MOTOR FACTOR

DIAGNOSTICS & TOOLS

REMANUFACTURING

DENSO pushes environmental benefits into limelight

PROFESSIONAL DECEMBER

Hundreds of new lines in Sealey’s latest promo

2022

VOLUME 22 ISSUE 11 DECEMBER 2022 6-9 NEWS 15-23 BUSINESS & TRAINING REMANUFACTURING Wallet and eco-friendly product by Carwood..................................................................................28 Autoelectro bolsters hybrid portfolio..................................................................................................30 DENSO pushes environmental benefits of remanufacturing into limelight............................32 How parts are produced ‘really makes a difference’......................................................................34 DIAGNOSTICS & TOOLS Hella Gutmann ‘paving the way for the future of the independent’....................................................................36 More solutions from Tool Connection!................................................................................................................................37 Hundreds of newlines in Sealey’s latest promo..........................................................................................................39 PROFESSIONAL MOTOR FACTOR DECEMBER 2022 I 3 REGULARS Viewpoint...........................5 News....................................6 Factor Focus....................10 Product Spotlight..........40 10-14 PEOPLE & INDUSTRY 24-27 MARKET TRENDS & ANALYSIS CONTENTS

Editor TOM HENMAN Group Editor KIERAN NEE Group Manager ROBERT GILHAM Senior Account Manager ALEX DILLEIGH

Design DONNA BOOTH

Editor TOM HENMAN Group Editor KIERAN NEE Group Manager ROBERT GILHAM Senior Account Manager ALEX DILLEIGH

Design DONNA BOOTH

Goodbye, old friend!

Group

Production Manager CAROL PADGETT

Production

Assistant KERRI SMITH

Professional Motor Factor is an essential business magazine for those with decision-making responsibilities within motor factors.

To be removed from this magazine’s circulation, please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Walstead Roche

Published by HAMERVILLE MEDIA GROUP

Regal House, Regal Way; Watford, Herts; WD24 4YF

Tel: (01923) 237799

www.pmfmag.co.uk tom@pmfmag.co.uk Twitter: @PMFmag Facebook: @ProMotorFactor

LinkedIn: Professional Motor Factor Magazine

Copyright © 2022

There’s no escaping the gloomy economic or geopolitical forecast, and I’m sure you’ll join me in hoping next year will bring some muchneeded positive news and we’ll see light at the end of the tunnel.

I’ve touched upon the various challenges and realities over the last couple of months, so, as this is the last issue of the year, I wanted to share some of my highlights: bringing this magazine to you gives me tremendous satisfaction, but, more than that, bridging the gap between magazine and reader gives me greater pleasure.

Being invited to factor premises, leaping on a factor storyline or being met with genuine enthusiasm when approaching factors for comment or interview – national distributor or independent – has, I believe, generated stronger, more personal and engaging content.

There is an appetite to be part of the Professional Motor Factor journey, and I’m grateful for all those that have responded positively to my e-mails, social messages, phone calls or requests in the magazine itself – it puts the magazine in a good place heading into 2023. Of course, I don’t get everything right, so please continue to offer constructive feedback too.

Next year, I’ll be back out in the field – more so than ever! – and hope my commitment to you will be warmly greeted and reciprocated.

A special thanks to our commercial partners; without them, we wouldn’t be able to bring you the magazine every month, digital material, and, now, the podcast content –Professional Motor Mechanic Podcast, in case you’ve not listened to it yet! Something to do over the next couple of weeks, perhaps!?

It’s not lost on us that marketing, during tricky economic times, can be one of the first departments to be hit. I would argue, however, that brand health during a recession is even more important, and studies would back that up too: in Peter Steidl’s Survive, Exploit, Disrupt: Action Guidelines for Marketing in a Recession, he notes that companies that increased spending during a recession actually saw a 4.3% increase in profits, compared to those that cut their budgets (0.8% increase).

Professional Motor Factor: Certificate of Average Net Circulation for the 11 issues distributed between July 2021 and June 2022

Net total: 3,260 United Kingdom: 3,260

Before I leave you for a couple of weeks, as you may have read in the national press, Ford has confirmed that the production of the beloved Fiesta will stop next summer after 47 years. Of course, you’ll be selling replacement for years to come, but to hear that the humble supermini will be killed off is genuinely sad.

Like many of you, I owned a Ford Fiesta; in fact, my first car was a silver X reg 1.25 Zetec – I always emphasised the Zetec bit! – with a white instrument cluster and botch job of a radio fitted. I was one of the first in my school year to pass a driving test, so, as a result, the responsibility fell onto me to either ferry my mates around, or be used as a taxi driver by my parents, but I didn’t care because I loved the car!

Yes, I ran out of fuel on the A6 in Bedfordshire and, yes, I crashed it on my parents’ drive despite only trickling along at 4mph, but it pained me to get rid of it and it remains one of my favourite cars to have owned.

If you’ve got a Fiesta story, why not send it over to tom@pmfmag.co.uk? I’ll include it in the January issue.

In the meantime, on behalf of everyone on the Professional Motor Factor team, I wish you and your family a happy Christmas and a prosperous new year.

Tom Henman Editor

Tom Henman Editor

PROFESSIONAL MOTOR FACTOR DECEMBER 2022 I 5

As we edge towards Christmas, wave goodbye to one year and welcome a new one, I hope you all have an opportunity to recharge the batteries and spend some quality time with family during the festive period, and you return to work full of verve and enthusiasm.

VIEWPOINT The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication. (Pg 18) ©New Africa/AdobeStock (Pg 24) ©Dusko/AdobeStock (Pg 25) ©standret/AdobeStock (Pg 32) ©blacksalmon/AdobeStock

GSF holds annual Servicesure awards ceremony – Oly’s Autos comes out on top!

National garage chain Servicesure, owned and operated by GSF Car Parts, has crowned Oly’s Autos the Autocentre of the Year in its annual awards.

The Rhyl business won the top award, beating stiff competition from a Servicesure network of more than 600 independent garages from across England, Scotland and Wales.

The fifth annual Servicesure Autocentre of the Year Awards, held at Coombe Abbey in Coventry, brought together nominees, event sponsors and representatives from GSF.

Oly’s Autos Owner, Oliver Basketfield, said: “We were completely shocked, happy and excited to have won the award. We try really hard to put everything we can into the business, so it’s great to get this kind of recognition to show we’re doing it right.

“The business has grown over the years,

and Servicesure (has) offered us great support since we became a member. In particular, we’d really like to thank Ben Spencer from the Servicesure team and Andy Jones Williams at GSF Rhyl for their service and support.”

Established in 2019, Oly’s Autos is run by husband and wife team, Oliver and Emma, servicing customers across Rhyl, Denbighshire and Conwy.

The awards’ independent judging panel also cited Oly’s Autos’ easily navigable website, the quality of their workshop and demonstrable commitment to safety as key factors behind their win.

GSF Car Parts Managing Director for Branch Sales and Operations, Steve Gray, said: “With more than 600 Servicesure members across the UK, it takes something really special to come out on top at these awards, and that’s exactly what Oliver and

LKQ Euro Car Parts reveals training tier upgrade

LKQ Euro Car Parts has launched a new membership tier for its LKQ Academy to ‘give technicians more flexibility in their training journey’.

The LKQ Academy Platinum offers workshop customers access to 20 training days – across 25 locations – and 20 eLearning courses annually for £2,499 a year, with no limit to the number of staff who can be trained.

The new Platinum membership covers the full LKQ Academy training catalogue. Resources range from technical education to business support and management courses.

All courses are IMI-approved and are updated regularly to reflect the latest trends in the independent aftermarket.

For individual technicians, LKQ Academy also offers Gold, Silver and Bronze tier memberships, which begin at £649 for a 12-month period.

“The Servicesure Autocentre of the Year Awards celebrate our member garages delivering a first-class service to their customers, just as everyone at GSF’s 180-plus sites endeavours to do day in, day out too.

“In the year ahead, we’ll be working closely with our stakeholders, suppliers and training providers to support new and existing Servicesure members as they adapt to emerging opportunities in the evolving aftermarket.”

MAHLE Aftermarket and Autosupplies Chesterfield relationship tightens

MAHLE Aftermarket has highlighted its commitment to supporting Autosupplies Chesterfield with the unveiling of a newly-wrapped van.

The new MAHLE-based livery will promote the MAHLE and Autosupplies partnership around Chesterfield and the surrounding areas, with the motor factor a key customer of MAHLE filtration parts and equipment.

MAHLE Sales and Marketing Manager, Jason Smith, said: “We’re delighted to promote our valued relationship with Autosupplies by displaying our branding across their fleet of vans.

“Autosupplies is a leading, well-respected motor factor across the area, so we’re proud to further support the business and attribute our brand with the company with the new livery.”

Autosupplies Managing Director, David Clarke, added: “MAHLE (is) our tier one filter supplier, and we’ve been a customer of them for many years. As our flagship brand, we’re pleased to push the MAHLE name into the aftermarket and promote our strong relationship.

“With Autosupplies Chesterfield’s hourly delivery service across such a vast area, the new livery will be seen by a large number of customers.”

6 I PROFESSIONAL MOTOR FACTOR DECEMBER 2022

the team at Oly’s Autos delivered.

NEWS

(L-R): Jason Smith and David Clarke

(L-R): Wynne Evans, Oliver and Emma Basketfield, and GSF Head of Garage Programmes, Paul Dineen

Record-breaking Ben’s Big Breakfast 2022 hailed a ‘major success’

Ben has reported that the automotive community, once again, banded together to make, bake, and sell breakfast food to show support and raise lifesaving funds for the automotive charity –breaking records in the process!

Over the course of a week, the nation got together and tucked into all manner of classic breakfast goods, such as bacon rolls, pastries, full English, and continental style morning feasts.

The event encouraged automotive colleagues to get together for a chat and check-in with each other, while also raising vital funds for their charity.

Ben Director of Partnerships, Engagement and Income, Matt Wigginton, said: “Another year of Ben’s Big Breakfast, another success. What a tremendous event it has been this time around. We’ve seen record numbers of breakfast food brought in and sold – more than any of us would have estimated.

“It all makes a huge difference. Even the simple things, like having a quick chat in the morning and checking up on colleagues, can really support them with any struggles they’re facing.

“You have no idea sometimes what your co-workers are dealing with, so that cake and catch-up really does brighten people’s days and opens a line of dialogue. Well done to everyone who donated and brought in breakfast goods, and thank you for helping us to continue supporting the people in our automotive family who need us most.”

face of strong competition from within the group’s supplier base.”

Comline Auto Parts (Comline) has been named Component Supplier of the Year by A1 Motor Stores’ members – a feat achieved for a fifth time by the all-makes brand.

Having first won the award in 2016, repeated in 2017 and then again in 2019 and 2021, Comline received 70% of the votes cast by A1 members to return to the winners’ circle.

The result was met with satisfaction by Comline and is testament to the “sustained growth and customer service enjoyed by the A1 Motor Stores membership”.

Regional Sales Manager, Alistair Large, represented Comline at A1 Motor Stores’ annual convention in Altea, Alicante, where

the brand was also the Arrival Day sponsor. He was thrilled to accept the accolade on behalf of the brand and vowed that Comline would continue its work in bolstering the partnership further.

He said: “On behalf of everyone at Comline, I am thrilled to be in receipt of this award, and I would like to thank the A1 membership for its continued support. There is no higher praise than that received from your valued customers, so being elected as Component Supplier of the Year is a fantastic achievement, particularly in the

A1 Motor Stores Purchasing Manager –Components, Toni Spiridon, added: “A1’s relationship with Comline spans many years, and we have grown this together into a thriving partnership. Comline’s success with our group is largely due to them doing the basics very well: quality product, respected brand and backed by a team that cares about supporting our members. So, there’s no doubt why our members voted for Comline as our A1 Component Supplier of the Year.”

@PMFmag ProMotorFactor Professional Motor Factor tom@pmfmag.co.uk www.pmfmag.co.uk

Comline named A1 Motor Stores’ Component Supplier of the Year – for the fifth time!

(L-R) Alistair Large and A1 Motor Stores Operations Director, Simon Salloway

MOTORSPORT ROUND-UP

TMD Friction sets arena for ‘little car meets large truck’ match-up

TMD Friction’s braking product lines continue to prove their credentials on the racing circuit, with its braking brand, Mintex, providing the stopping power to various racing and rallying championships nationwide, including Lewis Brown in the Quaife MINI Challenge.

TMD Friction’s CV braking brand, Textar, is also no stranger to high-octane circuit racing, with Textar emblazoned across the front of John Newell’s MAN racing truck in the British Truck Racing Championship (BTRC).

In a ‘little car meets large truck’ match up, Mintex-sponsored MINI Challenge racing driver, Lewis, and Textar-sponsored BTRC driver, John, sat down at the recent Convoy in the Park event to discuss how their braking applications are different.

The drivers will lean on the brakes differently, for instance, in order to find the

right over or understeer balance on each track.

Lewis said: “On corner entry, in the MINI I will tap the brakes if the rear of the car steps out in order to force understeer under braking and get the car straightened up again.

John, meanwhile, said: “It’s different in the truck racing as the opposite applies; I’ll try and slide first, rather than coast into corners as some drivers would in the MINIs or touring cars. With the brakes still on I’ll then increase power, so as soon as we’re out of a sequence of bends I’m fully on power and off the brakes to get the best run down the straight as possible.”

In the Quaife MINI Challenge, a feeder series to the British Touring Car Championship, each MINI series III hatchback racing car runs Mintex F2 brake pads on the front axle, with Mintex

M1144 pads on the rear. Conversely, in the BTRC, there is no specification on controlled, mandatory braking equipment – with all crews running any brand of brakes they want. On John’s MAN truck, though, the front pads are Textar’s highperformance pads, with trailer brakes on the rear axle.

The MINI Challenge features standard air cooling via large vents in the front bumper and aero package, with John’s specialist MAN racing truck benefitting from water cooling.

The cooling spray is applied manually to the centre of the brake disc, to keep brake temperatures as close to the 400°C optimum as possible. The water hitting the hot brakes creates a spectacle as the spray turns to steam under heavy braking, often into the first corner of the race.

TMD Friction said water cooling, in the

8 I PROFESSIONAL MOTOR FACTOR DECEMBER 2022

(L-R): Lewis Brown and John Newell

high-octane setting of the racetrack, will prevent brake fade. As the rear brake force is gradually depleted as the race meeting goes on, John can overcome this by increasing the rear brake bias every few laps.

A significant driving dynamic affected by the brake setup is tyre temperature –something that can make or break handling.

John explained: “Not having the right brake temperature can mean you have no turn in. The brake heats the disc and elevates the pressure of the tyre, meaning it heats up quicker.”

Despite the differences in power and weight, a lap of Donington Park’s National layout will only see just over 10 seconds’ difference between Lewis’s MINI and John’s MAN truck.

The MAN weighs five times more than the MINI but delivers 1,200bhp to the MINI’s 280 – with top speeds of 100 and 130mph respectively. This means on a fast circuit, like Donington Park, a MINI JCW

racing car will record a 1:12 lap time, with the MAN truck setting a 1:25.

On longer circuits, with more corners like Snetterton, the gap is similar, but relatively less when considering the lap distance, with the MINI setting a 2:02 to the truck’s 2:24.

In wet conditions, the MINI Challenge field will increase rear brake bias, to improve rear grip and set the car up to be more balanced; however, in truck racing,

this isn’t a weapon in the arsenal John turns to, in order to be able to attack in the challenging conditions.

Lewis said: “When we brake, it will usually lift the rear wheels, so in wet weather this can cause a loss of grip. When we are racing in wet weather, we’re braking much sooner. So, with the bias set rearward, the car handles much better and won’t be putting weight onto its nose and maintain rear grip.”

‘The DIY market is growing once more!’

While video calling has become a mainstay of our daily lives, the technology and usability of it can sometimes be a bit fiddly and frustrating – I think it took us 15 minutes to get going, but, once the connection established and I could see him and he could hear me, it was well worth the initial irritation.

I hope he won’t mind me saying that while I worked with Dave a few years back, I never got to know the real Dave, and I’d like to think that the hour’s conversation I had with him gave me a genuine insight into his life and career.

It started with him holding a cigarette in one hand, with a can of a well-known diet soda in the other, and I initially wondered if he thought I was Jeremy Paxman! I reassured him that my questions were not designed to trip him up, nor were they controversial – and, actually, while it was meant to be an interview, I would describe it more as a conversation that could have taken place at the local pub!

While our chat was jovial, full of humour – at least from Dave’s side! – we actually

10 I PROFESSIONAL MOTOR FACTOR DECEMBER 2022 PEOPLE & INDUSTRY FACTOR FOCUS

While restrictions on our movements may be a distant memory, video calling remains a useful tool, so when we offered CAAR Joint Managing Director, Dave Owen, the opportunity to participate in an interview, that avenue was appreciated given that Dave now lives up in northern Scotland!

(L-R): The late Mike Fisher and Dave Owen at a CAAR trade show

started on a sombre note and that was the passing of Dave’s colleague, Mike Fisher, who sadly passed away back in August this year.

Dave knew Mike for 35 years, crossing paths for the first time when Mike was a sales manager at Maystar. As a salesman, Mike had “few equals” and the pair worked together for 18 years. They’d speak every day on the phone.

Dave recalled: “The one thing that has remained a constant with CAAR – and always will be – is that we’re a family group. Members have always been our friends, people who can contact us at any time, and I can remember Mike’s delight when a new member, who had previously been part of another group, told us at one of our shows that he thought CAAR was a like a big family – the ultimate compliment that we could receive, and Mike was instrumental in that.”

Dave can still feel the pain of the countless hours he and Mike spent on their knees preparing the marquee, tables and chairs for the annual CAAR show!

Mike was a “devoted family man” and his death has left a “huge void” within the group.

Day-to-day roles

Today, the day-to-day running of the business is in the hands of Dave and chief executive, Mike Webb.

Dave, who penned a regular ‘Doris Minor’ column for Autotrade in-between factoring, is responsible for account management, member liaison and administration, but his biggest project is the upkeep of the website – we’ll come onto that shortly! – while Mike can usually be found out in the field, racking up the miles, meeting suppliers and members.

It’s a formula that’s worked well – and continues to, according to Dave: “During the COVID-19 pandemic, Mike was tearing his hair out – or he would if he had any! He was beside himself, not able to go out and enjoy the role that he thrives in. He loves meeting members and suppliers.

“During lockdown, my role was largely unchanged! It was business as usual! I got my head down and worked on our website www.caarparts.co.uk – which is an important part of our business and our USP. It gives members a much greater presence in their local area.

“For every order the website generates, it triggers far more phone calls and store visits. Because it’s a website for local people, they’ll go on, find the product they want and then, by and large, they’ll ring up the shop

and that’ll spur them on to make further phone calls or enquiries in the future.”

In effect, CAAR has one e-commerce site, which is, currently, only linked to FPS. Everything that FPS stocks, CAAR will list on its website at retail price.

How does it work? Once a customer enters their postcode on the main site, they’ll be redirected to a bespoke, storeliveried member website – I gave it a go myself, and, upon entering my postcode, I was sent to TM Autoparts in Northamptonshire.

If an order is placed online, that will be distributed by FPS and will be with the appropriate store the following day for the consumer to collect. Some CAAR members do offer carriage, but they try to avoid that, because the idea is to attract people into the store!

There are 300,000 products on the website, which is mirrored against the FPS catalogue – even commercial parts!

Dave added: “I would say 90% of orders from the website are for components – only 10% are for accessories.”

Essentially, the overwhelming majority of orders are for people that are maintaining their own vehicles – I was curious to know if Dave was surprised or, more specifically, concerned that customers were taking jobs on themselves, as opposed to referring them to workshop professionals.

He replied: “The DIY market is growing once more! A lot of the jobs on a vehicle are still straightforward. There are things, of course, that require a professional’s help, like engine

management, but brakes haven’t changed much, nor have filters or suspension. Changing spark plugs is a little more difficult, but that’s more to do with time rather than skill.

“I think we’ll see more of this as well; I’m convinced that consumers, during a recession, can’t justify (or even afford) paying garages £60, £70, £80 an hour for jobs that they can tackle themselves. If they’re not up to doing it themselves, many customers have a neighbour or a friend who is.

“The DIY market has always been with us. Mechanics, when they visit our member stores, will get a better price than consumers anyway – they’ll get a trade price. We’re competitive against large wholesalers and retailers, but we don’t heavily discount on the website.

PROFESSIONAL MOTOR FACTOR DECEMBER 2022 I 11 PEOPLE & INDUSTRY FACTOR FOCUS

“For every order the website generates, it triggers far more phone calls and store visits. Because it’s a website for local people, they’ll go on, find the product they want and then, by and large, they’ll ring up the shop and that’ll spur them on to make further phone calls or enquiries in the future.”

New members and retention

CAAR has 330 members on its books; traditionally, the group will take on between 15 and 25 new sites-a-year but lose a few as well due to movement or they decide to call it a day.

I was curious to know how CAAR goes about its recruitment drive and what incentives there are for members to, one, sign-up and, two, stay for the long haul.

Dave said: “We don’t tend to see much ‘group swapping’; we tend to gain new business off the back of new factors joining the profession or our suppliers’ reps doing an excellent pitching job if they feel that their customer would benefit from being a CAAR member. Factors will also come across our website and be impressed. It’s not easy, though; the windows of opportunity are narrowing.”

With more competition and fewer independents, I wanted to give Dave the opportunity to pitch CAAR to me!

Grinning, he said: “We always say “your business, your choice”, so nothing is imposed on you. We have great

relationships with our suppliers. We advertise CAAR (and so our member stores) in at least 10 consumer magazines every month, from Car Mechanics to Classic Car Weekly. Those readers are the people who, by and large, like getting their hands dirty, and they’ll also have their modern day-today vehicles as well as a classic!

“At the end of the year, you’ll receive great rebates, and we give you the website for free! Give it a go!”

Is CAAR a retailer or a motor factor organisation?

Dave said: “The old days of factoring and retailing have gone forever – it’s a complete meld. When I started in the trade nearly four decades ago, people couldn’t get through the door of a motor factor if they weren’t in the trade – and there may be a few that still have that mindset – but I believe 99% don’t care who the customer is!”

Fire still burning strong

Dave has turned his hand to several things during his life, like the aforementioned articles for trade magazines, but he’s also got stuck into other businesses; however, after moving to Scotland, he decided to solely focus on CAAR. After such a long career in the industry, I wanted to know what kept that drive and determination intact.

He said: “I love the game! It’s silly really, but to get the customer the right part and for the right price, so they leave with a smile on their face, is something our members still get a buzz from. A customer might’ve been to the dealer, been quoted £100 for a set of pads and they’ve sold him a quality set for £35. Wow. I love everything about it! Having a conversation with a member about their day-to-day experiences (good and bad) on the counter brings back the buzz that I used to enjoy when doing it.

“I’m getting on for 68 – I’m knocking on now! – and while I’ve been involved in family businesses for the last 40 or 50 years, I love my cars. I always have done. I’ve got a workshop, ramp etc so I can get my hands dirty and keep my eye in. It’s my passion.”

For more information about CAAR, www.rdr.link/FFP001

“Often, mechanics will ask the customer to supply the parts needed, and that’s where our members come in.”

12 I PROFESSIONAL MOTOR FACTOR DECEMBER 2022 PEOPLE & INDUSTRY FACTOR FOCUS

“There are 300,000 products on the website, which is mirrored against the FPS catalogue – even commercial parts!”

Movers & Shakers

Alliance Automotive Group

Alliance Automotive Group (AAG) has announced the promotion of Kris Halliwell, who from 1st January 2023, will be promoted to the position of director of European key accounts.

Kris has been with AAG for nearly four years, during which time he has “significantly developed” the key accounts business in both the passenger and CV segments. He joined the AAG team as part of the Platinum International acquisition in 2018, where he had been an executive board director since 2007, undertaking leadership roles in logistics, supply chain and key account strategic development.

Growth within the key accounts team is one of the “critical initiatives” within AAG’s strategic Vision 2025 plan and has nearly doubled its key account European business within the last three years.

AAG said this growth will come from an additional share of traditional customer base: fast fitters, auto centres and CV players; however, it believes there are new customer areas that can be targeted, such as insurance, leasing, fleet and new EV OEMs.

AAG is implementing digital solutions built internally and expanding workshop footprints within countries to “enhance the attractiveness” as a partner to customers.

Clarios

Clarios has recruited Theres Gosztonyi as vice president aftermarket for Europe, Middle East and Africa (EMEA).

Clarios Vice President and General Manager EMEA, Werner Benade, said: “We are excited that Theres Gosztonyi is joining our team at Clarios. She brings 18 years of profound management experience in the automotive sector. By appointing her, we aim to strengthen our customer focus and to ensure a sustainable and profitable growth in the region.”

Before Clarios, Theres acted as Michelin’s vice president B2C aftermarket, where she was responsible for northern Europe including DACH and UK. Prior to that, for more than 15 years, she worked in sales and marketing at Daimler AG, most recently as head of sales for MercedesBenz Trucks eastern Europe.

Theres said: “Mobility is one core element of people’s freedom. With the transformation of mobility towards electrification, autonomous driving and multimodal transportation, the power supply provided by batteries will play a key role. Together with my team, I will work hard so that Clarios, with its VARTA brand, stays ahead of competition and offers the right products and services for our customers and consumers.”

PEOPLE & INDUSTRY APPOINTMENTS

PMF introduces this month’s movers and shakers, as they begin a new stage of their career.

Ring’s Golden Ticket promotion

to supporting motor factors ahead of new product launches’

Ring is supporting its customers ahead of new product initiatives by running a Golden Ticket promotion. The brand believes the campaign will improve the prospects of selling its currentgeneration inspection lamps and battery care products.

Ring has hidden 200 golden tickets in various battery care and inspection lamp packs as part of the new promotion, with Amazon and Just Eat vouchers up for grabs.

Ring Marketing Director, Henry Bisson, said: “Supporting our valued motor factor customers is key whilst also rewarding loyal customers for their support throughout the year.

“Purchases of our MAGflex range of inspection lamps and high-end battery care product range all come with a chance of winning – don’t miss out!”

Featuring in Ring’s Golden Ticket promotion is the RBAG750 graphical battery analyser, which can provide a complete health check of a vehicle’s battery and electrical systems.

Compatible with both 12V and 24V vehicles, the analyser can detect battery charging problems by checking that alternator voltages fall within normal operating ranges, as well as assess the potential for starting problems by measuring battery voltage drop during engine cranking. All results can be printed on the device or sent to a computer via a USB connection.

Technicians can also win in the Golden Ticket promotion with qualifying orders of Ring’s smart charger range.

Ring’s SmartCharge RSCP5024 and RSCP60T products are designed with the

professional in mind, delivering 50A and 60A continuous charging respectively, to deal with the demand of 12V and 24V battery recharging during diagnostic or data upload work.

Ring reported that its smart charger and battery maintainers keep batteries in good condition without the risk of overcharging –automatically adjusting to long-term maintenance mode when the battery is full.

Meanwhile, also part of the initiative, is Ring’s popular MAGflex inspection lamp

range, providing technicians with the required lighting for any job, designed to offer complete versatility and reliability in the workshop.

This includes the compact MAGflex Mini 250, powerful MAGflex Max 500, the versatile MAGflex Slim 500 and the MAGflex Headtorch 250 for a hands-free option.

Ring’s inspection lamps are built to last, with impact protection rating of IK7 or IK8 and have IP54 or IP65 rating to prevent dust and water ingress. All the lamps are rechargeable via USB-C technology for a more secure and consistent charge connection.

Golden tickets will go out in orders until the end of December, and the deadline to claim any prizes is the end of January.

For more information about Ring, www.rdr.link/FFP002

PROFESSIONAL MOTOR FACTOR DECEMBER 2022 I 15 BUSINESS & TRAINING PROMOTION

‘commitment

OESAA launches training roadshow to inspire today’s and tomorrow’s automotive professionals

The Original Equipment Suppliers Aftermarket Association (OESAA) Chairman, Nigel Morgan, is encouraging you to share news of the recently launched OESAA Academy Live with your customers, so they and their apprentices can take advantage of a unique training opportunity.

OESAA Academy Live is a series of free-to-attend events dotted around the UK, which will strengthen the skills of this and the next generation.

Held at IMI-approved colleges, in collaboration with OESAA members, the inaugural event will take place at Lincoln College on Friday 13th and Saturday 14th January, with the next at Castleford College on Friday 24th and Saturday 25th February.

Further dates and venues will be announced in due course.

The format

During Friday’s morning session, a diverse range of presenters will illustrate their career paths, to show potential routes and roles in the industry. In the afternoon, participating OESAA members will hold intimate seminars for apprentices. These will be purposely designed to help further their learning and prepare them for the real-world in the automotive industry.

Meanwhile, on Saturday, working professionals will be able to immerse themselves in 45-minute sessions with those same OESAA members. These will be devised to offer a ‘taster’ of training packages directly available from OEMs.

Doors on Saturday will open from 9am for breakfast and registration, with training getting underway at 10am. The final session will conclude at 4pm.

Which brands are attending?

Brembo, DENSO, HELLA, Laser Tools, MAHLE, Schaeffler, VARTA UK and ZF have all confirmed their attendance at the opening two events, such has been the appetite for OESAA members to highlight the latest technologies and products in their respective categories, as well as offer best practice techniques – whether that be diagnosis or installation.

Brembo’s Siti Abdullah and Dale Reynolds will focus primarily on the various technological advancements of braking. Vehicles are more powerful and heavier than ever, yet the industry demands components be lighter and kinder to the environment – Siti and Dale will discuss whether traditional servicing methods are still valid.

DENSO’s Mike Sadler will present the latest on spark plugs in Lincoln and glow plugs in Castleford respectively, while Schaeffler REPXPERT, Andy Vaux, will offer a masterclass in INA engine systems.

Meanwhile, Ashley Craig from VARTA UK will deliver battery know-how on reallife, everyday challenges faced in the workshop. If technicians can’t find the battery on-board, don’t know how to program/code a replacement battery, or are unsure which technology to fit, Ashley will be there to put visitors on the right path.

Experts from Laser Tools will also be present and will open the doors to their always-popular tech van. They’ll showcase the brand’s vast array of specialist, innovative tools and be ready to discuss visitors’ questions and needs.

on young people, apprentices and professionals”

Lincoln College Learning and Skills Lead –Automotive Engineering, Pete Jackson, said: “Over the last year, I’ve been working to raise awareness of current technology seen in the automotive industry. This role has been part of my Technical Teaching Fellowship, awarded by the Education and Training

“Focus

16 I PROFESSIONAL MOTOR FACTOR DECEMBER 2022 BUSINESS & TRAINING ROADSHOW

Foundation and the Royal Commission for the Exhibition of 1851. Not only has this project raised my own awareness and that of my team, but I have been able to work with other colleges and organisations from both industry and education.

“The OESAA roadshows allow the twoday events to focus on young people, apprentices and those working in the industry. This includes teachers as well as business owners. One thing that is evident is the ‘want’ for information and knowledge from everyone I’ve spoken to. It’s great that OESAA members are taking time out to facilitate these events.”

Nigel added: “As an organisation, we have consistently demonstrated our commitment and passion in bolstering the technical and business acumen of professionals. Autoinform Live, whether hosted in the UK or Ireland, is always a well-supported event, but we are now ready to expand and take this successful model on the road – inspiring today’s and tomorrow’s generations.”

BUSINESS & TRAINING ROADSHOW

For more information about OESAA Academy Live, www.rdr.link/FFP003

Top-tips for a more energy-efficient business

With rising business costs and pressures on resources, energy efficiency has become more important than ever! Experts at Love Energy Savings, a multi-award-winning business utilities retailer, has compiled a list of useful tips to help your business improve in this particular area:

Lowering energy consumption is highly profitable for businesses. Effectively reducing energy costs means you have much more cash flow available to invest in equipment, salary increases, modernisation, renovation works and more.

Upgrade your thermostat

Smart devices are not just for domestic environments; a business can hugely benefit from investing in smart technology, especially a programmable thermostat. The thermostat doesn’t even need to be a smart device; simply installing a thermostat that can be programmed during business hours can help reduce heating and cooling costs by up to 30%, according to Carbon Trust.

Hot water heaters

Whilst also considering switching business water suppliers, investing in a more ecofriendly, energy-efficient hot water heater can be a great idea.

This is also a great idea in office environments, as water heaters can usually be installed directly where the old water heater tank was kept. This conserves energy as you won’t continue to heat copious amounts of water throughout the day.

You may also wish to consider the option of a solar hot water system. This water heating system pushes water through solar-heated tubes. Both of these options benefit from piping insulation: an inexpensive, but highly effective means of encouraging heat retention.

Install motion-sensitive light switches

Lighting costs are usually the biggest contributors to the energy bill. Simply installing motion sensors for lighting can help your business become much more energy-efficient and help reduce those energy bills.

A great place to start is in areas around your business premises that are not occupied throughout the day. This can help with saving energy, by stopping employees from leaving lights on when areas are not in use.

Make the most of daylight

Maximising the amount of daylight that enters an office space should be something that all building owners should prioritise. Make use of skylight windows, particularly on the north or south side of your building. Operable windows or skylights are an effective solution, as they allow hot air to escape when it’s warmer, which in turn reduces the cooling load.

Upgrade your lighting

LED lighting is a hugely popular choice right now, largely because of its proven energy consumption minimising effects. So, if your lighting setup needs an upgrade, LED is the way to go. Switching to LED lighting has the potential to reduce your electrical costs by up to 60%, according to Carbon Trust.

LED lighting also boasts the benefit of

minimal heat generation, ultimately lowering air conditioning load and thanks to the long lifespan of LED lighting, cutting maintenance costs, too. The majority of LED lighting users note an improvement in the clarity and crispness of their lighting, which can help make for a more productive and happier workspace.

It’s also worth switching old-fashioned bulbs for compact fluorescent bulbs with a low energy consumption. Typically speaking, lighting an office costs approximately £3 per sqm each year, compared with £1 per sqm each year in an energy-efficient office space.

Perform regular maintenance checks on equipment

Heating Ventilation Air Conditioning (HVAC) is one of the quickest and easiest means of elevating energy efficiency. The proper maintenance of HVAC systems will make for a building that uses 15% to 20% less energy than those without a maintenance plan. It’s important to ensure that your maintenance plan is inclusive of refrigerant level checks.

After-hours usage

The term ‘phantom electric loads’ refers to the electricity consumed by electronic devices when they aren’t actually in use. Devices, such as clocks on the oven or microwave and lights that are set up on a timer, are just a couple of examples. While these may seem fairly insignificant, did you

18 I PROFESSIONAL MOTOR FACTOR DECEMBER 2022 BUSINESS & TRAINING ENERGY SAVING

know that they can contribute to up to 10% of your energy bill?

The most effective way to minimise phantom electric loads is to unplug equipment where possible, or failing that, set up standby times. Another energy saving technique is to incorporate smart power strips to help ensure power is being consumed.

Switch business energy suppliers

On top of reducing energy consumption, you could also switch your commercial energy supplier. This could save your business hundreds of pounds per year. These energy saving measures can help free up cash to be invested in other areas of your business.

For more information about Love Energy Savings, www.rdr.link/FFP004

PROFESSIONAL MOTOR FACTOR DECEMBER 2022 I 19 BUSINESS & TRAINING ENERGY SAVING

Lucas Oil keen to share important message with next generation

Additives are increasingly seen as advanced engineering solutions, as toolbox accessories that should be used to support planned maintenance programmes.

That’s the message that the team broadcasted from a stand at the recent MECHANEX exhibition – which, next year, will be reinvigorated and named PMM Live. As well as targeting your customers, technical colleges and their engineering faculty lecturers are very much in the US additive manufacturer’s thoughts.

The Lucas Oil Academy wants to equip technical colleges and the young learners on their vehicle maintenance modules with a greater understanding of additive technologies. It hopes to help them accept, more readily, the use of additives and to encourage their use when they return to their professional environment.

LOA is the training arm of Angleseybased Lucas Oil UK, which distributes the range of oils, additives and lubricants manufactured by the company’s US parent. To date, the LOA team has been working with local educational establishments, such as Coleg Menai in North Wales.

There, for example, two groups of Motorsport Engineering Level 1 students have been exploring ways in which a selection of additives from Lucas Oil can help to reduce engine wear and increase overall engine performance. The project will end next year with a race-off involving project cars that each group will have built during the course.

Dan said: “It’s time to address a wider audience of college lecturers around the UK. We want to help more of them and

their young learners to understand the practical, economical and operational benefits that using additives can provide.”

Additives can be ideal solutions for a number of different running issues; for example, a diesel-driven car that’s being used mainly on the school run will be susceptible to DPF issues and may benefit from a Diesel Deep Clean additive. Furthermore, a vehicle that’s only a marginal MOT test failure may be helped to pass its subsequent re-test with the help of a fuel additive, such as Upper Cylinder Lubricant. Also, Engine Oil Stabilizer can provide greater internal engine protection for a vehicle that’s frequently parked up for extended periods.

The latest additive technologies are very advanced, according to Lucas Oil; for instance, Complete Engine Treatment was designed for – and is compatible with –fuel systems and oil systems. As well as increasing engine efficiency and fuel economy by removing carbon, tar and resin

deposits, it’s an additive that can combat impurities in the oil or in the fuel before they are deposited.

Dan added: “We also want learners to appreciate that additives are not just about treating issues within fuel and oil systems. Used appropriately, problem solving additives, such as Transmission Fix and Power Steering Stop Leak are greener, more sustainable solutions. They can also help extend component life when, beforehand, the only alternative answer might have been component replacement.”

More recently, the additive focus has been on problems associated with higher levels of ethanol in the latest E10 fuels. The potential for damage to components, such as rubber fuel pipes in older cars and even some of the newer models, has been well documented, but Lucas Oil said the ‘fuel separation’ that occurs inside fuel tanks is a direct result of the increased ethanol content in fuel. This process and its potential for adversely affecting engine performance is less widely appreciated.

With support from the LOA, the next generation will be better placed to diagnose problems that an appropriate additive solution may be able to address –it’s a win-win for mechanics and those stocking Lucas Oil products.

22 I PROFESSIONAL MOTOR FACTOR DECEMBER 2022 BUSINESS & TRAINING NEXT GENERATION

As well as reaching out to automotive professionals, the Lucas Oil Academy is geared to work with more UK technical colleges too, and that is an ambition of the company’s UK Sales and Operations Director, Dan Morgan.

For more information about Lucas Oil, www.rdr.link/FFP005

NGK Academy off to promising start

The portal includes more than 270 technical training videos across a myriad of technical subjects/components, produced by automotive training experts, Our Virtual Academy (OVA). They have also created a

suite of bespoke training videos specific to spark plugs, with further NGK/NTK product focussed training promised in the future.

The spark plug training videos, three of OVA’s core training videos and other existing NGK/NTK training content, will be

free to access once users have enrolled on the portal; however, NGK confirmed there will be a charge for accessing the full suite of 270-plus videos.

Encouraging early feedback

Visitors to the recent MECHANEX show “rushed to sign-up for a free trial”, which, ordinarily, would cost £89.99+VAT.

NGK Spark Plugs (UK) Marketing Manager, Mark Hallam, said: “Workshop visitors to our stand were eager to learn more about NGK Academy and to take up the offer with no obligation to buy.

“Automotive technology is changing rapidly, and this initiative will help technicians deal with the complex challenges that they face. Trainee technicians were especially keen to discover how they could learn new skills, which will hopefully enable them to have a successful career in the automotive industry for many years.”

NGK Academy is available online 24/7, 365 days of the year, meaning training can be undertaken during downtime.

BUSINESS & TRAINING ONLINE PORTAL

NGK Academy is here! Primarily, it is aimed at supplying essential training to your workshop customers; however, the ignition and sensor specialist is keen for you to explore its offering too, as well as share the message with your customers.

For more information about NGK, www.rdr.link/FFP006

TALK OF THETRADE

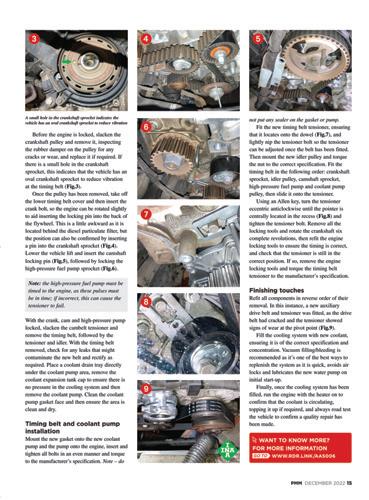

In this first article, we feature Carwood, an OE-approved turbo remanufacturer and technical service provider, and highlight oil contamination, one of the most common reasons for turbo failure:

“Since 95% of turbo failures are caused by issues other than the turbo itself, it’s important to determine why it failed and fix it before a new one is fitted. If not, the replacement unit could fail too, costing (the garage), and (their) customer, more time and money. Although accurate failure analysis can be a challenge for even the most experienced of technicians, by understanding the likely causes and symptoms, issues can be correctly pinpointed and remedial action taken.”

But what is oil contamination? The article continued: “With tolerances measured in microns, and operating speeds of over 300,000rpm, today’s modern turbochargers require a constant supply of clean, good quality oil to keep them running properly. Unfortunately, dirt, fuel, water, combustion residues and other contaminants can easily contaminate the oil, with even the smallest particles causing rapid wear to key components, and, potentially, serious damage to the turbocharger, and sometimes the engine.”

WWW.RDR.LINK/FFP007

ACtronics, meanwhile, discussed a van-related issue, specifically, on the instrument panel on a 2017 Ford Transit Custom which its team had come across:

“Simply, there wasn’t a decent power supply towards multiple devices. Strangely, though, the car was able to start with ease. “So, it can’t be the battery”, you might think. However, in this generation of the Transit Custom, two batteries are located under the driver’s seat: one is the starter battery, while the other is to supply power to the on-board network.

“And you might have guessed it by now: that second battery turned out to be the cause of all the problems… Needless to say, after replacing the battery, all problems were immediately resolved.

“Unfortunately, this situation is common with the Ford Transit Custom.

“Although in this case the instrument cluster was working perfectly fine, these devices do regularly malfunction. Devices, such as the Ford Focus II and the Fiat 500 cluster, are frequently offered for repair. Strangely enough, we’ve noticed the number of revision requests increase during the winter period.

“We suspect the lower temperatures are causing this increase. So, keep in mind there is a bigger chance of a defective instrument cluster in this period.”

WWW.RDR.LINK/FFP008

this final Talk of the Trade of 2022, where stories are pinched from PMM, we deliver communiques from Carwood, ACtronics, Champion and Andy Brooke. 24 I PROFESSIONAL MOTOR FACTOR DECEMBER 2022 MARKET TRENDS & ANALYSIS INDUSTRY INSIGHT

In

INSIDE THEISSUE

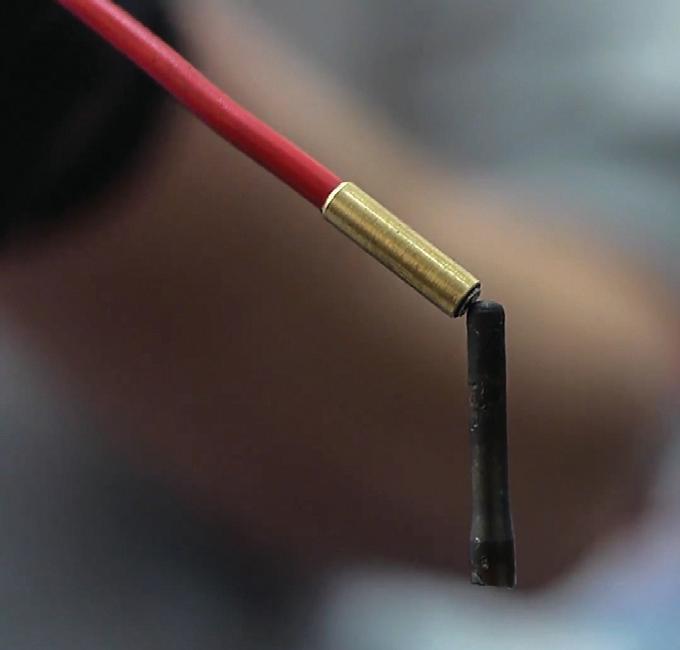

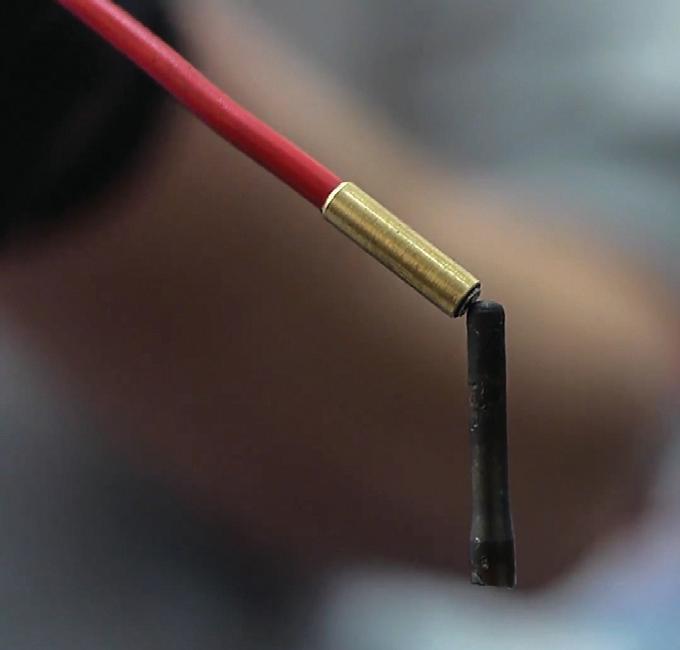

PMM readers were given an education by Champion on how to diagnose specific spark plugs issues:

Fuel additives

Appearance: Reddish/brown or purple deposits/coloration on the core nose insulator

Cause: Use of fuel additives

Effect: Misfire. Normally additives are non-conductive – some are, however, and if the deposit build-up is excessive, it can create an earth leakage path for the spark

Remedy: Replace spark plugs and ensure that any additives used are compatible with the engine manufacturer’s ignition and emission systems and added in the correct proportion

Worn-out spark plug

Appearance: Centre and/or ground electrodes are rounded and the gap is excessive

Cause: General wear (spark plug has come to the end of its life); however, the greyish tan/white colour indicates that the plug is in the correct heat range and that the fuel/ignition systems and engine are generally in good condition

Effect: An increased gap will multiply the workload on the ignition system and may cause misfire, poor fuel

economy, and damage to other ignition components

Remedy: Replacement is recommended with new plug of the same heat range

Ash deposits

Appearance: Light brown deposits encrusted on the centre and/or ground electrode

Cause: Often due to excessive fuel (or oil) additives; however, general engine wear can have a similar effect on the spark plug

Effect: Ash deposits can ‘shield’ the spark, leading to misfire problems

Remedy: Ensure plug is of the proper heat range and check for engine wear.

WWW.RDR.LINK/FFP009

PMM Editor, Kieran Nee, travelled to Wrexham to visit and interview Andy Brooke, managing director of Maverick Diagnostics and now director of the Automotive Training Academy –a newly opened academy dedicated to EV training.

Straight in, Kieran asked if readers should be focussing on EV training now – Andy was clear:

“Right now! There are so many EV and hybrid vehicles being sold in Britain –particularly hybrids. People really bark on about battery EVs, but there are more hybrids being sold.

“Technicians need to be looking at those hybrids to ensure the future of their workshop. Battery EVs are a slightly different matter, really. There aren’t as many being sold as people actually think, but there are still opportunities in there to repair battery EVs.

“There is a lot of need for EV training right now. I think a lot of people are burying their heads in the sand.

“That’s why we’ve built this facility specifically to do hybrid and EV IMI training levels one to four – four being the more sophisticated one.”

WWW.RDR.LINK/FFP010

PROFESSIONAL MOTOR FACTOR DECEMBER 2022 I 25

Auto Spares Wales comes out on top!

Professional Motor Factor continues to generate diverse, interesting content, all of which we bring to you every month. That material spills onto our digital platforms too, so to sign-off the year, we thought it’d be worth offering an insight into what’s caught the eye of our digital audience in 2022 – perhaps you’re one of them and you read the articles below!

Auto Spares Wales details its journey

“Go big or go home” was the attitude of Steve Jones and Tony Griffiths when they made the decision to inject their own cash into Auto Spares Wales, a two-branch factor in south Wales. The directors revealed their journey so far after celebrating the independent’s one-year anniversary in February.

WWW.RDR.LINK/FFP011

CTEK provides an insight into its strategy

CTEK Global Aftermarket Division and Product Manager, Gary Brown, took on our questions and offered us a comprehensive insight into CTEK’s strategy after announcing major investment in a new team and infrastructure.

WWW.RDR.LINK/FFP012

The bilstein group explains Blue Print and febi

When it comes to umbrella brands in the independent aftermarket, the bilstein group, with 21 international subsidiaries, is one that stands out. The company shed light on Blue Print and febi, as well as a tool it said makes finding parts much easier.

WWW.RDR.LINK/FFP013

Autoelectro considers evolution of remanufacturing

Autoelectro UK Sales Manager, Nick Hood, revealed why the remanufacturer chose the practice back in 1986, how the process has evolved and what the future may look like.

WWW.RDR.LINK/FFP014

Kalimex explains

how to make money from marketing

Factors promoting JLM Lubricants' products to trade customers are notching up healthy sales – with help from Kalimex, according to MD Mike Schlup.

WWW.RDR.LINK/FFP015

PROFESSIONAL MOTOR FACTOR DECEMBER 2022 I 27 MARKET TRENDS & ANALYSIS DIGITAL DIGEST

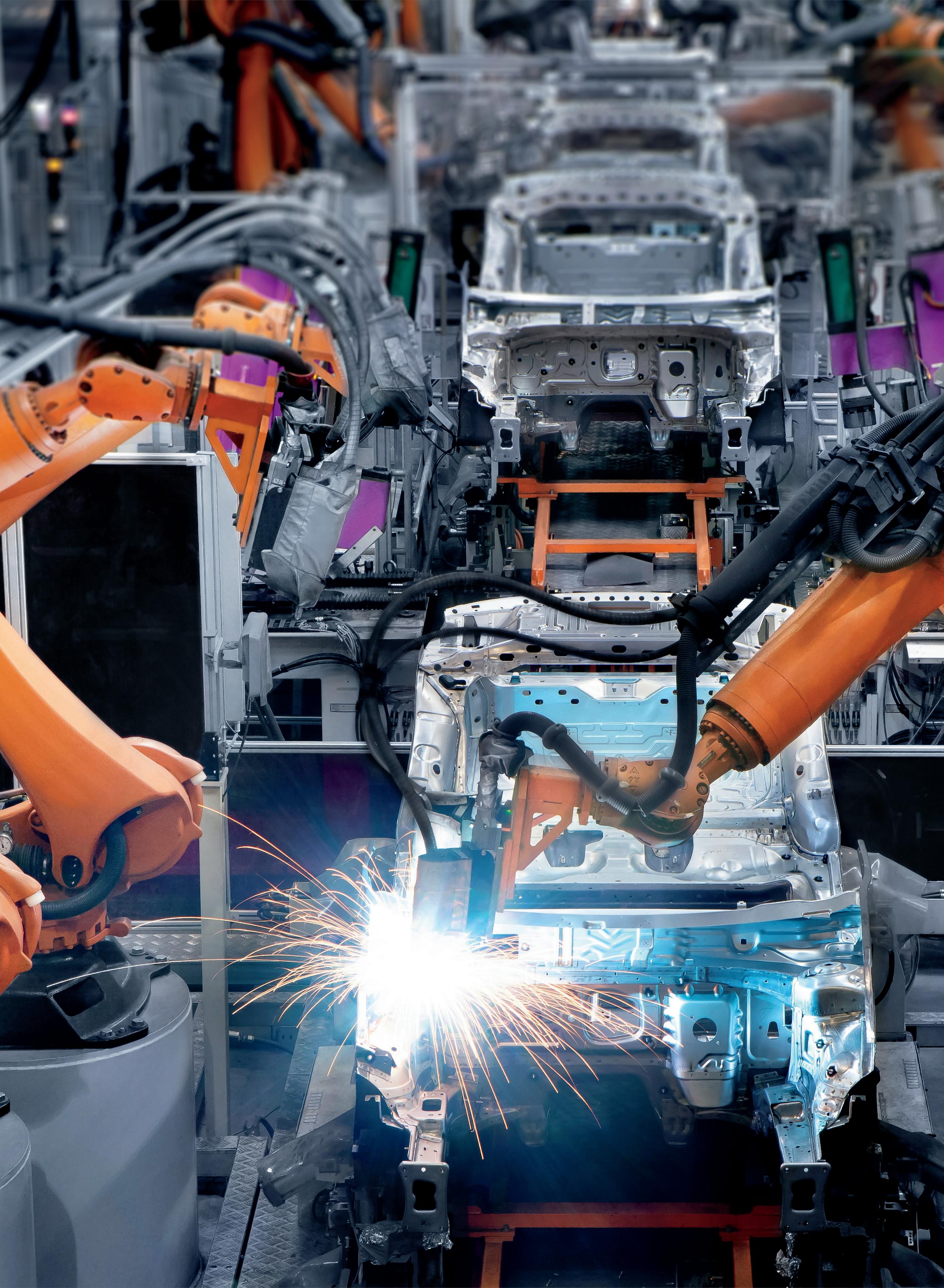

Wallet and eco-friendly product by Carwood

In an effort to tackle global warming, consumers are readily adopting more sustainable behaviours. Indeed, in a recent UK report by Deloitte, more than 40% said they would choose brands that have environmentally sustainable practices and values. The automotive industry is no different.

At the same time, soaring inflation – the

result of COVID-19, Brexit and war in Ukraine – is forcing increasingly costconscious consumers to cut back on spending. As such, around two-thirds of people believe car ownership is currently unaffordable. And, more worryingly for the aftermarket, are now choosing to delay essential vehicle maintenance and repairs.

As the climate and cost-of-living crisis

28 I PROFESSIONAL MOTOR FACTOR DECEMBER 2022 REMANUFACTURING

With the cost of living and climate crisis high on everyone’s agenda, there’s never been a better time to buy remanufactured parts, according to Carwood. Here, Carwood Deputy Managing Director, Simon Quantrell, explains what’s driving the demand, and how the brand's OE-approved sustainable solutions offer a genuine alternative to new:

deepens, creating a perfect storm for many industries, it’s easy to see why automotive businesses are adopting a cautious outlook for the future. But whilst there are challenging times ahead, it’s also an opportunity for forward-thinking companies, you included, to show that they’re willing and able to respond to changing market and customer needs –those that adapt now will be those that reap the rewards moving forward.

Remanufacturing: a solution to the climate and cost-of living crisis

One such opportunity is remanufactured product. Not to be confused with repairing or reconditioning, remanufacturing – the process of returning a used product to a like-new, or even better than new condition – is both better for the planet and the enduser’s wallet. Addressing two critical and very topical issues head-on.

So, if you haven’t already, now is the perfect time to introduce a reman parts programme from an OE-approved supplier, like Carwood.

With more than 50 years’ expertise in the automotive, defence and motorsport industries, we supply a wide-ranging programme, including OE-approved fuel pumps and injectors, turbochargers, DPF cleaning, engines, hydraulics, starters and other coil wound electrical components to companies across the globe. Amongst our customers are the world’s top vehicle and engine manufacturers, the Ministry of Defence, independent and factory-owned race teams, and of course, the aftermarket.

Whilst the fundamentals of remanufacturing may not have changed

much since we started out – parts are inspected, cleaned, rebuilt, calibrated and tested – the level at which this is done, and the know-how and equipment needed to do it to OE-standards has.

Take injector testing as an example; whereas injection systems previously ran at idle mode, full speed, and one or two other operating points, today’s Euro 6 equivalents use variable injection timings and volumes and can perform multiple injections during a single combustion cycle.

Because of this, our factory-trained technicians have to perform up to 700 test steps, using the latest OE test plans and equipment, just to calibrate the injector. This is a critical step, which allows the ECU to adjust fuel delivery and optimise engine performance when the injector is installed back into the vehicle.

Proven OE-quality at an affordable price

It’s through this meticulous, OE-driven approach, that we can offer a same-as, or even better-than-new product, with warranties to match. Yet because we reuse core, it’s a fraction of the cost, meaning you can offer your customers a cost-effective alternative to new, without compromising on the quality of the product.

Better for the environment too

But that’s not the only benefit: in retaining both the material and value added – labour, energy and processes – from the original product, remanufacturing also offers a number of significant advantages for the environment.

By reusing the core, remanufacturing can save up to 70% of the resources versus new. And because much of the material already exists in its final form, and, therefore, only a fraction of the work is required to process it, it uses a lot less energy than new too – around 85% less –and creates less greenhouse gas emissions. Finally, by keeping material in use for longer, there is significantly less waste to dispose of, meaning less ends up in landfill.

By choosing a Carwood remanufactured pump, injector or turbocharger, you can offer your customers an environmental and cost-friendly product that’s as good as new, sometimes even better. At a time when consumers are keen to live sustainably, whilst also tightening their purse strings, this makes perfect business sense.

For more information about Carwood, www.rdr.link/FFP016

PROFESSIONAL MOTOR FACTOR DECEMBER 2022 I 29 REMANUFACTURING

Autoelectro bolsters hybrid portfolio

From

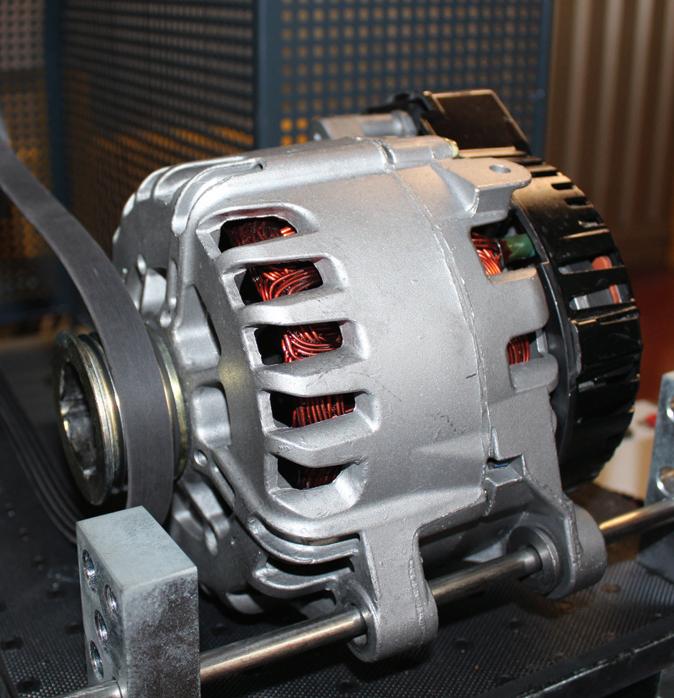

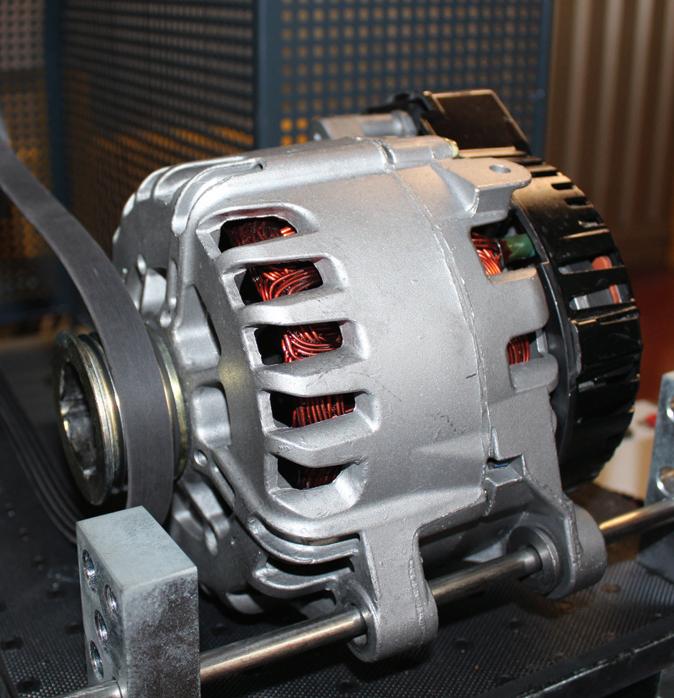

For more than three-and-a-half decades, it has embraced rotating electrics and accrued a deep understanding of the product range, championed the environmental benefits of remanufacturing by extending the life of components via its in-house facility in Bradford, to produce starter motors and alternators of all generations.

To serve the timeline of the-now classics, the introduction of start/stop technology, combined starter motors and alternators, and 48V units, Autoelectro boasts the latest test bench equipment –essential in being able to respond to requests, whether it for a bestselling vehicle or off-highway application!

While all the technology is packed into the iconic red and white box, which includes fitting instructions and, with specific part numbers, valuable technical notes, Autoelectro’s 1986 Dashboard is a “fantastic, additional resource for customers to search for part numbers, discover new-to-range updates, latest press material, organise old core returns, track deliveries in real-time and chat to inhouse experts directly”.

What’s more, the company has recently launched a parts identification campaign –where a customer can send photos of an unknown part, via WhatsApp, and be identified by Autoelectro staff.

Autoelectro continues to deliver With the impetus of hybrid and electric hybrid vehicles, and more pushing through to aftermarket workshops, Autoelectro has reflected this trend by developing a significant range of references.

By adding references for hybrid models for manufacturers, such as Peugeot, Mercedes, Audi, Fiat, Ford, BMW, Hyundai, Land Rover, Suzuki, and Volvo, Autoelectro Director, Harnek Bhogal, said its product experts have “truly delivered a range that covers all bases”.

He added: “We’ve been working tremendously hard in developing part numbers for these types of vehicles, complementing our comprehensive, existing range, and these significant additions support that commitment. We are confident this range, in addition to the outstanding service we’ve offered for the last 36 years, will be a success with our loyal customer base.”

For more information about Autoelectro, www.rdr.link/FFP017

30 I PROFESSIONAL MOTOR FACTOR DECEMBER 2022 REMANUFACTURING

a 1970 Alfa Romeo Spider 1.6 to a 2020 Audi A4/A5 2.0 petrol/hybrid, Autoelectro

believes it has the tools – knowledge, experience and equipment – to quickly cater customer requests and offer exceptional customer service.

DENSO is widely recognised as one of the world’s largest OE component manufacturers and system suppliers, with an extensive aftermarket portfolio. Its remanufacturing programme, however, is less well-known, despite being active in the European market for more than 10 years.

To raise aftermarket awareness of the environmentally sustainable components, DENSO Europe, Pan European Strategic Marketing Manager, Fatiha Laauich spoke with Andre Koppenol, manager of the remanufacturing team and his colleagues, who are collectively responsible for the OE quality range.

“So, why does DENSO have a remanufacturing programme?”

“It’s actually threefold: to deliver high quality products of the same standards as the original component on the vehicle but manufactured in an environmentally friendly and sustainable way.”

Q“Where do DENSO remanufactured components fit in the aftermarket?

DENSO pushes environmental benefits of remanufacturing into limelight A Q A

“Today, if a product like a starter or alternator fails, or the battery in their hybrid vehicle breaks down, European motorists have a choice as to whether they replace it with a brand-new unit or a remanufactured one.

“Each of these components is the same in terms of its quality; in fact, in some circumstances, such as when it’s rebuilt according to the latest OE standards compared to a new unit of a four-year-old

32 I PROFESSIONAL MOTOR FACTOR DECEMBER 2022 REMANUFACTURING

design, one could even say it’s better. So, the choice for the consumer is whether they prefer a remanufactured unit that is more environmentally friendly and cheaper to purchase, or a completely new one.

“However, we’d obviously encourage our customers to highlight the environmental and potential newer technology benefits of the remanufactured unit.”

focussed facilities.

“A question that often arises is the difference between remanufacture and repair?”

“An example of a repair would be if there was a problem with a solenoid on a starter, which could simply be replaced, and the fault rectified. In contrast, remanufacture is when the unit is completely disassembled and every component is cleaned, examined, tested and recycled, or if necessary, replaced. It is then rebuilt and tested against the standard of the original unit, so that as far as its performance and reliability is concerned, it will become, in effect, a new unit.

“However, a distinction needs to be made when it comes to diesel components, such as injectors, which due to their complexity cannot be repaired in the sense of replacing just one small part –they have to be completely remanufactured.”

“It’s worth adding that the DENSO Service Repair Network is an important part of DENSO’s service and repair solution for both the independent aftermarket and VM dealer networks. It provides them with a comprehensive diesel support package that means that any diesel fault can be diagnosed and repaired by a specialist, with an extremely high level of competence. The network, therefore, follows our QCD (quality, cost and delivery) principle, which means that an end-user can simply walk in with a problem and leave with a high-quality, low-cost and quick delivery solution.

“To reiterate, although the decentralised DENSO Service Repair Network is the only route for the independent sector, the VMs have a choice of either option. Some have opted for the DENSO service network, which is great and enables them to keep a high degree of control as the defective part is collected, remanufactured and returned entirely through the network. Others have this work undertaken by DENSO directly and this is a particularly effective solution, both economically and environmentally, for servicing vehicles that are no longer in production.”

“On the subject of batteries, is DENSO’s remanufacturing process only for nickel or also lithium-ion?”

“And

“No, because for diesel pumps and injectors there are two sides to remanufacturing: the first is the remanufacture of diesel injectors carried out by DENSO in our own facilities, which is an operation only for our VM partners and their dealer networks; the second, diesel parts remanufactured through our DENSO Service Repair Network, a service offered to both VM dealers and the independent aftermarket.

“This network is made up of independent diesel specialists based throughout Europe, that are trained and authorised by DENSO to execute diagnostics, service and repair to DENSO standards. This means they are able to remanufacture these components to the same OE standards as us – the only meaningful difference being that they are more limited in their production capacity compared to our mass production

“Bearing in mind that a remanufactured component needs to be completely dismantled and cleaned and any substandard parts replaced with original parts, is the process really any more environmentally friendly than manufacturing a completely new unit?”

Q

A Q A Q A Q A

“In short, yes! Our philosophy is to reuse as much as possible, and in the case of alternators this is usually around 85% and with batteries it’s close to 90%. This automatically provides great environmental gains, but there are also considerable CO2 reductions in not having to produce every part from scratch. So, the process is considerably more environmentally friendly.”

“At the moment, it is only the nickel batteries primarily used for hybrid vehicles, not pure electric, as lithium batteries are extremely difficult to remanufacture. Presently, we only carry out this process for our VM partners and are the only company that does this in a mass production capacity, and it is there to support the VM dealer network.”

“Is the DENSO remanufacturing programme for passenger car applications only?”

“No, we also cover LCV applications for diesel, either through our VM partners or the Service Repair Network. When it comes to starters and alternators, we also cater for both LCV and heavy-duty vehicles, as well as some off-road references.

“In addition, we are always looking at what other product groups we can add to our remanufacturing/repair solutions, and e-compressors and invertors are among the components that are on our agenda. So, our already comprehensive offering is only likely to grow, particularly as DENSO is committed to reducing its carbon footprint and increasing product sustainability.”

For more information about DENSO, www.rdr.link/FFP018

is that process only carried out by DENSO?”

PROFESSIONAL MOTOR FACTOR DECEMBER 2022 I 33 REMANUFACTURING

A Q

“DENSO is committed to reducing its carbon footprint and increasing product sustainability.”

How parts are produced ‘really makes a difference’

Long-standing collaboration

In business for the past 37 years, GROUPAUTO member, ABC, has been in operation almost as long as Shaftec – and the two have worked together for the past quarter of a century.

The short answer to all of this is yes!” says Rachel. “At ABC, we stock a full range of Shaftec remanufactured products, and it really makes a difference to us and to our customers that we know exactly where and how the parts are produced. Because Shaftec literally does everything from the core selection to the actual remanufacturing process, through to individual part testing under one roof at

its Midlands-based UK facility, we can be sure that they have almost total process control, and then we can pass that assurance on.

“We know that Shaftec is stringent in its core selection process and, therefore, know that our customers will be fitting parts of OE quality. Parts that are as good as new, tested as new, and perform in that way for the lifetime of the part.”

ABC is a wholesale company, which supplies local garages within a 35-mile radius – and the person on the street who still does their own repairs – with critical automotive components for MOT failures, service parts, cleaning, styling and audio parts, together with consumables from a host of well-known brands. ABC also offers a bespoke, on-site paint and bodywork service.

Shaftec Key Account Manager, Joe Toakley, commented: “It’s a real privilege and pleasure to work with the guys at ABC: honest, hard-working, knowledgeable people that truly understand the ethos of remanufacturing and the benefits it brings

34 I PROFESSIONAL MOTOR FACTOR DECEMBER 2022 REMANUFACTURING

With more than 40 years of experience, Shaftec is well-qualified to fly the remanufacturing flag, but what do its customers think? Do remanufactured parts always hit the spot when it comes to quality, range, availability, performance, and value for money?

Motor Factor

Manager,

Davies, and Business Director, Andy Melmoth, tell us:

ABC

Business Development

Rachel

“

to the customer, the environment, and the industry at large.”

“Shaftec’s remanufactured portfolio fits the bill”

ABC was established in Abergavenny in 1985 by Dave Melmoth. The business was born after he saw a gap in the market and decided to use his expert knowledge of the industry to service local automotive needs.

Just four years later, in 1989, ABC moved to the current, more central threeunit facility in Abergavenny, Monmouthshire. Being just off the A40, it offers easy access to the area’s motorway systems, allowing for an improved service for its loyal customers. And with the purchase of Pontypool Motor Factors almost 10 years ago, the successful twosite business is thriving today.

“Business was booming in 1989, and we were running out of space!” was Andy’s short answer when asked why he had moved the business to new premises so soon after opening.

Andy continued: “When the business first started our ratio of customers was split between the local garages and the person on the street. With technology moving at

such a fast pace and with cars becoming ever more complicated, that ratio is now heavily biased towards the garages. The industry has changed so much since we started. There were no computer systems then, and you had to memorise all the part

numbers for the cars of the day!

“Our garage customers now expect a quick fix and that means that parts turn around must run on maximum efficiency. They need a diverse range of parts, often same-day, so we need to work with suppliers, like Shaftec, that can offer us an excellent range and good availability. Furthermore, it’s now more important than ever that we offer our customers a real choice – and Shaftec’s remanufactured portfolio fits the bill as the driver gets OE quality with excellent performance at a lower cost.”

In line with Shaftec, the team who work together at ABC are a vital part of the success of the business. The business operates 22 delivery vehicles that leave the central depot regularly at peak times throughout the day to ensure that trade customers receive that same-day delivery service.

Andy concluded: “We really do pride ourselves on our reliability and our choice of new and remanufactured products at competitive prices, as we strive to keep our customers happy on every level.”

For more information about Shaftec, www.rdr.link/FFP022

REMANUFACTURING

Hella Gutmann ‘paving the way for the future of the independent’

For many reasons, not least to minimise the number of unwanted parts returns, it’s clearly an advantage to you if your workshop customers are able to undertake effective diagnostic processes; in fact, according to Hella Gutmann, they can benefit further if they choose to become a supplier of the brand’s range of equipment – so, how can they? Head of Hella Gutmann UK, Neil Hilton, offers his opinion:

One of the major challenges facing independent workshops is cyber security management (CSM). Among other features, the latest vehicle models have electric, or partially electric, drivetrains, extensive connectivity and a wide range of advanced driver assistance systems (ADAS) functions. These developments go hand-in-hand with expanding data volumes and new on-board network architectures, which VMs are increasingly securing against unwanted access, by means of CSM.

To support independent workshops to communicate with these and future vehicles, we implemented the CSM function in our mega macs range of diagnostic devices in 2020. This allows verified users with a single Hella Gutmann registration to diagnose secured vehicles without accessing the VMs’ portal and is a genuine multi-brand function that is being successively expanded.

Without official access to CSM, many current diagnostic tools in the market will have less and less capabilities. We have also just released our Smart Component Help, an additional function within our software to further assist a technician in identifying the correct part to replace on the vehicle to complete a repair, which also improves efficiencies for you in terms of unwanted returns.

With the recent addition of Renault, Kia and Hyundai, the CSM function has been extended to allow mega macs users to save considerable time and

administration when working on protected vehicles from these VMs, as well as those from Alfa Romeo, Fiat, Chrysler, Jeep, Mercedes-Benz, Audi, Cupra, Seat, Škoda and VW.

Vying with dealers

Our recent introduction of the macsRemote, which is a remote services product, enables aftermarket workshops to complete work previously reserved for VM franchised dealers. They can now compete with these dealers with the level of service they can offer their customers.

The macsRemote is a connected repair solution that extends the capability of an independent workshop, as it provides diagnostic access to vehicles and systems.

It allows independents to legitimately access VMs’ own data, to diagnose diagnostic faults and activate solutions from the moment a vehicle leaves the showroom, and so bridges the data gap between their existing diagnostic tools and the latest new model registrations.

The mega macs X is a standout diagnostic tool within reach of the independent sector and provides users with the utmost flexibility with an array of options

DIAGNOSTICS & TOOLS

36 I PROFESSIONAL MOTOR FACTOR DECEMBER 2022