These Canadian Companies See Promise in Our Prairie.

These Canadian Companies See Promise in Our Prairie.

Ftractors and hard work. They’re also about smart tools, like drones that check crops from the sky and machines that know exactly where to plant seeds. New technology is helping farmers grow more food with fewer resources. That means using less water, less fuel, and making less waste.

But it’s not just the tools that are changing— it’s the people, too. A new generation of farmers is stepping up, bringing fresh ideas and new ways of thinking. They still respect the old ways, but they’re also focused on caring for the land, keeping soil healthy, and making sure farming works for the long haul. They care about where our food comes from, and they want to do things right.

People are also starting to see how important farmers really are. With the world facing big changes, farming matters more than ever.

Farmers are the ones growing the food that ends up on every table.

There will still be hard times. Weather, money, and rules can make farming tough. But I believe farmers are ready. Farmers are smart, strong, and not afraid to try new things.

The future of farming isn’t just about getting by—it’s about doing better. And I can’t wait to see what comes next.

Brady Drake Future Farmer Editor

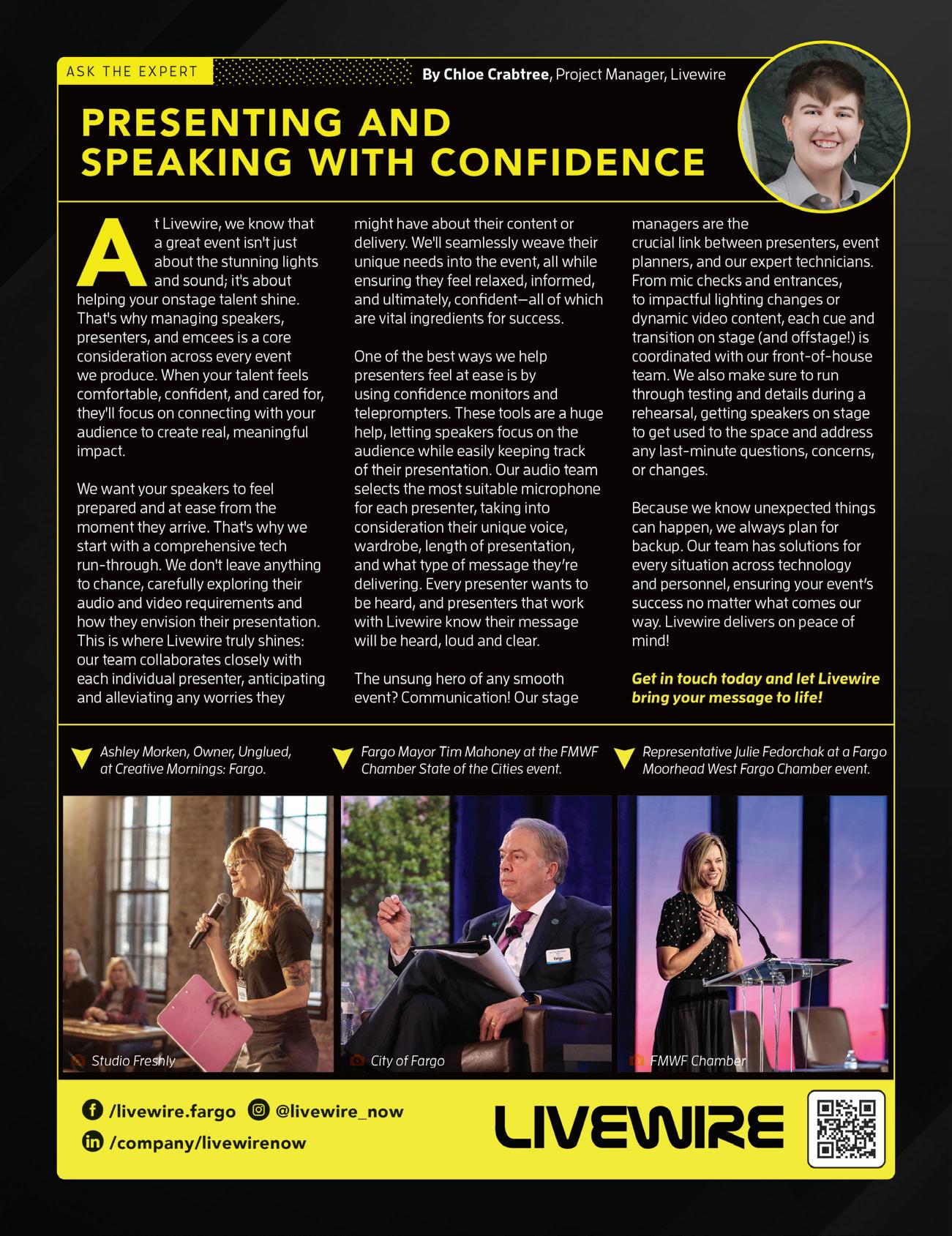

ADVERTISING

Sales

Business

DISTRIBUTION

Mike Dragosavich

Brady Drake Brady@SpotlightMediaFargo.com

Kim Cowles

Ty Betts

Nathan Rice, Madi Simpson, ADM, and Stephanie Blumhagen

Kellen Feeney

Megan Suedbeck

Sarah Cabler

Sara Jentink

Tammy Fogle

Paul Hoefer Paul@SpotlightMediaFargo.com

Al Anderson Al@SpotlightMediaFargo.com

Austin Cuka

AustinCuka@SpotlightMediaFargo.com

Matt Purpur

Matt@SpotlightMediaFargo.com

ClientRelations@SpotlightMediaFargo.com

Jessica Ventzke

Tyler Duclos

Missy Roberts

John Stuber

Written by Scott Wagendorf based on an interview with Alex Vasichek, Financial Planner

Before you consider "how to," transfer equipment to the next generation of family farmers, you may want to reflect on the "what," "who," and "when." What are your goals? Who’s involved? When do you hope to complete the transfer? "There are a lot of ways to do it and every client is different," advises Alex Vasichek, an Agriculture Focused Financial Planner at Elevate Financial in Fargo, N.D. "But you’ll need a strategy and a plan; and be able to execute on it."

This is a simple, direct and total sale, where the former owner no longer has any financial interest in the item or items being sold. Chances are, the current owner still needs income from their equipment; especially during the transition phase. This strategy buys some of the equity off prior generations.

Pros:

• Immediate income for owner

• Allows next generation to use equipment

• Owner no longer responsible for maintenance

Cons:

• Depreciation must be recaptured

• Owner loses access to equipment

• Increased tax burden

Cons:

• Depreciation recapture still due in year of sale

• Seller not entitled to depreciation

A lease-to-own agreement seems similar to an installment sale in that the seller receives income from the arrangement over time and the buyer is able to use the equipment immediately; however he or she doesn’t own it outright until the last payment has been satisfied. The primary differences are the tax implications 1) The lease payments are treated as ordinary income by the IRS in the year received, and; 2) The purchase occurs at the end of the lease so owner pays depreciation recapture taxes when the value of the machinery has significantly declined.

Pros:

• Lease payments deductible for buyer

• Owner pays depreciation recapture at the end

Cons:

• Buyer does not own equipment until lease is paid off

Giving a piece or pieces of equipment to a family member or friend without expecting payment in return. It may be combined with any other method discussed here depending on the nature of the familial relationship and needs of the partners. “Just as an example, 50% of equipment value could be gifted and the other 50% financed on installment, based on your unique situation and needs,” says Vasichek.

Pros:

• No capital gains tax due

Cons:

• Possible tax burden above federal gift allowance

• No stepped-up basis for recipient

The seller and buyer set up an operating partnership that provides for ownership shares equivalent to each partner’s contribution to the business. Vasichek believes this is the method clients prefer most often. “In this situation it’s likely both the senior and junior partners already farm together and each owns a percentage of the equipment and thus shares. The younger partner can buy additional shares from the older one over a prescribed period of time or at will.

Pros:

• Liability protection for owner

• Spreads out payments and tax burden

Cons:

• Set-up and administration costs of LLC

• Causes owner to become a business partner

• Subject to capital gains tax

If the owner does not need the income from the equipment it may be transferred at death, according to a will. Vasichek is not a fan of this method: “This isn’t much of a strategy unless the owner plans to farm until an indefinite date in the future.”

Pros:

• Stepped-up tax basis for inheritor

Cons:

• No immediate access for next generation

• Requires impartial third-party executor

Any of these strategies can be effective depending on the needs of the seller and buyer, according to Vasichek. “But don’t go it alone.

We recommend consulting with an Agricultural Focused Financial Planner and tax professional to understand the cash flow and tax implications of each strategy. Think of equipment transfer as one part of a wholistic approach to financial planning” concludes Vasichek.

Alex Vasichek Agricultural Focused Financial Planner

Solutions can come from anywhere in the world and Grand Farm continues to look to its neighbors in the north to bring agricultural innovation to upper midwest Farms. Grand Farm once again hosted a cross-border AgTech showcase in Fargo. as part of its AgTech Week 2025. Facilitated by the Consulate General of Canada, this initiative brings cutting-edge Canadian startups to the heart of the Midwest, connecting them with local growers, researchers, and industry leaders. This year’s event underscored the shared commitment to advancing sustainable farming, automation, and ag innovation on both sides of the border. We had the opportunity to sit down with Consul General Beth Richardson, along with several of the featured AgTech companies, to learn more about their work and why North Dakota remains a vital hub for global agricultural progress.

As Canada’s Consul General in Minneapolis, Beth Richardson plays a key role in advancing economic and diplomatic ties between Canada and the U.S. Midwest. A seasoned diplomat with international experience in cities like Seoul, London, and Moscow, Richardson brings both global perspective and a deep-rooted understanding of prairie life, having grown up in rural Alberta.

Now overseeing Canada’s relations with Minnesota, Iowa, Nebraska, North Dakota, and South Dakota, she focuses on building connections that strengthen trade, particularly in agriculture—a sector that drives billions in cross-border commerce each year.

In this Q&A, Richardson shares insights on tariff tensions, the evolving ag-tech landscape, and how American producers can engage directly with Canadian companies and the Consul to fuel innovation on both sides of the border.

Q: What is the Consul General of Canada to the United States?

A: We’re based in Minneapolis and responsible for Canada’s relationship with five U.S. states— North Dakota, South Dakota, Nebraska, Minnesota, and Iowa. A big part of what we do is build connections with U.S. partners to expand trade, investment, and

security cooperation. Grand Farm has been an incredibly valuable partner for us. We’ve been a member since 2021, and every year our Canadian Technology Accelerator program—CTA for short—focuses on ag tech. Our office, along with counterparts in San Francisco and our embassy in D.C., supports about 10 Canadian companies that are looking to expand into the U.S. and Mexico. Grand Farm is essential to this,

especially when our companies come to experience Fargo as an ag tech hub. Through Grand Farm and the Greater Fargo Moorhead Development Corporation, they get immersed in a well-connected, collaborative agriculture ecosystem. That’s really the key reason we partner with Grand Farm—because it gives Canadian companies the opportunity to plug into something that can help them succeed in the U.S.

As for how companies are selected—it’s a competitive process managed by the Trade Commissioner Service, our counterpart to the U.S. Commercial Service. Companies apply and are assessed based on criteria like export readiness. This year, the CTA AgTech cohort ran from January to June. They’ve already been to San Francisco for World AgriTech in March and spent a week in Mexico. This Fargo trip is their third and final outreach visit. Depending on demand in Canada, we typically run this accelerator once a year, and the next round will include a new group of companies.

Q: Are there any opportunities—or significant scaling events—that have come out of these kinds of collaborations or visits? Have you seen anything meaningful come from it?

A: I can give you a couple of examples. There’s an Ontario company that set up a pilot plot at Grand Farm in 2020. They leveraged the farm’s infrastructure, and after that successful pilot, they launched a five-acre field trial with NDSU in 2024. The company focuses on ultra-highpressure water jet technology for no-till nutrient application. That approach gave them a foothold in the U.S. market—American farmers were exposed to the system, and it helped the company grow their presence here. Another example is an Ontario company that developed software for biosecurity in hog and poultry operations. They’d already been active in Canada— which makes sense, especially in Manitoba, a major pork-producing province. But since biosecurity is also a priority for pork producers in the U.S., they’ve made a number of

connections here and have now set up a U.S. subsidiary in the Midwest to deliver that technology directly to American farmers.

Q: The majority of our readers, and the people this magazine gets mailed to directly, are producers themselves. How can they get involved with the Consul or with these companies? Is that something you’re looking to do—whether it’s through trials, product adoption, or something along those lines?

A: Oh, absolutely. The short answer is yes. We have two trade commissioners here who focus on agriculture. And of course, American businesses are always welcome to reach out to learn more about what’s happening in Canada.

Our primary mandate is to help Canadian companies succeed in the U.S., and a big part of that success comes from building the right networks—with entrepreneurs and businesses here. So yes, we absolutely do matchmaking. If anyone is interested in learning more about the Canadian tech being developed, we’d love for them to get in touch with us.

Q: What else should I know for the article?

A: I guess there are two things I’d like to say. First, the tariff debate between the United States and Canada is having a negative impact—it’s been really disruptive to our trade relationship. Between just North Dakota and Minnesota, we’re talking about $3 billion in agricultural trade annually. Canada–

U.S. ag trade overall is worth about $75 billion. The important thing to understand is that most of what we trade in agriculture is not finished product—it’s inputs. When tariffs are added to those inputs on either side, it limits the capacity of producers in both countries to grow and compete. About 70% of what we export to the U.S. goes to American companies, so tariffs really squeeze margins and threaten producers’ ability to succeed. And ultimately, those costs get passed on to the consumer. We need to move beyond the tariff debate and return to the kind of productive, long-standing trade relationship we’ve had with the U.S. for generations. The second point is about the incredible creativity happening in agriculture right now. There’s a real change that often goes unrecognized outside the farming sector—agriculture is intersecting with clean tech, the circular economy, and renewable energy. A lot of Canadian companies operating in the U.S. are using agricultural byproducts in innovative ways. What used to be discarded is now being turned into inputs for bioenergy, soil improvement, and more. I really believe this is a form of national development—one that improves soil health, reduces input intensity, and opens up valuable new markets. And I want to commend everyone involved in driving that progress.

By Geneva Nodland

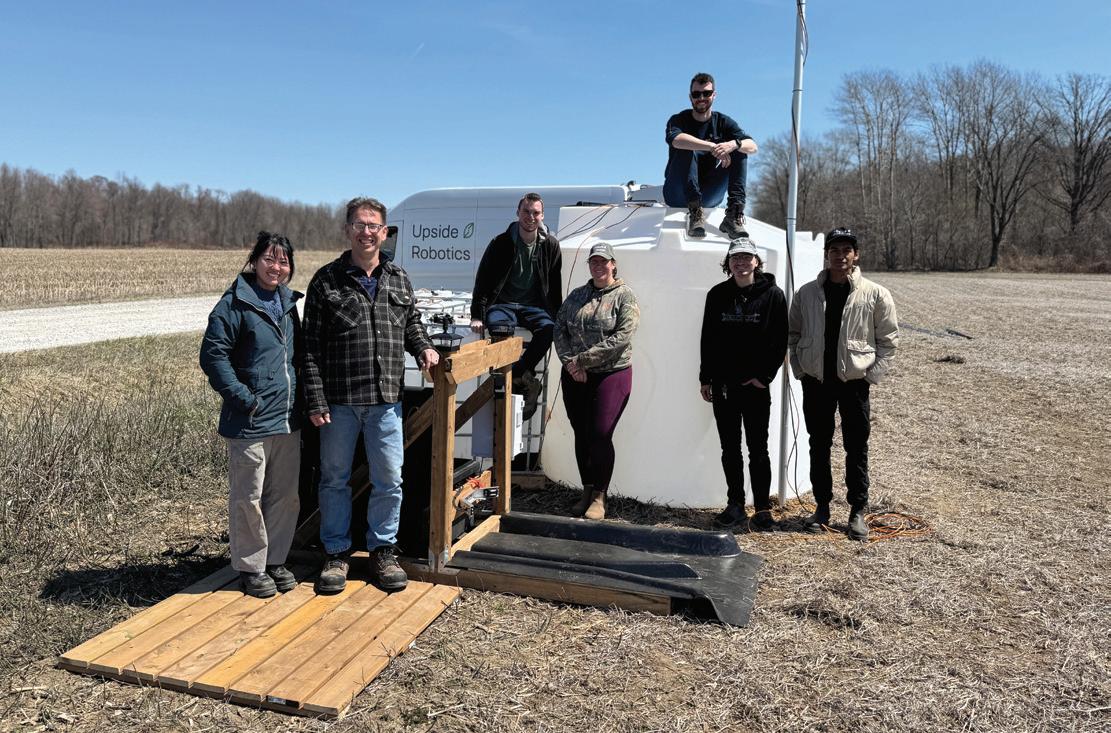

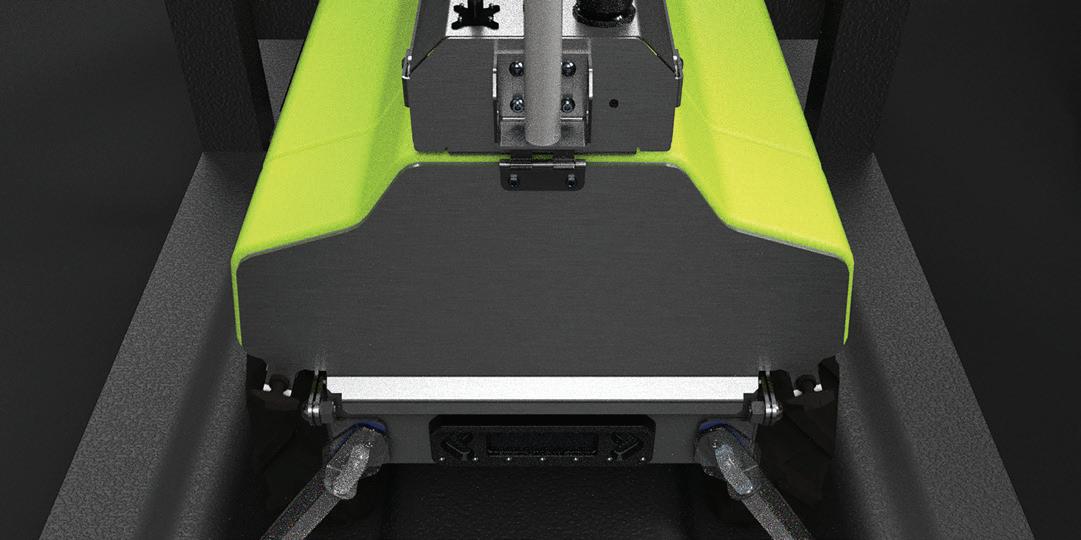

Provided by Upside Robotics

Startup Name: Upside Robotics

LinkedIn: /company/upside-robotics

Headquarters: Waterloo, Canada

Representative for AgTech Week 2025: Jana Tian, CEO

Q: Introduce us to your founder(s) or team members attending AgTech Week 2025.

A: Representing Upside Robotics at AgTech Week 2025 is Jana Tian, whose journey to agricultural innovation began in an unexpected place—the food industry. During her fiveyear tenure at Unilever, Jana developed food products for iconic brands like Ben & Jerry's, gaining firsthand insight into a troubling trend: the declining nutritional quality of our food supply. She witnessed how excessive chemical fertilizer use was not only affecting food quality but also depleting the soil of vital microbes that naturally enhance fertility.

As a passionate food lover, Jana became determined to make food healthier by addressing the problem at its source—farming practices. Her mission led her to team up with Sam, a robotics engineer from the University of Waterloo who had developed autonomous vehicles for automotive giants like GM and BMW. With his expertise in robotics and shared vision of using technology for positive impact,

they formed the perfect partnership to revolutionize agricultural practices.

Q: Give us your elevator pitch—what does your startup do?

A: Upside Robotics has developed lightweight autonomous robots that revolutionize how farmers apply fertilizer. Their system operates 24/7, applying precisely timed nutrients throughout the growing season while dramatically reducing nitrogen usage and protecting soil health. Already proven to cut fertilizer costs by up to 70% without sacrificing yield, these nimble 150-pound robots replace the need for massive 40,000-pound tractors that compact soil and diminish productivity.

Q: What inspired the creation of your startup?

A: The inspiration behind Upside Robotics emerged from observing

three critical agricultural trends converging simultaneously. First, the dramatic increase in tractor size (from 2,900-pound machines in the 1940s to today's 42,000-pound behemoths) has led to severe soil compaction issues, with ground pressure increasing from 8 PSI to over 30 PSI. Second, the agricultural labor crisis reached a breaking point, making traditional farming methods increasingly difficult to maintain. Finally, skyrocketing input costs, particularly for fertilizers, created urgent economic pressure on farmers.

Rather than requiring billions in R&D to develop fully autonomous farming systems, the team identified an immediate problem they could solve today—precision fertilizer application—that would deliver immediate ROI while building toward the future of agriculture.

Q: What problem in agriculture are you solving?

A: Upside Robotics addresses multiple interrelated challenges in modern agriculture.

• Fertilizer waste and environmental impact:

Conventional farming typically applies nitrogen in just 1-2 massive applications, leading to significant waste through leaching and volatilization, contributing to greenhouse gas emissions. Each acre of conventionally fertilized farmland produces approximately 0.33 tonnes of CO2 equivalent emissions.

• Soil degradation from heavy equipment:

Modern tractors weighing 20-30 tons severely compact soil, reducing water infiltration, limiting root growth, and diminishing long-term productivity.

• Labor shortages and timing constraints: Traditional equipment requires skilled operators and optimal weather windows, restricting when crucial applications can occur.

• Rising input costs: With fertilizer prices climbing, the economic pressure on farmers intensifies, squeezing already thin margins.

Q: Who are your customers or end-users?

A: Our customers are now mainly corn growers of all sizes, but eventually we can service any crops planted in 30" rows or wider spacing.

Q: What makes your solution unique or innovative?

A: What makes Upside Robotics unique is its multi-faceted approach

that delivers immediate value while building long-term competitive advantages.

• Micro-applications instead of bulk applications: With fertilizer prices climbing, the economic pressure on farmers intensifies, squeezing already thin margins.

• Soil-friendly footprint:

At just 150 pounds, their robots eliminate soil compaction issues, preserving soil structure and health for long-term productivity.

• Data-driven intelligence: Each robot continuously collects field data through its sensor array (temperature, humidity, plant imagery, soil conditions), creating an unprecedented feedback loop that powers increasingly intelligent application prescriptions.

• Dual-purpose approach: Unlike many AgTech solutions that

only collect data, Upside's robots perform essential farm tasks while gathering intelligence, delivering immediate ROI to farmers from day one.

• Scalable economics:

Starting with 70 acres in 2024 and expanding to 1,200 acres in 2025, their model is rapidly scaling toward a projected 5 million acres by 2030, with each robot system capable of servicing 80-100 acres.

The company's approach represents a fundamental shift in agricultural practice: rather than relying on calendar-based applications of massive nutrient loads, Upside enables continuous, responsive feeding based on real-time plant needs—similar to how humans eat multiple small meals rather than two enormous feasts per year.

Q: Tell us about a recent milestone, pilot project, or success story.

A: A landmark achievement for Upside Robotics came during their 2024 field trials, where they successfully demonstrated the potential of their technology across 70 acres with seven different customers. In one particularly notable case, their autonomous robots reduced nitrogen application by a remarkable 70% while maintaining comparable yields to conventionally treated fields. This was accomplished through an innovative approach of eight precisely timed fertilizer applications throughout the growing season, replacing the traditional one or two bulk applications.

"What made this trial so significant was proving that our core thesis works in real-world conditions," Jana said. "By applying fertilizer in multiple small doses that align with the plant's actual uptake curve, we eliminated waste without sacrificing productivity. One farmer told us he'd never seen corn respond so well to such minimal nitrogen inputs."

This success has catapulted Upside Robotics from its initial 70-acre trial to securing commitments for 1,200 acres under management in 2025— a 17-fold increase. They've expanded their customer base to 13 farms across Ontario, covering diverse soil types from sandy to clay to loam, and spanning from Chatham

in the south to Port Elgin in the north.

A: Upside's solution integrates several cutting-edge technologies into a cohesive system.

• Autonomous robotics:

Their lightweight (150 lb) robots navigate independently through crop rows, delivering precise nutrient applications while collecting data. The robots operate 24/7 during the growing season from April to October.

• Advanced sensing technology:

Each robot is equipped with a comprehensive sensor suite including temperature and humidity sensors, canopy cameras, RGB cameras, and multispectral imaging – all linked to precise GPS location data captured every 10 seconds.

• AI-driven prescription system:

Using the terabyte of data collected monthly per robot, Upside has developed algorithms that predict plant nutrient needs based on growth stage, environmental conditions, and crop health indicators. These algorithms generate customized fertilizer prescriptions that continuously evolve throughout the season.

• Field base stations:

Each robot system includes a base station that serves as both a charging hub and

data collection point, allowing the robots to operate continuously while transmitting crucial field information.

• Management zone mapping: Rather than treating fields uniformly, their system divides fields into zones based on soil characteristics, topography, and historical yield data, enabling customized treatment for each area (e.g., 70% nitrogen reduction in low-yielding areas versus 50% in higher-yielding sections).

"What sets our technology apart is integration," Jana said. "Each component—the robotics, the sensors, the AI—works in concert to create a closed feedback loop. We're not just applying fertilizer; we're creating a continuous conversation between the technology and the growing crop."

Q: If applicable, describe how sustainability fits into your mission or solution.

A: Sustainability isn't just part of Upside Robotics' mission—it's the fundamental driver behind everything they do. Their approach addresses

multiple dimensions of agricultural sustainability.

• Dramatic reduction in fertilizer use:

By applying nitrogen in small, precisely timed doses that match plant uptake, they've demonstrated 50-70% reductions in fertilizer use. This directly translates to approximately 0.33 tonnes of CO2 equivalent emissions avoided per acre.

• Soil health preservation:

The lightweight robots (150 lbs) replace traditional equipment that can weigh up to 60,000 lbs when loaded, virtually eliminating soil compaction issues.

• Water quality protection: Reduced fertilizer application means less runoff into waterways, helping to prevent nutrient pollution that leads to harmful algal blooms and aquatic dead zones.

• Greenhouse gas mitigation: Nitrous oxide, a greenhouse gas 298 times more potent than CO2, is a major byproduct of excess

nitrogen fertilizer. By reducing application rates by 50-70%, Upside directly reduces these emissions proportionally.

• Data-driven regeneration: Their ultimate goal extends beyond efficiency to actively improving soil health. "In 2025, we're not just focusing on reducing inputs," Jana said. "Half our trial fields will explore how our precision application can actually boost yields by 15% while using 70% less fertilizer—proving that sustainable farming can be more productive, not less."

The company has also commissioned a soil compaction study with the Vineland Research Center to quantify the soil health benefits of their approach, with results expected in June 2025.

"Our vision of sustainability is comprehensive," she said. "It's about creating a virtuous cycle where reduced inputs lead to healthier soil, which leads to more nutritious food, which ultimately supports human health. We're addressing sustainability not just at

the environmental level, but at the nutritional and economic levels too."

Q: Why are you attending AgTech Week in Fargo?

A: "Fargo represents a critical gateway to the U.S. corn belt for us," Jana said. "While we've established a strong foothold in Ontario with 1,200 acres under management, the U.S. market with its 100 million acres of corn represents our path to true scale."

The timing is strategic for Upside Robotics. Having proven their technology through rigorous trials across diverse growing conditions in Canada, they're now ready to make their U.S. market entry. North Dakota and the surrounding region offer ideal expansion territory with their strong agricultural focus and progressive farming operations.

"The transition from our Canadian test market to U.S. expansion is a pivotal moment for us," she said. "Fargo sits at the edge of some of the most productive agricultural land in North America, making it the perfect launchpad for our U.S. operations."

Q: What are you hoping to gain or showcase during the event?

A: Upside Robotics has three primary objectives for AgTech Week.

First, they're seeking to establish partnerships with early-adopter farms for their 2026 U.S. pilot program. "We're looking for innovative operations ready to pioneer the next generation of fertilizer application," Jana said. "Our ideal partners understand both the economic and environmental benefits of precision application and are willing to be at the forefront of this transformation."

Second, they aim to connect with potential distribution partners who can accelerate their market entry. "While we've gone direct-to-farm in Canada, scaling to millions of acres requires strategic distribution relationships," Jana said. "We're exploring territory exclusivity arrangements with partners who share our vision and can commit to deploying multiple robot systems."

Third, they're initiating conversations with U.S.-based Series A investors who understand agricultural technology's potential. "Our 20242025 results demonstrate that our technology works and farmers want it. Now we're ready to scale, and that requires growth capital from investors who understand both the technology and agricultural landscapes."

Q: Have you participated in U.S.-based ag events before?

A: This marks Upside Robotics' second major U.S. agricultural event, following their participation in the World Agri-Tech Innovation Summit in San Francisco earlier this year. That event proved valuable, resulting in promising discussions with King Ranch in Florida's sweetcorn sector and introductions to several CPG companies and equipment manufacturers interested in their technology and data capabilities.

"World Agri-Tech gave us important insights into the U.S. market, but it was primarily focused on coastal innovation hubs," Jana said. "AgTech Week puts us directly in conversation with the heartland farming community, which is exactly where we need to be as we plan our U.S. expansion."

Between these two events, the company has established a methodical approach to U.S.

market entry, focusing first on high-value specialty crops in Florida before expanding into the broader commodity crop markets of the Midwest.

"Our previous U.S. event taught us that American farmers are incredibly receptive to technologies that deliver clear ROI while addressing environmental concerns," Jana said. "We're excited to build on that foundation at AgTech Week and begin establishing our U.S. presence in earnest."

Q: How can readers of Future Farmer best support you?

A: "The agricultural community thrives on connections, and Future Farmer readers represent some of the most forward-thinking voices in the industry," Jana said. "There are several meaningful ways they can support our mission."

First and foremost, Upside Robotics is actively seeking innovative farmers for their 2026 U.S. pilot program. "We're looking for operations of any size who want to be at the forefront of precision fertilizer application," Jana said. "Particularly those managing corn acres who are concerned about both rising input costs and environmental impact."

For agricultural suppliers, equipment dealers, and agronomic services providers, Jana highlights partnership opportunities. "As we scale from 1,200 acres to our target of 5 million acres by 2030, we're establishing a network of technical support and distribution partners across North America. We're especially interested in connecting with those who already have strong relationships with progressive growers."

Industry professionals can also support Upside by sharing data and insights. "The more diverse growing conditions we encounter, the smarter our algorithms become," Jana said. "Farmers willing to share historical field data—even anonymously— contribute to building solutions that work across varied agricultural environments."

For readers involved in agricultural research, Upside welcomes collaboration opportunities. "We're particularly interested in partnerships that can help quantify the long-term impact of reduced soil compaction and optimized nutrient application on both productivity and environmental outcomes."

Q: Is there anything else you'd like to mention?

A: What drives us at Upside Robotics is the conviction that the future

of agriculture doesn't require choosing between productivity and sustainability—they can and must go hand in hand," Jana said.

"When we started, many questioned whether lightweight robots could handle the demands of real-world farming. After watching our systems operate 24/7 through challenging weather conditions while delivering precisely what plants need exactly when they need it, those questions have been answered."

Jana is particularly proud of their data-driven approach to agricultural innovation. "Every day, each robot collects a terabyte of field data monthly that informs our decisionmaking. This isn't theoretical—it's practical knowledge being applied in real-time to grow better crops with fewer inputs."

"While we're currently focused on precision nutrient application,

the platform we're building has implications for pest management, weed control, and eventually automated harvesting—all with the same lightweight, soil-friendly approach."

"The agricultural system is at a turning point," she said. "Farmers face unprecedented pressure to produce more food with fewer resources while reducing environmental impact. At Upside, we believe the answer isn't bigger equipment or more chemicals—it's smarter, more responsive systems that work in harmony with natural processes. That's the future we're building, one acre at a time."

By Geneva Nodland

Provided by Picketa Systems

Startup Name: Picketa Systems

LinkedIn: /company/picketasystems

Headquarters: Fredericton, New Brunswick

Representative for AgTech Week 2025: Xavier Hébert-Couturier, CEO

Q: Introduce us to your founder(s) or team members attending AgTech Week 2025.

A: Xavier Hébert-Couturier - Chief Executive Officer & Co-Founder (Attending Ag Tech Week) Maxime Dumont - Chief Operating Officer & Co-Founder, Dominic Levesque - Chief Technology Officer & Co-Founder, and Zachary Andersen - Chief Growth Officer/VP of Sales & Co-Founder.

Q: Give us your elevator pitch— what does your startup do?

A: Picketa Systems is transforming agronomy’s status quo and unlocking its untapped potential through real-time technology.

Our tool, the LENS, is a portable plant tissue analysis platform that delivers critical nutrient insights in seconds. No more delays, guesswork, or missed windows. Just fast, critical data that fits seamlessly into agri-business workflows.

We believe tissue analysis should be as accessible and essential as any everyday tool—The LENS is to an agronomist what the hammer is to a carpenter. That’s why we’re on a mission to make real-time nutrient management the new standard.

For agri-businesses, Picketa is the ultimate nutrient management system, unlocking the full power of tissue data to drive better decisions, better yields, and a better future for agriculture.

Q: What ag technologies are at the core of your solution?

A: The LENS (Leaf Evaluated Nutrient System)—is powered by multispectral optical sensing, AIdriven nutrient analysis, and a cloudbased platform for decision support.

The LENS uses light-based scanning to instantly analyze plant leaves for 13 nutrients. It combines:

• Optical sensors to capture plant tissue responses

• AI models trained on lab-validated data for accurate nutrient predictions

• A cloud platform (Fieldbook) for visualizing trends and managing data

• Support for custom critical levels to tailor nutrient thresholds to local conditions

Q: What inspired the creation of your startup?

A: Picketa Systems was inspired by the challenges we saw growing up in northwest New Brunswick, where managing high-value potato crops without irrigation made tissue analysis a critical—but deeply flawed—practice. With some of us having worked in the industry ourselves, we experienced the inefficiencies of traditional sampling: collecting leaves, shipping them to labs, and waiting weeks for results that often came too late to act on.

Scan this QR code below to meet the founders of Picketa and learn more about what they do!

During our senior engineering project at UNB, we saw an opportunity to change that. What began in a basement brainstorming session for a school project became a mission to push the limits of chemometrics and bring real-time tissue analysis directly to the farm. We built the LENS to give growers instant, accurate insights on crop nutrition—no lab needed. Today, it’s helping of growers across North America turn tissue data into smarter decisions, faster.

Q: What problem in agriculture are you solving?

A: Picketa is solving a fundamental problem in modern agriculture: the lack of timely, actionable plant health data, specifically when it comes to understanding crop nutrient levels.

For decades, plant tissue analysis has been a valuable tool for identifying nutrient deficiencies and guiding fertilizer decisions. But the traditional process is slow, cumbersome, and reactive. Growers must collect leaf samples, label and ship them to a lab, and then wait days—or even weeks— for results. By the time they receive that information, the crop may have already progressed past a critical stage, reducing the opportunity for effective intervention. On top of that, the process is labor-intensive, expensive, and often inconsistently applied due to logistical constraints.

This creates a critical gap in the precision agriculture toolkit. While many tools exist to monitor weather, soil, and satellite imagery, there has been no fast and practical way to assess what’s happening inside the plant in real time.

We are addressing this problem with the LENS. In seconds, growers and agronomists can scan a leaf and receive real-time insights into nutrient levels, allowing them to make immediate, informed decisions about fertilizer application and crop management.

With real-time plant data, we’re helping agri-businesses move from reactive to proactive crop management. Our goal is to make tissue analysis more accessible, more frequent, and more impactful—so growers can respond faster, reduce waste, optimize yields, and ultimately farm more sustainably and profitably.

A: Picketa Systems serves a wide range of stakeholders in the agriculture industry, but our primary customers are agronomists, crop

consultants, progressive growers, and researchers who are looking to make more informed, timely decisions about crop nutrition.

These are professionals and producers who understand the value of plant tissue analysis but are frustrated by the slow, manual nature of traditional lab-based testing. Many of them work in regions or with crops where nutrient timing is critical—such as potatoes, corn, canola, and other high-value or nutrient-sensitive crops.

We also work closely with agribusinesses, cooperatives, and large farm operations that want to integrate real-time nutrient data into their broader precision agriculture workflows. These organizations often have in-house agronomy teams or service providers who rely on accurate, fast data to deliver results for their customers.

Q: What makes your solution unique or innovative?

A: What makes Picketa Systems truly unique is our ability to bring labquality plant tissue analysis directly to the field, in real time. Traditional tissue sampling methods are slow, costly, and reactive. They require manual collection, shipping to a lab, and waiting days or weeks for results that may arrive too late to inform timely crop management decisions.

Our platform, the LENS, changes that. It combines advanced chemometric modeling, spectral imaging, and cloud-based analytics to deliver instant, on-site insights into a crop’s nutrient levels, without sending a single sample to a lab. What used to take weeks now takes seconds.

This level of accessibility and speed is a game-changer for agronomists,

growers, and researchers who want to be proactive rather than reactive. The LENS fits seamlessly into existing workflows, offers consistent and accurate results, and empowers users to make decisions in the moment, when they matter most.

Beyond the hardware, what truly sets us apart is our commitment to continuous calibration and improvement. We’re not just building a tool, we’re building a system that grows smarter with every scan, tailored to real-world crop conditions and grounded in practical farming experience.

Q: Tell us about a recent milestone, pilot project, or success story.

A: One of Picketa Systems’ most exciting recent milestones is our partnership with Cargill to pilot the LENS in Camrose, Alberta.

This collaboration marks a pivotal moment as we expand beyond potatoes and corn to include canola, a critical broadacre crop in North America.

The pilot with Cargill explores how the LENS can enhance agronomic strategies by providing instant plant nutrient data, enabling growers to fine-tune fertility decisions with a level of speed and precision that traditional lab testing can’t match. The goal is to support Cargill’s commitment to 4R Nutrient Stewardship—applying the right nutrient source, at the right rate, time, and place—while improving sustainability and profitability across their vast grower network.

This success builds on a year-long effort to calibrate the LENS for canola. In collaboration with HiTech Seed Productions, we began collecting samples in Chile in late

2023 and continued through trials across North and South America. After validating performance across two seasons, the LENS now reliably analyzes canola with the same accuracy users have come to expect from our potato and corn models. The Cargill pilot serves as a major step toward scaling this new capability.

Importantly, this collaboration allows Picketa to engage directly with farmers and agronomists across Cargill’s network—demonstrating the value of the LENS in real-world conditions, gathering feedback, and refining our models further. As one of the most recognized global leaders in agriculture and food production, Cargill brings both reach and credibility, helping us show how real-time tissue analysis can shift decision-making from reactive to proactive.

This milestone demonstrates our continued commitment to expanding the LENS platform to more crops and regions, while helping growers unlock their full agronomic potential. With canola now supported, and crops like soybeans, wheat, and cotton in development, the LENS is well on its way to becoming the new standard in tissue analysis.

Q: If applicable, describe how sustainability fits into your mission or solution.

A: Sustainability is at the core of Picketa Systems’ mission. Our LENS technology empowers growers to make informed nutrient decisions in real-time, helping them apply the right amount of fertilizer— no more, no less. By reducing overapplication, we help lower input costs, limit nutrient runoff, and protect soil and water health.

We align closely with the principles of 4R Nutrient Stewardship—applying the right source, at the right rate, at the right time, and in the right place. With real-time insights from the LENS, farmers can improve their yield potential while minimizing their environmental footprint. The result is more efficient, data-driven agriculture that’s better for both the farm and the planet.

Q: Why are you attending AgTech Week in Fargo?

A: We’re attending AgTech Week in Fargo because it brings together the heart of what we care about— agriculture, technology, and collaboration. This week is all about accelerating innovation, and that’s exactly what Picketa is here to do.

We’re excited to connect with forward-thinking growers, agronomists, researchers, and agtech

leaders who are shaping the future of farming. Events like this help us learn from the community, share how the LENS is transforming real-time nutrient management, and explore new partnerships that push the industry forward.

Q: What are you hoping to gain or showcase during the event?

A: We’re hoping to connect with agronomists, researchers, and industry leaders who are passionate about practical innovation in agriculture. We want to showcase how the LENS makes real-time plant tissue analysis possible.

We’re also looking forward to hearing from others tackling big ag challenges, exploring collaboration opportunities, and getting feedback that helps us make our technology even more useful and impactful.

Events like this are where new ideas take root.

Q: How can readers best support you?

A: Here are a few ways to support us.

• Spread the word: Let agronomists, growers, and ag retailers in your network know about real-time tissue analysis and the LENS.

• Connect with us: If you're interested in optimizing crop nutrition or bringing innovation to your operation, reach out to info@ picketa.com or picketa.com.

• Share your insights: We’re always learning from the ag community. Feedback, ideas, or even a simple intro can go a long way.

• Follow our journey: Stay in the loop by signing up for our Field Notes

newsletter (picketa.com/fieldnotes) or following us on social media:

@picketa.systems /picketasystems /company/picketasystems @picketasystems @xpicketa

Q: Is there anything else you'd like to mention?

A: We’re just getting started. We’re on a mission to make real-time tissue analysis the standard in crop management. With the recent launch of canola and a growing network of agronomists across North America, we’re excited about what’s ahead.

By Geneva Nodland

Provided by Sultech Global Innovation Corp

Startup Name:

Sultech Global Innovation Corp

LinkedIn:

/company/sultech-global-innovation-corp/

Headquarters:

Crossfield, Alberta, Canada

Representative for AgTech Week 2025: Conor Wrafter, Corporate Development Officer

Q: Introduce us to your founder(s) or team members attending AgTech Week 2025.

A: Founder & CEO, Head Operations, Murray Mackinnon is a project management professional with a proven track record in managing and delivering multi-disciplinary projects.

At Sultech, Murray has been responsible for the design, development, and construction of Sultech’s patented and proprietary sulphur micronization process equipment. His knowledge and expertise evolved the process from a lab concept to a commercially viable, and first-of-its-kind, sprayable formulation.

Murray also leads research and development, product commercialization, and industry promotion. His prior experience managing and delivering multi-disciplinary oil and gas projects around the world, enables him to successfully launch Sultech into a global market.

Q: Give us your elevator pitch— what does your startup do?

A: Headquartered in Crossfield, Alberta, Sultech is a plant nutrient and soil amendment company that uses patented technology to convert sulphur (“S”) recovered from natural gas processing and crude oil refining into an organic, micronized, elemental sulphur (“S”)

fertilizer that better enhances crop production and soil health at both a lower cost and with less greenhouse gas (“GHG”) emissions than existing synthetic fertilizers, such as Ammonium Sulphate (“AMS”).

Q: What inspired the creation of your startup?

A: A desire to play a role in addressing one of the greatest challenges of the 21st century, how to reconcile the world's need to produce more food to feed the growing global population without compromising the planet’s resources through more deforestation and expansion of the existing agri-ecosystems.

Q: What problem in agriculture are you solving?

A: Our product line delivers unique value propositions and scalable solutions to the key priority problems of falling yields, arable land

degradation, and growing sulphur deficiencies.

• Sulphur deficiency in soil has grown into a critical problem globally as we simultaneously reduce atmospheric deposition of sulphur through emission standards and grow more crops that require high levels of sulphur at a greater intensity to feed an expanding population.

• Sodic and sodium-affected soils are recognized as being among the most important land degradation problems at a global level for agricultural production, food security, and sustainability. Soils that have been irrigated by mineralized or salinized water can, over time build high enough concentration of soluble salts to cause nutrient imbalances or toxicity to sensitive plants. The high level of sodium in the soil also results in a poor physical soil structure that reduces crop emergence, root growth, and water infiltration. Reduced water infiltration can lead

to water runoff and soil erosion problems.

Q: Who are your customers or end-users?

A: Sultech will target three groups of customers with its products.

1. Manufacturers of existing plant nutrient and soil amendment products seeking to enhance their value proposition through the addition of micronized sulphur as value-add raw material input.

2. Distributors of plant nutrients and soil amendment agriculture products.

3. Growers' associations seeking to buy directly from manufacturers at volume.

End users include:

• Broadacre cropping enterprises

• Horticulture enterprises

• Organic regime-compliant cropping enterprises

Q: What makes your solution unique or innovative?

A: To our knowledge, Sultech’s Micronized Elemental Sulphur Suspension commercial grade fertilizer SulGroTM 65 (0-0-0-65) is the only Micronized Elemental Sulphur Suspension product under development for large-scale crop (Canola, Wheat, Pulses) nutrient application and soil amendment. SulGroTM 65 is a suspension of fine S° particles within the specification of conventional agricultural chemicalmixers & sprayers.

Additionally, Sultech’s broadcast products SulGro™ 85, SulGro™ 100, and SulGro™ Max "are available in a range of particle sizes for use as a value-add raw material input in

synthetic co-granulated fertilizers or for surface broadcast, applied alone or blended with other plant nutrients and soil amendments.

Their advantage is that their "product line matches and surpasses current market offerings in terms of particle size at a lower raw material cost to the client."

Q: Tell us about a recent milestone, pilot project, or success story.

A: Since 2021, Sultech has been developing its products and executing purchase orders from a commercial demonstration plant ('CDP') and is raising funds to build "two full-scale 50,000 metric tonne per annum ('mtpa') commercial plants in North America.

Significant milestones and inflection points include:

• White paper on efficacy for sprayable elemental sulphur fertilizer published (Bremer et al 2021 CJSS Short Form).

• Completed research with Dr. Bryan Hopkins – Grace, Idaho, US Potato yield performance & soil amendment (Irrigated).

• Notice of Allowance for United States Patent Application No. 16/766,961 received June 2022. Request for examination in Canada filed in Fall 2022.

• PhoSul LLC, located in Sugar City, ID becomes the first US-based recurring customer.

• Participation in COP28 at the invitation of the Government of Alberta and the U.S. Government GreenTech Delegation.

• Notice of Allowance for United States Patent Application No. 17/896,354, a continuation of United States Patent No. 114549277 received May 2024.

• Won 2nd out of 147 companies in the Abu Dhabi National Oil Company (“ADNOC”) Sulphur Innovation Challenge.

• Through our relationship with the Trade Commissioner Services and NRC/IRAP we are exploring collaboration with the Commonwealth Scientific and Industrial Research Organization (CSIRO), an Australian Government agency focused on environmental integrity and natural resources sustainable use and Embrapa, the Agricultural Research Corporation, focused on increasing agricultural productivity in Brazil’s agricultural landscape.

• Sultech’s products are Organic Materials Review Institute (“OMRI”) listed as allowed for use in compliance with the CFIA Canadian Organic Regime. SulGroTM Max is OMRI-listed as allowed for use in compliance with the USDA National Organic Program.

• Sultech is finalizing small plot protocols for the first trials on corn and soybeans in Iowa.

A: Like mineralization of soil organic sulphur fertilizers based on elemental sulphur or Thiosulfates must first be oxidized to sulphate for plant uptake, and this process relies on microbial activity in soil and is impacted by:

• Particle size (affecting surface area and thereby microbial access); and

• Environmental factors such as moisture, temperature, and pH (likely through their effect on the composition and abundance of the microbial community).

Sultech’s proprietary patentprotected technology and related intellectual property convert elemental sulphur (S°) directly into a product line that surpasses current market offerings in terms of particle size.

As a crop nutrient independent scientific evidence has verified our product line’s ability to make sulphates available to the plant within 7-10 days of application, achieve 95% product oxidization to plant available sulphates over the full growing season, resulting in matched performance in ideal conditions and outperformance of synthetic fertilizer in adverse environmental conditions at a lower nutrient and net

application cost. This season-long availability and outperformance of synthetic fertilizers amid the new “normal” of extreme weather, such as drought or too much moisture, provide significant agronomic and economic benefits to producers.

Sultech’s micronized elemental sulphur is a cutting-edge technology that is expected to replace traditional sulphur fertilizer products and challenge the dominance of ammonium sulphate and ammonium thiosulphate as a source of plant nutrient sulphur.

As a soil amendment, the acidifying effect of the oxidation of elemental sulphur improves soil health and restores arable land degradation in several ways.

• Lowers the soil pH of alkaline soil to increase nutrient supply and plant growth, and improve crop performance and marketability

• Restores sodic and calcareous soils by converting exchangeable sodium to sodium sulphate, which is removed by leaching below the root zone.

• Renders inert phosphates soluble and undoes phosphorus fixation. Phosphorus fixation occurs when applied phosphates, regardless of the fertilizer brand or chemical composition, combine with other minerals to form insoluble compounds and become unavailable to crops.

Soil amendment applications are typically determined by economics rather than by the amount required for optimal crop production and soil health. The combination of Sultech's low-cost production process and a superior mean particle size presents end users for the first time with the ability to maximize economic returns through optimal application.

Q: If applicable, describe how sustainability fits into your mission or solution.

A: A commonly used source of plant nutrient sulphur is ammonium sulphate (AMS), which is a granular formulation, consisting of 24% sulphur (S) content as well as 21% nitrogen (N) content. Therefore, to produce 1 tonne of S nutrient from AMS, one would need to produce 4.08 tonnes of AMS. The production of 4.08 tonnes of AMS, at an LCA emissions factor of 0.69 CO2e/tonne, results in 2.875 tonnes of CO2e emissions.

Additionally, the production of 4.08 tonnes of AMS would also produce 0.875 tonnes of N nutrient.

By contrast, Sultech’s proven technology will source molten sulphur directly from sulphur recovery facilities for the immediate conversion to plant nutrients and soil amendment products through the injection of molten sulphur at high velocity into a water/polymer blend, followed by the separation of the resulting micronized slurry from the water. The Sultech process does not require ammonia feedstock and only requires the energy necessary to thermally maintain the molten sulphur at a consistent temperature from the Sulphur Recovery Unit to injection.

The production of 1 tonne of S by Sultech results in 0.01 tonnes of CO2e emissions based on an LCA emissions factor of 0.01 CO2e/tonne. Using UREA to adjust for the missing N in Sultech's product line, at an LCA emissions factor of 0.91 CO2e/tonne Urea, 1.731 tonnes of CO2e emissions result from the production of 0.875 tonnes of N.

The result is a GHG emission advantage of 1.2 tonnes of CO2e per tonne of S produced vs. AMS,

resulting in a 40% reduction of CO2e emissions.

Additional Environmental Benefits include:

• Reduced Fertilizer Need: Due to the increased nutrient density of SulGro and urea, a less combined fertilizer volume needs to be used per hectare to achieve the same nutrient profile.

• Nitrogen Cycling: While not yet fully quantified, several research studies discovered that micronized elemental sulphur produces lower nitrogen dioxide emissions due to the interaction between sulphur and nitrogen cycling in the soil.

Sultech’s sustainability framework helps accomplish a number of United Nations Sustainable Development Goals.

• Zero Hunger which provides organic, eco-friendly fertilizers that enhance soil health and increase production yield by up to 40% and ensures sustainable food production systems that perform better under increasingly adverse weather conditions.

• Good Health and Well-Being

Sultech’s micronized sulphur fertilizers improve nutrient uptake, resulting in more nutritionally rich products for consumers.

• Clean Water and Sanitation

Micronized sulphur has significantly lower leaching risks compared to existing synthetic fertilizers by reducing runoff contamination, delivering full benefits directly to the crop helping to keep water sources clean.

• Climate Action

Sultech’s products lead to reductions in GHG emissions during the production process and

transportation compared to synthetic fertilizers.

• Life on Land

Sultech’s fertilizers promote natural soil health, biodiversity, and support long-term agricultural sustainability.

Q: Why are you attending AgTech Week in Fargo?

A: Increases in Sulphur deficiency symptoms observed in crops throughout the Midwest are likely attributed to higher removal rates from increased yields, a decrease in atmospheric S deposition, and declining soil health/quality.

Sulphur trials in Ohio in 2024 through the Ohio State University found that corn plots receiving Sulphur yielded more in 3 of 4 trials, by up to 6 bushels per acre. In Iowa State University tests from 200709, 28 of 47 sites planted to corn responded to sulphur, boosting corn yields.

Sultech is interested in establishing relationships in the extension

community as we look to build production to serve the US market. Sultech would be interested in contributing in kind (product/ application support etc) to future studies in this area.

Q: What are you hoping to gain or showcase during the event?

A: SulGro 65 is a first-of-its-kind micronized elemental sulphur suspension for spray or liquid kit application. Our broadcast product line (SulGroTM 85, SulGroTM 100, and SulGroTM Max) is available in a range of particle sizes for use as a value-add raw material input in synthetic co-granulated fertilizers or for surface broadcast, applied alone or blended with other plant nutrients and soil amendments. Our product line matches and surpasses current market offerings in terms of particle size at a lower raw material cost to the client.

Q: Have you participated in U.S.-based ag events before?

A: Presented at the Start-Up Showcase session of the World Agri-Tech Innovation Summit in San Francisco in March 2023.

Q: How can readers best support you?

A: Insight into treatment application rates and field logistics best practices. Verification of product market fit potential, leading to early adoption opportunities.

Q: Is there anything else you'd like to mention?

A: SulGroTM 65 (0-0-0-65) is packaged in Totes (1.15 Metric Tonnes) at a 65% analysis to deliver 750 KG of micronized S° per Tote. The S° is packaged in water and contains < 2% by weight dispersant/surfactants for safety and ease of handling.

To date, SulGroTM 65 has been successfully loaded using a conventional agricultural chemicalmixer and applied via a standard high clearance sprayer at seeding and mid-season (foliar) at rates of 10, 20, and 40 kg S/ha canola through industry standard nozzles (fan, drip & boomless).

SulGroTM 65 has been applied in combination with various herbicides to determine its effect on the efficacy of the herbicides. The results showed that when a pH corrector (PHIX, AIM, HEAT) is added to the blend, SulGroTM 65 did not affect the efficacy of the herbicides. These results confirmed the potential for logistical savings in sulphur application by applying it in conjunction with fall or spring burndown as opposed to as a separate application.

By Stephanie Blumhagen, Executive Director, FARRMS | Photos provided by Stephanie Blumhagen

For 25 years, the Foundation for Agricultural and Rural Resources Management and Sustainability—better known as FARRMS—has been quietly transforming North Dakota’s agricultural landscape. While it may look like an education nonprofit from the outside, FARRMS’ deeper mission is to build community, empower farmers, and grow a resilient local food system.

“We are growing the community of farmers, and together we are re-envisioning a sustainable local food future for our state.” — Stephanie Blumhagen, Executive Director, FARRMS

Each year, FARRMS serves over 200 beginning and small-scale farmers through a combination of education, mentorship, and financial support.

“Our programs are deeply rooted in collaborative, hands-on learning, ensuring that every lesson is practical, relevant, and community focused.”

- Jake Callander, Farmer Educator, FARRMS

Check out our programs

FARRMS supports farmers in their first decade of production— those most in need of guidance, connection, and capital. Their programs are designed to be farmer-led, community-focused, and sustainability-driven.

A 12-week online course offered each winter, Farm Beginnings helps participants:

- Develop a Whole Farm Plan

- Learn from local farmers and ag professionals

- Get matched with a mentor for one-on-one support

FARRMS hosts free or low-cost sessions on:

- Soil health and organic certification

- Marketing and business planning

- Financing and farm resilience

Recordings are available on YouTube @farrms6206.

- Microloans help cover startup or expansion costs

- Special grants (like the 2025 RISE grant) support farmers in crisis

- Staff provide one-on-one help with business plans, budgets, and funding applications

• Mentors are paired with new farmers for seasonal support

• Summer mentorships include farm visits and online discussions on topics like spring planning, marketing, mental health and burnout, and end-of-season wrap-up

• Mentors are compensated for their time, recognizing the value of shared experience.

At its core, FARRMS is about more than education— it’s about connection. In North Dakota, where many rural areas are still classified as “frontier,” smallscale farmers often find themselves isolated, far from others who share their values and vision.

FARRMS was built to change that.

“We want our programming to be relevant and practical, but more importantly we want to show new farmers that there are others nearby who are farming in this way—and they are not alone.”

- Stephanie Blumhagen, Executive Director

FARRMS designs every program with community in mind. Local farmers are invited to lead webinars, host farm tours, and mentor new growers—roles for which they are compensated, recognizing the value of their time and experience. The organization also offers travel scholarships to help farmers attend regional conferences and trainings, expanding their networks and perspectives.

Connection happens online too. FARRMS’ blog, Producer’s Perspective, gives farmers a platform to share stories and tips—from food preservation to livestock care. And in-person events like the annual Soil Health Field Day at Menoken Farm always end with a farmer social, where growers can relax, share ideas, and build relationships.

FARRMS’ newest initiative, Nourishing Our Roots, is a farmer leadership program designed to empower growers as leaders, teachers, and advocates. Through six in-person workshops, participants gain:

• Conservation knowledge

• Public speaking and storytelling skills

• Tools for working across differences

Graduates leave equipped to mentor others, speak at events, and lead within their communities— strengthening both the local food system and the social fabric that supports it.

To ensure its programs remain relevant, FARRMS regularly conducts farmer focus groups and leads the annual North Dakota Local Food Producer Survey, keeping its finger on the pulse of emerging needs and opportunities.

CONTINUED>

FARRMS is a founding member of the North Dakota Local Food Development Alliance, a coalition working to build a resilient statewide food system. They also partner on a food hub feasibility study led by the North Dakota Association of Rural Electric Cooperatives.

- Farmer Directory: Photos, bios, and product listings at farrms.org/farmer-directory

- Annual Farm Tour: A motorcoach tour south of Fargo visits four unique farms, ending with a celebration at Crooked Lane Farm.

- Farmer Calendar: Features 12 farms with professional photos, stories, and recipes— farmers keep the photo sets for their own marketing. 1500 calendars are distributed statewide.

FARRMS has seen a surge in interest in local food production, driven by rising consumer demand for locally grown and sustainably produced food.

- Farmers markets across ND often sell out within hours

- A 2019 study found that demand for fresh produce in just 10 northeastern ND counties could support 50–60 more growers.

- Over 60% of respondents to the 2023 ND Local Food Producer Survey said demand exceeds supply

National trends:

- Organic food sales grew by 8% annually over the past decade

- In 2021, organic retail sales topped $52 billion

- In 2020, farmers markets and on-farm stores made up 59% of direct-to-consumer sales

Meanwhile, 1 in 4 rural ND towns have lost their grocery stores. Local food production isn’t just a market opportunity—it’s a food access solution.

In honor of their 25th anniversary, FARRMS is seeking to raise $25,000 by June 2026—a dollar for every year of impact. With recent federal cuts to local food grants, community support is more important than ever.

“Whether it’s $10, $100, or $1,000, every donation matters. A donation to FARRMS is helping to create a more sustainable, healthier future for North Dakota’s communities.” — Stephanie Blumhagen Your Donation Supports:

- New farmer training and mentorship

- Microloans and scholarships

- Local food access in rural communities

- Farmer-led education and leadership development

A significant portion of FARRMS’ funding flows directly to farmers through:

- Scholarships

- Microloans and grants

- Stipends for mentors and speakers

- Travel support for conferences and training

FARRMS’ programming is farmer-led, meaning local farmers shape the content, lead workshops, host tours, and advise through surveys and councils.

Donate online: farrms.org/donate

Or mail a check to: FARRMS PO Box 2024 Minot, ND 58702

See FARRMS in Action! Join us for

Unlocking Organic Success: A Soil Health Field Day at Menoken Farm Wed. Sept. 10, 2025, 10:00 AM – 4:30 PM CDT

Menoken Farm, 1107 171st St NE, Menoken, ND 58558, USA

Join the FARRMS, Northern Plains Sustainable Agriculture Society (NPSAS), and Acres USA for a FREE educational field day at Menoken Farm on Wednesday, September 10th. Whether a seasoned farmer or just starting, this is a great opportunity to learn the secrets to healthy soil and organic success.

Field to Feast – A Fargo Area Farm Tour

September 18, 2025 from 12 PM – 7 PM

Bus pickup/drop-off: Scheels Arena Parking Lot (SE Corner), 5225 31st Ave S, Fargo ND

Tickets: $100 – Includes motorcoach transportation, grab-and-go lunch, evening grazing table.

Purchase tickets:

Founded in 2000, FARRMS was created to support a new generation of farmers and strengthen rural economies. With a vision of thriving sustainable North Dakota communities, FARRMS’ mission Through educational programs, social connections and financial support we are empowering ND farmers to create sustainable profitable enterprises.

Their work is guided by three core goals:

1. Support early-career farmers

2. Promote environmental stewardship

3. Increase local food access

Learn more at farrms.org or follow them on social media: - Facebook & Instagram: @farrms.nd - YouTube: @farrms6206

Jake Callander started Nature's Roots Farm in 2020, offering a wide variety of vegetables, fruit, and flowers. He connects with customers through farmers markets, CSA subscriptions, and sales through the Red River Harvest Cooperative. With a couple years farming experience before taking Farm Beginnings, he credits the class with building his confidence to view and operate his farm as a business, enabling him to make informed decisions. Jake is also the FARRMS Farmer Educator where he shares his passion and knowledge to empower farmers throughout North Dakota.

Adam and Apryl Mawby of Gardendwellers Farm and Ranch embarked on their farming journey together in 2020. They are dedicated to being good stewards of the land, offering a diverse range of products including pastured lamb, chicken, pork, raw milk, culinary herbs, garlic, and natural herbal skincare. The couple attributes FARRMS with providing an invaluable network of fellow farmers, combating the isolation often experienced in agriculture by fostering a strong community where they can exchange ideas and gain new perspectives. They continue to build relationships by serving as mentors in Farm Beginnings and the Summer Mentorship.

Lori Martin launched Roving Donkey Farm in 2012, specializing in diversified vegetables and fruit. As her farm has evolved, she has strategically shifted her focus to wholesale markets, primarily supplying schools and restaurants. She recommends Farm Beginnings to other aspiring farmers as it gave her the foundation to start her own farm. Lori actively gives back to the FARRMS community by sharing her valuable expertise in record keeping by presenting in FARRMS' business planning webinars.

Mike and Alecia Pretzer started The Double Batch near Rugby, ND in 2013. They relocated to family land near Taylor, ND in 2018, establishing a deep connection to the century-old farm. Through a home-based bakery, they craft hand-kneaded yeast breads and sell them at local farmers markets. Their journey in local foods was shaped by Farm Beginnings, which introduced them to the vibrant local foods community. Believing in the freshness, health benefits, and sustainability of locally grown produce, they actively support local foods by serving on the board of the North Dakota Farmers Market & Growers Association (NDFMGA).

By Madi Simpson

For over a century, SB&B has operated at the crossroads of tradition and innovation, serving as a trusted connection between Upper Midwest farmers and food manufacturers around the world.

SB&B traces its origin back to 1906, when John B. Sinner established a farm near Casselton, ND. By 1952, the operation had formalized into a farming partnership—Sinner Brothers & Bresnahan (SB&B)—led by John’s descendants and their brother-in-law. Today, the fifth generation of Sinners and Bresnahans are continuing the legacy as active partners.

Over the decades, SB&B evolved from a traditional farm into a multi-faceted operation.

“What started as 750 bushels from our own farm in 1988 has now grown to over 2.6 million bushels of USA food-grade identity-preserved soybeans,” the team shared.

Key milestones include the formation of SB&B Foods in 1998 and Identity Ag Processing in 2004, establishing dedicated food-grade soybean facilities in Casselton, ND, and Bloomer, WI. Today, the organization supports more than 35 employees and supplies approximately 100 global customers across 10+ countries.

It makes us proud to continue on a legacy of strong values, entrepreneurship, and reputation spanning multiple generations.”

A FATHER, 2 SONS & A GREAT FRIEND

Our grandfathers unofficially sowed SB&B over 100 years ago. They settled near a farm in Casselton, ND, and began specializing in identity preservation long before it was an industry term. They focused on seed production and direct sales to local farmers, which helped them capture premium markets and fulfill the needs of their customers and neighbors.

SB&B’s growth has been made possible through partnerships with more than 200 growers across North Dakota, Minnesota, South Dakota, and Wisconsin. Unlike transactional arrangements, these grower relationships are built on a shared purpose: to create resilient markets for Midwest farmers through high-quality, identity-preserved soybeans.

“Being farmers ourselves gives us a unique perspective,” they said. Grower support includes agronomic seminars, leadership development, and even international supplier trips.

“We bring our customers out to the fields in the summer to meet our suppliers. We’ve humanized the transaction, which gives the suppliers a great sense of pride to provide quality since they know which customer is purchasing them.”

All of the farmers we are working with are sincerely trying to provide the safest, highquality soybeans they can to the customers.”

1. Contract & Planting: Begins the traceability process with field maps, previous crop history, etc.

• Unique lot numbers are assigned at this stage

2. Harvesting & Storage: Product is harvested and supplies are stored in isolated, on-farm grain bins or delivered directly to SB&B off the field.

• Full production contracts

• Quantity & quality checks reported post-harvest

3. Delivery from Growers: Product is delivered to SB&B’s Casselton or Bloomer facility by grower partners for specific customer orders.

• Varieties selected for delivery based on customer shipping orders

• Grower lots are paired based on customer criteria

• Matched to a customer contract

4. Identity Preserved Receiving: Product is quality checked and received into dedicated IP grain bins.

• Quality checks are performed before receiving into the facility

• Once approved, the product is segregated and stored by lot number

5. Cleaning & Processing: Soybeans are cleaned and processed over a series of specialized equipment to ensure a highquality finished product.

• Impediments removed

• Uniform size and color established

• Consistent product profile before shipping

6. Quality Confirmation: Trained staff confirm that the cleaned product meets internal and customer-specific standards.

• Visual and mechanical inspection

• Cleared for final staging

7. Packaging & Loading: Product is staged for packaging and loading into containers or trucks, based on destination and customer needs.

• Labeled by lot number

• Sealed for secure transport

8. Documentation & Shipment: Upon shipment, SB&B’s logistics team generates IP documentation and sends it to the customer.

• Full traceability from field to delivery

• Ensures transparency and product integrity

Richard Sinner & William Jr Sinner join SB&B (4th Generation)

Robert Sinner joins SB&B (4th Generation)

Thomas Bresnahan and Patrick Bresnahan join SB&B (4th Generation)

1st international shipment of soybeans to Japan

SB&B Foods, Inc. established to manage the marketing and sale of an extensive line of identity preserved, non-GMO, and organic foods to customers worldwide. Our capabilities grew when we established Identity Ag Processing, LLC., a new state-ofthe-art cleaning facility.

Heading into 2025, SB&B is entering its biggest planting season yet with record customer demand. Expansion is being fueled by genetic innovation, digitization, and trusted supply chain relationships. A private breeding program launched in 2018 is already delivering strong IP soybean varieties for food manufacturers and contracted growers.

Two major tech rollouts are underway: a custom traceability platform and a field stewardship program. The latter allows growers to measure reduced water runoff, soil erosion, and phosphorus loss, with a carbon intensity metric being added soon.

We have been piloting programs that further enhance our traceability offerings by capturing on-farm data directly into a customized traceability platform.”

Looking forward, SB&B is committed to the long-term health of the regional food-grade soybean economy. Their leadership team is focused on bringing new markets, genetics, and tools to the grower network, ensuring the region continues to play a vital role in global food supply chains.

| sb-b.com

Supplying

Foods

Bean growth is off the charts, spurred by consumer demand and increased consumption of the versatile, proteinpacked ingredient. Market research shows that the U.S. bean market for dry and ready-to-eat (RTE) beans is valued at 2.2 billion, and it is growing yearover-year.

This steady demand fuels bean innovation. ADM is helping ensure beans meet consumers’ high standards as the largest dry bean producer in the U.S. due to an industry-leading vertically integrated supply chain and a forward-

thinking approach that prioritizes profitability for everyone involved, from the farmer to the food processor.

ADM employs a field-to-fork philosophy that supports, financially and otherwise, every part of the supply chain. From initial bean breeding and innovation to western seed production, our system ensures that Midwestern farmers receive the seed they need. After planting and harvesting, they deliver their crops to Midwest elevators, where the beans are cleaned and prepared for shipment to end users.

The revolution in dry bean development is happening in the consumer-friendly traits selected by expert plant breeders. For many years, most breeding programs have focused on traits that benefit the farmer directly, such as high yield and superior agronomic performance. Now, the latest in breeding practices both benefit farmers and have prioritized consumerpreferred traits like taste, texture, color, and increased nutrition, making for a product that demands a higher price at market.

Seedwest is situated in Idaho because its climate and state regulations provide the perfect conditions to ensure seeds are high quality and free of pests and pathogens. Idaho is arid and not conducive to pathogen growth, breaking what’s known as the “disease triangle” of host, pathogen, and environment. Additionally, seed inspection standards and certification are stricter in Idaho, helping ADM seeds meet lofty standards.

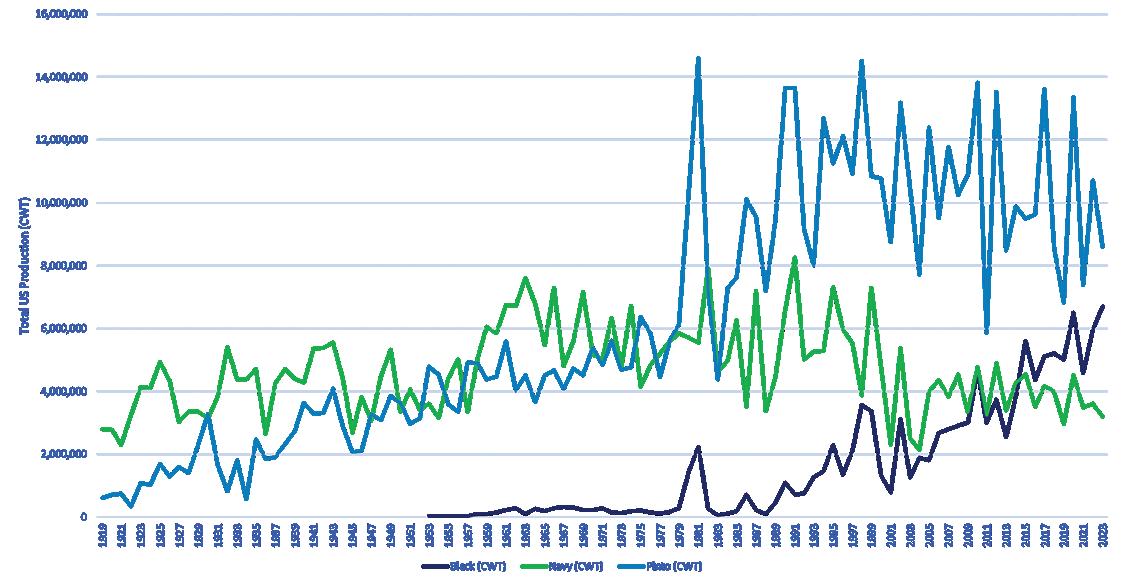

The breeding pipeline and breeding objectives account for virtually all bean market classes, from great northerns and kidney beans to yellow and cranberry beans and everything in between. However, the lion’s share of the crops is devoted to the big three: pinto, navy, and black beans.

Black bean breeding has recently been a subject of much emphasis, as black beans have shown consistent growth in use going back decades (Figure 1). Pinto and navy beans have remained solid, but black beans are on the rise as they’ve increasingly been incorporated into the American diet and in more applications, from the cans on the grocery shelf to the burritos in quick service restaurants.

Figure 1 – United States Department of Agriculture: National Agricultural Statistics Service

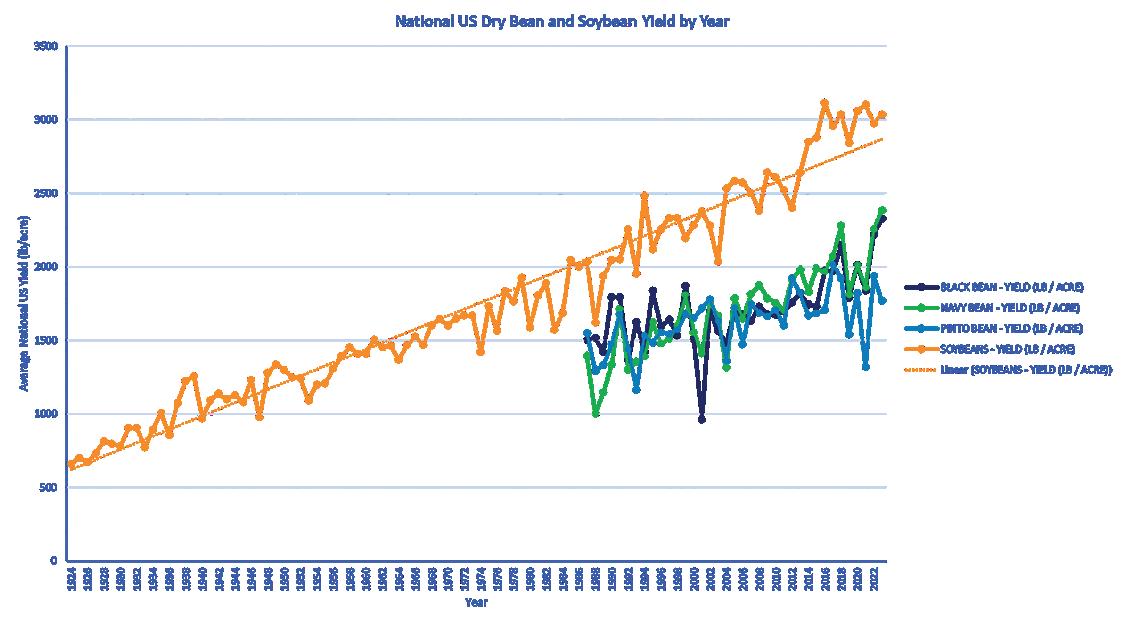

ADM’s bean breeding pipeline is non-GMO and what is considered a “conventional” program, which is a straightforward process of cross-pollinating one plant with another and then selecting, inbreeding, and testing plants for several years. In contrast to other commodity crops, dry beans are unique in the fact that each bean market class requires its own breeding pipeline, which multiplies the effort to breed better beans of all types.

Once a hybridization is made between two plants, bean breeders go through several generations of the progeny, selecting for desirable traits with each one. Once a stable, pure-breeding line is established, rigorous testing of the new experimental line begins. Widespread testing is conducted across the target production environment to measure agronomic characteristics like yield, maturity, plant architecture, lodging resistance, and resistance to diseases, pests, or abiotic stresses like salinity, flooding, and droughts.

It takes 7 to 10 years to winnow out one or two select varieties that meet all the criteria to be the next highquality commercial bean variety. However, ADM’s full pipeline of bean seeds has lines at every stage of that process, so new lines are continuously advancing towards commercialization.

Figure 2 – United States Department of Agriculture: National Agricultural Statistics Service