PROFESSIONAL M OTOR M ECHANIC

ENTER THE CPD ZONE! YOU COULD EARN ONE CPD CREDIT THIS MONTH

Also inside: THE LONG READ: WHEN ITCOMES TO CLOSING THE SKILLS GAP , WHAT OPTIONS DO WE HAVE?

NEIL PATTEMORE CALLS FOR GARAGE EVIDENCE ON VM ISSUES YOUR LETTERS READ AND ANSWERED! Let’s get technical: EGR SYSTEMS EXPLORED

FREE TOTHE TRADE PMM

JULY

AUGUST 2024

/

LCV CLUTCH REPLACEMENT TIPS AIR SUSPENSION CALIBRATION GUIDANCE THE RELATIONSHIP BETWEEN DPFS AND TURBOS EXPLORED THE IMPORTANCE OF CORRECT WHEEL ALIGNMENT EXPLAINED

Editor’s Picks

PMM delves into the number one issue facing the aftermarket today: the skills crisis. Does money hold the answer, or is it going to take more

overcome years of neglect?

As part of the month’s CPD Zone, Delphi is taking us through a step-by-step guide on calibrating air suspension. Make sure to scan to QR code at the end of this feature to claim your CPD point.

Neil Pattemore, technical director at UK AFCAR, outlines how there is no substitute for providing ‘real life examples’ when fighting for a fairer landscape for independent workshops seeking RMI data. Make sure to go to page 30 to find out more!

Could summer be the perfect time to offer servicing to your customers? That’s what tool specialists Draper are arguing and offering its best products to get the job done.

Contents VOLUME 25 ISSUE 7 JULY/AUGUST 2024

Total Average Net Distribution 53,353 1st July 2022 – 30th June 2023 PMM JULY/AUGUST 2024 3 Regulars 6-9 NEWS & VIEWS 11-13 GARAGE MATTERS: THE SKILLS CRISIS 15-27 CPD ZONE 28-34 SPECIAL REPORTS 36-39 BUSINESS & TRAINING 40-41 A LOOK ONLINE: LR DEFENDER 59 TOP FIVE ARTICLES 60 PIT STOP 61 OUT & ABOUT 62-65 IN THE WORKSHOP

Features

11 MONEY AND SKILLS

24 TECHNICALLY SPEAKING

creativity to

30 DATA ACCESS

43 READY FOR SUMMER?

49-53 TYRES & WHEEL ALIGNMENT 43-47 TOOLS& GAR AGE EQUIPMENT 55-56 A/C& THERMAL M ANAGEMENT Image credits: p.49 ©AdobeStock/mbruxelle

Editor KIERAN NEE

News and Products Editor

FREYA COLEMAN

Digital Manager

KELLY NEWSTEAD

Group Manager

ROBERT GILHAM

Senior Account Manager

ALEX DILLEIGH

Magazine Designer

GEMMA WATSON

Group Production Manager

CAROL PADGETT

Production Assistant

CLAIRE SWENDELL

Distribution Manager

KARL CLARK

Subscriptions

PROFESSIONAL MOTOR MECHANIC is a business magazine for firms and individuals involved in all aspects of the motor trade. It is published eleven times a year and is available nationally FREE to the trade through leading motor factors. It is also available through the post at a cost of £30.

EUROPE and OVERSEAS

UK £30 post paid

Air mail £80 post paid

Europe £50 post paid

Printed by

PCP Telford

Published by

HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts, WD24 4YF. Tel: Watford (01923) 237799 Fax: (01923) 246901

E-mail: pmm@hamerville.co.uk

Sales enquiries: pmmsales@hamerville.co.uk Website: www.pmmonline.co.uk

Copyright © 2024

COOKING UPA STORM

I’ve started watching the Bear recently, which is a programme on Disney+, set in the windy city, in a sandwich shop. This particular sandwich shop is, three episodes in, at least, a hive of both chaos and creativity – everyone shouts over each other, there are sauce stains all over the place, the staff are all pulling in different directions and everyone believes they know what’s best for the shop. The owner was, until the death of his brother, the chef de cuisine at a top Michelin starred restaurant. Having now taken over the reins from his big bro, he is struggling (again, only three episodes in) to keep everyone in check. Now, why am I writing about this? Because I liked it? Not really, so far it’s a needlessly melodramatic version of the amazing UK drama Boiling Point. I’m writing about it because it made me reflect on the numerous factors which can come together seamlessly to bring a workshop owner to their boiling point (I should have led with the Boiling Point reference really, it is much better).

Let’s look at some of the agitating aspects present in these crisis point kitchens that could easily find a home in a workshop: Firstly, and most noticeably, everyone shouts when they need to relay information. I’m not saying there is never a time for shouting, but really it should be a last resort, otherwise you get to the point where shouting becomes the norm. Plus, when everyone is shouting at the same time, you need to start shouting even louder to make yourself heard – and the person you’re shouting to is also shouting, so they’re not listening! Secondly, there is mess everywhere. Ok, it’s unlikely that the mess in your workshop is going to be Bolognese sauce slopped on the wall or a bucket of veal stock dashed on the floor, but whether it’s a kitchen or a garage, one thing is true: mess begets mess. The kitchen staff on the Bear do a poor, half-hearted job of cleaning at the end of the day. One easy way to get a good start in the morning is to do a thorough clean and tidy the evening before – oh and, try not to spill things in the first place. Thirdly, no one knows, or cares, who’s in charge. This isn’t strictly true for Boiling Point, where the central focus is the loss of control of the head chef, but is certainly true for the Bear, where the gun-toting best pal of the former owner keeps hanging around like a boorish bad smell. It’s unlikely that you will have any gunslinging Italian Americans bossing everyone around at your workshop (if you do, put this magazine down and call the police!), but it’s not beyond the realm of possibility to have “senior” staff who have developed their own way of doing things and aren’t against undermining the authority of the actual garage owner. Lastly, there is a disconnect between the vision of the owner and that of the staff. If you want to turn your bottom of the barrel sandwich shop into, I don’t know, some kind of gourmet sandwich shop, you need to communicate that vision to your staff and make sure they’re on board. That way, when you start calling them Chef, they understand why (and probably quit to go to a sandwich shop with a less insane owner). Likewise, if you want to up your workshop’s game, or change its direction, you need to make sure your staff are on board and see your vision. Otherwise, all you’re doing is cooking yourself up a recipe for disaster! Now, I don’t know about you, but I’m getting kind of hungry...

KieranNee Editor

VIEWPOINT

The publishers and editor do not necessarily agree with the views expressed by contributors,nor do they accept responsibility for any errors of translation in the subject matter in this publication. Listen on Amazon Podcasts Listen on Spotify Podcasts Listen on Apple Podcasts Associate member Find every episode at www.pmmonline.co.uk/podcasts Also available: JOIN M E EACH M ONTH ON THE PMM PODCAST

PMM NEWS

NEWSIN BRIEF

■ DATA EXPOSES UK DRIVERS’ CAR AFFORDABILITY GAP WITH THE EU A recent study conducted by Vignetteswitzerland.com has unveiled the least affordable European countries where drivers face the highest financial barriers when purchasing their car. The UK ranked as the seventh least affordable.

■ REPAIR SECTOR MAKES THIRDFEWEST REDUNDANCIES Recent research from Money.co.uk has revealed that the motor repair sector made the third fewest redundancies last year, highlighting the extent to which the skills shortage is limiting workshops’ ability to change staff.

■ HELLA CELEBRATES 125TH BIRTHDAY IN GERMANY AND 65TH IN UK To celebrate the milestone, it’s putting limited-edition merch into the hands of customers including a ‘Masters at Work’ football table. Enter on the company’s website.

■ DELPHI INVESTS £500,000 IN ACADEMY EXPANSION The Warwickbased academy has said it will double in size by extending into a neighbouring unit, bringing the total floor space to 1,430 square metres. The new academy facilities are expected to be operational soon.

with Freya Coleman

with Freya Coleman

Automotive vacancies fall

Despite vacancy rates having fallen slightly from 23,000 to 22,000 according to a report from the IMI, the sector remains as having the highest vacancy rate of all industries.

The figures in the IMI’s UK Automotive Vacancy Overview report confirm that the sector continues to face a multitude of challenges which are exacerbating the job vacancy crisis. One of the most significant is the increasingly technological advances in automotive, uplifting the technical knowledge

and experience required for many job roles. This means each vacancy is competing against tech roles across a wider range of industries.

Automotive vacancies peaked in early 2023, reaching 30,000. The current figure of 22,000 vacancies is therefore a significant improvement. However, it does not go far enough. With the number of vacancies remaining stubbornly high for the past 12 months, the sector continues to buck the nationwide trend for all industries.

Protecting the right to repair

The IAAF calls for ‘smart regulation’ to protect the right to repair.

The UK automotive aftermarket supports over half a million jobs, generating some £20bn to the UK economy and providing over 75 per cent of the vehicle repair volume in independent workshops. As the automotive landscape undergoes profound transformations, embracing sustainability initiatives and adapting to emerging technologies, both challenges and opportunities are presented. However, this new automotive landscape creates restrictions on the abilities of the UK’s independent aftermarket to continue to provide competitive consumer choices, as vehicle manufacturers increasingly use new

technologies to distort the access to, and the use of, vehicle data and information.

The rise of electrification, softwaredefined vehicles, and remote access to vehicle generated data and information heralds a new era of mobility, demanding innovative solutions and new business models. It is imperative that we continue to ensure effective competition.

In the next five years, we call on the UK Government to recognise this contribution of the UK Aftermarket and to address these changes to vehicle design and technology and implement ‘smart regulation’ that will be essential to secure the sector's ability to compete, particularly concerning access to critical vehicle data and information.

6 JULY/AUGUST 2024 PMM

in association with

More money left in your pocket

Falling UK inflation is set to have a big impact on independent garages, the IGA explains how this is a good thing.

With the inflation rate going down, prices of supplies stabilise or even drop which means you can get your hands on parts, tools at lower prices, helping you save money and boost your profits. Next up, high inflation often makes people cut back on spending, including car maintenance and

repairs. But with inflation dropping, people have more disposable income. Futhermore, with a lower inflation rate, prices become more stable. You can set consistent prices, making it easier for customers to plan their expenses and trust your services. Lastly, you can use these benefits to outshine bigger chains by passing on some of the savings to your customers through competitive pricing and improved services.

26 %

say that it is safe to make hands-free calls while driving according to May’s Startline Used Car Tracker. It also showed that 36 per cent don’t make hands-free calls because they believe them to be risky.

£

9000

worth of tyre damage caused by potholes as reported by Cottenham Tyres and Autocentre in Cambridgeshire in a single month this year, over four times its usual amount.

27 %

of automotive workers have reported issues managing their mental health according to a new report from the industry charity Ben. This is compared to 16 per cent of UK workers in other industries.

FOR UP-TO-DATE NEWS, SIGN UP FOR OUR WEEKLY E-NEWSLETTER. SIMPLY SCAN THE QR CODE NEWSIN NUMBERS

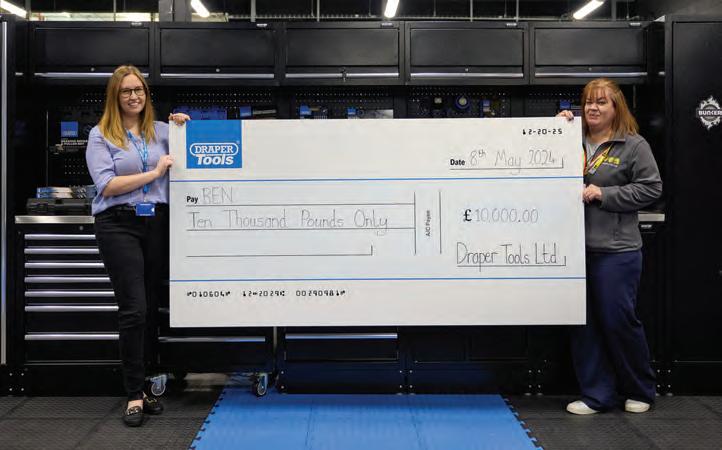

In pictures: A new partnership kicked off between Draper Tools and Ben with a visit from Ben representatives to Draper’s Hampshire head office. During the visit, Draper Tools presented a special donation of £10,000 to the charity.

PMM NEWS

East Boldon Motors scoops award at

first REPXPERT

Awards

The Professional Motor Mechanic team attended Schaeffler’s inaugural REPXPERT Awards in Coventry, where one Sunderland garage took the top prize.

Apprentice technicians from the east midlands and northwest, along with a garage in the northeast were named as the first-ever winners at the awards, which took place at the Schaeffler REPXPERT Conference –the first of its kind. East Boldon Motors took home the Workshop Award, having been judged to have used their REPXPERT membership most efficiently.

Mia Reeves of Bear and Bee Garage in Grantham, Lincolnshire was named Apprentice of the Year after garage cofounder Russ Houlden put forward her nomination. The category sought to find the most promising apprentice technician in the sector, based on technical proficiency or progress. Andrew Mather of Stockport Truck Centre in St Helens –also an apprentice – was honoured with the Extra Mile award, which recognises those who have gone above and beyond normal expectations.

The conference was held at Coventry’s Manufacturing Training Centre and the names of the winners were announced to an audience of over 200 attendees.

with Freya Coleman

Silverhook Oil Case Ends Up with Trading Standards

The VLS has been left with no choice other than to escalate a 5W30 PCEO investigation concerning Silverhook's 5W30 Supreme Plus to Trading Standards after the company failed to bring the product into compliance.

The case was opened in August 2023 after VLS received a complaint alleging that the product was making erroneous claims, such as Ford, BMW, Dexos, etc., with no supporting manufacturer specifications or numbers. The complainant also alleged that it was unlikely that all the bespoke additive packs for each of these specifications could be included in one oil.

VLS reviewed and upheld the complaint as the claims were not specific and required clarification. Some claims were also mutually exclusive.

The Lubricant Marketer responded to the complaint. However, VLS considered that the response was insufficient, the complaint was not fully resolved and concluded the investigation. In May 2024, VLS undertook a six-month review of the case in line with its stated process. The technical review panel had concerns about the product meeting the fuel economy requirements of ACEA C2 and ILSAC GF-6 whilst meeting the tough durability requirements of VW 504.00/507.00. Evidence of support for PSA

B71 2290 (ACEA C2/C3 based) had still not been provided.

Other inconsistencies in the performance claims were still present as well as several inaccurate performance claims. Consequently, VLS believes that the product is still non-compliant and is reporting it to its Primary Authority partner, Buckinghamshire and Surrey Trading Standards and to SAIL-Europe under the EELQMS Lubricant Marketer Letter of Conformance for claims made against the ACEA engine oil sequences.

EVs need to be more affordable

Half of motorists say the government should do more to make electric cars affordable, new research shows.

June’s new Startline Used Car Tracker also finds that 35 per cent believe action should be taken to make electric cars easier to buy, 34 per cent that more money should go into making chargers more widely

available, and 26 per cent that power from chargers should be cheaper. If there was more government support, 29 per cent of motorists say that it’s more likely their next car would be electric. Conversely, just 4 per cent report that their next car will be electric whatever the government does.

8 JULY/AUGUST 2024 PMM

in association with

CPD online training announced

In a direct bid to support the continuous upskilling of vehicle technicians in an era of automotive technological advancements, Autotech Training has launched Autolearn, a Learner Management System (LMS).

The online learning platform, powered by Autotech Training, wil aim to help vehicle technicians engage in Continued Professional Development (CPD), ensuring compliance and proficiency in repairing and maintaining EVs and ADAS-enabled vehicles.

Supporting mandatory IMI TechSafe recognised CPD routes, Autolearn will offer modular, bite-sized e-learning courses adaptable to meet the busy schedules of learners. An estimated 8,000 individuals will need to undertake essential CPD training before next April to remain IMI TechSafe registered and compliant. Vehicle technicians who have achieved an EV certification are required to complete a total of 18 hours of CPD over three years, while those who have embarked upon ADAS training must pursue 10 hours to maintain compliance.

DATES FORTHE DIARY

■ Schaeffler has announced its upcoming REPXPERT 2CT training course is scheduled to take place on 16th – 17th July, at the South Devon College Skills Academy in Newton Abbot, Devon. The two-day course combines theory with hands-on practice to equip technicians with the confidence and repair solutions needed to efficiently undertake VW double clutch system repairs.

■ MechanexPMM Live is headed back to Sandown Park in Surrey on the 12 th and 13 th of November . The event is free to attend (and so are the bacon rolls!) so scan the QR code to register now.

MESSAGE ME YOUR NEWS AT FCOLEMAN@HAMERVILLE.CO.UK

MONEY TALKS–

“To hear more about the skills shortage and what garages can do to attract staff, listen to the PMM Podcast’s recent episode “The Skills Crisis: Is Money the Answer?” by scanning the QR code.

but is it loud enough to attract the next generation?

PMM editor Kieran Nee writes about the skills crisis in the automotive aftermarket.

Itagged along on an EV course a few years ago near my hometown, Southend-on-Sea. I arranged the visit for first thing Monday morning so I could go home for the weekend and on a chilly February morning, I and 15 technicians huddled around a sleeping Prius in a huge college sports hall just off the arterial road out of town. In the down time as our assessor prepared our tests (don’t worry, I didn’t take one), we got chatting. First, I spoke to one guy about what he liked and didn’t like about working in a garage, but soon enough most of the group had piled into the conversation, each one adding their own variation on what remained a steady theme: the pay was “pants” (a rather polite bunch, us Saffenders). One guy working in a garage nearby was

“When a tech is already being paid 35-36 thousand, or in London, 38-39 thousand, how much more can you offer them to come and work for you instead?”

Andy Savva, The Garage Inspector

incensed at the thought of recommending a life of car repair to the younger generation, “no way,” he yelled, “why would anyone get into this industry? There’s no money in it at all.” Another nodded, adding that he’s in the process of joining the AA instead. This was far from the only time money was raised when I asked technicians particularly, but also garage owners, about their jobs. In fact, among technicians it was almost a certainty that the response to anything would come back to pay –to the point where I just stopped asking. What was the point? I had a similar experience, but the inverse, with organisations, commentators, you know, the kind of people who appear in magazines; I would ask whether pay should be higher and the response would be that training, career progression, the working environment, inclusivity… you name it and it was more important than pay. I don’t like to let my cynical side take over too often but, try as

hard as I might to see the positive side of the story, I remained resolutely unconvinced.

Then, as the pandemic restrictions began to loosen and confidence returned, the country went through... not exactly a boom, but the numbers went up – some more than others. Prices rose, jobs rose and, undeniably, wages rose –garages bore the brunt of all three. We devoted the first episode of the PMM Podcast to the rising cost of parts and the following two episodes to pricing jobs and hiring staff respectively. What we didn’t ask at the time, however, was whether staff should be paid higher, although one garage owner in Walthamstow, when I asked whether he was pricing his jobs too high, did memorably deadpan back to me “well, we’re not exactly driving around in Bentleys are we?”

Well, quite. It’s hard to get a grasp on the true average pay for a technician in the industry, and of course it varies hugely throughout the UK, but I don’t think it’s an

PMM JULY/AUGUST 2024 11

Andy Savva speaking on the PMM Podcast

exaggeration to say some areas have seen quite considerable wage rises. This was confirmed when I spoke to Jennifer Webb, owner of HR Vitals, which is a company dedicated to improving worker relations in the independent aftermarket – if you’re thinking that sounds obscure, then I’m doing Jen a disservice. Hers was one of the busiest talks at last year’s Blend event and she has just started a regular column in this very magazine – don’t let the term HR put you off, she is talking to garages every day and is helping them create better teams in the workshop. When I put it to her that the number one complaint I’d come across was money, she argued that “on average, we [used to see] technician salaries between £2630,000. Now, it's usually sitting around £35,000. Some even go as high as £50,000.” I spoke to Andy Savva, the Garage Inspector, in his kitchen in North London and he quoted similar figures: “What are you going to do –” Andy asked me, in the passionate way that he asks all questions, which makes you feel the weight of every word, “when a tech is already being paid 35-36 thousand, or in London, 3839 thousand, how much more can you offer them to come and work for you instead?”

Technology shift?

The latest figures from the IMI show that vacancies within the “motor trades” sector remain stubbornly high, despite having come down from 23,000 to 22,000. Per 100 employees, that represents a drop from 4.1 vacancies to 4 – the joint highest in the country, alongside “Accommodation & food service activities”. Where the latter category will be predominantly minimum wage jobs and will have seen its numbers decimated by

Brexit and the minimum salary requirement for new migrants being set at a whopping £38,000, no such arguments can be made for the former category. The IMI’s own assessment for the automotive sector’s inability to fill job roles is due to the “increasingly technological advances” of modern vehicles –a.k.a, cars are getting too complicated to fix. Those same technological advances, the IMI goes on to argue, means a “rising number of technical roles … and in the near future means the pool of applicants is potentially wider than ever.” The press release goes on to wave the usual flag for “changing perceptions” to “attract talent from other sectors”.

repair, it’s hard to see how this is the explaining factor behind the major deficit in skilled workers that the industry is facing. Of all the people I’ve spoken to over the years about the skills shortage, no one has mentioned people leaving the industry due to repairs being too complicated and by the IMI’s own logic, it should have actually attracted more people into the industry.

Whilst cars are getting more complicated, and vehicle manufacturers are ramping up efforts to monopolise the more technologically advanced aspects of car

“On average, we [used to see] technician salaries between £26-30,000. Now, it's usually sitting around £35,000. Some even go as high as £50,000.”

Jen Webb, HR Vitals

I personally think it is unlikely the car repair sector will be attracting workers from other, more technologically focused sectors, in any great numbers any time soon, or ever, for that matter. But if wages have gone up as Jen and Andy say they have, why is there still such a huge skills gap? Well, according to the IMI, 18 per cent of vehicle technicians are over the age of 55, which means that rather than technology pushing technicians out of work, they’re probably just retiring as they normally would.

New blood

Two years ago I visited Brands Hatch to speak to Autotech Recruit’s Gavin White about what the industry needs to do to attract younger people into the industry, it rained quite heavily and you could hear that and the sound of the British superbikes whizzing by every few minutes. In other words, it was podcast gold. Gavin had brought with a young technician, Tom, who shared with me

12 JULY/AUGUST 2024 PMM

Edward Cockill speaking to PMM at his workshop

his thoughts on why people his age weren’t interested in going into car repair. Not only, according to Tom, was it down to the pay, but also the working conditions. Essentially, the job was too dirty for young people who like to be “clean and perfect” all the time – his words, not mine.

Again, like the rising wages of recent years, workshops are a lot cleaner and tidier than they ever were before. Visiting Edward Cockill recently at Uckfield Motor Services in East Sussex recently, I was shocked at how clean and tidy everything was – it felt more like a state of the art factory floor than an aftermarket workshop. Correspondingly, Ed consistently has at least one, and sometimes two, apprentices on the go at any one time. This summer’s Mechanex-PMM Live show saw garage owner Dean Lomas give a (largely improvised) talk on the importance of apprentices to his workshop.

The message from these garages is clear: you need to go the extra mile to attract staff. As Ed told me, “it is a bit of a pain, but you’ve got to look it as an investment.” Truth be told, I think both Ed and Dean enjoy giving young people in their area a chance, even if it doesn’t always work out. It might not be such a risk, however. GiPA’s Quentin Le Hetet explained, at last year’s IAAF Conference, that 80 per cent of workshops with an apprentice know that at the end of the apprenticeship, they will offer the apprentice a full time job. If that sounds suspiciously high, it might be

“Firstly, workshops need to keep the staff they already have; secondly, workshops need to attract new staff; and lastly, the industry as a whole needs more staff.”

because so few workshops have apprentices in the first place – 23 per cent. Meanwhile, according to Quentin, 90 per cent of independent garages claim it is “very challenging” to find workshop staff.

Three way problem

You might say there are three factors at play here: Firstly, workshops need to keep the staff they already have; secondly, workshops need to attract new staff; and lastly, the industry as a whole needs more staff.

Now wages have gone up and workshops have been cleaned up and order imposed, what next?

Some fantastic workshops are still struggling to hire staff and especially young technicians. As the IMI report from earlier showed, there is simply a deficit of staff within the industry. Ironically, it is the shortage of staff which has pushed competition up and in turn made wages rise, rather than wages rising in order to attract new staff.

Workshops are competing fiercely amongst themselves

“To hear more about the skills shortage and what garages can do to attract staff, listen to the PMM Podcast’s recent episode “The Skills Crisis: Is Money the Answer?” by scanning the QR code.

for a reduced pool of skilled technicians. If the workforce hadn’t been so restricted in the first place, wages never would have risen… it’s a cruel irony that to be paid a fair wage, the industry as a whole needs to suffer from a shortage of talent.

But why is the motor repair trade, which offers reliable employment filled with mentally stimulating tasks and a wide range of opportunities, not a more attractive prospect for young people? Andy puts it down, at least in part, to the Blair-Brown years: “I think we missed a whole decade, when people were told that in order to succeed, you must go to university.”

I attended university at the tail end of those years and I do agree, many people were told to go to university who really would have been better off doing an apprenticeship. I worked on building sites in between term times and quickly learnt that a manual job was in no way the “stupid” option compared to a graduate job. But it was exhausting and took up all my time as without the overtime the money wasn’t worth it. Andy’s suggestion on the PMM Podcast episode "The Skills Crisis: Is Money the Answer”, in which I spoke to Ed, Andy and Jen about how workshops can go the extra mile to attract staff, was a four day week. I couldn’t say whether it would work or not, but it’s certainly the kind of blue sky thinking this industry needs right now, rather than pie in the sky ideas about recruiting computer programmers to change clutches.

PMM JULY/AUGUST 2024 13

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABK001

Jen Webb, new columnist for PMM, speaking to Kieran via video call

PMM THE PODCAST

WHAT DO CHANGING A BATTERY, CHANGING A BABY (JUST THE NAPPY) AND CHANGING YOUR MORNING RADIO STATION ALL HAVE IN COMMON?

THEY OFFER THE PERFECT OPPORTUNITY TO LISTEN TO THE PROFESSIONAL MOTOR MECHANIC PODCAST WITH KIERAN NEE.

HEAR ADVICE ON PRICING JOBS, MANAGING PARTS SUPPLY, ELECTRIFICATION, RECRUITMENT AND MUCH MORE.

Listen on Google Podcasts Listen on Apple Podcasts Listen on Amazon Podcasts Listen on Spotify Podcasts LISTEN NOW ON YOUR PODCAST PLATFORM

CHOICE

OF

YOU ARE NOW ENTERING

PMM has teamed up with the CPD Group to offer you the chance to gain CPD points while you read every issue!

Continuing professional development (CPD) can be broadly defined as any type of learning you undertake which increases your knowledge, understanding and experience of a subject area and your role within it. To help professionals to better document and prove this process, our new CPD Zone features articles that have been checked, verified and accredited by a thirdparty specialist organisation.

The content within the CPD Zone will provide you with 1 CPD Credit, or 1 hour’s worth of continuous professional development.

Once you have read through the articles contained within, you will be able to scan the QR code at the end of the last article. This will provide you with a downloadable certificate, personalised to you. This can then be used as part of your ongoing CPD record, as needed to satisfy various organisations and schemes. Regular readers of PMM, therefore, could earn 11 CPD points just by reading the magazine each month.

DO NOT SCAN THE QR CODE UNLESS YOU HAVE READ ALL OF THE CONTENT WITHIN THIS SECTION!

CPD relies on self-certification, which in turn relies on professionalism and honesty from those who participate. We have great faith in the diligence and professionalism of our readers – we are called Professional Motor Mechanic, after all. It is fairly safe to assume that if you are picking up PMM each month, then you are already interested in reading and understanding technical content. Indeed, we are a lifeline for many in the industry who rely on us to spread the word on the latest changes and developments originating with the OEMs.

THIS PROCESS IS COMPLETELY FREE

Don’t worry – you won’t have to pay a penny to gain your CPD points each month. It’s on us!

All certificates are valid for one year from the issue date. If you have any issues downloading the certificate or using the system please email us at: pmm@hamerville.co.uk

NEW USERS –

ACCESS YOUR BESPOKE CPD CERTIFICATE IN FIVE STEPS

Read ALL of the articles within this month’s CPD Zone

Scan the QR code or enter the RDR.Link in your web browser –both are found at the end of the last article in this section

Enter your email address

Fill out your details on the contact form

Download your certificate for use as part of your annual CPD record

PREVIOUS USERS –ACCESS YOUR CPD CERTIFICATE IN FOUR STEPS

Read ALL of the articles within this month’s CPD Zone

Scan the QR code or enter the RDR.Link in your web browser –both are found at the end of the last article in this section

Enter your name and email address

Download your certificate for use as part of your annual CPD record

PMM JULY/AUGUST 2024 15

READ ME TO COLLECT YOUR CPD POINT CPDZONE

COMMON FAULTS

Troubleshooting Turbos: DPF related failures

It is widely understood that a faulty turbo can damage the DPF, however, did you know that the reverse is also true –a defective or blocked filter can cause premature turbo failure. Although not as common an issue, and sometimes a tricky one to spot, by understanding the possible causes and symptoms, technicians can make a more informed diagnosis. Carwood explains.

Fitted to diesel vehicles from 2009, the diesel particulate filter, or DPF for short, is designed to stop soot and other harmful particles produced during the combustion cycle from exiting the exhaust. The trapped soot must then be periodically emptied or 'burned off' through regeneration.

Yet just like any other filter, they can easily become blocked and obstruct the flow of gas through the exhaust system. If the gas cannot be expelled from the engine quickly enough, it will start to build up, creating

does the temperature of the gas in and around the turbo’s turbine housing. Whilst this may only cause problems such as oil leaks and coking initially, if left unchecked, the turbo can very quickly fail, or the ECU may put the vehicle into limp mode. Either way your customer is liable for an expensive repair bill.

What causes a blocked DPF?

There are several factors that can cause the DPF to block prematurely and/or stop DPF regeneration from working effectively, or

engine fails to reach the optimum temperature for regeneration.

■ Warning light: a dashboard warning light or a diagnostic trouble code stored in the ECU can also prevent regeneration.

■ Wrong engine oil: sulphated ash and/or additives contained in some oils can block the filter prematurely. To prevent build-up a low ash, low sulphur engine oil should always be used.

■ Faulty components: a faulty fuel injector or turbocharger can cause the vehicle to run rich, creating excessive soot. Similarly, a faulty EGR valve can increase the production of diesel particulates, both causing the DPF to become blocked quicker than normal.

16 JULY/AUGUST 2024 PMM READ ME TO COLLECT YOUR CPD POINT CPDZONE

Oil in turbine housing and on nozzle ring

Nozzle ring seized due to heavy carbon build up

Low tank: many vehicles will not initiate an active regeneration if the fuel or Eolys additive tank is less than a quarter full. Overdue service: the DPF on a poorly serviced vehicle may fail sooner since factors such as oil quality and level can also prevent regeneration.

What are the signs of turbo damage due to a blocked DPF?

The following signs are good indicators of a DPF related issue. The amount of damage this will cause largely depends on how much the DPF is restricting the flow of exhaust gas.

Fault code triggered – this may include exhaust pressure control, EGR, DPF regeneration and/or turbo boost control related codes.

■ DPF warning light illuminated.

■ In severe cases it may cause the vehicle to go into limp-home mode, limiting it to certain speeds or revs, to protect it from further damage.

■ Reduced turbo efficiency given the exhaust’s inability to remove gas from the engine.

■ Discolouration of parts within the CHRA due to heat transfer. Whilst this is typical of other issues, mainly oil starvation, the pattern will help streamline your diagnosis. Discolouration that starts at the turbine wheel and continues through the shaft to the compressor side is a clear signal of excessive temperatures caused by rising back pressure.

■ Oil leaks can occur when the rising back pressure forces the exhaust gas past the shaft seal on the turbine side, and into the

“A faulty fuel injector or turbocharger can cause the vehicle to run rich, creating excessive soot.”

CHRA, displacing the oil, and pushing it through the seals on the compressor side. Often this is mistaken as a worn shaft seal.

■ The additional back pressure can also push exhaust gas through the small clearances in the wastegate, creating a build-up of carbon in and around the wastegate and its control mechanisms. If bad enough, the wastegate door can stick in the open or closed positions and the ECU will no longer be able to control boost pressure.

■ Excessive temperatures, again due to the backpressure, can also cause the oil within the CHRA to carbonise. Often misdiagnosed as insufficient lubrication or oil contamination, this causes premature wear to the shaft, thrust plate, seals, and bearings and restrictions in the feed lines.

■ Carbon build up in the turbine side piston ring(s), piston ring grooves and oil flinger groove, preventing effective oil control.

■ Over time, the excessive heat inside the turbine housing can cause the turbine wheel to fail from high cycle fatigue.

How

to prevent DPF related turbo failures?

Although it can take some time for a DPF to block, once this happens, turbo failure can occur very quickly. Therefore, it’s always advisable to follow some simple measures when replacing or refitting a turbo:

■ Always check the vehicle’s DPF – if the soot levels are high enough to stop the DPF from regenerating on its own, a forced regeneration, usually via a diagnostic scan tool, may be required.

■ If the blockage is severe, the only way to completely remove the particles is to either fit a new OE quality filter, or have it professionally cleaned by a company like Carwood.

■ Encourage your customer to drive for 30 minutes or so, at speeds over 50mph, every few hundred miles. This will allow the exhaust temperature to get hot enough to burn off any excess soot.

■ Use manufacturer approved engine oil –this is designed to produce as little diesel particulate material as possible.

How to resolve a DPF related failure?

■ Remove the DPF and have it professionally cleaned off-vehicle.

■ Thoroughly check and clean the entire exhaust system – replace components as required.

■ Fit new oil feed and return pipes whenever installing a turbo.

■ Check and clean the intercooler and pipes – replace if needed.

REMEMBER!

Always diagnose and fix what caused the original unit to fail. Whilst this may add to the bill, it is far more cost and time effective than having to fit another turbo, or an engine, soon after.

PMM JULY/AUGUST 2024 17 WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABK002

Wear to the thrust bearing where the thrust collar sits

Journal bearing has a mushroom effect due to fretting

REGISTER FOR FREE AT WWW.MECHANEX.INFO THE HANDS-ON TRADESHOW FOR INDEPENDENT WORKSHOPS TOP AUTOMOTIVE BRANDS ● LATEST PRODUCTS AND INNOVATIONS ● SPECIAL SHOW DISCOUNTS ● FREE CPD TECHNICAL SEMINARS ● FREE ENTRY ● FREE PARKING ● FREE PROFESSIONAL MOTOR MECHANIC T-SHIRT ● FREE BACON ROLL The regional Tradeshow for aUTo rePair Professionals PROFESSIONAL MOTOR MECHANIC MECHANEX FEATURING LIVE YORKSHIRE EVENT CENTRE HARROGATE YORKSHIRE EVENT CENTRE HARROGATE 15TH & 16TH MAY 2025 SANDOWN PARK S URREY SANDOWN PARK S URREY 12TH & 13TH NOVEMBER 2024

DIAGNOSTIC GUIDE

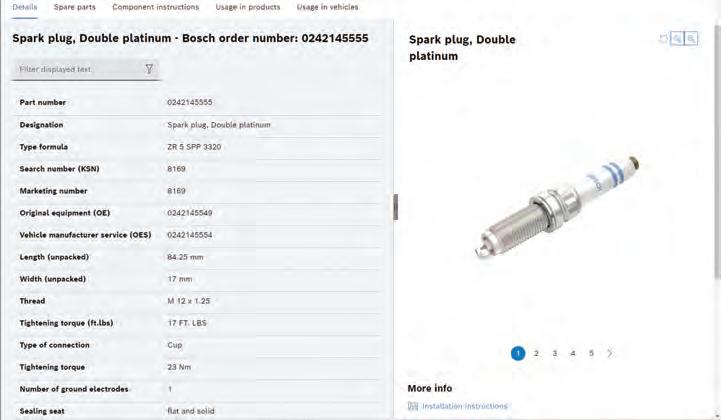

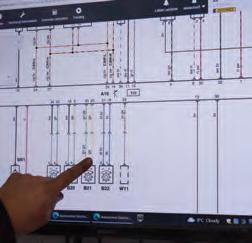

Using Bosch’s ESI[tronic] 2.0 software: a monthly guide

Last month in our guide to Bosch’s KTS diagnostics software, ESI[tronic] 2.0, we looked at the built-in multi-meter and oscilloscope. This month, we investigate the maintenance and equipment tabs.

In the last instalment, we explored the added benefit of vehicle diagnosis with the built-in multi-meter or oscilloscope functions included in the KTS Vehicle Communication Interface (VCI).

This time, we’ll be looking at the vast amounts of vehicle service information and maintenance data that is available in Bosch ESI 2.0, alongside examining the Bosch spare parts catalogue, all of which are important features for daily workshop use and vehicle maintenance. If you subscribe to

the ‘Advanced + Maintenance’ or ‘Master Package’, you’ll have access to the ‘Maintenance’ function in ESI[tronic] 2.0 online. Among other things, these include information about service times, the parts needed, the tyre size and pressure, as well as centralised programming information. Moreover, vehicle-specific workflows also feature in these packages, which allow you to carry out every repair in accordance with the manufacturer’s specifications and are therefore covered by the manufacturer’s warranty.

Service schedules

Once you have selected a vehicle in the ESI[tronic] 2.0 program, choose the ‘Maintenance’ tab at the top of the screen. This will present the ‘Subcategories’, which will appear on the left-hand side of your screen with many different information sources related to the vehicle’s service and maintenance requirements.

Depending on the vehicle make and model that you’ve chosen, you now need to select the type of service required. This consists of

Your path to diag success!

PMM JULY/AUGUST 2024 19 READ ME TO COLLECT YOUR CPD POINT CPDZONE

two parts: you first select the ‘basic’ service schedule based on mileage or months interval and then in the second part you can add additional service items which might also be needed based on the mileage of the car or the time period since the last service. By clicking on ‘Show steps’ a drop-down list shows you the details of each service item (Fig.1).

By clicking on the ‘Create a maintenance plan’ soft key at the bottom of the screen, you can create a specific service check-sheet to be displayed on screen. The check-sheet can be printed out and completed manually or filledout electronically throughout the job and printed at the end – a nice feature that prevents any greasy fingerprints spoiling the list (Fig.2).

Navigation tips

Once you have selected the required service operations, you will then see a list of needed service parts. This section will list out the necessary spare parts, such as oil and filters, along with capacities that will be needed to complete the service work on the vehicle ( Fig.3 ).

Next, the ‘Service Illustrations’ will provide all the available diagrams you’ll need while servicing the vehicle – such as transmission oil

“In the ‘Timing Belts/Chains’ tab, you’ll then find detailed instructions and diagrams for changing the belt, chain or timing gears –when they’re due for replacement or there’s a need for an engine re-build.”

level plugs, auxiliary drive belt routing, cabin filter location and A/C service port locations (Fig.4). If needed, you can expand each individual diagram to full screen to view it in more detail. An addition that is really helpful on today’s complex vehicles.

The ‘Service Indicator’ tab will then guide you through the service light reset process for the vehicle you’re working on (Fig.5). This may involve a ‘manual’ push button reset as described or the instruction to reset the service interval by means of a diagnostic test routine. In this last case, you can easily click on the ‘Diagnosis’ main tab and go straight to the maintenance service task to reset the service interval.

On diesel vehicles, the ‘Diesel Exhaust Gas After Treatment’ tab will be active and demonstrates how the DPF system works and how to initiate a passive diesel particulate filter regeneration. DPF problems on vehicles are increasingly common due to short journeys – making this a particularly useful section of data to be aware of.

Likewise, the ‘VIN Plate Location’ tab offers a vehicle specific diagram of where to find identification details, such as VIN and engine numbers, as well as the exact position of the bonnet release safety catch, which can be difficult to locate on some models (Fig.6).

Accessing repair data

Next, the ‘Tyre Pressures’ tab lists all of the recommended tyre pressures for the vehicle model selected. In some cases, this can be quite a long list due to fitment variations. However, the search bar can be used to narrow down the options by wheel size or tyre width. Remember, the manufacturer specified front and rear tyre pressures are also given in bar and psi for ‘laden’ and ‘un-laden’ situations. The ‘Technical Data’ tab is highly useful as it supplies essential information about the following:

20 JULY/AUGUST 2024 PMM

READ ME TO COLLECT YOUR CPD POINT CPDZONE

■ Vehicle designation

■ Fuel injection system

■ Ignition adjustment and emissions

■ Starting and charging systems

■ Service checks and adjustments

■ Fluid types and capacities

■ Tightening torque settings

■ Minimum brake component thicknesses

■ Air conditioning system service and repair data

Wherever possible, the list will have icons that will present you with important additional information and diagrams that can help you do the job properly and efficiently (Fig.7).

In the ‘Timing Belts/Chains’ tab, you’ll then find detailed instructions and diagrams for changing the belt, chain or timing gears –when they’re due for replacement or there’s a need for an engine re-build. With such a complex task, it’s critical to have the correct information to complete the job properly and this section will give you peace of mind that the manufacturer’s procedure has been followed (Fig.8).

The ‘Auxiliary Drive Belts’ tab guides you through the auxiliary drive belt and belt tensioner system operation. You’ll find all the details, text and diagrams showing the removal and installation procedure of the system components, as well as tightening torques of the mounting bolts.

In the ‘Wheel Alignment’ section, the recommended suspension geometry measurement values and setting data is displayed. The tolerances and diagrams for the toe-in, camber and caster adjustments to the front and rear wheels of the vehicle (where applicable) can be used with suitable wheel alignment measuring equipment to correctly align the wheels on the car.

Finally, ‘Key Programming’ allows you to access all the information required for key battery replacement and remote central locking synchronisation (Fig.9). With many cars having ‘keyless’ entry and start systems, the instructions and diagrams in this section can be a real assistance in remedying any key problems.

Now that we have covered all of the ‘Maintenance’ section sub-tabs, do not forget that you can click the ‘Print’ icon, next to the ‘Main Menu’ soft key in the top right-hand corner of the screen at any time. You can also produce a screenshot of the data or print out the diagrams and text for reference.

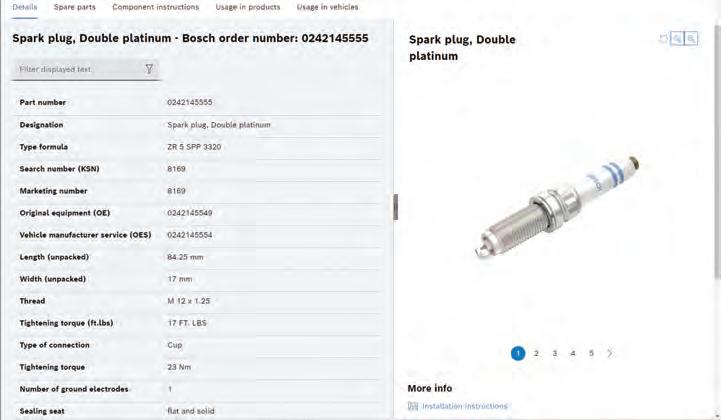

The last main tab is the ‘Equipment’ tab. Then, the original ESI[tronic] parts list will appear directly on the screen. The parts list contains all available information on every component made by Bosch for the vehicle that you’ve selected. This includes descriptions, model year ranges, diagrams, pictures and Bosch part numbers for the components (Fig.10).

Bosch parts are grouped in the categories of engine, bodywork, suspension and drivetrain. Depending on the vehicle manufacturer, the parts made by Bosch on the vehicle can range from batteries, alternators, starter motors and engine management sensors to wipers, lighting products, filters, brake components and fuel system pumps or injectors. There is now also a text search function in the ‘Equipment’ tab. This function allows you to type in the name of the component you are searching for, and whilst you type this a list of Bosch parts will be narrowed down accordingly and instantaneously (Fig.11).

Next month we take a look at ADAS calibration.

PMM JULY/AUGUST 2024 21 WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABK003

BEST PRACTICE

Clutch

and DMF replacement tips for LCVs

Schaeffler LuK’s Alistair Mason is giving some valuable information on clutch and dual mass flywheel replacements for Vauxhall Vivaros and Movanos, which also covers some Fiats, Mercedes, Nissans and Renaults.

The reason behind this article is that we receive a lot of technical phone calls and warranty enquiries relating to the clutch and dual mass flywheel products on these vehicles and with a little guidance most of these can be eliminated. The first area we need to look at is organising the correct parts, the following information will help the parts supplier identify the correct parts:

■ Is the vehicle front or rear wheel drive?

■ Date of construction.

■ Engine serial number.

We can now focus on the repair, the easiest and advised method of gearbox removal is to remove the front subframe, this gives more space and visibility for a successful clutch and DMF replacement.

Dual mass flywheel replacement

1.6 dCI engine – the flywheel has a timed senser ring for the engine speed and position senser, this flywheel can fit in one of eight positions, when fitting the flywheel, the small hole in the centre of the DMF must align with the small drilling in the crank otherwise the vehicle will not start (Figs.1 and 2), this service information is attached to the part on REPXPERT.

The 2.0 variants generally run a solid flywheel. When bolting the DMF to the crank, the bolts must be tightened and torqued in an

even and sequential manner, to eliminate the risk of buckle or tilt to the flywheel.

Clutch replacement

Apply a light smear of high melting point grease to the gearbox input shaft and insert the clutch plate, this will ensure the clutch is correct for application and also evenly distribute the grease, remove the clutch plate and remove any excess grease. Always use a clutch alignment tool.

Where the vehicle is fitted with a selfadjusting clutch, always use a self-adjusting clutch tool to eliminate any risk of judder and unintended clutch adjustment, this also removes the risk of stripping threads in the new DMF (Fig.3).

Concentric slave cylinder replacement

There are generally two variants of CSCs for these vehicles –they have either a two or three bolt fixing CSC. The two bolt fixing CSCs can come with an option of connector pipes and it is very important to select and mount the correct pipe before refitting the gearbox (Fig.4).

These CSCs can be difficult to bleed after replacement, a ‘top tip’ is to prefill the CSC with new and the correct grade of clutch fluid prior to fitment and place a rag over the pipe

during gearbox fitment as some fluid will be expelled. Never dry squeeze a new CSC, as this can cause internal damage and always flush the old clutch fluid from the reservoir and master cylinder through the pipe to a drainer, so not to contaminate the new CSC seal.

Gearbox installation

Prior to installing the gearbox, ensure that all the alignment dowels are installed in the gearbox correctly and clean up if required (Fig.5). These can be a tight fit and are known to crush if not fully aligned, this will then lead to misalignment issues that can cause DMF centre bearing failure.

Using a transmission jack, bring the gearbox close to the engine, spend a little time aligning the gearbox to the engine and then ease the gearbox into position and onto the dowels, do not force the gearbox onto the dowels or draw the gearbox on using the bell-housing bolts.

Final checks

When the repair is complete, always carry out a diagnostic check on the engine, any fault on the engine can lead to a premature DMF failure.

PMM JULY/AUGUST 2024 23

READ ME TO COLLECT YOUR CPD POINT CPDZONE WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABK004

HOW TO Calibrate air suspension

Delphi has supplied this step-by-step guide on calibrating air suspension courtesy of its Masters of Motion hub for independent garage technicians.

Air suspension brings many benefits for drivers and passengers including the reduction of noise, vibration and discomfort. However, like many in-vehicle systems calibration is needed from time to time, particularly when a part is replaced. This guide takes you through the steps needed to calibrate the air suspension on a BMW X5. Some air suspension systems feature air springs front and rear, or have a combination of coil springs and air springs.

Calibration is required following an air spring or height sensor replacement. Some vehicles will only require a static height calibration which can be completed in the workshop. Others will need a static calibration in the workshop and a dynamic calibration performed whilst the vehicle is being driven on the road. This guide sees Phil Mitchell, european workshop solutions manager at Delphi, talk us through the process at Delphi’s in-house training workshop in Warwick.

WATCH!

STEP Fill the bellows

To ensure the air system is refilled after completing a replacement job on an air spring or height sensor, technicians must run a ‘filling the bellows’ ‘diagnostic function in the ‘electronic height control’ module using the Delphi BlueTech VCI diagnostic tool.

STEP

Navigate to ‘height level adjustment’

Technicians can watch Phil completing the air suspension calibration and other videos by scanning the QR code below

In the ‘body control’ module, go to ‘adaptations and calibrations’ and run the ‘height level adjustment’ function. Delphi’s diagnostic software outlines the necessary test conditions needed to successfully complete the process. Technicians should follow the manufacturer's instructions, ensuring that the vehicle is on level ground, the steering wheel is straight, and the tyre pressure is correct. The vehicle's load must remain constant during calibration – any movement will disrupt the calibration.

STEP Calibrate air suspension

With battery support connected to the vehicle, confirm that the final checks have been made and that the vehicle is ready before performing the calibration.

24 JULY/AUGUST 2024 PMM READ ME TO COLLECT YOUR CPD POINT CPDZONE

WANT TO KNOW MORE?FOR MORE INFORMATION WWW.RDR.LINK/ABK005

BEST PRACTICE

Exhaust gas recirculation systems

Ron Merralls, technical services manager at Niterra, gives his advice on dealing with issues surrounding EGR valves, which are crucial for reducing NOx emissions.

Carrying out a thorough health check on a customer’s car when it enters the workshop can create a number of new business opportunities for proactive garages. Not only does it give them the chance to find and then fix a problem, but the resulting success also enables them to educate customers on the necessity of agreeing to a health check every time their vehicle enters the workshop – resulting in healthy running cars and healthy profits.

One area where this is particularly important is when dealing with a car’s exhaust gas recirculation system whose principal role is to reduce the amount of harmful nitrogen oxides (NOx) that are produced during the combustion process.

Controlling emissions

NOx is created when high combustion temperatures enable the nitrogen and oxygen present in the air-fuel mixture to combine. EGR valves come in three different types –‘pneumatic’, ‘electric’ and ‘electric with cooler’ – and operate by taking some of the exhaust gases from the exhaust manifold and then reintroducing these gases into the intake manifold, mixing them with fresh air.

Originally developed at the beginning of the 1970s, EGR valves first started to be used in Europe in the 1990s in order to meet

“An EGR valve found to be blocked, or coked, means that any associated pipework may also be blocked, so should be checked, and cleaned.”

the ‘Euro 1’ emission standards. Today, 100 per cent of diesel cars are equipped with EGR valves and 30-50 per cent of petrol cars, making EGR valve knowhow an invaluable revenue source. When an EGR system issue is encountered, ensure that the root cause of the problem is found on the vehicle before replacing the valve. It is necessary to check that the vehicle is running the latest software as this can cause EGRrelated faults to arise with an EGR valve.

contamination, then check the entire EGR system, including throttle body. If a separate cooler is in the circuit, it could also be clogged.

Replacing an EGR valve

When replacing an EGR valve, some may not appear to initially function effectively – engine performance may not immediately improve, smoke may be emitted from the exhaust, and EGR related fault codes may be produced. As with many EGR valves, some vehicle models are required to undergo a ‘learning cycle’. The vehicle must be driven for the vehicle engine management system ECU to recognise that the valve has been replaced (as it has learned to compensate for the faulty valve’s inefficiency and needs to adapt to the improved working parameters of the new EGR valve).

Electronic intervention is sometimes possible to ‘Adapt the EGR’ to the vehicle via diagnostic test equipment.

Note that a fault code is only a guide and that the problem can often frustratingly lie elsewhere. It relates to the system affected and cannot directly identify a specific faulty component, but rather the area to begin investigation; so, the cause could be with, for instance an exhaust temperature sensor, MAF sensor or pressure sensor that can affect the overall EGR system operation.

An EGR valve found to be blocked, or coked, means that any associated pipework may also be blocked, so should be checked, and cleaned. If you do find severe

Many new models will even be equipped with two EGR types (low pressure and high pressure), which means that the replacement part market for these types of valves is likely to grow, corresponding to the level of EGR fitment in the vehicle parc. Using a vehicle health check consistently in your garage can build trust and transparency with your customer, increase your chances of first-timefix, and optimize your high quality EGR service and repairs for this growing demand.

26 JULY/AUGUST 2024 PMM READ ME TO COLLECT YOUR CPD POINT CPDZONE

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABK006

COMMON FAULTS

Why was the Jeep Grand Cherokee ’s sunroof rattling?

Autodata hears from a garage trying to solve the mystery of a 2015 Jeep Grand Cherokee whose sunroof rattles whilst driving.

The problem:

“A customer of ours is complaining of a rattling noise from the sunroof when driving on their 2015 Jeep Grand Cherokee. We have experienced the rattling noise on road test and have tightened all accessible nuts and bolts on the sunroof panel, but have not found the cause of the fault. Have you any ideas where to start to fix this car?”

What does Autodata recommend?

The fault you describe has been reported by other Grand Cherokee owners and it is due to an unsatisfactory design of the sunroof assembly retaining bolts. Specific retaining bolts are available from

Jeep parts department and are required to rectify this fault. Ensure the sunroof is fully closed before disconnecting the battery. Lower the headlining to gain access to the sunroof assembly retaining bolts. Remove and replace the sunroof assembly retaining bolts one at a time. Tighten the sunroof assembly retaining bolts to the correct torque setting of 9 Nm. Carry out road test to ensure the rattling noise has been resolved.”

WANT TO KNOW MORE?FOR MORE

REDEEM YOUR CPD CREDIT

Congratulations, you have reached the end of the CPD Zone! To access your CPD credit from The CPD Group, scan the QR Code or WWW.RDR.LINK/ABK037

INFORMATION WWW.RDR.LINK/ABK036

A look inside: YouTube

Your favourite trade magazine is now on YouTube, bringing you reviews and video guideson the best tools and workshop solutions. Find us at @professionalmotormechanic .This month we’ve got Ant from AAK giving us his thoughts on AJD Tools’ new sensor simulator.

Hey it’s Ant from AAK, back again, good to see a familiar face. This time he’s got a sensor simulator from AJD Tools to review. Oh and it looks like he’s got the wiring kit along with it. Now he’s got the whiteboard out – anyone else feel like they’re back at school?

On a serious note, this tool really does mean business, cutting out so much time testing wires and components – a huge help when it comes to diagnostics.

Not only has this tool helped Ant with the infamous Ford EcoBoost, but it has also come into its own when testing AdBlue injectors – another workshop regular. And that wiring kit? It makes life a thousand times easier – no more improvising!

TO WATCH THIS VIDEO AND THE OTHERS ON THE PMM YOUTUBE CHANNEL, SIMPLY SCAN THE QR CODE

28 JULY/AUGUST 2024 PMM

Show me the EVIDENCE!

Neil Pattemore, technical director at UK AFCAR, an alliance of 11 UK organsiations who share a common interest in the future and prosperity of the aftermarket, is emphasising the role real-life evidence has to play in the fight for a fairer landscape for independent workshops seeking to access RMI data when undertaking vehicle repairs.

‘It’s elementary, my dear Watson’, as a well known sleuth from Baker Street reportedly once said. Even if this phrase never actually appears in any of the Sherlock Holmes novels, the principle is important when looking for evidence related to the future success of any independent workshop in the UK aftermarket. You may now be asking why ‘evidence’ is something critically important in your ability to service and repair vehicles, so let me explain why this has increasingly become the case.

In simple terms, as we all know, today’s vehicles have become ‘computers on wheels’ with software controlling most of the functions and the associated diagnostic tools being ever more powerful to communicate with the vehicle and its on-board systems.

However, the access to the vehicle’s systems has also changed. With the OBD port supporting decreasing levels of data and information, whilst the telematics interface supports an increasing level of access ‘over the air’ to the vehicle manufacturers’ embedded applications for diagnostics, service and maintenance requirements and other vehicle functions. This has created a

widening gap between what is available to the vehicle manufacturer and what is then made available to the workshop – whether that is an authorised repairer or (even worse) an independent workshop.

This highlights how the vehicle manufacturer has increasingly become the sole and controlling source about the way that a vehicle can be accessed, together with what information and data is made available to provide ‘repair and maintenance services’.

If we go back to when vehicle electronics first became commonplace, all access was via a physical connector which soon became the standardised OBD connector we still use today. This supported access to all the data necessary to diagnose, service and repair and equally allowed ‘reverse engineering’ for diagnostic tool manufacturers to develop their multi-brand tools.

As the vehicle manufacturer implemented an increasing range of electronically controlled systems in their vehicles that required electronic data and dedicated communication protocols, it became clear that the vehicle manufacturers controlled the source of the technical requirements needed to diagnose and repair a vehicle.

SPECIAL REPORT

30 JULY/AUGUST 2024 PMM

Subsequently, it was necessary to have legislation to ensure effective competition in the aftermarket between main dealers and independent workshops and as the UK was part of the European Union, this was discussed and ultimately implemented as EU legislation. This was done in two elements –firstly under Competition Law which was implemented as the original ‘Motor Vehicle Block Exemption Regulation’ (MV-BER) and which came into force in 2002. However, although this introduced the principle of ‘non-discrimination’ between ‘authorised repairers’ (i.e. main dealers) and ‘independent operators’ (which included independent workshops, but also parts providers, publishers of technical information, diagnostic tool manufacturers, technical trainers etc.) there were diverse interpretations across some vehicle manufacturers as to what the legislation actually meant in practical terms.

To better understand these ‘grey areas’, the European Commission requested evidence from the aftermarket, as well as receiving questions requesting guidance from some of the vehicle manufacturers. It became clear that although the MV-BER described the key

“Unfortunately, as the years have passed, vehicle technology has progressed exponentially, creating new challenges for the aftermarket.”

Neil Pattemore

principles of the political and legal intent, there were many elements where the technical details were open to interpretation which could not be defined in Competition Law.

Subsequently, the European Commission decided to include these technical requirements as part of (the then new) ‘Euro 5’ legislation, introduced in 2007. This was generically described as being the ‘access to repair and maintenance information’ (RMI). This provided better clarity, as well as introducing the requirement for vehicle manufacturers to declare their compliance with the legislation as part of their ‘whole vehicle type approval’. Should any ‘non-compliance’ issues be identified by an independent operator or an aftermarket trade association, the legislation also included that this could be checked by the vehicle type approval authorities.

So far this was ‘all fine and dandy’ as our American cousins say!

Changing landscape

Unfortunately, as the years have passed, vehicle technology has progressed exponentially, creating new challenges for the aftermarket. It was becoming clear that legislation needed to be revised to keep pace with the (rapidly) evolving technologies which had reared their ugly head.

However, for the legislator to play ‘catchup’ is not easy, as they generally react to what is known and not what may be coming over the horizon. There may be ‘specific certainties’ which will have a predictable impact, but these are rare. A good example currently is the (mandated) vehicle type approval requirement for cybersecurity that applied from July 2022 for new vehicle types being approved and will apply for new vehicles being sold from July 2024 (I must add here that low volume/specialist vehicles have slightly different dates). For other revisions to the legislative requirements, generally it needs to be based on evidence from the marketplace.

This has become particularly important as the aftermarket itself has also evolved from workshops competing at a local level, to now include the vehicle manufacturers themselves

entering the aftermarket to sell their own services, which includes many aspects that would otherwise have been performed only once a vehicle was in a workshop. This has created new business models for the vehicle manufacturers and their authorised networks, but is distorting competition in the aftermarket in a number of different ways. This is most directly related to the exclusive ability for the vehicle manufacturers to remotely communicate to the vehicle and its data, using over-the-air access with embedded diagnostic and servicing requirements algorithms. This provides a significant advantage and can reduce the cost of diagnosis and repair by 50 per cent.

Quite simply, independent repairers do not have the same ability.

To counter this type of threat, the aftermarket associations in Brussels and some of their members funded legal challenges via the European Court of Justice (the ECJ) – all of which were found in favour of the aftermarket. However, challenges made by the vehicle manufacturers against one of the verdicts is resulting in amendments to the vehicle type approval requirements to address the conditions of accessing the vehicle and its data via the OBD port – quite important for the aftermarket!

This brings me back to how you can help the aftermarket associations to help you in ensuring the right legislative support will be in place: evidence!

There is no substitute to providing ‘real life examples’ of where the things that you were once able, or should be able to do, but can’t, need to be logged. This only takes a simple action – WWW.RDR.LINK/ABK007 and enter the relevant details and information, which can then be collated to show the issues that need to be addressed. The future of your business and the wider UK aftermarket is in your hands.

WANT TO KNOW MORE? FOR MORE INFORMATION

PMM JULY/AUGUST 2024 31

WWW.RDR.LINK/ABK008

yourlet ters ANSWERED

Noise annoys

ATTN. KIERAN NEE (EDITOR), HAVING READ THE ENCLOSED NEWS ITEM ABOUT CAMERAS THAT CAN DETECT CARS WITH EXCESSIVELY LOUD EXHAUST, I FELT COMPELLED TO CONTACT YOU ON A QUESTION THAT HAS BEEN ON MY MIND. HOW COME THE EXHAUST LEVEL OF AMERICAN MOTORBIKES HARLEY DAVIDSON IS TOLERATED?

Regards, M. Saleem, Birmingham

Are you suggesting that certain rules in this country simply go unenforced? Surely not. Anyone who has been knocked over by an electric scooter riding on the pavement will surely disagree…

Ich bin ein EV...

Dear PMM, I was in Berlin recently on a much needed break from the workshop.

My wife said why don’t we go to Berlin for a weekend, good idea. I was on one of the walking tours when something caught my eye. I enclose a photo of something which reminded me of an episode of the PMM Podcast (Episode 12, Classic Cars: The Comeback) where you visited a company putting EV motors into classic cars. Instead of the classically British Mini, however, over in Berlin they’ve electrified something a little more Soviet… the Trabant!

Regards, E.V. Lover

Part numbers

Hi,

I'm here glancing through the PMM Jan 24 issue and I see a couple of articles neglecting to mention a crucial piece of information, namely which vehicle are you writing about.

Page 23 , common fault with camshaft bracket. The article is much more useful if we're told which vehicle, as are the Febi part no.s given. I can work out it's VW group, as it's TFSI, but…

Page 53 . Charger Intake Hose. As a general piece, fine. Specific part number to which vehicle, don't know…

On the plus side, nice reference piece on piston seizure etc. I’ll keep that safe for another day.

Ross, My Motors

Yes, that sounds like it would be quite useful information to have. Our apologies for letting those slip through the net.

Competition

Dear Ms Coleman,

Can I ask if there are any ongoing competitions? Because I used to regularly enter them online through the PMM website but for quite some months when I'm perusing, nothing shows up? Maybe my settings aren't right?

Regards, John

Radburn

We temporarily retired our competitions to focus on other things, but due to popular demand we have brought them back. So, Freya, get cracking

Write to us at pmm@hamerville.co.uk or send us a good old fashioned letter at PMM, Regal House, Regal Way, WD24 4YF.

Show feedback

“ DEAR PMM, GREAT SHOW MECHANEX HARROGATE WAS. ONLY ISSUE WAS I DIDN’T KNOW WHERE IT WAS! I WAS GOING AROUND IN CIRCLES IN THE CAR PARK LOOKING FOR IT AND COULDN’T FIND IT BECAUSE THERE WAS SOME OTHER SHOW GOING ON NEXT DOOR. BETTER SIGNAGE NEXT TIME PLEASE! ”

I think you might be on to something, you’re hired

“DEAR PMM, GOOD TO SEE YOU’RE BACK UP NORTH WITH THE PMM LIVE SHOW BUT CAN’T WE GET SOME TECHNICAL SEMINARS PLEASE? I’M GLAD YOU HAD SOME DIFFERENT PEOPLE OTHER THAN THE USUAL CROWD YOU SEE AT EVERY OTHER SHOW BUT SOME ACTUAL TECHNICAL DEMOS WOULD BE GOOD. ”

We’re working on it, but it’s easier said than done!

SPECIAL REPORT 32 JULY/AUGUST 2024 PMM

TheHRdepartment wouldlikeaword!

In her second column for PMM, Jennifer Webb, owner and director of HR Vitals discusses recruitment, retention and resignations –the three Rs that the HR Vitals team spend most of their time working on. FOR MORE

What if I told you that there are themes that run through all three of these Rs? If you get the recruitment wrong, then the retention (for the employee to be happy at your workplace) is a lot of effort for not a great result, and resignation is inevitable. Sometimes resignation is healthy, it is fine for people to move around to different workplaces. But sometimes, it is the end of a stressful relationship.

So how do you get the successful recruitment and retention? The answer is to consistently communicate what you are really good at. What are

LIFEIN AN EV GARAGE

you naturally good at with the company? Is it upskilling? Is it the atmosphere at work? Is it being a team player? Business expansion? Whatever it is, make that run all the way through your business, recruitment and retention, like a stick of rock!

Employers – focus on what you and your team are passionate about.

If you aren’t sure what your thing is, ask yourself what you enjoy the most? What do you find easy? What is common sense to you? – don’t presume that there is no value in these things, they actually influence your workplace the most.

Technicians – talk to your bosses about the tasks that you really enjoy.

Finding EV customers

This month, Matt Cleevely discusses customers and how to find them –especiallyones with EVs!

When we first opened Cleevely EV, we didn't have any customers with EVs. This is common for any new garage business. Attracting and keeping customers takes time and effort, especially with EVs. We've already discussed how EV numbers are growing rapidly in the UK, so it stands to reason that some of your current customers will likely be considering an EV for their next car. The question is, do they know that you’re EV-ready?

A GiPA report in 2021 found that 57 per cent of EV drivers change their garage, seeking out an EV specialist instead. Unless you’re actively promoting your EV capabilities, you risk losing even your most loyal of customers when they make the switch to electric. They’ll be seeking out an EV specialist that’s doing a better job than you at marketing their EV expertise. Once they’ve found that other garage, chances are,

You will build a stronger work place, you are more likely to attract the right people, and retention will be like a walk in the park. There is nothing better than an employee who loves their job, when communication is easy and the employee may even come to their boss with ideas. To be heading in the right direction for this – be consistent about what you are good at.

they’ll also start taking their second car to them too – usually an ICE vehicle.

Just because you’ve done your EV training and have invested in the equipment, don’t expect EV work to automatically start coming in. It won’t. And don’t assume that your customers will tell you that they’re getting an EV. They won’t. It’s down to you to tell your customers, your ICE customers, that you’re EV ready.

Six years ago, our goal was to encourage more EVs to come into our workshop and become the first EV specialist in Cheltenham. We ended up becoming the largest independent EV specialist in the country because we reached out to EV owners and invited them to bring their cars to us.

We’re not naive though. This isn’t going to last forever. As more garages gain the confidence to start working on EVs, our customers will likely prefer the convenience of a local EV specialist. And that’s fine. The number of EVs is growing, so there’s plenty of work for us all. I just want that local specialist to be a fellow independent garage owner. I want it to be you.

FORMOREINFORMATIONGOTO WWW.RDR.LINK/ABK010 PMM JULY/AUGUST 2024 34

INFORMATION GO TO WWW.RDR.LINK/ ABK009

DIAGNOSTIC training courses

PMM catches up with one young apprentice who has recently attended the Automotive Training Academy, run in partnership with Maverick Diagnostics.

Tiana Fear of K Motors attended a recent Jaguar Land Rover Diagnostic Tool training course. She was one of around 10 participants that enjoyed two days at the IMIaccredited training facility in Wrexham, which boasts a partnership with Maverick Diagnostics.

The JLR dealer diagnostic tool training course provides hands-on instruction in ATA’s classroom and workshop, focusing on using JLR tools effectively. The curriculum covers TOPix access, program selection, diagnostic procedures, symptom selection and navigation, warning lamp selection, diagnosis of DTCs, vehicle specifications, data logging, oscilloscope basics, car configuration files, health checks, vehicle networking, and TOPIx Cloud. Reflecting on why she signed-up, Tiana said: “Every day is a challenge; I never know what vehicle is going to arrive in the workshop, nor the issue that I’m about to encounter, and with vehicle technology evolving, I need to ensure my skills continues to evolve too.

“Being young, my company is keen on retaining me and is actively supporting my pursuit of knowledge. Hybrids and EVs, for

example, are specific areas where I want to bolster my knowledge and skills. I believe there is a substantial gap in understanding between traditional vehicle mechanics and electrical systems. Bridging this knowledge divide is crucial, and I am eager to contribute to this field.”

Tiana’s verdict on the course? “I really enjoyed it – I don’t believe people can ever learn enough!”

Following her passion

Tiana’s journey into the sector wasn't just a career choice; it was – and continues to be –her passion. It was a legacy passed down from her father: “It was a passion of my dad’s. He loves his cars, particularly motorsport, and that enthusiasm ignited my own interest. I love fault-finding; it keeps me active and gives me immense satisfaction when I’ve found a solution to a problem. It’s a difficult but incredibly rewarding job.”

From tinkering in her father’s garage to racing motorbikes and rebuilding engines, Tiana’s love for automotive and motorsport, in particular, was evident early on: after completing two years of full-time college, she dived headfirst into a garage environment, thirsty for real-world experience and indepth, on-the-job training.