Knowledge Series:

Molded Spherical Joints with Floating Metal Flanges

DISCLAIMER

While the FSA makes every reasonable attempt to ensure that the information contained in this document is accurate and curren t, the FSA, its officers, directors, volunteers, and authorized agents are not responsible for any errors or omissions contained therein nor are they responsible for any results obtained from the use of or reliance upon its content. All information is provided “AS IS,” with no guarantee of completeness, accuracy, timeliness or of the results obtained, and without warranty of any kind, express or impl ied. In no event shall FSA or its officers, directors, volunteers, or authorized agents be liable to you or anyone else for any decision made or action taken in reliance on the information contained herein or for any for any consequential, indirect, special, or similar damages, even if advised of the possibility of such damages. The information contained in this document is for informational purposes only and does not constitute professional advice. It also includes references to certain standards that may change over time and should be interpreted only in light of particular circumstances. It is your sole responsibility to confirm the current state of any referred to standards. FSA reserves the right to modify or update the document content and to modify this Disclaimer at any time, effective upon posting of an up dated version of this Disclaimer.

© (April, 2023), Fluid Sealing Association. All Rights Reserved.

Molded Spherical Joints with Floating Metal Flanges: Introduction

• Included in this section:

• What is a molded spherical expansion joint with floating flanges?

• Molded Spherical Expansion Joint Design Configurations

• Common Applications for Molded Spherical Expansion Joints

• Advantages of Molded Spherical Expansion Joints

• Common Available Elastomers

• Installation Considerations

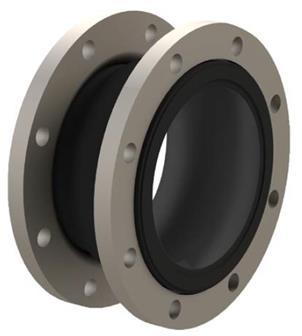

Molded Spherical Joints with Floating Metal Flanges

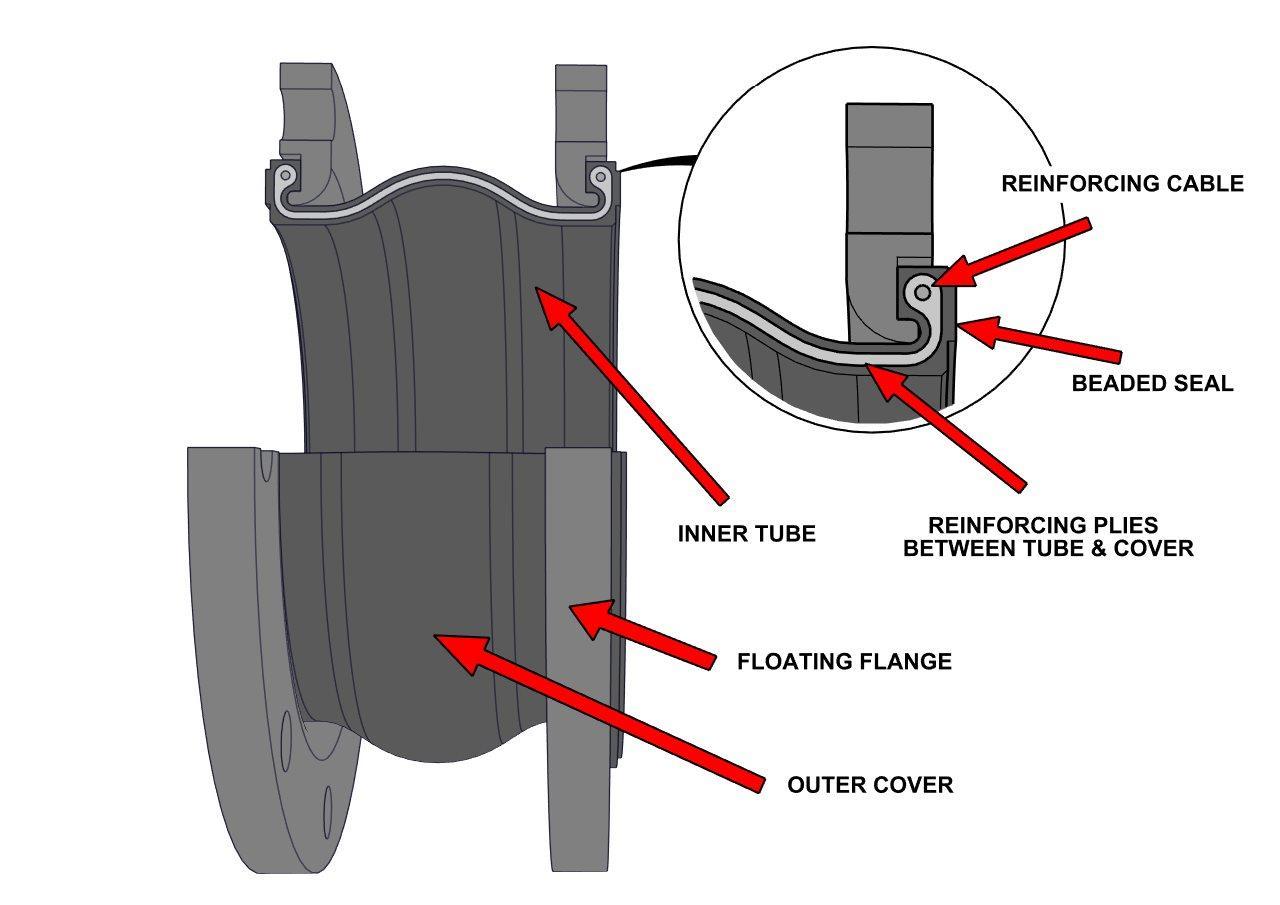

• What is a Molded Spherical Expansion Joint with Floating Metal Flanges?

• Molded spherical type expansion joints incorporate the movement and vibration dampening capability of spool type expansion joint joints into a compact and robust device.

• The distinguishing features of the molded spherical expansion joints joints are the shape of the body, floating flanges and the beaded seal.

• Design Notes:

• Spherical body shape

• Floating flanges

• Beaded seal with reinforcing cable

• Reinforcing plies

• Inner tube and outer cover can be different elastomers

Molded Spherical Joints with Floating Metal Flanges

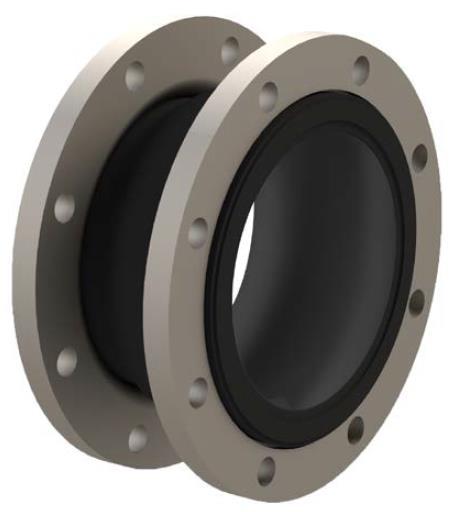

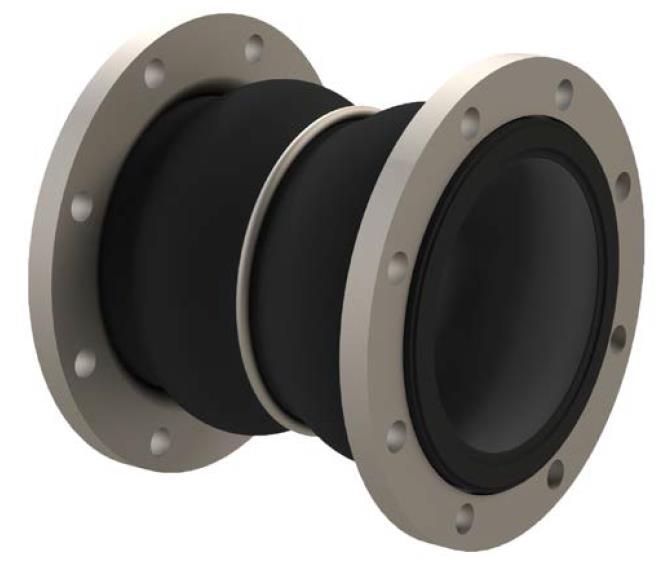

• Typical spherical type expansion joint configurations:

• Single Sphere

• Double Sphere, for applications requiring greater movement than a single sphere

• Double Sphere Union, for smaller-sized threaded pipe applications

Molded Spherical Joints with Floating Metal Flanges

• Common Applications of Molded Spherical Joints:

• Applications requiring vibration or sound dampening

• Commonly installed as pump and equipment connectors to acoustically isolate rotating equipment from system piping

• Corrosive media applications not appropriate for metallic expansion joints

Molded Spherical Joints with Floating Metal Flanges

• Advantaged of Molded Spherical Joints with Floating Metal Flanges:

• Spheres are a very strong yet flexible expansion joint. The shape is inherently stronger than a spool type expansion joint, and results in uniform pressure distribution throughout the wall.

• Spherical joints have a distinct advantage over metallic expansion joints for corrosive applications and installations requiring a high cycle life.

• The contour prevents sediment accumulation and creates less turbulence and pressure drop than spool joints.

• The seal bead eliminates any requirement for gaskets between mating flanges.

Molded Spherical Joints with Floating Metal Flanges

• Common available Elastomers:

• EPDM

• Neoprene

• Butyl

• Nitrile

Molded Spherical Joints with Floating Metal Flanges

• Installation Considerations

• Don’t use expansion joints to compensate for pipe misalignments

• Tighten bolts to proper torque according to the manufacturer’s specifications

• Always include control units

• Check temperature and pressure limits against operating conditions

• Check material compatibility with medium in the pipes and environment of installation

• Follow the instructions!

For additional technical information regarding Molded Spherical Expansion Joints with Floating Metal Flanges as well as other rubber expansion joint designs consult the Fluid Sealing Associations Technical Handbook for Expansion Joints Piping (https://www.fluidsealing.com/)