2 minute read

REFELECT AND CRITICAL APPROACH ON CLIMATE EMERGENCY

by Gloria He

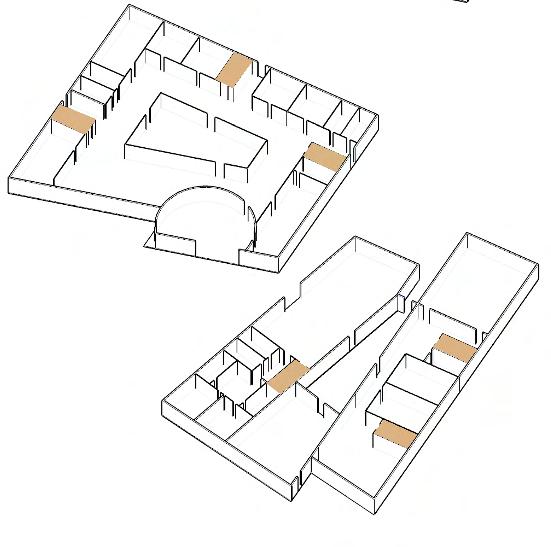

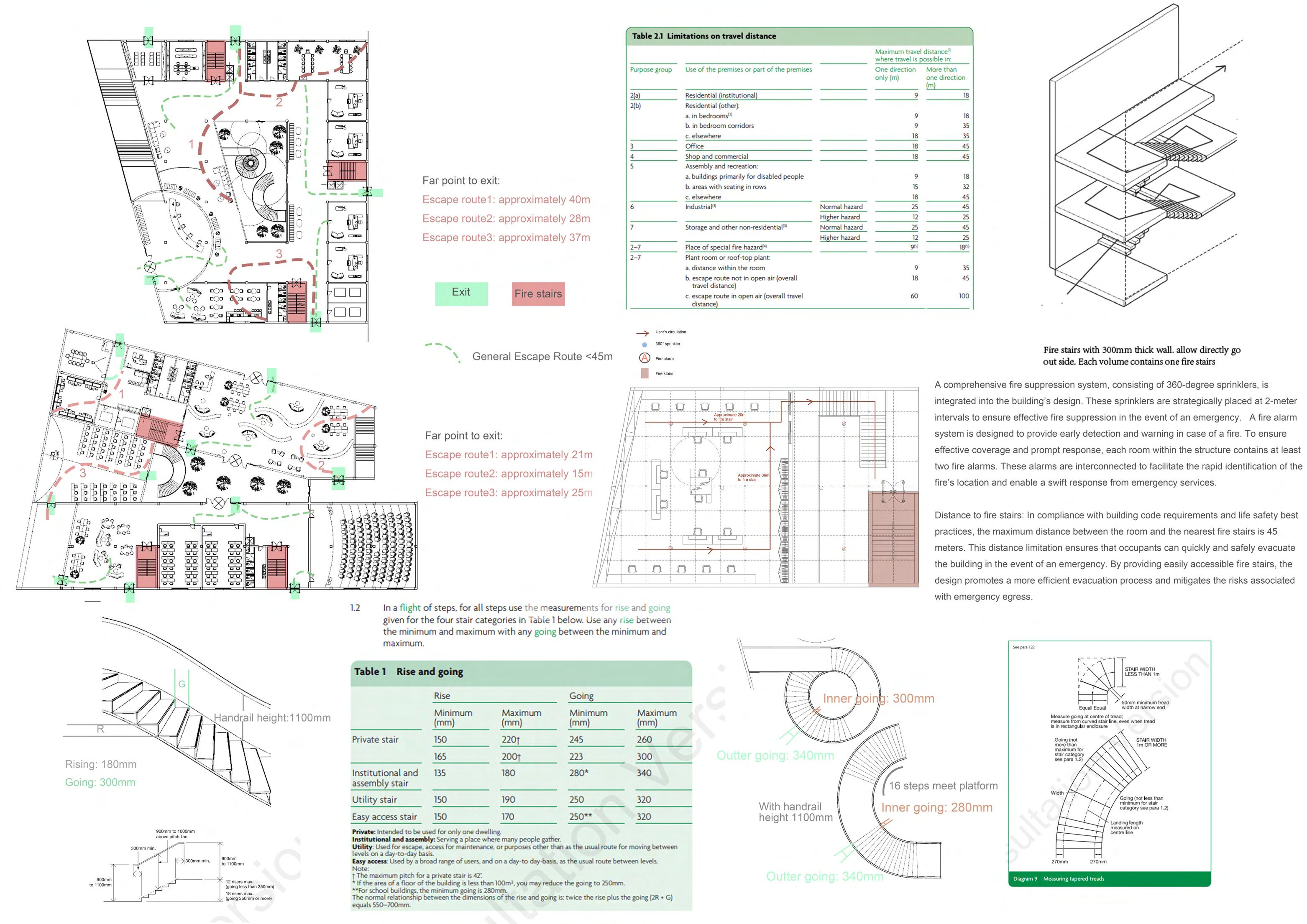

To gain more daylight, added several skylights and windows for different directions. After the improvement, the DA and UDI analysis data show that the building still has comparatively lower annual sunlight radiation but enough useful daylight illumination, it implies that while the intensity of sunlight it receives might not be as high, it is consistent enough during the day to provide useful light. Consider using good insulation materials to reduce heat loss and improve energy efficiency.

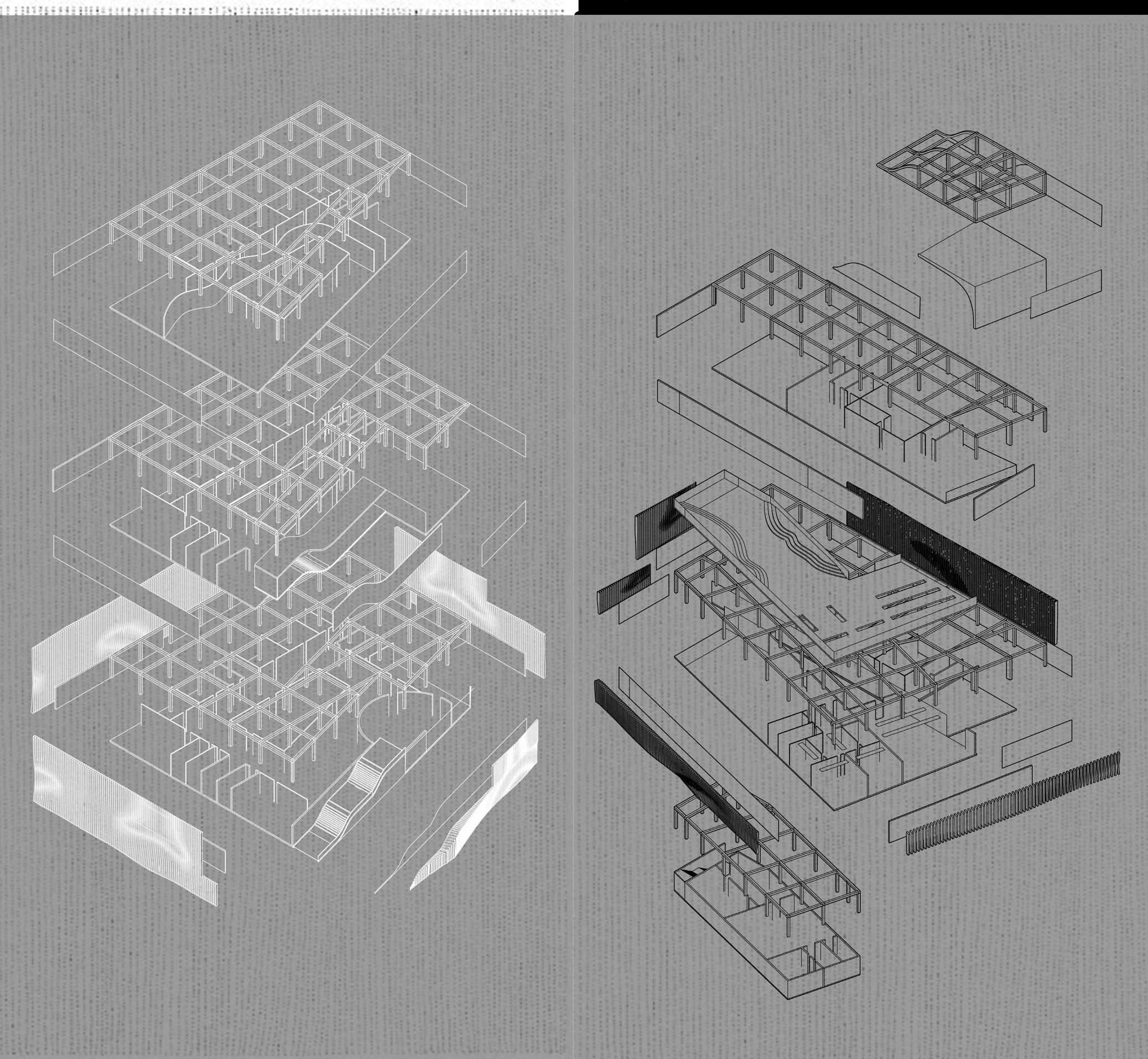

To enhance the thermal performance of the exterior walls, tried to minimize thermal bridging by employing continuous insulation. Besides, different insulating materials were tested to evaluate their effectiveness in further improving the wall assembly’s thermal performance. When using Expanded Polystyrene (EPS) as the insulating material, the total R-value increased to 7.838 m²·K/W, resulting in a reduced U-value of 0.127 W/ m²·K. Alternatively, if Polyisocyanurate (PIR) is employed as the insulating material, the total R-value is 8.682 m²·K/W, and the U-value is further lowered to 0.115 W/m²·K.

Advertisement

Glazing design also be an important part of the strategy for improving the thermal performance of buildings. The initial glazing design consists of an inner double-layered glass panel, supplemented with a 60mm metal panel, shading devices installed within the gap, and an outer layer of laminated safety glass. Upon evaluation, the U-value for this configuration is determined to be approximately 1.587 W/m² K.

To enhance the thermal performance of the glazing system, several modifications were proposed and implemented:

1. Replacing the double-layered glass with a triple-layered glass panel provides an additional layer of insulation, thereby improving the system’s thermal resistance.

2. Incorporating low-emissivity (Low-E) coatings on the glass surface to minimize the amount of infrared and ultraviolet radiation that can pass through the glazing without compromising visible light transmission.

3. Substituting the air-filled cavity with a low-conductivity gas, can further reduce heat transfer through the glazing system due to its lower thermal conductivity compared to air.

Following the implementation of these modifications, the U-value of the glazing system was successfully decreased from the initial value of 1.587 W/m²·K to a more energy-efficient value of 0.528 W/m²·K.

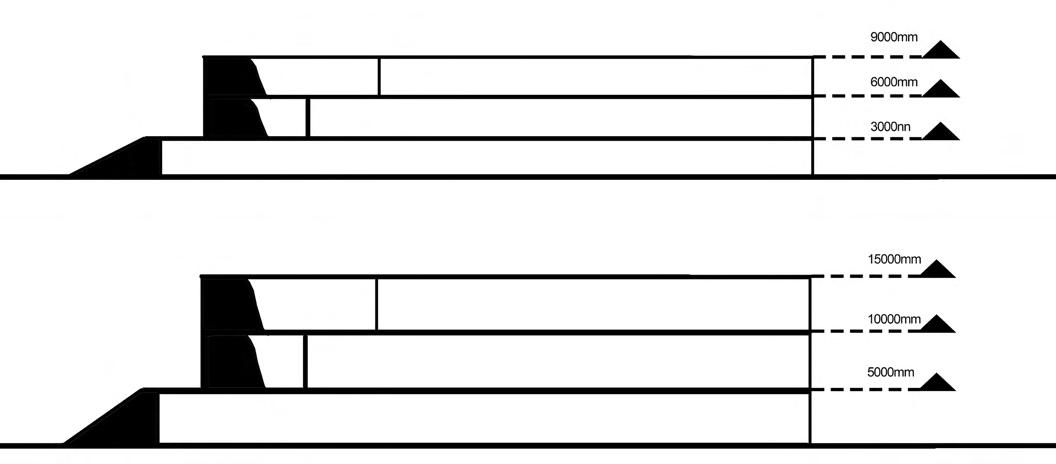

In the absence of any shading device, the annual solar radiation reaches an elevated level of 749.75 kWh per square meter. Acknowledging the importance of shading strategies, three iterations of shading devices were examined.

The first iteration involved the implementation of a vertical louver as the shading device. This configuration resulted in a 22% reduction in solar radiation exposure, indicating its effectiveness in mitigating the impact of direct sunlight on the building envelope.

In the second iteration, a horizontal louver was employed as the shading device without specifying the angle. This design decision led to a further decrease in solar radiation, with a 29% reduction observed. This result highlights the potential advantages of utilizing horizontal louvers over their vertical counterparts.

The third and final iteration examined the efficiency of a horizontal louver set at a 45-degree angle. This configuration demonstrated a remarkable 74% reduction in solar radiation, significantly surpassing the performance of the previous iterations.