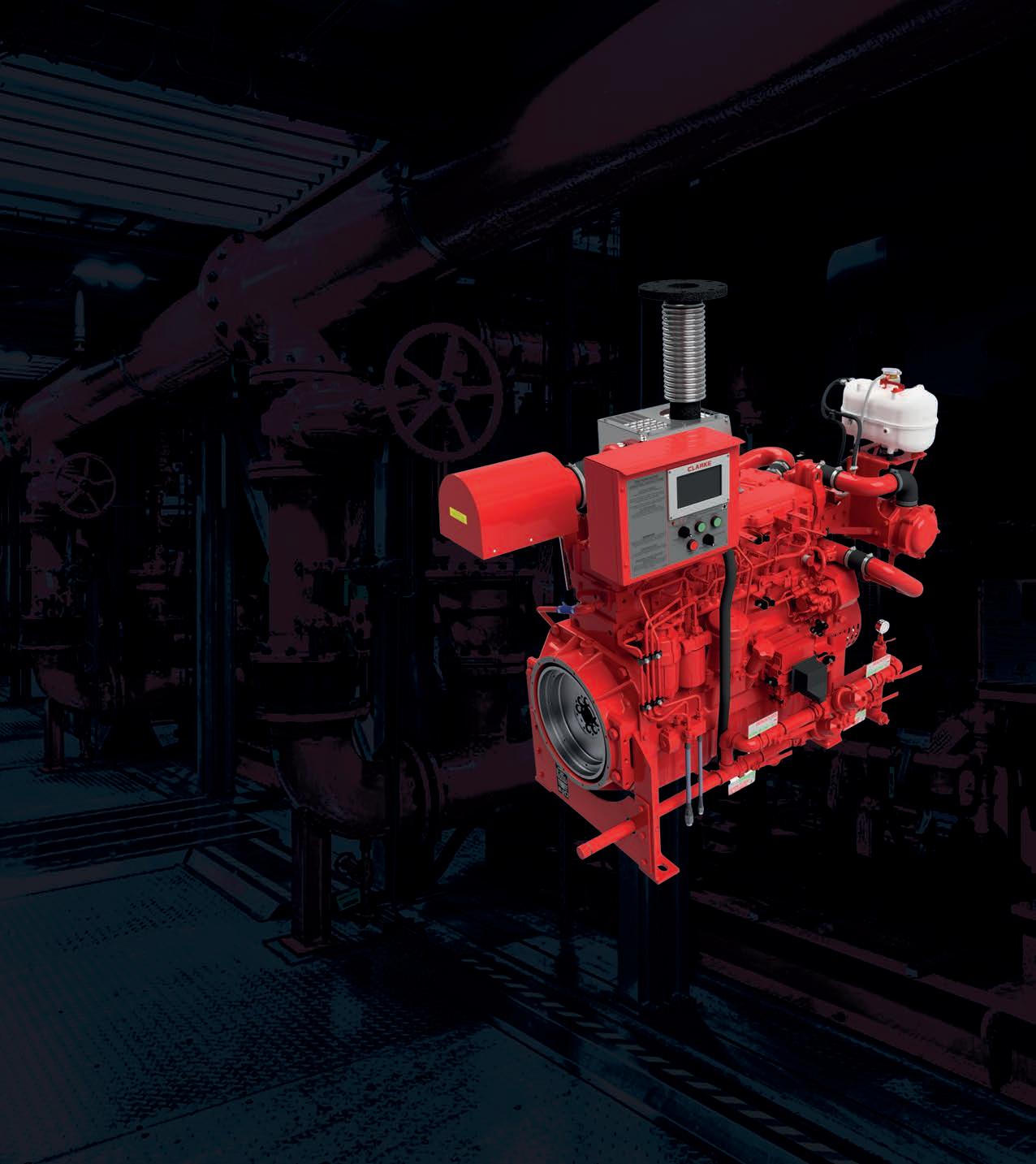

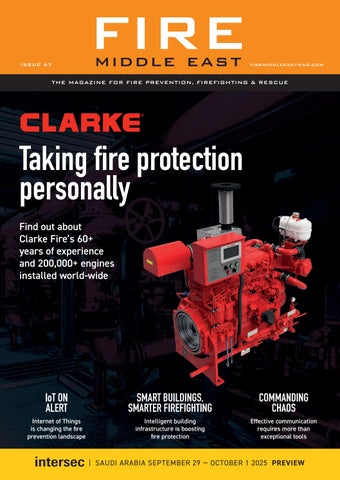

Find out about Clarke Fire’s 60+ years of experience and 200,000+ engines installed world-wide

Industrial Fire Brigade Incident Command

Brand new, innovative training location

40 years of experience

Realistic fires : liquid, gas, class A fuels

Tailor -made scenarios on client's request

Training supported by XVR (virtual reality), scale models, full scale fire simulators

o

360 safety solutions; education, training and consultancy

Advice on and training progammes based on national and international industrial standards and best practices

06-10 October 2025 17-21 November 2025 30 March-03 April 2026 13-17 July 2026 14-18 September 2026 19-23 October 2026 02-06 November 2026

Industrial Fire Team Leader 10-14 November 2025 15-19 June 2026 16-20 November 2026

EDITORIAL

Publisher Mike Dingle +44 1752 267330 mike@firemiddleeast.co.uk

Editor

Cora Lydon +44 7834 244613 editor@firemiddleeast.co.uk

ADVERTISING

Worldwide

Ryan Bickerton +44 1752 265802 ryan@firemiddleeast.co.uk

Gareth Driscoll +44 1752 260603 gareth@firemiddleeast.co.uk

Rahul Vara +44 1752 604352 rahul@firemiddleeast.co.uk

Will Russell +44 7800 513300 will@firemiddleast.co.uk

Digital Editor Britt Jones britt@firemiddleeast.co.uk

Production Team Freya Tucker freya@firemiddleeast.co.uk

Marketing Manager

Mark Doyle +44 7517 452283

PUBLISHED BY

MDC Middle East Ltd

+44 (0)1752 267 330 6 Woodside Lane, Plymouth, Devon, PL4 8QE, UK

This publication may not be reproduced or transmitted in any form in whole or in part without the written consent of the publishers.

©MDC Middle East Ltd. 2025

For subscriptions and advertising enquires, or for further information on the magazine visit our website at: firemiddleeastmag.com

Welcome to our special issue dedicated to Intersec Saudi Arabia, a key event in the region’s fire and security calendar. As the official media partner, we are proud to be attending the show and in this issue we bring you an exclusive look at what to expect. Inside, you’ll find a detailed guide to the agenda (page 75), a list of the visionary speakers (page 81) and a chance to hear from some of the show’s exhibitors (from page 85), ensuring you make the most of your time there.

This issue also features a special profile on Clarke Fire (page 16), celebrating an impressive 60-year legacy in the sector. The company continues to invest heavily in R&D and reveals they’ll have some exciting announcements later this year. Elsewhere, we explore the divisive topic of Large Language Models (LLMs) and their role within the industry, highlighting the

importance of thoughtful and careful prompts and reminding us that these powerful tools are only as effective as the human engineer guiding them (page 30). Finally, don’t miss an excellent piece from fire expert Bob Rea, who delves into the vital subject of communication on the fireground, reinforcing that trust is the non-negotiable foundation of effective teamwork (page 58).

Cora Lydon Editor editor@firemiddleeast.co.uk

firemiddleeast Fire Middle East Magazine

03 Up front

Foreword from the Editor

06 Regional news

The latest regional fire safety and protection news

12 International news

Fire-related news and advancements from around the globe

15 Product showcase

Find out about some of the newest products to reach the market

71 Diary

Diary dates for forthcoming fire safety exhibitions, conferences and events

16 Cover story

For over 60 years, Clarke has served the fire protection industry. Its global workforce, with over 2,500 years of combined technical knowledge, supports over 200,000 installations worldwide

20 Parking’s electric shift

Eiad Shami, Principle Fire and Life Safety Consultant, WSP Middle East, considers the remediation of existing car parks to accommodate electric vehicles

27 Precision under pressure

Jason Voerman, Regional Sales Manager – MEA, Firedos, looks at why smart pressure regulation is the backbone of foam fire suppression systems

30 Smart or risky?

Faris Alzahrani, OHS and fire safety practitioner, investigates large language models (LLMs) in Fire Safety Engineering and explores how they can aid fire safety experts without compromising safety

33 No longer blind

Anthony D. Parfitt, Chairman, founder and inventor of Ci Global, looks at how intelligent building infrastructure is transforming fire response, and envisages a future where prevention leads

37 Safety in unity

Cross-sector collaboration is the nonnegotiable foundation of a safer future, says Zahi Daher, International Business Development Manager, KSA, NFPA®

40 United for safety

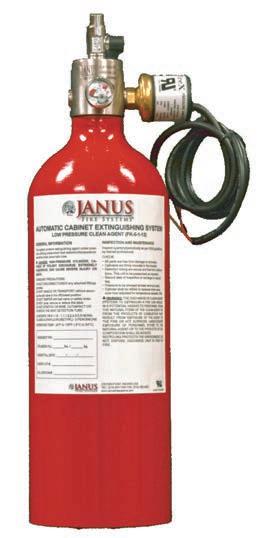

We speak with Sam Malins, Group CEO, Reacton and Mowafaq Al Braim, General Manager, Al Aswad Fire Protection Co, about the synergy between the two companies as they forge a new partnership

42 The hidden threat

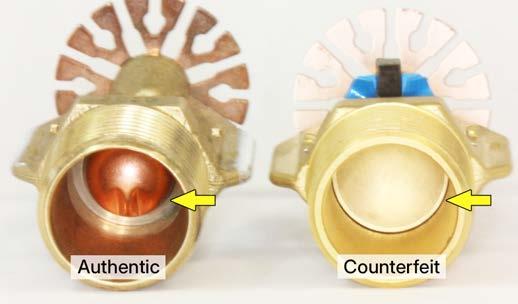

In the fire protection industry, system reliability is not a convenience; it’s a life safety imperative. Mark Fessenden, Managing Director of the International Fire Suppression Alliance (IFSA) looks at the challenges of counterfeit equipment

50 Case study: Iraqi Ministry of the Interior

In a bid to streamline its emergency services, the Ministry of Interior in Iraq turned to Hytera

52 Bridging response and risk reduction

Fire safety solutions expert Peter Stephenson highlights that the future of firefighting vehicle procurement lies not in tradition, but in a data-driven, risk-based approach to fleet management

73 Intersec Saudi Arabia

Everything you need to successfully navigate the forthcoming exhibition and get the most out of your attendance

74 Welcome from show director

75 Agenda

81 Meet the speakers

85 Meet the exhibitors

Principle Fire and Life Safety Consultant, WSP Middle East

Eiad Shami specialises in fire risk management for evolving urban landscapes, including hospitality and tourism-driven developments.

International Business Development Manager for Saudi Arabia, NFPA®

Zahi leads NFPA’s initiatives across the Kingdom, working to advance fire and life safety standards in line with Saudi Vision 2030.

OHS and fire safety practitioner

Faris Alzahrani is a fire safety professional specialising in Building Codes and Standards, Design and Analysis of Life Safety.

& Supporters

56 Revolutionising safety

Stefanie Steudel, Product Manager Fire Alarm Systems – Remote Services, Bosch Building Technologies, writes about the transformative power of Internet of Things (IoT) in fire prevention

58 Commanding chaos

Bob Rea explores the hallmarks of effective communication under pressure and why trust is key

65 From frame to finish

Brett Shinn, Thomas Bell-Wright International Consultants, looks at the unsung role of supporting constructions for doors – what’s their role, are they standard or associated and how do we test them?

69 #IWMC2025 highlights

Find out about what’s coming up at the International Water Mist Conference 2025

Enquire about 2026 sponsorship packages

A UAE rescue team continued operations for a fifth consecutive day to fight forest fires in multiple regions of Albania, acting in close coordination with local authorities under the directive of President Sheikh Mohamed bin Zayed Al Nahyan. The mission deployed aircraft and a specialised team equipped with advanced monitoring tools to tackle the fires effectively. Over several days, the team conducted 15 aerial sorties, dropping over 600,000 kilograms of water to contain the blazes and prevent their spread towards residential areas. Despite facing extreme heat and rugged terrain, the emirate’s efforts have been critical in managing fire activity and reducing risk to communities.

“We are deeply honoured. Our strategic collaboration with NFPA has elevated our workforce capabilities and fostered a holistic safety ecosystem across Abu Dhabi.”

Abu Dhabi Civil Defence has earned global distinction for its proactive leadership in fire and life safety. Through collaboration with NFPA, the authority has achieved significant reductions in firerelated fatalities, invested in high-impact training for professionals, and fostered a resilient safety culture across Abu Dhabi. The recognition reflects both a strategic commitment to innovation and tangible results in public safety. The authority’s Director General, H.E. Brigadier General Salem Abdulla Al

Dhaheri, commented: “We are deeply honoured. Our strategic collaboration with NFPA has elevated our workforce capabilities and fostered a holistic safety ecosystem across Abu Dhabi.”

A standout achievement is the three-year certification programme developed in partnership with NFPA. This initiative offers advanced training for engineers, inspectors and hazardous materials specialists, reinforcing ADCDA’s dedication to professional development and operational excellence.

Dubai’s rapid industrial expansion is driving greater fire safety complexities. As manufacturing and logistics facilities proliferate, so do risks tied to flammable materials, complex equipment, electrical systems and heightened human activity. Proactive fire risk assessments have become essential to manage these emerging challenges effectively. In Dubai, where industry and logistics play a strategic role in economic development, industrial facilities are multiplying.

These environments, which often involve complex manufacturing processes and high human activity, naturally carry heightened fire risks due to equipment, electrical systems, flammable materials and open flames.

While fire safety engineering programmes exist in various parts of the world, there is no nationally licensed undergraduate programme in the UAE specifically dedicated to fire risk analysis. While master’s and doctorallevel programmes in fire engineering do exist, practical industry experience plays a pivotal role in conducting effective assessments. Dubai Civil Defence has mandated that any fire protection design or audit must be conducted by DCDapproved and certified consultants.

On 16 July 2025, a devastating fire broke out at the Corniche Hypermarket Mall, a five-storey shopping centre in Kut, Iraq, claiming 67 lives, with dozens injured and at least 11 still missing.

The blaze began near a perfume section, possibly triggered by an air conditioning unit explosion, and was greatly worsened by the building’s lack of emergency exits, alarms, fire extinguishers and use of flammable materials. Rescue efforts saved many, but recovery operations continue amid tragic losses and identification challenges.

The government has launched investigations, taken legal action, declared three days of mourning, and called for reforms in building safety protocols. The fire has also prompted political fallout, including the resignation of the provincial governor, underscoring longstanding concerns over Iraq’s construction oversight and safety standards.

Ten firefighter and rescue workers were killed and 14 others were injured while fighting wildfires in a forested area of Eskisehir province, north-west Türkiye. Forestry Ministry Ibrahim Yumakli said five of the dead were forestry personnel and five were members of the AKUT rescue organisation. The team were trapped when a sudden change of wind swept the fire towards them and they were engulfed. The cause of the fire is not known, but

Türkiye has been facing extreme high temperatures and wind shifts over the summer months. Turkish President Recep Tayyip Erdogan shared his condolences on X: “I pray for God’s mercy on our brothers and sisters who fought at the cost of their lives to protect our forests, and I offer my condolences to their families and our nation.” Hundreds of wildfires have forced tens of thousands of people out of their homes in Türkiye this year.

A young Saudi man has been recognised for his exceptional bravery by King Salman, following a recommendation from Crown Prince Mohammed bin Salman, after his life saving action when he came across a burning tuck at a fuel station.

Maher Fahd Al Dalbahi jumped into the truck, which the driver had abandoned, and drove it away from the fuel station, preventing catastrophic damage and almost certain loss of life. Al Dalbahi suffered first and seconddegree burns to his face, head and limbs. He was promptly transferred to King Saud Medical City in Riyadh, where specialised medical teams are providing treatment.

Prince Mohammed bin Abdulrahman (Deputy Emir of Riyadh) personally called Al Dalbahi and instructed health authorities to ensure he receives the best possible medical care. In recognition of his exceptional bravery, King Salman, following a recommendation from Crown Prince Mohammed bin Salman, awarded Al Dalbahi the King Abdulaziz Medal (First Class) along with a 1 million Riyal (approx. $267,000) cash reward.

Thirty two people have gone on trial in Türkiye over a hotel fire at a ski resort, which killed 78 people including 36 children. More than 130 people were injured when the 12 storey building was destroyed. Thirteen of the defendants face up to 1998 years in prison on 78 charges including “Manslaughter with possible intent”. Both survivors and experts have said that the hotels’ fire alarms didn’t work. It’s also alleged that an inspection report drawn up a month before the fire showed a lack of fire safety measurements, but that the hotel owners failed to act on it because it would have been too costly.

The end of August saw Arabian Shield Cooperative Insurance Co. announce that it had reached a final settlement agreement with Arabian Centres Co, for an insurance claim that was related to the 2022 fire at Dhahran Mall in the Eastern Province.

In May 2022 a partial fire broke out in the mall, which the Civil Defense teams were able to contain. Although there were no major casualties there was damage to parts of the mall. The settlement value totalled SR250 million.

School buses in the United Arab Emirates are to be a whole lot safer, thanks to Reacton Fire Suppression systems being retrofitted to the transport following a government directive.

As of April 2025, the Ministry of Industry and Advanced Technology

brought in new rules that required older buses with 22 seats or more to be fitted with fire safety systems.

According to the Ministry, around 2,500 buses have already been fitted with the automatic extinguishers, out of a 17,000-strong fleet.

Jordanian Civil Defence personnel are continuing to provide support to Syria to combat waves of fire which have swept along large areas of the Syrian coast. This move is part of a broader Jordanian strategy aimed at supporting Syria’s stability and territorial integrity, a point His Majesty King Abdullah has emphasised on multiple occasions. The JCD’s participation, led by Brigadier General Munther Al-Ajarmah, takes on added importance in light of the increasing scale of the fires that have devoured thousands of dunams of land, including forests; has displaced dozens of families; and caused significant environmental and economic losses.

Effectively protecting people and property from fire can be complex. Advanced simplifies the challenge without compromising on safety.

Whether you need powerful networking, smoke control and fire audio for large-scale UL projects; extinguishing control and fire system redundancy for critical sites; or fast, fuss-free EN solutions for smaller, wireless installations, Advanced brings you fire safety peace of mind.

Advanced will

be in attendance at Intersec Saudi Arabia later this month. Shadi Elhag, Business Development Manager – Middle East, tells us more about what visitors can expect

From 29 September to 1 October 2025, the Riyadh International Convention & Exhibition Center (RICEC) will once again host Intersec Saudi Arabia, bringing together fire safety professionals, security specialists and decision-makers from across the region. At Stand 5-D36, Advanced will showcase its portfolio of UL and EN fire protection technologies, demonstrating how the company is supporting the Kingdom’s ambitious development plans with reliable, adaptable solutions.

UL platforms

Saudi Arabia’s rapid urban expansion continues to drive demand for UL-listed fire safety systems, particularly for tall buildings, mission-critical infrastructure and major residential developments. Advanced’s Axis AX platform, approved to UL 864 10th Edition, is engineered to meet these needs with scalability, powerful networking and high performance at its core.

The system can be configured for anything from a small two-panel network to a 200-node installation, delivering fast communication, advanced cause-andeffect programming and straightforward setup. Available in red or grey enclosures, Axis AX also provides design flexibility to suit a wide range of environments.

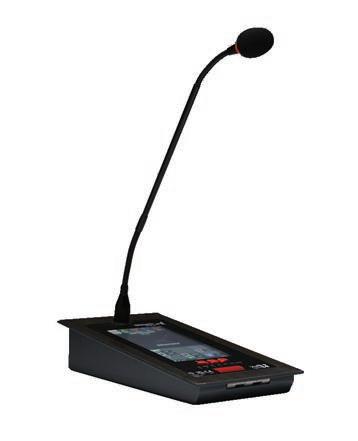

Where voice evacuation is required, Axis AX offers integrated audio with both pre-recorded and live paging, supported by multiple channels for clear messaging. PerfectSync technology ensures strobes

and audio remain coordinated across even the largest networks, eliminating confusion during an evacuation. An optional emergency telephone system further enhances communication in high-rise or multi-use buildings.

EN solutions

Saudi Arabia is one of the few markets where both EN and UL standards are widely specified. For EN projects, Advanced’s enhanced Axis EN panel delivers faster processing, improved configuration options and more energyefficient power supplies.

Hybrid operation allows wired and wireless devices to be combined within a single installation, making Axis EN particularly effective for heritage or operational sites where cabling would be disruptive. Its compatibility with mesh wireless devices ensures dependable performance while minimising installation impact.

beyond detection

Alongside its control panels, Advanced will highlight complementary technologies that expand protection across different building types.

AlarmCalm, available in Axis EN systems, reduces false alarms by enabling tailored investigation delays and verification strategies. Separate settings can be applied to kitchens, bedrooms or public areas, cutting costly and disruptive evacuations.

DynamixSmoke provides intuitive smoke control configuration for fans, dampers and stairwell pressurisation. Its grid-based interface simplifies programming while supporting interlocks, post-alarm purging and automated testing.

Redundant panel options ensure continuity during faults, providing vital resilience for critical facilities such as telecoms hubs, hospitals and data centres.

ExGo delivers reliable gas extinguishing control with EN approvals, protecting high-value assets in singleflooding zones where water damage is unacceptable.

Oman’s Bidbid Tunnel, a critical infrastructure project along the Bidbid-Sur road, is equipped with a sophisticated Axis AX fire safety system from Advanced

For smaller applications, AxisGo provides the power of the Axis EN platform in a compact, single-loop panel that is non-networkable but quick to set up via Advanced’s ConfigTool.

For conventional systems, QuickZone continues to provide dependable protection across up to 32 zones. Easy to install and maintain, it is available in both standard and XL formats, fully approved to EN54 Parts 2 and 4.

The demand for adaptable fire protection across Saudi Arabia is greater than ever. Advanced is working closely with regional distribution partners while seeking new collaborations to further strengthen fire safety provision in the Kingdom. By combining world-class engineering expertise with a commitment to usability, innovation and sustainability, Advanced is helping customers meet today’s regulations while preparing for future safety challenges.

Visitors to Intersec Saudi Arabia 2025 are invited to meet the team at Stand 5-D36, where Advanced will demonstrate its range of fire protection technologies and discuss project requirements. advancedco.com

The International Association of Fire Chiefs (IAFC) has announced the IAFC Fire Chief of the Year 2025 honourees at Fire Rescue International (FRI) in Orlando, FL. This year’s recipients have been named as Volunteer Fire Chief Daniel Krushinski of the East Franklin Fire Department in Somerset, New Jersey, and Career Fire Chief Jeremy Craft of the Lehi Fire Department in Lehi, Utah. Krushinski has spent more than two decades in the fire service and has helped establish a Water Rescue Team and secured specialised rescue boats in response to lessons learned from Hurricane Ida. Craft’s career has been focused on a commitment to firefighter health and safety, and has campaigned for presumptive cancer coverage, early screening and accountability measures to help protect firefighters statewide.

The mainstage of Belgium’s Tomorrowland festival was completely destroyed by fire less than 48 hours ahead of the festival site opening to 100,000 people. Several hundred firefighters worked to save the main stage. Antwerp prosecutors have opened an investigation, though they said the fire appeared accidental. Initially the fire was thought to have been started during pyrotechnic testing, but it seems that it was caused by a fault with the lighting rig. Experts from the firefighting and entertainment industry are not surprised by how quickly the fire spread, due to most of the stage being constructed from wood and polystyrene –both of which are highly flammable.

Over 1,000 first responders are to receive awards as part of India’s Independence Day celebrations this year. The honours include Gallantry Awards, the President’s Medal for Distinguished Service and the Medal for Meritorious Service. Sixty two medals have been awarded to members of the fire service, including six medals for gallantry, five presidential medals for distinguished service and 41 medals for meritorious service.

US shipping company Matson has temporarily banned the transport of electric vehicles (EVs) and plugin hybrid vehicles (PGEVs) on its ships over safety concerns. The decision affects routes between Hawaii, Guam, Alaska and the US Mainland, which creates problems for private owners and car manufacturers trying to move cars in the pacific. The decision has come after the sinking of the Morning Midas in June, a British owned ship, where a fire started on a deck carrying EVs, which would likely have been intensified by Lithium-Ion batteries. The loss of this ship follows the loss of the Fremantle Highway and the Felicity Ace, both of which were carrying EVs when they were lost.

The South African city of Tshwane is seeking legal instruments to prohibit private firefighting services operating in the city without proper authorisation. The city alleges that these services are contravening national and local legislation governing emergency services. However, the metro’s legal team has been hit with a judgment ordering them to pay costs to the Sinoville Firefighting Association as they did not obtain the necessary mandate in time to act on behalf of the metro in the court application.

Eighteen individuals from India are to be recognised by Singapore with the Singapore Civil Defence Force (SCDF) Community Lifesaver Award for saving 16 children and six adults from a fire at a threestorey shophouse that housed a children’s enrichment centre, Newtonshow Camp and the Tomato Cooking School. The group of construction workers came to the aid of 22 individuals, including the sevenyear-old son of the Deputy Chief Minister of Ahdhra Pradesh, when they became trapped in a fire.

High output, robust audible and visual warning signals for demanding environments

The AlertAlarm range of alarm horn sounders are the next generation of audible signals for fire alarm notification in industrial and harsh environments

The robust thermoplastic or aluminum enclosures are rated Type 4/4X and capable of alarm tone sound output of up to 124dB(A). The compact Xenon strobe and LED multifunction beacons can be installed as standalone visual signals or combined with an audible alarm device

UL, cUL, ULC and DNV approved for industrial or marine fire applications, the AlertAlarm range is also MED and CPR compliant (EN54-3 & EN54-23). All signals feature low current consumption and E2S auto-synchronization technology.

www.e2s.com

For over 40 years, Jewers’ has been supplying bi-folding doors to the emergency services.

Our sideways-opening doors provide full-height headroom and a clear line of sight allowing emergency vehicles a safe and quick getaway every time.

Fully insulated doors help temperature regulation, minimizing heat loss in cold environments and maintaining a cool atmosphere in hot climates. Additionally, our fully glazed doors not only allow natural light to illuminate the station but also enhance its aesthetic appeal.

For rapid, reliable, secure, and durable doors that are designed, installed, and maintained to your needs.

Email: postroom@jewersdoors.ae

Ledlenser has revealed its fourth generation of the P-Series, which features the use of 75 per cent recycled aluminium, making it an environmentally friendly choice for users needing reliable lighting in various settings.

The P7R is an updated version of a classic Ledlenser flashlight, featuring enhancements such as increased brightness, improved handling and a Mode Select Ring. This new mechanism allows users to easily switch between light modes, activate transport lock and access USB-C charging, even in low visibility or while wearing gloves.

Its design includes One Touch Focus, allowing for easy adjustment of the beam from floodlight to spotlight, which is useful in demanding conditions. This model, along with others in the P-Series, features the Advanced Focus System, which optimises lighting transitions. ledlenser.co.uk

Teledyne FLIR OEM has announced a collaboration with Japanese drone manufacturer ACSL to integrate its advanced thermal imaging modules into new drone payloads.

The partnership has focused on ACSL’s SAMO thermal payload, which combines a 64MP visible camera with the Hadron 640R dual thermal-visible camera system. This payload incorporates FLIR’s patented Multi-Spectral Dynamic Imaging (MSX) technology, which overlays visible details onto thermal imagery for improved clarity.

The SAMO system is designed for realtime imaging, supporting applications in

EVAC+CHAIR has recently unveiled its Evac+Power 1000H. Designed for rapid deployment and ease of use, this new model enhances manoeuvrability and simplifies storage.

Equipped with an integrated 36 V lithium-ion battery, the 1000H delivers smooth and controlled stairway ascent and descent, providing up to 90 minutes (or 150 flights of stairs) of continuous use on a full charge. This allows for the evacuation of multiple people quickly and safely when every second counts.

Claire Blakemore, Managing Director of Evac+Chair, commented: “…whilst a fire

Ajax Systems is redefining fire safety via the introduction of the EN54 Line – the most user-centric and fully wireless fire detection and alarm system tailored for commercial and municipal sites.

“EN54 Line is more than a new product line — it’s our statement and a real revolution in fire safety. Intuitive, scalable, and future-ready — these are the main pillars of our latest innovation,” said

Aleksandr Konotopskyi, Chairman of the Supervisory Board at Ajax Systems.

The CIE features built-in Ethernet, Wi-Fi and dual SIM slots, eliminating the need for separate communicators. It maintains continuous communication with monitoring stations and Ajax apps while managing up to 200 addressable devices and 40 fire zones. ajax.systems

public safety, disaster response and inspection. ACSL’s foldable SOTEN drone, which features a weather-resistant design, a flight time of 25 minutes, and a swappable payload capability, is intended to enhance operational efficiency in these sectors.

The companies showcased the SOTEN drone and SAMO payload at the Commercial UAV Expo in Las Vegas from 2 to 4 September 2025. oem.flir.com/en-gb/

might be the first scenario that springs to mind where an Evac+Chair could be utilised, they can also be deployed in a wide range of scenarios such as during health emergencies, lift failures and natural disasters.”

evacchair.co.uk

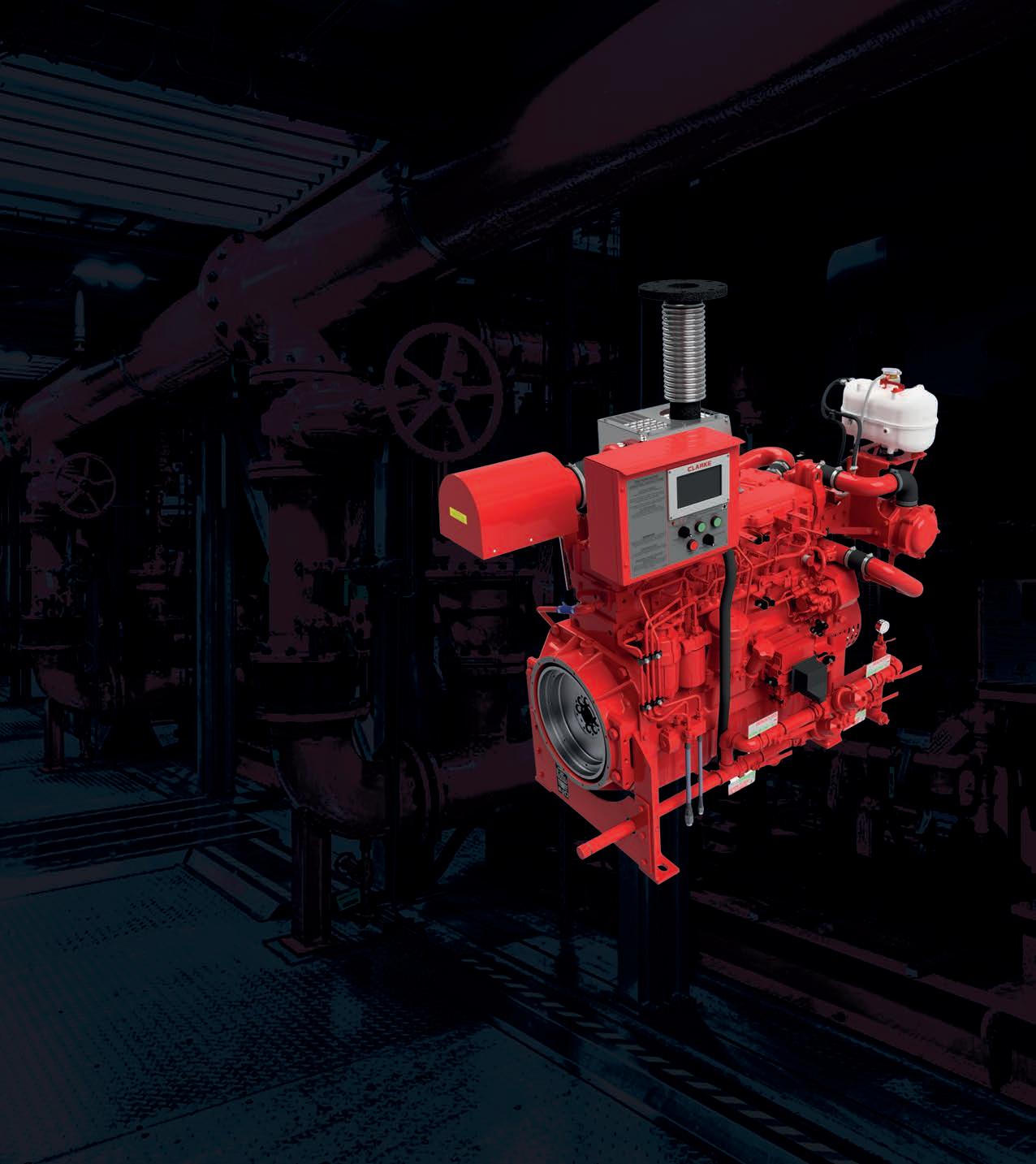

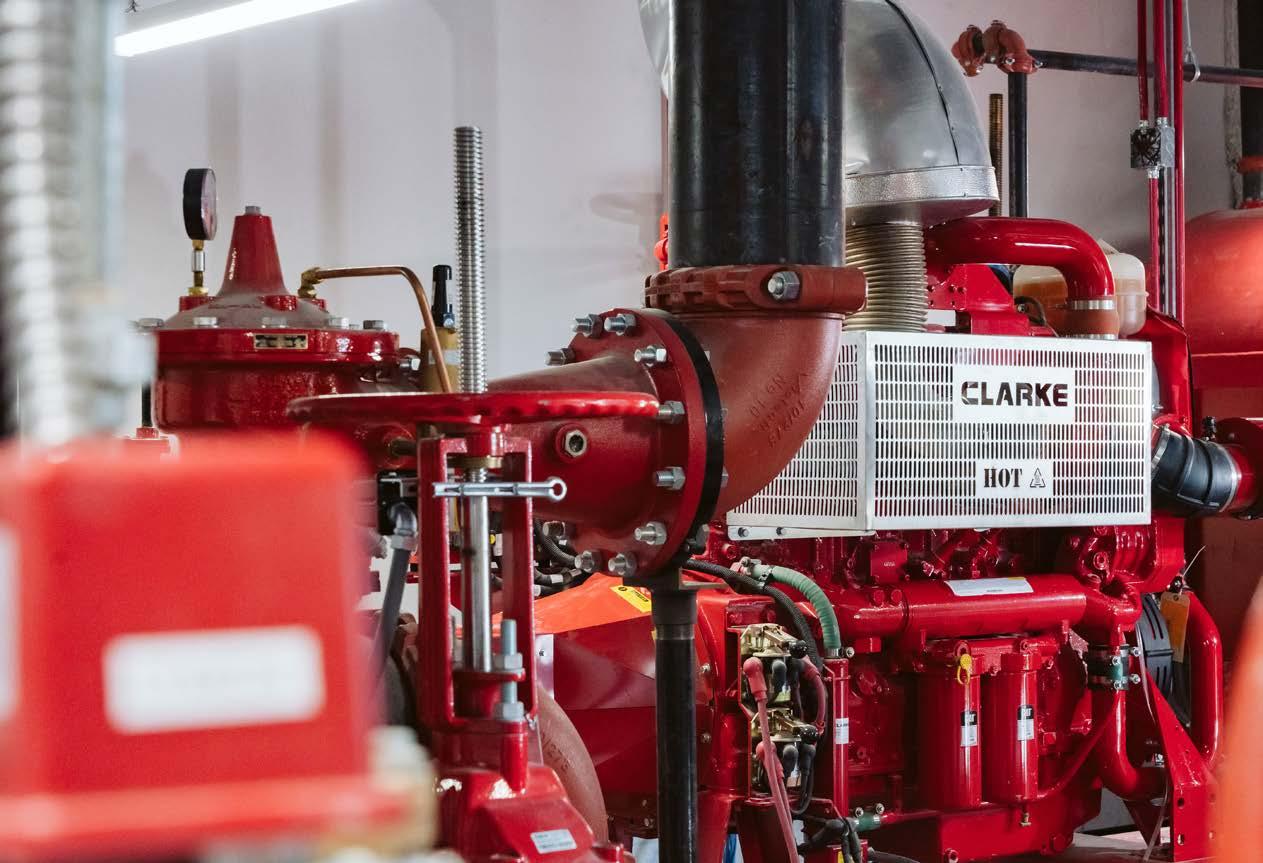

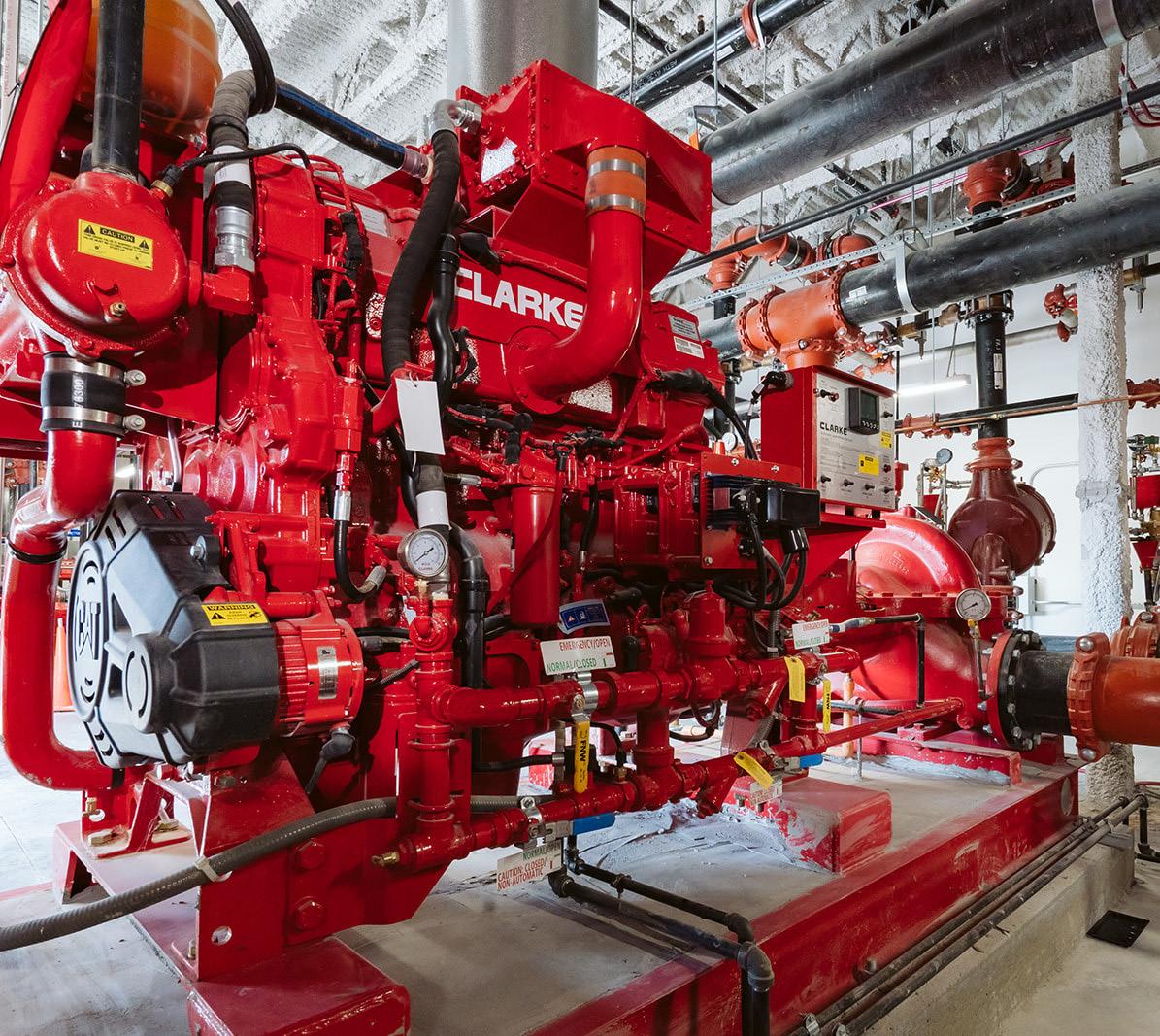

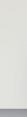

For over 60 years, Clarke has served the fire protection industry. Its global workforce, with over 2,500 years of combined technical knowledge, supports over 200,000 installations worldwide

In a small corner office of a regional distributorship of GM Diesel in 1964, a key decision was made: To begin selling General Motors’ diesel industrial engines as fire pump engines. Within 15 years, Detroit Diesel Engine Division (formerly General Motors’ Diesel Industrial Engines) transferred its fire pump engine certification and global marketing to

Clarke GM Diesel, effectively setting the stage for the development of the industry’s most influential and dedicated fire pump engine manufacturing company: Clarke Fire Protection Products.

Since the 1980s, Clarke has focused on improving the reliability and operation of fire protection systems. It has developed industry solutions such as dual starters

and dual electronic control modules for reliable engine starting; pump-ready bases and driveshaft couplings for alignment and vibration control; engine enclosures for weather protection; and variable speed pressure-limiting drivers to manage system pressure. Since 2010, Clarke has grown significantly into the industrial and energy sectors with engine

platforms capable of up to 1200HP and specialised options to support onshore and offshore energy projects worldwide.

Engineering innovation at Clarke is more than just a marketing buzzword. Its passion has been rooted in designing and engineering a better fire pump engine for pump companies around the world. This engineering and thereby ‘continuous improvement’ culture continues to define the company’s mission to protect people and property at all costs.

Within the last year, two global product enhancements were released with end user maintenance teams and service dealers in mind. Clarke’s new Touch Screen Engine Instrument Panels (TSP) include intuitive touch screen commands for operating the engine, testing alarms and conducting start-up and annual tests. The new platforms also include event data recording and electronic circuitry protection technology.

In addition, Clarke’s NSR heat exchangers were engineered to enhance cooling performance, provide options for aggressive sea water and to give service providers the ability to remove and clean the heat exchangers’ cooling components as needed for long term maintenance.

Why choose a diesel fire pump engine?

Diesel fire pump engines provide the best value when considering installation costs and minimising potential losses when compared to electric motors. A major advantage of this type of driver is its reliability as it can operate independently from the electric grid.

How do fire pump engines work?

When exposed to heat in a fire, fire sprinkler heads activate and release pressurised water from sprinkler piping. Sensors detect the pressure drop, which sends a signal to the fire pump controller, which then automatically starts the engine and provides power to the pump to increase water flow and pressure to the sprinkler lines.

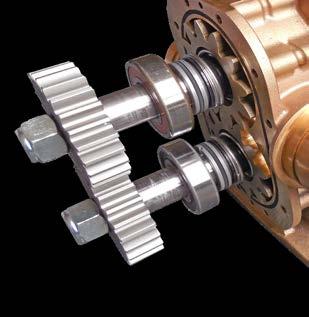

Why should I buy Clarke Genuine Parts instead of third-party components?

Only Clarke Genuine Parts are manufactured to the precise specifications of Clarke diesel engines. Third-party components may compromise performance, void warranties or even put lives at risk due to incompatibility or failure under fire system conditions.

Clarke’s new Touch Screen Engine Instrument Panels (TSP) include intuitive touch screen commands

Clarke’s NSR heat exchangers were engineered to enhance cooling performance

“Clarke is a quality product, obviously... It’s synonymous when you talk about diesel engines... most cases, they’re going to say Clarke. Most of the competitors are obviously chastened for good reason. It’s not just that, they’ve been ahead of the game the whole time. They also have been leaders in the market and innovation, and in what they’re doing”

Jason Halle, Regional Sales Manager, Peerless Pump Company

When you buy Clarke, you are buying ‘Sleep Insurance’ investing in a Clarke Diesel Fire Pump Engine provides peace of mind, knowing your project is protected by a supplier partner who has demonstrated longevity in the fire protection market and has shown the ability to adapt to changing market conditions, while still providing a competitively priced product that meets the performance requirements of the fire pump and site conditions.

Remember that the engine you choose is an investment in the reputation of your business which should never be tainted by a poorly performing product or supplied by an alternative supplier with unproven technology. Clarke provides reassurance that when parts or service are required, Clarke has service dealers and technicians to quickly resolve the issue. Clarke makes you part of a family of fire protection professionals who know how important it is to use only the most reliable components in protecting lives and property. Over the expected 20-25year operational life of a fire pump, Clarke engines prove to be the total lowest cost investment for end users based on their longevity and easy serviceability. This means you can sleep soundly knowing Clarke was the right choice.

Trusted solutions require trusted partners. Just as its customers trust Clarke to provide a fire pump engine for their specific installation and application, Clarke trusts the original equipment manufacturers (OEM) to provide a robustly designed, well-built product. Clarke’s relationship with

world-class OEMs illustrates its commitment to achieving excellence through every engine sold and installed. John Deere, Caterpillar and HD Hyundai Infracore embody the same world class manufacturing principles of using technology, lean methodologies, continuous improvement and problem solving that Clarke has relied on for over 60 years.

Clarke continues to invest significantly in R&D to develop new engine platforms that will benefit customers operating in the commercial, industrial and energy market sectors. It is also close to completing several projects in the coming months and promises to share more details about these exciting developments with customers towards the end of 2025.

Listed Models GP30, GP60, GP120, GP160, GP200, GP500

Unlisted Models GP300 & GP350

Self-priming, handles viscosities up to 5,300 cPs (including fluorine-free foam). Versatile for electric, PTO, engine, water or hydraulic drives. TungstenCarbide mechanical seals support 10BAR when flushing. Wetted components can run dry indefinitely.

significant modifications. Allow us to guarantee long-lasting performance and reliable product support. Available in seven models ranging from 110 LPM to 1900 LPM.

from the date of shipment. For more details, contact Trident.

Eiad Shami, Principle Fire and Life Safety Consultant, WSP

Middle East, considers the remediation of existing car parks to accommodate electric vehicles

The global shift toward electric mobility is no longer a speculative forecast, it is a present-day transformation. With governments pushing for decarbonisation, manufacturers phasing out internal combustion engine (ICE) vehicles and green infrastructure policies advancing, electric vehicles (EVs) are now becoming the dominant occupants of parking facilities in cities worldwide. This transition, however, introduces a profound fire and life safety challenge: existing car parks were never designed for the unique risks posed by EVs.

Recent fire events involving electric vehicles and battery energy storage systems (BESS) have underscored the severity of thermal runaway, smoke toxicity, re-ignition and suppression limitations in real-world settings. From EV fires in underground parking structures to charging station malfunctions in residential towers, each incident contributes to a growing consensus among fire professionals.

Legacy car parks require urgent remediation to remain safe now they face a new hazard profile, compliant and operationally resilient.

The EV fire risk landscape

Lithium-ion batteries under abuse conditions can enter thermal runaway, releasing flammable electrolytes, generating extreme heat, and creating self-sustaining fires. A single cell failure can cascade through an entire pack, exceeding 1,100°C, and producing toxic gases. Unlike ICE fires, which are localised, EV fires engulf the whole vehicle and produce dense, toxic smoke.

The invisible onset of EV fires and latent re-ignition risk after suppression are particularly dangerous in underground or poorly ventilated structures, where escape routes can be compromised quickly.

car park limitations

Most car parks built before 2020 were not intended to host EVs or charging infrastructure. Key limitations include: Lack of fire-rated separation between charging areas and building cores.

Outdated detection systems relying solely on smoke detection.

Low-capacity sprinkler or standpipe systems with no consideration of lithium-ion suppression needs.

Characteristic ICE Vehicle EV Vehicle

Ignition Source Fuel system, engine Battery thermal runaway

Smoke Toxicity CO, hydrocarbons HF, CO, VOCs, soot

Fire Duration Typically localised, shorter Long, may reignite

Detection Visibility

Audible and visible earlySilent onset possible

Suppression Effective with sprinklers Requires prolonged cooling, large water volumes

Peak Heat Release Rate

Fire Growth Rate

Moderate and gradual (~ 2 – 4 MW)

Slower growth allows more occupant reaction and firefighter intervention time

Limited ventilation rates that are designed to address CO2 control, especially in basement levels.

No integrated gas detection or toxic fume extraction.

No zoning control, allowing mixed use of ICE and EVs side-by-side.

Moreover, emergency procedures and maintenance remain optimised for ICE risks and are ill-equipped for EV hazards, even as operators promote EVs by allocating prime parking near asset entrances.

Real-world incidents highlight the risk

Several recent global fire events offer critical lessons:

Stuttgart, Germany (2022): An EV caught fire in an underground car park, filling multiple basement levels with smoke. Suppression took hours, and re-ignition occurred during vehicle extraction.

Shanghai, China (2021): A charging station malfunction caused a battery fire in a commercial building’s car park, leading to partial structural collapse.

Arizona, USA (2019): A lithium-ion battery system exploded during suppression operations, severely injuring four firefighters. While not a vehicle fire, the battery dynamics mirrored EV hazards.

High and rapid (~5–7 MW); escalates quickly after runaway

Rapid fire growth leaves less time before untenable conditions and peak HRR are reached

These events reinforce the importance of both physical system upgrades and emergency planning modifications tailored to EVs.

Most car park fire design assumptions stem from 1970s–80s ICE vehicles with lower plastics and fuel loads. Modern cars, with higher polymer content, drive faster fire growth, higher heat release and more smoke, even before EV hazards are considered. Events like the Liverpool Arena fire (2017) and Luton Airport collapse (2023) show current design parameters are already outdated.

for fire and life safety remediation

To transition existing car parks into future-ready infrastructure, remediation strategies should be both holistic and phased, accounting for fire science, code compliance and operational resilience.

Zoning and fire compartmentation

Designate dedicated EV charging zones, located near exits and away from vertical shafts, mechanical rooms, or building cores.

Install fire-rated barriers or enclosures around charging areas, especially when installed in enclosed or basement zones.

Use thermal separation and spacing between chargers and vehicle bays to limit lateral fire spread.

Apply post-installed fire barriers where feasible, such as suspended fire-rated ceilings or concrete block enclosures.

Detection and early warning systems

Given the silent onset of thermal runaway, enhanced detection is vital. Detection systems should be selected based on location type, ventilation conditions and fire risk profile.

Recommended (baseline for EV zones): Multi-criteria detectors (smoke + heat) Especially in areas where ventilation may delay traditional smoke detection.

Offers better immunity to nuisance alarms compared to single technology detectors.

Air sampling detection systems (e.g., VESDA)

Useful in enclosed or poorly ventilated underground levels, where early smoke particles may accumulate before a fire is visible. Recommended if ceiling heights and obstructions reduce effectiveness of point detectors.

Optional (project-specific enhancements):

Thermal imaging cameras or infrared sensors

Only in high-density EV charging clusters or where EV turnover is high (e.g., public or fast-charging facilities).

Supports continuous temperature monitoring of battery packs; not usually needed in low-volume private car parks.

Hydrogen fluoride (HF) or CO detectors

Recommended in underground or semi-enclosed car parks where smoke control is limited and vented battery gases may accumulate. Should be integrated with mechanical ventilation control.

While HF and CO gas detectors are increasingly used in battery energy storage systems (BESS) to identify early stages of thermal runaway, this approach has not yet been widely adapted to car park environments despite their clear relevance.

Suppression systems

While sprinklers contain vehicle fires, they fall short for lithium-ion events. EV zones should use higher-density heads, supplemented by water mist or fog systems, remote charging shutoffs and drainage with oil-water separators. Alternatives like foams or inert gases may help but require compatibility checks.

“EV fires tend to involve the full vehicle body and generate a dense smoke plume with low visibility and high toxicity”

Smoke control and ventilation

Because smoke inhalation causes most fire fatalities, EV car parks should provide 10–12 ACH ventilation, detection-linked extraction fans, HF/CO/VOC monitoring, pressurised egress routes and backup power for life safety systems.

Passive protection: structural and compartmentation elements

Concrete car parks resist fire, but EV heat can still cause spalling and steel deformation. Protection should include coatings on structural elements, retrofitted barriers, sealed voids and regular inspection of passive systems.

safety measures and emergency planning

Operational readiness is as vital as infrastructure. EV charging should be limited to supervised hours, with inspections, thermography and fire drills built into routine practice. Coordination with civil defence, digital sharing of layouts and team training on suppression, battery risks and evacuation complete the framework.

Codes, standards and the future of regulation

Remediation should align with current and emerging codes, including but not limited to:

Saudi Building Code (SBC 201) and Saudi Fire Code (SBC 801)

NFPA 88A – Parking Structures

NFPA 855 – Energy Storage Systems

UL 9540A – Battery Fire Testing Methodology

IEC 61851 / NEC 625 – EV Charging Installations

SFPE Fire Risk Index Tools for LithiumIon Batteries

As regulations evolve, it is anticipated that EV-specific clauses will become codified in national standards; remediation should be designed with forward compliance in mind.

From legacy to future-ready

The rise of EVs is inevitable, but the preparedness of our infrastructure is not. Car parks once considered low risk, now face an emerging class of hazards that demand proactive remediation. Integrating fire engineering design, system upgrades and operational excellence is no longer optional, it is critical for life safety, property protection and business continuity.

By adopting a future-ready approach, asset owners and designers can not only safeguard their facilities but contribute to a safer, smarter and more resilient urban environment. The investment in safety today is a safeguard for tomorrow’s mobility.

wsp.com

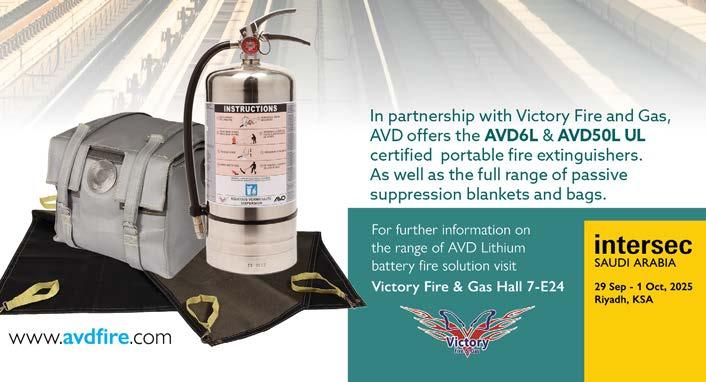

AVD Fire is making a call for collaboration, with its lithium-ion battery fire solutions ready to advance Saudi Arabia’s public sector protection

Saudi Arabia’s Vision 2030 is driving rapid transformation across smart cities, transport, renewable energy and digital infrastructure. Central to this shift is the widespread use of lithium-ion batteries — powering everything from electric vehicles (EVs) and metro systems to energy storage, defence equipment and data centres.

But with this innovation comes risk. Lithium-ion battery fires are fast, volatile and extremely difficult to control using traditional extinguishers. For public sector organisations across the Kingdom, a new class of suppression technology is essential.

AVD Fire, a UK-based leader in lithiumion fire safety, is bringing its proven solutions to Saudi Arabia. The company’s specialist Lithium-Ion Fire Extinguishers and Fire Blankets are engineered to suppress and contain these unique fire risks, protecting people, assets and infrastructure.

Lithium-ion batteries can enter thermal runaway when damaged or overheated, releasing toxic gases, re-igniting repeatedly, and in some cases exploding. The consequences for public safety are severe — from EV fires in car parks and depots to energy storage failures in public buildings.

Traditional water, powder or foam extinguishers are ineffective and may worsen the danger. AVD Fire’s solutions are based on Aqueous Vermiculite Dispersion (AVD), a patented agent that rapidly cools and smothers fires while forming a protective, non-conductive barrier to prevent re-ignition.

Proven in the Middle East

AVD Fire’s products are already operational across the region:

Qatari Civil Defence Approval –

Official certification for use of AVD Fire’s lithium battery fire extinguishers.

Dubai Metro Network – AVD fire blankets installed across the entire metro system, covering all platforms and carriages.

These achievements demonstrate the trust placed in AVD Fire by regional authorities and underline the technology’s scalability in public sector projects.

Product range for Saudi Arabia

AVD Fire now offers its complete range to organisations in the Kingdom:

Lithium-Ion Fire Extinguishers –Portable units (2L, 6L, 9L,) and mobile trolley versions (25L & 50L) for airports, industrial plants, transport depots, and military facilities.

Fire Blankets – Containment for all Electric Vehicles, and high batterypowered equipment. Essential for car parks, metro stations and emergency response.

Applications

Transport & EV Infrastructure –Protecting government fleets, charging stations, metro systems and depots. Airports, Defence, Critical Infrastructure and Emergency Services

– Equipping brigades with lithium battery fire extinguishers and EV fire blankets to handle newgeneration risks.

Smart Cities and Renewable Energy – Fire safety for solar farms, battery energy storage and connected infrastructure.

Education and Research – Protecting universities and laboratories working with advanced energy storage.

Partnership opportunities

While AVD Fire has established success in Qatar and the UAE, the company

does not yet have a business partner in Saudi Arabia. We are actively seeking new partnerships with distributors, government suppliers and organisations specialising in civil defence, transport and critical infrastructure safety.

This is a unique opportunity to bring world-leading lithium-ion battery fire suppression into the Kingdom at a crucial stage of national development. All AVD Fire products are performance-tested, and supported by full training and technical documentation.

Contact us

To explore how AVD Fire’s Lithium-Ion Fire Extinguishers, lithium battery fire extinguishers and fire blanket solutions can support your department’s fire safety strategy — or to discuss partnership opportunities in the Kingdom — please visit: www.avdfire.com

AVD Fire will be at 29 September –1 October 2025 at the Riyadh International Convention & Exhibition Centre (RICEC)

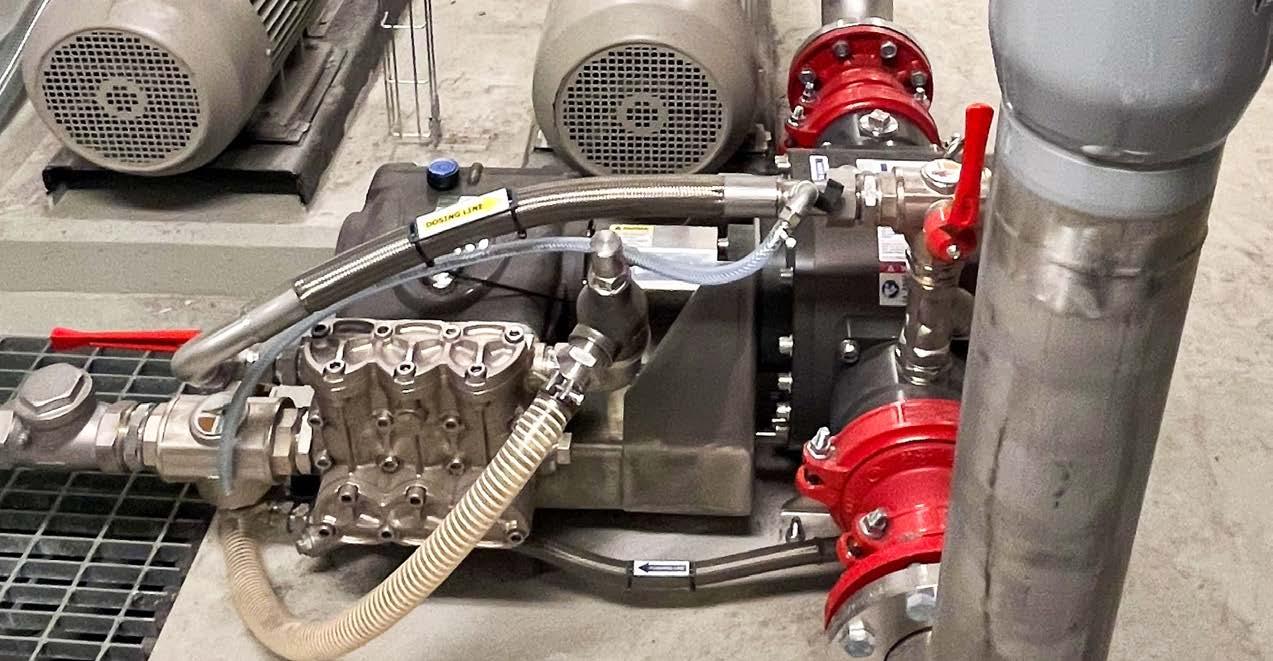

GEN III is the next evolution level of hydraulic foam proportioners for firefighting from FireDos. Sturdier, smaller, safer, and more functional: GEN III features a lot of improvements which make operation even more e cient and comfortable. The proportioner consists of a water motor and piston pump and handles all types of foam agents, even extremely high-viscous, alcohol-resistant and fluorine-free ones. Furthermore, GEN III is a purely mechanic system and allows testing the proportioning rate in a cost-saving and eco-friendly way, producing no foam at all.

Purely mechanical and highly reliable

Constant proportioning rate over a wide flow range

Cost-saving and eco-friendly

GEN III foam proportioners allow testing the proportioning rate without producing foam or premix.

Jason Voerman, Regional Sales Manager – MEA, Firedos, looks at why smart pressure regulation is the backbone of foam fire suppression systems

In high-hazard environments such as refineries, chemical processing plants, aircraft hangars and tank farms, foam fire suppression systems are a first line of defence against flammable liquid fires. But while the foam itself often takes centre stage, what’s less visible (but no less vital) is pressure regulation. Behind every effective knockdown is a finely tuned balance of pressure and proportioning.

Getting the balance wrong can mean the difference between a successful suppression effort and system failure. Let’s explore why pressure control is essential in fixed foam proportioning systems, the tools available to achieve it, and how smart system design ensures readiness when every second counts.

The hidden variable

Foam proportioning systems work by mixing a foam concentrate with water at a

precise ratio; typically, 1%, 3% or 6%, to produce a solution discharged through nozzles, monitors or other delivery devices. Achieving this ratio in the venturi type proportioners consistently depends on stable pressure across both the water and foam concentrate inlets. This is in contrast to variable viscosity water driven foam proportioners which are largely unaffected.

Venturi type proportioning systems are calibrated for specific flow rates and pressures. If those pressures fluctuate due to pump surges, elevation changes, valve restrictions or variable demand, the system may deliver a foam solution that’s too lean (ineffective) or too rich (potentially corrosive and wasteful). Either scenario can compromise firefighting performance.

Proper pressure control ensures the foam concentrate enters the mixing point at the correct pressure relative to water

flow, enabling consistent, reliable foam generation.

There are several methods used to manage and stabilise pressure in foam systems. The right choice depends on system complexity, operational demands and long-term maintainability.

PCVs are the most widely used solution for regulating foam concentrate pressure. These valves automatically adjust to maintain a steady outlet pressure. When system pressure exceeds the valve’s set point, the valve throttles to maintain balance.

PCVs are available in various configurations: spring-loaded, diaphragmoperated and pilot-operated, each suited to different flow profiles. For high-volume

“Getting the balance wrong can mean the difference between a successful suppression effort and system failure.”

systems, pilot-operated valves are often favoured due to their fast response and fine-tuned precision.

Relief valves don’t control pressure during normal operations, but they play a key safety role. If a pressure spike occurs due to thermal expansion, valve closure or pump surge, a relief valve opens to release excess pressure and protect the system.

These valves are usually installed downstream of the PCV and set to open slightly above their calibration point.

In smaller or more stable systems, passive control devices like orifice plates and balancing valves help restrict flow and maintain predictable pressure levels. These are cost-effective but lack real-time adjustability, making them best suited for systems with minimal pressure variation.

One of the most common design questions in foam systems is where to install the PCV: upstream or downstream of the proportioner. Both approaches are valid, and the decision depends on system layout and performance goals.

Most systems place the PCV upstream of the proportioner. This ensures that the foam concentrate enters at a controlled and stable pressure. When water supply pressure fluctuates, as it often does in hydrant-fed systems or systems with long piping runs, an upstream PCV helps maintain a consistent mixing ratio. It also protects the proportioner from pressure spikes, which can lead to premature wear or performance issues.

However, in systems where backpressure is high or variable, such as those with elevation changes or long discharge piping, it may be advantageous to install the PCV downstream. This configuration regulates outlet pressure, ensuring smooth flow through the proportioner. It’s also useful in gravity-

fed systems where the foam concentrate tank is positioned above the proportioner, helping to prevent siphoning and providing more precise flow control.

Each configuration comes with tradeoffs. Upstream placement offers better protection for the proportioner and is generally more forgiving under variable flow conditions. Downstream placement helps manage challenging hydraulics but allows pressure surges to reach the proportioner before being controlled. Designers should choose based on layout, flow dynamics and the specific demands of the facility.

System design best practices

To get the most from a pressure-regulated foam system, several best practices should be built into the design process:

1. Model the system early

Hydraulic modelling can help identify pressure drops, flow imbalances and elevation-related challenges before construction begins. This allows for smarter component selection and PCV placement.

2. Match valve type to application

Not all valves perform the same. Ensure the selected PCV suits the system’s flow rate, pressure range and foam concentrate type. Pilot-operated valves, for example, offer better performance in high-volume or variable-pressure environments.

3. Include gauges and monitoring points Gauges should be placed before and after key components like the PCV, proportioner and pump. In more advanced systems, pressure transmitters with remote monitoring can help detect early signs of imbalance or valve failure.

4. Design for maintenance and uptime

Bypass lines, typically fitted with manual or automatic isolation valves, are installed around PCVs to enhance system flexibility. Their key benefits include:

Commissioning and testing: During startup or maintenance, bypasses

allow flow testing or flushing without engaging the PCV.

Redundancy: If the PCV fails or becomes blocked, the bypass maintains flow continuity, albeit at unregulated pressure; a valuable failsafe in critical systems.

Maintenance: A bypass line around the PCV allows the valve to be inspected, tested or replaced without taking the system offline. This is especially important in facilities where uptime is critical.

5. Schedule regular testing and recalibration

Pressure settings may drift over time. Routine testing ensures the system remains within its design envelope and continues to deliver accurate proportioning.

Pressure isn’t

Effective foam fire suppression hinges on precise hydraulic performance, with pressure regulation serving as a critical control parameter. In systems utilising balanced pressure proportioning or variable flow-rate injection, maintaining stable inlet and discharge pressures is essential to ensure accurate foam concentrate mixing. Deviations in pressure can lead to under- or over-application, compromising extinguishment efficiency and potentially escalating fire hazards. In high-risk environments, pressure control is not merely a design consideration, it is a performance determinant. Ensuring pressure stability across all operating scenarios is fundamental to delivering reliable, repeatable fire suppression outcomes. By prioritising pressure control during design, selecting the right valves and placement strategy, and committing to ongoing system validation, engineers can safeguard lives, assets and operations. In facilities where downtime isn’t an option, precision isn’t a luxury; it’s nonnegotiable. firedos.com

With

Faris Alzahrani, OHS and fire safety practitioner investigates large language models (LLMs) in Fire

Engineering and explores how they can aid fire safety experts without compromising safety

Large Language Models (LLMs), like ChatGPT, Claude and Deepseek, offer a significant shift for fire safety. Although they bring transformative opportunities, they also introduce profound risks. The challenge is to adopt LLMs without affecting core values, such as preserving lives and assets. Remember, our profession is built on values, codes, empirical evidence and accountability.

The impact brought by LLMs will surely be felt in fire safety. This is a result of LLM’s advanced language and pattern processing. They’re crucial in:

1. Information Retrieval – LLMs can be used to quickly recall information or generate summaries at a superordinate level, saving time that would otherwise be spent on manual searching.

2. Communication – LLMs can free engineers’ time from drafting texts and formal reporting for client communications.

3. Ideation – It serves as a brainstormer, generating lists of possibilities (e.g.,

common sources of false alarms) for deeper human investigation.

The LLM’s fundamental operations on probabilities, not truths, are the greatest danger. LLMs focus on predicting the next word in the sequence instead of the next accurate technical fact. This creates critical risks such as:

Hallucinations – The models can generate sections of technical documents that are fabricated, yet appear convincing.

Outdated Knowledge – An LLM’s knowledge is stagnant after the model training data cutoff date, making it unaware of the latest updates.

Content Blindness – They cannot physically grasp the unvoiced boundaries of the projects or the intent behind a code clause.

The difference between being a helpful tool and a serious risk hinges on one fundamental skill: prompt engineering. The efficacy and safety of the results rely on the user’s ability to form professional prompts.

Scenario: An inspection of a dry valve sprinkler system reveals a missing clapper latch assembly.

Poor prompting: “What is wrong with a dry valve if the clapper’s latch is missing?”

The LLM’s misleading answer: “A missing clapper latch may result in reduced efficiency, but routine maintenance should resolve it.”

The risk: This answer is technically incomplete. It doesn’t explain why, and what authoritative references are needed to classify the deficiency. An inexperienced technician could document this as an “observation” without highlighting its implications.

The well-engineered prompt: “Act as a senior fire inspector examining systems in a warehouse that has 500 sprinklers installed. You note a missing clapper latch in a dry-valve, with a capacity of 1150 gpm. Classify the deficiency according to NFPA 25, 2017 edition, detailing

What is wrong with a dry valve if the clapper’s latch is missing?

What is the maximum travel distance to an exit in an office building?

1) Chapter/Section reference, 2) Deficiency classification, 3) Implication for system operability.”

The LLM’s answer (paraphrased): “According to NFPA 25 (2017 Edition), a missing clapper latch is a critical deficiency.

Reference: NFPA 25, Chapter 13, which governs dry pipe valves.

Classification: This is typically classified as a ‘Critical Deficiency’ as it prevents the valve from functioning as designed and renders the entire system inoperable. When the most remote hydraulically-calculated sprinkler activates, the water flow through the valve assembly is minimal. In the absence of a latch, the clapper may close. In such scenarios, a lot of force, between 3 to 5 times, is acting on the clapper’s upper side. Mostly, the clapper will not reopen until water is drained from the upper-side.

Required Action: The deficiency must be corrected immediately. The system should be tagged and considered impaired per NFPA 25 Chapter 16. Implication: The system may not control a fire.

The value: This precise prompt forces the LLM to formulate its response against an authoritative standard. It provides actionable information that is professional and code-compliant.

Case example 2: calculating travel distances

Scenario: You are performing a life safety analysis of a business occupancy.

The weak prompt: “What is the maximum travel distance to an exit in an office building?”

The LLM’s inadequate answer: “The maximum travel distance in a sprinklered office is typically 300 feet, as per NFPA 101.”

The risk: This is a risky and oversimplified assessment. An untrained person could just take the 300 ft. and measure a direct line on a drawing without considering the obstacles that an occupant may encounter, leading to unsafe designs.

The professionally engineered prompt: “Define travel distance per NFPA 101 Life Safety Code, 2018 edition, for a sprinklered business occupancy. Express how it is measured in a realworld environment with obstructions like furniture and partitions.”

The LLM’s accurate answer (paraphrased): “Per NFPA 101 (2018 Edition), 7.6.1, travel distance is defined as the actual path the occupant would take to the nearest exit from any point within a building.

Measurement: It must be measured along the natural and unobstructed walking path and include all fixed obstructions, furniture, etc.

Maximum Limit: For a sprinklered business occupancy, the maximum travel distance is 300 ft (Chapter 38.2.6.3); however, the distance must be measured based on the path taken, not a straight-line distance.”

The value: This specifically prompts the model to outline the most ambiguous concept regarding egressing and be anchored to the code’s intended application.

The deployment of LLMs brings ethical and legal issues for which the engineer is legally liable and responsible, such as:

Accountability – The engineer who seals a design is fully accountable. Liability cannot be transferred for an LLM. Insurance will not cover errors caused by an AI that the engineer didn’t catch.

Standard of Care – A court in a negligence claim will evaluate the Engineer’s standard of care if exercised or not. Those who blindly rely entirely on an LLM would fail the test unquestionably.

IP and Privacy – If confidential information or copyrighted documents are shared on a public LLM, it creates a significant privacy and intellectual property risk. No one has complete control over how that data is used, stored or possibly leaked.

The engineers are the conductor LLMs will undoubtedly be integrated into fire safety workflows. Despite being amplifiers of human judgment, they are not substitutes for it. Think of an LLM in its current state as a junior engineer: bright, fast and knowledgeable but in need of continuous oversight. That is, a managed tool. The best approach is to combine engineering with advanced prompt design while training LLMs to boost efficiency and output quality.

Systematic testing and verification must be applied to all generated content through primary driving documents such as codes, standards, and datasheets. The engineer must be the conductor, able to assess the tool’s capabilities, interpret results in light of professional benchmarks, and process each output in line with the profession’s requirements. Such tools can be used for drafting, summarising and assumption testing. They must never be trusted to conclude, certify, or make code-informed judgments that form the core of the business. Remember, people’s lives and properties are dependent on you!

WELCOME TO VISIT US AT INTERSEC SAUDI ARABIA IN BOOTH 5-C36, together with FFS and ESS.

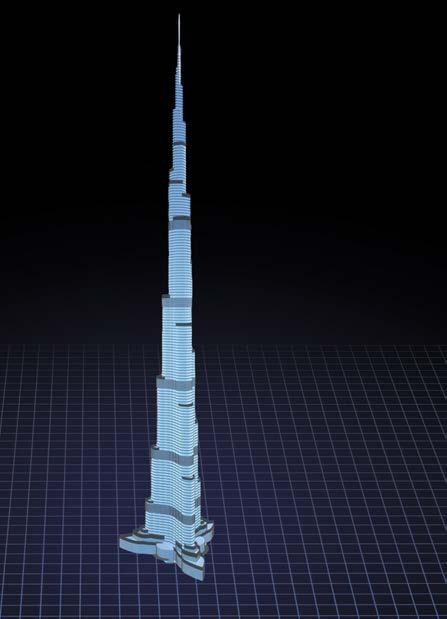

Anthony D. Parfitt, Chairman, founder and inventor of Ci Global, looks at how intelligent building infrastructure is transforming fire response, and envisages a future where prevention leads

Our approach to fire safety is still stuck in the past. Buildings are fitted with the same old technologies that activate in response to a fire that has already started, rather than preventing a fire before it even has the chance to start.

As a result, when a building fire breaks out, incident commanders can be forced to make critical decisions with partial, outdated, or no information at all. Many firefighters are operating in the literal and metaphorical dark.

Tragically, around 13,500 people still lose their lives in building fires worldwide each year, according to the latest Centre of Fire Statistics research.

This is hard to believe against a technological backdrop where we’ve put robots on Mars, built 3D printers that can produce customised meals, and engineered medicines that target cancer cells with surgical precision – to name just a few.

But times may finally be changing. Across the Gulf region and beyond, we are starting to see a quiet shift towards connected building safety systems that use live incident data to give emergency services real-time visibility.

The Middle East is uniquely positioned to lead this change. Governments here are already committed to next-generation infrastructure, from Dubai’s goal to be the world’s safest and smartest city, to Saudi Arabia’s Vision 2030.

With rapid urbanisation, high-rise development and growing pressure on firefighting resources, the need for safety infrastructure enabled by AI and IA is no longer optional. It’s urgent and vital.

The future of fire safety will be based on not just new technology, but also a new mindset.

Where the old approach waited for a fire to start, modern intelligent infrastructure works continuously to prevent ignition and prepare for a more rapid, targeted response.

Embedded sensors are at the heart of this transformation. Unlike conventional smoke and heat detectors that simply sound alarms, these sensors are embedded into a building’s electrical systems and connected safety devices. This means they can detect and prevent fire risks and other dangers early before they escalate.

Ideally these operate on edge computing, allowing them to process data locally and act in milliseconds using intelligent autonomy IA. This doesn’t have to wait for instructions from the cloud to instantly shut off power to a faulty circuit or close a gas or water valve to stop a leak.

Take the case of an overloaded electrical socket. Heat builds, melting

insulation and exposing live wires to carpets, curtains, or other flammable materials, potentially sparking a fire. With embedded thermal sensing, this never happens. The moment the temperature crosses a pre-set safety threshold; power is instantly cut. This removes the supply of electrical ‘fuel’ before a fire even has a chance to start.

Even the most advanced prevention systems can’t eliminate every fire risk. Human behaviour is unpredictable – candles can fall, cooking oils can overheat, and accidents can and do happen. As a result, next-generation safety strategies will need to combine prevention with technologies designed to limit and contain harm when incidents do inevitably occur.

One of the most valuable emerging tools is Unmanned Aerial Vehicle (UAV) technology – drones – which provide instant situational awareness during a fire. Across the Middle East, fire services are already putting them to work. Abu Dhabi Civil Defence recently unveiled Suhail, the world’s first jet-powered firefighting drone, while Saudi Arabian authorities deployed an AI-powered UAV for the first time during this year’s Hajj annual pilgrimage to support firefighting and rescue operations.

Drones can give incident commanders a real-time aerial view, with thermal imaging to locate occupants and identify safe exit routes before crews enter. Many also carry microphones and loudspeakers, enabling rescuers to issue clear instructions – and reassurance – to people trapped inside.

In a fire, every second counts, and smoke robs people of both time and

clarity. As visibility drops, confusion sets in. Obstacles become harder to avoid. Disorientation increases the risk of injury or worse.

Laser-guided navigation systems address this long-standing challenge for fire crews and rescue teams by projecting guidance paths that remain visible even through heavy smoke. Instead of relying on instinct, occupants and firefighters can follow colour-coded laser patterns on floors and walls to reach safety — with green indicating a clear route and red marking fire or danger.

When integrated with a smart building management system, the technology can adjust escape routes dynamically, using real-time hazard data to guide people away from danger. This is what firefighting should look like in the 21st century. No more blind spots or guessing.

Behind these advances lies a powerful enabler: live 3D building maps that act as digital twins of real structures. Far from static blueprints, they are dynamic, data-rich, live models that use real-time sensor readings, occupant locations and environmental conditions throughout a building.

Some systems go further, delivering these maps through AR headsets so incident commanders can move through and see inside a building remotely, as if they were physically present.

Until recently, creating a 3D map was slow and expensive. But AI has changed all that. Modern systems can now generate maps from standard floor plans in minutes and populate them with live data streams from building sensors, security systems and mobile devices.

The result is a continuously updating and fully comprehensive operational picture that gives commanders the insight

to direct teams and deploy resources where it will have the greatest impact. Put simply: get people safely in and safely out in the shortest time with the lowest risk.

Advances in AI and intelligent autonomy are driving a fundamental shift – from reactive firefighting to proactive prevention and intelligent emergency response.

By embedding sensors throughout buildings, creating real-time 3D situational awareness, deploying drones and guiding people through smoke-filled environments with lasers, the industry is moving beyond the limits of traditional fire safety approaches.

For the Middle East, this is more than an upgrade; it is an opportunity to pioneer and lead, setting the global standard for next generation building fire and safety infrastructure. One that other countries will want to follow once they see the results.

With the right investment and commitment, Gulf cities could become global models for how smart buildings protect lives and property in an increasingly urban and densely populated, high-rise world.

The question is no longer whether the technology exists or works – but how quickly it can be deployed at scale.

ci.global

As the climate changes, the demand for firefighting solutions that offer flexibility, advanced features, and long-term reliability has increased.

Designed and developed side-by-side with firefighters, the M1 SCBA supports this evolution with a modular design that addresses the multifaceted needs of modern first responder operations.

Key features include:

Easy, Comfortable & Lightweight

Enhanced Cleaning & Maintenance

Modularity for the Future

Connectivity & Smarter Data

Learn more about the future of breathing protection here:

Real-time, Lifesaving Monitoring

Cross-sector collaboration is the non-negotiable foundation of a safer future, says Zahi Daher, International Business Development Manager, KSA, National Fire Protection Association® (NFPA®)

Saudi Arabia stands at the forefront of a historic transformation. Vision 2030 has propelled the Kingdom into one of the world’s most ambitious development journeys, with giga-projects like NEOM,

Qiddiya and The Red Sea reshaping the nation’s urban and economic landscape. Yet, as we race to build futuristic cities and world-class infrastructure, one truth must remain non-negotiable – safety is

the foundation of progress. Too often, fire and life safety are viewed as a technical requirement, it is important, yes, but secondary to the greater goals of scale, speed and

innovation. This mindset is not only shortsighted but also dangerous. A single lapse in safety can undo decades of progress, damage reputations, and, most critically, cost lives. If Saudi Arabia or any other country in the region is to build cities that endure for generations, fire safety must be embedded not as a box-ticking exercise, but as a core pillar of nation-building.

The power of an ecosystem approach

What does it take to safeguard communities on such a grand scale?

The answer is not a single authority or a singular regulation, but a comprehensive system that connects them all. Fire safety is the outcome of an intricate and interdependent ecosystem; a framework built on critical elements that must be in perfect alignment.

The core of any effective fire safety strategy is its foundation, a robust system of codes and standards. These aren’t simply regulations, but the distillation of generations of expertise and scientific knowledge from fire protection engineers and safety professionals. By incorporating the latest codes and standards into its 2025 Saudi Building Code (SBC), Saudi Arabia is ensuring that local realities are matched with the standards of safety, allowing for innovation while grounding development in a framework of integrity and resilience.

This foundation is nothing without a robust governance and enforcement framework. The most comprehensive guidelines are meaningless without consistent and authoritative oversight. It is this system of governance, from fire authorities and civil defences to regulators and building inspectors, that holds the entire network accountable. It ensures that regulations are applied rigorously throughout every stage of a project, from initial design to final operation.

The human capital of the ecosystem is equally vital. The effectiveness of any code is dependent on the professionals who interpret, apply and enforce it. The rapid pace of Saudi Arabia’s development demands a new generation of safety professionals equipped with more than just theoretical knowledge. They need continuous, specialised education and training to translate complex codes into practical application in the real-world environments of giga-projects.

Finally, we have technology as a powerful enabler. While Saudi Arabia’s vision to lead in advanced technologies is a perfect fit for modern fire safety –with smart detection, AI analytics and blockchain tools offering unprecedented speed and accountability – it is a fundamental mistake to confuse these innovations for a complete strategy.

Without being anchored in a wider ecosystem of robust standards, trained professionals and strong governance, technology becomes a facade. It creates a false sense of security, hiding dangerous vulnerabilities.

True fire safety is only achieved when every piece of the system, including standards, governance, people and technology work together in harmony. When these elements are aligned, they create a self-reinforcing cycle of safety and resilience. The breakdown of even a single component – a lapse in training, a gap in governance or an unaddressed technological vulnerability – can compromise the entire system, often with devastating consequences.

Saudi Arabia’s Vision 2030 is not just about building cities, it is about building sustainable, safe and thriving communities. Fire safety is central to that aspiration. No single authority, developer or technology provider can shoulder this responsibility alone. Longterm partnerships between the public and private sectors, as well as with international safety organisations, are essential for sustaining progress beyond the construction phase.

Encouragingly, such efforts are already well underway. Government agencies and regulators are partnering with global safety leaders to tailor international standards to the local context, equip professionals with the right training and adopt the latest safety innovations. These initiatives are not isolated projects, but they are part of a broader, integrated framework designed to connect all critical elements to create safer communities.

For instance, the NFPA Fire & Life Safety Ecosystem™ provides an integrated framework, connecting codes, standards, education, advocacy and technology to minimise risk and prevent loss from fire and other hazards. This model consists of eight interconnected components that must all function together to protect people and property.

By working together and applying tools like the Fire & Life Safety Ecosystem, we can ensure that we build not just landmarks, but sustainable communities, with safety and resilience at their heart. This is the enduring legacy of a vision built on a foundation of non-negotiable safety.

nfpa.org

12 – 14 January 2026

Dubai World Trade Centre

The world’s premier event for Security, Safety and Fire Protection.

50,000+

Visitors

1,300+

Exhibitors 61 Exhibiting Countries 140+ Visiting Countries

ENQUIRE TO EXHIBIT