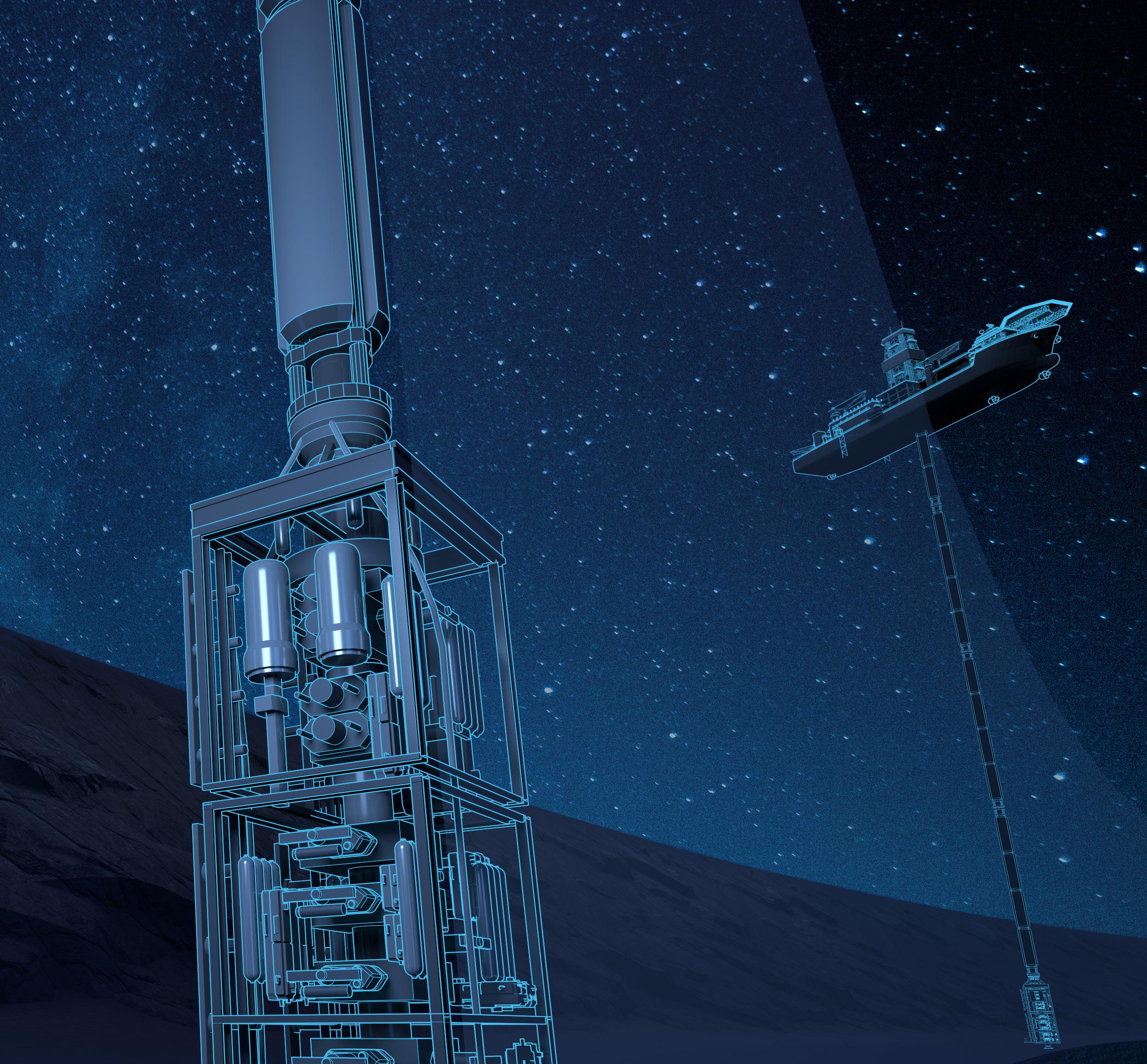

Drilling

Essential flow control solutions for surface and subsea control systems.

We keep operations flowing.TM

Oil and Gas OEMs, Drilling Contractors and Operators have trusted Gilmore’s reliable hydraulic valve solutions to perform in extreme environments for over half a century.

Meeting demands of control system applications

Global regulatory agencies are driving a higher level of safe drilllng and operating standards that focus on safe work processes and equipment reliability performance. Both offshore and onshore operators are linking performance objectives to incentive-based, long term service contracts based on equipment performance, driving the demand for more reliable flow control products.

To meet this criteria, Gilmore’s flow control products have undergone endurance testing to ensure improvement in cycle life and performance. Material selection and design improvements are designated by Product Engineers and supported with field and lab performance data to achieve this benchmark. The result is reliable flow control solutions which provide end users with predictable maintenance schedules for maximized uptime.

Committed to improving the reliability of essential infrastructure

Gilmore is focused on driving reliable products for severe and critical applications. The release of the GEN2 and Mark IV products solidified that commitment. These products are designed to exceed offshore industry requirements with an increase in cycle life proven through extreme qualification testing to meet the demand of 5-year service life under normal operating conditions.

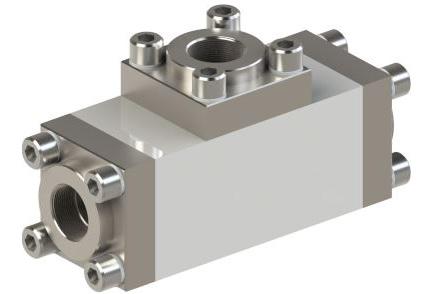

The GEN2 design was thoughtfully planned with the same footprint as legacy products so that equipment upgrades are seamless and keep replacement costs low. The Mark IV

design establishes a new benchmark for reliability and serviceability in drilling control systems where redundant hydraulic pressure supplies are required.

Gilmore continues to build on its energy heritage and experience, through the development of new adaptable and modular technologies that go beyond standard applications, pushing the envelope of valve reliability.

Agility to customize

Gilmore drilling control solutions can be tailored to exact client specifications to meet the demands of in-service systems in addition to those under development. We welcome the opportunity to be involved in the new product development process from beginning through to the end of its full service life through successful deployment.

We keep operations flowing.TM

Mark IV Shuttle Valve GEN2 Disc Shuttle Valve Stackable Mark III Shuttle Valve GEN2 V-Seal Shuttle Valve

Application experience:

• Surface Blowout Preventer Control Systems

• MUX Blowout Preventer Control Systems

• Acoustic Pod Controls

• Flow Diverter Skids

• Hydraulic Power Units

• Intervention Riser Systems/Workover Rigs

Drilling product features and benefits:

• Qualification exceeds API 16D and IADC Control Valve

Qualification Testing Recommendation

• Designed for minimum 5-year reliable service

• Comprised of modern corrosion resistant alloys for long term subsea applications

• Optimized serviceability and modularity for simple maintenance