LABOUR

Examining labour shortages in Canadian manufacturing p.8

ENVIRONMENT

The challenge to reduce waste in Ontario p.14

BUSINESS

How acquisitions help expand production capacity p.16

A 3D PRINTER ABOARD A SHIP

Could 3D printing disrupt parts manufacturing for ships? p.10

APRIL 2024 PLANT.CA

SUBMIT APPLICATION HIRE STUDENTS GET WAGE SUBSIDY Get Talent Get Money Get Started apply today Today’s students will become part of your workforce. You can help shorten the distance. 1 2 3 WORK INTEGRATED LEARNING WWW.EMCCANADA.ORG/WIL

8 REDEFINING THE LANDSCAPE

Turning the tides on labour shortages in Canadian manufacturing.

Cover story

10

A 3D PRINTER ABOARD A SHIP

Could 3D printing disrupt parts manufacturing for ships?

14

THE SUSTAINABILITY RESPONSIBILITY

Ontario manufacturers challenged to reduce waste.

16 BUSINESS OPERATIONS

Gincor Werx acquires Wiltsie Truck Bodies to expand their production capacity. 8

10

14

16 19

2024

APRIL

INSIDE

In every issue 4 EDITORIAL 6 NEWS BULLETINS 19 OPINION COLUMN Getting on the bus of the future by Richard Kunst. 21 TECH CENTRE Cover photo credit: Dmitry / Adobe Stock @PLANT_Magazine April 2024 / Plant 3

BY MARYAM FARAG

BY MARYAM FARAG

Embracing the future

As the new editor of Plant magazine, I’m happy to welcome you to an issue that marks a new chapter in our journey together.

Canada’s manufacturing landscape is rich with potential, driven by a collective ambition to not only excel in production efficiency and innovation, but also to lead in sustainable and responsible manufacturing practices.

As we navigate the challenges of environmental sustainability, the issue features how Canadian manufacturers are integ rating Cleantech solutions into their operations. From leveraging renewable energy sources to adopting waste reduction techniques, these stories illuminate the path toward a greener, more sustainable manufacturing sector.

Equally transformative is the rise of 3D printing technology, or additive manufacturing, which has emerged as a cornerstone of innovation in manufacturing. This issue also covers how Canadian companies are harnessing the power of 3D printing to revolutionize product development, from prototyping to full-scale production.We explore the impact of this technology on reducing lead times, enhancing customization, and driving efficiency, all while opening up new possibilities for Canadian manufacturing on the global stage.

Manufacturing is the backbone of our economy, driving innovation, creating jobs, and fostering growth across diverse industries. As we navigate through the ever-evolving landscape of technology, sustainability, and globalization, Plant remains committed to serving as your trusted companion,

offer ing valuable insights and perspectives to help you thrive in this dynamic environment.

In every issue of Plant, you will find a rich collection of stories – from profiles of pioneering companies and visionary leaders to in-depth features on cutting-edge technologies and best practices.

We will delve into the challenges and opportunities facing the manufacturing sector, exploring topics such as digital transformation, supply chain resilience, workforce development, and environmental sustainability.

But beyond the headlines and statistics, Plant is about the people behind the machines – the passionate innovators, dedicated workers, and forward-thinking entrepreneurs who drive progress and shape the future of Canadian manufacturing.

As your new editor, I am committed to upholding the legacy of excellence that Plant is known for, while also embracing new ideas and perspectives to ensure that we remain at the forefront of industry innovation. I invite you to join me on this journey as we explore the opportunities, confront the challenges, and celebrate the achievements of the Canadian manufacturing community.

Please reach me at mf arag@annexbusinessmedia.ca for any suggestions, questions or comments. I’m always happy to hear from our audience.

From all of us at Plant magazine, stay safe and well.

MARYAM FARAG, EDITOR

Comments? E-mail mfarag@annexbusinessmedia.com

C ANADA’S MANUFACTURING VOICE

APRIL 2024 • Volume 83, Number 1

READER SERVICE

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: (416) 510-5113

Fax: (416) 510-6875

email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400

Toronto, ON M2H 3R1

EDITOR Maryam Farag

226-931-4194 · mfarag@annexbusinessmedia.com

SENIOR PUBLISHER Scott Atkinson 416-510-5207 · satkinson@ annexbusinessmedia.com

NATIONAL ACCOUNT MANAGER Ilana Fawcett

416-829-1221 · ifawcett@annexbusinessmedia.com

MEDIA DESIGNER Curtis Martin

ACCOUNT COORDINATOR Debbie Smith 416-510-5107 · dsmith@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER Beata Olechnowicz 416-510-5182 · bolechnowicz@annexbusinessmedia.com

GROUP PUBLISHER Paul Grossinger pgrossinger@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

ANNEX BUSINESS MEDIA

111 Gordon Baker Road, Suite 400 Toronto, ON M2H 3R1

Tel (416) 442-5600 · Fax (416) 510-5134 www.annexweb.com

SUBSCRIPTION RATES

Canada – $77.52 per year

USA – $205.02 (CAD) per year

International – $205.02 (CAD) per year

Single copy – Canada $12.00

Add applicable taxes to all rates. Combined, expanded or premium issues, which count as two subscription issues.

ISSN: 1929-6606 (Print), 1929-6614 (Online).

PUBLICATIONS MAIL AGREEMENT NO. 40065710

Return undeliverable Canadian addresses to: PLANT Circulation Department, 111 Gordon Baker Rd. Suite 400, Toronto, ON M2H 3R1

©2024 Annex Business Media. All rights reserved. Performance claims for products listed in this issue are made by contributing manufacturers and agencies. PLANT receives unsolicited materials including letters to the editor, press releases, promotional items and images from time to time. PLANT, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort. This statement does not apply to materials/pitches submitted by freelance writers, photographers or illustrators in accordance with known industry practices.

PRINTED IN CANADA

EDITORIAL

Connect with Plant magazine @PLANT_Magazine facebook.com/PlantMagazine/ /plant-magazine plant.ca

4 Plant / April 2024 PLANT.CA

The Secret to Keeping Electronics Cool! !

Bene ts of Cabinet Cooler® Systems

• Less expensive to purchase than refrigerant A/C units

• Less expensive to operate than refrigerant A/C units

• Quicker to install than heat exchangers and refrigerant A/C units

• Little to no maintenance

• More reliable in dirty, hot, or remote environments than alternative cooling products

• Not a ected by machine vibration which can cause refrigerant leaks

• Ambient temperature does not a ect performance like it will with alternative cooling products

NEMA 12

For large heat loads up to 5,600 Btu/hr.

• Enclosure remains dust-tight and oil-tight

• Measures 8" (203mm) high

• Mounts top, side or bottom

NEMA 4 and 4X

For heat loads up to 5,600 Btu/hr.

• Enclosure remains dust-tight, oil-tight and splash resistant

• Suitable for wet locations where coolant spray or washdown can occur

Type 316 Stainless Steel

For NEMA 4X applications available for heat loads up to 5,600 Btu/hr.

• Resists harsh environments not suitable for Type 303/304SS

• Ideal for food and chemical processing, pharmaceutical, foundries, heat treating and other corrosive environments

Hazardous Location and ATEX

For use with classi ed enclosure purge and pressurization systems. Available for classi ed environments up to 5,600 Btu/hr.

• Maintain NEMA 4/4X integrity

• For hazardous/explosive environments

• CE compliant

High Temperature

For NEMA 12, 4 and 4X applications. Available for heat loads in many capacities up to 5,600 Btu/hr.

• Suitable for ambients up to 200°F (93°C)

• Ideal for mounting near ovens, furnaces, and other hot locations

Don’t Blow A Fan on an Open Cabinet!

It is an OSHA violation that presents a shock hazard to personnel.

The fan blows hot, humid, dirty air at the electronics.

The Real Solution!

Stop electronic downtime with an EXAIR Cabinet Cooler System! The complete line of low cost Cabinet Cooler Systems are in stock and can ship today. They mount in minutes through an ordinary electrical knockout and have no moving parts to wear out. Thermostat control to minimize compressed air use is available for all models. All Cabinet Coolers are UL Listed, UL Classi ed and /or CE Compliant.

Non-Hazardous Purge

Keep a slight positive pressure on the enclosure to keep dirt from entering through small holes or conduits. For use in non-hazardous locations.

• Uses only 1 SCFM in purge mode

• For heat loads up to 5,600 Btu/hr.

• NEMA 12, 4 and 4X

If you would like to discuss an application,

11510 Goldcoast Drive Cincinnati, Ohio 45249-1621 (800) 903-9247/fax: (513)

contact:

671-3363

Cabinet Cooler Systems

GO TO https://exair.co/18_440

INDUSTRY

FRANKLIN ELECTRIC RANKED ONE OF THE BEST PLACES TO WORK IN INDIANA

Franklin Electric Co. Inc. has been named to the Indiana Chamber’s 2024 list of Best Places to Work in Indiana.

The Chamber announced this year’s winners on its website; rankings will be unveiled at an awards event held on May 8. The recognition is one of several the company received in the past 12 months, including awards at the national level presented by Newsweek and USA Today.

The Indiana Chamber uses the Best Places award to recognize companies that demonstrate a commitment to fostering workplace cultures that instill pride in their employees. In addition to company input, the Chamber’s nomination review process includes a comprehensive employee survey component.This survey helps identify a company’s strengths and weaknesses and weighs heavily in compiling the winning list. The Workforce research Group handled the selection process.

“The fact that this award utilizes our employees’ input makes this recognition especially meaningful,” said Gregg Sengstack, Chairperson of the Board and Chief Executive Officer. “We’re proud to call Indiana home, and we always strive to create a workplace culture that is positive, supportive and valued.”

Winners were selected from four categories: small companies of between 15 and 74 U.S. employees; medium companies of between 75 and 249 U.S. employees; large companies of between 250 and 999 U.S. employees; and major companies with 1,000 or more U.S. employees. Franklin Electric was one of only two major companies based in Fort Wayne, IN, named to this year’s list.

GOVERNMENT GOVERNMENT OF CANADA SUPPORTS ESTABLISHMENT OF TWO AUTOMOTIVE AND MOBILITY TECHNOLOGY PILOTING SITES

During the Canadian International AutoShow, Filomena Tassi, Minister responsible for the Federal Economic Development Agency for Southern Ontario (FedDev Ontario), and Vance Badawey, Parliamentary Secretary to the Minister of Transport, announced an investment of $8-million for the Ontario Centre of Innovation (OCI), through the Ontario Vehicle Innovation Network (OVIN), to establish two live-environment piloting sites to support the development and commercialization of new transportation technologies and innovative solutions in southern Ontario.

of Innovation (OCI). “With the establishment of world-class testing sites through the Ontario Vehicle Innovation Network, we are thrilled to support more than 40 companies to pilot cutting-edge electric, as well as connected and autonomous vehicle technologies. This initiative not only drives economic growth but also accelerates our progress toward a more sustainable future for all Canadians.”

$8$ MILLION announced by FedDev Ontario as an invetsment for the Ontario Centre of Innovation

With one location in Toronto focusing on urban transportation and the other in Windsor/Sarnia focused on cross-border and multi-modal scenarios, these sites will act as a launch pad for over 40 SMEs as they pilot and commercialize over 40 new technologies, predominantly within the ZEV and CAV areas.

“Southern Ontario plays a vital role in driving economic growth, especially when it comes to CAV and EV-related innovation and production,” said Filomena Tassi, Minister responsible for the Federal Economic Development Agency for Southern Ontario. “OVIN’s Pilot Zones in Toronto and Windsor/Sarnia will support the testing and validating of cleaner and more efficient mobility technologies, which will help make a brighter future for us all.”

This project will create 345 jobs and contribute to “Canada’s goal of reaching net-zero emissions by 2050 through the deployment of cleaner and more efficient technologies.”

While at the AutoShow, Minister Tassi had the opportunity to view up and coming EV technologies at Electric City, meet with companies supported by OVIN, and test drive the future of mobility in an EV vehicle at the AutoShow test track.

“Today’s announcement by the Government of Canada marks a significant milestone in advancing clean automobility innovation in southern Ontario,” said Claudia Krywiak, President and CEO, Ontario Centre

BUSINESS OPERATIONS

STANTEC SELECTED TO DESIGN £4 BILLION BATTERY MANUFACTURING FACILITY

Stantec has been selected to provide integrated design services for Ag ratas, Tata Group’s global battery business, who are building a battery cell manufacturing facility on the Gravity Smart Campus in the United Kingdom (U.K.).

The new advanced manufacturing facility, comprising three separate buildings with associated ancillary structures, will create up to 4,000 jobs on site over the lifespan of the project and thousands more in the supply chain.

“The Agratas facility will be pioneering in battery cell production, addressing demand in the advanced manufacturing space in the U.K. head-on, while benefiting productivity, the climate, and the economy,” said Gord Johnston, president and chief executive officer of Stantec. “Stantec has strong capabilities in the advanced manufacturing space, and we look forward to working closely with Agratas to provide our significant breadth and depth of experience and support the successful completion of its project.”

“We look forward to working with Stantec to design the U.K.’s largest battery cell manufacturing facility. Using state-of-the-art technology, our facility will power the transition

NEWS

Visit plant.ca for the latest new products, news and industry events. 6 Plant / April 2024 PLANT.CA

to electric mobility and clean energy storage,” said Joe Hibbert, vice president of Capital Projects, Agratas. “Our partnership with Stantec is the next step in our mission to deliver best-in-class battery solutions for our global customers.”

AUTOMOTIVE

HYUNDAI CANADA RECOGNIZED FOR 2024 BEST WORKPLACES

Hyundai Auto Canada Corp. has been recognized for the second consecutive year among Canada’s Best Workplaces with Most Trusted Executive Teams list by the Great Place to Work Institute.

Over 90 per cent of Hyundai Canada’s team members suppor ted the statement, “Our executives fully embody the best characteristics of our organization,” in addition to the leader ship team’s competence

in creating a sustainable and equitable business environment.

“I commend our executive team for their continued momentum of fostering a work culture in which all team members feel welcome and accepted,” said Don Romano, president and CEO of Hyundai Canada. “Part of our work ethic is enabling transparent communication because we believe great things can happen when people feel comfortable enough to collaborate and share. We encourage employees to voice opportunities and ideas regardless of their seniority level. I appreciate all HAC team member s for trusting our process and collaborating with the leadership team and one another to deliver on our business plans despite all the challenges that our industry faced in 2023.”

The results are based on direct and anonymous team-member feedback where the organization must be Great Place to Work- Certified and receive

exceptionally high scores from employees on the Trust Index survey.

BUSINESS OPERATIONS

GM TO INVEST US$150 MILLION IN CANADIAN MINER

BY SADI MUKTADIR

Canadian mining company Nouveau Monde Graphite, announces that it has agreed to a multi-year supply agreement with a unit of General Motors, and will receive $150 million in equity investment from the automaker.

Panasonic Energy and GM concurrently commit to multiyear offtake agreements for NMG’s active anode material, covering approximately 85% of NMG’s planned Phase-2 fully integrated production, from ore to battery materials.

of its Becancour plant to GM for an initial term of six years, once it reaches full production.

The popularity of graphite anodes has risen due to their use in the EV manufacturing. With the Cdn. government focused on building out the electric vehicle supply chain, graphite and lithium operations across Canada have seen increased investments from global auto players.

In addition to the supply agreement, GM will invest $150 million in two streams to advance construction of the second phase of the Nouveau Monde’s Matawinie Mine and Becancour battery material plant.

Under the agreement, the mining company will provide 18,000 tonnes per annum of refined graphite from the second phase

Strategic partner Mitsui and long-time investor Pallinghurst inject a total of US$37.5 million into NMG’s development, the aggregate proceeds of which will be used to repurchase their previously announced convertible notes.

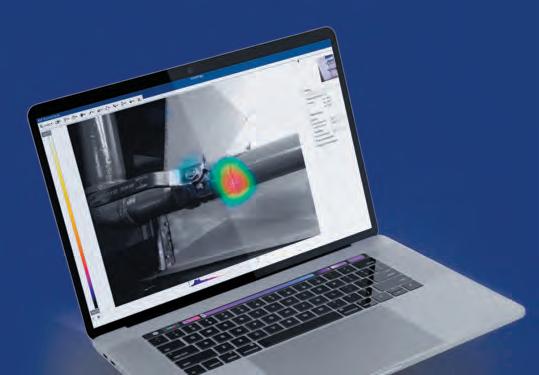

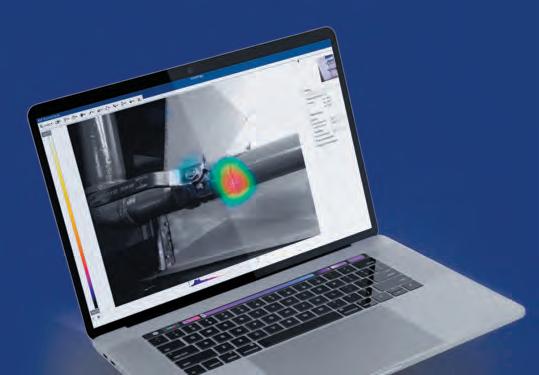

NEXT-GENERATION Si2-LD PRESSURIZED LEAK AND MECHANICAL FAULT DETECTION AUTOMATED FOR MANUFACTURING ON-SCREEN GAS LEAK QUANTIFICATION DETECT FAULTY BEARINGS INSPECT FROM SAFE DISTANCES REDUCE OPERATING COSTS Machine learning-powered analytics provide data-driven decision support on the Acoustic Viewer and FLIR Thermal Studio. PLT_TeledyneFlir_April24.indd 1 2024-03-08 1:20 PM

@PLANT_Magazine April 2024 / Plant 7

Redefining the landscape

Turning the tides on labour shortages in Canadian manufacturing

BY EMILY NEWTON

Even though the labour shortage in Canada is at an all-time high, no comprehensive solution exists. As the skilled labour shortage Canada’s manufacturing industry is experiencing worsens, the need for a plan becomes increasingly cr ucial.

The labour shortage in Canada Is worsening

Although Canadian manufacturing has experienced skill scarcity for years, its recent g rowth is unparalleled. The percentage of manufacturers reporting understaffing increased to over 80% in 2022, up from 39% in 2016. The labour shortage more than doubled in less than a decade.

This issue isn’t limited to select positions — most manufacturers have reported urgent shortages in skilled and general assembly roles. The demand for both is similar. While administrative and supervisory jobs are less affected, they remain understaffed.

Experts expect the labour shortage in

Canada to continue worsening. According to some estimates, it will increase from 200,000 job openings in 2023 to 600,000 by 2030. While the trend seems to be at its peak currently, all indicators suggest it will remain an ongoing issue.

Why is manufacturing declining in Canada?

While many industry stakeholders have expressed concern over the rising skilled labour shortage Canada is experiencing, no comprehensive solution has yet been identified. Those who take action find their efforts insufficient because they aren’t approaching the issue correctly.

While supplementing the workforce with immigrants can be a viable strategy, nearby countries likely won’t be of any assistance. For example, the United States will have 2.1 million job openings in manufacturing by 2030. Hiring locally may be equally challenging.

While most manuf acturers increased

salaries, they still aren’t competitive. In 2021, Canada’s federal minimum wage was $15 hourly. In the same year, manufacturers paid $28.84 per hour on average. Skilled workers know they can get more elsewhere, so they aren’t incentivized.

Although manufacturers clearly need labour, most aren’t automating. While many believe it isn’t a viable strategy, some simply can’t afford to. According to one survey, six in 10 manufacturers weren’t utilizing automation technology in 2023. Only 12% reported widespread adoption.

Why is Canada facing a labour shortage?

The labour shortage in Canada is a multifaceted issue stemming from geopolitical trends, shifting expectations, public perception and an aging workforce. There are a few key f actors driving skill scarcity in the manufacturing industry.

Poor hiring is one of the biggest reasons Canadian manufacturers face a labour

Photo

credit: bnenin / Adobe Stock

LABOUR FEATURE

8 Plant / April 2024 PLANT.CA

shortage. As workers continue to retire, young people aren’t replacing them — many choose alternative career paths because they don’t view manufacturing as lucrative or worthwhile.

Many Canadians view manufacturing jobs as risky because they consider the industr y low-paying, unsafe and unfulfilling. Historically, their opinion of hands-on, blue-collar work hasn’t been favourable. However, the attitude of current workers also affects public perception.

As workloads worsen and workers increasingly become discontent in their roles, the belief that manufacturing is thankless and unpleasant fur ther cements itself in the public’s mind. This impacts hiring since the demand for convenient, satisfying work is trending.

The impact of the skill and labour shortage in Canada Manufacturers have experienced substantial financial, talent, opportunity and reputation-related losses because of the skilled labour shortage Canada faces. Understaffing has forced many to delay or cancel deliveries, increasing operational costs and reducing sales. The consequential client dissatisfaction left a lasting impact on their customer retention rates.

These lost business opportunities and declining customer satisfaction rates have been financially damaging.

According to one study, manufacturers individually reported losses of $2.8 million in 2022. The Canadian manufacturing industry lost $7.2 billion because of late delivery penalties and declined contracts.

The same study revealed labour and skill shortages are forcing manufacturers to put off investment and expansion plans. In 2022, those cancellations caused $2.1 million in losses per company — costing the industry an additional $5.4 billion.

Even though manufacturers have been forced to postpone or cancel most contracts and internal projects, the labour shortage in Canada ensured workers remained overworked. Consequently, many are growing dissatisfied with their work. As burnout increases and motivation deteriorates, employee retention rates decline.

The inability to invest in new projects, take on new contracts and retain talented workers will permanently

affect many manufacturers. When they are unable to innovate, their forward momentum will stagnate. Their competitiveness and future earning potential will be significantly impacted.

Ways to overcome skill scarcity in manufacturing

While no out-of-the-box solution exists, Canadian manufacturers can leverage numerous strategies to permanently strengthen their workforce.

1. Facility Transformation

Leveraging state-of-the-art equipment and prioritizing cleanliness can combat the general public’s perception that manufacturing positions are unhygienic or high-risk, potentially increasing interest. This move can also improve employee retention.

2. Collaboration and Outreach

60% manufacturers weren’t utilizing automation technology in 2023

The aging workforce and lack of fresh talent are significant drivers of the skilled labour shortage Canada faces. Companies can collaborate with higher education institutions or develop outreach programs aimed at youth to dissuade young people from alternative career paths.

3. Automation Investment

Manufacturers that digitize their machinery, software and equipment can ease the burden on their current workforce and fortify themselves against further shortages. Staggered adoption and strategic implementation may make investment more affordable.

4. Upskilling and Reskilling

Manufacturers should collect performance data to objectively and swiftly address skill gaps. Considering that 68% of workers are willing to learn new professional skills, this strategy can be impactful. Upskilling and reskilling eliminate the need to source talented individuals since they all but guarantee candidates can learn critical, specialized skills on the job.

Strategies for sourcing and hiring skilled workers

Administrators can combat the labour shortage in Canada by restructuring their hiring processes.

1. Harness Digital Engagement

Social media and online spaces are ideal platforms for broadening the talent pool and targeting youth. Young people can revitalize the manufacturing industry, so hiring professionals would be wise to develop targeted outreach campaigns.

Digital onboarding is another way to ensure candidates meet skill requirements. Promark Electronics, a Canadian electronics manufacturer, leveraged online tools to reduce instruction length from six weeks to two while maintaining perfor mance goals.

2. Update Wages and Benefits

Manufacturing wages continuously increase by 5% year-over-year, but the skilled labour shortage Canada faces has only worsened. Similar industries like construction, warehousing and utilities pay much better, so they’re often preferred.

Administrators should restructure pay and benefits to address the expectation misalignment between candidates and employers. Retirement packages, maternity leave, mental health days and disability programs are attractive incentives — and can even increase employee retention.

3. Leverage Awareness Campaigns

Underrepresented groups often have no idea their unique expertise is desirable since the industry doesn’t favour them. For instance, women filled only 28% of manufacturing roles in 2019. Hiring professionals should tap into this untouched resource by leveraging awareness campaigns and publicizing their diversity and inclusion effor ts.

BASF Canada Inc., a chemical manufacturer, made substantial progress in this regard. It developed a three-year strategy to improve its diversity and inclusion efforts, even going as far as to establish a governance and oversight team.

T he Skilled Labour Shortages Canada Faces Can Resolve

Although the skilled labour shortages Canada faces in the manufacturing industry seem insurmountable, professionals can overcome them if they leverage proven strategies and carefully consider a context-specific approach to their situation.

Emily Newton has eight years of creating manufacturing articles under her belt. She loves helping people stay informed. Her work in Machine Design, American Machinist and Design and Development Today, showcases her ability to identify newsworthy stories.

@PLANT_Magazine April 2024 / Plant 9

A 3D printer aboard a ship

Could 3D printing disrupt parts manufacturing for ships in the future?

BY MATT JONES

University of New Brunswick’s Marine Additive Manufacturing Centre (MAMC) focus heavily on 3D printing and where it could be applied to find efficiencies in the shipbuilding industry.

At the Centre’s facility – in a Saint John metal fabrication plant – a roughly million-dollar printer efficiently turns powdered metals into replacement parts for ships. The MAMC’s leadership says 3D printing could revolutionize maintenance and repairs on ships.

“With these new 15 warships that Canada is going to build in the next 25 years, we know that each of these ships are going to

be more advanced than the last one,” says Dr. Mohsen Mohammadi, the director of the MAMC. “If we have a metal 3D printer with different types of metal powder on board the ship, when there’s a damaged part they can print a replacement part. The cost savings for the Navy, in terms of sending a ship back to the shores of Newfoundland or Halifax or Vancouver, is immense.”

For the uninitiated, 3D printing uses digital design files to create objects by gradually adding thin layers of material. Plastic 3D pr inting has become fairly common, but 3D printing metal is somewhat more novel. The entire approach is often referred to as ‘additive manufacturing’ because you

Dr. Mohsen Mohammadi of the Marine Additive Manufacturing Centre of Excellence (MAMCE) says 3D printing replacement parts for ships could present a significant cost savings and could disrupt the shipbuilding industry.

are actually building on to something, rather than the more traditional approach of carving metal parts out of the material.

While the most immediate route would be to place a 3D printer on the ship itself, Mohammadi does have an alternate solution as well.

“The second idea that we have is what if we have 3D printers in isolated areas of the North, for example on Resolute Bay, which is sitting at 76 degrees north,” says Mohammadi. “If you have good internet communications with them, we can control these machines from the shores of Halifax or Newfoundland or Vancouver. The other aspect of this, I’m envisioning that we can

3D PRINTING COVER STORY

10 Plant / April 2024 PLANT.CA

Photo credit: University of New Brunswick’s Marine Additive Manufacturing Centre.

actually involve the Indigenous communities that we have in the North to help us protect our shores.”

The MAMC’s Lockheed Martin research chair, Hamed Asgari, also told CBC News of a further concept he is researching – 4D printing. In that case, the product is created with dynamic materials that can change as a result of temperature, pressure or humidity. This would allow the manufacture of ship hulls and other components that would adjust to shifting water temperatures or pressure.

“These alloys are intelligent, they are smart, they are able to change their shape,” said Asgari.

Mohammadi says that most newer ships, such as the aforementioned 15 new warships, would very easily adopt new technologies and should be able to house a 3D printer with little problem. However, the idea of satellite support units providing 3D printed parts in smaller communities could also service older ships that travel those water as well. To say nothing of how this concept could be applied in the wider marine industry.

“Adopting new technologies always incorporates some disruption to our previous practice.”

“Adopting new technologies always incorporates some disruption to our previous practice,” says Mohammadi on the potential impacts of 3D printing on the traditional ship building industry. “It is inherent in new technologies that they disrupt the current way that we do things. Do we want this to be disruptive? It’s actually a double edged sword – we want to change the way we do things to make them more efficient. But we need to train the workforce. If we can actually adopt these new technologies they will make us more efficient, but we will need to modify our training, we will need to be agile in forming the minds of our technicians, engineers and researchers.”

It may very well be inevitable that 3D printing (and other potential new technologies) will radically change the way that industr ies such as shipbuilding and parts manufacturing operate. However, Mohammadi notes that in his view this technology is still very much in its infancy, with a lot more room to grow. In fact, that’s one of the factors that led to the creation of the MAMC. And the MAMC can help companies determine whether they need to start investing in 3D printing technology.

3D PRINTING COVER STORY

MAMCE Lockheed Martin Research Chair Hamed Asgari is working on “4D printing,” where the product is created with dynamic materials that could shift depending on temperature, pressure or humidity.

12 Plant / April 2024 PLANT.CA

Photo credit: University of New Brunswick’s Marine Additive Manufacturing Centre.

“The small and medium enterprises active in marine shipbuilding, defense, aerospace and naval aviation, they can bring their projects to us because we brought down the obstacles for them to practice

this new technology,” says Mohammadi. “They can practice, they can see the benefits of this technology. There are pros and cons to it, for sure, and they will see if this technology can help them, can make them

more agile or more flexible and make them more productive.”

The primary challenge that Mohammadi sees in the adoption of 3D printing in the mar ine sector (and beyond) is certification. New technologies need to be certified, through extensive testing, simulation and modelling and ensuring that results are consistent and reliable.

“If we see all of these together, with regulatory bodies for different sectors, I think we are also with this method bringing down the obstacles for small and medium enterprises to adopt these new technologies,” says Mohammadi.

Mohammadi is quick to thank UNB’s Office of Research Services for their support in the establishment of the MAMC, as well as technical partners such as JD Irving Group and Lockheed Martin Canada. He also notes that the work of his own students and postdoctoral fellows has been invaluable.

“If we want to adopt new technologies, we need these researchers to actually help us discover these new things,” says Mohammadi. “So their hard work has to be acknowledged.”

24_001487_Plant_SPR_CN Mod: February 27, 2024 9:08 AM Print: 03/04/24 page 1 v2.5 1-800-295-5510 uline.ca ORDER BY 6 PM FOR SAME DAY SHIPPING π HEAVY-DUTY SHELVING PLT_Uline_April24.indd 1 2024-03-06 3:30 PM

@PLANT_Magazine April 2024 / Plant 13

Photo credit: Dmitry / Adobe Stock

The sustainability responsibility

Ontario manufacturers challenged to reduce waste

With an eye on the need for sustainability and environmental responsibility, supply-chain-analytics platform provider The Owl Solutions have introduced the Save a Tonne Challenge. The challenge is designed to reduce waste materials used in packaging and production by asking Ontario manufacturers to commit to reducing their waste by at least one tonne per year.

“From our perspective, and we have been doing a lot of research on this the last few years, we’re facing a silent packaging waste crisis,” says Hugo Fuentes, president, CEO and founder of The Owl Solutions. “There’s millions of tonnes of paper, plastic and metal ending up in landfills each year. This is a silent crisis – it’s impacting us and it will impact us more in the coming years and we wanted to do something about it.”

The Owl Solutions work with many manufacturing companies and engage with their information and have identified a significant opportunity to help companies be more aware of the impacts of their practices so they can take action. Fuentes says there are several key means through which companies can achieve these reductions.

“A typical manufacturing company procure ingredients or parts form many suppliers and places around the world,” says Fuentes. “That’s the first flow of packaging waste into their facilities, whenever they’re bringing in a container of something, that container comes with wrapping paper, plastics, pallets, many things that are part of the normal shipping process of a product from a supplier to a customer. Not a lot of companies really scrutinize that inbound flow. They don’t really assess, for instance, how many tonnes of carboard, how many tonnes of plastics they’re bringing in.”

When companies dig into these logistics, they can identify which companies and inbound products are producing the most waste, and possibly identify alternatives that produce less waste. Then, after identifying excess waste sources in your inbound products, you can start identifying further efficiencies with your outbound products.

“If you’re a manufacturing company

BY MATT JONES

shipping a product, when you’re designing your product, you’re making decisions around ‘what kind of packaging should I use, what kind of plastic, what kind of cardboard configuration,’” says Fuentes. “Many times, those conversations internally within the company are not necessarily considering the packaging waste component of this. That’s another area of

clear improvement – if companies have more visibility and are more aware of the different impacts of the use of different packaging elements, they could make better decisions.”

A third avenue for improvement is with regulations – there are many local government regulations regarding who is accountable for the end of life of the

CLEANTECH FEATURE

14 Plant / April 2024 PLANT.CA

The Owl Solutions CEO and founder Hugo Fuentes hopes that the Save A Tonne challenge will help Ontario manufacturers rethink their packaging processes.

packaging, called an Extended Producer Responsibility (EPR). EPR initiatives seek to transfer the responsibility from public hands like municipalities into private hands and making producers responsible for the cost of managing the problem. The Save a Tonne challenge dovetails with EPR initiatives, as companies begin to realize that ignoring these issues will cost them more and more money

“When there’s less packaging inbound, there’s less fees that you have to pay to waste management companies to go to your facility and pick up the product,” says Fuentes. “The second thing is on the EPR fees – if you’re showing that you’re shipping less packaging in your products, you can show the regulatory bodies that you’re liable to paying less fees. You’re avoiding costs.”

The challenge is meant to be quantitative – reducing a tonne of waste for an individual company doesn’t make a huge difference, but if 1,000 companies participate in the challenge then 1,000 tonnes of waste have been diverted from landfills. Many companies working together can have a significant impact even if they haven’t made a massive change to their own operations.

“Instead of putting pressure on one or a few companies to save a lot, what we’re saying is we would like to have a lot of companies committing themselves to save one tonne a year,” says Fuentes. “When you think about one tonne a year, it’s actually about three kilograms a day roughly, which is very minimal. But when you multiply that 10 times, for example, that’s a much bigger impact.”

Fuentes also stresses that there are no fees or signup costs or anything related to taking part in the challenge – this is not a business endeavor for The Owl Solutions, it’s an attempt to build community initiatives.

“We’re here just to support in the background, trying to promote this initiative and to try and push things forward,” says Fuentes. “We’re not selling things out of this intitiative, we’re promoting it and I think it’s a win for everyone.”

The Save a Tonne Challenge is not set up with a specific beginning or end date. Fuentes says they are simply looking to make an impact and engage in dialogues around the topic. He would like to see a celebration of milestones in the campaign, and regular review of how the program can be altered as necessary – for instance, Fuentes noted the possibility of increasing the challenge to reducing two tonnes of waste in the future if the numbers support it.

“I’m a supply chain management expert,” says Fuentes on The Owl Solutions’ interest in this topic. “In our work with manufacturing companies, we touch a couple of things all the time. One is their supply chain management processes. We help them understand their processes.”

Fuentes notes that 20 years ago, manufacturing companies wouldn’t have much data available about their processes – today they may have so much data they are unable to make sense of it.

“We started our company on the supply chain management side of things, but down the road we realized how important it is to bring in this initiative of sustainability, and supply chain and manufacturing is the perfect place to take action in using some of this data and best practices to identify where a company could be more sustainable,” says Fuentes. “That’s why we’re so interested in pushing this forward, because we have seen results, we have seen how a company that had no clear visibility of their waste management impacts, when they see the information and have access to those insights, the way they operate starts transforming. They can do much more things, do it more effectively and they can save money and be more environmentally friendly. It’s a win-win-win.”

FILTER BUILD PROGRAM in partnership with Parker Canada

As Canada’s largest distributor of Parker components, Wainbee has implemented the Filter Build Program.

The program covers a wide range of hydraulic filtration products satisfying approximately 70% of hydraulic filter applications.

• Parts inventory offers filter configuration flexibility

• Shorter lead times for quick delivery

• Lower assembly cost for competitive price advantage

• Designs include ecological element disposal as well as extended life for filter performance

• Configurations to assist with building Bill of Materials for Build Program Filter assemblies: CS, CN, GLF, ModuflowTM, PT & WPF

• Build Centre test stands & facilities will be inspected & approved by PCD personnel before initial certification & once every three years thereafter

1-888-WAINBEE (924-6233) | WAINBEE.com

Motion & Control · Filtration · Automation Solutions

CN SERIES

GLF SERIES

PT SERIES

WPF SERIES

PLT_Wainbee_April24.indd 1 2024-03-12 10:39 AM

@PLANT_Magazine April 2024 / Plant 15

How acquisitions can help expand production capacity

Truck manufacturer Gincor Werx acquires Wiltsie Truck Bodies

BY MATT JONES

Custom work truck manufacturer Gincor Werx have announced the acquisition of Wiltsie Truck Bodies. Representatives for Gincor say that the acquisition will largely help expand their production capacity.

Vice President of Business Development Christian Stang describes it as a ‘bolt on or tuck in’ acquisition.

“They do a lot of the products that we currently do at some of our other facilities,” says Stang. “So it opens up some production capacity for products we currently build elsewhere. And it helps take away some of the bulges in the order book – we’re always trying to keep things somewhat steady and we’re always trying to develop a good client experience.”

Aylmer, Ontario-based Wiltsie Truck Bodies have been producing custom truck body designs for over 60 years. Their truck body offerings cover everything from service trucks to grain bodies and cube vans. The company also offers repairs, painting, wheelbase changes and lift-axle calibrations, in addition to distribution for brands such as Grote, Whiting and Tommy Gate.

“We try to keep good relationships with many of our competitors,” says Stang on how the purchase came together. “We’re often doing what we call ‘co-opetition’ – we compete on some things but we cooperate on others. Anybody that’s followed our company’s history know that we’re aggressive with growth, we were on the Profit 500 Fastest Growing Companies for five or six

years in a row. We’ve always got some feelers out there as to when people are ready to sell. I think the seeds were planted years ago and it came to fruition last year and it probably took us about a year to put this together and get all the terms and get the right agreement put in place.”

Stang notes that while Wiltsie will eventually be rebranded as Gincor, for their customer s business will likely continue largely as usual. For Wiltsie’s employees, there may be more changes but those changes could also run both ways.

“For us, it’s a matter of putting in our best practices and trying to keep some of their best practices,” explains Stang. “What this acquisition means to Gincor is to be able to better support our current existing

BUSINESS OPERATIONS FEATURE

16 Plant / April 2024 PLANT.CA

Photo credit: fotogurmespb / Adobe Stock

“It’s a matter of putting in our best practices and trying to keep some of their best practices,” says Gincor Werx VP of Business Development Christian Stang on the recent acquisition of Wiltsie Truck Bodies.

client base in southwestern Ontario. Bringing our best practices into that business, and then we start looking at their processes and procedures. Is there something that we can learn? We believe that we can always learn something from somebody.”

The acquisition of Wiltsie is the fifth significant acquisition Gincor have made since 2015. Stang notes that Gincor have learned much regarding how to approach these acquisitions since that time.

“You can’t have five different accounting systems,” says Stang. “So as we do more of these its ‘okay, how do we tailor our list of key things we’re going to do when we purchase a business.’ What are their accounting systems? What are their processes? What can we keep, what needs to change. We try to make it as seamless as possible. We’re trying to deliver a better experience for everybody. And that includes the employees, because they truly are the lifeblood of our business.”

Stang notes that he is sometimes asked if Gincor are purchasing an asset with the goal of shutting it down but he doesn’t believe in that approach. If it doesn’t add value to the company, why are they even thinking about buying it? Stang says that his family’s business (the business was started in the 1970’s by Stang’s father’s uncle and two partners) want to build something for the future and to make a difference and to enrich the lives they touch. That ethos also drives Gincor to ensure as seamless a transition as possible for employees.

“[Changing ownership] can definitely cause a lot of strain,” says Stang. “’What does that mean for me? Are they going to do this or that?’ We’re always trying to enhance the client experience and when I say clients, I look at my employees as clients as well. It sounds strange to think of employees as a client, but when you’re looking at a client, from a business standpoint, you’re trying to make them happy so they’ll come back. You also have to do right by your employees so they’ll want to come to work.”

As an example, Stang cites how for one of the company’s previous acquisitions, they invested in enhancing the company’s

lunchroom. Acknowledging that some might consider such an investment “hoopla,” Stang says the company is committed to making things better for the people working for them. He cites a quote by Virgin Group founder Richard Branson - ‘Clients do not come first. Employees come first. If you take care of your employees, they will take care of the clients.’

“From an accounting standpoint, to justify an investment into a lunchroom, there’s no easy way of measuring what the results of that are,” says Stang. “What’s your return on investment on that? I think that’s where people get caught up. But we’re trying to make it easier from clients. What do we gain? We’re going to better service our clients. And the employees have had a good run with a good family business – Wiltsie has been around for almost 70 years. You don’t stay in business that long if you’re not doing things right. So we’re just looking to improve on what was already good. They’ve got a good name in the industry and they’ve got a good following. So how do we add to that?”

Gincor Werx President and CEO Luc Stang noted in a news release that Gincor are pleased to have the opportunity to build on the foundation that the Wiltsie family built over the years.

“This foundation, and its client base, have been built by men and women who have a passion for the industry where it all happens,” said Luc Stang. “It’s all about the people and that’s what makes this latest acquisition a great fit for all stakeholders. We look forward to bringing Gincor Werx to the former Wiltsie Truck Body team to help enrich the lives of each other and those we serve and partner with. Welcome to the family.”

Representatives for Wiltsie Truck Bodies did not respond to a request for an interview as of press time.

DRIVING INNOVATION: ITALIAN POWER MOTION AND TRANSMISSION SYSTEMS Elevate your operations with Italy’s high-quality, reliable and technologically advanced integrated systems Never miss a beat with Italian power systems EXPLORE ADVANCED PRECISION SOLUTIONS machinesitalia.org PLT_ITC_April24.indd 1 2024-03-07 9:56 AM

@PLANT_Magazine April 2024 / Plant 17

Condition monitoring for all your critical assets

As an IIoT platform, ifm moneo combines the level of operation technology with the level of information technology. Sensor data generated in production plants can be read, processed easily and used as a basis for sustainable corporate decisions.

Ready for more?

Start your digital evolution now with moneo, the new open and industry-independent IIoT platform from ifm.

moneo – simply made for you!

www.ifm.com/ca vibration pressure energy temperature level • • • ••

•

Getting on the bus of the future

Your tomorrow technology is alive on a farm near you

During my formative years, I used to work on a dairy farm. As a dairy operation, we were quite advanced in the use of technology, which allowed our herd to be ranked #23 within Ontario.

However, recently I had the opportunity to visit a state-of-the-art dairy operation in Quebec, and not only did it quickly make me feel very old, but made me wonder if what I was witnessing was the result of continuous improvement or the injection into the industry of disruptive technology.

All I can say is there is a lot of discussion about autonomous vehicles and Industry 4.0, but based on what I have seen, both are very active within the dairy farm industry.

The Dairy Herd

Back in the Day

We had 80 head in our milking line which meant we actually looked after 160 heads on a daily basis. My day started at 6:00 a.m. to do the first milking of the day and we would do it again at around 4:30 p.m. We got to know the characteristics of our animals, and they got to know us. This meant that as we were milking our cows we were

BY RICHARD KUNST

inspecting them to insure they were healthy. Ultimately, we were tied to our herd and our obligation to milk them so we could never venture more than four hours away from the farm to insure we would be back in time to do the milking.

During my tenure, we evolved from automated bucket milkers, where we still had to dump the milk into a pail and carry it to our milk house to filer and collect it into our bulk milk tank. And what a joy it was when we upgraded to a pipeline milker; using vacuum milk transferred from the cow directly to our bulk milk tank. We still had to clean the cow before milking and that strong emotional attachment to the animals remained.

My morning reward after chores had been completed was going for breakfast and finally being able to enjoy a warm shower.

Today

We have an App for that. The milking never stops. The cows are now attended to on their own schedule by a robotic milking machine. The robot is much more competent than I ever was, as the cow enters the robotic cell, their temperature is checked, and based on the production level they are given a pre-determined amount of feed (grain).

TECHNOLOGY COLUMN

Photo credit:

/ Adobe Stock @PLANT_Magazine April 2024 / Plant 19

Chanelle Malambo

As they are being milked, the quality and quantity of milk is being monitored and recorded for later analysis. The milk is automatically conveyed into a bulk tank, never tr uly being exposed to the elements. Should any of the measurements not be within an acceptable range, the cow is diverted to a holding pen and an alert is issued to the farmer electronically.

The farmer in essence rises whenever they want and can casually sit and enjoy breakfast with the family, and when so inclined, glances at their smart phone to review any alerts, but begins to process all of the data collected in order to make the appropriate decisions. For instance, if a cow should be retired from the line, or be provided some sort of medical aid, while already calculating what their income will be for the month.

In my mind, it is the effective culmination of using AI, block chain and Industry 4.0

The Barn

Back in the Day

We actually had a pretty nice modern barn but definitely not by today’s standards. In our barn, our cows were assigned a specific stable and secure in stanchions with a shared water bowl. Animal waste was collected in a gutter where our stable cleaner scraped it away, dumped it into a hydraulic pump to be stored in a pit located far away from the barn.

Ventilation was assisted with fans but you could always be assured that, thanks to the heat emitted from the animals, our barn was warm.

Today

The barns are engineering marvels where the interior temperature can be maintained at a consistent temperature.

The use of temperature sensors induces the side walls of the barn to raise or lower accordingly to adjust the interior temperature optimal for the animals.

The roof is manufactured using translucent

panels to allow for the entry of defused but natural light, so no additional lighting is really necessary.

The parameter of the barn but still inside has a robotic sweeper to constantly escort stray feed back into the manger for the animals to access ... think I-Robot.

In this example, animal waste is collected from below a slated floor and pumped to an irrigation sprayer to help fertilize a targeted field relatively close to the barn. Another field pass eliminated.

Meanwhile, the farmer is sitting in his home watching TV while glancing at his App that monitors the barn and the herd without having to put on his heavy coat and rubber boots to go check in-person.

The Crops

Back in the Day

We ploughed, we disced, we cultivated and then we planted our crops. We waited patiently until they were ready for the harvest.

We did already have certain crops that had been modified and tailored to prosper in our growing conditions. We used our sense of sight, smell and taste to determine the optimum time for the crop to be harvested. The actual harvest was conducted primarily based on Tribal knowledge for the best harvest route and which fields would provide the optimum yield for a particular crop.

During my time, agricultural equipment did get larger so we could cover more area in one pass. Still typically, for example, for growing corn we would have to invest in 4-6 passes across a field, including the harvest round. If we decided to plant the same crop in the same field the following year we mentally took note on the density of fertilizer to apply and where.

Today

The best way to explain the current state is to start by conducting a harvest using a combine.

Step into the climate-controlled cab. Yes, climate controlled so you can harvest wearing your Sunday best attire.

Turn the beast on, lights flash, displays light up, and cameras begin to record. You quickly realize you are sitting in the middle of a technology hub. This machine is amazing. As it harvests, it is collecting reams of data regarding yield, moisture content, obstructions and in my case, this combine was attached to a 40-foot table, which means we were harvesting a swath of 40-feet-wide in every pass.

But the magic didn’t stop there. The machine was being guided by a GPS map that had been created earlier in the season or even years past that automatically guided the combine through the field on a pre-determined route.

Did I mention that the land speed of the combine was constantly being adjusted to maximize the through-put capability of the combine? A heavy yield the combine would slow and light yield let us speed it up, and, of course, when the grain hopper was full, it signaled the driver and alerted the grain hauler to retrieve the load - usually if synchronized without stopping or pausing the harvest.

The operator had no need to touch any controls or even the steering wheel since the combine was harvesting autonomously.

But it gets better. Based on the knowledge captured during harvest and scrubbed through some AI.The following year, during planting, the harvest knowledge was used to determine the density of seed planting and fertilizer application to improve yield (a constant learning model).

The farmer is also using a zero till methodology so no more need for annual ploughing, reducing both cost and the emission of g reen house gases.

I think the transformation that is happening in agriculture is a combination of continuous improvement and the influx of disruptive technologies, but if we look at what is happening even just in the dairy sector, it provides a good insight to where the rest of business and industry will be evolving towards.

Just this past week I was speaking with a former resident of Leamington, Ontario - which used to be the tomato growing capital of Ontar io - who told me that green houses are the norm where farmers erecting greenhouse covering hundreds of acres are no longer the talk of the town.

I now find myself being old and reminiscing about the old days, but not necessarily the good old days.

Guess it is your time to seek innovation, automation and get on the bus of the future, since what we think is coming is already here and proving it works.

TECHNOLOGY COLUMN

20 Plant / April 2024 PLANT.CA

Photo credit: panuwat / Adobe Stock

MOVU ROBOTICS AND PEAKLOGIX PARTNER ON AUTOMATION SOLUTIONS FOR WAREHOUSES

Movu Robotics, a warehouse automation solutions company, has announced a strategic partnership with supply chain integration partner PeakLogix, an Alta Material Handling company.

This partnership means Movu Robotics and PeakLogix can offer the benefits of Movu’s plug-and-play robotics portfolio as part of their solutions for customers in the North American market.

Since 1989, PeakLogix specializes in providing material handling solutions and warehouse optimization services. The company offers a range of services, including warehouse design, equipment integration, software solutions, and project management. PeakLogix helps businesses maximize efficiency and productivity in their warehouse operations through tailored solutions based on their specific needs and requirements.

The Movu portfolio is built around a range of sub-systems designed to provide easier, scalable, flexible and energy efficient solutions accessible for all kinds of warehouses and quick to roll out. These include the Movu atlas, a pallet shuttle system for multiple deep lane storage; Movu escala the robotized 3D storage and fulfilment system; Movu ifollow Autonomous Mobile Robots (AMRs) for collaborative picking or transport of load carriers such as pallets; and the Movu eligo picking arm robot; as well as the appropriate supporting software.

OPTRONICS EXPANDS COMPLIANT BLACKOUT LIGHTING FAMILY WITH TWO THINLINE, LED SURFACE-MOUNT, LED STOP/TURN/TAIL LAMPS

Optronics International, a manufacturer of vehicle harnesses, electronic control systems and LED lighting for the global transportation industry, announced the release of its smoke-lens Thinline STL59SRSHB Series 9-LED and STL87SRSHB Series 11-LED surface-mount, stop/turn/tail lamps.

The two new, thin, surfacemount-style lamps are the latest additions to Optronics’ family of eight smoke-lens LED lights. First introduced in 2020, Optronics’ blackout lights are renowned for their truly black appearance when not illuminated and their ability to meet FMVSS 108 and CMVSS 108 compliance when illuminated. The lamps are also on the leading edge of commercial vehicle styling. Some lighting manufacturers, especially those catering to the automotive aftermarket, have tried to respond to the increasing preference for less noticeable blackout-style lighting. However, initial efforts fell short of complying

with FMVSS 108 and CMVSS 108 photometric standards.

The new 9-LED and 11-LED lamps are both examples of Optronics’ dedication to creating the darkest possible smoke-lens lights. The company’s engineers innovated by using black printed circuit boards (PCBs) inside the lamps, minimizing re flection when the lights are off. Unlike conventional LED lights that feature white or re flectiv e chrome-like PCBs to boost brightness, Optronics’ smoke-lens lights rely on their high-intensity LEDs to achieve the necessary brightness levels for compliance with federal photometric standards.

As the sole commercial lighting manufacturer to offer genuinely compliant blackout lights, Optronics has met market demand head-on. The company now offers an extensive selection of LED smoke-lens lighting products. This range includes everything from small, 3/4-inch round, single-diode

marker/clearance lights to diamond-shaped, three-diode marker/clearance lights, as well as 4-inch round, six-diode backup lights and 6-inch oval, six-diode stop/turn/tail lights, among others. The company is also planning a blackout version of its popular Fusion Series stop/ turn/ tail/backup combo lamp.

The lamps’ lenses are made of tough polycarbonate material that is sonically welded and resistant to dust and moisture. The lamps employ a solid-state, surface-mount device (SMD) design that protects their electronics against moisture, shock and vibration. Like all LED products from Optronics, these lamps come with a no-hassle, one-diode lifetime warranty protection that will replace a lamp if even one diode fails.

The lamps’ lenses are made of tough polycarbonate material that is sonically welded and resistant to dust and moisture.

Lift, Load and deLiver with SeLLick! Lift, Load and deLiver with SeLLick!

Whether you need to deliver a skid of blocks to a jobsite or move a 16,000 lb. load of steel, Sellick has the forklift that is right for you. We have been engineering and manufacturing rough terrain forklifts for over 50 years and our nationwide dealer network offers superior support for all your parts and service requirements. Call toll-free or e-mail us today for all your material handling needs.

1-877-SELLICK (735-5425) sales@sellickequipment.com

PLT_SELLICK_APR23_CSA.indd 1 2023-03-07 1:34 PM NEW PRODUCTS TECH CENTRE

@PLANT_Magazine April 2024 / Plant 21

NEW PRODUCTS TECH CENTRE

FIAT 500E: FIRST STELLANTIS BEV FOR CANADA ROLLS OFF THE LINE

The first all-electric Fiat 500e vehicles destined for Canada rolled off the line at the Mirafiori Assembly Plant in Turin, Italy. An all-new, all-electric take on the FIAT brand’s most storied and iconic model, the Fiat 500e will arrive on this side of the Atlantic by the end of the first quarter as the first North American battery-electric vehicle (BEV) offering from Stellantis.

The lightest passenger BEV in the market, the Fiat 500e delivers an estimated range of up to 240 kilometres, enabled by a 42 kilowatt-hour (kWh) battery with a Level 2 (11-kW) charge time of four hours and 15 minutes (30 amp). BEV capability combined with quintessential design cues make it unmistakably FIAT, with style and sustainability at its core.

“We’re thrilled that the Fiat 500e has officially begun its journey to reach customers in North America,” said Olivier Francois, FIAT CEO and CMO Global of Stellantis. “The 500e registered more than 185,000 units worldwide since its launch and is playing a relevant role in the green transition of cities across the globe, continuing the Brand’s electrification journey.”

In Europe, the 500e is leading the electric city car market for the second year in a row as FIAT’s most awarded vehicle ever. Ranking first in Italy, Germany, Spain, Belgium, and Austria, its massive success is creating a highly anticipated launch in North America.

FIAT is beginning the introduction of the Fiat 500e to North America

with one effortlessly chic model, the (RED) Edition. FIAT has partnered with (RED) to introduce the coolest, most ethical car in urban mobility, with features including red-painted exterior mirrors, LED headlamps and front grille details, sitting on 17-inch diamond-cut alloy wheels. Inside, a striking red dashboard is the focal point. Available exterior colours are Tuxedo Black, Glacier White and Red by (RED). Every time a (RED) product is purchased, it triggers a donation to the Global Fund to support life-saving prevention and treatment programs in communities most in need.

The 500e is Canada’s lowest 2024 model year MSRP electric vehicle (EV) with a starting price of $42,190 ($39,995 MSRP plus additional fees) and is positioned to optimize government EV rebate eligibility with up to $5,000 in federal rebates and up to $7,000 in provincial rebates. It is available at dealerships in Quebec and British Columbia by Spring 2024, then will expand to other markets as production ramps up.

E-Z LOK HELICAL THREAD INSERTS AND KITS FOR SOFT METALS

E-Z Lok, a manufacturer and master distributor of threaded inserts for metal, plastic and wood now offers E-Z Coil and thread repair kits.

Wire or helical coil threaded inserts quickly repair or reinforce tapped

holes in soft metals. Made from 18-8 stainless steel wire, these helical coil inserts are corrosion resistant and can withstand temperatures up to 800°F. Furthermore, they offer corrosion resistance and protection from wearing and stripping.

E-Z Coil helical insert coils are manufactured by forming the stainless steel wire into a diamond shape and then winding it into a spring. Prior to installation, the insert diameters are larger than the tapped hole. During installation, the insert diameter of the helical coil insert is reduced, allowing the insert to thread into the hole. Once properly installed, the radial pressure of the released insert holds the insert firmly in place.

Thread Repair kits are available in both standard and economy, and in a variety of sizes. Each Economy E-Z Coil™ Thread Repair kit includes a set of inserts, an STI tap, and an installation tool. The standard kit also includes a tang break tool and drill bit.

LEIFELD PRESENTS NEW MACHINE FOR THE PRODUCTION OF ROBUST HYDROGEN TANKS

Leifeld Metal Spinning GmbH launches hydrogen tanks manufactured with the necking-in machine AFC (Aluminium Forming Center). The machine forms the ends of the aluminum cylinders for hydrogen storage using a special necking-in process. As hydrogen tanks underlie high operating pressures in their application, the entire neck area is optimized in its wall thickness profile during the forming process for long-term durability. In addition to the standard necking-in machine, the German machine manufacturer also offers a machine type that combines the necking-in and flow forming technology to form both, the entire pressure vessel body and the necks. Customers can choose between two equipment options for preheat-

ing the material: gas burner or induction system. Once the pipe ends have been heated, the material is necked in. The process is completed by controlled loading and unloading as well as automated programming.

Hydrogen tanks operate under immense pressure. Scratches or other defects on the surface would be catastrophic. To prevent damage to the material, the R&D team, led by Benedikt Nillies, Technical Director at Leifeld, has come up with several solutions. For example, the heating of tube ends in the machine: “Normally, the tube ends are heated by a gas oven or an induction system outside the machine,” said Benedikt Nillies. However, during subsequent loading, the component cools down. “We want to prevent this,” Nillies continues. “With the AFC machine, the tube ends are either heated by an integrated heating device with a gas burner or electrical induction to processing temperature uniformly. We can precisely adjust the temperatures to the desired level. This avoids coarse grain formation and preserves the material’s strength.”

To keep the surface intact, Leifeld offers various spinning rollers - from simple necking-in rollers to actively driven forming rollers. The rollers rotate upon contact with the part, preventing surface defects by avoiding material buildup on the roll. The support device was specially designed so that it can absorb the forming forces even with very thin wall thicknesses. The cylinder is held stably in a precise position, ensuring tight tolerances and surface accuracy even at high forming forces and forming speeds. The innovative support system can be used for parts up to six metres in length.

Hydrogen tanks are currently primarily used in cars, trucks and buses. However, Benedikt Nillies also sees the possibility of using hydrogen tanks manufactured on LEIFELD machines to power rail vehicles and aircraft as feasible: “ We are continuously developing the process and have received initial inquiries from other industries. Additionally, we are currently working on automating loading and unloading systems in order to adapt the machine even more efficiently to the customer’s material flow.”

22 Plant / April 2024 PLANT.CA

LEARN HOW CANADIAN MANUFACTURERS ARE PROGRESSING WITH ADVANCED MANUFACTURING CANADA’S MANUFACTURING VOICE PUBLISHED BY DOWNLOAD THE 2024 ADVANCED MANUFACTURING REPORT SPONSORED BY

LS Electric® iX7 Servo Systems

Starting at $964.00 (100W system with cables and I/O breakout)

•

extremely fast, real-time, deterministic, and synchronized communication for high precision motion.

• Multiple input power options:

• 110VAC single-phase up to 400W

• 230VAC single-phase up to 2.2k

• 230VAC three-phase in all sizes

• Use with any CANopen over EtherCAT (CoE) compatible PLC/hostvcontroller or one with ModbusTCP capability

• Fully digital with 1kHz velocity loop response

• 45-day money-back guarantee

• One-year warranty

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

• Palletizers

• Pick-and-place applications

• Rotary tables

• Flying cutoff systems

• Precision machining tools

• Automated welding systems

• and much more

PLCs with a 4-axis EtherCAT positioning module start at $691.00 (not including servo systems)

the #1 value in automation Order Today, Ships Fast! * See our Web site for details and restrictions. © Copyright 2024 AutomationDirect, Cumming, GA USA. All rights reserved. 1-800-633-0405 Research, price, buy at: www.automationdirect.com/servos Multi-Axis Servo Systems with EtherCAT® These iX7 systems offer EtherCAT or ModbusTCP control at a fantastic price! Online LS Electric Servo System Selector Tool www.automationdirect.com/selectors/ls-ser vo Use our LS Electric Servo System Selector Tool to size your system, and to specify all the required and optional accessories for YOUR application. Get ALL the parts you need on the first order! The LS Electric XGB PLC controls up to 16 axes of EtherCAT® motion with several positioning methods including linear, circular, helical, and ellipse interpolation. Seven homing routines are also available and the FREE software offers a graphical interface so you can see the motion in action! The XGB series

is a perfect control solution for: Need an EtherCAT controller? LS Electric® XGB PLC CPUs starting at $299.00 (w/FREE software) Complete Servo Systems starting at: $964.00 (100W) LS Electric iX7 servo systems offer advanced multi-axis motion control along with EtherCAT networking. The EtherCAT protocol provides

PLC

PLC

Orders over $49 get FAST FREE SHIPPING Our shipping policies make it easier than ever to order direct from the U.S.! 45 4 5dayMoney-BackGuarant e e Lorem ipsum Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days. *Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees. See Web site for details and restrictions at: www.automationdirect.com/canada To see all products and prices, visit www.automationdirect.com All prices shown are U.S. Dollars

9 standard servo systems from 100W to

3.5kW

BY MARYAM FARAG

BY MARYAM FARAG