14

the way

contractors overcome budget, worker shortages to keep region rolling CONSTRUCTION | A SPECIAL EDITION OF PRAIRIE BUSINESS

PAGE

Paving

Highway

jlgarchitects.com 100% EMPLOYEE OWNED Inc. Magazine’s 50 Best Places to Work in America | Architect Magazine Top 50 US Firm From the foundation to the rooftop, from Day One to Day 1,000 – when it comes to building trust, we’ve got you covered. We hire the best designers in the country who support, reassure, and challenge you, our client, by always doing what is right because you work hard for your money. We do, too. WE’VE GOT YOUR BACK

TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBU SINESSMAGAZINE.COM PB INSIDE CONSTRUCTION SPECIAL EDITION FEATURES DEPARTMENTS 14 ROAD CONSTRUCTION ROAD WORK AHEAD BUDGET AND WORKER SHORTAGES ARE A CONSTANT CONCERN 6 EDITOR’S NOTE HELLO FROM THE NEW EDITOR BY TOM DENNIS 8 South Dakota SOUTH DAKOTA ECONOMY GROWS WITH REGULATION AND INITIATIVE BY SCOTT STERN 10 North Dakota CONSTRUCTION IS BIG CONTRIBUTOR TO NORTH DAKOTA ECONOMY BY RUSS HANSON 12 Minnesota CONSTRUCTION INDUSTRY REBOUNDS AFTER RECESSION BY SHAWNTERA HARDY 22 Q & A: HIGHER ED CONSTRUCTION MANAGEMENT AND ENGINEERING GARY SMITH DEAN | NORTH DAKOTA STATE UNIVERSITY COLLEGE OF ENGINEERING | FARGO 24 Q & A: HIGHER ED CARPENTRY EARL TORGERSON ASSISTANT PROFESSOR OF CARPENTRY BISMARCK STATE COLLEGE 26 Q & A: HIGHER ED CONSTRUCTION ELECTRICITY STAN KOVARIK FACULTY MEMBER, CONSTRUCTION ELECTRICITY NORTHLAND COMMUNITY & TECHNICAL COLLEGE EAST GRAND FORKS, MINN. 30 Construction Data 18 DEVELOPMENT BROWNFIELD VS GREENFIELD DOWNTOWN DEVELOPERS FAVOR DEVELOPING EXISTING BUILDINGS 20 PLANNING FIT TO DRINK THE DESIGNERS’ CHALLENGE: A GRAND FORKS WATER TREATMENT PLANT THAT CAN SUPPLY DRINKING WATER FOR THOUSANDS ON THE COVER As infrastructure ages, contractors struggle to hire enough workers, partly because of the low unemployment rate. IMAGE: North Dakota Department of Transportation prairie people VISIT WWW.PRAIRIEBUSINESSMAGAZINE.COM TO SEE THESE AND OTHER NEW HIRES, PROMOTIONS AND AWARD WINNERS IN THE REGION. KEITH LUND JONATHAN RENTZ HAS BEEN NAMED PRESIDENT AND CEO OF THE GRAND FORKS REGION ECONOMIC DEVELOPMENT CORPORATION. HAS BEEN PROMOTED TO RELATIONSHIP MANAGER AT ALERUS FINANCIAL CORP. RENTZ HAS BEEN WITH ALERUS SINCE 2010.

8

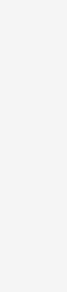

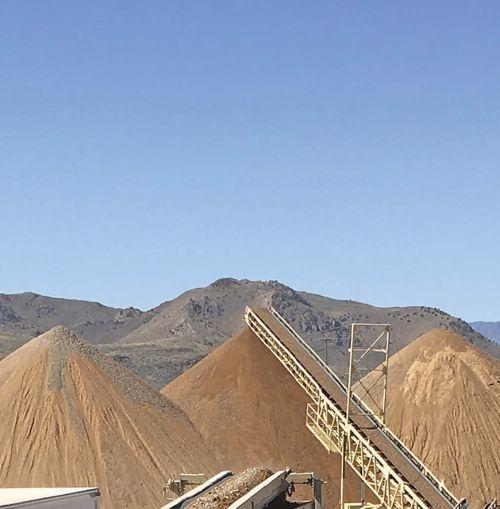

Contractors work to fill available construction jobs and cope with tight budgets in the region. IMAGE: North Dakota Department of Transportation

Fisher Sand & Gravel Co. is the parent company of Fisher Industries. We were founded in southwest North Dakota in 1952, and have 65 years of experience in the aggregate processing and mining industries. We are ranked as one of the top 25 sand and gravel producing companies in the U.S. We operate throughout the United States and have permanent locations in Arizona, California, Louisiana, Montana, Nevada, New Mexico, North Dakota, South Dakota, Texas, and Wyoming.

WE OFFER:

SAND & GRAVEL

CONTRACT CRUSHING

COMMERCIAL CRUSHING MANAGEMENT

GENERAL HIGHWAY CONSTRUCTION

HEAVY CIVIL EARTHWORK

| |

3020 Energy Drive Dickinson, ND 58601 (701) 456-9184 (800) 932-8740

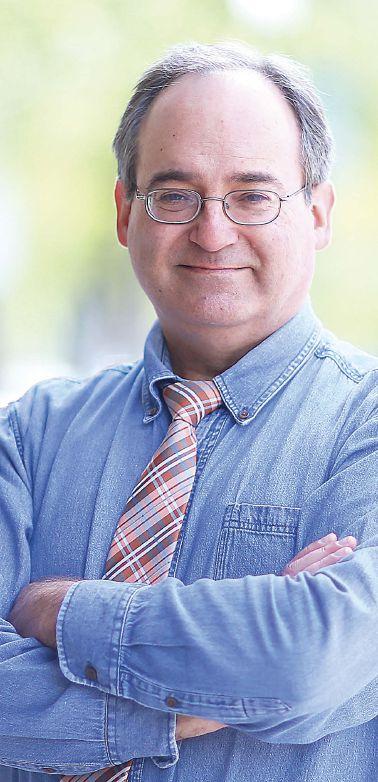

’m Tom Dennis, and I’m honored to introduce myself as the new editor of Prairie Business.

Hello from the new editor I

I like to think I’m bringing two important qualities to the job. The first is the past two decades. I edited the editorial page of the Grand Forks Herald during that time, and through that experience, I learned a lot about the history, geography and culture of our region.

The second quality is the few decades before that. Before moving to Grand Forks, I’d lived in New York City, Seattle and Portland, Ore., as well as in various small towns in Massachusetts, Pennsylvania, Maryland and Rhode Island. I even lived in Caracas, Venezuela, for a couple of years as a kid.

What those experiences gave me is a tremendous appreciation for life right here in the Upper Midwest.

I love living here. I think our region’s dynamism, quality of services and quality of life are superb.

I’m convinced that our population centers such as Grand Forks, Fargo, Sioux Falls and Bismarck will keep growing as more Americans learn about the unmatched family-friendliness of our cities.

And I’m thrilled to edit the magazine that covers the engine powering this growth: business. That coverage continues today with this “Construction” issue, in which Prairie Business describes the progress and expansion that’s happening everywhere you see a tower crane. Hope you like it! Feel free to call me at 701-780-1276 or email me at tdennis@ prairiebusinessmagazine.com with any questions, comments or story ideas for future issues. PB

PUBLISHER KORRIE WENZEL

AD DIRECTOR STACI LORD EDITOR TOM DENNIS CIRCULATION MANAGER BETH BOHLMAN

LAYOUT DESIGN, AD DESIGN JASON MAGSTADT SARA SLABY KRIS WOLFF

ACCOUNT MANAGER NICHOLE ERTMAN 800.477.6572 ext. 1162 nertman@prairiebusinessmagazine.com

Prairie Business magazine is published monthly by the Grand Forks Herald and Forum Communications Company with offices at 375 2nd Avenue North, Grand Forks, ND 58203. Subscriptions are available free of charge. Back issue quantities are limited and subject to availability ($2/copy prepaid). The opinions of writers featured in Prairie Business are their own. Unsolicited manuscripts, photographs, artwork are encouraged but will not be returned without a self-addressed, stamped envelope.

SUBSCRIPTIONS

Subscriptions are free www.prairiebusinessmagazine.com

ADDRESS CORRECTIONS

Prairie Business magazine Box 6008 Grand Forks, ND 58206-6008 Beth Bohlman: bbohlman@prairiebusinessmagazine.com

ONLINE www.prairiebusinessmagazine.com

TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM 6

CONSTRUCTION SPECIAL EDITION TOM

tdennis@prairiebusinessmagazine.com 701.780.1276

DENNIS

EDITOR Good reading, Tom Dennis

South Dakota Economy Grows with Innovation and Initiative

By Scott Stern

As a South Dakota native and commissioner of the Governor’s Office of Economic Development, I feel a real passion for watching businesses expand and our economy grow. Through prudent government and responsible regulation, we have maintained one of the best business climates in the nation, and there is truly no better place than South Dakota for companies to call home.

I’m proud to say that numerous businesses from around the world are doing just that.

In 2016, Royal Canin USA, a subsidiary of Mars, Inc., announced the construction of a new state-of-the-art manufacturing facility in North Sioux City. The facility represents a $100 million investment. With operations on five continents, the company could have invested anywhere, but they chose South Dakota.

North Sioux City saw additional growth when Red’s All Natural Burritos, based in Franklin, Tenn., announced its expansion to the state and community. Red’s All Natural Burritos markets a variety of frozen products, including burritos, bowls, enchiladas and taquitos, which can be found in large retail chains across the nation.

And, in early May, Ag Processing Inc., (AGP) a cooperative, celebrated its expansion with a groundbreaking ceremony for its new soybean crushing facility in Aberdeen. The facility will process more than 45 million bushels of soybeans a year, so the economic impact is huge. In addition, the project will create about 50 new jobs.

As much excitement as these types of announcements garner, it is important to note that they don’t just happen by accident. Our economic development team is constantly working with community and business leaders on a number of projects and initiatives that help make doing business in South Dakota a reality.

We are currently working to fill Foundation Park, South Dakota’s first megasite. The business park, located in northwest Sioux Falls, sits on more than 800 acres, has access to two major interstates, is minutes

away from the Sioux Falls Regional Airport, and is fully serviced by the BNSF railroad. The park will contain a mix of heavy and light industrial sites, ranging in size from 2.5 acres to 100+ acres.

In May, we were happy to announce Foundation Park’s first project. Win Chill, LLC, a 205,000 square-foot, full-service refrigerated foods warehouse and distribution center, acquired 54 acres from the Sioux Falls Development Foundation. It’s an exciting project not only for Sioux Falls, but also for South Dakota’s economy.

But sometimes, we can have the perfect site with the right building and all the desired infrastructure in place, and outside factors – such as workforce or housing – can still prevent us from finalizing a deal.

That’s why we are moving forward with our Bulldoze, Build and Beautify program. The goal is to help community and economic developers fulfill workforce housing needs while beautifying their communities. More than 3,000 blighted properties have been identified, and state officials are working on cost-efficient ways for these sites to be repurposed into affordable housing for a growing workforce.

One thing I really like about projects such as these is that they can apply to both urban and rural areas.

Growing up in Freeman, S.D., I got to see firsthand how South Dakota’s business climate benefits homegrown companies. With experience working my family’s business, and then in the corporate world, I’m proud to say that there is no better place to run a business – big or small – than in South Dakota. We are open for business! PB

Scott Stern COMMISSIONER

DAKOTA GOVERNOR’S OFFICE OF ECONOMIC DEVELOPMENT

8 TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM PB SouthDakota CONSTRUCTION SPECIAL EDITION

SOUTH

SCOTT.STERN@SDREADYTOWORK.COM

A 100% Employee-owned, American Company 10-1647 (2017-05) ©2017 Border States Industries, Inc. borderstates.com Supplying products and services to the construction, industrial and utility industries. Looking to REDUCE LABOR COSTS? One of the largest expenses on a construction project is the cost of labor. Using our SupplyTrax Material Management solutions to save you time and money will make a big impact on your profitability. Find out how. Contact your local Border States branch or call 866.483.7289. Job Site Boxes and Carts Kitting Job Site Trailers Material Staging Job Site Containers

Construction is Big Contributor to North Dakota’s Economy

By Russ Hanson

For decades, the construction industry has suffered from an image problem. That’s reflected in sayings such as, “If you can’t do anything else, you can always do construction.” The image of a construction worker has typically included worn or torn jeans, beat-up hand tools and a dirty work situation. Construction work also has been thought of as an occupation offering lower-tier pay and benefits.

All of those are misnomers, especially in the 21st century.

Technology has evolved in our industry, and all levels now are technical. That means our workforce needs to be computer literate, as iPads are a key tool used by construction crews to help them with their projects. Equipment is highly technical, and much of it is computerized.

And construction work provides a competitive wage, with most companies offering their full-time employees health insurance and retirement benefits.

In fact, construction employment wages are a big contributor to the North Dakota economy, much bigger than many realize. In 2015, 34,000 individuals were employed in the construction industry. That compares with about 20,000 a decade ago.

A major component of the increase was the economic boom of 2011-14, so considering our softening economy, it will be interesting to monitor the numbers in years to come. But many companies that arrived during the boom are confident the economy will recover and are staying in the state. That suggests the industry numbers may not be reduced by much.

Statewide, construction employee wages were $2.2 billion in 2015. Construction employees earned an average of $65,000 a year in 2015 and about the same amount in 2014.

The overall average is a little misleading, as wages can vary greatly depending on location. In some counties, wages were less, but the counties where lots of construction projects are underway actually are in excess of the statewide average – by quite a bit in some cases.

For example, the wage average in Ward County is $65,000, in Williams County it’s $83,000, in Mountrail $73,000, and McKenzie County leads the state at $93,000. Grand Forks, Burleigh and Cass county averages were in the mid- to upper-$50,000 range.

Remember, this is just the wage and doesn’t include health insurance and retirement benefits. The bottom line is that construction is a healthy industry where a person can earn a decent living. Furthermore, many of

the dollars in those wages are returned to the North Dakota economy.

Construction workers provide the workforce needed to build, maintain and repair North Dakota’s infrastructure of all kinds –highways, water development and vertical building. One of the key elements of a sound economy is quality infrastructure, and North Dakota construction employees are proud of their quality work in this area.

The economic boom years provided many challenges for the state. Because of the fast-growing population in oil country and elsewhere in North Dakota, roads needed repair and reconstruction, schools and water treatment plants had to be built, and jails and hospitals were expanded and constructed.

From 2011-17, multiple billions of dollars were invested in these infrastructure needs. Today, with the slowing economy, fewer resources are available for such investments, though many needs remain. Highway construction funding is a visible example. For the past four years, the North Dakota Department of Transportation had construction programs valued at about $800 million per year, and the 2015 North Dakota Legislature passed “Surge Funding” to provide $1.2 billion in infrastructure funding for the 2015-17 biennium.

In contrast, the scenario for construction funding looks to be drastically different for the next few years. The North Dakota Department of Transportation will have an expected $465 million program in 2017 and $275 million in 2018, a far cry from the resources of previous bienniums.

It will be interesting to see how those changes will affect North Dakota’s economy and the safety of our infrastructure system.

But whatever resources are available, the North Dakota construction industry can be counted on to build those projects successfully and safely. PB

Russ Hanson EXECUTIVE VICE PRESIDENT ASSOCIATED GENERAL CONTRACTORS OF NORTH DAKOTA RHANSON@AGCND.ORG

10 TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM PB NORthDakota CONSTRUCTION SPECIAL EDITION

Construction Industry Rebounds After Recession

By Shawntera Hardy

The Minnesota construction sector was hit harder than any other industry during the last recession, losing nearly 38,000 jobs. By the time the dust had settled, an astonishing 32 percent of the industry’s jobs in the state had vanished.

The good news is construction is staging a remarkable comeback. Industry employment is at the highest level in a decade in Minnesota and just 11,000 jobs shy of its record high.

A booming economic recovery combined with high-profile projects in recent years, including the new U.S. Bank Stadium in downtown Minneapolis and the 11-mile Green Line light rail project, helped jumpstart construction into one of the fastest-growing industries in the state. Construction employment in Minnesota expanded at more than triple the pace of jobs overall in the state during the past 12 months and nearly double the national rate.

Growth won’t be slowing any time soon, with the industry expected to add another 10,300 jobs by 2024. That doesn’t include thousands of replacement openings that will need to be filled because of retirements or people leaving for work in other fields.

Clearly, construction is on a roll and an important part of the Minnesota economy. According to an estimate by the Associated

General Contractors of America last year, the construction sector contributes $14 billion to the state’s gross domestic product and accounts for $7.3 billion in wages and benefits annually.

The industry is attractive to workers because it pays median hourly wages of nearly $18 an hour, compared with $14 an hour for jobs overall. Another desirable feature: Just 20 percent of construction jobs require more than a high school degree, compared with 36 percent of jobs for all industries the state.

Education requirements in construction tend to be low because the industry follows a training model that is different from other industries, not because the jobs are low-skilled or low quality. For example, many companies offer on-the-job training and apprenticeships.

Help Wanted

Ironically, an industry that was hemorrhaging jobs just a few years ago is now struggling to find workers. Construction industry officials in Minnesota say finding enough skilled labor will be their biggest challenge in coming years, with more than 26,000 new and replacement jobs needing be filled by 2024.

A couple of factors are at play. One is that the industry is aging and will experience increased retirements in the next decade. A second factor is that many high schools and colleges have dropped vocational programs that fed the industry pipeline in the past. That trend, combined with parents who are encouraging their children to pursue four-year degrees, means fewer young people are gaining construction skills these days or showing interest in the field.

One of the keys to addressing the industry’s labor challenge is more recruitment of people of color and women. While the industry has made progress in becoming more diverse in recent years, men still comprise 86.4 percent of the Minnesota construction workforce. Women account for 13.6 percent of construction workers, while people of color comprise just 4.8 percent of the workforce.

Construction officials acknowledge that more work needs to be done to build a more diverse workforce. A number of efforts are underway, including Trade Up, a collaboration of trade groups, construction companies and other stakeholders that enables low-income students at Saint Paul College to train for careers in the construction trades.

The state’s Pathways to Prosperity Program also supports initiatives that train women, people of color and other underserved groups for work in construction and other careers. In another effort, Construction Tomorrow sponsors career fairs around the state to give high school students a taste of what it’s like to work in the industry.

Minnesota’s construction sector is healthy and growing. In order to make sure that success continues, the industry must invest in attracting a more diverse workforce. Hiring people from diverse backgrounds isn’t just good for business, it’s good for Minnesota. PB

12 TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM MINNESOTA CONSTRUCTION SPECIAL EDITION Shawntera Hardy COMMISSIONER MINNESOTA DEPARTMENT OF EMPLOYMENT AND ECONOMIC DEVELOPMENT SHAWNTERA.HARDY@STATE.MN.US

13

Road work ahead

But not as much as needed, as workforce shortages and tight funding limit the work the region’s highway contractors can do

By Rob Swenson

By Rob Swenson

14 TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM PB ROADCONSTRUCTION CONSTRUCTION SPECIAL EDITION

Kevin Gutknecht compares the nation’s sprawling interstate highway system to Baby Boomers. Like Americans born between 1946 and 1964, the oldest stretches of the interstate highway system are entering senior status.

Building interstate highways began in 1956, and like an increasing number of Boomers, the system has parts that need to be repaired or replaced.

“Quite frankly, all of the infrastructure is aging,” said Gutknecht, communications director for the Minnesota Department of Transportation.

Plus, a lot of other highways and roadways in the Northern Plains are older than the interstates and also in growing need of repair.

But North Dakota and South Dakota, like Minnesota, are confronted by road-building challenges such as budget limits and worker shortages as the states try to keep up with construction needs.

Minnesota’s most recent 20-year transportation plan indicates that if revenues aren’t increased, an $18 billion funding gap could develop over that time, Gutknecht said.

Budget slowdown

The next two years will be especially challenging in North Dakota because state and federal funding allocated for roadway construction has been reduced from a total of nearly $1.2 billion to about $755 million. Downturns in state revenue from the slumping oil and agricultural industries are significant factors in the budget reductions for road construction, said Russ Hanson, executive vice president of Associated General Contractors of North Dakota, a trade group.

15 Road Construction

LEFT/ABOVE: Traffic passes in a work zone on Highway 23 in the Minot District.

Widening Highway 200 project west of Killdeer toward US 85

During the past few years, North Dakota had benefited from onetime infusions of extra money, Hanson said. But “the next two years will be significantly different, with less funding.”

Hanson expects most roadwork in the next couple of years will be maintenance and repairs rather than reconstruction.

The 8,600 miles of roadway maintained by the state of North Dakota are in good condition now but will deteriorate over time, said Wayde Swenson, director of the office of operations in the North Dakota Department of Transportation.

Hundreds of millions of dollars in added funding will be needed in the future to catch up with projected construction needs. If there’s an upside to the soft economic conditions, it’s that bidding for roadconstruction contracts is highly competitive, Swenson and Hanson said.

North Dakota has been averaging about five bidders per project, up from past levels of three or four, Swenson said.

Darin Bergquist, secretary of the South Dakota Department of Transportation, said construction bids have been coming in favorably for about the past 18 months. That ended an extended period of rising prices.

“We’ve been getting very good prices,” Bergquist said. “That frees up money so we can do some additional work.”

The stabilization of energy prices has been a big factor helping hold down construction costs, he said.

Help wanted

But finding enough workers is a big challenge for road builders, Bergquist said: “I know our contractors are struggling.” The Transportation Department has trouble keeping its road crews fully staffed, too.

Toby Crow said that attracting workers and keeping them are the biggest challenges facing the construction industry in South Dakota.

He is the executive vice president of the South Dakota Associated General Contractors’ highway and utility chapter.

“That is the biggest difficulty companies are having right now: finding workers of all types,” Crow said. “It’s very, very difficult. The unemployment rate is so low.”

South Dakota’s unemployment rate in March was 2.8 percent. Coincidentally, a report by the Associated General Contractors of America indicates that the state is employing more people in all forms of construction than ever before. About 20,900 people were working in construction in March, according to the South Dakota Department of Labor and Regulation.

Capacity and congestion aren’t big issues on highways in South Dakota, Bergquist said. “Our focus and the vast majority of work we do is to try to maintain the condition of our existing system,” he said.

Maintenance and repair will be the major, near-term objectives of road crews throughout the region this construction season.

“I think starting next year, you’ll see more overlays rather than new construction,” said Greg McCormick, estimator and project manager for Northern Improvement Co., which has offices in Fargo, Bismarck, Dickinson and Williston, N.D.

“I think it’s slower for most paving companies, and next year looks to be even slower.”

Northern has about 730 employees now, but the total is likely to drop to under 200 in the winter months. Winter drop-offs in employment are typical for road-construction companies.

McCormick is optimistic about the long-term prospects, however. Northern Improvement has been riding the ups and downs of the regional economy for 83 years, he said.

“We’re still positive about North Dakota’s economy as a whole,” McCormick said. “We expect to be doing this a long time.” PB

Rob Swenson SPECIAL TO PRAIRIE BUSINESS

16 TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM PB

SPECIAL EDITION

ROADCONSTRUCTION CONSTRUCTION

ROBSWENSONMEDIASERVICES@GMAIL.COM

Traffic though construction zone on widening Highway 200 project west of Killdeer toward US 85

17 001583096r1

Brownfield vs. greenfield

it comes to

By Aimee Erdman

Everyone loves a great makeover.

TV series such as Fixer Upper, Flip or Flop and the like captivate viewers by showing transformations from grungy to glam. Watching the ugly duckling emerge as the beautiful swan just feels good.

But for a city thinking about its downtown, is the emotionally satisfying decision the best choice economically? Environmentally?

The folks at Kilbourne Group say yes.

“Downtown revitalization creates long-term vitality and financial solvency for a community,” says Mike Allmendinger, president of Kilbourne Group, a development firm focused solely on downtown Fargo.

Kilbourne Group began with Doug Burgum’s love of downtown Fargo, born out of his mother’s adoration of the neighborhood and its historic buildings and her dismay during the urban renewal phase of demolition. The younger Burgum had determined that he could have the biggest impact on the region through mixeduse historic renovation and urban infill in downtown.

Downtown dream

In 2003, the opportunity to renovate Renaissance Hall materialized. After the building had sat empty for years, the owner had decided the only course of action was to raze it. Burgum offered to take ownership of the building, and he and Mike Allmendinger worked together to renovate it.

Burgum subsequently donated the building to North Dakota State University. And as Burgum and Allmendinger imagined the economic and activity impact of adding thousands of college students in downtown every day, a bigger dream emerged. They’ve been working closely together for more than a decade to revitalize downtown Fargo.

18 TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM DEVELOPMENT CONSTRUCTION SPECIAL EDITION

Mike Allmendinger

When

downtown development, Kilbourne Group in Fargo brings this old saying to life: Everything old is new again

Kilbourne Group bought and is renovating the Black Building in downtown Fargo, the tallest building in North Dakota when it was built in 1930.

Burgum’s curiosity regarding city economics and the impact of downtowns evolved into the broader vision of Kilbourne Group, which was incorporated in 2006. The company started with three projects in Fargo: 300 Broadway, 102 Broadway and the Smith, Follett & Crowl building.

Together, Burgum and Allmendinger worked on storefront design and prioritizing retail on the ground floor. They purposefully designed walkability principles into each project and patiently waited for retail tenants.

Out of this partnership, the values and mission of Kilbourne Group were born.

“Our work is about making downtown Fargo as vibrant as it can be, which leads to a smart, healthy city. The impact we desire is a healthier city, both physically and financially, and to make our downtown a competitive differentiator,” said Allmendinger.

Fixer upper or money pit?

Saving downtown isn’t without its challenges, however. Historic renovation in an existing area can come with more risk and thereby more expense than building structures in open, undeveloped land at the edge of town.

For decades, cities have incentivized edge development through infrastructure buildout, which is paid for through special assessments and city funding, which means by taxpayers.

Other challenges include environmental cleanup, the added cost of building up rather than out, the fact that downtown land tends to be more expensive and have a higher tax rate, and the reality that infrastructure rehabilitation doesn’t get the same federal and state cost share as new infrastructure for greenfield projects does.

Brownfield (redeveloping existing structures) and infill (building and repurposing unused space in an existing development) build on infrastructure already in place. Greenfield construction, or using currently undeveloped property for a project, requires a substantial commitment and investment from the community.

Infrastructure such as water, sewer, and roads all need to be paid for by the city, as does the maintenance of the new systems. Greenfield development certainly has its place. Big Box retailers who need more square footage and parking typically look for greenfield development opportunities. Retail and restaurants might be looking to expand into growing neighborhoods and new developments, where greenfield construction is the only option.

But focusing solely on outward expansion is shortsighted, Allmendinger says.

“A vibrant downtown with walkable, mixed-use development generates higher density and creates more property taxes per block than any area in a city. Also, the mixed use creates an 18hour city and a high level of activity, all of which helps people have great experiences in downtown.”

Mixed-use buildings attract diverse and unique businesses, which in turn build a creative community through the impromptu communication and networking that often happen in a vibrant district.

Ultimately, revitalization honors the history and culture of a community by saving a landscape that tells their story.

Allmendinger believes this model works in small and large communities alike.

“There are at least 58 communities in the state with Renaissance Zones. Small communities are having success with downtown revitalization projects too,” says Allmendinger. PB

19 Development Aimee Erdman SPECIAL TO PRAIRIE BUSINESS ERDMANCLAN@GMAIL.COM

Kilbourne Group’s Roberts Commons project, built on the site of a downtown Fargo parking lot, will feature a 445-stall parking garage surrounded on three sides by residential, retail and food-and-beverage development.

From river water to drinking water

The Grand Forks Water Treatment Plant’s design reflects the plant’s vital function, JLG Architects says

By Bianca Bina

By Bianca Bina

The Grand Forks Regional Water Treatment Plant is a work in progress. It’s been moving toward completion since at least 2014, when JLG Architects presented its proposal to the city and won the bid. Now, construction is set to wrap up in 2020.

But this is not a typical construction project, JLG Architects says. And the process is more complex than it is for the usual projects they take on.

“It’s a really complicated coordination project, because it’s a little more large-scale pipe” to consider than the pipes used in, say, an office building, says Production Leader Chris Heidrich. “It involves a bit more engineering than a typical project, so there’s a lot of coordination involved.”

Heidrich joined JLG in 2015 and immediately began working with Principal in Charge Scott Jordan-Denny to get the project running. Jordan-Denny is the designer of the project and was involved from the project’s first mention at the firm. Heidrich takes the design and oversees the project, walking clients through the design and documenting the process.

“I kind of envision the big idea, and then Chris makes it happen,” he says.

Getting started

In the case of the water treatment plant, Grand Forks-based engineering company AE2S approached JLG to head the project from beginning to end. While cost is a large part of the planning process, it’s the who, what, when, where, and why that the architects really need to understand.

When clients approach JLG, they generally know what it is they want, Jordan-Denny says. But the clients don’t always consider the nitty-gritty details, which is where the firm comes in. “The typical client knows what they want, but they don’t know how to get there,” he says.

Building occupancy, room size and location, electrical and hydraulic requirements are all taken into consideration on top of budget; and for the water treatment plant, that was no easy feat. The team had

to coordinate a plan that would allow space for the project’s designspecific water filtration, pumping and treatment system.

“In some instances, like the water treatment plant, we do case studies and do some tours of other facilities,” says Director of Construction Services Tom Behm. He oversees the construction of projects, makes sure workers follow the construction documents and resolves issues.

It’s also important for the client to consider the future. “When we first meet the clients, we ascertain their goals and put some measures around that,” Jordan-Denny says. “What does success look like five years from now?”

The team then develops two or three different approaches based on the client’s requests, proposing a variety of angles from which the project can be approached.

“We really want them to realize their vision,” Heidrich says. “When they come to us, we want to make sure there’s a smooth process.” Part of that is offering a range of possibilities, listening to the client and adjusting the vision.

“We have to be flexible,” Jordan-Denny says. “Usually it becomes obvious pretty quickly which option is the winner, and so you’re constantly honing in on a decision that you can latch onto, that the team can latch onto, and really refining that.”

In brainstorming sessions, the JLG crew got to thinking about one cohesive vision. “What really got us going was this idea that we’re taking river water and turning it into drinking water,” Jordan-Denny says. “And you’re going from dirty brown, muddy water into something you can drink.”

The ideas started flowing, and plans emerged for a building whose flow and aesthetic would show the process of treating water. A play on interior and exterior texture with various materials such as perforated

20 TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM PB

CONSTRUCTION SPECIAL EDITION

PLANNING

metal, rusty steel and concrete would help set the feel for the building, while the layout would make learning about the treatment process simple and intriguing for visiting students.

After presenting the various ideas and combinations, the team hopes the client will choose the best. “We have our favorites, and we usually make a recommendation, but ultimately it’s their decision,” Heidrich says.

Construction

After organizing the big picture, agreeing on a design and finding the right contractors for the job, construction moves forward.

Every square inch of the project is documented in construction binders. These include information on the entire project, with descriptions of everything from the screws and carpet to the siding and parking lot.

“Hopefully, by the time we’re done with that big stack of drawings, someone should even be able to build the project without talking to us,” Jordan-Denny says.

Of course, problems can arise and questions can be posed, but they’re handled by an assembled team and manager. A team of professionals is hired to help decipher pricing and catalog the available options, alerting contractors, owners and JLG of any issues.

For example, the water-treatment plant needed to scale back on the desired 20-million-gallon capacity, in order to meet budgetary requirements. The size of the project decreased 50,000 feet and the gallon quantity was adjusted.

The adjustments continue to this day. A building committee, made of representatives from different departments and organizations involved in the project, comes together every two or three weeks to decide on changes to the plans, however major or minor they might be. The committee then meets with the owner or board of directors to approve the changes.

Until the project is complete, the entire process “takes a lot of communication skills on our side,” Jordan-Denny says. And JLG has years remaining to keep the communication between various groups going.

The team is proud of the way the design process came together. “We were able to get creative as a design team, and the engineers were able to get creative on how the tanks related to each other,” Heidrich says. “We were able to really make the most of the footprint of the building.”

Behm says, “It ended up pretty close to the initial layout.”

As construction continues, the team’s communication with other players will remain the priority. Keeping a flow and following the details while maintaining the original idea will ensure the end product will be a proud accomplishment, Jordan-Denny says.

“If you can go back to that original concept where you’ve got a strong design and strong goals, and you can measure your value-engineered project against those and say, ‘Yeah, we’re meeting all those goals,’ then you’ve done pretty good.” PB

21 Planning Bianca Bina MARKETING SPECIALIST, GRAND FORKS HERALD 701 780-1174 BBINA@GFHERALD.COM

Construction management and engineering

WHAT ARE SOME OF THE MAIN SKILLS STUDENTS LEARN AND HOW WILL THOSE SKILLS BE APPLIED IN THEIR CAREERS?

A.

North Dakota State University College of Engineering Fargo

Q.

Dean

WHAT’S THE AVERAGE ENROLLMENT IN NDSU’S CONSTRUCTION MANAGEMENT AND ENGINEERING DEPARTMENT FOR A SEMESTER?

Q. A.

In the past three years, the average undergraduate enrollments are 42 students enrolled in construction engineering and 170 students pursuing construction management degrees. As a whole, the two programs combined experienced a 27 percent increase in undergraduate enrollment during the past three years.

Students in the construction engineering and construction management programs learn skills important to meet the needs of the growing and changing construction industry in their future careers. Some of the fundamental student outcomes from both of these programs include skills in problem solving, analyzing and interpreting data, working in teams, understanding professional and ethical responsibility and enhancing written and oral communication skills.

Specifically, the construction engineering program combines the fundamentals of civil engineering design with the principles of construction. Students take a core group of construction courses in the areas of estimating, scheduling and construction operations. They also take math, science and engineering courses to learn the principles of design as they relate to analyzing and solving problems in the construction industry.

The combination of skills produces well-rounded construction professionals who are prepared to enter a variety of construction sectors, including commercial, residential, transportation and infrastructure systems. With their technical elective credits, students can specialize in areas such as structures, water resources and transportation.

The construction engineering degree is accredited by the Engineering Accreditation Commission of ABET. Graduating seniors are eligible to take the Fundamentals of Engineering exam, the first step toward completing their license as a Professional Engineer.

The construction management program is designed to prepare students for the construction, business and management aspects of working in the construction industry. The coursework focuses on construction techniques and management of the overall construction process, including the efficient use of people, equipment, materials and processes to maximize project operations. The construction management program requires a minor in business management.

The construction management degree is accredited by the American Council for Construction Education. Students in the program are encouraged to take the Associate Construction exam from the American Institute of Constructors. The exam is the initial step in achieving Certified Professional Constructor certification.

Gary Smith

22 TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM Q&AHigherEd CONSTRUCTION SPECIAL EDITION

HOW LONG DOES IT TAKE TO FINISH THE PROGRAM, AND WHAT DEGREE OR CERTIFICATE DO STUDENTS EARN?

At the undergraduate level, NDSU offers Bachelor of Science degrees in construction management and construction engineering. Both are designed to be four-year programs. At the graduate level, NDSU offers a Master of Science in construction management as well as a doctorate in civil engineering with an emphasis on construction.

NDSU also offers a Graduate Certificate in Construction Management for students who have earned their undergraduate degree in construction, engineering, architecture or other related discipline. The ninecredit certificate program provides an online graduate-level learning experience in estimating, scheduling and project management.

DO MOST STUDENTS WHO FINISH THE CONSTRUCTION PROGRAM LEAVE THE REGION FOR EMPLOYMENT POST-GRADUATION?

The program has graduated 123 students over the past three years. Of the 106 graduates who reported their employment status through a survey, 34 percent are employed within 100 miles of Fargo. Overall, 47 percent are employed in North Dakota, 34 percent in Minnesota and 19 percent are employed elsewhere.

WHAT ARE SOME OF THE MOST COMMON CAREERS STUDENTS PURSUE AFTER GRADUATION?

Graduates of the construction engineering and construction management programs have a wide range of employment opportunities with government agencies, consulting companies and construction companies. They typically work on public infrastructure projects, commercial construction, industrial construction or residential construction.

In general, students who graduate will take entry-level positions in the industry and often have their first assignment at a project site as an assistant to a project manager or a field engineer. They often rotate into project estimating and scheduling roles as needed within the company. In most cases, graduates have had an internship with the company or other companies prior to employment.

23 Q & A Higher Ed Q.

Q. Q. A. A. A.

Earl Torgerson

Assistant Professor of Carpentry

CARPENTRY

Q. Q. Q.

WHAT’S THE AVERAGE ENROLLMENT IN BISMARCK STATE COLLEGE’S CARPENTRY PROGRAM FOR A SEMESTER?

BSC Carpentry accepts 24 students in the program each year.

WHAT ARE SOME OF THE MAIN SKILLS STUDENTS WILL LEARN, AND HOW WILL THOSE SKILLS BE APPLIED IN THEIR CAREERS?

Students learn residential carpentry skills: blueprint reading, site layout and foundation construction, framing, exterior finish, cabinetmaking, interior finish, codes and house design. The training is built around the actual construction of a home each year in the Bismarck area. Emphasis is placed on sustainable/ green building, and our program has been recognized by the U.S. Environmental Protection Agency’s Homes Across America Program for practices associated with high-performance and resource-efficient home building.

In 2010-11, the BSC Carpentry program was the first in North Dakota to earn certification from the National Association of Home Builders Residential Green Rating Program.

HOW MANY YEARS DOES IT TAKE TO FINISH THE PROGRAM, AND WHAT DEGREE OR CERTIFICATE DO STUDENTS EARN?

Bismarck State College

Q. Q.

DO MOST STUDENTS WHO FINISH THE CARPENTRY PROGRAM LEAVE THE REGION FOR EMPLOYMENT POSTGRADUATION?

A. A. A. A. A.

Historically, 100 percent of our students who are interested in working in the field are offered jobs. Many land in the Bismarck area, others find jobs in their home towns across the state and region. Students continuing on to earn their AAS Degree often stay to work in the Bismarck area.

Students who successfully complete the first year of training are awarded a certificate in residential construction. They are prepared for skilled entry-level jobs in the home-building industry. Students can go on for another year of school to earn an Associate of Applied Science degree.

WHAT ARE SOME OF THE MOST COMMON CAREERS STUDENTS PURSUE AFTER GRADUATION?

Because students are trained in and exposed to so many areas of residential construction, they are recruited for a variety of roles. Home framing is the most common job for graduates, also cabinet making and exterior finish.

Working in construction can be a path of opportunities for motivated individuals. Graduates can go from carpentry to subcontracting to general contracting and even ownership of their own business.

This is my 22nd year teaching residential construction at BSC. During that time, I have also owned a home-building and land-development business. I have seen education in the industry move toward resource-efficient training, greater focus on building a healthy environment for homeowners and increased concern for the welfare, health and safety of workers.

Students are more interested in exploratory education than in the past. The last decade also has seen an increase in female and nontraditional students in residential construction.

24 TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM Q&AHigherEd CONSTRUCTION SPECIAL EDITION

Stan Kovarik

Faculty

member, Construction Electricity

Northland Community & Technical College, East Grand Forks, Minn.

CONSTRUCTION ELECTRICITY

Q. A.

WHAT IS THE AVERAGE ENROLLMENT IN NORTHLAND’S CONSTRUCTION ELECTRICITY PROGRAM?

Our full enrollment for the year is 23. All 23 students take the same classes.

26 TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRA IRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM Q&AHigherEd CONSTRUCTION SPECIAL EDITION

After owning his own business for many years, Stan Kovarik became an instructor in the Construction Electricity program at Northland Community & Technical College. IMAGE: NICK NELSON

27 Manning Mechanical, Inc. is a full-service mechanical contractor located in Fargo. Manning operates in the tri-state area of North Dakota, South Dakota and Minnesota. We have extensive capabilities, knowledge and experience in the mechanical field. This includes commercial, institutional, multi-family, design build, HVAC, piping, and commercial service work. CONTACT US FOR EXCELLENT CAREER OPPORTUNITIES Manning Mechanical, Inc. We Control the Elements Commercial – lndustrial – Service 4210 19th Avenue North Fax 701-293-68623 • www.manningmechanical.com (701) 293-9774 001589133r1

Q. Q.

A. A.

WHAT ARE SOME OF THE MAIN SKILLS STUDENTS WILL LEARN, AND HOW WILL THOSE SKILLS BE APPLIED IN THEIR CAREERS?

Our Program Description puts it this way: “The Construction Electricity diploma program prepares students to build, install, maintain and repair electrical systems that provide heat, light, or power for residential, commercial and industrial structures.”

I teach seven different classes, and the first thing we do in every class is stress safety. That’s pretty redundant, but it’s vital, because when you’re in the electrical business, you’ve got to think “Safety” before you do anything else.

So, the first part of every class is safety.

After that, students learn theory — what electricity is, and how it is produced. They learn blueprint reading, a skill all electricians have to know. We teach them about motors, and we teach residential, commercial and industrial wiring. We also teach the National Electric Codes.

By the end of the first year, each student can literally wire a home. And they do: we wire a brand-new home. I don’t take any tools with me to the site; it’s a hands-on education for the students, who do all the work.

So, at the end of the first year, a student who didn’t know the difference between a black wire and a white wire actually wires a brand-new home. And the home is sold at the end of the year.

It’s an excellent education.

WHAT KIND OF A DEGREE OR CERTIFICATE DO THE STUDENTS EARN?

At the end of the two-year program, a student earns a diploma. As important, he or she has also taken a big step toward becoming a journeyman electrician.

To become a journeyman electrician, you need 8,000 hours of work. That’s four years at 2,000 hours per year. At the end of their two years at Northland, the students get 2,000 hours credited to them.

So, they actually have started the apprenticeship program. They have completed 2,000 hours already, so they can go into three more years of an apprenticeship, then take their journeyman’s exam.

A.

WHAT’S THE DEMAND LIKE FOR GRADUATES?

Basically, all of our graduates find jobs. In fact, the job market is so good that our challenge is keeping students in the program long enough to complete it.

In Williston, N.D., for example, they’re hiring now. I had a couple of former students tell the rest of the students here, “If you want to work, we’ve got work for you right now.“ In other words, the oil patch is coming into play again.

And right now in Minneapolis, the schools there can’t even get students to enroll because people are hiring them right off the street.

Here is another example: these days, there are 8,000 more jobs for electricians in the United States every year than there were the year before. That’s not because of retirements; it’s because the industry is growing that fast. Think of everything that’s needed in the computer and the electrical industries, and you’ll see where that demand for electricians comes from.

And to top it off, for every three electricians retiring these days, there are only 1.5 newcomers going into the business. So it’s going to be just crazy. The job availability is going to be fantastic.

28 TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM PB Q&AHigherEd CONSTRUCTION SPECIAL EDITION

Q.

Motors such as the one pictured are disassembled and reassembled by students in the Construction Electricity program as part of their education at Northland Community & Technical College in East Grand Forks, Minn. IMAGE: NICK NELSON

Q. A. WHAT KIND OF A SALARY CAN A GRADUATE EXPECT?

Here is another quote from our Program Description: “According to Minnesota State’s CAREERwise website, the median hourly pay as an Electrician in the state of Minnesota is $29.17 per hour. The employment outlook through 2024 is expected to grow approximately 10.6 percent, a very high-growth career.”

Here’s another example of how that that high demand shows up. Two of my students went to work for Encore Electric out of Denver, Colo. The company actually found apartments for them and got everything arranged for them, so they’re pretty excited about that.

If you’re 19 or 20 years old and you find yourself sought-after in that way, you know you’re in the right line or work.

29 Conex Containers For Sale or Rent • Cargo Worthy, Wind & Water Tight Units • 10’, 20’ & 40’ Sizes Available • Delivered When & Where You Need Them • Container Depots in Minneapolis, MN, Thief River Falls, MN, Grafton & Williston ND, and Chicago, Il Mike DeSautel, Owner 701-360-1411 • storage-pros.com 001585529r1 Q & A Higher Ed

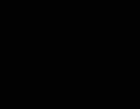

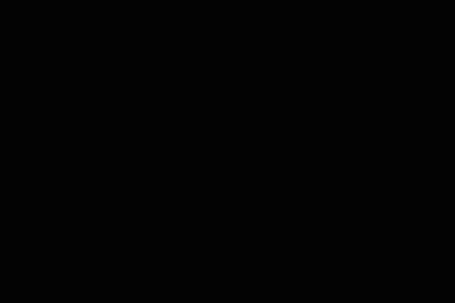

30

25

10

35 2

20

[Quarter Billions Dollars

4

6

8

Total SD ND MN 2011 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017

Grand Forks

Fargo

Bismarck

Sioux Falls

80

60

100 SD ND MN

40

20

120 0

SD ND MN 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 Grand Forks 2.2 2.1 2.0 2.1 2.1 2.3 2.6 2.4 2.7 2.8 3.8 Fargo 6.1 6.5 5.8 5.5 5.5 6.2 6.5 6.8 7.9 7.8 7.9 Bismarck 3.2 3.4 3.4 3.4 3.7 3.8 4.5 4.5 4.9 4.4 4.7 Sioux Falls 6.6 6.9 6.4 5.6 5.5 5.7 6.0 6.4 6.6 6.9 7.6

Real Average hourly construction earnings Local Construction employees [thousands]

[12 months through March 20xx] Year-over-year 0 15

2017 2016 2015

12 2012 2013 2014 2015 2016 Construction employees state thousands (employees) 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017

0 500 1000 1500 2000 2500 3000 3500 4000

2014 [q2] 2014 [q4] 2015 [q2] 2015 [q4] 2016 [q2] 2016 [q4] Grand Forks 10.89 5.75 4.41 5.32 5.55 3.63 Fargo 8.56 7.19 6.29 7.08 6.50 5.73 Bismarck 8.16 6.21 5.70 5.87 1.48 0.003 Sioux Falls 3.48 4.30 5.01 6.01 4.95 4.78

30 TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM PB ConstructionData CONSTRUCTION SPECIAL EDITION

GDP of all construction work

3]

housing permits

DATA PROVIDED BY DAVID FLYNN , CHAIR OF THE UNIVERSITY OF NORTH DAKOTA DEPARTMENT OF ECONOMICS. REACH HIM AT DAVID.FLYNN@BUSINESS.UND.EDU change in housing prices [Percent]

REDUCE TIME WITH UPKEEP

Keep your business moving forward without having to worry about your building systems not functioning properly.

HELPING YOUR BUILDING RUN BETTER ON LESS

SAVE YOUR

Save your business money while you work and while you sleep. Don't tie up your money in a building that's meant to move your business forward.

KEEP

Your building should work for you. With CxS Connect, your building’s systems consistently run more them last longer.

The immense power of CxS Connect provides your building with the ability of having an energy manager watching your facility 24 hours a day, 7 days a week.

BUSINESS

MONEY

YOUR RESOURCES HEALTHIER LONGER

MONITORING

FACILITY

CxSConnect.com to see how we could CxS Connect is a service offered by Commissioning Solutions, Inc.

commissioning could be a game-changer for your school, your campus, your business or your client’s next big project. *Results may vary.

Visit

Connected

By Rob Swenson

By Rob Swenson

By Bianca Bina

By Bianca Bina