SaMASZ Groupers Testimonial - Multi Ag Ltd – Waimate

“ I read about these mowers in the Ag Contractor magazine and thought we would give them a go. Price wise very well valued - service and back up from SaMASZ NZ is second to none, would’t question it… and yeah going forward think it’s a good business opportunity for us, because of the value and getting the job done with good parts back up & warranty period.”nd first choice for my next replacement...”

Scott - Multi Ag Ltd – Waimate

WHAT OUR CUSTOMERS THINK...

Steve Wood talks about his Double Rear Butterfly SaMASZ mowers

Check out what Bailey Thompson from GJ Graham Contracting has to say about SaMASZ

Check out North Canterbury farmer Alex Ferguson’s discussion about his two sets of SaMASZ triple mowers with roller conditioners.

SaMASZ Review - Jaiden Drought - Farm Trader NZ

‟ Two of the major reasons these SaMASZ mowers are gaining popularity is that they come with a two-year manufacturer’s warranty, providing operators with peace of mind and assurance of the product’s quality. And if they do break down, parts for these mowers are competitively priced. Chatting with the crew at KJR Contracting, these wellutilised mowers have completed their second season and have they have held up very well. There are no signs of stress on the frame and the paint is still excellent.”

Jaiden Drought - Farm Trader NZ

It’s our ‘go to’ mower’.. It’s done over 10,000ha and some rough hectares at that, and he’s never had to weld up the frame (which he’s had to on some other brands he’s used) It’s run over posts and drain cleanings, but in general I haven’t had anything go wrong with it... ‘Its solid, and that is a big thing. You go to work every day, and it goes every day

Steve Wood Contracting - Northland

David O’Neill Contracting Ltd based out of Omarama covers a vast area from Tekapo to the Lindis Pass down to Kurow and up the Haka Valley.

These mowers get a fair bit of abuse on Stoney Country. At night sometimes it looks like a fireworks display - they handle it.

We use 2 sets of SaMASZ mowers full time each mowing 2500 - 3000 hectares and a third set which is older as a backup.

Great mowers and the first choice for my next replacement.

David O’Neill Contracting - Omarama

Talking to ACT MP

Mark Cameron about his SaMASZ experience

I’ve been running SaMASZ mowers for 9 seasons, had a real good run with them. We do 1500 to 2000 hectares a year with them - stony conditions, rolling hills, a lot of steeper stuff.

The floatation’s just second to none I reckon. They sit on the ground good, follow the contour, don’t leave too much behind, and leave a nice clean finish –probably the cleanest finish I’ve seen. We’re real happy with them.”

Joe Herbert, Otago Contractor

Getting into the tail end of the season and not an issue all season... Front mower just over 1 year old and the rear mowers 3 years old now... Very strong mowers.

Bailey Thompson from GJ Graham Contracting

I bought a SaMASZ 3m belt drive mower in 2023 after a lot of research and love it! It’s well-built, easy to use, and mows great—plus I used half the diesel compared to my old mower on the same area with the same tractor. Very strong mowers.

Johnny Frater, Paeroa

Watch the SaMASZ Farm Trader review here:

David O’Neill Contracting mowing a heavy whole crop - Omarama Joe Herbert, Otago has been running SaMASZ for 9 seasons!

Jaiden Drought - Farm Trader

SaMASZ KEY NUMBERS EUROPEAN HAY MOWER SPECIALISTS

In 2024 SaMASZ celebrates their 40th anniversary. In 1984, engineer Antoni Stolarski started manufacturing agricultural machinery in Poland.

160,000

With a presence in more than 70 countries and more than 160,000 mowers produced since 1984

In 2022 SaMASZ produced an incredible 4000+ machines - really impressive!

NEW ZEALAND

SaMASZ Mowers – New Zealand’s Top Choice for Grass Harvest Equipment

SaMASZ Mowers – New Zealand’s Top Choice for Grass Harvest Equipment

• Trusted by farmers and contractors across New Zealand for performance, reliability, and precision

• Wide range of equipment including mowers, tedders, and rakes

• Reliable, low-maintenance, and durable

• Backed by local support and 2-year warranty

• Aiming to be NZ’s #1 mower brand by 2027

The

96.2HA 4HA

The new state of the art SaMASZ Factory in Poland occupies more than 4 hectares - impressive!

Guinness World Record

The largest area of grass mowed by a triple-disc mower in 8 hours is 96.2 hectares (237 acres), achieved by SaMASZ.

FarmShop team meeting with Chairman of the Board Antoni Stolarski and other key staff at the impressive SaMASZ factory in Poland.

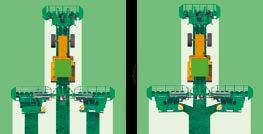

PerfectCUT CUTTERBAR

100% Key Break Away

• Sits between the gear wheel and drive shaft

• Absorbs impact forces or sudden shock

• Protects the cutterbar from major damage

• Reusable – just replace the shear key

200% Hydraulic Break Away

• Protects the cutterbar from major damage

• Hydraulic system allows the mower to swing back safely on impact

• Automatically returns to working position

3.

• Reliable protection for tough operating conditions 1. 2.

300% PTO Slip Clutch

• Protects the driveline from sudden overloads

• Prevents damage to the gearbox and mower components

• Reduces repair costs and downtime

cutterbar

• Superior break away system

• Superior driveline gearing

• Triple cutterbar protection

Key break away

Planetary Drive

• Drive transmitted onto discs through large gear wheels only - less RPM, less wear, less fuel and much quieter

• Idle wheels drive only a particular disc and not any other drive gears

3 layers of cutterbar protection

• The bottom of the PerfectCUT cutterbar is protected by both sliding skids and wear plates offered as standard equipment

• The bottom of the cutterbar is completely covered and 100% protected

Check out the

3. Cutterbar bottom

2. Sliding skid

1. Wear plate

Wear plate (blue)

Skid plate (black)

Cutterbar bottom (green)

PerfectCUT CUTTERBAR

Hardened discs

Hardened knife holder pins

◦ modernized shape of the pin increases knife stability

◦ longer resistance to wear thanks to Geomet® coat

◦ separate, replaceable element of the cutting disc

◦ special shape improves smooth crop flow and reduces workload

◦ high abrasion and wear resistance

◦ easy replacement

Design

◦ robust, strong and durable

◦ fully welded

◦ thick, 6 mm steel shell

Central knife holder

◦ improved shape of the holder enables thorough cleaning of the cutterbar

◦ made of high quality hardened steel

◦ 360* range of rotation

◦ quick and easy replacement

Disc module with SafeGEAR system

◦ additional protection for gears inside the cutterbar

◦ strong, sealed bearings

◦ quick and easy module replacement even in the field

◦ reusable after key replacement

Boron Hardened knives (L=110 mm 141/3”)

◦ SaMASZ logo proves the highest quality

◦ quick knife replacement with special mounting lever

◦ Wear resistant - up to 3 x life span

25 mm / 1” thick spur gears

◦ protected with SafeGEAR system

◦ higher abrasion resistance.

◦ ensure accurate power transfer

◦ perfect 4 tooth fitting

◦ low-noise operation

◦ low-noise, sealed 2RS bearings

DISC MOWERS

Machine category

• Rear-mounted

• Side suspension

• cutterbar

• Belt drive

Model name

• KDT 262

• KDT 302

• KDT 352

Working width

• 2,60 m / 8’7”

• 3,00 m / 9’10”

• 3,50 m / 11’4”

Power demand

• from 75 HP

• from 80 HP

SaMASZ KDT Rear Belt Drive Mowers

Tough, Efficient Rear Mowers Built for New Zealand Conditions

• Heavy-Duty Design

• Side Suspension System –improved contour following

• Compact Transport Position

• KENNFIXX® Hydraulic Couplers

• Integrated 2-Speed Gearbox

• PerfectCUT Cutterbar

• Breakaway Safety System

• Low Tractor Power Requirement

• from 95 HP Check the mower out

Support springs

◦ stepless adjustment of ground pressure

◦ high level of ground following

Safety guard

◦ lifted for easier maintenance

◦ safety curtain - protects against stones

◦ resistant to weather conditions

◦ lifted side guard decreases transport height

◦ turf protection Belt drive

Mechanical safety breakaway device

◦ protection of mower against damage

◦ drive transmission through 4 V-belts

◦ automatic tensioning

◦ low-noise operation

◦ additional protection of the machine

Side suspension

Designed to float laterally and follow ground contours effectively

Mechanical breakaway device

The mower has a mechanical safety device that activates when an obstacle is encountered.

Two-swath cutterbar configuration

Available on the KDT 352 model, which can fitted with a special cutterbar with two additional disc drums.

TECHNICAL SPECIFICATION

DISC MOWERS

Machine category

• Rear-mounted

• Central suspension

• cutterbar

• Direct drive

Model name

• KT 301

• KT 341

Working width

• 3,00 m / 9’10”

• 3,50 m / 11’4”

Power demand

• from 95 HP

• from 105 HP

SaMASZ KT Rear Direct Drive Mowers

Smart Design. Clean Cut. Built for NZ Conditions.

• 3 transport and parking positions for safe, compact storage and easy maneuverability

• Hydropneumatic pressure relief system ensures optimal ground adaptation and reduced wear

• Patented transport lock for secure and stable road travel

• KENNFIXX® hydraulic handles for quick, clean, and user-friendly connections

• Integrated 2-speed gearbox for efficient operation in varied field conditions

Check the mower out

Central suspension

◦ work unit located in the center of gravity, even support across the whole cutterbar width,

◦ perfect ground following enabling work on uneven ground

Safety guard

◦ lifted for easier maintenance

◦ safety curtain - protects against stones

◦ resistant to weather conditions

◦ lifted side guard decreases transport height

Patented latch

◦ unique mechanical solution

◦ reliable and easy operation in three modes: transport, work, parking

Ground pressure relief system

◦ adjustable work unit support - high level of ground following,

◦ spring-type as standard,

◦ hydropneumatic type (optional).

Hydraulic safety breakaway device

◦ protection of mower against damage

◦ if an obstacle is hit, the unit is retracted by 30° and at the same time lifted by approx. 35 cm / 1’2”

3 x Transport and parking positions

The special design of the suspension arm of the cutting unit allows transport in three different positions.

Behind tractor for easy shed storage

Side - fast and easy

Hydropneumatic pressure relief system

Automatically adjusts ground pressure for consistent cutting, reduced wear, and optimal performance across uneven terrain.

Behind tractor for road and gateways

KENNFIX hydraulic connector

TECHNICAL SPECIFICATION

Necessary hydraulic couplers 2 x double acting (spring suspension) 1 x double acting + 1 x single acting (optional hydropneumatic suspension)

Necessary hydraulic couplers

x double acting (spring suspension) 1 x double acting + 1 x single acting (optional hydropneumatic suspension)

/ 3235

PTO shaft tractor - mower: with friction overrunning clutch, built in: no clutch

Swath guides [pcs.] Metal swath guides in conditioner

• S - tine conditioner

• W - roller conditioner

• H - hydropneumatic suspension

QUICK SET UP GUIDES

1. Set plough arms at 55 - 60 cm from ground.

2. Quick reference guidecheck gap between bump stop is 150 -200mm.

3.

More hydraulic pressure (shortened springs) = less ground pressure... Good for rough and stony ground (but slows down reaction time).

4. Less hydraulic pressure = more ground pressure... (Longer springs) Fast reaction and contour following, good for clean country mowing).

QUICK SET UP GUIDES

SETTING GROUND PRESSURE ON THE KT MOWER

1. Plug in to tractor and mower.

2. Turn on (Green light on).

3. Power up to pressure with hydraulic lever.

4. Turn off (green light off).

5. Put hydraulic remote into float for mowing.

QUICK SET UP GUIDES

3 WORKING POSITIONS FOR THE KT MOWER

1. Park position.

2.

3.

Mowing position.

Mow with RAM in float.

Higher and lower with remote at headlands.

To speed up headland lift reaction turn (blue knob) anti-clockwise.

Turn clockwise to slow down headland lift.

4. Transport position.

Pull strings and lift (if mower does not lift, release pressure).

QUICK SET UP GUIDES

HYDRO-PNEUMATIC DIRECT DRIVE KT MOWER

1. Connect to tractor in the park position.

2. Take pressure out of RAM - gauge at 0.

3. Put main hydraullic RAM into float.

4. Lift plough arms up until gap appears.

5. Pull strings then lift into transport position and lift mower.

DISC MOWERS

Machine category

• Rear-mounted

• Central suspension

• cutterbar Model name

• XT 350

• XT 390

Working width

• 3,50 m / 11’4”

• 3,90 m / 12’1”

Power demand

• from 105 HP

• from 120 HP

Built for Modern Farming –The New XT Series Mowers

• Automatic locking system for headland turns

• Hydraulic lift for easy raising at headlands and transport

• Adjustable lower hitch pins for quick attachment to different tractor types

• KENNFIXX hydraulic quick connector

• Smooth hydropneumatic pressure relief adjustment controlled from the tractor cabin steering panel (standard feature)

• Transport position angled at 125° for safe and compact movement

• Machine can be securely parked in transport position using 4 support legs

• Saves valuable shed and storage space

Check the mower out

Safety guard

◦ lifted for easier maintenance

◦ safety curtain - protects against stones

◦ resistant to weather conditions

◦ lifted side guard decreases transport height

Machine mowing setting indicator:

◦ helps to adjust the height of the hitch

◦ easily visible from tractor’s cabin

125° inclined transport position

◦ decreases transport height to 3,97 m with 3,90 m working width

◦ increased stability during transport thanks to balanced centre of gravity

◦ improved visibility in side mirrors

Hydropneumatic suspension:

◦ innovative hydropneumatic lightening system

◦ integrated with hydraulic safety breakaway device and lifting cylinder

◦ operated by steering panel directly from tractor’s cabin

Unique safety breakaway device:

◦ integrated hydraulic breakaway in hitch and frame

◦ First disc lifts over 50 cm, with 30 cm minimum clearance

– market-leading range

◦ Cutterbar auto-returns to working position

Warning plate with LED lights

Support legs:

◦ 4 support legs allow parking in transport position

◦ saves space considerably

Transport position

The XT mower folds to a compact 125° angle, making it easier to fit in your shed. Folding closer to the tractor’s centre also saves space and helps keep the mower stable during storage and transport.

Hydropneumatic pressure relief system

The hydropneumatic pressure relief system offers stepless, easy adjustment from the tractor cab for consistent ground pressure across all terrain. A pressure gauge on the mower frame lets the operator quickly fine-tune settings.

TECHNICAL SPECIFICATION

3-point hitch cat.

DISC MOWERS

Machine category

• Trailed

• cutterbar Model name

• KDC 300

• KDC 340

• KDC 390

• KDC 430

Working width

• 3,00 m / 9’10”

• 3,50 m / 11’4”

• 3,90 m / 12’9”

• 4,30 m / 14’1”

Power demand

• from 80 HP

• from 90 HP

• from 100 HP

• from 110 HP

SaMASZ KDC Trailed Mower –Versatile, Efficient, Built for Kiwi Conditions

• A smart alternative to 3-point linkage mowers –ideal for smaller tractors

• Central drawbar allows mowing from either side of the tractor

• trailed suspension system - with 63 cm of vertical travel allows the cutterbar float for a clean cut

• wide wheels guarantee stability

• pairs well with a front-mounted mower for greater working width and productivity

• built for clean, efficient mowing on both flat and rolling terrain

Check the mower out

Drawbar Arm:

◦ center mounted,

◦ enables working on both sides of the tractor and helps maneuvering

Drive Transmission:

◦ PTO shaft placed inside drawbar

◦ protection against damages & weather

Intersecting axis gear:

◦ change of rpm from 540 to 1000 by rotating main gearbox 180°.

Hitch

◦ turnable for convenient manouvering

Central drawbar

Centrally positioned drawbar makes it possible to work from either side of the tractor.

Safety guard:

◦ lifted for easier maintenance

◦ safety curtain - protects against stones

◦ resistant to weather conditions

◦ lifted side guard decreases transport

Warning plate with LED lights

◦ as standard equipment

Support springs:

◦ high level of ground following, on uneven ground and steep slopes

◦ even support across the whole working width

◦ adjustable pressure on the ground

Conveyor belt

The conveyor belt on KDC ST and WT models removes the need for raking.

SaMASZ Testimonial - Future Feeds in Canterbury NZ

”We purchased our SaMASZ trailing mower because we could see the build quality was very robust, and serviceability was great and user friendly, which keeps us going at crucial times of the year. Since operating the mower, we haven’t had to touch it mechanically despite covering some fairly rough ground. The adjustments you can make have meant we have been able to mow a wide range of crops and get a perfect cut every time.”...

Future Feeds in Canterbury NZ

Watch Future Feeds

SaMASZ in action here:

TECHNICAL SPECIFICATION

PTO shaft tractor - mower: with friction clutch, built-in: 1. no clutch, 2. with overrunning clutch, 3. with overload clutch, 4. wide-angle u-joint

DISC MOWERS KDF

Machine category

• Front-mounted

• Pull-type suspension

• cutterbar Model name

• KDF 302

• KDF 352

• KDF 392

Working width

• 3,00 m / 9’10”

• 3,50 m / 11’4”

• 3,90 m / 12’9”

Power demand

• from 80 HP

• from 90 HP

• from 100 HP

SaMASZ KDF Pull-Type Mower –Smooth Ground Following, Clean Cut

• Pull-type suspension allows the mower to operate independently of the tractor for better contour following

• Equipped with the robust PerfectCUT cutterbar for consistent cutting performance

• Excellent ground following range of +/- 63 cm –among the best in the market

• Adapts easily to uneven terrain for a clean and uniform cut

• New hitch height indicator

• Addition of knife box and key holder for changing knives

Check the mower out

KDF

Pull-type hitch:

◦ the highest range of ground following

◦ mechanical transport lock

◦ mounted on front 3-point linkage triangle: tractor’s triangle in standard equipment

Intersecting axis gear:

◦ drive transmission through PTO shafts

◦ change of rpm direction by rotating main gearbox 180°,

◦ low-noise operation

Safety guard:

◦ lifted for easier maintenance

◦ safety curtain - protects against stones

◦ resistant to weather conditions

◦ lifted side guard decreases transport

Support springs:

◦ even ground pressure across full width for cleaner fodder and turf protection, even at high speeds.

Ground Following

The KDF mower’s pull-type suspension and PerfectCUT cutterbar enable independent ground following with a market-leading +/- 63 cm range, ensuring a clean cut across uneven terrain.

Hitch

The KDF mower connects via a standard hitch triangle. For tractors with short lower links, an extended version is available.

Tine Conditioners

S versions are equipped with a tine conditioner - resulting in faster drying process of the mowed material and no need for a tedder.

TECHNICAL SPECIFICATION

•

•

PTO

DISC MOWERS XDF

Machine category

• Front-mounted

• Pull-type suspension

• cutterbar Model name

• XDF 301 SH

• XDF 351 SH

Working width

• 3,00 m / 9’10”

• 3,50 m / 11’4”

NEW

Power demand

• from 80 HP

• from 110 HP

XDF Front Mower – Built for NZ Conditions and Maximum Efficiency

• Pull-type hitch pulls the cutterbar (not pushes) –ideal for front mowers.

• Quick-change blades and modules – easily swapped in the paddock to reduce downtime.

• 22° lateral tilt and 860 mm vertical travel –excellent ground adaptation.

• Hydro-pneumatic suspension – in-cab pressure adjustment with easy-to-read gauge.

• Choice of conditioner – flail or roller; this model fitted with heavy-duty ‘bear claw’ tines.

• NZ-specific conditioning setup

Check out some of the key features of the SaMASZ XDF mower

XDF

Central greasing

◦ all greasing spots in one location

Hydropneumatic suspension:

◦ ground following feature independent of the tractor in the range of + 520mm / - 340 mm

◦ lateral tilting range of up to 22°

◦ smooth adaptation to the ground contours

V-claw tines (Bear Claw)

Correct suspension height sensor

◦ perfect cutting quality

◦ turf protection

Tine conditioner with V-claw tines

◦ accelerates drying

◦ less tractor time

◦ harvest economy

• NZ-specific bolt-on design for easy maintenance

• 5 & 7-stage adjustable baffles

• Swinging mount lets tines deflect on obstacles

• Limited tine movement increases bolt durability

• Double helical spacing for uniform conditioning

• Aggressive flail angle boosts conditioning

• Improved turning of mown material

• Even swath, better loosening & aeration

Central greasing

All greasing points are conveniently grouped in one accessible location for easier maintenance.

Integrated gearbox

◦ direct drive to cutterbar & conditioner

◦ easy 700/1000 RPM change via handle

◦ adjusts conditioning to suit field conditions

Hydraulically controlled side guards

Side guards

Hydraullic adjustment for easy width setting to suit paddock conditions

Swath guides

Ground following

Rocker suspension system enables ground following feature independent of the tractor. In combination with the pull-type hitch, the mower features lengthwise ground following range of + 520 mm / -320 mm and lateral tilting of up to 22°

TECHNICAL SPECIFICATION

DISC MOWERS KDD

Machine category

• Two-sided, rear-mounted

• Central suspension

• cutterbar Model name

• KDD 861

• KDD 911

• KDD 941

Working width

• 8,60 m / 28’2”

• 9,10 m / 29’10”

• 9,40 m / 30’10”

Power demand

• from 140 HP

• from 160 HP

SaMASZ KDD MegaCUT – Maximum Coverage, Built for NZ Conditions

• Generous working width – Ideal for large-scale NZ farms and contractors

• PerfectCUT cutterbars – Built tough for clean, precise cuts

• Hydro-pneumatic suspension – Smooth ground following with in-cab control

• Quick blade change system – Fast, tool-free servicing in the paddock

• Hydraulic breakaway – Cutterbars lift and pivot to avoid damage

• Compact transport fold – Easy and safe road transport

• Optional conditioner units – Flail or roller for faster drying

Check the mower out

Ground pressure relief system

◦ adjustable work unit support - high level of ground following

◦ spring-type as standard

◦ hydropneumatic type (option)

Warning plates with LED road lights standard

4 support legs:

◦ support legs enable parking of the machine in transport position

◦ saves space considerably

Central suspension

◦ centrally balanced unit for even support across the full cutterbar width

◦ perfect ground following enabling work on uneven ground

Hydraulic breakaway device

Protects the cutterbar. If it hits an obstacle, it pivots back 24° and lifts 35 cm, then resetting to the working position.

Overlapping of cutting units

Overlapping of front and rear mowers is factory set for 375 mm (1’ 2/5”). MegaCUT set always presents three windrows.

KENNFIXX hydraulic handles

Standard KENNFIXX handles make hydraulic hookup easy. Colour-coded hoses are simple to identify.

KENNFIXX

hydraulic connector

TECHNICAL SPECIFICATION

PTO shaft tractor - mower: no clutch, built-in: with friction overrunning clutch

H - Hydro-pneumatic suspension

DISC MOWERS

KDD ST, KDD WT

Machine category

• Two-sided, rear-mounted

• Central suspension

• KDD 861 S / W

• KDD 941 S / W

• KDD 861 ST / WT

• cutterbar Model name

• KDD 941 ST / WT

Working width

• 8,60 m / 28’2”

• 9,40 m / 30’10”

• 8,60 m / 28’2”

• 9,40 m / 30’10”

Power demand

• from 160 HP

• from 180 HP

• from 200 HP

• from 220 HP

SaMASZ GigaCUT –

Built for NZ’s Biggest Farms and Toughest Conditions

• Built for professionals – Trusted choice for large farms and contractors

• Proven worldwide – GigaCUT performance tested in the toughest conditions

• PerfectCUT cutterbar – Precise, reliable cutting all season long

• Highly versatile – KDD ST and WT models work with or without conveyors

• Adaptable setup – Easily adjust to different crops, conditions, and preferences

Check out this video on the design of SaMASZ Conditioners

KDD ST, KDD WT

Ground pressure relief system

◦ adjustable work unit support - high level of ground following

◦ spring-type as standard

◦ hydropneumatic type (option)

Warning plates with LED road lights standard

4 support legs:

◦ support legs enable parking of the machine in transport position

◦ saves space considerably

Hydraulic safety breakaway device

◦ protection of mower against damage

◦ if obstacle is hit the unit is retracted by 24° and at the same time lifted by approx. 50 cm / 1’ 8”’

Control panel

• Control left/right units for lifting and locking

• Adjust left/right pressure relief separately (version “H”)

• Control left/right conveyor belts—speed and lifting, separate or synchronized

• Fold/unfold units for transport and work

Hydraulic unit

• Advanced hydraulic unit reduces tractor load

• Radiator & fan ensure reliable cooling under heavy use

• Fan has reverse gear to clear dust during operation

Close-up sensors

◦ adjustable

◦ provides easier working on headlands

Adjustment of cutting units

• Overlapping of front & rear mowers is factory set for 375mm (14 3/5”). Presents three windrows.

KDD ST, KDD WT

Conditioning intensity adjustment

The flail conditioners have a corrugated plate, which lets you adjust conditioning intensity to suit the crop.

Conveyor belt

Conveyor belts combine swaths from three mowers into one, eliminating raking for faster, more efficient work.

Using the control panel, the operator controls belt speeds independently via the panel, allowing tailored operation to match conditions and harvest flow.

Integrated gearbox

Mowers equipped with a tine conditioner mowers feature a 2-speed transmission with lever control to switch between 700 and 1,000 rpm for adjustable conditioning intensity.

Conditioners

Conditioners used in KDD ST and KDD WT mowers speed up forage drying process. A reliable and efficient solution results in excellent quality of dried material. Thanks to the use of conditioners, not only more effective work is achieved, but also time savings as there is no need for a tedder.

Conveyor cleaning mechanism

Conveyors have mechanical cleaning for drive rollers to ensure trouble-free operation.

S - tine conditioner

CONFIGURATIONS OF WORK WITH TRANSPORTERS

Independent Row Option

One Swath Width Only

TECHNICAL SPECIFICATION

- mower: no clutch, built-in: with overrunning friction clutch

- mower: no clutch, built-in: with overrunning friction clutch

Swath guides Metal swath guides in conditioner

• H - Hydro-pneumatic suspension

Swath guides

• S - tine conditioner

• W - roller conditioner

• T - Conveyor belt

• H - Hydro-pneumatic suspension

mower:

Metal swath guides in conditioner

- mower: no clutch, built-in: with overrunning friction clutch

Metal swath guides in conditioner

DISC MOWERS KDD STH ISOBUS

Machine category

• Two-sided, rear-mounted

• Central suspension

• cutterbar Model name

• KDD 911 STH ISOBUS

• KDD 941 STH ISOBUS

Working width

• 9,10m / 29’10”

• 9,40 m / 30’10”

Power demand

• from 200 HP

• from 220 HP

SaMASZ KDD STH – Smart ISOBUS Control for Maximum Efficiency

• ISOBUS control – Full mower operation from the tractor terminal

• Integrated conveyor belts – reduce raking

• PerfectCUT cutterbars

• Hydro-pneumatic suspension – Smooth ground following with in-cab adjustment

• Quick-change blades

• Hydraulic breakaway system

• Adjustable conditioning intensity

• Heavy-duty flail conditioner – Made for NZ

• Mechanical roller cleaners – Keep conveyors running smoothly

Check the mower out

SaMASZ Imported to New Zealand by

KDD STH ISOBUS

Integrated gearbox

◦ direct drive to cutter bar and conditioner

◦ simple speed change (700 / 1000 rpm) via handle

◦ adjustable loosening intensity for field conditions

Conditioner with V-claws

◦ speeds up the drying process of the cut material

◦ reduces the number of passes

◦ designed specifically for NZ conditions

Hydraulic safety breakaway device

◦ protects the mower from damage

◦ cutting unit tilts backwards by approx. 24°, while simultaneously lifting by approx. 35 cm

Warning plates with LED road lights standard

Hydro-pneumatic relief

◦ reduced machine pressure on the ground

◦ adjustable with an innovative hydraulic system’

Swath conveyor

◦ combines swaths from three mowers into one

◦ speeds up green fodder collection – no raking needed

◦ own hydraulic system for drive and speed controly

Overlap (911 only)

◦ increased front mower overlap with extra inner disc on cutter bar.

◦ Clean cut with no fringes, even on slopes or when turning.

New ISOBUS & hydraulic latch system

Hydraulically foldable side covers

New hydraulic latch and hydraulic side guard control from the comfort of your tractor seat (no more strings).

TECHNICAL SPECIFICATION

• S - tine conditioner

• T - Conveyor belt

• H - hydropneumatic suspension

OVERLAP OF CUTTING UNITS AND SWATH WIDTHS IN SETS

E¹ swath width of the front-mounted mower

E² maximum swath width with active conveyor belts (front + rear-mounted mowers) F swath width of rear-mounted mowers without active conveyor belts

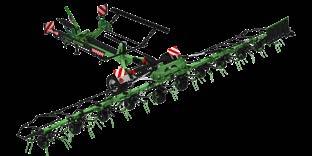

TEDDERS

P4, P6, P8

Machine category

• 3-point mounted

Model name

• P4-531

• P6- 771

• P8-890

Working width

• 5,30 m / 17’5”

• 7,70 m / 25’3”

• 8,90 m / 29’2”

Number of rotors

• 4-rotor

• 6-rotor

• 8-rotor

SaMASZ P4, P6, P8 Tedders –Fast, Even Forage Spreading for NZ Conditions

• Available in 4, 6 and 8-rotor configurations to suit various farm sizes

• Designed for fast, even spreading and fluffing of forage

• Rugged frame and heavy-duty construction for durability in tough conditions

• Straightforward, maintenance-free gearboxes

• Quality finish: Seven-step paint process gives excellent paint quality

• Double-acting lift rams

• Impressive two-year manufacturer’s warranty

• Tine holders keep any broken ones in check

P4, P6, P8

Mechanical transport lock

Hitch

◦ swinging for better ground following

◦ turning for easier manouvering

Damping braces◦

◦ stabilize the machine during operation

Warning plates with LED road lights

Hydraulic cylinder

◦ simultaneous fold-down, even on slopes

◦ innovative design of cylinder’s piston in P6-651 and P6-771

Gearbox

◦ oil operating gearbox

◦ low noise operation

◦ maintenance-free use

Adjustable driving chassis

◦ high range spreading angle

◦ stability on wet fields

Gearbox cover

◦ prevenst grass winding

Protective rails

The truss design of the protective rails increases the stability of the entire machine. In addition, it protects it from damage if it runs into an obstacle.

TECHNICAL SPECIFICATION

Machine category

• Trailed Model name

• P10-1100 T

• P12-1330 T

Working width

• 11,00 m / 36’

• 13,30 m / 43’6”

Number of rotors

• 10-rotor

• 12-rotor

SaMASZ P10 & P12 Tedders – Exceptional Ground Following, Maximum Productivity

• Built for contractors and large-scale farmers

• Working widths up to 13.30 m (43’6”) for maximum productivity

• Ideal for both flat paddocks and rolling hills

• Advanced lateral flexibility for excellent ground following

• Delivers clean, even crop spreading

• Patented tool-free adjustment system for quick angle changes

• Fast setup and reduced downtime

• Reliable, consistent performance season after season

Check the tedder out

P10, P12

Safety guards

◦ unique design in truss pattern

◦ highly impact and obstacle-resistant

Patented folding mechanism

◦ Hydraulic folding/unfolding via central cylinder

◦ integrated turnable cylinders eliminate need for additional manoeuvring

Trailed hitch

◦ easy and quick mounting

Ground following

Adjustable driving chassis

◦ high range spreading angle

◦ stability on wet fields

Warning

plates

with LED road lights

Gearbox with solid grease

◦ hermetically closed

◦ maintenance-free use

◦ low-noise operation

Turning cylinder on wheels

◦ Switch between work and transport position

◦ No need to reposition the tractor

Curtain (standard)

◦ prevents throwing of grass during work at the end of the field

◦ hydraulic folding

Integrated mechanical brakes

◦ stabilize wheels during work and transport

◦ prevent uncontrolled wheel turning

Gearbox cover

◦ prevenst grass winding

Every rotor has been mounted on a separate frame. Consequently, there are two pivot pins per rotor. Such a design enables a large range of independent ground following in relation to neighbouring rotors despite the large working width of the machine.

TECHNICAL SPECIFICATION

Tires (with inner tubes)

[kg / lbs]

x8 (side), 18x8,5-8 x2 (central), 340/55-16 x2 (transport)

600 / 5 732

x8 (side), 18x8,5-8 x2 (central), 340/55-16 x2 (transport)

786 / 6 142

PTO shaft (built-in) tractor - tedder: wide-angle with overrunning clutch built-in: with overload clutch

Z SERIES RAKE

Machine category

• Single-rotor

• 3-point mounted

Model name

• Z-470

Working width”

• 4,70 m / 15’5”

TECHNICAL SPECIFICATION

Working width [m / ft] 4,70 / 15’5”

Windrow width [m / ft] 0,80 - 1,50 2’7” - 4’11”

Transport width [m / ft] 3,80 / 12’8”

Transport width without arms [m / ft] 2,30 / 7’7”

Working capacity [ha/h | ac/h] ~5,60

Number of arms [pcs.] 13

Rotor diameter with arms [m / ft] 3,80 / 12’8”

Number of tines [pcs./arm] 4 RPM 540

Recommended RPM 300 - 350 3-point hitch cat. II

Power demand [HP] from 50

Tires (with inner tubes) 16 x 6,5–8 Weight [kg / lbs] 830 / 1830

PTO shaft

Check the rake out

Z2 SERIES RAKE

Machine category

• Twin-rotor

• Hydraulic width adjustment

• Independent rotor control

Model name

• Z2-780

• Z2-840 H

• Z2-960

Working width

• 7,20 – 7,60 m / 23’7” - 24’11”

• 7,60 – 8,40 m / 24’11” - 27’7”

• 8,80 - 9,60 / 28’10” - 31’5”

TECHNICAL SPECIFICATION

This is a classic twin-rotor rake, designed for maximum efficiency. It is a versatile and reliable solution which has been tried and tested globally, from the Americas through Europe to Asia. The simple center delivery design offers high performance, is user friendly, and comes with a wide range of accessories as standard.

Tires (with inner tubes) 16 x 6,5–8 (under rotors) / 340/55-16 (rear)

[kg / lbs]

PTO shaft

040 / 4 500

16 x 6,5–8 (under rotors) / 340/55-16 (rear)

420 / 5 335

tractor - rake: wide-angle, built-in: 1. with overrunning clutch, 2. with overload clutch

Windrow central central

Check the rake out

Z2-960 SERIES RAKE

Machine category

• Twin-rotor

• 3-point mounted

• Independent rotor control

• Hydraulic width adjustment

Model name

• Z2-960

Working width

• 8,80 - 9,60 / 28’10” - 31’5”

NEW Z2-960: for even wider coverage and improved productivity

• Easy transport with foldaway guards

• Superior contour following for cleaner raking

• Mechanical lock for safe transport and headland turns

• KENNFIX hydraulic connectors for quick hook-up

• Auto windrow curtain drops into working position

• Forced steering system keeps the rake tracking behind the tractor

• Wide rear wheels for stability on the road and in the paddock

• 15 arms per rotor – more arms, cleaner pickup, and greater yield

• Independent rotor control Hydraulic width adjustment

Check the rake out

Z2-960

Hitch

◦ swinging for better ground following

◦ turning for easier manouvering

Warning plates with LED road lights

Oil operating gearbox

◦ low-noise operation

◦ maintenance-free use

◦ quick and simple connecting rod replacement

great stability in all conditions Drive shaft inside the drawbar

Wide, 6-wheel tandem chassis

high level of ground following

Working width

tandard on the Z2-960 rake is hydraulic adjustment of the working width from 8.80 m to 9.60 m (28’10” – 31’5”), giving you more flexibility to match the swath width to your specific needs.

Gearbox

• 15-arm solid grease gearbox

• Hermetically closed design protecting against dirt and dust

• Quick replacement of rods due to bolted design

• No need for greasing

• Independent rotor control

• Hydraullic width adjustment

TECHNICAL SPECIFICATION

Working width

Transport width

Z2-960

[m / ft] 8,80 – 9,60 / 28’10” – 31’5”

[m / ft] 2,95 / 9’8”

Transport height [m / ft] 3,95 / 12’11”

Transport length [m / ft] 6,95 / 22’9”

Rotor diameter

Swath width

[m / ft] 4,20 / 13’9”

[m / ft]

~1,50 – 2,30 / 4’11” – 7’6”

Working capacity [ha/h] ~13,00 – 14,00 / 32,00 – 34,00

Necessary hydraulic couplers [pcs] 2 x double acting

Number of arms per rotor [pcs] 15

Number of foldable arms for transport [pcs] 3

RPM 540

3-point hitch cat. II

Power demand [HP]] from 70

Tires

transport wheels: 340 / 55-16

rotor wheels: 16 / 6.50-8

Weight [kg / lbs] 2 760 / 6 085

PTO shaft tractor – rake: wide-angle with overrunning clutch

Windrow central

TWIST 710P

FRONT AND REAR MOUNT RAKE

Machine category

• Basket rakes

• Front or rear mount Model name

• TWIST 710P Working width

• 6,70 - 7,10 m / 21’11” - 23’3”

TECHNICAL SPECIFICATION

TWIST 710P

Working width [m / ft] 6,70 - 7,10 / 21’11” - 23’3”

Windrow width [m / ft] 0,80 - 1,30 / 2’7” - 4’4”

Transport width [m / ft] 2,50 / 8’2”

Transport height [m / ft] 3,40 / 11’1”

Necessary hydraulic couplers 1 x double acting Working capacity [ha/h | ac/h] 7,10 / 17

Number of raking bars per unit [pcs.] 5 (optionally 6)

3-point hitch cat. II

Power demand [HP] 80

Tires (with inner tubes) 18 x 8,5 - 8 (x4)

Drive type Hydraulic [l/min | GPM]

Safety mechanism

machine protection during transport

Hydraulic drive

◦ stepless rotation speed adjustment

◦ low-noise operation

◦ no need of PTO shaft

Tine bar

thorough raking for cleaner fodder

ANTI-CORROSION E-COAT PROTECTION

1. Shot blasting

2. 7-stage acid wash

3. Pre-undercoat treatment

4. Zinc phosphate undercoat

SaMASZ 7 stage paint process for the New Zealand market

Durable Protection with E-COAT Technology

1. Shot blasting – Removes impurities and preps the metal surface

2. 7-stage acid wash – Deep cleans and pre-treats for coating adhesion

3. Pre-undercoat treatment –Further primes the surface

4. Zinc phosphate undercoat – Adds strong corrosion protection

5. Electrophoretic top coat (1st layer) –Even, durable base coating

6. Electrophoretic top coat (2nd layer) – Extra protection and finish quality

7. Oven baked – Hardened and sealed for longlasting durability

Check out the

5. Electrophoretic top coat (1st layer)

6. Electrophoretic top coat (2nd layer)

7. Oven baked

SaMASZ paint process