THE BUSINESS MAGAZINE FOR THE ELECTRICAL TRADE

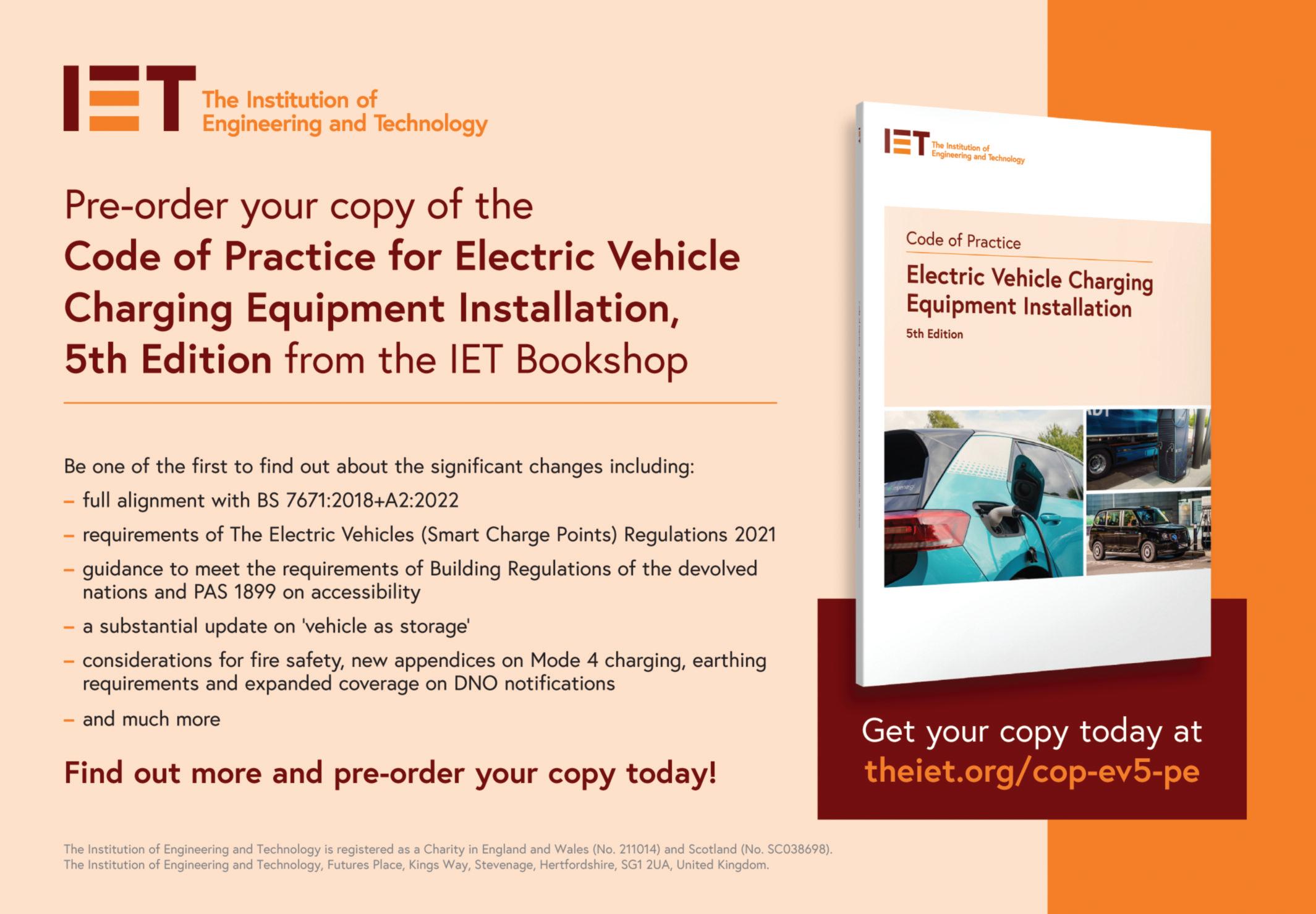

8 The key things electricians need to know to stay ahead of the ‘prosumer’ curve

11 Where should fire detectors be used?

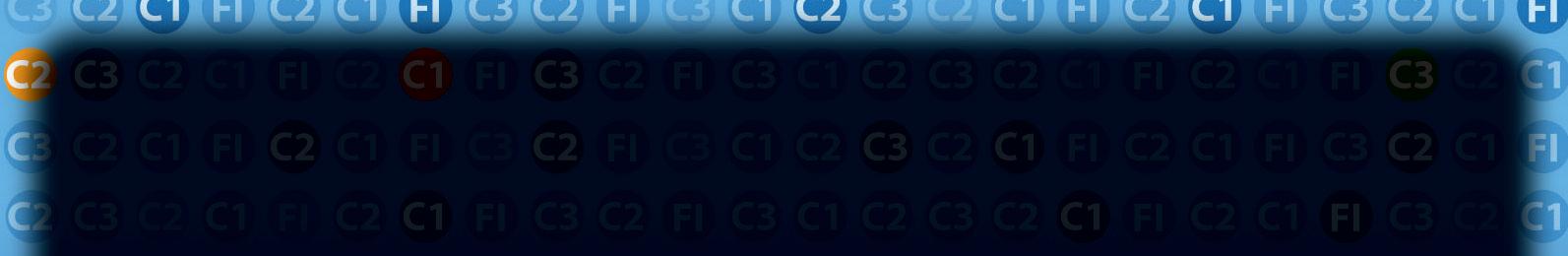

14 ‘Codebreaking’ the latest on-site finds from electricians on the job

17 Guidance on the installation of twisted pair network cables

20 The five ultimate leadership tips that trade business owners should know

24 Why is it important to enclose single insulated cables?

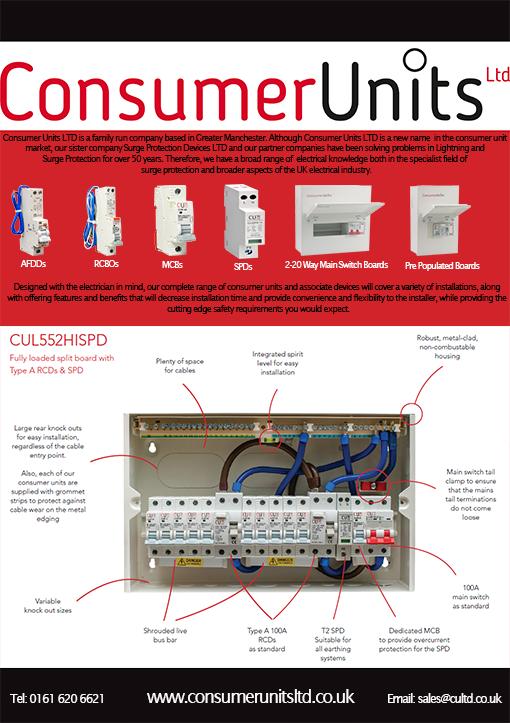

26 Answering some of the common questions around the use of SPDs, following Amendment 2

28 The continued importance of safe isolation, Lockout & Tagout

32 Taking a closer look at the requirements for automatic disconnection in case of a fault

34 Why business success is based on consistency rather than greatness

37 Looking at some of the component parts that may be employed in an electrical energy storage system (EESS)

39 What type of lighting is best for use on snooker tables?

43 How should RCBOs be used in the workplace?

44 A closer look at Part F of the Building Regulations for commercial and industrial buildings

46 ‘Codebreaking’ the latest on-site finds from electricians on the job

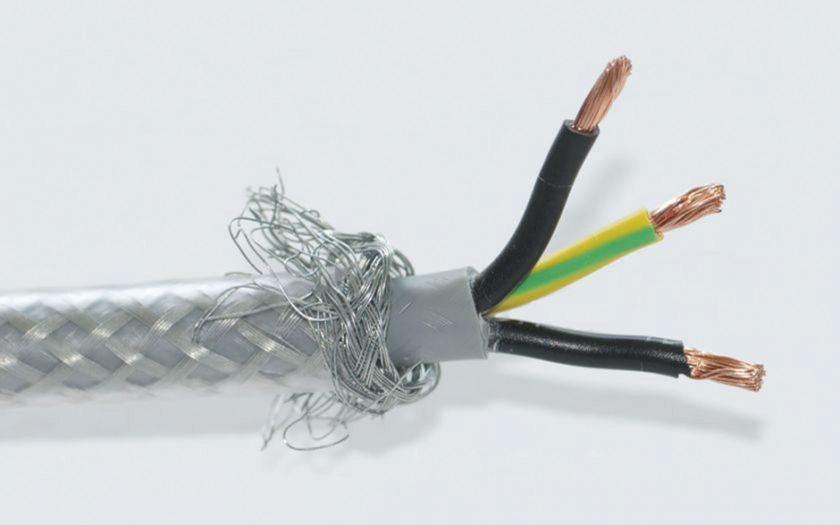

48 Identifying the different types of control cables and why a new scheme should help to improve the quality of cables being sourced and used

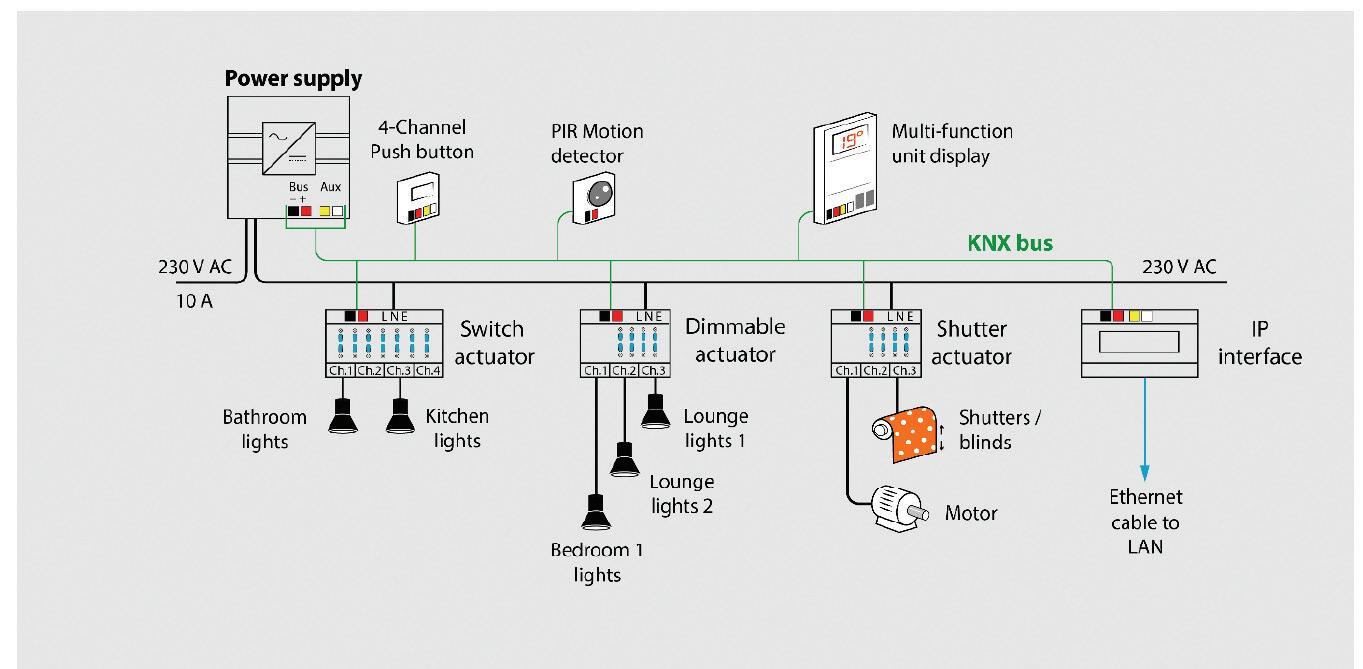

52 Understanding the function(s) of a communication Bus system and its ability to permit interconnected control of devices using twisted multi-pair cable

54 Considering the necessity of maintaining signal integrity for life safety services

56 What is a ‘hazardous area’?

58 ‘Codebreaking’ the latest on-site finds from electricians on the job 62 Five ways to improve your business

63 How to check if the fire qualification you’re signed up for is government-approved 64 Understanding the

66 The dangers involved with electric arcs and the considerations electricians must make in their choice of protective wear

86 Unified Glare Ratings explained

89 Taking a closer look at the requirements for carrying out risk assessments

93 Summarising the requirements in Section 704 for the use of reduced low voltage (RLV) supplies on building and construction sites

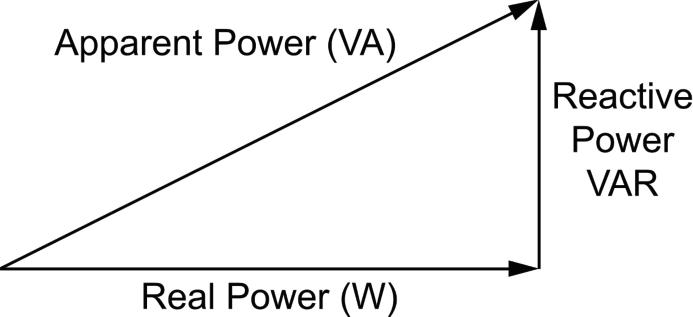

96 What is power factor and what purpose does it serve?

98 What makes a fire installation compliant?

100 ‘Codebreaking’ the latest on-site finds from electricians on the jobs

70 Best practice when safely isolating live circuits

72 ‘Codebreaking’ the latest on-site finds from electricians on the job

75 The environmental factors that should be considered when selecting, installing and using electrical supplies and equipment on-site

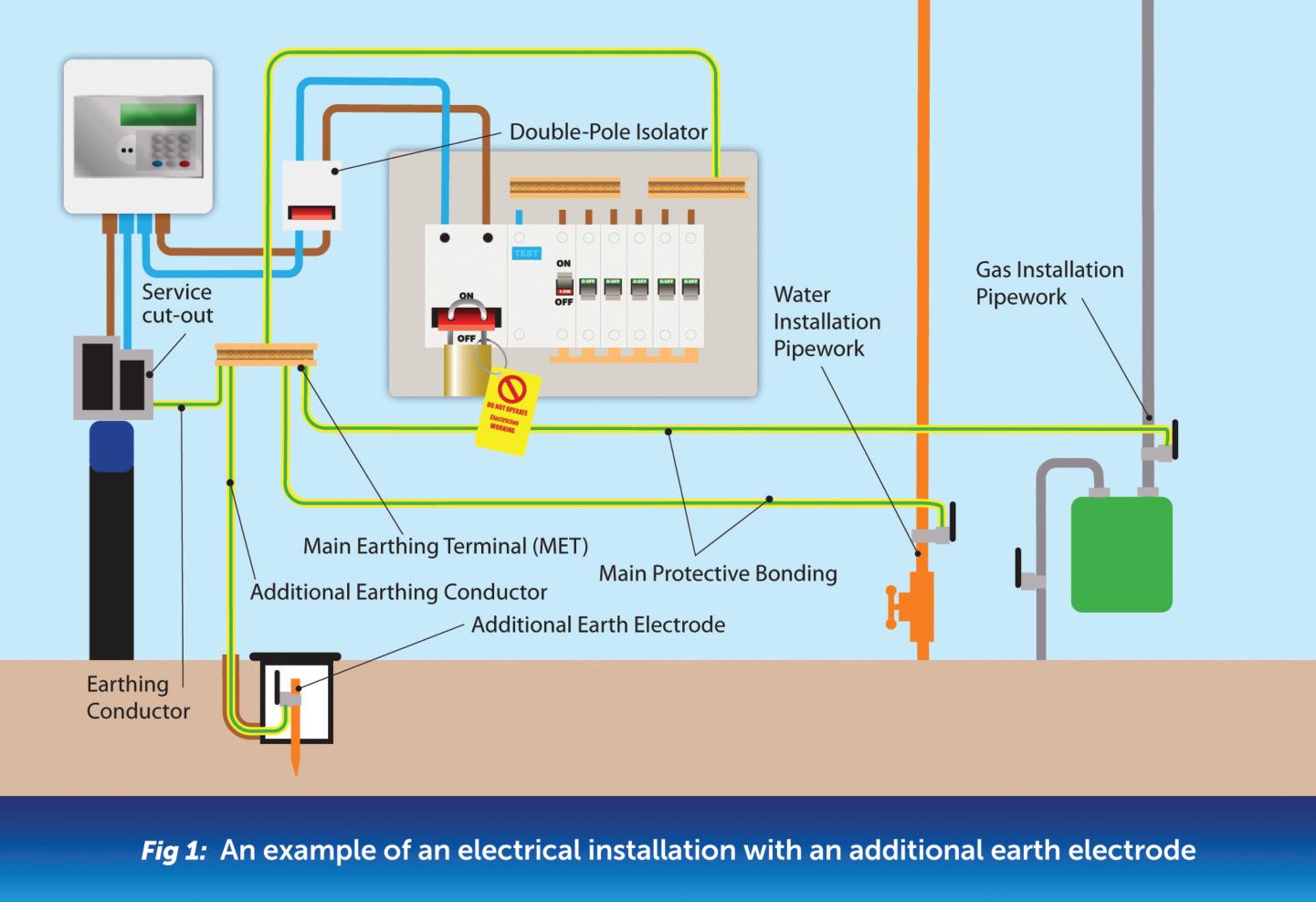

79 Dealing with a common query related to the use of Earth Electrodes

80 How to make marketing work for your business

82 The considerations professionals must be aware of when installing a new consumer unit

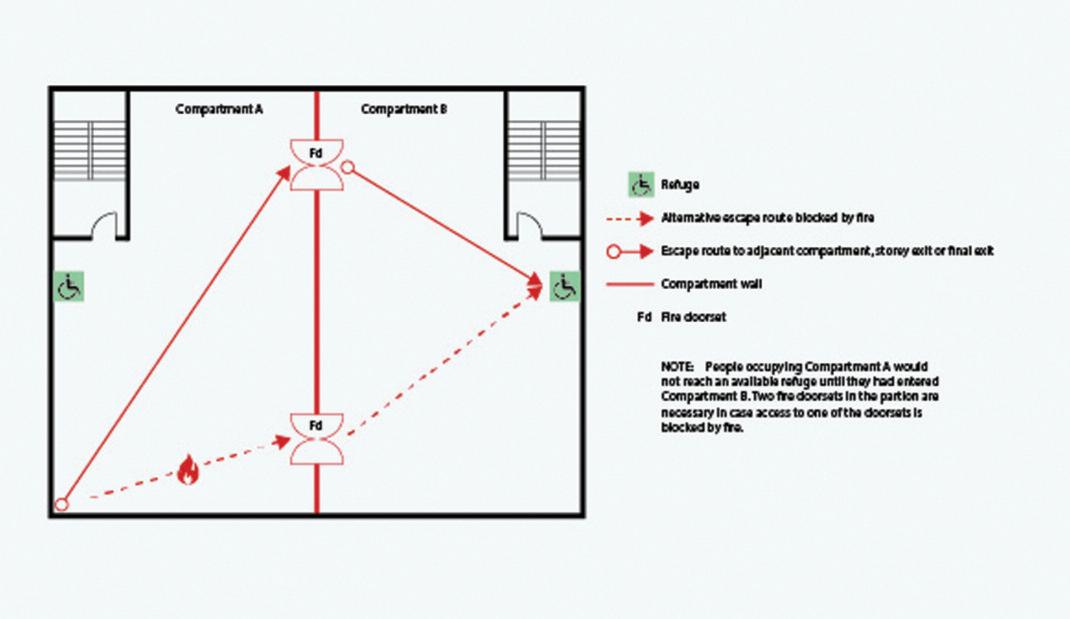

84 A look at the specific recommendation for refuge areas to be provided with an emergency voice communication (EVC) system

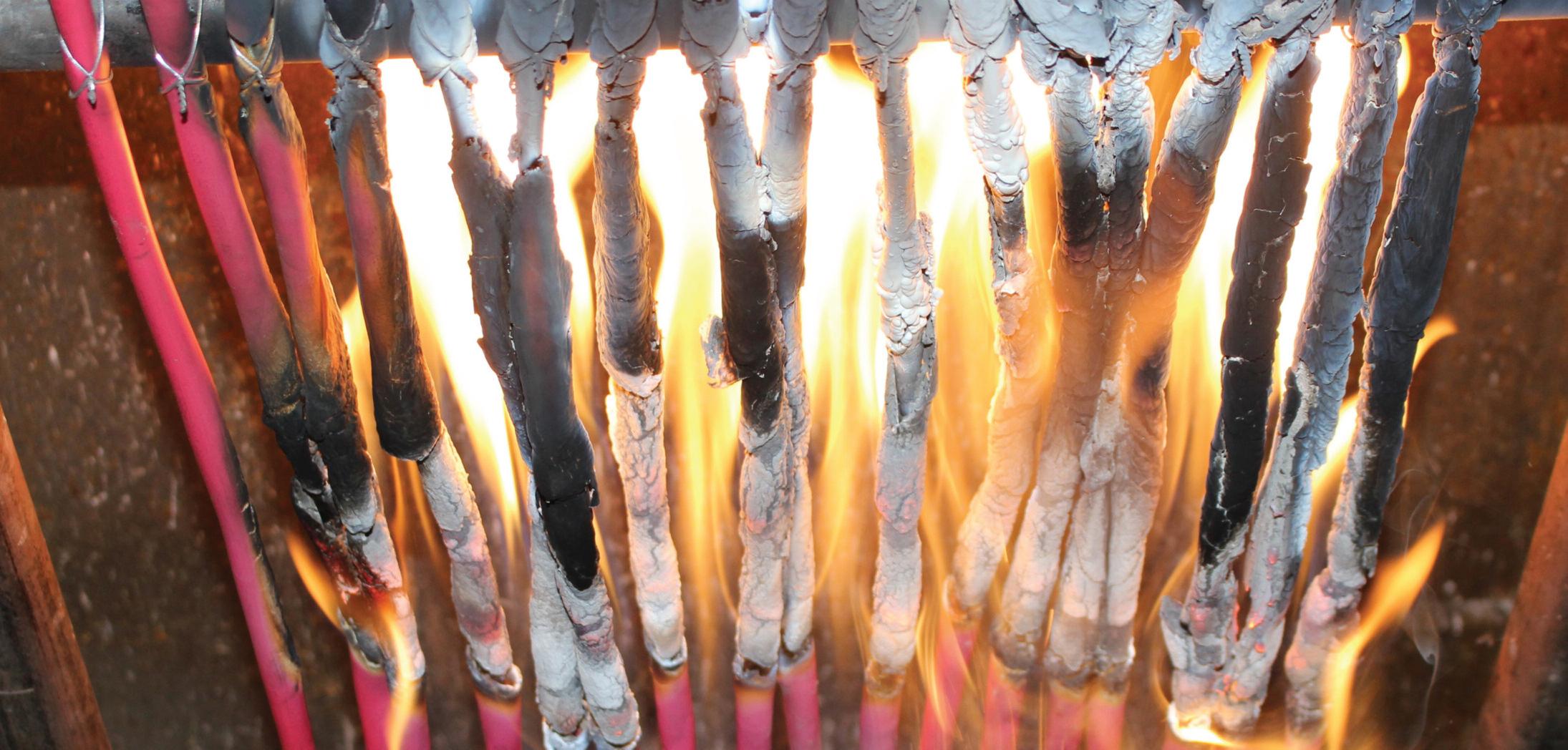

102 Where did halogen-free flame retardant cables come from and why are they important?

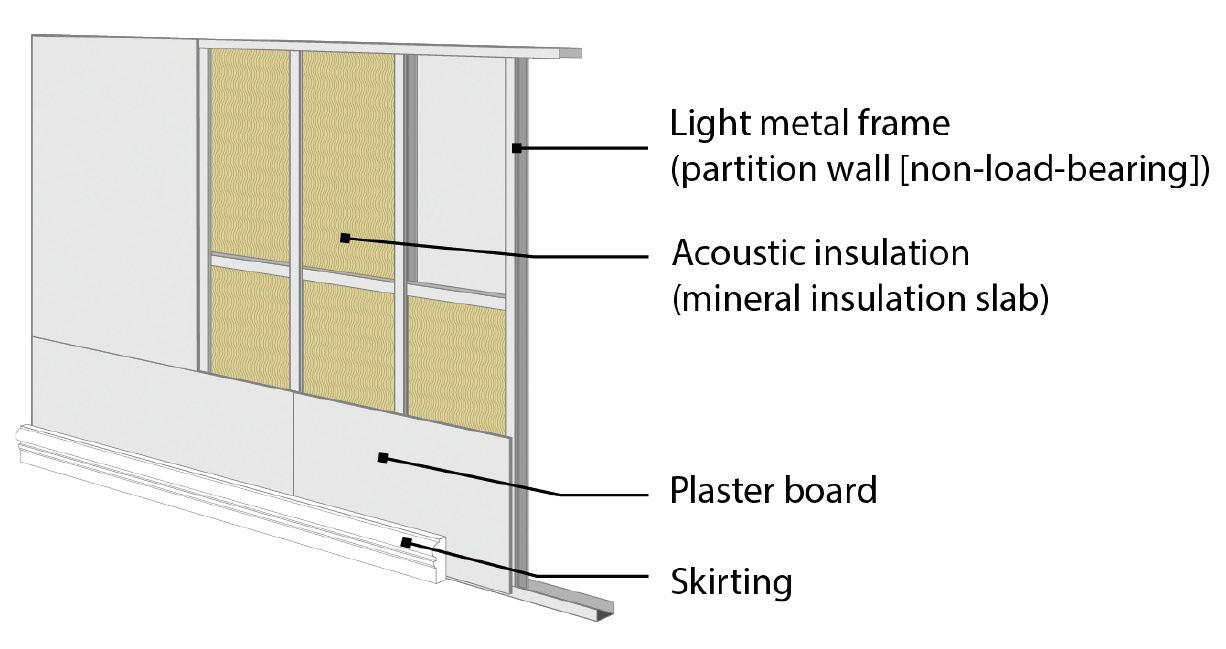

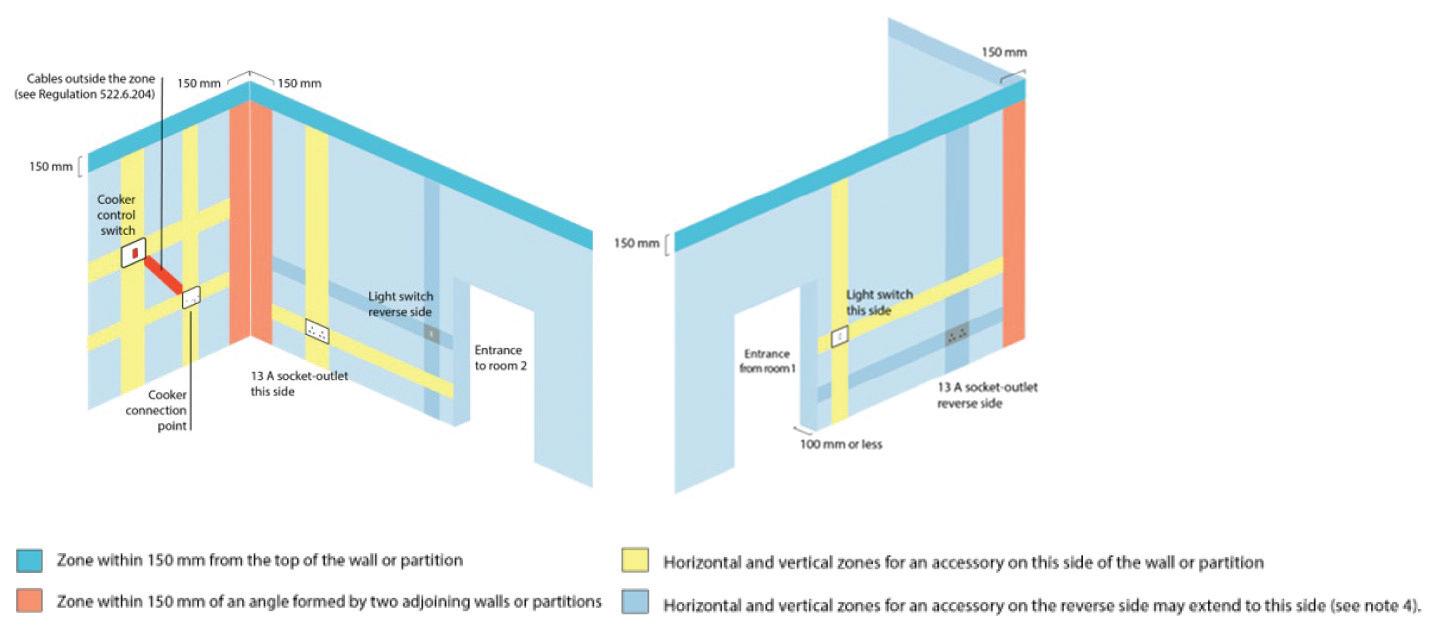

104 Why you need to apply due diligence when installing cables in thin walls and/or partitions

106 How to improve sales conversions in your business

108 ‘Codebreaking’ the latest on-site finds from electricians on the job

110 What is the best way to deal with employee bereavement?

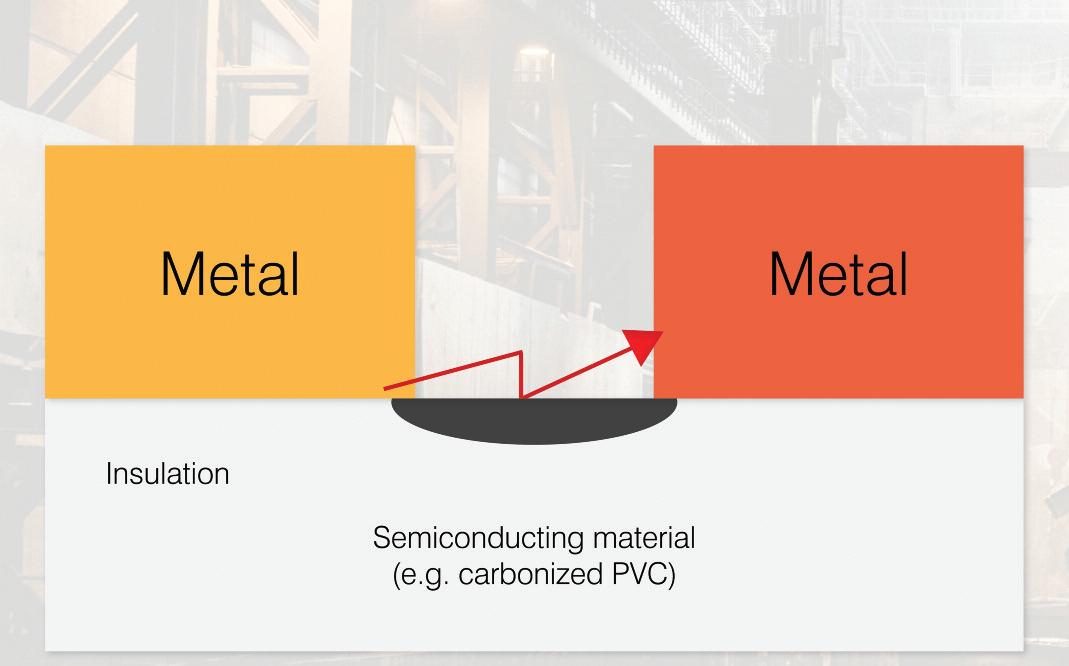

112 Delving deeper into the technology behind AFDDs

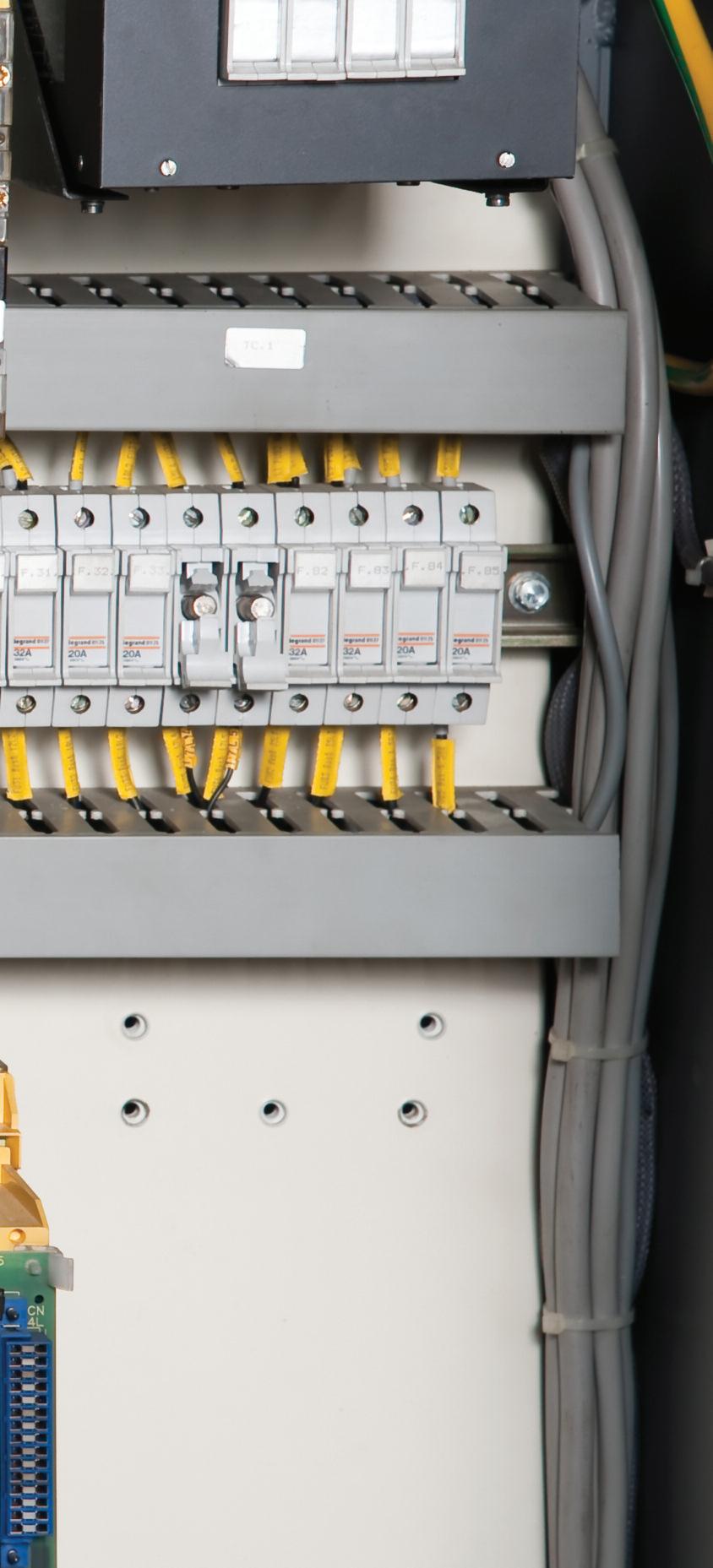

114 Taking a closer look at selectivity requirements for distribution circuits

116 How does maximum demand work and why is it important?

W O R K T H R O U G H E A C H S E C T I O N A N D E A R N 6

C P D C R E D I T s ( o r 6 h o u r s o f l e a r n i n g )

T O WA R D S YO U R P R O F E S S I O N A L R E C O R D !

continuing professional development (CPD) can be broadly defined as any type of learning you undertake which increases your knowledge, understanding and experiences of a subject area or role

To help professionals to better document and prove this process, the CPD Book contains content and articles that have been checked, verified and accredited by a third-party specialist organisation

Collectively, the content within this specially designed publication has been deemed worthy of 6 CPD credits, or 6 hours’ worth of CPD, with each individual section providing 1 credit, or 1 hours’ worth of CPD.

Once this content has been consumed, readers will have the

opportunity to scan a QR code which will provide a bespoke, downloadable certificate that can be used as part of a professional’s ongoing CPD record

THE CONTENT WITHIN EACH SECTION!

A large element of CPD involves self-certification and relies on professionals being honest about what they have actually read, consumed and digested A QR code has been placed with the final article in each of the six learning sections within this publication and ONLY once you have read ALL of the articles within each section, should you then scan the code to receive your bespoke certificate

By skipping any of these steps, you’re not just cheating the system, but yourself and your fellow professionals at the same time!

CERTIFICATE IN FIVE STEPS

1. Read ALL of the content and articles included within the six sections

2. Find the QR code with the last article in each section and scan

3 Enter your email address

4. Fill out your details on the contact form

5. Download your certificate for use as part of your annual CPD record

PREVIOUS USERS – ACCESS YOUR CPD CERTIFICATE IN FOUR STEPS

1. Read ALL of the content and articles included within the six sections

2. Find the QR code with the last article in each section and scan

3. Enter your name and email address.

4. Download your certificate for use as part of your annual CPD record

All certificates are valid for one year from the issue date If you’re having any issues with downloading your certificate or using the system, please email us at: pe@hamerville.co.uk

to know to stay ahead of the ‘prosumer’ curve.

“A building that is an active component of the energy network and that moves beyond a unidirectional flow of energy into the building to that of bi-directional flow ” BS7671: Part 8 Chapter 82: The Energy Prosumer

As the UK attempts to use less fossil fuel and move towards a Net Zero Carbon 2050, significant new demands will be placed on our existing energy systems Many more of us will become prosumers This will have three important implications for the electrical and wider electrotechnical sector:

1. More business: prosumer activity is set to provide huge opportunities for retrofitting existing buildings and installation in new buildings

2. Attracting talent: as one of the sectors at the centre of a building and infrastructure Net Zero Carbon 2050, the demand for modern technology and techniques will help to drive recruitment

3. Trusted experts: the electrical services sector will become increasingly relevant to policy conversations about

the UK’s energy direction and future, and to clients, making it a principal agent of positive change

Prosumerism: why now?

“Energy generated from renewable energy accounted for over 43 per cent of the energy provided to the electricity grid in 2020 ” BS 7671 (March 22): Part 8, Chapter 82 The Energy Prosumer

The UK regularly generates more electrical energy from renewables Renewables' share of total generation was 42 8 per cent at the end of 2021, up by 2.1 per cent on 2020. This trend is set to increase However, growing reliance on renewables raises issues such as

consistency of energy supply.

To ensure a sufficiently consistent UK energy supply, the ECA has actively lobbied government and industry stakeholders in three key areas:

1. Generation

2. Storage

3 Energy efficiency

In reality, we need a combination of effective measures across these three areas But even focusing on points two and three improved storage and energy efficiency could save the UK economy £30-£70 billion according to BEIS’s ‘Transitioning to a net Zero energy

system: Smart Systems and Flexibility Plan 2021’ (view this at: bit ly/3xLuonF)

The ECA Guidance Note ‘Planning for a Green Pivot v 1 2’ identifies many opportunities for low-carbon electrotechnical activity, outlined in the diagram on page 36

Looking at three of these opportunities in more detail:

i) Transport: building the domestic and commercial infrastructure

Electric vehicles (EV) have already entered an early exponential growth phase In 2015, just over 1 per cent of new vehicles registered also had a plug, compared with almost 19 per cent in 2022 (according to the Society of Motor Manufacturers and Traders). Key factors such as current fuel prices and the none-too-distant 2030 ban on the sale of new internal combustion engine (ICE) vehicles will reinforce this trend and increase the need for Electric Vehicle Charge Point (EVCP) installation and maintenance for both domestic and commercial use

ii) Heating: making homes carbon-efficient

As part of the Boiler Upgrade Scheme,

a £450m government grant came into force in May 2022, providing £5,000 for households to install air source heat pumps (ASHP)

Furthermore, with no VAT on heat pumps for the next five years, support for this sector looks set to continue, so electrical contractors may decide to invest in training and certification on the basis of improved predictability

As the carbon intensity of grid electricity falls, for new or well-insulated houses, the direct electrification of heating – such as underfloor heating, infra-red heaters, or ‘smart’ storage heaters – may become more and more worthwhile following forthcoming changes to the Building Regulations (which have historically penalised electric heating)

On a domestic scale, solar PV is once again back in vogue With high energy prices set to continue, this solution is growing in popularity for both retrofit and new-build projects. The combination of the Green Homes Grant and Building Integrated PVs (BIPV) has boosted the appeal of solar PV installations for new builds especially

Electrical Energy Storage Systems (EESS) offer a whole new level of flexibility and convenience, allowing users to buy energy from the grid when usage and prices are low, and sell it back at peak times As EVs become ubiquitous, Vehicle to Grid (V2G) charging will become an integrated feature of many homes, making use of the EV’s significant electric battery

To do the work needed to meet our Net Carbon Zero targets, electricians will need to add new skills to their arsenal This means training and certification will be incredibly important, both for businesses and qualified electricians looking to expand their capabilities It will also be vital for the career progression of any new and prospective industry entrants

Electrical energy storage system (EESS), Electric Vehicle Charge Point (EVCP) and heat pump training and Building Automation and Control Systems (BACS) are areas where technicians can expand their skillset right now.

For installers looking to work within funded schemes, MCS certification is required In some circumstances, they will need PAS 2030 when installing under a PAS 2035 Retrofit program

At the outset of this article, I mentioned the recent addition of Chapter 82 to The Wiring Regulations It highlights how the electrical systems within our buildings will need to interact with a smart and decarbonised energy grid. It introduces a couple of new terms: Energy Prosumer and Prosumer Electrical Installation (PEI)

To understand fully connected systems such as PEIs, electricians will need to understand how the various elements on-site generation, energy storage, heating systems, EV charge points, to name a few – fit together, both with each other and with other trades Incorrect specification or installation could lead to expensive mistakes down the line, when a whole building doesn’t work as intended

The electrotechnical sector has a vital role to play in shaping the UK’s decarbonisation given our understanding of the technologies involved and the need for qualified and competent installers to deliver on the government’s objectives

In late March 2022, the IET Wiring Regulations (BS7671 – 18th Edition) were amended to address amongst other things energy efficiency and prosumer

installations, formally introducing us to the terms ‘Energy Prosumer’ and ‘Prosumer’s Electrical Installation (PEI)’

ECA has produced guidance in this emerging area, including the Chapter 82 Energy Prosumer Guide. Additionally, ECA’s ‘Planning for a Green Pivot v1.2’ document covers an array of Net Zero Carbon 2050 opportunities for ECA Members, in particular guidance on support schemes, training and accreditation

The terms, Energy Prosumer, and Prosumers Electrical Installation (PEI) are set to become more common as the industry gears up for Net Zero Carbon 2050

As one of the industries at the forefront of sustainability and Net Zero, we are faced with a unique and unprecedented set of opportunities When these sustainable technologies can be designed to work together the effects can be ground-breaking

However, ongoing training and accreditation will be vital to ensure that installations are carried out in a timely manner (to satisfy government objectives), effectively (to satisfy consumer needs), and efficiently (to satisfy Net Zero Carbon 2050 targets)

The energy prosumer model offers significant opportunities, and a range of new challenges. To work efficiently and effectively, solar panels, batteries, EV chargers and heat pumps will need to work in harmony This means they will need to work as a prosumer system, and not just as individual product types It is therefore vital that designers and installers have sufficient training and skills to make this possible, and to make sure that the technologies are configured to work collectively

Ultimately, customers will become much more aware of their own energy use and production as we move beyond the status quo of taking grid supply, and its flat charges, for granted Load-shifting will become a prominent part of prosumer installations, especially for heating and EV charging A combination of rising or, at best, highly variable energy prices, plus new legislation and standards are shaping the future of UK grid supply and interactions

Below is just one example of what installers will increasingly encounter as we begin to engage with the prosumer environment:

Where a building is expected to run independently of the grid (in what is called ‘island mode’), specific earthing conditions and controls should be applied In addition, checks will be needed to ensure that the local system will be running in-phase with the grid prior to grid re-connection Additionally, installers will need to consider dedicated circuits when running in island mode

o f f l e x i b i l i t y.

The microgrid controller at the heart of this project uses a web-based user interface that communicates real-time energy use, savings and CO2 emissions data This microgrid controller also links directly to third-party sites, such as weather forecasts, to decide whether/when to deplete or charge the batteries

For example, if the user has specified cash saving, then weather forecasting data is combined with energy tariff predictions to decide when to use power, when to store it, and when to sell it back to the grid

Sustainable technologies used:

● 135kWp rooftop solar PV system

● 6kWp carport solar PV + 5 EV charge points

● 216kWh battery storage in bespoke ISO container

● Schneider Microgrid Controller

“It is fantastic to be able to work on this unique, innovative project, implementing new systems and technologies in a way that we hope will be a beacon to future developments The innovations included in the scheme fit perfectly with the University’s aims to enhance its sustainability and reduce its carbon footprint by generating its own renewable power ”

Chris Phillips, Contracts Manager, RDM

I have recently been asked to look at a fire alarm in a building, which is a category BS 5839-1:2017 L1 system. Correct me if I am wrong, but is an L1 supposed to have detectors everywhere? I have looked at the system, and there are detectors missing from cupboards, a toilet and, worse still, a stairway lobby. Also, are you a real Doctor?

Thank you for your Question, Mr S Ives (Fire Risk Assessor)

If you look in Clause 8 2 f of British Standard 5839-1:2017 it states, certain areas may be classed as areas of low risk

The standard states in clause 8 2 f, in categories L1 and P1, automatic system detectors should be installed in all rooms of the premises; however, the following rooms may not be protected if they are at low risk of a fire occurring:

● Bathrooms/shower rooms and toilets

● Toilet lobbies and stair lobbies

● Small cupboards less than 1 m2

There are a couple of notes within clause note 8 that state that in some buildings, such as shopping centres and hospitals, toilets may not be low risk because of the risk of arson

Note 9 states that a riser cupboard that has a fire-stopped floor and ceiling may be considered a cupboard. Note 10 states that detection may be excluded from the same such areas in L2, L3, and L4 category systems

Now here's the bit that does not sit comfortably with me: this clause states: ‘these areas need not be protected if they are of low fire risk’ (see 3 33) This means that for a fire alarm engineer to make this decision, they are deciding that the areas are low risk and then signing a document accordingly

When you look at Clause: 3 33, Low-risk areas or rooms, it states: ‘a room or area that contains very little or no combustible substance and has no ignition sources, which any foreseeable fire is unlikely to spread to cause a threat to escape by occupants or damage to property’.

To me, it is far better for a qualified, competent fire risk assessor to make that decision

Stair lobbies are one of the areas of low risk that I have highlighted for change in the next update of the standard as I do not feel these should ever be classed as an area of low risk

Going back to the original question, it would appear that the designer deemed the areas you

Shower rooms and bathrooms are fairly easy to judge However, pay close attention to the cupboards because what is contained in the cupboard may make it high risk –many will contain a consumer unit or a server, or even flammable liquids; all of these would not be of low risk

Now on to the second part of your question: am I a real Doctor?

The short answer is ‘yes’ I was given an honouree Doctorate in 2014 for the work that I did to help a university with a fire detection system dissertation It does say ‘Doctor’ on my driving licence etc but I’ve not really used the title as its honouree I have just passed a full PhD, however, and am now a fully qualified Doctor. As of earlier this year, I am also now a Professor

DO YOU HAVE A QUESTION YOU'D LIKE ANSWERED?

EMAIL YOUR QUERIES TO: TOM@ZZEUS.ORG.UK

GET

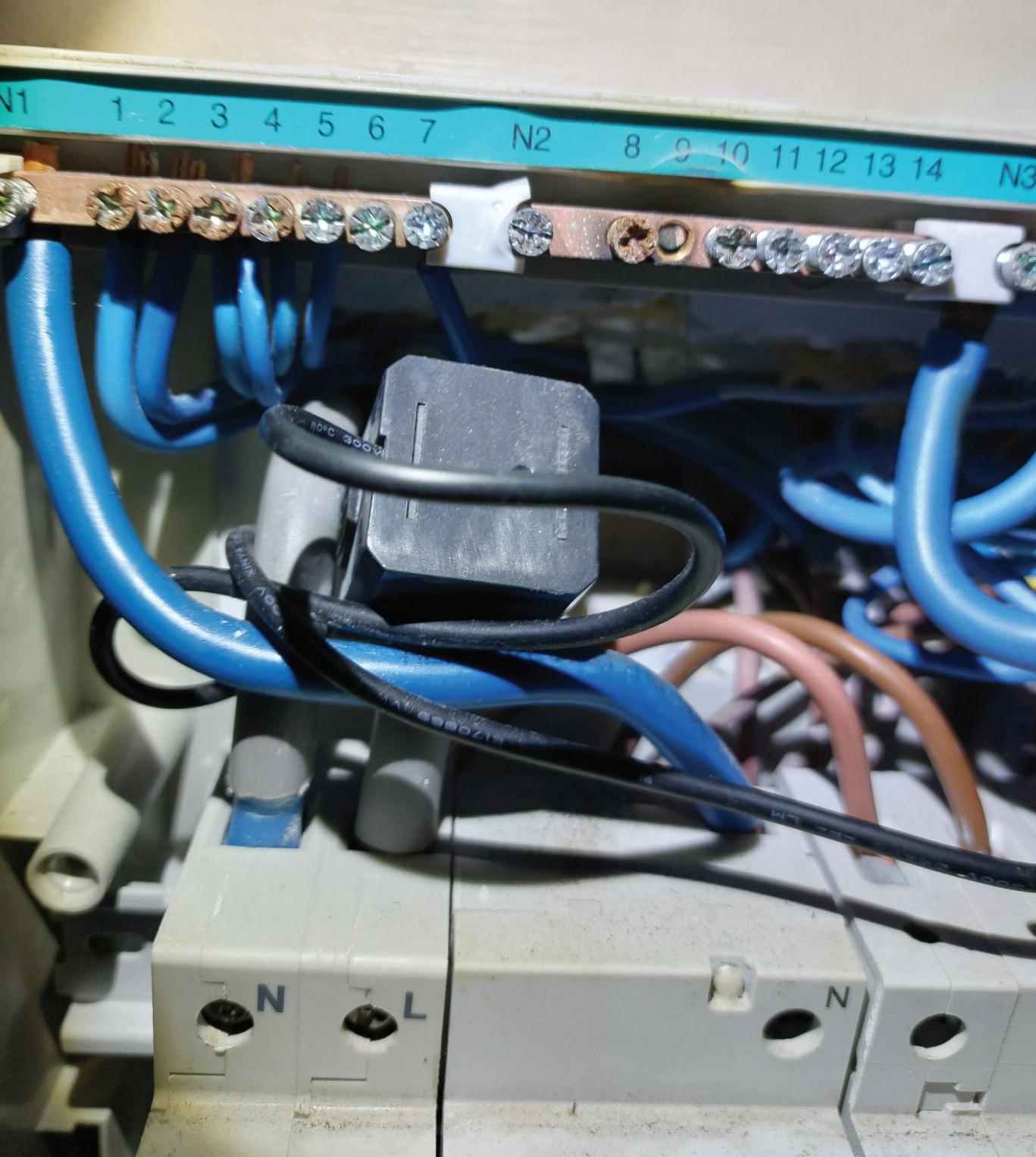

Some things just never seem to change, which is ver y frustrating. There are so many defects here that it's tough to k now where to star t, so I'll tr y and group the various issues together where I can:

1. Terminations and single insulation not taken into an enclosure are a problem as there is no adequate mechanical protection There are a few of those issues in the photo.

2. Terminations not adequately suppor ted may cause strain on them, leading to loose connections and possible arc faults and fires This would explain the intermittent flickering operation repor ted by the Client.

3. Cpc is not taken to each accessor y and point in a circuit, which means there is no shock protection after the first accessor y We can see where the cpc has been intentionally cut and left out of the way on the 3- core flex

B Single insulation and conductor

enclosure

4. The termination of the cpcs in some of the flat twin and ear th cables is not adequate Twisting cpcs together is neither a reliable method to ensure adequate termination nor will it aid in periodic inspection and maintenance.

5. I can’t see from the photo if there is any access to live par ts where the terminal connectors are used A couple of them seem to have multiple conductors in them, which may or may not give rise to access to live par ts

The shameful thing here is that the work seems to have been a recent install, which means the low level of sk ills shown is likely to be found in other installations by the same installer This type of work manship is only ever going to receive an unsatisfactor y result on an EICR

not taken into an

526.6

134.1.1, 526.1, 526.3, 526.5

134.1.1, 416.2 FI C2 C2 C2 C2

Need help with cracking those all-impor tant EICR codes? Ever y month the technical team at NAPIT will be studying your latest ‘Caught on Camera’ photos and offering advice on the next steps, should you find a similar installation. If you want the team at NAPIT to help crack your codes then send your pic tures through to us at: pe@hamer ville.co.uk

DAYS

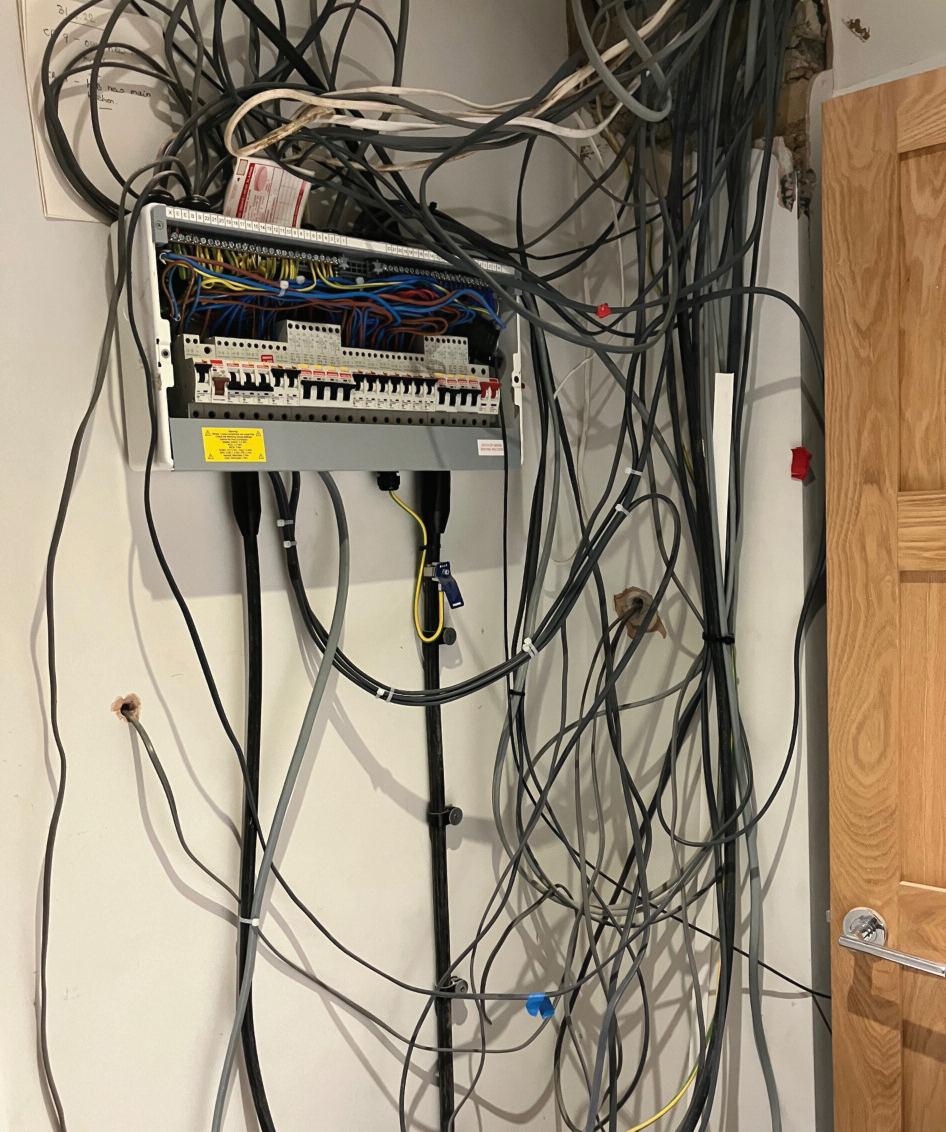

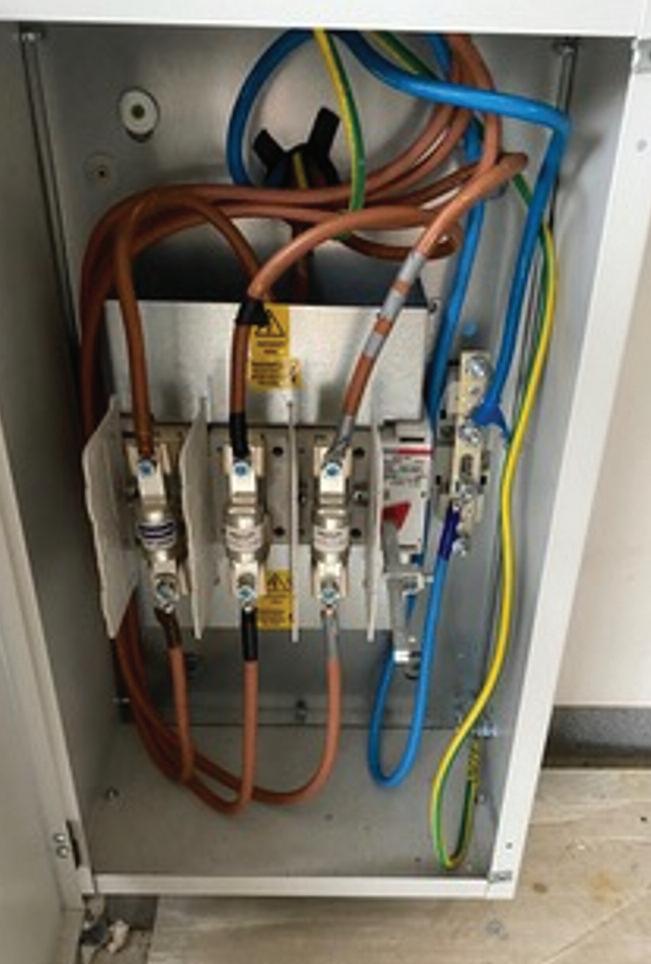

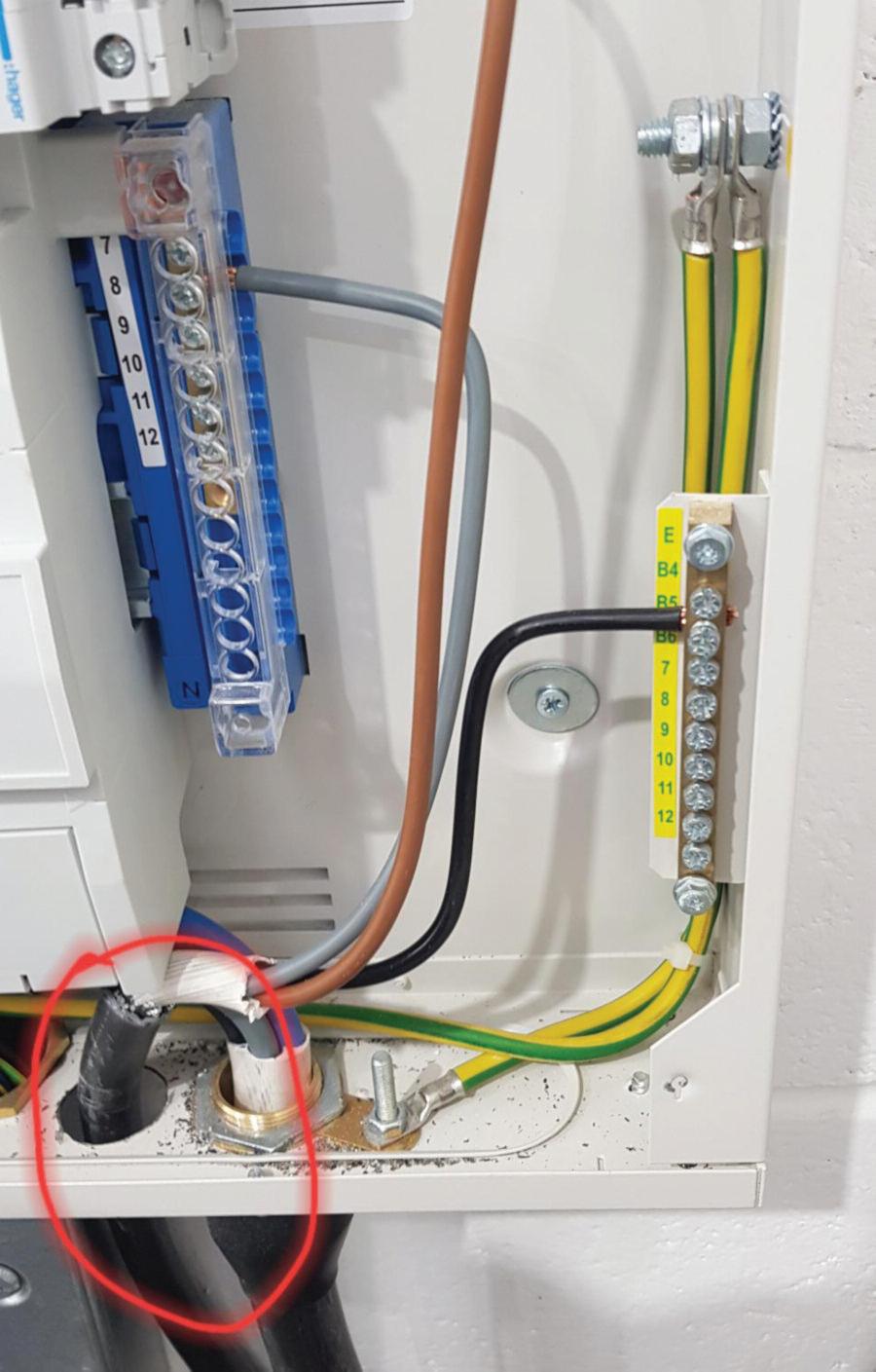

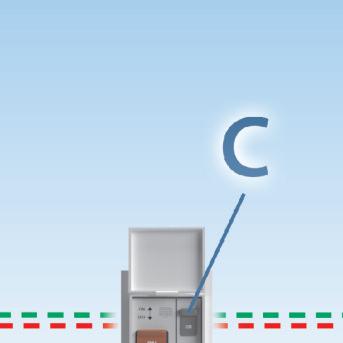

Wow, just wow! A work in progress is one thing, but this is pretty astounding

From the top, the lid being left off and not even in sight to be replaced is leaving this installation dangerous, with access to live par ts before we even star t Even though this isn’t strictly an EICR, the Client has called someone in to give an opinion which can be seen to be an EICR of sor ts

The unacceptable cable management is next up and is a pretty easy fix that could have been avoided from the star t with some well-placed trunk ing I’m not quite sure what the cable connected through the CU front opening is doing, but it will need to be re -routed, as the cover won’t fit with it there!

The state of the cables inside the CU is difficult to see from the photo, so I’ll leave that out of the equation I will comment on the SWA bottom right, though, as it seems to have a BS 951 clamp on it, with a conductor then entering the metal CU in a different opening to the SWA This could have eddy current issues with high loadings; I’m not sure why that ’s been done, as the SWA gland would have adequately and acceptably transferred any cpc requirements to the CU

The BS 591 clamp is also not designed to be used in this way, as adequate torque to the armouring cannot be confirmed, and by doing this, there is a risk that the SWA cores can be crushed and damaged

C

This is a totally unacceptable and dangerous installation that could easily be rectified by a sk illed and competent installer

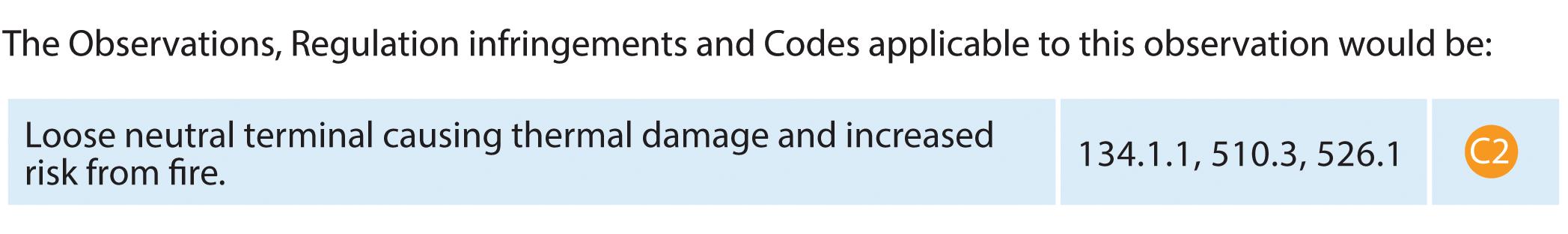

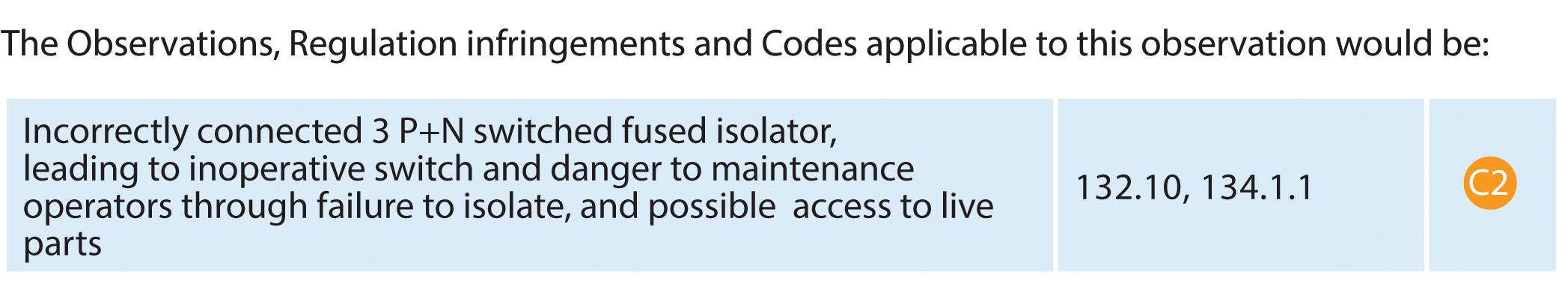

The Observations, Regulation infringements and Codes applicable to this observation would be:

A cable appears to prevent the CU lid from being tted, causing access to live parts 134.1.1,

No adequate cable containment, the strain on terminations134.1.1, 522.8.5

SWA has a BS 951 clamp used to direct a cpc to the CU, as well as its own SWA gland, also causing a potential eddy current issue on high load with conductors entering a metal enclosure through di erent openings

134.1.1,

The 18th Edition Codebreakers publication is priced at £17.99 (members) or £19.99 (non-members). Hard copies and digital issues are available.

* Prices exclude VAT, postage and packaging

CLIVE HAMILTON: I WAS ASKED TO VISIT A SITE WHICH WAS WIP ( WORK IN PROGRESS) AND THE SPARK WAS STRUGGLING! BEAR IN MIND THE ‘OTHER’ SPARK WASN’ T ON SITE AND THIS WAS LIVE WITH THE COVER NOWHERE TO BE SEEN – NOTHING SURPRISES ME ANYMORE! IT SEEMS THERE ARE FEWER SPARKS TRYING TO FOLLOW GOOD PRAC TICE AND THE REGULATIONS THESE

Many commercial and industrial installations employ networking cables for their main infrastructure of Ethernet networks, enabling a permanent and reliable link for communication between items of equipment such as workstation computers, printers and network servers

However, some devices, such as those used to control office lighting, work on a connected bus system operated through a software interface including, typically, multi-pair cables having a screened data pair and unscreened power pair Within the home, smart devices such as entertainment equipment, lighting and heating control systems often require a network connection. This connection, typically based on a local area network (LAN), allows such devices to:

● access internet-based data sources and services; to retrieve the latest information such as the weather conditions for enhance energy efficiency,

● give the user greater control and monitoring of connected devices while away from the home, to further improve energy performance and/or provide increased security property monitoring.

In larger premises, the use of access points (AP) for expansion of the wireless network may be an option, although these devices typically require a separate network cable, such as a twisted pair cable, which allows for data and power to be transmitted within the same cable.

This is often referred to as Power over Ethernet (PoE)

A l t h o u g h m a n y d e v i c e s c a n c o n n e c t w i r e l e s s l y t o a n e t w o r k , s u c h c o n n e c t i o n s a r e g e n e r a l l y l i m i t e d i n r a n g e, s u s c e p t i b l e t o s e c u r i t y b r e a c h e s a n d c a n s u f f e r f r o m i n t e r f e r e n c e d u e t o e x t e r n a l i n f l u e n c e s , l e a d i n g t o p o o r s i g n a l q u a l i t y o r l o s s o f s i g n a l a n d c o n s e q u e n t l y, f a i l u r e o f e q u i p m e n t

For this reason, the installation of dedicated data network cables may be a favourable option In addition to improving the reliability of connected devices, having a direct link to the LAN also permits larger amounts of data to be transferred at increased speed whilst reducing the latency1 between input and output devices

Twisted pair data cable

N e t w o r k i n g d a t a c a b l e s a r e c o m m o n l y m a d e u p o f f o u r t w i s t e d p a i r s o f c o p p e r c o n d u c t o r s , a l t h o u g h o t h e r v a r i a n t s o f c a b l e s a r e a v a i l a b l e ( s e e F i g 2 ) . T h e t w i s t e d p a i r s a r e t y p i c a l l y u s e d f o r c a r r y i n g d a t a s i g n a l s , a d i g i t a l p u l s e o r t h e v a r i a t i o n s i n v o l t a g e b e t w e e n ( T X + a n d T X- ) a n d ( R X + a n d R X- ) c o n d u c t o r s 2 Ty p i c a l l y, n o t a l l t h e t w i s t e d p a i r s w i t h i n

The team at NICEIC provide guidance for the contractor on the installation of twisted pair network cables to BS ISO / IEC 11801 and BS EN 50173 series, and compliance with BS 7671 requirements.

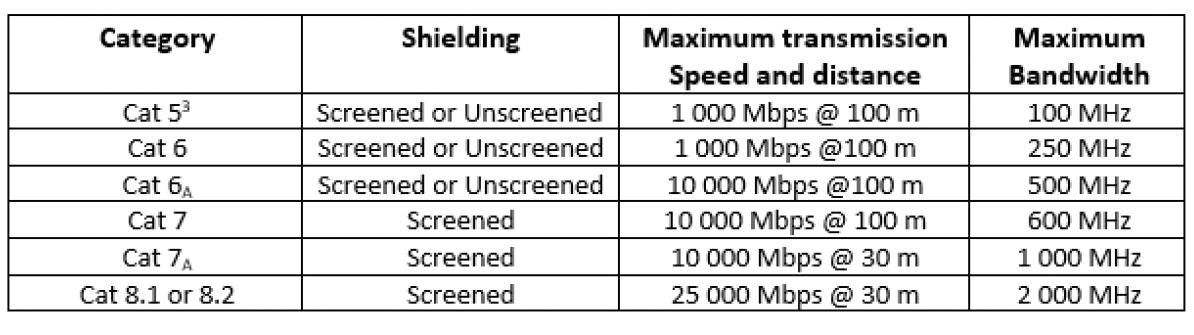

t h e c a b l e a r e u s e d f o r t h e t r a n s m i s s i o n o f d a t a T h e p e r f o r m a n c e a n d a b i l i t y o f a c a b l e t o t r a n s m i t l a r g e a m o u n t s o f d a t a f o r a p a r t i c u l a r a p p l i c a t i o n d e p e n d s m o s t l y u p o n t h e c a b l e’s g r a d e o f c o n s t r u c t i o n T h e s e g r a d e s a r e g e n e r a l l y c a t e g o r i s e d ( C a t e g o r y 5 - C a t e g o r y 8 2 ) a n d a r e u s e d t o i d e n t i f y t h e a m o u n t o f d a t a t h e c a b l e c a n c a r r y, a m e a s u r e o f h i g h a n d l o w b a n d w i d t h , a n d t h e s p e e d a t w h i c h t h e d a t a c a n b e t r a n s m i t t e d f r o m i t s s o u r c e t o o u t p u t d e v i c e ( t r a n s m i s s i o n s p e e d ) ( s e e Ta b l e 1 )

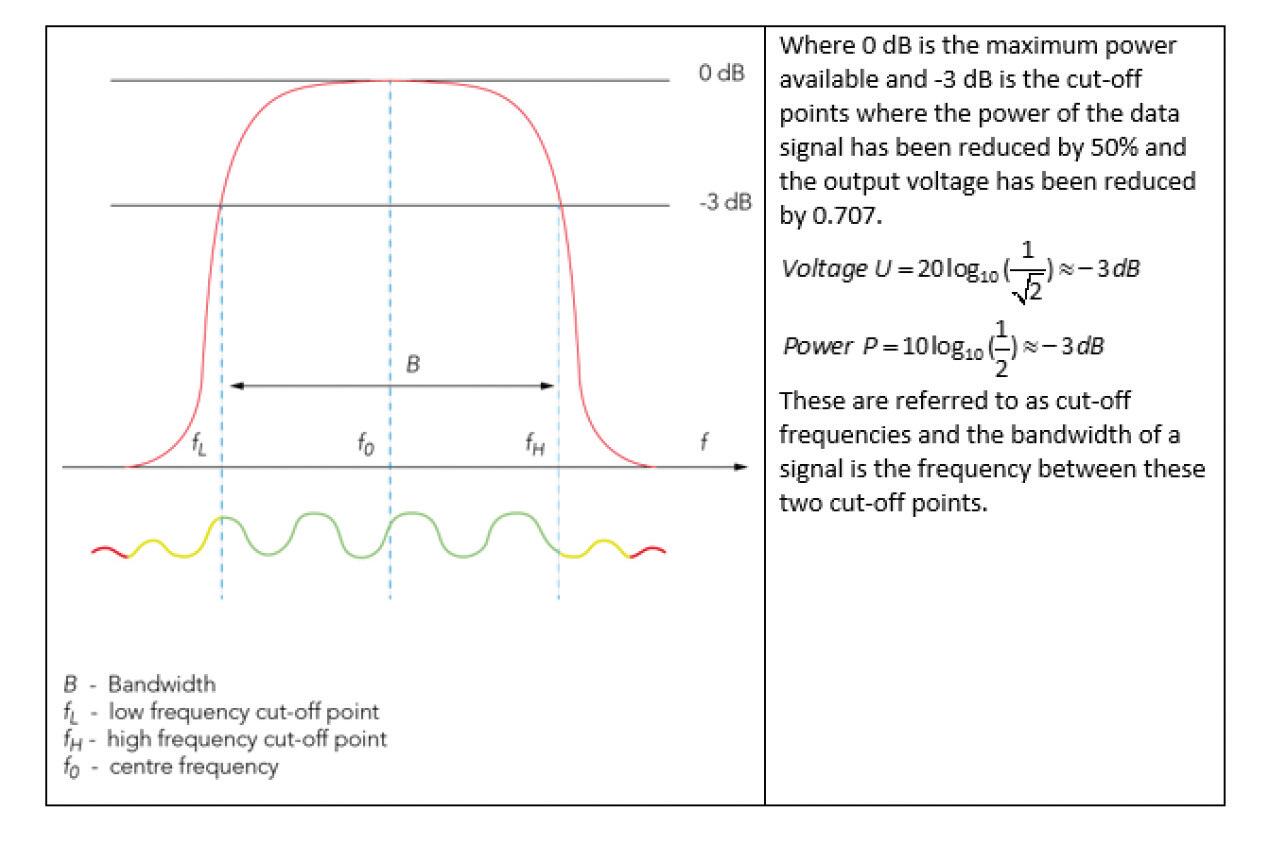

The bandwidth is the ability of a cable to carry a signal ranging across upper and lower bands of frequency over a period of time For example, a Category 5 cable having a maximum bandwidth of 100 MHz would be able to process a signal between point’s f L and f H on a frequency response curve, as shown by Fig 1

The method of construction varies between the Categories and relates to the performance of the cable For example, a screened Category 6A cable as shown in

Fig 2, is capable of transferring greater amounts of data per second in comparison to that of an unscreened Category 5 cable. This is due to the improved construction, which includes:

● An outer sheath; this may vary between manufacturers but mostly consists of PVC, polyethylene or low smoke halogen (LSZH) insulation3

● Interior separation used for mitigating the unwanted coupling of adjacent conductors and preventing induced noise (crosstalk) transference between each twisted pair of conductors

● Inner aluminium foil screen prevents external noise (alien crosstalk4) from disrupting the transmitted signal

● C onductors, vary in cross-sectional area (csa) between categories

Typically for Category 6A the csa is

0 258 mm2 solid copper, generally covered with high density polyethylene insulation, arranged in four twisted pairs

● The twisting arrangement of conductors varies in pitch between the pairs of conductors within the cable and is measured in twists per inch (TPI) This helps to reduce the internal crosstalk or electromagnetic interference between pairs of conductors, allowing for pure signal distribution with less error

The TPI is typically increased between the pairs of conductors in a Category 6A cable compared with that of a Category 5 Cables having stranded copper conductors provide greater flexibility and would typically be used for patch cables or for final connections to portable devices

The connection of electronic equipment is referenced in the IEC 60603-7 series and relates to the interface of Category cables and the termination of conductors, as shown in Fig 2 There are two standards for the connection of RJ-45 terminations, these include T-568A and T-568B (defined in the US standard ANSI/TIA/EIA-568 2-D), which relate to the order of terminations of conductors within that standard

It is critical to have correct and adequate terminations at both ends of the cable. Any poor termination will reduce signal strength, cause a loss or noise in the transmitted signal creating distortion and data error

The PoE applications use either two or four pairs to deliver power to terminal devices; power can be transmitted over data conductors

Other applications may include the distribution of a DC power supply through a device such as an Ethernet switch, used to connect equipment such as lighting controllers, IP cameras and wireless access points over the same data network cable

The requirements of BS 7671 are applicable to the installation of network data cables within a building – refer to (110 1 2 indent (vi))

Network cables are often distributed throughout the fabric of a building, usually from a central location, which makes it possible for them to be in contact with, or close proximity to, other cables having different operating voltages

To minimise the risk of interference between cables of different voltage levels:

● Band I and Band II circuits shall not be contained in the same wiring system as circuits having a nominal voltage exceeding that of low voltage, and

● Band I and Band II circuits shall not be contained within the same wiring system, unless one or more of the conditions in indents (i) to (iv) of Regulation 528.1 are met.

Where network cables of Band I are installed in a duct or shared void underground, and/or cross with cables of Band II, segregation should be provided to achieve a minimum separation of 100 mm Where this is not practical, mechanical protection shall be provided (528.2).

Similarly, network cables are often terminated within patch panels or media cabinets enabling peripheral equipment such as Ethernet switches, routers and entertainment equipment to be contained within one location However, mixed voltages are likely to be grouped within the same assembly in which segregation will be required (515 2)

It is important to recognise, that where necessary, adequate support must be provided for Band I networking cables to prevent their premature collapse in the event of a fire (521.10.202). This may be achieved in a number of ways including:

● metallic clips inside or outside of plastic trunking

● metallic saddles holding plastic conduits

● metallic clips on wall-mounted cables.

Cables installed in steel trunking/conduits and on top of cable tray/ladder rack are not considered to be an entanglement risk Similarly, additional support is not required for cables installed in floors, above ceilings or behind plasterboard. Furthermore, the methods used for sealing low voltage cable penetrations within a building structure also apply where data networking cables are installed Such sealing arrangements are a fundamental requirement of the Building Regulations in England, Wales, Scotland and Northern Ireland, in addition to the requirements of Regulation Group 527 2 of BS 7671

Where it is necessary to install network data cables for equipment within a building, installers need to be mindful of the suitability of a cable for a particular application; reference should always be made to manufacturer’s recommendations

In addition, where such types of cable are likely to be installed in proximity to cables of mixed voltages, creating a potential for interference and signal error, segregation shall be provided

The need to provide adequate support for Band I networking cables for the prevention of premature collapse in the event of a fire must also be considered

1 The term latency describes the time delay of a data signal having been sent from a source and the receiving device acting upon the signal received

2. TX+ and TX- are the pair used for transmission whilst RX+ and RX- are the receiving signal pair

3 Manufacturers often reference a cable sheath having (LSZH), although Construction Product Regulations (CPR) specify a particular code highlighting product conformity for example BS EN 50399 B2ca s1a d1 a1

4. Alien crosstalk is referenced in BS ISO / IEC 11801 series, which relates to the induction electromagnetic interference from neighbouring cables

Owning a business takes you through the highest of highs and the lowest of lows You’re taking huge personal risk on a daily basis and on top of that you’re responsible for the actions of everyone in your company Of course, there can be huge rewards to reap, but the long and short of it is that it starts and ends with you, the way you build and lead your business, and you can always improve on that.

This year could be another difficult one for businesses, but here are five tips that can help you to be a better business manager:

1. Put structure, systems and policies in place

Without good structure, systems and policies your business has little chance to

grow A big reason trade business owners ‘burn out’ is that it’s easy to fall prey to the false perception that you need to be everywhere at once: quotes and invoices can’t be sent out without you checking over them, the job can’t be finished without you looking over it, and so on What you should be doing is building a business that works for you, not the other way around The way to do this is by setting up policies, systems and processes that are black and white and leave little room for interpretation. These include your materials management policy, your customer service promise, your company values etc If anything goes wrong in a business it’s usually because there’s an issue with the systems or the structure or procedure that the business is built on, and that’s what needs your attention.

The first step here is hiring the right people with the right attitude If you’re hiring individuals who are not up to scratch because they were a bit cheaper and the rest of your team have to pick up the slack, it hurts the productivity of the team as a whole and they will probably resent you for it

The next step is to onboard them properly and make sure they understand your systems, processes and values. For instance, if one of them turns up on a job and he/she hasn’t really slept but didn’t know that your company values are safety and high-performance, is that your fault or theirs? The answer is probably both

The last step is to train them Training is a great way to show that you care about employees’ mental and professional

2 Invest in your teamwellbeing on a personal level and also to show that you’re going out of your way to help them grow Moreover, if you don’t train your people, you’re never going to get the best out of them.

If you doubt yourself sometimes and you’re not overly confident about running or managing your business, here’s a tip: practically no one is. Most tradespeople don’t have a business background and even those who do are never really 100% sure things are going to work out But if your default is to doubt things will work, you can be sure they won’t pan out

If you don’t believe in yourself and your business, you can bet your bottom dollar you’ll see it affect your staff, your productivity and your profitability Having said that, everyone goes through periods of self-doubt, it’s in our nature So if you are feeling down on the company, don’t let your staff see it and definitely don’t take it out on them. Talk to your friends or

other business owners who’ve been through the same things You’ll be blown away by how many other people have been through the same problems and found a way around it.

This is an easy one If someone makes a grave error in your business, you have to be ok with that Delegation is an essential part of growing your business and other people are rarely going to do things exactly the way you want it But, if someone slips up again and again, the consequences are on you It sounds tough but if the process is broken, fix it and if the person can’t be helped, let them go.

Most business owners will hate this one, because most of us know it’s something we should be doing and it will never be more relevant than it is today. Too often, we shuffle a Profit/Loss or cashflow

forecast to the back of our minds and convince ourselves that we have more important things to do If we’re being honest, most of us are just a bit scared to look or don’t know what to look at.

The reality is nothing is more empowering for a business leader than getting a firm grip on your finances because it gives you the ability to make strategic decisions for your company If you’re a little bit in the dark on where your numbers are, download a free cashflow forecast template from the internet and fill it out

In summary, you don’t need to be the best at everything to be a better leader The most effective leaders largely achieve results because of the people and structures they place around them. But you do need to look after your team, be someone they can respect and, more than anything, you need to back yourself

What have we been missing?

Often overlooked is the importance we should place on enclosures to ensure any conductors and their respective terminations are adequately protected from mechanical damage and accidental contact, especially from ordinary persons

The most common problem we see when we look at installations, either new or existing, are single insulated cables not taken into an adequate enclosure

Whether the exposed single insulation is the result of 6491X cable improperly used, from missing trunking lids (which is very common), or from a sheathed cable with the sheath removed, exposing single insulated cables, such as 6242Y flat twin and earth, 6945X armoured or 6181Y meter tails, the problem is the same.

Why is this a problem?

Single insulation does not provide any mechanical protection, which means it’s susceptible to the rigours and abuses of everyday life. I say abuses because the seriousness of injury from electricity is very much maligned, and there is an assumption that the cable will protect you from the electricity flowing through it against all things – from walking on it to hanging things off it

As single insulation does not possess any mechanical protection properties, by

its design, we need to ensure it’s protected in some way, and that’s where enclosures come in and why they’re so important BS 7671 is very specific when it mentions and defines an enclosure.

According to Part 2 Definitions, an enclosure is:

‘A part providing protection of equipment against certain external influences and in any direction providing basic protection.’

That’s not enough on its own, though, so greater clarity is given in Regulation 526 8, which in turn refers to 526 5, requiring single insulation to be treated as any termination or connection in a conductor. In requesting this, the single insulation must be taken into either:

● An accessory complying with a suitable product standard

● An equipment enclosure complying with an appropriate product standard

● An enclosure partially formed or completed with non-combustible building materials, or

● A combination of two or more of the above

What’s the solution?

A reason for leaving single insulation

outside of an enclosure that we often hear is that there isn’t room in the given enclosure to fit the cables and terminate them adequately As we look at enclosures, we can agree that this is an issue in some cases, but there certainly is no excuse to do it, as there are devices to help overcome this

Where there isn’t room in a manufacturer’s enclosure, distribution board (DB) or consumer unit (CU) to adequately encase the single insulated cables, extension and spreader boxes can be used These items provide an extra section of enclosure that can house single insulated cables to allow a tidy and adequate connection inside the main enclosure

Fig 1 and Fig 2 illustrate the two main types of spreader boxes

Individual entry spreader boxes are designed to allow the sheath of larger cables to be stripped back so that the single insulated conductor can enter the enclosure This facilitates good termination of the conductors without tight radiuses or undue stress on the terminations

Multi-cable spreader boxes, or extension boxes as they are sometimes called, effectively extend the enclosure This allows the sheaths of multiple cables to be stripped back so that the enclosure, generally a CU, is free from masses of cable entries that can cause stress on the eventual terminations and from the issues associated with the close confines of switchgear

Although most of these pieces of equipment are designed to be used with a specific manufacturer’s enclosure, there are alternatives

Where a consumer unit, especially in a domestic setting, requires multiple armoured cables, simple trunking adequately installed can do the job just as effectively

Providing the correct lids and end plates are used, different trunking sizes can be re-purposed to provide a tidy interface between multiple cables and a CU/DB, especially for CU/DB changes, where space and existing cable lengths are challenging

If we look at Fig 3, we can see that a CU/DB has been installed using a section of 100 x 100 mm metallic trunking. Fitted neatly along the top edge of the CU/DB, it

provides a useful interface to terminate several armoured cables

This, in turn, allows the single insulated conductors of these types of cables to enter the CU neatly without causing any obstructions In the same way, flat twin and earth cables have also been installed this way, which stops the sheathes from cluttering the inside of the CU/DB

The following are some useful outcomes of this type of design for an installation practice:

● Removes unnecessary clutter from the CU/DB or enclosure

● Reduces stress on terminations and conductors

● Promotes air circulation and cooling for

terminations, conductors and devices within the main enclosure

● Allows clear identification and access for future periodic inspections

Although the example in Fig 3 uses metallic trunking as a spreader, because of the extra stress incurred by the armoured cable glands, this does not preclude the use of plastic trunking

Generally, plastic trunking is more than acceptable for utilisation in this way, especially where flat-sheathed cables, such as flat twin and earth used in domestic and less complex installations, are the only cables used in the installation

Using plastic trunking in this way isn’t a problem in domestic installations with metallic CUs as the trunking does not contain switchgear, and as such, it is not required to be of metallic construction, as is the CU

Something to remember, however, is that whenever a site-manufactured spreader/extension box is used in this way, it must be fit for purpose and include the correctly fitted end plates and trunking lid The key to a safe installation lies in its design. Without a solid understanding of design principles, we run the risk of falling short of the most basic requirements

Since the release of the 18th Edition there has been an increase in the use of Surge Protection Devices, and this is only growing with the additional requirements in Amendment 2 As always with a new subject matter, there are a few frequently asked questions that I hope to cover in this article:

QWill an SPD need replacing after every surge?

No, an SPD is designed to take multiple surges and internally reset after each overvoltage An SPD will only need changing at the end of its life (the warranty is manufacturer dependent) and this will be shown in the status indication on the front of the unit

QWhen do I need to use a Type 1?

With the increase in availability of consumer units with the SPD already installed, it is becoming more of a consideration as to whether this is the correct device A Type 1 will be needed in a domestic installation, if the property is supplied via an overhead cable. Outside of domestic installations, a Type 1 device

will also be required if the structure has an external lightning protection system

QWhy do some manufacturers need an MCB (Miniature Circuit Breaker) before the SPD?

According to BS7671, all SPDs shall be protected from overcurrent, which can be done through the use of an MCB or internal fuse. As a company, we specify the use of MCBs with all of our devices The MCB will provide a back-up in case of a failure within the SPD, while also protecting the cable and giving a point of isolation for the SPD

QHow do I measure the cable lengths to ensure I meet the BS7671 requirements?

If the SPD is installed within the consumer unit, cable lengths will automatically be suitable When installing outside of a consumer unit, you must ensure that all cables combined are less than 1m in length. Length A will be from where you take your live supply to the MCB (this is ‘0’ if the MCB is on the busbar), Length B is from the MCB to the SPD and Length C is from the SPD to the closest earth point (not the MET) For a more detailed explanation of this, please look at the installation guide available on our website.

QWill an SPD installed in the consumer unit protect the whole domestic property?

An SPD in the consumer unit will massively reduce the risk of any internal damage within the electrical installation from overvoltage coming from the mains supply Obviously, there are other routes of entry into the electrical system, via aerials, telephone lines or any external cables, but there is no requirement in BS7671 to protect these routes

QDo I need to install Type 3 devices in a domestic installation?

There is no requirement to use Type 3 devices. The Type 2 on the consumer unit provides an enhanced level of voltage protection for the installation Type 3 devices would only be used in specific specialist circumstances

If you have any questions that I haven’t covered in this article, or would like any specific help with a project or installation, please contact me directly at: kirsty@surgedevices.co.uk

Every electrician with experience of working on a busy site knows how it feels to take responsibility for the other professionals around them When you are dealing with live electricity there’s no room for calculated risks and educated guesses.

The only way you can ensure your and your colleagues’ safety is by adopting adequate isolation procedures

For electrical systems where the supply has been cut off to allow dead working, Regulation 13 of the Electricity at work Regulations 1989 applies as follows:

‘Adequate precautions shall be taken to prevent electrical equipment, which has been made dead in order to prevent danger while work is carried out on or near that equipment, from becoming electrically charged during that work if danger may thereby arise ’

This establishes a clear requirement to ensure that conductors and equipment may not be inadvertently energised In other words, safe isolation

In practice, this means not only cutting off the supply but also ensuring the method of disconnection is secured in the OFF position and a caution notice or label is posted at the point of disconnection.

According to the Reporting of Injuries, Diseases and Dangerous Occurrences Regulations (RIDDOR) and although it is difficult to know how many of the following statistics were caused by inadequate safe isolation, in the five years between 2017 and 2022, there were 531 non-fatal incidents and 24 fatalities reported to the HSE which were caused by contact with electricity

The number of fatalities did drop dramatically during 2019 and 2020 due to

TOO LATE!

STEP 1: Check with the user that the supply is safe to isolate

STEP 2: Prove that your voltage indicator operates correctly with an approved proving unit

STEP 3: Test the circuit that you are isolating is powered off by performing the following combination of checks: Line-Neutral, Line-Earth and Earth-Neutral

STEP 4: Re-prove that your voltage indicator operates correctly with your proving unit

STEP 5: Refit the cover on the distribution board, Lockout and Tagout

STEP 6: Re-test again on the circuit that you are working on to confirm it is safely isolated

Covid-19, however, this does translate that you have roughly a 1 in 22 chance of being fatally injured if you are involved in an electrical incident in the UK To put this into a little more perspective, this is a dramatic difference compared to the 1 in 500 from other causes.

As well as electric shock, other electrically related injuries arise from burns, arcing and fires Many of the injuries can take a long while to heal and often result in life-changing conditions

With the 18th Edition AM2 now in full effect, safe isolation is continuing to be enforced across the industry, especially by bodies such as the NICEIC and NAPIT Although nothing has changed in the way of the testing requirement on installation test equipment, safe isolation is critical for the safety of yourself and the others around you

The preferred method is to isolate equipment or circuits using the main switch or distribution board switch disconnector The method of isolation should be locked off using a unique key, retained by the person carrying out the work, and a caution notice posted at the point of isolation

Where more than one operative is working on a circuit, a multi-lock hasp can be used to prevent the operation of the main isolator until such time as all persons working on the installation have completed their work and removed their padlocks from the hasp

”The practice of placing insulating tape over a circuit breaker is not an adequate or acceptable means of securing the device in the OFF position ”

Following the isolation of equipment or circuits and before starting work, it should be proved that the area you are about to work on is in fact dead The recommended method for doing this is by use of a test lamp or a two-pole tester (as recommended in HSE Guidance Note 38)

The test lamp or voltage detector should be proven to be working on a known live source or a proprietary

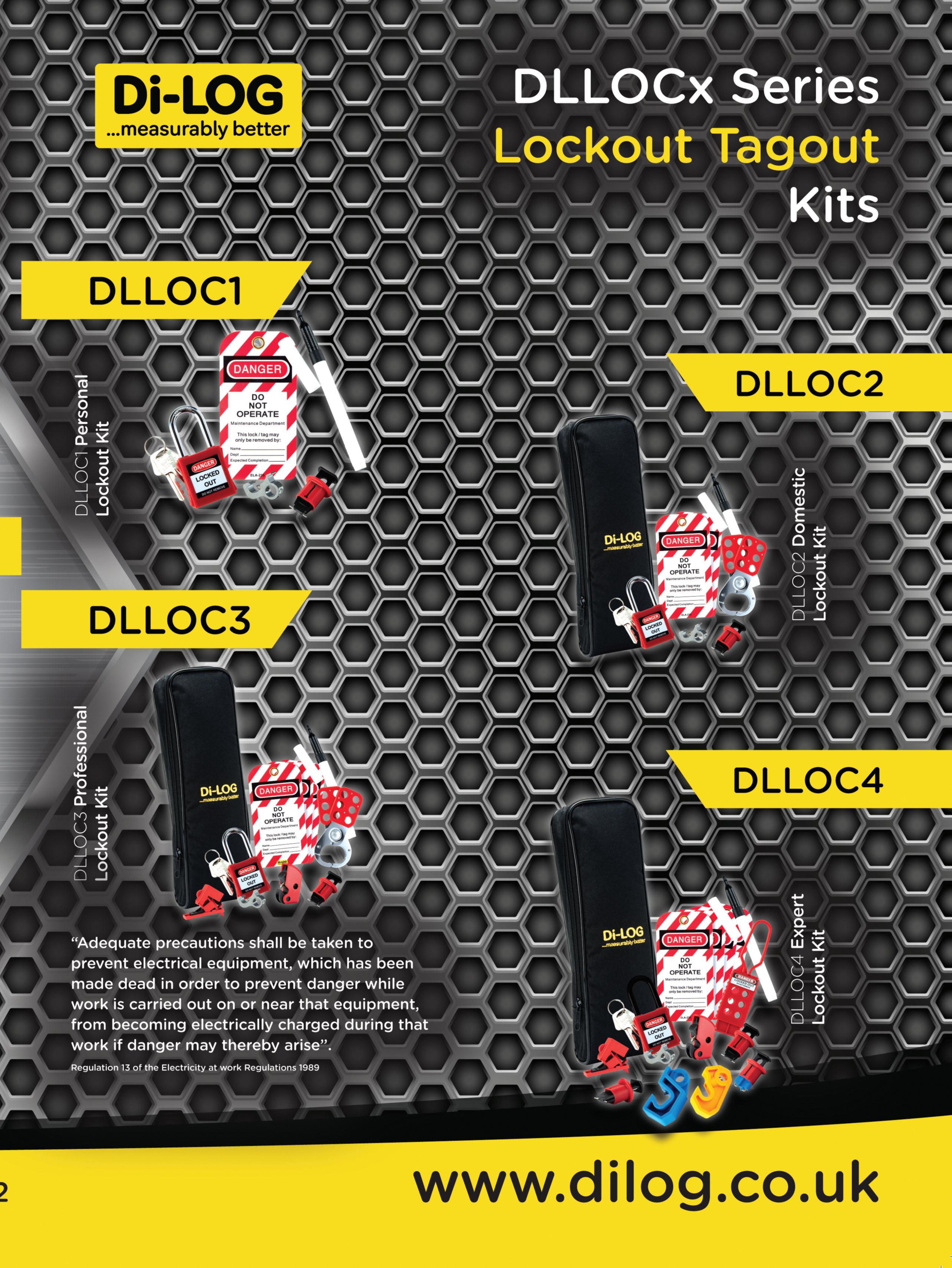

The Di-LOG range of ‘Lockout Kits’ are designed with safety, versatility and affordability in mind With the entry-level DLLOC1 – Personal Lockout Kit, you get a 38mm steel padlock, a universal MCB lock, a standard ‘pins-out’ MCB lock and a warning tag

The higher the level of the kit the more features are included By adding items such as multiple isolation lockout hasps the kits enable multiple persons to work on the same circuit, with the ability to hold up to six lockout padlocks

The DLLOC3 – Professional and DLLOC4 – Expert kits provide more scope to safely isolate a broader range of MCBs and main switches Items such as the larger universal MCB lockout device, large main switch lockout device, a fully insulated padlock and hasp, ensure all commercial and industrial applications are covered

proving unit All line, neutral, and protective conductors should be tested to prove they are dead

Electricians who regularly work on installations that have been energised should be equipped with devices for proving that conductors are dead Di-LOG’s latest range of safety equipment for working on LV Electrical Equipment includes an array of Lockout Kits, ranging from a simple single MCB ‘Personal Lockout Kit’ for isolation of individual circuits to the industrial ‘Expert Lockout Kit’ with mostly fully insulated lockout devices for virtually all individual and main sources of energisation.

GET MORE DETAILS ABOUT DI-LOG’S RANGE OF LOCKOUT KITS AT: WWW.RDR.LINK/EAN021

SECTION 1 ENDS!

SCAN THE QR CODE TO CLAIM YOUR CPD CREDIT FOR THIS SECTION OR VISIT

WWW.RDR.LINK/EAN041

BS 7671 Chapter 41 deals with protection against electric shock, and this is where the requirements for automatic disconnection in case of a fault can be found

The disconnection times stated in Table 41 1 are influenced by the type of earthing system and the voltage range used. Also, RCDs are included within the design for fault protection for certain installations, meaning there are many different parameters to be met

In general, there are two aspects involved with this protective measure:

● Basic protection is used to prevent contact with live parts, and

● Fault protection is provided by the protective earthing system and automatic disconnection in case of a fault

Fig 1 relates to TN systems and shows the

path of the Earth fault current in the event of line to Earth fault in one of the circuits. For clarity, only one circuit is shown, and it supplies a load with a metal casing that is connected to the Earth via the circuit protective conductor (CPC) The example shown is for a TN-S earthing system

The direction of the Earth fault current path is indicated by the arrows in Fig 1 It will be observed that the fault current flows in a loop It returns back to the supply transformer via the protective conductors, then goes through the winding of the transformer and returns to the fault within the installation via the line conductor

For TT systems, refer to Fig 2, where the mass of Earth between the installation and the origin forms part of the Earth fault current path

The resistance met by the fault current is known as impedance due to the presence of the transformer winding in the path, and the symbol for impedance is Z This fault path is called the Earth fault loop impedance and is abbreviated to Zs

The unit of impedance is the same as the unit of resistance, which is an ohm. The intention is that the fault current will be high enough to disconnect the overcurrent protective device within the required time, known as the disconnection time

The value of the Earth fault current is directly related to the value of operating voltage and Earth fault loop impedance, known simply as Ohm’s Law

Therefore, the lower the value of Zs, the higher the value of the Earth fault current and the quicker it will operate the protective device in order to disconnect the faulty circuit.

As the severity of an electric shock depends not only on the value of the current flowing but also upon the time that the current flows, BS 7671 quotes the maximum disconnection times for each type and rating of overcurrent protective device This means that the protective device of the circuit must operate to disconnect the electricity supply within these times in the event of a fault to Earth

Regulation 411 3 2 2 states that disconnection times in Table 41.1, found in

The experts at NAPIT take a closer look at the requirements for automatic disconnection in case of a fault.

BS 7671, shall be applied to final circuits with a rated current not exceeding:

● 63 A with one or more socket-outlets, and

● 32 A supplying only fixed connected current-using equipment.

The disconnection times for 230 V AC final circuits, found in Table 41 1, are:

● 0 4 s for TN systems

● 0.2 s for TT systems.

You should be aware that when disconnection is achieved in a TT system by an overcurrent protective device and protective equipotential bonding of all extraneous-conductive-parts has been carried out, in accordance with Regulation 411 3 1 2, the maximum disconnection times for TN systems may be used

In distribution circuits, i e , sub-mains, and for final circuits not covered by Regulation 411 3 2 2, Table 41 1 does not apply In TN systems, the disconnection time must not exceed 5 s; in TT systems, the disconnection time must not exceed 1 s (see Regulations 411 3 2 3 and 411 3 2 4)

When the Earth fault loop impedance, Zs, is measured using an Earth fault loop impedance tester, the reading obtained must be less than the relevant maximum value of Zs in the appropriate table.

Maximum Zs values are given in BS 7671

Tables 41 2, 41 3 and 41 4 The headings of these tables must be carefully noted to understand how each table is to be used

It should be noted that BS 7671 Tables 41 2, 41 3 and 41 4 all have a similar note at the end of the table.

This note states that the maximum impedance given in the table should not be exceeded if the impedance is measured when the circuit conductors are at their maximum operating temperature (i e , 70°C) Usually, the circuit conductors will be at much less than this when testing is carried out They may be assumed to be 20°C

Values taken at 20°C can be corrected to 70°C for 70°C cables by multiplying the maximum value of Zs by 0 8, as stated in Appendix 3 of BS 7671

Maximum Zs figures for commonly used devices, corrected for temperature, are produced in Table 1

RCDs used for fault protection

For TT Earthing systems, RCDs are often used to provide fault protection This is mainly due to the fact that Earth electrode

resistance is too excessive to meet the maximum Earth fault loop impedance requirements for the circuit’s protective device It is important that the electrode resistance remains stable and therefore should be as low as practicable (under 200 Ω is deemed satisfactory) Table 41 5 of BS 7671 lists the maximum Earth fault loop impedance values to ensure effective RCD operation, as summarised in Table 2.

Conclusion

We commonly see multiple protective devices used throughout installations, with ratings for different applications It is vital inspectors are careful to note the exact characteristics of the device to ensure the correct look-up table is used to confirm ADS can be achieved

When I first came across the above quote, I thought it would be from one of the great business minds or geniuses It was, in fact, said by Dwayne Johnson, otherwise known as wrestling superstar, The Rock

The Bright ‘Operations sector’ is about consistency of the ‘work’ of your business, the products and services it delivers The Operations sector is one of the ‘legs’ of our Bright 7 sector

model When you strengthen it to carry the weight of your business, you can grow bigger, go further and achieve things faster

To carry out installations consistently and to a high standard we use the following W O R K S process:

For this, we’ll utilise another acronym –F L E X – to ensure your systems are flexible, yet can still work under pressure

F

Map out your customer journey from start to finish A good idea is to create a flowchart with post-it notes or use a whiteboard This will help you to identify where things are working (or not) and can assist with identifying bottle necks or hot spots

L

Using the flowchart, we now need to ‘brain dump’ from all the team into a ‘how to’ manual List down (in step-by-step checklists) exactly how each area of the business works, much like a recipe book This does not have to be just text, it can be supported with photos, videos or screen captures

In order to engage the team with new or existing systems they need to be involved Training or brainstorming with them to get their ideas for improvements is crucial as they will know where problem areas are By showing that you’re willing to implement their ideas your team are much more likely to get behind them and will be more engaged in the business

The X-Factors are the ‘wow’ elements of your business – the things that will make your customers say: “wow that’s amazing” It’s those little touches that add to the experience and stay in your customers’ memory, meaning they’re more likely to tell others about you, helping you to win more referral work.

THE SECOND LETTER IN W.O.R.K.S IS ‘O’ WHICH STANDS FOR OPTIMISE. Once you've mapped out your flowchart, it’s time to look for ways to optimise it by improving existing systems or adding new technology to create better efficiencies

Could there be a better software system? Does your phone system need upgrading to incorporate things like VOIP, on-hold sales information or auto-attendant call routing? Does your website need an overhaul to include pop-ups, call backs or a live chat

option? Can you improve on training? There’s some excellent field service operations software systems available in the market, such as simPRO, which manages your operations from enquiry to invoicing Our clients love it, but we’ve found that you really need to have an office team member to use it well. For smaller 1-5 employee companies that may utilise their van as their office, the likes of Tradify, Servicem8 or Klipboard can be used

THE THIRD LETTER OF W.O.R.K.S IS ‘R’ WHICH STANDS FOR RESULTS. Ultimately, if you want to produce a great result for your clients you need to incorporate an element of project management to make sure they're getting what they want By managing the whole process and delivering the results along the way, you’ll start to realise that this is where the magic happens!

THE FOURTH LETTER OF W.O.R.K.S IS ‘K’ WHICH STANDS FOR KNOWLEDGE. This is about protecting the knowledge in your business Are you backing up your computers into the cloud? Have you got Disaster Recovery plans in place to keep the business running in the event of an emergency? How can you make sure that the information that might be in team members’ heads remains in your business?

THE LAST LETTER IN W.O.R.K.S IS ‘S’ WHICH STANDS FOR SPECIALIST. Finally, I would highly recommend that you have a ‘specialist’ in the business –someone who works specifically on operational organisation This could be an Operations Director/Manager and really needs to be someone who knows how to make sure that all the things you undertake as a business are done well, consistently and managed properly across the whole company

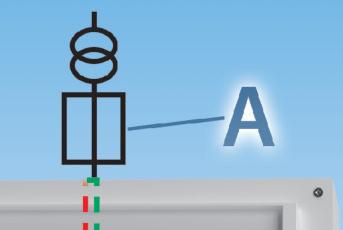

before we start, it should be noted that such types of storage media may be connected in various configurations to the host installation and/or any embedded generation. Manufacturer’s instructions should always be consulted

Any EESS consists of a number of component parts, including:

● Batteries

● Inverters

● Charge/discharge control equipment

● DC/DC conversion equipment

● Thermal management equipment

● EESS control equipment

● Independent earthing arrangement (where required)

● Monitoring and metering equipment (not discussed here)

All of these components may be arranged in a series of modules comprising several of the individual functions Their functionality is summarised in this article.

Within the scope of BS 7671, that is operating at a voltage not exceeding low voltage, an EESS may be categorised as a:

● residential EESS, or

● commercial and industrial EESS

An EESS may be designed and built for a particular application or it may be assembled from a range of component parts to provide the desired functionality. A self-contained EESS system is one in

which the components have been matched and assembled at the factory and is ready to be installed on delivery to site

Although exact terminology used in the various standards and guidance documents varies, an EESS may be constructed from a number of subsystems, including:

● the control subsystem containing the communication, management and protection functions and the user interface, and

● the primary subsystem containing the energy storage and power conversion functions and the point(s) of connection to the electrical power system

The two most commonly employed battery types in an EESS are deep-cycle lead-acid and lithium-ion

The following characteristics and factors will have an influence on choice of battery type employed:

● Operational lifespan.

This can be affected by a number of factors including:

■ The frequency of discharge, and

■ The depth of discharge (DOD) (greater DOD generally equates to shorter battery life)

■ Characteristic calendar life (projected life irrespective of usage)

■ Overcharge tolerance (lithium-ion batteries are more prone to damage than lead-acid)

● Required effective/usable energy storage capacity

● Charge/discharge efficiency. This can be affected by factors such as:

■ Battery type

■ Ambient temperature

■ Battery operational temperature

■ Battery age

■ Frequency of maintenance

● Required recovery time.

This is the time needed by an EESS, for the specific operating mode and operating conditions, to recover from a duty cycle so that it can be sufficiently recharged to serve the following duty cycle

Generally, lead-acid batteries perform less well across most of the above categories. However, they may still offer

the most cost-effective option in some cases based on the nature of the system and operational expectations

The arrangement of individual batteries or cells to create batteries/battery banks in order to achieve the desired terminal voltage and output current can vary. A system containing battery storage but no local generation is defined as a battery energy storage system (BESS) (see Fig 4)

Inverters: types & characteristics

An inverter is a static semi-conductor device (power converter) which converts DC to AC. Inverters often include additional functionalities, discussed later in this article

A number of types of inverter may be employed within an EESS to permit:

● Grid connection

● Standalone operation (without grid connection)

● Combination grid/standalone operation

● Bi-directional operation, which can allow output to the grid and/or the installation and also act as a charger for the storage batteries. Both grid connection and standalone bi-directional inverters are available

It should be noted that where an EESS is installed at a premises with an existing PV system designed to operate in parallel with the DNO supply only, and is not forming part of a prosumers low-voltage installation (PEI), the associated inverter will shut down when loss of mains or fluctuation in the supply characteristics outside of nominal parameters is detected

If any form of continued battery charging and/or operation of loads within the premises is required a second inverter or other power conversion equipment (charger/charge controller) will need to be

installed or the existing inverter could be replaced

This may be seen as the favourable option where the inverter has been operating for some time, as inverters are often the first component to fail and may be near end of life

In an EESS, an inverter/battery charger is a two-way device which converts:

● DC power from the batteries into AC to supply loads within an installation, and

● AC energy into DC energy to charge batteries

A charge controller sends power in one direction only to charge the batteries whilst also preventing current from draining back into the source of supply.

Inverter/chargers are not designed to charge batteries directly from the DC current provided by an unstable source such as, for example, a PV system A charge controller is needed to match the PV output voltage to the battery and to regulate charging.

In general, an EESS will contain both an inverter/battery charger and a charge controller to ensure optimum functionality and efficiency

In the case of an EESS utilising a PV generator, there may be insufficient capacity to charge the storage batteries effectively using a charge controller alone in the winter or during extended periods of cloudy weather This can affect energy availability and so an inverter/charger will be required to keep batteries adequately charged from the grid supply.

A DC/DC converter makes it possible to:

● Raise/step-up battery output voltage

● Provide a constant DC output voltage regardless of fluctuations in battery output voltage

● Provide galvanic isolation of the battery from the rest of the EESS to provide, for example, corrosion mitigation

It can also simplify the matching of multiple battery sets to the EESS.

Battery discharge controller

A discharge controller can provide the following:

● Control of the rate of discharge

● Prevention of further discharge of batteries when their depth of discharge (DOD) limit is reached (that is, the percentage of total capacity that can be utilised)

● Feedback on battery temperature to optimise efficiency and/or minimise damage

● Control of the times at which batteries can discharge to loads

● Prevent discharge until battery charge thresholds have been reached

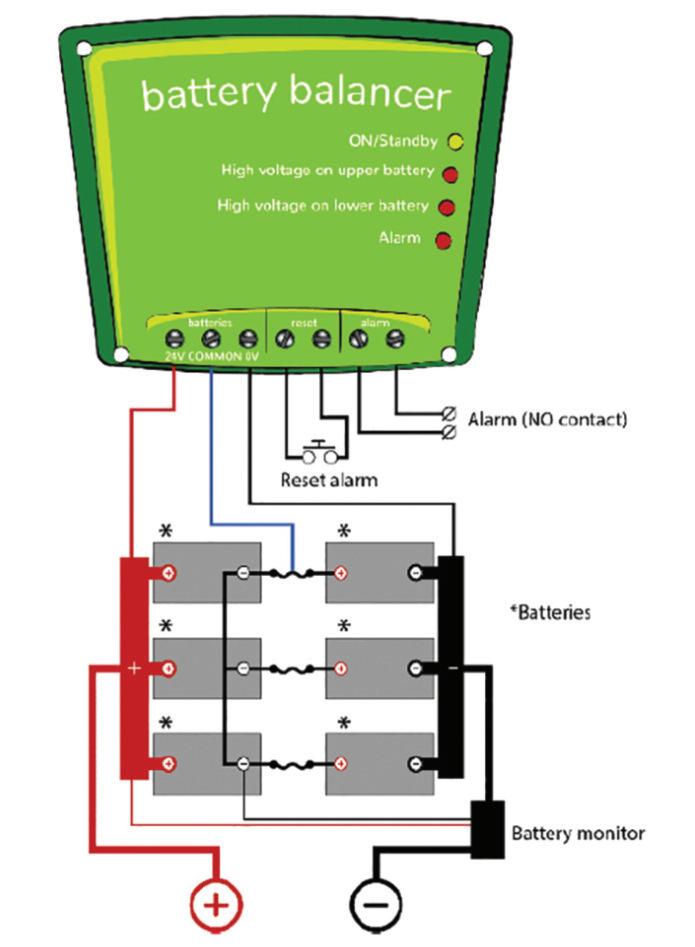

Battery balancer

The service life of batteries forming part of a bank can be shortened considerably by a charge imbalance

A cell or battery having even slightly higher internal leakage current in a bank of several series connected cells or batteries will cause undercharge of the whole battery in relation to the other cells or batteries to which it is connected in series, which may also be subjected to overcharging

Left untreated this can set up a cyclical passage of current between batteries or cells and a resultant temperature increase or thermal runaway. Overcharging can cause damage due to excessive gassing.

In the case of L-Ion batteries the aforementioned effects can result in an explosion and/or fire hazard For lead-acid batteries, undercharging can cause sulphation of the batteries/cells with the lower initial state of charge

Although varying in complexity, thermal management systems maintain the component parts of an EESS within their normal operational temperature limits to maintain functionality and efficiency and to prevent thermal damage At the most basic level, this could be a thermal cut-out In more complex systems, particularly where continuity of supply is essential, it might trigger cooling equipment to start and/or instigate some degree of non-essential load shedding

This term is often used where multiple components/functions such as inverters, battery chargers and controllers, DC/DC converters, battery discharge controllers and thermal management equipment are integrated into a single unit

This may monitor the availability and quality of the connected sources of supply, control charge and discharge operations and may also interface with external resources such as those of distributors and suppliers. It may also instigate other actions such as making/breaking the connection to a public distribution network, load shedding, information exchange and provision of information to building user/operator

An EESS operating in Island mode; that is, where supply to all or part of an installation is maintained from internal sources although the supply from the grid has been disconnected, cannot rely on the earthing arrangement provided by distributor when running independently of the DNO supply (551 4 3 2 1) as doing so could place persons working on the distribution system in danger

A typical EEES consists of a number of component parts designed to provide a system which is both economical and remains reliable for its predicted service life An EEES may be assembled from a number of components or sub-sets, or may be manufactured as a self-contained system

The column where you get to put your lighting questions to the head of the Ovia lighting business, Mike Collins, and his team of technical experts

BEEN ASKED TO QUOTE FOR LIGHTING

TO BE SUSPENDED OVER A NUMBER OF SNOOKER TABLES APPARENTLY, THERE IS A CIBSE AND SPORTS ENGLAND (LG4) REQUIREMENT THAT THE LIGHT VALUE SHOULD BE 500 LUX ON THE TABLE WITH A MAX OF 0 8 REDUCTION FACTOR THE CUSTOMER IS CONCERNED THE FULL LED MAY HAVE A HIGH GLARE FOR THE SNOOKER PLAYERS AND THAT PARTS OF THE EXTREMES (POCKETS) MAY BE IN SHADOW. CAN YOU SUGGEST CAT 2 OR DIFFUSED LIGHTING THAT CAN REDUCE GLARE? THE TABLES ARE FULL SIZE (12 FT X 6 FT), WITH A REFLECTIVE INDEX IN THE LOW 40S OR LATE 30S

The guidelines for snooker are split into three categories based on the level of competition that is being played

Assuming that this isn’t elite level snooker and is more toward recreational, for this application 500 lux is required on the table with a desired unifor mity of 0 8 This is quite a high level of unifor mity and should ensure vir tually no shadowing

Unifor mity is the ratio of the minimum lighting level to the average lighting level in a specific area, in this case a snooker table. The higher the level of unifor mity the less difference there is between the minimum and average level of illumination If the customer has concer ns regarding the glare, we’d steer more toward a UGR friendly luminaire UGR stands for unified glare rating and measures the amount of discomfor t causing glare UGR 19 is considered a good level of glare for wor king at a computer and is at the lower end of the glare rating. In summar y, we would aim to achieve 500 lux with a unifor mity of 0 8 using a UGR 19 luminaire The Ovia Inceptor Slate is a premium range of LED panel lights with a low UGR19 diffuser, making them ideal for this type of installation

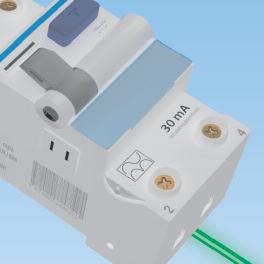

In the workplace power continuity is an important factor. Business services must not be interrupted by unwanted power outages That’s why RCBOs (Residual Current Breaker with Over-Current) should be used when there is also a requirement for 30mA protection for the users of the installation Additionally, personal safety is an equally important factor

Protecting users to Amendment 2

Regulation 411 3 3 of the Wiring Regulations was revised by Amendment 2 This regulation now requires additional protection by means of a 30mA device for users of socket outlets (not rated higher than 32A) in locations where they’re liable to be used by persons of capability BA1, BA2 or BA3

The terms BA1, BA2 or BA3 probably need some further explanation Appendix 5 includes a list of external influences, and under the sub-heading of ‘Utilization’ BA refers to the capability of persons BA1 is described as an ordinary person (a person

who is neither a skilled person nor an instructed person) BA2 as children, and BA3 as disabled

No exceptions permitted

So, in all locations where socket outlets (not rated higher than 32A) are liable to be used by ordinary persons, disabled persons, or children, additional protection by use of a 30mA device is mandatory No exceptions are permitted

Providing protection

Providing additional protection and maintaining power continuity is actually quite easy Each circuit should be protected by an individual Type A 30mA RCBO This will meet the requirements of Regulation 411 3 3 and the requirements of the business because it will eradicate unwanted tripping and guarantee that all healthy circuits remain in service.

Other considerations

In a modern workplace, school or

university environment, for example, the connected equipment, and portable devices will have a significant impact upon the design of the installation and will no doubt bring DC influences and PE currents into consideration for both the designer and installer

Regulation 531.3.2 requires protective conductor currents (standing earth leakage not due to a fault) to be limited to 9mA for a 30mA device in order to help to avoid unwanted tripping, but that can’t be achieved if several circuits are protected by one device

Designers will not only have to take account of PE currents when dividing the installation into the necessary number of circuits, there are also the requirements of Chapter 31 & Regulations 314 1 to consider Regulation 314 1 requires the installation to be divided into the necessary number of circuits to:

-

the possibility of unwanted tripping of RCDs, - facilitate safe inspection, testing and maintenance

Wherever additional protection by a 30mA device is required each circuit should be served by an individual Type A RCBO in order to meet the requirements of BS7671, including Amendment 2

Amendment

to the 18th Edition Wiring Regulations, the team at Electrium provide us with more detail as to the correct use of RCBOs in the workplace.

The experts at Vent-Axia provide advice on Part F of the Building Regulations for commercial and industrial buildings.

Part F of the Building Regulations came into effect from 15th June 2022, but how do they affect commercial and industrial clients?

With Part F (Means of Ventilation) focusing heavily on health and wellbeing, a key addition to the document is a new section on monitoring indoor air quality (IAQ) Other key points include designing ventilation systems to minimise external pollutants entering indoor spaces, and assessing ventilation requirements when installing energy efficiency measures to ensure good IAQ.