XDF 351 SH / WH

Front disc mower

Hydro-pneumatic suspension

Pull-type hitch

SH – Tine conditioner | WH – Roller conditioner

TECHNICAL DETAILS

PerfectCUT

CUTTERBAR

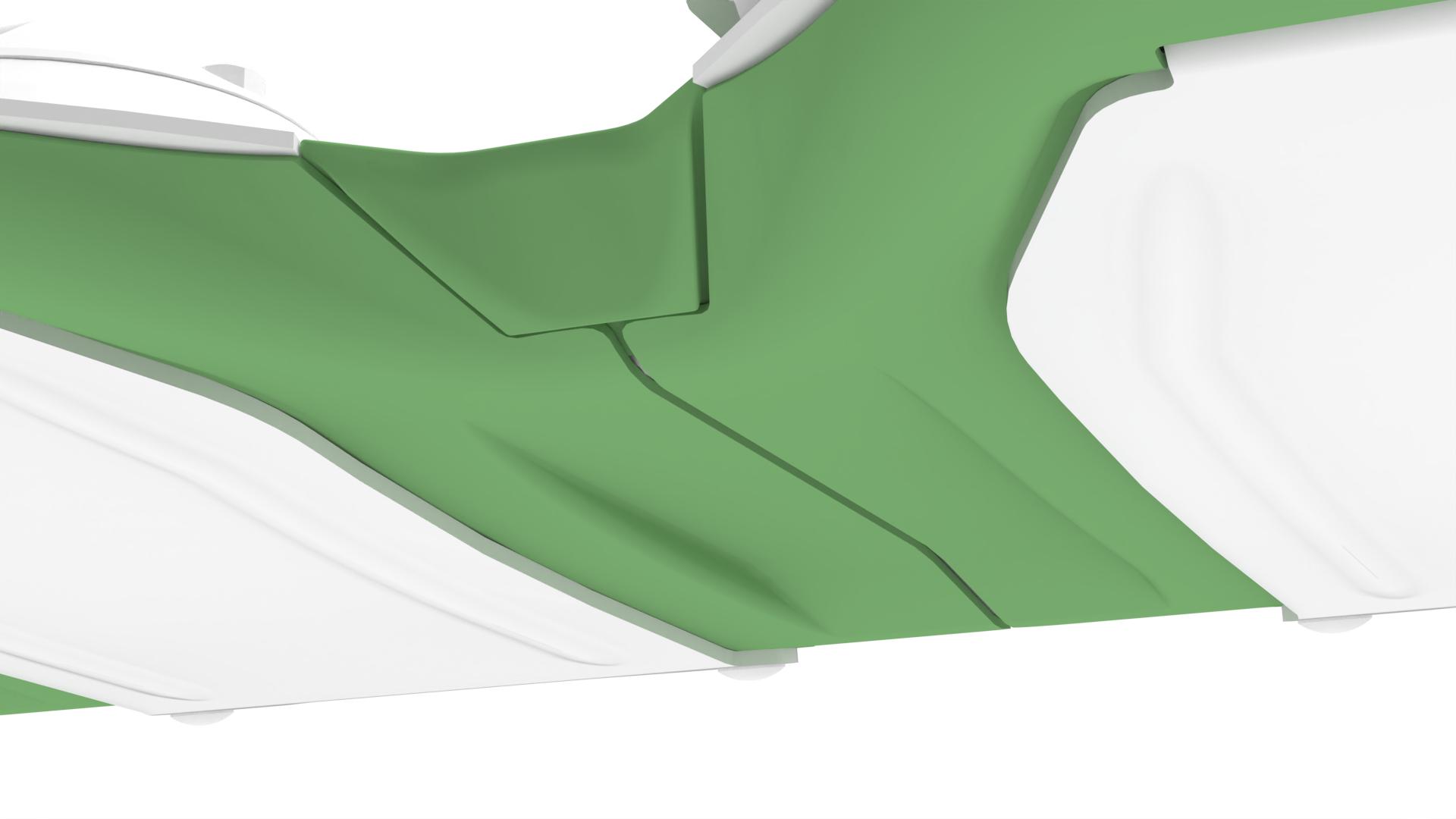

WELDED DESIGN

The most durable design of cutterbars

Much more resistant to twisting than bolted

cutterbars

Enables perfect fitting of components (skids, inserts) into the cutterbar shape

WELDED DESIGN

100 % leak-proof EVERY SINGLE PerfectCUT cutterbar is leak tested

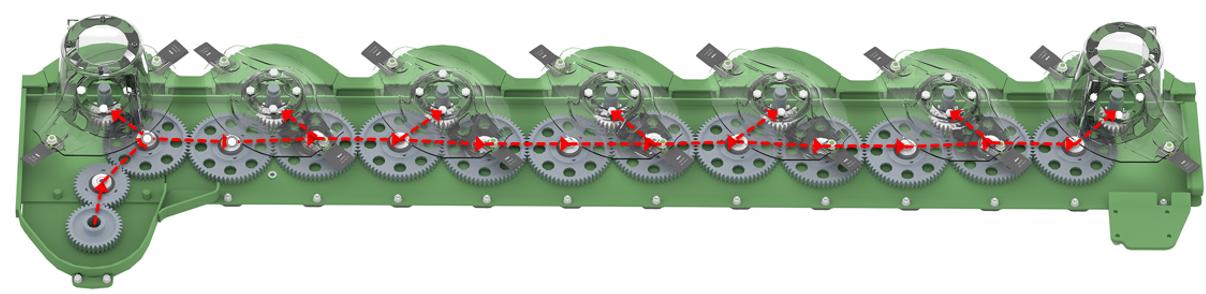

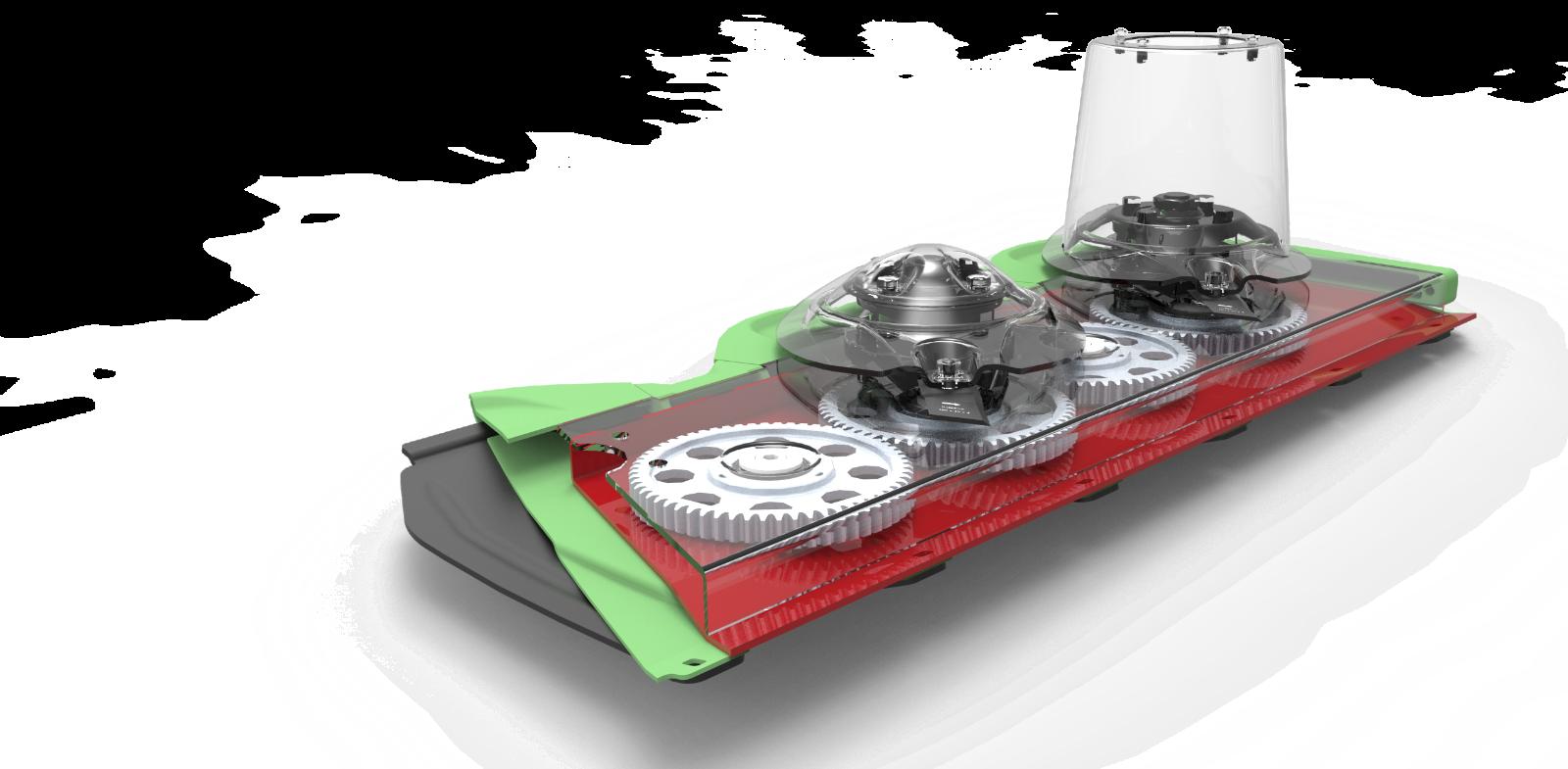

PLANETARY DRIVE

drive transmitted onto discs through large gear wheels only (Ø

215 mm)

idle wheels drive only a particular disc and not any other drive gears

GEARS

Precisely ground, large gears (215 / 21 mm) with constant meshing of 3,5 teeth

High level of gears meshing ensures: constant, loose-free power transmission trouble-free operation

Large gears also means: durability longer service life of bearings quiet operation

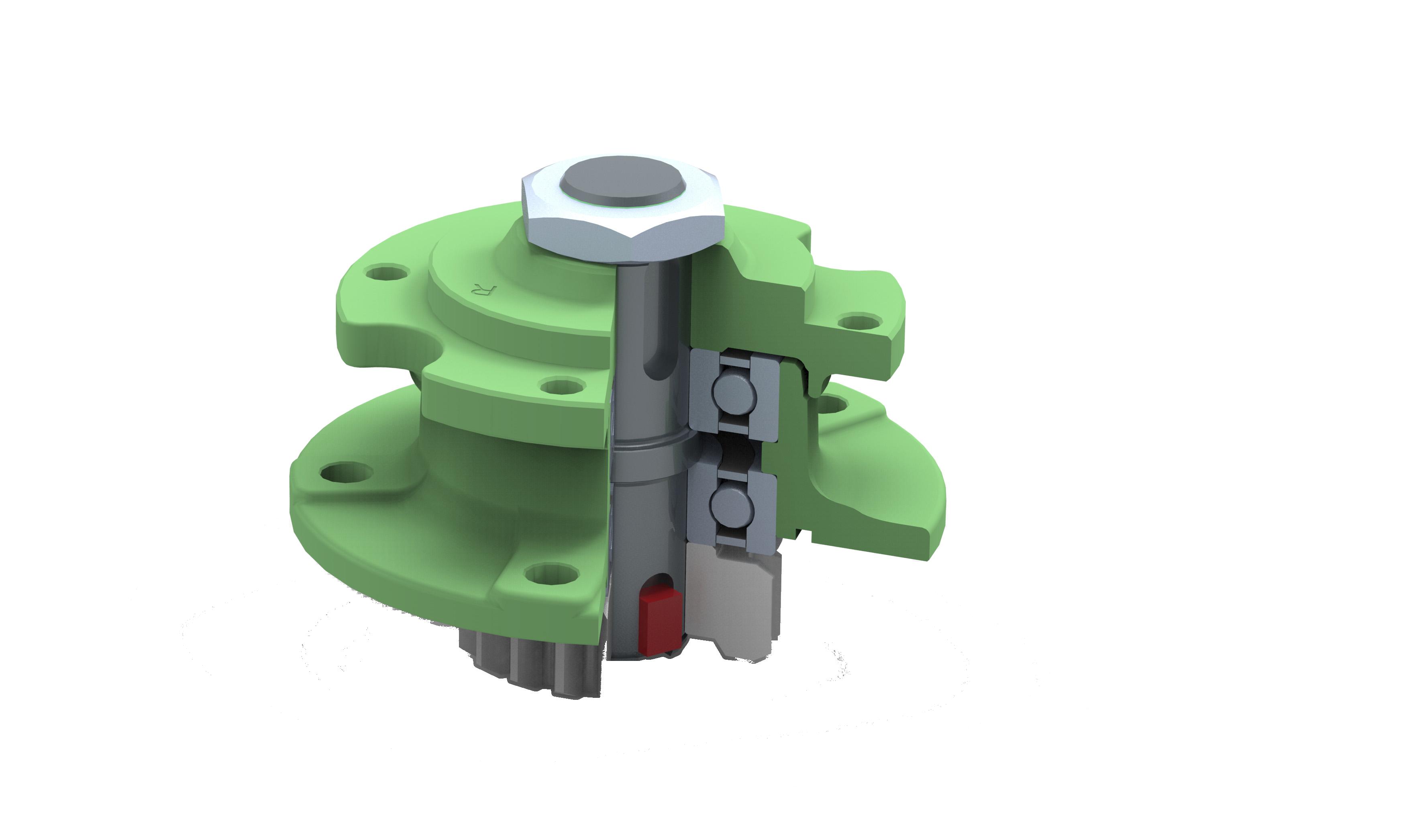

SYSTEM

standard equipment of each disc in every mower

key between gear wheel and drive shaft

absorbs forces generated during impact or when a disc is blocked protects the cutterbar from heavy damages

reusable after key replacement

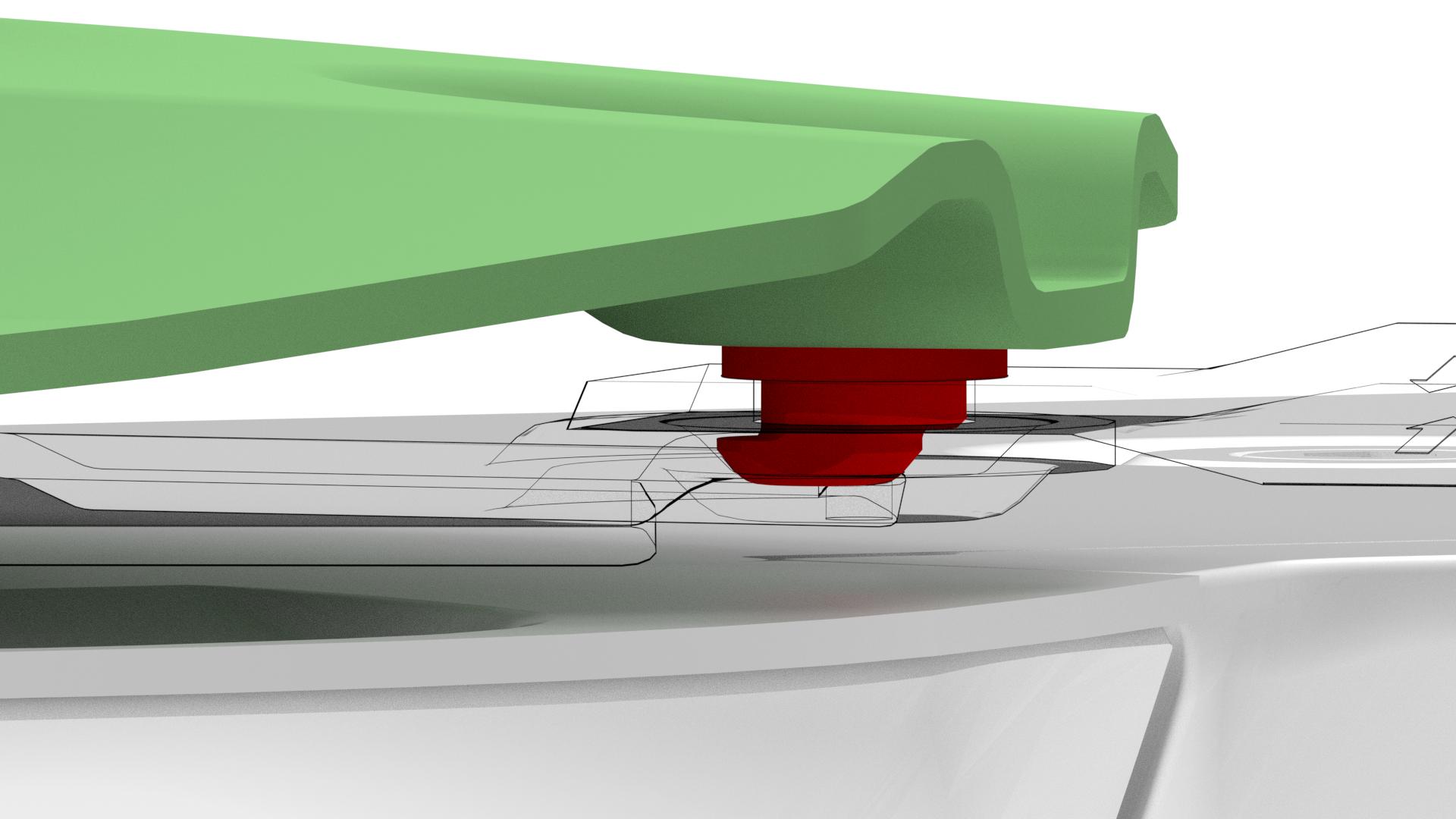

BLADE PIN

Special shape of the blade pin prevents falling out of the blades

Additionally, the pin is a separate and a replaceable element of the cutterbar

As a result, if it worns out, there is no need to replace any other parts of the cutterbar

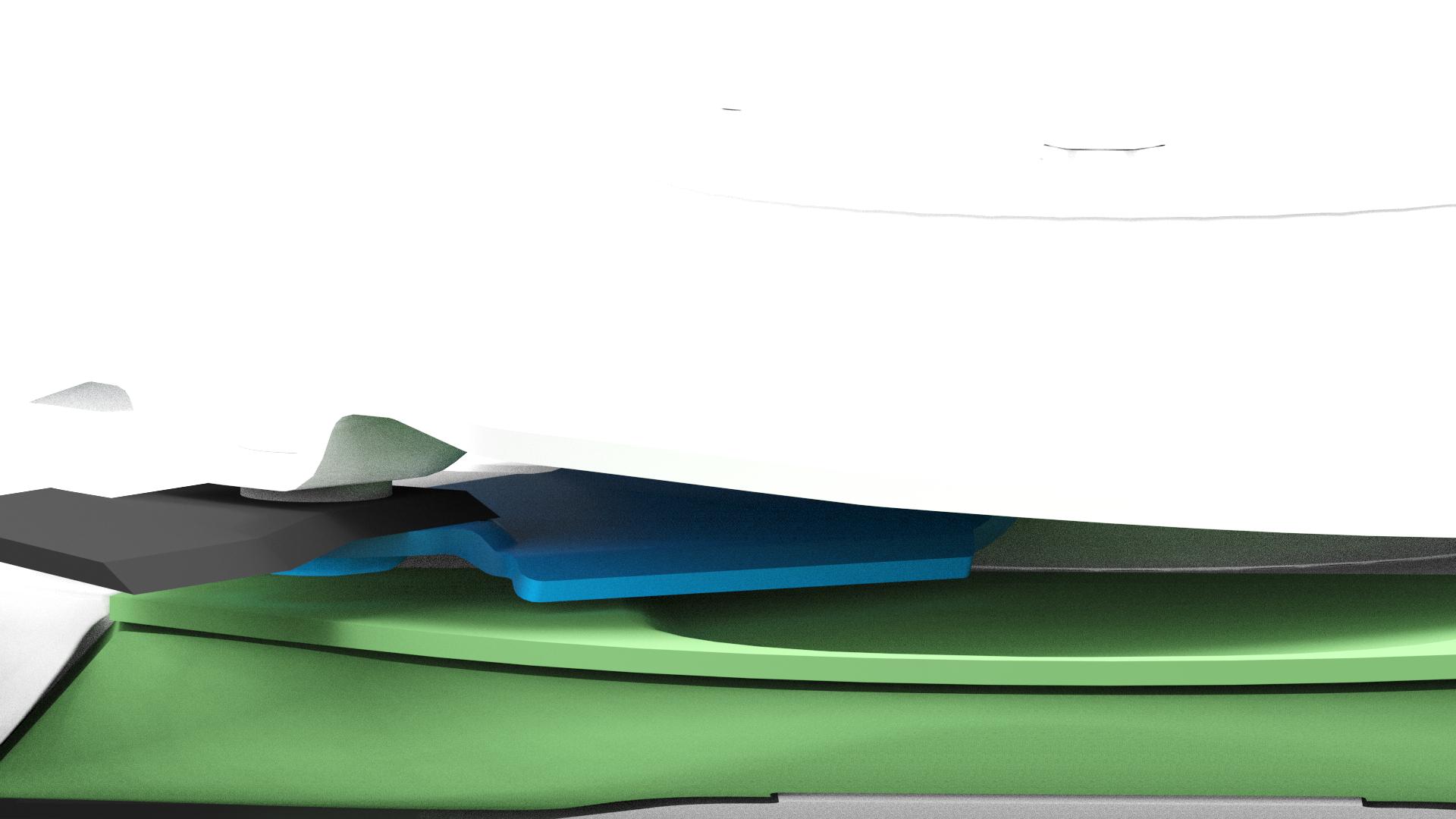

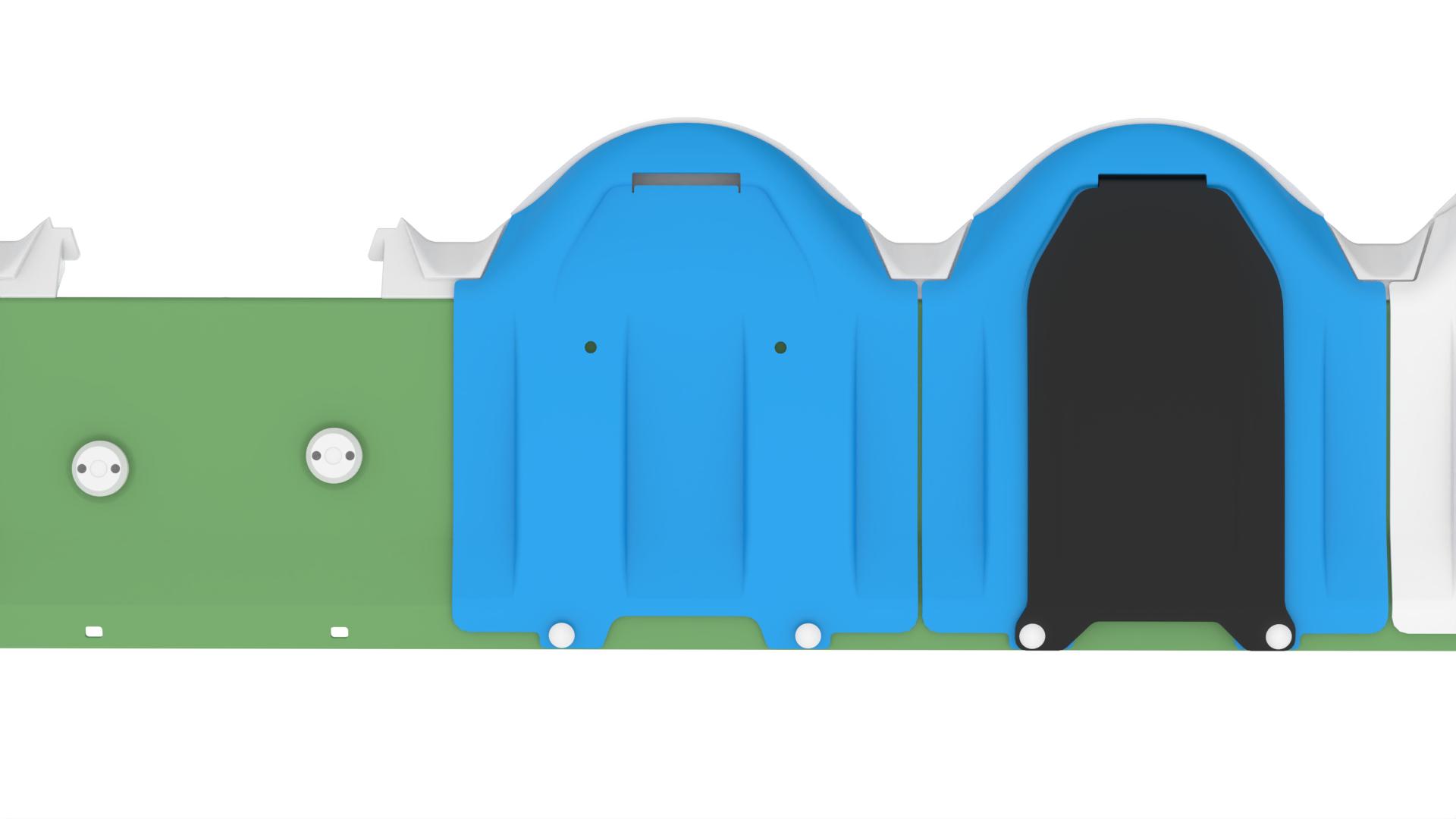

CUTTERBAR BOTTOM

Specially profiled sliding skids and wear plates create a „passage” at the bottom of the cutterbar

That kind of solution separates the dirt from the mowed material

CUTTERBAR UNDERSIDE PROTECTION

The bottom of the PerfectCUT cutterbar is protected by both sliding skids and wear plates offered as standard equipment

The bottom of the cutterbar is completely covered and 100% protected

CUTTERBAR UNDERSIDE PROTECTION

Wear plate

Sliding skid

Cutterbar bottom

„300%” CUTTERBAR PROTECTION

100% due to coverage of the cutterbar bottom by sliding skids additional wear plates

XDF 351 SH / WH

Front disc mower

Hydro-pneumatic suspension

Pull-type hitch

SH – Flail conditioner | WH – Roller conditioner

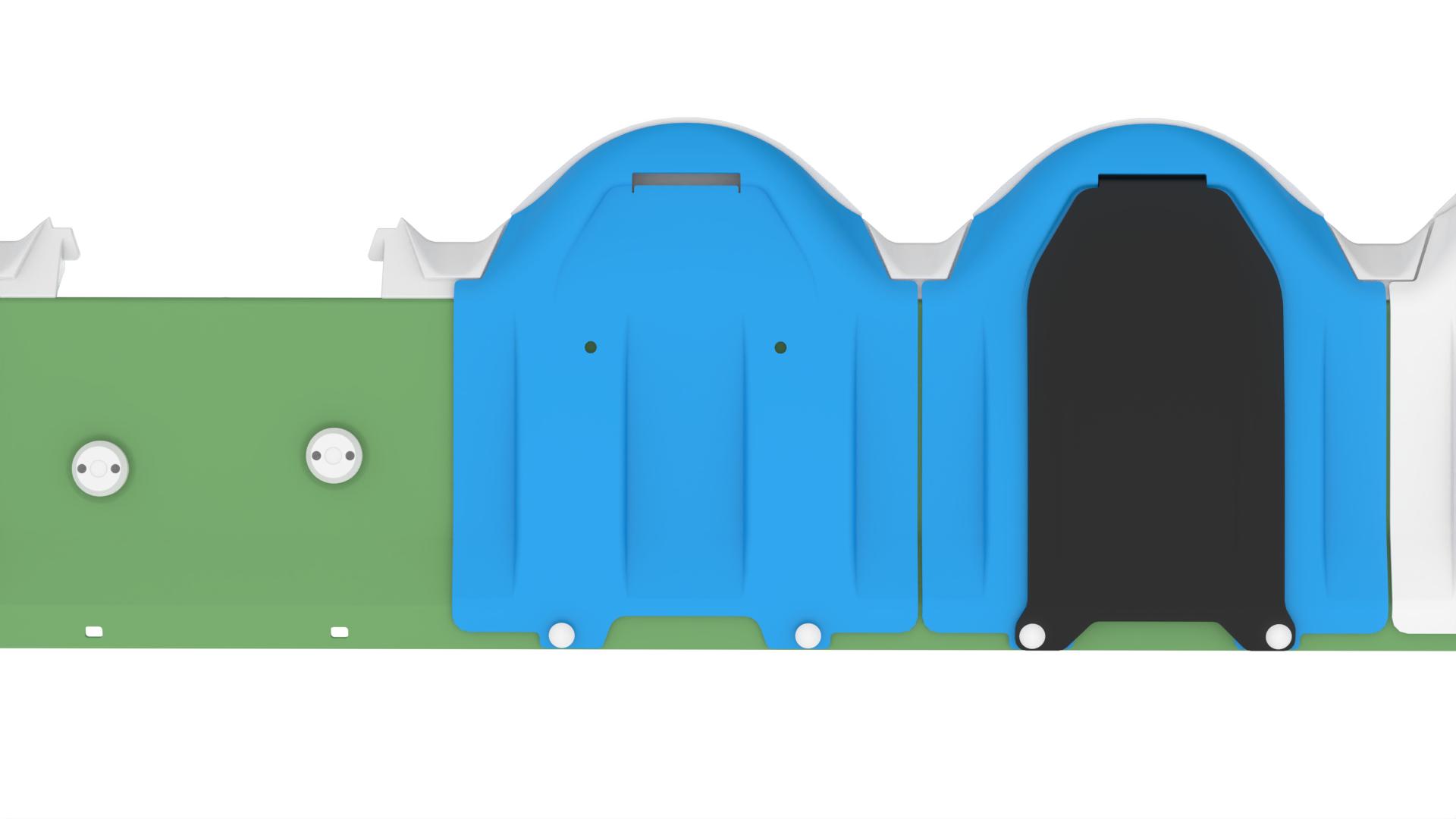

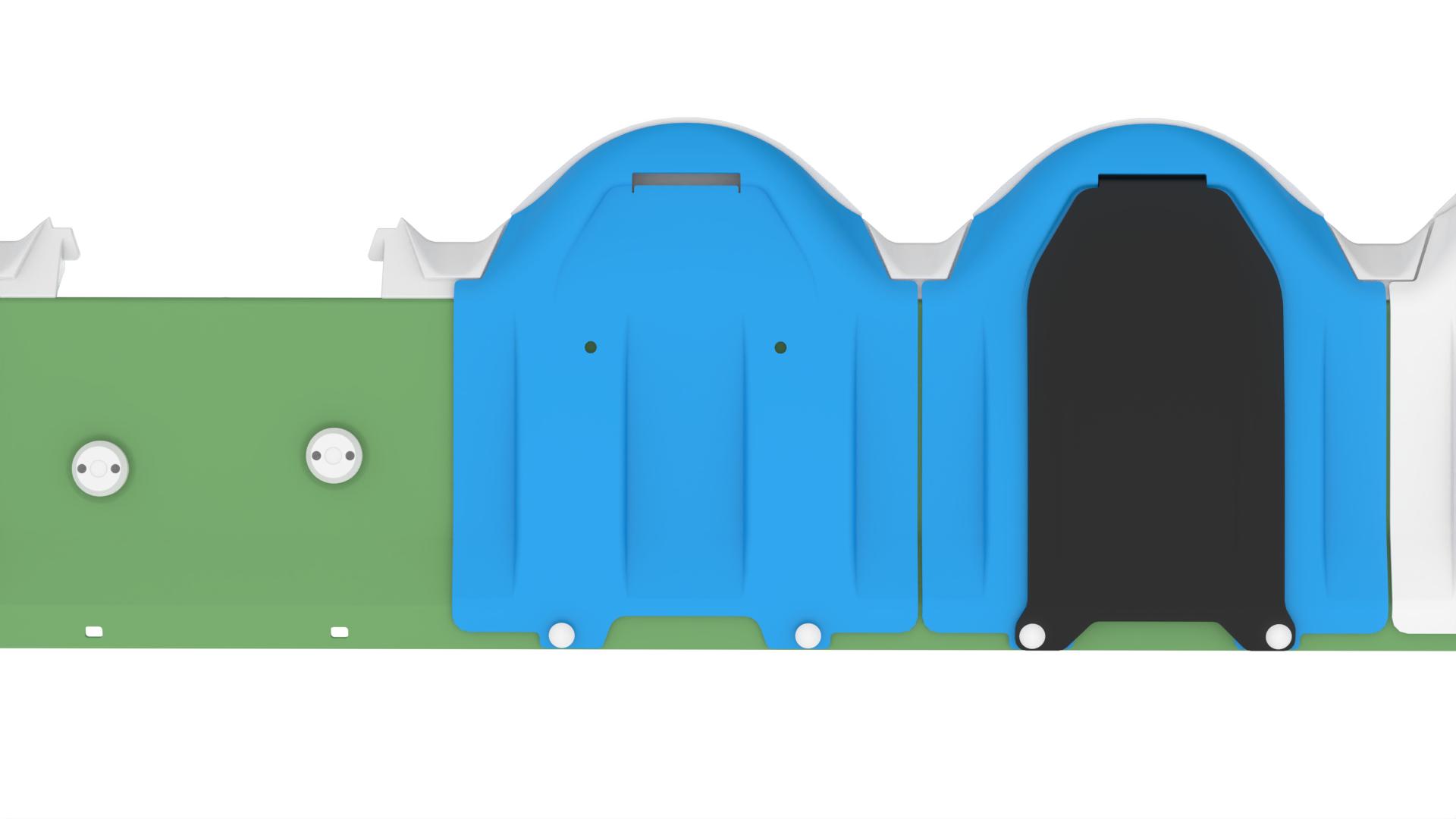

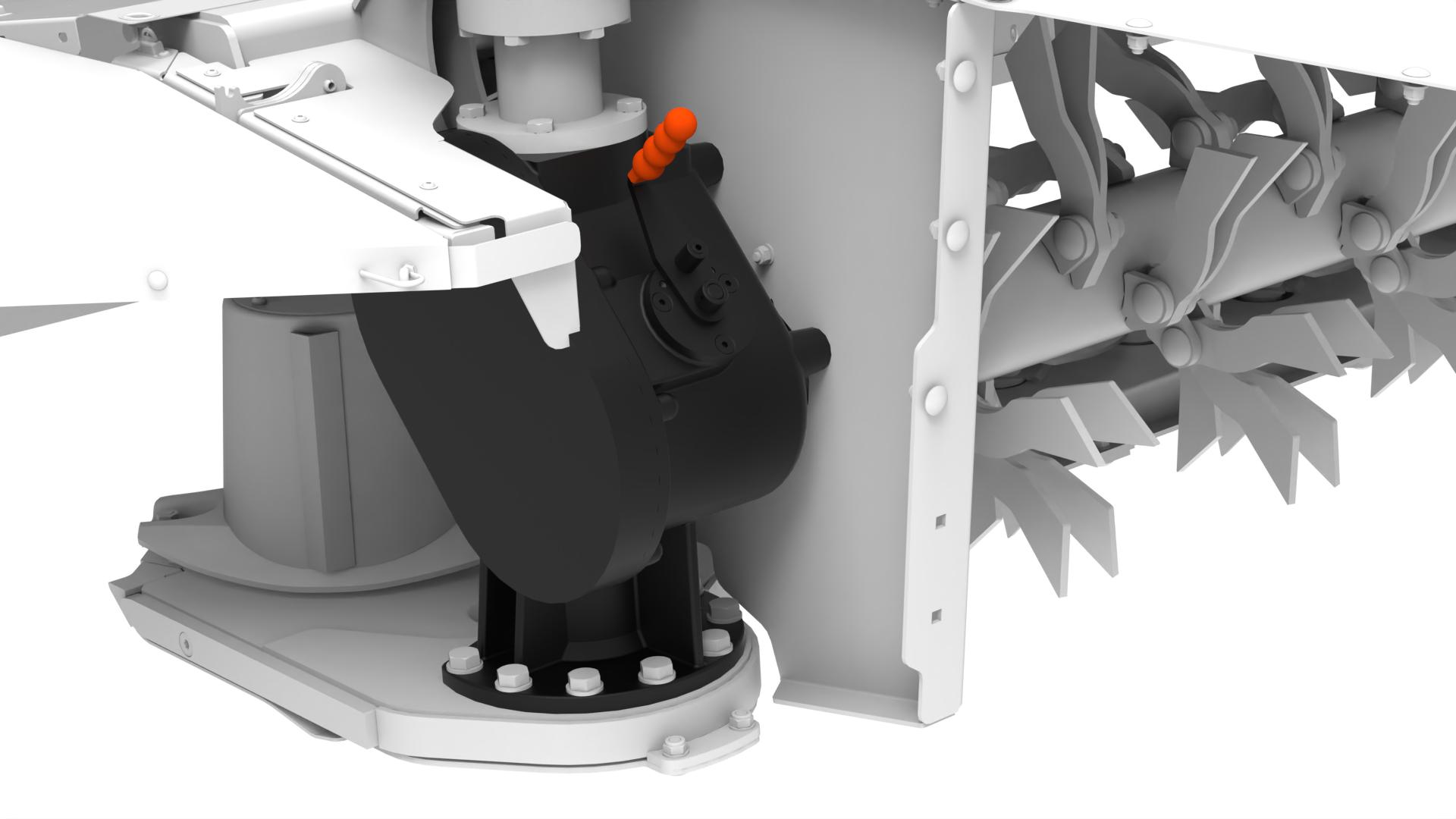

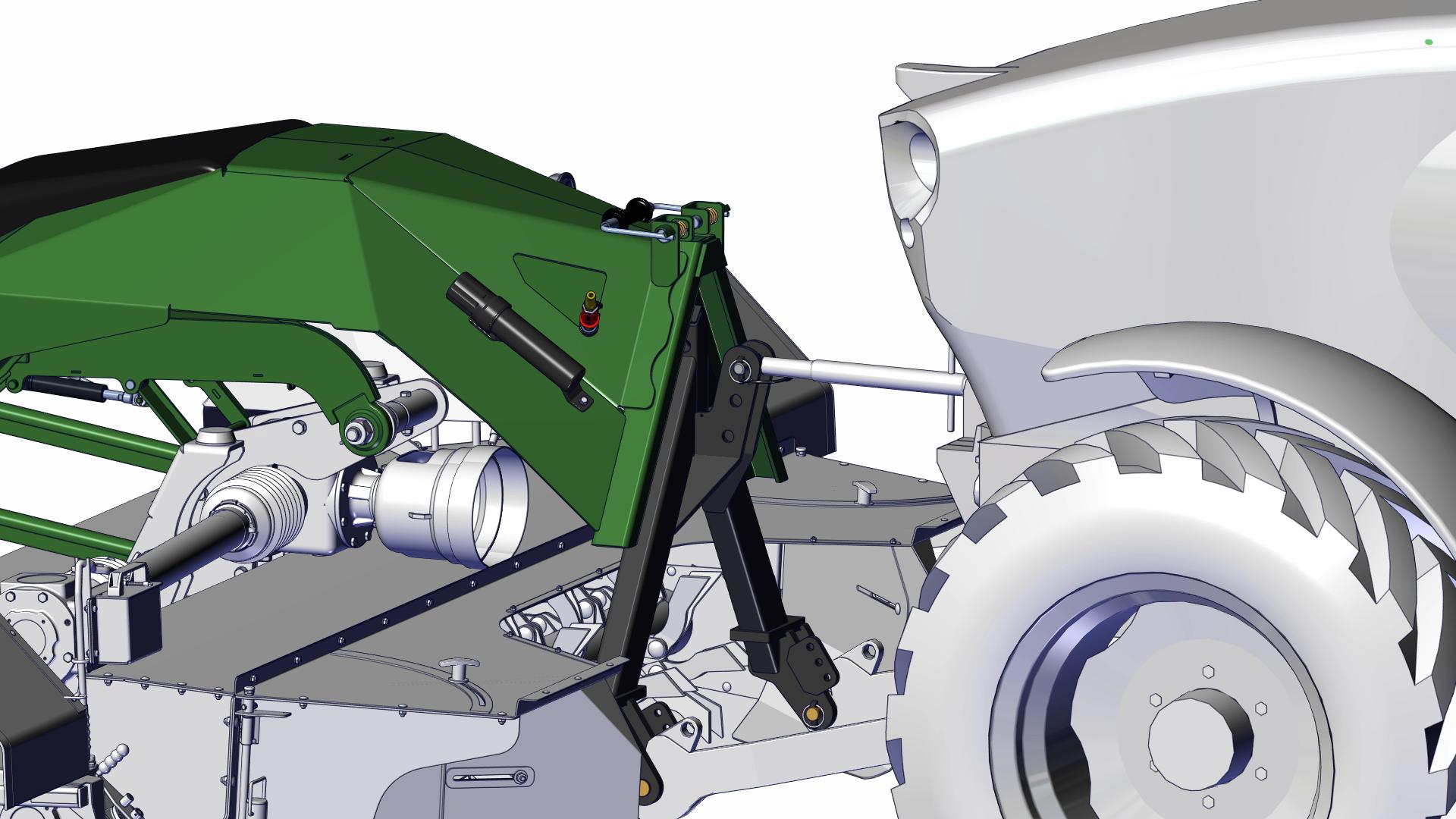

GROUND FOLLOWING

Rocker suspension system enables ground following feature independent of the tractor In combination with the pulltype hitch, the mower features lengthwise ground following range of + 520 mm / -340 mm and lateral tilting of up to 22°

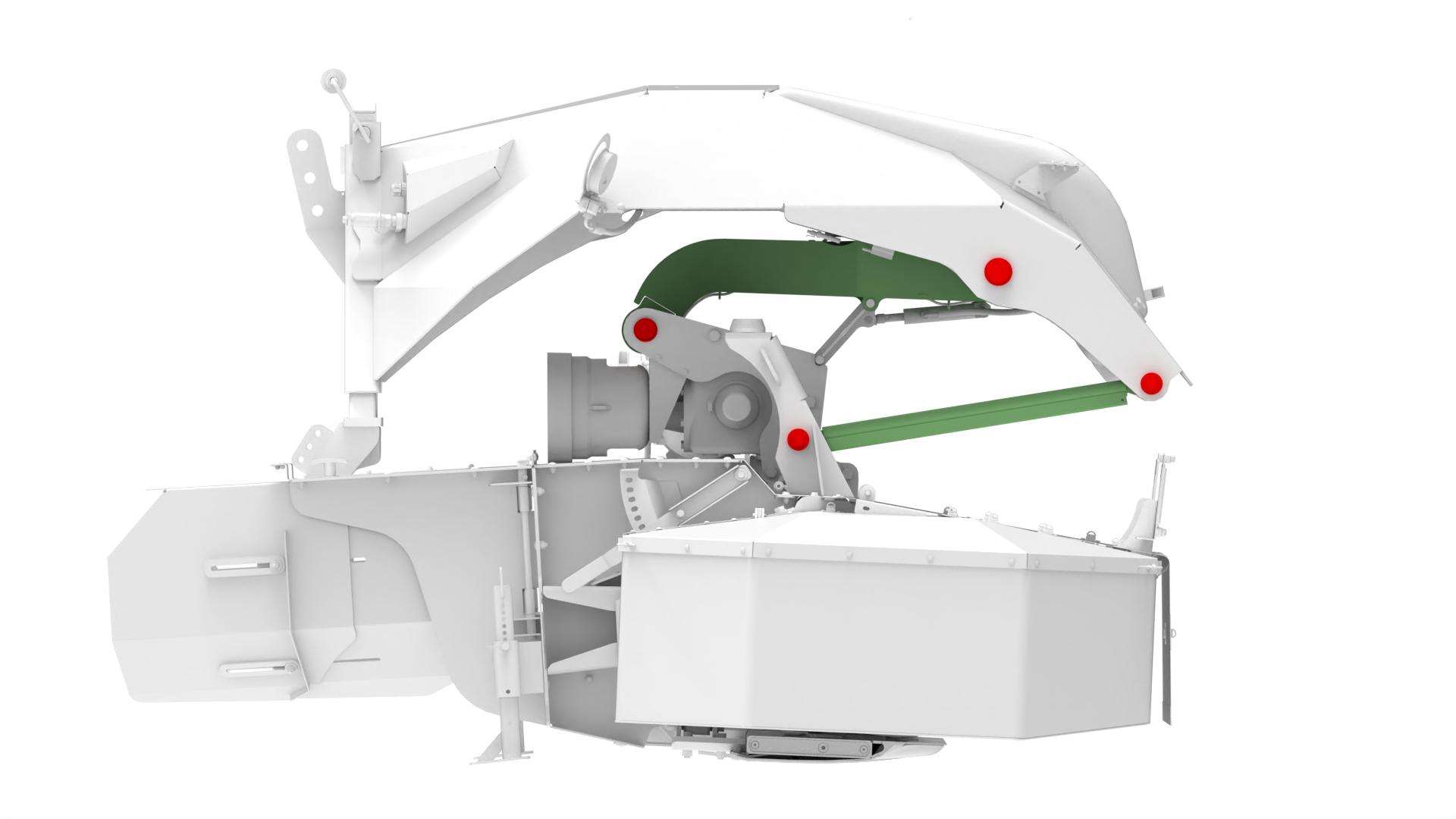

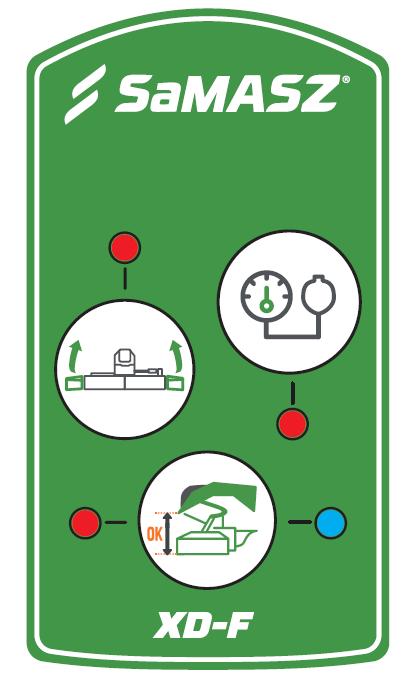

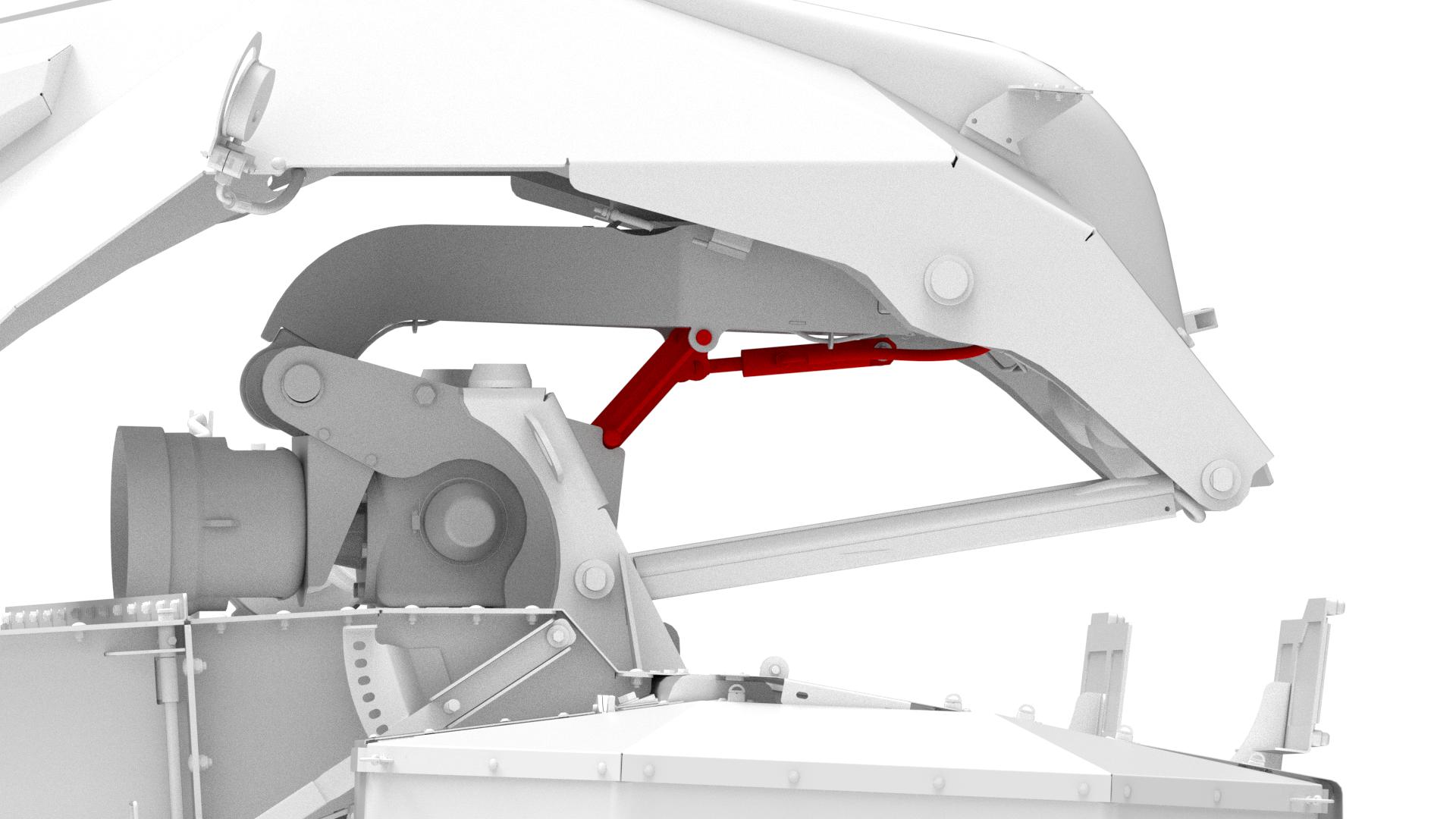

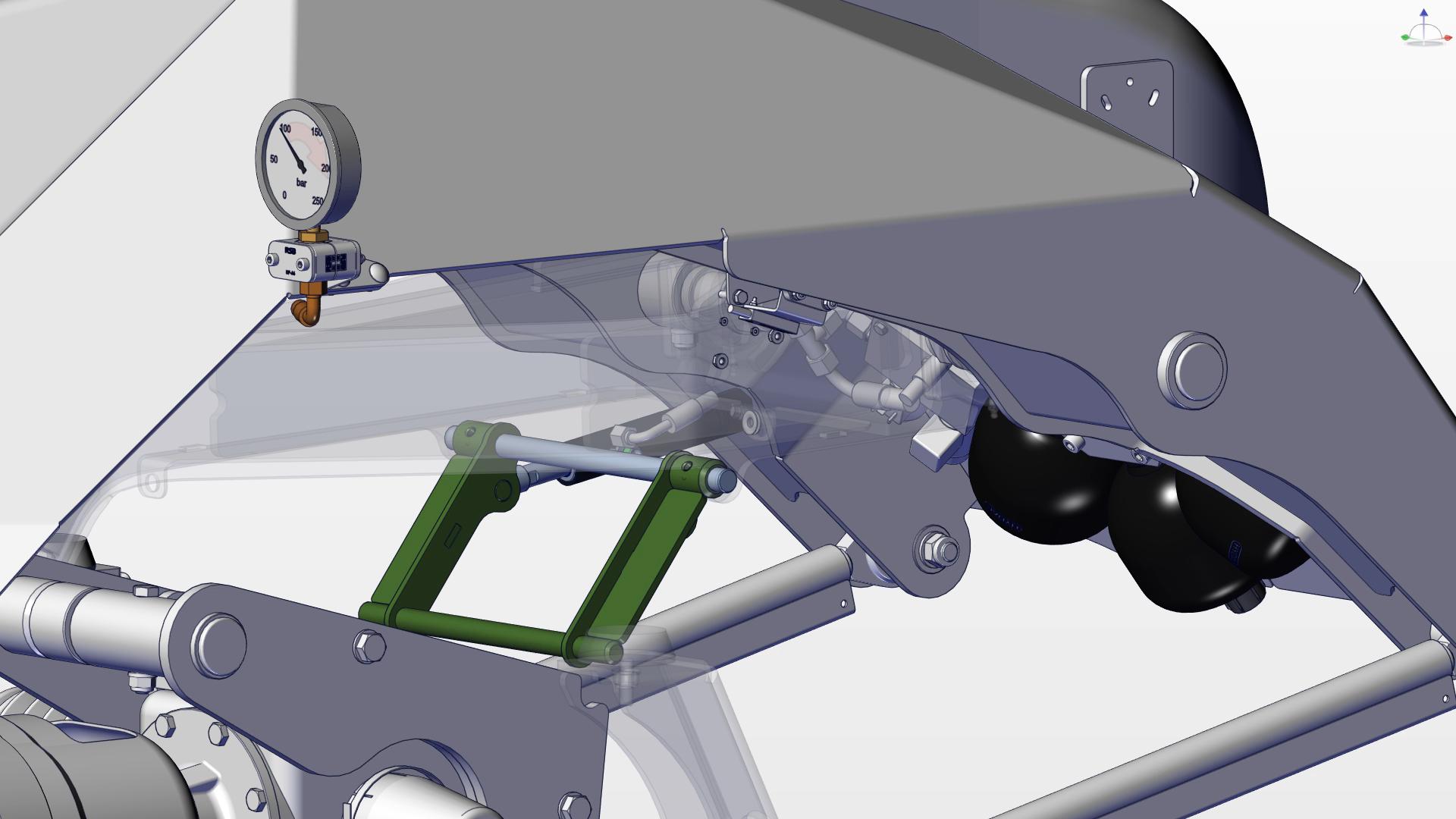

HYDRO-PNEUMATIC SUSPENSION

The mower is equipped with hydro-pneumatic suspension

Instant adjustment is possible using the control panel –

even during work

A clearly visible manometer indicates the pressure in the system

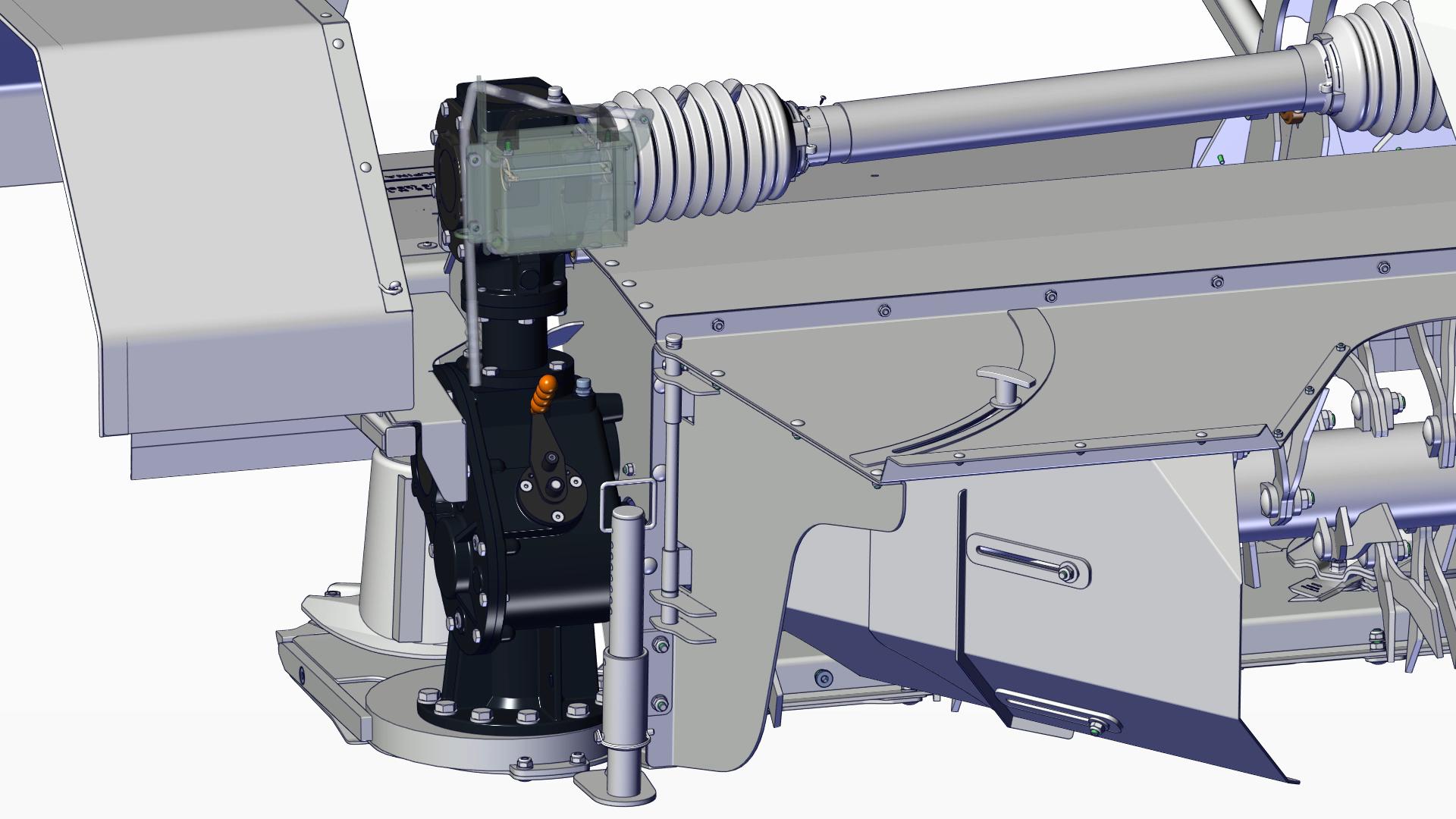

SETUP OF THE MACHINE FOR WORK

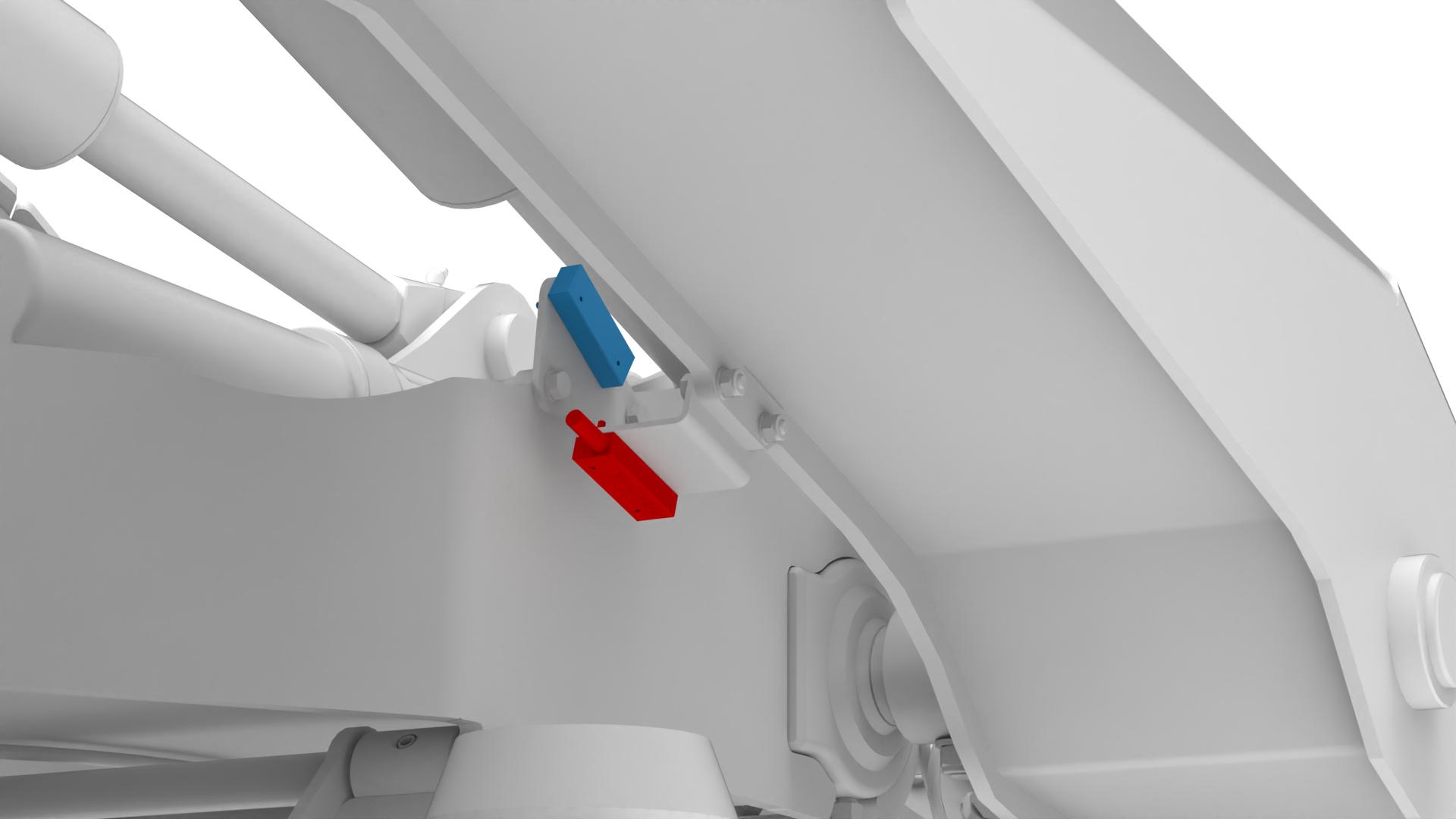

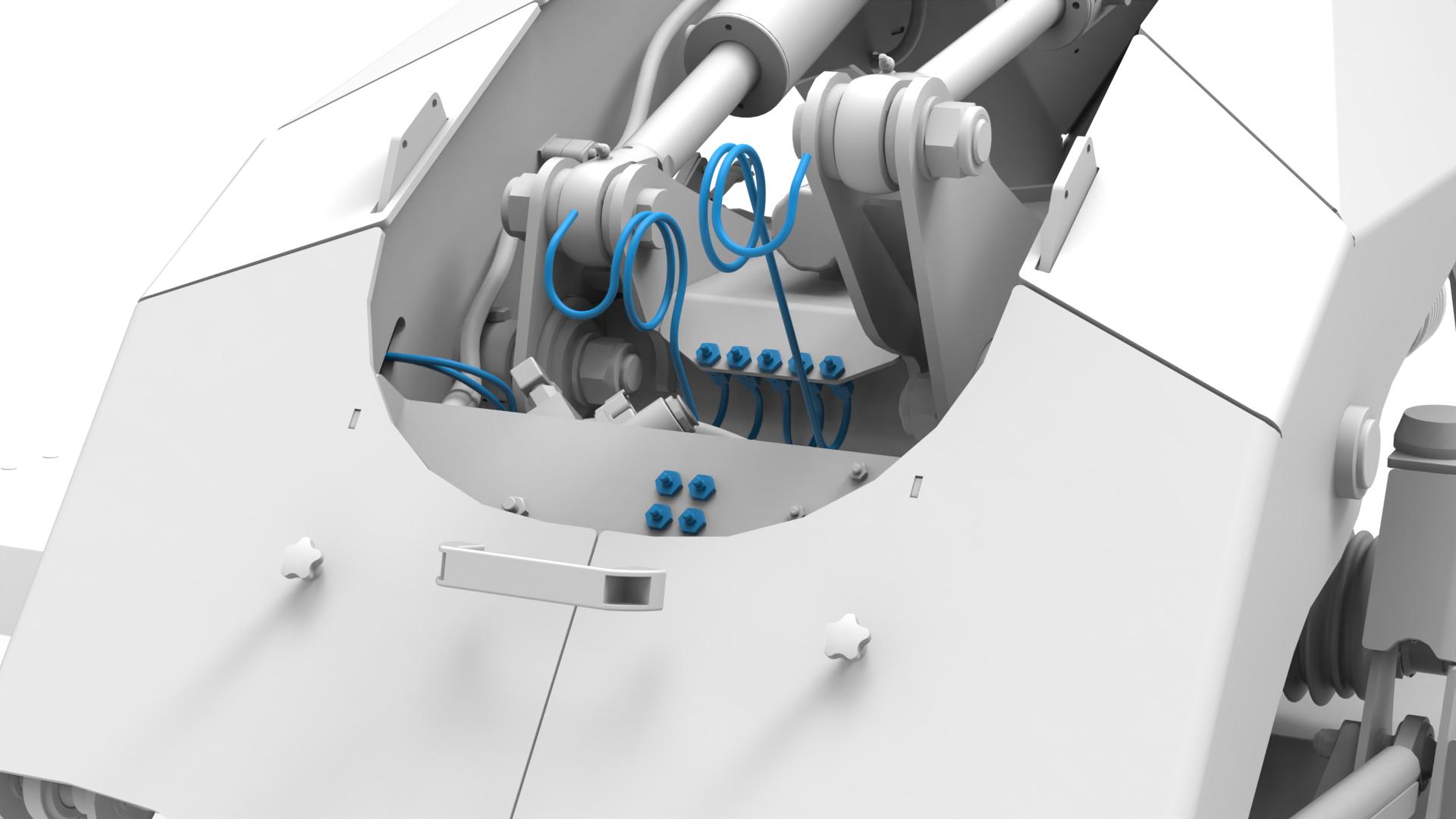

The hitch is equipped with integrated system of sensors system

They signal the correct hitch height on th control panel

CONDITIONERS

SH – Flail conditioner

WH – Roller conditioner

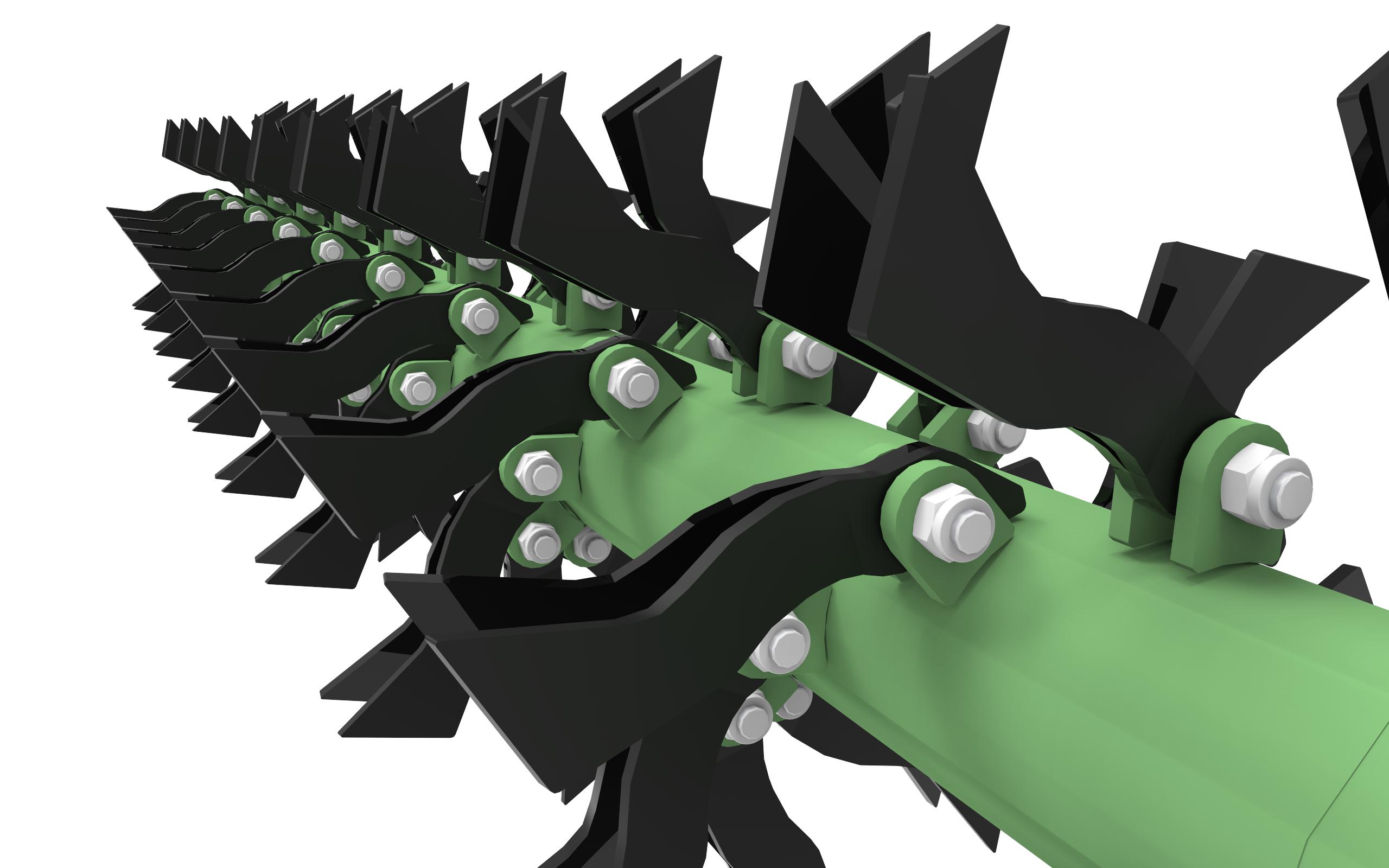

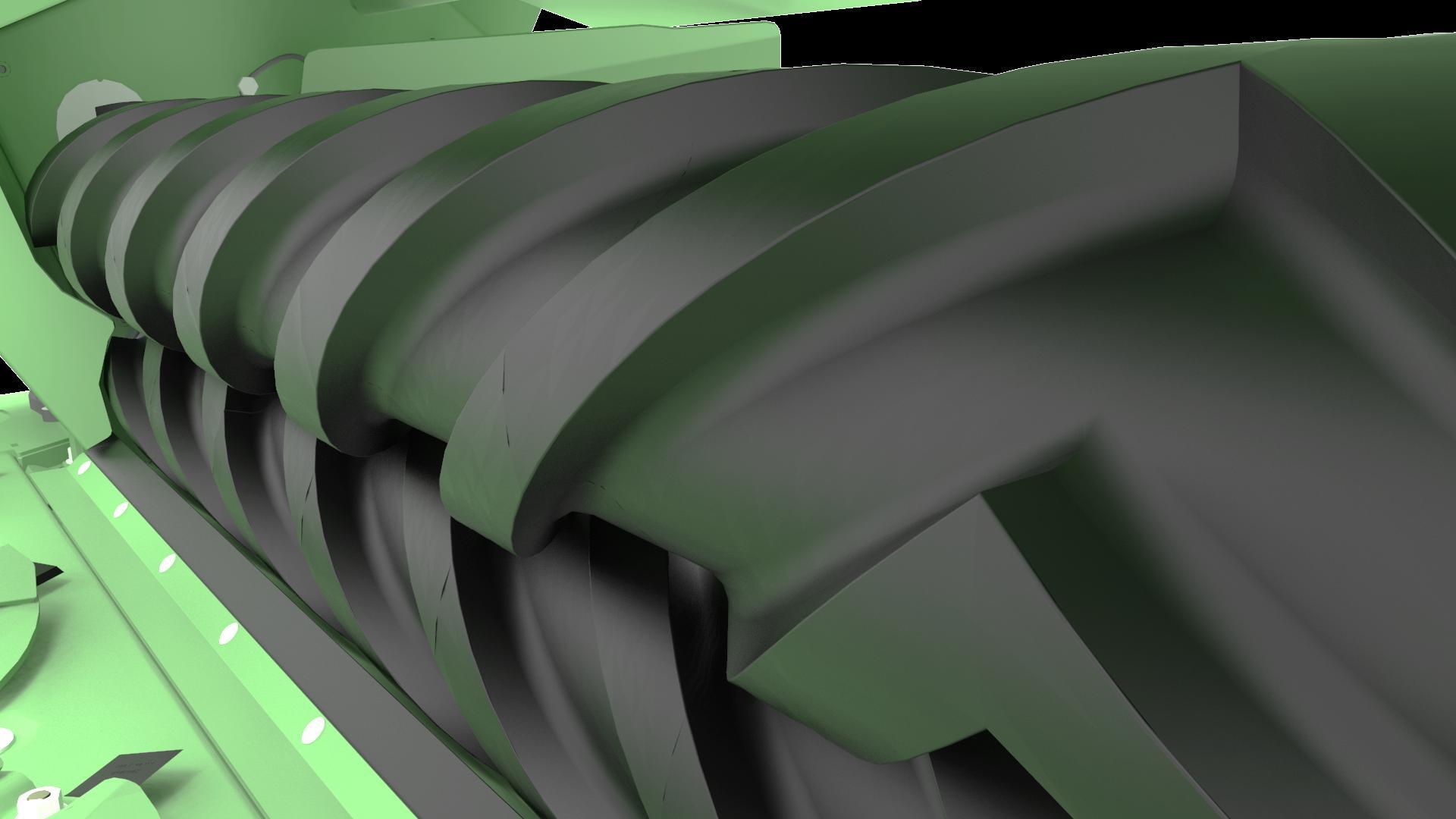

SH VERSION: FLAIL CONDITIONER

Boosted intensity of conditioning due to aggressive angle of flails

Better results in turning over mown material

Perfect loosening and aeration of the green mass and a guarantee of evenly shaped swath

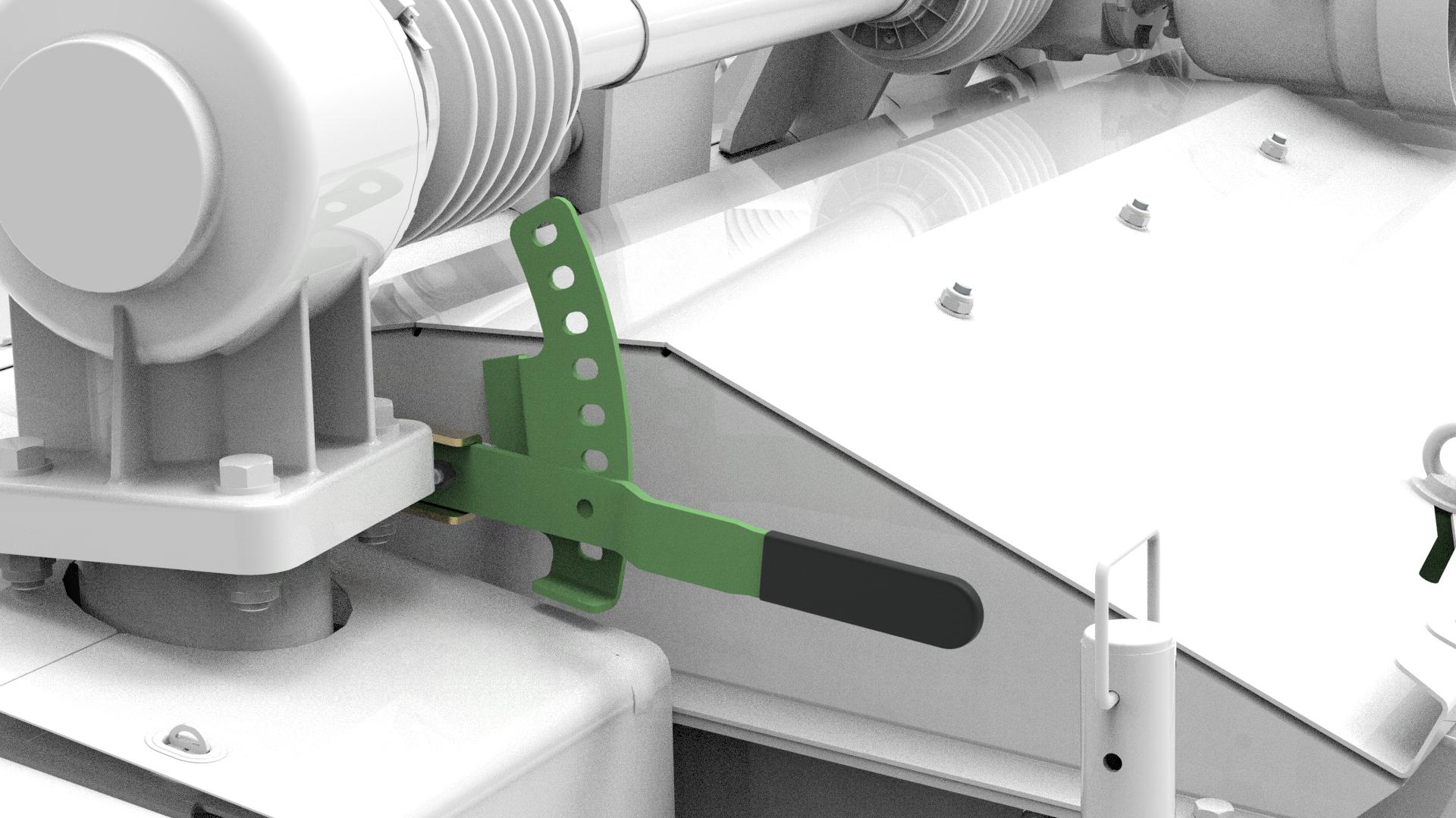

SH VERSION: 2-STEP GEARBOX

The drive of the cutterbar and the flail conditioner by an integrated

The gearbox enables choice between two speeds of the conditioner: 700 or 1000 RPM Enables adjustment of conditioning to field conditions

SH VERSION: FLAIL CONDITIONER

The intensity of conditioning is additionally adjusted by a handle which either widens or narrows the volume of material

8-step conditioning adjustment available

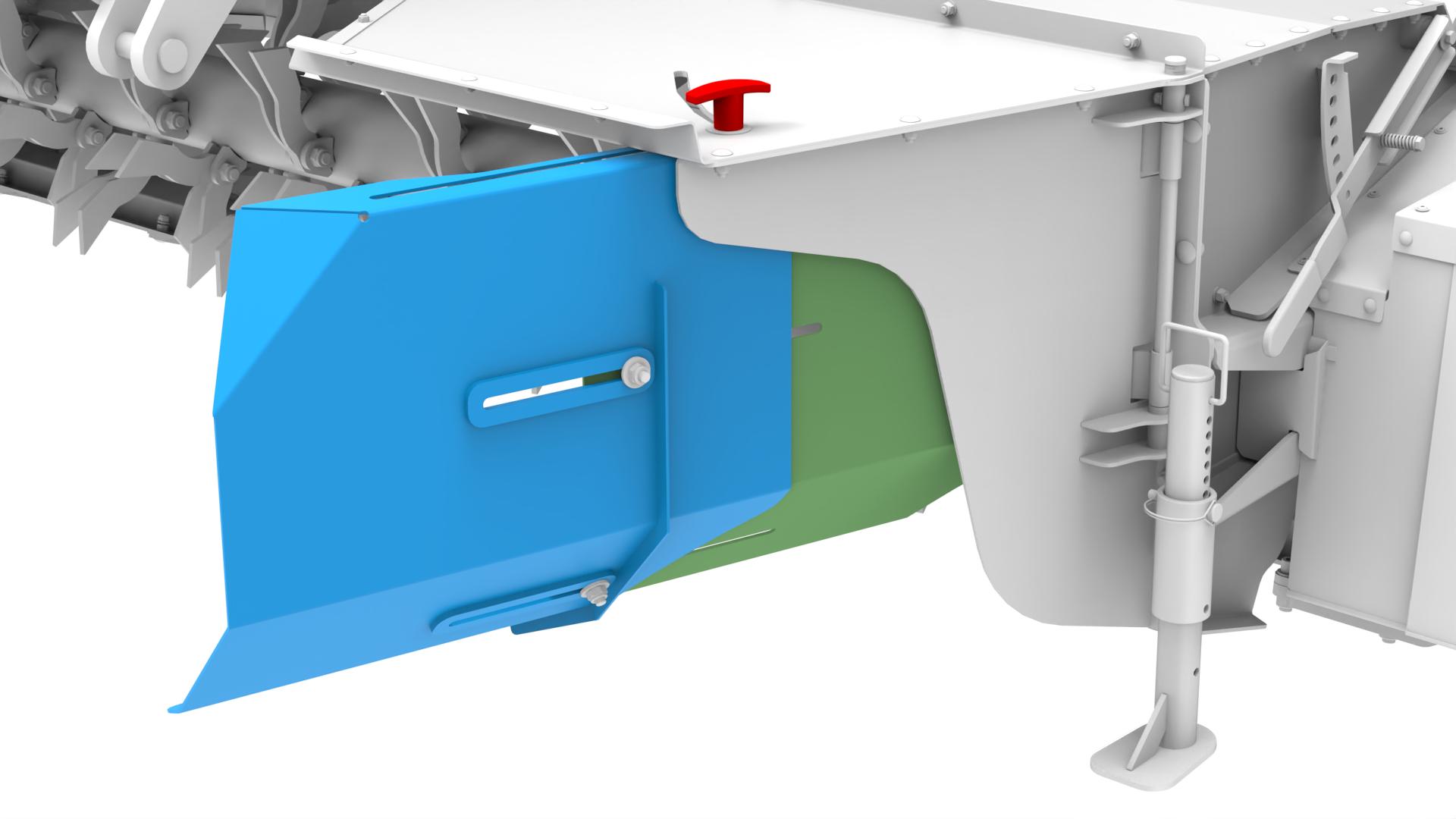

SH VERSION: SWATH GUIDES

Swath guides have a stepless adjustment

Possibility to adjust swaths according to individual needs

WH VERSION: INTEGRATED GEARBOX

The drive of the cutterbar and the roller conditioner via integrated gearbox

Constant, loose-free drive system for the most difficult and demanding working

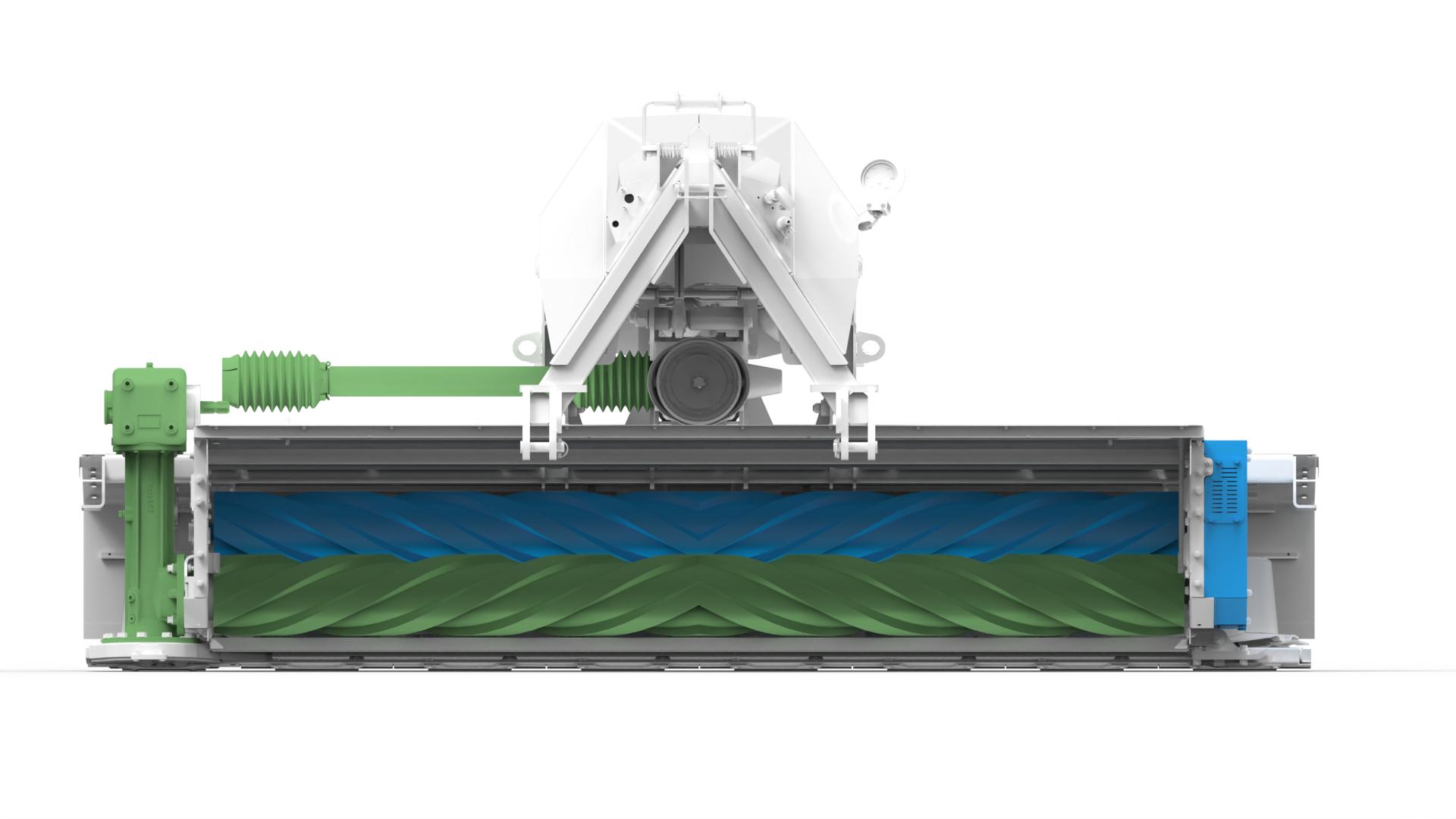

WH VERSION: ROLLER CONDITIONER

The contoured rubber rollers actively contribute to the conditioning of the legumes, while protecting their valuable parts

The crushing proces reduces the drying time of the material by about 25%, which helps to preserve the high protein content of the crop during short harvesting windows

COMFORTABLE SOLUTIONS

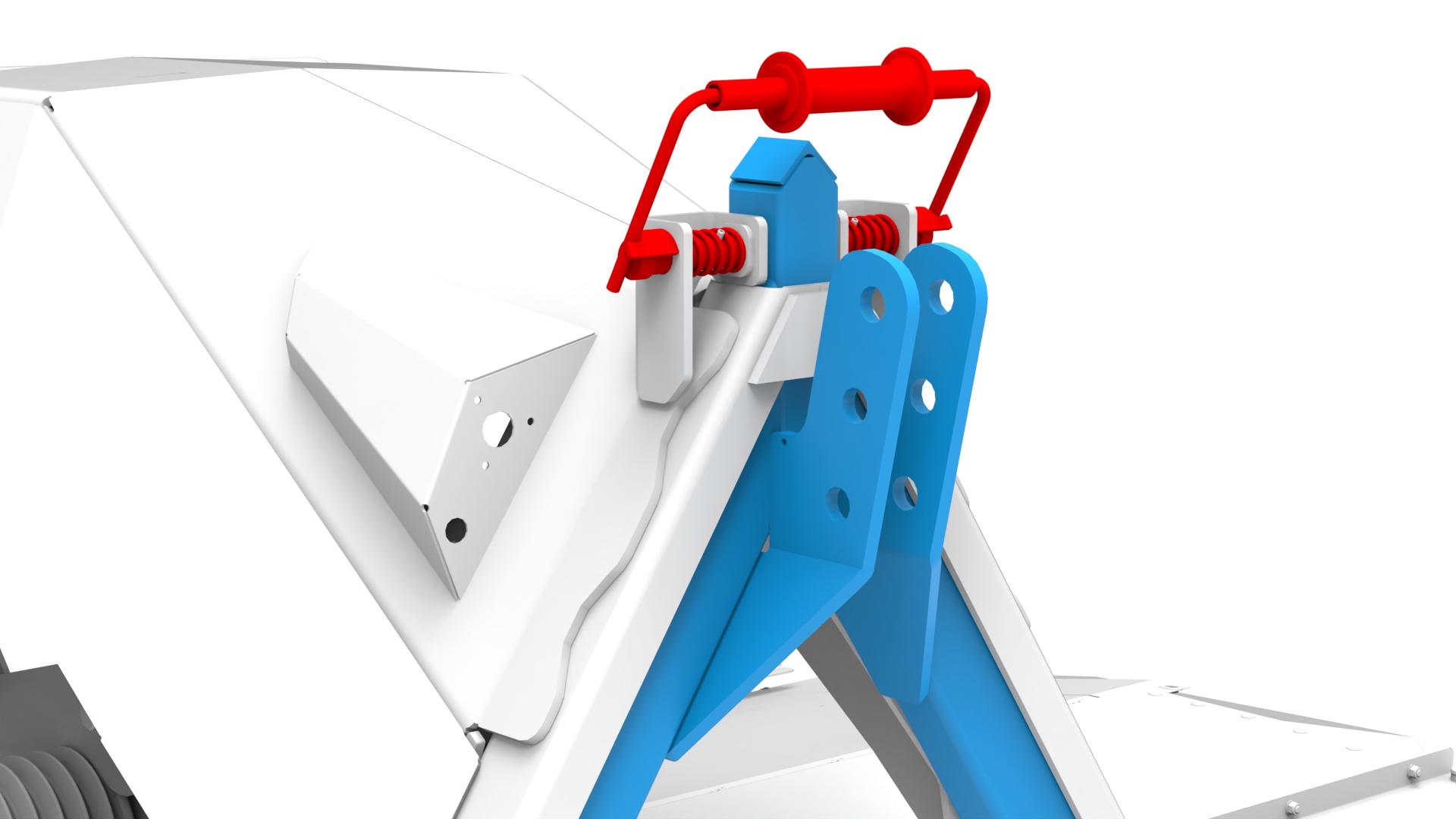

COMFORT: HITCHING UP THE MOWER

The mower is hitched up to the tractor with a mounting triangle (standard equipment)

Patented hitch of the mower was designed in a way that after uncoupling from the tractor, the triangle automatically locks

This system also makes it possible to uncouple the machine very quickly and comfortably

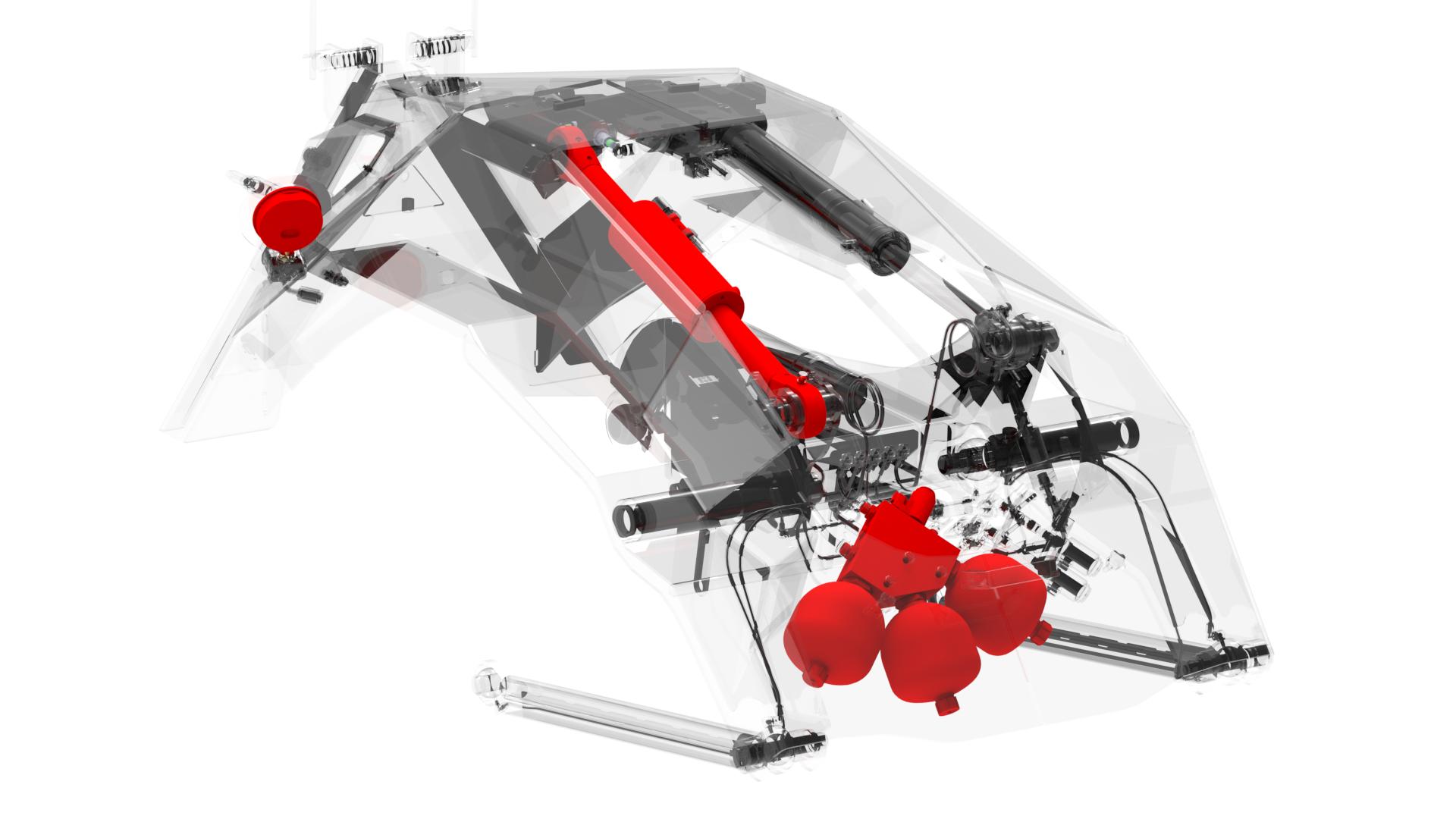

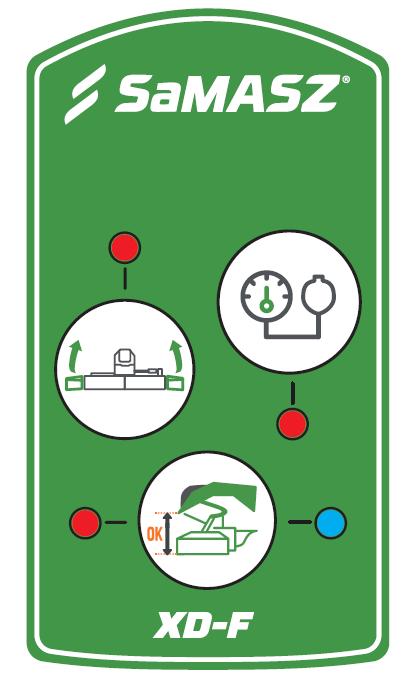

COMFORT: MACHINE CONTROLS

All the functions connected with a machine setup are operated by a control panel from the tractor cab =

ONLY 1 x single acting hydraulic connector

To adjust pressure or fold the side guards, simply press a buton on the control panel and activate theconnected hydraulic section

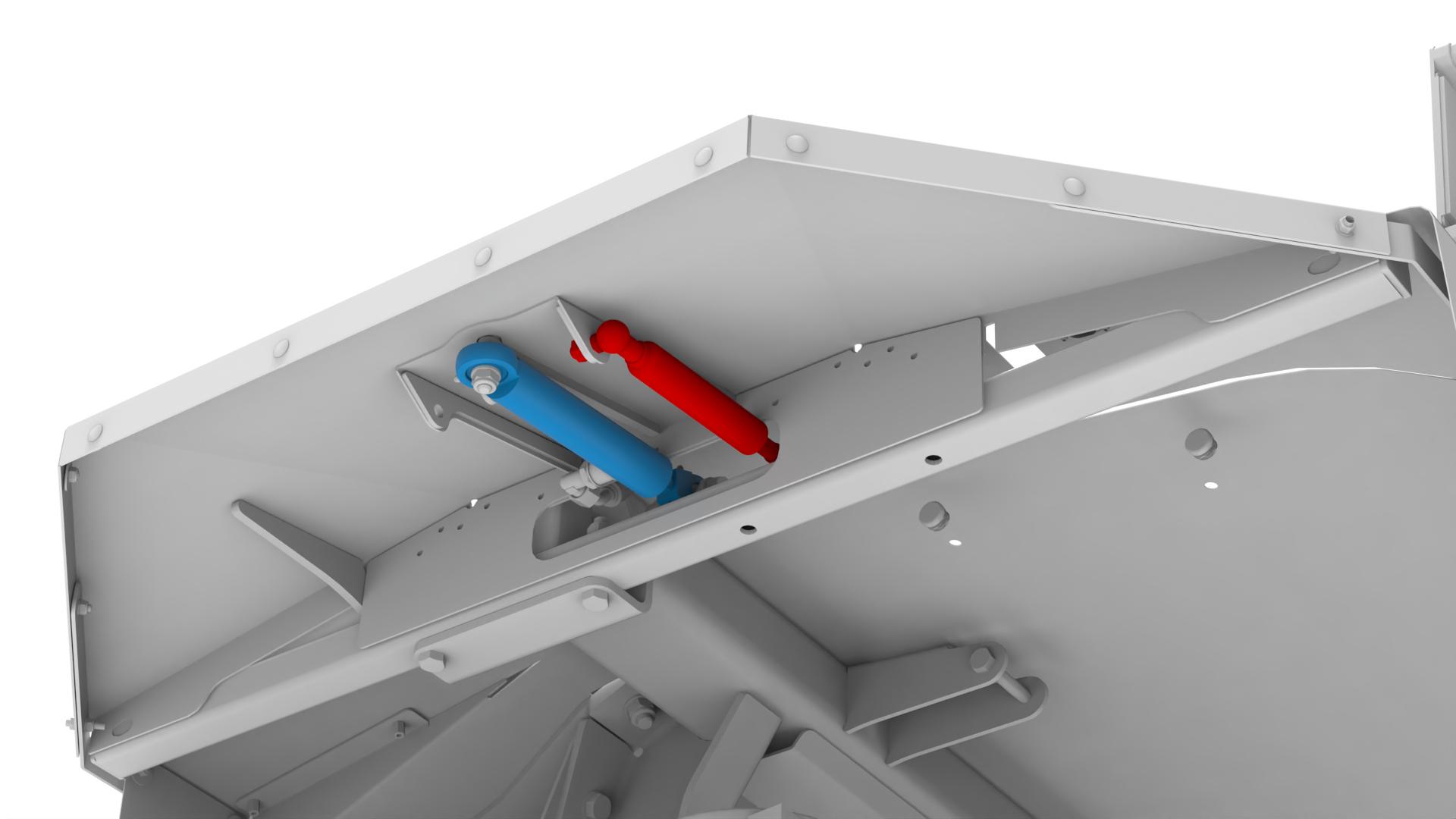

COMFORT: HYDRAULICALLY FOLDED SIDE GUARDS

Side guards are hydraulically folded

Thanks to the use of an additional gas cylinderconnected with the control panel, this function too is operated from the same and only single-acting

COMFORT: UNCOUPLING THE MACHINE

Patented mechanism automatically swings in and out the support foot on which the mower suspension rests The extended foot holds the entire mower suspension, and thus the lower hitching points, at a convenient and clearly visible height from the tractor cab, which makes it much easier to hitch up a mower again

COMFORT: GREASING

All the greasing points are located in one place and are easily accessible This increases the convenience of operating and servicing of the machine