NEW Airfix Pulling Tower

See details on page 2

Keep up to date? See details on page 3 WORLD LEADER IN CAR BODY

See details on page 2

Keep up to date? See details on page 3 WORLD LEADER IN CAR BODY

ECO DESIGN 2019/1784

The Facts

The new ECO Design regulations are aimed at reducing carbon footprint and apply to Welding Equipment used in a professional capacity.

• They are based on the electrical energy consumption of the welding machine

• Efficiency limits have been set for when the machine is in use and on standby

• The effect of this is that many older technology machines will not meet the standard required

There are two technologies used to produce welding machines:

1. Transformer Technology

• Sometimes also called ‘Step Voltage’ for MIG welding.

• As a generalization, transformer welding machines will not meet the new regulations. So this regulation will progressively mark the end of transformer welders.

2. Inverter Technology

• These machines use complex electronic switch mode power supplies.

• They are typically lighter, smaller and may have electronic control panels.

• As a generalization, an inverter welder will meet the new regulations.

What does this mean for professional welders?

• For welding machines in current use there is no impact. They can continue to be used

• If a new machine is purchased from 1st January 2023, it will need to meet the new regulations

• When looking to buy a new welding machine, make sure it is ECO Design 2019/1784 compliant

• Manufacturers will have to ensure spare parts are readily available for at least 10 years for all machines

Advantages of the NEW ECO Design 2019/1784

• The latest technology inverter machines are often equipped with advanced features, so improve the welding process

• Energy savings of more than 20% are achievable from the best machines

• The mandating of good spare parts provision reduces the whole life costs of running a machine & minimises premature scrappage with associated environmental benefits

• Reduces carbon footprint

GYS are the largest manufacturer of welding machines in Europe and through a large UK subsidiary in Rugby we are well placed to provide all that is required by the new regulation.

All of the machines in this brochure are ECO Design Compliant - look for the logo

Operates from 10 Amps

Intelligent Synergies

• Class leading specification

• Max current 200Amps

• Single Phase

• Synergic control for Steel, AlSi, AlMg, CuSi3, CuA18, CrNi

• Enter wire diameter, metal type, thickness and gas, the product will automatically determine the settings

Easy to use 3.5” Digital Screen

• Memory for popular repeated jobs (up to 200)

• Portability - settings can be transferred to another machine

• Precise control Output adjustable in increments of just 0.1A

• Easy or Expert mode

SIMPLIFIED SETTINGS

• High quality 4 roll wire feed for smooth wire delivery

• Euro torch connector

• Support for gas bottle

Single phase 10-200A current range

Memory for popular repeated jobs (up to 200)

Portability - settings can be transferred to another machine

Precise control

Output adjustable in increments of just 0.1A

Easy or Expert mode

Can take 200mm wire reels

High quality 4 roll wire feeder rollers for consistent speed and supply

Integrated gas bottle shelf

Operates from 10 Amps

Intelligent Synergies

Easy to use 3.5” Digital Screen

ref: U75140

Single phase

10-200A current range

Memory for popular repeated jobs (up to 200)

Portability - settings can be transferred to another machine

Precise control

Output adjustable in increments of just 0.1A

Easy or Expert mode

Can take 200mm wire reels

High quality 4 roll wire feeder rollers for consistent speed and supply Integrated gas bottle shelf

Reference: U75140

The adjustable inductance (Self) changes the arc characteristics in MIG / M welding and all precise w

£2,025.00

£2,556.00

TIWELD range is designed and om a reinforced, galvanised-steel ompact" versions feature otection pads to better protect elding machine from routine knocks.

SAVE TIME INCREASE EFFICIENCY NO TORCH CHANGE NO GAS CHANGE NO WIRE REEL CHANGE

ref: U75165

Single phase

10-200A current range

Memory for popular repeated jobs (up to 200) Portability - settings can be transferred to another machine

Precise control

Output adjustable in increments of just 0.1A

Easy or Expert mode

Can take 200mm wire reels

High quality 4 roll wire feeder rollers for consistent speed and supply

Integrated gas bottle shelf

The adjustable inductance (Self) changes the arc characteristics in MIG / MAG welding and allows for even more precise welding as a result.

£2,599.00

£3,261.30

Pulse MIG welding offers advantages for welding of aluminium as it reduces heat input critical for thin panels.

Car manufacturers are moving to specify pulse MIG welders to take advantage of this technology. The introduction of pulse MIG also brings new levels of electronic control through powerful software that ensures operation is faster and easier for the technician.

220A Single phase pulse mig welder

Reduces temperature while maintaining penetration

15-220Amp inverter

Meets car manufacturers specification

U65024

U75024

The adjustable inductance (Self) changes the arc characteristics in MIG / MAG welding and allows for even more precise welding as a result.

AUTOPULSE

ref: 069855

ECO POWER

220A Single phase pulse mig welder

15-220Amp inverter

Holds 2 different torches: steel & aluminium

Two 4m3 bottle supports to carry 2 gas types

Meets car manufacturers specification

Cable support

The adjustable inductance (Self) changes the arc characteristics in MIG / MAG welding and allows for even more precise welding as a result.

AUTOPULSE 220

ref: U36703

220A Single phase pulse mig

15-220 Amp

Holds 3 different torches: steel & aluminium

Two 4m3 bottle supports

The MULTIWELD range is designed and built from a reinforced, galvanised-steel frame. The "compact" versions feature impact-protection pads to better protect the welding machine from routine knocks.

2 gas types

Meets car manufacturers

Cable support

Ideal for car body repair earth clamp steel torch

The MULTIWELD range is designed built from a reinforced, galvanised-steel frame. The "compact" versions feature impact-protection pads to better the welding machine from routine

TRACEABILITY

PORTABILITY

5 MODES

- Dynamic Standard

- Pulse

- Pulse in Pulse

- Manual - Cold Pulse

FULLY DIGITAL

65+ SYNERGIES

UPDATES

-Easy USB updates

M3 KIT

mig

AUTOPULSE 320 - T3

ref: U59184

Three phase 400V

15-320 Amp

Holds 3 different torches: CuSi, steel & aluminium

Can take 200mm wire reels

High quality 4 roll wire feeder rollers for consistent speed and supply

Digital screen and simple user interface

Output adjustable in increments of 0.1v for precise control

Two 4m3 bottle supports to carry

2 gas types

Models S X 3 & Y

adjustable inductance (Self) changes characteristics in MIG / M elding and allows for e precise welding as a result.

The MULTIWELD range is designed and built from a reinforced, galvanised-steel frame. The "compact" versions feature impact-protection pads to better p the welding machine from routine knocks.

Also included in the kit is a box of contact tipsMB15/MB25

The adjustable inductance (Self) changes the arc characteristics in MIG / MAG welding and allows for even more precise welding as a result.

The MULTIWELD built from a reinforced, frame. The "compact" impact-protection the

£8,014.71 £5,599.00

GYS have introduced major developments to SPOT welding machines in the last year, we now offer a choice of 3 machines all with the revolutionary new Genius Gun

- Quick change change the arm in 5 seconds no need to disconnect coolant pipes or to grease the connection

- Tilt the arm to increase access

- Automatic G Gun - automatic settings with all G arms

- Automatic X Gun - add the optional G (X) arm with automatic operation (unique to GYS)

- Faster operation - up to 20 welds per minute

- Integrated GYRO for optimum manoeuvrability

- Range of G arms - 12 in total offering access of up to 100 cm

STEEL

EASYLINER 39.02 KIT PLUS ref: U53019

Dent puller for steel body panels

Maximum welding current 3800A

Easy operation with microprocessor control

Automatic welding

Panel shrinking capabilities, slide hammer and stud welding

Preset adjustable power setting for designated tools

GYSPOT 39.02 accessories kit

trolley

Reference: U53019

manuliner for gun £1,898.16

STEEL

SPEEDLINER EXPERT 230 KIT ref: U35045

240V, single phase, auto body repair station including spotter

Spotter with automatic contact ignition

Maximum welding current 3800A

Microprocessor control

Easy operation | Automatic welding

Time per weld can be selected in manual mode | Power optimisation

Multifunction gun

GYSPOT PRO 230 levelling bar levelling lever without hook

accessories kit for spotter

consumables box for steel 3 lifting rods 150/300/ 500mm

ringmatic ring load 6 gripping multihook head 4 gripping multihook head

manuspot set of 2 x 55mm ext. joints magnetic earth

accessories storage reinforced levelling bar protection cover

Reference: U35045

£3,950.00

£4,244.67

ALUMINIUM STEEL

Dent Pulling Workstation ref: U35073

Increase repair quality and productivity

Professional steel and aluminium dent pulling system

GYS easy tool connection system

New manual quick release system

Easy tool identification with pre-set parameters

Steel shrinking, stud, wavy wire and pulling keys capabilities

Max welding current 3800A (steel) and 7500A (aluminium)

Reference: U35073

GYSDUCTION AUTO is a powerful instantaneous induction heater

Designed specifically for car body repair

GYSDUCTION is supplied as a powerful generator with accessories of your choice (see table below)

Modular system

2400W power output

Instant heating, no flame

Only heats metal parts with accuracy whilst protecting the adjacent parts (no need to remove engine parts) Remove parts without using solvent.

As a supplement to the inductors, the scrapers are essential to remove logo/badges and stone chip protection

To quickly and easily remove all adhesives and strips and side mouldings in a few minutes without any damage

DENT

To peel off welded metal and burn off stone guard protection with the heated scraper. It is also suitable to remove glass (rear window, rear quarter, light, panoramic roof ..)

To warm and release all types of mechanical parts in a few seconds such as bolts, screws, shock absorbers, track rod ends...

SPIRAL INDUCTOR

To warm and release all types of mechanical parts in a few seconds such as bolts, screws, shock absorbers, track rod ends...

Extraction Unit

GYSDUST SELF EXTRACTOR ref: 077058

Designed for aluminium repairs. Suitable with all types of pneumatic commercial sanders

ATEX Rated Category 3 Group II 7kg dust container capacity

Supplied with earth lead to dust bag & 5m hose

Vehicle Lifting

Slimline design fits under low level vehicles

Fully pneumatic - no electric supply needed

Lifts vehicles up to 2.2T

Lifts front or back of vehicle up to 60cm

Two lifts to raise entire vehicle - Fully pneumatic

Directional wheels

Articulated arm

W x H x D: 140 x 55 x 14 cm / 120Kg

SPOTLIFT PRO MOBILE ref: 055896

Mobile Hydraulic Vehicle Lift

Skates rotate the vehicle up to 360º

Fully pneumatic - no electric supply needed

Lifts vehicles up to 2.2T - Max vehicle height 58cm

Hydro pneumatic pump, no electric supply needed

Pneumatic lift designed to lift the front or rear of the vehicle

£2,746.00 £2,350.00 Reference:

055896

£3,454.00 £2,950.00

GYSPRESS 10T

Riveter ref: U63303

Integrated pressure gauge | Quick arm change design

10 tonnes of pressure | Arm rotates 360 degrees

Magnetic matrix for easy positioning

Traceability has been a normal function on spot welders for more than 10 years elevating levels of safety in the repair process.

The GYSPRESS connected offers digital traceability. It gives a comprehensive report showing:

- Rivet reference number

- Die reference number

- Pressure set

- Actual pressure achieved

Allowing faster, error free and safer riveting.

GYSPRESS Connected is a breakthrough in safety and usability for the bodyshop riveting tool.

GYSPRESS CONNECTED

Riveter ref: U63861

Integrated pressure gauge | Quick arm change design

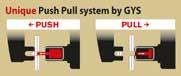

10 tonnes of pressure | 2 tonnes pull - Unique Push Pull system

Arm rotates 360 degrees

Magnetic matrix for easy positioning