PreSet 2D

The EROWA PreSet 2D is a multi-functional, customizable measuring and presetting device that belongs in any workshop.

The EROWA PreSet 2D presetting station is a measuring and presetting device with crucial benefits. Please ask us for a personal consultation. Together with you, we can develop measuring strategies or special processes for your workpieces.

Measurement I The patented 2D edge probe makes it easy to determine the angle and start point of a taper.

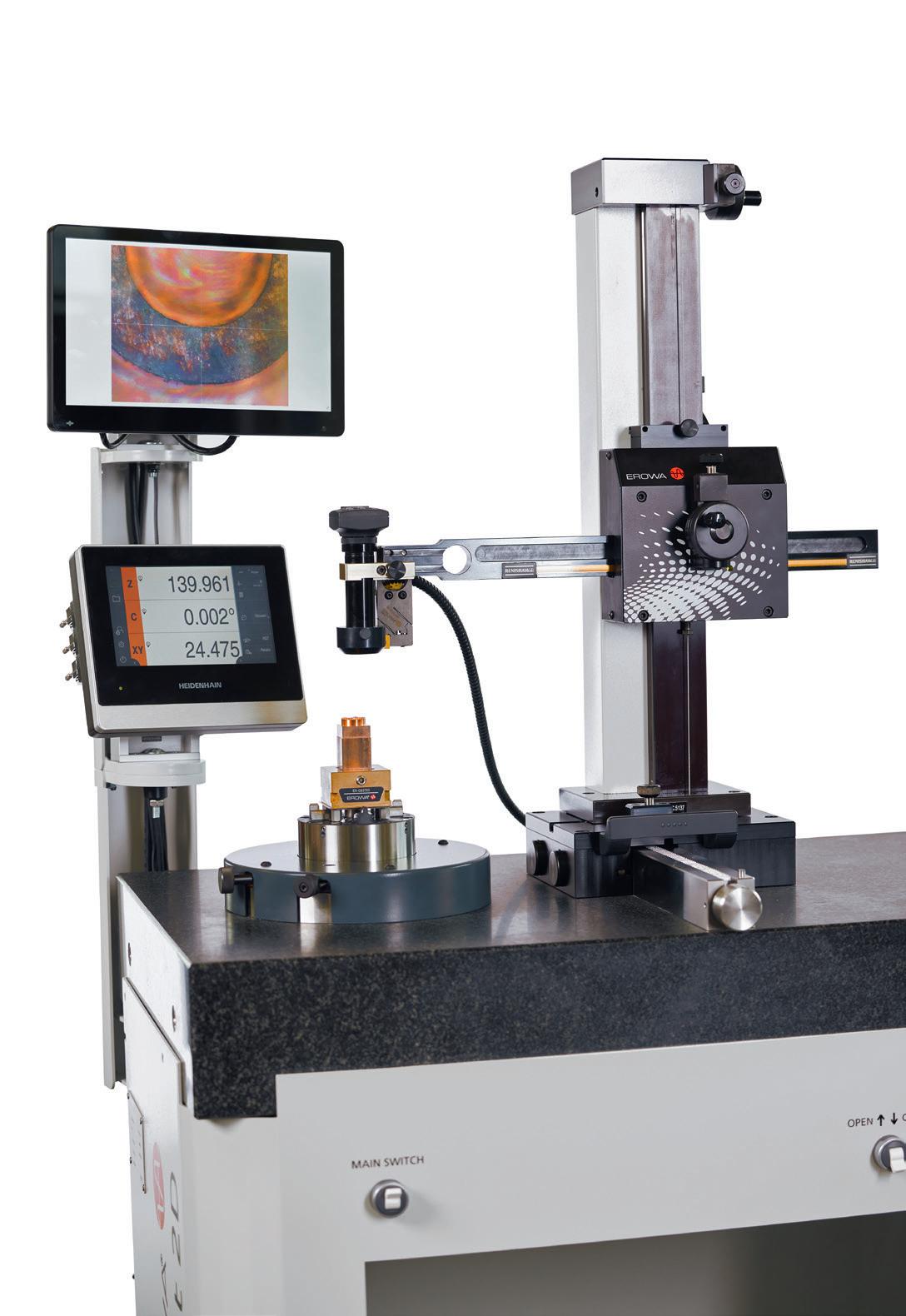

Presetting I Quickly and easily determine the offset data of electrodes and workpieces with prepared programs and graphic support.

Measuring microscope I The optional measuring microscope can be used to measure and generate diagrams of edges that are not accessible with a dial gage or 2D edge probe.

Alignment I Always correct – the air bearing of the C-axis. The high-precision concentricity identifies even the most minute deviations on the electrodes.

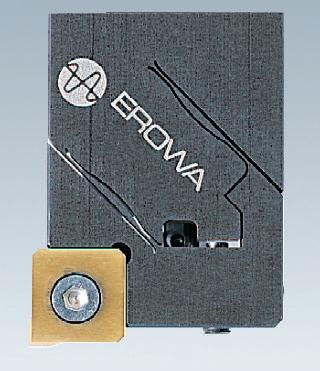

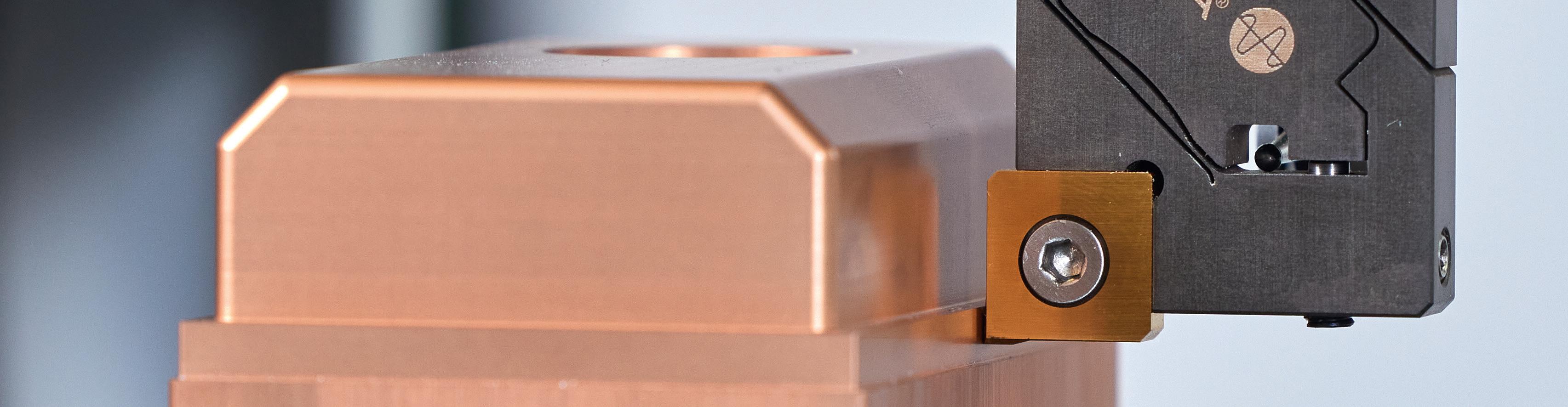

Adapting I The EROWA UnoSet adapter on PalletSet W offers the option of determining the zero point for WEDM.

Space-saving I The PreSet 2D table-top version positions the measuring device exactly where it is needed, making optimum use of the working area.

The sophisticated and user-friendly design accounts for all common shopfloor tasks. Whether mobile on wheels or as a table-top version in a fixed location – the presetting station can be used wherever it is needed.

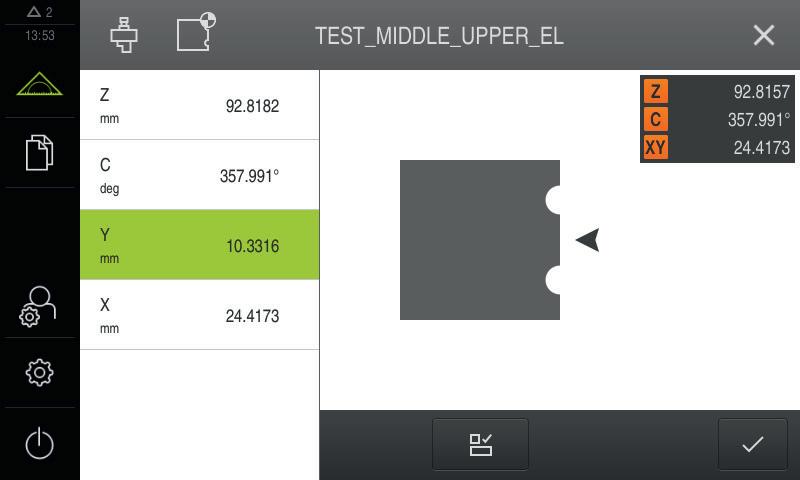

01 | Display

The modern display with integrated measuring macros makes it possible for anyone to determine offset values quickly, completely and reliably.

02

Two-axis measuring device with digital evaluation; resolution of the axis display: 0,001 mm.

03

Granite plate with DIN quality 876/00; supplied with quality certificate and measuring report.

The high-precision EROWA air bearing allows concentricity measurements in the 0,001-mm range, while still being robust and reliable.

05

Thanks to the air bearing technology, the axes can be moved at the press of a button. Adjustments can be made with maximum precision.

06 | PreSet 2D (mobile version)

The presetting station is comprised of the measuring device, the measuring plate with clamping system and the substructure on whees.

07 | PreSet 2D (table-top version)

In the table-top version, the device can be used on an existing workbench to save space.

The Heidenhain display unit offers reliable recording and easy evaluations of measured values. The integrated animated measuring macros make it significantly easier to determine the offset data of electrodes or workpieces.

Easy-to-read display of the axis position. Status display of the reference identi fication and clearly structured soft key functions with plain text make everyday use easy.

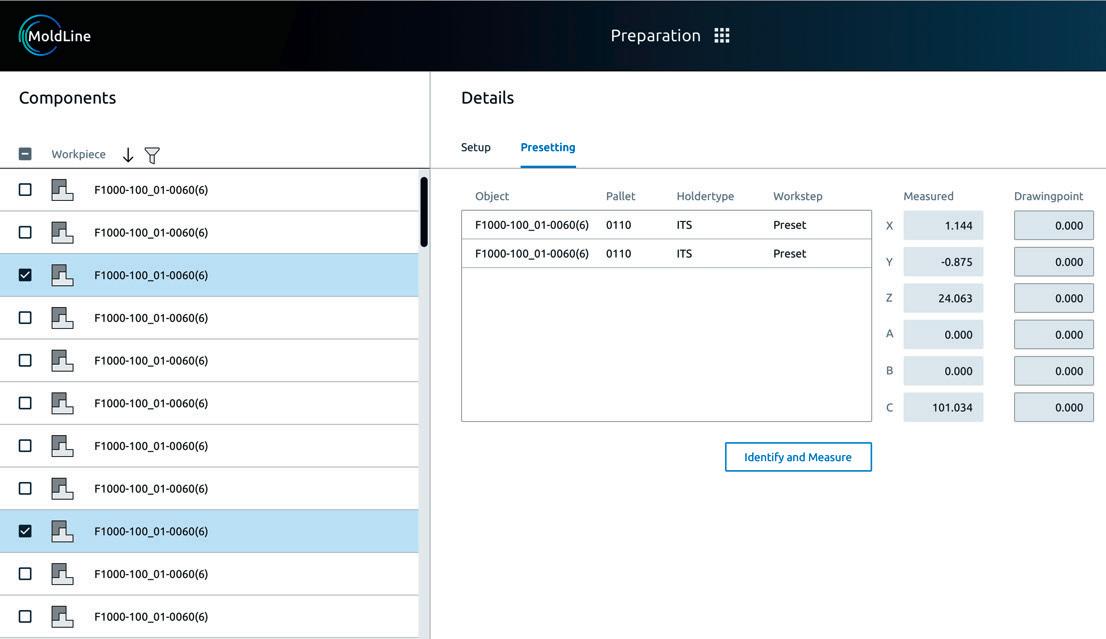

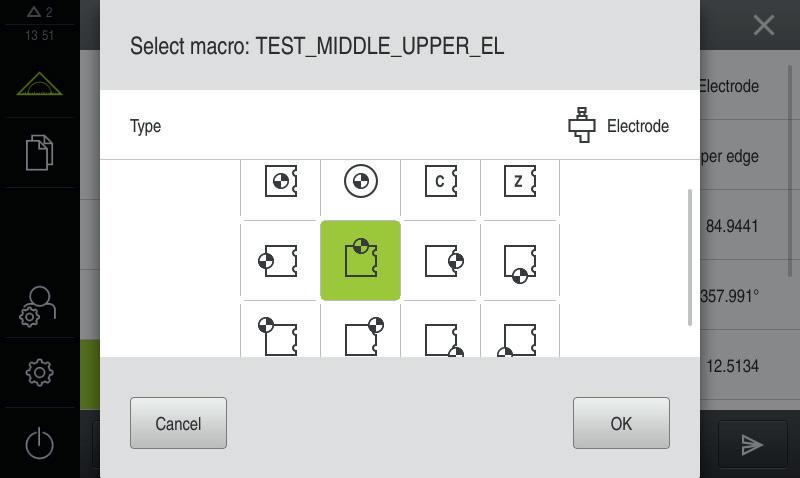

Prepared programs make it easier to determine the offset data of electrodes or workpieces on the EROWA pallets. Programs are available for all variants.

The graphic support for the correct process allows anyone to correctly record the offset data.

With just one mouse click, the recorded offset data can be transferred to all EROWA process control systems, where the machine-specific data are computed automatically and then transferred to the machine.

PreSet 2D

X-axis travel 240 mm

Y-axis travel 320 mm

Z-axis travel 335 mm

Evaluation unit Heidenhain GAGE - CHEK 2000 with EROWA preset macros Interface USB/Ethernet for data transfer to QuickLinkXT/JMS 4.0

Probe system EROWA 2D edge probe

Space required 700 x 1000 mm

Compressed air supply min. 6 bar dry

without C-axis

with carriage Table-top version

PreSet 2D UnoSet ER-057208 ER-158556

PreSet 2D PalletSet W ER-057209 ER-158557

PreSet 2D UPC / ITS Chuck 100 P ER-057210 ER-158558

PreSet 2D ITS Compact Combi ER-057211 ER-158561

PreSet 2D ProductionChuck 210 ER-057212 ER-158559

with C-axis with carriage Table-top version

PreSet 2D+C ITS Chuck 100 ER-057213 ER-158560

PreSet 2D+C ITS Compact Combi ER-057214 ER-147394

PreSet 2D - Complete equipment The package contents of the order numbers include the following:

• Measuring plate with carriage or table-top version • Table-mounted chuck

• Digital display with GAGE-CHEK 2000 preset macros • Two-axis measuring unit • EROWA 2D edge probe • Operating instruction • Cleaning agent for granite slab

For further details and questions about customized designs, please contact your EROWA dealer.

EROWA 2D edge prob ER-057471 Precise probing of sharp edges, angles, diameters and lengths.

Probe insert A ER-008623 B ER-008562 C ER-008831 D ER-008628 for 2D edge probe.

3xM2 probe insert E ER-009899 ø 2 mm F ER-003350 ø 1 mm G ER-003358 for 2D edge probe.

Mini PC incl. monitor ER-147724 Integrated solution for direct data trans fer to the control system or image trans fer from camera systems.

Microscope ER-008756 To view profiles, indentations and bore holes, with a magnifying factor of 30.

Cold light ER-095529 for the microscope: for optimal light on the area to be magnified.

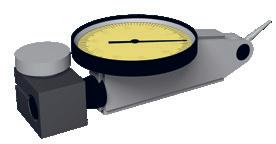

Lever gauge ER-059439 Analog gauge with a diameter of 38 mm and a resolution of 0,002 mm.

Camera system ER-158911 For transferring the captured views of the microscope to the mini PC monitor.

Taper adapter ISO 30 ER-008852

Taper adapter ISO 40 ER-008854

For presetting cutting tools with the cor responding taper holders.

QuickLinkXT

For data entry and processing in machinespecific formats. QuickLinkXT is a simple program for transferring data from the EROWA PreSet 2D presetting station to a machine control.

EROWA Group Business Network: a member of ORENDA Holding Ltd. Subject to technical changes. Registered trademark of EROWA AG, Copyright © EROWA AG, for a number of products of EROWA AG patents are existing or pending.

EROWA AG 059288-05 en / 12.22

Important things need to be planned. And your next step is certainly among the important things. It is your start into a new, efficient era. We are pleased to be with you on the way. As consultants, in practice. For you to know at all times what you’re engaging in. The next EROWA branch office is not far – take the step.

USA

EROWA Technology, Inc.

North American Headquarters 2535 South Clearbrook Drive Arlington Heights, IL 60005 USA Tel. 847 290 0295 Fax 847 290 0298 e-mail: info.usa@erowa.com www.erowa.com

Singapore

EROWA South East Asia Pte. Ltd. 56 Kallang Pudding Road #06-02, HH@Kallang Singapore 349328 Singapore Tel. 65 6547 4339 Fax 65 6547 4249 sales.singapore@erowa.com www.erowa.com

Japan

EROWA Nippon Ltd. Sibadaimon Sasano Bldg. 2-6-4, Sibadaimon, Minato-ku 105-0012 Tokyo Japan Tel. 03 3437 0331 Fax 03 3437 0353 info@erowa.co.jp www.erowa.com

Italy

EROWA Tecnologie S.r.l. Sede Legale e Amministrativa:

Via Alfieri Maserati 48 IT-10095 Grugliasco (TO) Italy Tel. 011 9664873 Fax 011 9664875 info@erowa.it www.erowa.com

Unità di Treviso:

Via Leonardo Da Vinci 8 IT-31020 Villorba (TV) Italy Tel. 0422 1627132

Switzerland

EROWA AG Knutwilerstrasse 3 CH-6233 Büron Switzerland Tel. 041 935 11 11 Fax 041 935 12 13 info@erowa.com www.erowa.com

France

EROWA Distribution France Sarl PAE Les Glaisins 12, rue du Bulloz FR-74940 Annecy-le-Vieux France Tel. 4 50 64 03 96 Fax 4 50 64 03 49 erowa.france@erowa.com www.erowa.fr

Spain

EROWA Technology Ibérica S.L. c/Via Trajana 50-56, Nave 18 E-08020 Barcelona Spain Tel. 093 265 51 77 Fax 093 244 03 14 erowa.iberica.info@erowa.com www.erowa.com

China

EROWA Technology (Shanghai) Co., Ltd. G/F, No. 24 Factory Building House 69 Gui Qing Road (Caohejing Hi-tech Park) Shanghai 200233, PRC China Tel. 021 6485 5028 Fax 021 6485 0119 info@erowa.cn www.erowa.com

Benelux

EROWA Benelux b.v. Th. Thijssenstraat 15 6921 TV Duiven Netherlands Tel. +31 85 800 1250 benelux@erowa.com www.erowa.com

Germany

EROWA System Technologien GmbH Gewerbegebiet Schwadermühle Roßendorfer Straße 1 DE-90556 Cadolzburg/Nbg Germany Tel. 09103 7900-0 Fax 09103 7900-10 info@erowa.de www.erowa.de

Scandinavia

EROWA Nordic AB Fagerstagatan 18A 163 53 Spånga Sweden Tel. 08 36 42 10 info.scandinavia@erowa.com www.erowa.com

Eastern Europe

EROWA Technology Sp. z o.o. Eastern Europe ul. Spółdzielcza 37-39 55-080 Ką ty Wrocławskie Poland Tel. 71 363 5650 Fax 71 363 4970 info@erowa.com.pl www.erowa.com

India

EROWA Technology (India) Private Limited No: 6-3-1191/6, Brij Tarang Building Unit No-3F, 3rd Floor, Greenlands, Begumpet, Hyderabad 500016 (Telangana) India Tel. 040 4013 3639 Fax 040 4013 3630 sales.india@erowa.com www.erowa.com