growsmart

Scion Nursery appeals to an inner nerd.

A glimpse into the future of forestry and plant propagation. Southern Cypresses. Automation does the heavy lifting, we review the journey with Patrick Milne.

Plant by plant, we’re growing a future for NZ.

We are on a mission to restore the planet’s life-giving vitality.

For the past 30 years we have developed and delivered outstanding services and expertise to our client partners including eco-sourcing, propagation, supply and implementation of plants at scale for re-vitalisation projects nationwide.

Kauri Park Group is New Zealand’s largest wholesale native and urban landscaping plant nursery. From humble beginnings our growth has been borne from our mission to rejuvenate and regenerate New Zealand’s landscapes into thriving ecosystems. As we’ve grown over the last 30 years we’ve expanded into eco-sourcing, propagating, growing, supplying, planting and maintenance of nationwide regeneration projects at scale, all the while staying true to our mission and commitment to New Zealand and our growing partners. We do this by delivering an outstanding customer experience, consistent quality and adapting to our partners’ needs. Your growth is ours.

30 years in business run by 3 generations of ecovitalists.

100,000,000 plants grown by Kauri Park, and on our way to 200,000,000!

250+ species of plants that we grow Let’s grow. Together. Call 0800

50 ha of nurseries growing plants and photosynthesising

growsmart

Grow Smart Publication Team

Karina Williams

Molly Lewis

Contact

PrimeHort Distributors

2168 State Highway 1 Kaiwaka

Email: sales@primehort.co.nz

Phone: 0800 12 77 46

Editor

Kirsty Millar

Design Philippa White

Photography

Tegan Hoyle

The information contained in this publication is given in good faith and has been derived from sources perceived to be reliable and accurate. Whilst every effort is made to ensure the accuracy and correctness of the information, PrimeHort gives no warranties, express or implied, regarding the information nor does it accept any liability for any opinion or information (including the accuracy or completeness thereof) or for any consequences flowing from its use. The information and views expressed in this publication are not necessarily the views or opinion of PrimeHort’s, its editorial contributors, freelancers, associates or information providers. Independent advice is recommended before acting on information or suggestions contained herein. Readers who rely on this information do so at their own risk. Reference to any specific commercial product, process, or service whether by trade name, trademark, manufacture, or otherwise does not constitute an endorsement or recommendation by PrimeHort.

No part of this publication may be reproduced in any form without the prior written permission of the publisher.

GROWING SMARTER

Welcome to Grow Smart

brought to you by the team at Primehort.

Grow Smart has landed! We couldn’t have done it without our contributors, advertisers, or you – our valued readers. There were plenty of learnings as we turned our hand to publishing, and we thank the wonderful horticultural professionals who were interviewed in our launch issue. Sharing knowledge and honesty about industry challenges is how this publication will be a success.

“In this second issue, we drill down on the protected cropping industry and champion stories from growers who are achieving excellent outcomes from greenhouse technologies and a can-do attitude.”

Smarter efficiencies and sustainability are critical in the horticultural industry and that’s our theme for this magazine. Every article will explore ways to Grow Smart… maximise crop yields and streamline productivity.

Today’s nursery owner is evaluating a competitive world of nursery automation and greenhouse technologies to drive success. PrimeHort is dedicated to finding the stories that match your curiosity and help you weigh up the options available.

Grow Smart aims to be a trusted resource for the horticultural community. As a foot soldier in this dynamic environment, our best direction comes from you - so please let us know how we’re doing! Enjoy.

Sincerely,

Ernie Wearmouth GENERAL MANAGER | PRIMEHORT

Inside issue two

PrimeHort General Manager Ernie Wearmouth shares how this issue champions the stories from growers who are achieving excellent outcomes.

Owner Patrick Milne describes his strategic journey into mechanisation over the past 12 years.

We step inside Scion Nursery, offering a glimpse into the future of forestry and plant propagation.

Check out the latest PrimeHort products designed to boost productivity and crop yields.

DaRos Outdoor Irrigation Booms.

Biodegradable Coco Fibre Matting is pulling its weight to protect the landscape of this iconic location.

We profile PrimeHort’s Growing Media expert and take a closer look at Coir (coco peat).

DaRos Irrigation Booms double LeaderBrand’s capacity for a sustainable future.

Check out how PrimeHort delivers a smooth commercial greenhouse project for its customers.

Automation does the heavy lifting for Southern Cypresses

Owners Patrick and Lynne Milne review their 12-year journey into mechanisation and how embracing change is key to success.

Based in Kaiapoi in Canterbury, Southern Cypresses was established in 1997 and is owned by Patrick and Lynne Milne. This family-owned business is a wonderful example of how growth and success is directly attributed to a willingness to embrace change and be lifelong learners.

Patrick explains how nursery automation plays a pivotal role at Southern Cypresses, and we look at how everything has been strategically phased in over a period of 12 years.

Humble beginnings.

Patrick is a registered forest consultant and worked for the NZ Forest Service for 30 years before he decided it was time for a change. He’d always been interested in growing things, so thought he’d establish a bare-root nursery.

The Milne’s purchased some land and Southern Cypresses was born, with a focus on second-tier forestry species, Cypresses and Redwoods. For the next eight years, they grew

upwards of 75,000 open ground plants per annum.

Around 2008, Patrick joined the New Zealand Forest Nursery Growers Association (NZFNGA) and attended an AGM in Australia, he adds, “while at the AGM, we visited a containerised nursery north of Brisbane - I thought it was pretty clever, so I returned home with the drive to do something similar. And so began the next stage of our vision.”

Scaling up.

Converting to containerised planting was a complete sea change from a bare-root system, and it’s hats off to the Milnes for their radical change of approach after nearly a decade of tried and true growing.

The husband-wife duo continued to build their business, taking it from one modest tunnel house to multiple tunnel houses. Today, the business is fully containerised with an annual capacity of over two million seedlings.

Why the shift to containerised planting?

Along with the advantage of being able to scale up quicker, there were plenty of benefits that appealed to the Milnes. Most importantly, it opened the doors to all sorts of exciting automation, and Patrick found it a very easy and tidy operation once everything was established.

By controlling the growing environment, Patrick and Lynne have been able to extend their season. Aside from January and February, they are sending plants out until November and start again in March. They have been able to foster a wonderful, tight-knit team of mums with school-aged children, and have kept the working day mostly within school hours.

The numbers do the talking.

In 2024, the nursery comfortably handled 300,000 Eucalypts, 150,000 Hybrid Radiata, 50,000 ordinary Radiata, 350,000 Redwoods and the balance in other species. Most things are contracted today, “if we’re not contracted, we look carefully before growing it” says Patrick. All plants go out in boxes on pallets and get delivered directly to planting sites for forestry companies and farm foresters (for carbon forests or smaller woodlots).

Natives are now being phased out because the nursery is less suited to native tree species. Patrick had hoped to dedicated 10 percent of the nursery to Beech, Totara and other native trees, but has found them to be problematic to grow at scale. “The preoccupation with eco-sourcing limits itself to where the seedlings will go, and the seed is variable from 3 months to 18 months - then if it does germinate, it’s hard work and a very manual process to keep the weeds out of the nursery.”

Nursery automation does the heavy lifting. Nursery automation has been phased in over a 12-year duration. In Patrick’s words, here is a brief timeline:

DaRos RC2 Trayfiller – March 2013

First up was a Trayfiller (prior to this it was all done by hand). That just revolutionised things for us. The nursery went from one person doing a few hundred trays a day, to a few hundred an hour – a significant difference.

DaRos Seeder – November 2013

Another game-changer for the team, where one person used to sow 20-35 trays per day (at 1-4 seeds per cell) we increased to three people doing up to 1000 trays in a five-hour day. This kind of scaling up alters your entire business philosophy.

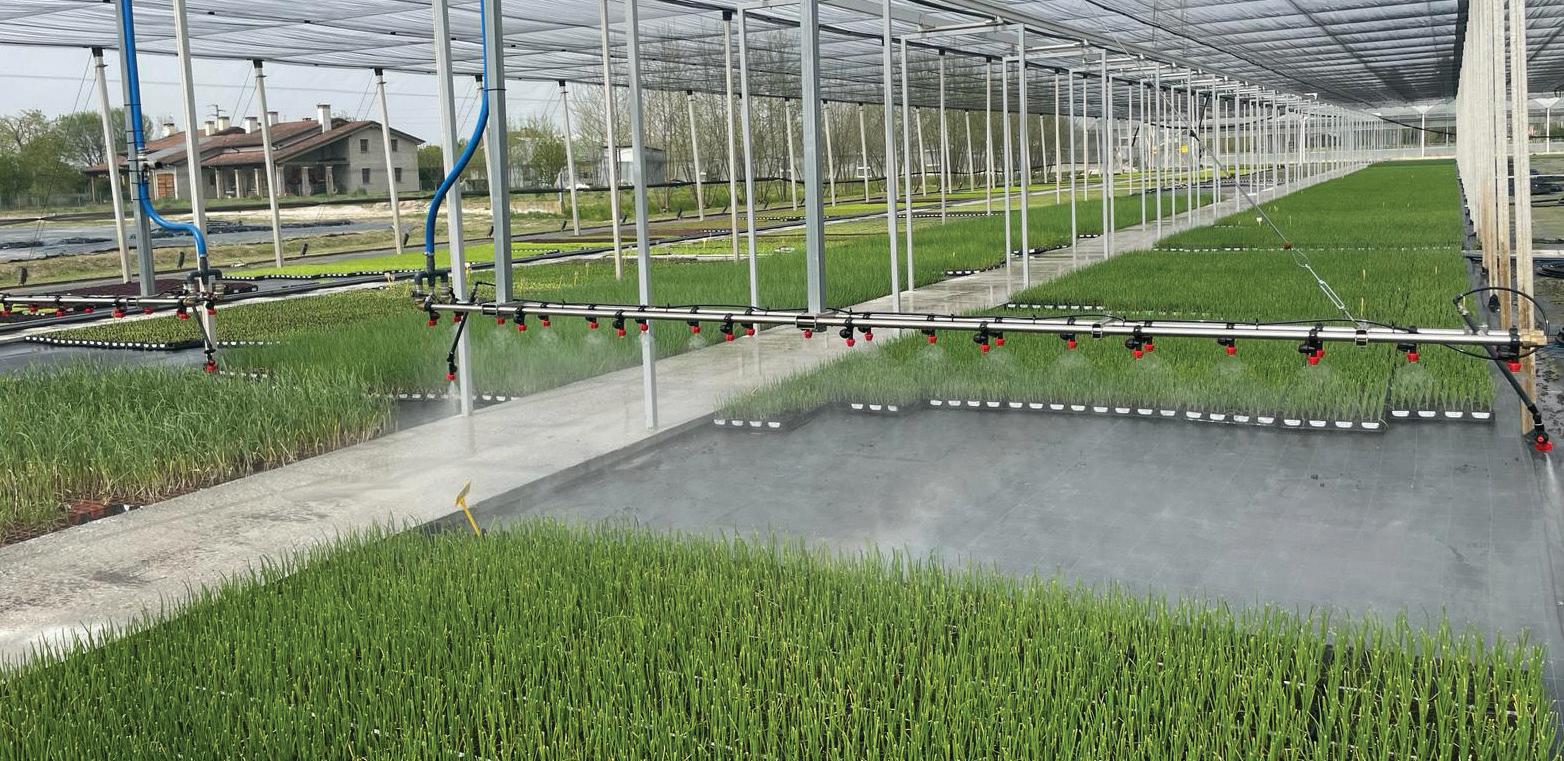

DaRos Overhead Irrigation Booms – October 2014

Next up, overhead travelling irrigation booms in the seed growing tunnel house – for the first time we had good control of watering seed trays and young plants.

Venti V003 Trimmer - September 2016

The Trimmer was a major advancement for the nursery as the previous practice of topping trees with a hedge trimmer was tedious and somewhat difficult to ensure they were all uniformly topped. Progress rocketed from one person topping a few tables a day, to easily topping five tables an hour!

DaRos DP4 Tray Destacker – August 2018

The Destacker removed the menial task of manually putting trays into the Trayfiller, and also freed up a staff member to do much more useful work.

Plug Depopper - April 2022

This adjustable Depopper gently removes the young plants from their trays and has freed up two of our staff from using a single tray foot operated manual Depopper, allowing their efforts to shift to grading and packing - it works extremely well.

DaRos Overhead Irrigation Booms – May 2023 & November 2024

By the end of 2024 we’d installed overhead travelling irrigation booms across the 90% of the nursery. The booms have dramatically improved our watering capabilities. They do the whole nine yards - fertiliser, herbicide, insecticide, water and more. A radio network has been set up in the nursery, enabling us to have smart phone access and control the booms remotely

DaRos Transplanter – November 2024

A Transplanter makes sense as we’re doing more and more plants from cuttings. They’re grown in small jiffy plugs which need to be transplanted into cell trays for growing on for planting out. We hope to do 200,000 hybrids per year, which is a lot of transplanting effort by hand when a machine can replace it

A continual program of improvement.

Southern Cypresses used to employ a lot of seasonal workers and students, but this is no longer required and has reduced staffing headaches considerably. Patrick still splits his time between the forest and the nursery. He adds, “Lynne runs the nursery and has it really humming. We could not achieve what we do without automation - we certainly couldn’t do that number of seedlings with just 4-5 people.”

The Milnes son Kelvin is currently attending the School of Forestry at the University of Canterbury and will complete his education next year. Currently, he is very keen to eventually take over the business.

“It’s a fantastic succession plan to have in the wings, and we’ll continue to look at automating for greater success because it pays for itself reasonably quickly and the gear is easy to operate – it wouldn’t get used otherwise.”

If you could recommend anything to industry peers, what would it be?

“Don’t think about what to do next year – think longerterm! What’s your vision for the next 5-10 years, where do you want your business to be? As an example, with better foresight I would have designed our nursery facilities very differently. We began by growing a few plants, which soon shifted to “right let’s try a little containerised nursery”.

“If I’d known from the start that we’d shift to a containerised nursery, growing two million seedlings, the set up would look completely different (we’ve outgrown the current design). We would have all our nursery facilities in the middle and the plants growing around the outside, instead of having them down one end and the plants up the other.”

“We don’t need more land; we just needed our growing facilities in the middle! Because it takes time and effort to move seedlings around the nursery – from seeding to packing out, and the stages in between. Our seedlings are all on rolling tables so we’re not lifting things as such, but it’s getting them from A to B that can make all the difference. Have a clear vision of where you might want to be!”

Finally, if you are making big changes make sure it’s led by science not by gut feeling or YouTube videos! That’s not good for the industry (or the country). It’s numbers and science that are key.

Southern Cypresses is a shining example of hard graft, courage to invest in growth, and mechanisation playing its part.

What’s new?

Propagation Greenhouse

Bespoke design for growers seeking a high-quality facility for seed and cutting production.

• 6m x 15m total footprint 90m2

• Two separate growing zones (6m x 7.5m each)

• 8mm twin-wall polycarbonate for superior insulation and durability

• Four manual roll-up side vents for optimal airflow (with anti-bird/ insect netting)

• Fits up to 16 propagation tables

Enquire about optional extras! Call our Automation expert today 0800 12 77 46.

Da Ros TP-24 Transplanter

Triple the production capacity of earlier models!

Over 20,000 plants per hour. Equipped with up to 24 self-driving, double movement fingers, allowing growers to achieve uniformity in plant spacing and depth, leading to consistent, healthier growth.

Call our Automation expert for more information: 0800 12 77 46

Coir Crush Blend

60:40 Coir Pith and Coir Chip

This grade is ideal for larger container sizes such as the 0.5L, 1L, 2L, 5L and for raised garden beds.

• 100% natural product

• Readily absorbs water

• Excellent growing medium

• Good air-filled porosity

• pH 6-7

• RHP Certified

SmartGro

Nursery Plant Cart

Hot-dip galvanised frame to prevent rust, weldmesh deck and safe anti-tip protection.

Max load 200kgs. Designed to do the heavy lifting around the nursery, do

SCION NURSERY

We highlight the incredible work being done at Scion Nursery, led by Matt Dunn and his talented team, offering a glimpse into the future of forestry and plant propagation in New Zealand.

Matt Dunn

“This is the best job I’ve ever had. It appeals to my inner nerd – I love the variety and challenges it brings.”

Matt’s journey with Scion began in June 2022, following his years of experience gained in garden centres and nurseries since 1991. He even recalls when PrimeHort started in 2002, he was at Palmers Garden Centre in Rotorua at the time. While his introduction to forestry and research may be more recent, it perfectly suits his love of problemsolving. Today, Matt leads a seven-member team, working on fascinating projects that range from plant propagation to cutting-edge forestry trials.

About Scion Nursery

As a Crown Research Institute (CRI), Scion’s focus is on supporting scientific research. The nursery’s role is to provide optimal growing conditions and oversight for numerous science and commercial pilot projects. In 2022, Scion recalibrated its operations, stepping back from largescale commercial plant production to make room for more research projects.

“You can’t grow commercial quantities at research prices,” Matt explains. “The more you handle a plant, the more expensive it becomes.”

This shift allows Matt’s team to dedicate their efforts to assisting scientists with intricate proof-of-concept trials and partnering with commercial nurseries if studies require evidence at a larger scale.

Current projects

The work at Scion is as varied as it is innovative. From field trials for commercial foresters to tissue culture propagation, here are some of the exciting projects underway:

1) Field trials for commercial foresters

The nursery germinates thousands of seeds for trials, often from specific tree origins, where genetic markers determine the strongest candidates for growth. They are planted in indoor sand beds and grown into mini hedges . Cuttings are taken from these mother plants and grown to a suitable size for field trials around New Zealand. These trials, which take up to 2.5 years, involve multiple team members at various stages.

2) Tissue culture propagation

Scion’s team works with somatic embryogenesis (SE) and organogenesis (OG) shoots, receiving these delicate specimens in petri dishes filled with gelbased growing media. The team carefully deflasks and nurtures them using paper pots and highhumidity environments. Tissue culture is a manual, temperamental and precise process, involving tweezers and misting systems to ensure the plants stay healthy .

“Imagine them as plants coming off life support and we’re now tasked with developing them in a gentle manner,” Matt says, “The automated misting is very dense small droplets; when it goes off you can’t see a metre into the greenhouse. It’s not the most pleasant environment to work in. Scion currently has about

50,000 plants in this phase, divided into multiple trials, including research for forest genetics and commercial propagation.”

The nursery work sits with the ‘forest genetics’ team, which is spread around Scion’s campus and includes two propagation scientists. These two scientists spend a lot of time in the nursery; one of them has a background in tissue culture, so is doing plenty of hands-on work between the genetics team and the nursery. Matt’s providing the right ‘facility’ and it’s very collaborative, he says, “We’ve only talked about Pine in the article, but we’re doing Redwoods, Cypress, and hopefully going into the indigenous space –there are Puriri in the sand beds right now.”

3) Fertiliser and herbicide trials

The nursery is also testing a new fertiliser and herbicide, derived from by-products of other industries. The goal is to determine which combinations work best for different species, such as Pine or Eucalyptus. Results can emerge in as little as three months for simpler trials, or up to a year for more complex tests, like examining soil microbiomes. Typically the testing for the reports is done by the Plant Protection Chemistry and Physics team.

4) Chatham Island revegetation help

Scion is also involved in a long-term project to help restore indigenous plant life on the Chatham Islands. The nursery team helped set up a couple of nurseries but have also been growing and shipping plants back to the island. Scion is helping repair ecosystems that have been largely converted to farmland. “It’s not easy getting plants back to the Chatham’s, with just one flight a week carrying freight, passengers and tourists,” Matt explains. “The biological controls in despatch are intense, with the added pressure of limited shelf life of plants in boxes.”

But Matt finds the work particularly rewarding, he grins, “So I’ve been working with plants for a very long time. You learn the common name and botanical names, then the Māori name, and now I’m learning the Moriori too.”

5) Biodegradable pot trials

With a focus on sustainability, Scion is currently trialling three types of biodegradable pots, with plastic pots as the control. The plants were grown in these pots in a split pot trial, with no favouritism to how they were laid out. They were kept in their individual pots and grown and hardened-off under normal nursery conditions. Once ready to be planted out, they were measured at six months old for height and root collar diameter, and their planting locations recorded.

The plants in the biodegradable pots do not require transplanting, as they are made from materials designed to break down (and even provide fertiliser for the plants). The plants are effectively eating the pots! The results of these trials, focusing on native species such as Mānuka and Kanuka, will be reviewed as this article goes to print.

The role of automation

Automation has transformed the way Scion operates, allowing the team to focus on multiple projects. However, Matt reminds staff not to take the automation for granted.

“Just because something is automated, it still needs to have human oversight. That might be replaced one day by a camera or AI, but not yet.”

From automated misting systems in the greenhouses to intelligent irrigation, Scion’s nursery is becoming more efficient, allowing the team to focus on what really matters –growing plants.

“I’d rather spend five minutes pushing buttons than moving 60,000 plants from one zone to another,” Matt says. Automation allows Scion to recreate the right environment around the plants, rather than moving the plants to different conditions, resulting in significant cost and time savings.

The nursery also employs a reverse osmosis system to recapture and clean water, which is reused in the greenhouse. This water-saving technique ensures minimal waste while maintaining optimal growing conditions. Even the sand beds used for micro-hedging are designed to maximise efficiency, recapturing excess water for reuse.

Another favourite feature are the wet walls, with the latest installed in February 2023. During the set-up it was about

40 degrees in the greenhouse. The electrician switched it on and the wet wall and two fans dropped the temperature to 25 degrees within five minutes. If the nursery is growing plants that need heat to form roots, but don’t like warm humidity, having this cooling effect is a game-changer. “You can zone off areas, because it’s fully automated. It also means the roof vents won’t need to open, “which is great because that’s as efficient as running the air-conditioning with your car windows down,” Matt says. “Last summer they only opened twice because the shade screen and wet walls kept the temperature below 28 degrees, even with heated tables going. It is fantastic climate control.”

Artificial lighting allows Scion to extend photo periods to suit studies such as Poplar Rust, which started in April 2024.

“To study Poplar Rust you need leaves with the rust on it, so going into autumn wouldn’t normally be the ideal time to study a deciduous tree, but by replicating spring/summer we’re able to keep deciduous trees evergreen through winter. Even some of them that had gone into dormancy thought it was spring and came back out of dormancy.”

Automation is creating a dynamic environment at Scion. There are even flight crew working on drone testing, where they’re teaching the drones to measure trees e.g. height and volume of wood.

Future innovations

Matt sees automation as the future of nurseries. If he had a magic wand, he would like to see an intelligent spray boom/spider cam that could pass over crops, identifying issues such as moisture content, any pests or fungus, and applying remedies precisely where needed. This would allow for significant reductions in water and chemical usage while ensuring each plant gets exactly what it needs.

Matt believes the industry will continue moving toward containerised growing, where climate control is more manageable. “Bare-root growing is back-breaking work, but with containerised systems, you can make the work more ergonomic and efficient,” he says.

Scion’s stool and sand beds are all at hip height. The team has done both styles of work and is far happier taking the cuttings off the inside beds. “I wonder if in future, robots might be used for tasks such as cutting propagation – in which case it could be multi-storied stool beds”.

Team dynamics

Scion’s team is a tight-knit group. Many are locals, and several bring over a decade of experience. Matt credits the team’s success to its collaborative spirit. Whether it’s a complex scientific project or a day spent weeding, the team comes together to get the job done, fostering a positive work culture. “There’s always science happening, but the gut feel, and experience of a nurseryman will always be invaluable.”

“There is a great second-tier of leadership, and the wider industry is very helpful,” Matt says.

Scion Nursery’s blend of automation, innovation, and a skilled team ensures it is well-equipped to meet the challenges of modern forestry and plant science, all while pushing the boundaries of what’s possible in the field.

Quick-fire Q&A:

What are the top four things Matt would recommend to forestry growers right now?

1. Water recapture, cleaning and reuse

2. Paper pots, so there isn’t the need for singleuse plastic

3. Get more efficient with your facilities. Greenhouses can be adapted as plants grow, instead of shifting plants from place to place around a nursery. Greater environmental control indoors means less cost and effort spraying for pests and diseases.

4. Try to move away from soil-based growing media. If you can, use waste product (from the industry) and turn it into growing media, instead of peat which isn’t sustainable.

SIDE NOTE: In September 2024, Matt received the Scion Industry/Stakeholder/External Customer Engagement Award for his exemplary work with external customers.

DA ROS Outdoor Booms

NEW! A DaRos Outside Irrigation Boom delivers precision watering, uniform coverage, and efficient resource use.

These booms have programmable settings to enable tailored irrigation schedules, reducing water waste and encouraging healthier plant growth.

Adjustable spray patterns make it versatile for a variety of crops, perfect for nurseries and horticultural operations. Automation ensures consistent results and significant time savings. Best of all, it helps plants thrive while optimising water and energy use—essential for sustainable and profitable growing.

• Sturdy design for outdoor durability.

• Flexible installation on a “T-bar” or “Corridor” frame.

• Long-lasting stainless steel parts and protective covers for motors and control panel.

• Compatible with Dosatron for chemical or spray applications.

• User-friendly software with options to:

- Water specific zones. Schedule watering days, times, and speed.

- Add an electro valve for left-and-right watering control (optional).

• Includes a double spray boom for irrigation and spraying chemicals.

• Can connect to a weather sensor for weather-responsive watering.

Optional Extras: 3-way nozzles for additional spray options. Mobile app and handheld remote control for convenience.

GROWING MEDIA EXPERT

Meet Andrew.

PrimeHort’s Grower Support expert, Andrew Wearmouth spoke to Grow Smart about R&D of potting mixes and how growing Bananas isn’t such a crazy idea.

How long have you been at PrimeHort and what is your role?

I feel like I’ve been here a long time, yet 12 months has flown by. My role is two-fold: (1) Development of Growing Media to improve plant growth and the bottom line of NZ nurseries and the general horticulture industry. (2) New Crops. Northland has a compatible environment for Banana production… it’s early days, but good things are happening. We have introduced several cultivars into tissue culture and are researching the best hydroponic solutions for production of bananas inside greenhouses. We are also in communication with the Government about an Import Health Standard (IHS) for banana imports. Watch this space.

Why do you enjoy doing what you do?

I really enjoy the culture at PrimeHort. We have a system where the team are given charge of their own sector of the company to make it fly. It’s smart because you feel a sense of ownership, like it’s your own business within the wider setting – with support from a well-qualified team. I’m also finding it rewarding to work with established potting mix manufacturers to formulate custom blends and ensure we can produce in bulk to meet demand. We are even discussing organic mixes too, which is exciting.

How does your industry background play a part in your current role?

I have a background of 40+ years in the horticulture industry which is great to bring to my current role. I owned a cut flower & flower bulb export and plant breeding business for 21 years. I then worked at Kauri Park (New Zealand’s most prominent native tree nursery) for 13 years, where my role was varied, including two years as Nursery Manager

setting up growing systems, developing potting mixes, weed control and general nursery management. I specialised in a Mānuka breeding programme, selecting a variety of Mānuka throughout NZ for high levels of UMF. This selection is now held in a genetic orchard at Kauri Park Nurseries. I advised farmers and landowners on revegetation projects and carbon sequestration yields.

I researched selective herbicide weed control and variations for about 150 native species, leading to hundreds of different weed control trials! I love identifying the choke points in a nursery, and not surprisingly, it often boiled down to lack of weed control.

I think the main benefit of this background is that I speak a grower’s language. I can offer practical, experience-based advice to help nurseries boost profitability and efficiency.

Growers are striving for more sustainable and cost-effective Growing Media solutions - what’s a couple of things you wish every grower knew?

More knowledge around Coir would be number one. Made from the husk of a coconut, Coir is a soilless media, so it has no natural weeds and is sterile. Because it’s not peat, it is sustainable. Whereas once peat has been mined, it’s not replaceable any time soon.

Coir has a naturally high cation exchange capacity (CEC), in layman terms – it holds essential nutrients well and maintains its pH. In our Coir trials, we are finding it is replacing the need for peat and pumice. We’re still using bark, mostly because it’s cheap. So the combo of the two e.g. bark for lowering the cost and Coir for adding the magic like air filled porosity, moisture holding capacity and CEC, is resulting in an ideal mix.

Our early trials (mostly natives and some amenity species) are now providing valuable feedback, and the Coir-based mixes are all outperforming the standard mixes the nurseries are using. It’s still early days but the signs are very positive.

Horticulture is a rapidly evolving industry; how do you keep up?

Mostly listening and seeking out the right people for knowledge, particularly with Coir where there are some offshore champions in the Netherlands who really know

Coir, just add water!

Alan from Langshott Farms has been growing for 32 years.

He’s trialled a few different growing mediums over the years and Coir is his number one choice. The results do the talking at this stunning organic garden in Bream Tail, Northland.

Alan highlights the benefits of using Coir in the veggie beds at Langshott Farms:

1. Organic and reliably disease-free

2. Nice to work with, hands don’t get dirty!

3. Remains damp but never wet

4. Excellent value for money, with 1 block hydrating to 60L

5. Pour into an ‘easy fill’ bag and just add water

this space. I’m looking into the Dutch RHP quality mark (certification system) and how it might relate back here to guarantee Coir blends as an optimal nutrient medium.

I’m a bit of a thinker, so I enjoy problem solving and identifying cost savings in the horticulture industry. In a nutshell, lots of reading, talking to a network built up over 40 years, and questioning to understand customer needs and challenges. I’m also knee deep in research from Australia regarding a new Banana cultivar resistant to Panama disease. If you’re not learning, you’re not growing!

When you’re away from the desk, what are you up to?

Spending time with family and friends. I’m a Papa to five grandies which is real blessing. We have a large family and a lot of friends all around the world. My wife and I like going across to Australia where her family, and one of our daughter’s resides, plus other countries further abroad. Life never slows down.

Andrew looks forward to helping you drive sucess with Growing Media, give him a call today.

Built for the Hardworking Growers of New Zealand

YOUR BLUEBERRIES

ARE IN GOOD POTS

Made from 100% recycled, unbreakable Polyethylene, these containers changed blueberry cultivation forever. Their smart bottom design optimizes root oxygenation and drainage, preventing water stagnation and pathogens growth. Durable and sustainable, they offer growers a long-lasting, high-performance solution.

kaiwakaclothing.co.nz

and drainage, preventing water stagnation and pathogens growth. Durable and sustainable, they offer growers a long-lasting, high-performance solution.

A Pristine Landscape at Te Arai Links

Nestled along a stunning coastline, Te Arai Links is an unparalleled destination for both relaxation and adventure. Home to two of the world’s top 100 pure links golf courses, this exclusive address also hosts a variety of activities, including mountain biking, water sports, tennis, and pickleball.

A scenic 75-minute drive from Auckland’s CBD, or a 25-minute helicopter ride, Te Arai Links welcomes its visitors to an otherworldly setting, where sweeping sand dunes, ocean vistas, lush greenery and luxury accommodation are set against one of New Zealand’s finest white sand surf beaches.

The accommodation at Te Arai Links has a distinct design aesthetic, from its suites, villas, and cottages, everything blends into the environment to create a sense of calm, beauty, comfort and functionality. Attention to detail is a hallmark of Te Arai Links, and this diligence is carried across every touchpoint of the brand, from its golf courses, accommodation, hospitality and landscaping.

Seen here is PrimeHort’s Biodegradable Coco Fibre Matting pulling its weight to protect the landscape of this iconic location. Coco Fibre is a sustainable and aesthetic fabric that sits comfortably among the natural beauty at Te Arai Links - keeping it easy on the eye while it nurtures the plants as they develop.

Biodegradable Coco Fibre Matting is an eco-conscious solution for erosion control and landscaping projects of every size and scope. Crafted from natural coconut fibre, this matting is available in three weights: 300gsm, 450gsm, and 1200gsm and is able to cater to various project requirements.

Designed to support the establishment of vegetation, the matting acts as a protective shield for soil. It’s biodegradable nature ensures minimal environmental impact, and aligns very well with our customers sustainable practices.

Coco Fibre Matting

• Suppresses weed growth, while also allowing for some light penetration.

• Enables moisture retention, helping the establishment of vegetation while insulating seed and root zones against temperature fluctuations.

• Creates optimal growing conditions, promoting healthy plant growth.

• Environmentally friendly.

• For added strength and durability, we offer a variant with PP reinforcement, available in 450gsm. Please note this option is not 100% biodegradable due to the presence of nylon, instead of jute.

LeaderBrand Scales Up Irrigation

LeaderBrand scales up with additional DaRos Irrigation Booms: Doubling capacity for a sustainable future.

LeaderBrand are a household name and one of New Zealand’s largest horticultural businesses, delivering fresh produce to Kiwi families and markets around the world.

PrimeHort works with the nursery teams at LeaderBrand in Pukekohe, Gisborne and Ashburton. The company mantra of ‘straight up quality’ resonates with our team as we set about delivering innovative nursery supplies and mechanisation to this hardworking sector.

In 2023, the PrimeHort team installed four large DaRos Irrigation Booms into LeaderBrand’s original glasshouse in Gisborne, with a fifth boom recently installed in September 2024. Gisborne is also the home of LeaderBrand’s Future Farm facility, which is an impressive 11-hectare undercover greenhouse.

Next up, PrimeHort installed six large DaRos Irrigation Booms for LeaderBrand’s South Island farm in Chertsey (near Ashburton), which brings their tally to 12 booms and will double their seedling capacity.

Installation within 4 weeks.

The nursery in Chertsey is in a very picturesque setting, overlooking the Canterbury Plains with the majestic Southern Alps in the background. Despite some average weather, PrimeHort finished the install in less than a month.

The installation of fully automated irrigation booms will

make the watering of crops extremely efficient. Uniform water distribution, reduced labour and smarter water usage are the key advantages.

With this extension, LeaderBrand now has the capacity to produce 12 million seedlings at any one time throughout the year. General Manager, Mike Arnold adds, “The irrigation booms ensure uniform plant growth, which is crucial for achieving consistent crop quality and even maturity at harvest. This reliability is equally important in seed multiplication, where synchronised flowering of male and female plants optimises pollination.”

As a specialist propagator for the seed industry, LeaderBrand continues to provide top-tier results in both

fresh market crops and seed production. Mike and the team chose the DaRos Watering Booms because they are not heavy or stressful on a greenhouse structure and are the highest quality in the DaRos family of automated watering. The boom can be controlled via a mobile app (which is highly programmable to suit growers needs). Double rail booms empower growers to fine-tune irrigation schedules based on real-time data – resulting in higher yields, reduced costs, and more sustainable operations.

Everyone wins.

The level of technology at LeaderBrand is not only good for the New Zealand economy but is excellent for helping generate growth and regional jobs. Greenhouses allow them to fast-track crop growth in a more sustainable manner. LeaderBrand are

no longer at the mercy of New Zealand’s volatile weather, which means they can guarantee the delivery of healthy and affordable fresh vegetables – all year round.

The DaRos Watering Boom consists of durable modular aluminium profiles with a standard height of 120mm to avoid any bending, independent of greenhouse construction. The boom runs safely inside the profile without noise thanks to the special Vulkollan wheels. The aluminium profile makes the system light and easy to install, and the full control panel with touch screen is easy to follow and allows immediate programming.

Additional benefits include:

• Water pipe movement is uniform with the use of the big wheel / recoil system

• The water pipe is barely visible and there is no pipes hanging down affecting access or walkways

• No components that can cause oxidising in the water

• There is no sideways swinging movement, giving a very even watering and no sound when the boom is in operation

• Option of mobile dosing/fertigation unit for each boom and individual spray nozzle that reaches the edges of the greenhouse and internal walkway

PrimeHort congratulate the LeaderBrand team on being at the forefront of nursery automation. Their commitment to ‘straight up quality’ is setting the standard for healthy communities nationwide. We look forward to working closely with them in their growing endeavours.

PROJECTS ROADMAP

PrimeHort has been supplying quality commercial greenhouses for the Horticulture industry since 2019.

The PrimeHort ‘Design to Delivery’ Roadmap was developed to visually outline the steps involved in a greenhouse project. From small installs through to fullycustomised multi-span buildings, equipped with irrigation booms, climate control and nursery automation - every project follows this dedicated roadmap to ensure success. And we don’t stop there… At the completion of your project, we continue to offer a ‘one-stop-shop’ for your day-to-day horticultural essentials. From bags, pots and trays, growing media, fabrics, and nursery automation - when you are a PrimeHort customer, we grow smarter together every day!

Here is a little more detail behind the PrimeHort ‘Design to Delivery’ Roadmap:

1. INITIAL CONTACT

Over an initial conversation, we discover what it is you require from your greenhouse project and offer ideas.

2. SITE VISIT

Our services kick in with a site visit to review sizes, weather patterns, vehicle access, location of services and more. Requirements are discussed in detail, along with potential design options. We discuss your business goals and budget and assess the practicalities to make it happen.

3. PROVIDE PLANS & SPECIFICATIONS

Based on the site visit and customer discussions, preliminary concept plans are completed, including a floor plan, elevations and layout drawings. At this stage, client feedback is vital to ensure we have interpreted the design and budget correctly, and any fitout ‘extras’ are clearly defined before commencing. From here, we complete full plans and specifications and gain client approval.

3.5 CONSENTS (as required)

We review Council rules and apply for the various consents as required, or we can assist you through this process, including any jargon and paperwork that comes your way. We want to make the process as stress free as possible.

4. ENGAGE ENGINEERS & COUNCIL (as required)

All greenhouse structure and equipment is ordered and earthworks begin.

5. CONSTRUCTION COMMENCES!

We get the installation underway, using the documentation to guide us.

6. SIGN-OFF & WARRANTIES

We ensure you are 100% satisfied with your project and talk through an aftersales care and servicing programme.

PrimeHort ‘Design to Delivery’ Roadmap

1. INITIAL CONTACT

• Discovery Session

• Define Project Scope

• Budget Discussion

Client Brief / Project Ideas Assess Site (wind, sun, views, services) Planning Check

CONCEPTS

• Floor Plan & Elevations, Layout Drawings

• Client Feedback

• Define Fitout ‘Extras’

• Budget Check

(as required)

• Building Consent

• Resource Consent

• Earthworks Permit

• Wastewater Management

• Impermeable Surfaces / Stormwater collection

ENGINEERS & COUNCIL (as required)

• Order Structure/Materials

• Earthworks Begin

SIGN-OFF & WARRANTIES

• Aftersales Care

• Servicing Programme

NATURE MEETS ELEGANCE.

Discover the art of cultivation with Torium. Our premium kitset greenhouses and glasshouses are designed to elevate both your gardening experience and outdoor space. Shop a curated collection where meticulous German craftsmanship is matched with easy-to-assemble greenhouses.

Torium offers the perfect balance of simplicity and unmatched quality. For those seeking something truly unique, explore our exquisite range of European glasshouses, celebrated for their architectural brilliance, durability, and high performance.

Torium is more than just a greenhouse—it’s a sanctuary for your plants and you.

www.primehort.co.nz | www.toriumglasshouses.co.nz