Excavators aren’t just jobsite staples — they’re the backbone of your operation. Built with hard-nosed durability and relentless reliability, the 210 and 250 P-Tier Excavators were made to tackle the toughest work and keep your crew moving forward. And with financing offers available now, it’s easier than ever to add these machines to your fleet. Learn more at Deere.com/BigDeal.

VIDEO NETWORK eqtoday.co/k2p285

DIGGING DEEPER PODCAST eqtoday.co/s7sfkm

PREMIUM CONTENT eqtoday.co/9pd73s

The ForConstructionPros Product Directory houses the construction industry’s most comprehensive library of thousands of new equipment and products for contractors. For more of the latest releases in earthmoving, concrete, asphalt, construction technology and more, scan the code or visit eqtoday.co/equipintros.

Kathy Wells Editor-in-Chief Equipment Today kwells@iron.markets

Dedicated to the commercial concrete and masonry construction industries, World of Concrete (WOC) 2025 was held Jan. 20-23 in Las Vegas, Nevada, and welcomes tens of thousands of industry professionals to zero in on the future of the trades through education, tech integration and business-to-business solutions and partnerships.

Compared to last year’s event — which also marked the show’s 50th anniversary — the 2025 installment not only nearly matched 2024 registration and attendance numbers, but also exceeded the exhibitor count by more than 100, bringing together some of the latest heavy machinery, tools, products and services for material handling, concrete reinforcement, concrete masonry, cement production and decorative concrete, repair, demolition and reconstruction.

Every year, the trade show finds new ways to educate, inform and advance the efforts of the industry

and the many people in it. One prime example of this comes in the form of technology, which has been a recurring theme across the last decade of WOC events.

The drive for tech integration is happening on every level of the construction playing field. From backoffice operations to on-site solutions, elements of technology have been implemented and established in the day-to-day actions of contractors and their teams. On the equipment side of operations, today’s latest earthmoving products do not come to market without boasting new tech features or upgrades, many of which now come on standard on most models.

At WOC 2025, Kubota introduced its new SPL 97-3 compact track loader, offering several now-standard tech features, including 7-inch touchscreen and integrated backup camera, as well as adjustable track response, which allows for tailoring of the machine to the operator. This also has a passcode enabled keyless start,

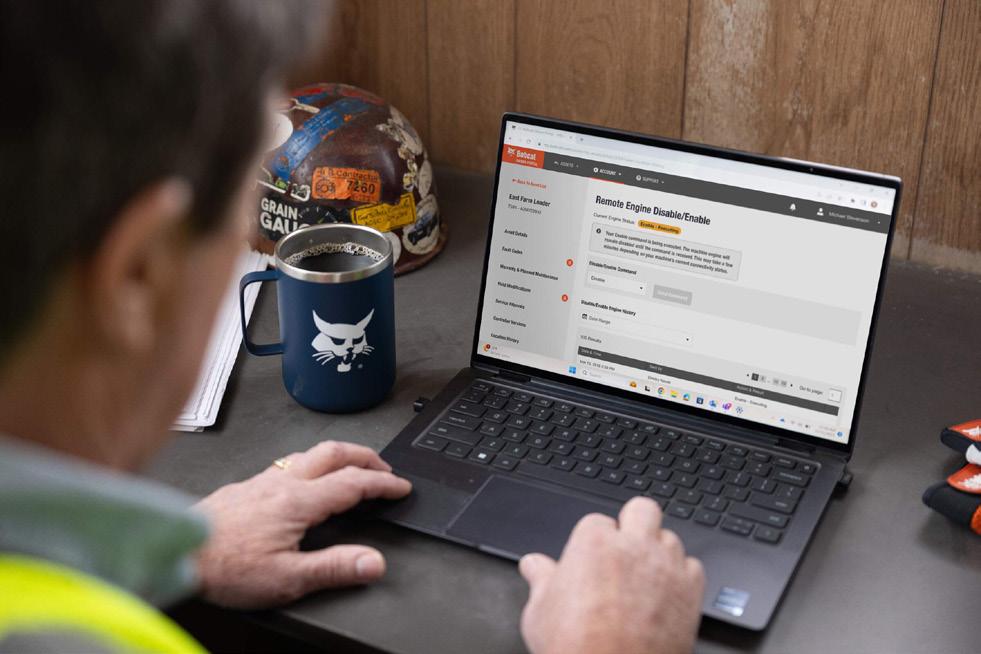

so you can program up to 51 separate pass codes, turning on or off certain features again to tailor that machine to the experience level or needs of the operator. Joining Kubota in facing the future head-on, several WOC 2025 exhibitors and major OEMs debuted new releases with techforward features throughout the show, including Ford Pro, Wirtgen, Bobcat, Cemen Tech, Stellar, Brokk, Toro and more. These offerings are among a wave of similar tech-focused features that newer operators have come to expect in their equipment on the construction jobsite of the future.

However, in-cab tech features are just the beginning of technology in action transforming the jobsite. Sites today are beginning to feature even more accelerated solutions, such as new robotics, autonomy features and automated tasks, that help to deliver more efficiency and productivity. For instance, at the show, Dusty Robotics showcased its robot that performs the automated layout tasks that skilled trades have traditionally done by hand, snapping chalk lines. Dusty offers a combination of hardware, software and services designed to fit into existing construction work processes by printing digital models directly on the jobsite floor.

In attending my first WOC show over a decade ago, I was introduced to some of the early potential jobsite tech held for improving processes and productivity. But, much like the construction industry itself, it has taken time to fully embrace the scope of possibilities and applications within the construction environment. Some of what I first saw in 2015 is now considered standard. Will this year’s innovations become the new standard in 2035? To say the least, there’s certainly more tech to come.

Take care,

Highlighting hundreds of next-level solutions for challenging construction

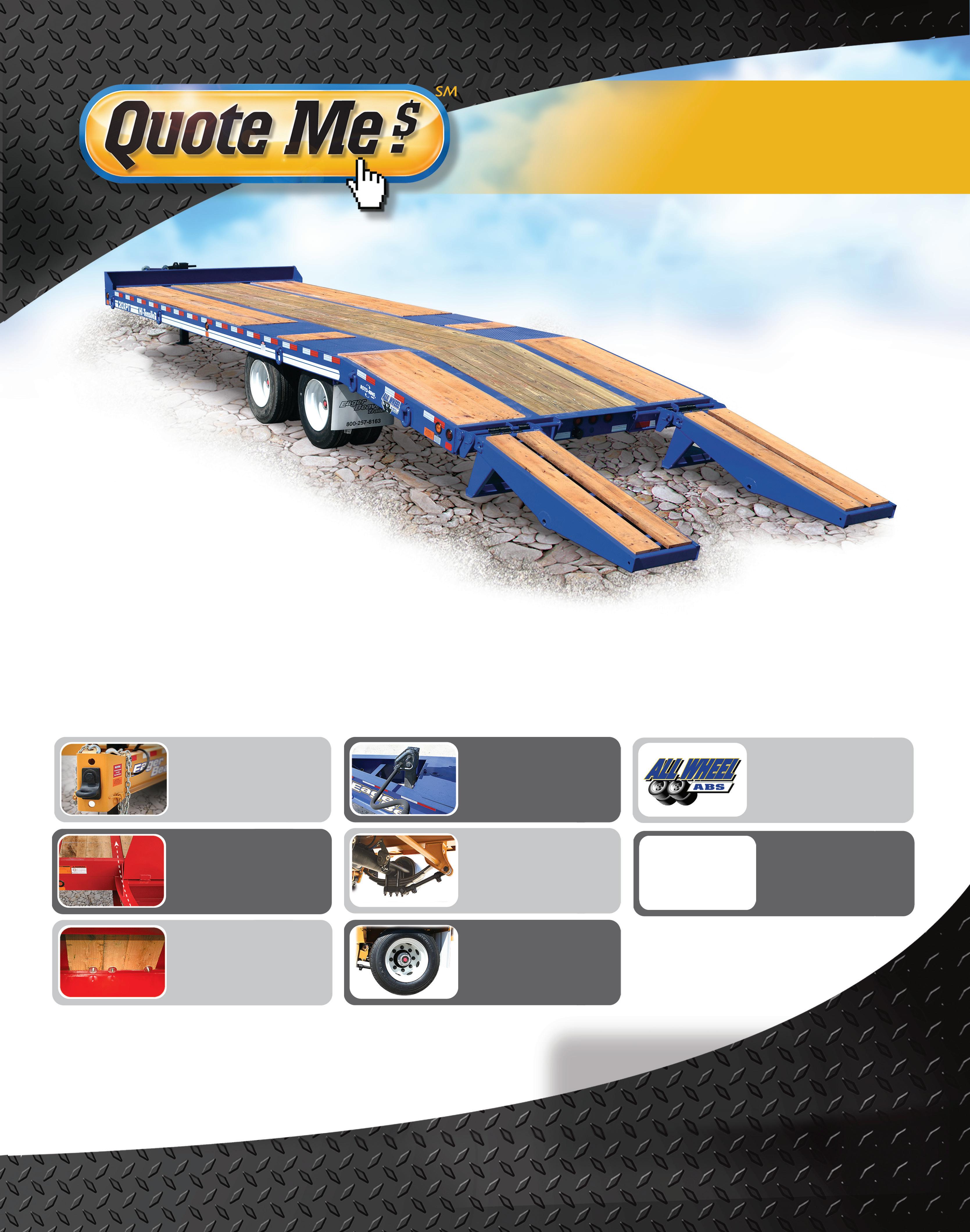

Equipment Today’s Annual Equipment Showcase is a special issue designed to highlight industry-leading equipment and solutions for the commercial and highway/heavy construction market.

In cooperation with original equipment manufacturers (OEMs), we receive hundreds of new product submissions throughout the year, including the most cutting-edge releases fit for use in any and all jobsites and applications across the construction sector.

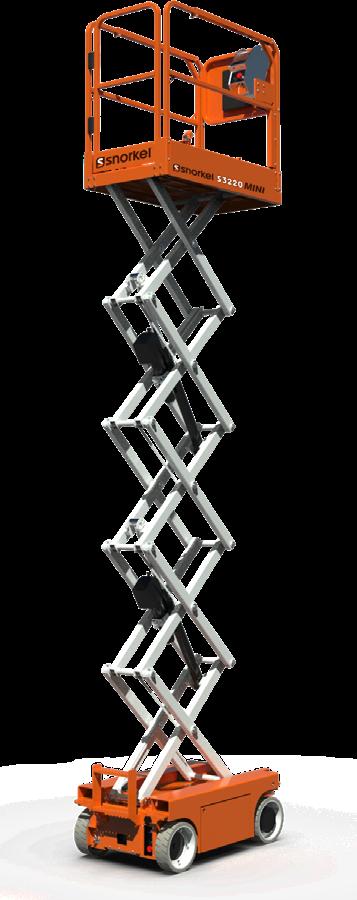

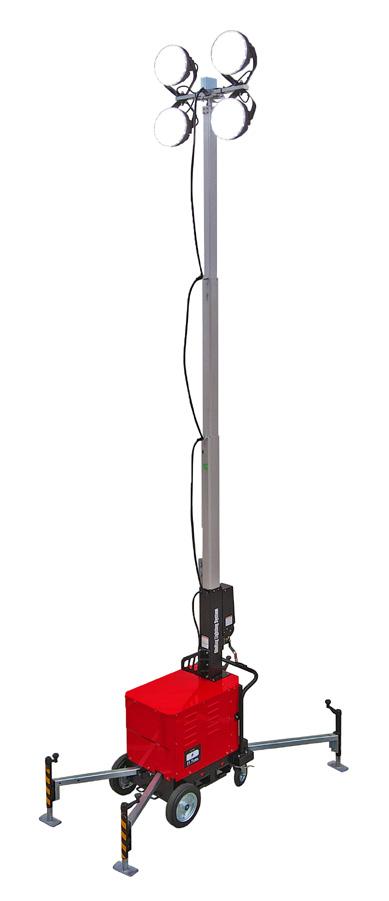

This year’s print installment features 45 pages highlighting hundreds of the latest launches now available to contractors and project teams. Within these pages, readers can browse products across eight main categories: Earthmoving, Attachments, Lift Equipment, Worksite Equipment, Fleet Maintenance, Trucks and Transportation, Roadbuilding, and Technology.

If you’re looking for a more interactive experience, we encourage you to check out the ForConstructionPros Product Directory at eqtoday.co/equipintros to access these products and thousands more. The Product Directory is updated daily with incoming new product announcements and equipment launches, so be sure to save this page and refer back to it as your go-to resource for new product information.

Read More eqtoday.co/equipintros

Manitou has launched the MTA 519, a compact telehandler that is compact at 5 ft., 11 in. wide and 6 ft., 4 in. tall, with a tight turning radius of 10 ft., 10 in. This makes it small enough to fit through garage doors and down ramps. It includes a maximum load capacity of 5,500 lbs., a 19-ft, 1-in. maximum working height and outreach of up to 11 ft., 2 in. for loading and unloading materials on the second floor of a structure. It also features five different tire options and a ground clearance of 13 in. for working on varied terrain. The new MTA 519 features a 74-hp engine that is also placed low within the framework of the machine, along with power and drivetrain components. This allows for a low, sloping hood for visibility, as well as access to daily service and preventive maintenance serving points.

Weighing 7,350 lbs., this machine is easily towable and with a Rated Operating Capacity of 1,890 lbs. (@35% of tip), the ST27 comes with a 74-hp Kohler KDI 2504 turbocharged engine. The compact design, measuring 60-in. wide and under 80-in. in height, offers reach at dump height of 36.5 in. The ST27 offers a hinge pin height of 120 in. and dump height of 94.3 in. It features a 2-speed standard travel drive that offers a 9.1 mph speed resulting in faster cycle times. There is a standard auto-shifting 2-speed drive system that can be active or disabled. It automatically senses the operators need to shift. The auto feature engages in and out of the two speeds based on joystick input and eliminates the need for manual shifts.

With impressive lift capacity and an industry-leading 12-ft. lift height, the Bobcat S850 is the largest skid-steer loader in the lineup. The S850 helps you do more than ever before, but still in a compact frame. Standard controls include Power Assist; Leading uptime protection; Powerful Bobcat Tier 4 engine and hydraulics; Fast cycle times

The CASE CX50D mini excavator is a 5-tonne class machine that powers a range of specialized attachments for various jobs. It comes standard with multifunctional hydraulics and a second auxiliary circuit, as well as an optional third auxiliary circuit for advanced attachments like tilt rotators and grapples. It also offers another optional dedicated auxiliary circuit to power mulchers. Crews can also take on material handling tasks safely with the optional Object Handling Kit that includes check valves on the boom and arm. Equipped with rubber belt tracks, two travel speed options are available on the mini excavator. This machine comes pre-wired for telematics equipment.

The SY265C offers selectable working modes that match performance output to the job at hand. Other efficiency features can help save up to 10% on fuel costs, while the high-performance cooling system with electronic control fan clutch ensures clean and quiet operation in any conditions. Powerful and reliable powertrain and hydraulic components offer long life in the most demanding applications. Optimized positive flow hydraulics improve operating efficiency by up to 5% and fuel efficiency by up to 10%. A high-performance cooling system equipped with electronic control fan clutch provides clean, quiet operation. Comes loaded with standard features and is backed by SANY’s 5-year warranty or 5,000 hours of proven reliability. Specs include: Boom Length: (5,900 mm) 19 ft. 4 in. Stick (Arm) Length: (2,950 mm) 9 ft., 8 in. Transport Length: (10,290 mm) 33 ft., 9 in. Transport Width: (3,390 mm) 11 ft., 1 in. Transport Height: (3,255 mm) 10 ft., 8 in. Upper Structure Width: (3,150 mm) 10 ft., 4 in. Cab Height: (2,957 mm) 9 ft., 8 in. Blade Height Track Width (standard shoe): (800 mm) 31 in. Track Gauge: (2,590 mm) 8ft., 6 in. Ground Clearance (minimum): (470 mm) 19 ft. Tail Swing Radius: (3,105 mm) 10 ft., 2 in. Track Length on Ground: (3,830 mm) 12-ft., 7-in. Track Length: (4,636 mm) 15 ft., 3 in. Ground Pressure: (39.3 kPa) 5.7 psi. Engine: Cummins QSB 6.7T4F; Displacement: (6.7 L) 408.9 in³. Hydraulics Positive Flow Control with Pilot Control; Main Hydraulic Pump Axial Piston - Variable Displacement; Operating Flow (maximum): (520.0 L/min) 137.4 gal/min; Operating Pressure (maximum): (34.3 MPa) 4,975 psi; Power Boost Pressure (maximum): (37.3 MPa) 5,410 gal/min. Travel Motor Axial Piston with Park Brake; Travel Pressure (maximum): (34.3 MPa) 4,975 psi. Travel Speeds (maximum): (3.5/5.5 km/hr) 2.2/3.4 mph; Travel Effort (maximum): (227.0 kN) 51,032 lbf. Grade Capability: 35 degrees. Swing Motor Axial Piston with Swing Brake; Swing Pressure (maximum): (27.5 MPa) 3,989 psi. Swing Speed (maximum) 10.6 rpm. Undercarriage (standard): Steel Track. Track Shoe Width (standard): (800 mm) 31 in. Track Rollers (per side): 9. Carrier Rollers (per side): 2.

The three models, L 526, L 538 and L 546, in the latest Generation 8 have bucket sizes between 2.2 and 3.0 m³ in the standard version and are characterized by an increase in performance compared to the previous generation. The new L 526, for example, has around 20% more engine power and over 20% higher breakout forces than its predecessor. The newly designed lift arm ensures maximum breakout, holding and lowering forces.

It has optimized z-bar kinematics and improved working hydraulics. Increases in engine power and tipping loads prepare the wheel loaders for demanding operations in various sectors, such as excavation, recycling or log handling. Available in Europe, the L 538 and L 546 models also have performance increases in various areas: for example, with the optimized travel drive, providing increased traction to ensure that the new wheel loaders accelerate dynamically in everyday work, and can penetrate powerfully into all materials.

Volvo CE L180

3-Pass Rehandler

Volvo Construction Equipment’s L180 3-Pass Rehandler is ideal for loading, material transfer and transporting on construction sites. The company took the L180H, swapped in larger 875/65 R29 tires and a long boom, added a rehandling counterweight and created a new truck-

loading variation called the L180 3-Pass Rehandler. The machine is designed for rehandling applications, with a high tipping load and long reach to fill a truck in three passes. The rehandling counterweight allows for a bucket that is approximately 0.25 yd³ (0.19 m³) larger than that on a standard L180H. Customers can choose between four different buckets to find the right fit based on material density: 6.3 yd³, 6.8 yd³, 7.2 yd³

and

SANY SY50U Compact Excavator

SANY’s SY50U compact excavator offers a zero tail swing radius and independent boom swing built to work in tight spaces. The selectable work modes help to deliver power where it’s needed and optimize fuel use. Designed with easy access to service points to reduce downtime for scheduled maintenance. The Tier 4 final power plant, advanced SLSS hydraulic system, optimal power control and work mode selection improve speed and power while reducing fuel consumption. Zero tail swing radius and independent boom swing allow operation in extremely confined spaces. Easily accessible service points and a detachable radiator screen are among the features that make scheduled maintenance more convenient. All models feature standard auxiliary lines to run powered attachments. The SY80U boasts a spacious, comfortable, climate-controlled cab to keep you cool in the summer and warm in the winter. Standard safety features on all models include, but are not limited to, high visibility, intuitive control layouts, ergonomic joysticks and switches, adjustable and comfortable operator seats, camera systems and LED work light packages. Operating Weight: (5,300 kg) 11,684 lb. Ground Pressure (31.6 kPa) 4.6 psi. Engine: Yanmar 4THV88C; Displacement: (2.2 L) 134.3 in3; Gross Power (29.1 kW) 39.0 hp. Hydraulics Load Sensing with Pilot Control: Main Hydraulic Pump Axial Piston - Variable Displacement Operating Flow (maximum) 110.0 L/min 29.1 gal/min; Operating Pressure (maximum): (24.5 MPa) 3,553 psi. Travel Motor Axial Piston with Park Brake: Travel Pressure (maximum): (24.5 MPa) 3,553 psi; Travel Speeds (maximum): 2.7/4.0 km/hr 1.5/2.5 mph; Travel Effort (maximum): (40.7 kN) 9,150 lbf. Grade Capability: 35 degrees. Swing Motor Axial Piston with Swing Brake: Swing Pressure (maximum) (19.1 MPa) 2,770 psi; Swing Speed (maximum) 10 rpm. Undercarriage: (standard) Belted Rubber Track. Track Shoe Width (standard): (400 mm) 16 in. Track Rollers (per side): 4. Carrier Rollers (per side): 1.

The new dump truck further complements the extensive Liebherr earthmoving machinery range. The TA 230 is completely redesigned to suit the most challenging requirements, built for maximum durability, featuring new curves with hard edges and tested to the limit. With outstanding handling abilities, unbeatable off-road capabilities and a newly designed dump body, the Liebherr TA 230 is right at home moving material in extremely challenging terrains. A modern cab with large all-round windows and a short, angled bonnet provide excellent visibility of the trucks travel, working and articulation zones at all times.

This 74-hp machine has a rated operating capacity of 1,950 lbs. and high-flow auxiliary hydraulics that make the machine compatible with high-power attachments. The 1950 RT is built with numerous track widths and tread patterns. The radial lift arm design enables ground engaging work. Added auxiliary hydraulic performance provides a platform for running a range of attachments. The machine includes the IdealTrax track autotensioning system, a swing-out cooler that keeps the engine compartment clean and engine temperatures down, and the Manitou EasyMANAGER fleet management platform (telematics).

The HX90A is the company’s first 9-ton compact excavator. Designed to deliver power and fuel efficiency, the HX90A is a solution for digging and trenching and a wide range of jobsite applications. Weighing 20,040 lb. (9,090 kg) and powered by a Yanmar engine that provides 65 net hp (48.5 kW) at 2,400 rpm, the HX90A balances strength with fuel economy.

The DX100W-7 mini wheel excavator is capable of reaching speeds up to 24 mph and features a roomy cab, with low noise and vibration levels paired with high visibility. The machine comes equipped with three steering modes including four-wheel crab, which is designed to offer precision and maneuverability in tight spaces without the need to reposition the entire machine. The reinforced articulated boom features an additional pivot point. The DX100W-7 has a 1.35-ton counterweight for digging and lifting performance. It also features a large hydraulic capacity, so it can hoist and maneuver heavy loads. The excavator has a standard hydrostatic system that uses hydraulic fluid for responsive operation and control. By transferring power directly from the engine to the excavator wheels, the system provides high torque even at low speeds. Also standard is the around view monitor (AVM) camera system with a 270-degree view, equipped with ultrasonic sensors. The sensors alert operators of nearby objects as they back up the machine. A standard overload warning device is another safety feature and protects the machine against wear and tear.

The Volvo CE A50 delivers 10% more productivity and 8% greater fuel efficiency compared to the previous generation’s A45G FS. It also features improved fullsuspension technology for faster travel speed and a smoother ride. The truck has faster cycle times and improved efficiency over its competitors and fills a need in the market with its 50-ton capacity. Volvo CE pioneered the full hydraulic suspension concept in 2007, and now, the A50 takes the concept to new heights as the only full-suspension machine in its size class. As a result, it offers shorter cycle times, an increase in production per operator hour and lower costs compared to its standard suspension counterparts. A new electronic system and a new Volvo-developed transmission boost fuel efficiency, and the machine’s design allows for adaptation to future drivetrains as needed. As for software, the Volvo Co-Pilot display shows operators the important info they need and offers a range of smart solutions like Haul Assist with on-board weighing. These digital tools can boost uptime, further reduce fuel consumption, improve site logistics and maximize productivity across the most challenging of tasks. The A50 offers the same updated features and enhanced benefits as the other six models in Volvo’s new articulated dump truck series. Most notably, it delivers unrivalled traction, stability and fuel efficiency thanks to the Volvo drivetrain with Terrain Memory and Volvo Dynamic Drive (predictive gear selection). Visibility and safety are enhanced on the new-generation models with upgrades like a wider field of vision that exceeds industry standards, a tailgate with longer arms (to open wider and faster), and a host of improvements inside the cab. Maintenance costs are reduced by up to 6% over 12,000 hours of operation due to simplified servicing and longer change intervals.

John Deere Extended-Reach 326 P-Tier Telescopic Wheel Loader

Offering a similar build and design to the 324 P-Tier Wheel Loader, the 326 P-Tier is equipped with telescoping linkage, providing operation and extended reach capabilities. The new 326 P-Tier Telescopic Compact Wheel Loader offers more than 16 ft. of reach from its telescopic lift arm, providing lifting powers while still being compact enough to work in tight spaces. Controlling the telescopic arm can now be done at an operator’s fingertips, thanks to the mini-joystick located on the main control lever. Now equipped with the Load Torque Indicator System, operators can utilize visual and audible alarms if stability limits are exceeded during lifting, lowering or extension, providing protection against overloading. Once limits are reached, movements with the telescopic lift arms are only possible if the movement improves the stability of the load helping to keep the machine operating at maximum capability and performance. Optimizing loading and stacking processes, electro-hydraulic controls are customizable from the 9-in. touchscreen display, offering Auto Return-to-Dig and Auto Lift and Lower functions to lower cycle times. The 9-in. touchscreen display also provides key information including warnings, status and machine-positioning information. In terms of visibility, the 326 P-Tier features an overhead window with dedicated wiper blade and optional boom-mounted lights, in addition to LED lights, which provide an increased view. The 326 P-Tier features a standard 23-mph top speed. For tight jobsites, the Articulation Plus steering system delivers a full 30 degrees of articulation plus 10 additional degrees of rear-wheel steering.

It’s not backbreaking work when you have a solid steel backbone.

Make light work of hard work with Kubota construction equipment. The reliable, comfortable and all new KX040-5 excavator and SVL97-3 track loader are ready to do the heavy lifting.

The Vermeer XR2 is not just a hydro-excavator, it’s an on-site recycling system.

The XR2 vacuum excavator is the industry’s first vacuum excavator equipped with a shaker deck that separates liquids and solids to allow contractors to stay on the jobsite longer, work efficiently and reduce disposal expenses. Material excavated with the XR2 is fed through an onboard deceleration tank that exits through an airlock onto a shaker deck where solids and liquids are then separated. The solid material is moved by conveyor toward the rear of the machine where it is discharged and can be carried away or left on the jobsite, depending on the material. Used, slurry water is pumped into the fluid storage tanks for disposal. The design of the XR2 can help expand the use of vacuum excavation for everything from utility potholing and stitch boring to slot trenching and general construction, equipping you to do more.

The KATO IC70R caters to material handling and transfer projects on construction sites, as well as rental applications. This crawler carrier offers 360-degree rotation and a three-way opening dump bed for versatile operation. Equipped with a joystick for control, the machine does not need a wide-load permit and can be deployed in tight work areas. The IC70R measures 18 ft., 2 in. (length) and offers a maximum dump height of 14 ft., 11 in. A 65-degree dump angle supports thorough material transfer. Powered by a 188-hp Kubota V5009 engine, the crawler carrier features two travel modes. Low travel mode allows the machine to travel up to 5 mph, while high travel mode offers 7.5 mph of travel speed. A 75.2-gallon fuel tank enables extended use on jobsites.

John Deere744 X-Tier and 824 X-Tier Wheel Loaders feature the John Deere Electric Variable Transmission (EVT) E-Drive system. Both models are equipped with a JD9 diesel engine as the primary power source, however, the torque converter and traditional transmission have been replaced by the EVT system. In addition, the E-Drive component provides instant power. Focusing on cab comfort, operators can expect a quiet cab environment attributed to the constant engine speed. Operators can also access seating and an AM/FM radio with Bluetooth capabilities. With the Advanced Vision System and Advanced Object Detection, operators can utilize a range of views on both sides of the loader and visibility beyond conventional mirrors. Also, dynamic reversal projected path lines assist with visualizing the anticipated reversal path for line of sight. The loaders are now equipped with John Deere Pile Slip Assist. Operators can experience proactive differential lock ahead of pile engagement which reduces tire slip, improves bucket fill and lowers cycle time.

The TL80VS is designed for construction, utility and rental applications. The vertical-lift unit is equipped with a variety of features, including lift-height and high-flow attachment capabilities. The 9,610lb. TL80VS is a construction-grade, durable machine. A 2,900-lb. rated operating capacity and 74-hp Yanmar Tier 4 Final diesel engine offers performance on the jobsite. A 10-ft., 6.5-in. max bucket pin height supports the TL80VS’ ability to load dirt into trucks and conduct at-height tasks. Users can navigate the jobsite with a top travel speed of 8 mph. The new TL80VS is equipped with a torsion axle suspended undercarriage featuring a pivot link system at the rear axle. The linkage technology uses a spring load that reduces oscillation and stabilizes the machine for ride quality and material retention. Additionally, the TL80VS can be optioned with a 34.3-gpm high flow with performance maximized by large line sizes, hydraulic coolers and direct-drive pumps for reduced power loss and increased flow and pressure directly to the attachment. Inside the cab, operators can access a standard mechanical suspended seat and 7-in. touchscreen display. Full, 360-degree visibility enables jobsite awareness and safety, supported by a removable roof hatch escape.

Powered by a 115.3-hp engine, the DEVELON DTL35 helps operators gain traction and maneuverability in tight spaces. The DTL35 compact track loader is equipped with a D34 engine, which is also used in the DEVELON DD100 dozer. Two rubber track patterns are available, and both include a wide and narrow version. A wide multi-bar track comes standard, while a block pattern is optional. Ride control reduces shocks and vibrations, which offers stability for the bucket and minimizes spillage when the compact track loader navigates rough terrain while carrying full loads. The auto return to dig automatically returns the arms to the lowered position. The standard two-speed travel feature includes: the higher speed (up to 9.2 mph) for traveling long distances or moving between jobsites and the lower speed (up to 6.1 mph) for stabilizing the machine during controlled movements in challenging conditions.

The SANY SY335C LC Excavator offers heavy-duty digging and lifting performance. This machine is powered by a 280.3-hp Cummins L9 engine and is capable of digging up to 22 ft., 4 in. deep. Equipped with a long undercarriage, the excavator generates a maximum swing speed of 9 rpm. The boom measures 20 ft., 2 in. for extended reach in rugged work areas. Standard auxiliary circuit configurations include one-way and two-way primary auxiliary and two-way secondary auxiliary circuits with dedicated auxiliary rotate pump. The SY335C has a large fuel tank, holding up to 143 gallons of fuel. For visibility, the machine comes equipped with both blind-side and rear-view cameras. Operators can access a 10.4-in touchscreen display inside the cab. This excavator features USB charging, Bluetooth connectivity and 12/24V low voltage outlets for powering devices. For safety, the machine comes with a motion alarm with cancel switch, overload alarm and electric horn. Customer can add the following optional components to the SY335C to meet their operating or project requirements: quick coupler, heavy-duty or high-capacity buckets, centralized lubrication system and protection screens for the cab.

New Holland ML35T and ML50T Telescopic

Two new telescopic reach models — the ML35T and ML50T — have been designed to give operators reach and hinge pin height when loading or moving materials is required. With their compact design, low ground clearance and balanced weight distribution, the machines allow operators to navigate tight spaces and minimize ground disturbances. The telescopic boom design of the ML35T and ML50T models redefine reach capabilities for SAL models. The flexible nature of these booms allows operators to retract and extend as needed to handle jobs with various height needs. With increased elongation of the boom, these models are designed for space-limited sites, delivering horizontal and vertical outreach. Operators also use the telescopic boom to maneuver and handle materials at elevated heights, such as loading concrete debris over dump truck box sides. Both models feature a hinge pin height of around 170 in. (4.3 m).

Takeuchi has launched the TCR50-2 crawler dumper for moving heavy materials across challenging terrain. Previously available from Takeuchi in other parts of the world, the manufacturer is now bringing the crawler dumper to North America. Weighing 14,440 lbs. with a 118hp engine, the TCR50-2 crawler dumper is a versatile dump carrier for a range of applications. With a 65-degree dumping angle and 8,157lb. maximum loading weight, the TCR50-2 allows operators to carry up to 2.7 cu. yd. of material while rotating and dumping it in a single cycle. The TCR50-2’s ability to rotate its dump bed 180 degrees reduces both the need to reposition the machine and deterioration of its rubber tracks. The TCR50-2’s operator’s station features a 5.7-in. multi-information color display with standard 180-degree rearview camera, hydraulic joystick controls, adjustable suspension seat, air conditioner, radio with USB functionality and cup holder.

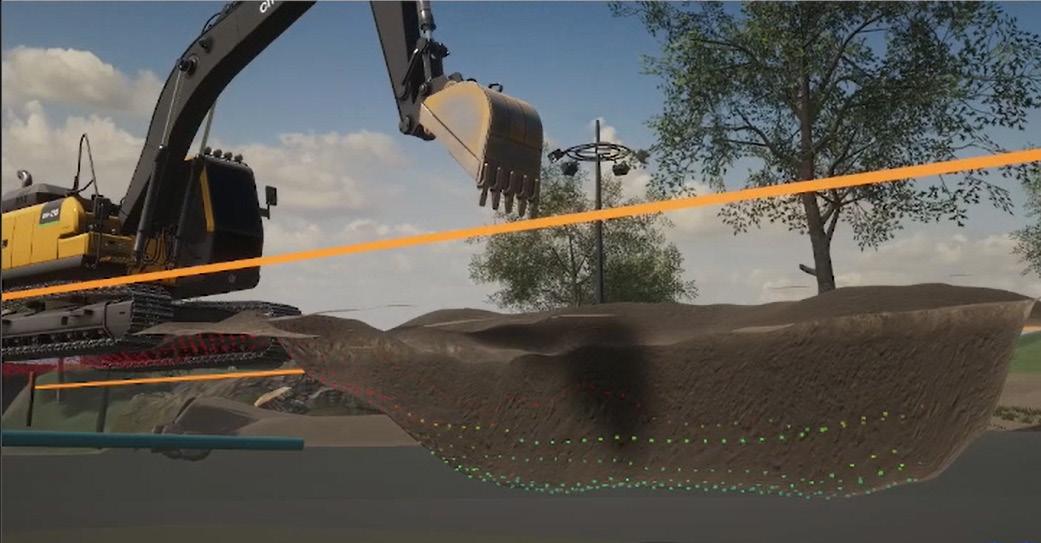

John Deere offers the updated 350 P-tier excavator, manufactured in Kernersville, North Carolina. The excavator offers SmartGrade technology as a factory option and field upgrade kits. Customers can choose from 2D guidance, 3D guidance, 2D SmartGrade Ready Control, and SmartGrade 3D Control. These grade management options allow customers to choose a level of technology that’s right for them with the ability to upgrade as their business grows. Overdig protect limits the bucket’s cutting edge from going below the target design surface. Visibility around the machines has been improved with the option of a right, rear and left camera system with LED surround lighting that provides 270-degree visibility and is integrated into the primary display in the cab. This model comes standard with front LED work lights. Owners and operators also have the option of a heated air suspension seat, leather heated and cooled seat, additional deluxe LED work lights, as well as cold weather and debris packages for those who tackle jobs in any weather condition. Outside the cab, the machine is equipped with a new, larger hood design and better serviceability. Each cooler is individually removable, and operators or technicians have access within the compartment. The excavator features electric on-demand cooling fans that reduce engine load, in-line after treatment for less restriction and system complexity, along with increased front piping diameter to cut down hydraulic restriction.

The B760 backhoe loader features a lift capacity of more than 2,200 lbs. at full reach, digging depth of 18 ft., 5 in. and nearly 180 degrees of backhoe swing for less repositioning. The backhoe loader comes with a standard-equipped extendable arm that provides up to 8 in. of additional dig depth. The B760’s performance and versatility extend throughout the machine, with the front-end loader providing a lift capacity of 7,985 lbs. with its standard, general purpose bucket. Powered by a turbocharged 3.4L Bobcat engine, the B760 delivers powerful, high-torque performance. It achieves emissions compliance without the use of a diesel particulate filter (DPF). Features include: Ride control for reduced bucket spillage; Automatic return-to-dig positioning; Eight work lights for long days of loader and backhoe operations; A 1.4-cu.-yd. general purpose loader bucket for jobsite versatility; Pilot controls for backhoe workgroup operations; Auxiliary hydraulics to power attachments from the front and rear.

Volvo Construction Equipment has introduced the new-generation EC230 Electric excavator for North America. This machine from Volvo CE is designed to meet the growing demand for large, powerful equipment with reduced environmental impact. The 23-ton EC230 Electric is a general-purpose crawler excavator that first launched in early 2023. It has a breakout force of 33,500 lbf., a maximum digging reach of 32 ft., 7 in. and a maximum digging depth of 22 ft., 1 in. Early users have found that the EC230 Electric excavator reduces emissions. For instance, Skanska used it to load trucks of export material from an underground tunnel as part of a transit line renovation in Los Angeles. The machine reduced hourly carbon emissions by 66% over the 90-day test period. In a 90-day pilot with Sunbelt Rentals, the midsize electric excavator delivered an 80% carbon reduction rate in comparison to its diesel equivalent. The updated version of the EC230 Electric excavator offers an improved battery for longer runtime. It also has the updated cab and styling that is part of Volvo’s latest series of excavators.

Terramac’s new Wheeled Dumper Series provides a versatile, high-speed alternative that complements the rubber track crawler carrier, catering to a range of ground conditions and operational needs. The introduction of the Wheeled Dumper Series offers customers a choice when ground conditions are less rugged. The Wheeled Dumper Series is available in a variety of models and sizes. The rear dump, swivel dumper and multiview swivel dumper are designed for performance in diverse construction applications.

The SANY ST230V compact track loader operates on a Yanmar 4TNC98CT engine and offers a 2,430-lb. rated operating capacity with a max breakout force of 5,733 lbf. The multifunctional control panel features one-click startup and one-click unlock, alongside a 7-in. LCD display. The spacious cab features auto-temp HVAC, and airsuspension seat and pilot controls. Standout features of the ST230V include: 36.2 high-flow hydraulic system; hydraulic quick-coupler-ready design; auto-reversing radiator fan; airride seat; flip-down door. Available mid-2025.

Volvo Construction Equipment has introduced the midsize L120 Electric wheel loader for North America, designed to meet the growing demand for large, powerful equipment with reduced environmental impact. The L120 Electric wheel loader is a 22-ton machine with 6-ton lifting capacity and a recommended rehandling bucket capacity of 5 yd³, giving it nearly identical performance capabilities as its conventional counterpart. Its 282-kWh lithium-ion battery system can run for five to nine hours on a single charge, depending on the application. Charging options include a 50-kW DC mobile charger that will charge the L120 Electric from empty to full in about six hours or a 150-kW DC fast charger that can charge it from empty to full in two hours. The L120 Electric wheel loader is equipped with separate electric motors for propulsion and hydraulics. The system recoups deceleration energy to extend battery runtime, reduce brake wear and minimize the need for axle oil cooling. The loader also features active cooling and heating of the high-voltage batteries as well as passive cooling for the electric motors, transmission and hydraulic oil. It includes many of the same features as its diesel equivalent, including on-board weighing with the Volvo Load Assist system, torque parallel linkage, electro-hydraulic lever controls and auto bucket-leveling functions. The electric loader is compatible with a range of Volvo attachments, such as buckets, forks, grapples, brooms and snowplows.

Hitachi Construction Machinery has implemented a full-model change of the EH4000AC-3 rigid dump truck to develop the EH4000AC-5 (nominal payload of 242t, gross machine operating weight of 427t). By applying metal fabrication technologies accumulated through the manufacturing of hydraulic excavators, the company increased the durability of the machine, with a payload of 242t. This is a payload increase of 21t compared to the EH4000AC-3. The EH4000AC-5 evolved the Hitachi AC drive system cultivated through the current EH AC3 series models and strengthened the brakes, suspension and other aspects of the undercarriage to achieve smooth, stable driving and deceleration performance. In addition, the change to a fully electric specification equipped with batteries and trolley dynamic charging systems that receive power from overhead lines installed at mines is also compatible with the EH4000AC-5 similar to the current EH-AC3 series models. With a maximum speed of 65 kph, the truck is equipped with a new feature that allows operators to select from three different driving modes (High Power Mode, Power Mode and Eco Mode) according to the site environment. Operators can select Eco Mode when they wish to reduce fuel consumption or High Power Mode to maximize driving performance. In terms of the deceleration performance, braking capabilities were updated by changing the hydraulic brakes from front dry brakes to wet brakes and adjusting the retarder auxiliary brakes. Information regarding the safety conditions around the machinery, loading conditions and more is displayed on the monitors to support safe operation by customers.

The TB395W excavator weighs 23,424 lbs. when equipped with outriggers and a blade. It’s powered by a Tier-4-Finalcompliant diesel engine delivering 114 hp at 2,200 rpm and up to 339 ft. lbs. of torque. A closed-loop, load-sensing hydraulic system delivers control of the work equipment and a range of hydraulic attachments. The TB395W features two steering modes -- 2WS (two-wheel steering) and 4WSC (four-wheel with crab steering). A two-piece boom with long arm allows for clearance between the bucket and dozer blade due to arm-mount position. This design allows TB395W operators to pull the bucket all the way back to the dozer blade, which is designed for working in narrow spaces or moving an obstacle out of the way. An Auto Cruise feature enables operators to set and adjust their travel speeds with a toggle switch. Auto Cruise is designed for using attachments that require a consistent, repeatable travel speed, such as a mulcher, mower or trencher. The excavator’s 13 ft., 5.2 in digging depth and 27-ft. cutting height makes it useful on construction sites. The TB395W offers a maximum bucket breakout force of 13,241 lbs., a maximum arm digging force of 8,925 lbs. and a traction force of 12,994 lbs. The TB395W is equipped with three auxiliary circuits that cater to different hydraulic requirements. The primary circuit delivers 32 gpm for use with hydraulic attachments. The secondary circuit provides 14.5 gpm, offering flexibility for a wide range of applications. Additionally, the third auxiliary circuit is specifically designed for use with a hydraulic quick coupler.

The telehandlers are powered by the Cat C3.6TA (turbocharged and aftercooled) engine that meets U.S. EPA Tier 4 Final/EU Stage V emissions standards. The 74 hp (55 kW) engine includes a zero-service diesel particulate filter (DPF) and does not require diesel exhaust fluid (DEF). A 115 hp (86 kW) option for the TH0842, TH1055, and TH1255 models also uses selective catalytic reduction (SCR) technology. The telehandlers offer three operator station options: open canopy, enclosed cab with heat and enclosed cab with heat and air conditioning. The redesigned interior features an ergonomic control layout, standard tilt steering column, and a new full color LCD monitor that provides machine information in a choice of four languages – English, French, Spanish or Portuguese.

The new CASE 580EV electric backhoe loader carries over the same dimensional loading and digging specifications and delivers the same breakout forces as the four-wheeldrive, 97-hp CASE 580SN diesel model — marking an upgrade in performance since CASE first debuted its Project Zeus electric backhoe concept at CONEXPO in 2020. With this new production unit, CASE took customer feedback and made several updates from thermal management to operator controls to electrify a machine with comparable specs to the 580SN. CASE also included new features, like an 8-in. color display, air conditioning, a front-dash display and adjustable four-corner, multicolored LED strobe lights. Powered by a 400V, 71-kwh lithium-ion battery platform that’s charged with the same type of Level 2 J1772 adapter found in automotive EVs, the new electric backhoe loader is designed to deliver up to eight hours of operational runtime on a single charge, depending on the application. The battery platform also uses a thermal management system with system-specific cooling circuits to regulate temperatures and help maintain performance in hot or cold conditions. The four-wheel-drive 580EV uses two independent electric motors for the PowerDrive transmission and hydraulic pumps feeding the loader, backhoe and steering systems for performance in loading applications. The 14-ft. backhoe also includes an Extendahoe to boost reach, while features like ProControl swing dampening, PowerLift/PowerBoost and electrohydraulic controls support use on the jobsite. Electrification also provides performance features like torque response and peak torque at any rpm, so operators don’t need to wait for an internal combustion engine to ramp up to meet load demands. The cab has features like heating and air conditioning, an 8-in. touchscreen display, customizable work mode/sensitivity settings, push-button start and operator security codes. Multicolored, four-corner strobe lights also let operators work safely and meet regulatory requirements, with adjustable colors, strobe patterns and an “always-on” feature for low-light conditions when strobes are not needed.

The KATO HD308US-7 is designed for earthmoving projects in urban areas and tight spaces. With an operating weight of over 19,000 lbs., the machine caters to construction and rental applications. This fixed boom excavator offers a combination of strength and agility. With a bucket digging force of nearly 15,000 lbs., the HD308 is powered by a 57-hp Yanmar engine for reliable performance under heavy loads. The engine’s design and the fuel tank capacity of over 34 gallons reduce the need for frequent refueling. The cabin of the HD308 features a large screen that displays multiple camera views, including rear and side perspectives, supporting safety and situational awareness. Another screen provides access to control settings and monitor and adjust machine parameters. The excavator’s hydraulic system supports powerful digging and lifting capabilities. Additionally, the excavator offers versatile auxiliary flow options: the first line has a maximum flow of 30 gpm, while the second line provides 16 gpm. These auxiliary flows enable the use of a variety of hydraulic attachments.

The John Deere 333 P-Tier compact track loader is designed for lifting, transporting and material handling tasks on worksites. This machine is powered by a 105.8-hp Yanmar engine and delivers a bucket breakout force of 13,750 lbs. The 333 P-Tier can be equipped with SmartGrade Ready including 2D grade control or 3D SmartGrade with Topcon. The machine also includes a new hydraulic system. In addition, On Board Diagnostics enable an operator to navigate through a diagnostic and settings menu structure to look up detailed information on current machine settings and active codes. With the new monitor option, active diagnostic trouble codes will also contain detailed descriptions about the issue and not just the code number.

Hitachi ZAXIS-7 Super Long Front Excavator

The ZX210LC-7H Super Long Front (SLF) excavator provides 50 ft., 4 in. (15.35 m) of reach at ground level and a 39-ft., 2-in. (11.94-m) dig depth. A proprietary hydraulic circuit has been engineered for safe operation. It includes an upgraded swing motor for next-level reach and control as well as Hitachi genuine bucket attachments that pair with the new ZAXIS-7 Super Long Front excavators. A part of the ZAXIS-7 series, the 54,900-lb. (24,900-kg) ZX210LC-7H SLF is a dedicated longreach excavator. The ZX210LC-7H SLF is the first of multiple long-reach excavators to be introduced to the market. The ZAXIS-7 SLF offers a redesigned operator station featuring large space with minimal vibration and noise. The heavy counterweight, proprietary hydraulic circuit and swing motor support operation of the super long arm. The hydraulic control valve is responsive, even when operating at or near maximum extension. Two work modes (Economy and Power) allow operators to tailor operations for jobsite conditions.

An AERIAL ANGLE camera gives users a 270-degree bird’s-eye view where they can choose from multiple image options to see the machine’s immediate environment on an 8-in. (20.32-cm) antiglare LCD monitor.

HD Hyundai Construction Equipment North America has announced the addition of the 258-net-hp (192 kW) HX355A LCR, a 35.5-ton compact-radius excavator, to its lineup of fullsized crawler excavators. With an operating weight between 78,483 and 79,807 lbs. (35,600 and 36,200 kg, respectively) HX355A LCR fits between the Hyundai HX350A and HX380A conventional-swing excavators. The compact-radius design allows the excavator to perform a multitude of jobs within confined areas typically reserved for smaller machines. The HX355A LCR is typically equipped with a 1-¾-yd3 (1.34 m3) bucket and features 18 in. (475 mm) of ground clearance. Hyundai also offers an 11-ft., 10-in. (3.6 m) dozer blade as an option. The HX355A LCR has four selectable power modes and one-touch power boost for control. The HX355A also comes with an integrated SPC (smart power control) system. SPC uses sensors and software to monitor the excavator’s workload in real time. Based on this data, it automatically adjusts engine power and hydraulic flow to match the required digging force.

The JCB 370X heavy-duty excavator in the 35- to 40-ton sector has the ability to move 18 tons more material per gallon of fuel than competitive models and includes a Tier 4 Final 322 hp Cummins diesel engine. The 370X has a new JCB UX user interface, with 10-in. color touchscreen display and controls and increased hydraulic pressures. The Cummins L9 diesel engine is an 8.9-L, 6-cyl. with 322 hp available at 1,700 rpm, delivering power within a reduced operating rev range to increase fuel economy and reduce overall noise levels. The Kawasaki tandem hydraulic pump operates with an increased 5,076 psi pressure, rising to 5,511 psi during power boost cycles. Operation gets a boost from the valve block and a hydraulically operated cooling fan with reversing function. A heavier counterweight contributes to added stability, while larger structures cope with the additional forces. Increased service pipework diameters and raised hydraulic pressures result in more power at the dig end, which has been redesigned with cast boom foot and hydraulic ram pivot points for additional strength and longevity. The 370X is supplied with a 21 ft.-monoboom, with a choice of three arms up to 13 ft.

The new Cat 275, 275 XE, 285 and 285 XE mark the expansion of the next generation design for Cat’s CTL line, joining the 255 and 265. All next generation Cat CTL models feature a redesigned engine compartment that places the engine and cooling package lower into the frame for improved stability, giving the operator confidence in handling heavy loads throughout all aspects of the work cycles. Meeting U.S. EPA Tier 4 Final/EU Stage V emissions standards, the four new CTL models are powered by the Cat C3.6TA engine. These new engines maintain horsepower across a wider rpm range compared to the previous engines powering the D3 series and boast significant torque increases – 50% for the 275 and 285. With a vertical lift design, these new next generation machines feature significant increases in lift height, breakout forces and ROC to elevate loader flexibility and performance. The 275 and 275 XE CTLs have a lift height of 134.4 in (3415 mm), 8 in (203.2 mm) higher than the 299D3, plus a 37% increase in tilt breakout force and 19% increase in ROC. Their new closed-center auxiliary hydraulic system allows these machines to operate all Cat Smart Attachments with the standard hydraulics provided. Standard hydraulic system pressure increases 5% to 3,500 psi (24130 kPa) in the next generation models. The 275 machine is equipped with standard hydraulic flow and is shipped from the factory outfitted as “High Flow ready.” High Flow functionality is activated via a new software enabled attachment (SEA), permitting on-machine or remote activation of increased hydraulic flow to 34 gal/min (129 l/min) for the 275 at standard hydraulic system pressure.

Yanmar CE ViO35-7 Mini Excavator

The 24.4-hp true zero tail swing excavator includes 360-degree visibility, a 25% increase in travel speed under load and a 7% improvement in excavator efficiency. The 8,047lb. model has increased excavation capabilities thanks to greater breakout forces and improved cycle times under load. Plus, a higher torque swing motor boosts power for backfill work involving swinging and usability on slopes. This is all powered by a three-pump hydraulic system that leads to less risk of slowing down during simultaneous operations — such as with the boom, stick, swing and curl functions. With 25% faster travel speeds under load, operators can move quickly around the jobsite. It’s also easier to transition to slower tasks thanks to the auto kickdown feature built into the two-speed operation. The model includes a durable undercarriage, cylinder guards, hose guards, strategic placement of the boom light to limit risk of damage, Yanmar’s diesel engine and more. The new model includes simplified fan belt tension adjustment thanks to the rearward location of the alternator. Its engine also doesn’t require the addition of a Diesel Particulate Filter (DPF), allowing for simple operation and service. Yanmar configures the ViO35-7 for convenient maintenance, including easy access to grease points and filter locations. Lastly, problems are easier to diagnose either by the owner or over the phone with a service center due to clear and intuitive error information on the display. Yanmar offers a standard hydraulic quick coupler, which is upgraded on the ViO35-7, providing easy attachment switching by allowing operators to engage or disengage — as well as see the status of — attachments without leaving the operator seat.

ASV has introduced the VT-80 midsize compact track loader for construction. Powered by a 74-hp Tier-4 Final Yanmar engine, the 8,955-lb. VT-80 provides power and performance and offers a 2,800-lb. rated operating capacity. The VT-80 is part of ASV’s redesigned line of midsize compact track loaders. The machine features ASV’s patented Posi-Track undercarriage with dual-level suspension for traversal over tough terrain. The 7-in. color touch display supports operation, allowing operators to monitor machine specs, service history, schedules and more. Automated features like the return-to-dig and work tool positioner functions are designed for repetitive tasks. Standard hydraulic flow has been increased to 24.7 gpm, while high flow of 34.3 gpm can be utilized for attachments. The cab of the MAX-Series model features 360-degree visibility and a pressurized cab to keep dust and debris out. The machine is designed with a smaller overall machine footprint compared to previous models, allowing work in tight spaces. Combined with the performance and agility of ASV’s Posi-Track rubber track undercarriage, the compact track loader can reach remote jobsites.

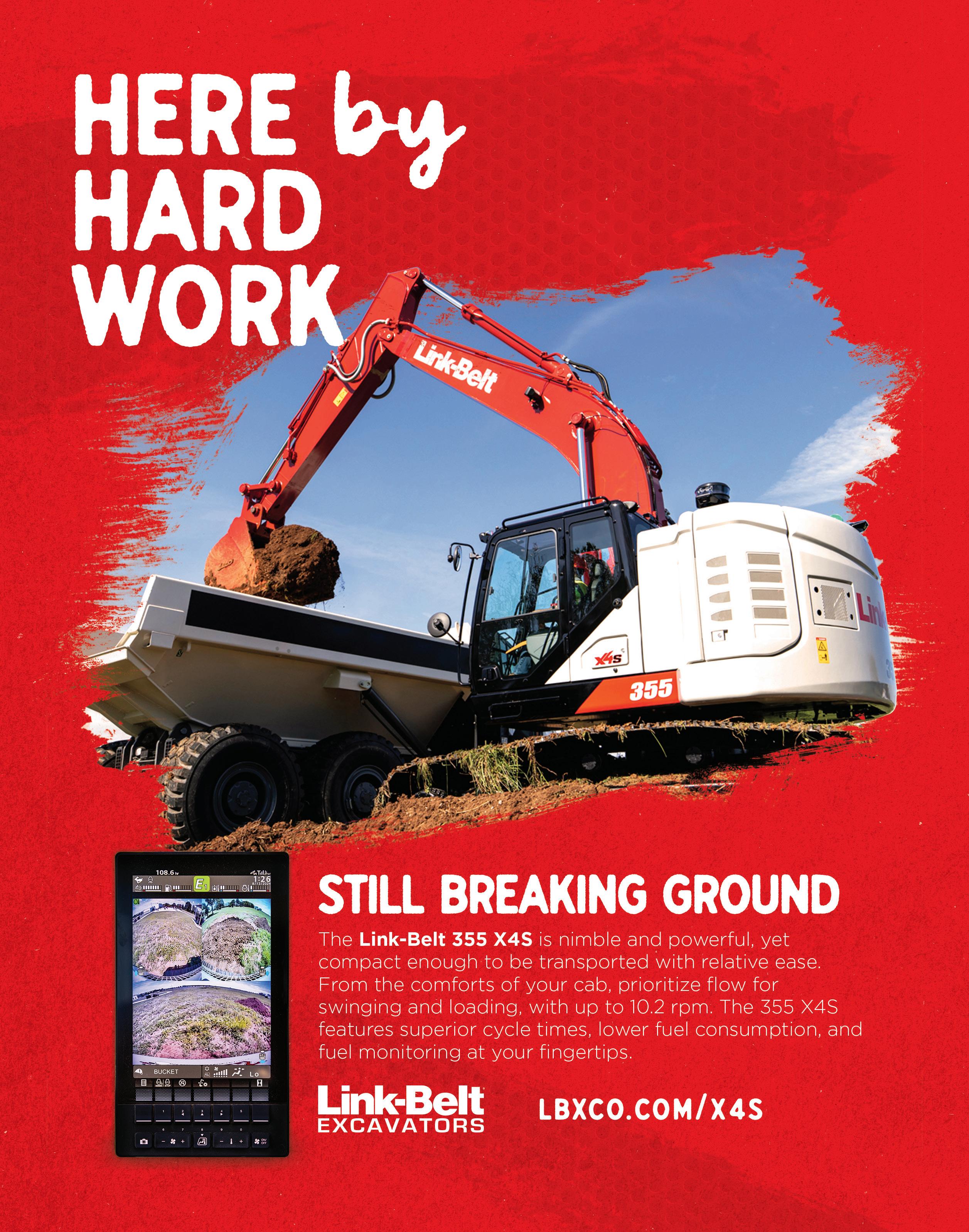

The 370 has advanced technology, including Digital Level, Dynamic Stability Assist, Height and Depth Alarm, and Payload. The 83,776-lb. 370 X4S includes an electronically controlled hydraulic pump system and Tier 4 Final engine with 268 hp. Maximum dig depth is 24 ft., 2 in. and reach at ground level is 36 ft., 1 in. Bucket digging force is 56,160 lbf. Bucket capacity is 1.26-2.93 yd3. Maximum travel speed is 3.5 mph. The heart of these machines lies in their electronically controlled hydraulic pump system and the industry-recognized SSC (Spool Stroke Control) system. This innovative combination enhances efficiency and control, while the Isuzu AQ-6HK1X Final Tier 4 engine, known for its exceptional fuel economy, powers the machine. Notably, the 370 achieves up to 7% improved fuel consumption without requiring a Diesel Particulate Filter (DPF), eliminating the need for maintenance or replacement. Operators can select four power modes- Speed Priority, Power, Eco, and Lift, allowing them to optimize power, precision, and fuel savings for each task, resulting in enhanced cost-effectiveness.

New Holland E90D Midi Excavator

• 4-cyl., 300-in. displacement engine

Hydraulic system delivers 42 gpm flow

• Dump height and dig depth of almost 7 ft.

• Bucket breakout force of 13,000 lbs.

• Operating weight of 20,305 lbs.

• Comes standard with one-way and two-way auxiliary hydraulics, along with a second set of two-way auxiliary hydraulics, for wide range of attachments

• Dedicated constant flow provision for mulchers allows operators to run their mulchers efficiently without sacrificing hydraulic flow for other attachments

The KATO HD25V5 Compact Excavator supports digging operations construction sites. Designed for work in tight spaces, the machine is powered by a 23.6-hp Kubota engine with a fuel capacity of 11 gal. During use, the compact excavator delivers 4,721 lbs. of bucket digging force, allowing operators to carry out site preparation tasks. This machine features an 18-in. bucket. Equipped with a four-pump system, it offers a maximum digging depth of 8 ft. for reaching deep into the ground. The HD25V5 can travel up to 2.7 mph on high and 1.5 mph on low. Operating features include auto-parking brake, neutral engine-start and more.

O ering versatility and high productivity in a compact package, Wacker Neuson utility track loaders allow you to do more and do it more e ciently. Ergonomic controls are intuitive and a spring suspension provides all day comfort and added stability. Contact your local dealer to see how Wacker Neuson helps keep your jobs on track.

Three GEHL compact track loaders (the VT210, VT230 and VT275) deliver updates in safety and serviceability over previous GEHL CTLs. These models are vertical lift and feature a new lift arm design for visibility. The operator experience has also been upgraded with an update on GEHL’s patented folding door — and the new cab offers visibility with a new window and roof design. Breakout forces and tank capacities are increased for long operating times — all with a focus on lower total cost of ownership (TCO). Auxiliary hydraulics (both standard and high flow) have been upgraded and GEHL offers a full and expansive lineup of Manitou Group attachments to make these machines versatile. The patented track-tensioning system tensions the track to the proper tension when the machine is started and relieves the tension when the machine is turned off. Instead of greasing for proper tension every 50 hours or so, GEHL uses a hydraulic system to keep constant tension on the tracks. As this happens automatically, it takes less time to achieve proper tension. It also increases track life by up to 15% by keeping proper tension at all times and guarding against over tensioning. Over-tensioned tracks wear from the inside out and rob horsepower from the machine as it takes more effort to turn the track.

The Hitachi ZW80 offers productivity, comfort, advanced technology, environmental performance and easy maintenance. Bucket capacity (m³) ISO Heaped: 1.2 yd³ (0.9m³). Engine Rated Power (kW)66 hp (49kW). Operating weight (kg): 12,600 lbs. (5,715kg). Breakout force (kN) 8,270lbf (36.8kN).

The 3CX is the foundation of JCB’s backhoe lineup, offering a balance of power and fuel efficiency. With advanced hydraulics and a strong loader arm, it delivers excellent lift capacity and breakout force. The 74-hp JCB EcoMAX engine provides high torque at low rpm, maximizing fuel savings without compromising performance. The six-speed AutoSHIFT transmission ensures smooth and efficient operation, reducing operator fatigue and increasing productivity.

The 3CX Plus builds on the 3CX’s capabilities with an increased 109-hp engine delivering 381 lb-ft of torque. The extra hp and torque provides a machine with superior roading and loading than the standard 3CX. The new 3CX Pro model features an even more refined powertrain, making it the fastest backhoe in the world with a top speed of 31 mph. The 4CX Pro is JCB’s most powerful and versatile backhoe. With equal-sized wheels for superior traction, it offers four-wheel steer for exceptional maneuverability in confined spaces.

The heavy duty lift cylinders delivers increased lift capacity and breakout force, making it ideal for demanding applications. Updates across the line include four-wheel drive and an automatic torque lock, improving traction and reducing fuel consumption when roading. High-flow hydraulics system allows operators to run powered attachments efficiently, expanding its versatility across different applications. The Parallel Lift Loader Arms ensure that materials stay level during lifting, improving precision and reducing spillage. All new models have the 6-speed transmission for enhanced operator control, while the highcapacity hydraulic pump allows for smooth, efficient operation even under heavy loads.

The redesigned cab features a 7-in. display, Bluetooth connectivity, ergonomic joystick controls, and improved visibility through larger mirrors and LED work lights. This ensures that operators stay comfortable and focused throughout their shifts.

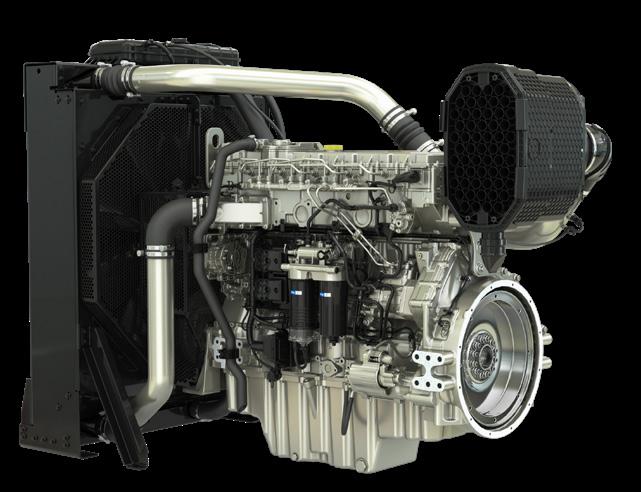

The HD130 dozer is a 15-ton-class machine equipped with a 4-cyl. Tier 4 Perkins 1204J engine. The HD130 can be ordered as either an LGP (low ground pressure) model or in an XL configuration. The LGP model has an operational weight of 33,730 lbs. (15,300 kg) and ground pressure of 4.98 psi (34.3 kPa), while the XL configuration weighs 31,907 lbs. (14,500 kg) with a ground pressure of 6.16 psi (42.2 kPa). Both feature a track length of 8 ft., 11 in. (2,720 mm). The HD130 comes standard with a 2D grading system that simplifies precision grading for novice operators. The system controls the blade functions, enabling faster and more accurate grading without the need for GPS or lasers. Standard electrohydraulic controls enhance ease of operation and accuracy, and the ergonomically designed joystick helps reduce operator fatigue. Blade movement, slope and tilt can be adjusted to three different levels of control via the monitor. Other key specifications include maximum travel speed of 5.6 mph (9.0 km/hr), eight lower track rollers, and shoe width of 30 in (760 mm) with LGP blade. The HD130 dozer comes Trimble-ready from the factory, so Trimble Machine Control can easily be installed, offering enhanced precision and guidance for complex designs and construction projects. This feature allows for more accurate and efficient operation in challenging work environments.

LBX Co. introduced three new Long Front Excavators: the 220, 260, and 370 X4S. At the core of these machines lies an electronically controlled hydraulic pump system and the industry-recognized Spool Stroke Control (SSC) system. This combination ensures precise control and performance in various applications. The 220 model extends to 50 ft., 10 in., while the 260 takes it to the next level, reaching 59 ft., 9 in. The 370 model boasts the longest reach, extending to 60 ft., 10 in. Digging deeper isn’t an issue with these machines, as the 220 model can dig up to 39 ft., 5 in., the 260 model can reach 47 ft., 9 in., and the 370 model can dig to a depth of 46 ft., 3 in. The Isuzu Final Tier 4 engine, known for fuel economy, powers the machines with optimized swing speed. The design eliminates the need for a Diesel Particulate Filter (DPF), reducing maintenance costs and environmental impact. Choose from four power modes — Speed Priority, Power, Eco, and Lift — to tailor performance to specific tasks. The Long Fronts feature a lengthy 500-hour fuel filter service interval, enabling operators to work longer between filter changes. Additionally, the DEF tank’s low consumption rate of only 2% to 3% compared to diesel fuel allows for extended operation between refills. Fuel consumption in SP mode is improved by 4% for the 220 LF, 4.5% for the 260 LF, and 3% for the 370 LF (compared to the X4’s SP mode). All service points are conveniently accessible at ground level for easy access.

Haul Truck

Komatsu’s HD605-10 mechanical haul truck is a 70-ton rigid frame machine designed for quarry, mining and aggregate applications. This truck offers a tight turning radius for navigation on narrow haul roads and ergonomically designed cabin features for working long shifts. With increased horsepower and high-strength steel for reduced operating weight, the machine is built to provide speed on grade. Additional features include a MacPhersonstrut-type independent front suspension that allows the vehicle to traverse uneven road surfaces, the ability to regulate fuel consumption for lighter work with “economy” and “economy light” modes and controlled downhill descent with the automatic retard speed control function. New operator features include hill start assist, throttle lock, retractable sun visor and waiting brake. Maintenance elements include a full LED light package, plastic resin wheel chocks, maintenance-free batteries, brake performance checks and ground level Komatsu Oil and Wear Analysis (KOWA) sampling ports.

The Cat 903 compact wheel loader is designed to make work easier with its Cat C1.7 engine, offering 17% more horsepower than the previous model. The increase in power delivers improved performance when pushing, operating on grades, and using drive, steer and lift functions simultaneously. It provides a higher full turn tip load rating of 5,516 lbs. (2552 kg). Designed to provide comfort, the operator’s workstation features legroom, ergonomic pedal positioning, easy entry and exit, and optional speed-sensitive ride control. The multifunction joystick provides fingertip control of the standard third-function hydraulic system. Minimal engine overhang results in excellent rear and corner visibility, allowing for efficient operation in confined areas. Providing improved comfort, the seat design includes yellow touch points, making it easier to find the preferred operating position. The 903 can be optionally equipped with a hydraulic skid steer loader (SSL) coupler for faster and more efficient work tool changes. It provides a viewing window that enables the operator to see the fork tips when using available compact wheel loader style forks. The auxiliary hydraulic system delivers higher than previous flow of up to 14.5 gal./min. (54.9 l/min) at 3,336 psi (230 bar) for increased hydraulic power to operate hydraulic work tools likes power box rakes and grapple.

Take the guess work out of buying online with bidadoo.

Trained experts inspect the equipment from its chassis down to its sprockets, create a detailed Verified Conditions report, and upload photos and video to every listing.

Our five-star rating system confirms the quality of the equipment you’re purchasing. A quality and condition rating is given to product specifics like chassis, undercarriage, engine, hydraulic system, and more.

Your purchase is protected through eBay’s Business Equipment Purchase Protection.

All inspections are completed by bidadoo experts, a trusted eBay partner with over 20 years of industry experience.

Get end-to-end support at every step through bidadoo experts for questions about the product, shipping, financing, or liens and warranty.

Chassis

Sheet Metal/Body

Paint/Decals

Frame

C-Frame/Push Arms

Blade Linkage Pins/Bushings

Belly Pans

Undercarriage

Track/Show&Link Condition

Track Tensioners

Front Idlers

Sprockets

Rating Key

Based on age and use

Poor Very Good

This wheel loader is an ideal four-pass match with 70-ton trucks such as Komatsu’s new HD605-10 haul truck. The WA700-8 also offers improvements in performance, efficiency and operator comfort compared to its predecessor, the WA700-3. Compared to the previous model, the WA700-8 delivers: Up to 8% more gross power and 15% more torque, making it a robust choice for demanding work environments; 6% increase in lifting force and rated load, allowing operators to handle larger volumes of material with greater ease; Up to 8% more fuel efficiency, helping reduce operating costs while maintaining high productivity. The WA700-8 features a comfortable cabin with technology designed to help reduce operator fatigue on long shifts, including a new advanced joystick steering system and electronic pilot control levers for precision and ease of operation. Automation features such as an automatic digging system, semi-automatic approach, and semi-auto dump systems simplify repetitive tasks, helping operators optimize load cycles. The loader’s modulated clutch system offers precise control for smooth transitions between forward and reverse, which is critical during truck-loading operations.

This 24,000-lbs. (110-kN) class drill replaces the D23x30 S3 in the Vermeer utility drill lineup, with a 100-hp (74.6-kW) Cat 3.6L Tier 4F/Stage V engine. The D24 delivers a max peak thrust and pullback of 24,700 lbs. (110 kN) and a continuous thrust and pullback of 22,000 lbs. (98 kN). It also features 3,080 ft.-lb. (4,176 Nm) of rotational torque and a 45-gpm (170-L/min) mud pump.

Packed with advanced features and technology, the Vermeer D24 HDD enables crews to efficiently install utilities — including fiber, power cables and water infrastructure in congested urban areas. A standout feature of the Vermeer D24 HDD is its automated rod exchange (ARE) system. This technology increases onboarding velocity for new operators, reduces workload for skilled operators and maximizes wear part component life through highly controlled processes. With a single button push completing the entire rod changeout sequence, ARE eliminates up to 19 manual steps, streamlining operations and enhancing overall efficiency. The D24 operates at just 88 dB(A) at the operator’s ear with a guaranteed sound power level of 100 dB(A). This low noise output minimizes disturbance in sensitive urban areas, enhances onsite communication, and helps contractors meet certain local noise regulations.

Cat Next-Gen D8 Dozer

The next generation design makes it easier for operators to transition to different machine sizes. The bulldozer’s elevated sprocket offers better ride and balance than lowdrive undercarriages, and its long undercarriage delivers the D8’s renowned performance of high penetration forces and superior dozing performance. The Cat C15 engine offers an increase in horsepower over the previous build to take on a wide range of dozing, ripping and grading tasks. The D8 dozer’s next generation cab offers more space than the previous design complete with a wide air suspension seat with multiple adjustment options. Featuring an integrated rollover protective structure (ROPS), the next generation cab provides 17% improved visibility than the previous design1. It can be removed in approximately 30 minutes to facilitate machine servicing. The 254-mm (10-in.) touchscreen main display has built-in key features assistance to give operators an overview of the machine, technologies and helpful tips. When the machine is in reverse, the standard high-definition rearview camera feed shows prominently in the display. Distributed air from the heating, ventilation and air conditioning (HVAC) system effectively circulates around the operator and helps reduce window fogging and frosting. Assist technology features minimize operator input, boosting productivity for less experienced operators and decreasing effort and fatigue for everyone, while delivering quicker and more precise outcomes. Cat Assist with Attachment Reader Option (ARO) standard features include: Visibility improvements based on virtual visibility analysis; Comparisons made from a D8 (21B) model to the Next Generation D8 (22A) model; Feature not operational indoors or in areas where a GNSS/GPS signal is not available.

The SVL97-3 has a rated operating capacity of 3,459 pounds, and a new onepiece sealed cab for a clean, quiet work environment. It comes standard with KubotaNOW Telematics and a swing-out radiator for ease of service. The SVL97-3 features a Kubota engine, new hydraulic system, travel performance, and efficient cooling system. Equipped with a powerful 96.4 hp Kubota engine, common rail system and diesel particulate filter muffler, the SVL97-3 increased its top speed to 8.4 mph and has a rated operating capacity of 3,459 lbs. at 35% tipping load, more than 250 lbs. more than the capacity of the previous model. Plus, an optional 300 lbs. of counterweight can be added for an additional 200 lbs. of operating capacity. Multifunctionality is improved as cycle times of the loader arms are quicker than previous models. Plus, an auto-downshift system brings the unit from highrange to low-range automatically when the machine enters a turn or goes into a pile of material. This allows the operator to keep the machine in high range, allowing the system to downshift automatically when needed, keeping the engine at higher rpm for more power when you need it. The single-piece cab allows for a clean, quiet work environment and houses a variety of new comfort features now standard on the SVL97-3. This new model comes standard equipped with a heated, air-ride seat on closed cab models, and the reconfiguration of the HVAC vent count and locations creates an efficient and comfortable climate control system in the cab. A 7-in. LCD touchscreen allows for a passcode-enabled keyless start and includes a rearview camera function for ease of operation. The operator station also includes backlit switches for the operator to see the controls in low-light conditions and delayed shut-down LED exterior lights to keep providing illumination after the machine is powered down. The inclusion of Kubota Shockless Ride (KSR) is standard on closed cab models and buffers the loader arms over uneven terrain to keep material in the bucket. Available Spring 2025.

These high-performance Wolf America wheel loaders, built with the demands of today’s workforce in mind, bring versatility, durability, and competitive pricing for a wide range of applications. Full-size, mini and telescopic models are available, each featuring a standard quick hitch and a variety of compatible attachments, including buckets, forks, pushers, cutters, augers and more.

Wolf America offers a “try before you buy” program, offering travel reimbursement for customers making the trip to the company’s headquarters in West Bend, Wisconsin, to purchase equipment.

Mecalac offers a foldable-canopy version of the MCL2, MCL4, MCL6 and MCL8. The quick-folding canopy allows operators to leverage the loaders’ benefits in areas with limited overhead clearance, making a spot once inaccessible to machines now a reality. This compactness is especially valuable on a farm where operators are completing work in areas such as livestock stalls and milk parlors. A folding canopy allows users to work in areas inaccessible by traditional, larger loaders. The loaders are equipped with hydraulic and maneuverability options, M-Drive and Speed Control. With M-Drive, the engine speed can be controlled independently of travel speed, allowing power and hydraulic flow to be adapted to best suit the job at hand. Speed Control allows operators to set the maximum travel speed from 1 mph to the max speed of 19 mph (MCL6 and MCL8 only). Operators can easily fold down the canopy in seconds by removing a pin on each column and simply pushing the roof back. This reduces the machine’s height by as much as a foot (0.3 meters) to less than 6.6 ft. (2 m).

The new EC260 replaces the EC250 in Volvo’s lineup, and the new EC300 is an update of the previous series’ model. Like the other models in the new series, the EC260 and EC300 excavators feature up to 15% greater fuel efficiency, increased productivity, enhanced safety and a host of cab upgrades. Features 10 work modes, including two specific to power and four specific to automatic ECO modes.

Designed for tree and limb removal operations, the Woodcracker tree saw with grapple is compatible with three Manitou rotating telehandlers — the MRT 2260, MRT 2660 and MRT 3060 Vision+. When matched with the MRT 3060 Vision+, operators can reach heights of more than 98 ft. and outreach to more than 84 ft. The maximum lifting capacity for the MRT with the tree saw attachment is 8,000 lbs. Built from highstrength steel and capable of cutting tree branches and trunks up to 29 in. in diameter, the new Manitou tree saw rotates into position to cut, hold and deliver each limb. It can also be matched with the Manitou rotating telehandler remote control to give the operator flexibility in how and where they perform the work.

Mecalac has introduced its MR50 and MR60 Tiltrotators to the North American market. The MR50 Tiltrotator is available as an option for the 9MWR and 11MWR wheeled excavators and the 10MCR crawler-skid excavator. The MR60 Tiltrotator is available for the 15MWR wheeled excavator and 15MC crawler excavator. Both tiltrotators come equipped with the twin CONNECT coupling system. The system includes a tiltrotator fitted between two CONNECT quick couplers along with a grading bucket designed to match the machine and system. The Mecalac MR50 and MR60 Tiltrotators allow for 360-degree rotation in both directions as well as a 40-degree tilt left and right for various attachments, including hydromechanical tools such as grapples.

Crafco has unveiled the EZ Patcher skid steer attachment for pavement repairs. Designed by Crafco’s Equipment Engineering department from the ground up, this patented technology offers safe application of repair material. The EZ Patcher provides roadwork agencies and contractors with a method for repairing long, linear cracks such as deteriorated longitudinal joints or utility cuts, using a repair material known as mastic — a binder and aggregate mix that is heated and applied to distressed pavement for a durable, weight-bearing repair without extended road closures. The new EZ Patcher joins the Crafco family of mastic melter/applicators, including the trailermounted Patcher II (200-gal. capacity) and Patcher 4 (400-gal. capacity), as well as the 10-gal. Hot Mastic Applicator cart.

Bobcat super-flow planers are highpowered attachments capable of milling concrete and asphalt up to 7 in. thick. The super-flow planers are available in 24-in. and 48-in. cutting widths. These versatile attachments utilize the extra hydraulic power available in the Bobcat T86 compact track loader and S86 skid-steer loader equipped with super flow generating up to 42 gpm and 4,061 psi. Bobcat also offers a 40-in. planer compatible with both superflow and high-flow hydraulics. In all, Bobcat offers six planer attachments that accommodate standard, high-flow and super-flow hydraulics. To cater to different cut angles, the attachment is capable of oscillating up to +/- 15 degrees.

Equipped with a mid-mount variable cutter system (VCS), this machine offers optimized versatility with cut widths ranging from 2 ft. to 5 ft., achieving a maximum cut depth of 14 in. Powered by a Tier 3 or Stage 5 Cummins QSL-9 engine rated at 430 hp, the RX-405 ensures performance and productivity on every jobsite. One of the standout features of the RX-405 is its design, including a secondary conveyor that can swing 60 degrees on each side, providing a full conveyor swing of 120 degrees. This, coupled with a 750-gallon water tank — the largest in its class — ensures limited interruption and maximum efficiency even in the most demanding environments. Astec updated the ergonomics and appearance of the controls to improve operator comfort and usability. Additionally, a new operator environmental awareness system will make its debut at the show. Set to be available on the RX-405 and all milling machines in Q4 of 2024, this real time view of the machine from above will enhance safety and visibility to obstructions, thereby boosting productivity. In addition to this cutting-edge technology, the RX-405 offers a range of other customizable options to suit the diverse needs of contractors and rental agencies. Options include a 24V LED night light package, Guardian telematics, auto lubrication system, rear object detection system, vacuum dust extraction kit and more.

Carbide rockwheels and diamond saw attachments are available for excavators of all sizes and various applications. Carbide rockwheels offer a cutting solution for soft to medium hard rock and concrete cutting applications with a minimum width of roughly 2 in.

• Diamond saw rock wheels (AQD Series) cut the hardest rock including granite, basalt, etc., as well as reinforced concrete

The Toro grapple rake attachment allows operators to grab, drag, lift, and place materials with ease. The grapple has two heavy-duty cylinders capable of producing 3,000 pounds of clamping force at the tine tips, insuring you can grab ahold and not let go. Twin heavy-duty hydraulic cylinders. 35.5-in. (87.6 cm) width guarantees access to tight areas. Tines constructed of 3/8-in. (1 cm) AR400 steel. Four greaseable pivots reduce wear.

The SQ90 fully automatic coupler system is targeted toward excavators up to 70 tons in the demolition industry.

• Provides increased safety and the ability to change hydraulic powered work tools in seconds without leaving the cab

• Compliant with the Open-S standard

• Upgraded Front Pin Lock safety solution offers mechanical lock of the front shaft to limit the risk of an unintended drop of heavy demolition tools

• Hydraulic couplings with Qplus technology enable higher hydraulic flows with less pressure drops

The E-Z Grader skid-steer attachment boasts a built-in roller compactor, retractable ripper shanks and deployable wings for superior performance. The attachment is designed for seamless compatibility with all top skid-steer brands. The E-Z Grader is a multifaceted attachment designed to deliver precise grading across a wide range of projects with the ability to grade in both 2D and 3D. This innovative tool is perfect for various applications, including warehouses, parking lots and athletic fields.

Turn your compact loader or excavator into a powerfully precise demolition machine with the Hydraulic Breaker with Nail Point - HB880. The HB880 provides powerful force to break through concrete, rock and asphalt and delivers efficiency by matching hydraulic capacity of the carrier to the breaker, allowing consistent machine-to-breaker performance. The auto power regulates pressure automatically, ensuring hydraulic breaker operation regardless of changes in outdoor temperature, delivering maximum performance across a large range of carriers. It also

limits excessive pressure at the time of start-up, preventing possible downtime.

The cylindrical design improves access to jobs in confined areas, providing accurate attachment operation in more operating environments. Quickly and easily switch the hydraulic breaker attachment from a loader to an excavator with the Bob-Tach and X-Change attachment mounting systems, maximizing attachment utility. Designed for minimum downtime, the internal power cell has fewer moving parts. Also, the attachment design includes only 12 main service parts, reducing time spent on maintenance and improving overall lifetime of the attachment.

Genesis GRP 480

Hydraulic Mobile Shear