Waterfall Pumps’ unwavering promise: Certified reliability protecting the region’s most critical assets

PERFORMANCE OVER PRESCRIPTION

BEYOND COMPLIANCE

The role of Fire Strategy Reports in building design

GECO M&E proudly announces its partnership with KIDDE, a global leader in fire detection and protection solutions.Together, we bring state-of-the-art life safety technologies to the UAE designed to protect families, properties, and businesses with unmatched reliability.

EDITORIAL

Publisher Mike Dingle +44 1752 267330 mike@firemiddleeast.co.uk

Editor

Cora Lydon +44 7834 244613 editor@firemiddleeast.co.uk

ADVERTISING

Worldwide

Ryan Bickerton +44 1752 265802 ryan@firemiddleeast.co.uk

Gareth Driscoll +44 1752 260603 gareth@firemiddleeast.co.uk

Rahul Vara +44 1752 604352 rahul@firemiddleeast.co.uk

Will Russell +44 7800 513300 will@firemiddleast.co.uk

Digital Editor Britt Jones britt@firemiddleeast.co.uk

Production Team Freya Tucker freya@firemiddleeast.co.uk

Marketing Manager

Mark Doyle +44 7517 452283

PUBLISHED BY

MDC Middle East Ltd

+44 (0)1752 267 330 6 Woodside Lane, Plymouth, Devon, PL4 8QE, UK

This publication may not be reproduced or transmitted in any form in whole or in part without the written consent of the publishers.

©MDC Middle East Ltd. 2026

For subscriptions and advertising enquires, or for further information on the magazine visit our website at: firemiddleeastmag.com

As 2026 begins, the fire safety conversation across the Middle East is reaching new heights marked by innovation, collaboration and a shared commitment to raising standards.

Our cover story this issue shines a light on Waterfall Pumps Manufacturing (page 16), whose ascent from local manufacturer to global safety leader is truly inspiring. Their story reflects the region’s broader transformation – where technology and trust go hand in hand.

We’re also delighted to bring you an exclusive eight-page supplement from Fomtec (page 57), taking a deep dive into the company’s pioneering work in firefighting foam and sustainable solutions reshaping performance expectations worldwide.

Beyond that, this issue is brimming with expert insight. Firedos’ Stuart Phythian explores how to adapt to the new foam frontier (page 27); Ruediger Kopp of FOGTEC unveils the sustainable power of high-pressure water mist in icons such as the Mecca Royal Clock Tower (page 35); while Peter Stephenson examines how passive fire protection is transforming the design of vertical cities (page 41).

You’ll also find discussions ranging from cutting-edge fire safety integration led by experts at Cundall (page 31); and lithium-ion battery fire risks (page 95); to AI in fire engineering with Anis Jayaram of Jensen Hughes (page 109), and the hidden pollution of sprinkler system discharge (page 99).

Of course, one event dominates the early 2026 calendar – Intersec Dubai. In our dedicated section, we’ve brought together everything you need to navigate the show: exhibitor previews, speaker highlights and insight into what you can expect as an attendee courtesy of the Show Director (from page 123). Fire Middle East will be on the ground throughout the event, reporting live and connecting with partners and readers. Come say hello – we’d love to see you there, you can find us on stand 5 A-09. You can also find us hosting the brand new Intersec Pulse Studio – where we’ll be diving deeper into the hottest topics with the sector’s thought leaders. Find out more on page 127.

And it doesn’t stop there. We’re already gearing up for the Fire Middle East Conference returning to Riyadh this April – now in its third year and fast becoming one of the region’s must-attend platforms for thought leadership and knowledge exchange. Learn more on page 20.

With so much momentum building, 2026 is already shaping up to be an extraordinary year for fire and life safety in the Middle East.

Cora Lydon

Editor editor@firemiddleeast.co.uk

03 Up front

Foreword from the Editor

06 Regional news

The latest regional fire safety and protection news

12 International news

Fire-related news and advancements from around the globe

14 Product showcase

Find out about some of the newest products to reach the market

142 Diary

Diary dates for forthcoming fire safety exhibitions, conferences and events

16 Cover story

23 Performance over prescription

Amer Al Merabi, Associate Consultant FLS, AESG, covers the evolving future of fire and life safety in Saudi Arabia

27 Performance practicality and proof

Regional Director, Firedos, Stuart Phythian, advises on adapting to the new foam frontier

31 Synergy in action

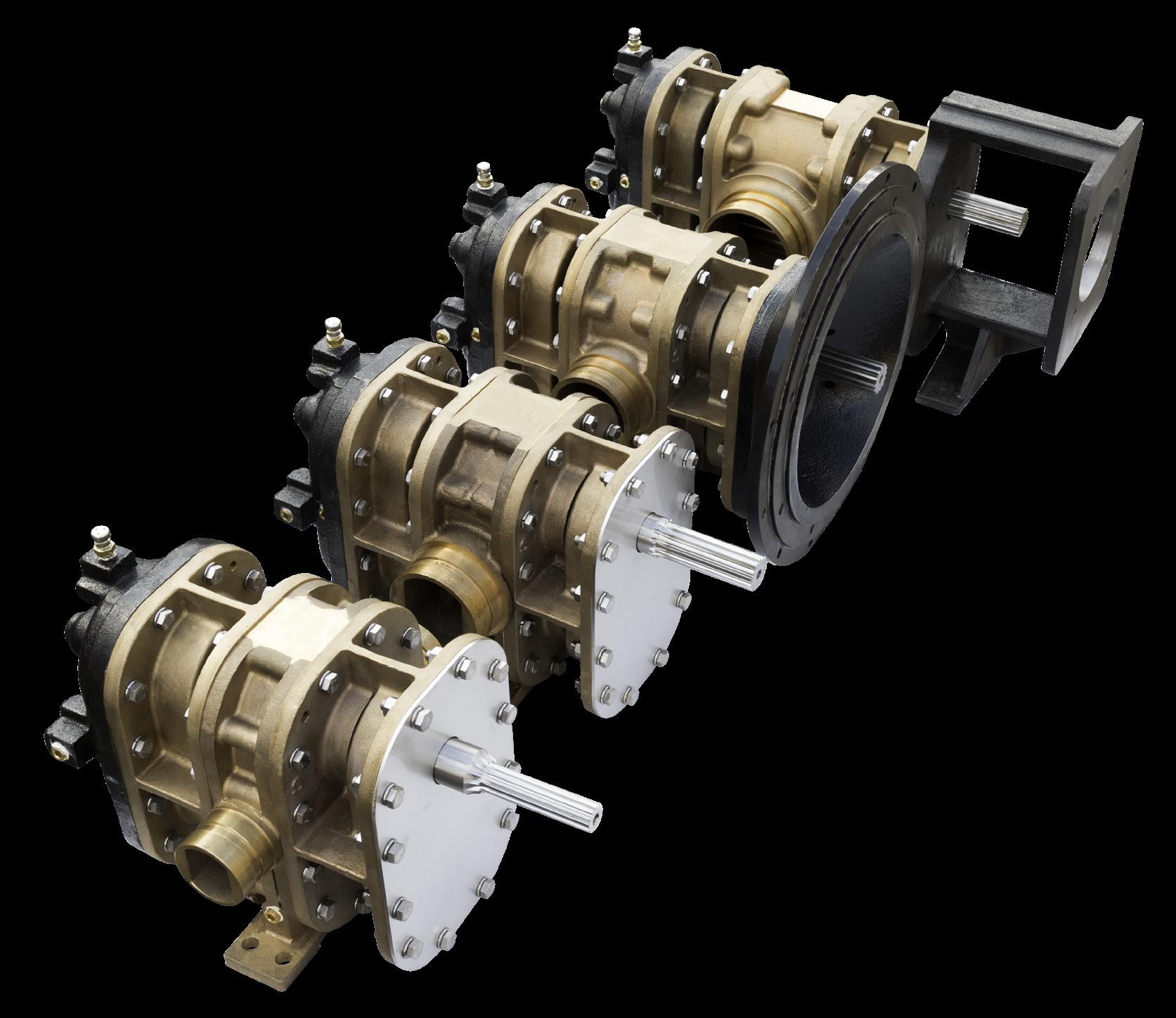

Since its establishment in 2015, Waterfall Pumps Manufacturing (WF) has transcended from manufacturer to become a guardian of safety

20 From insight to action

Read more about the Fire Middle East Conference – coming to Riyadh in April 2026 – the must-attend events for leaders in the sector looking to stay ahead

Discover how the latest integration between fire and security systems creates smarter, safer buildings, according to Mina Zakhary, Principal Fire Consultant and Smitha Mathew, ELV Lead Engineer at Cundall

35 Future-proofing tall towers

Ruediger Kopp of FOGTEC Brandschutz GmbH, explores how high-pressure water mist technology is safeguarding icons like the Mecca Royal Clock Tower while shaping the future of sustainable, efficient fire protection in the region’s most ambitious structures

41 Building fire-safe vertical cities

Peter Stephenson, Fire Safety Solutions Expert, explores passive fire protection and compartmentation for major projects in the Middle East

48 Raising the bar on fire safety in the Middle East

Barry Allan, PPG, discusses why global standards should drive passive fire protection

54 Beyond compliance

Redefining the role of Fire Strategy Reports in building design and operation is Vinay Deshpande, Founder & Managing Director, Vitruvius Fire Safety Consulting FZ-LLC

65 IWMA 24th Conference

Following its 24th annual conference, the IWMA reflects on the growing interest in water mist

68 Celebrating 20 years of fire protection leadership

Piping Logistics’ CEO Jeroen De Smedt discusses the strategic decisions, technical innovations and long-term vision driving expansion across the Gulf region and beyond

71 Fire detection in the heat zone

Ali Al Musabih, Jensen Hughes, considers the impact of ambient temperature extremes on ceiling jet development and fire detection systems and the critical design implications

76 The art and science of firefighter training

Bob Rea QFSM, MBA, FInSTR, MIFireE, MIoL, TechIOSH, reflects on the true value of firefighter training

81 The gap that protects Fahri Yiyin, takes a closer look at the minimum distance between Class I-II-IIIA liquid chemical storage tanks

84 Securing the boom

Faris Alzharani, OHS and Fire Safety Practitioner, explores fire risk management systems in construction sites and shares the vital importance of Construction Fire Safety Plans

91 125 years of fire safety

As industry leaders gathered at Intersec Saudi Arabia to discuss the region’s evolving fire safety landscape, Fire Middle East caught up with Frederic Frantz, Senior Vice President of International Sales and Marketing at Potter Global Technologies

95 When power ignites

Yasser Amer Ahmed, Fire Protection Specialist, offers a technical and standards-based analysis of managing and minimising the risks of lithium-ion battery fires

99 The hidden pollution within For more than a century, fire sprinkler systems have silently discharged polluted water into the environment. As the Middle East accelerates its sustainability goals, Camillo Longo asks: what’s really coming out of those drain valves?

105 Saudi Sicli’s vision for fire protection

Hear firsthand from Ahmad Sagr, COO of Saudi Sicli, as Fire Middle East magazine caught up with him on the buzzing floor at Intersec Saudi Arabia

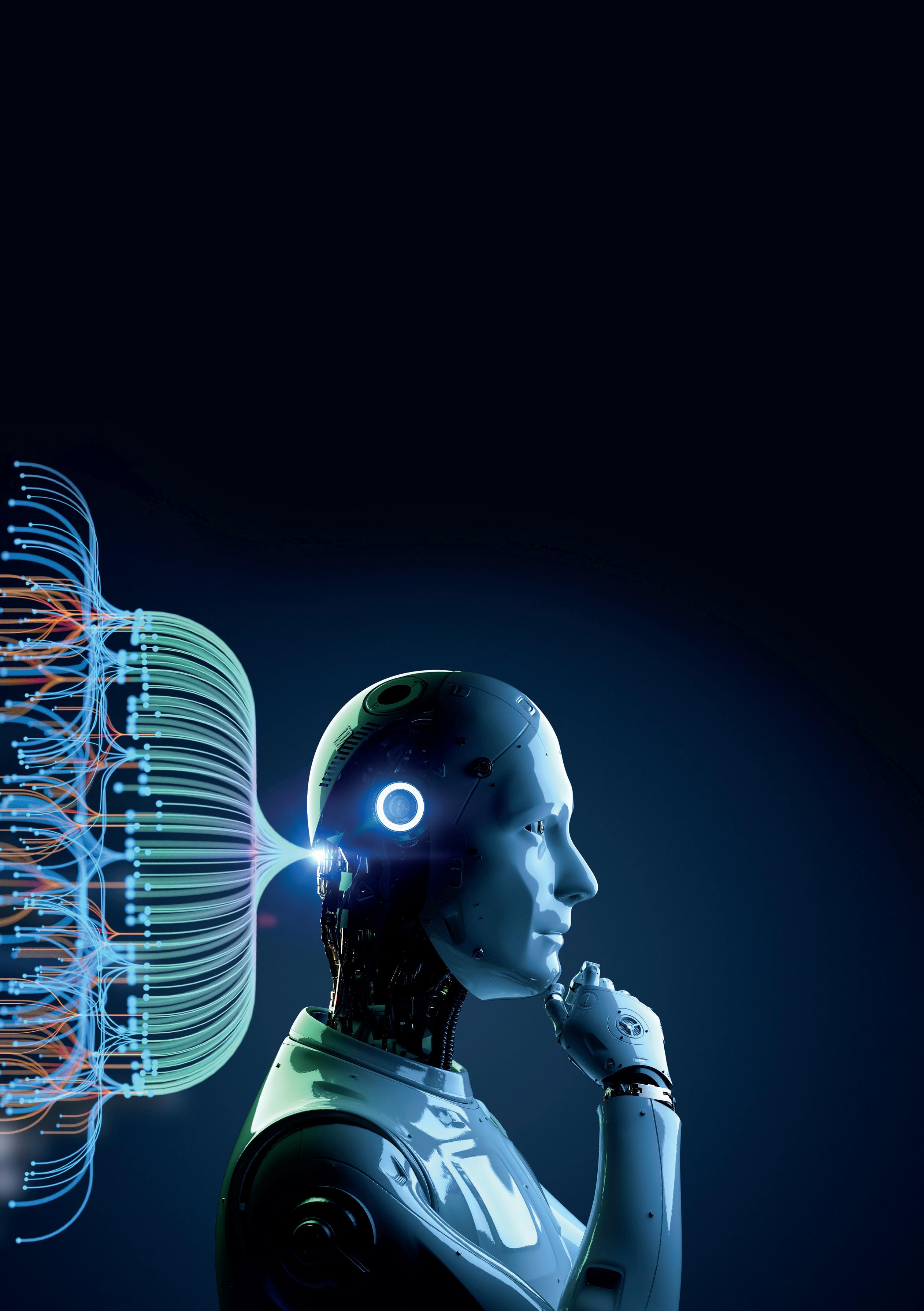

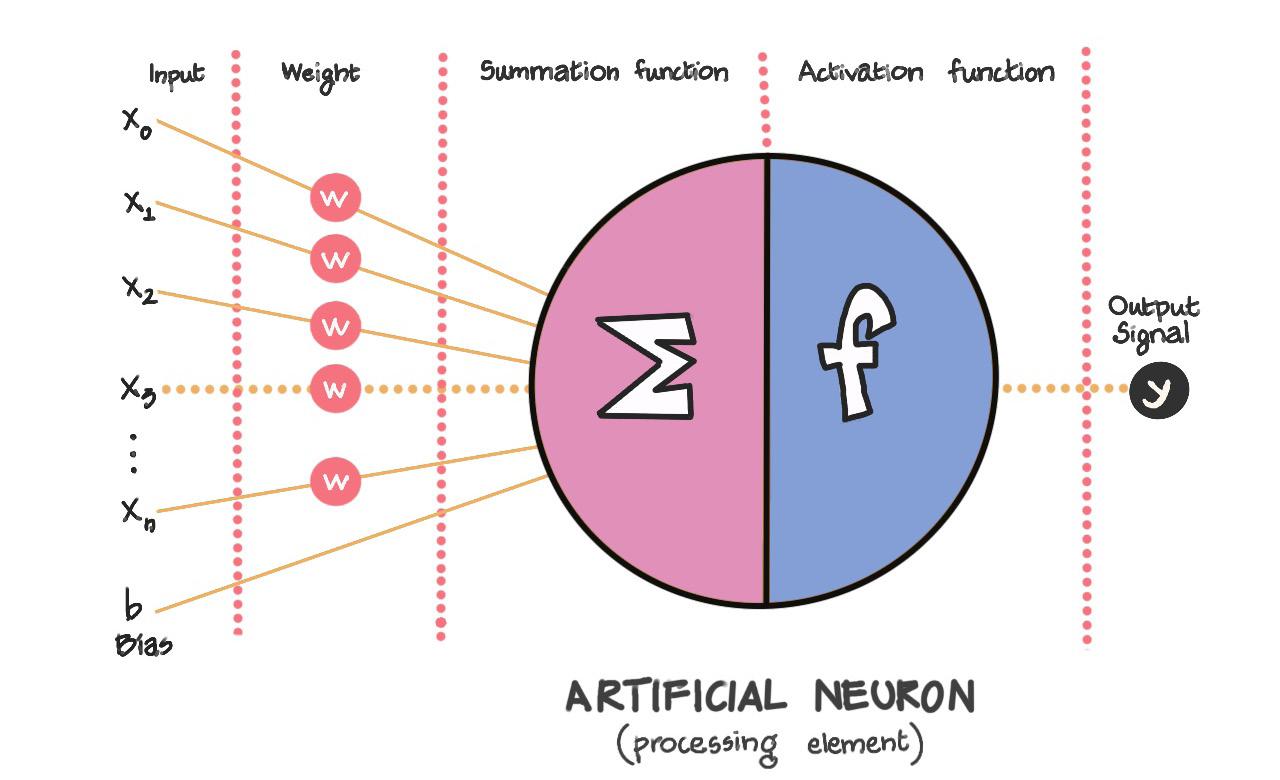

109 The human behind the machine

How are today’s fire engineers blending the world’s most advanced AI tools with traditional expertise to reshape fire safety, while keeping trust, ethics and responsibility at the heart of innovationAnis Jayaram, Jensen Hughes, tells all

112 When the first blast isn’t the last

Yan Cavalluzzi for NCT Consultants

explores how evolving Houthi drone warfare in the Red Sea increases risks of secondary chemical incidents, posing serious humanitarian and strategic challenges

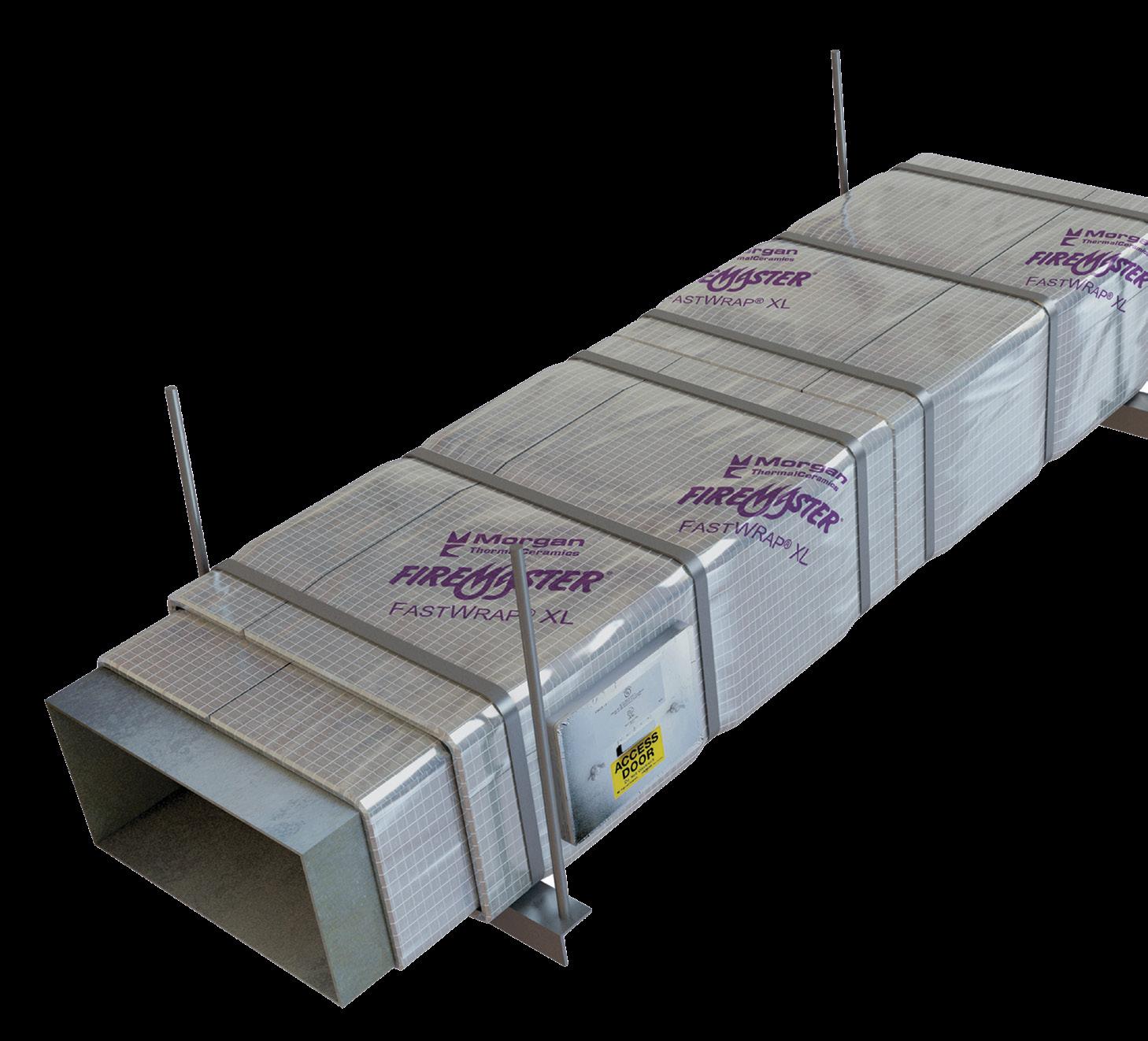

116 Raising fire safety standards in building ventilation

How Morgan Advanced Materials’ insulated duct systems are reshaping building safety across the UAE and Middle East

123 Intersec Dubai

Everything you need to successfully navigate the forthcoming exhibition and get the most out of your attendance

123 Welcome from show director

125 Meet the speakers

126 Meet the exhibitors

127 Intersec Pulse Studio

57 Fomtec

Find out in greater depth how Fomtec is driving the future of firefighting foam innovation

66 Advanced

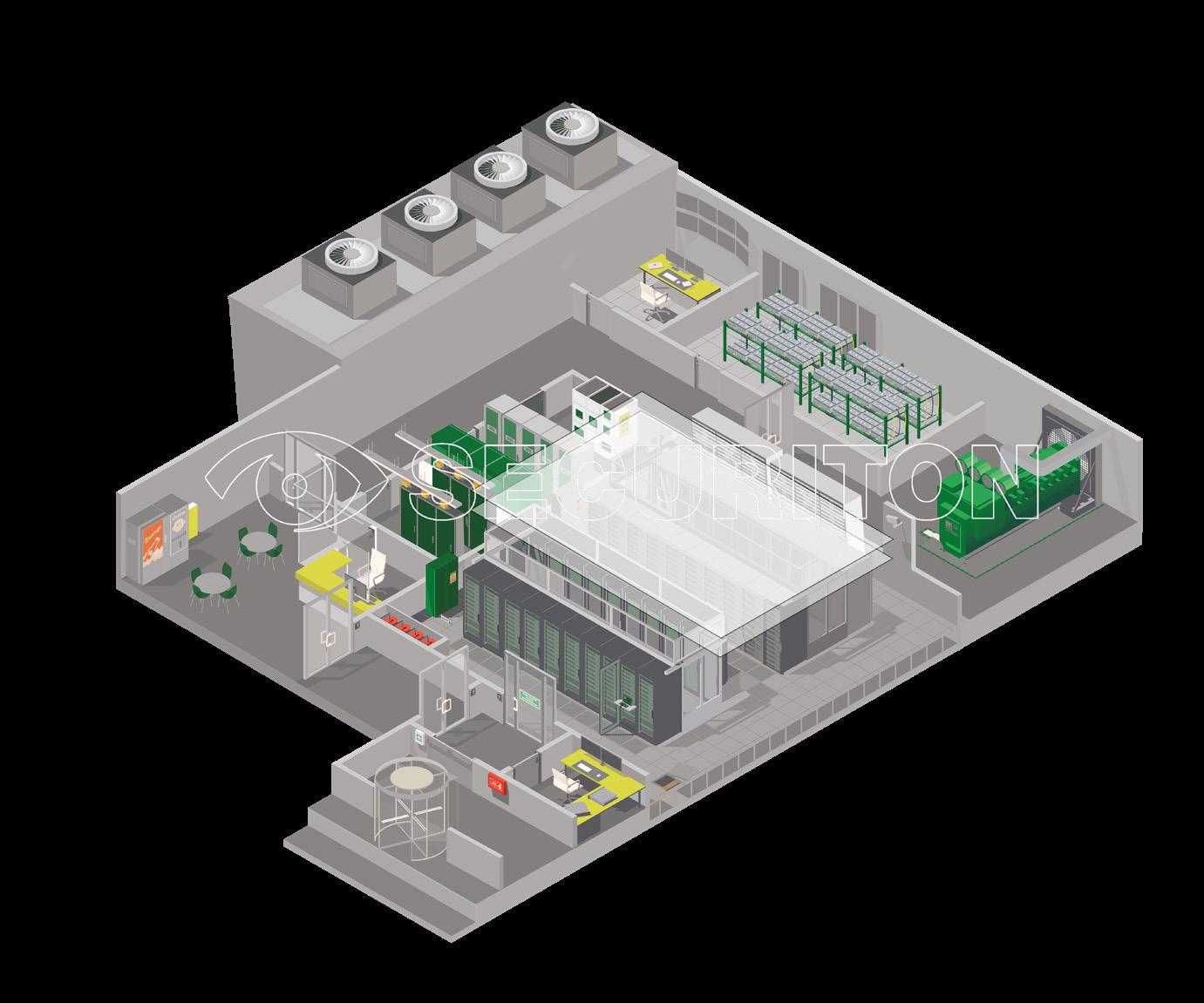

83 Securiton

88 Vox Ignis

102 Fire & Gas Detection Technologies 104 Kentec

President Sheikh Mohamed bin Zayed Al Nahyan has sent a message of condolence to President Xi Jinping following a major fire in a Hong Kong residential complex that resulted in numerous deaths and injuries.

The fire, which swept through a large residential block, has claimed at least 159 lives, making it the deadliest fire in Hong Kong for decades and surpassing the toll of London’s Grenfell Tower fire in 2017. According to the BBC 2,311 firefighters were involved in the operation to bring the fire under control.

Investigators pinpoint plastic netting – intended to catch falling debris – and combustible polystyrene foam panels on exterior windows as

key accelerators, creating an “external chimney effect” that shattered glass and fuelled vertical and lateral spread, worsened by bamboo scaffolding. Despite regulations mandating flame-retardant treatments, substandard materials evaded inspections, echoing Grenfell Tower’s cladding failures.

The tragedy underscores urgent needs for stricter audits of renovation materials in high-rise megaprojects, enhanced flame-retardancy enforcement and performance-based testing amid Vision 2030’s dense urban growth. Authorities now probe negligence, signaling a global push for non-combustible alternatives in cladding and scaffolding.

The Middle East fire suppression systems market is expected to grow steadily over the next decade, rising from an estimated US$1.22 billion in 2024 to US$2.07 billion by 2033.

According to industry forecasts, the sector will expand at a compound annual growth rate of 5.9 per cent from 2025 to 2033, which is due to stricter fire safety regulations, rapid construction activity and more awareness of safety standards.

Saudi Arabia is expected to record the strongest growth, with forecasts

indicating a 7.5 per cent CAGR, which is supported by major infrastructure projects under Vision 2030.

The UAE is also projected to expand quickly, helped by smart city initiatives and enforcement of updated building codes.

Residential developments are becoming a key area of demand, with this segment forecast to grow at 7.6 per cent as governments mandate suppression systems in high-rise and multi-family buildings.

Dubai’s rapid industrial expansion is driving greater fire safety complexities. As manufacturing and logistics facilities proliferate, so do risks tied to flammable materials, complex equipment, electrical systems and heightened human activity. Proactive fire risk assessments have become essential to manage these emerging challenges effectively. In Dubai, where industry and logistics play a strategic role in economic development, industrial facilities are multiplying.

These environments, which often involve complex manufacturing processes and high human activity, naturally carry heightened fire risks due to equipment, electrical systems, flammable materials and open flames.

While fire safety engineering programmes exist in various parts of the world, there is no nationally licensed undergraduate programme in the UAE specifically dedicated to fire risk analysis. While master’s and doctorallevel programmes in fire engineering do exist, practical industry experience plays a pivotal role in conducting effective assessments. Dubai Civil Defence has mandated that any fire protection design or audit must be conducted by DCDapproved and certified consultants.

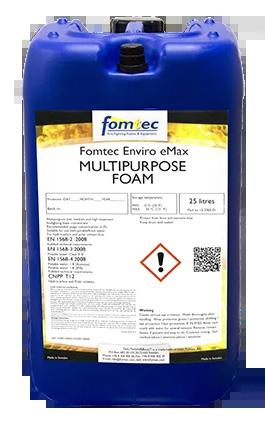

Low-viscosity Fluorine Free Foams (F3) and C6 based fluorinated eco-friendly foams are just part of our industry leading range of specialist fire-fighting foams. Visit the website to find out more about our complete product range, including Standard and AR type foams suitable for hydrocarbon and polar solvent fires.

Twenty Druze from Syria’s southern Suwayda province are set to participate in a firefighting training programme in Israel, the first initiative of its kind, Israeli media reported.

According to Yedioth Ahronoth, the participants will take part in a three-week intensive course using advanced Israeli firefighting simulation systems. The training will cover a range of emergency scenarios, including vehicle fires, residential and commercial incidents, as well as rescue techniques in hazardous environments. Upon completion, the trainees are expected to return to their communities equipped with professional firefighting gear and a new fire truck to establish a local firefighting centre in the Druze area of the Israeli-occupied Golan Heights. The programme is led by National Security Minister Itamar Ben-Gvir in coordination with Israel’s National Security Council. Syrian authorities have not commented on the reports.

Vallfirest has signed a new agreement with Heliswiss Ibérica to handle distribution and after-sales service of its Water Hog firefighting bucket across Europe, the Middle East and Africa.

The deal means Heliswiss Ibérica will take charge of delivering the equipment, providing technical assistance and supporting customers after purchase. Vallfirest said the partnership is designed to speed up delivery times and give aerial operators a dedicated point of contact for maintenance and repairs.

Heliswiss Ibérica specialises in aircraft maintenance, repair and overhaul, as well as leasing and equipment distribution.

The Water Hog bucket is part of Vallfirest’s aerial product line for wildland firefighting. The company said it was developed to meet today’s tougher fire conditions, including more intense flames, faster spread and more demanding logistical challenges.

CEO Javier Baena said Heliswiss Ibérica’s industry experience and regional presence enhance the value the company can provide.

The agreement is expected to have a direct impact on helicopter operators, fleet managers and procurement teams involved in wildland firefighting across the region.

University of Bradford researchers in the UK are pioneering AI-driven wildfire detection using robotic dogs, drones and 6G networks in a pilot set for Greece next year. The system analyses real-time HD video, satellite imagery and sensor data to spot early smoke, heat signatures and dry vegetation, triggering instant alerts to emergency responders via highbandwidth 6G links.

Part of the EU-funded 6G-VERSUS project, the trial integrates quadruped robots for scouting dense terrain, delivering supplies and supporting search-and-rescue, while drones provide aerial oversight and communication relays. Led by Dr Kamran Mahroof, the initiative addresses escalating wildfire risks amid climate change, aiming to enable faster interventions and reduce environmental damage.

For Middle East fire professionals, the technology offers potential adaptations for arid brushfire zones and urbanwildland interfaces, enhancing regional resilience against seasonal fire threats.

Researchers at Peking University have developed a composite fibre blending long carbon nanotubes with aramid that sets a new record for protective materials, absorbing 706.1 MJ per cubic metre – three times stronger than Kevlar under high strain-rate impacts.

The fibre achieves a dynamic strength of 10.3 GPa while remaining just 1.8 mm thick, by aligning nanotubes with polymer chains to distribute impact forces efficiently, overcoming traditional strength-toughness trade-offs. Led by Professor Jin Zhang and published in Matter, the innovation reduces porosity through softened aramid and stretching, enabling rapid load transfer.

The development could lead to lighter, less bulky PPE vests and helmets that cut heat stress during extended operations in harsh climates, though scalability challenges remain for mass production amid durability concerns like UV and sweat exposure.

68% faster inspections by teams using purpose-built software 59% higher audit confidence when using software

A new report from Scannable reveals a stark digital divide in PPE management, with 48% of safety teams in high-risk sectors like construction, mining, oil & gas and rope access still relying on spreadsheets, paper or generic tools, despite 31% adopting specialised software.

Teams using purpose-built software complete inspections 68% faster — under two minutes per item — versus 44% of all

surveyed teams taking over three minutes, saving significant administrative time for inventories exceeding 1,000 items. Software users also report far higher audit confidence, at 59% “very confident” compared to 32% for manual methods.

In oil & gas and mining, 60% cited missing equipment as a top failure reason, alongside 40% incomplete records, while construction faces high wear-and-tear rates.

NAFISCO has launched a new brand identity and strategic transformation programme to reinforce its role as a leading fire protection specialist in Saudi Arabia. The refreshed brand is designed to reflect its focus on complex, high-risk environments, including industrial plants, energy infrastructure, aviation, healthcare and major real estate projects.

The company’s multi-year roadmap centres on enhancing engineering accuracy, improving project delivery and service responsiveness, and embedding a stronger performance culture supported by a Balanced Scorecard approach. Aligned with Saudi Vision 2030, the strategy aims to meet rising regulatory and stakeholder expectations for advanced fire and life-safety solutions on large-scale developments.

12 - 14 January, 2026 Dubai,

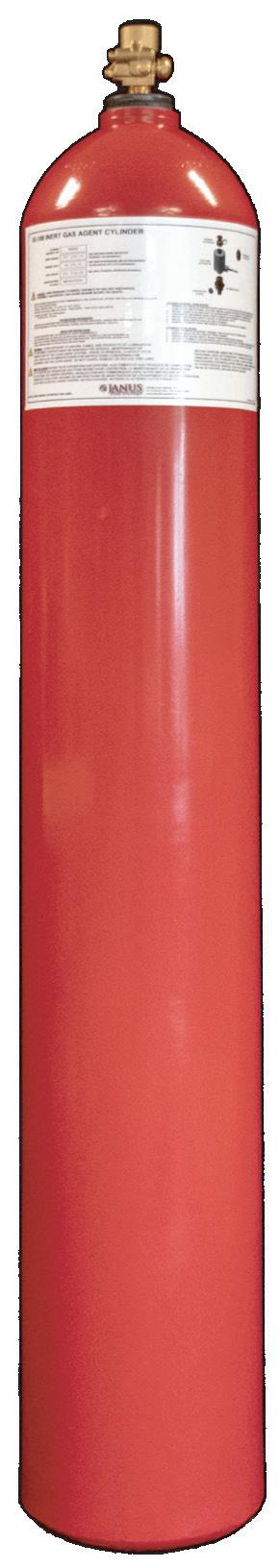

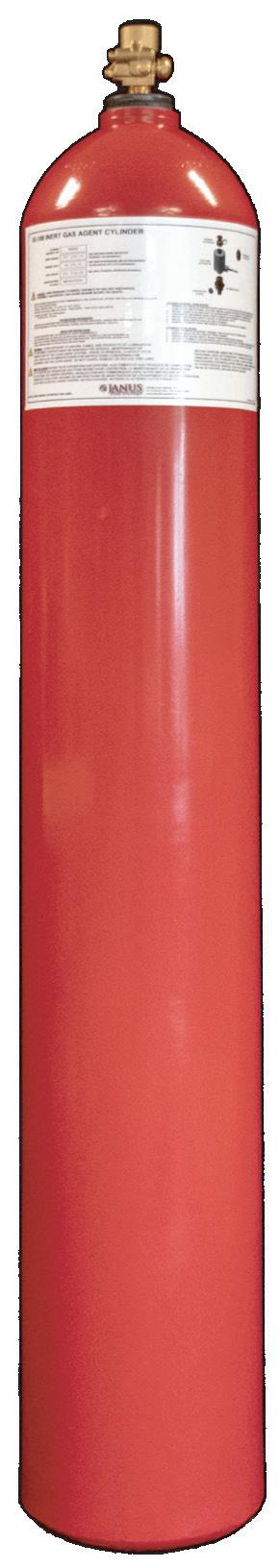

Cylinder drying device

Hyundai Motors is recalling 135,386 model-year 2024–2025 Santa Fe SUVs in the US after discovering that improperly installed starter motor terminal covers could cause an electrical short and increase fire risk in a crash. The defect, which currently has no linked accidents or injuries, affects vehicles built between late December 2023 and early July 2025. Dealers will inspect and, if necessary, reinstall the B+ terminal cover free of charge, with owner notification letters due from 1 December 2025.

Finland’s flag carrier Finnair has begun replacing around 1,700 seat covers after a cleaning mishap raised questions over their fire resistance and forced the airline to cancel about 70 flights and ground eight Airbus A321s. The covers had been washed with water rather than the specified method, prompting concerns that flame-retardant properties might have been compromised and disrupting travel for an estimated 11,000 passengers. Finnair has leased in extra aircraft and says all affected jets should return to service once new, compliant seat covers are installed.

South Korea has completed the first at-sea trials of an AI-driven autonomous fire suppression system designed to tackle oil fires aboard naval vessels, marking a potential step-change in marine firefighting safety. Developed by the Korea Institute of Machinery and Materials, the system uses sensors, directional monitors and AI algorithms to verify real fires, track flame movement in rough seas and deliver targeted foam or water streams at distances of up to around 24 metres. Detection accuracy has been reported as above 98% in both open and shielded fire scenarios.

Women are slowly reshaping Pakistan’s emergency services as female firefighters join front-line crews in Karachi, challenging stereotypes in a field where women still account for less than one percent of personnel nationwide. Inspired by pioneers such as Shazia Perveen, the country’s first woman firefighter, around 50 women are now serving in Sindh with a further 180 in training as divers, medics and responders. Senior officers are reporting that female teams are already proving their value in complex urban incidents.

Australia’s government has warned that two new savanna fire management (SFM) carbon credit methods under the ACCU scheme may not be finalised until March 2026, pushing back previous expectations. The delay follows stakeholder feedback and likely revisions to draft methods designed to expand crediting for emissions avoidance and sequestration, including use of the new Savanna Carbon Accounting Model (SavCAM). Carbon market commentators note the uncertainty for existing SFM projects and planned Indigenous-led initiatives, although consultations and submissions on the draft methods are continuing.

A man in his 50s suffered burns after a lithium power bank in his trouser pocket ignited in the Qantas business lounge at Melbourne Airport, filling the room with smoke and forcing the evacuation of about 150 people. Staff helped douse the flames by getting him into a shower before paramedics transferred him to hospital in stable condition. Qantas has since said it is reviewing its policies on passengers carrying lithium batteries amid a series of similar aviation incidents.

PGI has revealed it now offers the BarriAire Carbon Shield™ Elite Pro and Elite Pro Short hoods, UL certified to the new NFPA 1970 particulate-blocking standard.

Both models deliver 99.9 per cent particulate efficiency using the industry’s most flame-resistant fibre, providing advanced protection against heat, toxic particulates and carcinogens.

According to the company’s product specification description, the hoods are now even softer, more breathable and produced without intentionally added PFAS, which is setting a new benchmark for firefighter safety in the region. pgi-products.com

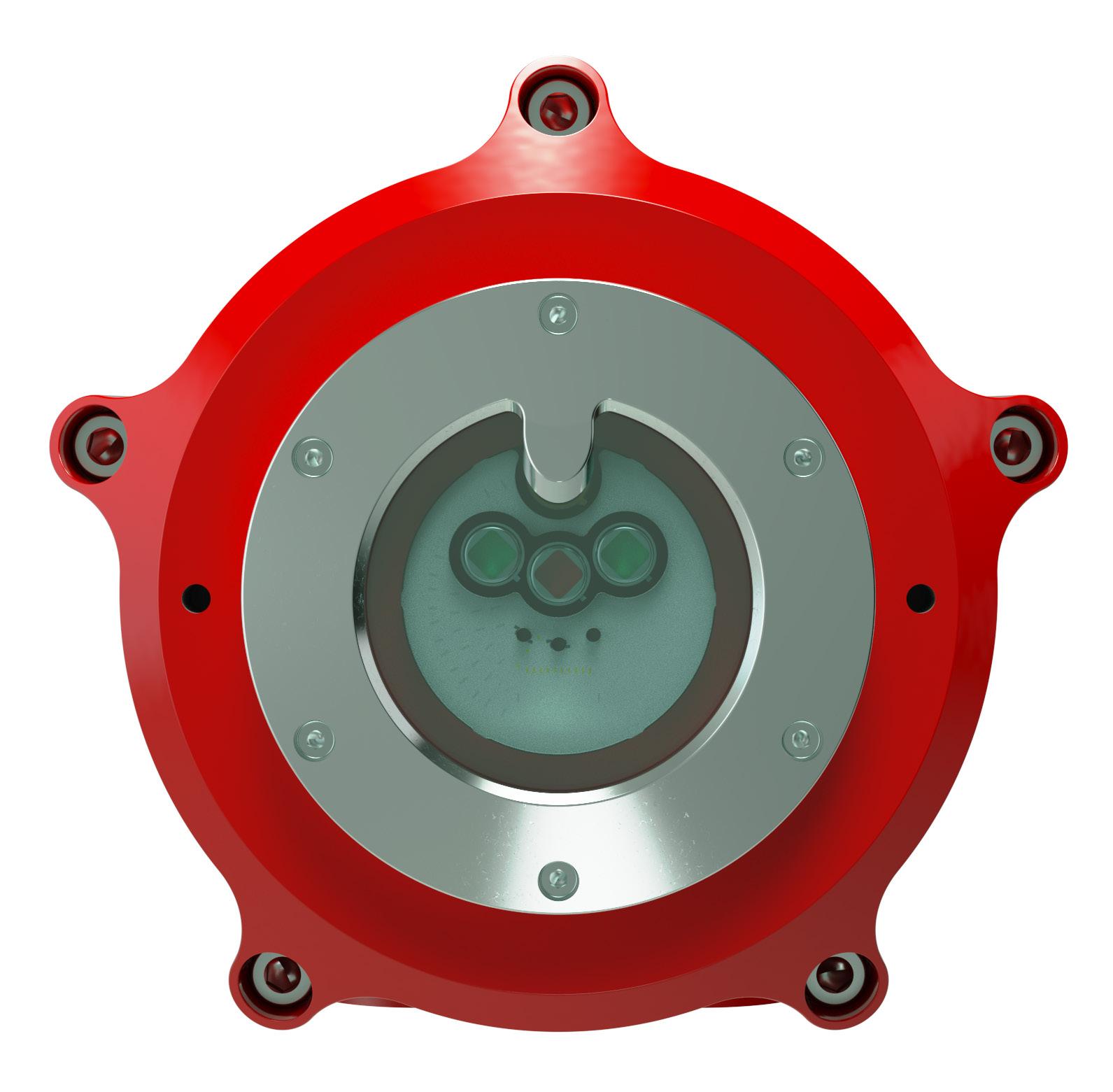

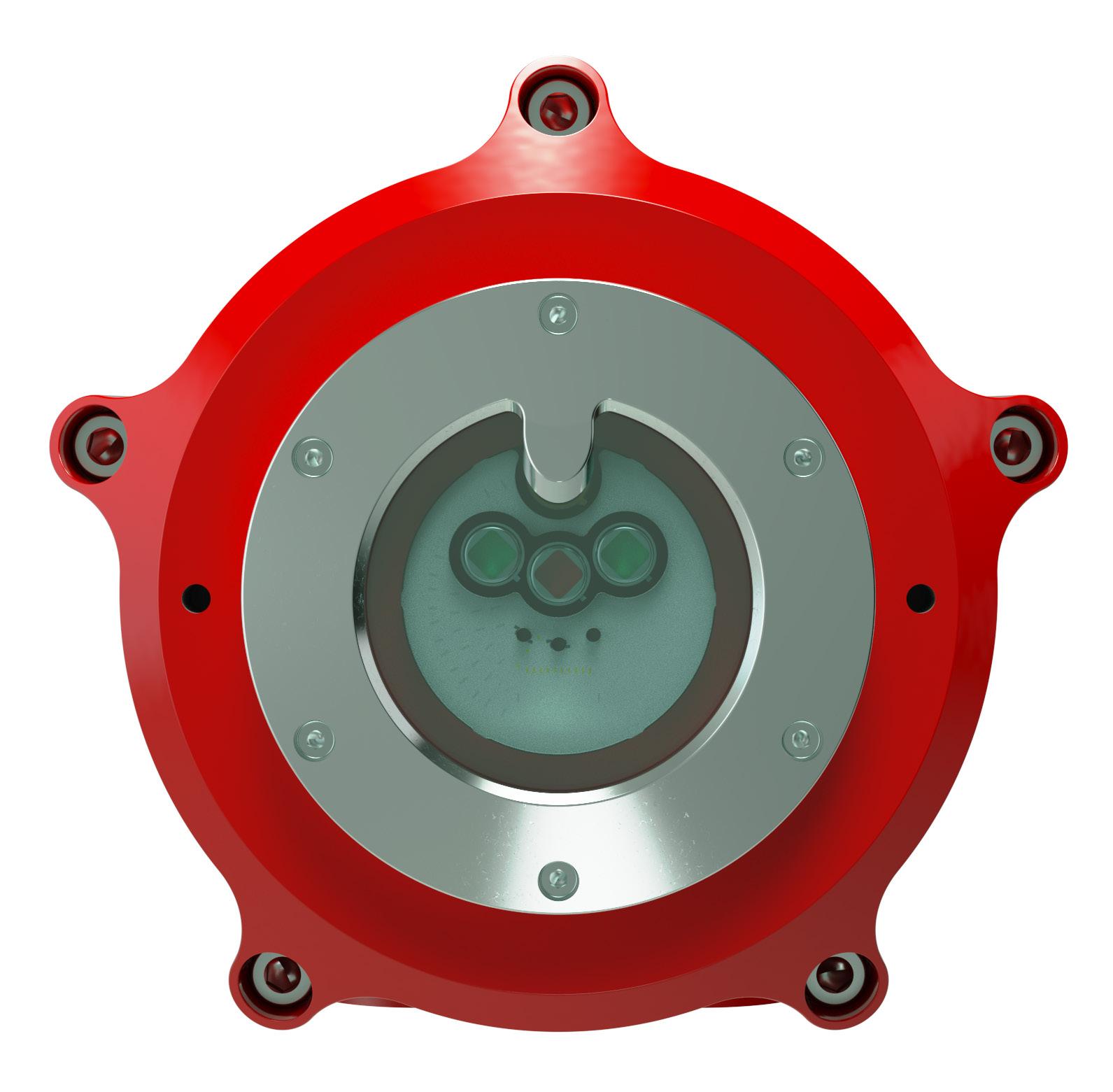

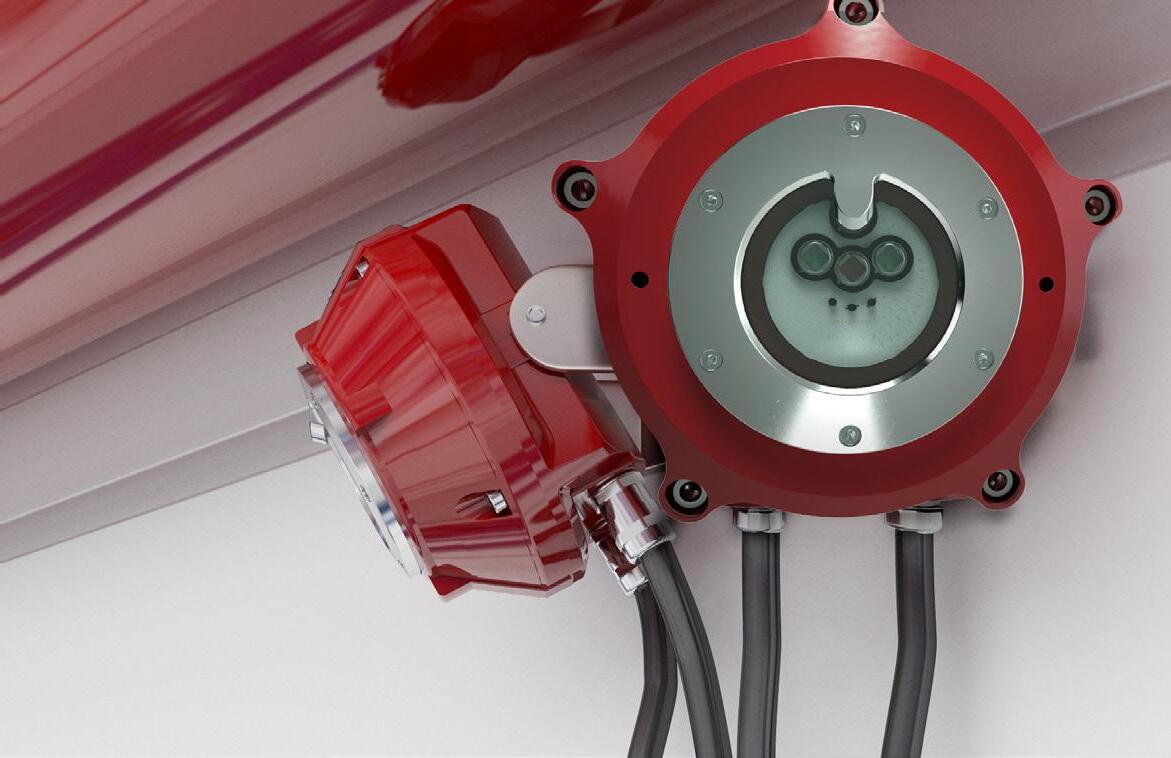

Teledyne Gas and Flame Detection previewed its next-generation gas detector at ADIPEC 2025. The next-generation gas detection technology uses intelligence, reliability and safety to keep people safe.

It integrates advanced sensor options, making it suitable for challenging operational settings. It has a touchscreen panel, and is customisable to user needs for enhanced monitoring capabilities.

The system also accommodates various gas sensors and offers networking flexibility. teledynegasandflamedetection.com

International has launched its Chartek 2218E solution, a shop-applied, boronfree epoxy intumescent designed for hydrocarbon pool-fire protection.

This product delivers a two-hour UL 1709 rating in a single-coat application over Charlok reinforcing mesh. It provides the lowest UL 1709-certified thickness and weight for W10x49 steel, applied in one pass to 5.7 mm.

The coating targets efficiency gains for fabricators and applicators in highdemand sectors like oil and gas, where passive fire protection for structural steel remains critical amid tightening project timelines and budgets. Chartek 2218E builds on International’s established Chartek range, previously proven in Middle East energy infrastructure, by streamlining onsite and workshop processes without compromising fire resistance performance. international-pc.com

Nightstick has introduced the FORGE II (NSP-4638B), its most compact fire helmet light yet.

Building on the original FORGE, the new model delivers 350 lumens and 7,360 candela in a slimmer profile just 2.36 inches long and 3.4 ounces.

Designed for MSA Cairns 1010/1044 and many other traditional fire helmets – as well as full-brim hard hats – the FORGE II offers clear visibility through smoke and steam up to 172 metres.

A rear, green ‘Follow Me’ LED improves crew tracking, while a glove-friendly tail switch provides high and low modes. A lateral swivel allows for fast beam adjustment without shifting gear.

Constructed from aircraft-grade aluminium with a hardanodised finish, the light is IP67 rated, 2-metre drop tested and meets NFPA 1971-8.6 (2018) helmet lighting standards. It ships with a CR123 battery and is covered by Nightstick’s Limited Lifetime Warranty. nightstick.com

For over 40 years, Jewers’ has been supplying bi-folding doors to the emergency services.

Our sideways-opening doors provide full-height headroom and a clear line of sight allowing emergency vehicles a safe and quick getaway every time.

Fully insulated doors help temperature regulation, minimizing heat loss in cold environments and maintaining a cool atmosphere in hot climates. Additionally, our fully glazed doors not only allow natural light to illuminate the station but also enhance its aesthetic appeal.

For rapid, reliable, secure, and durable doors that are designed, installed, and maintained to your needs.

Email: postroom@jewersdoors.ae

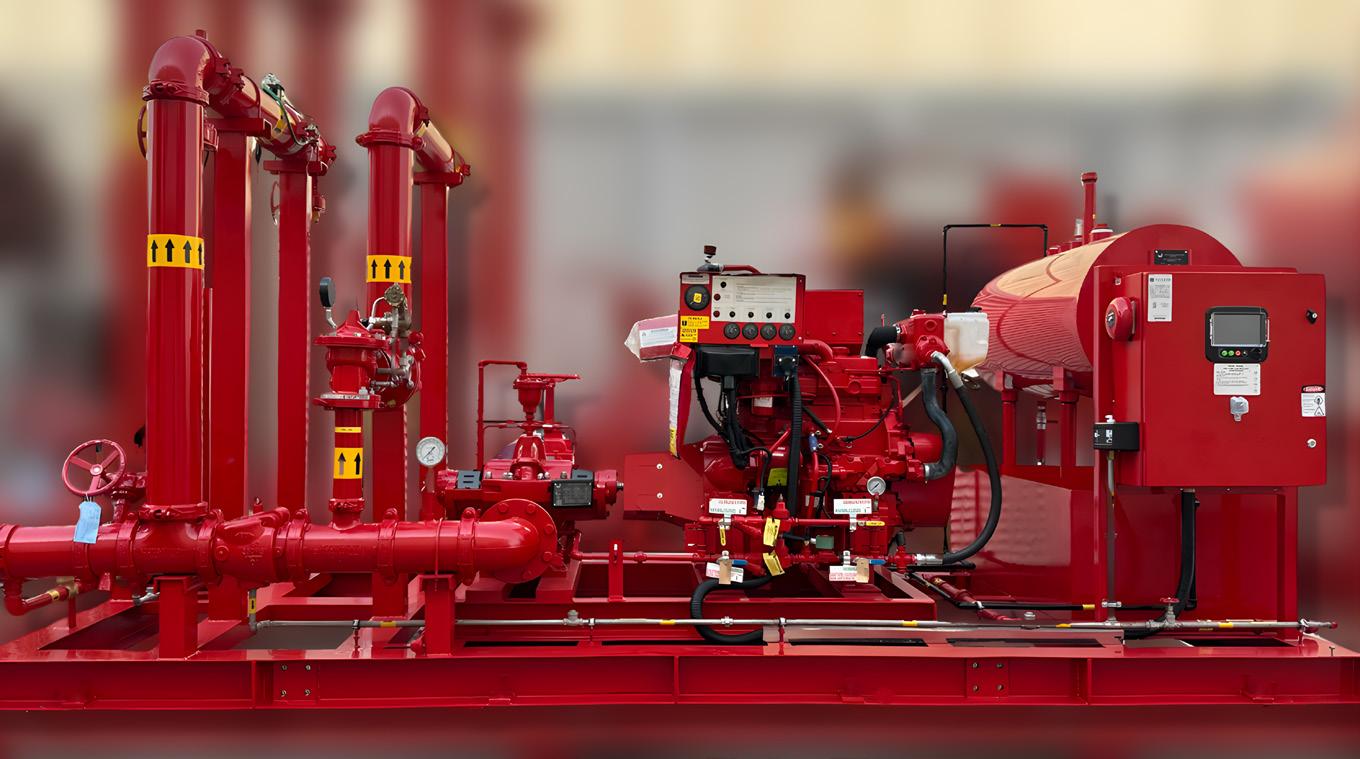

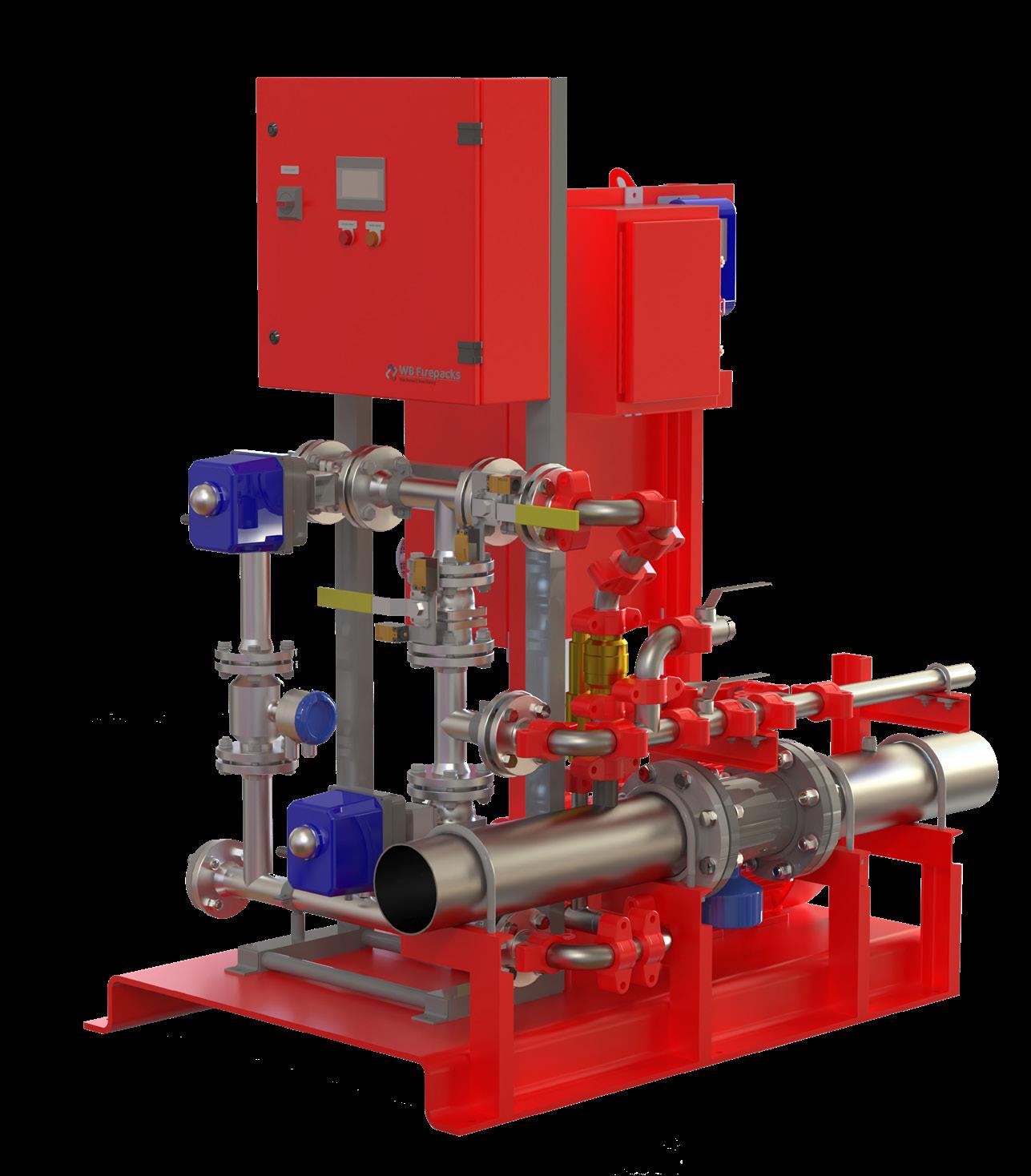

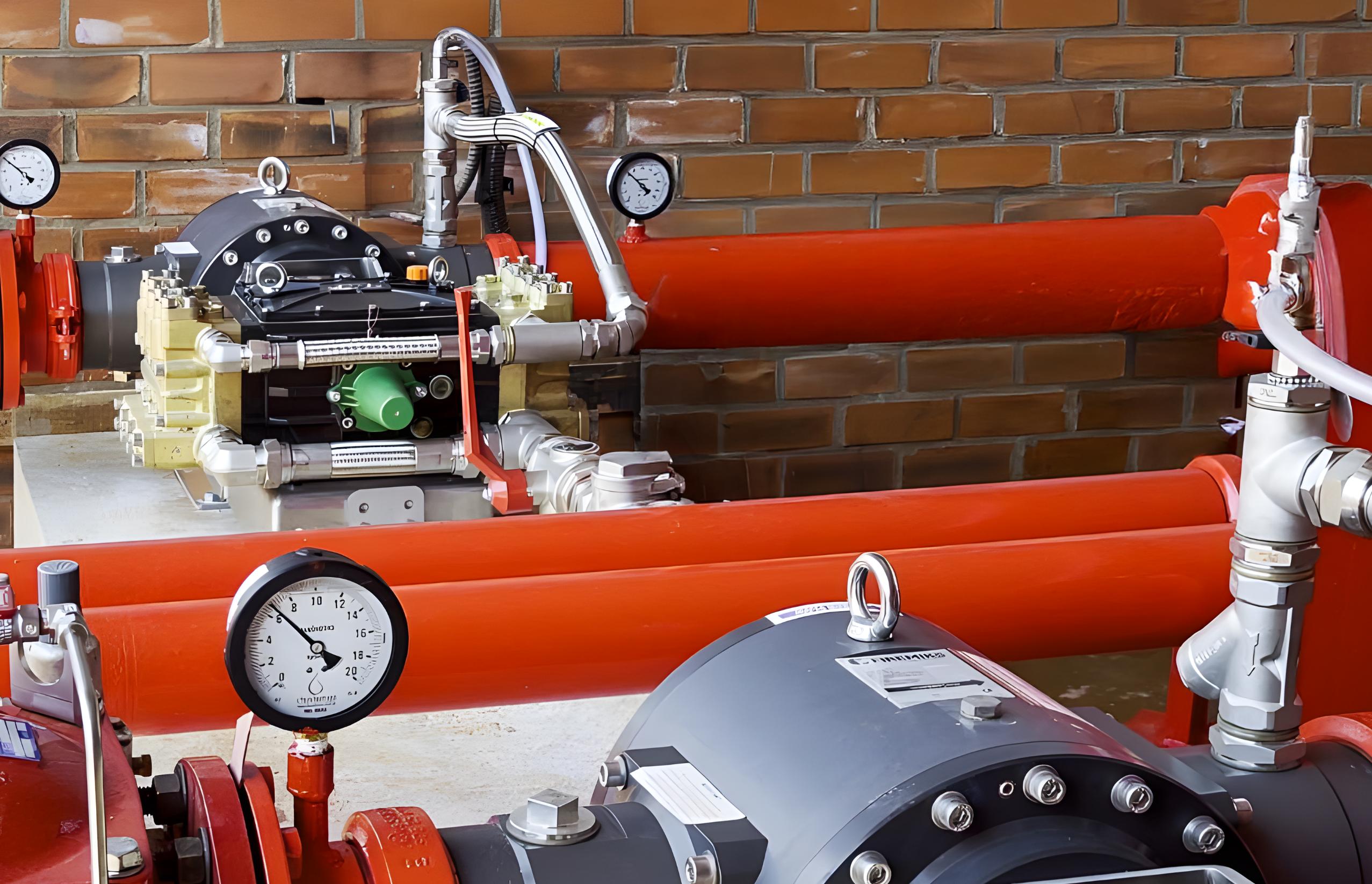

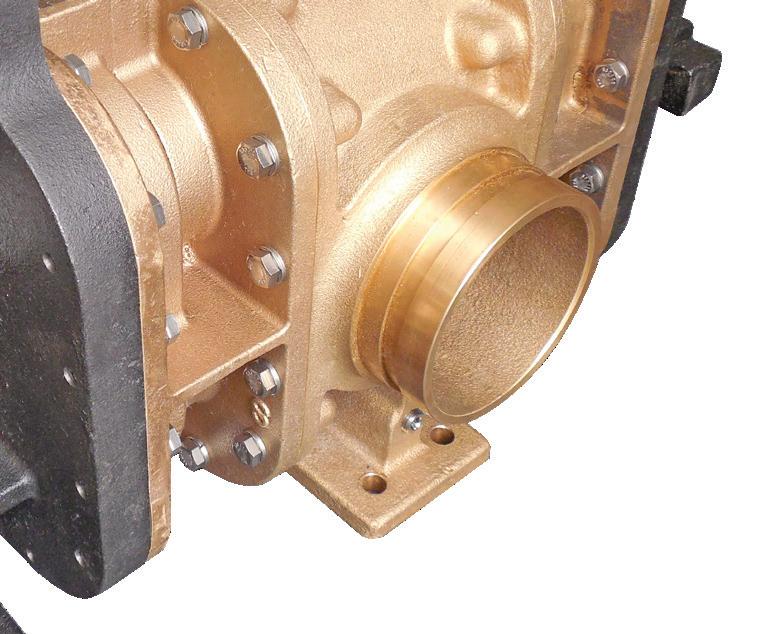

Since its establishment in 2015, WF has transcended its role as a mere manufacturer to become a guardian of safety, a partner in protection, and a global leader in certified fire pump technology. From initial design and rigorous testing to global support and continuous innovation

In the critical moments of a fire emergency, when lives and assets hang in the balance, the reliability of a single system can dictate the outcome. This system — the heart of a building’s active fire protection — is the fire pump. Waterfall Pumps Manufacturing (WF) was founded on the unequivocal belief that this heart must not merely beat; it must perform with unwavering certainty under the most extreme conditions.

The WF journey: A meteoric rise forged in quality

WF’s trajectory since 2015 is a case study in strategic growth driven by an uncompromising commitment to quality and certification.

The foundational years (2015 - 2018):

Laying the cornerstone WF began not with a simple goal of producing pumps, but with a vision to set a new benchmark for reliability in the fire protection industry. Understanding that trust must be built on verifiable standards, the company’s early strategy was threefold:

1. Cultivate a culture of quality: The initial pursuit and subsequent achievement of the ISO 9001:2015 certification was a deliberate declaration of intent. It embedded a process-oriented, qualityfirst mindset into the company’s DNA from the very beginning, ensuring consistent operations and continuous improvement.

2. Secure Third-Party Validation: With a robust quality management system in place, WF immediately targeted the gold standards in fire safety: approvals from Underwriters Laboratories (UL) and the Authority Having Jurisdiction (AHJ). These were not just checkboxes for marketing; they were critical milestones that provided the independent, third-party validation necessary to earn the trust of engineers, specifiers and insurers. This early endorsement set WF apart from generic pump manufacturers and established its credibility.

3. Invest in Core R&D: Parallel to the certification drive was a deep investment in research and product

development. A dedicated team of engineers worked to design centrifugal fire pumps that were not only compliant but also superior in hydraulic efficiency, durability and serviceability.

The expansion phase (2019 - 2024): Scaling excellence

The solid foundation allowed for rapid and strategic expansion. Key milestones during this period included:

Product Line Diversification: Building on the success of their initial offerings, WF achieved FM Approvals, a parallel and equally rigorous certification demanded by global industrial and commercial projects. They also expanded their UL listings to cover higher-capacity models, directly responding to market demand for larger, more powerful systems.

Infrastructure Leap: To accommodate growing complexity and volume, WF relocated to a larger, state-of-the-art facility. The centrepiece of this new plant was a fully automated, highprecision test bay. This investment was transformative, allowing WF to conduct complex hydraulic performance tests in-house with exceptional accuracy, drastically reducing lead times and ensuring every pump met its specified performance curve before shipment.

Strategic Product Introductions: This period saw the launch of new, critical product lines, including Vertical Turbine Fire Pumps for below-grade water sources, pre-packaged Fire Pump Houses for turnkey solutions, and ULlisted Diesel Fuel Tanks. Each launch addressed a specific gap in the market and demonstrated WF’s engineering capability.

Industry Recognition: The culmination of these efforts was the receipt of the INTERSEC Innovative Fire Protection Product of the Year Award, a testament to WF’s growing reputation as an innovator and a reliable force in the global fire-safety landscape.

The present day: A specialist

Today, WF operates from a fully integrated, multi-certified factory (ISO 9001, ISO 14001 and ISO 45001), signifying worldclass standards in quality, environmental management and occupational health and safety. Every pump that leaves the facility is not just a product but a certified lifesafety device, bearing the marks of UL, FM and compliance with NFPA 20, having been verified by calibrated, high-precision testing equipment. The company’s entire identity is now crystallised around a powerful differentiator: WF is not a general pump manufacturer; it is a UL/FM firepump specialist. This focus is the bedrock

of its value proposition and its standing among global leaders.

The unwavering commitment to certification: Why UL, FM & NFPA are non-negotiable

WF’s insistence on third-party certification is a core tenet of its mission. The company educates its clients that in fire protection, certification is not a luxury — it is the very definition of reliability.

NFPA 20: The Rulebook. The National Fire Protection Association’s Standard for the Installation of Stationary Pumps for Fire Protection is the comprehensive guide that dictates every aspect of a fire pump system’s design, installation and operation. WF engineers design every product from the ground up to comply with this standard.

UL 448 & FM 1311/1312/1319: The Proving Grounds. While NFPA 20 sets the rules, UL and FM are the independent judges. Their standards involve some of the most rigorous testing imaginable. Pumps are subjected to endurance runs, overload tests and performance verification under a vast range of flow and pressure conditions. The certification process also includes annual audits of the manufacturing facility, ensuring ongoing compliance, material traceability and consistent production quality.

The tangible benefits of a certified WF pump:

Guaranteed Reliability: A WF pump is engineered to start and operate flawlessly, even after months or years of standby, precisely when a fire creates extreme demand conditions.

Verified Performance: The performance curves (flow, pressure, horsepower) provided with every WF pump are not theoretical; they are empirical data points verified by an independent laboratory. This allows fire protection engineers to design systems with absolute confidence.

Regulatory and Insurance Compliance: Nearly all civil defense authorities, major insurance companies and reputable consultants worldwide mandate UL/FM certified pumps for commercial and industrial properties. Using a WF pump streamlines project approvals and can lead to favourable insurance premiums.

Global Market Access: UL and FM marks are recognised and respected across continents, making WF products readily acceptable for projects from the Middle East to Latin America and the Far East.

Product ecosystem:

Engineered for every application

WF’s product range is a meticulously curated portfolio designed to address every conceivable water source and installation scenario in modern fire protection.

The industrial workhorse

These pumps are the backbone of largescale fire protection systems where failure is not an option.

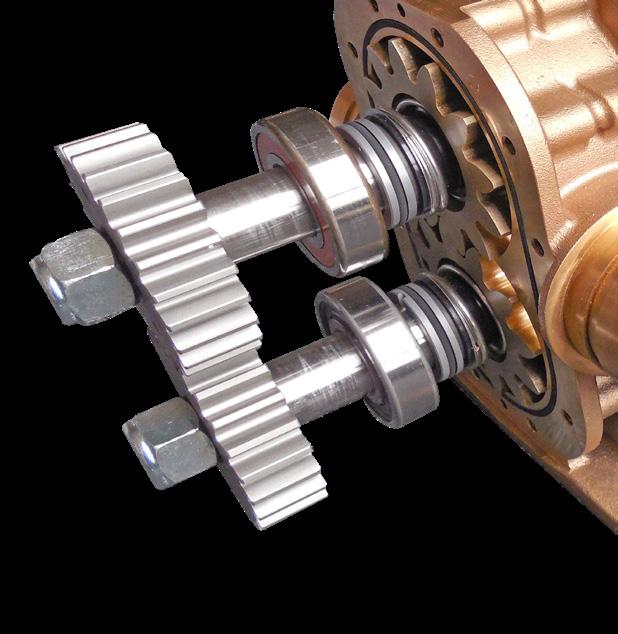

Deep Dive into Engineering: The ‘split case’ design is a critical feature for maintainability. The casing comes apart horizontally, granting full access to the impeller, shaft and bearings without the need to disconnect the pump from the piping system — a massive advantage for routine inspection and swift repair. The double-suction impeller is a hallmark of advanced design; by allowing water to enter both sides simultaneously, it balances axial thrust, minimising wear on bearings and seals, which translates to smoother operation, less vibration and a significantly extended service life.

Configuration Flexibility: Available with electric motors (suited for both 50Hz and 60Hz power grids) or diesel engines for standby power, each configuration is mounted on a solid steel baseplate with a flexible coupling to ensure perfect alignment and absorb operational stresses. Available in a range of MOC starting from cast iron to super duplex.

Ideal Application: Primarily used where the water source is at or above ground level, providing positive suction pressure, such as from a city main or a ground-level storage tank. They are ubiquitous in power plants, refineries, large manufacturing facilities and highrise complexes.

The compact guardian

Where space is at a premium, but performance cannot be compromised, the End Suction pump delivers.

Deep Dive into Engineering: The ‘back-pull-out’ design is its standout feature for serviceability. The entire rotating assembly — including the impeller, shaft and bearings — can be withdrawn from the back of the pump without disturbing the volute casing or the connected piping. This drastically reduces maintenance downtime and costs. The precision-cast, enclosed impeller is dynamically balanced to exceptional tolerances, ensuring minimal vibration and maximising the lifespan.

Configuration Flexibility: Like its larger counterpart, it is offered with electric or diesel drivers on a unified baseplate, providing a compact, pre-assembled and easy-to-install package. Available in a range of MOC starting from cast iron to super duplex.

Ideal Application: Perfect for commercial buildings, hospitals, schools and smaller industrial units where the water source is above ground and footprint is a key consideration.

The subsurface solution

When the water source lies below ground, as in a well, tank or basement, WF’s Vertical Turbine Pumps are the engineered answer.

Deep Dive into Engineering: This is a multistage pump, meaning it uses a series of impellers (bowls) stacked vertically to build pressure incrementally. This design is inherently suited for lifting water from significant depths. The engineering excellence is evident in the details: stainless steel line shafts for corrosion resistance, water-lubricated PTFE spider bearings for smooth rotation and long life, and renewable wear rings to maintain hydraulic efficiency over time. For dieseldriven versions, FM-approved right-angle gear drives efficiently transfer power from the horizontally mounted engine to the vertical pump shaft.

Configuration Flexibility: Available with electric or diesel power, these pumps save valuable floor space by being installed vertically, often in dedicated pump rooms or wells. Available in a range of MOC starting from cast iron to super duplex.

Ideal Application: Essential for applications like offshore platforms, buildings with suction tanks in basements, municipal wells serving industrial parks and any project where the water source is located below the pump level.

4. UL-LISTED DIESEL FUEL TANKS: The guarantee of uninterrupted power

A diesel-driven pump is only as reliable as its fuel supply. WF manufactures its own UL 142 listed tanks, ensuring complete system integrity.

Deep Dive into Engineering: WF offers both single-wall and double-wall tanks. The doublewall design provides critical secondary containment, preventing environmental contamination and ensuring operational safety in the event of a primary tank leak. Constructed from high-grade steel with corrosion-resistant coatings (or stainless steel for highly corrosive environments), these tanks are built for longevity and reliability, featuring integrated mounting pads, vents and fill connections designed specifically for fire pump applications.

5. WF FIRE PUMP HOUSE: The ultimate turnkey solution

This product represents the apex of WF’s engineering integration — a complete, pre-packaged system within a robust, weatherproof enclosure.

Deep Dive into Engineering: The WF Fire Pump House eliminates the variables and risks associated with traditional field installation. Every component — the pump, driver, controller, jockey pump, valves, gauges, flowmeter and piping — is meticulously assembled, aligned, piped and wired within the controlled environment of the WF factory. The

entire assembly is then hydrostatically tested to ensure leak-free integrity before shipment.

Enclosure Features: The house itself is an engineered structure featuring fire-resistant and insulated cladding, forced ventilation with weatherproof louvres, non-slip flooring, internal lighting and proper drainage. For diesel packages, it includes the UL-listed fuel tank, dual battery banks, a cooling loop and a compliant exhaust system.

Key Advantages:

Single-Source Responsibility: The client deals only with WF for the entire system.

Reduced Installation Time and Cost: The unit is simply placed on a prepared concrete pad and connected to site utilities and piping.

Highest Quality Assurance: Factory assembly ensures precision and quality control that is difficult to achieve on a construction site.

Customisability: can be built in using standard shipping container for easy transport and can be customised to specific project needs.

WF’s products are not just manufactured for the world; they are engineered for its diverse challenges. With a presence across Central and South America, Africa, the Middle East and the Far East.

Serving Critical Sectors:

Oil & Gas: Providing robust, dieseldriven systems for remote refineries and flammable liquid storage.

Data Centres: Ensuring mission-critical uptime with redundant, highly reliable pump systems protecting invaluable digital infrastructure.

Power Generation: Safeguarding utilities, substations and desalination plants.

Aviation: Protecting airports, hangars and fuel farms with systems that meet the strictest safety codes.

Commercial & High-Rise: Ensuring the safety of occupants in offices, hotels and mixed-use developments.

This global and sectoral diversity is supported by a carefully selected network of distributors, ensuring local expertise, timely spare parts availability and expert technical support are always within reach.

Resting on its laurels is not in WF’s vocabulary. The company is poised for a new phase of strategic expansion in 2026, focused on cementing its leadership.

Facility and Capacity Enhancement: Further investments in advanced manufacturing technologies, including automation and robotics, to increase production capacity and enhance precision.

Product Line Expansion: The introduction of additional UL/ FM certified products and more sustainable designs.

Testing Capability Upgrade: Continuous investment in the test facility to handle future standards and even larger, more powerful pump models.

Waterfall Pumps Manufacturing stands as a testament to what is possible when a company dedicates itself entirely to a mission of profound importance. By fusing engineering excellence with an unwavering commitment to thirdparty certification, global support and continuous innovation, WF has not just built a successful business; it has built a trust. In a world where risk is ever-present, the consistent, reliable operation of a fire pump is a non-negotiable safeguard. WF’s singular focus on being the world’s premier UL/FM fire-pump specialist is its covenant with its clients: a promise that when every second counts, their equipment will perform, protecting lives, preserving property and engineering a safer world for all.

info@wfpumps.com wfpumps.com

The Fire Middle East Conference is emerging as the region’s premier strategic forum for fire protection leaders, regulators, innovators and project developers to converge, exchange insights and drive forwards the future of fire safety. Hosted in Riyadh and deeply aligned with Saudi Vision 2030, this high-calibre event transcends traditional conferences by functioning as a dynamic working summit. It catalyses policy evolution, practical fire safety solutions and enduring collaborations essential for safeguarding giga-projects, urban megastructures, critical infrastructure and ambitious national developments across the Middle East.

Since its inception, the Fire Middle East Conference has demonstrated remarkable trajectory, with the 2025

edition drawing over 200 senior professionals from government, industry and international expertise. Held at the Voco Hotel in Riyadh, last year’s event sparked passionate discussions on fire safety innovation, regulatory alignment and operational resilience, earning acclaim as a “golden thread” connecting stakeholders in the Kingdom’s transformative landscape. The 2026 edition – the third annual iteration which will take place on 29 April – amplifies this success with greater scale, refined formats and broader participation, positioning it as an indispensable gathering for those shaping fire standards amid rapid urbanisation, tourism expansion and infrastructure boom.

For government entities, civil defence authorities and regulatory bodies, the conference provides a secure, executivelevel arena to interface directly with

fire safety leaders from national oil giants, mega-developments like NEOM and Qiddiya, utilities, aviation hubs and hospitality giants. Sessions are meticulously crafted to bridge global benchmarks with local imperatives, empowering officials to refine codes, enforcement mechanisms and compliance strategies that bolster economic diversification, investor confidence and public safety.

At its heart, the conference prioritises actionable dialogue through diverse, engaging formats: keynote presentations, moderated panel debates, hands-on workshops and real-world case studies. These elements facilitate candid exchanges on pivotal challenges the sector is facing such as performancebased fire design and high-rise evacuation protocols to industrial fire risks, passive protection systems and integration of smart technologies in fire suppression. Cross-disciplinary panels align fire strategies with smart city initiatives, sustainable construction and emergency response frameworks, fostering consensus on certification, interoperability and adaptive standards vital for the region’s evolving built environment.

This collaborative ethos ensures participants leave with tangible outcomes – refined policies, joint ventures and innovative pathways – directly supporting Vision 2030’s pillars of resilience and liveability.

Intentionally scaled for quality over quantity, the Fire Middle East Conference hosts hundreds of C-suite attendees, senior regulators and decision-makers from sectors spanning energy, real estate, transport, healthcare, events and leisure. Last year, structured networking – including dedicated breaks, hosted lunches, evening receptions and VIP roundtables – created prime opportunities to cultivate relationships that have the potential to yield pilots, contracts and strategic alliances.

“Year-on-year attendance builds continuity, transforming fleeting encounters into sustained partnerships that propel fire safety advancements”

Year-on-year attendance builds continuity, transforming fleeting encounters into sustained partnerships that propel fire safety advancements.

Education anchors the agenda, with content delivered by anticipated regional luminaries and global specialists –much like the compelling keynotes from 2025 that ignited passion for fire safety innovation. Attendees gain insights into lessons from landmark incidents, giga-project implementations and vital topics. Case studies showcase on-site applications of evolving codes, from NFPA alignments to Saudi Building Code evolutions, equipping leaders to navigate complexity and pre-empt risks.

This forward-leaning curriculum strengthens institutional capabilities, enabling proactive governance of increasingly intricate fire landscapes driven by mega-scale builds and technological convergence.

We are once again joined by industryleading companies who are supporting our goals and ambitions. Our headline sponsor is Potter Global Technologies, who will be ‘powering’ the whole event and lending their expertise and crucial knowledge of the sector to ensure our event aligns with what our readers need. As a leading provider of innovative fire alarm, suppression and mass notification

systems, Potter is perfectly placed to respond to the region’s booming fire protection market.

We have also confirmed both Jensen Hughes and Blazemaster Fire Protection Systems as 2026 Fire Middle East Conference sponsors. Both organisations are returning sponsors and are firmly aligned with the needs of our audience.

For 2026, the organisers are scaling the conference with more educational sessions, expanded content and stronger advisory boards to ensure the discussions remain tightly aligned to market needs and regional priorities. With a clear vision to become the premier meeting place for fire leaders in the Middle East, the conference offers investors, sponsors and participants a unique opportunity to influence the agenda, showcase innovation and help raise standards at a pivotal moment for the region’s fire and safety landscape.

Join us in Riyadh

Fire Middle East Conference 2026 29 April 2026 | Voco Hotel, Riyadh, KSA

firemiddleeast conference.com

Amer

In recent years, the Middle East, and Saudi Arabia in particular, has experienced an unprecedented surge in ambitious, high-profile projects. From giga-projects that redefine urban development to the restoration of historic cultural assets, the scale and complexity of construction continues to expand. As buildings grow more innovative, the limitations of purely prescriptive fire and life safety codes become increasingly evident. This has accelerated a global shift towards performance-based design (PBD), a methodology that evaluates how a building performs under fire or emergency conditions rather than relying exclusively on pre-defined code checklists. Saudi Arabia, with its forwardlooking development agenda and rapidly evolving regulatory landscape, is uniquely placed to embrace and lead in this transformation.

International model codes and standards, such as those published by the NFPA, ICC and SFPE, are steadily and continuously steering towards performance-based methodologies. While prescriptive codes remain essential as a baseline, they are no longer sufficient on their own to address contemporary challenges such as:

Innovative architectural forms that defy traditional layouts and geometry;

Advanced building technologies including AI-driven systems and smart infrastructure; Net-zero buildings requiring integrated design approaches;

Renovation of heritage structures where prescriptive solutions may be impractical; Accelerated construction schedules and modular construction;

Giga-scale developments often the size of small cities.

Saudi Arabia’s transformation efforts under Vision 2030 amplify each of these factors. Large master-planned districts, super-tall towers, mixed-use megastructures and heritage conservation initiatives demand flexibility beyond the rigid frameworks of prescriptive codes. Performance-based design provides the analytical tools, engineering rigour and adaptability required to support such advanced development without compromising safety.

A common misconception among architects, engineers, contractors and even Authorities Having Jurisdiction (AHJs) is that performance-based design introduces unnecessary risk or complexity. In practice, the opposite is often true.

A well-crafted performance-based solution typically exceeds the minimum

intent of prescriptive code requirements. Through rigorous analysis, such as fire and smoke modelling, egress capacity evaluation, tenability assessments and risk-based engineering, performancebased design can reveal vulnerable areas that a prescriptive approach might overlook. It also provides flexibility for developing robust safety strategies tailored to the building’s actual use and behaviour, rather than forcing a design to conform to generic assumptions embedded in the code.

For example, a large open atrium, a feature often restricted by prescriptive codes, can be designed with advanced smoke management strategies validated by computational models. The resulting design is not only compliant but safer, more efficient and more aligned with architectural goals.

The value lies in the confidence it gives stakeholders: performance-based designs are not arbitrary; they are thoroughly justified, peer-reviewed, repeatable and grounded in engineering science.

A fundamental cultural shift is required for the broader industry: architects and engineers should not treat codes as checklists or design manuals, but rather as safety outcome frameworks. A common issue in the region is ‘designing by checklist’, where the building is forced

“Performance-based design represents far more than a technical alternative to prescriptive codes”

to comply with prescriptive requirements even if they undermine the design vision.

Instead, a more modern approach should:

1. Begin with the building concept — the intended experience, use, flow and functionality.

2. Identify the fire and life safety objectives the building must achieve.

3. Determine the strategy to meet these objectives, which may involve prescriptive provisions, performancebased solutions or a combination of both.

4. Validate that the design satisfies the code’s intent, regardless of the method used.

This approach reinforces an essential truth: codes exist to ensure intent, performance and safety, not to restrict innovation. Intent is the critical concept embedded within the SBC and NFPA codes and SFPE guidance. By understanding intent rather than solely memorising requirements, designers can craft safer buildings and more efficient solutions.

While PBD offers enormous value, it is not a simple process or a ‘shortcut’ and must not be approached casually. Developing or reviewing a performance-based design requires competence, experience and a multidisciplinary understanding of several factors, including:

Code intent and philosophy, not merely the text, but why specific requirements exist.

Fire dynamics and behaviour, which differ dramatically in complex geometries.

Human factors and egress behaviour, including mobility profiles and crowd dynamics.

Interaction between multiple alternative solutions; a single engineered solution may function well alone, but several applied together may produce unintended consequences.

Building life cycle and operational requirements, since the validity of many engineered systems depends on proper long-term maintenance.

Commissioning and acceptance testing, which must confirm the design performs as intended.

Interface between fire safety systems, including smoke control, detection, suppression and mechanical systems.

Emergency response considerations, particularly how Civil Defence teams will interact with the building in real scenarios.

These examples highlight that performance-based design is not a plug-and-play exercise. It demands collaboration among fire engineers, architects, MEP designers, façade consultants, operators and authorities.

Saudi Arabia, with its growing pool of specialists and expanding academic focus on fire safety engineering, is wellpositioned to cultivate this competence locally creating a knowledge base that supports the nation’s ambitious future developments.

A common error is treating performancebased design as a template that can be reused repeatedly. This undermines the fundamental purpose of PBD and introduces significant risk.

Performance-based solutions are developed based on assumptions and variables that are unique to each building, such as:

Occupant profiles

Fire load densities

Airflow patterns

Geometry and compartmentation

HVAC configuration

Material selections

Operational practices

Maintenance capacity

Emergency response strategies

Changing any one of these parameters can invalidate the entire analysis. For example, a smoke management strategy developed for an atrium with a fixed fire load and known occupancy will no longer be valid if the space is converted into a retail environment with higher hazards.

Because of this, performance-based designs in Saudi Arabia should include:

Clear documentation of assumptions and limitations;

Defined operational requirements to keep the strategy valid (e.g. maintaining clear paths, limiting fuel loads, periodic testing);

Commissioning plans ensuring the system performs as modelled;

Procedures for re-evaluation if building usage or internal layouts change;

Clear communication with facility operators, who become responsible for preserving the conditions under which the PBD solution was approved.

As Saudi Arabia advances towards large-scale developments that evolve over decades, the life cycle validity of engineered solutions becomes just as important as their initial approval.

Saudi Arabia has the chance to become a global leader in performance-based fire engineering. The Kingdom’s mega and giga projects, such as in NEOM, Qiddiya, Diriyah and the Red Sea developments, provide ideal environments for advanced PBD methodologies.

Performance-based design represents far more than a technical alternative to prescriptive codes; it is a mindset shift towards innovation, collaboration and genuine safety performance. In the context of Saudi Arabia’s ambitious development landscape, PBD provides the freedom needed to achieve world-class architecture while maintaining the highest standards of fire and life safety.

By embracing performance-based methodologies, investing in local expertise and fostering a deeper understanding of code intent, the Kingdom stands to become a leader in modern fire safety engineering. The future of safe, innovative and sustainable buildings in the Middle East will not be built through checklists alone, but through informed, performance-driven design grounded in engineering rigour.

aesg.com

WHEN PUMP ROOM WALLS BLOCK CRITICAL FLOW DATA, SMART MONSTER™ BREAKS THROUGH.

Wirelessly connect your Smart Monster™ gauge to our mobile app via Bluetooth™. Then, with Hose Monster®’s Long Range Connect, you can utilize your cellular or Wi-Fi network to send pressure readings to unlimited distances. Get the data you need straight from the app, with no extra hardware required. No wires. No limits. Just seamless connectivity at your command.

Join us at Intersec Dubai this January! The Hose Monster team will be in Hall 4, Stand No. 4-G38 with Noventis Safety group alongside DetectorTesters and GVI. Come see how we’re pushing the limits of connectivity and putting critical data in your hands.

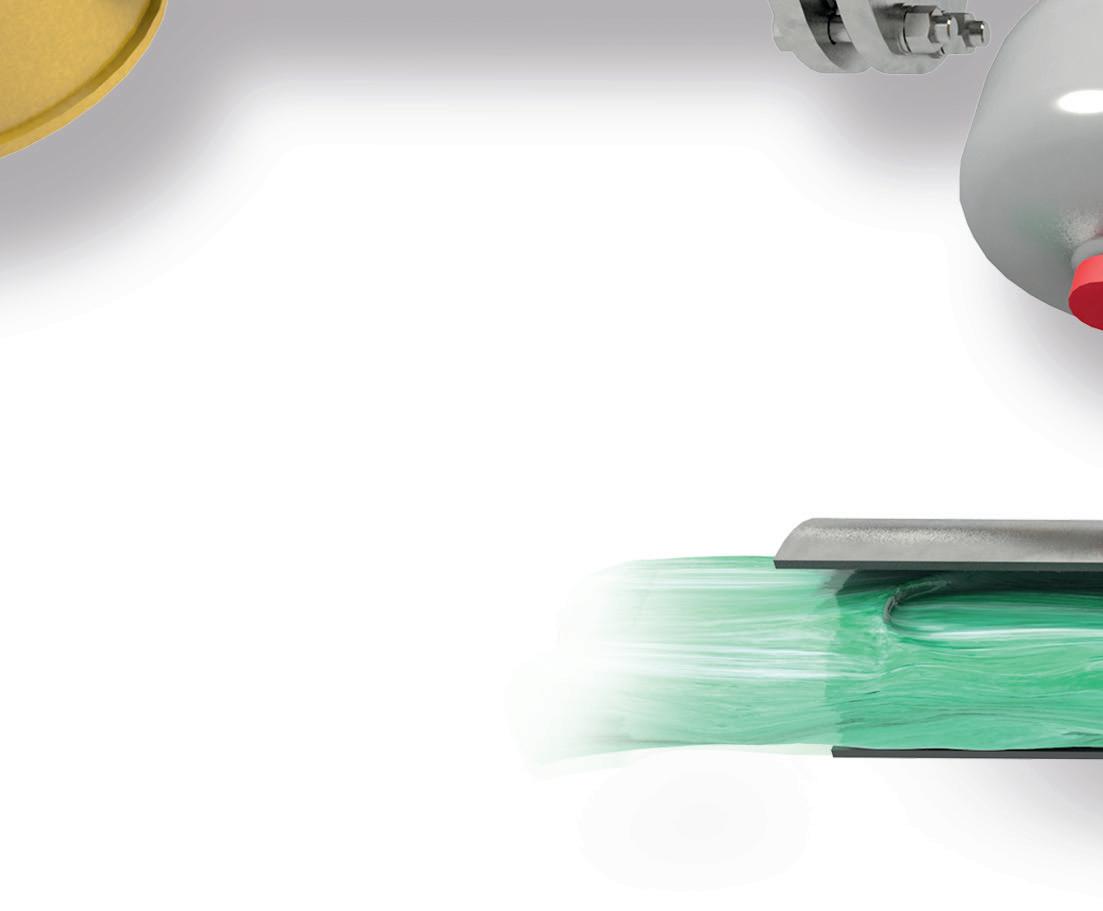

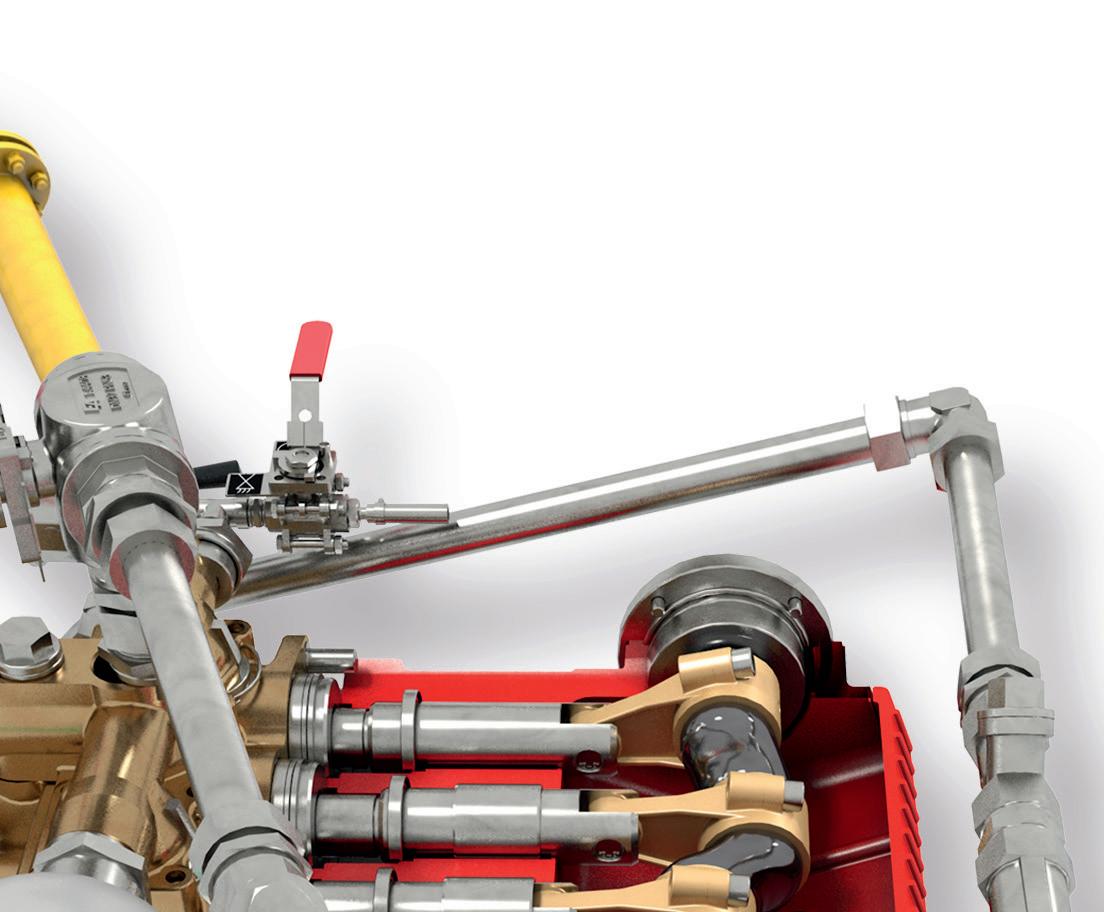

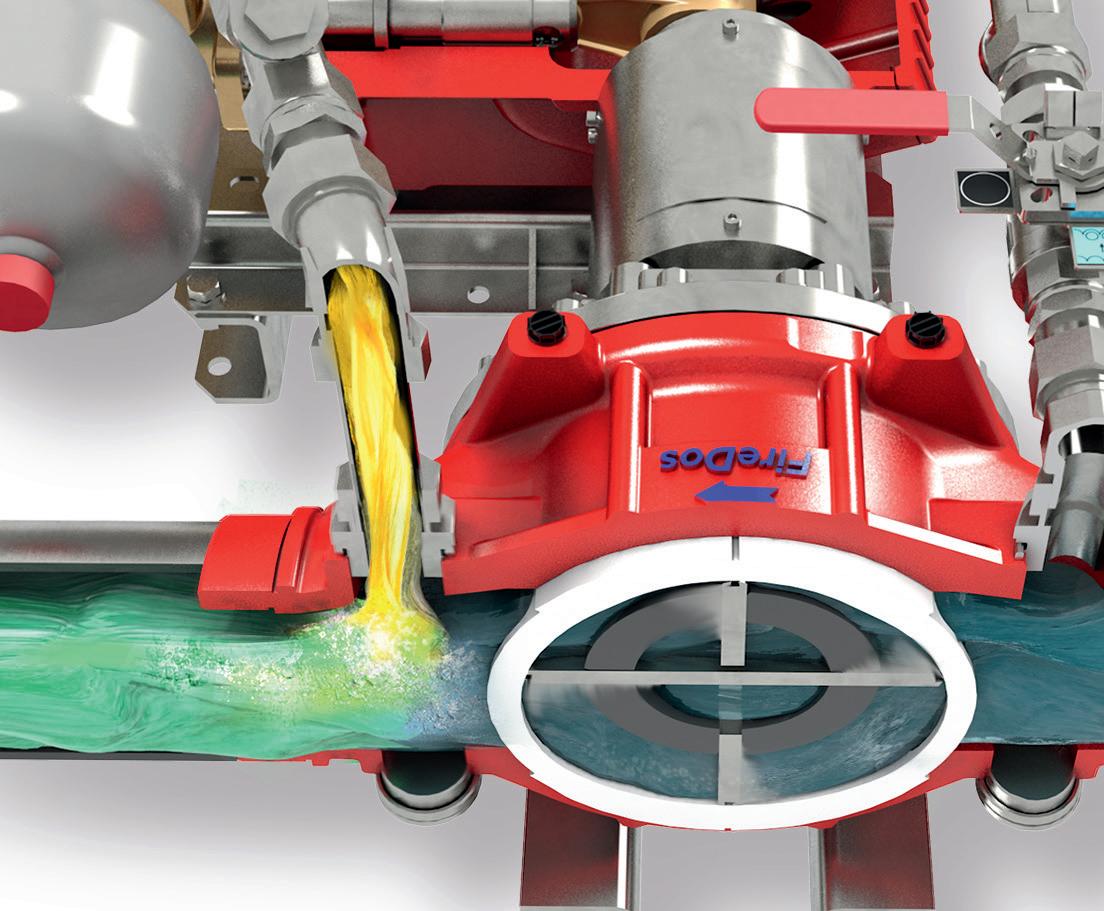

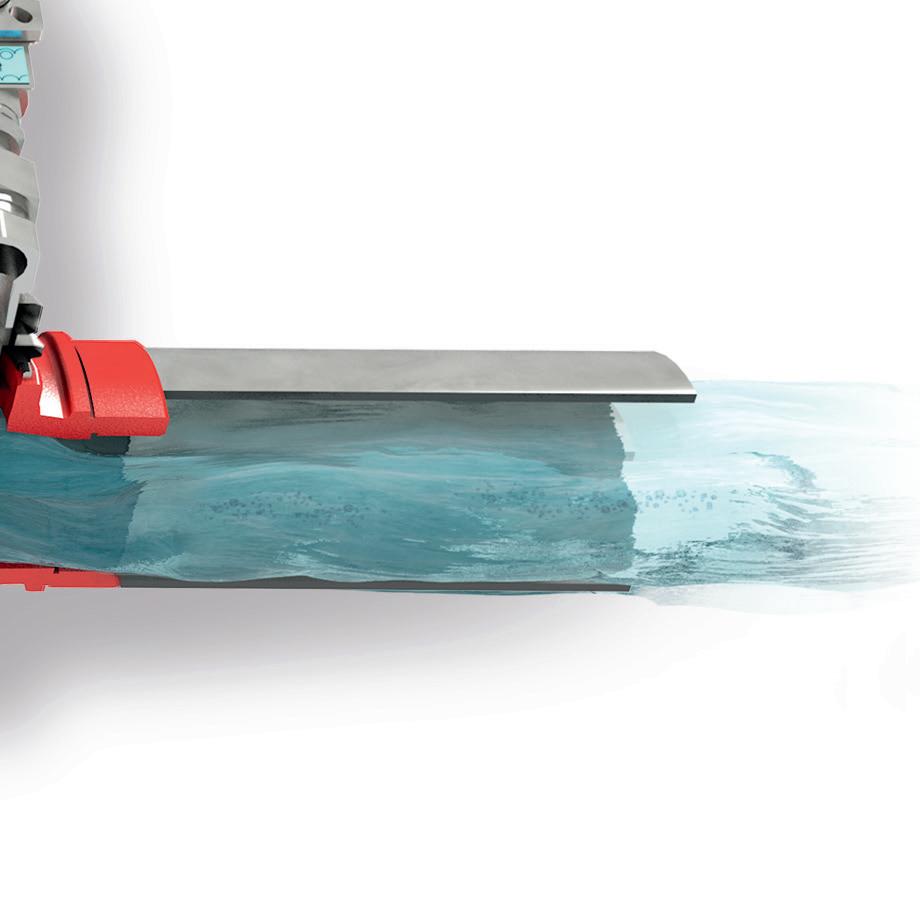

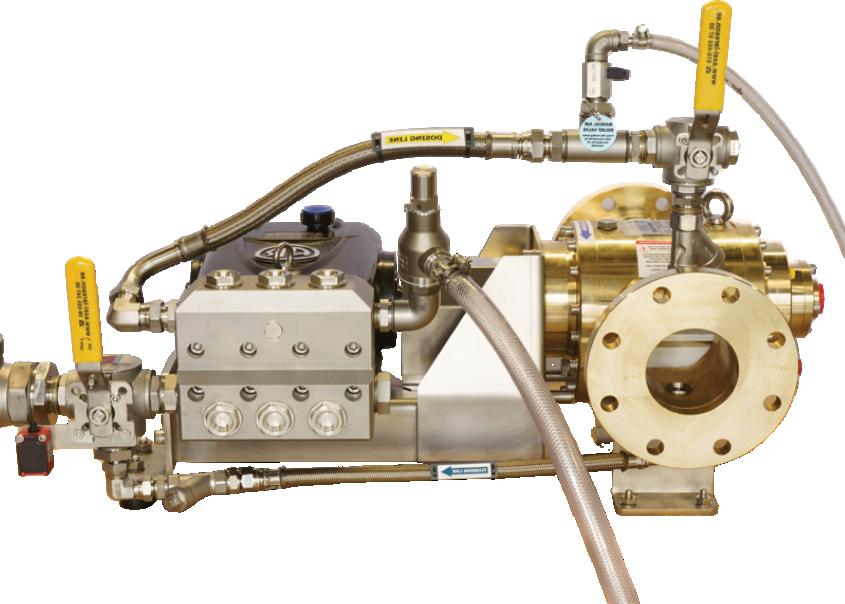

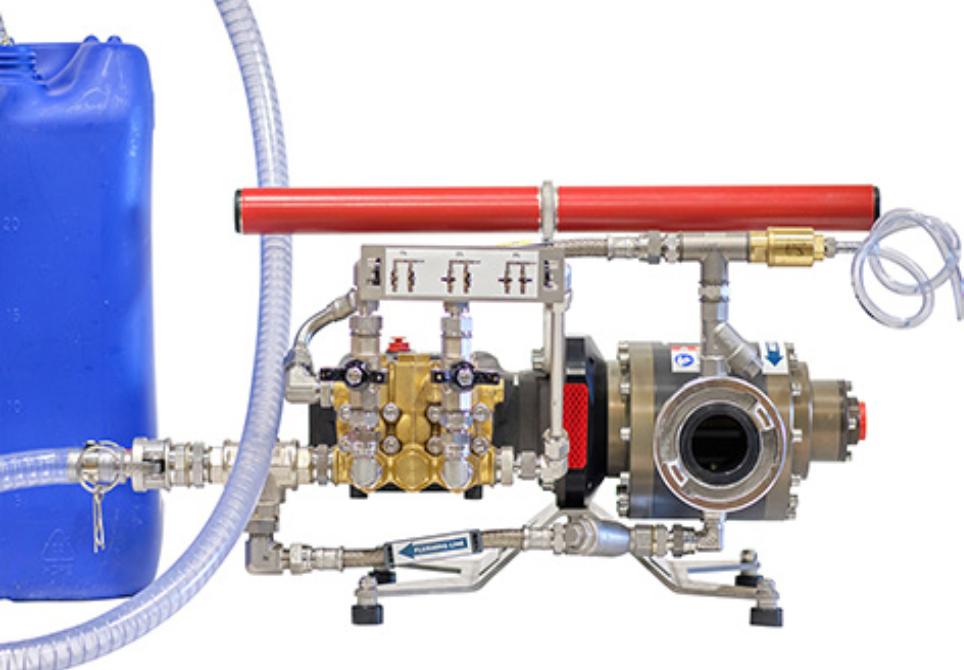

GEN III is the next evolution level of hydraulic foam proportioners for firefighting from FireDos. Sturdier, smaller, safer, and more functional: GEN III features a lot of improvements which make operation even more e cient and comfortable. The proportioner consists of a water motor and piston pump and handles all types of foam agents, even extremely high-viscous, alcohol-resistant and fluorine-free ones. Furthermore, GEN III is a purely mechanic system and allows testing the proportioning rate in a cost-saving and eco-friendly way, producing no foam at all.

Purely mechanical and highly reliable

Constant proportioning rate over a wide flow range

Cost-saving and eco-friendly

GEN III foam proportioners allow testing the proportioning rate without producing foam or premix.

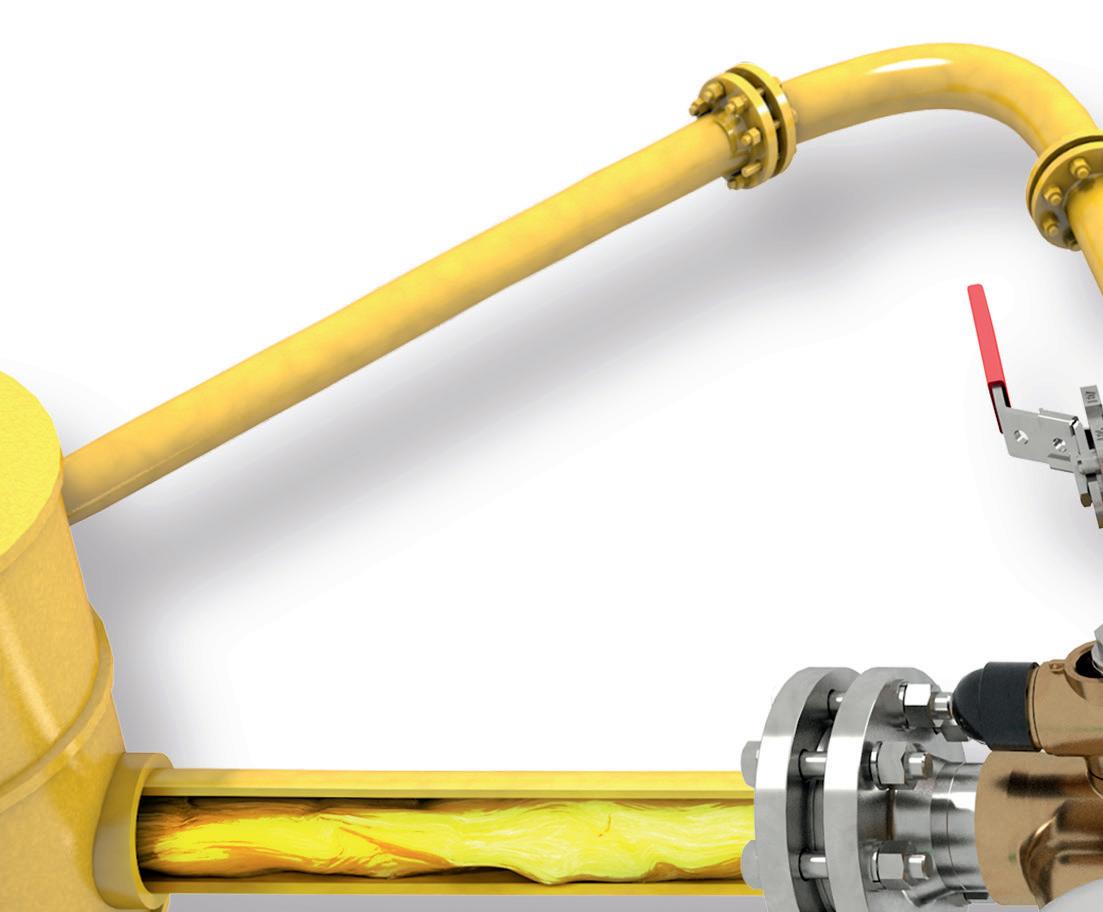

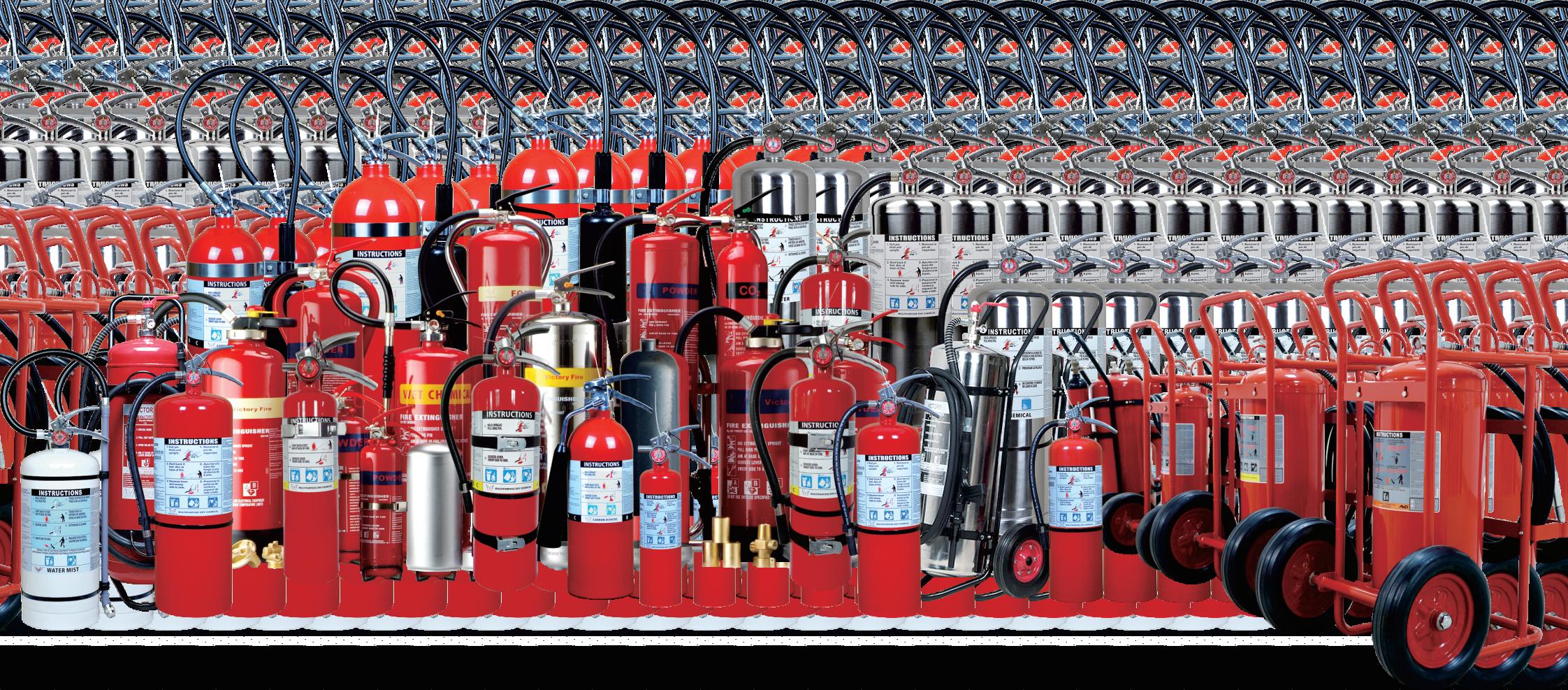

Stuart Phythian, Regional Director, FireDos, advises on adapting to the new foam frontier

The global fire protection landscape is undergoing its most significant transformation since the introduction of aqueous film-forming foams (AFFF) more than half a century ago. The shift to fluorine-free firefighting agents, driven by environmental regulation across Australia, the European Union and the United States through the EPA’s PFAS roadmap, is redefining how engineers and end users approach system design.

For regions such as the Middle East, Africa, India and Southeast Asia, this is not a distant movement; it is already underway. The challenge now lies not only in compliance but in maintaining performance and reliability under new chemical and physical realities.

One of the least understood hurdles in transitioning from fluorinated foams is viscosity. Traditional AFFF behaves much like water; easy to pump, predictable and simple to proportion. Fluorine-free foams, however, are often non-Newtonian: they flow sluggishly at rest but shear-thin under motion. That behaviour creates challenges in systems not designed for such rheology.

Viscosity affects everything. Pressure losses rise, pick-up rates fluctuate, and venturi-type inductors, the workhorses of many legacy systems, struggle to draw concentrate effectively. NFPA 11 proportioning tolerances (−0/+30%) can quickly be exceeded, resulting in either

weak foam that collapses too soon or heavy, sticky foam that fails to project or spread properly.

End users must pay close attention to application rate, the quantity of finished foam delivered per square metre, and coverage density. Most fluorine-free foams depend on mechanical expansion rather than the chemical film once created by long-chain fluorinated surfactants. This leads to longer drainage times and often reduced spread.

Balance is essential. A slow-draining foam may smother effectively but struggle to flow across hydrocarbon

pools or complex obstacles. Discharge densities and nozzle configurations must therefore be based on actual test data for the specific foam, not on legacy AFFF assumptions. Simply changing the concentrate without recalculating the hydraulics risks failure when performance is most critical.

Certification remains the foundation of confidence. For high-risk sites such as tank farms, aircraft hangars, chemical storage or marine facilities, independent third-party validation should be nonnegotiable. Global approvals such as FM, UL, EN 1568, EN 13565 and ICAO provide measurable assurance that the foam performs as claimed.

Yet certification should extend beyond the foam. System components such as proportioners, pumps and monitors must be tested using the actual concentrate and viscosity expected in service. Testing with water or a generic foam provides little assurance of real-world performance.

The industry is increasingly moving towards system-level certification, validating foam, hardware and control logic together. Only through this integrated approach can fire protection systems achieve both performance and sustainability.

Foam proportioning is at the heart of every system, where viscosity, pressure and flow converge. Traditional inductors and bladder tanks, though simple, are highly sensitive to back-pressure and viscosity variation. They rely on suction created by high-velocity flow through a restriction, a principle that falters as resistance increases.

By contrast, modern water-driven foam proportioners use the energy of the water flow to drive a positive-displacement dosing pump. This approach maintains proportioning accuracy regardless of pressure fluctuations or concentrate thickness while offering an exceptionally wide operating range. Even at low flow rates or system pressures, proportioning remains stable and repeatable.

In practice, this enables the creation of centralised proportioning systems capable of feeding multiple risk zones through a single unit. Maintenance becomes simpler, spare parts are reduced, and hydraulic losses are minimal, a decisive advantage when handling viscous synthetic foams. The outcome is a system that performs

“Even the best system is only as dependable as its maintenance regime”

consistently across a variety of scenarios without the calibration drift typical of venturi devices.

When moving to viscous SFFF or 1×3 concentrates (1% for hydrocarbons, 3% for polar solvents), system hydraulics must be reconsidered. Flow regimes transition from turbulent to laminar more quickly, increasing pressure loss. Designers should use viscosity correction factors in the Darcy–Weisbach equation, referencing the foam manufacturer’s data. Higher viscosity means greater pumping energy, larger pipe diameters, or both if the system is not optimised.

Water-driven foam proportioners mitigate this by directly harnessing hydraulic power from the water stream. This eliminates external energy sources and reduces overall pressure drop, a key benefit when upgrading legacy systems not designed for viscous media.

The next major development is the universal 1×3 foam, engineered to suppress both hydrocarbon and polarsolvent fires at 1% and 3% respectively. Advances in surfactant chemistry and formulation stability are enabling this dual-range performance. Field and third-party tests already show burnback resistance and blanket integrity comparable to, or exceeding, legacy ARAFFF foams.

Operationally, one foam means simplified logistics and reduced stockholding. However, many 1×3 formulations sit near the upper limit of viscosity tolerance, demanding equipment that can accommodate them without redesign. Systems offering low pressure loss, high metering accuracy and self-driven proportioning are proving most adaptable to this new generation of foams.

Even the best system is only as dependable as its maintenance regime.

Foam concentrates should be analysed annually to confirm viscosity, pH and surface tension. Proportioning devices must be tested under realistic flow conditions, using water for regular checks and foam for periodic full-scale validation. Installations should also allow sampling and flushing without environmental discharge. Closed-loop test systems, concentrate return lines and controlled drainage are becoming standard as sustainability expectations tighten worldwide.

The transition to fluorine-free suppression is not simply a chemical substitution; it is a chance to modernise the entire protection strategy. Each element of the system must work together, hydraulically and mechanically. When proportioning, discharge and foam chemistry are aligned, performance improves and energy demand falls.

Water-driven foam proportioners with wide flow ranges and minimal pressure loss embody this integrated philosophy. They offer resilience across foam types, from legacy AR-AFFF to the most viscous synthetic formulations, without the instability or flow-rate sensitivity common in suction-based devices. In short, they represent a proportioning approach built for the era of sustainable suppression.

As Intersec Dubai approaches, the conversation is shifting from what products are banned to how systems can evolve for sustainability without compromising safety. The future of firefighting foam will not be defined by what has been removed but by what has been engineered to perform better. Through informed design, validated proportioning and data-driven testing, this transition can deliver cleaner, safer and more reliable outcomes, proving that the next generation of fire protection can be both sustainable and strong.

firedos.com

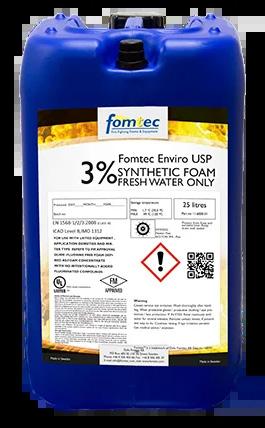

FOMTEC© ENVIRO USP

VISIT US AT INTERSEC IN DUBAI, UAE. YOU WILL FIND FOMTEC IN STAND 4-A38, together with ESS and FFS.

Fomtec Enviro USP is designed to be an effective fluorine-free alternative for sprinkler systems, type II and III discharge devices. ICAO level B. NEW GENERATION SFFF WITH NO PARTIALLY HYDRATED POLYMERS • APPROVED FOR SPRINKLER, UL 162 LISTED FM 5130 APPROVED • VDS APPROVED

Superior Fire Performance: EN 1568 Part 1, 2 & 3 (Rate 1A), ICAO Level – B and IMO1312 and MED for marine use: FOR CLASS A & B FIRES • 100% BIODEGRADABLE • LOW, MEDIUM & HIGH EXPANSION

For full specifications, please visit Fomtec website or scan the QR code www.fomtec.com

www.olympia-electronics.com

One luminaire, sixteen possibilities

Dynamic Light allows quick selection of up to 16 different marking signs, static or animated, for ultimate flexibility in emergency lighting. Available in standard and hybrid versions, designed for shopping malls, airports, and modern buildings.

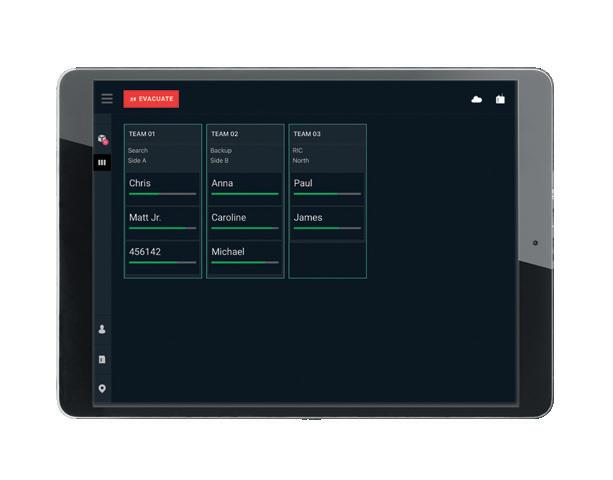

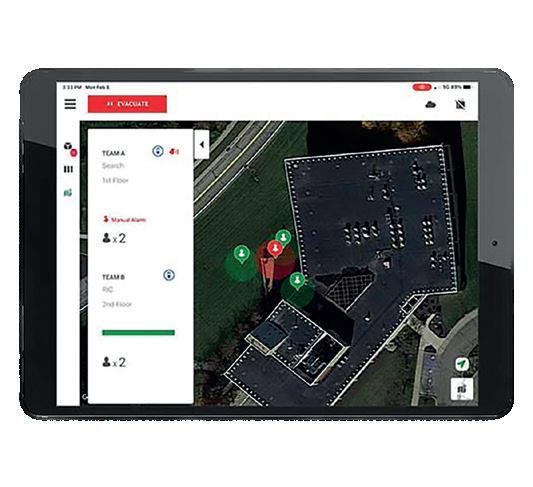

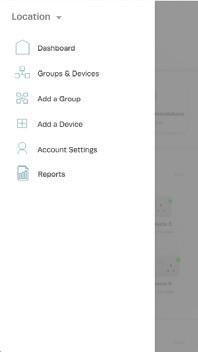

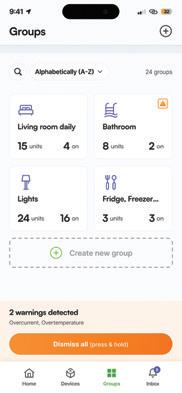

Fire & life safety and security systems are no longer standalone solutions; they are increasingly integrated to work seamlessly together in protecting people, property and business continuity. Sharing components, infrastructure and intelligence, these systems complement one another to deliver a unified safety ecosystem.

Discover how the latest integration between fire and security systems creates smarter, safer buildings, offering more control when every second counts, according to Mina Zakhary, Principal Fire Consultant and Smitha Mathew, ELV Lead Engineer at Cundall

This integration represents more than a technical upgrade — it is a transformative approach that redefines safety by making buildings adaptive and responsive to occupants’ needs. For example, a fire alarm sensor might trigger the life safety system while a connected security system manages evacuation routes and access control during emergencies.

By coordinating functions like door unlocking and smoke control activation, integrated systems enable faster, more efficient emergency responses. Such interoperability is vital for comprehensive risk management strategies in the Middle East’s rapidly evolving built environment, where the stakes for safety and operational resilience are higher than ever.

“The result is a new generation of proactive buildings: ones that learn, evolve and respond dynamically to emerging risks”

This interconnected intelligence reduces human error, accelerates decision-making and enhances coordination between responders and building operators. It’s not just about safety it’s about operational resilience.

As the MENA region advances in its digital transformation journey, AI driven analytics, IoT sensors and cloud-based command platforms are becoming the new standard. Predictive maintenance, real-time occupancy mapping and adaptive evacuation algorithms are already reshaping how facilities from hospitals to high rises manage emergencies.

The result is a new generation of proactive buildings: ones that learn, evolve and respond dynamically to emerging risks.

1.

In the event of an emergency, a fire or a break-in, connected systems can respond faster than in a manual case. For example, when a fire is detected, the fire alarm can signal the security system to release certain doors, providing faster access to emergency exits. Conversely, if a security breach is detected in a fire exit route, security personnel can promptly intervene to keep the exit open and safe for evacuation specially in airports and detention facilities.

When fire safety and security systems are combined into one platform, building managers and security staff can oversee and control everything from one place. This centralisation simplifies operations and ensures safety and security work smoothly together. If an alarm goes off, the system quickly shows where the fire is and highlights any security issues, like

blocked exits or unauthorised people in restricted zones. Video surveillance systems are essential for monitoring activity within and around a building. By integrating CCTV with fire safety systems, security personnel can monitor not only security events but also observe the progress of a fire or smoke spreading in real-time. This visual data can be used to direct fire response teams to the affected area more quickly, improving overall emergency response. Furthermore, video footage can be crucial for post-incident analysis and investigation.

As part of the fire strategy, access controlled door requirements should integrate in harmony with the security goals. This is essential in places like data centres, hospitals, institutional or correctional facilities where some areas must stay secured even during a fire. Proper integration makes sure fire safety doesn’t interfere with security, and security doesn’t block fire safety

The harmony between the fire safety and security systems has a great impact on the construction cost as well. Instead of maintaining separate systems, using integrated solutions lowers complexity and cuts operating costs. Additionally, having all systems work together smoothly reduces the chances of mistakes or breakdowns in either system

Integrating fire strategies with BAS enhances the safety of modern buildings. While BAS controls lighting, HVAC and other utilities, it also plays a vital role during a fire and other emergency events,

for example it can automatically shut off HVAC to prevent smoke from spreading. It can also adjust lighting to guide people safely to evacuation routes. Additionally, BAS provides building managers with realtime information to help them make quick, informed decisions during emergencies.

The evolving dialogue between fire safety and security

Across the Middle East and North Africa, the built environment is entering a new era – one defined by connectivity, intelligence and resilience. The once clear divide between fire & life safety and security systems is rapidly dissolving, giving way to a future where both disciplines operate as a unified ecosystem serving a single purpose: protecting people, assets and continuity.

Traditionally, fire engineers and security consultants worked in parallel worlds. FLS focused on early detection, alarm activation, evacuation and suppression, while security targeted surveillance, access control and threat mitigation. Yet as cities grow smarter and buildings more digitally connected, these systems can no longer afford to work in isolation. The next generation of safe buildings will rely on seamless data flow and system collaboration between these two disciplines.

This convergence is not merely a technical alignment it’s a human-centric evolution. It redefines how occupants interact with their surroundings, ensuring that every person regardless of ability, background or circumstance can move through a space confidently, securely and intuitively.

Intelligence in integration: Monitoring, detection and notification systems

Future buildings won’t just react to problems they will predict and adapt to them.

When these systems communicate, they transform a building into a living organism — aware, responsive and capable of making informed decisions in real time.

A smoke detector triggers a fire alarm, and simultaneously, access-controlled doors unlock to guide evacuation routes.

CCTV cameras automatically pan towards affected zones, giving operators instant visual confirmation.

Voice evacuation and mass notification systems deliver multilingual instructions, tailored to the specific incident and zone.

Building Management Systems (BMS) unify fire, security and HVAC responses, ensuring clarity and control under pressure.

vision

The future of fire & life safety and security in the MENA region is predictive, autonomous and data driven. Buildings are evolving from static structures into intelligent ecosystems that continuously sense, analyse and adapt.

Imagine a building that detects an anomaly, cross-verifies it through thermal cameras and environmental sensors, and reroutes occupants via adaptive evacuation signage all before a human even raises an alarm. Picture an operations centre that uses AI to predict high-risk scenarios days in advance, optimising system readiness automatically.

This is no longer a futuristic fantasy; it is the direction of regional innovation. Many cities across the MENA region are investing heavily in smart infrastructure, AI-enabled monitoring and digital twin technology. These systems allow fire and security networks to merge into a single digital command structure – one capable of responding faster, smarter and with greater precision than ever before.

Ultimately, this convergence reflects a cultural and operational evolution: from protection to prevention, from isolation to integration, and from compliance to intelligence.

The synergy between fire & life safety and security represents far more than a technical upgrade, it is a redefinition of safety itself. It’s about transforming buildings into environments that protect, empower and adapt to the people within them.

As the MENA region continues to set global benchmarks in innovation,

sustainability and smart urban design, its commitment to integrating FLS and security will define the next chapter of architectural and engineering excellence.

The future belongs to those who design beyond compliance; those who fuse safety, technology and human experience into one seamless vision of smart, inclusive and resilient living.

cundall.com

Ruediger Kopp, Managing Director of FOGTEC Brandschutz GmbH, explores how high-pressure water mist technology is safeguarding icons like the Mecca Royal Clock Tower while shaping the future of sustainable, efficient fire protection in the region’s most ambitious structures

High-rise architecture has come to define the skylines of the Middle East – and with it, entirely new fire safety challenges. Densification, multifunctional use and increasingly complex building geometries present architects, engineers and operators with new challenges. Fire protection is particularly important in densely built-up and populated areas. Today’s fire protection systems must not only reliably protect people, property and infrastructure, but also combine sustainability, architectural quality and economic efficiency.

In this area of conflict, high-pressure water mist has established itself as one of the most forward-looking technologies: it is effective, resource-efficient and architecturally flexible. The full potential of this technology is particularly evident in high-rise buildings, where space, weight and integrability play a decisive role. Examples of this include the Mecca Royal Clock Tower in Saudi Arabia and the Gasometer in Berlin. These stunning buildings showcase how a fire protection system incorporating high-pressure water mist can be seamlessly integrated into architecturally sophisticated high-rise buildings.

The principle of high-pressure water mist is as simple as it is effective: water

is forced through special nozzles at a pressure of around 100 bar, atomising it into droplets, some of which are microscopically small. This increases the reaction surface of the water more than a hundredfold. Upon contact with the source of the fire or the hot fire gases, the droplets evaporate in a fraction of a second; the resulting water vapour extracts heat from the environment and simultaneously displaces the oxygen.

The high cooling capacity of the water mist and the binding of smoke quickly lower the ambient temperature and improve visibility. This creates optimal conditions for evacuation and access for the fire services. At the same time, the building and adjacent areas are protected.

Compared to conventional sprinkler systems, a fire protection system with high-pressure water mist requires up to 90 percent less extinguishing water. The reduced water consumption minimises secondary damage and operational downtime after a fire. The effectiveness of the technology has been proven for every application through full scale fire tests under real conditions.

High-pressure water mist combines technical efficiency with planning

freedom. Due to the low water volume, only small pipe sizes with a diameter of 12 millimetres to a maximum of 60 millimetres are required for main risers. This saves space, simplifies installation and allows integration even in filigree or listed structures. The high pressure enables stable system performance even across large building heights – a crucial aspect in high-rise buildings over 100 metres.

Modern high-pressure water mist systems have redundant pump modules and separate power supplies. This means that protection remains fully intact even in the event of partial failures or maintenance.

In addition, the systems utilise very compact pumps and significantly smaller water tanks. This is particularly important in high-rise buildings, as it means less static load, less space requirements and thus more usable space.

Another important aspect that is becoming increasingly significant is sustainability. High-pressure water mist works without chemical additives and is therefore harmless to humans and nature. The low water consumption also means that only a small amount of contaminated extinguishing water is produced. In addition, almost exclusively stainless steel components with a long service life are used. The technology

thus meets today’s environmental, social and governance (ESG) requirements and contributes to environmentally conscious building operations.

The reliability of a high-pressure water mist fire protection system is based on extensive full scale fire tests that demonstrate fire suppression, temperature control and damage limitation. The basis for the consistently performance-oriented testing approach are fire test protocols for office and residential areas, raised floors and

suspended ceilings, as well as storage and technical rooms (VdS 3883-1/3/5 and EN 14972-2/3/6). The requirements for high-rise buildings with a height of more than 45 metres are described in the VdS 3188 standard.