Knowledge Series: Designs for Reduction of Turbulence & Abrasion

DISCLAIMER

While the FSA makes every reasonable attempt to ensure that the information contained in this document is accurate and curren t, the FSA, its officers, directors, volunteers, and authorized agents are not responsible for any errors or omissions contained therein nor are they responsible for any results obtained from the use of or reliance upon its content. All information is provided “AS IS,” with no guarantee of completeness, accuracy, timeliness or of the results obtained, and without warranty of any kind, express or impl ied. In no event shall FSA or its officers, directors, volunteers, or authorized agents be liable to you or anyone else for any decision made or action taken in reliance on the information contained herein or for any for any consequential, indirect, special, or similar damages, even if advised of the possibility of such damages. The information contained in this document is for informational purposes only and does not constitute professional advice. It also includes references to certain standards that may change over time and should be interpreted only in light of particular circumstances. It is your sole responsibility to confirm the current state of any referred to standards. FSA reserves the right to modify or update the document content and to modify this Disclaimer at any time, effective upon posting of an up dated version of this Disclaimer.

© (April, 2023), Fluid Sealing Association. All Rights Reserved.

Designs for Reduction of Turbulence & Abrasion

• The open-arch design of the Standard Spool Type Expansion Joint may be modified to reduce possible turbulence and to prevent the collection of solid materials that may settle from the solution handled and remain in the archway.

• Included in this section:

• Filled Arch Type

• “Top Hat” Liner

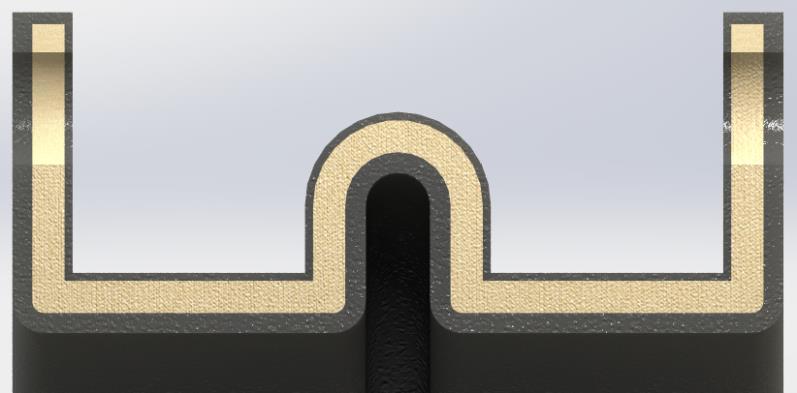

Filled Arch Type

• Filled Arch Type Rubber Expansion joints:

• Provided with soft rubber arch bonded internally to the expansion joint

• Smooth bore reduces turbulence of media and prevents build up in comparison to the standard “open arch”

• Movements of filled arch expansion joints are 50% of the size equivalent “open arch” designs

• Spring rates of filled arch expansion joints are typically 4X that of an open arch expansion joint

• Open Arch vs. Filled Arch Movement & Spring Rate Comparison

Open Arch Expansion Joint

Filled Arch Expansion Joint

“Top Hat” Liner

• “Top Hat” Liner Type Rubber Expansion joints:

• Sleeve extending through the bore of the expansion joint

• Generally made from metal, hard rubber or fluoroplastic

• Ideal for applications with high flow rate and/or abrasive media

• Not recommended for use with high-viscosity media

Designs for Reduction of Turbulence & Abrasion

For additional technical information regarding rubber expansion joint and reduction of turbulence & abrasion as well as other rubber expansion joint designs consult the Fluid Sealing Associations

Technical Handbook for Expansion Joints Piping (https://www.fluidsealing.com/)