Reducing DOC levels to improve drinking water quality How to minimize the impact of problematic wastewaters Upgrading Rivière-du-Loup’s aerated wastewater treatment ponds ACADEMIC INSTITUTIONS AND TRAINING PROVIDERS ES&E ANNUAL GUIDE TO JUNE 2024 WWW.ESEMAG.COM @ESEMAG

ipexna.com 1-866-473-9462 EXPLORE OUR SOLUTIONS Pipe, Valves & Fittings Systems to meet all Your Project Needs

ONLINE AND PORTABLE INSTRUMENTATION

Optical Fluorescence Dissolved Oxygen

Near Infra Red Total Suspended Solids

pH, ORP

Microwave Density

Ultrasonic Interface Level

Spectrophotometric Online

FLOWMETERING

Multi Parameter Single – Dual – Multi-Channel-Wireless

Ultrasonic Doppler – Transit Time

Insertion/Immersion/Clamp-On

Venture/Flume Partially Filled Conduit

Non Contact Radar

WASTEWATER SAMPLERS

Indoor or Outdoor

Refrigerated or Non-Refrigerated

Portable or Stationary

SEPTAGE RECEIVING SYSTEMS

Integrated Billing System

Solutions For WAS TEWATER TREATMENT

Fully Automated Control and Data Collection

ADDITIONAL SOLUTIONS FOR: Flow – Level – System Integration – Field Service Mississauga, Ontario Montreal, Québec 800-595-0514 www.cancoppas.com controls@cancoppas.com

Editor and Publisher STEVE DAVEY steve@esemag.com

Managing Editor PETER DAVEY peter@esemag.com

Contributing Editor DAVID NESSETH david@esemag.com

Sales Director PENNY DAVEY penny@esemag.com

Sales Representative DENISE SIMPSON denise@esemag.com

Accounting SANDRA DAVEY sandra@esemag.com

Design & Production MIGUEL AGAWIN miguel@esemag.com

Circulation BRIAN GILLETT ese@mysubscription.ca

TECHNICAL ADVISORY BOARD

Archis Ambulkar, OCT Water Quality Academy

Gary Burrows, City of London

Patrick Coleman, Stantec

Bill De Angelis, Metrolinx

Mohammed Elenany, Urban Systems

William Fernandes, City of Toronto

Marie Meunier, John Meunier Inc., Québec

Tony Petrucci, Black & Veatch

Environmental Science & Engineering

is a bi‑monthly business publication of Environmental Science & Engineering Publications Inc. An all Canadian publication, ES&E provides authoritative editorial coverage of Canada’s municipal and industrial environmental control systems and drinking water treatment and distribution.

Readers include consulting engineers, industrial plant managers and engineers, key municipal, provincial and federal environmental officials, water and wastewater plant operators and contractors.

Information contained in ES&E has been compiled from sources believed to be correct. ES&E cannot be responsible for the accuracy of articles or other editorial matter. Articles in this magazine are intended to provide information rather than give legal or other professional advice.

Canadian Publications Mail Sales Second Class Mail

Product Agreement No. 40065446 Registration No. 7750

Subscription Changes?

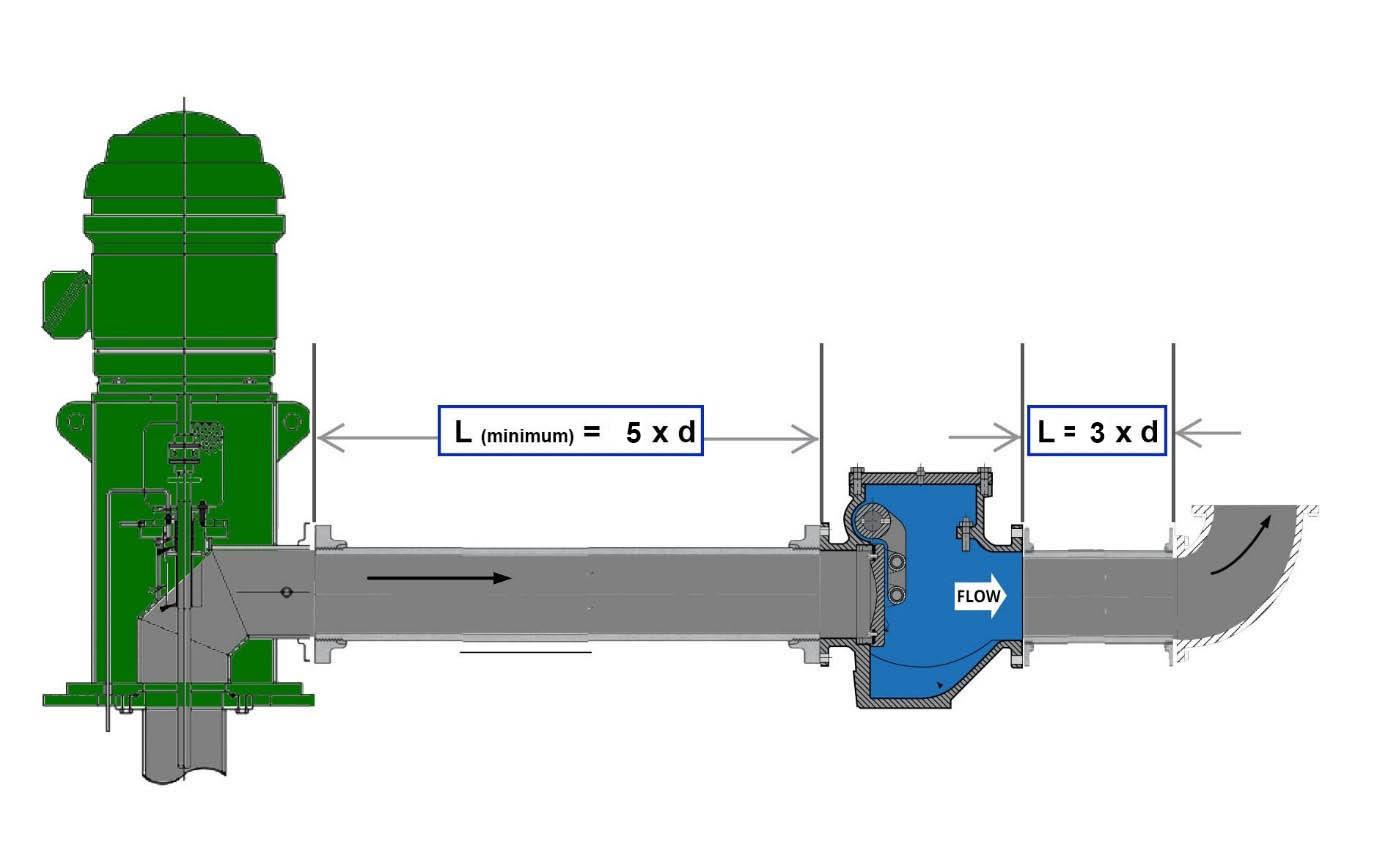

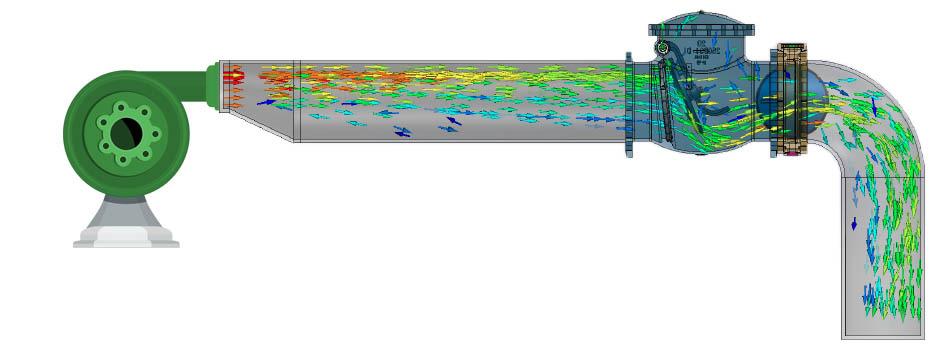

Please email reader subscription changes to ese@mysubscription.ca, or call 705-502-0024

Advertising Penny Davey Sales Director 416 807 3812, penny@esemag.com

FEATURES

6 Toronto to host IWA World Water Congress & Exhibition this summer

8 Cruise lines and ports using shoreside electricity to cut emissions

9 Ottawa hosts global treaty meetings to fight plastic pollution

10 Ice jam monitoring improves flood forecasting and response times

12 Upgrading Rivière-du-Loup’s aerated wastewater treatment ponds

14 Pressure sewer systems can cut new residential development costs

18 Capacitance is a reliable and costeffective method to monitor for industrial spills and leaks

20 Canada invests $15M to support biomanufacturing supply chain for wastewater surveillance

22 How a rural Alberta water treatment plant reduced DOC and improved water quality

26 Toronto pauses stormwater charge consultations

27 Montreal’s newest sponge park will retain over a million litres of rainwater

28 Concordia researchers analyze alternative factors for water main breaks

38 How to minimize the impact of problematic wastewater from upstream distilleries and industry

40 BCWWA’s annual conference & tradeshow returns to Whistler

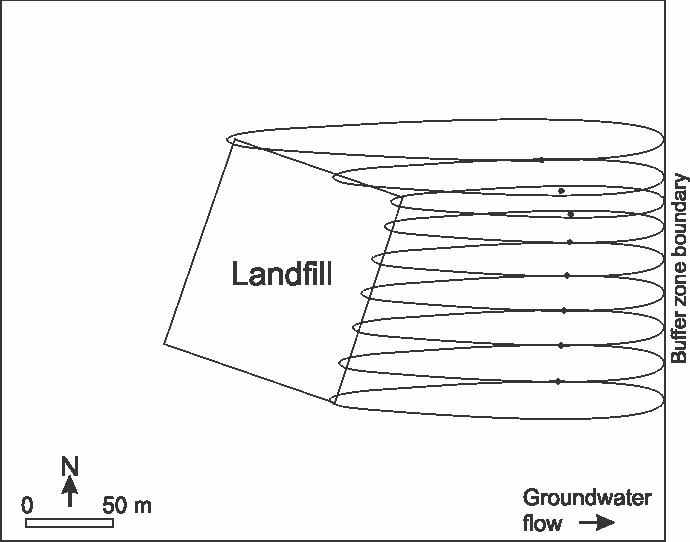

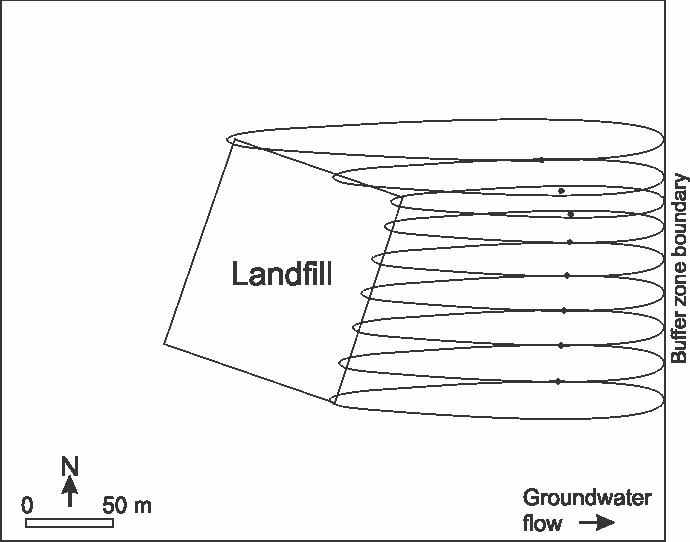

42 Study shows CAC can be injected to prevent PFAS-contaminated groundwater from moving further

44 Buffer zone monitoring strategies to detect leachate in groundwater

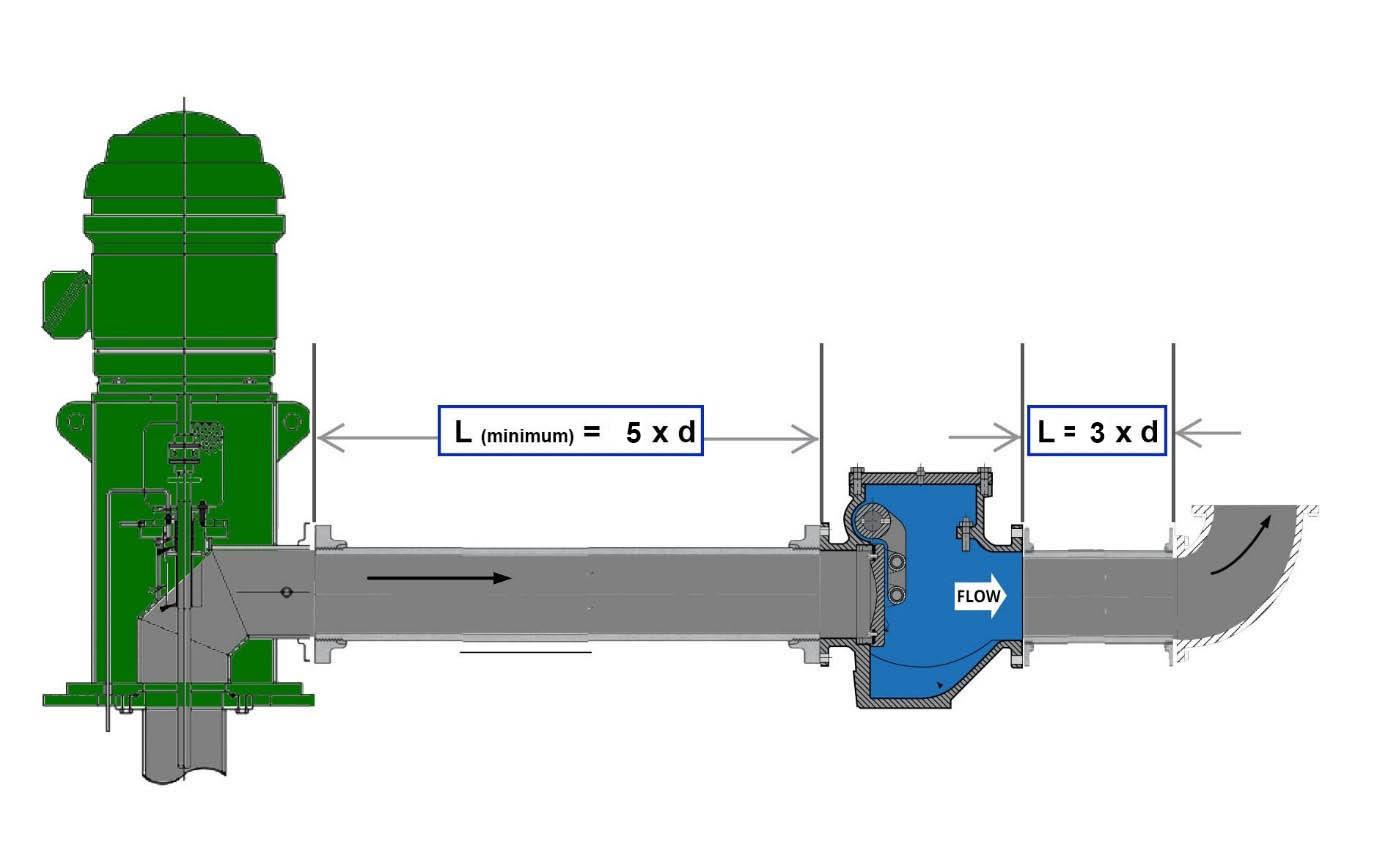

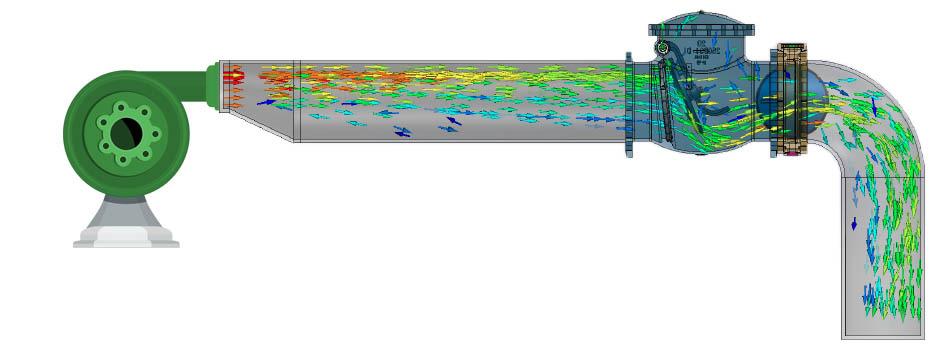

48 Check valve installation considerations to maximize backflow prevention performance

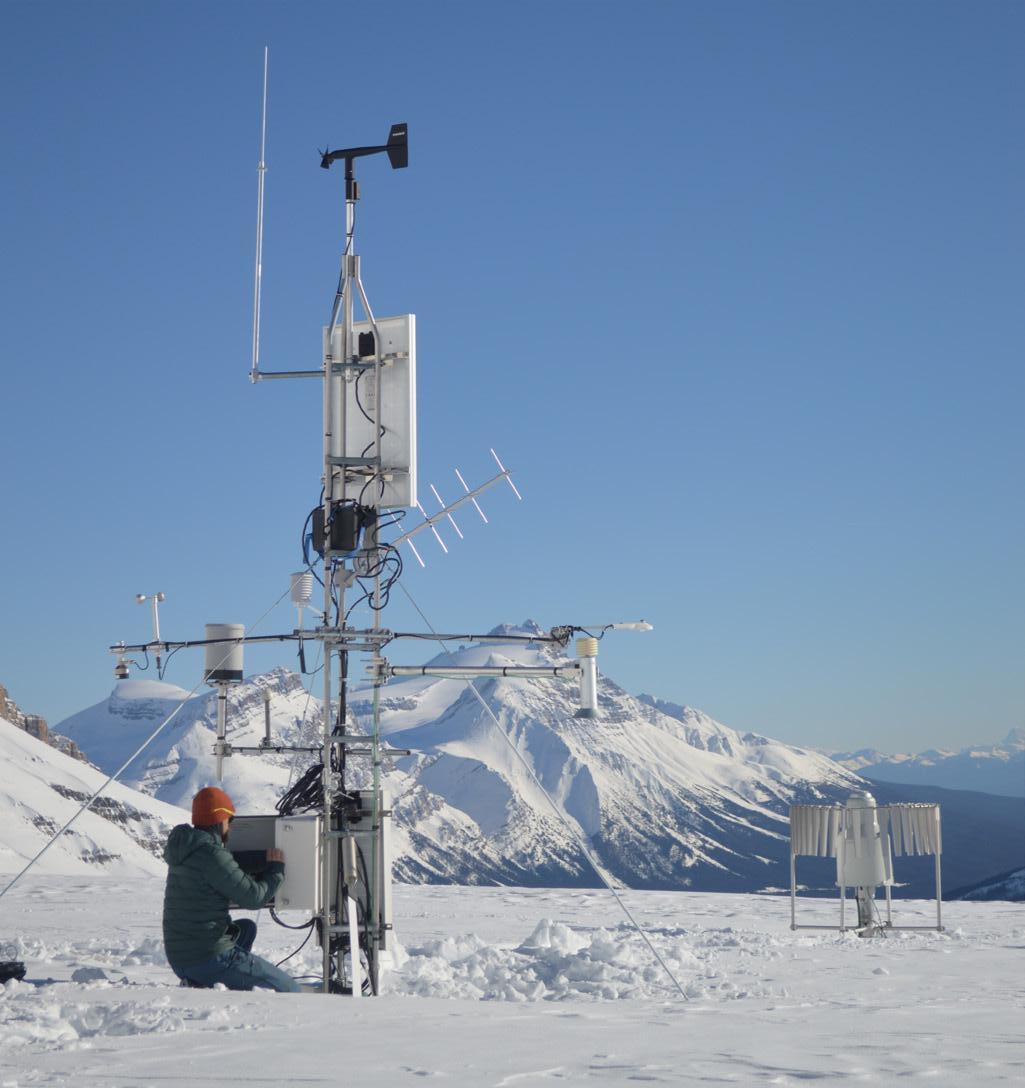

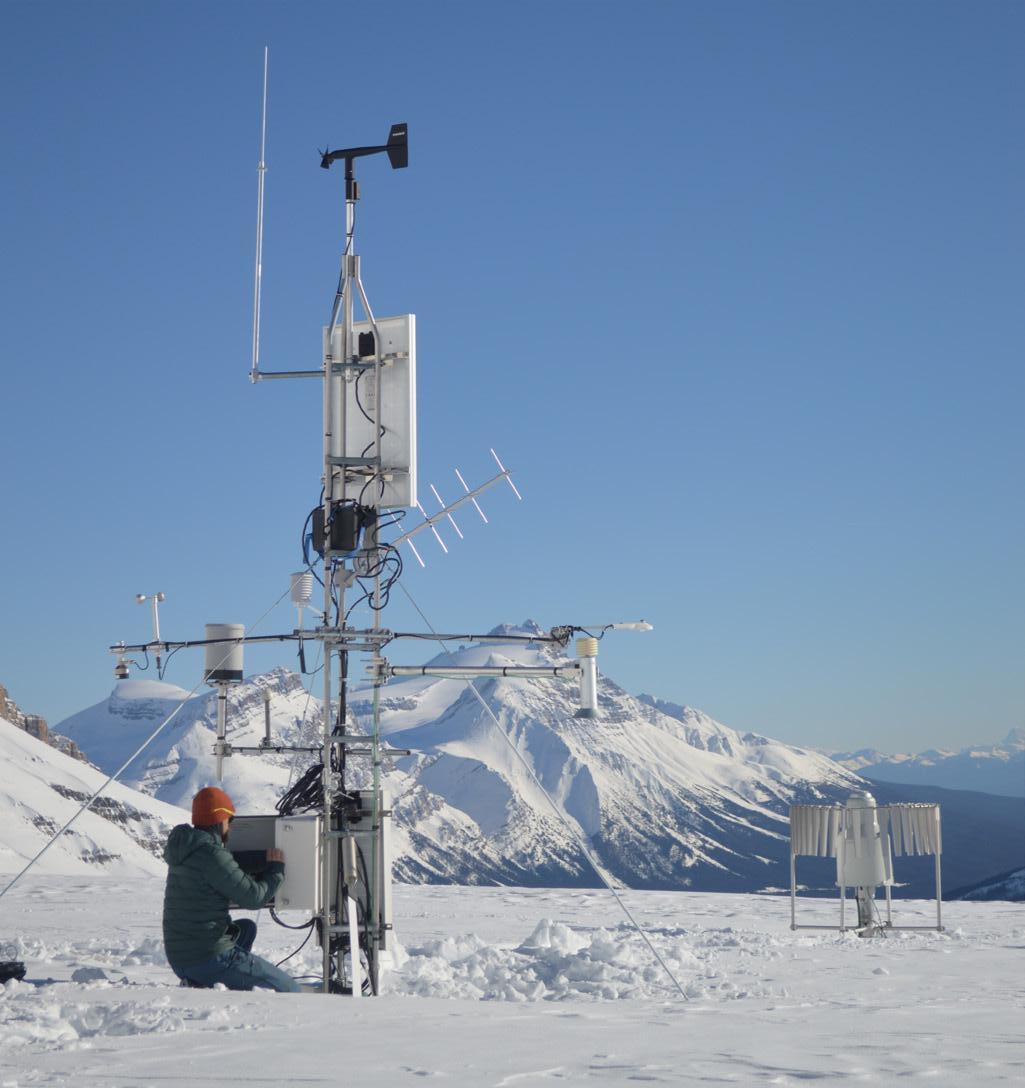

50 Global Water Futures network connects nine universities

52 Walkerton Clean Water Centre offers hands-on water treatment training

53 University of Waterloo launches climate change diploma for graduate students

54 Dalhousie partners with Atlantic First Nations Water Authority

55 ES&E’s Annual Guide to Academic Institutions and Training Providers

62 Collingwood and New Tecumseth agree to move forward with WTP expansion

DEPARTMENTS

Denise Simpson Sales Representative 905 960 4064 denise@esemag.com

Environmental Science & Engineering

220 Industrial Pkwy. S., Unit 30 Aurora, Ontario L4G 3V6

Tel: (905)727 4666 www.esemag.com

30 Effectively ensuring safety in biogas facilities

34 New funding showcases Ontario’s dedication to critical water infrastructure

36 Ensuring chemical compatibility in water treatment equipment

57 Professional Cards

58 Product Showcase

62 Ad Index

Cover photo credits: Caroline Aubry-Wake, University of Saskatchewan

Mark Ferguson, University of Saskatchewan University of Saskatchewan

Veolia Water Technologies Canada Azura Associates

June 2024 • Vol. 37 No. 3 • ISSN-0835-605X www.esemag.com @ESEMAG Environmental Science and Engineering Magazine

4 | June 2024

CONTENTS

50 12

o mple te ra n g e o f ma rke t p ro du c t s. Le t u s sh ow yo u

Cleaning, DO Control, AlphaMeter

Mixers – Anoxic & Swing Zones, Sludge Holding, Digester; Mechanical, Hydraulic and Gas Bubble

Tank Components – Covers, Fabric Ba es, Troughs, Weirs, Scum Ba es, Skimmers, Decanters, Swivel Joints, Telescoping Valves, Density Current Ba es, Launder Covers, Watertight Doors

Primar y & Secondar y, Circur, Chain & Flight, Inclined Plate Settlers, Weir Washing

Biological – SBR, MBR, RBC, MBBR, MABR, Oxidation Ditch, BioMag, CoMag Polymer – Liquid and Dr y Systems

•

Rotary Lobe Pumps & Grinders

• Disinfection – UV, Ozone

• Tertiary Filters – Travelling Bridge, Disk, Membrane

• Sludge Thickening & Dewatering –Disk Thickener, Gravity Thickener, Filter Press, Screw Press, Centrifuge

• Anaerobic Digesters – Sludge Conditioning, In-line Screening, Degritting, Membrane Gas Holders, Liquid Mixing, Nutrient Recover y

• Sludge Drying – Belt, Fluid Bed and Solar

• Septage Receiving – Screens, Dump Stations, Truck Access & ID, data gathering & equipment control

• Sludge Treatment, Transport & Storage – Cake Pumps, Silos, Sliding Frames, Live Bottom Hoppers, Push Floors, Truck Loading, Alkaline Stabilization

• Odour Control – Tank Covers, Chemical & Biological Treatment, Activated Carbon

• – Stations Pump & Stormwater CSO, Tipping Buckets, Bending Weirs, Flushing Gates, Flow Regulating, Vor tex Valves, Storm Screens

• Digester Gas – Gas Holders, Gas Conditioning: chilling; compressing; and removal of moisture, sulphur, carbon dioxide and siloxane, complete Co-Generation facilities

t e wat e r, Biosolids & Bi o g a s

T: (905) 864-9311 F: (905) 864-8469 www.proaquasales.com 7-264 Bronte St. S., Milton, ON L9T 5A3 04 16

Toronto to host IWA’s 2024 World Water Congress & Exhibition

Last summer, at the invitation of Robert Haller, executive director of the Canadian Water and Wastewater Association, I had the pleasure of meeting several senior officials and staff members of the International Water Association (IWA). They were on a site visit to the Metro Toronto Convention Centre as part of the planning process for their 2024 World Water Congress & Exhibition, which is being held August 11 – 15.

Headquartered in the United Kingdom, IWA is the largest association for the global water sector, having members in 140 countries. The association was launched in its current identity in 2000, building on a 75-year heritage of connecting water professionals around the world. These include scientists, researchers, technology companies, water and wastewater utilities, and wider stakeholders involved in water management.

The IWA World Water Congress & Exhibition is the global event for water professionals covering the full water cycle. As the Congress rotates through cities and countries, each event has an extra emphasis on issues of specific interest to the region.

According to the Association’s website, the 2024 theme is “Shaping our Water Future”, and it will provide opportunities for participants to network and to share insights and experience on the latest trends in best practice, innovative technologies, and management approaches.

Haller explains that while this is an International Water Association event, it is being co-hosted by the Canadian Water and Wastewater Association (CWWA) and the Canadian Association on Water Quality (CAWQ). CWWA and CAWQ are the governing members of the IWA for Canada and work to bring a Canadian voice to the international world of water. They have also worked on the development of this event to ensure it is very relevant to North American participants.

“The Congress, with its massive technical program, is one of the most respected professional forums for our industry,” says Haller, adding that “this portion of the Congress is expected to attract over 4,000 registered delegates to participate in sessions, panels, workshops and forums.”

The technical program includes four full days of sessions highlighting research, innovation and utility leadership. The program includes a Utility Leaders Forum spread over three days and many more utility-relevant workshops. There are sessions focused on water services in Arctic regions, and a forum on “Indigenous Peoples and Water from a Global Perspective” is being worked on.

The exhibition portion of the event attracts innovation

The exhibition will feature innovation and entrepreneurs from around the world and is expected to draw 6,000 participants.

and entrepreneurs from around the world. The exhibition floor is expected to draw another 6,000 participants. Half will be from North America and half will be global visitors. Visiting the exhibition is free for advance registrants.

Why is it being held in August? According to Haller, “this special event has the full support of both AWWA and WEF, so a time was chosen to be sufficient distance from both ACE and WEFTEC. But this is a very different event than those two. We don’t suggest you come to one or the other, but rather take advantage of this global event this year as a bonus.”

The last time IWA held this event in Canada was in 2010 and Montreal was the host city. I would encourage everyone to attend this year’s event in Toronto, as it will be a long time until it returns to Canada. For more information, visit www.worldwatercongress.org.

Steve Davey is the editor and publisher of ES&E Magazine. Please email any comments you may have to steve@esemag.com

6 | June 2024 EDITORIAL COMMENT BY STEVE DAVEY

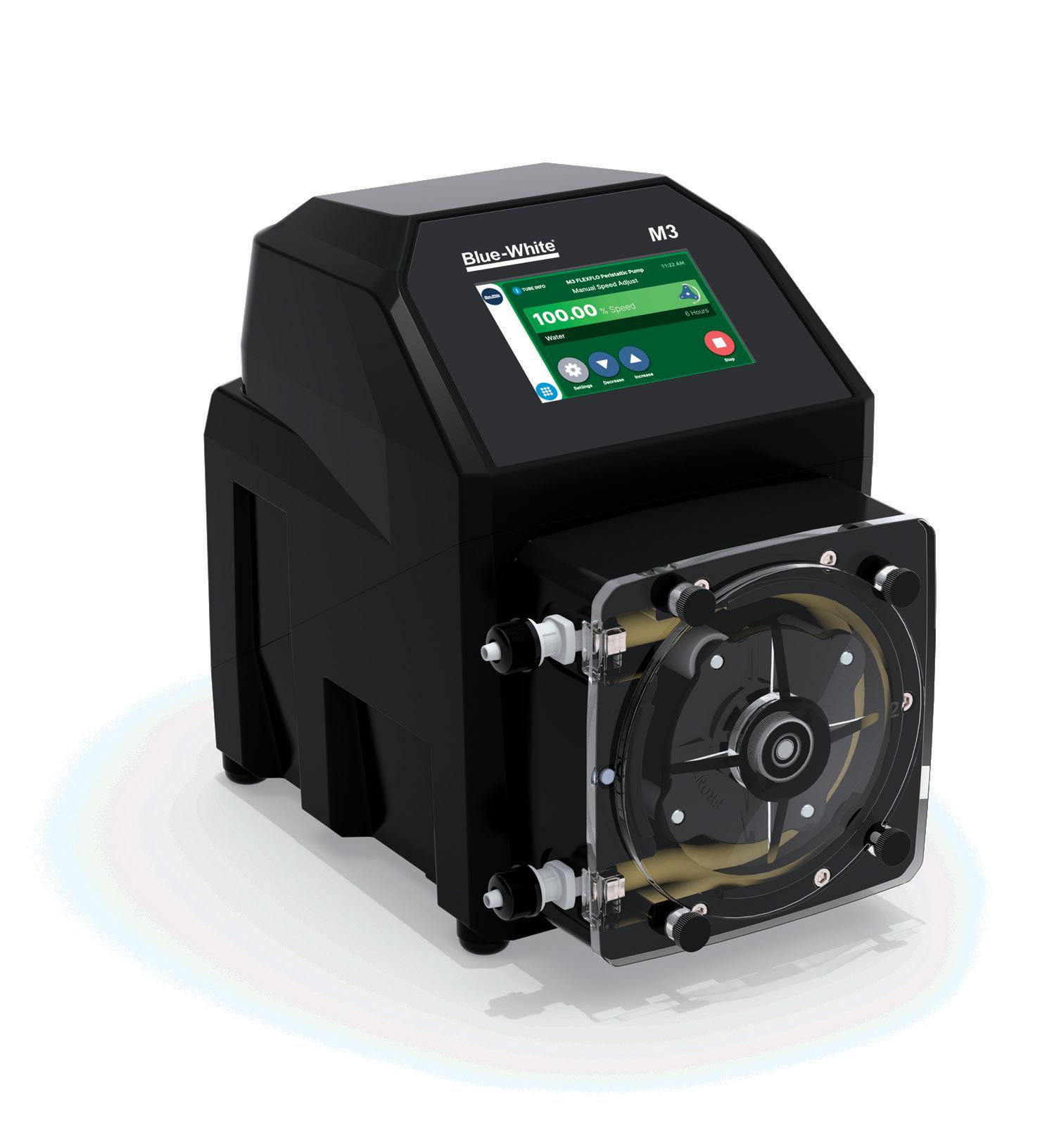

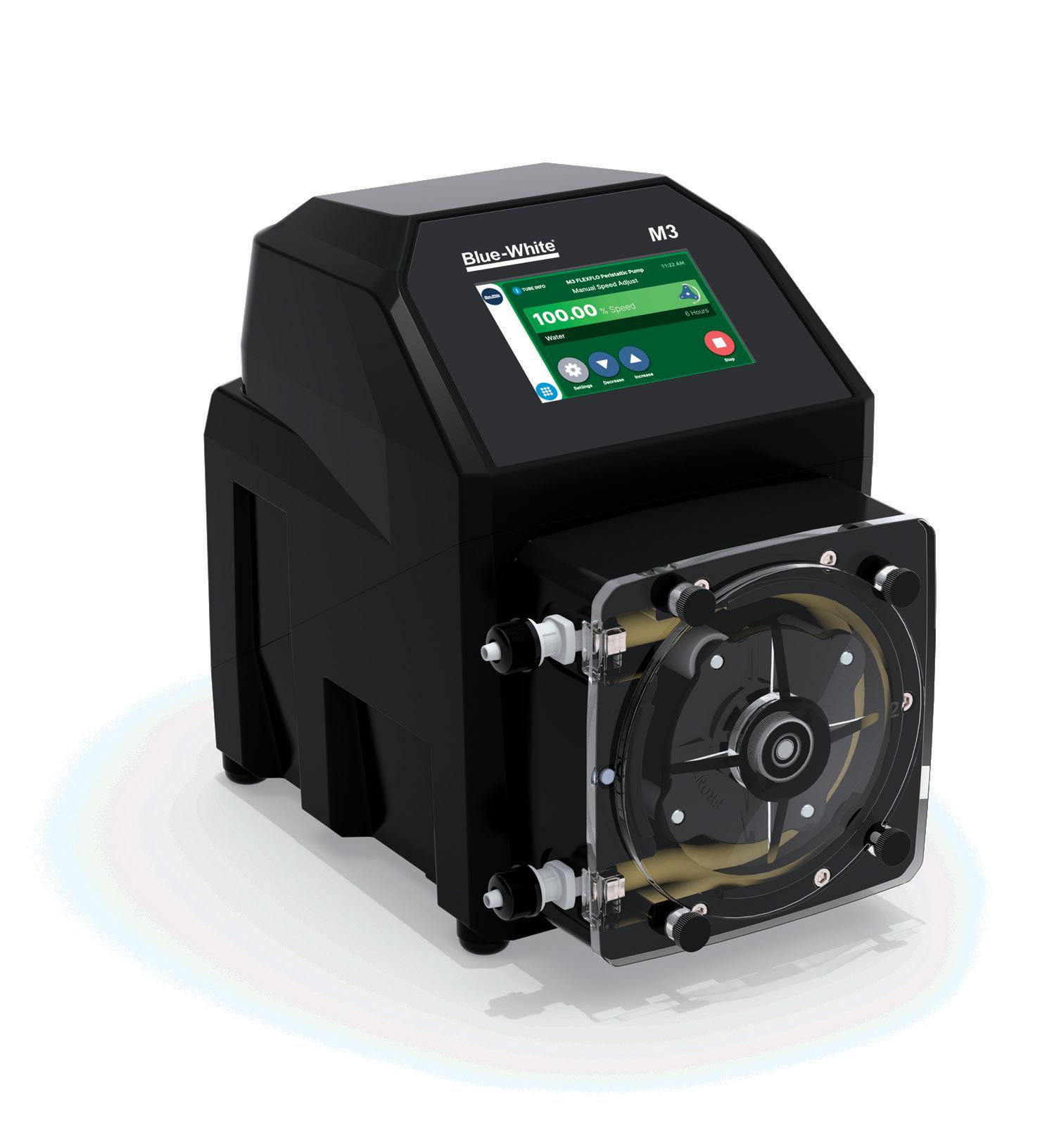

CHEM-FEED® MD1 Multi-Diaphragm Metering Pump CHEM-FEED® SKIDS One, Two, or Three Pump Complete Metering Systems FLEXFLO® M3 Peristaltic Metering Pump Learn more about Our Skids, M3, and MD1 at www.blue-white.com Fluid Metering Solutions Made Simple® Top Performance Solutions for Effective Chemical Dosing Quick Shipping, Easy Install, Fast Startup.

Cruise lines and ports using shore-side electricity to cut emissions

Recently, the United Nations International Maritime Organization and its participating maritime countries set their greenhouse gas (GHG) emissions strategy to achieve net zero “by or around” 2050. As a result, the shipping industry, including cruise lines, is adopting various strategies to achieve this ambitious goal, including new fuels, air scrubbers and shore-side electricity (SSE) systems.

One significant strategy being adopted by cruise lines and ports is SSE, also called “cold ironing” or shore power systems. According to some estimates, the industry can lower CO2 and other pollution emissions up to 98% by shutting down all on-board power generation from diesel engines and connecting to shore power supplied by the local utility.

Those additional pollutants include sulphur dioxide (SO2), nitrogen oxides (NOx) and particulate matter (PM). Overall CO2 reduction depends partially on the electricity sources of the port’s grid. If, for example, a port depends upon renewable energy sources such as wind, solar, or hydroelectric power, the GHG emissions reductions can be significant.

As a result, many cruise lines and ports are adopting the technology. Carnival Cruise Lines, for example, says that as part of its emission abatement program, 57% of its ships are fully equipped to leverage shore power technology, even though less than 5% of the ports it uses offer shore power connections. But the number of ports adopting the technology is growing.

The Cruise Line Industry Association indicates that 40% of its global members’ ships are set up to operate in SSE in 29 ports, which is up 20% year over year. And of new builds ordered between now and 2028, 98% are either planning to be fitted with SSE systems or be configured to add it in the future.

Adoption is expanding across the globe. The California Air Resources Board’s 2020 At-Berth Regulation is driving the expansion of shore power across

the state. International shore power standards for high-voltage systems are being implemented to make it easier for ports to choose the appropriate equipment.

One of the technical challenges, however, is determining exactly how much emissions are being reduced by SSE. Today, innovators in the design of standalone shore-to-ship power solutions like Kingston, WA-based Watts Marine are addressing that issue with improved reporting systems based on information gathered from the underlying power protection system components.

Watts Marine has installed its shore power system at ports in Seattle, WA; San Diego, CA; San Francisco, CA; Halifax, NS; Vancouver, BC; Brooklyn, NY; and Long Beach, CA. An estimated 500 ships connect to their shoreside equipment each year.

The company’s patented custom shore power system consists of proprietary equipment designed specifically for the cruise ship industry. It includes dual-voltage electrical service equipment, cus-

tom-developed electrical cable handling equipment, and customized electronic monitoring and control equipment.

Once a cruise ship or ocean transport vessel equipped to receive shore power docks in port, an operator selects the ship to be connected from a database that is integrated into the customized automation system which determines the proper operating parameters. To make the connection, five flexible power and control cables are lifted by a specially designed cable positioning device and connected to the ship’s electrical system through marine standard plugs and sockets. A shore-side operator then closes the breaker and power is supplied to the vessel.

For more information visit www.novatechautomation.com

Environmental Science & Engineering Magazine 8 | June 2024 GHG REDUCTION

Left: The patented custom shore power system consists of proprietary equipment designed specifically for the cruise ship industry. Right-top: Watts Marine utilizes information collected by NovaTech’s Orion automation system to calculate the total emissions reduction across all main pollutants while a ship is connected to shore power. Right-bottom: One of Watts Marine’s cruise ships.

Ottawa hosts global treaty meetings to fight plastic pollution

By ES&E Staff

Nine small and medium sized Canadian companies will each receive up to $150,000 to develop sustainable and cost-effective solutions to help better reuse plastics or improve the end-of-life management of plastic film for consumer items.

The funding comes as Canada welcomes the world to Ottawa for the fourth session of the Intergovernmental Negotiating Committee on Plastic Pollution, which aims to develop innovative solutions for plastic waste in partnership with World Wide Fund for Nature (WWF) International.

“A whole-of-society approach for the development and implementation of a global deal to end plastic pollution is crucial,” Canada’s Minister of Environment and Climate Change, Steven Guilbeault, announced in a statement. “This means engaging with all levels of government as well as the private sector, non-governmental partners, the science community and Indigenous partners to ensure that all voices and perspectives are considered.”

Federal data from the Ministry of Environment and Climate Change estimates that more than four million tonnes of plastic ends up as waste each year, and less than one-tenth of that is recycled. In March 2022, 175 nations agreed to make the first legally-binding treaty on plastics pollution, including in the oceans, by the end of 2024.

The new $3.3 million in funding to support Canadian organizations that are developing innovative solutions to address plastic pollution comes through the Canadian Plastics Innovation Challenges. The funding is targeted towards sectors known to generate some of the greatest quantities of plastic waste and pollution, and may have technological gaps with opportunity for innovation.

Among the phase one recipients of the new funding are:

• Circulr Inc., based in Toronto, has created modular reverse vending machines for the collection of reusable goods.

• MLVX Technologies Inc., based in Vancouver, has created an AI-powered hyperspectral system for sorting plastic film and flexible packaging.

• Les emballages PickPack Inc., based in Granby, Quebec, has developed rigid and reusable packaging for the delivery of fragile e-commerce products, as well as a system for measuring the impacts of reuse and circular logistics.

• Sparta Manufacturing Inc., based in Notre-Dame, New Brunswick, is working on the development of an accelerated ballistic separator for improved sorting of plastic film.

Environment and Climate Change Canada is contributing an additional $2 million in funding for advancing a circular economy for plastics in Canada toward 12 projects for organizations to develop solutions to address challenges.

Sparta Manufacturing Inc. President Bruno Lagacé tours the company’s manufacturing facility with New Brunswick’s Minister responsible for Economic Development and Small Business, Greg Turner.

Sparta Manufacturing Inc. President Bruno Lagacé tours the company’s manufacturing facility with New Brunswick’s Minister responsible for Economic Development and Small Business, Greg Turner.

June 2024 | 9 www.esemag.com @ESEMAG PLASTIC POLLUTION 800-327-3248 sales@harmsco.com www.harmsco.com Learn more about America’s most trusted LT2 Solutions Today! Approved installations in the US and Canada! Stainless Steel Housing 3.6-log cyst reduction 6,056 lpm LT2 Flow Rate Save up to 20% Energy GWUDI / Reclaimed water The premium choice for LT2 installations across the US and Canada Don’t Settle for Less than the Best #1 MostTrusted LT2 Filtration

River ice jam monitoring improves forecasting and response times

By Katy Curtis

Every river engineering project requires piecing together data to form a clear picture of a site’s unique characteristics. In remote, and sometimes not so remote locations, an absence of river data requires getting to know the site in more creative ways. This creativity was required for a project in the Town of Golden, British Columbia, where the team at Matrix Solutions was consulted to design a river ice monitoring system.

Ice jams in Golden are highly dynamic and can cause water levels to rise by several metres in a few hours. In the past these events threatened critical infrastructure in the town, such as dikes and the Highway 95 bridges, and caused winter flooding. The ice jams initiate in a rugged upstream canyon that is generally inaccessible except by railway and helicopter observation, so ice conditions in the canyon are usually unknown –meaning ice jams have historically happened without warning.

The intent of the ice monitoring system was to bring greater awareness and possible predictive tools about when an ice jam may be coming, allowing for improved forecasting and response.

FILLING IN THE HISTORICAL DATA GAPS

To inform the design of the system, Matrix Solutions set out in 2017 to collect as much data as possible about the history of ice jams and flooding in Golden. The team had been working on the Kicking Horse River for almost 20 years at that point, but many mysteries still remained about the ice processes along the river. These initial studies were funded by Public Safety Canada, Emergency Management British Columbia, the Columbia Basin Trust, and the Town of Golden.

The Golden Museum provided a wealth of historical information, including photographs, maps, survey plans, and newspaper articles with mentions of ice jams dating back more than 110 years. News articles reported on ice jams approximately every six years, which could have been lower than actual ice jam activity, since only more extreme events would have made the press.

Speaking to local historians and long-term residents filled in other pieces, including pointing to a potential connection between reduced threat of ice jam events following river dredging. Matrix Solutions cross-referenced these anecdotal reports with dredging approvals dating back to 1979. Data from the Water Survey of Canada (river discharge, water level, freeze-up and break-up dates) and Environment Canada (temperatures) helped fill in other clues about the Kicking Horse River and the surrounding area.

In addition, the town provided more than 30 years of historical cross-sectional data from the river. Since the turn of the century, the Matrix Solutions team has had the opportunity to conduct numerous site visits, capture site photographs, and

collect technical data from river surveys for hydraulic modelling and sedimentation studies.

Overlapping each data source provided engineers and the town with a greater degree of clarity about the behaviour of the Kicking Horse River and ice conditions. This led to an effective design for the monitoring system.

BETTER FORECASTING AND RESPONSE OUTCOMES

In 2019, the river ice monitoring system was designed and installed with funding from the Union of BC Municipalities. The monitoring system includes cameras for visual and timelapse monitoring, pressure transducers to monitor water and ice levels, and a temperature gauge to measure river temperature.

The monitoring system was accompanied by a detailed flow chart, developed in conjunction with key stakeholders, to guide response actions when various triggers are present. Triggers include conditions in the canyon and at the Highway 95 bridges, water and atmospheric temperatures, and time of year.

Data from the monitoring system and this decision matrix are being used to help the British Columbia Ministry of Transportation and Infrastructure and the Town of Golden more effectively assess the risk of ice jams; and to calibrate response procedures when there is an ice jam event. Data is also being used to verify engineering design levels for design and upgrade of town infrastructure.

Katy Curtis is with Matrix Solutions Inc., a Montrose Environmental Company. For more information, email: info@matrix-solutions.com

Ice jam conditions in 2014 at Kicking Horse pedestrian bridge.

Credit: Louise Rande

Environmental Science & Engineering Magazine 10 | June 2024 STORMWATER

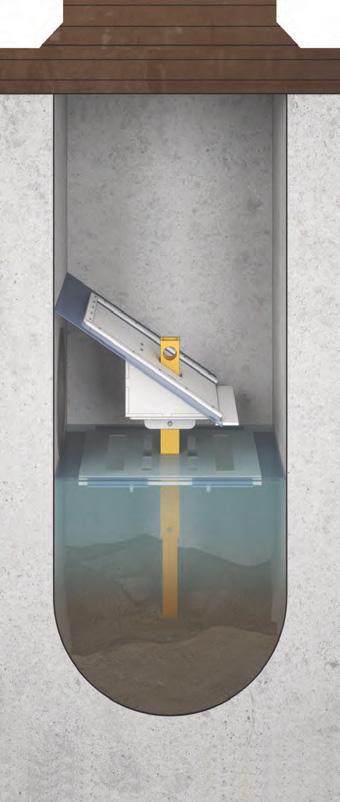

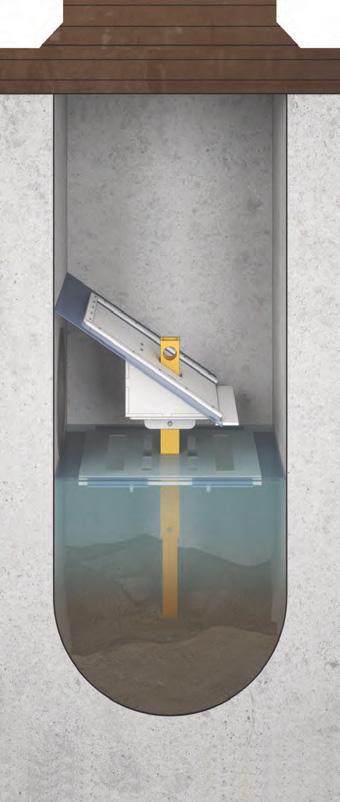

Upgrading Rivière-du-Loup’s aerated wastewater treatment ponds

By Marc-André Desjardins, Robert Lafond, Genevieve Pigeon and Yves Comeau

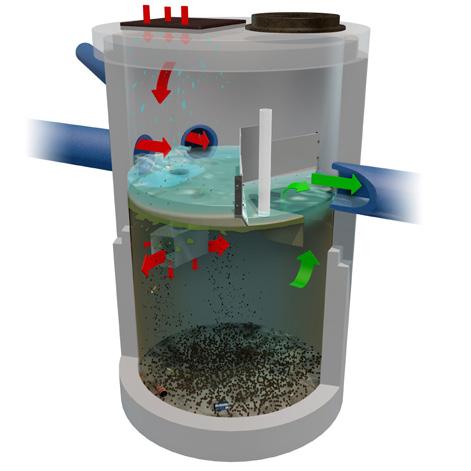

In 2016, the City of Rivière-du-Loup in Quebec embarked on a bold and innovative journey to upgrade its water reclamation facility (WRF).

The WRF, which uses aerated ponds for wastewater treatment, was initially commissioned in 1997 to serve a population of around 15,000 inhabitants. However, as the city grew, so did the demands on the WRF, necessitating an increase in its treatment capacity.

The city’s initial plan was to install a moving bed biofilm reactor (MBBR) with suspended packing, upstream of the ponds. However, the high costs of the bids received led to the cancellation of this call for tenders. Undeterred, the city returned to the drawing board in 2016, this time inviting bidders to propose innovative and economically advantageous solutions. The city was willing to support the project authorization process of the successful bidder,

even setting aside a significant amount to cover the costs of the ministerial authorization process.

The city’s 2016 call for tenders set the new design flow rate of the WRF at 31,500 m³/d, which was almost double its existing capacity.

The city adopted a two-envelope formula with technical proposal and price provided separately. Among the evaluation criteria of the technical proposal, the “innovation” criterion accounted for no less than 25%. A “sustainable development” criterion worth 10% was also considered, with the city wanting the proposed solution to meet its requirements in this area with a minimized carbon footprint and optimal energy efficiency.

The city awarded the project execution contract to a group with Veolia as technology provider and designer and AXOR Experts-Conseils (now FNX-INNOV) as engineering firm, for a total

cost of approximately $3.6 million before taxes. The project team proposed by the group also provided for the collaboration of Polytechnique Montréal as scientific guarantor.

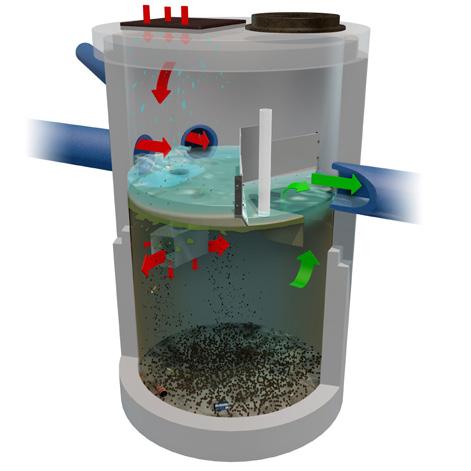

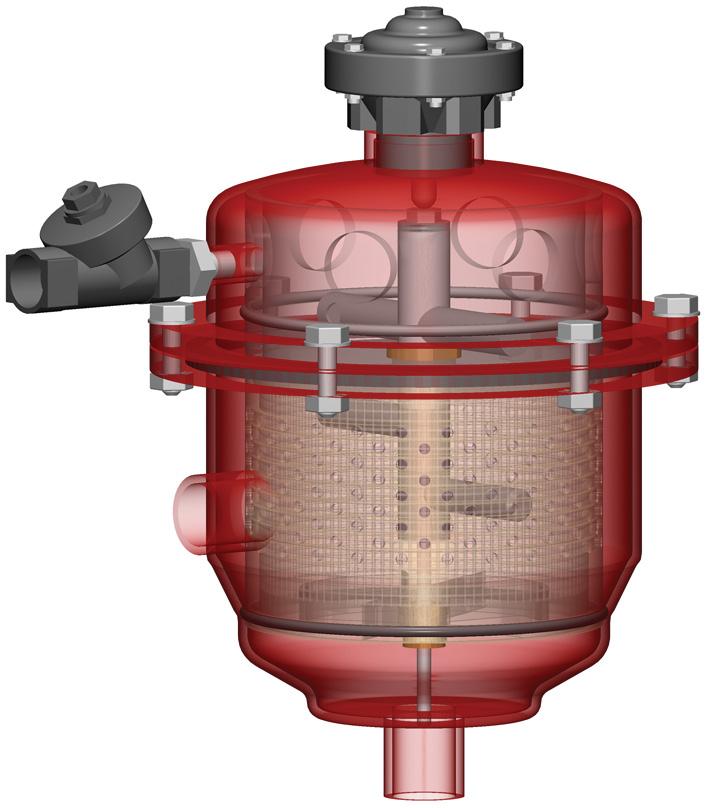

The solution put forward by the group was to convert the first cell of pond #1 (pond #1A) into a completely mixed pond by adding directional surface propeller aerators with the objective of reducing soluble carbonaceous biochemical oxygen demand (sCBOD) contained in raw water. To compensate for the hydraulic retention time in the subsequent ponds being too short, the group proposed adding a “goalkeeper” after the ponds in the form of a ballasted flocculation clarifier of the Actiflo® type.

Performance tests carried out as part of this project made it possible to validate the ability of the Actiflo clarifier to comply with normative requirements, which was the anticipated result follow-

Environmental Science & Engineering Magazine 12 | June 2024 WASTEWATER

Rivière-du-Loup’s water reclamation facility, which uses aerated ponds for wastewater treatment, was initially commissioned in 1997.

ing modelling carried out during the authorization process.

This highlights the potential of adding tertiary treatment to the outlet of aerated ponds in order to increase their capacity to the extent that sCBOD has been sufficiently reduced beforehand, which is generally the case in ponds.

Moreover, the project underscores the potential of modelling and performance testing in the development and implementation of innovative solutions.

The group used a combination of simulation models to demonstrate the treatment capacity of the proposed solution.

This was followed by performance tests, which validated the ability of the Actiflo clarifier to comply with normative requirements. This approach not only provided assurance of the solution’s effectiveness but also contributed to a better understanding of the BOD removal mechanisms in ponds.

Rivière-du-Loup’s decision to invite bidders to propose innovative solutions, rather than sticking to conventional design guidelines, opened the door to a solution that not only met the city’s needs but also offered a cost-effective alternative to the initially proposed MBBR.

The project also highlighted the importance of collaboration in achieving innovative solutions. The successful execution of the project was the result of a collaborative effort. Each party brought their unique expertise and perspective to the table, contributing to the development of a solution that was both innovative and effective.

Furthermore, the project demonstrated the potential of tertiary treatment as a means of increasing the capacity of aerated ponds. By adding the Actiflo clarifier to the outlet of the ponds, the group was able to significantly increase the treatment capacity of the WRF, while also ensuring compliance with normative requirements.

This approach could offer a viable solu tion for other municipalities facing simi lar challenges, particularly those with lim ited space for additional ponds.

The success of the Rivière-du-Loup project offers valuable insights and les sons for other municipalities and enti ties looking to upgrade their wastewater treatment facilities. It underscores the importance of being open to innova

By adding the Actiflo clarifier to the outlet of the ponds, the group was able to significantly increase the treatment capacity of the water reclamation facility, while also ensuring compliance with normative requirements.

tion and the potential of unconventional solutions.

The city’s decision to include a “sustainable development” criterion in its call for tenders reflects a growing recognition of the need to balance economic, social, and environmental considerations in the pursuit of development. The solution proposed by the group not only met the city’s needs in terms of increased treatment capacity, but also aligned with its sustainability goals, a minimized carbon footprint, and optimal energy efficiency.

Marc-André Desjardins is with FNX-INNOV. Email: mdesjardins@fnx-innov.com

Robert Lafond is with Veolia Water Technologies Canada. Email: robert.lafond@veolia.com

Genevieve Pigeon is with the City of Rivière-du-Loup. Email: genevieve.pigeon@villerdl.ca

Yves Comeau is with Polytechnique Montreal. Email: yves.comeau@polymtl.ca

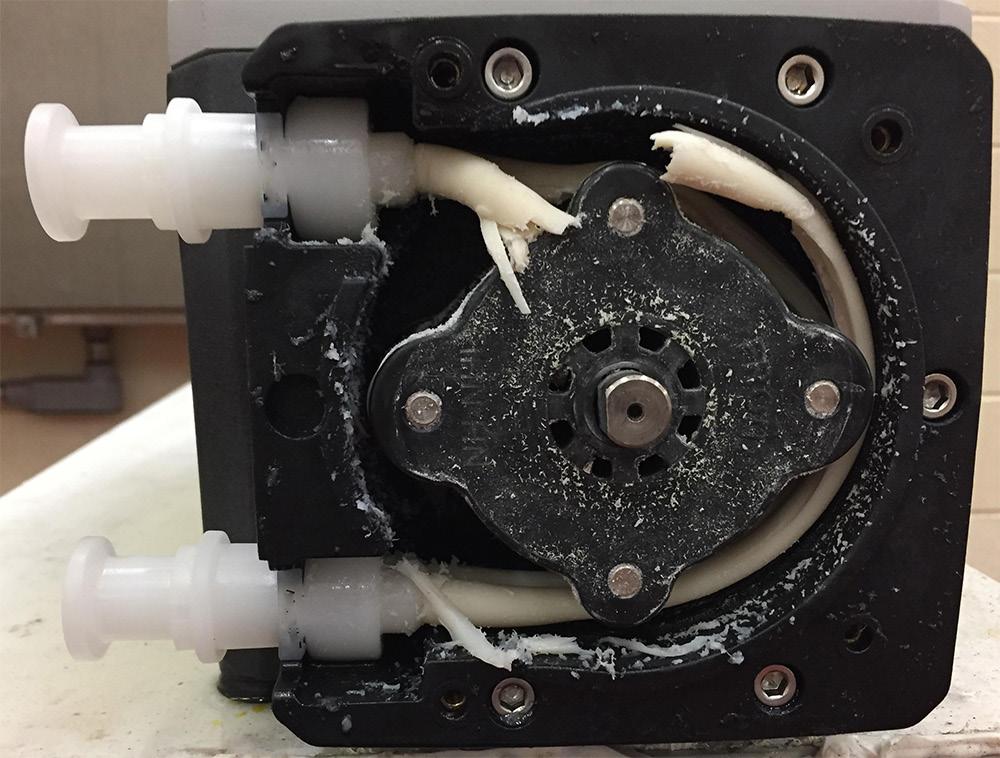

June 2024 | 13 www.esemag.com @ESEMAG ® C M Y CM MY CY CMY K Waste Water products plus PERIPRO 4.5 x 4.875 Holistic.pdf 1

PM ntc.social@netzsch.com

1/19/2023 3:40:41

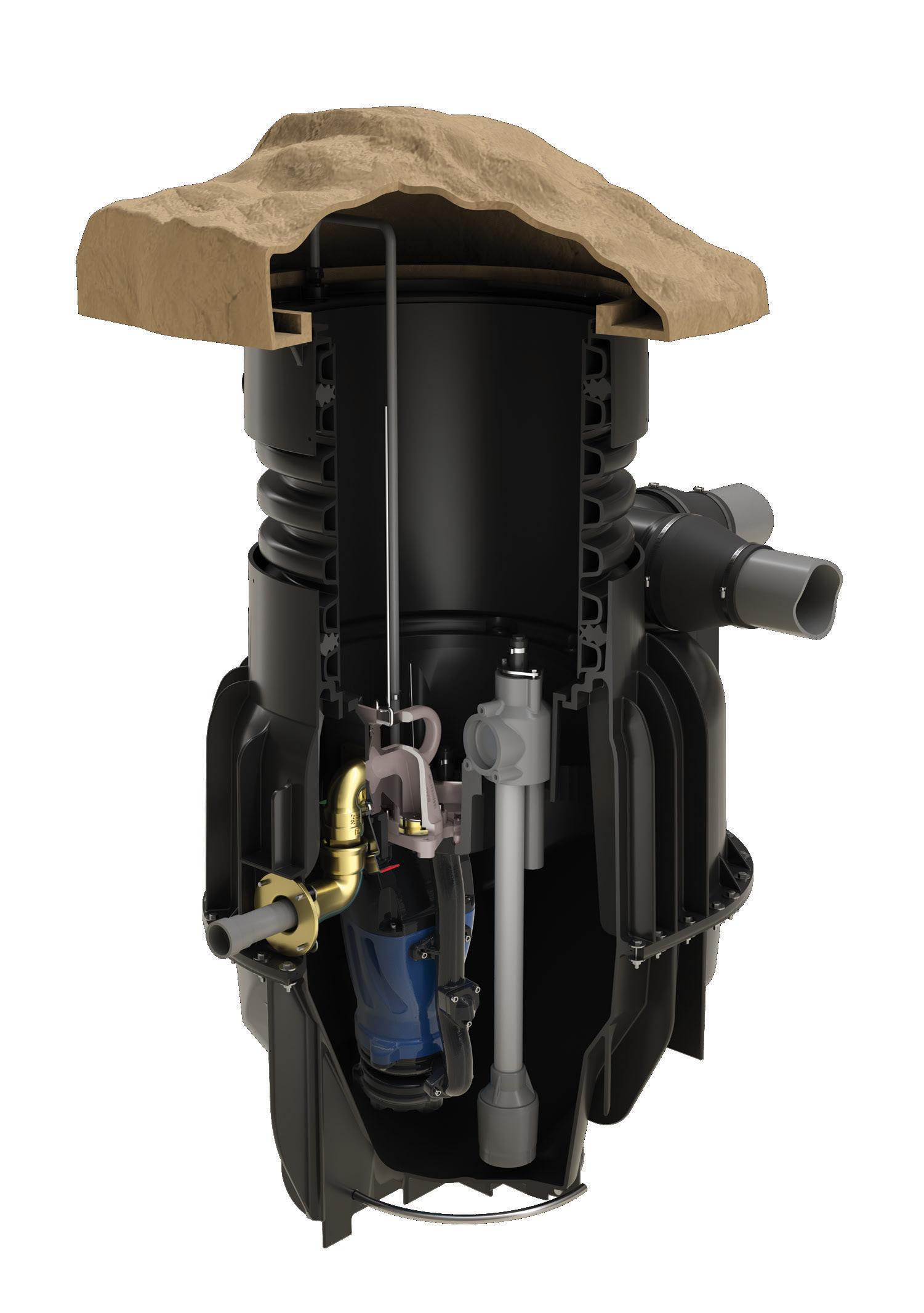

Pressure sewer systems can cut new residential development costs

By Mackenzie May

Across Canada, housing development continues to boom. According to Statistics Canada, as of February 2024, the current investment in residential building construction across the country is more than $13 billion. As development continues, infrastructure must also be expanded to support growth, and this includes water and wastewater planning.

As development occurs in rural areas with minimal existing infrastructure, continued expansion becomes more costly for builders. When installing new sewer infrastructure, the most common method of collection is using gravity sewer systems to transport wastewater. This traditional approach, while effective in many contexts, poses challenges in areas with rugged terrain or low population density, often necessitating extensive excavation and costly installations.

Keeping the financial impacts in mind, alternative sewer solutions may offer more economical options for infrastructure expansion.

EQUIPMENT COST

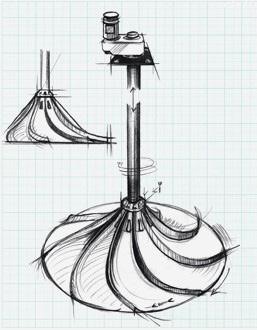

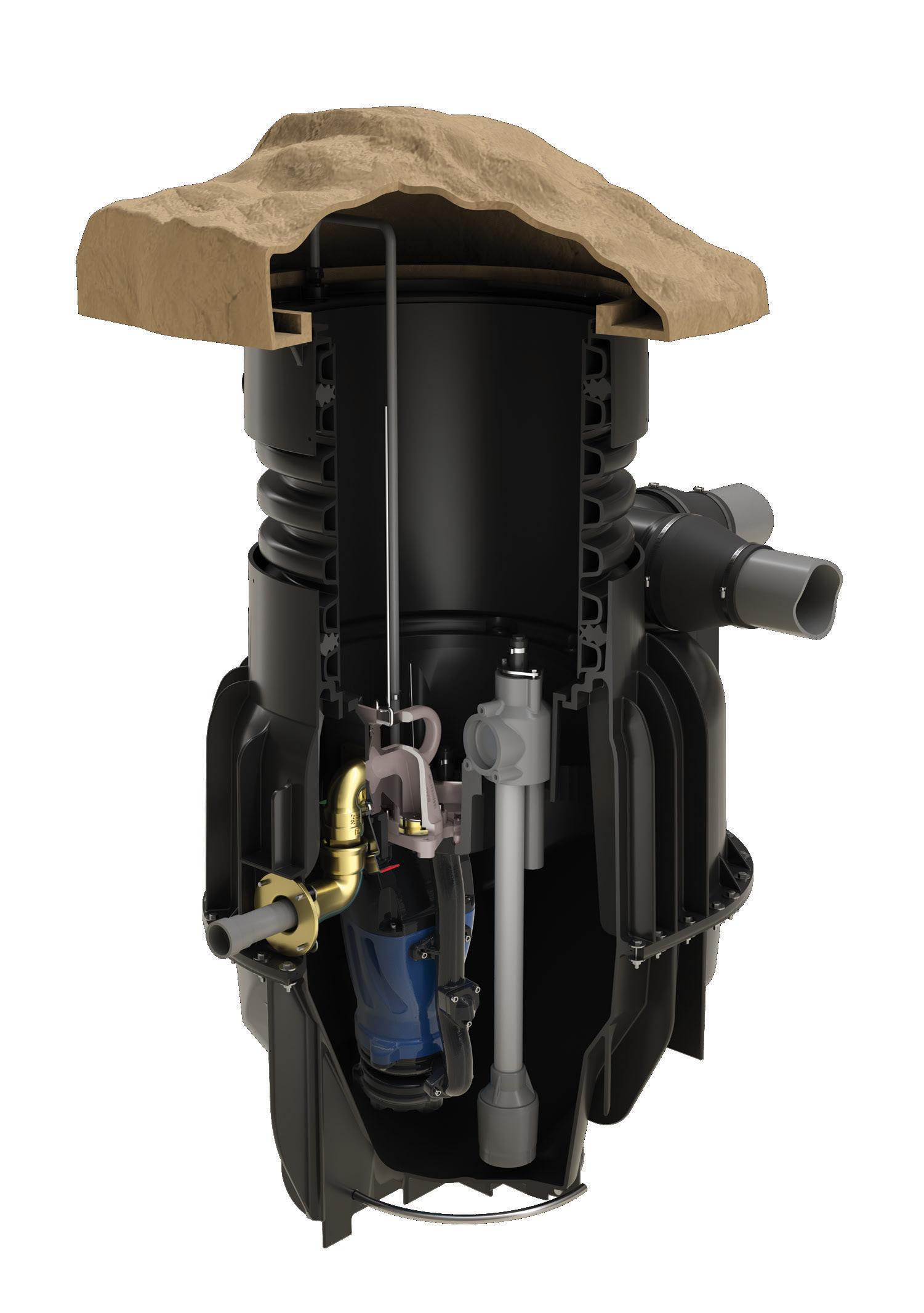

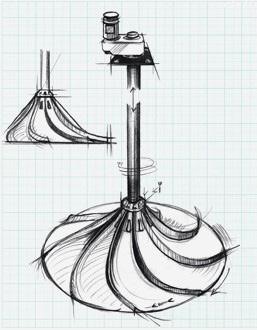

A pressure sewer system utilizes a network of grinder pumps which are used to transport wastewater through small diameter pipes under pressure to a collection or treatment system. Each home is equipped with a grinder pump station, which consists of four main components: a basin, a 1-2 HP grinder pump, a level control, and a control panel. Lateral piping from the basin ranges from 32 mm to 50 mm diameter, while the main sewer line is typically 200 mm to 300 mm in diameter. Pipe size may vary depending on the number of homes connected to the system. Hydraulic design considerations should aim for sufficient scouring velocity to prevent solid settlement.

A gravity sewer utilizes larger diameter pipes, typically 400 mm, up to 900 mm. Similarly to pressure sewers, gravity sewers require sufficient scouring velocity to prevent solid settlement. As a result, pipes must be installed at consistent downward slopes and lift stations are required when there is a need to transport wastewater to higher elevations.

Lift station equipment can be very costly, as it includes pumps, level controls, a control panel, variable frequency drives, telemetry systems, valves and pressure gauges. Depending on capacity, lift station pumps may start around 20 HP for small stations, and can get up to 150 HP or beyond. This means that that the equipment found in one lift station alone can exceed $100,000. Many municipalities have several lift stations, depending on the distance homes are located from the force main or treatment facilities.

While there are cases where a single development utilizing a pressure sewer would require hundreds of grinder pump stations, the overall cost of this equipment is rather small com-

pared to the cost of several lift stations. The cost of the equipment can be easily added to the price per lot when selling the development.

INSTALLATION COST

As discussed, gravity sewer systems utilize large diameter pipes, which must be installed at a consistent downward slope. To accomplish this, significant excavation is required. If existing infrastructure such as roads is already in place, they must be torn up during sewer installation.

Installation of lift stations also requires significant excavation, often several stories below ground level. The site of each lift station in a system may require a control building to be fabricated, which is often protected with fencing and gates to prevent unauthorized access.

Contractors preparing grinder pump stations for installation.

continued overleaf… Environmental Science & Engineering Magazine 14 | June 2024 WASTEWATER

UPGRADEABLE

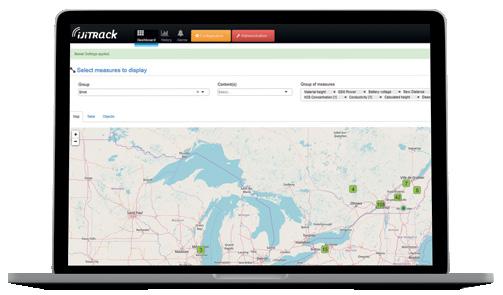

PR’eautech, Instrumentation & Odours Autonomous & Connected Solutions for effective monitoring! Visit us at the IWA Toronto! August 11-15 2024 Booth 635 Your Expert for analysis, control and monitoring of water GRAPHIC DESIGN: freelance-gazoline.com CLAIRE GROUP05/24 preautech.com ijinus.com Follow us on Follow us on Natural water - Wastewater - Overflow - Drinking water

systems AUTONOMOUS CONNECTED SOLUTIONS

SYSTEM

Partner specialized in the development of autonomous and smart measuring and data logging

Each home is equipped with a grinder pump station, which consists of four main components: a basin, a 1-2 HP grinder pump, a level control, and a control panel.

With pressure sewer systems, pipes are installed directly below the frost line via directional boring, eliminating the need for deep excavation and preventing the disruption of existing infrastructure. Piping follows the contour of the land, allowing them to be installed in various terrain types including rocky, hilly, and areas with high water tables.

This allows developers to utilize land that may have otherwise been considered too costly with traditional infrastructure. Minimal excavation is required to install basins on each lot.

It is important to note that pressure sewer systems have the flexibility to be used on their own, or in conjunction with existing gravity sewer infrastructure. Depending on the individual scenario, the use of a pressure sewer can reduce or eliminate the need for a lift station.

DEFERRING UPFRONT COST

It is easy to forget that the infrastructure used in existing homes on a day-today basis had to be established before they were built. All of the equipment and installation expenses discussed thus far are spent long before owners occupy a new home. If considering a single new development project, the entirety of the sewer system must be planned and installed prior to breaking ground on homes.

In phased developments, which will be

built over the course of several years, this means that infrastructure, including piping and lift stations, must be developed for when the system will operate at full capacity. Even if that is many years away.

to provide the financing for the equipment. This notably reduces the upfront cost associated with development.

OPERATIONAL COST

If gravity systems could operate without lift stations, there would be little to no cost associated with operation. Unfortunately, lift stations come with large and complicated equipment which does require significant capital. Large horsepower pumps can cost thousands per year in electricity alone. Incorporating telemetry and monitoring features add additional monthly communication fees. Municipalities or service utilities also must employ operators and electricians to keep equipment functioning as expected. While operator jobs are not eliminated with pressure sewer systems, the electrical cost of the grinder pump is covered by the homeowner. Grinder pumps utilize very little electricity in comparison to lift station equipment, accounting for similar cost to other small household appliances.

MAINTENANCE COSTS

While there are cases where a single development utilizing a pressure sewer would require hundreds of grinder pump stations, the overall cost of this equipment is rather small compared to the cost of several lift stations.

Municipalities or service utilities who are familiar with lift station maintenance can feel overwhelmed at the prospect of having hundreds to thousands of grinder pump stations to maintain. The key difference is the frequency of service required. Most operators visit their lift stations for basic maintenance on a daily or weekly basis.

However, with grinder pumps, the average time between service calls is intended to be 7 to 10 years. With that said, nuisance calls for problems such as float issues or clogging can occur, but they are easily fixed, and if new parts are required, they are far less expensive.

With a pressure sewer system, developers can defer a significant amount of their equipment cost until the sale of a home. They simply must install the piping network upfront, while basins, pumps and controls can all be installed immediately prior to occupancy. This allows income from the sale of the home

Many municipalities or utilities charge a monthly sewer fee to residents, which provides a source of funding for standard service calls. Other solutions include charging homeowners for grinder pump service on a case-by-case basis. In some cases, homeowners own and are responsible for maintaining their own grinder pump stations.

Mackenzie May is with Crane Pumps and Systems. Email: mmay@cranepumps.com

Environmental Science & Engineering Magazine 16 | June 2024 WASTEWATER

ECOTRAN

Barnes Pressure Sewer Packaged Solution

INSTALLATION

Directional boring and field adjustable risers allow for faster installation and limited disruptions saving time and money.

AESTHETICS

The materials of construction and EcoTRAN technology allow for lower environmental interference and extended product life.

You were top of mind with this product’s design. The discharge valve, plug-and-play cord, and basin were engineered to simplify maintenance.

SERVICE

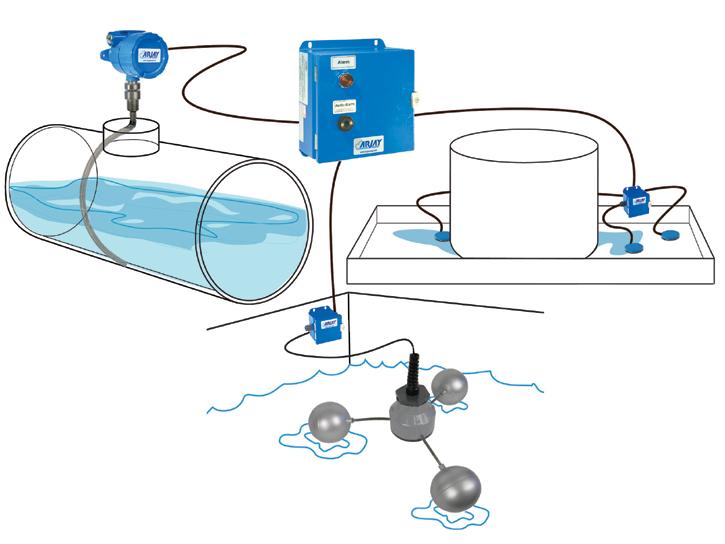

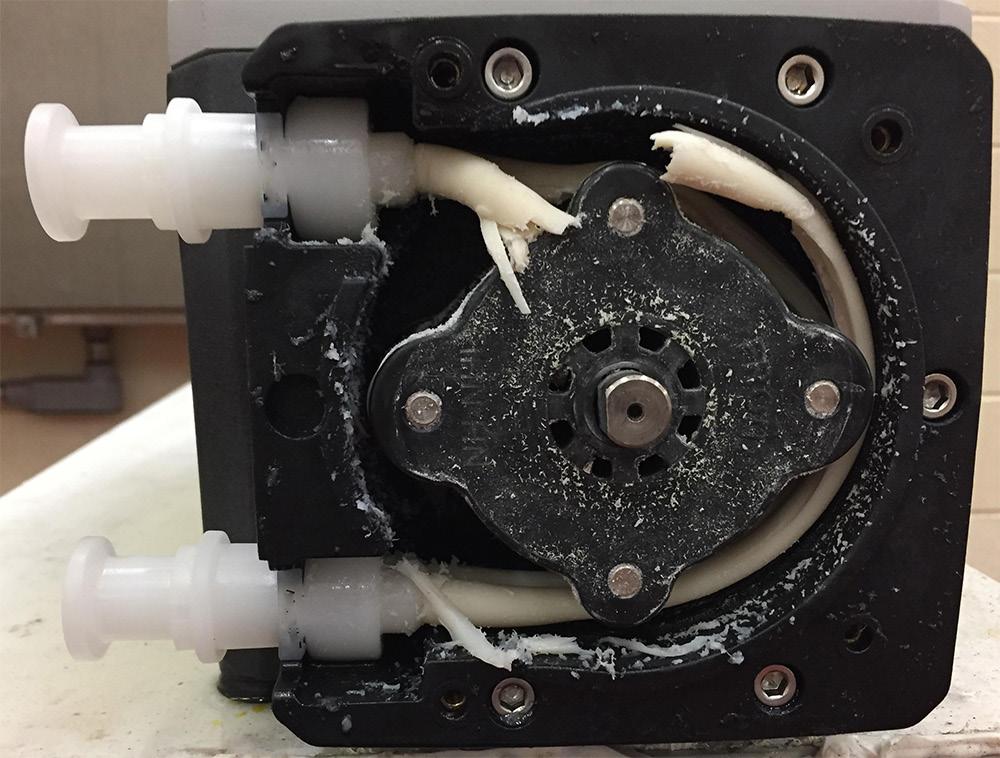

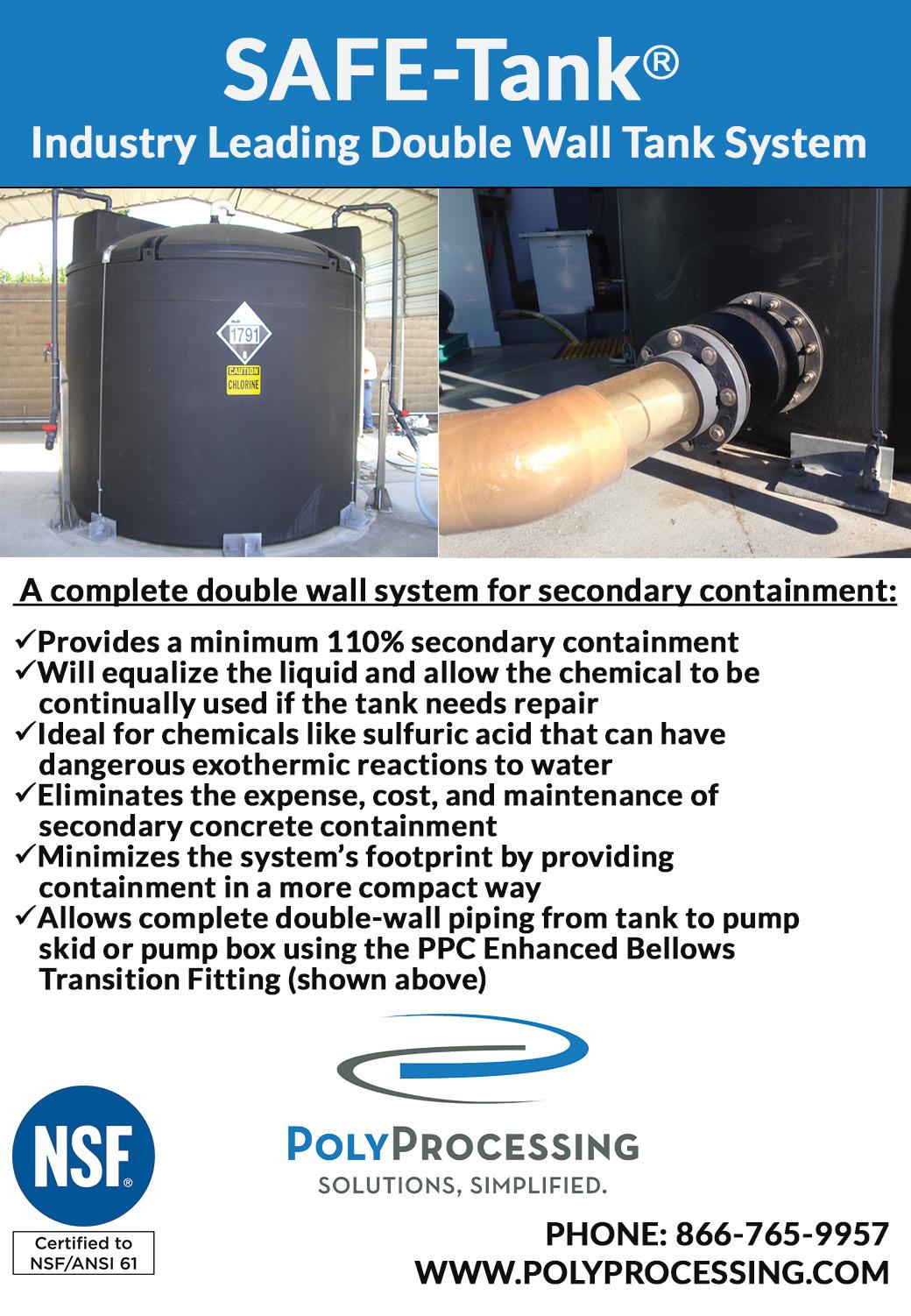

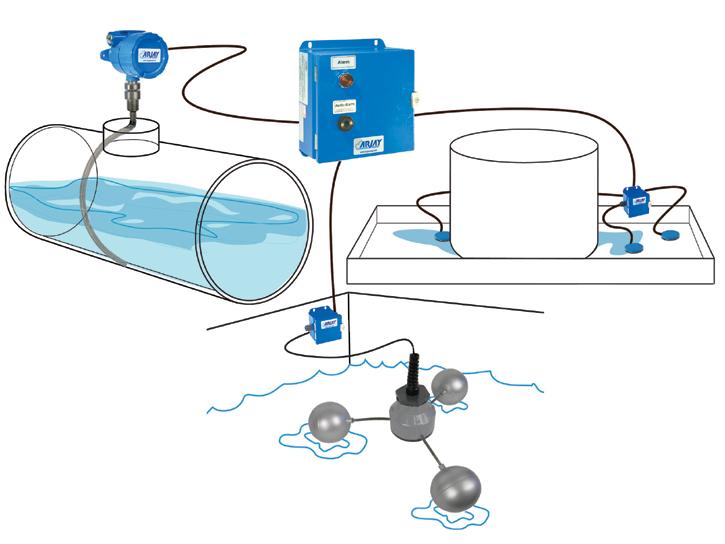

Capacitance is a reliable and cost- effective method to monitor for industrial spills and leaks

By Greg Reeves

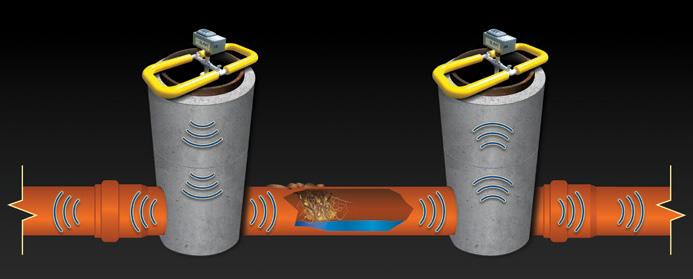

Capacitance technology has been used in industrial monitoring applications for over 100 years. Its classic probe design is typically known for high- and lowlevel alarm, continuous level monitoring and interface control. As new technologies for level applications are steadily being introduced, such as ultrasonics, radar and optical, capacitance continues to firmly hold its place as a reliable and cost-effective method for sensing and control.

In the early days of capacitance controls, industrial instrumentation was focused on improved automation and process control. Instrument selection was based largely on a product that could contribute to a company’s competitive edge and profit. However, for many years now, corporate sustainability has included environmental responsibility, and capacitance technologies have adapted well to this focus. Unique and creative

sensor design, coupled with advancements in precision components and microprocessors, have provided capacitance a stronger than ever place in the environmental monitoring space for applications such as spills and leaks.

Capacitance is unique in that it does not employ any mechanical moving parts or rely on sonic or optical transmission through a medium to work. The actual sensing element is really just a simple piece of metal.

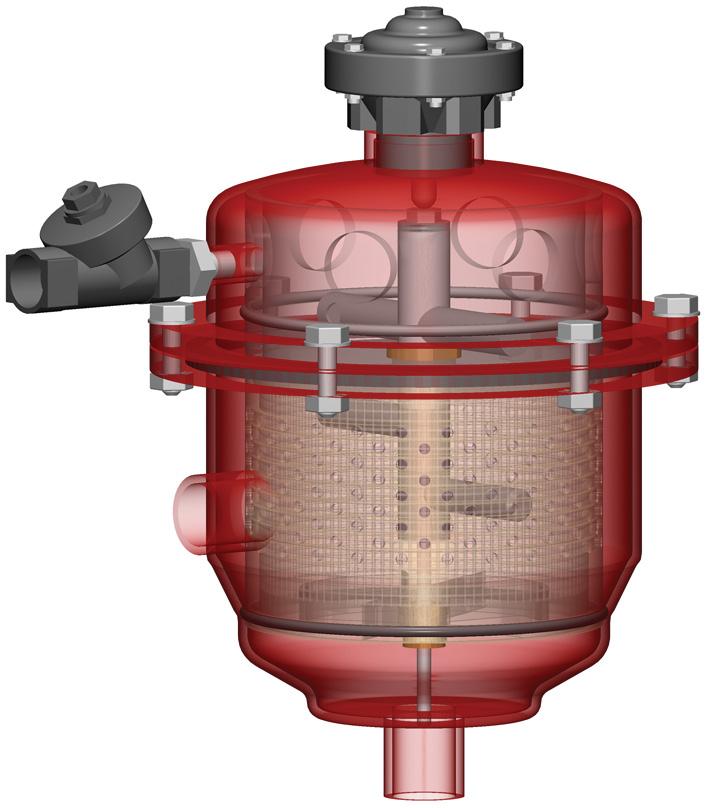

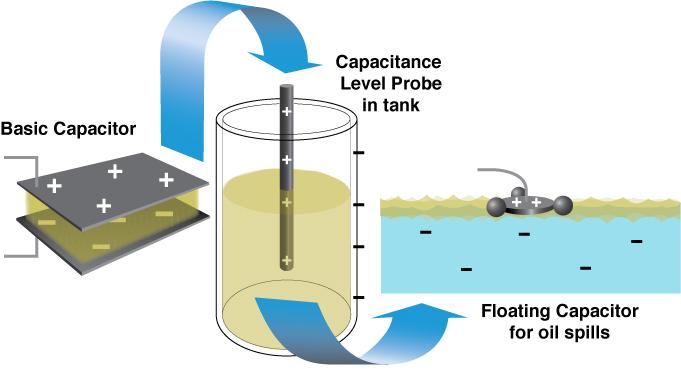

HOW DOES CAPACITANCE WORK?

A common conception of a capacitor is a small component that is used in electronic circuits or as a device used with motors and power machinery. On circuit boards it is often used to control and stabilize electronic signals. On machinery, it is more often used to build up and hold a charge. The charge can then be released in a controlled manner to kick-start motors.

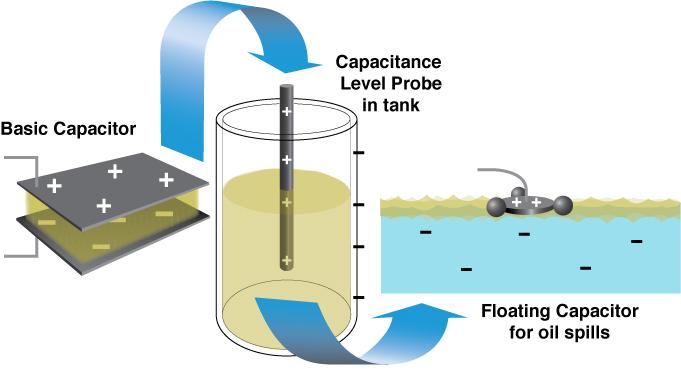

When applied to industrial process monitoring, capacitance is used in a totally different manner. A typical capacitor is comprised of a positive and a ground plate, separated by a medium in between. The performance of the capacitor can be dictated by the size and distance between the plates and the material between the plates. A material’s ability to hold an electrical charge is known as its dielectric. Different materials have different dielectrics and will behave differently within a capacitor.

For industrial measurements, such as level control, the two plates become the long sensing probe and the wall of the tank (see Figure 1). In an empty tank, the material between the two plates is air. Air has dielectric strength of about 1.0.

The capacitance field across the plates is measured in farads, and specifically for industrial level and spill control, it is usually in the picofarad range.

As the tank is filled with a liquid or solid, the air is being displaced by a material with a higher dielectric constant. This increases the overall capacitance reading between the probe and tank wall in a proportional manner. Through a control circuit, this reading can be tracked and calibrated to provide useable output signals, controls and display devices.

HOW CAN CAPACITANCE BE USED FOR ENVIRONMENTAL MONITORING?

In the above scenario, a level probe in a tank was used to describe a typical application of capacitance technology for automation and control. One of the unique features of capacitance is that the sensing plates can be virtually any shape or size and can be placed into any type of service. The capacitance sensor design and function are left up to the imagination,

Environmental Science & Engineering Magazine 18 | June 2024 SPILLS MANAGEMENT

resulting in endless applications and customer solutions.

An interstitial tank leak alarm is a good example (see Figure 2, upper left). Protecting groundwater from potential tank leak hazards is of prime concern. Most buried tanks and many above ground tanks are regulated to require double walls to help contain a leak. A tip-sensitive, flexible cable can play the role of a capacitor plate.

It can be snaked within the interstitial space of a double-walled tank to lay in the normally dry void near the bottom. In the event of the internal tank leaking product into the interstitial space, or a breach of the external wall, allowing groundwater in the space, the capacitance of the sensor will change due the displacement of air by the liquid. This can trig ger remote alarms.

Another example of unique capacitance sensor design is the use of sensing pucks. These can readily be placed in tank containments, electrical vaults, chemical storage units, pump pans or just about anywhere a normally dry condition may incur liquid during an upset leak situation (see Figure 2, upper right). Capacitance sensors are very sensitive and can be set to alarm at very low accumulations of liquid.

Stormwater runoff is another environmental concern of industrial facilities, particularly those that use and contain petroleum oil and fuel on site. Power utilities, refineries, air ports, steel plants, pulp and paper mills, and railyards are just a few such facilities that have concerns of trace oils getting into the stormwater runoff and leaving the site.

Strategically placed sumps throughout industrial sites act to contain debris and oils that might otherwise work their way to a local stream or storm drain. A unique solution to monitoring these sumps for oil accumulation is to float a capacitance plate on the water surface (see Figure 1 and Figure 2 bottom sketch).

installed, the initial setup is minimal and they are easily calibrated to the ambient normal conditions of the site. Any upset condition due to the presence, absence or change in a liquid condition will trigger an alarm for operator attention. With over 100 years of industrial service, new applications and solutions are found for capacitance technologies every day and environmental protection is no exception.

Greg Reeves is with Arjay Engineering. For more information, email: greeves@arjayeng.com, or visit www.arjayeng.com

The tethered sensor will ride the routine level changes from the sump pump action. In the event of an abnormal oil accu mulation, the water that is normally just below the floating sensor is displaced by separated oil, which has a lower dielectric. The capacitance reading changes and the controller alarms to lock out the sump pump and alert personnel.

Capacitance technologies have proven to be an ideal solution to many environmental monitoring concerns. They are physically very robust and electronically very sensitive. Once

Figure 1. Capacitance can be applied to industrial and environmental applications.

Figure 2. Capacitance sensor design and function are left up to the imagination.

June 2024 | 19 www.esemag.com @ESEMAG SOIL METEOROLOGY BIODIVERSITY GEOMATICS PROUD DISTRIBUTOR OF THESE BRANDS: AIR HEALTH WATER T (365) 527-2508 | F (365) 527-2509 | 1 855 527-5808 sales@geneq.com 910 Rowntree Dairy Rd., Unit #15 Vaughan, (ON) L4L 5W5 T (514) 354-2511 | F (514) 354-6948 | 1 800 463-4363 info@geneq.com 10700 Secant St. Montreal, (QC) H1J 1S5 Vaughan Montreal & SAFETY WWW.GENEQ.COM Critical Environment Technologies SCIENTIFIC INSTRUMENTS ENVIRONMENT

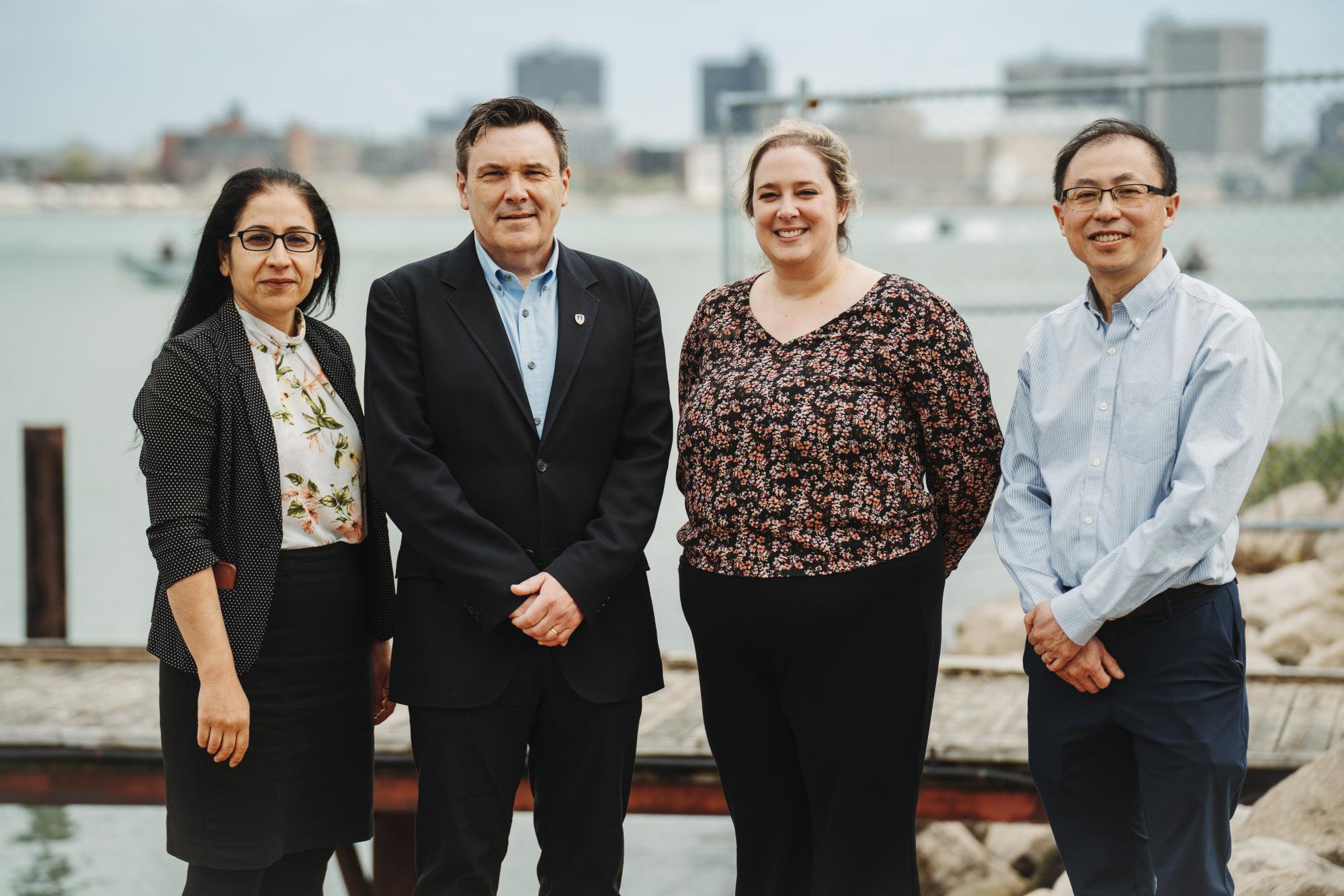

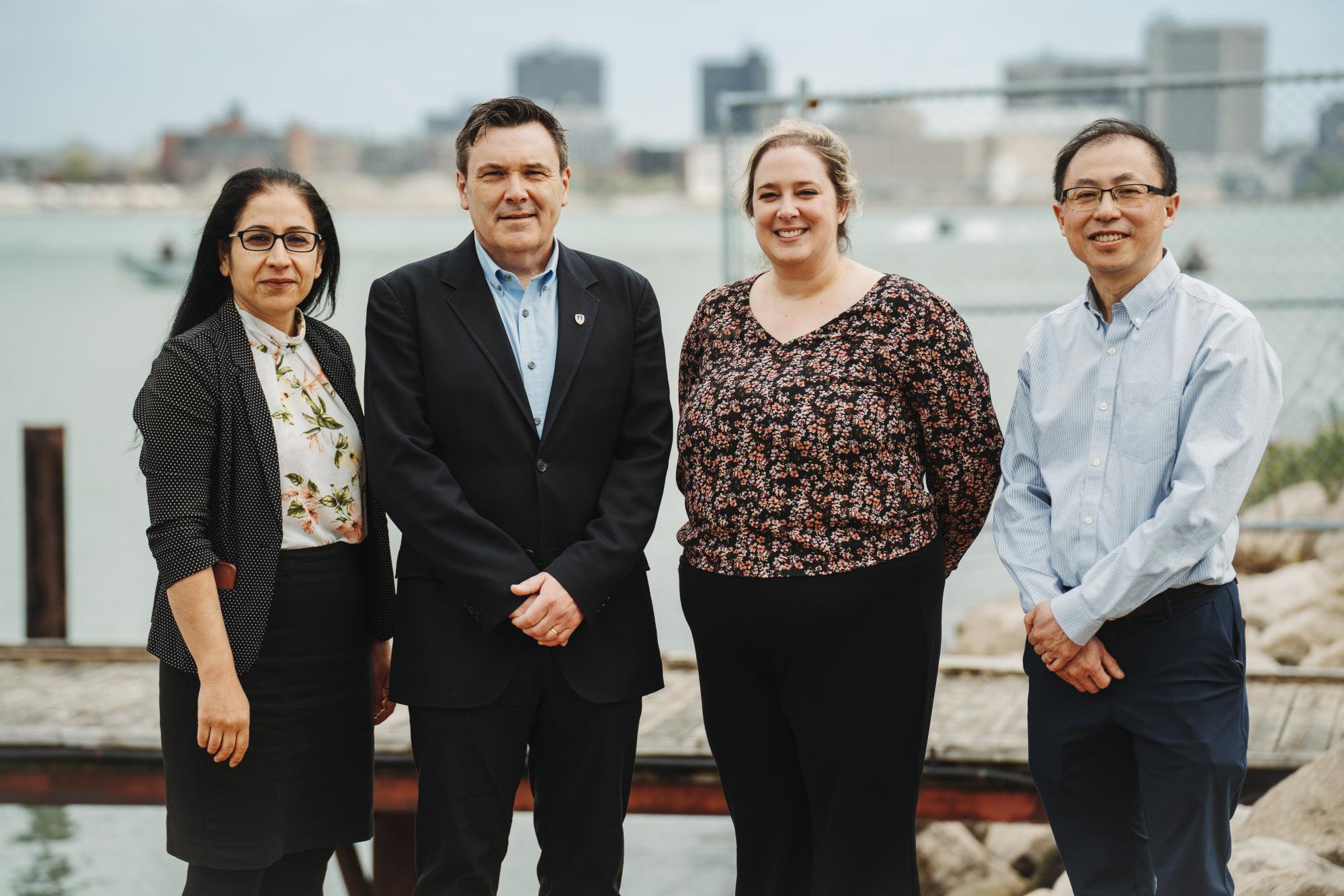

Canada invests $15M to support biomanufacturing supply chain for wastewater surveillance

By ES&E Staff

New federal funding of $15 million will help to support a wastewater surveillance network and bolster Canada’s biomanufacturing sector to improve health sector supply chains, cross-border trade and mobility, and explore new technologies in pathogen surveillance.

The Integrated Network for the Surveillance of Pathogens: Increasing Resilience and Capacity in Canada’s Pandemic Response (INSPIRE) brings together 43 researchers from seven universities and public and private agencies. The team consists of biochemists, microbiologists, engineers, computer scientists, and supply chain public policy experts.

INSPIRE will develop strategic partnerships with researchers in Michigan, Ohio, and New York, to create a cross-border pathogen surveillance network covering regions where many supply chains supporting Canadian industry originate.

The University of Windsor’s Cross-Border Institute will focus on optimizing cross-border policies and programs to make Canada a more attractive destination for life sciences companies.

“During the COVID-19 pandemic, we had supply chain shortages, we couldn’t get enough PPE in Canada, we weren’t making our own vaccines,” announced Dr. Mike McKay, director of the University of Windsor’s Great Lakes Institute for Environmental Research.

McKay is leading INSPIRE with Dr. Lawrence Goodridge, a professor in the Department of Food Sciences, and director of the Canadian Research Institute for Food Safety within the Ontario Agricultural College at the University of Guelph.

The project will build up Canada’s capacity to produce vaccines and therapeutics by advancing wastewater surveillance and developing technologies

that simplify and speed up sampling and pathogen detection.

“As we deal with the increasing emergence of infectious diseases, it’s imperative that we enhance our preparedness for future health crises,” says Goodridge in a statement from the University of Guelph.

The team also includes researchers from the University of Waterloo, University of Toronto and York University, as well as partners at more than 30 academic, public, private and not-forprofit institutions. University of Waterloo scientists Dr. Trevor Charles and Dr. Andrew Doxey have been granted $1.5 million in research funds to fulfill their part of the larger multi-institute team looking to advance wastewater analysis.

By using high-throughput metagenomic sequencing, Dr. Charles and his team will detect new, existing and emerging pathogens and antimicrobial resis-

tance, building on all the work done in Waterloo research labs tracking SARSCoV-2 and its variants, as well as with other viruses like influenza and RSV.

“This same technology also has potential for application in agriculture and food production, with implications for human, animal and crop health,” announced Dr. Charles. “A recent example is the emergence of avian influenza in cattle.”

For more information, email: editor@esemag.com

Dr. Arezoo Emadi, Dr. Mike McKay, Dr. Kendall Soucie, and Dr. Kenneth Ng are pictured along the Detroit Riverfront. Credit: UWindsor

Environmental Science & Engineering Magazine 20 | June 2024 WASTEWATER

ENGINEERS SPEC US AGAIN AND AGAIN. WE ARE GENERATIONS STRONG. PENTAIR.COM/200

How a rural Alberta water treatment plant reduced DOC and improved water quality

By Russ Swerdfeger

The pristine waters of Lake Christina in northeastern Alberta serve as a recreational attraction and also as the source water for Conklin, one of 11 Indigenous and rural communities that comprise the Regional Municipality of Wood Buffalo. For years, Conklin’s water didn’t require treatment for dissolved organic carbon, but recently, with heavier use and a larger plant, dissolved organic carbon (DOC) has crept up to exceed mandates.

DOC found in raw water sources with natural organic matter is a known precursor to the formation of disinfection byproducts (DBPs) which are created when disinfectant (either chlorine or chloramine) reacts with dissolved organic carbon to form halogenated organic compounds.

Despite its small size, Conklin serves about 250 residents and includes a post office, gas station, cafe, store, lounge, and school. The community found success with a fluidized ion exchange pretreatment system specifically designed for small water treatment plants. MIEX® Mini systems from IXOM Watercare utilize a small-particle resin that is fluidized and used as a pretreatment step to pull organics from untreated water before it reaches the plant. This pretreatment removes dissolved organic carbon, thereby reducing disinfection byproduct formation. Prior to installation, the manufacturer provided a pilot test.

PRIOR TREATMENTS STRUGGLED TO COMPLY WITH DBP RULES

Rural water systems across Canada face the problem of DOC carbon in source water, just like their larger counterparts, but struggle to find treatment options suited for a smaller operation and budget. Do-it-yourself solutions, chemicals and other options often don’t get the job done to meet compliance and other issues.

Canada requires water treatment plants to monitor for two disinfection byproducts in drinking water. Total trihalomethanes (TTHM) and haloacetic acids (HAA5) have shown to cause negative human health effects such as cancer and reproductive harm. Canada’s Guidelines for Canadian Drinking Water Quality (GCDWQ) require plants to provide quarterly water quality samples that show amounts no greater than 100 µg/L for TTHMs, and 80 µg/L for HAAs.

The water treatment plant was unable to comply with the regulations before installing the MIEX Mini plants. Staff conducted multiple-loading tests to determine the optimum treatment rate for their source water. The optimal rate is selected based on the treatment goals, economic feasibility, and diminishing DOC removal efficiency.

Steven Meunier, foreman of operations for water treatment at the Regional Municipality of Wood Buffalo tried treating DOC with a conventional coagulation treatment system of

potassium permanganate, soda ash and other chemicals, but the system struggled to remove DOC to levels low enough to minimize disinfection byproduct formation upon chlorination. Due to elevated DOC concentrations, the Conklin water treatment plant was sometimes unable to meet federal water guidelines for trihalomethanes and haloacetic acids (HAA) at 100 µg/L and 80 µg/L, respectively.

NEW TECHNOLOGY, WITH PILOT STUDY, SOLVES THE PROBLEM

As the DOC levels increased, Meunier looked for newer technologies, while also trying various solutions. “We have a big reservoir and a small population. We tried lowering contact time, aeration, as well as using different chemicals,” he said,

At a Water Week regional conference in Edmonton, Meunier met representatives from MIEX and IXOM Watercare, and started the conversation of how to fix his problem. He also checked with others in neighbouring provinces who had installed the a MIEX system and received favorable reviews. With the support of the Regional Municipality management team, Meunier arranged for a four-week pilot study at the Conklin water treatment plant.

“The major adjustment was dropping our coagulant use down quite a lot,” said Meunier. “The pilot study predicted we would drop coagulant use about 50%. That’s where we started, but ended up dropping it about 75%. That’s where it runs now. We’re getting better performance out of the actual plant than the pilot one.”

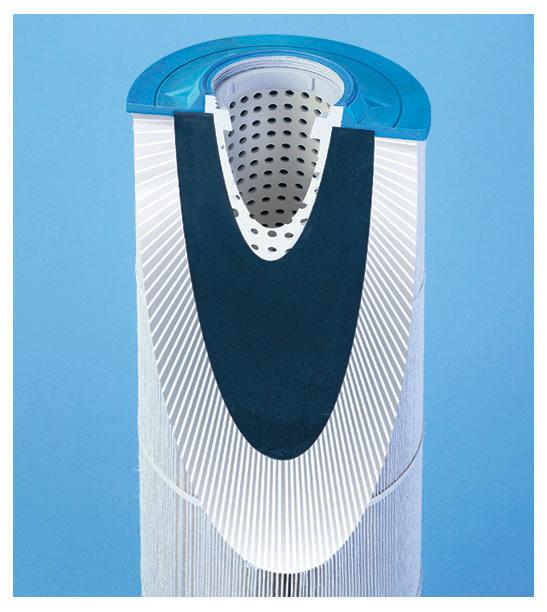

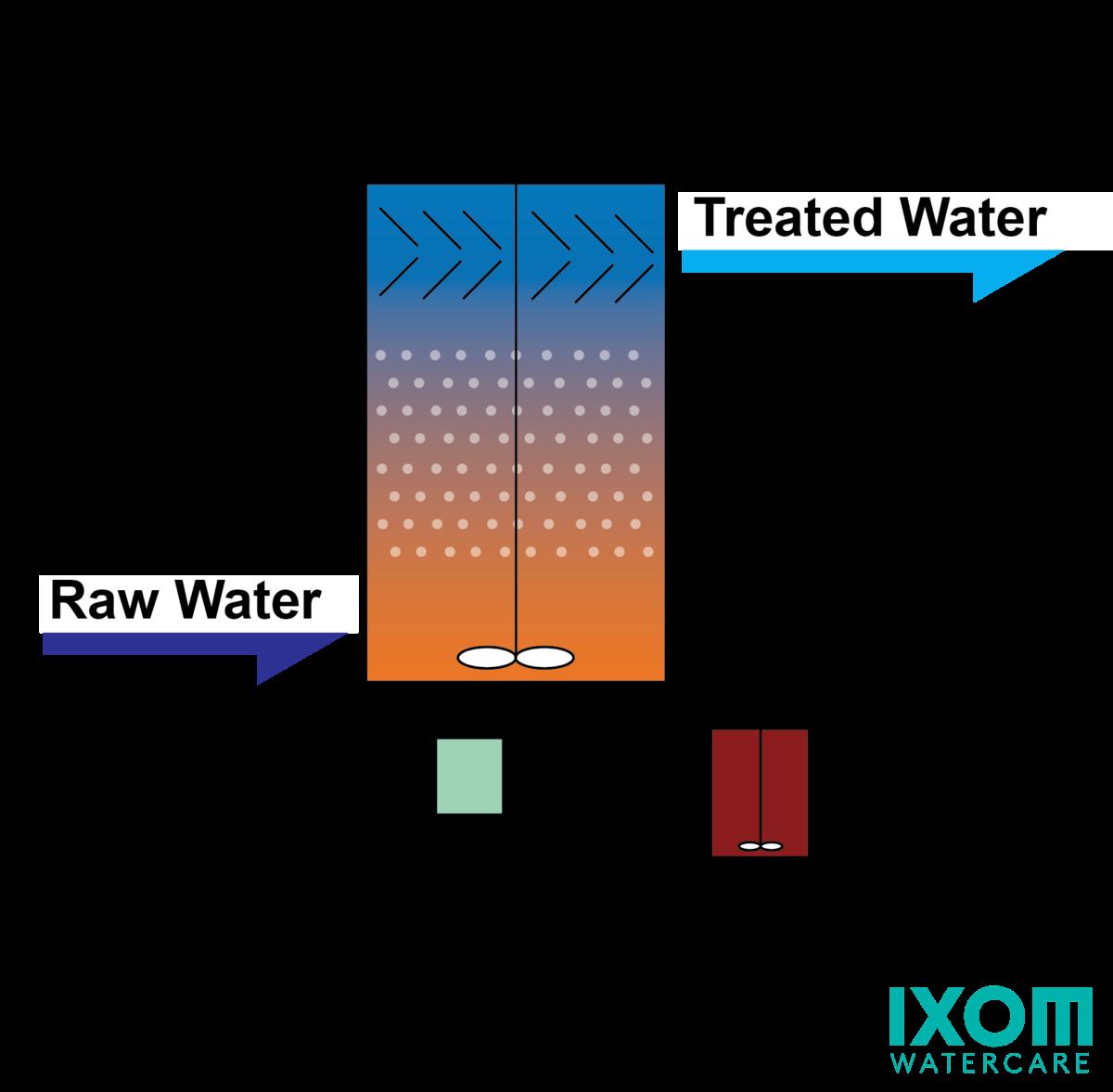

The MIEX Mini treatment process utilizes MIEX Resin, a

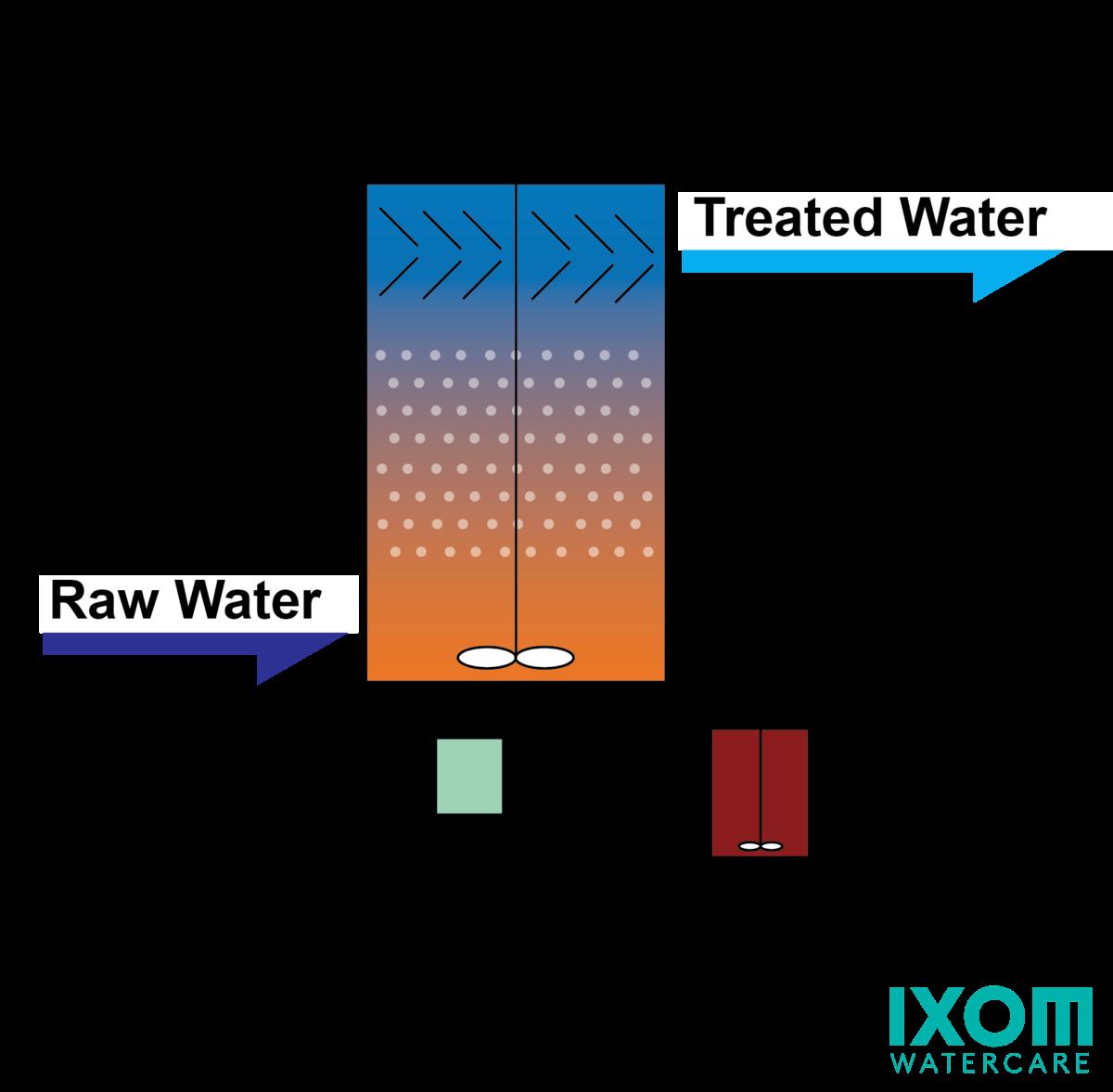

The regeneration cycle for MIEX Mini ion exchange pretreatment systems.

Environmental Science & Engineering Magazine 22 | June 2024 WATER

continued overleaf…

Pinnacle Ozone Solutions’ patented modular quad-block design operates in a small footprint to eliminate odour, oxidize colour, and kill bacteria.

Pinnacle Ozone Solutions delivers technically superior, energy efficient, and reliable ozone systems which do not produce harmful by-products, such as THMs and HAAs, which can result from chlorine disinfection.

The modular design ozone cells offer seamless system integration for drinking water and wastewater treatment facilities, delivering rugged, service-free operation within a small footprint. All while lowering your energy cost 20-40% and total operating cost 35-50% versus conventional systems.

LOWER YOUR COSTS BY UP TO 50%

To discover the unparalleled advantages of Pinnacle Ozone Solutions for your application, contact ACG-Envirocan today.

CREATE YOUR IDEAL DISINFECTION SOLUTION WITH OZONE GENERATING MODULES

CALL 905.856.1414 • 131 Whitmore Rd., Unit 7, Woodbridge, ON L4L 6E3 LE AD ERS IN INN OV ATION & SUST AI NA BILITY Ontario Pollution Control Equipment Association www.acg-envirocan.ca

magnetized ion exchange resin, in a fluidized bed to remove charged constituents of DOC from drinking water supplies and therefore reduce treated water disinfectant byproduct formation that occurs during chlorination. Used as pretreatment to coagulation, the resin reduces the chemical demand necessary for coagulation, as a large portion of the organics are removed.

Coagulants are left to remove larger non-polar constituents, thereby decreasing coagulant dose and yielding a denser floc through minimized charge repulsions, with a reduced need for flocculant aids, polymers, and pH adjustment. Meunier is also able to reduce soda ash treatments by about 50%.

The reduction in coagulant reduces operating costs and sludge volumes generated by chemical additions, as well as increases filter efficiency due to less frequent backwashing. “It took us a while to drop down to a running average rate,” said Meunier. “Based on our research and pilot, I was optimistic. Based on the results, I was pleasantly happy. And I’m more than pleasantly happy about the decreased chemical use, and the operators all like the system. There’s not much day-to-day maintenance, and it’s not adding much extra work.”

Conklin is one of four communities in the area, and each will also eventually need DOC treatment. Now that Conklin is meeting its compliance goals for reduced THMs, Meunier will turn his attention to Fort McKay, with plans to install a MIEX system there.

Visit our website to view our hands-on training, virtual training and e-learning course options.

Browse our online Drinking Water Resource Library, and learn about Pilot Testing and Helpline services.

www.wcwc.ca

HOW FLUIDIZED ION EXCHANGE PRETREATMENT WORKS

MIEX is short for “magnetic ion exchange” The magnetic properties of these beads allows them to agglomerate and settle rapidly, or fluidize, at high hydraulic loading rates. Because of this feature, MIEX Resin is used in a continuous process, with ion exchange occurring in either a mixed tank or a fluidized bed reactor vessel.

Raw water is fed to the base of the reactor vessel for providing upflow fluidization hydraulics. Inclined plate settlers at the top of the reactor vessel assist with resin/water separation. Treated effluent overflows into collection launders and to downstream treatment processes. After the predefined volume of water has been treated, flow stops and the resin regeneration processes occur.

Water is drained from the vessel, and a brine solution downflows through the settled resin bed, regenerating the resin. The regeneration cycle takes approximately three hours, after which the system will resume treating water. Two systems on line can alternate for continuous duty; plant expansions are easy with the addition of redundant units.

The resin beads used in the process are manufactured to be much smaller than conventional ion exchange resins, providing four to five times the surface area, and allowing for rapid exchange kinetics.

DOC REMOVAL CHEMISTRY

When the resin comes in contact with water, negatively charged organic acids (i.e., DOC) are removed from the water by exchanging with a chloride ion on active sites on the resin surface.

In the regeneration process, resin loaded with DOC undergoes a reversed ion exchange reaction, where chloride ions are substituted for DOC, which is released from the resin into a concentrated brine (NaCl) solution. Other regenerants can also be used.

Russ Swerdfeger is with IXOM Watercare, who are represented in Ontario by Pro Aqua Sales. For more information, email scott@proaquasales.com

Environmental Science & Engineering Magazine 24 | June 2024 WATER

MIEX Mini units help Conklin comply with drinking water mandates.

Up to 50% reduction in mechanical room space required 90% fewer joints = 90% less risk of leakage Simple, consolidated operation AFTER simple. intuitive.

THE DICE

#20 – 220 Industrial Parkway S. Aurora, Ontario L4G 3V6 Tel: 1 (905) 841-4073 Fax: 1 (905) 841-4018 www.VissersSales.com THE EVOLUTION OF THE CHEMICAL METERING SYSTEM

BEFORE complex. cluttered.

Toronto pauses stormwater charge consultations

By ES&E Staff

•

The City of Toronto has paused its three stormwater charge public consultation sessions which were set for April, following the mayor’s instructions to align its potential implementation with Toronto’s broader climate resilience strategy.

Mayor Olivia Chow told local media she was caught off guard by the stormwater charge consultations, when she began fielding public complaints about it. The charge, or tax, was intended to begin in 2027 to address the amount of impermeable hard surface on a property, such as roofs, asphalt drive-

STORMWATER Stormwater Management Systems Inspect Smart GRAF EcoBloc Ontario Distributor 1.866.625.3929 | makeway.ca Canadian Supplier 1.800.665.4499 | barrplastics.com Watch it in action

Suitable for infiltration, detention and retention

Capable of HS-25

Storage Coefficient of 96%

•

•

•

System is fully inspectable and flushable

fund the infrastructure to manage it.

The stormwater charge is calculated by taking Toronto’s total stormwater management expenditures ($385 million) and dividing it by the city’s total impermeable surface area (22,857 hectares), which equals $1.68 per square metre of hard surface area.

L arger properties would likely see the largest jump in annual water costs if the stormwater charge is implemented. City officials estimate that properties larger than one hectare could face about a 10% annual increase in contributing to stormwa-ter infrastructure costs.

L arge properties represent approximately 1% of properties in Toronto, but account for 37% of the city’s total hard surface area. The city is also consulting on a potential stormwater charge credits program for large properties that implement long-term stormwater management solutions.

Several municipalities across North A merica have already implemented a stormwater charge, such as the Ontario communities of Mississauga, Brampton and Newmarket. Toronto itself has looked at the proposition for years, going back to about 2012

“Costs for stormwater management would be removed from the water rate and the stormwater charge would appear as a separate line on the utility bill as a fixed charge,” stated the City of Toronto’s stormwater consultation preview document.

Properties would be charged based on property type and size, and those without a water account would receive a stormwater charge-only bill, city officials noted.

Chow also told local media that before a stormwater charge comes to council, she would prefer to help homeowners figure out how to make green improvements to their properties and help rain to drain and infiltrate the ground more efficiently.

For more information, email: editor@esemag.com

Montreal’s newest sponge park will retain over a million litres of rainwater

By ES&E Staff

Montreal is set to build its largest sponge park ever as local officials aim to increase the city’s square footage of green infrastructure to absorb heavier and more frequent rainfall. In the fall of 2023, the city announced plans to build 20 sponge parks over two years. Its latest park project in the borough of Verdun will cover an area of some 4,300 m².

Drainage tree pits will also be built along the length of the park to allow water to infiltrate the soil. These features will temporarily retain more than a million litres of rainwater, over 40% of the capacity of an Olympic swimming pool, making it the first project of this scale in Montreal. As for the street, it will feature over 305 m² of sponge-like infrastructure in the form of draining vegetated pits.

The Verdun park will rank first among Montreal’s sponge parks, ahead of Pierre-Dansereau Park in Outremont, with a retention capacity of 627,000 litres, and Howard Park in Villeray-Saint-Michel-Parc-Extension, with a capacity of 624,000 litres. By way of comparison, the green space of Place des Fleurs-de-Macadam on the Plateau-Mont-Royal holds 160,000 litres of stormwater and runoff.

“At a time when the whole world is

confronted with the consequences of climate change, we have a responsibility to implement concrete measures to adapt to this new reality,” announced Montreal Mayor Valérie Plante, in a statement. “Sponge infrastructure is part of the solution, as it reduces the risk of flooding in vulnerable areas by capturing as much rainwater as possible, rather than directing it into the sewer system.”

The park will be built on land adjacent to the Atwater drinking water plant. Rue Dupuis will be resurfaced with a slight slope towards the park, and passages will be built under the sidewalk to allow water to flow directly into the park. Work on this project is scheduled to begin in the next few weeks and be completed during fall of 2025.

“The use of city-owned land, that of the Atwater factory, not only makes it possible to build this new resilient park, which will reduce the risk of flooding, but also to offer local residents quality landscaping, brand-new street furniture and a dog park. A win-win situation!” announced Marie-Andrée Mauger, mayor of the borough of Verdun. “At a time of climate change, the city continues to take advantage of every opportunity to improve its territory’s ability to adapt.”

For more information, email: editor@esemag.com

Local officials say drainage tree pits will also be built along the length of the park to allow water to infiltrate the soil. Graphic: City of Montreal

June 2024 | 27 www.esemag.com @ESEMAG STORMWATER

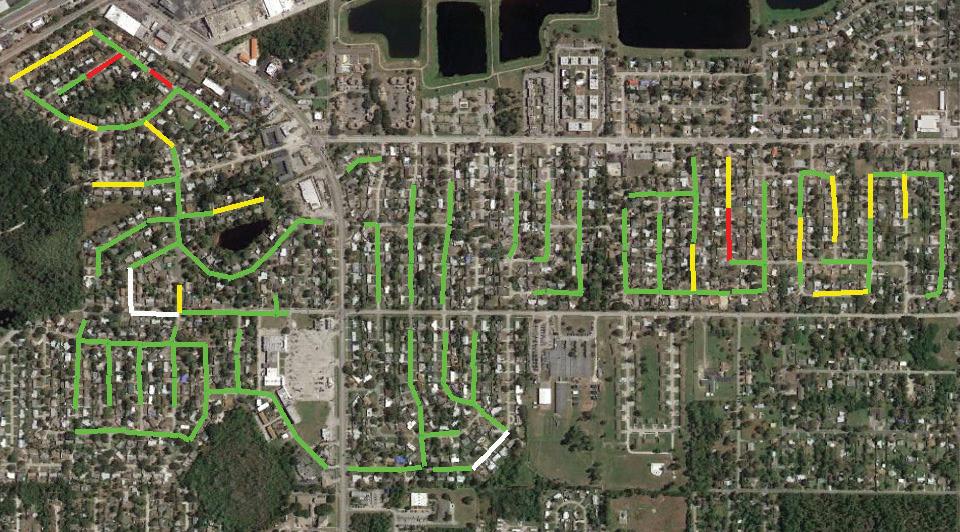

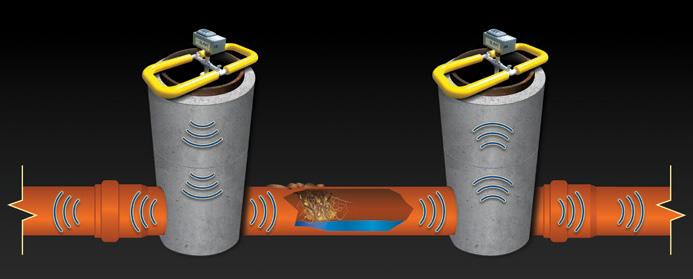

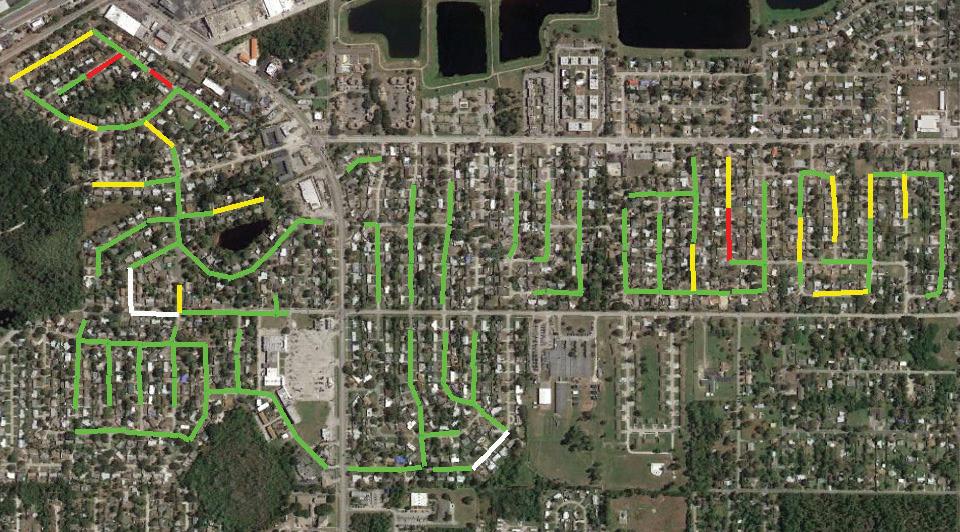

Concordia researchers analyze alternative factors for water main breaks

By ES&E Staff

While age, material and diameter are most often the culprits when it comes to water main breaks, a pair of Concordia University researchers has analyzed more than 62,000 breaks and found that the types of surrounding soil, or the type of pipe lining, coating or joint, are also notable factors.

The new paper published in the journal, Environmental Systems Research, includes data from 13 utilities in seven provinces, including inventories and histories of main breaks that covers almost 26,000 kilometres worth of pipes.

“It is very rare to find a study that includes so many cities,” explained study co-author Rebecca Dziedzic, an assistant professor in the Department of Building, Civil and Environmental Engineering at Concordia in Montreal, Quebec. “Having access to this kind of data allows us to see different perspectives and ways of collecting data, as well as each utility’s different goals and results.”

Researchers Sadaf Gharaati (left) with Rebecca Dziedzic.

Credit: Concordia University

Researchers Sadaf Gharaati (left) with Rebecca Dziedzic.

Credit: Concordia University

Environmental Science & Engineering Magazine 28 | June 2024 WATER It’s in our DNA. The innovative AERZEN Positive Displacement Blower, Hybrid and Turbo about efficiency and sustainability www.aerzen.com/canada Up to 55% energy saving potential in the biological wastewater treatment process Minimising CO2 footprint by 65% to achieve your common climate goals Optimizing blower technology mix for a sustainable aeration process

A recent Utah State University study created from utility survey data estimates that some 20% of water pipes across the U.S. and Canada are in need of replacement and contribute to some 260,000 water main breaks each year.

The utilities’ data for the Concordia study also has information on pipe diameter, material, length, installation year and failure year, among other variables, but the researchers were focused on lesser-known variables. For instance, seasons play a role in determining the risks of a water main break, the study found. Summer breaks can often be accidental due to Canada’s short but intense construction season. However, more failures are experienced in January and February, during freezing winters.

“The utilities can use the data to implement better practices, such as improving communication with construction crews about the location and types of water mains in a particular area,” Dziedzic explains.

When it comes to soil conditions, pipes in clay and sandy soils are more likely to break than pipes in damper environments, the study found. Clay soil breaks are usually related to bedding issues, while those in sandy soil are linked to the way the structures settle.

Universal joints were more likely to fail than collared ones, the researchers noted, particularly for circumferential failures. Joints and fitting failures were most likely in pipes less than 20 years old, and usually the result of poor installation rather than pipe quality.

The majority of historical breaks

recorded by the utilities occurred on older cast iron pipes. Because most of the PVC pipes were installed in the 1980s, or more recently, they have not yet reached the end of their expected service lives, the study found.

“The hope is that we continue to work together with the utilities to create better predictions of future breaks,” Dziedzic concludes. “This way, they can maintain

and manage their systems better within their budgets. Hopefully, we will be able to create better models that look at more factors and can help reduce the potential of restricting people’s access to clean water.”

Dziedzic co-authored the study with Sadaf Gharaati, MSc 22.

For more information, email: editor@esemag.com

STAINLESS STEEL LEVER HOIST

• Type 304 Stainless Steel Construction

• Food-Grade Grease Meets NSF H1 Standards

• Enclosed Gearing & Sealed Roller Bearing

• Weston-Style Braking System

• Ergonomic Handle with 360-Degree Rotation

• Twin Pawl Design

The researchers were focused on lesser-known variables. For instance, seasons play a role in determining the risks of a water main break.

June 2024 | 29 www.esemag.com @ESEMAG

CE, ASME/ANSI B30.16, AS1418.2, ASME/ANSI B30.21, NSF H1 FREE SPARE SET OF LATCHES

Effectively ensuring safety in biogas facilities

By David Ellis, Trisha Aldovino, and James Arambarri

Anaerobic digestion is an established method for managing organic waste, creating renewable energy, and also producing valuable soil amendments. Prioritizing safety at biogas and renewable natural gas (RNG) facilities helps maintain smooth operations.

From toxic gases and biohazards to common industrial safety risks, there are many aspects to consider in maintaining a safe working environment. These hazards apply to most biogas and RNG facilities. However, those that process food waste, municipal source separated organics (SSO), or the organic fraction of municipal solid waste (OFMSW), may face additional hazards.

The presence of hazardous gases may be the best-known concern for operational health and safety in a biogas facility. While hazardous gases should be treated seriously, they are not the only safety hazard to consider. Safety protocols at a biogas facility should also address biohazards, fire and explosion risks, maintenance and repair procedures, and common industrial risks.

Hazardous gases: Gases like ammonia, methane, carbon dioxide, carbon monoxide, hydrogen sulfide (H2S), and volatile organic compounds (VOCs) pose health risks ranging from irritation to death. Methane and H potential impact on health and safety. Methane is highly flam mable and explosive, while H2S can be extremely toxic, even in small amounts.

These hazardous gas risks are not unique to biogas and

RNG production facilities. Trained sewage treatment plant operators should be familiar with these gases and able to manage the risks appropriately.

A particular risk at organic waste processing sites comes from mixing different food waste and other organic waste materials in raw feedstock holding tanks. Sometimes, the

Azura’s principal engineer, Dave Ellis, standing in front of a feedstock storage tank and anaerobic digester wearing appropriate PPE.

Azura’s principal engineer, Dave Ellis, standing in front of a feedstock storage tank and anaerobic digester wearing appropriate PPE.

Environmental Science & Engineering Magazine 30 | June 2024 ANAEROBIC DIGESTION PANTONE 116 CPANTONE p179-15 U > > > > > > > WATCH VIDEO TM

Biohazards: Biogas facilities often deal with a wide range of organic materials, including liquid and solid food wastes, manure, and sewage sludge. Organic waste often contains biohazardous materials and that risk cannot be eliminated because biogas cannot be produced without it. We need to understand and manage these risks safely.

Organic waste often contains a variety of microorganisms, including bacteria, viruses, moulds and parasites that can cause infections and disease. Sewage biosolids host a plethora of pathogens. At food waste digesters, or any biogas facility treating chicken or other raw meat, operators are at a risk for exposure to salmonella and E. coli. SSO, or OFMSW digesters, may see materials like pet waste, diapers and hygiene products in the feedstocks.

The risk of exposure to biohazards is highest where an operator handles the feedstock or digestate. Areas like the feedstock receiving pits and digestate holding tanks are common points of exposure. During planned maintenance, operators also face increased risks when cleaning or maintaining these tanks and any piping, pumps, valves, instruments, or other equipment that touches the waste. Flushing and sanitizing systems before planned maintenance is routine. But what about during a breakdown?

Imagine a cracked pipe spraying raw feed material and aerosolizing the mate rial. The same risk can also occur when operators use hoses to spray off equip ment or wash down the feedstock area.

Including air quality controls in the design of the ventilation system, hygiene protocols, adopting industry best prac tices, and the appropriate use of per sonal protective equipment (PPE), can all work together to reduce the risk for those exposed to these biohazards.

Fire and explosions: Beyond the flammability of biogas, accumulation of dust around digestate drying operations also aggravates the risk of fire and explo sions in biogas facilities. Dust particles can be stirred up by vehicle traffic and moving equipment. Dust explosions are a great risk as a secondary event. For example, if a truck accidently hits part of the building, the impact can disturb accumulated dust on the tops of piping,

The most effective time to reduce risk is during the design and construction phases. Designing processes focused on hazard prevention removes significant risk.

ductwork, and structural steel, causing it to become airborne. This airborne dust is then the highest risk of a dust explosion, if there is an ignition source nearby. Potential ignition sources include:

• Friction from mechanical parts such as hot bearings.

• High-temperature equipment such as heaters, but also forklift exhaust piping.

• Electrical sparks, including static electricity, as well as from motors and lighting.

• Common electronics and hand tools such as flashlights and power drills.

• Flames from activities like smoking, welding, or other hot work.

Increased dust levels not only raise

explosion risks, but also affect air quality for on-site operators and the surrounding community.

Maintenance and repair: These activities can lead to exposure to biohazards, chemical hazards, and the accidental creation of confined spaces, all of which increase safety risks for workers. Some of the common repair events involving increased safety hazards are gas leaks, foaming due to digester upsets, and spills. Similarly, a planned maintenance event, like digester biological startup or reseeding, can result in creating temporary conditions that need special attention.

continued overleaf…

www.esemag.com @ESEMAG

For example, after digester repairs and reseeding, the digester headspace may need to be purged of oxygen. This prevents creating an explosive air and methane mixture, as the process biology begins creating methane.

It is important to take safety precautions even during routine maintenance and operations. Routine and repetitive tasks can pose a physical health risk to operators through overuse injuries. Repetitive tasks can also reduce an operator’s focus, which can lead to accidents. Personal factors, such as tiredness can further reduce an operator’s focus away from the task. Managers can reduce this risk by implementing job rotations, adequate break times, and automation.

Common safety hazard: Biogas facilities have all the same hazards that are common across most industrial sites. These hazards include slips, trips and falls, vehicle and heavy equipment traffic, and mechanical equipment hazards.

While these are common safety concerns, it is important to consider how they apply specifically to anaerobic digestion facilities.

Organic wastes often contain fats, oils and grease (FOG). This FOG material poses a heightened slip, trip, and fall risk

if there is a spill or even a small amount of material on the ground, like when a hose has been disconnected. The area can look simply wet, but in fact be greasy and very slippery. These FOG areas are also particularly challenging to clean with a simple cold-water hose.

Increased vehicle traffic for moving feedstock and digestate on- and off-site can lead to congestion. Congestion can be aggravated during poor weather when trucks may arrive close together in time, resulting in increased risk of accidents and injury. During poor weather, visibility in the yard area can also be reduced because of rain or snow. Site layout planning can mitigate this risk as can enhanced operator procedures around yard operations during low visibility periods.

Rotating equipment engineered to cut, shred, and break down coarse food waste materials in a biogas facility presents a particular risk to operators. The need for extra attention to be paid to placing and maintaining equipment guarding cannot be over stressed.

HAZARD CONTROL METHODS

Hazard control methods can be divided into four types. These include elimination and substitution, engineering controls,

administrative and work practice controls, and PPE. Each method plays a distinct role in minimizing risks and enhancing safety within a biogas or RNG facility.

Elimination: This hazard control method involves completely removing the hazard. In biogas facilities, various components like mixers, engines, storage tanks, and other processing units often require regular maintenance and inspections, sometimes even performed at heights. To eliminate the hazard of working at heights, technologies can be chosen where maintenance points are located at ground level.

For example, using mixers that operate from the bottom of digesters instead of the top removes the need for personnel to access elevated areas. This change eliminates the risk of falls and injuries associated with working at heights to access that piece of equipment.