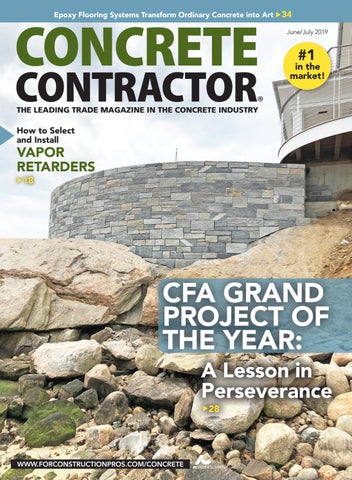

Concrete Contractor delivers original content to help concrete contractors build their projects and run their businesses more efficiently and profitably. Contractors prefer Concrete Contractor to learn about best practices in flatwork/slabs, foundations and walls, decorative concrete and new product information which are reoccurring themes in every issue. Concrete Contractor is dedicated to commercial and residential concrete contractors. WE KNOW THE INDUSTRY through our industry connections and as proud members of ASCC, ACI, CFA and TCA. We feature columns by industry icons Ward Malisch, Bruce Suprenant, Kim Basham and Joe Nasvik.