THE STACK

GEAR ALONE ISN’T ENOUGH — IT’S PEOPLE AND PARTNERSHIP THAT MOVE THE NEEDLE

If there’s one thing the 2025 Quarry Conference confirmed, it’s this: the waiting game is over. Our industry is moving again — not with hesitancy, but with confidence and clear direction. Across the country, we’re seeing a shift from ‘what if’ to ‘what’s next.’ Capital is flowing, quoting activity is up, and projects that once sat idle are now breaking ground.

But the real takeaway? The game is no longer just about gear. It’s about people and partnership.

Take Paul Takira and the Kuru Contracting team. Crushing 1,000 tonnes before lunch with a three-man crew isn’t magic — it’s mastery. Mastery of machines, of planning, and of people. PT’s leadership proves that modern output isn’t just tied to technology. It’s about creating a culture where smart thinking, proactive maintenance, and team-wide urgency are the norm.

Or consider Chad Empson of Silvertree Biomass Solutions. His crew doesn’t just clear forestry slash — they transform it. Their success is a result of not just having the right equipment, but the vision and backing to put it to work in bold, profitable new ways. The CBI grinder is impressive — but it’s Chad’s eye for value and Equip2’s long-game support that makes the model hum.

That focus on capability was front and centre at this year’s conference with the launch of Equip2 University — a training platform built to fast-track operator competence and reduce costly mistakes. The response was clear: the industry’s hungry for structured learning. As Jimmy Conway put it in his testimonial, Equip2 University gives teams “the right tools to

upskill, stay sharp, and stay safe.” And in a market where skilled labour is harder to find, that kind of investment isn’t just helpful — it’s essential.

We’re proud to be part of that shift. Whether it’s helping a crew double their output without doubling their hours, or equipping a biomass visionary with tools that turn waste into wealth, we’re not just selling steel. We’re building relationships, delivering training, and backing our partners when things get tough.

The gears are turning again in quarrying and material processing — fast. But the edge won’t go to whoever buys the flashiest gear. It’ll go to those who invest in their people, align with the right partners, and treat equipment not as a cost, but as a competitive advantage.

Because in this market, reliable output isn’t optional — it’s the new baseline. And together, we’re raising that standard.

Bert Hart General Manager

PROJECTS ON THE GO!

Tag us on Facebook, Instagram or Linkedin if you are working on a project and using Equip2 equipment.

@equip2solutions

#equip2

Washplant Inspection

R3e Crushing - Northland

B5e Ready for work! K4 - Olivers

At this year’s Equip2 Demo Day in Masterton you have the opportunity to watch the MWS Modular CSP10 and let it prove why it’s a game-changer for quarries producing up to 80,000 tonnes of washed product per year.

This compact, all-in-one plant screens aggregate while producing clean sand through its integrated cyclone and dewatering screen — even removing oversize material in the process. Its smart modular design means the entire washing process is contained in one area, working seamlessly with

You don't have to

existing mobile dry screens. That means no need for a separate rinsing screen and sand plant, keeping your total investment low. With its small footprint, ease of setup, and efficient production, the CSP10 is ideal for operators wanting high-quality results without the high costs.

Come see the future of compact washing plants — live at Equip2 Demo Day, in Masterton, New Zealand

FROM SLASH TO SOLUTION

In the forestry blocks of the Bay of Plenty, where fresh cuts mark the hillsides and the ground tells a story of logging past, there's a different kind of operation unfolding.

Among the fallen trunks and slash piles, you’ll find Chad — owner of Silvertree Biomass Solutions — not just cleaning up a site, but reimagining what forestry waste can become.

“We’re not just here to tidy up,” Chad says, motioning to the hulking CBI horizontal grinder rumbling in the background.

“We’re here to turn a problem into a product.”

Dirt to Debris: A Career Grounded in Earth

Chad’s journey into biomass solutions didn’t start with wood — it started with dirt.

“I was on machines at 16,” he recalls. “Loved it. Earthworks became second nature. But over time, we kept getting more tree jobs — removal, clearing, cleanup.”

At first, that meant doing what most did: burn the debris, bury the stumps, or cart it to landfills. But that didn’t sit right.

“Fresh trees don’t burn well. Stumps are worse. It felt wasteful. So we looked for a better way.”

That search led to biomass markets, where wood could be ground and sold — not dumped. It also led to one pivotal investment: a CBI horizontal grinder capable of processing whole trees into valuable byproducts.

And just like that, Silvertree was born.

“We saw waste — but we also saw value. And a way to give the land back its future.”

- Chad Empson

"Gear that’s built to work, and backed by people who don’t disappear after the deal."

The Right Tool for the Job

Choosing the grinder wasn’t a snap decision. Chad looked at several machines — but kept coming back to the CBI.

“It’s the way it’s built,” he says. “The whole hog box opens right up — no squeezing into a steel coffin to change a part. For health and safety, for efficiency, it just made sense.”

But the machine was only half the equation. The other half? Equip2.

“When downtime costs you thousands, you need a supplier who has your back,” Chad says. “Equip2 gave us the full tour, showed us the stockroom, and proved they had the wear parts we’d need. That was the clincher.”

More Than a Clean-Up Crew

Silvertree isn’t your average arborist team with a chipper in tow. They’re designed for scale, for speed, and for transforming waste into worth.

“We don’t just take what you can sell to the mill,” Chad explains. “We take everything. Slash, stumps, bin wood — we grind it all, right there on-site.”

On good feedstock, the machine can hit 250m³ per hour. For chunkier stuff, it still manages a solid 100. And every cubic metre has a destination: compost, animal bedding, boiler fuel — even specialized orders with screen-sized precision.

“Some want it chunky, some want it fine,” he grins. “We can do both.”

“We don’t leave behind a mess. We leave behind a usable product — and clean land.”

A Different Kind of Forestry Future

On a recent project at Rocky Mountain Bike Park, Silvertree was tasked with cleaning up post-logging bin wood. But Chad saw a bigger opportunity.

“We wanted to show what was possible. Not just remove slash — but give the land back, ready to be used again.”

And that’s exactly what they did. The ground, once hidden under debris, became visible again. And the waste? Repurposed into resources the park — and the planet — could use.

“You don’t just want a good machine — you want people who’ll help keep it running.”

Silvertree isn’t chasing small jobs. They’re after commercialscale clearing, where their gear and crew can move the needle — and move fast.

“We’re not a fit for someone with three trees on a lifestyle block,” Chad admits. “But for forestry operations, land developers, or big clearings? We’re built for that.”

And what makes it all work is the blend of experience, equipment, and support.

“We’ve worked with Equip2 for years on earth moving gear. When we looked at this grinder, it was a 12-month journey. Paul and the team were there the whole way.”

Even now, after the deal’s done, that relationship holds.

“If we hit a snag, they pick up the phone. They don’t just sell machines — they back them.”

Whether it’s a forestry block on the edge of town or a remote mountain being transformed into a bike park, Silvertree Biomass Solutions is proving there’s a better way to clear land — one that doesn’t stop at removal but keeps going until every piece of waste becomes something worth using.

And for Chad and his team, that’s the new standard.

From Waste to Worth

See how Silvertree transforms slash into solutions with the right machine and a mission that goes beyond clean-up.

Built for Big Jobs, Backed by Bigger Vision

Key Takeaways from

the Field:

From problem to product: Slash and stumps become compost, fuel, and bedding.

Built for scale: Horizontal grinder processes up to 250m³/hour on clean feed.

Clean land, clear conscience: Silvertree restores sites while creating revenue

Downtime minimized: Support from Equip2 ensures parts are on hand and help is close.

Fit for the future: A solution for forestry’s biggest headache - slash - that also delivers value.

CRUSHING THE STANDARD

How PT leads by example in the toughest terrain

In the rugged reaches of Gisborne’s East Coast, where storms meet stone and the terrain gives no freebies, crushing rock is more than just a job - it’s a rhythm, a standard, a reputation.

That’s where you’ll find Paul Takira, or PT, as everyone knows him.

“I’ve been called a lot of things, but mostly it’s just PT,” he laughs, standing in front of a roaring machine and a tightknit crew that seems to move like clockwork. With seven years at Kuru Contracting and a background in high-output oil exploration, PT brings a level of urgency and professionalism that turns contract crushing into a finely tuned craft.

From the shifting riverbeds of the Waipaoa to the hard rock greywacke of Marawhara Mountain, PT and his team deliver thousands of tonnes of aggregate to one of their key clients, forestry operator Ernslaw One. And they do it with the kind of consistency and smarts that make even seasoned operators take notice.

Built for Challenge

Crushing on the Waipaoa River means one thing: adaptation. “This region’s had more than its fair share of rain over the past few years,” PT explains. “When the material’s wet, you can forget about pulling the fines out effectively.”

Instead of grinding to a halt, PT’s team pivots. They swap in larger bottom decks, reconfigure flows, or shift to maintenance and extraction until the material improves. It’s about knowing when to push and when to prepare. “If we’ve got the stockpile, we’ll wait for dry weather and drop a heap out fast.”

Flexibility in the field isn’t optional - it’s essential. And that’s reflected in the way PT manages people and production alike.

High Output, Low Fuss

Currently, PT’s running a lean three-man team at Waipaoa - and still hitting numbers that surprise even him.

“Most days, we’ll be through 900 or 1,000 tonnes by lunchtime,” he says. “Then we go and extract in the afternoon to stock up for the next day.”

That sort of tempo used to take double the time. One of the key upgrades? A new generation of impact crusher. “The old unit - we had to fight all day to hit 250 tonnes an hour. This new setup? I’ve sat on 300 an hour for 10 hours straight. No stress.”

It’s more than just throughput. The upgraded gear has cut fatigue, improved reliability, and unlocked a rhythm that lets the team produce more with less. And in this industry, that’s gold.

“You’ve got to work with the material, not against it. If you fight the rock, you lose time.”

- Paul Takira (PT)

Efficiency upgrade: Crushing 1,000 tonnes before lunch - then extracting for tomorrow’s feed.

A Crew That Moves as One

What sets PT apart isn’t just numbers - it’s leadership. “I’m old school. I don’t look at resumes. I watch for attitude. Are they keen? Do they move with urgency?”

Once that spark is found, he invests in them. “You can teach anyone to quarry. What you can’t teach is attitude.”

His philosophy is simple: the crusher sets the pace. If the operator is on point, everyone matches the tempo - from extraction to loading to dispatch. And if they’re not? The whole system slips.

“You can ask any of my guys. Whoever’s on the crusher has to lead. That’s the standard.”

Reliable Gear, Smart Adjustments

Between two crews, PT’s fleet includes impact crushers, jaws, and screens - all under constant use. His approach to maintenance is proactive and planned. “You’ve got to do your daily inspections. Spot small issues early. Then slot in your maintenance during wet days or downtime.”

One of their veteran units - a K4 screen with 8,000+ hours - is still pulling its weight. “It’s reliable because we stay on top of it. That’s not luck. That’s how you run gear right.”

Recently, PT installed a secondary conveyor belt to split 100mm product - a minor adjustment that delivered major gains. “Took 20 minutes to install. Now, when we’re in finer material, I just turn it off and redirect back to the 65mm. Job done.”

Quiet Support, Big Impact

In remote parts of New Zealand, backup can’t be an afterthought. That’s where PT values his long-term suppliersnot just for their gear, but for their follow-through.

“When you’re hours up the coast and something goes wrong, you want someone who answers the phone. Who knows your site. Who actually helps.”

PT recalls calling for more than parts - sometimes calling just to see if anyone knew of upcoming work. “Most of the time, they had a lead. Gave us a contact. That’s rare. That’s value beyond the machine.”

The equipment matters. But what keeps him coming back is the confidence that someone has their back when things get tight. “There are cheaper machines out there. But you’re not just buying a machine. You’re buying the backup that keeps it crushing.”

When Experience Meets the Right Tools

PT doesn’t need babysitting. His crushing pedigree, field leadership, and high-output culture speak volumes. But even seasoned operators know: to stay productive, you need smart, modern tools - and service to match.

It’s not about bells and whistles. It’s about keeping uptime high, shifting gears fast, and knowing your machine will do the job, day in and day out. And for PT, that’s where the right equipment and right support combine to extend his crew’s advantage.

“The only way I know is high production, high pace. That’s what we’re here to do.”

More

Than Just Tonnes

PT’s story isn’t about chasing records. It’s about setting a standard - leading a crew, reading the land, adapting to the work, and keeping the wheels turning.

Whether it’s river run or hard rock, summer dust or winter floods, he has to find a way. Because when you run crushing operations in a place like Gisborne, there’s no shortcut - only smarts, skill, and gear that works as hard as you do.

For others in the industry - whether you’re managing your first quarry or your fiftieth - there’s something to take from PT’s approach. Experience matters. Leadership matters. But so does who you choose to work with. The right equipment and a responsive partner can make all the difference when the pressure's on.

“You can’t put a price on being able to call someone when you’re remote and stuck.”

Key Takeaways from the Field:

Click here to watch the full interview

Efficiency at scale: One crusher, three men, 1,000 tonnes by midday.

Adaptability built-in: Modular setup lets the crew shift output on the fly.

Culture of urgency: Attitude-first hiring turns rookies into operators.

Planned maintenance: Daily inspections + strategic downtime = minimal disruption.

Support that stretches: From service calls to job leads, relationships count.

THE 2025 QUARRY CONFERENCE: BOLD, ENGAGING, AND CONFIDENT

The 2025 Quarry Conference made one thing clear: the industry’s appetite for progress is back. After a period of cautious optimism, the tone this year was one of renewed confidence and clear intent. Projects are no longer on the drawing board — they’re breaking ground. Conversations weren’t speculative — they were strategic. For those who attended, the message was simple: the industry is moving forward, and it’s moving fast.

Real Conversations, Tangible Plans

More than any single keynote or display, it was the conversations that defined this year’s conference. Attendees — from site operators to business owners — were open about both their challenges and their momentum. Quoting activity is rising, capital investment is returning, and there’s a collective determination to stop waiting and start acting.

The sense of forward motion was visible in both formal discussions and casual chats. Whether it was project scoping, equipment upgrades, or workforce planning, the exchanges were practical, informed, and outcome-focused. Many commented that this was the most engaged they’d felt at a conference in years — a sign that the industry is no longer in “wait and see” mode.

A Technological Shift: Practical Innovation, Not Just Hype

This year's displays reflected a turning point in how the industry views innovation. Automation, electric-driven machines, and smarter plant configurations are no longer fringe technologies

— they’re becoming baseline expectations for future-fit operations.

One standout example was a crusher setup featuring a doubledeck after-screen with a mid-fraction belt — a configuration that drew consistent interest for its practical benefits, particularly among operations looking to lift productivity without sacrificing flexibility.

It’s clear that operators are looking for solutions that align with long-term efficiency, not just headline specs. Environmental performance, maintenance reduction, and usability are fast becoming as important as raw throughput.

Skilling Up: A Real Response to Labour and Knowledge Gaps

A major theme of the 2025 conference was workforce development. The reality is well known: the industry is struggling to recruit and retain skilled workers, and the cost of downtime from operator error or poor maintenance is rising.

In that context, the launch of Equip2 University stood out. Presented during a main-stage session, the platform offers

machinery-specific training via video modules and structured courses — designed to fast-track competency and reduce costly mistakes. It was well aligned with the conference’s theme of empowering the next generation and sparked meaningful discussion throughout the day.

Feedback from attendees was immediate: many see this kind of resource as essential, not optional. With new hires coming in younger and less experienced, and senior staff harder to replace, structured, repeatable training is filling a widening skills gap.

A Conference with Purpose

Beyond individual stands and presentations, the overall atmosphere of this year’s event was noticeably different. There was less hesitancy, fewer “what ifs”, and more focus on execution. The tone was serious, but positive — as if the industry had collectively decided that now is the time to move.

It’s clear that the industry is no longer sitting back. The gears are turning again — with purpose.

If You Missed It

The response to field events like the Equip2 Demo Day, scheduled for November, reflects this. With complimentary tickets now available, registrations during the conference surged. With Quarrymen hungry for opportunities to see real tangible results and gear working. An opportunity to get hands-on with equipment, validate decisions, and explore new capabilities. Click here to watch the

And as we know there is no substitute for being in the field learning, there’s still time to sign up for the massive Demo Day on November 11 or 13 shaping up to be a high-impact, experience-based event. It’s not just a display — it’s a working demonstration of what’s possible, and why it matters.

The 2025 Quarry Conference marked a shift. Confidence is returning. Strategic planning is turning into execution. Innovation is being embraced, but only when it’s practical, proven, and aligned with business goals. Training and knowledge-sharing are being taken seriously — not just for compliance, but for competitive advantage.

INSIDE THE AGGSTORM 8 AT APPLEBY QUARRY

How cutting-edge washing technology is producing cleaner, higher-quality aggregates for concrete production.

Standing nine metres above the ground at Fulton Hogan’s Appleby Quarry, Bert from Equip2 walks us through the impressive Aggstorm 8 wash plant. This modular MWS installation isn’t just about moving rock—it’s about refining it to exacting standards for concrete production, removing impurities that could compromise quality, and streamlining operations with smart design.

From Hopper to Finished Product

The process begins at a large feed hopper, where material— already screened to 0–20 mm—is introduced to the plant. Fed by a 23 m transfer conveyor, the aggregate starts its journey with water injected right at the start to aid washing efficiency. The first stage is a 12×5 linear-action screen, designed to liberate as much sand as possible from the incoming mix. The separated sand and stone then follow different paths for specialized treatment.

The Log Washer Advantage

From the screen, stone enters the dual-shaft log washer—a powerhouse of paddles and spray bars designed to scrub aggregates clean. Its primary mission:

Remove lightweight contaminants such as sticks and twigs, which can cause costly defects in finished concrete.

Scrub the stone to a high standard, ensuring a quality end product.

Operators can adjust water levels in the log washer via simple slot bars, allowing fine control over the removal of lightweights. Maintenance is equally straightforward—swing bolts and rubberbuffered doors make internal access quick and safe.

Screening and Sand Capture

A second 12×5 three-deck screen takes over, splitting material into three aggregate sizes. Each deck has independent water supply valves, giving operators flexibility to target cleaning where it’s needed most. Static spray bars with flexible couplings reduce wear and downtime.

From here, sand-laden water flows into a sump before being pumped to the CSP-12 cyclone plant for further processing.

Precision Sand Dewatering

The CSP-12, rated for up to 120 t/h, separates sand from silt and other ultra-fines. Inside, a polyurethane cyclone creates a vortex, sending silts out through the overflow while clean sand drops onto a dewatering screen.

The target: a sand moisture content of around 9%—dry enough to go directly into a concrete mix without delay. Adjustable water jets allow operators to fine-tune performance for different feed materials.

Designed for Maintenance and Flexibility

One standout feature of the Aggstorm 8 setup is its accessibility. From modular walkways and safety mats to rail-mounted pump skids that slide out for easy servicing, everything is designed with operator safety and maintenance speed in mind.

Even the aggregate conveyors—three in total, each 23 m long— are built for adaptability. Swivel chutes and wear-minimising flaps make it easy to reposition or adjust for future production changes.

Delivering Quality and Efficiency

Every stage of the Aggstorm 8’s process—from feed to finished product—is geared toward efficiency, product quality, and ease of operation. For Fulton Hogan, this means:

• Cleaner, more consistent aggregates

• Reduced contamination in concrete

• Lower maintenance downtime

• Better stockpile management thanks to long conveyors and flexible layouts

Burt sums it up simply: the combination of the Aggstorm 8 and CSP-12 delivers ready-to-use, high-quality sand and aggregate straight from the plant.

Equip2 supplies and supports MWS wash plants like the Aggstorm 8 across New Zealand and Australia. For more information or to arrange a consultation, contact the Equip2 team.

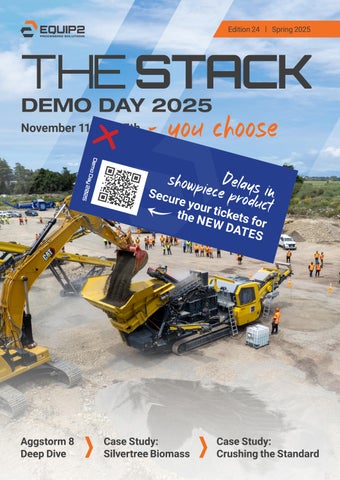

WATCH IT RUN. FEEL IT WORK. DEMO DAY 2025

November 25th or 27th

Demo Day returns this year — with bigger and better machines, more live demos, and more opportunities across the board.

Throughout the day, over 20 machines will run in full production. In 2023, the innovative i4e Impact Crusher turned heads. This year, the lineup grows with the R3h DD, the powerful R5 Impact Crusher, and the compact and efficient CSP-10 Sand Plant. It’s a collective opportunity to see how these machines perform under real conditions — not on paper, but in motion by the team who back them up.

Beyond the gear, it’s about practical conversations with industry peers — from operators and engineers to suppliers and site managers. Plus, attendees can earn 4 unrestricted CPD hours.

Whether you’re running a Quarry, managing a contracting operation, want to network or just keen to know your options, the Equip2 Demo Day will give you the insights and hands-on exposure to help you take your Quarry Game forward into 2026.

I4e Demo Day 2023

“Everything was extremely well organized. The hosting was amazing. Enjoyed having a beer with the team after the demos."

- Brendon, Ratahill

USED EQUIPMENT

KEESTRACK B4 JAW CRUSHER

Hours: 6,623 +/-

· Main Conveyor Hydraulic Foldable

· Pre-screen Bottom Deck Woven Mesh

· Loading Hopper Wear Plates 8 mm HB 450

· Jaw Plates Toothed 18mn 2cr Standard

Asking Price:

$429,000 NZD + GST

KEESTRACK H4E CONE CRUSHER

Hours: 3,500 +/-

· 3 Deck Post Screen

· Hybrid Electric Drive

· Metal Detector EGE 3000

· Radio Remote Control 10F, Functions

Asking Price:

$729,000 NZD + GST

KEESTRACK K5 SCALPING SCREEN

Hours: 135 +/-

· Plate Apron Feeder with Split Blackwall

· 65mm Punched Plate TD

· 40mm Woven Wire Screenmesh BD

· Main Conveyor 5000x1200mm

Asking Price:

$505,000 NZD + GST

POWER-SCREEN 1000 MAXTRAK

Hours: 13,485 +/-

· Automax® 1000 Cone Crusher

· Direct Feed System (no pre-screen)

· Hydraulic CSS Adjustment & Tramp Release

· Output up to 230 tph

· CAT Engine

Asking Price:

$175,000 NZD + GST

KEESTRACK R3 IMPACTOR

Hours: 8,310 +/-

· Post Screen

· Remote

· Magnet

· Returns Conveyor

Asking Price:

$300,000 NZD + GST

KEESTRACK S5 STACKER

Hours: 600 +/-

· 23-metre belt

· 1000mm wide

· Adjustable Speed

· Engine, Deutz 44kw Stage 5

Asking Price:

$189,000 NZD + GST

Thompson: 027 404 4430

Hart: 021 244 5797