Fast, durable, and economical complete wastewater treatment

Xylem’s DAVCO™ field-erected treatment plants (FETP) are ideal for expanding existing or new greenfield plants providing a solution for treating flows from 0.1 to 3 million gallons per day (MGD). Systems can be designed in a variety of configurations, including activated sludge processes, sequencing batch reactors, and oxidation ditch configurations.

Using shop-built components and field erection, the DAVCO FETP system offers an economical, sustainable treatment solution that can be operational in months instead of years!

Watch a webinar to learn more!

For more information, contact: Greg Chomic Heyward Florida gchomic@heywardfl.com 407-628-1880

Editor’s Office and Advertiser Information:

Florida Water Resources Journal

1402 Emerald Lakes Drive

Clermont, FL 34711

Phone: 352-241-6006

Editorial, editor@fwrj.com

Display and Classified Advertising, ads@fwrj.com

Business Office: 1402 Emerald Lakes Drive, Clermont, FL 34711

Web: www.fwrj.com

General Manager: Michael Delaney

Editor: Rick Harmon

Graphic Design Manager: Patrick Delaney

Mailing Coordinator: Buena Vista Publishing

Published by BUENA VISTA PUBLISHING for Florida Water Resources Journal Inc.

President: Richard Anderson (FSAWWA) Peace River Manasota Regional Water Supply Authority

Vice President: Joe Paterniti (FWEA) Clay County Utility Authority

Treasurer: Rim Bishop (FWPCOA) Seacoast Utility Authority

Secretary: Rim Bishop (FWPCOA) Seacoast Utility Authority

Moving?

The Post Office will not forward your magazine. Do not count on getting the Journal unless you notify us directly of address changes by the 15th of the month preceding the month of issue. Please do not telephone address changes. Email changes to changes@fwrj.com or mail to Florida Water Resources Journal, 1402 Emerald Lakes Drive, Clermont, FL 34711

Membership Questions

FSAWWA: Casey Cumiskey – 407-979-4806 or Casey@fsawwa.org

FWEA: Laura Cooley, 407-574-3318, admin@fwea.org

FWPCOA: Darin Bishop – 561-840-0340

Training Questions

FSAWWA: Donna Metherall – 407-979-4805 or Donna@fsawwa.org

FWPCOA: Shirley Reaves – 321-383-9690

For Other Information

FDEP Operator Certification: Ron McCulley – 850-245-7500

FSAWWA: Peggy Guingona – 407-979-4820

Florida Water Resources Conference: 267-884-6292

FWPCOA Operators Helping Operators: John Lang – 772-559-0722, oho@fwpcoa.org

FWEA: Laura Cooley, 407-574-3318, admin@fwea.org

Websites

Florida Water Resources Journal: www.fwrj.com

FWPCOA: www.fwpcoa.org

FSAWWA: www.fsawwa.org

FWEA: www.fwea.org and www.fweauc.org

Florida Water Resources Conference: www.fwrc.org

News and Features

4 Partnership Helps Restore Wetlands in Kissimmee Watershed

14 Contractors Roundup: Accelerating Infrastructure Delivery for a Resilient Water Future—Megan Ross and John Zelenka

18 Awardees Honored by FWPCOA for Excellence in Water and Wastewater

24 State of the Florida Water Industry Survey: The Results Are In!

32 From Avoidance to Action: 12 Drama-Free Ideas for Holding People Accountable— Kate Zabriskie

34 News Beat

46 Cape Canaveral Installs Innovative Reef Arches to Protect Water Reclamation Facility

50 Additional Author Credit for Article Published in July FWRJ

51 EPA Announces Next Steps on Regulatory PFOA and PFOS Cleanup Efforts, Provides Update on Liability and Passive Receiver Issues

Technical Articles

8 Collaborative Partnering on Regional Water Supply Planning in North Florida— Dan Rodrigo, Jeremy Johnston, and Shayne Wood 28 Turning Crisis into Opportunity: Panama City’s Localized Lift Station Solutions Calm the Storm—Kevin Kennoy, Tonny Peters, and Samar Mazloum

Education and Training

Columns

6 Speaking Out—Lisa Wilson-Davis 16 FWEA Chapter Corner: Introducing Making Waves With FWEA: A Brand-New Podcast Hosted by Megan Nelson and Mike Sweeney—Senuda Rajapakse

20 Let’s Talk Safety: Safety Tips for Employees Working Remotely or Alone

22 FWEA Focus—Joan Fernandez

44 C Factor—Kevin G. Shropshire

50 Test Yourself—Charles Lee Martin Jr.

Departments

Classifieds

Display Advertiser Index

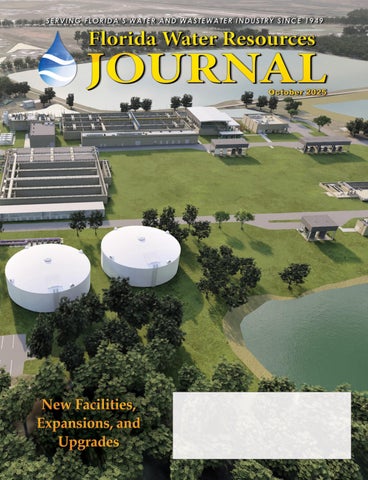

THE COVER: The Bee Ridge Water Reclamation Facility in Sarasota County is increasing its treatment capacity by 50 percent while implementing advanced wastewater treatment technologies to serve the region’s future needs. (rendering: Carollo Engineers)

Partnership Helps Restore Wetlands in Kissimmee Watershed

The South Florida Water Management District (district) has teamed up with Ducks Unlimited, a nonprofit conservation organization, to restore more than 6,500 acres of wetlands in the Kissimmee Chain of Lakes watershed in Osceola County.

A partnership with the district, Florida

Department of Environmental Protection (FDEP), and Ducks Unlimited is helping to restore interior sections of the Gardner-Cobb Marsh, the largest district property in the Upper Kissimmee Chain of Lakes.

Protecting and Restoring Wetlands

The marsh provides important hydrological, ecological, and recreational benefits for the region. Located near Cypress Lake, Lake Hatchineha, and Lake Kissimmee, the marsh is comprised of wetland habitats, such as wet flatwoods and prairie, swamps, and marshes. Restoration efforts will help enhance existing wetlands, reduce drainage, and provide important habitat for native waterfowl and wildlife. Recreational activities include bicycling, camping, fishing, hunting, kayaking, wildlife viewing, and more. Hunting in the area is managed by the Florida Fish and Wildlife Conservation Commission.

Working Together

The marsh was acquired by the district to support the Kissimmee River Headwaters Revitalization Project. Ducks Unlimited received a grant from FDEP to partner with

the district on the Gardner-Cobb Restoration Project, which includes the filling of miles of ditches to improve hydrologic conditions in the area. Ducks Unlimited has completed the second phase of the restoration effort.

Partnership in Action

The goals of the restoration project are to:

S Enhance existing wetlands by reducing drainage and extending the hydroperiod (number of days per year that an area of land is wet).

S Restore more than 6,500 acres of overdrained marsh and natural wet prairie floodplain.

S Provide habitat for native wildlife.

S Improve water quality in the Okeechobee watershed.

The district is committed to working with partner agencies and stakeholders to enhance water storage and restoration initiatives. These partnerships ensure that public lands are restored and protected for the people and the environment of south Florida.

Go to sfwmd.gov/restoration to learn more. S (photo: South Florida Water Management District)

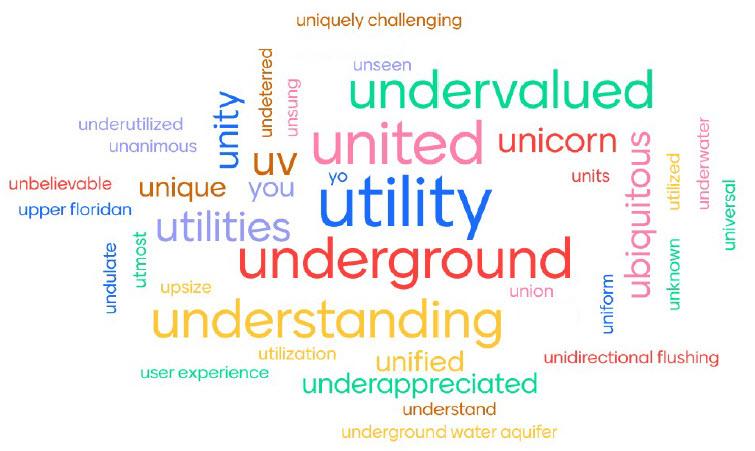

AUnited in Utility: U and Sometimes Y

Lisa Wilson-Davis Chair, FSAWWA

s I write this final installment of the “Vowel Series,” we arrive at the last letters: U—and sometimes Y. Over the past year, these columns have traveled through A, E, I, and O, each one offering a new way to highlight the words, values, and voices that define our water community. It feels fitting to close the circle with U and sometimes Y, letters that remind us of utility, unity, youth, and, most importantly, you, the people who make our industry and section extraordinary.

As my year of serving as chair of the Florida Section of the American Water Works Association is winding down, I find myself circling back to one central theme— utility—including the water and wastewater utilities we serve, and the broader utilization of our talents, time, and teamwork. Over many years, and in particular, over these past months, I have witnessed our volunteers and professionals give their utmost energy in ways both seen and unseen, reminding me when we are united in mission and true unity shines through.

Too often, the vital work of water and wastewater utilities is undervalued or underappreciated, and yet, what we do is

nothing short of unbelievable! From the uniform dedication of operators working night shifts, to the engineers tackling uniquely challenging problems with innovation, our success depends on understanding that every contribution matters. Whether managing underground infrastructure, safeguarding the Upper Floridan aquifer, or monitoring ultraviolet disinfection, we are part of a universal story, one that impacts every customer, every day.

We’ve tackled projects that might appear underutilized at first glance, but prove their worth when future needs upsize demand. We’ve studied unidirectional flushing and even improved user experience by embracing technology. The technical terms may sound dry, but when you look closer, they are as magical as a unicorn—an unseen backbone carrying the promise of safe water.

Of course, this work is about much more than infrastructure; it is about you Each of you—our members, colleagues, and partners—brings energy and purpose. From the seasoned professional to the young intern, from the youth program participant to the young professionals ready to lead, we are stronger together. Whether you are young at heart or “seasoned but spirited,” you remind us that leadership is a shared journey.

Sometimes our path is surprising. We encounter the unknown, respond to underwater emergencies, and handle the unsung challenges of balancing regulations, budgets, and long-term planning. Yet, we remain undeterred. We adapt, saying yes to innovation, sometimes exclaiming “Yikes”

when surprises and setbacks arise, and giving a resounding “Yippee” when success occurs.

And along the way, we keep our balance with small joys: sharing a cup of yogurt at a committee breakfast, savoring a yummy bite at a region Lunch and Learn, or laughing over a YOLO-style team story reminds us that service is more than just duty—it’s community. From bright yellow safety vests worn on the job and during some events, to the belief you belong here, our section thrives on belonging.

As I close this column, I think of yesterday and how far we’ve come, but also of the horizon yonder. The future is calling for new leaders, new technologies, and new partnerships. And my final thought is simple: Yowza, water is everything, and the people who keep it flowing are downright extraordinary.

And so, with U and sometimes Y, this series on vowels comes to a close. From A to E, I to O, and now U and sometimes Y, we’ve explored the words that connect our profession, our people, and our purpose. Each letter has given us a new lens to appreciate the unsung yet ubiquitous contributions of our members, and to celebrate the creativity and commitment that make the Florida Section thrive. These reflections remind us that whatever the letter or challenge, our shared story is always written with dedication, unity, and yes, a universal passion for water.

Here’s to the unanimous spirit of FSAWWA, to the ubiquitous commitment of our members, to the union of professionals who keep water flowing, and—most importantly—to you, our greatest utility of all. Until next month. S

Grow your septage, FOG, and sludge receiving business with a Raptor Septage Acceptance or Complete Plant.

Trippensee Shaw, Inc.

Eustis, Sebring, & Mount Dora, FL T: 407-222-0575 www.TrippenseeShaw.com

Florida Panhandle Only

T: 205.424.7570 www.eshelmancompany.com

NOT YOUR ORDINARY RECEIVING SYSTEM

Raptor Septage Acceptance Plant

Removes debris and inorganic solids from municipal and industrial septage, FOG, and sludge. This heavy-duty machine incorporates the Raptor Fine Screen for screening, dewatering and compaction. Accessories include security access and automated accounting systems.

Raptor Septage Complete Plant

With the addition of aerated grit removal, the Septage Acceptance Plant is offered as the Raptor Septage Complete Plant.

Cleaner Water for a Brighter Future®

Speak to one of our experts at 630.837.5640 or email us at sales@lakeside-equipment.com for more product information.

Collaborative Partnering on Regional Water Supply Planning in North Florida

Dan Rodrigo, Jeremy Johnston, and Shayne Wood

To protect north Florida water resources from reductions in spring and river flow resulting from groundwater withdrawals, the North Florida Regional Water Supply Plan Project Conceptualization Partnership (NFPartnership) was formed in 2023 as a voluntary collaborative effort among four public water utilities and three state agencies. The four participating public water utilities are:

S Clay County Utility Authority (CCUA)

S Gainesville Regional Utilities (GRU)

S JEA in Jacksonville

S St. Johns County Utility Department (SJCUD)

These are the largest water providers within the North Florida Regional Water Supply Planning Area, collectively serving over 1.3 million people. Other NF-Partnership members include:

S St. Johns River Water Management District (SJRWMD)

S Suwannee River Water Management District (SRWMD)

S Florida Department of Environmental Protection (FDEP)

S CDM Smith

The NF-Partnership’s mission is to identify potential large-scale groundwater recharge projects that can work in conjunction with conservation and other projects to meet the required minimum flows and levels (MFLs) for the Lower Santa Fe and Ichetucknee Rivers (LSFIR), and associated priority springs. This effort builds on the 2023 update to the North Florida Regional Water Supply Plan (NFRWSP), and other water supply planning efforts, to restore and protect these valuable natural resources, while ensuring adequate water supply for the region’s growing population and economy.

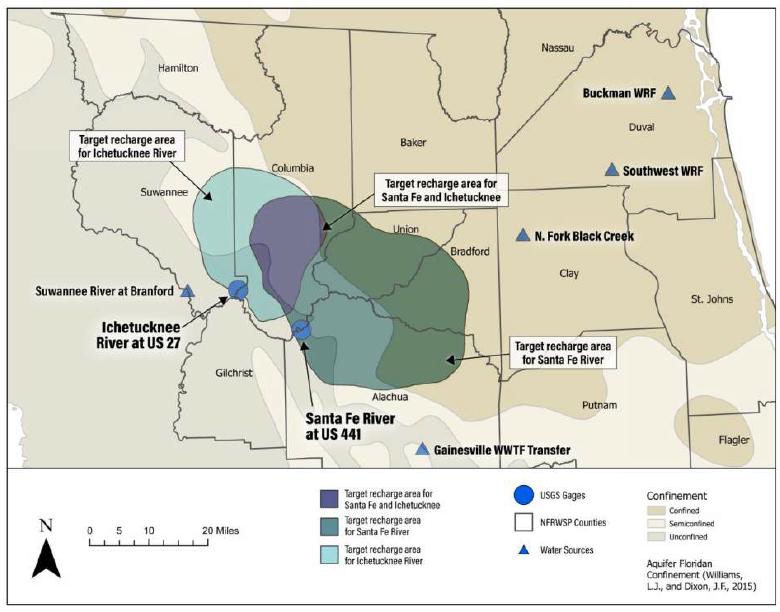

The NF-Partnership identified a conceptual recharge area, shown in Figure 1, based on preliminary estimates of recharge benefits using the North Florida Southeast Georgia regional groundwater model. While the conceptual areas shown adjoin the LSFIR, actual recharge locations will need to be sufficiently far away from the rivers to ensure regional benefit.

Dan Rodrigo is one water practice leader at CDM Smith in Los Angeles. Jeremy Johnston, P.E., is executive director at Clay County Utility Authority in Middleburg, Fla. Shayne Wood, P.E., PMP, BCEE, is senior project manager at CDM Smith in Jacksonville.

Regulatory Drivers

The SRWMD and FDEP reevaluated and proposed updates to the 2015 MFLS for LSFIR. The proposed MFLs have been developed to establish the limit at which further withdrawals would be significantly harmful to the water resources or ecology of the area. Table 1 summarizes the recovery and prevention requirements resulting from the status assessment for the proposed MFLs at the compliance monitoring points. The recovery requirements are based on current pumping and the prevention requirements are based on projected future pumping through 2045. A recovery and prevention strategy to meet these requirements must accompany the MFL rule upon adoption. This strategy must include a prioritized list of projects, timeline, costs, and benefits to the MFLs.

Additionally, in 2023, the SJRWMD and SRWMD governing boards approved the fiveyear update to the 2017 NFRWSP. The NFRWSP planning area encompasses the following counties: Alachua, Baker, Bradford, Clay, Columbia, Duval, Flagler, Gilchrist, Hamilton, Nassau, Putnam, St. Johns, Suwannee, and Union. The purpose of the plan is to protect natural resources, while ensuring there are adequate water supplies for all users in north Florida. Similar to the LSFI MFLs status assessment, the NFRWSP also identified impacts to the LSFIR as a water resource constraint for future demands.

The water management districts (WMDs) and FDEP have engaged stakeholders throughout the water supply planning and MFL development process to create projects and approaches that meet the proposed MFLs; however, the NF-Partnership recognized that efforts to date have not identified projects that fully meet the recovery and prevention goals. As such, the NF-Partnership initiated efforts to identify and screen potential large-scale projects

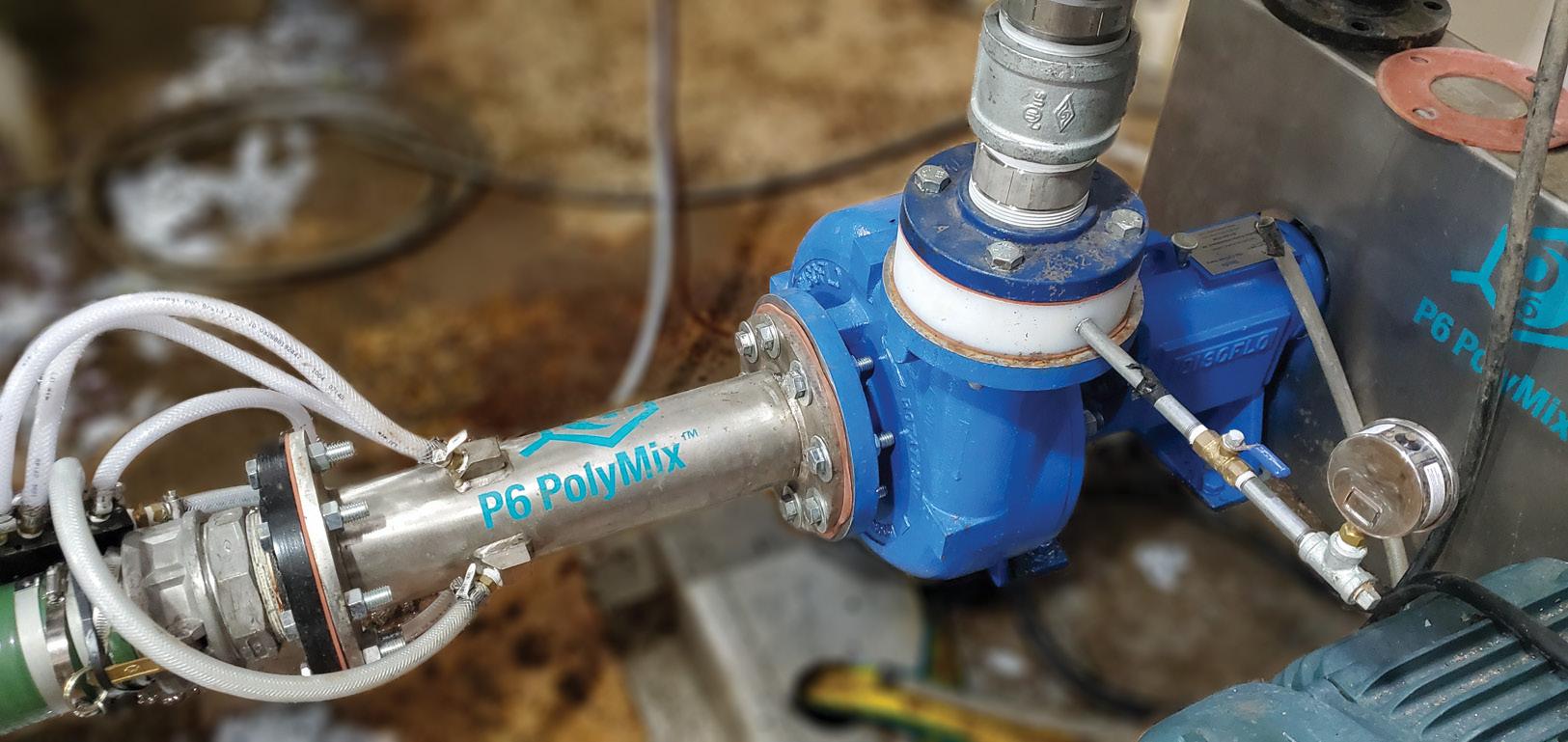

1. POLYMER REDUCTION: P6 PolyMix® Systems reduce polymer consumption by providing complete polymer/sludge mixing in a shear-sensitive manner. This patented mixing process allows long-strand polymer chains to remain intact and unbroken and wastewater floc to remain intact and unsheared. Typical applications result in a 25-50% REDUCTION IN POLYMER CONSUMPTION, thus saving the customer thousands of dollars in polymer expenses. By not breaking up the polymer chains, the dewatering equipment will experience less fouling, providing more reliability and reducing equipment cleaning costs.

2. DRIER CAKE SOLIDS: P6 PolyMix® technology optimizes the polymer and sludge mixing process, allowing INCREASE DEWATERED SOLIDS CONCENTRATION and INCREASED PERCENT SOLIDS CAPTURED. This unique mixing process results in more efficient sludge hauling, allowing customers to transport less water and more dewatered cake off-site.

3. ELIMINATION OF PUMP MAINTENANCE: P6 PolyMix® technology reduces pump parts and maintenance by utilizing the abrasion-resistant Discflo pumping principles of Boundary Layer/Viscous Drag. This principle can save the customer thousands of dollars in parts and maintenance over the lifetime of the equipment. All P6 PolyMix® systems in the municipal market include a 10-YEAR (extendable to 20 years) 100% WET END WEAR WARRANTY, No other pump manufacturer in the industry provides a wear warranty, let alone a 20-year wear warranty!

4. PUMPS & MIXES: P6 PolyMix® technology uses the unique principles of Boundary Layer/Viscous Drag for mixing polymer versus a mixer/check valve; this, paired with its unique InjeX™ polymer injection mixing chamber, is designed for MINIMAL POLYMER DEGRIDATION, allowing for maximum polymer savings. The hydraulic shear forces within the mixing pump provide a complete homogeneous wastewater polymer slurry fed to the dewatering equipment without breaking the long chain polymers or reducing floc size.

5. LOWER OPERATING PRESSURE AND INSTALLED HORESPOWER: P6 PolyMix® technology dramatically reduces the operating pressure by reducing back pressure within the piping system due to eliminating mixer/check valves. In some applications, customers have had a 75% REDUCTION IN PRESSURE Lower pressure allows the feed pump to operate at lower horsepower. HORSEPOWER SAVINGS OF UP TO 50% OR MORE are possible by installing a P6 PolyMix® system. Customers can see substantial long-term energy savings and reduced upfront capital costs associated with lower installed horsepower.

6. HOW IS IT APPLIED: P6 PolyMix® systems entirely replace bulky, expensive, outdated traditional sludge feed pumps. You can now replace thousands of dollars in equipment and regain valuable real estate space by switching to P6 PolyMix® and utilizing its unique compact design, patented process for eliminating mixer/check valves, and ultra-efficient polymer mixing process. Contact us to learn how P6 PolyMix® can revolutionize the efficiency of your BELT FILTER PRESSES, GRAVITY BELT THICKENERS, ROTARY THICKENERS, SCREW PRESSES, AND CRENTIFUGES.

Continued from page 8

to work in conjunction with water conservation to meet the MFL requirements, while also ensuring sustainable groundwater supply.

The four public utilities (CCUA, GRU, JEA, and SJCUD) have developed independent integrated water resource plans (IWRPs). These public utilities developed their IWRPs with planning horizons tied to projected population growth and capital infrastructure investments. The public utilities want their respective IWRPs to integrate with regional water supply development projects to protect vital environmental resources and sustainably manage the region’s water resources in perpetuity.

The WMDs and the public utilities understand that to address the long-term sustainability of important water resources (e.g., the Lower Santa Fe, Ichetucknee, and Suwannee rivers), large-scale, regional cross-district and cross-utility projects will likely be necessary. To address this need, the FDEP, WMDs, and public utilities agreed to work together to develop this NF-Partnership.

The specific steps implemented by the NFPartnership included:

S Performing a comprehensive identification and screening of over 800 alternative ways to connect available water sources and increase aquifer recharge to offset the impacts of current and future pumping to meet proposed LSFIR MFLs.

S Identifying a short list of potential alternatives for further evaluation.

S Developing planning-level costs for short-listed alternatives.

S Identifying next steps needed to further screen short-listed alternatives for potential implementation.

Process and Methodology Overview

The conceptual evaluation for the NFPartnership effort integrated a range of alternative water sources, recharge approaches, and treatment technologies based on utility IWRPs and the NFRWSP. Two groups of the NF-Partnership were formed: a management group and a technical committee. The technical committee met weekly to work through detailed evaluations in order to conceptualize, evaluate, and screen project concepts. Members of the management group met for six interactive workshops to develop objectives, review the work of the technical committee, and provide leadership direction.

The criteria used for project screening included:

S Estimated capital and operation and maintenance costs

S Implementation difficulty

S Potential environmental impacts

S Operational complexity

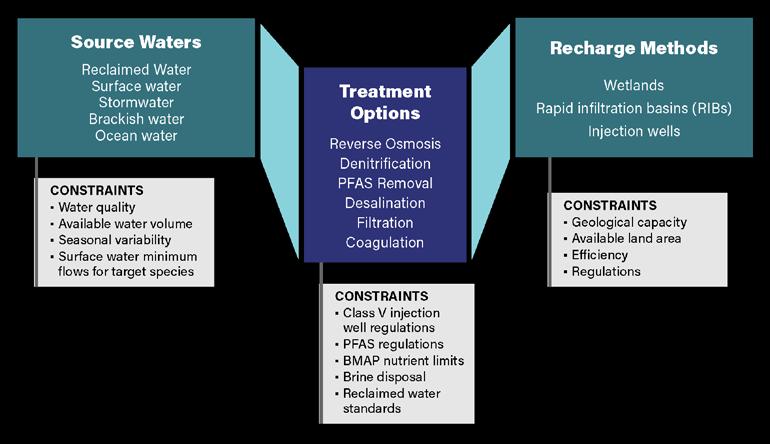

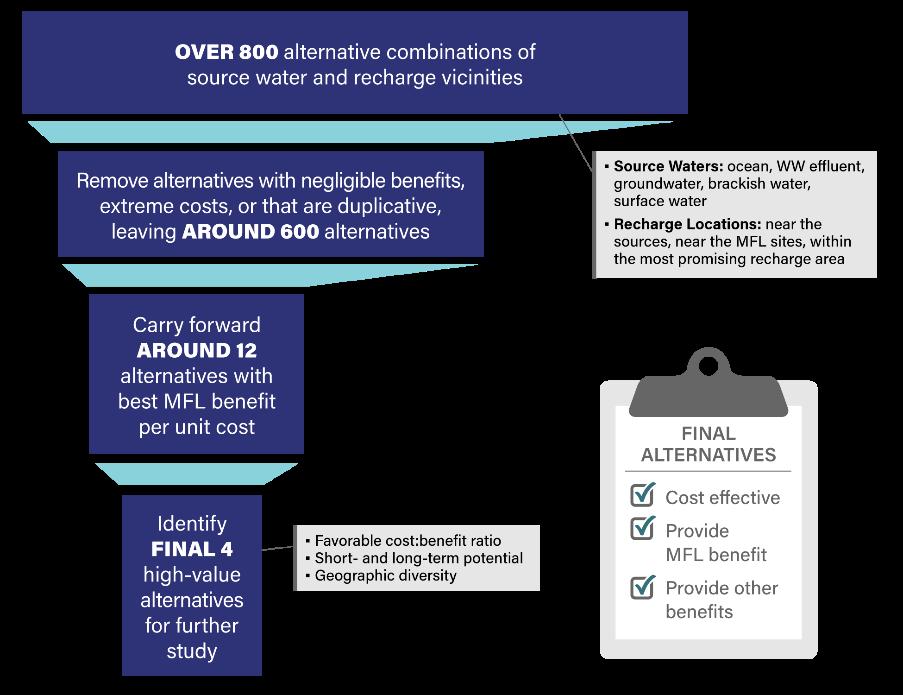

Figure 2. Conceptual alternatives developed by integrating source water, treatment, and recharge. (image: CDM Smith)

Figure 3. Three-tiered screening process for conceptual alternatives. (image: CDM Smith)

Table 1. Proposed Lower Santa Fe and Ichetucknee Rivers Minimum Flows and Levels Recovery and Prevention Requirements

cfs: cu ft per second

S Project development time

S Source water reliability

S Potential for regional benefits

S Ancillary benefits

Conceptual alternatives were developed by integrating source waters, treatment technologies, and recharge methods, as shown in Figure 2. By integrating source waters, treatment technologies, and recharge methods, several hundred potential alternatives were identified. The NF-Partnership technical committee applied three rounds of screening to these alternatives, each progressively refined in technical detail. Throughout the process, any alternative deemed to be infeasible was removed from further consideration by the group. The three-tiered screening process used by the NF-Partnership is summarized in Figure 3 and is described in detail.

Tier 1

In the Tier 1 screen, the NF-Partnership considered identified candidate water sources with variations in pathways into the MFL recharge areas. Project alternatives that provided less than 3 mil gal per day (mgd), or that exhibited significantly higher unit conveyance costs than other alternatives, were removed from consideration. Approximately 600 alternatives were identified for screening in Tier 1.

Tier 2

In the Tier 2 screening process, conceptual costs and potential benefits were determined for the remaining alternatives. Conceptual costs included source development, treatment, conveyance, and recharge. The potential benefits were estimated based on the expected combined flow benefit at the two MFL sites, based on the volume of water expected to reach the sites from a target recharge area. The Tier 2 screened alternatives were sorted based on the ratio of capital cost to MFL benefit. From this list, approximately 12 alternatives were chosen based on their value.

Tier 3

The short-listed projects in Tier 2 were then compared using a multicriteria scorecard that combined both the quantitative and qualitative features of each alternative. In the Tier 3 screen, conceptual cost estimates were further refined, MFL benefits were reported individually for the two sites, and a broad array of qualitative characteristics were examined (e.g., ancillary benefits, implementation ease, development time, operational complexity, reliability of source water, and potential for benefit to additional MFL water bodies). The project alternatives were discussed in their totality through facilitated discussions, and the NF-Partnership identified four projects to advance for more-detailed feasibility assessments.

Alterna-ve

1. JEA Reclaimed Water from Buckman and Southwest Water Reclama-on Facili-es

3. North Fork Black Creek

Recharge

4. Lower Suwannee/Branford Surface

Recharge

1 MFL benefits for JEA reclaimed water assume 90 percent recharge efficiency for rapid infiltration basins, MFL benefits for GRU reclaimed water assume 80 percent recharge efficiency for recharge wetlands, and MFL benefits for the remaining alternatives assume 100 percent recharge efficiency for recharge wells.

1 MFL benefits for JEA reclaimed water assume 90 percent recharge efficiency for rapid infiltration basins, MFL benefits for GRU reclaimed water assume 80 percent recharge efficiency for recharge wetlands, and MFL benefits for the remaining alternatives assume 100 percent recharge efficiency for recharge wells.

2 Full MFL requirements could be met based on current modeling and careful selection/design of recharge sites and methods.

3 Desalination options are shown for relative comparative purposes, but not recommended for further study at this time.

2 Full MFL requirements could be met based on current modeling and careful selection/design of recharge sites and methods.

3 Desalination options are shown for relative comparative purposes, but not recommended for further study at this time.

The NF-Partnership then conducted an extensive review and compiled cost data from previous projects to develop estimated costs. The effort considered permitting and environmental issues, such as nutrients, emerging contaminants and other issues, at a very high level.

Short-Listed Alternatives

The four short-listed alternatives are presented in Table 2. For reference comparison, three seawater desalination alternatives are also listed. Seawater desalination uses reverse osmosis to remove salt and other minerals from seawater to make potable drinking water, with brine concentrate from the treatment process being discharged back to the ocean.

The analysis by the NF-Partnership estimated the MFL benefits based on the volume of water from each source and preliminary

recharge benefits based on the conceptual recharge area.

A summary of the four short-listed alternatives, along with seawater desalination for comparative reference, is shown here

JEA Reclaimed Water: Includes reclaimed water from the JEA Buckman and Southwest Water Reclamation Facilities (WRFs) totaling 40 mgd. The preliminary project concept is based on the operation of a treatment wetland upstream of the recharge location. At 40 mgd, this alternative could address the full LSFIR MFL needs if recharged in a strategic location. The project would also assist JEA to meet its Senate Bill 64 nonbeneficial surface water discharge elimination requirements. GRU Reclaimed Water: Up to approximately 3 mgd of reclaimed water flow for aquifer recharge could be obtained by shifting flow between GRU WRFs. This alternative’s volume is not large

Continued on page 12

Table 2. Summary of Short-Listed Alternatives Plus Seawater Desalination

enough to meet MFL targets by itself, but may be beneficial in concert with the JEA alternative and/ or other alternatives.

North Fork Black Creek: Surface water would periodically be withdrawn from the North Fork of Black Creek and beneficially recharged. Preliminary analysis suggested that withdrawal of 5.2 mgd could potentially be available approximately 80 percent of the time, while meeting ecological flow needs. More-detailed hydrological analysis would be required to ensure source water availability.

Lower Suwannee River: Surface water would periodically be withdrawn downstream of the Branford Gage and beneficially recharged. Preliminary analysis suggests that withdrawal of 20 mgd could potentially be available approximately 45 percent of the time, while meeting ecological flow needs. More-detailed analysis would be required to ensure compliance with Suwannee River MFLs, and that there are no other adverse environmental impacts.

Desalination (for comparative reference, not recommended for further study): Several desalination alternatives were considered in the evaluation. As mentioned, Table 2 includes three seawater desalination alternatives for relative comparison with the other water sources, highlighted here.

S Desal-Coquina would desalinate ocean water from the east coast in the Jacksonville area and pump it to the conceptual recharge area.

S Desal-Gulf would desalinate water from a location on the west coast and pump it to the recharge area.

S Desal-Pumping Replacement would desalinate saltwater from the Jacksonville area and would replace groundwater as a water supply for all four utilities.

The desalination alternatives are not recommended for further evaluation due to the following:

S High capital and operation and maintenance costs

S Technical and regulatory challenges related to managing brine disposal

S Replacement of all four participating utilities pumping with desalinated seawater would not meet the full MFL requirements

S Seawater desalination does not address the requirements of Senate Bill 64 to put reclaimed water to beneficial use

Recommended Projects and Next Steps

Through facilitated deliberation, the NF-Partnership report recommended that both the JEA reclaimed water and GRU reclaimed water alternatives be carried forward for detailed

feasibility assessments. Additionally, as these alternatives are being assessed for feasibility, both the North Fork Black Creek and the Lower Suwannee River projects remain in reserve for additional analysis, pending the feasibility assessment outcome on the two reclaimed water projects. The detailed assessment on the two reclaimed water projects took priority given they provide additional benefits, including compliance with Senate Bill 64, which mandates that domestic wastewater utilities develop and implement plans to reduce or eliminate the discharge of treated wastewater into surface waters. This additional analysis is required to determine if the project concepts are technically feasible, meet environmental and regulatory constraints, and provide the required site-specific recharge potential. Additionally, the feasibility assessment will further define treatment needs and methods, refine costs, and develop plans for implementation and long-term management.

Details on the items that will need to be addressed include the following:

Technical Feasibility Studies of Selected Alternatives

Technical feasibility studies would include an evaluation of the treatment technologies needed to make source water suitable for the recharge options selected and site-specific hydrogeological evaluations of the recharge sites.

Technical feasibility studies should include the following key considerations:

S Water quality requirements and potential treatment technologies

S Intake, transmission, and pumping requirements, including potential routes for future consideration

S Source availability, including both reclaimed water sources and natural sources

S Recharge technology requirements to encompass the potential for rapid infiltrations basins, treatment wetlands, or recharge wells

S Modular, phased, spatially distributed, or hybrid project designs to maximize flexibility and cost efficiency

S Potential project design, permitting, and construction schedules that would allow for the MFLs to be met as soon as feasible and within 20 years

Governance and Cooperative Agreements

Development of the agreements for operation, future rehabilitation and replacement, and the governance of potential projects would be initiated. A framework on how offset benefits are distributed to users would also be developed.

Project Funding

The process of identifying and pursuing options for project funding would be initiated.

Communication

An outreach and communications strategy would be developed. Additionally, the NFPartnership report indicates a comprehensive evaluation of the potential recharge sites and environmental and permitting considerations that should be initiated. Performing an additional refinement of cost estimates for each alternative, identifying and pursuing options for project funding, and identifying funding for both feasibility studies and implementation of alternative components were also recommended.

Conclusions

The NF-Partnership’s collaborative screening and conceptual evaluation process has built a strong technical and institutional foundation for identifying viable regional water supply alternatives in north Florida. The use of a structured and consensus-driven framework allowed utilities and agencies to rigorously assess hundreds of conceptual alternatives and converge on a short list of high-potential projects.

The reclaimed water recharge projects advanced by JEA and GRU emerged as top priorities due to their strong alignment with the proposed LSFIR MFLs, regional water reuse goals, and SB 64 compliance requirements. These alternatives not only offer promising recharge potential, but also present opportunities for near-term implementation and long-term resilience.

Moving forward, detailed feasibility assessments are critical to confirm the technical, regulatory, and financial viability of the selected projects. These studies will refine treatment needs, site-specific recharge potential, permitting pathways, and implementation timelines. In parallel, establishing governance frameworks and securing funding will be essential to move these large-scale regional projects from concept to construction.

This partnership model—rooted in shared goals, transparent dialogue, and technical rigor—offers a replicable blueprint for future collaboration across Florida. This future collaboration could include other WMDs in the state, FDEP, and other local utilities. The commitment shown by the NF-Partnership marks an important step toward sustainable water supply management and springs protection in Florida for generations to come.

Acknowledgments

The authors wish to thank all participants of the NF-Partnership for their dedication, technical expertise, and desire to find collaborative approaches to meet the multiple water resources objectives in north Florida. S

Accelerating Infrastructure Delivery for a Resilient Water Future

Megan Ross and John Zelenka

Florida has entered a new era in water and wastewater infrastructure—one defined by public demands driving the need for urgency and action. Historic investments, water quality,

regulatory mandates, and lessons learned from recent hurricanes are driving utilities to deliver more—and faster. Whether it’s meeting future water demands through potable reuse, eliminating surface water discharges, or preparing for the next storm, the focus is shifting from planning to execution. Across the state, utilities, engineers, and contractors are rising to the challenge—leveraging funding opportunities, embracing collaborative delivery, and advancing projects that will define Florida’s water future.

Florida is Building Big—and Fast

The recent announcement of the expedited schedule for the construction of the Everglades Agricultural Area (EAA) Reservoir, one of the state’s most ambitious and transformative projects and the cornerstone of the Comprehensive Everglades Restoration Plan (CERP), underscores the urgent need for contractors to innovate and find ways to build water infrastructure faster. The project includes a combination of canals, stormwater treatment areas (STAs), pump stations, water control structures, and reservoirs to reduce harmful discharges to the northern estuaries, send more water south, and improve water quality in America’s Everglades. The CERP is a framework for restoring, protecting, and preserving the greater Everglades ecosystem (multiple completed and ongoing projects fall under this plan) to include the S-701 Pump Station, which will serve to increase freshwater flows into the Biscayne Bay and rehydrate coastal wetlands, and construction of the C-23/24 STA and North Reservoir for the Indian River Lagoon – South project (shown in Figures 1 and 2).

The EAA reservoir is a massive project originally slated to be completed by 2034. To construct this ambitious project, the state of Florida and the U.S. Army Corps of Engineers simultaneously signed a memorandum of agreement and memorandum of understanding in July (shown in Figure 3), committing to an expedited construction schedule, with a new completion date of 2029—five years ahead of the original completion date. Once the work is done, the reservoir will span an area larger than the island of Manhattan, serving both water quality and storage functions critical to south Florida’s environmental health and long-term water supply. The reservoir will store 78 billion gallons (enough water to fill more than 118,000 Olympic-sized swimming pools), making it one of the largest reservoirs in Florida, and it will lower water levels in Lake Okeechobee by about six inches.

This kind of leadership—funding major infrastructure, aligning state and federal partners, and fast-tracking delivery—exemplifies the tone for the entire water sector in Florida.

Figure 1. Recent construction of the S-701 pump station, part of the Comprehensive Everglades Restoration Plan Biscayne Bay Coastal Wetlands program. (photo: Kiewit)

Figure 2. Construction of the C-23/24 STA for the Indian River Lagoon – South, a Comprehensive Everglades Restoration Plan component. (photo: Kiewit)

Regulatory Drivers Are Shaping Utility Priorities

Several important regulatory changes are converging to reshape the infrastructure landscape:

S Senate Bill 64. Requires utilities to eliminate nonbeneficial surface water discharges by 2032, pushing utilities to invest in reuse, recharge, and other beneficial alternatives.

S Florida’s new potable reuse rule. Provides guidelines for direct and indirect potable reuse, giving utilities a pathway to safely and sustainably expand drinking water supplies.

S Biosolids land application restrictions. Limit outlets for Class B biosolids, prompting utilities to pursue alternative treatment options that reduce volume and open new outlets for beneficial reuse.

S Collection system action plans. Now required by the Florida Department of Environmental Protection (FDEP) for systems with a history of sanitary sewer overflows (SSOs), prompting major reinvestment in lift stations, force mains, supervisory control and data acquisition systems, and asset management programs.

S New stormwater regulations. In accordance with Senate Bill 7040 will implement additional treatment and maintenance standards.

S Final National Primary Drinking Water Regulation for per- and polyfluoroalkyl substances (PFAS) from U.S. Environmental Protection Agency. Issued in 2024, this sets enforceable limits on PFAS compounds in drinking water. While the initial compliance deadline was set at 2029, EPA has extended the deadline to 2031 for full implementation.

S EPA-developed biosolids risk assessment for PFAS. Expected to inform upcoming federal regulations on land application. This evolving regulatory landscape is creating significant uncertainty for utilities, as they must balance compliance with new state biosolids regulations, while preparing for more stringent future standards.

Resiliency: A New Imperative

Florida’s water infrastructure must do more than meet regulatory benchmarks; it must stand up to hurricanes, flooding, and other extreme weather events. Recent storms have underscored the importance of resilient design and the demand for operational continuity.

Utilities are hardening pump stations, elevating electrical controls, adding redundant systems, and integrating emergency response capabilities into their infrastructure plans. More than ever, resiliency is not a buzzword—it’s a design requirement. And it’s being addressed in every capital plan and construction project moving forward.

Collaborative Delivery Enables Faster, Smarter Projects

To meet aggressive timelines and keep up with overlapping infrastructure demands, many utilities are shifting to collaborative delivery models, like progressive design-build, construction management at risk, and publicprivate partnerships. These methods are ideal for complex, time-sensitive projects that require flexibility, early input, and fast-track construction.

Utilities have used these approaches to accelerate delivery, improve cost certainty, and foster better coordination between owners, designers, and builders.

Collaborative delivery enables utilities to:

S Engage builders during the design process

S Navigate regulatory and permitting issues in real time

S Adjust to changing conditions (e.g., lead times, site constraints)

S Deliver infrastructure with fewer change orders and smoother transitions to operation

Florida is Ready to Deliver

With strong policy direction and proven delivery tools, Florida’s water sector is wellpositioned to meet the moment, but success will depend on continued collaboration across agencies, utilities, engineers, and contractors.

The FSAWWA Contractors Council encourages utilities to:

S Embrace alternative delivery methods for complex and schedule-driven projects

S Prioritize resiliency and adaptability in infrastructure design

S Take proactive steps to meet biosolids,

collection system, and discharge reduction goals

S Begin planning now for potable reuse implementation

Florida is showing the nation what’s possible when urgency, innovation, and partnership converge. By working together—and delivering faster—we are building a more resilient, sustainable water future for every community across the state.

If you are interested in learning more about the Contractors Council or requesting support, please visit our website at www.fsawwa.org.

References

• 8 Things To Know About The EAA Reservoir. (n.d.). Retrieved from: https://www. evergladesfoundation.org/post/8-things-toknow-about-the-eaa-reservoir.

• ERP Stormwater Resource Center. (2025). Retrieved from: https://floridadep.gov/water/ engineering-hydrology-geology/content/erpstormwater-resource-center.

• Gov. Ron Desantis Announces Landmark Agreement with U.S. Department of the Army to Accelerate Everglades Restoration (2025, July 18). Retrieved from: https://www.flgov. com/eog/news/press/2025/governor-rondesantis-announces-landmark-agreement-usdepartment-army-accelerate.

• Progress Continues on the Everglades Agricultural Area Reservoir Project. (n.d.). Retrieved from: https://www.sfwmd.gov/ourwork/cerp-project-planning/eaa-reservoir.

Megan Ross, P.E., ENV SP, is business development manager with Kiewit in Tampa. John Zelenka is pursuit manager with Kiewit. S

Figure 3. Signing ceremony in Marco Island, July 2025.

FWEA CHAPTER CORNER

Welcome to the FWEA Chapter Corner! The Member Relations Committee of the Florida Water EnvironmentvAssociation hosts this article to celebrate the success of recent association chapter activities and inform members of upcoming events. To have information included for your chapter, send details to Melody Gonzalez at gonzalezm@bv.com.

Introducing Making Waves With FWEA: A Brand-New Podcast Hosted by Megan Nelson and Mike Sweeney

South Chapter Leadership Team Initiates Podcast

The Florida Water Environment Association (FWEA) is thrilled to launch its newest initiative—a podcast series titled “Making Waves with FWEA.”

This exciting series marks a fresh, compelling approach to sharing insights, spotlighting water issues, and driving meaningful conversations within Florida’s water community.

Meet the Hosts

The hosts for the podcast are:

S Mike Sweeney, Ph.D. – As the executive director of FWEA, Mike brings deep expertise from years of utility leadership, academic work, and consulting. With a background in environmental engineering and advanced degrees from Indiana University and Purdue University, he has held key roles at major utilities and as a consultant across North America.

S Megan Nelson, P.E. – A senior engineer at Orange County Utilities and the FWEA secretary, Megan brings technical knowhow and organizational leadership to the

microphone. Her experience in utility operations and chapter-level involvement enriches each episode with insider perspectives.

Together, Mike and Megan form a dynamic hosting team, with over 60 years of combined water-sector experience, dedicated to fostering thoughtful dialogue and professional growth.

Podcast Mission and Format

“Making Waves with FWEA” serves as a vibrant platform for exploring water-related challenges and solutions across Florida—and beyond. The podcast:

S Amplifies diverse voices from the science, technology, policy, and community engagement spheres.

S Demystifies complex topics, such as governance, regulation, utility partnerships, and emerging technologies through clear storytelling and expert interviews.

S Invites participation, encouraging listeners to suggest guests and topics via the Students and Young Professionals Committee.

As an on-demand medium, the podcast bridges the gap between FWEA’s in-person events and the daily lives of professionals—making it easier than ever to stay connected and informed.

Early Episodes and Engagement

In its inaugural episodes, the podcast has already begun delivering impactful content:

S Episode 1 – Water Governance at the Source, featuring Kristiana Dragash

S Episode 2 – Building Water Partnerships, featuring Lisa Wilson-Davis

S Episode 3 – Leading FWEA Forward, featuring Joan Fernandez

S Episode 4 – Inspiring Future Water Leaders, featuring Zachary Loeb

S Episode 5 – From Floods to the Future, featuring Manasi Parekh

S Episode 6 – Training Tomorrow’s Operators Today, featuring Jessica Green.

These first episodes set the tone—anchored in governance, collaboration, and innovation— with more to come from industry, regulatory, academic, and utility leaders.

Why This Matters for FWEA

This podcast aligns perfectly with FWEA’s mission to advance water science and practice while uniting professionals across disciplines and regions.“Making Waves with FWEA” complements traditional chapter gatherings and conferences by offering accessible, thought-provoking content that members can engage with anytime, anywhere.

Stay Tuned

“Making Waves with FWEA” is available now—stream it on Spotify and Apple Podcast. Be sure to subscribe, listen in, and help us amplify conversations that shape our water future.

Link to podcast on Spotify: https://open. spotify.com/show/4nfNwTmTADTiezMZ5Vw4pc

Link to podcast on Apple Podcasts: https:// podcasts.apple.com/ne/podcast/making-waveswith-fwea/id1834679372)

Senuda Rajapakse is podcast director and vice chair of the FWEA Manasota Chapter. S

Senuda Rajapakse

Melody Gonzalez

Megan Nelson and Mike Sweeney

Operators: Take the CEU

Members of the Florida Water and Pollution Control Operators Association (FWPCOA) may earn continuing education units through the CEU Challenge! Answer the questions published on this page, based on articles in this month’s issue. Circle the letter of each correct answer. There is only one correct answer to each question! Answer 80 percent of the questions on any article correctly to earn 0.1 CEU for your license. Retests are available.

This month’s editorial theme is New Facilities, Expansions, and Upgrades. Look above each set of questions to see if it is for water operators (DW), distribution system operators (DS), or wastewater operators (WW). Mail the completed page (or a photocopy) to: Florida Environmental Professionals Training, P.O. Box 33119, Palm Beach Gardens, Fla. 33420-3119, or scan and email a copy to memfwpcoa@gmail.com. Enclose $15 for each set of questions you choose to answer (make checks payable to FWPCOA). You MUST be an FWPCOA member before you can submit your answers!

Turning Crisis Into Opportunity: Panama City’s Localized Lift Station Solutions Calm the Storm

Kevin Kennoy, Tonny Peters, and Samar Masloum (Article 1: CEU = 0.1WW02015459)

1. What is the primary purpose of Lift Station 16 in Panama City?

a) To manage stormwater

b) To convey wastewater away from St. Andrews Bay

c) To provide drinking water

d) To generate electricity

2. What type of pump has been used to operate Lift Station 16 since 2018?

a) Electric pump

b) Solar pump

c) Diesel bypass pump

d) Manual pump

3. What is the primary benefit of relocating Lift Station 16 beyond the 500-year floodplain?

a) Reduced construction costs

b) Enhanced resilience against extreme weather

c) Increased water supply

d) Improved aesthetics

4. What environmental feature is protected by the new design of Lift Station 16?

a) Coral reefs

b) Mangrove forests

c) Seagrass habitats

d) Sand dunes

5. What innovative method was used to demolish the old sewer infrastructure?

a) Explosive demolition

b) In-situ demolition

c) Underwater demolition

d) Robotic demolition

Awardees Honored by FWPCOA for Excellence in Water and Wastewater

The Florida Water and Pollution Control Operators Association (FWPCOA) recognized several outstanding water/wastewater professionals, utilities, and facilities during a luncheon at the August FWPCOA Short School held at Indian River State College in Fort Pierce.

Safety Awards

Water B

Award Hollywood Water Treatment Plant, Seminole Tribe Water C Safety Award Big Cypress, Seminole Tribe

Wastewater A Safety Award Fort Myers Beach Water Reclamation Facility

Wastewater

Reuse A Safety Award Water Conserv II, Woodard & Curran

Dr. A.P. Black Award Amanda Hebert Wastewater, Polk County Utilities

Theodore Kamien Award John Wright City of Mulberry

Raymond Bordner Award

Hector Ortiz Wastewater, City of Altamonte Springs

Joseph V. Towry Award Frank O’Neal City of Winter Haven

Joseph V. Towry Award John Sowka Jr. Woodard & Curran

Emory Dawkins Award Edward Clark Editor, Region 10

Emory Dawkins Award Deborah Wallace Editor, Region 07

50 Year Award Steve Saffels

Appreciation Award Tom King

2025 FWPCOA AWARDS

Attendees at the awards presentation.

The array of awards.

Attendees at the awards lunch.

Kevin Shropshire presents award to Tom King.

Kevin Shropshire and Renee Moticker at the awards ceremony.

LET’S TALK SAFETY

This column addresses safety issues of interest to water and wastewater personnel, and will appear monthly in the magazine. The Journal is also interested in receiving any articles on the subject of safety that it can share with readers in the “Spotlight on Safety” column.

Safety Tips for Employees Working Remotely or Alone

Reductions in manpower and increases in workload have also increased the number of utility employees who are working alone.

While solo work may not automatically decrease a worker’s safety, there is no doubt that working alone increases a worker’s vulnerability to a variety of safety issues. This vulnerability applies not only to those who regularly work outdoors, but also to any employees whose work has them alone in an office or control room or frequently takes them out into the community. All these workers may encounter threats to their safety.

The following five steps can help you reduce the safety vulnerability of your workers. These tips apply to all employees and their management who must work alone or with others in remote locations where normal means of communication are unreliable or nonexistent.

Routine Communications Protocol

Add these steps to a workers preparation routine:

S Designate a key point of contact (POC) who is not a part of the remote team.

S Know who is working remotely and how long the work should take.

S Set regular check-in times for the entire work period. At each check-in, the POC should record the time and the information given by the remote worker.

S Evaluate lighting conditions; are they sufficient to ensure worker safety? At a building is there adequate lighting both inside and outside?

S Is access to a building locked and secure?

S The POCs should relay any anticipated changes in weather to those working remotely.

Emergency Communications Protocol

Add these steps to a workers preparation routine:

S If a check-in time is missed, the POC should try, for 30 minutes, to reestablish communications.

If this fails, the POC must:

S Assemble a search team and place the team on standby.

S Contact medical personnel, informing them that an emergency response may be needed.

S If an event includes an injury, after ensuring that medical attention has been provided, the responsible supervisor shall ensure that the appropriate incident/ injury reporting process is initiated.

Evaluate the Potential Hazards

Before entering a remote work location, all team members should identify and discuss potential safety issues:

Planning for weather conditions—both forecast and unexpected

Facing potential emergencies such as flooding, electrical contact, and running out of fuel in cold climates

Handling serious injuries or illnesses that might occur far from medical facilities

Guarding against animal attacks, snakes, and insects

Making contact with emergency agencies

Having and using the appropriate personal protective equipment (PPE)

Having the tools required to complete the job safely

Team members should also assess the risks and review work-related documentation, such as a job hazard analysis, to ensure all

mitigation and control measures have been addressed.

Situations Where Solo Work Should Not Occur

There are certain situations when working alone should not be permitted:

S Confined space entry

S Working on energized electrical conductors or equipment

S Power line hazards where use of a vehicle, crane, or similar equipment can come in contact with a live power line

S View obstruction where the operator of a vehicle, crane, mobile equipment, or similar material handling equipment does not have a full view of the intended path of travel

S The use of fall arrest equipment and scaffolds

S Work involving quick-acting, acutely toxic material as described by the Safety Data Sheet

S Use of supplied air respiratory equipment or self-contained breathing apparatus

S Risk of drowning

S Welding operations where a fire watcher is required

S Tasks based on the risk assessment conducted by the supervisor and the employee deemed to require more than one person

Conduct a Safety Tailboard or Tailgate Meeting

With all workers present, do the following:

S Discuss potential hazards and special precautions the work requires.

S Discuss the job’s processes, procedures, and tasks and the order in which they will be performed.

S Review appropriate safety procedures and PPE considerations. Inspect tools and ensure all PPE meets safety standards.

S Discuss assignments. Everyone must know their job—and the jobs of their coworkers.

S Establish a buddy system where coworkers watch out for each other.

S Ensure those with new job assignments, new tools, or new equipment are properly and completely trained on safety processes, procedures, and operation.

S Everyone should regroup and discuss potential safety issues when new substances, processes, procedures, tools, or equipment are introduced to the worksite.

S Report hazards and unsafe equipment to the supervisor before work begins.

S Discuss unusual and nonroutine situations.

S Discuss emergency procedures.

S Determine ahead of time who’s in charge in an emergency situation and who is the backup.

S Know where all emergency resources are located: emergency plan, fire extinguisher, first-aid and burn kits, and communication devices.

Resources

For additional information and ideas:

S Service NL (Newfoundland Labrador) Working Alone Safely Guidelines for Employers and Employees: www.gs.gov. nl.ca/ohs/safety_info/ si_working_alone. html

S Occupational Safety and Health Administration: www.osha.gov

S SafetyIQ www.safetyiq.com

S

AFWEA FOCUS New Facilities, Expansions, and Upgrades

Joan Fernandez President, FWEA

s we step into this October edition of FRWJ, I’m excited to highlight this month’s theme: new facilities, expansions, and upgrades. Across Florida, our communities are experiencing growth and change that call for innovative solutions in water and wastewater infrastructure. These projects are more than just bricks, pipes, and treatment processes; they represent our collective commitment to public health, environmental stewardship, and resilient communities. Whether through state-of-the-art technologies, expanded capacities, or strategic upgrades, the work being done today is shaping the future of water resources for generations to come.

Across the state, a number of communities are investing in improved wastewater infrastructure to meet growing demand and enhance environmental protection. In Sarasota County, the Bee Ridge Water Reclamation Facility is undergoing a major expansion and upgrade, adding advanced treatment technologies like Florida’s largest membrane bioreactor and increasing its capacity from 12 to 18 million gallons per day (mgd). This modernization will enable the facility to better remove nutrients, support reuse, and build in greater climate resilience, aiming for completion by the end of 2025.

Communities across the state are following suit with similar efforts. In Palm Coast, the city celebrated the recent completion of its Wastewater Treatment Plant 2 expansion, which doubled capacity from 2 to 4 mgd and incorporated advanced treatment systems to improve efficiency and environmental outcomes. Likewise, Freeport has finished a timeline of upgrades, including expanded aeration, new flow equalization basins, additional digesters, and filters. The plant has gone from 0.6 to 1.5 mgd, with future expansion to 2 mgd.

Smaller municipalities are taking action as well, often supported by state funding. Belleview secured $1 million from Florida’s fiscal year 2025-26 budget to expand its wastewater plant’s capacity from 1 to 1.2 mgd. This upgrade addresses aging septic reliance, regulatory needs, and future growth, with work expected to be completed by mid-2026. In Eustis, design and construction services are underway to enhance its Bates Avenue treatment facility, adding new clarifiers, filters, lift station improvements, and a biological nutrient removal train to support reliability and anticipated capacity needs.

Beyond capacity, efforts to harden systems for resilience and reliability are well underway. St. Johns County is revamping electrical systems at its Marsh Landing facility, including a new motor control center and backup generator integration to ensure seamless operation during storms and support future expansions. In St. Petersburg, an innovative flood barrier, known as Aquafence, has been installed at a key lift station serving

roughly 25 percent of the city’s population, including critical infrastructure to safeguard against hurricane-driven flooding. Together, these projects illustrate a statewide commitment to modernizing wastewater infrastructure through capacity expansion, advanced treatment, funding innovation, and infrastructure resilience.

FWEA Events

Looking ahead, we anticipate two standout gatherings that broaden our sphere of influence and advocacy.

The FWEA Utility Council (FWEAUC), in partnership with FSAWWA, is gearing up for its annual member meeting and Tallahassee Fly-In on October 14-16, offering a strategic blend of organizational collaboration and direct engagement with state policymakers in the capital. Toward month’s end, the Florida Water Forum 2025, slated for October 23-24 at the Loews Royal Pacific Resort in Orlando, is a “save the date” for high-impact dialogue on water policy, innovation, and leadership across the region. Check out the event calendar at our website, www.fwea.org, for additional event information.

As always, I welcome your questions, ideas, and collaboration on any initiatives you’re passionate about. Whether you want to discuss a column or article topic, get involved with FWEA activities, or simply connect, feel free to reach out. You can contact me anytime at fernandezji@cdmsmith.com or at 954.882.9566. S

Palm Coast Wastewater Treatment Plant 2 expansion.

photo: City of Palm Coast)

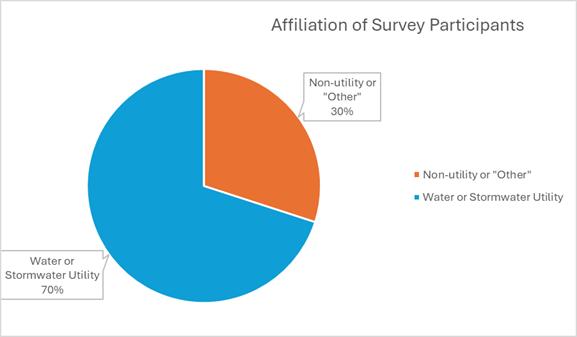

State of the Florida Water Industry Survey: The Results Are In!

Earlier this year, the Florida Water Resource Journal, partnering with SediVision®, a wastewater technology and engineering firm, launched the 2025 Florida Water Sector Survey. Although similar surveys have been conducted in the past with the support of FWRJ, this year’s study marked the first time the Florida water industry has been polled in this way in several years.

If you participated in the survey, your response is sincerely appreciated, and if you missed out on the opportunity to make your opinions and thoughts heard, we sincerely hope you will plan now to be a part of the 2026 Florida Water Sector Survey, launching next spring.

Hill Research, an independent, thirdparty research firm, conducted the survey, collecting responses from April to June 2025. The survey was made available through FWRJ, the Wastewater Visibility News blog, and direct email, and further promoted and made available through social media promotion. There were even opportunities to take the survey live during this year’s Florida Water Resources Conference, held in West Palm Beach.

Methodology

This survey had 140 participants in, or providing services to, the water industry sector in Florida. The resulting data collected is a nonprobability sample and no representations are made regarding the projection of the results herein to the entire Florida water industry sector.

Who Participated in the 2025 Florida Water Sector Survey

Characteristics of the survey participants included:

S 49 percent were involved in the Florida water sector for more than 20 years

S 9 percent were involved in the Florida water sector for less than five years

S 56 percent worked in operations or maintenance

S 20 percent worked in executive or management positions

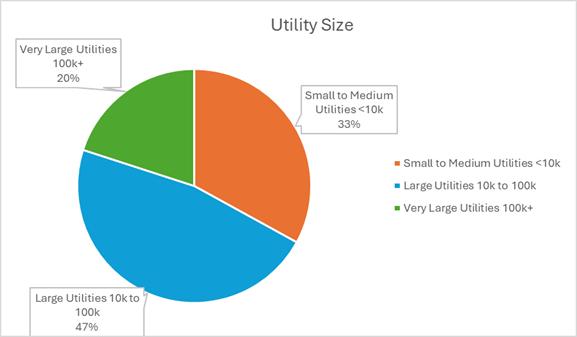

Utility participants represented utilities of all sizes.

Key Findings of the Florida Water Industry Survey

Findings of the survey included:

S Only 10 percent of respondents believe their organization is fully ready to meet long-term water needs.

S Respondents see the water and wastewater sectors as being in “slightly less” worse shape five years from now than they are today.

S Multiple questions point to key concerns surrounding infrastructure and capital needs, staffing (including retention and training), meeting operating costs, and contaminants.

S Contaminants that most concern respondents are microplastics, per- and polyfluoroalkyl substances, nutrients, and pathogens.

S Cybersecurity is recognized as important, but only 39 percent say their needs are fully funded and describe the threat as “critical.”

Other findings are shown in the charts and graphs that follow.

Using the Survey Results

To effectively use these survey results, you should analyze the data to find patterns, trends, and correlations, and then turn the findings into meaningful, actionable insights for your products, services, strategies, and marketing that can drive decisions for your company and create meaningful impact for the future.

About Florida Water Resources Journal

The FWRJ is a technical publication oriented toward water treatment and distribution, wastewater collection and treatment, and stormwater control. It’s owned by and is the official publication of three Florida associations:

S Florida Section of the American Water Works Association

S Florida Water Environment Association

S Florida Water and Pollution Control Operators Association

The FWRJ contains information and topics concerning Florida’s more than 3,000 domestic and 1,500 industrial wastewater facilities, its

7,000 drinking water systems, and a myriad of wetlands and other surface water agencies. The fourth largest population in the United States with over 16 million people, Florida is the third fastest growing state and is continually adding, repairing, and improving water and wastewater services. The magazine is published monthly and mailed on the first day of the month to all members of the sponsoring organizations, as well as to direct subscribers.

About SediVision

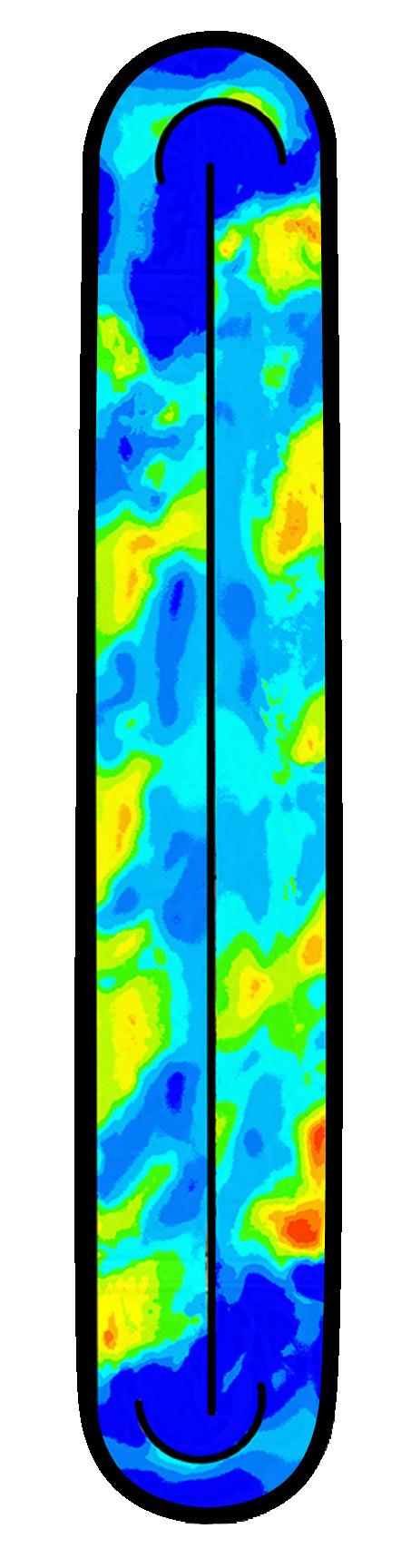

The concept driving SediVision

technology took root in the work of U.S. Submergent Technologies, LLC (USST), which is a submergent cleaning company established in 2011. The company provides sand, grit, and residual removal services from hard-toreach material in wet environments, including tanks and large-diameter pipes. Through the experience of cleaning hundreds of wastewater tanks for utilities, the team at USST recognized a persistent issue for utility managers: the inability to accurately estimate accumulated tank material due to the lack of visibility within wastewater tanks.

The challenges of seeing into the turbid

water in tanks left utility managers unable to plan or effectively allocate funds within wastewater budgets because they could not reliably assess conditions within the tanks. The development of SediVision technology was a direct response to help solve challenges facing utility managers and operators.

Developed in 2018 and refined through 2021, the technology, now patent-pending and trademarked as SediVision, provides complete visibility into wastewater tanks, delivering to treatment facilities critical information for accurately assessing system functionality and maintenance needs. S

Most implemented plans and programs

Least implemented plans and programs

Turning Crisis into Opportunity: Panama City’s Localized Lift Station Solutions Calm the Storm

Kevin Kennoy, Tonny Peters, and Samar Mazloum

The coastal city of Panama City is home to St. Andrews Bay, a unique estuary system that supports a rich diversity of marine life and some of the world’s most productive oyster beds. The bay’s clear waters and intricate ecosystem make it a top destination for fishing, boating, and ecotourism.

Supporting efforts to protect the bay’s water for the environment and local residents, Panama City depends on a resilient wastewater infrastructure system to manage and transport sewage effectively. Among its 137 lift stations, Lift Station 16 plays a vital role in conveying wastewater away from the bay and toward the St. Andrews Wastewater Treatment Plant (Figures 1 and 2). Its lowlying location has historically made it vulnerable in the system to environmental stressors, particularly storm surges.

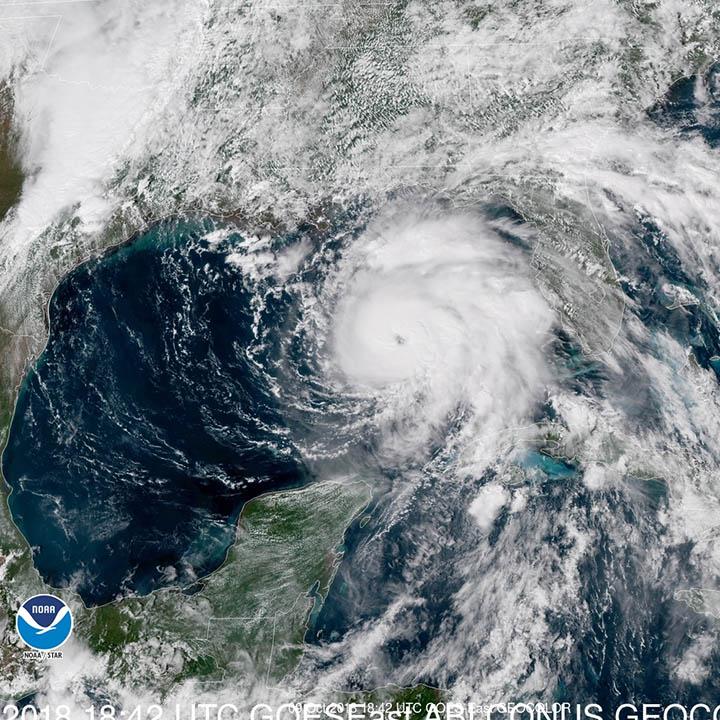

Hurricane Michael

When Hurricane Michael struck the Florida Panhandle in 2018 (Figure 3), ranked as a Category 5 catastrophic event by the National Oceanic and Atmospheric Administration, it brought winds of 160 mi per hour and deadly storm surges of up to 14 ft. This was followed by Hurricane Sally in 2020, which was a record-breaking precipitation event, with some areas seeing as much as 14 in. of rain in a 24-hour period. These storms caused severe damage

Kevin Kennoy, P.E., is vice president, client service team leader, at Barge Design Solutions in Panama City Beach, Fla. Tonny Peters, P.E., is senior project manager at Barge Design Solutions in Dothan, Ala. Samar Mazloum, Ph.D., is city utilities engineer, utilities division, with City of Panama City, Fla.

and exposed Panama City’s infrastructure vulnerabilities.

Lift Station 16 was severely damaged during these storms (Figures 4 and 5). Located in the flatlands near the bay, the already deteriorating infrastructure was significantly impacted, further exacerbating contamination concerns in the St. Andrews neighborhood. Sewer failures resulted in visible raw sewer overflows in the bay and backups into homes, worsening an already dire situation for the community. Without urgent funding and solutions on the horizon, the community impact could include years of recovery effort, putting residents and the environment at further risk.

Continued on page 30

Figure 1. Lift Station 16 is located on the shore of St. Andrews Bay in Panama City.

Figure 2. The influent sewer gravity system that feeds Lift Station 16 is in St. Andrews Bay.

Figure 3. Category 5 Hurricane Michael makes a direct hit on Bay County in October 2018. (image: National Oceanic and Atmospheric Administration)

When It Matters Most

¸ Wastewater treatment plant planning and design

¸ Wastewater collection and reclaimed water transmission

¸ FEDP and WMD regulatory permitting and compliance

Our Florida Offices barged esign.com //

¸ Gainesville, FL

¸ Jacksonville, FL

¸ Margate, FL

¸ Miami, FL

¸ Hydraulic and hydrologic modeling and analysis

¸ Pump station planning and design

¸ Storage tank design and rehabilitation

¸ Miramar Beach, FL

¸ Orlando, FL

¸ Panama City, FL

¸ West Palm Beach, FL

Don’t wait for a critical need.

Explore how we solve wastewater challenges before they become problems, contact:

Kevin Kennoy, PE

Kevin.kennoy@bargedesign.com

850-333-0199

¸ Planning and design

¸ Biosolids

¸ Wastewater master planning

¸ Regulatory compliance

Continued from page 28

Panama City’s Lift Station: History and Environmental Challenges

For decades, Lift Station 16 faced mounting environmental and lift station challenges. Located along the shores of St. Andrews Bay at the south end of Drummond Avenue, the infrastructure connected to the station was built over 50 years ago using obsolete terra cotta clay pipe and brick manholes. Though the original infrastructure was built under traveled beach roads, years of beach erosion left that infrastructure exposed and underwater. This led to increased inflow and infiltration into the station’s wet well, leading to increased

run times and surcharging of the upstream gravity sewer collection system. The station has been a constant source of contamination concerns for the environment and residents in the region and the frequent flooding was affecting the quality of life.

Manholes located in the middle of the bay further complicated wastewater management, posing contamination risks during high tides and storms. After Hurricane Michael, many lift stations in Panama City were damaged due to power outages, flooding, and structural impacts, leading to systematic sewage failures. Being one of the lowest structures in the system, Lift Station 16 was rendered completely inoperable, requiring the installation of a temporary backup/bypass pump, which will remain in use until the new lift station is installed.

Securing Federal and State Funding for Resilient Lift Station Solutions

Recognizing the urgency to create a robust and resilient long-term solution for the lift station system, particularly Lift Station 16, Panama City tapped into multiple grant programs, including the Hazard Mitigation Grant Program and Florida Department of Environmental Protection (FDEP) grant funds, to secure $5 million in government grants for the redesign of Lift Station 16. Barge Design Solutions was selected to lead the survey, analysis, and engineering efforts necessary for Lift Station 16’s reconstruction. This process required close, ongoing collaboration with the firm’s Miramar Beach office and the affected stakeholders, including FDEP, Florida Division of Emergency Management, City of Panama City, and local homeowners impacted by the construction. Working together, the team played a vital role in recovery efforts from the Panhandle’s strongest hurricane on record, while enhancing the city’s resilience against future storms.

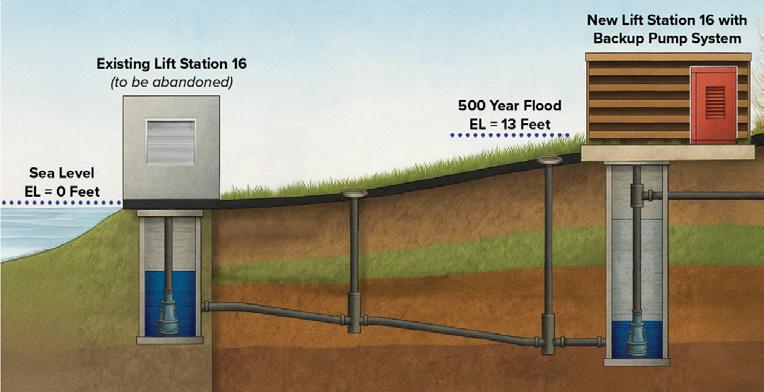

Relocating Beyond the 500-Year Floodplain for Long-Term Lift Station Resilience

To meet grant funding requirements and long-term reliability, Lift Station 16 was strategically relocated above the storm surge zone and beyond the 500-year floodplain (Figure 6). This design move not only safeguards critical infrastructure from extreme weather, but also ensures uninterrupted wastewater management. Beyond enhanced resilience, the relocation brings several key benefits:

Figure 4. Lift Station 16 has been operated by a temporary diesel bypass pump since Hurricane Michael in 2018.

Figure 5. More than half of Bay County’s sewage lift stations were damaged by Hurricane Michael.

Figure 6. Proposed project improvements include constructing a new modern lift station and a permanent, diesel-powered bypass pump located above the 500-year flood elevation.

S Backup power and bypass pumping to maintain functionality during power outages

S Implementation of an odor control system to mitigate concerns from nearby residents (Figure 7)

S Protection of St. Andrews Bay’s seagrass habitats, a critical food source for marine life, such as manatees, sea turtles, and fish populations

Knowing the station’s proximity to a residential area with historic significance, the team understood that space constraints would call for innovative engineering solutions. The new station’s design featured deeper sewer mains (up to 25 ft underground), necessitating wide trenching and daily coordination with contractors to minimize disruption for local homeowners. Daily trench closures were implemented to maintain accessibility for residents.

Rethinking Lift Station Location and Environmental Concerns

The project team worked directly with residents to ensure minimal impact on their properties during and after the construction phase of the project (Figure 8). For instance, the property of one of the residents was located within view of the new lift station. In a collaborative resolution, the homeowner agreed to sell a small portion of land for the lift station’s relocation, with grant funding covering the $125,000 acquisition cost. The project team also engaged with the homeowner to design a custom fence and landscaping plan, preserving the area’s aesthetic appeal.

To further protect St. Andrews Bay and reduce repair costs, the project team opted for an in-situ demolition method, where a structure is dismantled, deconstructed, or demolished onsite, rather than being removed and demolished elsewhere. The design sealed the old sewer infrastructure in place with lowpressure grouting of the gravity sewer and manholes, preventing potential water quality disturbances and expediting regulatory approvals to meet the grant requirements.

Building Resilience for Future Lift Station Infrastructure and the Community

The reconstruction of Lift Station 16 exemplifies a forward-thinking approach to infrastructure resilience. By leveraging federal and state resources, engaging with community stakeholders, and applying innovative engineering solutions, Panama

City turned a crisis into an opportunity for long-term improvement.

As part of a broader effort to support infrastructure recovery in Panama City, there are multiple initiatives to strengthen and modernize the community. This project is one of many designed to build resilience, joining many efforts, such as:

S Master planning and revitalization of three parks damaged by Hurricane Michael

S $10 million in critical water, sewer, stormwater, and roadway improvements

S Engineering upgrades for 13 lift stations to enhance flood resilience

Overall, Panama City has secured over $200 million in state loans and various

grants, leading to the largest infrastructure rehabilitation project in its history. These projects reflect a commitment to rebuilding a stronger and more sustainable infrastructure that can withstand future challenges, while improving the quality of life for residents.

Panama City’s construction on Lift Station 16 is scheduled to begin in the winter of 2025 and will be completed by spring 2026. More than just an infrastructure upgrade, this project embodies the strength of collaboration, innovation, and long-term resilience. By investing in a stronger, more reliable system, Panama City is not only rebuilding; it’s also fortifying its future, keeping the community prepared, protected, and positioned for growth when facing the storms of the future. S

Figure 7. The new Lift Station 16 will be located in a partially vacant lot with a screened fence and odor control system for aesthetic purposes.

Figure 8. The new Lift Station 16 includes plenty of space to ensure minimal impact to residents and access by city utility crews to provide proper maintenance.

From Avoidance to Action: 12 Drama-Free Ideas for Holding People Accountable

Kate Zabriskie

Most of us have been there. A deadline whooshes by, a teammate consistently shows up late to meetings, or someone just isn’t pulling their weight. And what do we often do? We avoid the situation, hoping the problem will magically resolve itself.

Spoiler alert: it never does.

Dodging these accountability conversations doesn’t help anyone; in fact, it usually makes things worse. When we let issues slide, we’re essentially signaling that standards don’t matter. Before long, missed deadlines pile up, trust crumbles, and frustrations boil over. So, how do we break this cycle? How do we muster the courage to address issues without being labeled the office hammer or hard-nose?

Here’s a practical roadmap to hold others accountable with respect, clarity, and confidence.

Preparation Is Your Best Friend