WHAT DOES ARTIFICIAL INTELLIGENCE MEAN for the forest industry?

CANADA’S TOP LUMBER PRODUCERS! Who’s on top?

SHOW PREVIEWS:

u Interior Logging Association

u BC Saw Filers

DENT CONSTRUCTION:

The big job of clearing for the Trans Mountain

March/April 2024 ON THE CUTTING EDGE OF INDUSTRY INNOVATION WITH THIS ISSUE... Visit LSJ’s website at www.forestnet.com

Pipeline expansion project

FEATURES

On the Cover:

It’s not often that a company has the opportunity to be involved with one of the largest construction projects in Canadian history—and for Jim Dent Construction (DENT), that opportunity has meant the last several years have been extremely busy, with the B.C.-based company being a key clearing contractor on the $31 billion Trans Mountain Pipeline expansion project. Read all about the work DENT did on the pipeline project beginning on page 10 of this issue (Cover photo courtesy of DENT Construction).

4 Spotlight

Artificial Intelligence (AI): What does it mean for the forest industry?

Major mill equipment companies are already employing AI in their equipment and processes, and it has the potential to deliver benefits to sawmills.

10

Clearing for Canada’s energy future

B.C.’s DENT Construction has been involved with some of the biggest construction jobs in B.C. in recent years, including clearing work for one of the largest construction projects in Canadian history—the Trans Mountain Pipeline expansion project.

18 Upgraded technology for Truro

An upgrade to the J.D. Irving sawmill in Truro, Nova Scotia is delivering increased recovery thanks to enhanced scanning and positioning technology.

22 Interior Logging Association: Jampacked schedule

B.C.’s Interior Logging Association offers a full meal deal with its AGM, convention, trade show and social activities, being held this year in Kamloops from May 9 to 11.

24

26 Canada’s Top Lumber Producers!

Logging and Sawmilling Journal’s authoritative listing of Canada’s Top Lumber Producers, produced in association with leading forest industry consultants FEA, reflects the changes that took place in the industry in the last year—with West Fraser and Canfor remaining the country’s top lumber producers.

32 Canadian success story — Cannon Bar Works

In a new feature in Logging and Sawmilling Journal, we focus on successful forest industry business stories, and the people behind those businesses. This issue, we look at Cannon Bar Works, which has been providing chainsaw users with high quality chainsaw bars since 1955, and its, President, Bill Challenger.

41

BC Saw Filer’s coming up in Kamloops

The sawmill side of the B.C. forest industry is facing challenges, such as a shortage of fibre and tough lumber markets, but there remains a strong need for the skilled workers, such as saw filers, that keep B.C. mills producing efficiently, and these topics and others will be discussed at the BC Saw Filer’s Convention being held May 24 to 25 in Kamloops, B.C.

46

The Last Word

Forest management must change to adapt to climate change or the industry will falter, says Tony Kryzanowski.

Logging & Sawmilling Journal - March/April 2024 3

on research

the

industry,

from the Canadian Wood Fibre Centre (CWFC). March/April 2024 Volume 55 • No. 2 Editor Paul MacDonald Contributing Editors Jim Stirling, Tony Kryzanowski George Fullerton Tech Update Editor Tony Kryzanowski Publisher/CEO Anthony Robinson • (778) 991-3500 E-Mail: arobinson@forestnet.com Associate Publisher Hannah Robinson • (778) 688-9127 E-mail: hannah@forestnet.com Social Media: Kaitlin Davidson Digital Marketing: Hannah Robinson Email: hannah@forestnet.com Subscription Enquiries (604) 990-9970 Fax: (705) 434-9052 E-mail: SubscribeLSJ@forestnet.com Design & Art Production Manager Sheila Ringdahl E-mail: artwork@forestnet.com Accounting Manager Shelina Jessa • (604) 731-1535 E-mail: accounting@forestnet.com Office P.O. Box 86670 North Vancouver, BC V7L 4L2 Phone: (604) 990-9970 Website: www.forestnet.com Subscriptions: Canada $58 a year; two years $70; three years, $85. Group accounts, six or more subscriptions, $25 per subscription per year. Outside Canada, $95 per year. Airmail $165. Single copy, Canada $6; elsewhere $10. Reproduction prohibited without permission of the publisher. ISSN 0226-7572. Back copies from 1996 onward are available through

website

Publications Mail Agreement No. 40064045 Return undeliverable Canadian addresses to CIRCULATION DEPT. PO Box 86670 Stn Main North Vancouver BC V7L 4L2 e-mail: SubscribeLSJ@forestnet.com POSTMASTER: Send US address changes to LSJ Publishing Ltd., PO Box 610, Edmonds, WA 98020-0610 Published March/April 2024 “We acknowledge the financial support of the Government of Canada” Logging & Sawmilling Journal is a member/associate member of the following industry organizations: DEPARTMENTS Calendar .......................................... 8 Tech Update................................... 38 Suppliernewsline 42 Ad Index/Subscriptions 45 Classifieds ..................................... 45

Included in this edition of The Edge, Canada’s leading publication

in

forest

is a story

our

www.forestnet.com

Printed on FSC®certified paper.

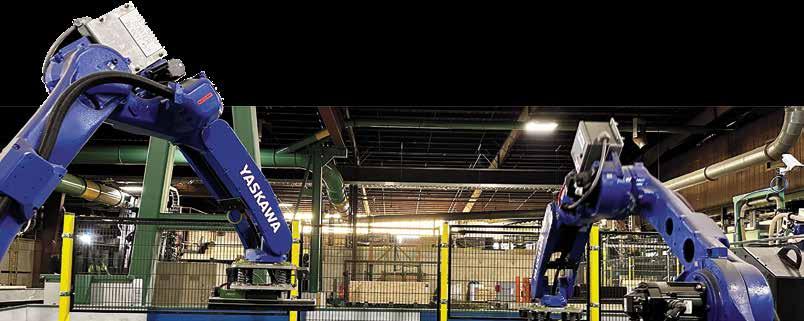

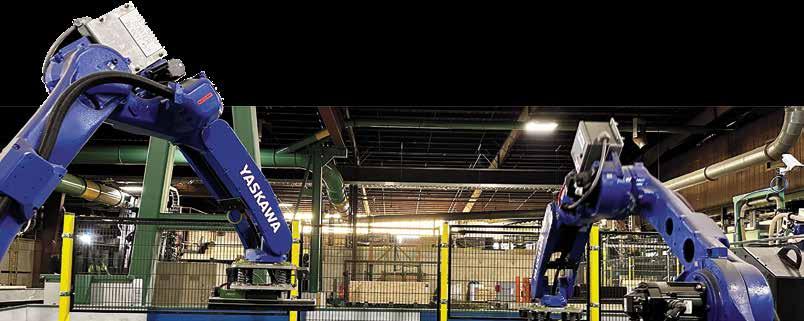

ARTIFICIAL INTELLIGENCE

(AI) is already at work in the forest industry

There is a lot of buzz out there about Artificial Intelligence, but AI-enabled systems are already improving sawmill performance in the Canadian forest industry—and there is plenty more to come.

By Tony Kryzanowski

By Tony Kryzanowski

First, it is important to note that Artificial Intelligence (AI) systems working today in Canada’s wood product manufacturing facilities—to monitor and optimize lumber production—are not ‘AI Chatbot’, which is so much in the news these days.

In the forestry sector, human programmers are using high quality data supplied by sawmills to train their own proprietary AI systems to execute specific actions, recognize problems, provide optimal solutions, and implement solutions with minimal human intervention.

These systems are machine centre-specific, meaning that a sawmill could have one Comact-branded AI system from BID Group optimizing their primary breakdown, one system from USNR optimizing their edger, a system from Carbotech optimizing their trimmer, and another one from Autolog optimizing lumber grading. But we aren’t too far removed from the

fully interactive HAL 9000 computer that became famous in the 1968 science fiction movie, 2001 A Space Odyssey. What was science fiction is now science fact.

“This is just the beginning,” says Diego dos Santos, Applied Artificial Intelligence Manager at the BID Group. “I see the wood products manufacturing sector being completely transformed and autonomous over the next 10 years, running at its best efficiency with the least operators possible, deploying smart systems using AI across the entire production line and providing operators with data to facilitate their decision making.”

That sentiment over AI’s growing influence within the sawmilling sector is shared by Scott Norton, Senior Vice-President for Automation Solutions at equipment manufacturer and installer, USNR.

“We are still in the process of determining where and when to apply an AI solution,” he says, “so I expect that 10 years from now, we will see AI-based so -

lutions that no one imagined today.”

For those companies still not engaged or on the fence about installing AI-based systems, there soon may be no alternative for the highest quality equipment.

“I think in 10 years from now, a big portion of the sawmills, if not all of them, will be equipped with AI-powered systems if they want to stay in business and keep up with the new technologies,” says Eric Michaud, Vice-President of Sales and Marketing at the Carbotech Group, which also owns Autolog.

“Most of the manufacturers will use it on a permanent basis on their optimization systems and eventually on their PLC or automation program,” he adds.

AI systems currently working in the wood product manufacturing sector are not meant to replace workers, but to allow existing employees to work more efficiently. It can also help companies faced with the challenge of chronic labour shortages to plug a hard-to-fill employee

4 Logging & Sawmilling Journal - March/April 2024

spotlight

position, as long as there is an AI system able to carry out that same task.

In some cases, it could literally save some sawmills from closing in more remote areas, where workers are particularly hard to find. And it could also help to attract young, more tech-savvy employees to the forestry sector.

In today’s increasingly automated world, the introduction of AI-enabled systems, including robotics, primarily aims to enhance precision, productivity, and safety, particularly in labour-intensive environments. While these innovations fill roles often deemed less satisfying due to their repetitive natures, the transition may lead to job displacement in rare cases where current employees find it challenging to adapt to new skills and tasks.

Since becoming part of the product offerings of several industry suppliers, there is no doubt that AI systems have delivered results that are transforming the lumber industry. That’s because properly trained AI-enabled decision-making systems have proven to be more accurate, reliable, significantly faster and more dependable than human beings in such functions as log management, lumber production, dimension and species identification and sorting, waste reduction, kiln drying, grading and planing.

“In the context of production lines going faster than ever, it would be impossible for humans to see and analyze all the defects that a grading system with vision and AI can do,” says Michaud. “They are more precise and more consistent.”

This is just the tip of the iceberg. It can also create a safer work environment, where a camera and an AI system can monitor production in dangerous environments, detect problems, and stop production or solve those problems without human interaction, for example, if a log or board is out of position, and even dangerously out of position, on a sorter, merchandizer or trimmer line.

It is not too far-fetched to think about one AI system capable of operating an entire sawmill with minimal human interaction. In fact, the BID Group is working on a system right now that can analyze the health of an entire sawmill, identify bottlenecks, and recommend changes in a fraction of the amount of time compared to current human-based, quality control methods. It also offers an AI system that can analyze data from two machine centres that operate AI programs from two different manufacturers, for customers to plan and problem solve specific issues related to its manufacturing process.

USNR is also working in the same space.

“All of our lumber grading products now include DNN (Deep Neural Networks) for defect classification—well over 100 systems,” Norton says. “These tools are superior to traditional algorithm-based solutions. We are now investigating other AI technologies to evaluate mill-wide data trends and solve other problems.”

What everyone agrees upon is that the whole AI landscape insofar as applications within the sawmilling sector is evolving.

“In some areas, our industry is quite

advanced in the usage of AI technologies,” says Norton, “but in others, we are just getting started. Our industry is quite advanced at using AI for lumber grading, but there are a lot of advances to come in data mining to improve operational flow.”

“AI is getting powerful so rapidly, the potential of it is extraordinary and scary at the same time because of its insane quick progression,” says Michaud. “AI is becom-

to page 6

LET US ASSIST YOU WITH YOUR LOG PROCESSING PROJECTS

Logging & Sawmilling Journal - March/April 2024 5

spotlight

STREAM FEEDER LOG TURNER LOG OPTIMIZER LOG MERCHANDISER carbotech.ca | autolog.com

from page 5

ing so powerful, we don’t see the end of this ascension—so who knows where we’re going with that?”

There are many specific AI system applications already available. Here are some examples:

• Improving the debarking process through wood species classification to tailor debarker settings and employing residual bark detection for closed-loop feedback adjustments;

• Better products sorting for enhanced

drying and grading process through wood species classification of boards;

• Optimal auto grading process through natural and manufacturing wood defects detection and classification;

• Enhancing quality control by identifying the cutting tool that has sawn the boards when there needs to be an adjustment because boards are off-size;

• Better process monitoring to identify production anomalies and issues that could generate long downtime periods, break mechanical equipment, or possibly injure an employee;

• And, management of robotic functions.

So, AI in lumber production is here and will only become more prevalent and advanced. For some companies, the question is where to start with the minimal amount of risk and smallest capital investment to learn more about it and evaluate its performance.

There are several companies today that can provide a one-stop solution to install these types of systems—all sawmill owners need to do is provide the financing. According to dos Santos, it’s a common misconception that transitioning to AIenabled systems is smoother and more cost-effective for already modernized sawmills with existing optimizations. Even less modern sawmills can successfully integrate AI technologies, potentially leveraging unique approaches and customizations to bridge technology gaps.

One of the least expensive systems for a company to get a feel for AI is a monitoring system, he adds, for use on one part of the production line, like the wave feeder, to monitor the log gap leading into the primary breakdown unit in an effort to maximize sawing productivity, because it often only requires one computer and one camera. Should a client appreciate and understand the results, they can then focus on bottlenecks in their manufacturing process and tackle one challenge using AI-enabled systems, evaluating training requirements and the return on investment (ROI).

A common concern is how quickly current AI systems could become obsolete. It’s important to understand that customers have the option to retain their existing version, which continues to perform effectively, while upgrades are available for those seeking enhanced capabilities. The biggest cost will be the initial hardware installation.

“The first client that bought AI from us in 2018, they still haven’t had to update any computers,” says dos Santos. “The decision to upgrade depends on whether the system meets your needs or if you identify areas for enhancement. In most cases, we simply update the software. Depending on the computer’s capabilities, we might add more power, such as extra memory or GPU cards to expand functionality. Our goal at BID Group is always to fully leverage and enhance the current hardware before considering more significant upgrades.”

Norton says—and others agree—that in the near term, equipment manufacturers

to page 8

6 Logging & Sawmilling Journal - March/April 2024

light

spot

spotlight

from page 6

will focus on AI-based purpose-built solutions once a company identifies a bottleneck, emphasizing that AI-based solutions are only the latest of many tools that companies like USNR can bring to the table. At present, it still hasn’t become an all-or-nothing proposition for companies.

“The traditional approach to capital expenditure is still a good approach—using vendors like USNR to help identify areas for improvement and the ROI that these technologies can achieve,” he says. “At USNR, we see AI as the newest, but still one of many tools that we can apply to a problem.”

CALENDAR

April 30 / May 1

Ontario Forest Industries Assoc. Annual Convention, Toronto, ON 416-368-6188, www.ofia.com

May 9-11

Interior Logging Assoc. Conf. and AGM, Kamloops, BC 250-503-2199, www.interiorlogging.org

May 17-18

Expo Richmond 2024, East Coast Logging & Equipment Exhibition , Richmond VA 804-737-5625

www.exporichmond.com

May 24-25

BC Sawfilers AGM and Trade Show, Kamloops, BC 250-260-1231, www.bcsfa.ca

June 4-6

Maritime Lumber Bureau AGM, Charlottetown, PEI 902-667-3889

www.mlb.ca

Computer-based lumber grading systems delivered the first taste of what AI-enabled systems could achieve

Artificial intelligence-enabled monitoring and optimization systems, currently sweeping the Canadian forest sector, have become more prevalent over the past decade.

The first hint that AI was knocking at the door of the forest industry was when computer-based lumber grading systems using machine learning entered the market from companies like Comact and Autolog around 2006.

Today, AI systems have advanced beyond machine learning to become deep neuro networks. AI deep learning-powered products started to become available through companies like the BID Group and USNR in a big way around 2018. Today, the BID Group has about 20 separate and specific optimizing and monitoring AI system applications from the mill infeed to the outfeed, and capable of performing specific tasks according to a client’s needs. Across a multitude of BID Group systems in the market, over 250 are currently operational with AI-enhanced features.

“With a deep neuro network, a computer will use data (inputted initially by a programmer for training) to learn to perform a specific task, and if there are errors and the AI system is alerted to those errors with better data, the AI system will find ways to fix the errors on its own. It will develop its own algorithm, and the user only needs to provide good data to make the corrections,” says Diego dos Santos, Applied Artificial Intelligence Manager at the BID Group.

The critical factor for these systems to work properly right from day one is for wood product manufacturing facilities to provide very high quality data to train the AI system as well as for correcting errors should they crop up down the road, dos Santos adds. Since the supplier incorporates AI into their equipment and proprietary programs, there’s no need for customers to have internal AI expertise or knowledge. The idea is to use customer’s data to tailor the AI application to the customer’s needs, as there is no one-size-

fits-all in wood processing.

“As the old saying goes, ‘garbage in, garbage out,’” says dos Santos. “The system’s accuracy depends on the quality of the data provided, which is supervised by humans. Once a system is consistent and providing good results, it will not try to continue learning and develop bad habits by itself. We tell it to continue learning only with new data that we provide.”

USNR has also been a pioneer developing AI-based systems.

“USNR has been installing AI systems for about 10 years,” says Scott Norton, Senior Vice-President for Automation Solutions at USNR. “Virtually every sawmill or planer mill in North America with automated lumber grading or defect recognition has AI installed today. In 10 years, it has changed from almost no one providing an AI-based solution to everyone supplying an AI-based solution. Our customers have benefitted from higher accuracy.”

8 Logging & Sawmilling Journal - March/April 2024

Wood chip combustion for a sawmill

Steininger Sawmill / Rastenfeld Austria

Since December 2020, energy has been generated at the Steininger sawmill with a Schmid wood chip combustion. The new plant of Schmid energy solutions supplies the drying chambers and the pellet plant with heat.

SÄGEWERK STEININGER

Neues Heizwerk Eigenbedarf

„At the end of 2019, we learned that our neighboring heating plant would cease operations in December 2020. The plant supplied our pellet factory and our drying chambers with the necessary heat,“ explains Johann Steininger. It quickly became clear to the sawmill operators that they would invest in their own heating plant and become independent of others.

2020 ist im Sägewerk Steininger ein neues Heizwerk in die Trockenkammern und das Pelletswerk mit Wärme der Coronapandemie konnte der straffe Zeitplan einge-

„We worked flat out to find the right system and the right partner. Schmid energy solutions offered us the best concept and guaranteed that we would be able to launch the new heating plant in December 2020,“ continues Steininger.

Das Wasser wird je nach Temperatur dem Schichtwassertank an unterschiedlichen Stellen zugeführt und das heiße Wasser von oben entnommen

Nöstler

Tight schedule

wir, dass unser benachbartes Heizwerk im DeBetrieb einstellen wird. Die Anlage versorgte aber und unsere Trockenkammern mit der notwendiJohann Steininger. Er führt gemeinsam mit seiSteininger, das Sägewerk Steininger in Rastendie Verantwortlichen rasch klar, selbst in ein investieren. Bei der technischen Planung stand den Ramler zur Seite. Mit Hochdruck machte man sich einem geeigneten Heizkessellieferanten. Fündig Schmid Energy Solution in Lieboch. „Schmid bot das garantierte uns, dass wir im Dezember 2020 mit starten können“, führt Steininger aus.

Straffer Zeitplan

The collaboration with Schmid began in March 2020 - in the middle of the first lockdown. The fuel requirement for the new boiler was that mainly bark as well as cross-cut wood could be used and that the system would supply the sawmill with thermal energy from December 10, 2020. Schmid started installing the UTSR-8000 moving grate combustion system in October 2020 and the heating plant was put into operation on December 1, 2020.

The 27‘296 MBtu / 8 MW system is designed for a fuel moisture content of 10 to 60 % and is ideal for the requirements of the sawmill. From bark to wood shavings, everything can be used.

Im März 2020 – mitten im ersten Lockdown – trat man erstmals mit Schmid in Kontakt. Die Anforderung seitens Steininger an den neuen Kessel war, dass überwiegend Rinde sowie auch Kappholz verheizt werden können. Die Wahl fiel auf eine 8MW-Anlage des Typs UTSR 8000. Zudem war Schmid als Generalunternehmen auch für die gesamte Elektro- und Wasserinstallation zuständig. „Wir wussten, dass wir am 10. Dezember vom benachbarten Heizwerk keine Wärme mehr bekommen. Damit wir aber sowohl die Pelletsproduktion als auch unsere Trockenkammern weiterbetreiben können, war eine zeitgerechte Inbetriebnahme unabdingbar“, sagt Steininger. Im Oktober 2020 startete die Montage, bereits am 1. Dezember konnte die neue Anlage in Betrieb genommen werden. Trotz der Coronapandemie schloss man alle wesentlichen Arbeiten sogar zehn Tage früher ab als geplant. „Das ermöglichte uns einen nahtlosen Übergang und wir hatten keinerlei Ausfall in der Pelletsproduktion beziehungsweise bei der Trocknung“, freut sich Steininger.

gen Wärme“, erzählt Johann Steininger. Er führt gemeinsam mit seinem Onkel, Gerhard Steininger, das Sägewerk Steininger in Rastenfeld. Damit war für die Verantwortlichen rasch klar, selbst in ein Heizwerk zu investieren. Bei der technischen Planung stand den Steiningers Franz Ramler zur Seite. Mit Hochdruck machte man sich auf die Suche nach einem geeigneten Heizkessellieferanten. Fündig wurde man bei Schmid Energy Solution in Lieboch. „Schmid bot das beste Konzept und garantierte uns, dass wir im Dezember 2020 mit dem neuen Heizwerk starten können“, führt Steininger aus.

Remote maintenance and service around the clock

20 08 | 25. 02. 2021

The control center for the entire system is located in the heating plant and can be reached around the clock via the remote maintenance module. Faults are reported to the heating engineer in accordance with the settings. Schmid also offers 24/7 support with its own service specialists. „This support is important to us and has been confirmed,“ confirms Steininger.

8000. Zudem samte Elektrowir am 10. mehr bekommen. auch unsere zeitgerechte ber 2020 startete neue Anlage mie schloss ab als geplant. wir hatten keinerlei bei der Trocknung“, Per Lader Kessel eignet mit ideal für Rinde bis Hobelspäne Er ist Geschäftsführer

Ein Schubboden rial in den Kessel ist zug-Wärmetauscher eine 100mm

Für die Heizanlage Elektrofilter

BRIEF INFO

Per Lader wird das Restholz zum neuen Heizwerk gebracht. „Der Kessel eignet sich für eine Brennstofffeuchte von 10 bis 60% und damit ideal für die Anforderungen des Sägewerks. Man kann also von Rinde bis Hobelspäne alles verheizen“, verdeutlicht Josef Strohmeier. Er ist Geschäftsführer von Schmid Energy Solutions in Lieboch.

The fuel is loaded into the 20‘482.5 ft3 / 580 m3 silo using a loader. The moving floor built into the silo can be driven over and the hydraulic pusher feeds the material into the boiler. All is controlled and monitored over the Schmid boiler control system with communication to BMS over Modbus. The boiler is equipped with a three zone combustion chamber and a three-pass heat exchanger. Steininger also decided to use a 10‘582 gal / 40‘000 l buffer tank to overcome the seasonal demands for peak and smaller load situations.

Ein Schubboden mit hydraulischem Einschieber bringt das Material in den Kessel. Sensoren überwachen dabei die Zuführung. Der Kessel ist mit einer Dreizonen-Brennkammer sowie einem Dreizug-Wärmetauscher ausgestattet. Die Brennkammerwand hat außen eine 100mm dicke Wärmedämmung mit Verkleidungsblech. Es folgt

You need more information?

Pleace contact us.

Schmid North America inc.

Phone +1 (519) 546 9592

info@schmid-energy.com

schmid-energy.com

Product type Moving grate combustion UTSR8000.42-1 visio

Control PersonalTouch visio with remote maintenance option

Fuel Wood chips and forest maintenance wood

Power 27‘296 MBtu / 8‘000 kW

Use Heat for operation, drying plant and pellet factory

Discharge / Silo Moving floor (Drive over)

Exhaust gas dedusting Multicyvlone

In operations since December, 2020

Owner Steininger Sawmill, Rastenfeld, Austria

As an innovative technology leader, we offer exciting energy solutions for an environmentally friendly and sustainable future.

The Schmid Group is a Swiss family business that has specialized in wood energy since 1936 and is one of the world’s leading manufacturers. Schmid combustion systems enable environmentally friendly heating and are in use around the globe.

We offer a wide range of products up to large-scale industrial plants with an output of 614 - 27‘296MBtu | 180 - 8000 KW. Our customers are in the field of agricultural, Sawmills, forestry sectors, the wood industry, real estate companies, energy service providers, commercial-, industrial Manufacturing companies and cities or municipalities.

Get more information here!

„Ende 2019 erfuhren wir, dass unser benachbartes Heizwerk im Dezember 2020 den Betrieb einstellen wird. Die Anlage versorgte aber unser Pelletswerk

mit der notwendi-

Zeitplan

2020

in

schmid-energy.com

und unsere Trockenkammern

Straffer

Im März

Schmid

Kessel war, werden können.

Johann Steininger (li.) und Josef Strohmeier zeigen den neuen Heizkessel von Schmid Energy Solutions

08 | 25. 02. 2021

Für die Heizanlage wurde ein komplett neues Gebäude errichtet, links der Elektrofilter und Josef Strohmeier zeigen den neuen Heizkessel von

Clearing for Canada’s ENERGY FUTURE

B.C.’s DENT Construction has been involved with some of the biggest construction jobs in B.C. in recent years, including clearing work for one of the largest construction projects in Canadian history—the Trans Mountain Pipeline expansion project.

By Paul MacDonald

By Paul MacDonald

It’s not often that a company has the opportunity to be involved with one of the largest construction projects in Canadian history—and for Jim Dent Construction (DENT), that opportunity has meant the last several years have been extremely busy, with the B.C.-based company being a key clearing contractor on the $31 billion Trans Mountain Pipeline expansion project.

The Trans Mountain expansion project is seen as a critical piece of energy infrastructure for Canada, nearly tripling the capacity of the existing pipeline to 890,000 barrels per day. The 1,150-kilometre pipeline runs from Strathcona County (near Edmonton) to a terminal in Burnaby, B.C.

Through the expanded pipeline, oil and refined products shipped on the line will be able to access growing markets in Asia—and DENT was part of making that happen.

DENT has a long and rich history in B.C. construction—in fact, the company is celebrating its 50th anniversary in 2024. It actually started out in Hope, B.C., an hour east of Vancouver, doing framing and building houses. It gradually moved into the heavy/ civil construction side of the business, where its focus lies today, including in the oil and gas sector. From pipeline clearing and facility preparation, to blasting, survey, concrete works, heavy civil and road construction, DENT has honed its skills to be a strong ally to the oil and gas sector.

And it has one heck of a lot of iron to do that work—it has over 1,000 pieces of equipment.

In addition to being involved with the Trans Mountain Pipeline project, the company has also worked on other mega projects in B.C., from the Site C Dam project in northeastern B.C. to the LNG terminal project in Kitimat, which, at $40 billion, is said to be the largest private investment in Canadian history.

contractorprofile

“It seems like we’ve been involved in just about all of the major projects in B.C. over the last few years,” says DENT Chief Operating Officer Jared Neumann.

And these projects come with a full set of challenges.

“Each of the projects is demanding, with intense environmental permitting,” Neumann notes, and there is always a great sense of pride in successfully completing a project.

There is still a strong family involvement to the business, with the third generation of the Dent Family now working for the outfit. Sandy Dent, the son of Jim Dent, the founder of the company, is now president of the company, and he has two sons, Clayton and Calvin, who are also involved in the business, Clayton on the engineering side and Calvin as a carpenter apprentice.

Although the company has literally hundreds of pieces of its own heavy equipment, Neumann noted they mostly rely on local logging contractors for work such as felling trees, both manual and with feller bunchers, and processing, in doing the clearing work, and building road access for projects such as the Trans Canada expansion. It’s a formula that works, he says.

“We always have and continue to subcontract out the bunching and processing,” he explains. “Usually, there are contractors or owner operators where we are operating, and we’ve also partnered to page 12

JDENT takes pride in First Nations partnerships

im Dent Construction (DENT) takes pride in the relationships they have with First Nations groups.

“We have 12 partnerships throughout B.C. and the Yukon,” says DENT Chief Operating Officer Jared Neumann. “We take pride that we are a long term partner with First Nations groups—it’s not just a one-off.”

That was a good fit with the work the company did on the Trans Mountain pipeline expansion.

Trans Mountain worked to identify aboriginal, regional and local capacity, and had the objective of maximizing economic opportunities that came

from the project. The company created an Aboriginal Procurement Policy, Training Policy for Aboriginal Peoples and Aboriginal Employment Policy and worked in partnership with aboriginal communities and construction contractors, such as DENT, to achieve those commitments.

For more than 40 years, DENT has actively engaged with Indigenous groups resulting in a history of Indigenous collaboration, partnership, and inclusion. DENT says it is committed to respectful engagement with Indigenous communities when working within traditional territories, and endeavours to build long-term impactful relationships.

Logging & Sawmilling Journal - March/April 2024 contractorprofile

Through the expanded Trans Mountain pipeline, oil and refined products shipped on the line will be able to access growing markets in Asia—and DENT Construction was part of making that happen, with its clearing work.

In addition to the Trans Mountain expansion, DENT was involved with clearing work for the $14.5 billion Coastal Gas Link project, from Dawson Creek, B.C. to the new LNG terminal being built on the B.C. Coast, in Kitimat.

from page 11

up with First Nations groups.” (see the sidebar story on the company’s relationship with First Nations groups).

That business model works best for the company, he says. “We find that is

a proven method. It works much better than if we were doing the logging—there is not the continuity of work or margins there to merit us investing in specific logging equipment.”

Equipment utilization is key for DENT, Neumann says.

T“If we had our own logging equipment, it might be busy for a while, doing the clearing in an area, but then it might be sitting around, waiting for the next clearing project.”

They’d also be moving the logging equipment a lot from location to location,

Trans Mountain expansion will help Canada get more bang per barrel

he expansion of the Trans Mountain pipeline—and the work that Jim Dent Construction (DENT) and other contractors did—will help Canada get full value for its oil.

While some oil was already being transported to the west coast previously, most of the oil from Alberta was heading south, to U.S. markets.

Currently, nearly all the oil produced in Western Canada goes to the U.S. Midwest. However, there’s a limit to how much oil this market needs. For much of the last decade, Canada has been selling into the United States at a discount to the world price for similar oil products.

Canada’s oil will fetch a better price now that there is the option of shipping more of it via Trans Mountain’s Pacific tidewater terminal on the B.C. coast.

Canada will now earn more on every barrel of oil that’s piped west, compared to those sold to existing customers in the U.S. Midwest market. The end result: more oil revenue for Canadian producers, and more oil royalties for governments.

And with oil sands production expanding in Alberta in the years ahead, new markets and new opportunities are emerging. As countries in the Asia Pacific region continue to grow, they need to secure sources of energy. Canada is a natural trading partner for these countries, and with an expanded Trans Mountain Pipeline system, Canada is now in a position to provide for their growing needs.

The original Trans Mountain pipeline was built in 1953 and continues to operate safely today. The expansion is essentially a twinning of this existing

1,150-kilometre pipeline between Strathcona County (near Edmonton), Alberta and Burnaby, B.C. It will create a pipeline system with the capacity of the system going from approximately 300,000 barrels per day to 890,000 barrels per day.

Some quick facts about the expansion:

• It will be approximately 980 kilometres of new pipeline

• 73 percent of the route will use the existing right-of-way, 16 percent will follow other linear infrastructure such as telecommunications, Hydro or highways and 11 percent will be new right-of-way

• It will include 193 kilometres of reactivated pipeline

• 12 new pump stations will be built

• 19 new tanks will be added to the existing storage terminals, in Burnaby (14), Sumas (1) and Edmonton (4)

12 Logging & Sawmilling Journal - March/April 2024

contractorprofile

especially with a job as big as the Trans Mountain expansion.

For the logging contractors DENT works with, they are already operating in a specific area, and have the equipment—the clearing work is kind of a bonus to the regular logging they are doing.

With the variety of projects the company has had on the go, they often find they are working with logging contractors they have worked with before, which is helpful.

“We try to do that as much as possible,” says Neumann. “Whether it is logging and clearing for a pipeline or oil and gas or a mining project, there is a learning curve there with safety, regulations and supporting paperwork.”

In effect, it’s helpful to work with people who are already familiar with what is required. For example, they have worked extensively with Sibola Mountain Falling, of Prince George. B.C.

In addition to the Trans Mountain expansion, DENT was involved with clearing work for the $14.5 billion Coastal Gas Link project, from Dawson Creek, B.C. to the new LNG terminal being built on the B.C. Coast, in Kitimat.

“That was another big job,” says Neumann. “As well as the pipeline work, we also cleared the site for the LNG terminal itself.”

And they worked with the Haisla First Nation Forestry Company, Haisla Northpac, performing right of way clearing and preparation activities in the Kitimat region of the project.

Clearing work included logging, processing, hauling of timber, and additional road building for the pipeline. The work was delivered in some of the most rugged terrain in northwestern B.C., without a safety incident. Due to the remote location and constrained access, helicopters were used to support clearing in some areas.

DENT brings a lot of expertise and experience to projects, says Neumann.

“We have the management team, the systems and processes in place that the project owners can have confidence in,” he says. It’s different than working in any other sector, he notes, and you need to be on top of your game, meet all the necessary regulations, and be able to execute.

The work the company takes on is not for the faint-of-heart—much of it is in steep B.C. ground. You could easily say that working in steep ground is in DENT’s DNA—and it delivers.

“Our organization has earned a reputation for collaboration providing solutions for complex projects in the most

challenging conditions,” says Neumann.

On the Trans Mountain project DENT also completed highway alignment, archaeological soil sifting, traffic control, and support work for the tunnel projects. DENT also performed access development and upgrades of roads to allow for the pipeline installation on Coastal Gas Link. Working under strict environmental regulations, crews upgraded the existing road system, built new access roads as required, and installed numerous bridges.

DENT started work on Trans Mountain in 2020 and wrapped up most of the clearing and access work in 2023.

While the majority of the logging work is done by contractors, the company initially picked up five Hitachi 370 Forester roadbuilders to assist in the clearing and road access side of projects. They have since added four Cat 558 roadbuilders and one 548 machine.

to page 14

Logging & Sawmilling Journal - March/April 2024 13 contractorprofile

DENT started work on the Trans Mountain expansion in 2020 and wrapped up most of the clearing and access work in 2023. The work the company takes on is not for the faint-of-heart—much of it is in steep B.C. ground.

from page 13

“We can use them as kind of Swiss Army knives, adding grapples and other attachments,” says Neumann. They also have two John Deere forestry pieces, a 2154 and a 3154, and a purpose-built Cat 558 log loader.

“We’re not just a Hitachi or Cat company,” noted Neumann. “With the shortage of equipment the last few years, it’s really been a matter of getting whatever equipment you can get your hands on, at times.”

To help deal with the equipment situation, they have rebuilt their Hitachi equipment.

“COVID changed a lot for us,” Neumann explained. They put a lot of work into rebuilding heavy equipment that they normally would have not rebuilt, due to the delays in getting new equipment and the tight used equipment market—but the approach has worked out well.

In terms of doing equipment rebuilds, there are not necessarily hard and fast rules about when rebuilds are done. Factors would include what is going on in the equipment market, and what jobs they have ahead of them. “We don’t really

14 Logging & Sawmilling Journal - March/April 2024

contractorprofile

have a set rule where we do a rebuild after X number of hours.”

Managing an equipment fleet the size that DENT has is a huge task in itself. “We have a group of heavy duty mechanics and an equipment manager that just looks after our fleet of equipment,” notes Neumann.

Their head office is in Hope, about 150 kilometres east of Vancouver. Home base for equipment is a 20-acre former Interfor dryland sort in Hope, with a large four-bay shop, office, and warehouse. A lot of equipment from all over B.C. will be headed back there for a winter freshenup, and any rebuilds. “Winter is the time of year when the company slows down a bit, and the mechanics get busy,” says Neumann.

As mentioned, the town of Hope is where the company started, and it continues to be a central location for reaching all areas of the province, with the community being at the centre of a number of major highways.

Several years back, when B.C. was hit hard by flooding, DENT was one of the “go-to” companies for doing everything to page 16

Logging & Sawmilling Journal - March/April 2024 15 contractorprofile

from page 15

from first response repairs, to dike, road and bridge repairs, much of it in the southern interior of the province.

DENT has also been involved in a number of run-of-river projects for independent power companies selling power back to BC Hydro, and the power company is their longest-term client.

There may be further run-of-river projects in DENT’s future, with BC Hydro having issued a power call, along with possible work on mining projects in B.C.’s “Golden Triangle”. Located in the northwest part of the province, the Golden

Triangle is so named because it hosts some of the richest gold ore bodies in the world, as well as abundant silver, nickel and copper deposits.

A challenge DENT has had with its completed projects, and going forward, will be getting skilled labour, says Neumann. “That’s been our biggest challenge—I think that has been the case in B.C. for the last couple of years.”

The company does its best to offer consistent, year-round work. It has also made some acquisitions, such as purchasing Speers Construction, of Revelstoke, B.C. DENT was able to help Speers with its equipment resourcing—and it also

got access to additional staff, both on the trades and management side.

DENT COO Neumann joined the company seven years ago, when they took ownership in a company, Westpark Electric, which has done power line construction for many of the power projects DENT built.

While there may be challenges ahead, the company is still looking forward to what’s to come—and starting the next 50 years as a business.

“We’re excited to see what the next decade is going to bring,” says Neumann.

DENT manages logging debris trap with First Nations partner

Related to the forest industry, Jim Dent Construction (DENT) also manages the Fraser River Debris Trap, working with a local First Nations Group, Shxw’¯owhámél First Nation.

Working with the Ministry of Emergency Management and Climate Readiness, the joint venture is responsible for the set of floating booms near Agassiz, in B.C.’s Fraser Valley, that captures thousands of logs during spring runoff and preventing

blockages and damage further down the river.

The booms were established in 1979 as a joint venture between the federal and provincial governments, and the coastal logging industry. The ministry took over in 2011.

As much as 100,000 cubic metres of woody debris—about 2,000 logging truck loads—is intercepted annually, mostly during the high-water period of the spring

runoff and during periods of excessive rainfall.

The joint venture had its hands full dealing with debris after the atmospheric river events of November 2021. Items captured in addition to woody debris included recreational vehicles and large portions of residential sundecks. This was in additional to thousands of cubic metres of silt that had to be dredged, to keep the trap operational.

16 Logging & Sawmilling Journal - March/April 2024 contractorprofile

Clearing for the Trans Mountain expansion: the project is essentially the twinning of the existing pipeline, and will create an expanded pipeline system, with the capacity going from approximately 300,000 barrels per day to 890,000 barrels per day.

Reliability that counts

MS 500i GAS CHAIN SAW

79.2 cc • 5.0 kW • 13.7 lb ①

The MS 500i is the first chain saw in the world to feature electronically controlled fuel injection, making it a true innovation. When it comes to professionally harvesting large trees, this high-torque machine cuts through wood with ease. Rapid acceleration and dynamic pivot behaviour mean that the MS 500i is perfect not only for felling and cutting into lengths, but also limbing. With sensor-controlled fuel metering, it is an excellent starter with outstanding engine performance, regardless of the altitude and ambient temperature. There’s also no starting lever, which makes starting very easy under all conditions. Its engine technology, which is revolutionary for chain saws, and resulting intelligent lightweight construction results in the best power-to-weight ratio on the market.

⬤ Optimum engine performance from the first pull under all conditions

⬤ Injection technology – built-in sensors measure air pressure and internal/external temperature that ultimately passes information to the control unit, which determines the optimum fuel quantity and ignition timing

⬤ Rapid acceleration in an unbelievable 0.25 seconds, enabling this high-torque machine to provide power immediately

⬤ Captive nuts are connected to the lightweight sprocket cover so they don’t get lost in the process of replacing the cutting attachments

Note: Wrap handle version is also available.

① Weight with powerhead only.

Scan code for more product information or visit www.stihl.ca

ƒ

TECHNOLOGY UPGRADED FOR TRURO

An upgrade to the J.D. Irving sawmill in Truro, Nova Scotia is delivering increased recovery thanks to enhanced scanning and positioning technology.

By George Fullerton

The J.D. Irving, Limited (JDI) Truro sawmill—formerly known as the Sproule Lumber mill—finished a seven-week shutdown in the summer of 2022, which saw major upgrades to the milling operation. The upgrades included extensions to the main sawmill building, new scanning and log breakdown equipment, and a new stacker and wrapper for dressed lumber.

“The upgrades will provide us with increased lumber recovery from logs, and improve our overall productivity and safety in our operation,” said mill manager Dylan Cook.

While the entire construction project extended over one year—with the installation of new advanced technologies and equipment as well as modifications to some of the existing equipment—actual mill production was completely shut down for only

seven weeks. The project extended the sawmill building footprint, and brought the planer processing equipment into the same building as primary breakdown.

The upgraded mill sports fresh paint and well-engineered catwalks, and safety warnings are prominently displayed. The filing room and millwright shops are located in the basement under the primary saw line. While the basement is currently storage for production supplies, those supplies are scheduled to be relocated to the old planer mill building. Overall, the upgraded sawmill is well-lit, clean and highly efficient.

The Sproule Lumber mill originated as a random length sawmill established by the Sproule Family, and was sold to JDI in 1990. Soon after the acquisition, JDI converted the random length mill to a twoline stud mill, sawing eight- and nine-foot logs, and marketing the lumber primarily in the northeast U.S.

The former mill layout had two separate saw lines with different sawing characteristics and recovery. The sawmill upgrade converted the primary breakdown to a single line, with enhanced scanning and positioning technology and highly efficient sawing technology.

The sawmill updates included en-

18 Logging & Sawmilling Journal - March/April 2024

sawmillupgrade

Green lumber is stored in the yard at the Truro mill until it moves into kilns. The mill’s Salton and American kilns currently have capacity to handle 115 million board feet annually.

hancing the three infeed conveyors and mechanical updates to the three doublering USNR debarkers. Debarked logs are scanned and delivered to one of the ten log bins according to size. Each bin load is sawn separately in an effort to control and limit the range of log positioning and saw re-setting.

Logs are delivered from the individual bins to a conveyor which travels the logs, first through a scanner which makes decisions for the Comact saw positioner and sawing solutions. A following scanner confirms the sawing solution proposed by the first scanner, ensuring maximum recovery from every log.

The new main saw is supplied by Comact. It saws slabs off either side of the log, and has the potential to saw one or two sideboards off larger diameter logs in a single pass. Sideboards are directed to the edger, which was in service at the previous mill prior to the upgrade.

For smaller logs, the process is to simply square off the cant with chipping heads. The cants then proceed to and are processed by an eight-saw gang saw.

Green lumber is unscrambled and moved on to transfer conveyors, and the flow is joined with the production flow of dressed lumber from the new Gilbert planer. The coming green and dressed lumber travels through the new GradExpert scanning technology which determines trim instructions for the new nine-saw Comact trim saw. Speed is currently at 182 lugs per minute, with room to increase that as familiarity with the whole mill system matures.

Mill Manager Cook explained that an Irving Forest Products spruce sawmill in Ashland, Maine has a similar production line, which has proven successful.

Both green lumber and ‘trimmed’ dressed lumber are coded with an identifying serial number and continue on to the drop sorter, with the last 14 bins accommodating the dressed lumber.

The sawmill upgrade also saw the drop

sorter extended by 14 bins to accommodate dressed lumber, making a total of 71 bins. Prior to the upgrade, the old planer mill had a low efficiency rating, relying on a crew of 17 workers to hand sort and pile the dressed lumber.

Wrapped lumber is loaded on centre rail cars in the millyard. The main market for the JDI Truro mill lumber remains the northeast U.S.

The green lumber is stored in the yard until it moves into kilns. The mill’s Salton and American kilns currently have capacity to handle 115 million board feet annually. Consequently, lumber production at the sawmill is at 115 million board feet, due to limited kiln capacity.

The Truro upgrade included a refit of the biomass boiler which supplies steam to the kilns, as well as heat to the mill in the cold season. The boiler can now burn bark from the mill process, which is fed to the system by wheel loaders.

Planer shavings are sold to regional farmers for bedding. Sawdust and some bark is supplied to a local biomass heating outfit. Pulpwood chips from the mill are trucked to the J. D. Irving, Limited pulp and paper mills in Saint John, New Brunswick.

The

to page 20

Logging & Sawmilling Journal - March/April 2024 19 sawmillupgrade

wood basket which supplies the

Above, Comact GradExpert technology instructs the trim saw at the Irving Truro sawmill. Delivered logs at the Truro operation are typically piled down in the yard and fed into the mill, oldest first. Truro operates its log yard with two Liebherr L50 loaders (below) with log trailers.

sawmillupgrade

from page 19

Truro sawmill extends to include the entire province of Nova Scotia. Around 70 per cent of the wood basket is made up of small private woodlots, with the remainder made up of industrial freehold. The log supply is a reflection of the forest land structure, with around 70 per cent of log supply coming from private woodlots.

In September 2022, tropical storm Fiona ripped across Nova Scotia and Prince Edward Island, knocking down a significant portion of the forest resource. Consequently, a good deal of the more recent wood supply has been coming from those wind-damaged stands. J.D. Irving Limited forestry staff associated with the Truro sawmill operation are engaging with woodlot owners to purchase stumpage.

Truckloads of logs entering the Truro mill are mass scaled. Wood produced on JDI harvest operations meet quality standards at roadside. Wood procured from other producers is subject to quality assessment as it comes into the mill yard. All wood producers can deliver to the mill, around the clock.

The spruce and balsam fir coming in on loads are separated in the milling process so that each species can be processed to its specific kiln drying schedule. Other softwood species including red pine, Norway spruce and jack pine, are piled down and batch-fed to the mill, and the green lumber segregated for its specific drying cycles.

Delivered logs are typically piled down in the yard and fed into the mill, oldest first. Truro operates its log yard with two Liebherr L50 loaders with log trailers. On the lumber side there are three Cat 950M wheel loaders.

During the seven weeks that the Truro mill paused production, many of the mill employees worked on the rebuild, handling non-technical work.

The sawmill operates double twelvehour shifts with work shift rotation, with a union workforce. Its 150 employees include around 20 supervisory and support staff.

The millyard is well-organized with designated walk routes that are welldefined and signed. The mill upgrade

included paving the log yard, and future plans include paving the lumber yard. Dylan Cook underlined that clean logs directly impact the efficiency and production of the upgraded mill.

For a number of years, J.D. Irving, Limited has been participating in programs which invite and support foreign workers to work in industries across the Maritime provinces and provide language and skill training. The JDI Nova Scotia mill and woodlands operations have benefitted through the program, employing six individuals from Brazil and 12 workers from Ukraine. The workers and their families intend to become permanent Canadian residents.

For several years, J.D. Irving, Limited has offered a program for newcomers which supports harvester and forwarder operators to transition to independent contractors.

J.D. Irving, Limited, like the majority of Canadian industries, is actively seeking to fill hard manual labour positions, and the Truro mill upgrades will go some distance to reduce the manual labour required in the mill. This will move their employees into better entry jobs and, at the same time, mitigate any soft tissue and repetitive movement work-related injuries.

20 Logging & Sawmilling Journal - March/April 2024

Comact scanners instruct log positioning and log breakdown solutions.

Wrapped lumber is loaded on centre rail cars in the millyard. The main market for the Irving Truro mill’s lumber is the northeast U.S.

B.C.’s Interior loggers will have a full schedule

B.C.’s Interior Logging Association (ILA) offers a full meal deal with its AGM, convention, trade show and social activities, being held this year in Kamloops from May 9 to 11.

By Jim Stirling

Logging contractors and their supplier partners in British Columbia’s South ern Interior region are a pretty re sourceful lot. They’ve had to be to adjust to adversity and the unexpected through the years.

While there’s not much in the short term logging contractors can do to influence a changing global economy and trading relationships amid evolving green technologies, they can—and are—finding better ways to do their job and help the regional economy in the process.

The Interior Logging Association’s (ILA) annual general meeting and convention is an important means to that end. The 66th edition of the annual event is scheduled this year for May 9 to 11 at the Coast Kamloops Hotel in the southern interior city. The fact that the ILA has been around that long speaks volumes about the effectiveness of its role within the regional log harvesting community.

The relationship was tested during the COVID epidemic and the enforced shutdown it created.

“We got through it because of our strong membership,” reflects Todd Chamberlain, the ILA’s general manager, based in Vernon, B.C. He recalls that he and Nancy Hesketh, the association’s office administrator, spent much of their time keeping the lines of communication open with the membership. They relied on ‘old tech’ methods like the telephone and newsletters. But another, more fundamental factor was also at play: “All of the

association’s membership share a passion for this industry,” says Chamberlain.

Part of that is probably because the entire membership has a vested interest in the success of the harvesting sector. The loggers may be on the front line of change but new regulations and legislative edicts affect every link in the supply and service chain both regionally and across the province.

Keeping two-way communication lines open with the provincial government is a year round priority with the ILA. But the relationship assumes a different dimension during the ILA’s annual convention. Senior members of the Ministry of Forests are always in attendance. Chamberlain says he personally invited B.C. Premier David Eby to address this year’s event. Whoever the government’s representative is and delivers the address, the ILA’s executive has its opportunity to communicate. In a frank and private meeting, they have the chance to quiz senior government officials. The exchange benefits both parties, reckons Chamberlain. The government’s presentation is set for a luncheon meeting Friday May 10.

A trade show is an integral part of the ILA’s convention experience, blending

both its business and social sides. The exhibitors take advantage of the opportunity to display or demonstrate the latest log harvesting equipment and services available on the market. The informal oneon-one nature of the trade show makes getting business done easier.

Chamberlain reports early commitments for both indoor and outdoor space at this year’s convention were at least on a par with last year’s successful event.

The BC Forest Safety Council will again be presenting a regional safety conference as part of the ILA convention. It will bring attendees up to date with the latest information on key factors affecting operating a safe work place. These are scheduled to include mental health issues, changes to first aid regulations and updates to company safety plans. This might include the latest regional hospital emergency room closures, summarizes Chamberlain.

The ILA convention organizers have other, lighter fare planned for the agenda. A log loading competition is on the menu. The timed event focus is on four stacked logs, each about 10 feet long. The objective sounds easy, the execution against the clock not so much.

Another feature in the proceedings this

22 Logging & Sawmilling Journal - March/April 2024 industryevents

year will be Tyler Welfing. He’s a Vernonbased chainsaw carver and he is scheduled to have some of his work on display. And he’ll entertain ‘cut to order’ requests from the audience.

The convention is crowned on the Friday night with a dinner/dance. Music will be provided by the Shawn Lightfoot Band. The winner of a silent auction will be revealed and therein hangs a bittersweet tale. Monies raised will be donated to further awareness of Chronic Traumatic Encephalopoly (CTE) which is a progressive and degenerative brain disease. The condition claimed Ty Pozzobon’s young life in 2017. Just a year earlier, Ty was

Canada’s bull riding champion, competing on the international rodeo circuit. Pozzobon’s extended family is dedicated to helping promote a better understanding of CTE and recognizing its signs. Many in the family work in the regional forest industry. Fred Lowe, a lifetime logging truck driver, is Ty’s grandfather and a family patriarch. Assuring Ty’s legacy has now become part of the ILA convention’s tradition.

The latest information on the ILA convention is available at www.interiorlogging.org

B.C.’s Interior loggers continue push for a Working Forest

It’s been another challenging year for the log harvesting sector in British Columbia’s Southern Interior region.

“The reality is that associations representing logging contractors have always had to deal with adversity, changes in government policy, adaptation to new technologies and certainly challenges faced in the labour market,” outlines Tim Menning, chairperson of the ILA for the last year.

“The job of representing the interests of logging contractors consists of an everchanging menu of interconnected issues, ranging from safety regulations to First Nation policies, environmental expectations and regulations, rate negotiations with major forest licencees and numerous other interactions with government and non-government agencies.”

Menning is a partner in Hytest Timber Ltd, a log contracting business he cofounded at Williams Lake in 1986. It was the beginning of a time for consolidation in B.C.’s Interior forest sector. Licencees competed for acquisitions to grow and gain timber cutting rights. Hytest originally worked for the family-owned Jacobson Brothers sawmill in Williams Lake.

It was subsequently purchased by Riverside Forest Products which in turn was acquired by Tolko Industries. Today, accessing adequate volumes of timber is a paramount concern for the ILA membership.

“The reduction in annual allowable cut due to the liquidation of the mountain pine beetle damaged stands—along with government initiatives like the old growth project coupled with a staggering

onset of regulatory burden—has contributed to our sector being forced to try to run our operations in the face of the highest cost of timber in North America,” continues Menning.

The exclusions of ever increasing volumes of B.C.’s publicly owned land is leaving the forest industry on the outside looking in. The idea of establishing and preserving a land base with a forestry first designation has been promoted by various forest industry organizations in recent years.

“I believe it’s imperative that government look to re-establishing the concept and support mechanisms required for a true Working Forest,” says Menning. “The deterioration of this promise has occurred over the last number of years to the point where the forest industry’s ability to access timber has become a residual function of regulatory processes rather than a driving priority.”

B.C.’s Southern Interior has been severely affected by wildfires in recent years. It culminated in 2023 with the province’s worst fire season on record. More than 2.84 million hectares of forest land were burned according to BC Wildfire Service statistics. The ILA and the wildfire service have been communicating during the winter to prepare for the 2024 season.

“The ILA has recently engaged with the wildfire service to offer advice and support to facilitate the timely and efficient disposition of our expertise and heavy equipment in delivering successful outcomes on the land base,” says Manning.

industryevents

ILA Exhibitor List

ACERA INSURANCE

ANSER MFG.

ASPEN CUSTOM TRAILER

AXIS FORESTRY

BC FOREST SAFETY COUNCIL

BCTS KAMLOOPS

BLACK TUSK HELICOPTERS

BRANDT TRACTOR

CANADIAN EQUIPMENT FINANCE

CARVEWEL CREATIONS

CRUX CHIROPRACTIC

DAWSON TRUCK CENTRES

DEARBORN FORD SALES

EVOLUTION MECHANICAL

FINNING (CANADA)

FIRST NATIONS FORESTRY COUNCIL

FREFLYT INDUSTRIES INC.

GREAT WEST EQUIPMENT

HEARING LIFE

JIM PATTISON LEASE

KAMLOOPS FORD LINCOLN

KAMLOOPS TIRECRAFT

LINDE CANADA

LOGGING & SAWMILLING JOURNAL

MACLEOD FOREST SERVICES

NOR-MAR INDUSTRIES LTD

NORTHFACE GRAPPLE TIPS

PEERLESS

PROFAB MANUFACTURING LTD.

R. JAMES WESTERN STAR

ROYAL INLAND HOSPITAL

S.T.E.P. BC CONSTRUCTION

SKYLINE MODELS

SMS EQUIPMENT INC.

SOUTHSTAR / QUADCO

STREAMLINE TECHNOLOGIES

SUPPLY POST

T-MAR INDUSTRIES LTD.

TEAAMS AREOMEDICAL

TEAM AUCTIONS

TELUS BUSINESS SOLUTIONS

THE INLAND GROUP

TOP DOWN ENTERPRISES INC

TRU

VALHALLA EQUIPMENT

VELOCITY TRUCK CENTRES

VESPER TRANSPORT LTD.

WAJAX

WARATAH FORESTRY

WELDCO BEALES

WESTERN GASCO

WESTLAKE CONTRACTING

WOODLAND EQUIPMENT INC.

WORKSAFE BC

Logging & Sawmilling Journal - March/April 2024 23

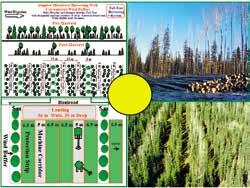

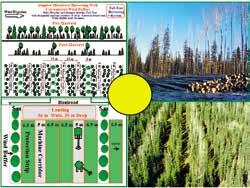

Partial harvest systems to meet specific within boreal mixedwood and pure

BY TONY KRYZANOWSKI

The Canadian Wood Fibre Centre (CWFC) technical development group of the Canadian Forest Service (CFS) and their partners have a history of developing innovative partial harvest systems that address issues of forest managers in the Prairies.

Here are a few options available to industry to address the current and anticipated consequences of a changing climate, as well as to help maintain a sustainable fibre supply as Canada continues to transition to managed forests.

These partial harvest systems—although heavily weighted to mixedwood stands featuring trembling aspen and balsam poplar with white spruce because of the type of industry and forests in the Boreal Plains—can also be applied in pure conifer white spruce and lodgepole pine stands. They also have adaptability to both natural and managed stands.

"There are a variety of reasons to consider partial harvest systems as we witness the greater impact of a changing climate on the commercial forest while we also experience a growing demand for fibre," says Derek Sidders, Program Manager, Technology Development and Transfer at CWFC. "It’s important to consider ways to maximize the values and health of the forest, which is where partial harvest systems play a significant role."

Furthermore, it’s also important to design a harvest pattern that not only results in diverse values but also recognizes the technology of the day that is operationally and economically realistic for both initial and follow up entries.

Sidders adds that fibre supply and sustainability can be heavily influenced and enhanced with the use of partial harvest systems where multiple harvest entries can selectively manipulate species distribution and values recovered from the stand, while also investing in future values that will be recuperated in 20 to 40 years, depending on the management objective.

For more information about these partial harvest systems, contact Derek Sidders at derek.sidders@nrcan-rncan.gc.ca.

Ecosystem Management Using Variable Retention in Mixedwood Stands

This partial harvest design for mixedwood sites was developed by CFS in conjunction with Alberta industry and the University of Alberta to try to harvest wood fibre in a way that mimics natural disturbances in the forest.

It features a harvesting system where there is both individual tree and group retention that mimics the aftermath of a wildfire. The Ecosystem Management Emulating Natural Disturbance (EMEND) research site, located in the Clear Hills Upland, Lower Foothills Eco-region of Alberta approximately 90 kms northwest of Peace River, is a good example of where this partial harvest system was deployed.

The basic design specification of this partial harvest system features concentrated machine corridors operating parallel to each other. Whether using feller bunchers and skidders or harvesters and forwarders, the distance between the width of each machine corridor provides access to each individual commercial stem in the stand from the corridor, as well as a route out of the stand for harvested trees or stems.

Based on the species composition and the management plan, the partial harvest objective using this method can vary. The goal could be to achieve a variable retention percentage of perhaps 20, 50 or 75 per cent, to remove specific species from the mixedwood stand or to strictly harvest fibre by vulnerability, value or diameter class.

If the goal is to harvest a certain amount of volume in a defined basal area, it is possible to use a systematic pattern of individual tree removal.

First, consider the removal from the machine corridor from the total stand composition which is commonly 25 per cent of the stand, and then based on the prescribed retention level, individual trees can be removed systematically from the remaining strips which continue to occupy 75 per cent of the land base. For example, by harvesting one tree and leaving two trees, 50 per cent retention is achieved and for 20 per cent retention, three trees are harvested with one retained.

The accompanying graphic demonstrates this pattern.

"The management objectives using this partial harvest method can be anything from a preference for final species diversity for multiple values such as ecological and long term production values," says Sidders, "or the objective could strictly be to provide commercial access to a species that grows faster in a mixedwood stand, with the intent of removing as much of that commercial species as possible, while releasing the shade tolerant and slower growing species in the understorey."

24 Logging & Sawmilling Journal - March/April 2024

management objectives

softwood stands

Commercial Coniferous Thinning Partial Harvest System

This method applies a design of either concentrated machine corridors using conventional logging equipment or ghost trails with a cut-to-length system in a mature natural coniferous stand where the fibre volume can be 400 to 550 cubic metres per hectare and the white spruce is well established at 1200 to 2000 stems per hectare.

The goal is to harvest commercial value while opening up the site to allow retained stems to take full production advantage of increased sunlight and nutrients while maintaining species health, diversity and keeping 50 to 70 per cent of the fibre volume intact.

Stems are harvested to meet the anticipated basal area removal level relative to the productive potential of the retained stems, with thinning conducted from above and below with the goal of meeting that 50 to 70 per cent retention level.

"Also, the higher the removal level, the greater the potential for the establishment of a natural understorey of white spruce originating from the overstorey that's retained. Enough light penetrates the stand for soil heating, germination, and access to micro-sites created from the first entry harvest," says Sidders. "Fifteen to twenty years later, you could have full juvenile spruce occupancy with trees above 1.3 metres in height where there is ground disturbance, as well as a significant increase in the retained stems to justify another entry."

Second entry is determined by the overall management objective, such as retained stem growth and established spruce regeneration, as well as the local forest manager's knowledge of historical growth response from each individual site.

Selective Harvest to Reduce Pest and Fire Vulnerability While Maximizing Fibre Recovery

This partial harvest technique, which is similar in design to the ecosystem management method, can be applied in a mixedwood stand, mixed conifer stand or pure conifer stand. Based on the species distribution and size of the trees of each species in the block, preferential harvesting is conducted to achieve specific value outcomes.

For example, to reduce stand vulnerability, the objective could be to remove larger stems, create space within dense stands, protect preferential species with low vulnerability or to remove dead and dying stems to eliminate any type of long term potential pest, pathogen or wildfire impact. The key to successful deployment of this design is the effectiveness of the pre-treatment sampling, the harvest pattern for access to all trees within the retention strips from the machine corridor, and, of course, a clear description of the trees to be removed and retained.

Understorey Protection in Mixedwood Stands

The stands targeted for this partial harvest application are mixedwood stands featuring a commercially mature stand of trembling aspen/balsam poplar with an established and well-distributed understorey of immature white spruce of at least 60 to 80 per cent stocking, but with larger conifer stems vulnerable to wind throw or sun exposure that require wind and light protection.

A machine corridor pattern is used so that the feller buncher can reach the mature deciduous component within the remaining stand while retaining the conifer understorey. The corridors are established so that there is a buffer within the remaining stand out of the reach of the feller buncher, creating, for example, a 5- metre wide wind buffer every 35 to 40 metres. North/south machine corridors are recommended since prevailing winds typically come from the west in the Boreal Plains.

"The conifer stems benefit from being retained (increased light, heat, water and nutrients) and having been given breathing room through this first entry," says Sidders. "They will expand their size to commercial value within 20 to 25 years post entry, assuming the spruce are healthy and 8 to 12 metres in average height."

Adaptive Understorey Protection

A new design method within this partial harvest system developed by the CWFC technical development team is called adaptive understorey protection. It uses the variable retention logging corridor model which eliminates wind buffers but keeps and distributes an additional 20 to 30 per cent of the deciduous stems within the retention strips to protect the understorey. This results in a more evenly distributed overstorey that maximizes growth potential of all retained softwoods in the understorey. It also allows the remaining deciduous to continue to occupy natural gaps within the retained stand and machine corridor, which maintains a diverse mixedwood stand and is significantly advantageous from an environmental and changing climate perspective while adding more value to the second entry harvest. There are numerous examples of these methods available for viewing both in commercial and research applications throughout the Boreal Plains region.

Logging & Sawmilling Journal - March/April 2024 25

pure

Canadian lumber production continues to fall

West Fraser and Canfor remained in the top two positions in the list of Canada’s Top Lumber Producers in 2023, with the industry as a whole continuing to see production volumes dropping.

By Mark Smith, Partner, FEA; Research by Chari Gimenez, FEA Canada

By Mark Smith, Partner, FEA; Research by Chari Gimenez, FEA Canada

In 2022, we saw total Canadian softwood lumber shipments drop by almost 2.2 billion board feet, a 9.4 percent decrease over 2021 total Canadian shipments. This trend has continued through

2023 with total Canadian lumber shipments dropping from 20.9 billion board feet in 2022 to 19.8 billion board feet in 2023, a further loss of 1.1 billion board feet. This means a combined loss of lumber supply for the two years of 2022 and 2023 equal to 3.3 billion board feet.

Last year in March 2023, FEA had noted that:

• Softwood lumber usage was expected

to decline still further in 2023, with residential construction, residential improvement, and industrial use all taking a hit as the economy slows. However, the fundamentals underlying softwood lumber’s main end-use markets remain strong, and markets are expected to recover in 2024.

This has subsequently proven to be the case. North American softwood lumber

26 Logging & Sawmilling Journal - March/April 2024 0 toplumberproducers

demand is driven by U.S. consumption, which has remained sluggish as rising home prices and interest rates have created enough uncertainty in the market to restrain demand. Nonetheless, FEA expects the U.S. housing sector will recover to some extent in 2024 due to favourable demographics, particularly the age-class distribution, and the accumulation of underbuilding. American and Canadian markets are forecasted to grow by two per cent and five per cent respectively due to this housing demand.

Total North American lumber shipments: down 1.4 billion board feet in 2023

Total North American softwood lumber shipments were down by 1.4 billion board feet in 2023 (57.2 billion board feet) as compared to 2022 (58.6 billion board feet) reflecting the ongoing, weak demand noted above. A similar decline was seen last year for the period from 2022 to 2021 with volumes decreasing by 1.8 billion board feet for that year. This means that over the last two years, shipment volumes have decreased by 3.2 billion board feet from North American mills, versus the volumes seen in 2021.

Looking at the figures in the introductory paragraph for total Canadian

shipments (down 3.3 billion board feet through 2022 and 2023), we can see that all the North American decline can be attributed to shipments from Canadian mills. Over this same two-year period, U.S. mills have actually shown a small increase (about +0.1 billion board feet).

Canadian Top 10: Shipments up by 0.2 per cent from 2022 to 2023