78

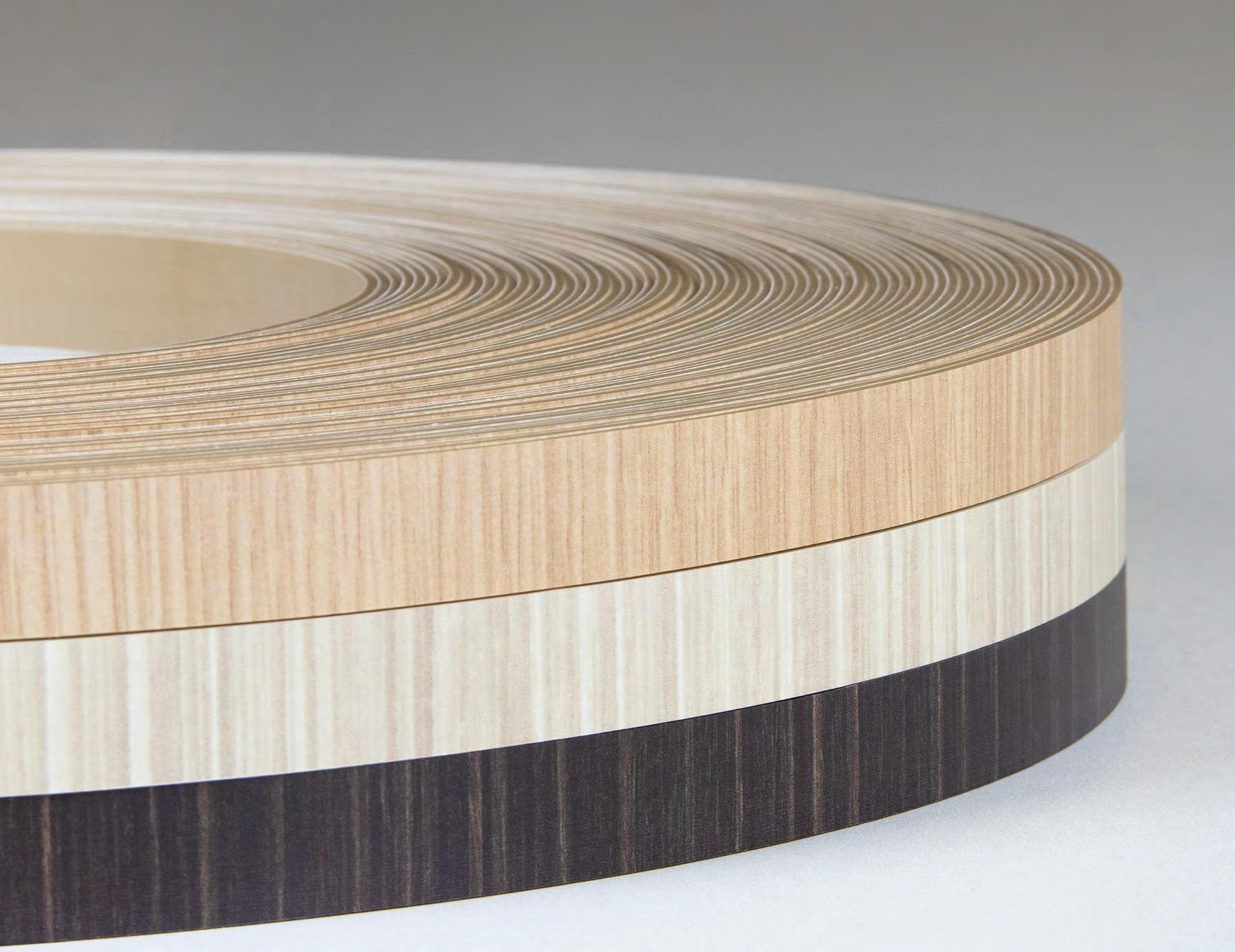

Warehousing, packaging & materials handling Combilift trucks help digital growth for English Woodlands Timber There’s a bit of a digital and e-commerce revolution happening in the tranquil setting of the South Downs, the home of hardwood timber specialist English Woodlands Timber. Since the start of the pandemic the company has pulled out all the stops for its online marketing activities, and as a result has achieved record sales as well as a large number of new customers. Catering for the bespoke and high-end construction, joinery, furniture and kitchen sectors, the company is experiencing huge demand for its niche products which include boards, cladding and structural timber as well as a wide range of species such as oak, elm, ash and sweet chest-nut. Fundamental to its success is the fact that each and every item stocked is now also availa-ble to view and buy via the web shop. Equally important however is the ability to efficiently fulfil what director Ian McNally calls the “pick, pack and dispatch” side of operations once orders have been received. For this, English Woodlands Timber (EWT) has switched to products from Irish handling specialist Combilift

which have been instrumental in enabling it to keep pace with the recent 50% growth in business. Having previously used mainstream counterbalance forklifts, Ian and his team were won over by the multidirectional abilities of Combilift’s C-Series trucks when they saw one in operation at another timber supplier. Having taken delivery of the first C4000E model in 2019, two of these 4t trucks are now in op-eration at the four acre site, together with two 2t capacity CombiWR4 multidirectional pedestri-an stacker trucks. The latter feature Combilift’s unique patented multi-position tiller arm which enables the operator to work at the side of the unit rather than at the rear when working in narrow confines for enhanced safety. EWT’s materials handling consultants Locators supplied all the trucks and also recommended a wider than standard fork carriage of 1950mm for the WR4 models, which increases load stability when carrying 6m long packs or boards. “What differentiates us from other suppliers is our quality and diverse range, best summed up as the choice of length,

width and thickness of our products,” said Ian. “But we need to ensure that our own pick, patch and despatch procedures match the ease and efficiency with which customers can select and buy packs and individual boards. The Combilifts can handle all the varied and awkward sized boards we stock, they are nimble, manoeuvrable and allow us to work more quickly.”