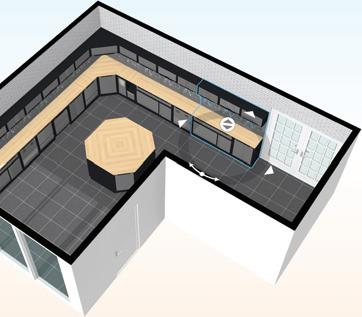

TOTHE TRADE PMM PROFESSIONAL M OTOR M ECHANIC DECEMBER2022 Let’s get technical INSTALLATION TIPS PROVIDED ON EPS STEERING, CLUTCHES& TIMING BELTS BEST PRACTICE ADVICE OFFERED ON BATTERIES, DPFS, AIR MASSMETERS & BRAKES COMMON FAULTS ON SPARK PLUGS, TURBOS & RADIATOR LEAKSEXPLORED ARE EVS REALLY AS COSTLY ASICE VEHICLES TO RUN? Exclusive interviews with JODY BEVAN & ANDY BROOKE KARCHER HD 5 / 12C PLUS PRESSURE WASHER REVIEWED NEW DIAGNOSTIC EQUIPMENT FROM DELPHI DVSA COMMENTS ON MOT FRAUD CLAMPDOWN

STAYING UP TO DATE

PMM hears from DVSA’s Caroline Hicks about what is being done to tackle MOT fraud.

FEMALE FOCUS

Jody Bevan from MNJ Autocare recently embarked on a journey to restore a classic car to raise money for the UK Sepsis Trust – find out more in this month’s female focus.

GOING ELECTRIC?

PMM’s Kieran Nee visits Andy Brooke, who is now director of a newly opened EV training academy, to find out if the future of the industry really is electric.

PUT TO THE TEST

Kitting out your workshop is no easy (or cheap) task. Hear what PMM reviewer John Hall thinks of the Kärcher High Pressure Cleaner HD 5/12C plus in this month’s product test.

Contents VOLUME 23 ISSUE 11 DECEMBER 2022 Features Total Average Net Distribution 54,319 1st July 2021 – 30th June 2022 PMM DECEMBER 2022 3 33-37 BATTERIES & IGNITION 39-43 EXHAUSTS & EMISSIONS 48-54 45-46 HYBRID & ELECTRIC VEHICLES Regulars 6-9 NEWS & VIEWS 11 TROUBLESHOOTER 12-13 CLUTCH CLINIC 14-15 BELT FOCUS 17-24 TECH TIPS 25-27 BUSINESS & TRAINING 28-31 SPECIAL REPORTS 55 WHAT’S NEW? 56-57 PRODUCT TEST 57 MYTHBUSTERS Editor’s Picks 25

30

45

56

AWARDS 2022

Editor KIERAN NEE Editorial Assistant FREYA COLEMAN Digital Manager KELLY NEWSTEAD Group Manager ROBERT GILHAM Account Manager ALEX DILLEIGH

Editor KIERAN NEE Editorial Assistant FREYA COLEMAN Digital Manager KELLY NEWSTEAD Group Manager ROBERT GILHAM Account Manager ALEX DILLEIGH

Magazine Designer GEMMA

WATSON

Group Production Manager CAROL PADGETT Production Assistant CLAIRE SWENDELL

Distribution Manager

KARL CLARK

Subscriptions

PROFESSIONAL MOTOR MECHANIC is a business magazine for firms and individuals involved in all aspects of the motor trade. It is published eleven times a year and is available nationally FREE to the trade through leading motor factors. It is also available through the post at a cost of £30.

EUROPE and OVERSEAS

1 year (11 issues) £50 Airmail 1 year (11 issues) £65

Printed by Walstead Peterborough

Published by

HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts, WD24 4YF.

Tel: Watford (01923) 237799 Fax: (01923) 246901 E-mail: pmm@hamerville.co.uk Sales enquiries: pmmsales@hamerville.co.uk Website: www.pmmonline.co.uk Facebook: /ProfessionalMotorMechanic Twitter: @pmmmagazine Copyright © 2022

Time fora refresh

How many of you reading this have got the same tired old signage you’ve had since you first opened shop? Yeah, I thought so. Well, we’re not exactly in a position to judge, having had the same livery since we first hit motor factor counters 20 odd years ago. You will have noticed, however, that we have just had a bit of a makeover and even something of a name change!

Yes, the magazine that was once officially called Professional Motor Mechanic, but known to everyone and his dog as PMM, has now become simply PMM. Well, the PMM still stands for Professional Motor Mechanic, but you know what I mean...

Why make a change after all these years? Well, there are several reasons, really. Firstly, the old masthead was starting to age. What was once a cutting edge new style had, in the age of TikTok and vaping become a bit dated.

Secondly, everyone calls us PMM – we even call ourselves PMM – so we thought we should just go with the tide of public opinion on that one. On a side note, when our designer Gemma sent through the design (a huge thanks, by the way, Gemma!) using our classic PMM red and black, I was immediately taken back to my teenage years huddled over the NME in my bedroom. Others have pointed out the resemblance to a certain “magazine for him” – we all had different interests growing up, I guess.

On a more serious note, refreshing the front cover has also refreshed the way we see the magazine itself. It has given the team renewed vigour and provided inspiration for further redesigns (watch this space). Whilst replacing the signage outside your workshop might not be top of your list of things to do this winter, at least remember that doing so isn’t simply about making the front “look nice.”

The sign above the door is the first thing potential customers will see when they arrive at your workshop. In an instant, that person will make a judgement on the rest of your workshop. A hand-painted, antique sign might say “family business, well trusted”, whilst a new, professionally designed sign in bright colours might say “we have expertise on modern cars and value our customers”. What a broken, stained, sun-bleached or non-existent sign certainly doesn’t say is “welcome, come on in”.

Of course, the actual work you do and the actual customer service you provide is more important than the sign, I would never suggest otherwise. The point I want to make, however, is that just as the “clothes maketh the man”, and the “logo maketh the magazine”, perhaps a positive, professional sign at the front of the workshop will promote a positive, professional working environment inside the workshop. Now, time to start working on next month’s PMM cover story, Blur vs Oasis...

Kieran Nee

Editor

VIEWPOINT

The publishers and editor do not necessarily agree with the views expressed by contributors,nor do they accept responsibility for any errors of translation in the subject matter in this publication. Listen on Amazon Podcasts Listen on Spotify Podcasts Listen on Apple Podcasts Associate member Find every episode at www.pmmonline.co.uk/podcasts Also available: JOIN M E EACH M ONTH ON THE PMM PODCAST

PMM NEWS with Freya Coleman

NEWSIN BRIEF

■ AUTODATA is celebrating its 50th anniversary by releasing 350 training videos to their existing comprehensive repair library. This adds to its bite-sized training courses and delivering on-site training across different subjects.

■ In its latest annual report, MOT fraud remains a key focus for the DVSA. In the report, the agency states it is testing the use of cameras in the MOT test to combat against fraud.

■ COMLINE has launched a steering and suspension brochure, featuring the brand’s range as well as the manufacturing and testing behind its portfolio.

■ TheInvestors in People gold accreditation has been awarded to MIRKA, with the company being praised for its relationships with stakeholders, its company culture and its strong management team.

A call for change

The Competition and Markets Authority (CMA) has written to the secretary of state with recommendations to introduce UK-specific block exemption regulations.

The current motor vehicle block exemption regulation (MVBER) is set to expire on the 31st May 2023 and sets out automatic exemptions related to the purchase, sale and resale of spare parts for motor vehicles. The CMA recommends that the UK motor vehicle block exemption order (MVBEO) be in place until the 31st May 2029, should be tailored to meet the needs of UK businesses and consumers and to be similar to existing MVBER for continuity purposes.

Stuart James, chief executive of the IGA, is happy with the attention the report draws to independent garages who are having

trouble accessing technical and vehicle data they need to carry out their jobs. He goes on to argue that “over 70 per cent of all service and repair work is carried out by independent repairers and the MVBEO will ensure their continued access to vehicle data, safeguarding consumers’ rights to repair their cars where they choose.”

UK AFCAR has also welcomed the new proposals calling them the “beginning of a long journey to ensure consumer choice and the aftermarket is protected”, but has also called for greater detail on how revisions to the regulation will be implemented. This is corroborated by Mark Field (pictured), chief executive of the IAAF, who claims this is just the start of a long journey that ensures customer choice and the ability for the aftermarket to compete.

6 DECEMBER 2022 PMM

“Over 70 per cent of all service and repair work is carried out by independent repairers”

Stuart James, IGA

Recognising excellence

The IMI has named BMW Group UK Academy in Berkshire the first IMI TechSafe centre of excellence.

The £17m purpose-built BMW academy opened in 2006 and is dedicated to training apprentices and keeping delegates up-todate on the latest products, techniques and technology. It has also partnered with the IMI for more than 12 years, contributing to the IMI expert working groups, attending EV steering groups and taking an active role in the IMI TechSafe sector advisory group.

With 76 per cent of technicians in the BMW UK network achieving IMI qualifications and TechSafe eligibility, it is little surprise the manufacturer-backed network has achieved this status.

IMI’s CEO Steve Nash said he looks forward to recognising more organisations that meet the criteria in the future.

NEWSIN NUMBERS

5.5 %

Amount advertised salaries for vehicle technicians have increased in the last six months. The rate of inflation year-onyear currently stands at over 10 per cent.

159,662

The average number of speeding offences that are made each year across England and Wales, says Forbes Advisor.

33 %

The rise in cost of vehicle repairs between January and June compared to the same period in 2021 according to data analysis from Intelligent Motoring.

The amount of years Ford has been selling the Fiesta, which is ending its production run next year. The favourite of first time drivers racked up over 22 million sales over its lifetime.

ME YOUR NEWS AT FCOLEMAN@HAMERVILLE.CO.UK PMM DECEMBER 2022 7

In pictures: Comline toasts Richardson Racing’s title-winning Porsche Carrera Cup GB season at its global headquarters in Luton.

MESSAGE

46

“We are comitted to delivering the highest level of training to longterm employees and new apprentices alike”

Phil Neal, BMW

Phil Neal from BMW group academy receiving the award from IMI CEO Steve Nash.

PMM NEWS with Freya Coleman

NEWSIN QUOTES

“

There are significant challenges facing automotive employers, for which there is considerable knock-on impact for both those working in the sector and the wide variety of individuals and organisations that rely on mobility for their daily lives and business. Government support would make a big difference to tackle these challenges.”

Hayley Pells, policy manager at the IMI, in an open letter to Anne-Marie Trevelyan, the then secretary of state for transport.

“ Any plans to extend the current MOT test frequency or failure to uphold MVBER and update vehicle type approval regulations will render any business support packages worthless in the independent aftermarket.”

Mark Field, IAAF, on the inadequacy of the government’s energy bill relief scheme.

“ SMMT congratulates Rishi Sunak on becoming leader of the Conservative party and prime minister. What we now need is a clear and compelling strategy for growth and stability. The automotive industry can help drive an economic recovery but we sorely need a period of stability and a framework for competitiveness.”

Mike Hawes, chief executive of the SMMT, on the appointment of the most recent Tory leader (correct at time of writing).

Bouncing back

AES Autoelectrical Services in North Yorkshire has overcome 12 months of adversity, thanks to Garage Services Online.

After owner Mark Shipman learnt he was unable to renew the lease on the garages’ premises, the future was uncertain. The new unit the garage secured was over 15 miles away from the original base, and the company lost over 50 per cent of the customers it had spent 12 years servicing. So, Mark says they adapted their offering and turned to Garage Services Online who run its website, no longer being able to rely on word-of-mouth. Garage Services Online

MOT madness

There has been a huge rise in the amount of MOT testers disqualified since the start of the pandemic.

This is according to a freedom of information request by BookMyGarage.com. The request revealed that 687 MOT testers have been stripped of their status, 50 per cent more than the previous two years. This usually occurs following improper or careless practices during the test procedure, or for issuing fraudulent certificates.

This information comes as the government mulls over the prospect of biannual MOT testing.

The IAAF, for example, is urging Mark Harper, the nex secretary of state for transport, to not mess with the current MOT test frequency. They argue that any extension to the test frequency will lead to an increase in road accidents and fatalities as there will be no formal inspection of a vehicle’s road worthiness for a further 12 months.

For example, MOTs are disproportionately high for electric vehicles when they are first tested at three years, due to their increased tyre wear.

changed the site to reflect the new AES and to make sure it attracted locals. AES

Autoelectrical Services saw instant results, not only regaining lost customers but also, apparently “thriving”.

8 DECEMBER 2022 PMM

Recent research has found that the majority of motorists consider the UK MOT test is important for road safety

GS Yuasa have teamed up with Tunnocks to offer a sweet pick-me-up to vehicle technicians.

Available for free with qualifying purchases of Yuasa and GS-branded batteries from participating distributors, the promotion will see vehicle technicians receiving a free pack of Tunnock’s snowballs with battery purchases this winter. Each pack contains eight snowballs as well as a unique code for the battery manufacturer’s exclusive competition. With a smart watch, a Gordon Shedden experience at Knockhill racing

circuit and three GS Yuasa ‘Winter Workshop’ kits up for grabs, workshops and technicians are encouraged to complete the entry form on the company’s website for their chance to win.

DATES FORTHE DIARY

■ The CAT Awards 2023 will return to Lowry on the 10th of February. The nominations are now open. The awards up for grabs include ‘Training Programme of the Year’, the ‘Environmental Award’ and ‘Garage of the Year’ among others.

■ Tickets have gone on sale for the UK’s first independent garage event dedicated to EV servicing and repair. EV Ready is set to be held at Brighton Racecourse on the evening of January 25th 2023. Around 40 aftermarket exhibitors will highlight the EV-related parts, equipment and training available to independents, including the likes of Pico Technology, Autotech Training and Schaeffler.

Sparking celebrations

Ten lucky garages have been celebrating after winning the NGK BoxClever promotion.

In the promotion, members of the company’s BoxClever independent garage loyalty scheme are encouraged to collect and return NGK single boxes in exchange for points which they can then redeem to select prizes of their choice. In the promotion, they were given double points to fit the company’s NTK Lambda, camshaft and crankshaft and

MAF and MAP sensors, earning 300 points for every Lambda sensor purchased and 200 points for every camshaft and crankshaft or MAF and MAP sensor fitted. Each time they purchased one of the products they were entered into a free prize draw where the 10 lucky winners each received 50,000 points.

■ IAAF Pride of Aftermarket Awards 2022 will take place on 8th December at the Double Tree by Hilton, Milton Keynes. Tickets are available on the organisation’s website. The awards dinner comes after the IAAF conference.

PMM JUNE 2021 9

ME YOUR NEWS

PMM DECEMBER 2022

Treat yourself MESSAGE

AT FCOLEMAN@HAMERVILLE.CO.UK

In pictures: The Blend 2022 conference event from garage management system Garage Hive took place on 17th of September.

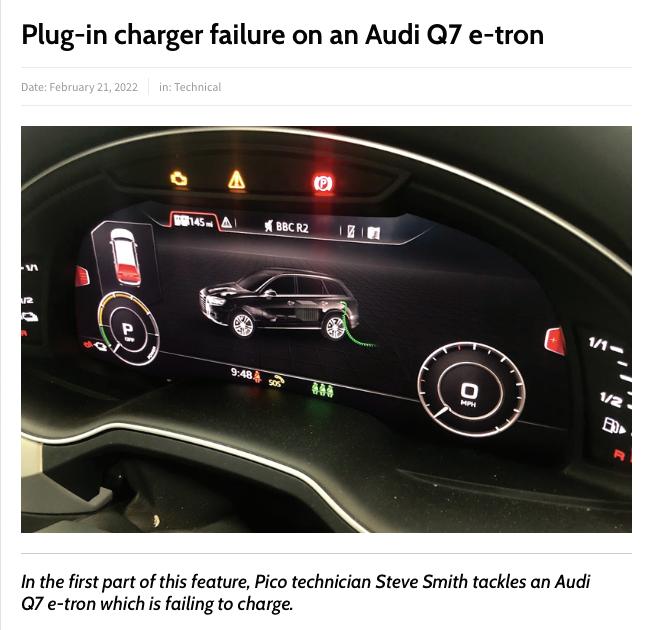

What is causing glitches in the

At first, it seemed like a simple case: On a 2017 Ford Transit Custom, the info display on the instrument panel kept on flickering and failing. The instrument panel was therefore immediately removed and sent to ACtronics for repair. However, during the entry test prior to the repair, the instrument panel appeared to work just fine. Could there be something else going on?

Unfortunately, it sometimes happens a car is sent to the workshop with some strange electronic malfunction, but the real cause of the problem is hard to find. In modern cars, performing a proper diagnosis is becoming increasingly difficult. So, in these cases it really helps when you’re pointed in the right direction. The Ford Transit Custom in this story (type 2012-2018) was just such a case.

Right after the instrument panel was sent back from ACtronics to the workshop, it was refitted into the car. All seemed ok for a while, but the Transit soon started to suffer again from several strange malfunctions. For example, the remote-control sometimes didn’t respond when pressing a button. However, the remote-control's battery was

recently replaced. Maybe a switch within the remote control was starting to fail? But after a thorough investigation all seemed fine regarding the remote control. So, what was causing this problem? And could it be related to the failing display?

Then, for no apparent reason, both rear light units failed. This couldn’t just be a coincidence: there must have been an electronic fault somewhere within the vehicle. So, looking for further clues, the Transit was read for error codes again:

■ U0073-88 – Communication bus interface module disabled

■ U0155-00– No communication with the IPC control module (Instrument Panel Cluster)

■ U0558-64 – Invalid data received from the front control/display interface module

Of course, these descriptions do not exactly tell you what the problem is, but we can draw an important conclusion: there are several modules triggering a fault code. So, what do these modules have in common? For starters, it’s important to check both ground and power supply. The power supply should be a constant feed without any fluctuation.

This, indeed, turned out to be the problem: there simply wasn’t a decent power supply towards multiple devices. Strangely, though, the car was able to start with ease. “So, it can't be the battery”, you might think. However, in this generation of the Transit Custom, two batteries are located under the driver's seat. One is the starter battery, the other is to supply power to the on-board network. And you might have guessed it by now: That second battery turned out to be the cause of all the problems... Needless to say, after replacing the battery, all problems were immediately resolved.

Unfortunately, this situation is common with the Ford Transit Custom. So always check the second battery in case of strange malfunctions. Although in this case the instrument cluster was working perfectly fine, these devices do indeed regularly malfunction. Devices such as the Ford Focus II and the Fiat 500 cluster are frequently offered for repair. Strangely enough, we’ve noticed the number of revision requests increases during the winter period. We suspect the lower temperatures are causing this increase. So, keep in mind there is a bigger chance of a defective instrument cluster in this period.

PMM DECEMBER 2022 11

TROUBLESHOOTER WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAS004

to

This time, it’s the instrument

FORD TRANSITCUSTOM DISPLAY ?

ACtronics returns this month

discuss another van-related issue the team has come across.

panel on a 2017 Ford Transit Custom.

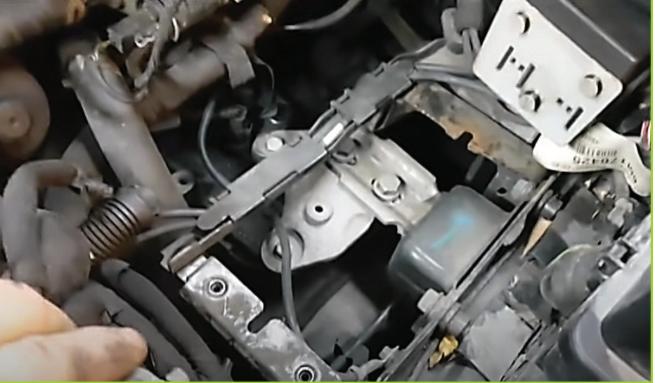

Replace the clutch on a Peugeot 207 Sport HOW TO

This month, Valeo Technical Trainer Stewart Lynch replaced the clutch on a Peugeot 207 Sport fitted with a 1.4 four cylinder petrol engine that has covered just over 59,000 miles.

C3. The 207 Sport was an ‘Urban’ hatchback and whilst it had nothing special on the in-car entertainment front, it was victorious in achieving an impressively reliable engine and is still a popular vehicle on the road today.

Before Stewart made the trip to the garage premises, the customer had reported that gear change had become difficult and vibration was being felt through the pedal. Upon arrival at the garage premises, Stewart took the vehicle out for a test drive so he could understand the issues being encountered by the customer. After diagnosis, a clutch replacement was advised and authorised by the customer.

The Valeo online TechAssist platform was used and the vehicle's VIN entered to obtain the correct clutch kit. With the vehicle on the ramp, open the bonnet and remove the battery, ECU (mounted within a protective case) and Air intake ducting. Remove the Engine cover and Air filter/box (Fig.1).

gearboxing mounting. Raise the vehicle to around waist height and remove the gearbox bolts around the bell housing and the starter motor, leave one of the lower large bolts in to prevent the gearbox from coming away from the engine, and remove the wheels and driveshaft hub nuts on both sides and remove the plastic wheel arch liner. In order to gain more access to the gearbox remove the bottom subframe strut and the bottom cross bar.

no contact area or support within the engine bay to allow an engine cradle to be used. Finally, remove the gearbox mounting bolts on the near side mount bracket. Remove the final bell housing bolt and ease the gearbox out and transport to a safe working area.

Remove the release arm from its mounting and ensure the release arm is gently removed from the metal ball joint/pivot. In this instance, the release arm was worn and the plastic ball socket/mounting (which fits over the metal ball joint) was damaged (Fig.3).

Next, drain off the gearbox oil, disconnect both bottom wishbone ball joints and remove the drive shafts. Disconnect the clutch slave cylinder from its mounting and remove the crank sensor from its mounting otherwise it will get broken during the refitting of the gearbox (Fig.2).

Next, remove the bottom exhaust mounting and support the engine with a transmission jack on the underside as there is

Remove the clutch assembly from the flywheel, check the flywheel for surface/heat damage or signs of wear and thoroughly examine the flywheel and check its integrity (hotspots/cracks etc). If in doubt, replace the flywheel.

CLUTCH CLINIC

12 DECEMBER 2022 PMM

“Before Stewart made the trip to the garage premises, the customer had reported that gear change had become difficult and vibration was being felt through the pedal.”

pressure plate, a direct consequence of the defective release arm (Fig.4).

TOP TIPS FROM THE TECHCARE ENGINEER:

■ To reduce the risk of potential spine damage please ensure the correct clutch alignment tool is used during the course of replacing the clutch assembly and the gearbox is fitted in line with the engine.

■ Ensure the guide tube is renewed during clutch replacement.

■ It is critical to ensure the correct gear oil that is specified by the manufacturer is used.

■ Check the integrity of the release arm; specifically the plastic molded ball socket that pivots on the gearbox mounting. Replace any wearing parts, bushes etc.

clutch assembly to the flywheel. Torque the bolts (according to vehicle manufacturer specifications) in an even and sequential order to ensure a correct installation (Fig.6).

At this stage, Stewart and the garage technician contacted the customer and shared video footage of the release arm and gained authorisation from the customer to replace the release arm.

It is also recommended to replace the guide tube clutch replacement because of the amount of wear and tear that can occur on the cylindrical tube (Fig.5).

Before proceeding with the fitment of the clutch, clean the gearbox of dust and debris and clean the input shaft with a soft wire brush. Next spray brake cleaner onto a clean cloth and wipe the input shaft so it is clean. Open the sachet of grease provided and empty it out onto some clean paper or card (please note there is no need to use all the grease

provided). If no grease is provided use a high pressure, high temperature grease such as BR2 type grease (do not use a copper based grease). Using a fine brush lubricate the gearbox input shaft with grease. Do not apply grease on to the input shaft using your fingers as this

Refit the gearbox and rebuild in reverse order. Refill gearbox oil according to the manufacturer’s specification. Please refer to the specific gear oil recommended for the transmission otherwise difficult gear selection issues can occur. Once the vehicle is on the ground, re-torque the hub nuts and wheel nuts to manufacturers specification. Once the repair is complete carry out a road test to ensure the clutch and gear change operations are correct.

PMM DECEMBER 2022 13

WWW.RDR.LINK/AAS005

WANT TO KNOW MORE? FOR MORE INFORMATION

Vehicle

The replacement schedule for this belt is every 144,000 miles or 10 years, so as the vehicle had reached its 10th birthday, timing belt replacement was advised, and authorisation given. This is a very popular PSA engine used by Citroën, Ford, Mazda, Mitsubishi, Peugeot, Toyota and Volvo. The repair time is 3.1 hours.

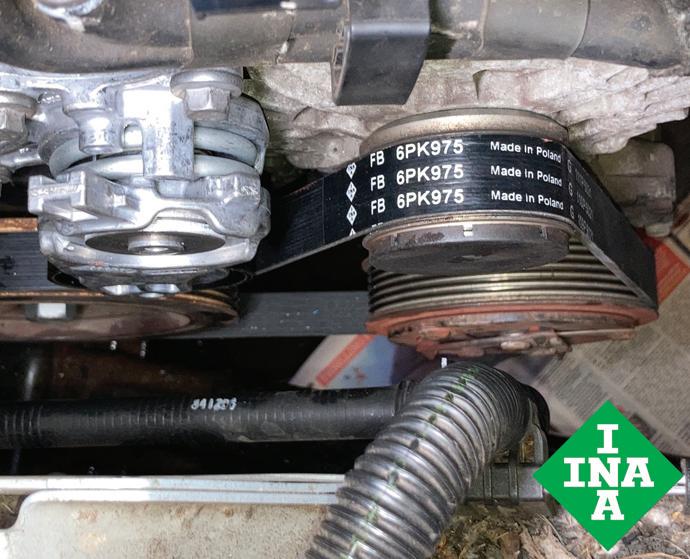

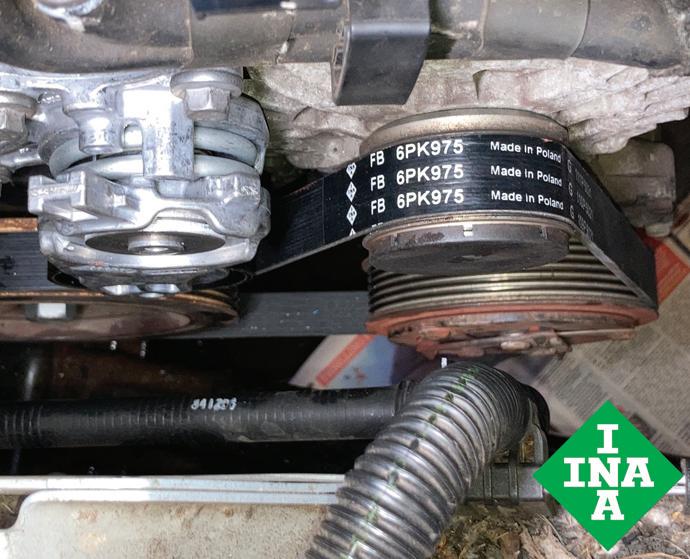

Timing belt and water pump removal

With the vehicle placed on the lift, raise it to waist height, remove the O/S/F wheel and wheel arch liner to gain access to the bottompulley. Lower the vehicle lift and remove the engine cover and then the auxiliary drive belt by releasing the tension from the tensioner. Detach the drive belt and inspect it for wear and cracks (Fig.1), replacing it if required.

The O/S engine mounting now needs to be removed (Fig.2), so support the engine, take off the O/S engine mounting assembly and then remove the upper timing belt covers. Rotate the engine in a clockwise direction until the camshaft alignment pin can be inserted, but do not insert the locking pin.

HOW TO

BELT FOCUS 14 DECEMBER 2022 PMM

Replace the timing belt and coolant pump on a 2012 1.6l Citroën C4 Grand Picasso

In this month’s INA Belt Focus, REPXPERT Alistair Mason is replacing the timing belt, coolant pump and auxiliary drive belt kit on a 2012 1.6 litre HDI Citroën C4 Grand Picasso that has covered more than 78,000 miles.

Always

■

■ Tools –

■ Tension –

■ Torque

Equipment used ■ Vehicle lift (two post is preferred) ■ Engine support ■ Crank and camshaft locking tools ■ Coolant drain pan ■ Cooling system vacuum bleeder

follow the Schaeffler 4Ts rule,

Temperature – Replace and tension the timing belt at an ambient temperature

Use the correct engine timing tools

The correct timing belt tension is critical on today’s engines

– Torque all bolts to the vehicle manufacturer’s specifications

Year

Engine

Mileage

Information Make Citroën Model C4 Grand Picasso

2012

1.6 litre HDI

78,000

Before the engine is locked, slacken the crankshaft pulley and remove it, inspecting the rubber damper on the pulley for any cracks or wear, and replace it if required. If there is a small hole in the crankshaft sprocket, this indicates that the vehicle has an oval crankshaft sprocket to reduce vibration at the timing belt (Fig.3).

Once the pulley has been removed, take off the lower timing belt cover and then insert the crank bolt, so the engine can be rotated slightly to aid inserting the locking pin into the back of the flywheel. This is a little awkward as it is located behind the diesel particulate filter, but the position can also be confirmed by inserting a pin into the crankshaft sprocket (Fig.4). Lower the vehicle lift and insert the camshaft locking pin (Fig.5), followed by locking the high-pressure fuel pump sprocket (Fig.6).

Note: the high-pressure fuel pump must be timed to the engine, as these pulses must be in time; if incorrect, this can cause the tensioner to fail.

With the crank, cam and high-pressure pump locked, slacken the cambelt tensioner and remove the timing belt, followed by the tensioner and idler. With the timing belt removed, check for any leaks that might contaminate the new belt and rectify as required. Place a coolant drain tray directly under the coolant pump area, remove the coolant expansion tank cap to ensure there is no pressure in the cooling system and then remove the coolant pump. Clean the coolant pump gasket face and then ensure the area is clean and dry.

Timing belt and coolant pump installation

Mount the new gasket onto the new coolant pump and the pump onto the engine, insert and tighten all bolts in an even manner and torque to the manufacturer’s specification. Note – do

not put any sealer on the gasket or pump.

Fit the new timing belt tensioner, ensuring that it locates onto the dowel (Fig.7), and lightly nip the tensioner bolt so the tensioner can be adjusted once the belt has been fitted. Then mount the new idler pulley and torque the nut to the correct specification. Fit the timing belt in the following order: crankshaft sprocket, idler pulley, camshaft sprocket, high-pressure fuel pump and coolant pump pulley, then slide it onto the tensioner.

Using an Allen key, turn the tensioner eccentric anticlockwise until the pointer is centrally located in the recess (Fig.8) and tighten the tensioner bolt. Remove all the locking tools and rotate the crankshaft six complete revolutions, then refit the engine locking tools to ensure the timing is correct, and check that the tensioner is still in the correct position. If so, remove the engine locking tools and torque the timing belt tensioner to the manufacturer’s specification.

Finishing touches

Refit all components in reverse order of their removal. In this instance, a new auxiliary drive belt and tensioner was fitted, as the drive belt had cracked and the tensioner showed signs of wear at the pivot point (Fig.9).

Fill the cooling system with new coolant, ensuring it is of the correct specification and concentration. Vacuum filling/bleeding is recommended as it’s one of the best ways to replenish the system as it is quick, avoids air locks and lubricates the new water pump on initial start-up.

Finally, once the cooling system has been filled, run the engine with the heater on to confirm that the coolant is circulating, topping it up if required, and always road test the vehicle to confirm a quality repair has been made.

PMM DECEMBER 2022 15

INFORMATION WWW.RDR.LINK/AAS006

WANT TO KNOW MORE? FOR MORE

A small hole in the crankshaft sprocket indicates the vehicle has an oval crankshaft sprocket to reduce vibration

When installing a remanufactured EPS steering rack, the first and most important thing to do is to remove any fault codes caused by the failed EPS steering rack, from the vehicle ECU using a diagnostic scan tool.

An important thing to note is that if the steering has failed and the light is illuminated on the instrument panel, then a fault code will be present. If your diagnostic scan tool cannot see a fault code, then the scan tool being used is not suitable for completing the installation and an alternative scan tool will need to be used. If fault codes aren’t removed before installing, the original fault codes can transfer to your remanufactured EPS steering rack and embed into the EEPROM chip, thus making the replacement product think it has the same faults as the previously failed unit.

When the fault codes have been removed, the next thing is to disconnect the vehicle battery. Now you can remove the old steering rack safely. A point to note is that you need to be careful when releasing electric

connections, as the plugs can be quite brittle and may damage. Now, install the new unit and connect all the wiring connections. Reconnect the vehicle battery.

It is important that you do not turn on the vehicle at this stage.

Getting to it

Attach the diagnostic scan tool via OBD II and turn the ignition on (but do not start the car). Using the diagnostic scan tool, tell the steering system the characteristics of the vehicle, for example: Mazda 6, 5 doors, 2000cc engine, 16 in. wheels etc. An important note at this stage relating to steering replacement on vehicles where the steering ECU is remote from the EPS steering rack, you should re-enter the VIN number during installation of the vehicle characteristics. This allows the steering rack to communicate properly with the vehicle (make sure that your diagnostic scan tool can perform and is suitable for this part of the installation).

During this section of installation, you will need to perform a steering angle sensor calibration. Please note that all EPS steering racks are calibrated during production, however, each one is individual and a calibration to the new steering product is essential.

Where a vehicle has a remote steering ECU, during the testing and simulation of the steering rack in the workshop environment, a stock steering ECU will be used from the specific vehicle. An important note to make is that the steering ECU denotes ‘zero’ position on the vehicle, not the EPS steering rack. The rack and the ECU are calibrated to ‘zero’. However, the ‘zero’ position of the steering ECU on the vehicle may be slightly different to the stock steering ECU used during testing and simulation, therefore the calibration is essential to avoid creeping or wandering of the EPS steering rack.

Typically, all differences fall within 0.5 Nm tolerance and a calibration is simple to perform, however, if the difference is greater than 0.5 Nm, then it will not calibrate and will need to be calibrated at your EPS steering rack remanufacturer, where a slight modification will need to be performed. It can be calibrated with the specific ECU from the vehicle so that they can be paired together ready to be re-installed on the vehicle.

Once calibration is performed, this completes the EPS steering rack installation process, and the vehicle is ready for use. It is now safe to turn on the car and drive it.

PMM DECEMBER 2022 17 TECH TIPS Complete Steering offers its advice to readers tasked with installing an EPS steering rack. WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAS007

Install an

HOW TO

electric power steering rack

Brake calipers

WATCH!

NEW RANGE

febi is offering a new range of brake calipers, with more than 500 articles for popular vehicles. These articles cover over 95,000 applications and a large number of vehicles on the road today.

TIME SAVINGS

A brake caliper replacement using a new febi caliper takes 50 per cent less time than carrying out a repair.

HIGHEST QUALITY

All febi brake calipers go through a rigorous inspection process to ensure that they are direct OE replacements and meet the high quality standards of the bilstein group.

EASY TO REPLACE

Replacing a brake caliper takes around half the time of a caliper repair, meaning replacement can be a more profitable job for workshops.

COMPLETELY NEW

febi’s brake calipers are completely new, with no remanufactured parts and no surcharge connected to the sales price.

18 DECEMBER 2022 PMM

The brake caliper is one of the main functional parts of the braking system.

Watch a detailed video from febi on brake calipers

Common Faults

FLUID LEAKS

One of the most common symptoms of a failing caliper is the presence of brake fluid on the caliper – the fluid is leaking through the seals.

VEHICLE PULLING

Being constantly exposed to high temperatures and pressure, seals can begin to wear out over time and will allow fluid to pass by them. Sometimes these leaks can be seen easily or are spotted during routine maintenance.

REDUCED STOPPING POWER

A reduction in braking power, or the increased effort required to brake, is a clear indication of a failing caliper. Often caused by fluid leaks, a ‘spongy’ feeling when braking is a result of the caliper not effectively clamping down on the brake disc.

VEHICLE PULLING

Any abnormal sounds when braking could indicate a caliper failure. High-pitched sudden ‘thudding’, or other impact sounds, could indicate a loose or ‘binding’ caliper. This looseness or ‘binding’ can also lead to premature brake pad wear

Why febi?

• As a parts specialist with manufacturing competence embedded in its history, febi only offers products with the highest degree of installation safety and durability.

• To underline its high product quality standards, febi provides a 3-Year Manufacturer Guarantee for all replacement parts.

• All febi brake calipers go through a rigorous inspection process using various testing equipment, including: High/low pressure leakage testing; high/low temperature testing; hydraulic performance testing; saltspray testing; rubber parts projector inspection; and 3D-coordinate measuring.

PARTS INSPECTOR

sponsored by

To find out more go to WWW.RDR.LINK/AAK008

COMMON FAULTS

Troubleshooting Turbos: OilContamination

In this article, Carwood, a leading OE-approved turbo remanufacturer and technical service provider, gives you some best practice advice on oil contamination, one of the most common causes of turbo failure.

Since 95 per cent of turbo failures are caused by issues other than the turbo itself, it’s important to determine why it failed and fix it before a new one is fitted. If not, the replacement unit could fail too, costing you, and your customer, more time and money. Although accurate failure analysis can be a challenge for even the most experienced of technicians, by understanding the likely causes and symptoms, issues can be correctly pinpointed and remedial action taken.

What is oil contamination

With tolerances measured in microns, and operating speeds of over 300,000 revs per minute, today’s modern turbochargers require a constant supply of clean, good quality oil to keep them running properly. Unfortunately, dirt, fuel, water, combustion residues and other contaminants can easily contaminate the oil, with even the smallest particles causing rapid wear to key components, and potentially serious damage to the turbocharger, and sometimes the engine.

What causes oil contamination?

Contaminated oil can be caused by a number of issues, the most likely being:

■ A damaged, blocked or poor quality oil filter and/or filter bypass valve

■ A build up of carbon in either the engine and/or oil feed and/or oil return pipes

■ Degraded engine oil due to excessive temperaturesand/orextendedservice intervals

■ Internal engine leaks such as faulty cylinder head gaskets or injectors causing water, fuel or coolant to mix with and dilute the oil –diluted oil is as good as no oil

■ Poor ongoing maintenance of the oil and lubrication systems

■ Accidental introduction of dirt or debris into the system during servicing

■ Metallic shavings or swarf deposits from engine wear, propagating debris throughout the entire system

■ Other foreign matter such as dust and dirt entering the engine cylinders through the air intake system

What are the signs of oil contamination?

Likeoilstarvation,contaminatedoilwill manifest itself in performance issues and component wear. Symptoms to look out for include:

■ Check engine light illuminated – further diagnostics will be required to pinpoint the issue

■ Loss in vehicle power –limp home mode

■ Grooves/scoring to journal bearing, journal bearing diameters of shaft, wheel and thrust components

■ Internal damage to the shaft and bearing from larger particles

■ Wear to oil flinger/flinger grooves leading to potential oil leaks

■ Excessive wear or damage to piston rings causing oil to enter the turbine side – this can result in increased oil consumption –remember piston rings are not 100 per cent oil seals

■ The turbine and/or compressor wheel coming into contact/rubbing against the housing bore, due to excessive play in the shaft from worn bushings/bearings

■ Blocked internal oil galleries restricting oil flow

■ Smell of fuel in the oil

■ Particles in the oil

How to prevent oil contamination?

The risk of oil contamination can be mitigated by following best-practice service procedures, such as:

TECH TIPS 20 DECEMBER 2022 PMM

■ Fit new, OE quality oil filters, at recommended service intervals, and when refitting a replacement turbo

■ Flush and change the engine oil with the correct grade and quantity of oil, in line with vehicle manufacturer guidelines

■ Fit new in-line micro filters and oil feed and return pipes, when installing a replacement turbo

■ Check the entire oil supply system during every service, and clean or replace components as needed

■ Only ever use OE quality fitting accessories – inferior quality gaskets and seals can easily break up and cause irreparable internal damage

■ Take care when servicing the vehicle to avoid any accidental contamination – for example cap components and/or pipes where appropriate, keep the working area clean of dust, chemicals and airborne particles, use clean tools, and check you have them all when the job is complete

Never use liquid sealant – it is liable to harden and break up when exposed to heat Check the engine for signs of wear, including swarf deposits

How to resolve oil contamination?

If an oil contamination related failure is confirmed, it’s important to address and fix the root cause, before replacing the turbocharger. Remedial actions should include:

■ Always conduct an oil system flush following the vehicle manufacturers guidelines, to ensure any trace of contaminated oil is removed

■ Fill with the correct grade and quantity of oil as recommended by the vehicle manufacturer

■ Fit new OE quality oil filters, gaskets, oil feed and return pipes, as per VM specification

■ Thoroughly clean the entire oil supply and return system, especially in higher mileage

vehicles –this may require the removal of the sump, oil pump and internal oil feed and return lines. Replace components where required

■ When replacing the turbo, perform an oil pressure test to identify any issues in the oil supply and return system, and check that it’s supplying at full pressure

Whilst this may add additional expense to your customer’s bill, it is far more cost and time-effective than having to fit another turbo, and potentially an engine, when they return with the same issue soon after.

For a right-first-time service, and few customer comebacks, remember to always diagnose and fix what caused the original unit to fail. Or you risk the replacement turbo failing too.

WANT TO KNOW MORE? FOR MORE INFORMATION

WWW.RDR.LINK/AAS009

KNOW YOUR PARTS

Bedding in brakes

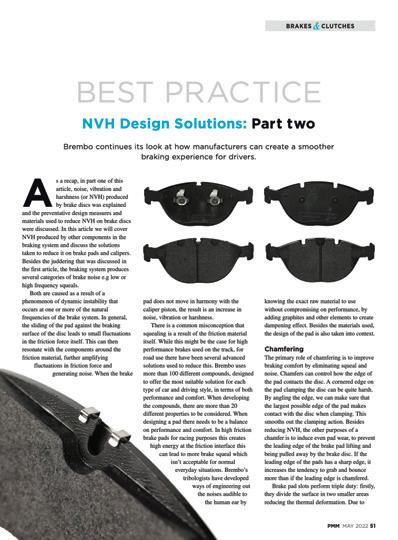

The brake pad is half the friction couple, with the brake disc being the other half, and both have to work together in order to deliver safe and reliable levels of braking under a wide range of operating conditions experienced in service. How they perform together will also influence the NVH (noise, vibration and harshness) behaviour of the brake and their service life.

Bedding the brake is thus an important step in having your brakes work safely and quietly each and every time you press the brake pedal.

Obviously, bedding the brake helps the brake pad and brake disc make progressively more intimate contact with one another – the real area of contact at a microscopic level is much smaller than the apparent area of contact – this helps ensure much more uniform loading between the two elements and avoids point contact. It also helps with

the thermal conditioning of the brake pad which is a complex mixture of different materials. This includes fibres, abrasives, lubricants, friction modifiers and fillers, all of which are bound together by a phenolic resin. With the formation of the microscopic operating film between the pad and disc that is created by the different materials in the pad interacting under operational pressures,

temperature and shear; it is this dynamic transient operating film which determines friction levels, wear rates and NVH behaviour

Bedding usually takes the form of progressively exposing the brake components to increasing levels of braking pressure and temperature. This can take many miles of driving during which the braking performance is at sub optimal levels. To address this issue, Juratek developed its Green Stripe for front axle brake pads which are designed to speed up the bedding process and deliver a great feeling brake which works straight “out of the box”.

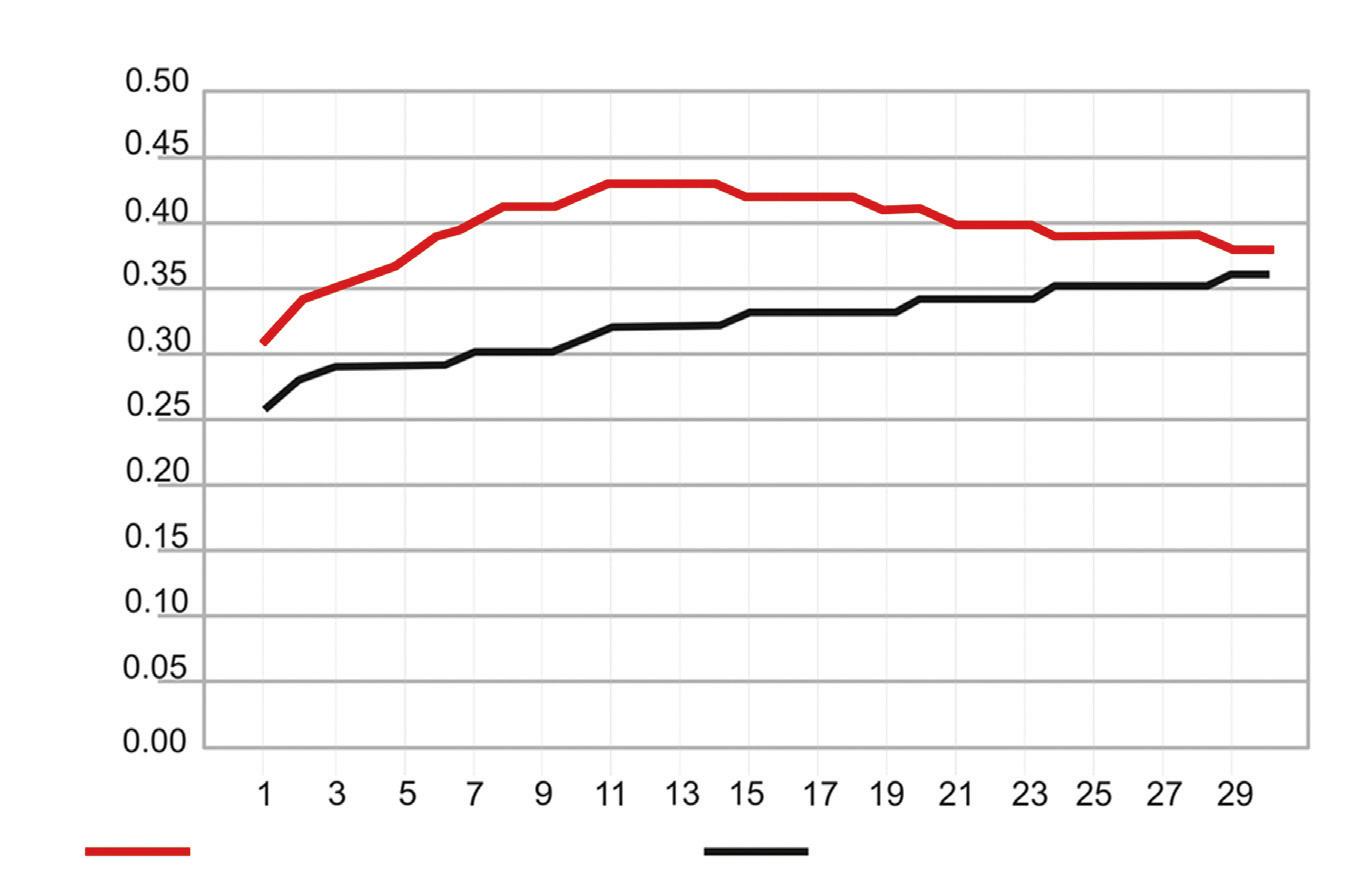

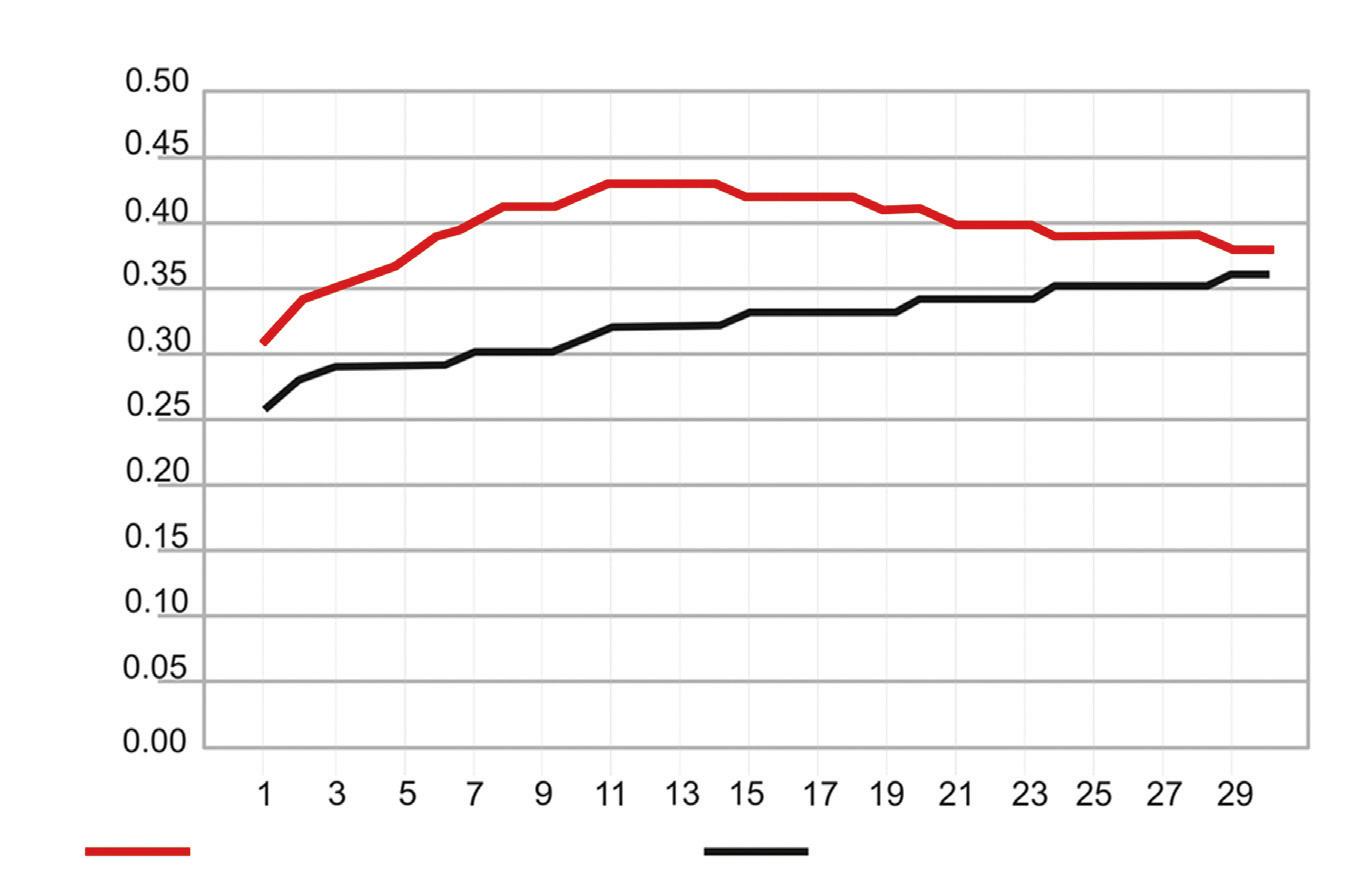

The Green Stripe consists of a mixture of high friction components held in a binder which is applied to the braking surface of the pad and then heat cured. As can be seen from the chart, it significantly reduces the time to achieve design levels of braking performance and helps in creating the interface energy to speed up conditioning of the brake pad components.

TECH TIPS 22 DECEMBER 2022 PMM

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAS022

Braking solutions provider, Juratek informs readers about the importance of bedding brakes to ensure they work safely. With Initial Performance StripWithout Initial Performance Strip Initial Performance: 80-30 kph @30 bar Brake Friction (AV)

PMM THE PODCAST

WHAT DO CHANGING A BATTERY, CHANGING A BABY (JUST THE NAPPY) AND CHANGING YOUR MORNING RADIO STATION ALL HAVE IN COMMON?

THEY OFFER THE PERFECT OPPORTUNITY TO LISTEN TO THE PROFESSIONAL MOTOR MECHANIC PODCAST WITH KIERAN NEE.

HEAR ADVICE ON PRICING JOBS, MANAGING PARTS SUPPLY, ELECTRIFICATION, RECRUITMENT AND MUCH MORE.

Listen on Google Podcasts Listen on Apple Podcasts Listen on Amazon Podcasts Listen on Spotify Podcasts LISTEN NOW ON YOUR PODCAST PLATFORM OF CHOICE

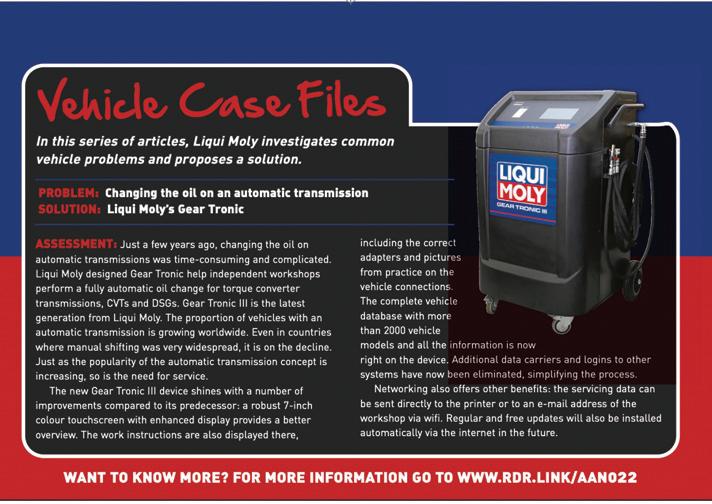

VehicleCaseFiles

ASSESSMENT: Leaking cooling systems are annoying and eliminating leaks can be very time-consuming. There is a simpler solution: Radiator Stop Leak by Liqui Moly. Simply add the additive to the coolant and it will reliably seal small leaks.

Small plastic particles are the secret ingredient of the additive. They circulate within the system together with the coolant. If the pressure drops as a result of a leak, the particles collect in this area to quickly and reliably seal the leak. The remaining particles continue to circulate within the cooling system, ready to seal the next leak.

Consequently, it is possible to eliminate leaks in the radiator (e.g. caused by stone chip) in a simple, straight-forward way. It is not necessary to replace lines or the radiator. The particles are small enough to not collect in the pump or block the filter.

For this reason, Liqui Moly Radiator Stop Leak is also great in

preventing leaks. Added to a sealed cooling system the substance constantly circulates within the system to immediately kick into action and seal any developing leaks. Vehicle users don't even notice that they would otherwise have a leaking cooling system.

The solution works for small cracks – bigger holes though are beyond the capabilities of this additive and require a complete repair.

Another great chemical tool for radiators is Liqui Moly Radiator Cleaner. Deposits in the cooling system prevent the exchange of heat and can block the thermostat. The radiator cleaner dissolves these deposits effectively. It is not aggressive to the materials: It does not contain any aggressive acids or lyes, it is acid-neutralising and compatible with rubber and plastics. It can also be used as a preventative measure during service to eliminate deposits before they become a serious problem.

In this series of articles, Liqui Moly investigates common vehicle problems and proposes a solution.

FOR MORE

PROBLEM: Leaking radiators SOLUTION: Liqui Moly Radiator Stop Leak WANT TO KNOW MORE?

INFORMATION GO TO WWW.RDR.LINK/AAS 011

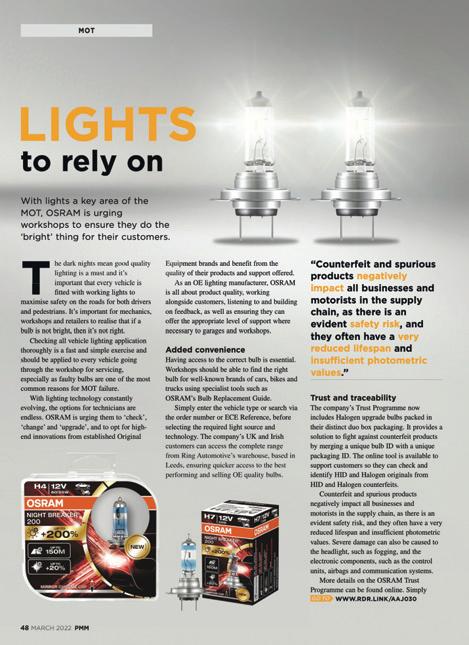

Tackling MOT FRAUD

With the amount of MOT testers disqualified on the rise, as reported on PMM ’s website recently, we thought we should hear from DVSA to see what they are doing to tackle the problem. Here, DVSA’s head of regulatory services and transformation, Caroline Hicks, outlines the lengths the organisation is going to to prevent MOT fraud.

The MOT is valuable in keeping the roads safe and minimising the negative effects transport has on air quality. The test being done to the right standard is essential for maintaining the integrity of the MOT.

Most test stations and testers carry out the MOT test to the necessary standard. We are really grateful for the professional nature of these, often small, businesses doing this work on behalf of the government. However, we know that some test stations do not carry out the MOT appropriately either through fraudulent intent, or through carelessness. DVSA is committed to dealing with that.

Recently released statistics (700 testers have been disqualified in the past two years – (WWW.RDR.LINK/AAS012) show how our approach to catching those that choose not to do things correctly has really paid dividends – and we would hope that they act as a warning to any other garages out there that may be flaunting the rules. Those garages and testers deliberately or flagrantly not following the rules – such as passing vehicles when they have not been tested –must understand that their behaviour is not acceptable – and they will be caught. We are getting better at catching those not doing things right!

Advances in technology, connected equipment and the additional data we receive helps us to identify where risks may occur at garages. We identify and investigate problems at test stations and with individual testers.

As well as identifying these patterns remotely, we also conduct a variety of physical interventions – for example, mystery shopper exercises or, where necessary, surveillance operations.

Under investigation

It is these individuals and businesses who we target to prevent them allowing unsafe and environmentally damaging vehicles on our roads. This also plays a part in supporting the industry and ensures that no one is unfairly disadvantaged by the greed and criminality of the dangerous few individuals seeking to dupe the system. We have increased our capability and capacity to investigate serious fraud and criminal activity using advanced technology and data analysis – and the statistics show it is working.

In the most serious cases, we will prosecute and ban testers or those that manage garages from the MOT. We are determined to ensure vehicles are receiving high quality roadworthiness checks (MOTs) to help keep Britain’s roads among the safest in the world.

In cases where tests are not being carried out to a good enough standard we will investigate. If we identify shortcomings in the delivery of these tests, and we determine it to be a resolvable or minor quality issue we will work with testers and stations to educate and enable the delivery of MOT tests.

We are fortunate to have so many compliant, trustworthy, and honest garages who deliver the MOT safely. We are fully committed to tackling and removing those in the MOT industry who undermine road safety and the integrity of the scheme.

If you believe there is an MOT tester who is committing fraud, we would be grateful to hear from you. We aim to investigate in all cases and will respond to any evidence supplied proportionately. For those managing garages and involved in testing, there is a wealth of guidance material on gov.uk on what is expected – including the MOT Testing Guide and the Testers’ Manual.

PMM DECEMBER 2022 25

BUSINESS & TRAINING WANT TO KNOW MORE? TO REPORT AN INCIDENT WWW.RDR.LINK/AAS013 FOR THE MOT TESTING GUIDE WWW.RDR.LINK/AAS014

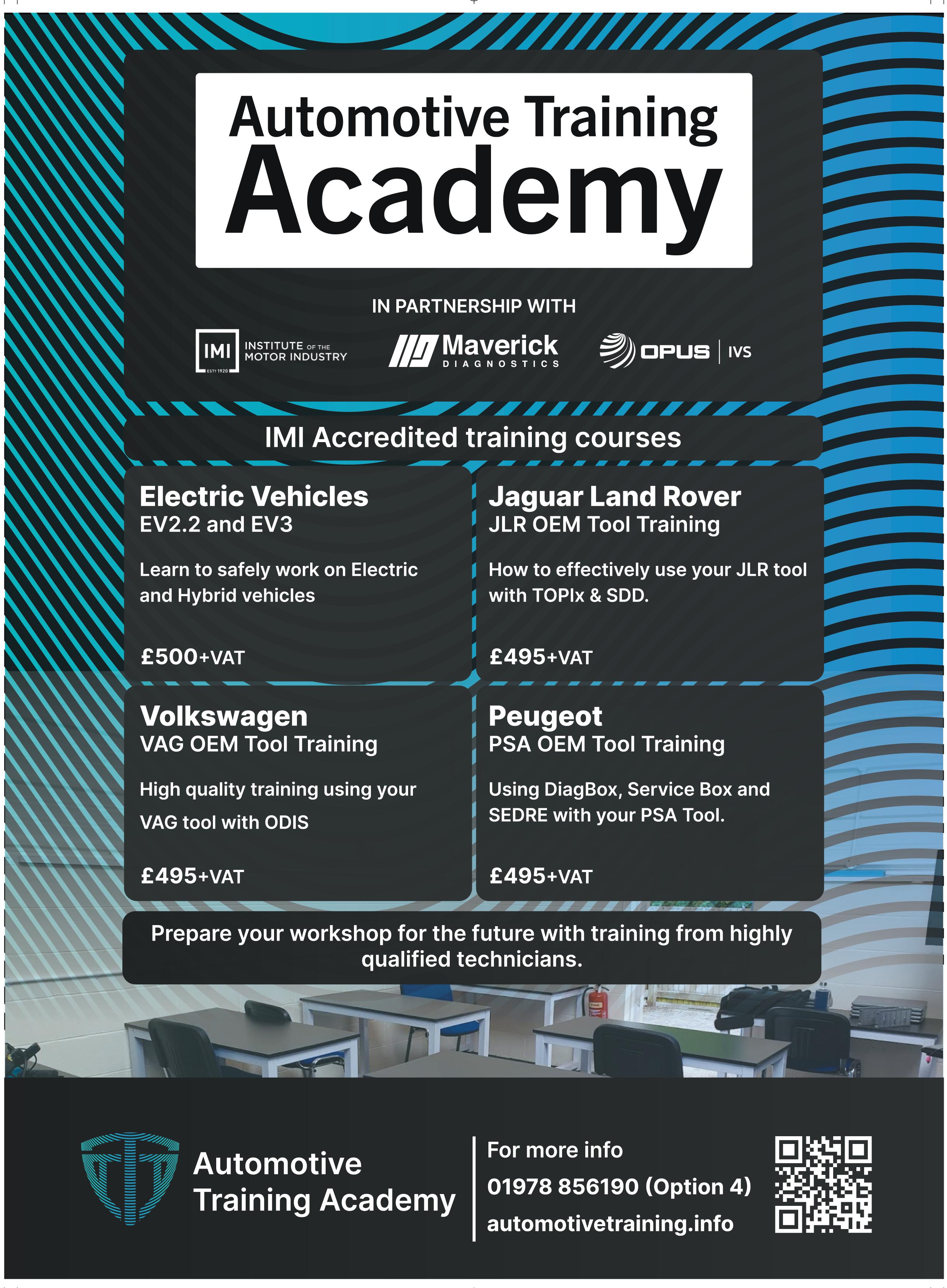

As vehicles become increasingly harder to access, investing in the right diagnostic solution is becoming more important for independents. Here, Delphi Technologies takes a look at why you need to think about the future as well as the present when shopping for diagnostic equipment.

FUTUREPROOF your business

It might be impossible to predict the future but it’s not out of the question for independent garages to ready themselves for any emerging trends in the aftermarket. Of course, being aware of changes, such as the rapid increase in cars with ADAS or some form of electrification, is one thing for garages, but having the equipment and the relevant training to evolve their service to suit is something entirely different.

“The shortage of technicians, especially outside of franchised dealerships, who are skilled to work on the complex technologies that are increasingly found in today’s cars is well documented. However, what’s not so apparent is the limited availability of hardware and software solutions that will be required in future to perform even some of the most basic automotive repairs,” said Julian Goulding, UK marketing manager, Delphi Technologies Aftermarket.

“As an example, it’s getting much harder to perform diagnostics on new cars as manufacturers incorporate Security Gateway technology, which works to protect the vehicle from hackers who may want to unlawfully access its systems. It’s scenarios like this that means a garage must choose its hardware very carefully if it is to have equipment that will be effective in the future as well as the present.”

Goulding continued: “The challenging financial climate makes selecting the correct diagnostic hardware even more important. Not only do the right diagnostic tools allow garages to explore other revenue streams but they also ensure a level of futureproofing, as the last thing any business wants to do, especially now, is buy more equipment than they need to.”

Decisions decisions

The availability of a huge array of diagnostic tools and fast-moving developments in the automotive industry mean it’s not the easiest task for garages and technicians to identify the best for them, but help is at hand from established suppliers like Delphi Technologies.

With decades of OEM expertise, Delphi Technologies is one of the very few businesses within the aftermarket to have such a comprehensive insight into emerging automotive trends. Consequently, it can apply this knowledge to its far-reaching aftermarket offering, whether it’s the introduction of first-to-market components, supplying unrivalled training support or developing class-leading garage equipment.

An illustration of this is the brand’s latest DS180 BlueTech diagnostic tool. It removes the guesswork for garages, coming complete with the technologies and capability that will ensure a workshop is able to future proof its diagnostic operation. Included in its specification is Pass-Thru capability, which opens the door to services such as ECU programming that were previously the preserve of franchised dealers and their OEspecific tools, as well as the support and calibration of most modern ADAS features. Security Gateway functionality is also a welcome feature.

Reassuringly, Delphi Technologies support doesn’t stop with the supply of its industryleading diagnostic tool. Although the DS180 BlueTech is designed to be easy to use and to remove any doubt for users as to what actions are required, such as instantly confirming when an ADAS recalibration is required, Delphi Technologies has made it even easier to operate with the availability of several related, ‘how to’ courses on the Delphi

BUSINESS & TRAINING

26 DECEMBER 2022 PMM

Technologies Academy – the company’s elearning platform.

In addition to the easy-to-follow guides that run users through how to physically operate the tool, the Delphi Technologies Academy adds videos that complement the DS180 BlueTech’s advanced features. Again, Security Gateway is a prime example. The elearning platform features a series of guides that introduce and explain the technology, providing an invaluable insight into how the Security Gateway functions and how it can be correctly negotiated to allow fault-finding. Notably, it details the need for manufacturer ‘tokens’ when there is the need to adjust settings install software updates.

These tokens are usually only available through the official OEM service site. Each individual OEM group has its own website –Volkswagen Group has one method, Fiat Chrysler Alliance another and so on. The Delphi Technologies Academy training takes viewers through the necessary steps to gain

access to the vehicle’s Security Gateway and get customers back on the road. The ‘how to’ element shows the steps needed to acquire a security token, with the BlueTech unit able to access many OEMs’ token requests via a onetime online form, saving technicians the hassle of registering each time they come across a different brand. Once registered through the Delphi Technologies site, the repairer’s credentials are saved for the next time they’re needed, saving valuable time. What’s more, registering through the DS180 BlueTech tool also removes any additional costs for accessing the OEM sites as this cost is included within the Delphi Technologies software license.

“The hurdles placed in front of independent repairers by automotive manufacturers are growing and while they may seem daunting, Delphi Technologies’ answer is to simplify diagnostics as much as possible. We do this by providing advanced yet simple to use diagnostic tools that are complemented with expert technical support and concise, efficient training to empower technicians in a friendly and accessible way,” added Goulding.

“Essentially, what we’re striving to do is give standalone garages the tools to secure their future, while also removing all the worry that they may have in regard to determining whether a diagnostic tool will enable them to grow their business and, perhaps most importantly, if it will be a waste of investment.” WANT TO KNOW MORE? FOR MORE INFORMATION

WWW.RDR.LINK/AAS015

The FAMILY way

Nestled on an industrial estate not too far from the rust-inducing salty air of the English Channel, Bognor Regis-based Hutchings Vehicle Services started out as a go-to centre for French-made cars from the likes of Citroën and Peugeot. Since opening its doors in 2005, however, the business has evolved into an all-makes garage that is part of the Eurorepar Car Service network.

“This is it!”, is Liz’s response when asked about the team at Hutchings. Indeed, while the business has gone from strength to strength, growing its customer base and expanding its service offering, Liz and Roy have never needed to bring in additional staff.

The pair, it seems, have been able to make things work by having a clear understanding of each other’s strengths and weaknesses. “I may not be allowed to touch emails,” says Roy, “but the workshop is my pride and joy. No matter what happens, we always work together when we need to.”

Behind the scenes and in the office is where Liz works her magic – taking care of every customer’s individual needs. It’s thanks to her quality of customer service that people come back time and time again.

“Having Liz in the office is very handy. People don’t want some greasy mechanic telling them what’s wrong with their car,” explains Roy. Confirming her husband’s sentiments, Liz says that “I tell the customers what they need to know, without all the jargon. They don’t need any of that tech talk that the average person won’t understand.”

Providing peace of mind

“It’s all about managing expectations,” she continues. “We make it our mission to ensure that the customer gets a fair price for any given job. If it’s a cambelt job, for example, a lot of garages will simply give a fixed price for a cambelt. But, of course, when you do a cambelt job, if it's driven by a water pump, you want a cambelt, a water pump, and a drive belt. We break down the price to let the customer know exactly what they need.”

For Roy, another secret to Hutchings’ success is his desire to keep up to date with industry news and developments. “I’ve always tried to keep up with what’s happening. The only problem for me is that whenever I need to attend a training course, I have no choice

Over the past 17 years, Roy and Liz Hutchings have built a workshop business driven by teamwork. Now they are enhancing their offering with the backing of Eurorepar’s supply network.

“We make it our mission to ensure that the customer gets a fair price for any given job”

SPECIAL REPORT

Liz Hutchings

28 DECEMBER 2022 PMM

but to shut the garage. This can make it quite difficult to stay on top of technical training and current practices, but it has to be done.”

To supplement his training, Roy keeps his knowledge topped up by reading trade magazines and by scrolling through technical and business content on YouTube and Facebook. But Roy has something else up his sleeve that is even more valuable.

“I was an early adopter of the EV training programmes. We’re geared up to work on electric cars as they gradually take over the market. I think that hydrogen and electric hybrid powertrains will dominate the market going forward, but whatever the outcome, we’ll be ready”.

Roy is already beginning to notice changes to the type of work that he carries out on a day-to-day basis. At present, providing diagnostic services to customers with electric cars is becoming much more common.

run by the Stellantis Group – Hutchings benefits from business, technical and marketing support, as well as access to one of the most comprehensive ranges of spare parts for all major makes and models. Of equal significance to Roy and Liz, however, is the fact that they remain proudly independent, focused on honest service and a willingness to go the extra mile for their customers.

Joining Eurorepar gave Hutchings a sense of security, but also a new sense of direction

The network’s professionalism, quality of parts and support are second to none. Eurorepar doesn’t discriminate, no matter the size of your establishment. But the main thing that sets Eurorepar apart from other initiatives is the value for money when it comes to parts – you’d struggle to beat it.”

Adding to Roy’s comments, Liz explained that “there was a time when we had a vehicle in the shop that we needed a part for, but the part wasn’t available in the country. Yet somehow, Eurorepar managed to get hold of the part –and it arrived all the way from France.”

“There’s no doubt that we’re excited about the future. There will certainly be challenges, but each day presents a new opportunity. With the continued support of Eurorepar and our loyal customers, we’ll always be proud to serve our local area.”

PMM DECEMBER 2022 29

“To supplement his training, Roy keeps his knowledge topped up by reading trade magazines and by scrolling through technical and business content on YouTube and Facebook”

TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAS016

WANT

FEMALE FOCUS

Restoration for good

PMM ’s Freya Coleman hears from Jody Bevan of MNJ Autocare about her journey in rescuing a classic car and raising money for charity.

Jody Bevan has been in the motor trade for 25 years, starting in 1997 in Saddleworth working on commercial vehicles, plant and machinery as well as everyday cars for routine maintenance and MOT preparation. Now, she owns her own business ‘MNJ Autocare’ in Springhead, Oldham.

She always had a dream to work on classic cars so when an old ford’s unit was offered to her behind her current workshop she couldn’t refuse. As a result, Jody has recently opened the new workshop ‘MNJ Classics’ but her first quest was to raise money and awareness for a chosen charity

whilst saving another classic car. Jody came up with the idea of purchasing an affordable starter classic car, that she and her team could recommission and raffle – all whilst documenting the affair on her Youtube channel ‘Auto Lass’.

After getting her friend Sarah Crabtree onboard, known from the TV show Bangers and Cash, to source a suitable starter classic car she could save and raffle, it became time to select the charity. Jody landed on the UK Sepsis Trust having suffered sepsis and septic shock herself in 2019, almost losing her life. Sarah sourced a 1981 Morris Ital 1.7HL and they chose the name –Igor.

Bump in the road

With everything set, Jody and her team got to work. They gained some sponsors who have been alongside Jody every step of the way, including Lucas Oil, Sykes Pickavant and Frost Restoration, with huge support also coming from ‘GEO Garage Equipment Online’.

There was sadly an unforeseen delay with Jody suffering two minor strokes in May causing her to be absent from work. However, Superman Errol as he is known on social media and YouTube or Errol Atherton –an 81 year-old friend of Jody’s and her team, also ex motor trade – took over Igor’s transformation for Jody in her absence.

Jody was able to return eight weeks later and get stuck right back in and said “it was a terrifying experience and one that I hope I never have to experience again. But life goes on and you only have one shot at life. I was so desperate to get back at it with my wonderful team. Errol really saved the day by stepping up and taking charge of Igor.”

A helping hand

Local businesses have been very supportive, offering help in any way possible. A large amount of parts and sundry items have been donated by Jody’s local motor factor ABS in Oldham (Alliance Automotive), a full set of Toyo tyres have been donated by AC Tyres in Oldham and Barclays Automotive Detailing from Oldham who fully valeted Igor and gave him a ceramic coat for free. Even Whittaker Design in Lees have shown huge moral support, creating a miniature mascot of Auto Lass for promotion.

But one business who went above and beyond is MB Autos in Mossley. Darren and Jake Moloney, a father and son team, have

SPECIAL REPORT 30 DECEMBER 2022 PMM

“I want to save the classics whilst helping others too”.

Jody Bevan

taken Igor, prepped and painted the car for free and also donated all the paint and materials, producing an incredible finish on Igor. Jody expressed her gratitude, and how she was “so grateful to the companies and businesses that have shown such great support. The Oldham business community have really pulled together on this one and when we all work together, it just shows what good can come of it”

Another one of Jody’s very good friends Craig Hughes, known from the TV series Salvage Hunters, kindly offered his services of any upholstery that needed doing. There was only the driver’s seat that required a repair, and they filmed the process throughout.

And the winner is...

The raffle live draw was set for the 24th August at Lucas Oil Products UK HQ in Llangefni, Anglesey. Craig accompanied Jody, choosing the winning ticket and the winner of Igor was announced – Brent Burnett from Liversedge.

Brent visited the Auto Lass workshop to meet Igor for the very first time. He was overjoyed by the transformation. He said that “Igor looks fantastic, Jody and her team have done an amazing job. I have watched all the videos and seen all the hard work that has gone into getting Igor to such a high standard.”

They also did the numbers and worked out that they had raised a grand total of £3,300 for The UK Sepsis Trust.

The future

Jody and her team are planning to recommission a starter classic car each year for a different charity. She says that “the next raffle car and charity will be announced soon. We have kindly been donated a car this time. I haven’t actually seen it in the metal yet but from the pictures, it looks doable and suitable. A car that ‘everybody’ knows and will have heard of” She will be announcing this in her next YouTube video, so make sure to go check it out!

Jody is also starting an ‘Auto Lass Star Apprentice’ promotion, where she is hoping to give young people recognition on her YouTube channel. Employers can nominate their apprentices and she will feature them.

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAS017

“Local businesses have been very supportive, offering help in any way possible.”

Replacing batteries on modern vehicles

Whilst some people look after their hearts better than others, everyone knows the benefits of doing so. Given that the battery is the heart of the car, the same rules apply. A bit of care and attention can pay dividends in ensuring that it increases the prospect of delivering maximum performance for longer.

Furthermore, like many other car components, when in need of replacing, the battery used to fit under the category of “one type fits all”. Today’s landscape is completely different. Indeed, as technological advancements and demands on batteries continue to abound, fitting the right battery is now an absolute necessity. This is being driven on two fronts. All modern cars are called upon to accommodate more and more electrical demands. No longer is the battery required to start the car and support the lights and wipers alone, but an expanding ensemble of systems such as air conditioning, heating, screens, electric seats and windows, sat navs and complete entertainment suites. Indeed, with such exhaustive power requirements coming into play, an increasing number of modern cars today feature an auxiliary battery, deployed to help take the strain.

Also at play here, which tends to exasperate the position, are cars that often only travel a few miles a day. The demand on the battery is excessive, with the poor old alternator not being given the opportunity to put anything back in. This results in a drain in more senses than one.

Start/stop

Let’s now add into the equation start/stop technology. Driven by EU legislation introduced to cut fuel emissions and improve economy, all of today’s cars feature such systems. Here, the message is a clear one –where AGM (absorbent glass mat) is order of the day, it is a replacement AGM that should be used as anything else will fail. Similarly, whilst it is possible to replace an EFB (enhanced flooded battery) with the more advanced AGM, this does not work the other way round.

The search results not only show the relevant Banner battery for the particular vehicle in question, they detail additional information in the form of the relevant part number, capacity, power rating and RRP. Extended technical information, such as the battery’s dimensions, layout, and engine compartment location can also be tapped into. The same also applies to full fitting details and the time involved in carrying out a new battery installation.

Despite being the heart of the car, the battery is a component that many motorists tend to overlook, until it fails. It then becomes a distressed purchase, and one often moaned about. But why, when compared to the cost of a tank of fuel a replacement premium battery represents genuine value for money? Let’s not forget, it will certainly keep the motorist’s car going for longer.

Battery locator

It is essential, therefore, to fit the appropriate Ah battery technology if premature failure is to be prevented. It is against this increasingly bespoke battery backdrop that manufacturers are playing their part in ensuring that locating the right battery is also now far easier than ever before. Look-up tools such as Banners Battery Finder (find URL below) are simple to tap into and vehicle registration number driven.

So whilst failure of the battery in a car is never life threatening, having one that is fit for purpose will not only keep your customer’s car ticking over but capable of meeting the day-to-day demands placed on it. The days of the budget battery are over and those fitting incorrect technologies shall face the consequences. After all, it’s worth remembering here that if we as humans found ourselves in need of a replacement heart, how many would opt for the budget variety?

PMM DECEMBER 2022 33

BATTERIES & IGNITION

TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAS018

Banner Batteries is hoping to provide technicians with the information and confidence necessary to successfully replace the beating heart of a car – the battery.

WANT

BEST PRACTICE

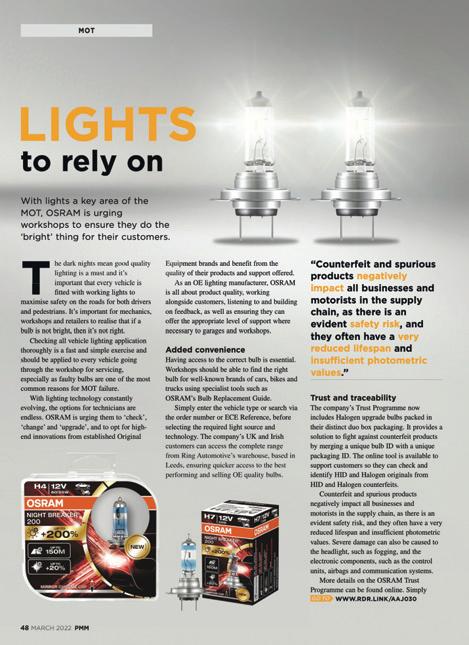

COMMON FAULTS Spark plug issues

TRACKING

OIL FOULING

Appearance Firing end of spark plug is ‘wet’ with lubricating oil.

Cause Usually a sign of advanced engine wear (excessive volumes of oil in the combustion chamber), oil fouling can also be caused by a fault in the crankcase breather system.

Effect Misfire due to oil deposits covering the firing end of the plug preventing the spark from ‘jumping the gap’.

Remedy Rectify the cause of excessive oil in the combustion chamber and replace spark plugs.

NORMAL SPARK PLUG WEAR/OPERATION

Appearance Greyish tan to white colour around the insulator, at the firing end.

Cause & Effect Confirms that the spark plug is in the appropriate heat range and has been firing correctly. Also indicates that the fuel and ignition systems are working efficiently and the engine is mechanically sound.

Remedy None required other than to check the spark plug gap and replace in line with manufacturer’s recommendations.

Appearance Black burn marks (carbon tracks) running vertically down the spark plug insulator towards the shell.

Cause Current discharge from the top terminal of the spark plug, down the outside of the insulator to earth; due to poor fitting/worn spark plug boot.

Effect Engine misfire.

Remedy Replace the affected plug(s) and plug lead(s).

OVERHEATING

Appearance Chalky white insulator (with no tan colouring) pitted or blistered electrodes. In some cases, the insulator will begin to turn grey or dark blue.

Cause Improper heat range plug, lean air fuel mixture, incorrect ignition timing, insufficient plug tightening torque and general engine overheating.

Effect General poor running conditions.

Remedy Identify the cause of overheating and rectify. Replace spark plugs in line with manufacturer’s recommended heat range.

ASH DEPOSITS

Appearance Light brown deposits encrusted on the centre and/or ground electrode.

Cause Often due to excessive fuel (or oil) additives, however, general engine wear can have a similar effect on the spark plug.

Effect Ash deposits can ‘shield’ the spark, leading to misfire problems.

Remedy Ensure plug is of the proper heat range and check for engine wear.

FUEL ADDITIVES

Appearance Reddish/brown or purple deposits/coloration on the core nose insulator.

Cause Use of fuel additives.

Effect Misfire. Normally additives are non-conductive – some are, however, and if the deposit build-up is excessive, it can create an earth leakage path for the spark.

Remedy Replace spark plugs and ensure that any additives used are compatible with the engine manufacturer’s ignition and emission systems and added in the correct proportion.

BATTERIES & IGNITION 34 DECEMBER 2022 PMM

Champion Spark Plugs offers readers of PMM a handy guide to spark plug diagnosis.

WORN-OUT SPARK PLUG

Appearance Centre and/or ground electrodes are rounded and the gap is excessive.

Cause General wear (spark plug has come to the end of its life). However, the greyish tan/white colour indicates that the plug is in the correct heat range and that the fuel/ignition systems and engine are generally in good condition.

Effect An increased gap will multiply the workload on the ignition system and may cause misfire, poor fuel economy, and damage to other ignition components.

Remedy Replacement is recommended with new plug of the same heat range.

COLD/CARBON FOULING

Appearance Soft, black, sooty deposits on the firing end of the plug.

Cause Rich air-fuel mixture, weak ignition, spark plug too cold or repetitive short journeys.

Effect Carbon deposits are conductive and can create earth leakage paths, often resulting in misfire problems which can lead to catalyst damage.

Remedy Check fuel and ignition systems, general engine performance and driving style before plug replacement. Confirm that the spark plug (part number) is correct for the application.

CORONA DISCHARGE STAIN

Appearance Discoloration of the ceramic insulator, near to the shell.

Cause Particles of oil/gas (in the spark plug well), becoming attracted to the ceramic by the magnetic field created by the high voltage current flowing through the spark plug.

Effect Not detrimental to spark plug operation.

Remedy Ensure that spark plug “well” is clean when installing new spark plugs.

DETONATION

Appearance Light detonation will cause black/grey spots on the insulator or ground electrode. Severe detonation can crack or even break the insulator or ground electrode.

Cause Abnormal combustion, causing pressure spikes/shock waves in the combustion chamber. Can result from inoperative exhaust gas re-circulation system, defective detonation sensor, lean air fuel mix, incorrect fuel octane rating or spark advance and loose fitted spark plugs.

Effect Misfire and/or general poor/uneven running which may result in engine damage.

Remedy Identify the cause and replace the spark plugs.

PRE-IGNITION

Appearance Melting (or partial melting) of the ground and/or central electrode.

Gasket shape on an incorrectly tightened plug

Gasket shape on a correctly tightened plug

SPARK PLUG TIGHTENING

Appearance Spark plug gasket has not been sufficiently crushed (see images).

Cause Incorrect tightening of the spark plug.

Effect If the plug is too loose, correct heat dissipation will be prevented, resulting in overheating of the plug which can lead to pre-ignition or detonation problems. Conversely, if the plug is too tight, damage may result to the insulator and internal components causing operating problems.

Remedy Tighten spark plugs to the manufacturer’s recommended torque value.

Cause Spark plug too hot, air fuel mixture excessively lean, incorrect ignition advance, defective exhaust recirculation system, faulty detonation sensor, cross induction in the spark plug leads or worn engine components.