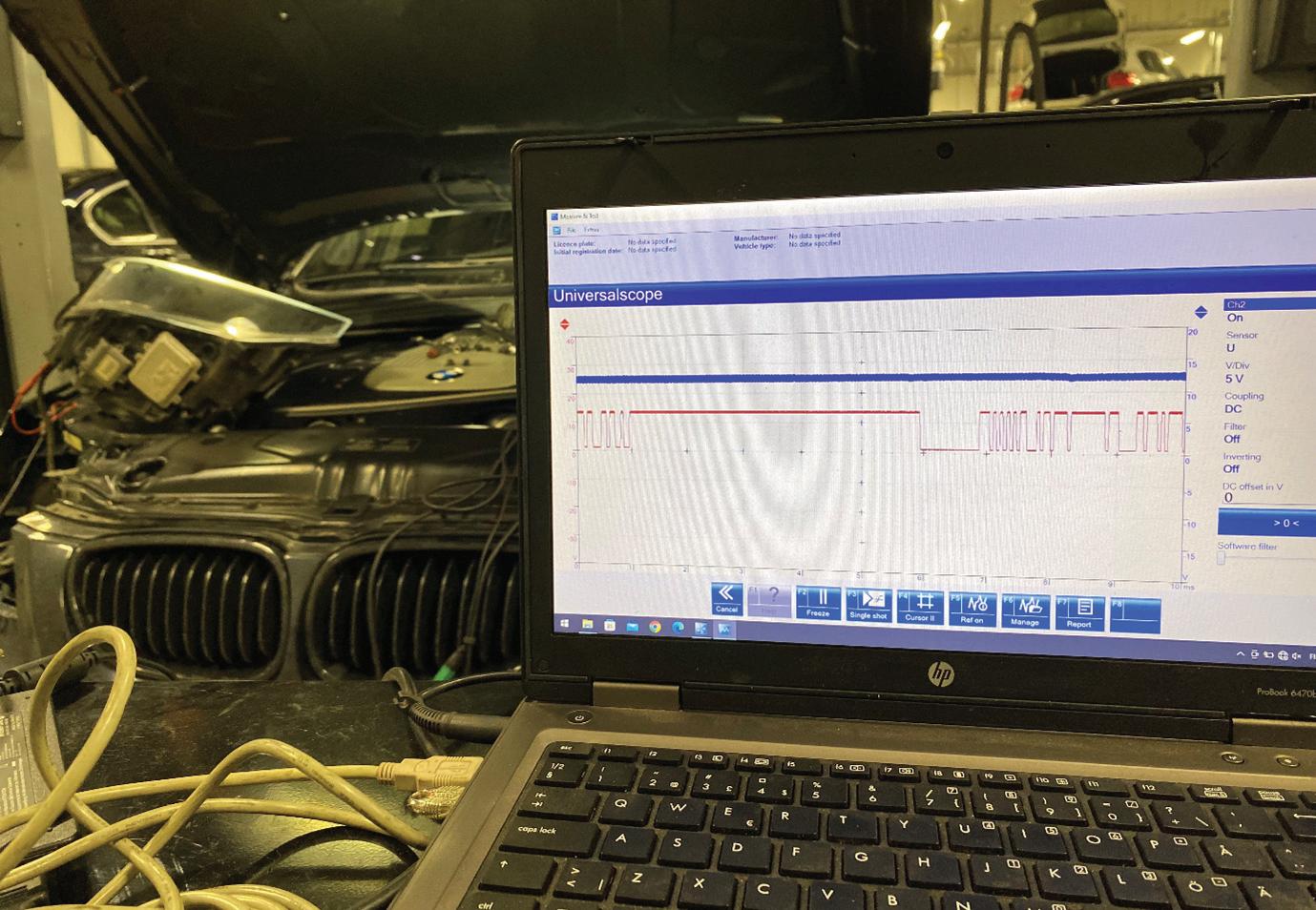

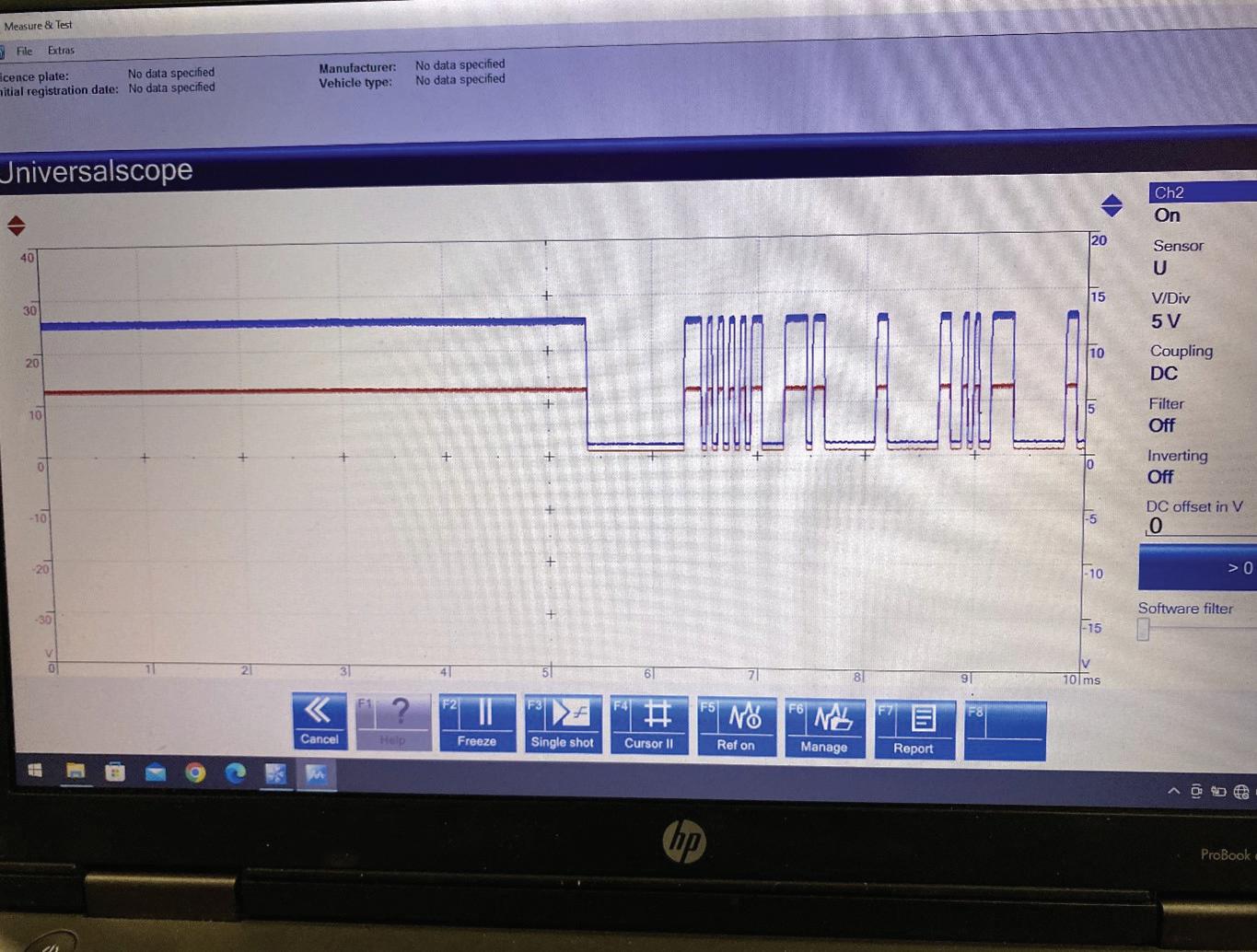

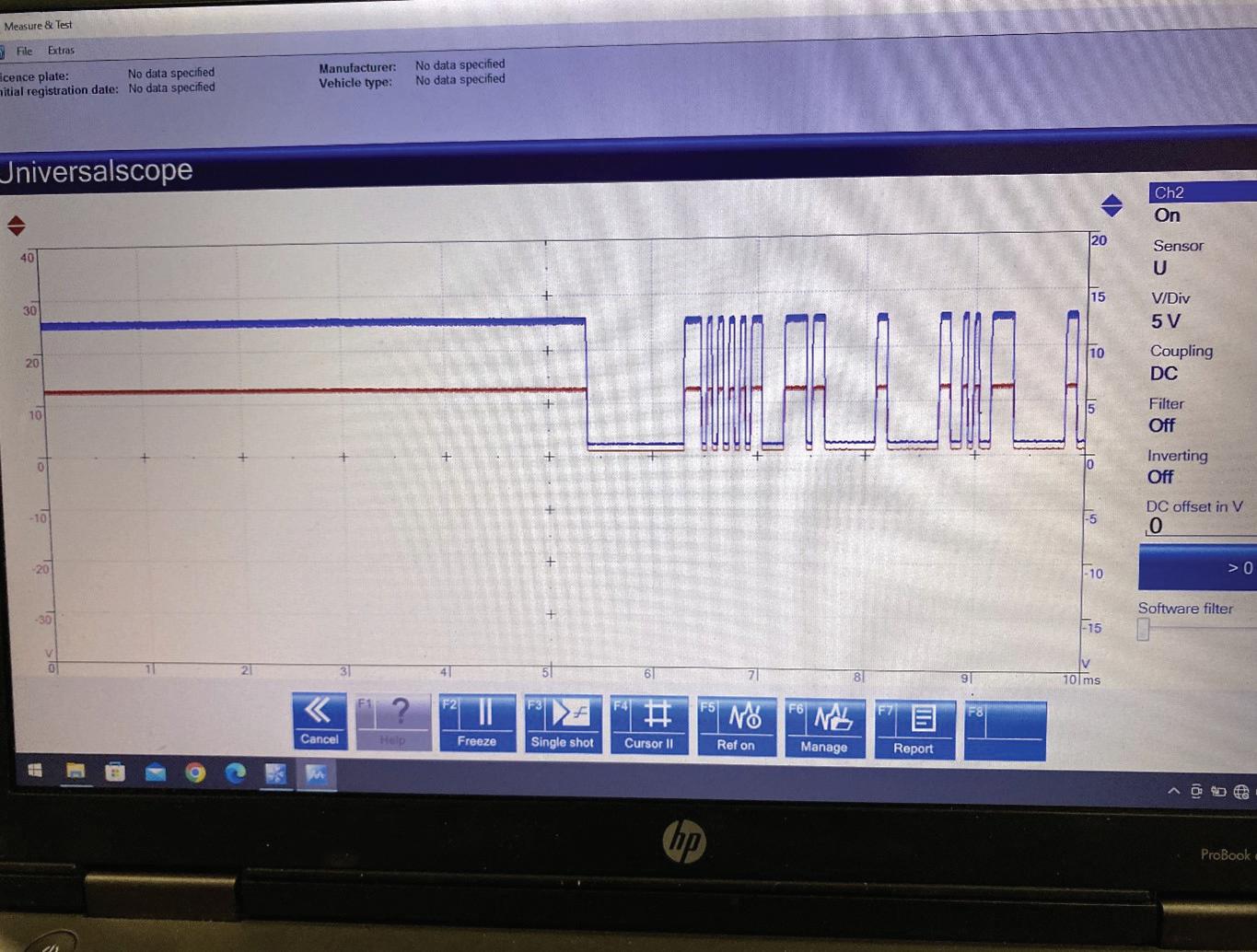

it required only a few screws and the lower panel removing under the steering wheel. What I was aiming for was to take a reading of the voltage on the LIN bus and compare it to the working side which happened to be the left side on this vehicle since the functional description didn’t include what precisely the LIN voltage should be.

Checking the left output from the headlamp showed a LIN operating at around 9.68 V with a 14 V battery support connected. In contrast to this, the right headlamp displayed a voltage of 10.89 V with battery support temporarily removed during testing as it was a little awkward to leave in place with the removed headlamp in the way. The battery was somewhat worn so the overall battery voltage was lower than 12 V. Of course, LIN voltage is not static but there shouldn’t be such a large difference between sides. With the battery support re-connected, the LIN voltage increased to over 12 V on the affected (faulty) headlamp. The amount measured at the headlamp control module inside the car was almost the same value as at the headlamp.

It seemed pretty obvious to me that there was a dominant voltage on the right LIN line which meant that I could be dealing with either a short to 12 V inside the headlamp control unit, internal failure/short to power of the left headlamp module SMC or the line itself had chafed and shorted to power somewhere. Finding the exact problem area would be a case of disconnecting the wire

and checking for continuity to 12 V. If this was confirmed, a further evaluation on the wire would be carried out using a voltage drop technique and/or making some strategic cuts in the harness which would separate a portion of the wire from the 12 V short to determine the affected area.

The customer, on a budget, decided that he would simply only like a new wire running in. “As cheap as possible,” were the exact words of the customer. This is something that I always try to avoid since

PMM MAY 2023 15

Figure 2: Correct LIN voltage in left headlamp

Figure 3: Right headlamp LIN Voltage higher than the left side under similar operating conditions (note lower battery voltage due to temporary battery support removal)

Figure 4: Blue trace short to 12 V / Red trace good LIN signal (Voltage divisions not to scale in the oscilloscope.)

there could be a raft of other wires in a similar condition so it is always best practice, where practicable, to find the actual break. However, it is the customer who pays us and I can only do what they are willing to pay to do in these cases unless a requirement breaches safety protocols such as with restraint systems bypassing etc. Those, clearly, are things I will not carry out.

With an obvious issue in the LIN line, I decided to use the scope to see the signal, or lack thereof. Hooking up the AVL Di-Test 2 channel scope revealed a nice LIN signal on the left working headlamp (the red trace shown in Fig.4) and, as suspected, dominant battery voltage with no signal on the right headlamp shown here as the blue trace.

The solution

The issue of deciding whether the issue was with the wire, headlamp control unit or the headlamp electronics itself was straightforward. The headlamp LIN was disconnected from the left headlamp and the pin output from the headlamp control unit was similarly disconnected. A straightforward measurement with the power probe maestro was taken that showed that the voltage on a disconnected wire was above 12 V. Continuity testing to 12 V with the fluke would achieve the same results.

All that remained was to run a temporary wire from the removed wire receptacle of the headlamp control unit to the disconnected headlamp module LIN connector. The result was immediate: the headlamp lit up and the swivel function of the adaptive lights moved when the steering wheel was rotated.

All that remained was to make the bypassed wiring harness good, cap off the dead wire, adjust the headlamps, erase the fault codes and carry out a function test. I would have liked to have been given permission to strip the harness and find the exact break or chafe but this would have cost a lot more and not everyone has the money to pay for extra time. Customer perception can be a difficult thing to overcome and we must do our best to do the job the way that we all would like to do where possible, customer permission willing.

16 MAY 2023 PMM WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAX002

Figure 5: LIN disconnected from headlamp control module. a short to 12v was confirmed

READ ME TO COLLECT YOUR CPD POINT CPDZONE

Figure 6: Restored LIN function between headlamp control module and headlamp module (SMC)

PMM THE PODCAST

WHAT DO CHANGING A BATTERY, CHANGING A BABY (JUST THE NAPPY) AND CHANGING YOUR MORNING RADIO STATION ALL HAVE IN COMMON?

THEY OFFER THE PERFECT OPPORTUNITY TO LISTEN TO THE PROFESSIONAL MOTOR MECHANIC PODCAST WITH KIERAN NEE.

HEAR ADVICE ON PRICING JOBS, MANAGING PARTS SUPPLY, ELECTRIFICATION, RECRUITMENT AND MUCH MORE.

Listen on Google Podcasts Listen on Apple Podcasts Listen on Amazon Podcasts Listen on Spotify Podcasts LISTEN NOW ON YOUR PODCAST PLATFORM OF CHOICE

HOW TO

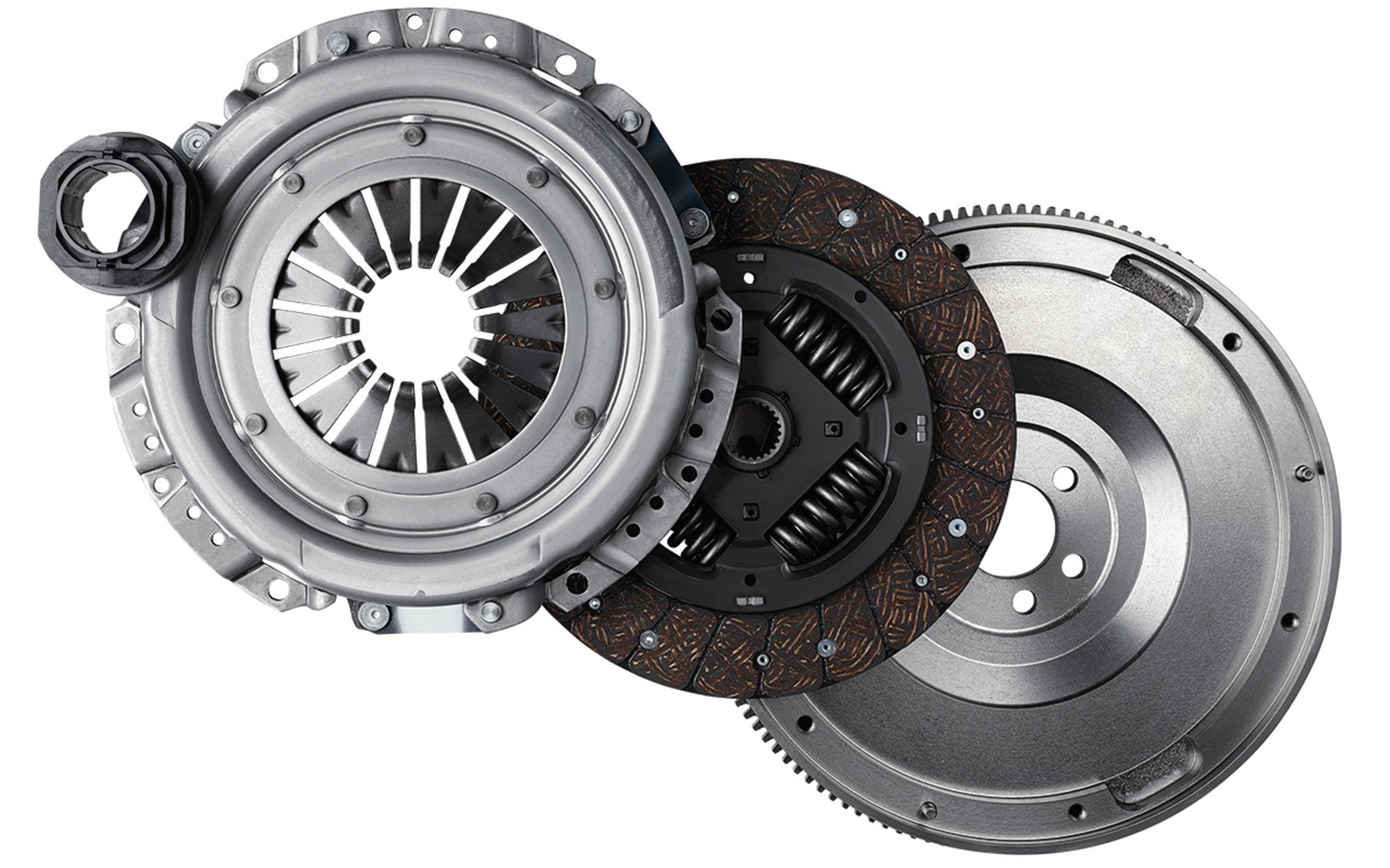

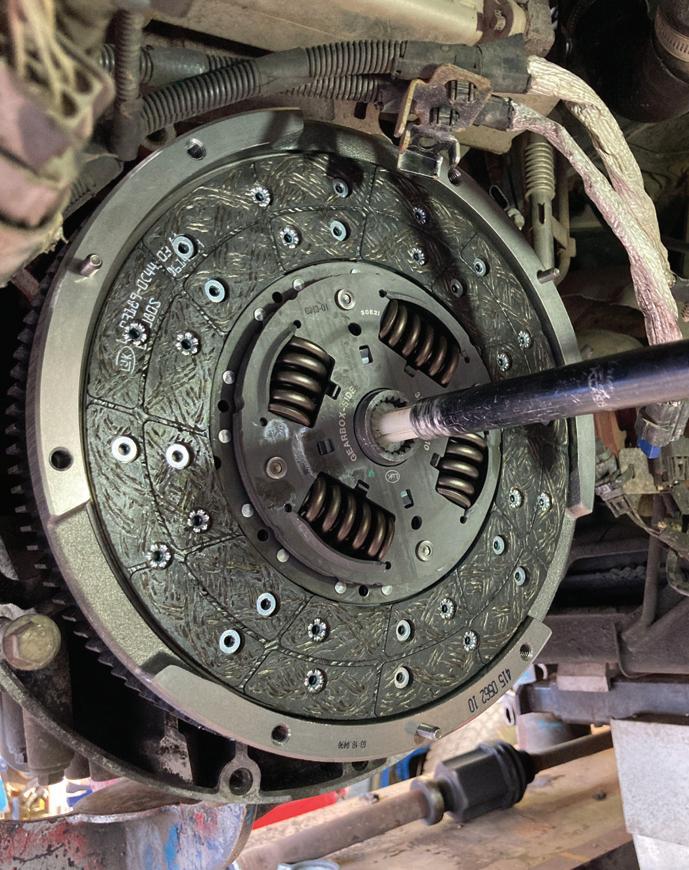

Replace the clutch on a Ford Transit II

In this month’s Schaeffler LuK Clutch Clinic, REPXPERT Alistair Mason is focusing on best practice clutch replacement to ensure an efficient and quality repair, using a front wheel drive 2012 Ford Transit fitted with a 2.2 TDCi engine that has covered more than 113,000 miles.

Vehicle Information

Manufacturer: Ford

Model: Transit

Year: 2012

Engine: 2.2 TDCi

Mileage: 113,000

Noticeably, there are more vans on the roads these days as delivery businesses are booming, mainly down to online purchasing increasing customer demands, as well as tradesman that rely on their vans to transport essential equipment. So, the key to these repairs is to carry out a fast and efficient repair, whilst eliminating any repeat repairs that will cause more downtime of the vehicle.

The vehicle in question was diagnosed with a worn clutch due to slight ‘clutch slip’ and the customer was also advised that it would be good practice to replace the dual mass flywheel (DMF), as the vehicle had covered more than 113,000 miles and usually transported heavy loads.

A Schaeffler LuK RepSet DMF kit was ordered for the vehicle, as this contains all components required to replace the clutch and DMF, and both are designed and manufactured to work together. It is therefore strongly recommended not to mix and match different brands in one system.

Prior to starting the repair, the QR code was scanned on the side of the box (Fig.1) using Schaeffler’s REPXPERT app, and the

technical documents were checked to find any service information or bulletins that were critical to the repair. A 30 second scan for information could easily save hours should a service instruction be overlooked, for example. So, with all the parts and information available, repair instructions and torque values printed off, it’s time to carry out the repair.

The advised workshop equipment:

■ Vehicle lift, two post or wheel free is ideal

■ Transmission jack

■ Engine support

■ Self-adjusting clutch tool

■ Waste oil drain system

■ Clutch bleeding tool, a vacuum bleeder is recommended

PMM MAY 2023 19

CPDZONE READ ME TO REGISTER YOUR CPD POINTS

With the vehicle positioned on the lift, it’s best practice to connect a ‘back up’ battery to retain the radio code, then disconnect the negative battery lead located under the driver’s seat. Open the bonnet, remove the engine cover, air filter/box assembly (which will allow good access to remove the gear cables), upper section of the gearbox mounting, electrical multiplugs and upper bell housing bolts. Then, clamp the flexible section of the hydraulic clutch pipe and disconnect the pipe from the concentric slave cylinder (CSC).

With the vehicle still placed on the ground, slacken both front hub nuts, raise the lift to access the underside, drain the gearbox oil and, whilst the oil is draining, remove both front wheels. Release both bottom ball joints, remove the hub nuts, release the O/S driveshaft support bearing, remove the outer CV joints from the hubs and then both front driveshafts.

Removal

Remove the lower gearbox mounting, starter motor, electrical multiplugs and bell housing bolts, but leave two easily accessible to support the gearbox until the gearbox is ready to be removed.

Lower the lift and support the engine with an engine brace and remove the gearbox mounting, then lower the engine slightly on the engine brace as this will aid gearbox removal. Raise the vehicle lift to access the underside, support the gearbox with a

transmission jack, remove the final two bell housing bolts and ease the gearbox away from the engine. When the gearbox input shaft is clear of the clutch, lower the transmission jack and remove the gearbox from the vehicle.

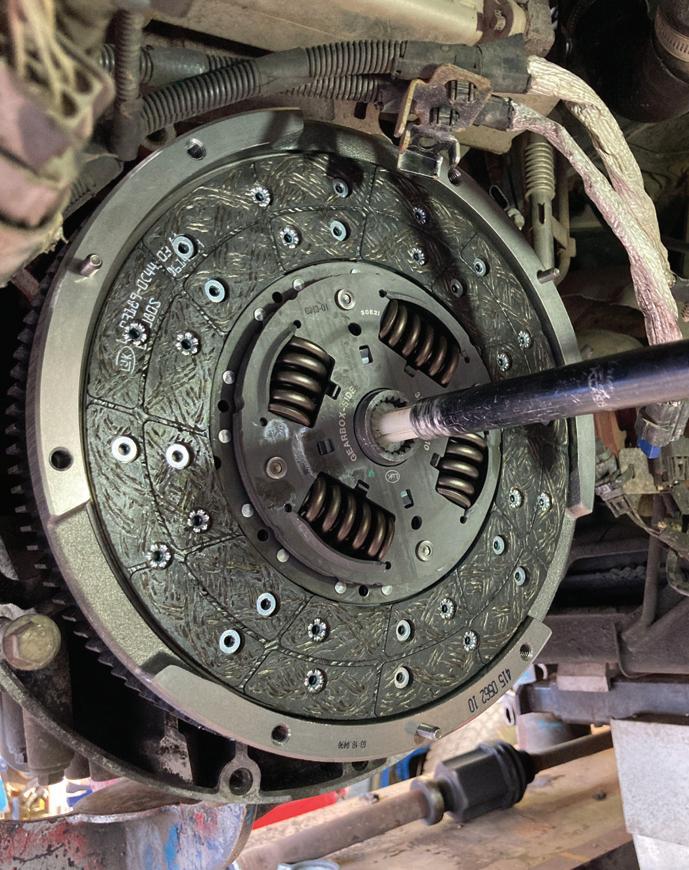

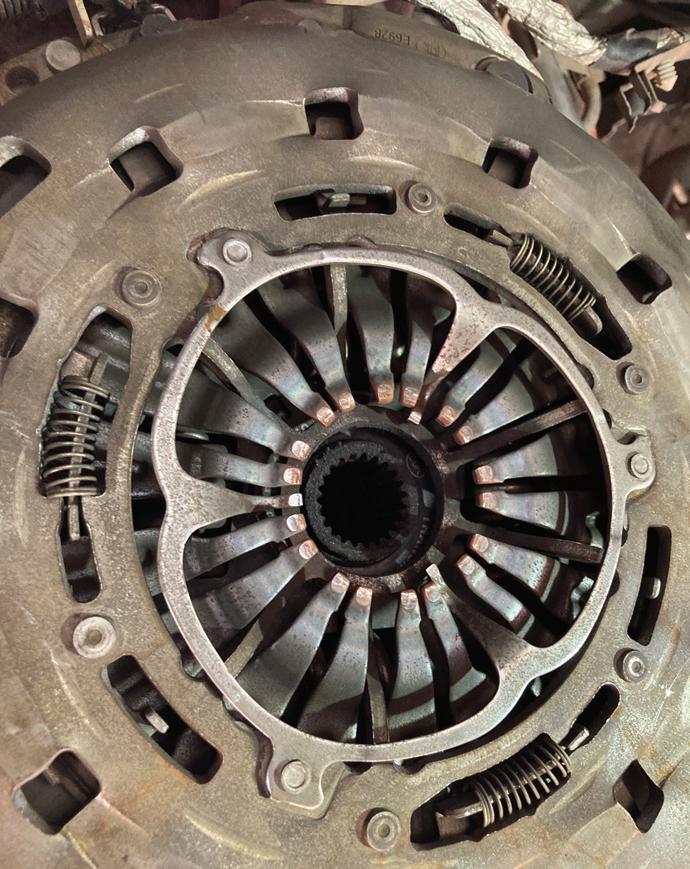

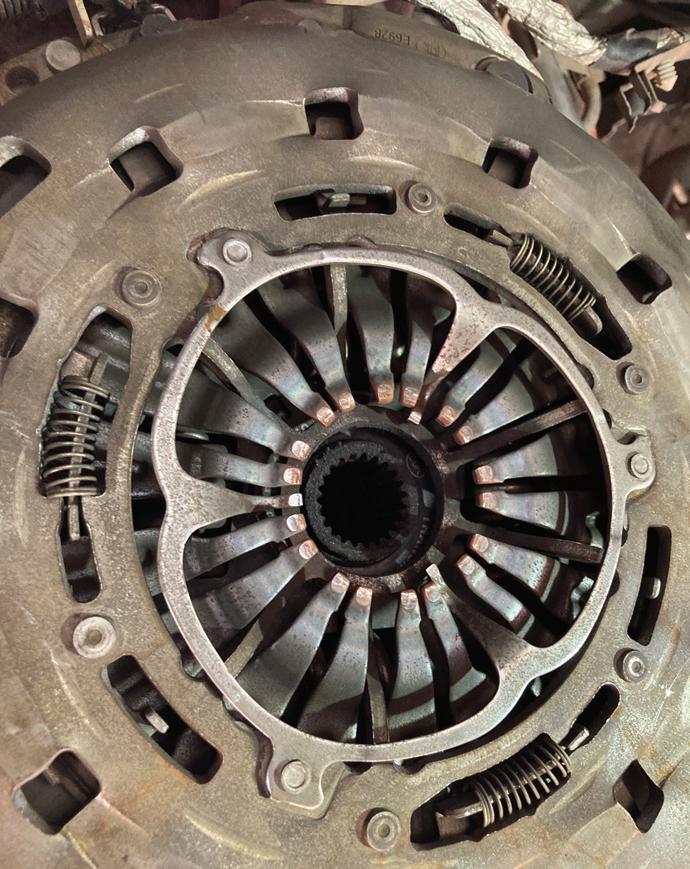

With the gearbox removed, a good indication of whether the clutch is at the end of its service life is if the three small, yellow adjusting springs have extended (Fig.2).

which are available on REPXPERT. With the flywheel removed, check the back of the engine for any oil or coolant leaks, rectify as required and then clean the back of the engine with clutch and brake dust cleaner.

Turning attention to the gearbox and the release system, remove the CSC, check the gearbox for any leaks and rectify if required. Clean the bell housing and input shaft area to prevent the old clutch dust from contaminating the new clutch and DMF.

Replacing the CSC

The CSC must always be replaced when replacing a clutch as the guide tube can become dirty, corroded and pitted and therefore damage the hydraulic seal when removing the gearbox.

Remove the six clutch assembly bolts, ease the clutch cover off the dowels and then remove the clutch assembly, noting which way round the clutch plate is as it is useful to refer back to.

Remove the DMF by detaching the eight flywheel bolts. In this case, slight ‘blueing’ was noticed on the flywheel surface, which would indicate the heat generated with clutch slip and was another good reason to replace the DMF, as this heat will affect the internal grease and arc springs and compromise the DMF’s performance. If required, the DMF can be tested for rotational free play and rock, full instructions and specifications for

Remembering to never squeeze the new CSC, as this can cause damage to the new unit, fit the new CSC supplied with the RepSet DMF kit, but ensure the seating area for the CSC is clean. Then mount the CSC squarely and ensure that all the bolts are tightened correctly.

Now apply a light smear of high melting point grease to the gearbox input shaft and mount the new clutch plate onto the input shaft (Fig.3). This will ensure that the clutch plate is the correct fitment and also evenly distribute the grease, then remove the clutch plate and wipe off any excess grease.

Going back to the clutch and DMF, ensuring that it is located correctly, mount the

20 MAY 2023 PMM

READ ME TO COLLECT YOUR CPD POINT CPDZONE

“When fitting a selfadjusting clutch, it is strongly recommended to use a self-adjusting clutch mounting tool.”

REPXPERT. Make sure the DMF face is clean and grease free using clutch and brake dust cleaner.

When fitting a self-adjusting clutch, it is strongly recommended to use a self-adjusting clutch mounting tool, as otherwise there is a risk that the clutch could adjust, the cover twist or even strip threads in the new DMF.

So, using the self-adjusting clutch tool, mount the clutch plate in position using the clutch alignment tool (Fig.4) ensuring the plate is facing the correct way (gearbox side facing away from the engine). Clean and degrease the clutch pressure plate, mount the clutch pressure plate onto the dowels of the flywheel, fit the self-adjusting clutch tool (Fig.5) and then ease the clutch pressure plate into position. Insert half of the clutch bolts and ‘nip up’, then remove the tool, insert the remaining bolts and torque to the manufacturer’s torque value.

Drain, flush, replace

Before refitting the gearbox, an important part of the job that often gets overlooked, is to drain, flush and replace the clutch fluid. This is because the fluid is usually old, brown in colour and is contaminated with moisture (Fig.6). This in turn, will contaminate the new CSC seal and potentially cause a failure a short time after the repair.

specification of new fluid, allow that to flush through the system, re-clamp the hydraulic clutch pipe, and refill the reservoir.

Finally, ensure the gearbox to engine alignment dowels are installed correctly (Fig.8) and all cables etc are clear of the bell housing area, so that they don’t get trapped as the gearbox is being installed.

Using the transmission jack, ease the gearbox into position, taking time to confirm the alignment is correct, and once the gearbox is mounted onto the alignment dowels, insert and tighten the accessible bell housing bolts.

clutch pedal in a steady manner, and always allow the system to stabilise before pressing the pedal again, as this can easily over pressurise the system and damage the new CSC.

After connecting the battery, reset all relevant electrical systems where required, and carry out a full road test to confirm a quality repair has been completed.

WWW.RDR.LINK/AAX003

PMM MAY 2023 21

TO KNOW MORE? FOR MORE INFORMATION

WANT

HOW TO

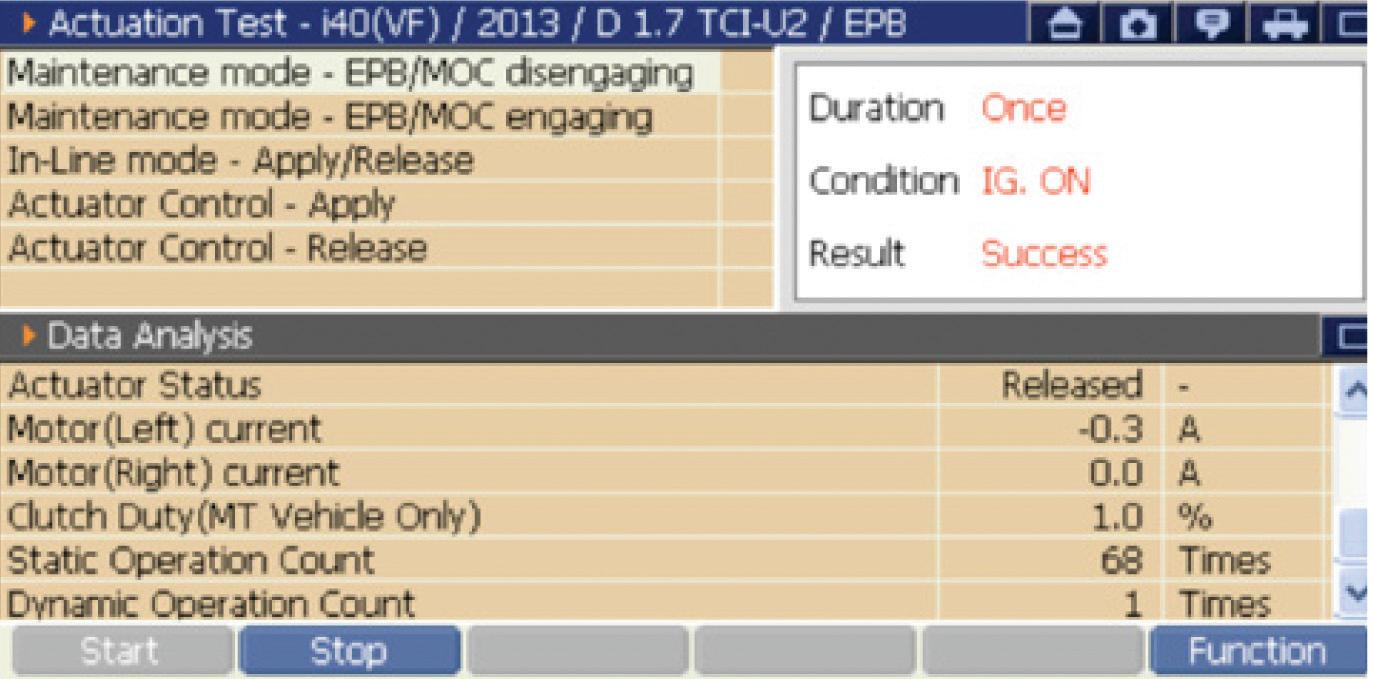

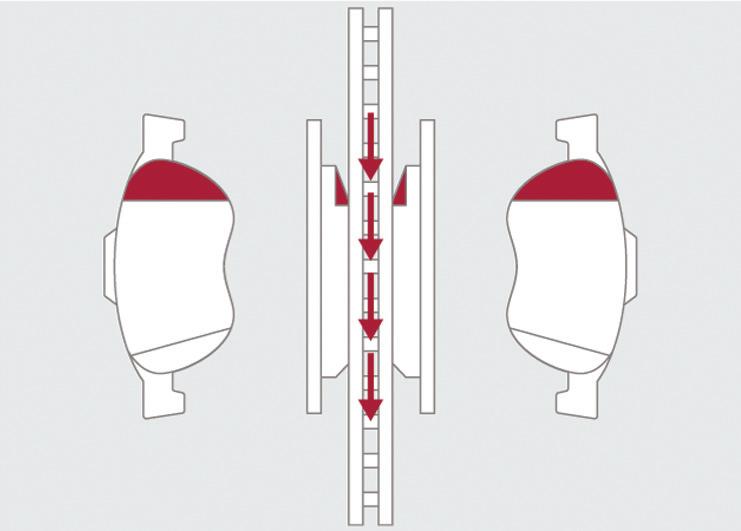

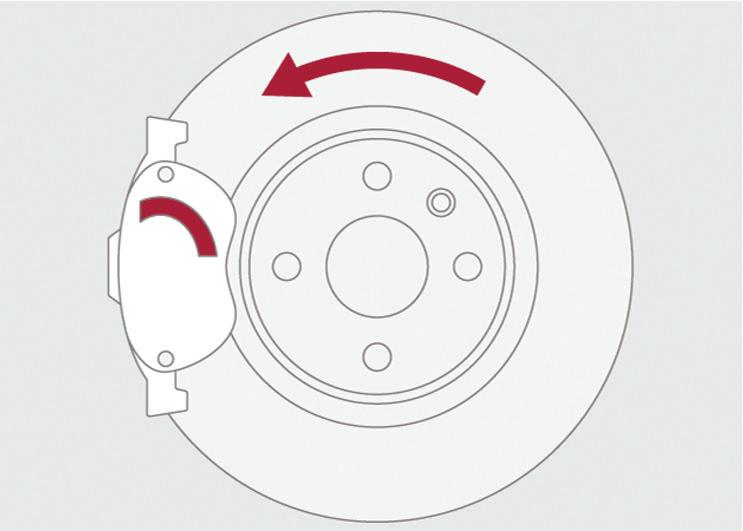

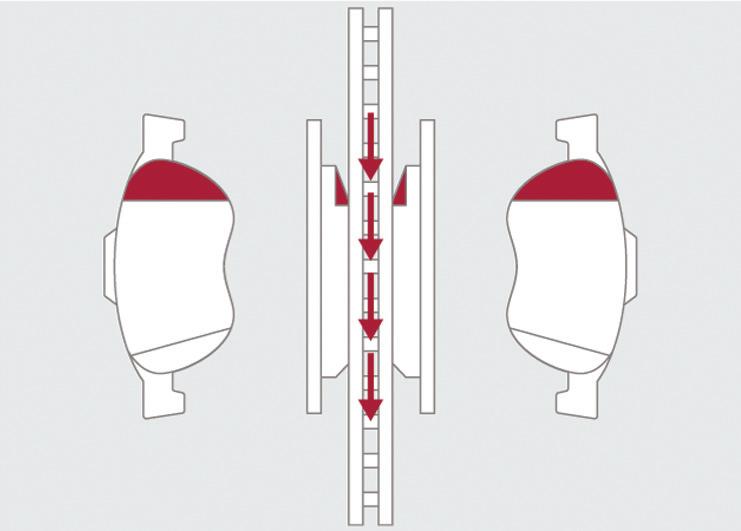

Change the rear brake pads on a Hyundai i40

Blue Print guides readers of PMM through the replacement process for the rear brake pads on the Hyundai i40.

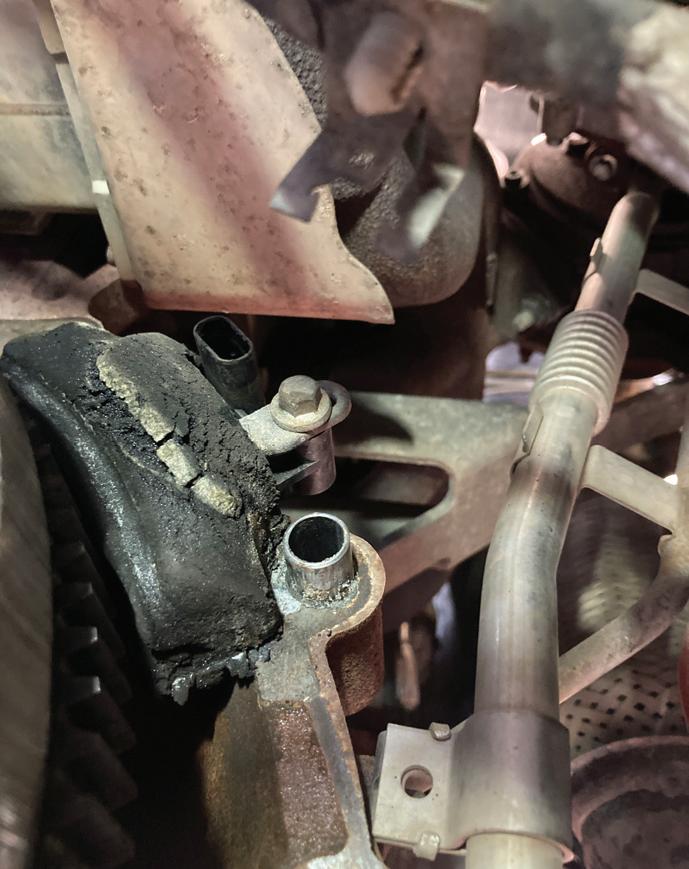

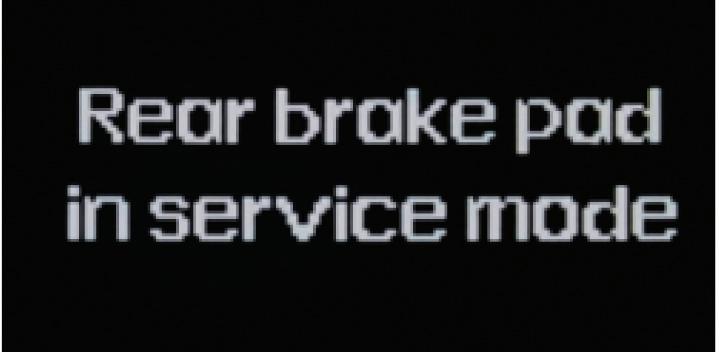

The Hyundai i40 saloon and tourer estate cars were designed specifically for the European market and, with its keen pricing, good looks, great quality and spot on selection of engines and trim levels, aimed to take on the Ford Mondeo at its own game. The i40 uses an electromechanical parking brake system similar to other manufacturers such as Volkswagen, Renault, Volvo, Ford and BMW. The following procedure is for changing rear brake pads and discs:

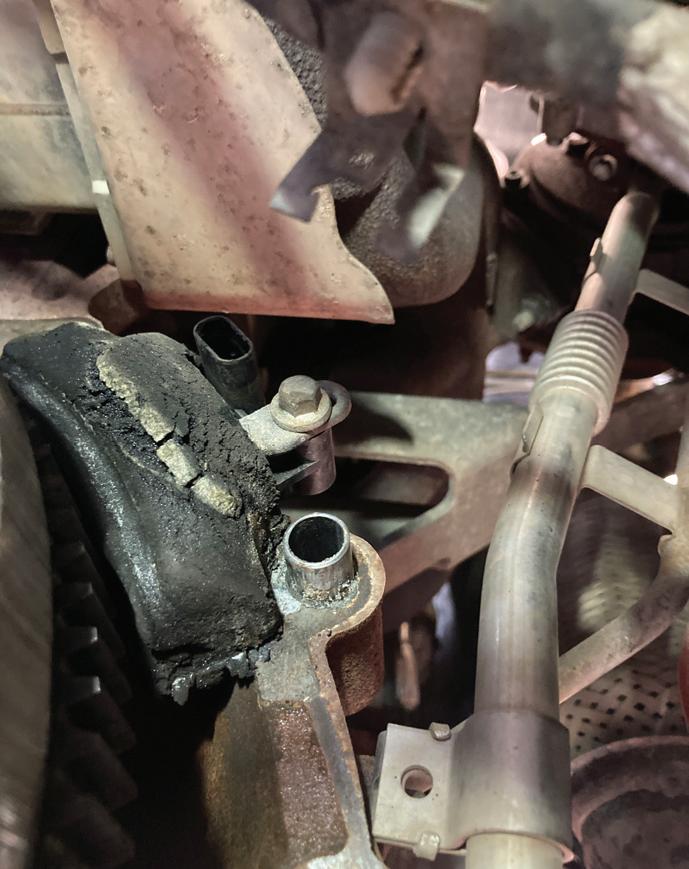

With the vehicle raised, remove the rear wheels and check the condition of the brake hoses, parking brake motor cable and connections, and the rear brake pads and discs. The minimum disc thickness is 8.4 mm and the minimum rear brake pad thickness is 2.0 mm.

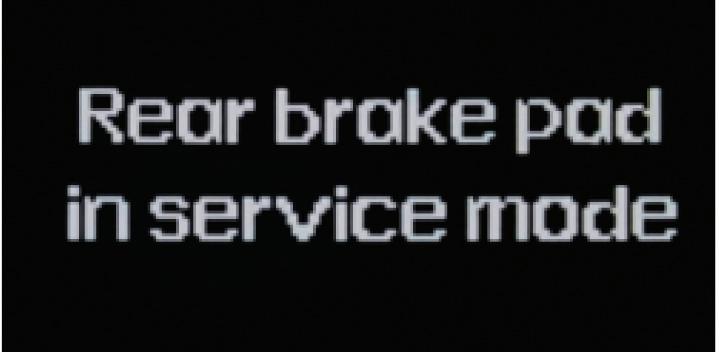

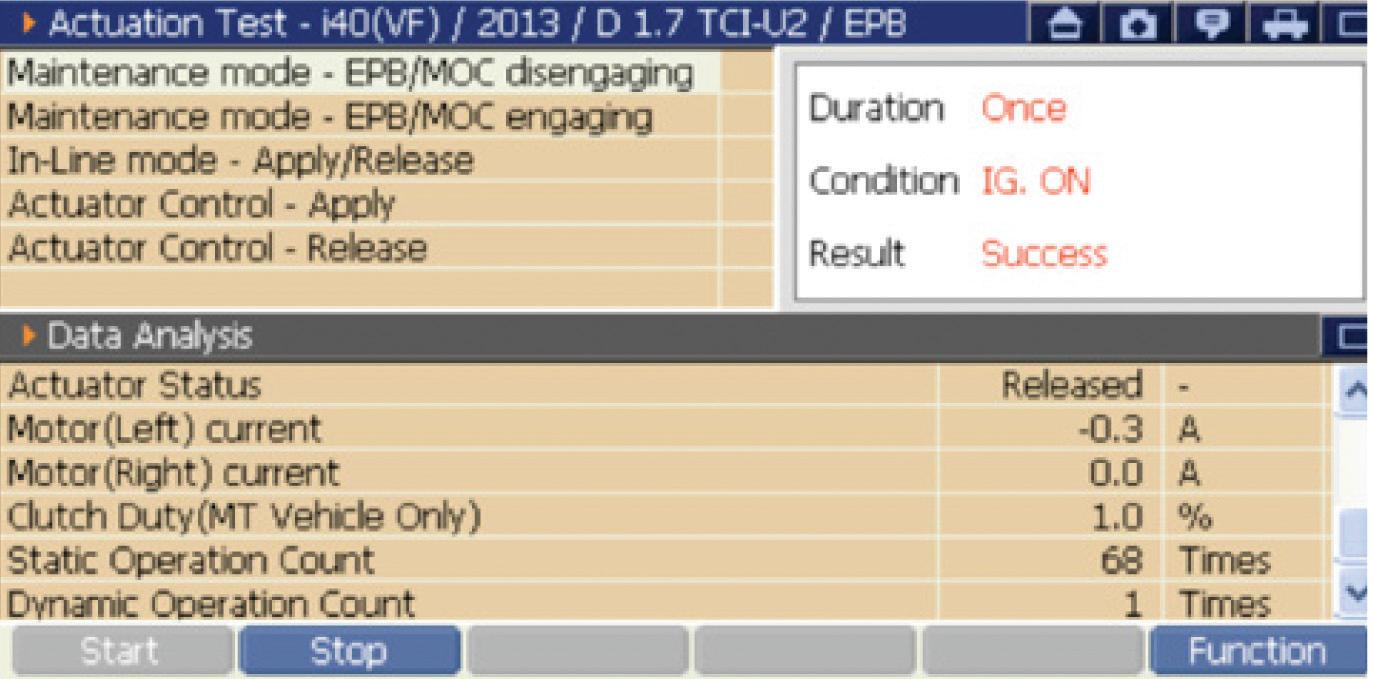

Carry out a braking system health check with regards to fluid level and condition, leaks, and check the operation of the parking and foot brakes. Note: It is advisable to connect a battery support unit as the parking brake motors draw a lot of current (approximately 14-20 amps) when in use With the ignition on, plug a diagnostic tool into the 16 pin diagnostic socket and check for fault codes in the EPB and ABS systems.

Perform

PMM MAY 2023 23

3 1 CPDZONE READ ME TO REGISTER YOUR CPD POINTS

the EPB motor wind back procedure using a suitable diagnostic tool.

2

4

Remove the two 12mm headed bolts on the brake caliper and remove the caliper carefully putting it to one side, without putting excessive stress on the brake hose and motor wiring.

There is no need to wind back the piston; it can just be pushed back

5 8

6 7 9 10

Remove the old rear brake pads and retaining plates.

In order to remove the caliper carrier (A), first remove a suspension link bolt (B). This will enable you to remove the two caliper carrier bolts (C).

Remove the rear brake disc retaining screws and then the old brake disc. Clean the mating surfaces and degrease (where necessary) the new brake disc before fitting.

Refit the caliper carrier bolts, the suspension link bolt, and then fit the new brake pads and retaining plates – once this is done refit the brake caliper.

Finally, rewind the EPB motors and check the operation of the parking and foot brakes, which includes checking for fluid leaks. Then recheck for fault codes in the EPB and ABS systems, refit the wheels and torque wheel nuts to 88-108 Nm and road test.

WANT TO KNOW MORE? FOR MORE INFORMATION

WWW.RDR.LINK/AAX004

24 MAY 2023 PMM

READ ME TO COLLECT YOUR CPD POINT CPDZONE

COMMON FAULTS

Oil Starvation and Turbos

Despite the issue being well documented, oil starvation continues to be at the heart of remanufacturer Carwood’s no-fault-found warranty returns. Like any turbo failure, it’s important to determine why it failed, and fix it, before a new one is fitted. Otherwise, the replacement unit will fail too.

What is oil starvation?

With modern vehicles demanding the power output of larger engines, but with the economy of smaller ones, today’s turbochargers operate at over 300,000 revs per minute and close on a 1,000°C temperatures. This puts a huge strain on the engine oil, the turbo’s lifeblood. So, if its supply is restricted, even momentarily, it can cause catastrophic damage to the bearing systems, destroying a turbo within a matter of seconds, and in severe cases, the engine.

What causes oil starvation?

Insufficient oil can be caused by many factors, including:

■ Low oil levels.

■ Incorrect grade or degraded, high-mileage, contaminated oil.

■ Short frequent journeys or repeated hot engine shutdowns causing carbon build up – this can block oil galleries.

■ Hard acceleration from cold starts not allowing sufficient oil to circulate.

■ Carbon deposits or other contaminants in the oil supply lines.

■ A bent or kinked oil feed or pipe.

■ A damaged, clogged or poor-quality oil filter.

■ Failure to prime the replacement turbo with oil during installation and before start-up.

■ Engine left idle for sustained periods, particularly in colder weather.

■ Incorrect or worn oil gaskets.

What are the signs of oil starvation?

There are a number of tale-tale signs, some more obvious than others:

■ Oil warning light illuminated.

■ Reduced fuel economy.

■ Poor engine performance – unable to achieve full boost pressure.

■ Engine overheating from increased metalto-metal contact.

■ Different or excessive noise from turbo.

■ Black exhaust smoke.

■ Blue discolouration of the shaft journal surface as a result of increased friction and heat.

■ Wear to the inside of the journal bearings causing the shaft to become out of balance – as result the wheels may contact and rub against their housing bores.

■ Broken/snapped shaft due to prolonged excessive temperatures.

■ Loose or missing compressor wheel nut following shaft seizure.

■ Excessive wear to the thrust bearing due to friction between bearing and collar.

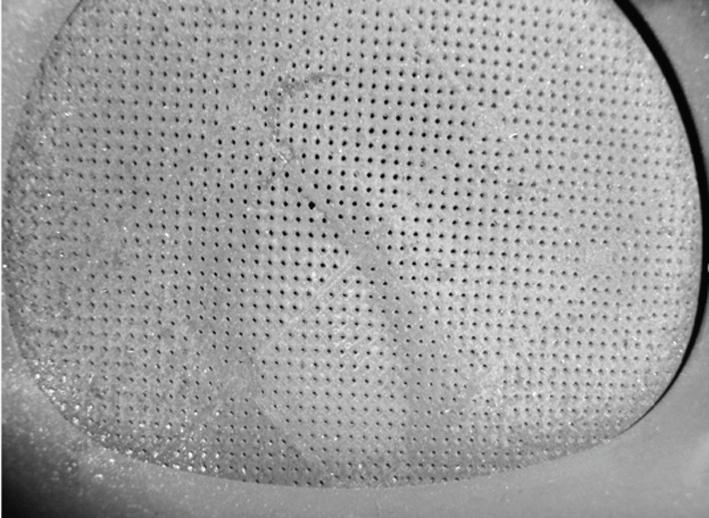

Blue discolouration of shaft and bearing fused onto shaft due to excessive heat and friction

■ Discolouration of and scoring to the thrust collar due to excessive heat and friction.

■ Transfer of bearing material onto the shaft.

How to resolve oil starvation?

If oil starvation is diagnosed, perform the following remedial actions:

■ Check and clean the entire oil supply system – this may require the removal of the sump, oil pump and internal oil feed lines. Replace components where required.

■ Fit new VM-spec filters, gaskets and oil supply pipes.

26 MAY 2023 PMM

READ ME TO COLLECT YOUR CPD POINT CPDZONE

Transfer of bearing material onto shaft

■ Flush and change the engine oil with the correct grade and quantity recommended.

■ Conduct an oil pressure test to identify any issues and check it’s supplying full pressure.

How to prevent oil starvation?

By adopting some simple, best-practice measures in your work, the risk of oil starvation can be minimised in the first place:

■ Check that the entire air induction system is clean and object free, especially in high-mileage vehicles.

■ Inspect all pipework for signs of wear and tear – clean and/or replace as necessary.

■ Always fit new oil feed and return pipes when replacing a turbo.

■ Never bend or use excessive force when fitting a new feed or return pipe, and

torque tighten at both ends, as per VM guidelines, to prevent leaks.

■ Ensure that the oil is at the optimum level –too little can starve the turbo of oil, but too much can cause a build-up within the bearing housing.

■ Always use fresh oil and new OE-quality oil and air filters, as specified by the vehicle or engine manufacturer.

■ Only ever use new, OE-quality gaskets, seals and fitting kits.

■ Prime the replacement turbo with the correct grade oil before fitting.

■ When starting a vehicle for the first time after fitting a turbo, crank the engine in one second bursts, at least 10 times, or if practical, for 10 seconds continuously, without starting. This will lubricate the bearings and shaft at a low enough rpm to prevent seizure or damage.

■ Once started, allow the engine to idle at tick over for a few minutes before revving or accelerating to enable full oil pressure

build-up which will eliminate any air or hydraulic locks.

■ Never use using silicone on oil gaskets –it can easily become detached and block oil passages.

For a right first time service, and fewer comebacks, always diagnose and fix what caused the original unit to fail – or you risk the replacement turbo failing too! Whilst this may add additional expense to customer’s bill, it is far more cost and time-effective in the long run, for you and the vehicle owner.

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAX005 Thrust collar discolouration and scoring due to heat and friction

Scoring and wear to thrust bearing

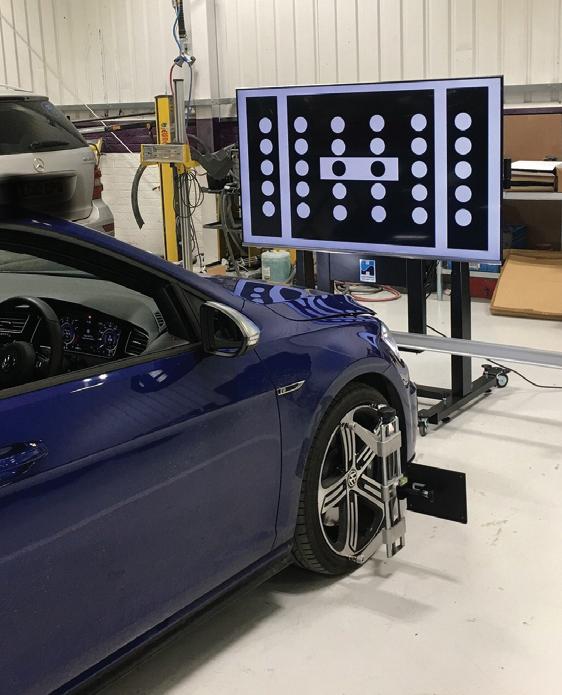

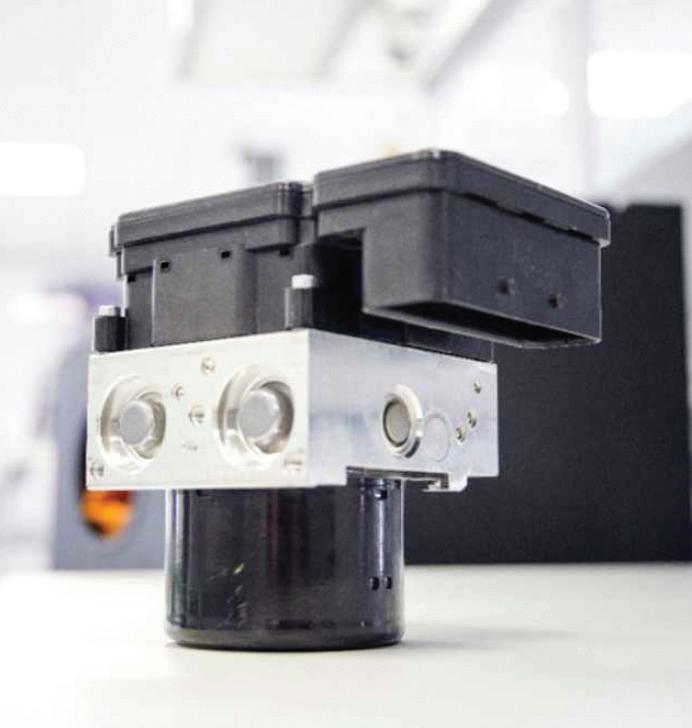

EQUIPOTENTIALEVBONDING

Last month, I described equipotential bonding as the process of connecting metalwork and conductive parts so that the voltage is the same throughout both. EPB is used to reduce the risk of damage and injury. This time we will look at how the tests are carried out.

Checking that the EPB is meeting regulations, is something that could become more common as more high voltage vehicles hit our workshops. It could also be a new income stream.

The EPB testing equipment shown as Fig.1, is computer-based so generates a results which are saved after each measurement. These results are dated and linked to the vehicle and technician, as proof that tests have been carried out by a specified person using calibrated equipment, at a specific date and time.

In principle the EPB test is simple, a known current (up to 1 A as per ECE R100 regulations) is made to flow and the voltage is measured. Resistance (R) is then calculated using the current flowing (I) and the measured voltage (V) using the formula: R=V/I.

‘Kelvin leads’ can be used, so the voltage at the test points is measured using a separate circuit to the one where the current is flowing. The special crocodile clip

(Fig.2) has each jaw insulated from the other. The clip is therefore attached to a twin core insulated cable.

My colleague Eliot Smith ( WWW.RDR.LINK/AAX006) and I tested the AVL DiTEST HV Safety 2000 on a Nissan Leaf. To even see the battery pack on a Nissan Leaf, a large protective cover has to be removed – not difficult but it does take time. The pack is painted and, as this is an older car, it was also a little corroded and dirty. We connected one lead after scratching a small amount of paint off (which was replaced!). In this way the connection is definitely to the actual pack rather than a bolt or strap.

We cleaned a chassis bolt and made the other connection. In this way, if the result was as required (less than 100mΩ) it would prove a low resistance circuit between the battery case and the vehicle chassis. Our result was 5mΩ, so well within specifications.

Checking the EPB on the motor and other components was simpler because they were easier to access. One connection to the

chassis, and one to the body of the motor after the area was cleaned. We got a result of 8mΩ.

Using the specialised equipment ensured accurate tests and kept a record. However, it is possible to complete an EPB test using a battery and variable resistor, together with an accurate ammeter and millivoltmeter. Make a circuit that causes 1 A to flow through the item under test (battery case as above) to the chassis. Measure the volt drop and calculate the resistance.

Because of the time involved in removing covers or access panels, we felt it would not be appropriate to carry out a full set of tests after every repair. However, if asked to carry out safety tests after major accident damage or other repairs, then EPB checks will be essential. These tests may also become a requirement at some point.

PARTTWO Sponsored by

MORE INFORMATION GO TO WWW.RDR.LINK/ AAX007

FIG.1 AVL DiTEST HV Safety 2000 measures EPB resistance with a resolution of just 1 mΩ at up to 1 A,

FOR

FIG.2 Kelvin lead crocodile clip showing insulated connections

FIG.3 Kelvin probe connected to the battery pack

READ ME TO COLLECT YOUR CPD POINT

FIG.4 Chassis bolt connection

BEST PRACTICE

Repairing Ford 1.0L EcoBoost “Fox” Engines

Belt manufacturer Dayco addresses some of the wider issues of the timing belt replacement on Ford’s 1.0 litre EcoBoost “Fox” engines.

Although with the correct locking tools, the belt and tensioner replacement and timing reset on this engine are not particularly complicated in themselves, several associated steps need to be understood and applied correctly, to ensure a full and thorough repair.

This begins with the sealant that must be used on the timing belt cover and the sump, to ensure there is no leakage when the engine is refitted and refilled with oil. It is strongly recommended that this is sourced through a Ford dealer, as its specification is crucial. As it only has a 10 minute window before it starts to become hard and unmanageable, it’s important for technicians to have all the tools and the cover bolts laid out and ready before applying the sealant. However, further preparation is necessary before the application stage.

Getting started

First, it is advised to replace the crankshaft oil seal before refitting the timing belt cover, but easier to fit the new one once the cover is secured in place. Second, replacing the water pump is another best practice procedure and as two of the seven bolts that secure it are incorporated into the timing belt cover, it’s also an obvious thing to do.

As the pump comes in a Dayco timing belt and water pump kit (the KBIOWP020 or KBIOWP030 dependent on the engine variant), it’s also an easy option for workshops when ordering the parts. Proper installation of the water pump is equally important. So, cleaning the mating surfaces and flushing out the old coolant, as well as priming the new pump, must not be overlooked and, to seal correctly, it only needs the new gasket supplied with the kit –no sealant should be used.

To ensure that the sealant applied to the timing belt cover is in the correct quantity and on the right surfaces, and that the specified tightening sequence and torque values are followed, technicians must refer to a reputable source of service and repair data, such as that supplied by Autodata or HaynesPro. Likewise for the refitting of the sump.

Up next

Two crucial steps remain on this side of the timing belt installation, one is to fit a new friction washer, which is a part that was not fitted when the engine was originally built and only comes into play when a timing belt replacement is carried out. The second is using the correct torque value and process for tightening the replacement crankshaft pulley bolt.

Although fitting the friction washer is straightforward, providing the mating surfaces have been cleaned with brake and clutch dust remover, installing the new pulley bolt and applying the correct torque, without the pulley slipping, is less so.

The correct torque for the bolt is 300 Nm plus 90°, so a torque multiplier will need to be used for the final tightening, but before that value is applied, the bolt first needs to be tightened to 25 and then 75Nm. However, as there is not a keyway in the pulley/crankshaft, to prevent it from slipping during the tightening procedure, a locking tool (supplied with the timing locking kit) must be inserted through a hole in the pulley, into the matching hole in the timing belt cover.

PMM MAY 2023 29

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAX008 CPDZONE READ ME TO REGISTER YOUR CPD POINTS

TROUBLESHOOTER

DPF warning light on a VAG vehicle

IVS 360 from Opus IVS is backed by over 100 OE-certified master technicians delivering live diagnostic repair guidance. Here, we follow the team as they diagnose a vehicle displaying a DPF warning light on the instrument panel cluster, along with the pre-glow warning light.

Symptoms:

1. DPF warning light on together with pre-glow warning light.

2. Loss of power.

3. Engine Management light on.

Fault Codes:

■ P2002 (8194) Particle filter bank 1 malfunction ECM - ECM

■ P242F (9263) Particle filter maximum load exceeded ECM - ECM

Cause:

■ High soot loading in the diesel particulate filter (DPF).

Repair step-by-step

Read the fault memory of engine ECM.

If no fault is logged, and only the DPF light is on, then the vehicle needs DPF regeneration.

a. The DPF light does not signify a fault with the vehicle but means that the vehicle has not managed to regenerate the DPF due to frequent short journeys, stop/start trips or insufficient exhaust gas flow.

b. To regenerate the DPF, change to a driving profile as described in the owner’s manual.

If a fault has been logged in the ECU: Action the fault, and carry out an emergency DPF regeneration

Inspect the intake and boost system for leaks (Including all the hoses and pipe work)

Read out the live data for the DPF pressure and temperatures with the ignition on and at idle, the engine must be above 80°C. DPF pressure should read:

■ Ignition on – 0 mbar +/- 1.5 mbar (If outside these specs, then the fault should be a defective pressure sensor or wiring defect)

■ Engine idling – 10 mbar +/- 5 mbar (Below would require checking the DPF is intact and over would suggest a partially blocked DPF)

Check if all the warning lights for DPF, preglow and engine management are on: If they are all on, these are the two reasons:

a. The soot loading is over 45mg. The vehicle is running in emergency operation.

b. The regeneration cut-off time of 4500 seconds has been exceeded.

c. The soot loading may not be above 45mg to carry out an emergency regeneration.

In either of the above cases, an emergency DPF regeneration would be required.

Note – The engine control module will not allow a regeneration if the soot loading is over 45mg. However, a professional clean and resetting the DPF learnt values may suffice.

Inspect other components in the exhaust system before you replace the DPF as it may not be necessary to do this.

Inspection of the following components would be required:

■ G450 - Exhaust gas pressure sensor

■ G506 / G448 - Temperature sensor before DPF

■ G507 / G235 - Temperature sensor before the turbocharger

■ G527 - Temperature sensor after the FPF

■ G70 - Air mass meter

■ G39 - Lambda probe

If you cannot find a fault with any of the above exhaust components rectify the DPF fault before you re-assess the soot loading of the DPF through the measuring groups.

REDEEM YOUR CPD CREDIT

Congratulations, you have reached the end of the CPD Zone! To access your CPD credit from The CPD Group, scan the QR Code below or WWW.RDR.LINK/AAX009

30 MAY 2023 PMM READ ME TO COLLECT YOUR CPD POINT CPDZONE

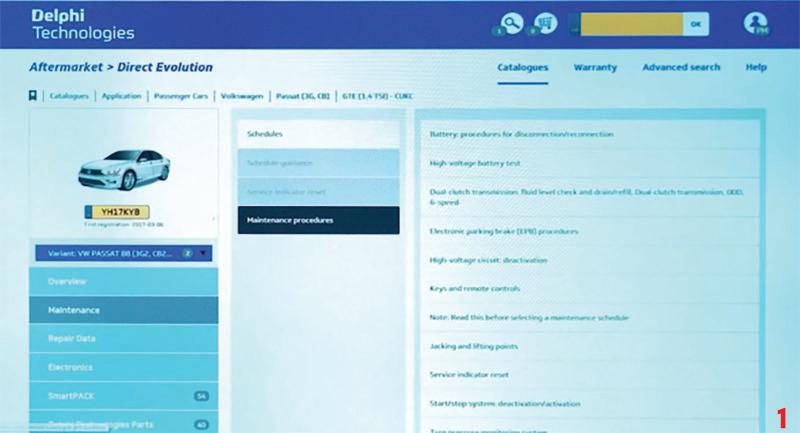

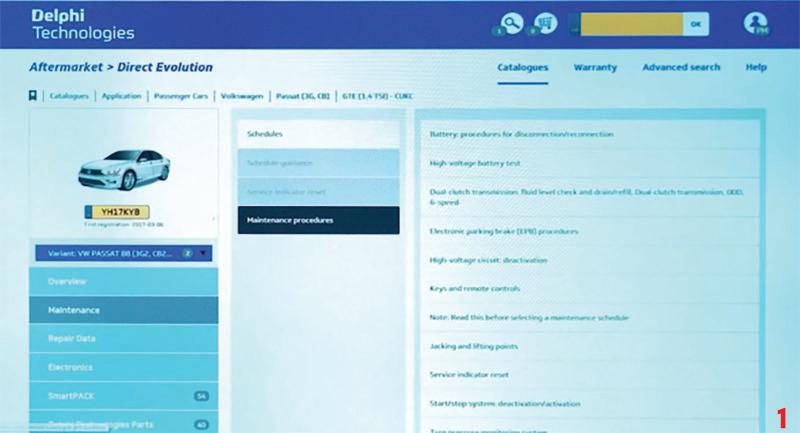

TRAINING for TESLAS

PMM’s Kieran Nee catches up with Delphi’s workshop solutions technical lead, Phil Mitchell to find out what the aftermarket company has got lined up to help technicians take on Tesla vehicles in their workshop.

It would be safe to say that the electrification of vehicles’ powertrains has galvanised the automotive industry in a way that hasn’t happened since the introduction of the diesel engine. All of a sudden, the cars we drive and how we drive them are regularly headline news and the source of heated debates between rent-a-gob pundits. There is a risk that this fast-paced (literally) technology will leave the repair sector behind if technicians don’t take it upon themselves to join training course and gain some accreditation.

To be fair, considering the speed with which the government is ordering a switch from ICE

vehicles to EVs, the aftermarket has done a commendable job of signing up for training on handling EVs. These courses, however, have mostly focussed on the health and safety aspect of working with EVs. What this training mostly provides workshops, is the ability to perform routine service and maintenance tasks in a safe manner with the battery successfully isolated. What most workshops have yet to tackle is anything to do with the battery or in-depth diagnostics on EVs. This is something that was emphasised in my recent chat with Delphi Technologies’ Phil Mitchell. Phil, now EMEA workshop solutions technical lead, will be familiar to

many readers for having provided Delphi training in the UK. He told me that there was a growing problem of specifically Tesla owners finding they were unable to get their vehicles repaired – or even serviced or having a tyre changed – by independent garages. Why might this be? Well, in Phil’s words, the aftermarket is “fairly scared of Tesla vehicles.” Phil contrasts Mr Musk’s vehiclecum-tech company with the legacy brands also active in the EV market, noting that when it comes to diagnosing Teslas with aftermarket tools, it’s difficult to know where to start.

Up until around a year and a half ago, Phil tells me, Tesla was a closed book when it

BUSINESS & TRAINING

came to releasing its data to the aftermarket. It was “excruciatingly expensive” to access its dealer tools, and there were no aftermarket diagnostics tools offering Tesla coverage. So, what has Delphi done to help the aftermarket with its Tesla dilemma? Phil explains: “We took a two-pronged attack. We are launching diagnostic software with Tesla capabilities and now, we are accompanying that with an e-training module on our Delphi Academy to guide technicians through some key

diagnostic processes for Teslas. The aim is to provide a full solution for workshops in order to enable them to work on Teslas.”

No aftermarket diagnostics tool will have as much capability as the dealer tool, so will the training academy’s online course focus simply on the tasks which the tool can complete? Not according to Phil: “We looked at the all the common jobs workshops will be doing – the ones they make the most money on – and we included lots of information

about the cars themselves, everything you would need to know to comfortably repair them. But we also look at what jobs you can carry out using the Tesla OE software, which you can’t using our tool.”

The 11-part e-learning course takes users step-by-step through getting set up and acquainted with Teslas and counts towards a user’s IMI CPD credits. WANT

TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAX010

“The aim is to provide a full solution for workshops in order to enable them to work on Teslas.”

Phil Mitchell, Delphi Technology

©AdobeStock/Moose

Real mechanics go to MECHANEX

2023 sees PMM once again rounding up the most important suppliers in the aftermarket to provide workshop owners and technicians with an engaging, informative day out of the workshop.

The UK’s longest-running trade show dedicated solely to the independent aftermarket will once again be held at Sandown Park on Tuesday 7th and Wednesday 8th November.

Mechanex is well known within the independent aftermarket for offering visitors a hands-on experience, bringing them the latest updates and expertise from across the industry and providing an exciting day away from the workshop.

7th-8th November

Registration to visit the show is free and so is parking, so why not come and take a look at what the biggest names in the aftermarket have to show you. In such a competitive industry, Mechanex is an opportunity you can’t afford to miss.

If you like PMM, you’ll love Mechanex –it’s simply the magazine in a live format.

NEW FOR 2023

This year, Mechanex will be featuring the brand new PMM LIVE format for the first time. PMM LIVE aims to educate and inform visitors to the show in the same way the magazine does. We will be keeping you up to date on the latest issues affecting your business on our seminar stand as well as bringing you our FutureDrive Zone. We’ll be hosting a raft of forward looking exhibitors who will be demonstrating the products and technology necessary for the workshops of the future. Plus, we’ll be hosting exclusive talks including a debate from the foremost experts in the field on the real future of how cars in the UK are powered.

TO FIND OUT MORE ABOUT THIS YEAR’S MECHANEX AND PMM LIVE GO TO WWW.MECHANEX.INFO BUSINESS & TRAINING

34 MAY 2023 PMM

The hands-on show for hands-on techs is more committed than ever to bringing PMM to life with new opportunities to debate the future of independent workshops.

The benefitsofoffering WINDSCREENREPAIRS

Garage owners and managers should always be looking for ways to both improve the service that is given to customers and increase their profit margins. Adding windscreen repair could be a simple way to do just that. Those who haven’t carried out windscreen repairs before might think, I don’t know how it works, it’s too expensive, I might not get a good result.

So, let’s break down how windscreen repair works, then consider which system is right for your business, and finally, ways to sell a repair to your customer as an add on service.

How does it work?

Windscreen repair simply works by removing air and debris from the break, filling it with resin, and curing it with an LED lamp. Firstly, examine the break, then drill out the crater. Place the bridge over the break, and the injector into the bridge, over the damage. Inject the resin and the plunger pushes it through the tiny cracks all around the break.

The “pressure on, pressure off” cycle ensures that air is removed from the break and resin fills the damage. Once that is done, remove the bridge, add a little pit fill resin to the screen and the damage is cured in 75 seconds with the LED lamp. Remove the

excess resin from the screen, polish it and you have a screen that is said to be as clear as a new one.

Which is the right kit?

Esprit windscreen repair equipment sell four kits –they all do the same quality job, but there are some differences in price, based on the number of repairs that they will carry out. The elite kit comes with an LED lamp, plus enough resin to carry out 40 repairs. It’s up to you what you charge for a repair, but the company recommends around £25-35. If you charge that amount, you’ll have made back the cost of the kit by the time you finish the resin provided, and after that, you just have to replace resin and other consumables. making each repair going forward cost around £1.50 to carry out, giving you a significant profit margin.

The compact kit is also available which contains the LED lamp but has enough resin for 20 repairs. This kit is better for the occasional repairer, but still contains all the same Esprit products as the elite kit.

Finally, the classic kit and the compact classic which come with the classic bridge and a UV lamp. This is the company’s lowcost option, but the kit still comes with all Esprit products, and the resin and can be upgraded to use the LED lamp.

Selling the repair

If your customer’s vehicle comes in for an MOT, a service or another repair, look at the screen for any chips or breaks. Repairing sooner is always better as if a break is left the car won’t pass its MOT, can turn into a large crack, normally necessitating a costly windscreen replacement.

Make sure your customer knows that when they come to MOT their car, windscreen damage will fail the MOT, but a repaired windscreen will pass. They don’t need to claim on their insurance, and possibly lose a no claims bonus. The cost benefits to the customer of repairing rather than replacing are easy to see.

Repairs only take around 20-30 minutes so they can be carried out as part of the service or MOT. If you charge around £25 for a repair, most customers who are having a service, MOT or other repairs to their car will agree that this is a low-cost way of preventing the need for a windscreen replacement.

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAX011 BUSINESS & TRAINING

36 MAY 2023 PMM

Esprit advises garages on how they can be improving their services through offering windscreen repairs, and the kits that could help garages achieve this.

PMM sits down with

Automechanika

Birmingham’s marketing director, Alex Jones to find out what’s new this year and what she’s most excited for.

AUTOMECHANIKA Birmingham, 6-8th June

Birmingham’s NEC sees the return of the biennial aftermarket trade show this June. We caught up with the show’s marketing director Alex Jones to find out more.

What does the show offer aftermarket technicians?

What doesn’t the show offer aftermarket technicians? There are 192 hours of free skills training across EV, ADAS, diagnostics, repair and maintenance, battery technology, hydrogen internal combustion, diesel, MOT, customer service, filtration – you name it, we’ll have bite size practical sessions.

What is the best thing about Automechanika?

It’s the Glastonbury of the automotive sector, it’s literally a city built full of new technology, tools and training. Registrations are at a record high and so the buzz hearing 12,000

automotive peers exchanging knowledge and debating the big topics like the supply chain, price rises, MOT tensions, skills gaps… this is where it all gets sorted out!

What are you personally most excited about?

The automotive industry is going through the biggest change in living memory, it’s tough out there for aftermarket businesses; disruption and changes are happening more frequently than ever and it’s harder to make a profit and plan for the future than ever before. So, the thing I’m most excited about is seeing all the work the team have put in come to life. Where the garages can park for free, pick up a free bacon roll and then get their hands on and compare technology and tools from 500 leading suppliers and benefit from the 192 hours of free skills training. All for free! Even if people can come for just one day, they will learn and see more than they can in 6 months from their workplace.

CATCH PMM AT AUTOMECHANIKA!

For the first time Professional Motor Mechanic will be exhibiting at Automechanika Birmingham, offering you the opportunity to come and engage with the team behind your favourite trade mag!

We’ll be bringing a touch of showbiz to the aftermarket show where we’ll be podcasting throughout the three days. We’re giving you the chance to appear on the PMM podcast, simply hop onto our stand (ZZ72) and get in the hot seat armed with nothing more than your opinion. So if you’ve got something to say (and we know you do), come and say it on the aftermarket’s number one podcast! We’ll also have the red carpet rolled out for the special occasion, so if you want to bag yourself a free PMM tshirt don’t forget to say CHEESE – you could even win the mystery prize…

AUTOMECHANIKA BIRMINGHAM TAKES PLACE 6-8TH JUNE AT NEC BIRMINGHAM.

IT IS FREE FOR WORKSHOPS TO ATTEND. TO FIND OUT MORE GO TO WWW.RDR.LINK/AAX044

A NEW chapter

The new logo aims to embody the ethos of Granville, the regular, uniform sides and angles of an equilateral hexagon represent the solid foundation of the business encased in the strongest shape in nature. The G in the icon is split into three parts to show its emphasis on quality, value and customer service. The aim of the modern icon paired with the brand’s traditional font is to remind customers that it still stands for the same fundamentals of service that the company have provided throughout the decades.

This new logo becomes flexible, with the colour of the icon reflecting the placement and colour scheme of the product on which it is placed. For example, for the more trade oriented Hypalube range, the icon becomes silver to fit in with the quality and value for

Launching oils into the 21st century

Whilst rebranding, the company decided to introduce a completely new look and feel to the Hyalube range, with the new trade bottle being the first to embody the new look. The strong lines and sharp corners are tempered slightly with rounded corners for a modern look whilst the bottle remains unmistakably Granville with the addition of subtle hexagons to add interest and grip to the chunky easy-grip handle.

The labels also feature strong branding with a sophisticated feel and colour coding to differentiate between fully synthetic, semi

winter/weight rating of the oil. The dark backgrounds said to complement the gun metal grey bottles to present a premium feel to the trade range.

Continued evolution

The coronavirus pandemic caused many businesses to revisit their supply chain, operations, stockholding and review their use of just in time production practices as a result of what would previously have been considered unprecedented global disruption. This allowed Granville to review its operations and supply chain and established a weakness which was in the sourcing of bottles.

To resolve this, it has invested in blow moulding equipment to be able to manufacture its own bottles as needed. This improves resilience, efficiency and is significantly more environmentally friendly as it will negate at least 100 truck journeys per year saving 1000 tonnes of CO2 per year. The ability to manufacture bottles and fill them on a single site is a major step forward for Granville’s evolution.

PMM MAY 2023 39

After 20 years of rectangular red and blue tram tracks, Granville has modernised its logo to reflect its evolving brand.

SPECIAL REPORT WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAX012

Granville has invested in blow moulding equipment to be able to manufacture its own bottles as needed.

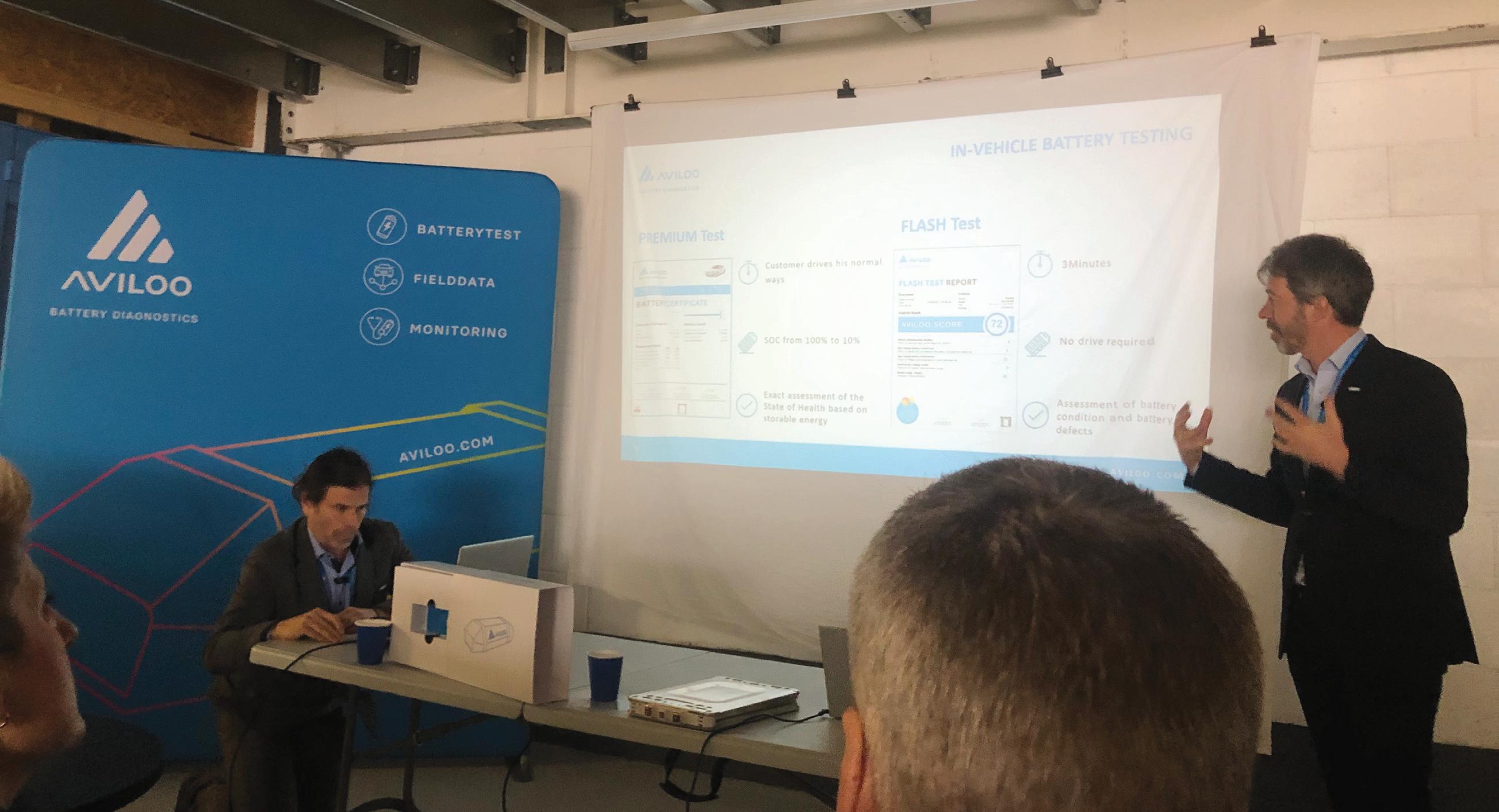

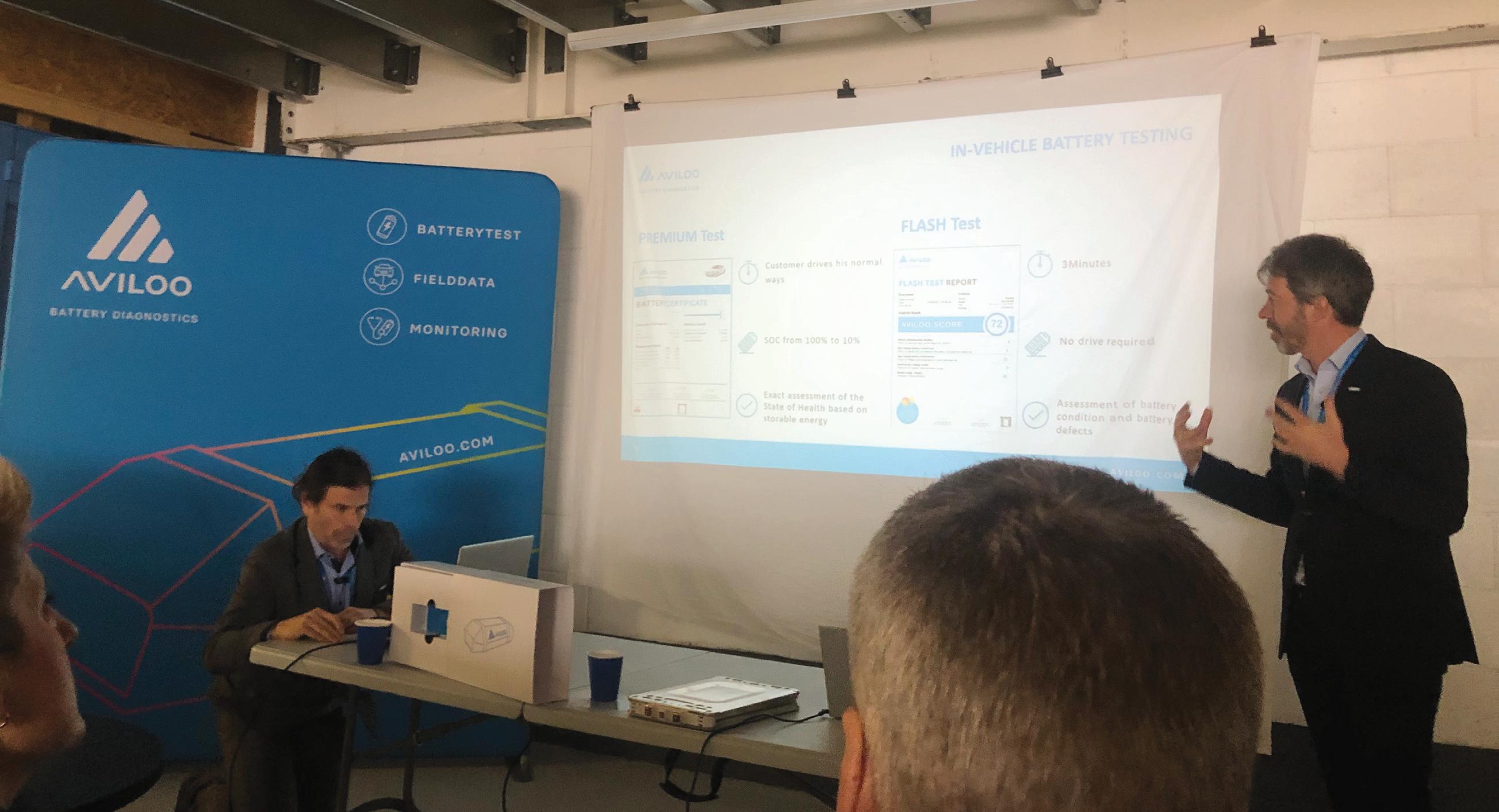

AUK BATTERYTESTING first

ACleevely’s EV garage in Cheltenham, journalists gathered to learn all about how workshop owners and technicians are now able to offer their customers a simple test that generates an insight into the condition of their EV battery.

In collaboration with Aviloo, a developer of battery diagnostic solutions, Maverick Diagnostics is primed to offer a UK aftermarket first: the fastest and the most comprehensive independent test that measures EV and plug-in hybrid battery condition.

We saw a demonstration of the ‘Flash’ test that in just three minutes generates an analysis of a traction battery while a vehicle is stationary. The diagnostic tool measures several parameters – vehicle communication, battery controller, HV battery state, LV

Aviloo, has partnered with Maverick Diagnostics to launch a tool and software package which will help UK garages to check the health of EV batteries for their customers.

system and battery history – before offering a manufacturer-independent test score between one and 100. Technicians can then illustrate that score and the test’s overall findings to customers with a report.

Aviloo chief technical officer, Nikolaus Mayerhofer, explained why battery testing on a regular basis is vital: “Traction batteries are chemical energy storage devices that are subject to a natural ageing process due to load and lose their storage capacity over time. Likewise, usage behaviour, such as permanent driving in the upper power range or frequent charging with high charging powers, can lead to faster battery ageing.”

How does it work?

First, the user plugs an Aviloo box into the OBD port of a vehicle.

Next, wait for a flashing yellow LED light to appear, which indicates the start of the test, then start the vehicle.

Finally, the LED light will turn green to signal that the test is complete. A report will then be immediately generated and sent to the e-mail address synced to the device. This is available on either the app or desktop.

Currently, the tests cover approximately 80 per cent of existing EV and plug-in

hybrid models and with daily work on the introduction of new models, that percentage is growing.

A game changer

As the number of EVs and plug-in hybrids continue to rise, there is a growing opportunity for independent workshops and demand from their customers to ensure their vehicle’s battery is in good health.

Maverick Diagnostics managing director, Andy Brooke, said: “Our partnership with Aviloo represents a game-changing opportunity for workshop owners and technicians. This is the first test of its kind. Customers can now see, in the simplest form, what condition their EV or plug-in hybrid’s battery is in. The technician can then use this accurate and reliable information to make a reliable assessment and, potentially, justify a battery replacement.”

Battery diagnostics solutions from Aviloo are now available in the UK through Maverick Diagnostics.

WANT TO KNOW MORE? FOR MORE INFORMATION

WWW.RDR.LINK/AAX013 SPECIAL REPORT

Austrian battery diagnostics and solutions company

40 MAY 2023 PMM

GOING DIGITAL

In-depth demonstrations on MAM Software’s latest mobile and web solutions took place, including a range of apps that deliver customers’ efficiencies in all aspects of operation management.

The company also unveiled many initiatives to deliver key benefits to all industries where its customers operate. For example, its new Konnect Online platform will enable KCS to quickly develop and deliver partner solutions that can be made available across all of its markets and core products.

“We recognise that our customers need our support as they work to deliver their carbon reduction strategies, and we are proud to develop and to showcase solutions that can help”, added James Mitchell, managing

director. “Our EasyAP solution, for example, enables customers to automate their accounts payable processes and to remove paper, filing and storage. They can extract invoices from email, import and match, and electronically file an image of the supplier invoice. This removes paper and printing, which results in a more efficient administration process.”

KCS also delivered updates to customers on the latest web strategies available. Customers can choose integrated B2B or B2C web trading products to support their strategies, together with a range of tools that enable a workshop to forge strong integrations with their customers and suppliers.

“Digitisation is not a scary word or strategy for our customers,” says James, “our customers were early adopters of our cloud technology as a means to outsource their IT infrastructure and reduce their energy consumption. They have been using handheld technologies to improve efficiencies but, up to now, the high hardware costs have always been a barrier to adoption. We can now harness the power of cloud computing to deliver cost-effective solutions into areas of the business that staff members manually controlled in the past.”

WANT

At its Konnect conference, spanning the 2nd and 3rd of March in Stratford-uponAvon, Kerridge Commercial Systems (KCS) welcomed over 400 delegates to unveil its sustainable initiatives.

TO KNOW MORE?

WWW.RDR.LINK/AAX014

Have your say ... ON THE MOT

With all this incessant talk about MOTs recently, with experts (and editors) falling over themselves to have their say, we thought it would be a good idea to present some of the opinions that have come to us from you, our readers.