Static Mixing Technology with proven benefits

Through experience, innovation and inspiration Statiflo continues to strengthen its reputation as the world leaders in the design and manufacture of static mixers, channel mixers, gas dispersion systems and associated technologies.

Statiflo Motionless Mixers offer many key benefits for chemical dosing applications. They are efficient and economical, delivering precise, predetermined results every time.

Key benefits include:

• Highly efficient mixing meaning a low pressure drop and a short overall length

• Continuous performance over a wide flow range

• Reduced chemical consumption

• Available in all sizes and materials

• Custom designed for each application

• CFD verification is available

Editor’s Office and Advertiser Information:

Florida Water Resources Journal

1402 Emerald Lakes Drive

Clermont, FL 34711

Phone: 352-241-6006

Editorial, editor@fwrj.com

Display and Classified Advertising, ads@fwrj.com

Business Office: 1402 Emerald Lakes Drive, Clermont, FL 34711

Web: www.fwrj.com

General Manager: Michael Delaney

Editor: Rick Harmon

Graphic Design Manager: Patrick Delaney

Mailing Coordinator: Buena Vista Publishing

Published by BUENA VISTA PUBLISHING for Florida Water Resources Journal Inc.

President: Richard Anderson (FSAWWA) Peace River Manasota Regional Water Supply Authority

Vice President: Joe Paterniti (FWEA) Clay County Utility Authority

Treasurer: Rim Bishop (FWPCOA) Seacoast Utility Authority

Secretary: Rim Bishop (FWPCOA) Seacoast Utility Authority

Moving?

The Post Office will not forward your magazine. Do not count on getting the Journal unless you notify us directly of address changes by the 15th of the month preceding the month of issue. Please do not telephone address changes. Email changes to changes@fwrj.com or mail to Florida Water Resources Journal, 1402 Emerald Lakes Drive, Clermont, FL 34711

Membership Questions

FSAWWA: Casey Cumiskey – 407-979-4806 or Casey@fsawwa.org

FWEA: Laura Cooley, 407-574-3318, admin@fwea.org

FWPCOA: Darin Bishop – 561-840-0340

Training Questions

FSAWWA: Donna Metherall – 407-979-4805 or Donna@fsawwa.org

FWPCOA: Shirley Reaves – 321-383-9690

For Other Information

FDEP Operator Certification: Ron McCulley – 850-245-7500

FSAWWA: Kim Kowalski – (407) 979-4814

Florida Water Resources Conference: 267-884-6292

FWPCOA Operators Helping Operators: John Lang – 772-559-0722, oho@fwpcoa.org

FWEA: Laura Cooley, 407-574-3318, admin@fwea.org

Websites

Florida Water Resources Journal: www.fwrj.com

FWPCOA: www.fwpcoa.org

FSAWWA: www.fsawwa.org

FWEA: www.fwea.org and www.fweauc.org

Florida Water Resources Conference: www.fwrc.org

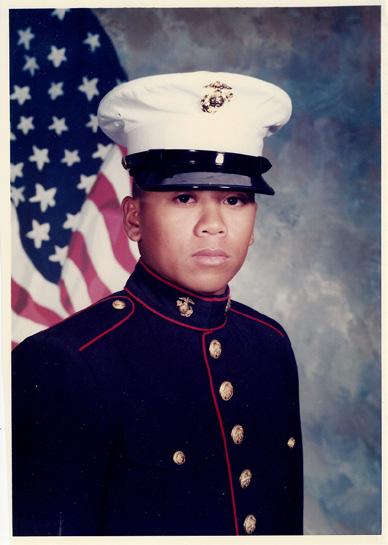

Salute to Veterans in the Water and Wastewater Industry

18 Happy Veterans Day!

18 EPA Guide: Introduction to Military Occupational Specialties for the Water Workforce

22 Memorandum of Understanding

23 Reader Profile: Veterans Edition—Arthur Bides

24 Honor Walk at Veterans Memorial Park

25 FSAWWA Veterans Service Recognition

News and Features

4 Water-AI Nexus Center of Excellence Launches

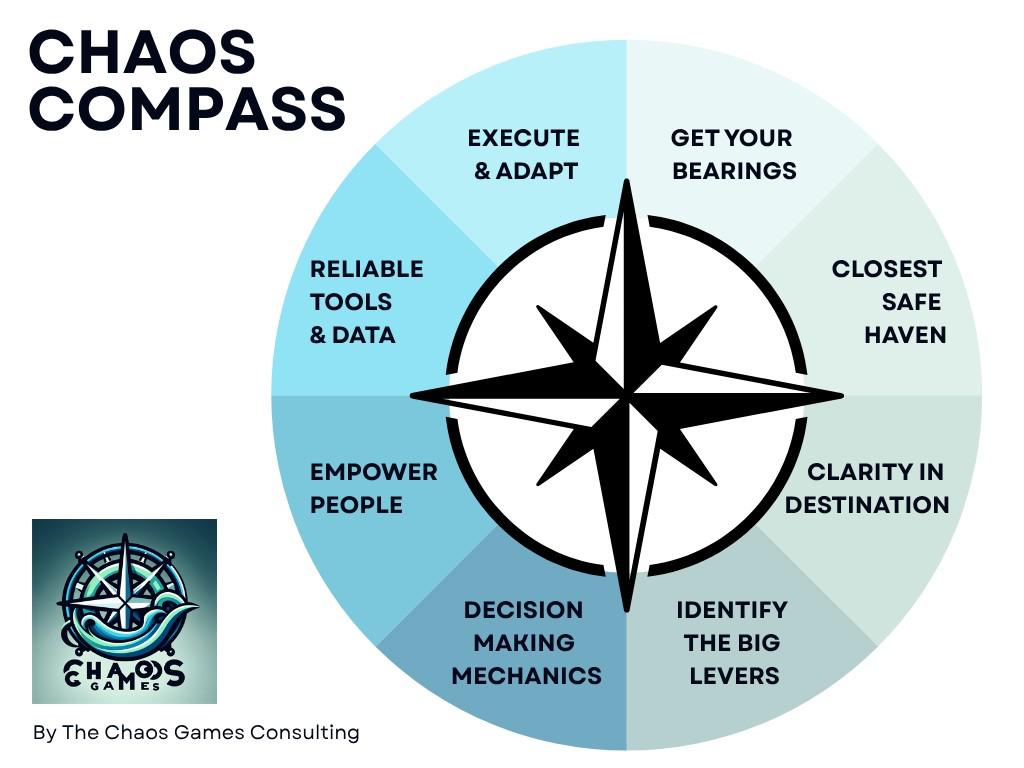

Drifting Isn’t a Strategy: 8 Steps to Stay on Course in Turbulent Times— Maartje van Krieken

2026-2027 AWWA Scholarships Now Open!

Technical Articles

Streamlining Per- and Polyfluoroalkyl Substances Treatment Process Selections— Phil Locke and Meg Simms

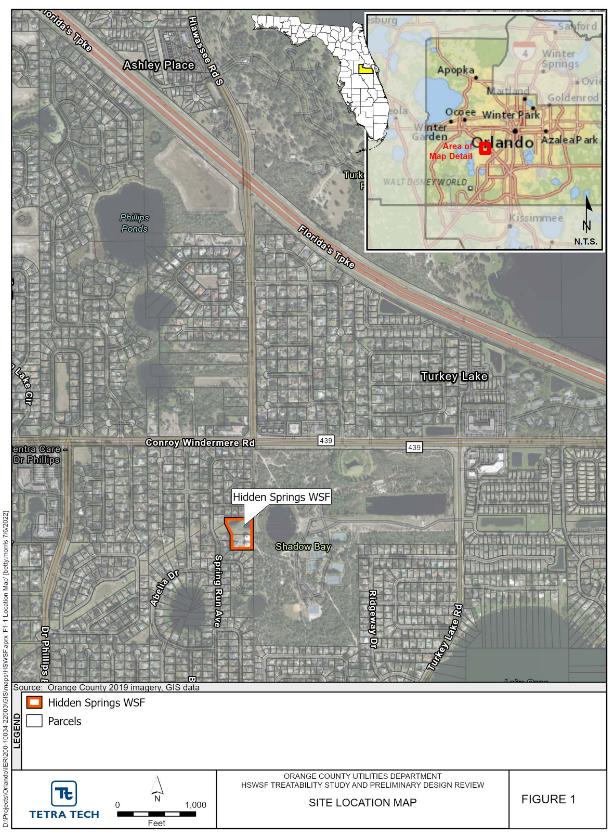

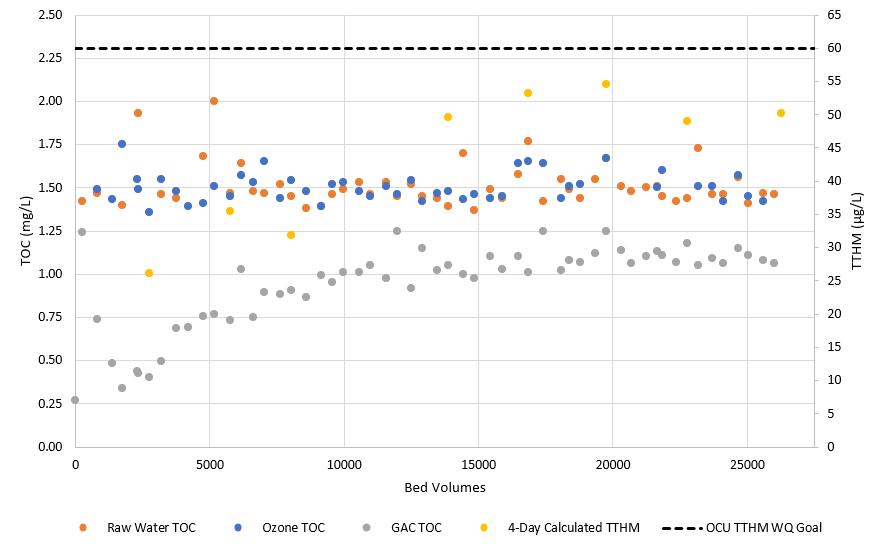

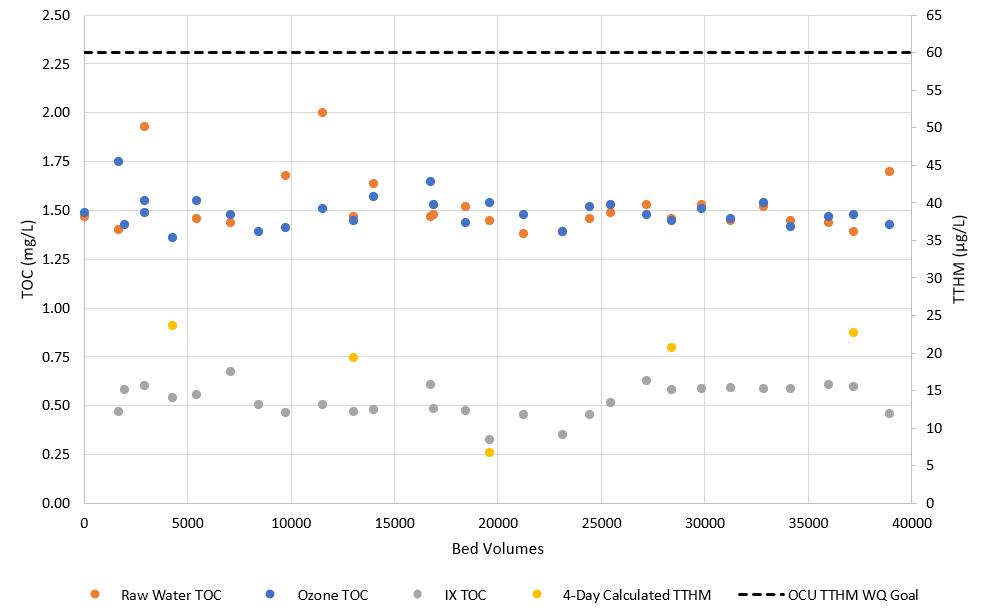

40 Unique Findings of Piloting With Ozone, Granular Activated Carbon, and Ion Exchange in Central Florida—Zach Protas, Jon Bundy, Kathy Traexler, and Austin Humphreys

Education

and Training

CEU Challenge

Fall Conference Schedule of Events

Fall Conference Registration Form

Fall Conference Poker Night, Happy Hour, and Topgolf

FSAWWA Fall Conference Incoming Chair’s Reception and BBQ Challenge

Florida Water Resources Conference

55 FWPCOA Training Calendar

Columns

26 C Factor—Kevin G. Shropshire

30 FWEA Focus—Joan Fernandez

38 Let’s Talk Safety: Quick Equipment Checks for Workers

39 Test Yourself—Charles Lee Martin Jr.

46 FWEA Chapter Corner: Spread the Word!

2026 Florida Water Environment Association

Video Contest—Samar Al Mashrafi and Debbie Sponsler

Speaking Out—Lisa Wilson-Davis

Departments

Classifieds 58 Display Advertiser Index

ON THE COVER: The American flag is a powerful symbol of freedom, democracy, and patriotism, and it represents the unity and values of the American people. It serves as a reminder of the sacrifices made for freedom and embodies the nation’s history and ongoing evolution. The colors of the flag have symbolic meanings: red signifies hardiness and valor, white represents purity and innocence, and blue symbolizes vigilance, perseverance, and justice. The salute to veterans begins on page 18. (photo: Google Images)

Water-AI Nexus Center of Excellence Launches

First-of-its-kind initiative to harness AI to solve critical water challenges

The Water Environment Federation (WEF), Amazon, The Water Center at the University of Pennsylvania, and Leading Utilities of the World announce the creation of the Water-AI Nexus™ Center of Excellence, a groundbreaking collaboration that will develop sustainable water practices for artificial intelligence (AI) infrastructure, while also using AI to solve global water challenges. This knowledge hub at the confluence of water and AI brings together water utilities, technology companies, and researchers to address the complex relationship between digital infrastructure and water sustainability.

The Water-AI Nexus was unveiled during Climate Week NYC, the largest annual climate event in the United States, and focused on two critical missions:

1. Water for AI: Ensuring AI infrastructure uses water as efficiently as possible

2. AI for Water: Leveraging AI capabilities to solve pressing water scarcity and management challenges

The center was also recently featured at the Water Environment Federation Technical

Exhibition and Conference (WEFTEC), held in Chicago in early fall, with three full days of dedicated content, a media panel with the founding leaders, panel discussions with industry experts, and networking opportunities for water and technology professionals.

“Water utilities worldwide are facing unprecedented challenges from climate change and aging infrastructure, while simultaneously working to serve communities that depend on reliable, affordable water services,” said Howard Carter, president of WEF. “The center will accelerate innovation by connecting water professionals with AI experts to develop solutions that benefit both sectors, as well as the communities they serve.”

Key Initiatives of the Water-AI Nexus

The key initiatives of the center include:

Framework Development

The center establishes standards and best practices for water use that can be shared across the data processing industry.

Insight Report

The release of the report, “Principles for Sustainable Water Use by Data Centers,” provides a roadmap for data center operators to minimize water impacts, while maximizing technological advancement. The report outlines four core principles:

S Strategic design and location

S Optimizing operational efficiency

S Using sustainable water sources

S Pursuing water replenishment to deliver water back to communities

Knowledge Sharing

The center will disseminate case studies and research findings through publications and events.

Cross-Sector Collaboration

The center unites water utilities, AI developers, researchers, and government officials. “We believe responsible innovation means both addressing our water footprint and using technology to solve global water challenges,” said Beau Schilz, water principal at Amazon

Continued on page 6

(photo: FWRJ staff)

Continued from page 4

Web Services. “At Amazon, we strive to reduce water use in our operations, which includes logistics sites, such as fulfilment centers, as well as in our corporate offices and grocery stores. We’re also committed to returning more water to communities than we use across our data centers by 2039. Being a founding leader of the center will help not only Amazon in its goals, but others as well, as we aim to collectively transform water management worldwide.”

The center brings together expertise across water, academic, and utility sectors to ensure AI benefits and reduces stress on water resources. By maximizing efficiency, eliminating unnecessary water use, and investing in community-tailored solutions, the sponsors can collectively ensure that technological advancement and environmental stewardship will—and must—move forward together.

“The Water Center at the University of Pennsylvania is proud to bring academic expertise to this critical collaboration,” said Howard Neukrug, its executive director. “By connecting research, industry practice, and policy development, we can accelerate innovations that address water scarcity, while enabling responsible technological advancement.”

Christopher Gasson, publisher of Global Water Intelligence and founder of Leading Utilities of the World, added, “The intersection of water management and AI is a turning point for the sector—both a critical challenge and unprecedented opportunity. The center will be a vital platform where utilities can directly collaborate with technology innovators to ensure water sustainability isn’t compromised by digital growth.”

Sponsors

Amazon

Amazon is guided by four principles: customer obsession rather than competitor

focus, passion for invention, commitment to operational excellence, and long-term thinking. Amazon strives to be Earth’s most customer-centric company, best employer, and safest place to work. For more information, visit www.amazon.com.

The Water Center at Penn

The Water Center at Penn is a communityfocused research center working to find integrated solutions to the multiple challenges facing the world’s water systems and their watersheds. It strives to be a trusted, reliable partner with work that accelerates water equity by connecting, convening, and collaborating across the sector. Its research approach is centered around working alongside communities, bringing their knowledge and expertise to the solutions addressing their water challenges, sharing power and responsibility, and encouraging communities to take the lead in determining priorities, questions to be asked, and the approaches to answering those questions. It also shares resources, education, training, and applied knowledge to support community goals. For more information, visit www.watercenter.sas.upenn.edu.

Leading Utilities of the World

Leading Utilities of the World is a network of the world’s most forward-thinking water and wastewater utilities, as defined by the network’s 14 distinct innovation areas. Its members represent the gold standard of utility innovation and performance throughout the developed world’s water sector. The organization is an initiative of the Global Water Leaders Group, a not-forprofit group helping to tell a better story for water worldwide by recognizing achievement, providing a network for sharing ideas, and inspiring others to improve. Primarily a CEOlevel organization, it’s funded by Jacobs, its foundation partner, and Grundfos, a corporate

member, and collaborates with WEF, its association partner. There are no membership fees for its utilities, which meet three times a year at major water conferences around the world. More information is available at www. leadingutilities.org.

WEF

A not-for-profit, nonpartisan organization, WEF provides water professionals with the latest in education and training. It’s leading the transformation to a circular water economy: reducing waste, recovering resources, and regenerating ecosystems. Founded in 1928, WEF’s mission is to inspire its 31,000 members and 75 affiliated member organizations—and the entire water community—in pursuit of human and environmental wellbeing. Its premiere event, WEFTEC, is the largest annual water quality exhibition in North America, attracting a diverse, global audience. More than 20,000 registrants and 1,000 exhibitors convene there to experience innovative solutions and gain expert insights that positively impact the future of water. For more information, visit www.wef.org.

Organizations across the water and technology sectors are invited to engage in this collaborative effort at water-ai-nexus. org—the central hub for the Water-AI Nexus community.

Media Contacts

Alyson Moses, managing director, marketing and communications, WEF 954-562-7023 amoses@wef.org

David Ward, Global Water Communications, Amazon 610-212-4768 dcdavidw@amazon.com S

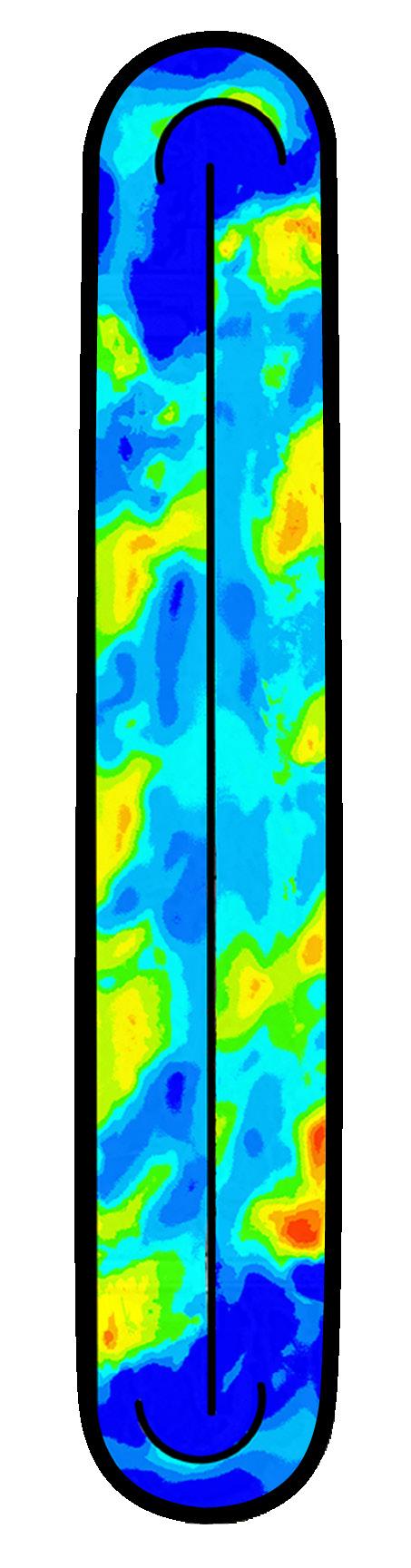

We have more than 60 years of experience in oxidation ditch technology and more than 2000 installations. Lakeside’s CLR process offers a variety of wastewater treatment options, including several operational modes, nitrogen and phosphorus removal, and an adaptable configuration, providing maximum flexibility with consistently high quality effluent. The CLR process is simple to operate and can be configured in several shapes, including the conventional racetrack, folded U-shape or concentric multichannel designs. Lakeside’s staff delivers full service from initial concept through construction to plant operation. The result: reliable results with minimal operator attention and maintenance. When performance counts, count on the industry leader for more than 90 years!

Streamlining Per- and Polyfluoroalkyl Substances Treatment Process Selections

Per- and polyfluoroalkyl substances (PFAS) represent a significant environmental challenge due to their persistence, bioaccumulation, and potential adverse health effects. Often termed “forever chemicals,” PFAS compounds resist breakdown in the environment, leading to contamination of soil, air, and particularly, water sources. This contamination poses a critical threat to public health, with exposure linked to conditions such as cancer, liver damage, and reproductive issues. The ubiquity of PFAS in products like nonstick cookware, firefighting foams, and waterresistant fabrics has further exacerbated their environmental presence.

The U.S. Environmental Protection Agency (EPA) has been grappling with the complexities of regulating PFAS since the early 2000s. Public pressure, legal battles, and increasing scientific evidence have pushed the agency to tighten regulations on these chemicals, culminating in the landmark April 2024 ruling. This new regulation not only sets stringent drinking water standards for PFAS, but also designates perfluorooctanoic acid (PFOA) and perfluorooctane sulfonic acid (PFOS) as hazardous substances under the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), also known as Superfund.

The Superfund designation carries profound implications for industries, municipalities, and water treatment facilities. It mandates the cleanup of contaminated sites and allows the government to recover costs from responsible parties. This regulatory move, combined with new drinking water limits, means that water treatment facilities must now prepare for complex, expensive upgrades to their systems to comply with the regulations by 2031.

This article examines the challenges that the new PFAS regulations pose to water treatment facilities, focusing on the technical, regulatory, and financial complexities of compliance. It provides an in-depth analysis of the available PFAS treatment technologies, discusses the secondary waste streams these technologies generate, and offers a roadmap for streamlining the treatment selection

Phil Locke and Meg Simms

process to meet the 2031 compliance deadline.

Regulatory Background and the Evolution of PFAS Policy

The EPA’s recent regulatory actions on PFAS are the result of over two decades of mounting evidence linking these chemicals to severe environmental and health impacts. The PFAS first came under scrutiny in the early 2000s, with public awareness growing after studies revealed widespread contamination of drinking water supplies in communities near industrial sites and military bases where PFAS-containing firefighting foams were used.

Initially, EPA responded by issuing health advisories and voluntary reduction programs for PFAS manufacturers. In 2006, EPA launched the PFOA Stewardship Program, in which major chemical companies agreed to phase out the production and use of PFOA and PFOS. These voluntary measures, however, did little to address the contamination already present in the environment.

By the 2010s, studies linking PFAS to various health conditions, such as thyroid disease, testicular cancer, and low birth weight, prompted further regulatory action. In 2016, EPA issued a nonenforceable health advisory level of 70 parts per tril (ppt) for PFOA and PFOS in drinking water. This was followed by state-level actions in places like Michigan and New Jersey, which set their own enforceable limits on PFAS in drinking water.

Public pressure for stronger regulation continued to build as lawsuits against major PFAS manufacturers, such as DuPont and 3M, shed light on the extent of the contamination and corporate negligence. High-profile cases, such as the contamination of the Cape Fear River in North Carolina and a site in Decatur, Ala., where thousands of people were exposed to PFAS-contaminated water, fueled the call for federal action.

Finally, in April 2024, EPA took a significant step by designating PFOA and

Phil Locke, P.E., is senior project manager and Meg Simms is an engineer intern with McKim & Creed in Clearwater.

PFOS as hazardous substances under CERCLA. This designation gives EPA the authority to require responsible parties to clean up PFAS contamination, and it enables affected communities to seek compensation for damages. Under CERCLA, any party that has contributed to the release of hazardous substances can be held liable for the costs of cleanup, which can be immense.

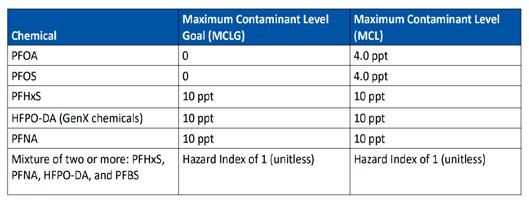

In addition to the CERCLA designation, EPA’s new drinking water regulation sets a maximum contaminant level (MCL) for PFOA and PFOS at 4 ppt, significantly lower than previous health advisories. This new standard forces water systems across the United States to assess their PFAS levels and implement treatment technologies capable of reducing concentrations to the new regulatory limits.

The regulatory landscape is further complicated by the potential for future regulation of additional PFAS compounds. While the 2024 regulation focuses primarily on PFOA and PFOS, other PFAS compounds, such as GenX chemicals and perfluorobutane sulfonic acid, are also under scrutiny. Water systems must therefore consider not only current regulations, but also the likelihood of future rules when selecting treatment technologies.

PFAS Treatment Technologies

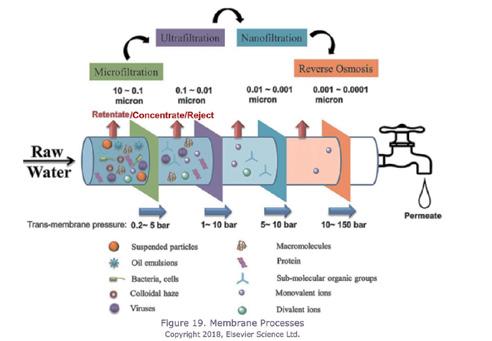

Removal of PFAS from drinking water requires advanced treatment technologies due to the unique chemical properties of these compounds. Traditional water treatment methods, such as coagulation, sedimentation, and chlorination, are generally ineffective at removing PFAS because of their resistance to degradation and the stability of their carbonfluorine bonds. The three main approaches to PFAS treatment—ion exchange, granular activated carbon (GAC), and membrane

Continued on page 10

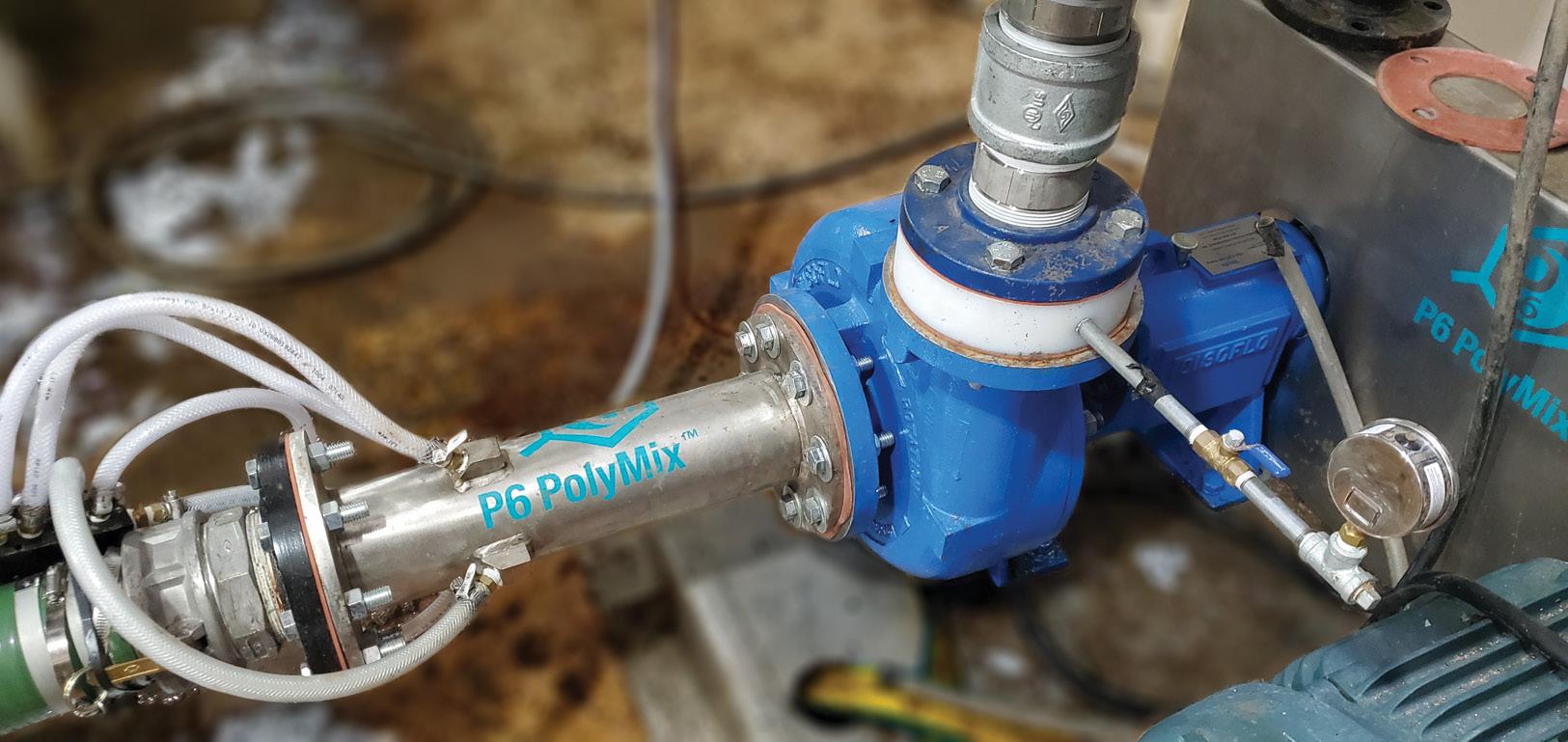

1. POLYMER REDUCTION: P6 PolyMix® Systems reduce polymer consumption by providing complete polymer/sludge mixing in a shear-sensitive manner. This patented mixing process allows long-strand polymer chains to remain intact and unbroken and wastewater floc to remain intact and unsheared. Typical applications result in a 25-50% REDUCTION IN POLYMER CONSUMPTION, thus saving the customer thousands of dollars in polymer expenses. By not breaking up the polymer chains, the dewatering equipment will experience less fouling, providing more reliability and reducing equipment cleaning costs.

2. DRIER CAKE SOLIDS: P6 PolyMix® technology optimizes the polymer and sludge mixing process, allowing INCREASE DEWATERED SOLIDS CONCENTRATION and INCREASED PERCENT SOLIDS CAPTURED. This unique mixing process results in more efficient sludge hauling, allowing customers to transport less water and more dewatered cake off-site.

3. ELIMINATION OF PUMP MAINTENANCE: P6 PolyMix® technology reduces pump parts and maintenance by utilizing the abrasion-resistant Discflo pumping principles of Boundary Layer/Viscous Drag. This principle can save the customer thousands of dollars in parts and maintenance over the lifetime of the equipment. All P6 PolyMix® systems in the municipal market include a 10-YEAR (extendable to 20 years) 100% WET END WEAR WARRANTY, No other pump manufacturer in the industry provides a wear warranty, let alone a 20-year wear warranty!

4. PUMPS & MIXES: P6 PolyMix® technology uses the unique principles of Boundary Layer/Viscous Drag for mixing polymer versus a mixer/check valve; this, paired with its unique InjeX™ polymer injection mixing chamber, is designed for MINIMAL POLYMER DEGRIDATION, allowing for maximum polymer savings. The hydraulic shear forces within the mixing pump provide a complete homogeneous wastewater polymer slurry fed to the dewatering equipment without breaking the long chain polymers or reducing floc size.

5. LOWER OPERATING PRESSURE AND INSTALLED HORESPOWER: P6 PolyMix® technology dramatically reduces the operating pressure by reducing back pressure within the piping system due to eliminating mixer/check valves. In some applications, customers have had a 75% REDUCTION IN PRESSURE Lower pressure allows the feed pump to operate at lower horsepower. HORSEPOWER SAVINGS OF UP TO 50% OR MORE are possible by installing a P6 PolyMix® system. Customers can see substantial long-term energy savings and reduced upfront capital costs associated with lower installed horsepower.

6. HOW IS IT APPLIED: P6 PolyMix® systems entirely replace bulky, expensive, outdated traditional sludge feed pumps. You can now replace thousands of dollars in equipment and regain valuable real estate space by switching to P6 PolyMix® and utilizing its unique compact design, patented process for eliminating mixer/check valves, and ultra-efficient polymer mixing process. Contact us to learn how P6 PolyMix® can revolutionize the efficiency of your BELT FILTER PRESSES, GRAVITY BELT THICKENERS, ROTARY THICKENERS, SCREW PRESSES, AND CRENTIFUGES.

separation such as reverse osmosis (RO)— have emerged as the most viable options for PFAS removal. Each method, however, has its own limitations, cost implications, and challenges in terms of waste management.

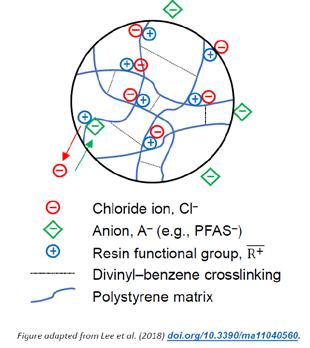

Ion Exchange

Ion exchange involves the use of resins to remove PFAS from water. These resins are typically either anion or cation exchange materials designed to selectively bind with PFAS molecules, effectively removing them from the water stream. Ion exchange works by exchanging ions from the resin for the ions in the water, with the resin binding to the PFAS molecules in place of more benign ions such as chloride or hydroxide.

Process Details

S Water containing PFAS passes through a column filled with resin beads.

S PFAS molecules, particularly long-chain compounds like PFOA and PFOS, are attracted to the charged surface of the resin.

S Over time, the resin becomes “spent” as it becomes saturated with PFAS and other contaminants, and it needs to be either regenerated or replaced.

Advantages

S Ion exchange resins are highly effective at removing both long- and short-chain PFAS, which makes this method versatile.

S The technology is relatively easy to operate and integrate into existing water treatment systems.

S It has a higher removal efficiency for short-chain PFAS compared to GAC.

Limitations

S Regeneration of the resins can be complex, as it requires the use of chemical solutions to wash the resin, generating concentrated PFAS-laden wastewater that must be properly managed.

S Spent resins must either be incinerated (a costly process) or landfilled in hazardous waste sites, further complicating waste management under the new CERCLA regulations.

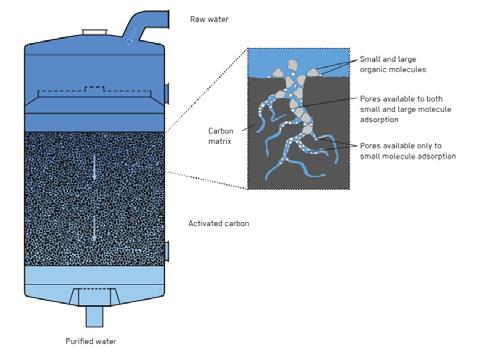

Granular Activated Carbon

One of the most commonly used treatment technologies for PFAS removal is GAC due to its relative simplicity and effectiveness in adsorbing contaminants. It consists of small granules of carbon that have been treated to have a large surface

area, enabling them to adsorb a wide range of organic compounds, including PFAS.

Process Details

S Water flows through a bed of activated carbon granules.

S The PFAS molecules, particularly longchain compounds like PFOA and PFOS, adhere to the carbon surfaces, removing them from the water.

S The GAC bed requires periodic replacement or regeneration as it becomes saturated with contaminants.

Advantages

S The GAC is particularly effective at removing long-chain PFAS, like PFOA and PFOS, which are more hydrophobic and therefore more likely to adsorb onto the carbon.

S The GAC can also remove other organic contaminants, making it a versatile option for treating a variety of water quality issues.

Limitations

S The GAC is less effective at removing short-chain PFAS compounds, which are more mobile in water and less likely to adsorb onto the carbon surface.

S Spent GAC must be either incinerated or regenerated, with the regeneration process requiring thermal treatment at high temperatures, which is both energyintensive and costly.

S Replacement intervals for GAC can be frequent, depending on the levels of contamination, which increases operational costs.

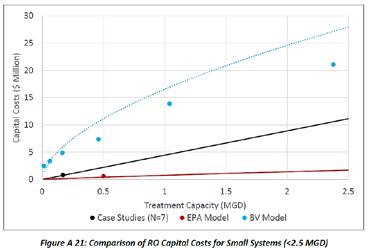

Membrane Separation: Reverse Osmosis

Membrane separation, or RO, is one of the most effective methods for PFAS removal, as it physically separates the contaminants from the water based on molecular size. The RO uses a semipermeable membrane to filter out not only PFAS, but also a wide range of other contaminants, including salts, metals, and organic compounds.

Process Details

S Water is pressurized and forced through a semipermeable membrane.

S The membrane allows water molecules to pass through, but blocks larger PFAS molecules.

S The process generates two streams (purified water and a concentrated brine) that contain PFAS and other rejected contaminants.

Advantages

S The RO is highly effective at removing a wide spectrum of PFAS compounds, including both long- and short-chain varieties.

S It also removes other types of contaminants, making it a comprehensive solution for water treatment systems facing multiple contamination issues.

Limitations

S The RO is energy-intensive due to the high pressure required to force water through the membrane, leading to higher operational costs.

S It generates a significant volume of concentrated brine, which poses a major disposal challenge, especially given the high levels of PFAS concentrated in the waste stream.

S Water loss can be significant, with some systems losing up to 20 percent of the treated water in the form of brine.

Emerging and Alternative PFAS Treatment Methods

In addition to these traditional technologies, several emerging methods show promise for addressing PFAS contamination, particularly with the need for improved management of waste streams and energy efficiency.

Electrochemical Oxidation

Electrochemical oxidation involves using electric currents to break down PFAS molecules in contaminated water. This process offers a promising way to destroy PFAS onsite, potentially eliminating the need for secondary waste streams such as spent resins, GAC, or brine.

Advantages

Electrochemical oxidation can potentially mineralize PFAS, breaking them down into less-harmful components. It could serve as a sustainable long-term solution by avoiding the generation of waste.

Challenges

The technology is still in the early stages of development and requires significant research and pilot testing before it can be implemented on a large scale.

Advanced Oxidation Processes

Advanced oxidation processes (AOPs) use powerful oxidants, such as hydrogen

Continued on page 12

PFAS Regulations

• Determine PFAS MCL levels to balance annual health savings costs with annual PFAS treatment costs:

• Health savings: $1.5B annually

• Initial PFAS treatment costs: $1.5B annually

• PFAS MCL levels established at 4 ppt (i.e., PFOA & PFOS)

• Higher MCL levels would result in lower annual treatment costs

Continued from page 10

peroxide and ultraviolet light, to degrade PFAS molecules. These processes are often used in conjunction with other treatment technologies to enhance PFAS removal.

Advantages

The AOPs have shown potential for breaking down certain types of PFAS, offering a complementary approach to technologies, like GAC and RO.

Challenges

High costs and energy requirements, along with the generation of intermediate byproducts that must be managed, are barriers to widespread adoption.

Adsorption Using Modified Materials

Researchers are investigating novel adsorption materials, such as biochar, carbon nanotubes, and molecularly imprinted polymers, to improve PFAS removal efficiency and reduce the generation of secondary waste.

Advantages

These materials can potentially offer higher adsorption capacity and selectivity for PFAS compared to traditional GAC.

Challenges

While promising, these materials are still largely in the experimental stage, and their large-scale applicability remains uncertain.

Challenges of Secondary Waste Stream Management

While traditional PFAS treatment technologies can effectively reduce PFAS concentrations in drinking water, they all share a common challenge: the generation of secondary waste streams that contain concentrated levels of PFAS. This waste must be carefully managed to prevent further environmental contamination and ensure compliance with regulations. The hazardous substance designation of PFOA and PFOS under CERCLA exacerbates these challenges by introducing legal liabilities and stringent disposal requirements.

Spent Ion Exchange Resins

Spent ion exchange resins represent one of the most difficult waste streams to manage in PFAS treatment systems. Once the resins become saturated with PFAS, they must be either regenerated or replaced, and the disposal of these resins poses significant environmental and regulatory challenges.

Regeneration

Regenerating resins involves washing them with chemical solutions, typically salts or acids, to strip the PFAS from the resin and restore its capacity; however, this process generates a concentrated PFASladen wastewater stream that must be managed. Some systems opt to dispose of this wastewater in hazardous waste landfills, but under the new CERCLA designation, this practice may trigger additional liabilities.

Disposal

If regeneration is not feasible or costeffective, the spent resin must be disposed of as hazardous waste. Given the hazardous classification of PFOA and PFOS, disposal options are limited, and costs are high. Incineration is often required to destroy the PFAS in the resin, but this method is costly and energy-intensive, and the efficiency of incineration in fully destroying PFAS is still being researched.

Used GAC Media

The GAC filters also generate significant waste in the form of spent carbon that is saturated with PFAS. The regeneration and disposal of GAC media represent key challenges in the PFAS treatment process.

Regeneration

Spent GAC can be thermally regenerated by heating it to high temperatures to burn off the adsorbed contaminants. While this process restores the carbon’s adsorptive capacity, it is expensive and energy-intensive. Additionally, some PFAS compounds may not be fully destroyed during the regeneration process, posing a risk of recontamination.

Disposal

Spent GAC that cannot be regenerated must be disposed of in hazardous waste landfills or incinerated. Incineration is costly, and recent studies have raised concerns about the effectiveness of current incineration technologies in completely breaking down PFAS molecules, potentially leading to the release of PFAS into the atmosphere.

Concentrated Brines From RO Systems

The RO systems, while highly effective at removing PFAS, generate a concentrated brine stream that contains the rejected contaminants. This brine represents a significant disposal challenge, particularly for systems with high levels of PFAS contamination.

Treatment Technologies

• Relatively easy column testing

• Can be thermally reactivated (also destroys PFAS)

• Coal-based GAC better than coconut-based for PFAS removal

• High NOM levels reduce runtimes

• Resins targeted for PFAS removal

• Smaller footprint than GAC

• Associated brine stream disposal

• NF effective for long-chain PFAS removal

• NF not effective for chloride / monovalent ion removal

• RO for higher TDS/chloride levels & other contaminants

• RO for increasing TDS/chloride levels Continued on page 14

Volume and Composition

The RO systems typically reject 10 to 20 percent of the incoming water as brine, depending on the system configuration and feedwater quality. This brine contains highly concentrated levels of PFAS, salts, and other contaminants, making it difficult to dispose of in an environmentally responsible manner.

Disposal Options

Options for disposing of RO brine include deep well injection, evaporation ponds, and discharge to a wastewater treatment plant; however, these methods come with significant environmental risks and regulatory constraints. Deep well injection is expensive and can lead to groundwater contamination, while evaporation ponds

require large amounts of land and can lead to air quality concerns. Discharging PFASladen brine to wastewater treatment plants can result in the contamination of sludge, which is often land-applied as fertilizer, further spreading the contamination.

Regulatory Requirements for Waste Disposal

The designation of PFOA and PFOS as hazardous substances under CERCLA has added a new layer of complexity to the management of secondary waste streams in PFAS treatment systems. Facilities that generate PFAS-laden waste are now subject to the requirements of hazardous waste disposal under both federal and state regulations. This includes the need for specialized permits, rigorous monitoring, and liability for contamination that may result from improper disposal.

Selection Criteria and Process

•

•

for some PFAS

• Targeted removal of PFAS through specialized resins

• Smaller footprint than GAC

• Highest level of PFAS removal

• Removes nearly all levels of contaminants (95-99%)

• Removes salts / organics

• Many different types of sorbents

• Renewable sources available

• Many sorbents can be regenerated many times

•

•

•

• Media more expensive than GAC

• Early breakthrough of short-chain PFAS

• Specialized resins do not effectively remove other contaminants

• High waste stream volume

• Increased groundwater supply required

• High energy usage

• Newer technology with limited data

• May take several years until municipalities are comfortable using this technology *Generally, not applicable for Southeast US

Costs and Liabilities

Improper disposal of PFAS waste can result in significant financial liabilities under CERCLA. Responsible parties may be required to pay for the cleanup of contaminated sites, and they may also face penalties for violations of hazardous waste regulations. In addition to these legal risks, the costs associated with proper disposal, particularly for incineration or hazardous waste landfilling, are substantial, placing a heavy financial burden on water treatment facilities.

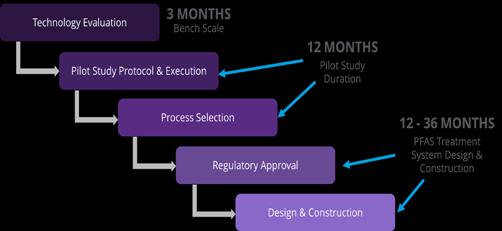

Regulatory and Technical Challenges of PFAS Treatment Implementation

The new PFAS regulations, particularly the hazardous substance designation for PFOA and PFOS under CERCLA, present significant challenges for water treatment facilities. The requirement to comply with the new drinking water limits by 2031 means that systems with elevated PFAS levels must act quickly to design, permit, and implement effective treatment solutions, but the technical, regulatory, and financial hurdles associated with this process are considerable.

Legal Requirements and Timelines

Water systems facing elevated PFAS levels must navigate a complex regulatory landscape to ensure compliance with the new standards by the 2031 deadline. The process typically involves several key steps.

Evaluating PFAS Levels

The first step is to determine the current levels of PFOA, PFOS, and other PFAS compounds in the drinking water supply. This requires extensive sampling and laboratory analysis, which can be time-consuming and costly, particularly for systems serving large populations or with complex water sources.

Identifying Treatment Solutions

Once PFAS levels are known, water systems must select the most appropriate treatment technologies based on site-specific conditions, including water chemistry, flow rates, and budget constraints. This process requires a careful evaluation of the available treatment options, including their effectiveness, operational requirements, and waste management considerations.

Securing Permits

Installing new treatment technologies

Bioactiflo™ Can Handle Your Wet Weather

The Bioactiflo™ system consists of the compact Actiflo® clarification process coupled with rapid soluble BOD uptake achieved when return activated sludge is combined with raw wastewater under aerobic conditions.

The Bioactiflo™ process will remove TSS and BOD achieving secondary standards (85% and < 30 mg/L). Bioactiflo™ is a proven solution for wet weather flow challenges, while providing overall WWTP operational flexibility.

www.veoliawatertech.com

typically requires permits from both state and federal environmental agencies. The permitting process can be lengthy and may involve public hearings, environmental impact assessments, and other regulatory reviews. The hazardous waste designation of PFOA and PFOS under CERCLA adds another layer of complexity to this process, as facilities must demonstrate that they can safely manage the waste generated by their treatment systems.

Developing Engineering Designs

After the selection of treatment technologies and the securing of necessary permits, water systems must work with engineers to develop detailed designs for the new or modified treatment facilities. This includes sizing equipment, designing waste management systems, and integrating the new technologies into existing infrastructure.

Constructing and Commissioning the Facilities

The final step in the process is the

• No additional schedule constraints (i.e., consent order, funding deadlines)

• Multiple processes will be tested

• Larger community with many people / departments

• Larger treatment plant and budget

• Longer client review & procurement periods

• Existing facility in poor condition

• Consent order for TTHM exceedances

• High chloride and TDS levels

• SRF grant with schedule requirements

• Smaller community with ease of access

construction and commissioning of the treatment facilities. This can take several years, depending on the scale of the project and the availability of funding and skilled labor.

Case Study: Implementation of PFAS Treatment Technologies

A notable example of the challenges associated with PFAS treatment implementation is the case of the city of Newburgh, N.Y. In 2016, PFOS was detected in the city’s drinking water supply, which came from a reservoir located near Stewart Air National Guard Base, where PFAScontaining firefighting foam had been used. The city had to act quickly to provide safe drinking water to its residents while also planning for long-term PFAS treatment solutions.

Initial Response

In the immediate aftermath of the PFOS discovery, Newburgh switched to an

Work Plans

alternative water source while evaluating long-term treatment options. The city installed a temporary GAC filtration system to remove PFOS from the contaminated reservoir water and simultaneously worked on plans for a permanent solution.

Long-Term Solution

Newburgh eventually opted to install a combination of GAC and ion exchange systems to provide comprehensive PFAS removal. The city also had to secure state and federal funding to cover the costs of the new treatment infrastructure, which were estimated to be in the tens of millions of dollars.

Challenges

The permitting and design process took several years, and the city faced significant public pressure to expedite the project while ensuring that the selected treatment technologies would provide long-term protection against PFAS contamination. Additionally, managing the secondary waste streams generated by the treatment systems, particularly the spent GAC and ion exchange resins, added another layer of complexity to the project.

Financial Implications for Water Systems

The costs associated with complying with the new PFAS regulations are substantial, particularly for small and medium-sized water systems with limited financial resources. In addition to the capital costs of installing new treatment technologies, water systems must also account for the ongoing operational and maintenance costs associated with these systems, as well as the costs of managing secondary waste streams.

Capital Costs

The capital costs of PFAS treatment systems vary, depending on the technology selected, the size of the system, and the level of contamination. Ion exchange and GAC systems are typically less expensive to install than RO systems, but they generate larger volumes of secondary waste that must be managed, which can increase overall costs.

Operational Costs

The operational costs of PFAS treatment systems include energy costs, chemical costs (for regenerating ion exchange resins, for example), and labor costs for system maintenance. These costs can be significant, particularly for RO systems, which require high energy inputs to operate.

Waste Management Costs

The costs of managing secondary waste streams, such as spent GAC and ion exchange resins or concentrated brines, are a major consideration for water systems. Disposal options for PFAS-laden waste are limited, and the hazardous substance designation under CERCLA further complicates the disposal process by introducing additional legal liabilities and permitting requirements.

Public Relations and Community Engagement

Effective communication with the public is a critical component of PFAS treatment implementation. Water systems facing elevated PFAS levels must be transparent with their communities about the steps they are taking to address the contamination and provide safe drinking water. Public concern about PFAS contamination is high, and water systems must work to build trust with their customers by providing clear, accurate information about the treatment process and the timeline for compliance with the new regulations.

Streamlining the PFAS Treatment Selection Process

Given the time constraints and the complexities of PFAS regulation compliance, water systems must streamline the treatment selection process as much as possible. The selection of the appropriate treatment technology is a critical decision that will have long-term implications for the system’s ability to comply with the new regulations, manage costs, and minimize environmental impact.

Desktop Evaluation

The first step in the treatment selection process is typically a desktop evaluation of the available treatment technologies. This involves gathering data on the effectiveness, costs, and operational requirements of each technology and comparing them against the specific needs and constraints of the water system.

Criteria for Evaluation

Key criteria for evaluating PFAS treatment technologies include capital costs, operational and maintenance costs, effectiveness at removing both long- and short-chain PFAS, ease of operation, waste management requirements, and water loss. Each of these criteria must be carefully weighed to ensure that the selected technology provides the best balance of performance and cost-effectiveness.

Weighted Scoring

In many cases, water systems apply weighting factors to each of the evaluation criteria based on their relative importance. For example, a system with limited financial resources may place more weight on capital and operational costs, while a system located near a hazardous waste landfill may place more weight on waste management considerations. Once the weighting factors are applied, each treatment technology is scored based on its ability to meet the criteria, and the results are used to make a final recommendation.

Pilot Testing and Validation

Once a treatment technology has been selected based on the desktop evaluation, it is often necessary to conduct pilot testing to validate the technology’s performance under real-world conditions. Pilot testing allows water systems to refine the design of the treatment system, identify potential operational challenges, and ensure that the technology will meet regulatory requirements.

Case Studies

Several municipalities have successfully used pilot testing to fine-tune their PFAS treatment processes. For example, the city of Wilmington, N.C., conducted a pilot study of GAC and ion exchange technologies before selecting a combination of the two for its permanent PFAS treatment system. The pilot study helped the city optimize the design of the system and reduce operational costs by identifying the most effective configuration for removing both long- and short-chain PFAS.

Scaling From Pilot to Full Implementation

Once the pilot testing is complete and the treatment technology has been validated, water systems must scale up the design to full implementation. This process involves working with engineers to develop detailed design documents, securing the necessary permits, and constructing the treatment facilities.

Engineering Design Considerations

Key engineering considerations include the size and configuration of the treatment equipment, the integration of the new technology into existing infrastructure, and the design of waste management systems. For example, systems using RO must ensure that they have adequate storage and disposal capacity for the concentrated brine generated by the process.

Project Management and Timeline

The timeline for implementing PFAS treatment systems can be tight, particularly given the 2031 compliance deadline. Effective project management is critical to ensuring that the project stays on schedule and within budget. Water systems must work closely with contractors, engineers, and regulatory agencies to coordinate the various phases of the project and address any challenges that arise during construction.

Conclusion

The new PFAS regulations from EPA, particularly the designation of PFOA and PFOS as hazardous substances under CERCLA and the new MCLs for drinking water, represent a major challenge for water systems across the U.S. Compliance with these regulations requires the implementation of advanced treatment technologies, careful management of secondary waste streams, and significant financial investment.

Water systems facing elevated PFAS levels must act quickly to evaluate their treatment options, secure funding, and begin the process of designing and constructing new treatment facilities. The complexity of the regulatory environment, combined with the technical challenges of PFAS treatment, means that water systems must carefully consider their options and streamline the treatment selection process as much as possible.

While ion exchange, GAC, and RO remain the most viable options for PFAS treatment, emerging technologies, such as electrochemical oxidation and advanced adsorption materials, offer the potential for more sustainable and cost-effective solutions in the future. The long-term success, however, of any PFAS treatment strategy will depend on the ability of water systems to manage the secondary waste streams generated by these technologies and to adapt to the evolving regulatory landscape.

By taking a proactive approach and carefully planning for the future, water systems can navigate the challenges of PFAS regulation compliance and continue to provide safe drinking water to their communities. S

Happy Veterans Day!

Welcome to the magazine’s eighth annual celebration of military service in the United States and the veterans who now work in the water and wastewater industry.

We’re proud to salute these brave and competent men and women who have served—and continue to serve—their country, both here and abroad. They are again helping their fellow citizens by working as water professionals.

Along with medical personnel, police officers, and firefighters, those who work in the water industry are also first responders, providing a vital service to help protect the health and well-being of the community. They are especially vital in times of disaster and crisis, and they provide expertise and support for the recovery efforts that follow—often for weeks and months.

The planet and all living things need water to survive, and the workers in our industry play an important part in ensuring that everyone has the clean, safe water they need.

This year’s section includes:

S EPA Guide: Introduction to Military Occupational Specialties for the Water Workforce

S Memorandum of Understanding

S Reader Profile: Veterans Edition—Arthur Bides

S Honor Walk at Veterans Memorial Park

To the heroic veterans who are now—and to those who will soon be—our colleagues: we appreciate you and salute you! S

EPA Guide: Introduction to Military Occupational Specialties for the Water Workforce

The U.S. Environmental Protection Agency (EPA) and the Department of Veterans Affairs have partnered to connect veterans with careers in the water sector. While serving in the Armed Forces many veterans held Military Occupation Specialties (MOS) that directly or indirectly translate into the types of positions needed in the water sector.

This guide highlights relevant MOS and tips for water and wastewater utilities considering hiring veterans.

What are Military Occupation Specialties?

The MOS is the job title and description used by the Army and Marines to describe each of its jobs. The U.S. Navy and Coast Guard use the term “Rating” and the Air Force uses “Specialty Code.” All of these terms are interchangeable.

Job Qualifications

When a utility is considering a veteran as a potential candidate to hire, knowing their qualifications and experience while serving in the military is important. There are several ways to do this:

S Match the veteran’s MOS with the corresponding page in this guide (see download instructions at the end of the article). This gives information on the water-related MOS, and the skills and duties required.

S You may request that the veteran provide copies of entries into their service record book (SRB), which provide evidence of specific training and qualifications. All branches of the Armed Forces keep records of every formal and informal training that a member receives. This will also cover on-the-job training, which may be the majority of training the veteran has received.

S You may request a copy of the veteran’s discharge papers, known as a DD214. This will provide information on the veteran’s rank, time in service, awards, etc.

S You may also request a copy of the veteran’s verification of military experience and training, known as Form DD2586. Please note

that the veteran may or may not have a copy of this form. It is not standard for veterans to receive this upon discharge. Additionally, this form will only contain “formal” training. All informal training and on-the-job training will be in the veteran’s SRB, which is a more comprehensive way to evaluate skills.

Contacting References

Contacting military references can prove to be very difficult, if not impossible. Most military members transfer duty stations every two to four years, which makes tracking them down a daunting task. Some of the veterans could also have been discharged and moved on to their own civilian careers, making it difficult to obtain updated contact information. When this occurs, there are alternatives:

S All military members are evaluated on their proficiency and conduct every six to 12 months. Some veterans may have copies of their evaluations, which should provide an accurate portrayal of their work skills and general work behavior.

S Award citations will also give the prospective employer a good picture of the veteran.

Jobs in the Water Industry

U.S. Army: Water Treatment Specialist

Overview

Water treatment specialists are primarily responsible for supervising or performing the installation and operation of water purification equipment, as well as dealing with water storage and distribution operations and activities. They also inspect facilities and food supplies for the presence of disease, germs. or other conditions hazardous to health and the environment.

Basic Skills

Water treatment specialists install, operate, and maintain equipment used to provide potable water and perform water quality analysis tests. They perform field water purification and treatment, water quality analysis, and generator and pump operations.

Soldiers ranked private through specialist (skill level 10) assist in water reconnaissance, site preparation, and setup of water treatment activity. They operate and maintain water treatment equipment; receive, issue, and store potable water; and perform water quality analysis testing and verification.

Some of the equipment and systems these soldiers use include:

S Forward area water point supply systems

S Hypochlorination units

S From 125- up to 600-gallon-per-minute (gpm) water pumps

S From 125- up to 3,000-gallon-per-hour (gph) light, medium, tactical (LMT) reverse osmosis water purification units

S From 500- up to a 50,000-gallon capacity collapsible fabric potable water tanks

S 300,000- to 800,000-gallon potable water storage and distribution system

These soldiers carry out the following tasks as part of their duties:

S Perform water reconnaissance (e.g., locating new water sources)

S Conduct water analysis testing

S Complete entries on water reports/logs/forms

S Operate reverse osmosis water purification units

S Setup/operate/dismantle and perform preventive maintenance check and services (PMCS) on ocean intake structure systems

S Operate and perform PMCS on diesel generators, pumps, and air compressors

S Operate and perform PMCS on a well head

S Set up/operate/perform PMCS and dismantle hypochlorination units

S Perform water quality analysis testing and verification

S Perform storage, transportation, and disposal of hazardous material and waste

Continued on page 20

Continued from page 19

Advanced Skills

As soldiers gain more time and experience in this MOS, they will earn the rank of a noncommissioned officer (NCO). These water treatment NCOs are the sergeants, staff sergeants, and sergeant first class and are considered the backbone of the skill and leadership of this MOS.

In addition to mastering the basic skills listed, the major duties for these NCOs are to train, supervise, analyze, and manage the work of the soldiers they lead. In addition to training and supervising junior soldiers, the following are some additional skills in which these soldiers maintain proficiency:

S Sergeants (skill level 20) operate, perform and install water purification equipment, water storage, and water distribution operations and activities.

S Staff sergeants (skill level 30) conduct water reconnaissance, develop water sources and water points, supervise and train soldiers to perform water treatment tasks, perform operator maintenance and inspect operational condition and maintenance of equipment, determine treatment method and treat water for purification, analyze and verify test results of raw and treated water, maintain and inventory water treatment equipment and chemical supplies, and prepare water treatment reports.

S Sergeant first class (Skill Level 40) directs water reconnaissance and water point development for division, corps, and echelons above corps; manages operation and ensures quality control of water supply, storage, distribution and purification activities; performs staff and advisory duties; furnishes reports to headquarters; develops area water supply and treatment plans; and supervises operations.

U.S. Navy: Utilitiesman

Overview

Utilitiesman, also known as seabees, work with plumbing, heating, steam, compressed air, fuel storage, and distribution systems. Their work also includes water treatment and distribution systems, air conditioning and refrigeration equipment, and sewage collecting and disposal facilities at Navy shore installations around the world.

Basic Skills

S Locate and determine quality and quantity of water sources

S Install and operate field potable water treatment and wastewater equipment

S Analyze water for chemical and physical characteristics to determine water purification treatment methods

S Install and maintain systems requiring plumbing and pipefitting skills

S Install, operate, and repair heating, piping, ventilation, and air conditioning systems

S Operate and maintain water and wastewater systems and treatment plants

S Identify and carry out procedures to limit or minimize the adverse effects of environmental pollution

S Interpret blueprints and prepare sketches for projects

S Provide estimates of material, labor, and equipment requirements for projects

Advanced Skills

Advanced utilitiesman are trained to perform more-complex duties as they advance. Some of the main areas and equipment learned include:

S Water treatment and purification

S Sewage treatment and disposal

S Facilities maintenance management

S Blueprint reading and technical drawings

S Planning, estimating, and scheduling

S Advanced base planning

S Planning plumbing projects

S Compressed air systems

S Boilers, ducts, and ventilation systems

S Air conditioning and refrigeration

S Solar energy

S Environmental pollution control

As part of the work advanced utilitiesmen perform with water treatment and purification operations, they learn and use more-specific skills, such as:

S Selecting water sources based on source quantity, quality, and reliability

S Selecting and utilizing water points such as surface water (streams, lakes, rivers), groundwater (wells, springs), seawater, rain, snow, and ice

S Developing water sources

S Determining water contamination

S Analyzing and verifying test results of raw and treated water

S Determining treatment method and treat water for purification

S Selecting, setting up, and operating water treatment equipment including distillation, reverse osmosis, filtration, and disinfection units.

S Emergency treatment methods

S Wastewater and sewage treatment

S Disposing of and monitoring sewage effluents

U.S. Air Force: Water and Fuel Systems Maintenance

Overview

Airmen working in the Air Force’s water and fuel systems maintenance learn many

skills throughout their careers. They work on plumbing, water distribution, wastewater collection systems, water and wastewater treatment systems, fire suppression, backflow prevention systems, and natural gas distribution systems; they also work on and liquid fuel storage, distribution, and dispensing systems.

Basic Skills

S Locate and determine quality and quantity of water sources

S Install and operate field potable water treatment and wastewater equipment

S Analyze water for chemical and physical characteristics to determine water purification treatment methods

S Perform planning activities and quality assurance to include service contracts and facility surveys

S Install, operate and maintain, and inspect and repair natural gas systems, plumbing, water and wastewater treatment systems, fire suppression systems, backflow prevention systems, aircraft hydrant refueling, and ground product dispensing systems

S Monitor systems operation to ensure efficiency and compliance with local, state, federal, and defense department regulations for safety and environmental regulations for hazardous materials

S Perform inspections, preventive maintenance, winterization, and overhaul of systems

S Operationally inspect and diagnose malfunctions in mechanical components using technical orders, manufacturer specifications, local procedures, codes, and directives

S Inspect condition and operation of electrical components

S Conduct fuel system components inspections and maintenance on fuel system piping

S Perform confined space entries to accomplish system maintenance

S Solve complex maintenance problems by studying layout drawings, wiring diagrams, and schematics to analyze, isolate, and troubleshoot system malfunctions

S Remove, repair, and replace defective components

S Install, modify, repair, and maintain a variety of new and existing utility distribution and collection systems and equipment such as sewage, water, gas distribution systems, backflow prevention devices, and fire sprinkler systems.

S Locate and tap main lines

S Coordinate locations of field latrines and pits with engineering and medical staff

S Analyze proposed work to determine resource allocation

S Initiate fuels facility sustainment, restoration and modernization, and military construction projects to include project review, monitoring, and acceptance

S Prepare cost estimates and supply procurement for in-service work

S Apply engineered performance standards to plan and estimate work

S Ensure planning activities comply with environmental, safety, and hazardous materials regulations

Advanced Skills

As airmen advance through the ranks, they increase their expertise and take on leadership roles. As the airmen are promoted, they advance through the following skill levels:

S 3E411 - Helper

S 3e431 - Apprentice

S 3e451 - Journeyman

S 3e471 - Craftsman

S 3e491 - Superintendent

(Note: Superintendents are senior master sergeants holding a community college of the Air Force associates degree. They serve in leadership/management positions and work with budgets, manpower, resources, and personnel management.)

United Services Military Apprenticeship Program:

U.S. Navy, U.S. Marine Corps, U.S. Coast Guard

Program Information

The United Services Military Apprenticeship Program (USMAP) is a formal military training program executed by the Center for Personal and Professional Development, which provides active duty Coast Guard, Marine Corps, and Navy service members the opportunity to improve their job skills and complete their civilian apprenticeship

requirements while they are on active duty. The U.S. Department of Labor provides the nationally recognized "certificate of completion" upon program completion.

Additional Military Jobs That Support Drinking Water and Wastewater Utilities

There are additional MOS in the Armed Forces that are not directly related to water treatment, but are relevant for some of the positions found at water and wastewater utilities. Some examples of these additional MOS include:

S Electricians: All of the branches of the Armed Forces have some type of electrician MOS or rating.

S Heavy equipment operators: Heavy equipment operators of all kinds can also be found in any branch of the military.

S Mechanics: Mechanics of all types can be found in every branch of the Armed Forces, including small generator mechanics, automotive and aircraft mechanics, and mechanics working on some of the largest engines in the world aboard ships.

Additional MOS may include jobs such as:

S Contracts and procurement

S Budgeting

S Administration

S Management

S Topographic surveyor

S Electronics repair

S Quarrying specialists

S Plumbers

S Laboratory technicians

S Computer and network administrators

S Metal workers

The entire guide can be found at water.epa. gov/infrastructure/sustain/ws_workforce.cfm.

Resource Links

• Department of Veterans Affairs (Vet Success): www.vetsuccess.va.gov/public/ military_ skills_translators.html

• Work for Water: http://www.workforwater. org/ American Counsel on Education: www. acenet.edu/news-room/Pages/Military-Guide Online.aspx

• United Services Military Apprenticeship Program: www.usmap.cnet.navy.mil/usmapss/ static/trades.jsp S

MEMORANDUM OF UNDERSTANDING BETWEEN DEPARTMENT OF VETERANS AFFAIRS

VOCATIONAL REHABILITATION AND EMPLOYMENT SERVICE AND U.S. ENVIRONMENTAL PROTECTION AGENCY OFFICE OF GROUND WATER AND DRINKING WATER OFFICE OF WASTEWATER MANAGEMENT

Promoting a Veteran Workforce for the Water Sector

A well-trained and knowledgeable workforce is vital to protecting public health and the environment, and ensuring the long-term sustainability of water and wastewater systems. For this reason, predicted losses to the water and wastewater workforce due to baby boomer retirements raise concerns. The report, Succession Planning for a Vital Workforce in the Information Age (2005), published by the American Water Works Association (AWWA) and the Awwa Research Foundation, projected that 37 percent of water utility workers and 32 percent of wastewater utility workers will be eligible to retire in the next 10 years. In addition, the U.S. Department of Labor estimates that the need for water and wastewater operators will increase by 20 percent.

Veterans represent a major recruiting opportunity for water and wastewater utilities. Prior military experience gives veterans an understanding of teamwork, discipline, and personal accountability that can make them excellent employees for these fields. In addition, many veterans already possess technical skills and training that are directly transferable to careers in the water sector.

A. Purpose

The Department of Veterans Affairs (VA) Vocational Rehabilitation and Employment (VR&E) Service and the U.S. Environmental Protection Agency (EPA) agree to work jointly on promotional activities that will help advance and improve employment opportunities for veterans with disabilities while supporting the development of a trained and competent workforce for the water sector. Both VR&E Service and EPA believe that working closely together can improve employment outcomes for veterans with disabilities while helping to address predicted losses to the water sector workforce.

This memorandum of understanding (MOU) establishes the framework for VR&E Service and EPA to encourage their respective departments, offices, and stakeholders to work cooperatively to promote water sector careers, educate stakeholders about VR&E programs, and provide improved services to their mutual partners. This agreement does not compel EPA or its partner organizations in the water sector to hire veterans; however, this document encourages the development of connections among employers in the water sector, EPA, and VR&E Service to facilitate the placement of veterans with disabilities into this essential employment sector.

B. Terms

VR&E Service will assign a point of contact (POC) liaison that will share information and coordinate activities to carry out and support the objectives of this MOU. Specifically the VR&E Service POC will:

• Serve as the contact person for state and local water sector employers interested in hiring veterans to provide information and guidance regarding joint VR&E and EPA activities.

• Work with EPA POC to create greater awareness of opportunities to employ veterans with service-connected disabilities within the water sector.

• Work with EPA POC to construct new lines of communication to

inform veterans with service-connected disabilities about training and employment opportunities offered in the water sector.

• Identify and encourage partnership opportunities between water sector partners and VA regional offices, including connecting VR&E employment coordinators (points of contact) with water sector stakeholders at the state and local level.

• Create a learning opportunity to share information crucial to these joint promotional activities. This includes information about VR&E programs, as well as workforce-related information such as position types, education, and skill sets required.

The EPA will assign a POC liaison who will share information and coordinate activities to carry out and support the objectives of this MOU. Specifically, the EPA POC will:

• Serve as a contact person to provide information and guidance regarding joint VR&E and EPA activities.

• Work with VR&E POC to create greater awareness of opportunities to employ veterans with service-connected disabilities within the water sector.

• Work with VR&E POC to construct new lines of communication to inform veterans with service-connected disabilities about training and employment opportunities offered in the water sector.

• Identify and encourage partnership opportunities between water sector partners and VA regional offices, including connecting VR&E employment coordinators with water sector stakeholders at the state and local level.

• Create a learning opportunity to share information crucial to these joint promotional activities. This includes information about VR&E programs, as well as workforce-related information such as position types, education, and skill sets required.

This agreement does not in and of itself authorize the expenditure or reimbursement of any funds, and nothing in this agreement obligates either party to expend appropriations or other funds, or to enter into any contract or other obligation. This agreement does not create any right or benefit, substantive or procedural, by persons who are not party to this agreement. This agreement does not apply to any person outside of VRE and EPA.

Further, this agreement will not be interpreted to limit, supersede, or otherwise affect either party’s normal operations or decisions in carrying out their mission or statutory or regulatory duties. This agreement does not restrict the parties from participating in similar activities or arrangements with other entities.

This agreement will become effective upon the date of signature of the parties and will remain in effect until terminated by either or both parties, but will be jointly reviewed at five-year intervals from the date of signature. S

FWRJ READER PROFILE: VETERANS EDITION

Arthur Bides, P.E.,

ENV SP, Associate DBIA Arcadis, Jacksonville

Work title and years of service.

I’m principal water engineer at Arcadis and have 12 years of experience in the water/ wastewater field.

Give some details about your military service.

I served six years in the Marine Corps and Marine Corps Reserves in Aviation Ordnance and eight years in the Florida Army National Guard as an engineer.

What does your job entail?

As a principal water engineer I lead technical delivery of water-related projects,

providing expertise in water supply, wastewater, drainage, and/or flood risk management. I manage multidisciplinary teams, ensure highquality client outcomes, support business development, and mentor junior staff.

What education and training have you had?

I have a bachelor of science degree in civil engineering from the University of Florida, a master’s degree in public policy from Jacksonville University, and a master’s degree in building construction from Auburn University.

What do you like best about your job?

What I like best about my role is the ability to make a tangible difference in my community—delivering innovative and sustainable water solutions that benefit both people and the environment, while working with a passionate team and continually developing my expertise.

What professional organizations do you belong to?

I belong to FWEA and FSAWWA.

How have the organizations helped your career?

Both FSAWWA and FWEA have been instrumental in my professional development, providing access to cutting-edge knowledge, valuable networks, and leadership opportunities. Their support has strengthened my technical expertise, enhanced my industry reputation, and empowered me to deliver innovative, sustainable water solutions for our communities.

What do you like best about the industry?

What I enjoy most about the water industry is its unique blend of societal importance, environmental stewardship, technical challenge, and continuous innovation. It’s a sector where every project matters—and where your work can leave a lasting positive legacy.

How has your time in the military affected your career in the industry?

My military experience has shaped me into a resilient and adaptable leader. These qualities have enabled me to manage complex projects, build effective teams, and deliver sustainable solutions in the water industry—always with a focus on service, safety, and excellence.

What do you do when you’re not working?

My hobbies are scuba diving and woodworking. I volunteer as the president of the Filipino American Jacksonville Chamber of Commerce, as well as volunteering as membership chair and veterans liaison for FSAWWA Region II. S

Honor Walk at Veterans Memorial Park

The Honor Walk at Veterans Memorial Park, located at Beacon Hill between Port St. Joe and Mexico Beach, was constructed directly on the bluff overlooking Highway 98 and the Gulf of Mexico. This beautiful setting provides a very fitting place to pay tribute to those men and women who are and have served the United States so faithfully.

In 2017 a committee of patriotic citizens and local veterans started planning and fundraising for the Honor Walk. A portion of the funds needed to create the walk came from friends and family members who chose to use this beautiful park to honor or memorialize a special veteran in their life with the Engrave a Brick program.

While the walk was funded in part by the brick program, the bulk of the funds required to make this beautiful park a reality came from the generous contributions of private citizens, organizations, and community-minded corporate partners. These American patriots— individuals, businesses, and companies—joined arms to assure that generations to come will honor the sacrifices these veterans have made to provide and protect American freedoms.

The centerpiece of the area is a large, lighted American Flag atop a flag pole 70 feet in height, with a gorgeous memorial below of the pavers honoring local veterans.

The park includes a beautiful amphitheater honoring the armed forces. There are also playgrounds, beach access, pavilions, a large dog park, and pickleball courts.

The entire honor walk area includes appropriate lighting to accommodate evening visitors. The perimeter of this special area of the park is surrounded by a low black iron fence with stone columns. The existing sidewalk that connects the parking to the beach boardwalk provides access to the walk area. Nine granite benches are strategically placed to provide visitors a place to rest, reflect, and enjoy the spectacular view of the gulf.

At the base of the American flag pole is a large five-point star set in a pentagon. Each facet of the star holds a monument stone towering 8 feet in height, 3 feet wide, and 12 inches thick— one monument to represent each branch of the service. The monument stones are anchored by black stone bases 40 inches long, 16 inches wide, and 12 inches high. Extending out from

opposite sides of the center base are two 20foot brick paver walkways. These walkways terminate with monuments placed in the center of smaller pentagon bases. The names of Gulf County veterans killed in action are engraved into one of these monuments. Extending out from the honor walk area toward the gulf is a semicircle wall of stone topped by five flag poles 50 feet in height, displaying the flags of each of the five branches of service. Memorials are included for the following wars:

S Vietnam

S Persian Gulf

S Panama

S World War II

S Lebanon/Grenada

S Korea

S World War I

The Honor Walk Committee, Gulf County Board of County Commissioners, is the organization responsible for installation of the Honor Walk. It was officially dedicated on Veterans Day, Nov. 11, 2020. S

Another Avenue of Training

Kevin Shopshire President, FWPCOA

all is all around us here in Florida.

The other day I saw a palm frond had browned and fallen from the tree; then, the thermostat hesitated a couple of hours before reaching the eighty-degree mark. I’d say it was breathtaking, but that was due to the ever-slightly-reduced humidity, laced with pollen.

I’ve been writing this year mostly about avenues of self-improvement. One of my topics was the ability of utilizing networking as a training source. Through in-person networking, you have the ability to establish a network of not just colleagues, but friends. I am happy to say I’ve established many friendships over the years through networking events, whether municipal colleagues, consultants, salespersons, or other water personnel.

One such friendship is with a sampler company’s sales representative. I won’t mention the company by name, as I’m not sure of their advertising status with this publication. I’ve known of this company almost the entirety of my pretreatment career. I’ve seen the company change names,