From here to the world

Area manufacturers describe their products’ global reach

PREMIER BUSINESS MAGAZINE OF THE NORTHERN PLAINS | AUGUST 2018

TOM SHORMA, PRESIDENT AND CEO, WCCO BELTING WAHPETON, N.D.

PAGE

20

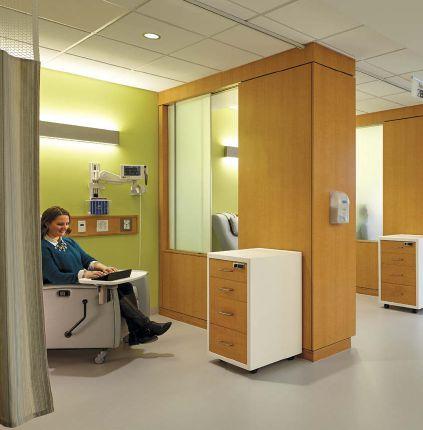

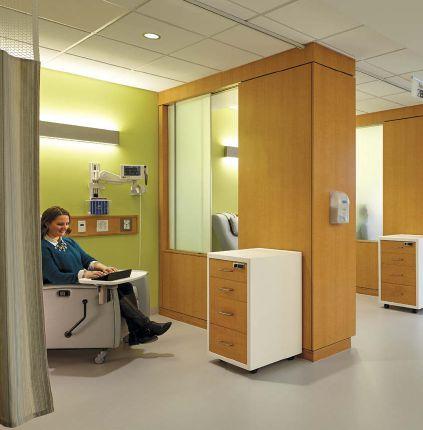

jlgarchitects.com 100% EMPLOYEE-OWNED ESOP Inc. Magazine’s 50 Best Places to Work in America | MSN Money’s 50 Most Admired Companies in the U.S. GOOD FOR YOUR HEALTH At JLG, we design healthcare facilities that care about you. Working closely together with our amazing regional health partners, we create patient-focused spaces that make it easier for doctors and nurses to improve response times and outcomes. It’s our people, taking care of yours.

Evolved.

Perfectly designed to thrive in its environment. Adaptable enough to evolve with the times. Building smart for a solid future. It’s second nature at KLJ.

LJ E NG .CO M

K

COST EFFECTIVE

For a flat monthly fee, you can colocate server equipment in any of our geographically diverse data centers. We handle security, power, backup systems and more.

GREATER RELIABILITY & FLEXIBILITY

Midco data centers come with our redundant, private network built in. Plus, you’ll enjoy 99.999% core network reliability and the flexibility to scale your bandwidth as your business needs change.

RESPONSIVENESS & TECHNICAL EXPERTISE

The experts at the Midco Network Operations Center monitor our fiber network and data centers 24/7/365. Our technical experts and customer care teams are highly trained and ready to work for you.

6 TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM JANUARY 2017 VOL 18 ISSUE 1 TAKE ADVANTAGE OF OUR INVESTMENT READY TO MIDCO? LET’S GO. Midco.com/DataCenters • 1.800.888.1300 © 2018 Midcontinent Communications. All rights reserved. Put Midco® Business’ state-of-the-art, weather-hardened data centers to work for you, and focus your IT capital on building your business.

These workers at 3M’s plant in Brookings, S.D., are making Tegaderm, a transparent medical dressing. 3M Brookings employs more than 1,100 people and makes more than 1,700 unique products.

IMAGE: 3M

ON THE COVER

Tom Shorma, president and CEO of WCCO Belting in Wahpeton, N.D., stands on the company’s production floor. WCCO Belting ships products used for harvesting to more than 20 different countries.

IMAGE: NICK NELSON/FORUM NEWS SERVICE

NEXT

N.D. STATE UNIVERSITY STUDENT KATE VOLK ANSWERS, ‘DOING RESEARCH’

34 CONSTRUCTION CORNER

ESSENTIA HEALTH’S UPCOMING PROJECT IN DULUTH WILL BE MINNESOTA’S BIGGEST-EVER HOSPITAL EXPANSION

8 AUGUST 2018 VOL 19 ISSUE 8 FEATURES DEPARTMENTS 20 MANUFACTURING MADE IN AMERICA THREE OF THE REGION’S “MAKERS” – AMERICAN CRYSTAL SUGAR, WCCO BELTING AND 3M BROOKINGS – EXPLAIN HOW IT’S DONE 10 EDITOR’S NOTE WE’VE COME A LONG, LONG WAY BY TOM DENNIS 12 WORKFORCE DEVELOPMENT APPRENTICESHIPS – AN ANCIENT TOOL – CAN MEET EMPLOYERS’ 21ST CENTURY LABOR NEEDS BY JOHN AIKEN 14 WOMEN IN CONSTRUCTION WOMEN IN THE TRADES CAN BOTH EARN HIGHER PAY AND GENERATE HIGHER PROFITS BY SOMMER JACOB 16 BUSINESS INSIDER A Q&A WITH PAUL KENNEDY, DAKOTA SUPPLY GROUP CEO 30 PRAIRIE PEOPLE 36 INSIGHTS & INTUITION 38 BY THE NUMBERS HEALTHY DESIGN TOMORROW’S PRAIRIE BUSINESS-AREA HOSPITALS WILL BE PACKED WITH TECHNOLOGY WHILE STILL FEELING LIKE HOME 26 ARCHITECTURE & ENGINEERING TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM prairie people VISIT WWW.PRAIRIEBUSINESSMAGAZINE.COM TO SEE THESE AND OTHER NEW HIRES, PROMOTIONS AND AWARD WINNERS IN THE REGION. FEBINA MATHEW DAVID SANDVIG SOUTH DAKOTA STATE UNIVERSITY FIELD CROPS PATHOLOGIST FEBINA MATHEW RECEIVED AN EARLY CAREER AWARD FROM THE AMERICAN PHYTOPATHOLOGICAL SOCIETY. MATHEW STUDIES PHOMOPSIS STEM CANKER, A THREAT TO SUNFLOWERS. DACOTAH BANK HAS PROMOTED DAVID SANDVIG TO SENIOR VICE PRESIDENT AND CHIEF RELATIONSHIP OFFICER. BEFORE HIS PROMOTION, SANDVIG SERVED AS A WEALTH ADVISOR FOR THE BANK. TABLEOFcontents

32 GENERATION

SUMMER

ASKED HOW SHE SPENT HER

VACATION,

9

EDITOR

The way things were

In Minot, N.D., construction already has begun on Trinity Health’s new $275 million hospital, as noted in this issue of Prairie Business. Other stories describe how medical products flow from the 3M plant in Brookings, S.D., to hospitals around the world, and how in 2011, the economic impact of the area’s sugar industry totaled $4.9 billion.

As such indicators suggest, the region is enjoying exceptional prosperity and growth.

So let’s take a moment to recall the way things were, less than 100 years ago. Here are a few passages from History of North Dakota, the classic work by the late University of North Dakota historian Elwyn Robinson:

n “Throughout the 1930’s, grasshoppers, menacing the whole Northern Plains, added their ravages to the damage of drought. In the spring of 1931, they began to destroy crops in Pembina and Adams counties, cutting binder twine on sheafs of grain, chewing up clothing and even roughening shovel and pitchfork handles with their powerful mandibles. They soon spread over large parts of the state.”

n “Many people were unable to pay their taxes. By the end of 1936, about three-fourths of the taxes in the southwestern counties were delinquent. … Thousands fled the stricken state. By 1940 the population was down to less than 642,000, a loss of 5.7 percent, or nearly 39,000 persons, in a decade.

n “In March 1935, after the terrible drought of 1934, some 37 percent of the state’s people were on relief, ranging from 72 percent in Divide County in the parched northwestern corner to none in Traill in the Red River Valley, which received its first federal help in November 1935.” The next time you see construction cranes swinging over Fargo or a housing development being built near Sioux Falls, think about the conditions in the 1930s, and remember: We’ve come a long way.

PUBLISHER KORRIE WENZEL

AD DIRECTOR STACI LORD

EDITOR

TOM DENNIS CIRCULATION MANAGER BETH BOHLMAN

LAYOUT DESIGN ANDY GOBLE

ACCOUNT MANAGERS

NICHOLE ERTMAN

800.477.6572 ext. 1162 nertman@prairiebusinessmagazine.com

JENNIFER LEROUX OLSZEWSKI

800.477.6572 ext. 1167 jlolszewski@prairiebusinessmagazine.com

Prairie Business magazine is published monthly by the Grand Forks Herald and Forum Communications Company with offices at 375 2nd Avenue North, Grand Forks, ND 58203. Subscriptions are available free of charge. Back issue quantities are limited and subject to availability ($2/copy prepaid). The opinions of writers featured in Prairie Business are their own.

Unsolicited manuscripts, photographs, artwork are encouraged but will not be returned without a self-addressed, stamped envelope.

SUBSCRIPTIONS

Subscriptions are free www.prairiebusinessmagazine.com

ADDRESS CORRECTIONS

Prairie Business magazine Box 6008 Grand Forks, ND 58206-6008

Beth Bohlman: bbohlman@prairiebusinessmagazine.com

ONLINE www.prairiebusinessmagazine.com

TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM 10 editor’snote

701.780.1276

TOM DENNIS tdennis@prairiebusinessmagazine.com

me at

Good reading, Tom Dennis I welcome your feedback and story ideas. Call me at 701-780-1276 or email

tdennis@prairiebusinessmagazine.com.

AUGUST 2018 VOL 19 ISSUE 8

11

Apprenticeship programs are a “time-tested model” that “employers can use to recruit, train and retain a highly skilled workforce,” says John Aiken, apprenticeship director for the Minnesota Department of Labor & Industry. And Minnesota, Aiken says, can help.

IMAGE: MINNESOTA

DEPARTMENT OF LABOR & INDUSTRY

A journeyman approach

How Minnesota helps employers set up apprenticeship programs

By John Aiken

ST. PAUL, Minn. – A statewide labor shortage and changing business landscape continues to challenge Minnesota companies to find and grow skilled workers.

By 2024, Minnesota is projected to have a shortage of nearly 400,000 workers in several key industries including construction, manufacturing, health care, information technology and transportation. This jobs gap poses real challenges to employers large and small – and impacts the future competitiveness of Minnesota in a global economy.

Apprenticeship is a proven model employers can use to recruit, train and retain a highly skilled workforce. This time-tested model delivers structured on-the-job learning in combination with classroom instruction to develop the highly skilled and motivated employees necessary to compete in the 21st century global economy.

Apprenticeship Minnesota at the Minnesota Department of Labor & Industry works with employers to explore apprenticeship models within their businesses and help them design their own programs

that provide apprentices with specific skills, rigorous training and jobrelated instruction tailored to the company’s needs.

Technical instruction, coupled with on-the-job training, equips apprentices with industry-specific knowledge that contributes directly to a business’s bottom line.

The apprenticeship model continues to expand with support from the business community and public investment.

In June, Apprenticeship Minnesota received a $1.8 million federal grant from the U.S. Department of Labor to support outreach, employer engagement and other apprenticeship initiatives throughout the state.

Other apprenticeship success stories, such as Pequot Tool & Manufacturing in Pequot Lakes, Minn., are growing as Minnesota companies discover the benefits of investing in an apprenticeship.

“Thanks to our apprenticeship program, we’re able to hire based on attitude and aptitude,” said Chad Shogren, president, Pequot Tool & Manufacturing.

12 TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM AUGUST 2018 VOL 19 ISSUE 8 WORKFORCEdevelopment

“Our apprentices work inside our organization to build the specific skills they need to be successful.

“It’s working very well. We’ve seen our employee retention rate increase as our turnover rate has dropped to less than half of what it was previously – and that’s half the industry standard.”

Assistance and informational tools

The Apprenticeship Minnesota website (www.apprenticeshipmn. com) provides information and tools to help educate both employers and potential apprentices about the potential of apprenticeships.

Employers can learn more about their opportunities and responsibilities as an apprentice sponsor, read about grants to reduce program costs and watch video testimonials from successful apprenticeship programs.

The website also features other video testimonials from current apprentices and information for potential apprentices, parents and teachers to learn more about the benefits of apprenticeship.

Grants and free services available

Apprenticeship Minnesota offers free services to help employers with the development, registration and launch of their apprenticeship strategy and program. There are cost considerations, but many can be reduced or addressed in other ways. For example, apprentice supervision, administrative support and related classroom

instruction are aspects of development that require expenses. But companies can leverage existing leadership and human resource functions to reduce costs.

The Minnesota Apprenticeship Initiative is also a useful resource for companies that are looking to build an apprenticeship program but need financial help. MAI currently offers grants in high-growth industries such as agriculture, health care, information technology and manufacturing to help employers with start-up costs associated with developing their apprenticeship programs.

Employers can get up to $5,000 for each apprentice to help cover costs, including apprenticeship-related supplies, materials, instruction and infrastructure.

More than 35 programs already have been developed in these industries to date as part of that initiative.

Today, Minnesota has nearly 200 active registered apprenticeship programs in high-growth and high-demand industries such as advanced manufacturing, construction, health care, utilities and transportation.

Prairie Business readers are welcome to contact Apprenticeship Minnesota (www.apprenticeshipmn.com) to find out more about how to build an apprenticeship program to meet the needs of their business. PB

John Aiken DIRECTOR OF LABOR STANDARDS AND APPRENTICESHIP MINNESOTA DEPARTMENT OF LABOR & INDUSTRY JOHN.AIKEN@STATE.MN.US

13

WORKFORCE DEVELOPMENT

Wealth builders

By Sommer Jacob

BISMARCK, N.D. – The number of women in construction has declined sharply since 2007, the U.S. Bureau of Labor Statistics reports. This is unfortunate, given the current need for more workers in the industry and the significant advantages that women have to offer, especially in leadership.

The number of women employed in the U.S. construction industry grew substantially – by 81.3 percent – from 1985 to 2007. But from 2007 to 2010, more than 2.5 million construction jobs were lost.

From the 2007 peak to 2010, more than 300,000 women workers left the construction industry.

Currently, women make up only 1.3 percent of the workforce in the construction industry. The majority of those are in support roles, such as office administration.

The reality is that a career in construction is no longer a dream for most kids, and rarely is even considered as a career path for women, especially women who are interested in leadership roles. Had you

asked me years ago, I wouldn’t have imagined myself slipping into a pair of work boots and leading a construction company, either! But there are big payoffs for everyone that could come from facilitating a change in the industry.

Opportunity for growth and profits

For example, recent studies suggest that companies with higher ratios of women in leadership are in better shape financially. One reason for this may be many women’s natural ability to be good communicators and collaborators -- two critical factors that foster efficiency and breed success.

There’s a real need to include more women in all industries, but there are some especially significant opportunities in the construction industry.

14 TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM AUGUST 2018 VOL 19 ISSUE 8 WOMENINCONSTRUCTION

When women lead construction companies, ‘the payoff is high’

Sommer Jacob, President, Northland Concrete & Excavation, Inc. Bismarck, N.D. IMAGE: PAMELA SMETTE PHOTOGRAPHY

According to the Peterson Institute, the payoff is high when women fill leadership roles in construction. Not only do companies benefit as a whole, but also women benefit on an individual level as well:

n Companies that are in the top 25 percent in the gender diversity of their workforce were 46 percent more likely to outperform the average in their industry.

n Women in construction earn, on average, 95.7 percent of what men make, compared to the national average of 81.1 percent.

Although the construction industry could benefit from more women at all job levels, change is more likely to come in leadership and management positions. And with so many openings pending (some project a shortage of 31 million skilled tradesmen by the year 2024), the industry must consider what can be done to support and include women filling those jobs, especially in leadership roles.

Construction professionals already are aware that their projects require high levels of collaboration in order to succeed.

Adding women who so often excel in communication and working cooperatively can be expected to improve overall workforce productivity.

Although only about 13 percent of construction firms are owned by women, 9 percent of women-owned construction firms achieve revenues of $500,000 or more, vs. 8 percent of all construction firms, the 2016 State of Women-Owned Businesses Report found.

It’s clear that women in leadership positions in construction are making a much bigger impact than one might expect on profitability for their companies.

What Can We Do?

Communities, industry leaders, educators and individuals must shoulder the responsibility to do what they can to help open the doors to the field and encourage women of all ages to consider a career in construction.

There are several organizations committed to supporting, encouraging and cultivating women leaders in the industry:

n The National Association of Women in Construction

n Women Construction Owners & Executives USA

n Professional Women in Construction

It takes courage and hard work to break into this male-dominated industry. At first, women may have to do more than their male counterparts and speak up about their accomplishments in order for their contributions to be noticed. But even though a lot is expected of women, and some men have a hard time getting used to a woman being in charge, the playing field in construction is fairly level, and women are held to the same standards as men.

The opportunities are there for those women who are willing to be the pioneers and bring about this much-needed change. PB

Sommer Jacob PRESIDENT NORTHLAND CONCRETE & EXCAVATION, INC. BISMARCK, N.D. SOMMER@NORTHLANDCE.COM

15

WOMEN IN CONSTRUCTION

Keeping water and energy flowing

DSG does just that, and Paul Kennedy aims to keep it that way

Q.

AFTER HIGH SCHOOL, YOU SPENT FOUR YEARS IN THE NAVY AND BECAME A CRYPTOLOGIC TECHNICIAN. WHAT DID YOU LEARN ABOUT LEADERSHIP AND LIFE FROM THE MILITARY?

A.

It was a great experience. I got up to E-5 in the course of four years and became a supervisor at a young age.

And as I reflect back on that time, one thing that really strikes me is that I learned a lot about people, and how this is a great big country with diverse wants and needs and life experiences – and that to maximize people’s abilities, you need to understand where they’re coming from.

I remember that distinctly because I grew up on the East Coast, so I’d never really spent time with anybody from the Midwest or West Coast or the South. And all of the sudden, I was in this potpourri of people with different life experiences.

Plus as a young manager, I had to manage people who were older than me. That took some getting used to as well.

Paul Kennedy CEO

Dakota Supply Group Fargo, N.D.

utility, communications, waterworks and automation trades.

In this interview, Prairie Business talks to Kennedy about DSG, his career, and the impact technology and the Internet are having on even age-old industries such as plumbing.

Also, as you get exposed to a lot of different managers in the service, you pick up on traits and think, “Hey, I sure as heck don’t want to be like that guy,” or “Now, over there is a leader whose got some character and leadership traits that I really admire.” And I’ve definitely tried to incorporate those lessons into my life.

Q. A.

WHAT WOULD SOME OF THOSE NEGATIVE AND POSITIVE EXAMPLES BE?

On the good side, it would be somebody who took the time to earn my respect, rather than just demanding that I give them that respect. In other words, it would be a person who took time to get to know me and understand where I was coming from. That made me want to go and be all that I could be for that leader.

On the flip side, it would be somebody who not only felt “rank has its privileges,” but also took that to the wall. So, regardless of what the job was, it was always, “Hey, I outrank you,” rather than trying to promote that team influence and team effort.

16 TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM BusinessInsider AUGUST 2018 VOL 19 ISSUE 8

Paul Kennedy, CEO of Dakota Supply Group, Fargo, N.D. IMAGE: DSG

Editor’s note: Paul Kennedy is the new CEO of Dakota Supply Group, a Fargo, N.D.-based distributor of products and services serving the plumbing, HVAC, electrical,

A. A. A.

AFTER THE NAVY, WHAT CAME NEXT?

After I left the Navy, I moved with my wife –who was also in the Navy, and whom I’d met there – to Bemidji, Minn., where she’s from.

And that’s where I got into the plumbing business: I went to work for one of her uncles, who was a plumbing contractor in Bemidji.

DID YOU START ON THE GROUND FLOOR?

I did. I’d been in the intelligence industry, but as you can imagine, there was not much market for that in Bemidji, Minn. But my wife and I had just decided that Bemidji was where we were going to call home; and because I didn’t have a job, I went to work for her uncle, who was in the plumbing business. And that’s how I started in the trades.

WHAT WAS IT ABOUT PLUMBING AND HEATING SUPPLY THAT KEPT YOUR INTEREST?

It just got into my blood. By the time I became a senior executive, I think I had a unique perspective, because I’d started out on the contracting side. And I’d worked my way up though contracting and into distribution – small branch management, outside sales, and into a senior executive role.

Q. TELL US ABOUT DAKOTA SUPPLY GROUP.

A.

In a nutshell, we are a leading distributor of electrical, plumbing, HVAC, utility, communications and waterworks products and services.

That’s the kind of work we do. But how we do it is, I think, even more special: We’re in 33 locations spread across Montana, North and South Dakota, Minnesota and Wisconsin. And our real key is that we’re employee owned, with roughly 700 employee owners.

We’re an ESOP, and that defines our level of engagement. Every day, every employee not only feels empowered, but also has the burden of being an owner. That comes into daily decision-making, as it pushes all of us to make sure we’re doing all we can to take care of the customer and drive our business forward.

Q. A.

WAS IT A PLUMBING SUPPLY COMPANY?

It was a plumbing contracting company. My first job was pumping septic tanks. So I worked in the field for a couple of years, and I ended up helping to manage the office for the business.

Then I went to work on the wholesale side as an outside salesman for a company in Park Rapids, Minn.

Then I was hired by Westburne Supply, a plumbing/ heating/electrical distribution company. They were a Canadian company, but they had a branch in Bemidji, and I became the branch manager.

I got promoted, moved to Fargo with the same company, and ran the branch business in Fargo.

Westburne was acquired in 2001 by Ferguson, which is a global leader in plumbing, HVAC, and waterworks distribution. And eventually, I became Ferguson’s VP for the North Central United States.

A few years and a few moves later, my wife and I moved to Ontario, and I took over the plumbing business for Wolseley Canada, which was Ferguson’s sister company in Canada.

Q. HOW HAS THE INTERNET CHANGED THE SUPPLY END OF THE INDUSTRY?

A.The Internet is both one of our biggest challenges and biggest opportunities. And it’s not just Amazon, but also companies that are competing more directly in our space – because, as you know, Amazon is more of a supply-chain and technology expert than it is an electrical, plumbing and heating expert.

So, understanding where where we can differentiate ourselves is critical to our success.

In DSG’s case, I really think our value proposition is the technical and product-specific expertise – what I call the “last mile” supply chain and other value-added supply-chain solutions that we can provide.

For example, I was in our Sioux Falls and St. Paul branches over the past few weeks, and I saw how we’ll unpack light fixtures from their packaging, then slide them into carts to make them easier for the contractor – our customer – to install once the fixtures get to the worksite.

So we’re coming up with those solutions that maybe an Amazon can’t.

The other piece is Amazon and others’ technology investment, which has forced all of us in every industry to raise our game. So, as a B2B e-commerce site, we want our contractors to be able to go online at a time that is convenient for them to get the information they need to better manage their business.

That’s the type of customer experience that we’ve got to provide.

17 Business Insider Q. Q.

Q.

Q. SO DSG’S TYPICAL CUSTOMERS ARE PLUMBERS, ELECTRICIANS OR OTHER CONTRACTORS WHO ARE LOOKING FOR SPECIALIZED MATERIALS?

Right. And they can come to one of our counters, they can call, they can email, they can fax, they can go online. There are lots of different ways for us to engage with them.

Q. A.

SO INNOVATION IS A DRIVER, EVEN IN A FIELD AS ANCIENT AS PLUMBING?

Absolutely. Think of it this way: It used to require five or six gallons of water to flush a toilet, but over the past 20 years, that’s now down to 1.2 or 1.6 gallons. Think of the hydraulic design behind that. How do you clear what needs to be cleared while using only 25 percent of the water that used to be required?

There’s a lot of design that goes into that, and into the piping systems that support it.

So that’s one piece. The other piece is the construction of the product. Twenty-five years ago, most water piping was copper tube. Today, it’s cross-linked polyethylene or PEX pipe. That means reduced costs, lighter weight, better durability, fewer connections and less chance of leaks.

Q. A.

WHAT’S NEXT IN PLUMBING AND HEATING?

Innovation and technology are driving our products, including from the Internet of Things –Internet-connected light bulbs, lighting controls, thermostats that anticipate when you’re going to be home and learn your daily routine, and so on.

Q. IT MUST BE SOMETHING TO HAVE WATCHED THAT EVOLVE OVER YOUR CAREER.

A.

If you’ve stayed in a newer hotel, you may have noticed the shower and thought, “Boy, I’m able to get a good shower from this, even though it’s using much less water than showers used to.” These days, it’s 1.5 gallons per minute or 1 gallon per minute out of a showerhead, vs. some of the old showerheads, which might have been 5 gallons per minute.

Same thing on the lighting side – the dynamics of LED lights. In many cases, they’re providing a better lighting experience while also drawing a significantly reduced power load and giving off less heat.

It’s very similar to computers, when you think back to how computer memory can be not only doubled but also made ever smaller in size. The leaps and bounds in plumbing, electrical or heating aren’t as quantum as that. But they are still pretty darn dramatic – and that makes this a very exciting time.

TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM 18 AUGUST 2018 VOL 19 ISSUE 8 BUSINESSINSIDER

A.

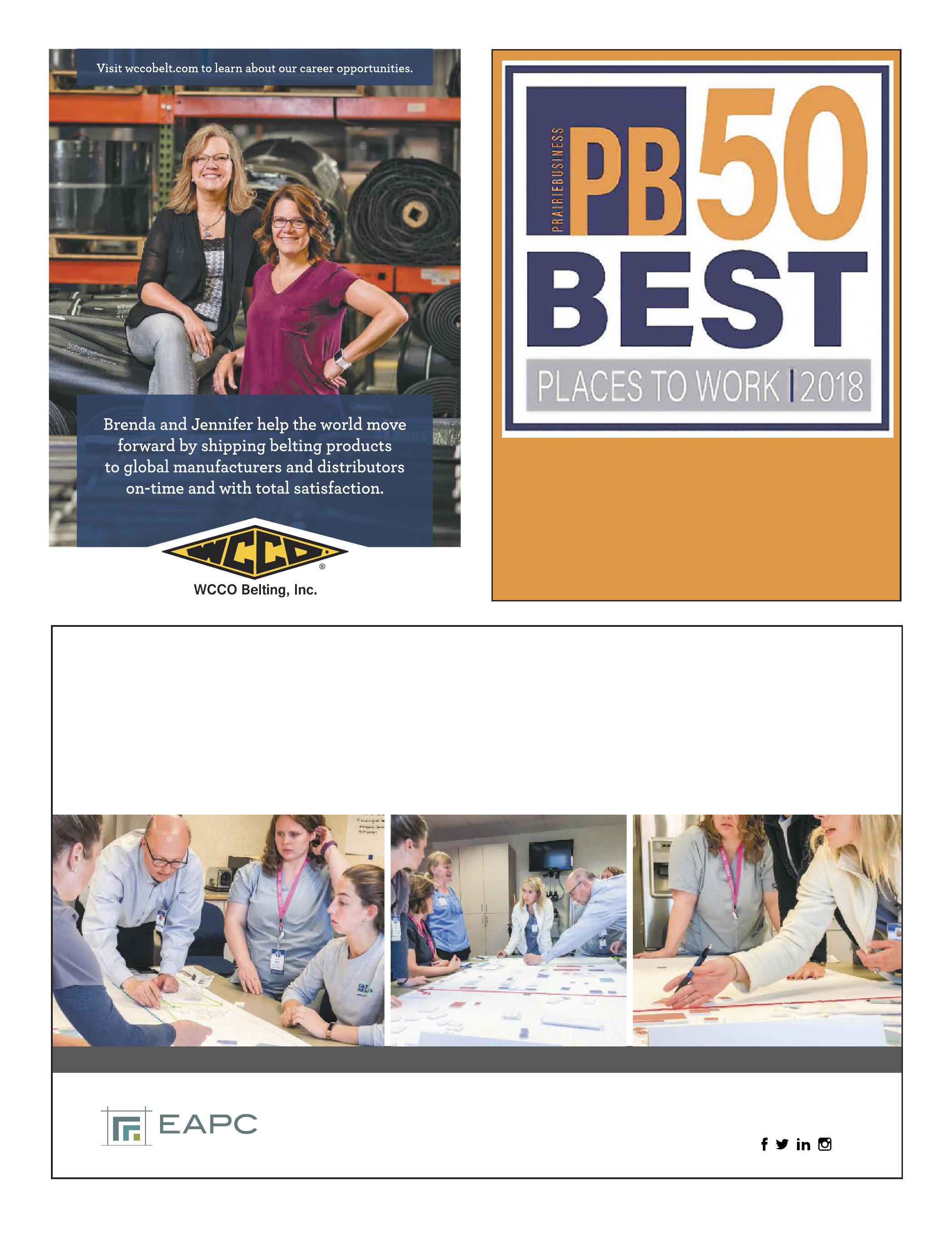

A new building will not fix a broken process.

In many of the LEAN-based space planning projects we have completed with clients, we have found that more than enough space exists in the current layout. By focusing on process flow, wastes can be identified and changes implemented to improve flow and patient satisfaction, ultimately reducing costs to the client both from an operations and capital perspective.

19

Connect With Us www.eapc.net/be EAPC Business Excellence’s Chad Frost provides space planning tools to healthcare leaders BUSINESS EXCELLENCE 001757595r1

in the September 2018 edition.

Coming

Makers

TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM 20 AUGUST 2018 VOL 19 ISSUE 8 MANUFACTURING

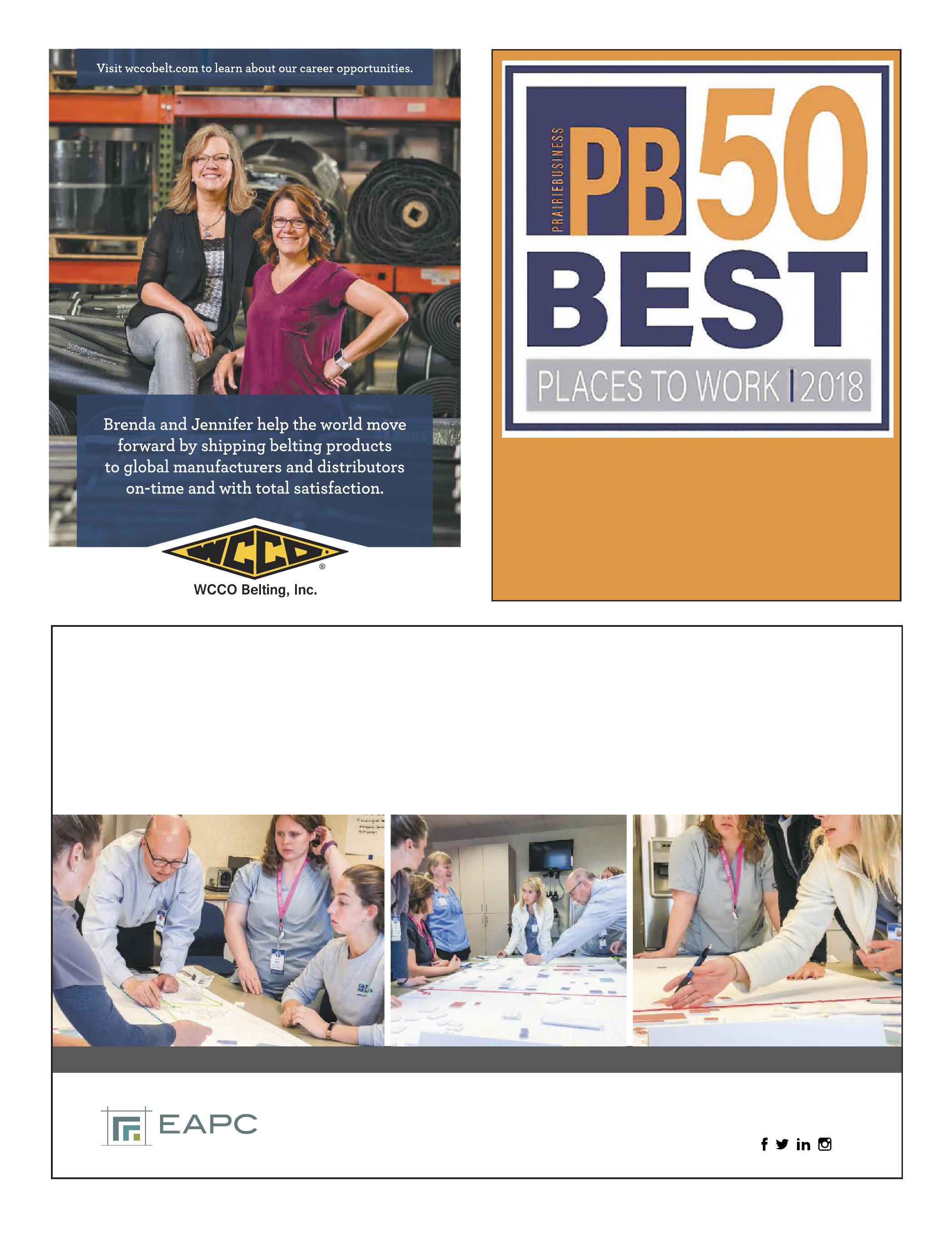

While the Wahpeton Canvas Co. – the company’s original name – made canvas belts, WCCO Belting makes vulcanized rubber products for use in the agriculture, construction and other sectors.

Pictured are Karley Serati, marketing services manager, and Tom Shorma, president and CEO.

IMAGE: J. ALAN PAUL

Manufacturing matters, and these three standout regional companies show why

By Tom Dennis

GRAND FORKS – Manufacturing is like the fuel injector of the engine of the region’s economy. It’s a comparatively small part that plays a very powerful role.

Manufacturing accounts for only about 9 percent of North Dakota and South Dakota’s gross state products. In Minnesota, the number’s a little higher, about 14 percent.

But “manufacturing generates more economic activity than other sectors,” said Stephen Gold, president & CEO of the Manufacturers Alliance for Productivity, in a 2016 interview.

“For every dollar of domestic manufacturing, another $3.60 of economic activity is generated elsewhere. For every manufacturing job, there are 3.4 jobs created in non-manufacturing industries.

“No other sector comes close to these numbers.”

Furthermore, manufacturing drives innovation. More scientists and engineers work in manufacturing (911,000) than in education (696,000), including colleges and universities, the National Science Board reports.

And the good-paying jobs in manufacturing are a reliable path to the middle class.

In short, “manufacturing helps raise living standards more than any other sector,” Gold concluded. That’s because “a vibrant manufacturing base leads to more research and development, innovation, productivity, exports and middle-class jobs.”

In this story, Prairie Business takes a look at three manufacturers – one each in Minnesota, North Dakota and South Dakota.

Their factories look nondescript when you pass them on the highway. But inside, each takes in raw materials and pumps out finished products, products whose sales pull millions or even billions of dollars into our region.

WCCO Belting

Speaking of “nondescript,” the word comes to mind when you see the WCCO Belting facility in Wahpeton, N.D. The building used to be a roller rink, and in some ways, it still looks the part.

But look closer.

See that flag, the white one with the blue “E” and star on it? That’s the President’s E-Star Award flag, and it testifies to WCCO Belting’s continuing success at exporting its products.

The E-Star exporting award was created by executive order of the president of the United States. And WCCO Belting is the only company in North Dakota to have received it.

So, that flag outside the building suggests that the inside deserves a look.

The look reveals a factory resembling a dry cleaner on industrialstrength steroids, as WCCO Belting’s 200 employees in Wahpeton use giant presses -- and the extreme heat and pressure they apply -- to turn rubber and fabric into custom-made rubber belts.

If you’ve ever seen a conveyor lift grain from a field into a hopper, you’ve likely seen a WCCO Belting belt. “We supply belting to every major farm equipment manufacturer in the world,” said Tom Shorma, WCCO Belting’s president and CEO.

“We ship directly into 24 countries.” And while agricultural belting makes up about half of the business, WCCO Belting also makes rubber conveyor belts for construction, industrial and other uses.

A key to the company’s success is a phrase that was used above: custom-made.

“Everything we make is custom,” Shorma said. “So, our typical competitor will go to a customer with a catalog and say, ‘Pick one.’ We go in with a brochure that describes our capabilities, and we say, ‘What do you want?’”

The customer spells out the belt properties that are needed – length, width, cleat pattern, puncture resistance and so on – and WCCO Belting complies.

“It’s just a different way of doing business that is unique to us,” Shorma said. “We are the best at what we do, and for the most part, we are the only ones who do what we do.”

As mentioned above, innovation is a big part of manufacturing. That’s true at WCCO Belting, as among its workforce are some 25 engineers. Their R&D efforts have resulted in multiple patents, as well as improvements to WCCO Belting’s products and production line.

Then there’s the culture that has resulted in multiple Prairie Business 50 Best Places to Work awards, the fact that nearly half of the workforce is female (well above the industry average), the fact that new employees – all of whom, including office workers, spend time on the factory floor – are told, “If you want a job, go elsewhere. If you want a career, stay here” …

“We had an industrial distributor visit,” Shorma said. “He’d lost a supplier. “He’s in the industrial-belting Hall of Fame; he’s won all kinds of awards. Before he came, he thought, ‘I’m going to have to help these guys.’

“Then he got here and said, ‘Who are you guys? Where did you come from?’ He had no idea we had this capability or capacity.

“So we ended up supplying him.”

21

MANUFACTURING

3M Brookings

South Dakota grows all kinds of crops. But some of the most unusual are cultivated not in the state’s farms or fields, but in labs –labs found inside 3M’s vast plant in Brookings, S.D.

The crops are spores. The farmers are 3M microbiologists, chemists and engineers.

The workers harvest the spores, then package them in vials for use in hospitals around the world.

And there, health workers use the spores to help determine whether surgical instruments have been properly sterilized.

TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM 22 AUGUST 2018 VOL 19 ISSUE 8 MANUFACTURING

The 3M Brookings plant in Brookings, S.D., makes 1,700 unique products and employs about 1,100 people. IMAGE: 3M

They do this by putting a spore-containing vial into the sterilizer with the instruments. After the cycle, the vial gets put in an autoreader, which detects whether the sterilization killed the tough little spores.

If it did, then the workers can trust that the process killed other organisms, too – and that the instruments can safely be used.

That’s science and innovation in action. And 3M’s Attest Biological Indicators are just a tiny fraction of the more than 1,700 unique health care products that are made in the 3M Brookings plant.

“For example, we make a variety of medical tapes,” said Dale Tidemann, plant manager.

“In fact, each year we make enough medical tape in Brookings to cover 21,000 football fields.”

One of 3M Brookings’ flagship products is Micropore tape. The surgical tape is used to secure dressings, IVs and other devices to skin.

“We’ve been making that here for 40 years, and in that 40 years, we’ve made a billion yards of Micropore tape,” Tidemann said.

“That’s enough to go to the moon and back. And that’s just one tape.”

3M Brookings employs more than 1,100 people. Most them gown up and put on special shoes, hairnets and other personal protective equipment before they step onto the production floor.

There they find a process that, in the case of the tapes, takes raw materials from railroad cars, fashions huge rolls called jumbos and then cuts, packages and (for many products) sterilizes the tapes before shipment.

Over time, the steadily growing workforce – 3M Brookings is one of the largest employers in Brookings – also has become more technical. So, 3M Brookings now partners to encourage STEM training.

“We continue to see a need for skilled workers,” said Becky Jirava, HR manager at the plant.

“For that, it’s important for us to make investments in technical institutes as well as colleges on the STEM front, and we’re looking to do that at the high school level as well.”

Along those lines, 3M Brookings maintains generous parental leave, volunteer service, personal wellness, charitable donation and other benefits to help not only employees, but also Brookings.

3M’s vision statement speaks of advancing every company, enhancing every home and improving every life. “At 3M Brookings, we talk about that last one a lot,” Jirava said.

“Improving every life, including the lives of our employees, our community and the people who use our products. That’s what we’re trying to do.”

23

MANUFACTURING

Its production of medical tapes (shown here) and other products make 3M Brookings 3M’s largest health care plant in the world. IMAGE: 3M

American Crystal Sugar

Direct economic impacts: $1.7 billion. Direct and secondary impacts: $4.9 billion.

Direct full-time employment: 2,473. Secondary full-time employment: 18,830.

That was the sugar beet industry in Minnesota and North Dakota in 2012. Which is why a team of North Dakota State University agricultural economists concluded the following:

“Although the sugar beet industry in Minnesota and North Dakota is not large in terms of acres or geographic area, the magnitude of key economic measures ... indicate that the industry contributes substantially to Minnesota and North Dakota economies.”

Substantially is right. As the numbers show, the sugar beet industry is central to the rural economies of the two states.

And American Crystal Sugar Co. in Moorhead, Minn., is central to the industry.

“American Crystal is the largest beet-sugar producer in the country,” said Lisa Borgen, vice president of administration at the cooperative.

“In the United States, 40 percent of all of the sugar that’s consumed is beet sugar. We produce 39 percent of all of the beet sugar, and 20 percent of all of the overall sugar production.”

And there’s more.

“On Oct. 1st, when we move the beets from the field to the piles, we start the most concentrated movement of a crop anywhere in the world,” Borgen said.

“The window is narrow, and the amount of crop that we have to bring in is huge.”

Local newspapers chronicle the migration, warning drivers to steer clear of the beet trucks and to watch for roads made slippery by spilled beets.

“There are about 12 million tons of beets that get piled,” Borgen said.

“During the harvest, there are 9 million farm truck miles that are driven, and it also takes about 10,000 extra people to move those beets. Isn’t that something?”

American Crystal is a cooperative, which means it’s owned by 700 grower/shareholders. The company employs about 2,000 people and runs six factories, five in the Red River Valley and one in Sidney, Mont.

“A couple of things stand out about American Crystal,” Borgen said.

“First, ours in an American-made product, and the people who grow it and who work in our factories are all really proud to be part of something that is made in America.

“Second, we’re always conscious of the financial impact we have up and down the valley.” It’s rewarding not only to create jobs, but also to help farmers stay on the land and pass the legacy of farming down to their children, she said.

Third, the technical skills needed to work in the factories continue to grow, which is why American Crystal has extensive training programs to help workers advance.

And fourth, “there’s pride that this is a process in which we start with tiny seeds, and we turn those eventually into 3 billion pounds of sugar. It’s just really amazing.” PB

TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM 24 AUGUST 2018 VOL 19 ISSUE 8 MANUFACTURING Tom Dennis EDITOR, PRAIRIE BUSINESS 701-780-1276 TDENNIS@PRAIRIEBUSINESSMAGAZINE.COM

An American Crystal Sugar worker inspects American Crystal’s finished product: packaged sugar. IMAGE: AMERICAN CRYSTAL SUGAR

Piling of sugar beets starts the sugar-making process at American Crystal Sugar’s factories in the Red River Valley. IMAGE: AMERICAN CRYSTAL SUGAR

25 001753244r1

TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM 26 ARCHITECTURE&ENGINEERING AUGUST 2018 VOL 19 ISSUE 8

Todd Medd, healthcare practice studio leader for JLG Architects of Grand Forks, N.D., stands near a screen showing Sanford Health’s newly opened facility in Fargo. JLG served as associate architect on the Sanford project.

SERVICE Health care architects use design to improve the hospital experience

IMAGE: NICK NELSON/FORUM

NEWS

Healing architecture

By Tom Dennis

GRAND FORKS, N.D. – When you’re talking about hospital architecture, there are a few words you don’t expect to hear.

One of them is “Disney.”

But when Prairie Business separately interviewed three architects who work for three different firms and are designing three different hospitals in our region, that word came up all three times. Interestingly, so did several other key words. For in the interviews, common themes emerged; and in this story, our hope is that by describing those themes, we can help residents understand what to look for as their new hospitals take shape.

Competition

We’ll get to the word “Disney” in a minute. But first, let’s focus on a word that helps explain why so many hospitals are being planned or built at the same time: competition.

No, competition isn’t the only reason why the metro areas of Grand Forks, Fargo, Minot, Sioux Falls, Rapid City and Duluth, as well as smaller communities such as Grafton, N.D., and Cooperstown, N.D., all will see or recently have seen multi-million dollar hospital projects. (The projects range from a proposed $26.2 million Cooperstown Medical Building to Essentia Health’s $800 million plan to revamp its medical campus in Duluth, one of the biggest medical expansion projects in Minnesota history.)

Coincidence helps explain the timing, too. In most of these communities, the hospitals date back decades, and the changes in modern medicine simply mean that many buildings are near the end of their useful life.

In Minot, for example, “the hospital operates out of two primary buildings, and one of them is approaching 100 years old,” said Kyle Wilson, partner at TEG Architects in Jeffersonville, Ind. TEG is the architect of record for Trinity Health’s plan to build a new, $275 million hospital in Minot.

“So for example, the ceiling heights are very low, and the rooms are semiprivate, which means you have two beds in every room. And the size of those rooms is probably smaller than what you’d want in a private room today.”

In the new Trinity Health hospital, all of the rooms will be private – including the rooms for infants in neonatal intensive care. (Twins, triplets and quadruplets will be cared for with their siblings in rooms with multiple bassinets.)

But competition does help explain why single rooms and other amenities have become the standard, Wilson said.

“On the patient side, you have choices on where your health care is delivered,” he said.

“Trinity Health wants to be the provider of choice. They want to be at the forefront of your mind, so there’s definitely a focus on patient satisfaction and staff satisfaction.”

Jason Nordling, a principal at BWBR Architects in St. Paul, Minn. agreed. And don’t miss the fact that “staff satisfaction” is listed right alongside “patient satisfaction” as a competitive force, Nordling said.

BWBR is the architect of record for Avera on Louise, Avera Health’s 82-acre, $174 million campus that’ll be the largest building project in Sioux Falls’ history. And throughout the campus, Avera will be taking care to make the staff areas attractive as well as functional, with an eye to boosting recruiting and retention.

“Fifty years ago, staff made a space work,” Nordling said.

27

ARCHITECTURE & ENGINEERING

This photo shows the operating room in Our Lady of Lourdes Regional Medical Center in Lafayette, La., a project on which TEG Architects served as architects of record. Operating rooms in the new hospitals being built in the Dakotas and Minnesota are likely to look something like this. IMAGE: TEG ARCHITECTS

“Today, we’re making workable spaces for the staff. We have people who do workplace design, and they’re designing collaborative and flexible staff spaces that include artwork, views of nature and other elements that are as important to staff as they are to patients.”

On stage, off stage

Speaking of staff, that brings us back to the Disney influence. Because one of the biggest differences between older and newer hospitals is the lesson of Disney World: the careful separation in new hospitals of the customers and staffers’ worlds.

“It’s called the ‘on stage’ and ‘off stage’ model,” said Todd Medd, healthcare practice studio leader at JLG Architects of Grand Forks, N.D., the company that’s the architect of record on Altru Health System’s $305 million hospital project in Grand Forks.

“On stage is where the patient is, and it starts from when the patients and visitors arrive on site. They’ll encounter a very calming, hospitalitybased environment, and that will continue into the elevators and up to their rooms.”

Meanwhile, physicians, nurses and other providers will use hallways, elevators and even entrances to patients’ rooms of their own.

“All of those back-of-house functions,” said Wilson of TEG, “such as your maintenance, your kitchen, your biomedical department, your materials management – those functions that are so essential for a hospital – the patient won’t see.

“Again, it’s the Disney concept where you’re just trying to hide some of the support functions so you can focus on the hospitality side.”

Understand, there are evidence-based health reasons for this change, said BWBR’s Nordling. By keeping the hustle-and-bustle “off stage” and the patient areas serene, patients will sleep better and be much less stressed. In any recovery process, that helps.

And consider: Once staff step into their own area, they’ll be much freer to collaborate and converse. For example, no longer will staff

have to stop talking about a case when a patient enters an elevator, because the staff will be traveling on elevators of their own.

Three zones

Let’s take a closer look at a patient’s room – the one that may have separate entrances for patients and staff.

That room is likely to have three zones, the architects agreed.

Near a door will be the caregivers’ zone, where nurses and other employees may find a workstation and supplies.

The patient’s zone will be in and around the bed. The smart bed, that is, the Star Trek-like wonder that will be monitoring the patient. But that’s another story.

Then there’ll be the family zone, which may be equipped with not only chairs, but also a sleeper sofa where family members can stay.

Comfort and hospitality are the keys.

Infection control

So is infection control, the architects said. “All of the finishes are being designed with that in mind,” Nordling said.

“So, they’re coming up with newer, better and quieter flooring that’s easier to clean, for example. And scrubbable ceilings that still have a high noise-reduction coefficient – things like that.”

Other infection-control elements will include anti-microbial coatings, seamless (and therefore easier to clean) sinks, automated bedpan washers and hands-free controls.

But does hospital architecture routinely specify that level of detail?

“I would describe it as excruciating detail, right down to the type of handle that’s on the door and the color of lighting that’s in the space,” Nordling said.

28 TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM ARCHITECTURE&ENGINEERING AUGUST 2018 VOL 19 ISSUE 8

This rendering of Avera on Louise, Avera Health’s 82-acre health campus that’s being built in Sioux Falls, S.D., shows the project’s “community wellness” theme. Inset photo: Atrium of Avera on Louise. IMAGES: BWBR ARCHITECTS

“We’re a firm that provides both architecture and interior design. So if you can see it, it was probably planned intentionally by the design team.”

Community wellness

One other big theme that emerged from the interviews is wellness. And not just patient wellness.

Brad Wehe is Altru Health System’s COO and will become CEO in January. When Altru envisions its remade campus in Grand Forks, “we’ve talked about this whole new era, because it’s so much more than a building,” he said.

It’s also the surrounding property. “Our decision to stay on that campus was really to create a ‘hospital in a park,’” he said.

“We want to be proactive with prevention and healing, not only inside the facility but also outside.”

So, if you as a visitor turn into the new Altru campus in years to come, “you’ll see trees and water and greenspace, and the building will incorporate sunlight and glass, so that you can be inside getting healed from the outside, and outside looking in and getting healed from the inside.

“Here’s what you won’t see: a huge facility that’s intimidating and is surrounded by parking lots,” he said.

In other words, hospital architecture these days includes landscape architecture, and that means trees, bike trails, gardens and walking paths that meander along nearby creeks.

As Nordling of BWBR explained, “the Avera on Louise campus will go beyond the idea that it’s there for sick people. It’s there for community wellness.

“And as a result, everything you’ll see will be built around the idea of being well rather than treating an illness.”

The goal is for people to use the campus not only when they need medical care, but also when they’re healthy – and are biking and walking to stay that way. PB

TOM DENNIS EDITOR, PRAIRIE BUSINESS TDENNIS@PRAIRIEBUSINESSMAGAZINE.COM 701.780.1276

29

ARCHITECTURE & ENGINEERING

PRAIRIE PEOPLE

BENEDICTINE HEALTH SYSTEM NAMES SENIOR VICE PRESIDENT, OPERATIONS/COO

DULUTH, Minn. – The Benedictine Health System named Steven Przybilla as senior vice president, operations/chief operating officer, effective July 1.

Przybilla has served as the interim SVP/COO since March, while also serving his current position as BHS vice president operations of the north region.

Przybilla joined BHS in July 2009 as administrator/CEO at St. Gabriel’s Community, Bismarck, N.D. He holds a bachelor’s degree in education from Moorhead State University, Moorhead, Minn., and completed his health care administrator licensure through the University of Minnesota.

PRAIRIE FAMILY BUSINESS ASSOCIATION HIRES EXECUTIVE DIRECTOR

SIOUX FALLS, S.D. – Laura Schoen

Carbonneau has been named executive director of the Prairie Family Business Association in Sioux Falls.

The association, an outreach center of the Beacom School of Business at the University of South Dakota, is a nonprofit resource for family businesses.

Carbonneau has spent the past 12 years leading the Pierre (S.D.) Area Chamber of Commerce. She also has worked as communications director for the South Dakota Department of Transportation and as executive director of the South Dakota Republican Party.

Carbonneau holds a bachelor’s degree in mass communications from the University of South Dakota. She began her duties at the Prairie Family Business Association in June.

HELMBOLT NAMED SDSU’S ADMISSIONS DIRECTOR

BROOKINGS, S.D. – Shawn Helmbolt has been named South Dakota State University’s director of admissions.

Helmbolt recently served nine months as the office’s interim director and has been its assistant director since April 2007.

At SDSU, Helmbolt completed his bachelor’s degree in history in 2002 and his master’s degree in counseling and human resource development-student affairs administration in 2007.

KRAUS-ANDERSON CONSTRUCTION HIRES SUPERINTENDENT

BISMARCK, N.D. – Kraus-Anderson Construction has hired John Brashears as superintendent in the company’s Bismarck office.

Brashears comes to KA with more than 30 years of construction management experience, the company reports. He previously served as superintendent with Consolidated Construction Company, Inc. in Bismarck.

He also was the owner and operator of Oxbow Bend, a company that managed a truck fleet transporting brine water and crude oil and relocating oil rigs.

BENCHMARK FOAM PROMOTES NEW PRESIDENT

WATERTOWN, S.D. – Benchmark Foam announced the promotion of Robert Reiter as the company’s new president.

Reiter has been with Benchmark Foam since 2016 and will now be responsible for the company’s strategic planning and growth. He’ll also oversee all operations including sales, marketing, manufacturing, accounting and quality.

Benchmark Foam is a manufacturer of expanded polystyrene foam and other specialty plastics.

30 TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM AUGUST 2018 VOL 19 ISSUE 8 PRAIRIEPEOPLE

GF YOUNG PROFESSIONALS HIRES EXECUTIVE DIRECTOR

GRAND FORKS, N.D. – Kathryn Kester has joined Greater Grand Forks Young Professionals as the organization’s executive director.

Kester graduated from the University of North Dakota with a bachelor’s degree in religious studies and nonprofit leadership. She first worked as volunteer coordinator for Global Friends Coalition and was promoted to program coordinator.

Kester first became involved with Greater Grand Forks Young Professionals as a UND student and continued as an active member after graduation.

Greater Grand Forks Young Professionals is a nonprofit dedicated to enhancing the community, creating connections and investing in the growth of young professionals.

31

PRAIRIE PEOPLE

Fieldwork SUMMER

Kate Volk, a senior majoring in biological sciences at North Dakota State University in Fargo, N.D., carries out field work earlier this summer at an NDSU test garden. Volk is one of a growing number of undergraduates who are conducting scientific research.

IMAGE: NDSU

Editor’s note: These days, more and more undergraduates are conducting research. One of them is Kate Volk, a North Dakota State University senior. Thanks to a Frank J. Cassel Undergraduate Research Award, Volk is studying how prairie smoke – a wildflower found in Minnesota, the Dakotas and elsewhere across northern North America – varies depending on its surrounding environment.

In June, Volk talked with Prairie Business about her summer research.

Q.

WHEN DID YOU FIRST GET INTERESTED IN PLANTS?

Kate Volk is studying biological sciences and botany at NDSU – and like many Science undergraduates, she’s spending her summer conducting research A.

I was gardening with my mom; I don’t know how old I was, but I was young. I remember her making a line in the soil and saying, “OK, put the seeds in there now,” and we did. Then it was just cool to watch them grow.

Later, my grandfather was a huge gardener, and I loved going out gardening with him.

And in the years since then, I’ve learned that I like studying plants. I think it’s because plants are everywhere. We use them all the time, and they’re beautiful.

I’m kind of a plant collector In my tiny apartment. I just like being surrounded by them; it feels good. And when it comes to earning a living, it’s good if you you can find something that you want to do. I’m lucky enough to have done that.

TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM 32 AUGUST 2018 VOL 19 ISSUE 8 GENERATIONNEXT

Q.

WHAT IS IT ABOUT PLANTS THAT IS SO INTERESTING?

Q. HAVE YOU BEEN SURPRISED BY THINGS THAT YOU’VE LEARNED?

A. A.

I think first, the beauty of them. The beauty is what got me. They’re just very interesting to look at, and there are so many different varieties.

Then there’s just the diversity and sheer wondrousness of it. It’s crazy to think that, for example, a giant sequoia – the redwood – grows from a seed that’s the side of a rice grain. And that’s not all: The seed stays dormant until conditions are right, and what I’m learning now is that hormones control a lot of that timing.

But just the fact that they can “sense” when the timing is right –that they somehow know – is cool. And I’m also excited that there’s so much that we still have to learn.

Q. TELL US ABOUT YOUR RESEARCH THIS SUMMER.

A.

It’s a huge project. I think Jill Hamilton – the professor I work for – has been doing this since graduate school. She and her husband gathered seeds of this plant Geum triflorum – the common name is prairie smoke –from Washington to Michigan and up into Canada.

They collected 22 different populations of the plant, because the prairie smoke in, say, Washington differs from the same plant in Michigan.

Now, we’re planting the seeds from those different populations in our test garden to see how the differences show up.

Q. A.

HOW DO YOU DO IT?

We apply New-Skin – a liquid bandage – to the leaves, then peel it off and put it on a microscope slide. The New-Skin gives you an impression of that very tiny area, including the stomata, and we photograph it. Then I look at the photographs and basically measure the apertures – the length and width. I count the apertures and take measurements.

I think I have about 1,400 pictures to look at!

Q. ARE YOU HOPING TO GO TO GRADUATE SCHOOL?

A.

s s s

Constantly. For example, there are tropisms – those are the responses that make biological organisms turn or move toward light or gravity.

One cool thing I’ve learned about gravity is that inside a plant’s roots, there are specialized plastids, or tiny organelles. And if a plant tips over, these plastids are loose within the cell, so they settle at the bottom of the cell wall.

That’s how a plant knows how to grow upright. It’s kind of like how we keep our balance, thanks to the canals in our inner ear.

There are so many things like that, and they’re all so interesting.

Q.

WHAT ARE THE SPECIFICS OF YOUR WORK?

I’m looking at the differences between stomata, which are the tiny openings through which the leaves take in CO2 and let out oxygen. How do those differ in plants that are from the different populations?

You might hypothesize that the plants that came from harsher conditions have more stomata, while plants from other environments might have larger but fewer openings.

That’s the kind of thing I’m looking at.

Q. THESE DAYS, DO ADVISORS RECOMMEND THAT UNDERGRADUATES DO RESEARCH?

I’d like to. I’d like to stay here, but it’s all about whether a professor has the funds at the time, too. I’d like to keep working with Dr. Hamilton; she is an amazing researcher.

In the long run, I always thought it would be cool to do plant-science research for a state park system or a conservation agency. There also are seed companies and other firms that employ plant scientists to do work.

A.

Yes, and it’s such a great opportunity. I’ve met so many great people, and I’ve learned so much from the hands-on work. You can’t really get that experience otherwise, and it opens so many doors.

Jill is pushing me, too, saying “I think you could publish this!” It’s a really good motivator.

Q. YOUR WORK WILL RESULT IN A PRESENTATION OF SOME KIND?

A.

Yes; as part of the scholarship, they want you to do a poster presentation or write it up, but I’m probably going to do both. Dr. Hamilton is so confident, and as I mentioned, she wants me to publish by the time it’s over.

It would be so cool if an undergrad got published; I think she knows better than I do where I will end up.

33

GENERATION NEXT

A.

Essentia Health in Duluth plans Minnesota’s biggest medical expansion

By Tom Dennis

DULUTH, Minn. – Three clinics, two hospitals and a rehab center, stairstepping five blocks down a steep hill, meaning that the complex’s lowest street entrance sits about 100 feet below the street entrance at the top. …

That’s Essentia Health’s geographic situation for its existing flagship campus near downtown Duluth. So it’s no wonder that when the talk first turned to a replacement project, Essentia executives seriously considered moving up and over the hill to a flat parcel in neighboring Hermantown, Minn.

But although the current location has its challenges, it also looks out over Lake Superior, meaning that it offers some of the most spectacular views of any city in the upper Midwest.

So the Vision Northland replacement and renovation project will stay in the existing footprint. And what a project it will be: at $800 million, it’ll be Minnesota’s biggest medical expansion, one that will result in a campus that’s both easier to navigate and takes fuller advantage of the site’s wonderful views.

After construction, “our hospitals will be next to each other, and the clinics will be next to each other on a two-block site,” said Scot Ramsey, Essentia’s administrator for facilities.

Essentia grew from a series of mergers between St. Mary’s and Miller-Dwan hospitals and the Duluth Clinic. “With this new project, we’ll keep Miller-Dwan, we’ll have a new St. Mary’s, we’ll have two clinics and a new outpatient facility, all connected. So you’ll easily be able to get from one to the other.”

That’s on the outside. Inside, the new St. Mary’s and other facilities will incorporate the advances that are described in the story on hospital architecture in this issue of Prairie Business (Page 26).

These include separating “front of house” from “back of house” functions, meaning that patients and visitors will use separate halls, elevators and room entrances than will the staff. “That is key to our design,” Ramsey said.

And it’ll be even more powerful in the Duluth project, because the staff functions now are spread out over so many buildings. So, coordinating and consolidating them should bring about tremendous efficiency, collegiality and communication gains, he said.

Here’s another change: acuity-adjustable rooms. “In the past, the patient’s location determined the care,” Ramsey said. In other words, if you were in the intensive care unit, you got intensive care; if you were in a surgical ward, you got pre-op and post-op care.

“Now, we’re going to design universal rooms that are acuity adjustable, so you can have a room be an intermediate care facility, an intensive care unit, a surgical bed or a medical bed,” he said.

Maternity rooms in many hospitals already show how this works. “That’s a great example of acuity adjustable, because you don’t have to move the mom. You have labor, delivery and recovery all in the same room.”

Like several of its counterparts around the region, Essentia also is thinking about tying the new construction into the surrounding neighborhood.

In Grand Forks, for example, Altru Health System’s plans will let the new Altru hospital take advantage of nearby parks and gardens. In

TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM 34 AUGUST 2018 VOL 19 ISSUE 8 CONSTRUCTIONCORNER

This is a preliminary conceptual drawing of Essentia Health’s Vision Northland project in Duluth, Minn. The plans are not finalized, so the look of the buildings may change. IMAGE: ESSENTIA HEALTH

Duluth, “as we move away from the current St. Mary’s building, we’ll be freeing up probably two or three or four city blocks for future development,” Ramsey said.

“There could be a grocery store, or housing, or entertainment activities and coffee shops, or all of the above. We think it could really be vibrant, and that if we invest $800 million in our new facility, there could be many multiples of that in the surrounding area over 20 years.”

The appeal of living and working on a hill overlooking Lake Superior is only going to grow over that time, he said. “And if we can grow a vibrant community with a focus on health and wellness, we think that’ll help us not only keep our staff but also attract them to Duluth.”

Essentia hopes to start construction in early 2019 and finish the project in 2022. PB

Tom Dennis EDITOR, PRAIRIE BUSINESS 701.780.1276 TDENNIS@PRAIRIEBUSINESSMAGAZINE.COM

SMARTER. L ea r n FASTER. EA R N

At North Dakota State College of Science, students learn smarter and earn faster by graduating in just two years. And with a 98%* placement rate and over 80 career options, building a rewarding career is a cinch.

Jump-start

35

CONSTRUCTION

CORNER

your career in Manufacturing

today by visiting NDSCS.edu.

*2017 North Dakota State College of Science Graduate Placement Report. Manufacturing Careers ◆ Automated Manufacturing ◆ Fabricator ◆ Production Machining ◆ Robotics Programmer ◆ Toolmaking ◆ Welder

INSIGHTs & INTUITION

What advice would you give to online applicants to make sure their job applications get read?

n Note the skills listed in the job description, and highlight those same skills in your resume. Write a unique cover letter that explains why you’re a great fit for the position.

n Craft for skimming! Make sure your most relevant bullets are first, and ensure your formatting is logical and easy to read.

n Discuss your key accomplishments for each position rather than just day-to-day tasks. Quantify results as much as you can.

DIRECTOR OF HUMAN RESOURCES ARVIG PERHAM, MINN.

Keep it short and impactful! Use key words that match the job listing. Many employers use systems that sift applications and resumes based on key words. If yours doesn’t have enough of them, it may never be seen by the human eye.

Bullet point strengths and experience; list up to seven strengths and 15 main types of experience using action verbs. List all work history with company, dates of employment, and title.

Tailor your resume to the opening. It’s OK to expand on your relevant experience while leaving out irrelevant experience. Make it easy to recognize within 3 minutes that you are qualified!

n Use your network! Know someone at the company? Let them know you’re applying, and ask them to refer you. This gets your resume in front of a recruiter again.

When I review resumes, I look for keywords or phrases that key me into the candidate’s experience. For example, if I were looking for a Project Manager position, I might look for things such as “KPIs” (key performance indicators), “budgeting” and “stakeholder review.”

I also look at previous experience and the success the candidate had at previous employers, meeting goals and improving the process counts, as these show how the candidate can drive change and help the company succeed.

TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM 36

INSIGHTs&intuition AUGUST 2018 VOL 19 ISSUE 8

TO

Q.

BROUGHT

YOU BY

TALENT ACQUISITION SPECIALIST EIDE BAILLY FARGO, N.D.

Christina Ranasinghe

Lori Meader

Ken Brazerol

SERVICE OPERATIONS / PROJECT MANAGEMENT OFFICE MANAGER NETWORK CENTER, INC. FARGO, N.D.

n Check your spam and junk mail, and make sure you received an automated response from the application process – meaning the system did receive your application.

n Wait 2 to 3 days, and then call HR about your application. These days, very few people actually call and follow up on their application.

n Many companies have an online assessment process. When a candidate fills out the assessment, it tells the company that the candidate is serious about the opening. Even though hiring competition is fierce, we still rely on our established processes to choose the best candidates. Only 17 percent of our applications make it to the interview process.

My advice for online applicants to make sure their application gets read would be to pay attention to every detail. Addressing your cover letter to the right company, writing on your resume the correct position that you are applying for, and proofreading before submitting are all important.

In addition, don’t forget to include everything that is being asked of you.

n Read the job posting thoroughly. Are you truly qualified for the position? If you are, use the same terminology in your application that was used in the posting. This will make it easy for the person reviewing your information to see that you’re qualified.

n Quantify your success. For example, instead of saying, “Top salesperson for three years running,” say, “Grew territory by 25 percent for three consecutive years, leading to top salesperson award all three years.”

n Finally, read ALL the instructions and follow them carefully. You don’t want to be knocked out of consideration for an incomplete application.

37

Heather Rye

VICE PRESIDENT OF HUMAN RESOURCES GATE CITY BANK FARGO, N.D.

Michelle Blakeman

SENIOR TALENT PARTNER, HUMAN RESOURCES

BLUE CROSS BLUE SHIELD OF NORTH DAKOTA FARGO, N.D.

Al Carlson

VICE PRESIDENT OF HUMAN RESOURCES, TALENT MANAGEMENT AND LEADERSHIP DEVELOPMENT

BTD MANUFACTURING MINNEAPOLIS-ST. PAUL

INSIGHTS & INTUITION

Per Capita Personal Income

Source: Bureau of Economic Graph Source: MinneapolisFed.org

Grand Forks: 2.6% Percent Change from Previous Year 20% 10% Q4-2012 Q2-2013 Q42013 Q2-2014 Q4-2014 Q2-2015 Q4-2015 Q2-2016 Q4-2016 Q2-2017 Q4-2017

via Haver Analytics Updated April 20, 2018 Bismarck: 2.3% Rapid City: 3.0%

0% -10%

Analysis via Haver Analytics Source: Bureau of Labor Statistics

Real GDP

February Fargo: 2.1% Sioux Falls: 2.4% Lincoln: 2.6%

Minnesota Montana North Dakota South Dakota Wisconsin United States Percent Change from Previous Year 20% 10% Q4-2012 Q2-2013 Q4-2013 Q2-2014 Q4-2014 Q2-2015 Q4-2015 Q2-2016 Q4-2016 Q2-2017 Q4-2017

Minneapolis/ St. Paul: 2.3% Rochester: 2.1% Cedar Rapids: 2.4% Omaha: 2.8% Des Moines: 2.1%

2016 Public School Spending Per Student By State

0% -10%

STATE TOTAL/PUPIL SPENDING RANK STATE TOTAL/PUPIL SPENDING RANK New York $22,3661 United States $11,762 AVG. Dist. of Columbia $19,1592 South Dakota$9,176 41 Connecticut $18,9583 Mississippi $8,702 47 New Jersey$18,4024 Oklahoma $8,097 48 Vermont$17,873 5 Arizona $7,613 49 North Dakota $13,373 16 Idaho $7,157 50 Minnesota $12,382 18 Utah $6,95351 United States $11,762 AVG.

Population trends In Minnesota,North Dakota, & South Dakota

Source: U.S. Bureau of the Census & Fred.StLouisFed.org

Resident Population in South Dakota Resident Population in Minnesota Resident Population in North Dakota

5,000

4,000

3,000

2,000

6,000 Thousands of Persons

1,000

Minnesota Montana North Dakota South Dakota Wisconsin United States 1920194019601980 0 2000

This graph from FRED, the economic data arm of the Federal Reserve Bank of St. Louis, tracks the populations of the three states in Prairie Business’ circulation area – Minnesota, North Dakota and South Dakota – from 1900 to the present. The shaded areas on the graph indicate U.S. recessions.

34 TWITTER.COM/PRAIRIEBIZ FACEBOOK.COM/PRAIRIEBUSINESS PRAIRIEBUSINESSMAGAZINE.COM AUGUST 2018 VOL 19 ISSUE 8

BYTHENUMBERs

Analysis

Updated

Source: Bureau of Economic Graph Source: MinneapolisFed.org 16, 2018

Regional Unemployment Rates, May 2018

Source: U.S. Census Bureau’s 2016 Annual Survey of School System Finances, as reported by Governing magazine

October 5th is

October 5th is

October 5th is

General Steel & Supply Company is the manufacturing division of Fisher Industries. We have been designing and fabricating high-quality aggregate processing equipment in southwest North Dakota for over 50 years. Our equipment pieces are being used by numerous companies all over the world.

General Steel & Supply Company is the manufacturing division of Fisher Industries. We have been designing and fabricating high-quality aggregate processing equipment in southwest North Dakota for over 50 years. Our equipment pieces are being used by numerous companies all over the world.

We strongly believe in inspiring the next generation of manufacturers, which we do by providing hands-on tours of our shops to area students, donating materials to local welding programs, and sponsoring manufacturing day events. Learn more about us at www.fisherind.com.

We strongly believe in inspiring the next generation of manufacturers, which we do by providing hands-on tours of our shops to area students, donating materials to local welding programs, and sponsoring manufacturing day events. Learn more about us at www.fisherind.com.

We strongly believe in inspiring the next generation of manufacturers, which we do by providing hands-on tours of our shops to area students, donating materials to local welding programs, and sponsoring manufacturing day events. Learn more about us at www.fisherind.com.

General Steel & Supply Company is the manufacturing division of Industries. We ing and fabricating high-quality aggregate processing equipment in southwest North Dakota for over 50 years. equipment pieces are by numerous companies all over the world. in inspiring of manufacturers, which we do by providing hands-on tours of our shops to area students, donating materials and sponsoring manufacturing events. Learn more about us at www.fisherind.com.

$77k+

$77k+

Manufacturing Supports more than U.S. Jobs! $18.5 Million $1.00 spent in manufacturing creates $1.40 for the U.S. economy

$1.00 = $1.40

$1.00 = $1.40 Annual average salary of $77k+

Manufacturing Supports more than U.S. Jobs! $18.5 Million $1.00 spent in manufacturing creates $1.40 for the U.S. economy

$1.00 = $1.40

$1.00 = $1.40

Annual average salary of manufacturing workers in the U.S. (800) 932-8740 | www.fisherind.com | 3020 Energy Drive - Dickinson, ND 58601

Manufacturing Supports more than U.S. Jobs! $18.5 Million $1.00 spent in manufacturing creates $1.40 for the U.S. economy

Annual average salary of manufacturing workers in the U.S. (800) 932-8740 | www.fisherind.com | 3020 Energy Drive - Dickinson, ND 58601

5th Supports than U.S. Jobs! $18.5 Million $1.00 spent in manufacturing creates $1.40 U.S. (800) 932-8740 | www.fisherind.com | 3020 Energy Drive - Dickinson, ND 58601

Annual average salary of manufacturing workers in the U.S. (800) 932-8740 | www.fisherind.com | 3020 Energy Drive - Dickinson, ND 58601

$77k+

General Steel & Supply Company is the manufacturing division of Fisher Industries. We have been designing and fabricating high-quality aggregate processing equipment in southwest North Dakota for over 50 years. Our equipment pieces are being used by numerous companies all over the world.