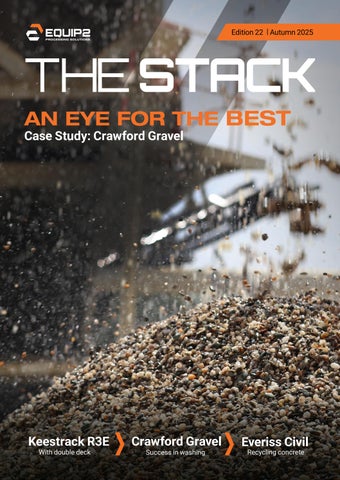

THE STACK

Case Study: Crawford Gravel

THE QUARRY INDUSTRY IN NZ:

The quarry and recycling industries have always been cyclical, with periods of boom and bust. While it’s easy to get caught up in the challenges of today, the key to enduring success lies in looking ahead and staying focused on the long-term objectives. Yes, it’s slow out there right now, but just as quickly as the tap turned off, it can turn back on, and will we be ready? Companies that thrive, especially in tough times, are those that demonstrate resilience and are committed to building towards their future goals.

An undeniable truth in the quarry and recycling sectors is the irreplaceable role of aggregates. The demand is heavily driven by the construction market, which remains a cornerstone of the economy. However, simply waiting for the market to improve isn’t enough. To truly survive and thrive, we must focus on what we can influence and make strategic changes today that will position us for long-term success.

Regardless of what’s happening in the industry, we can always make improvements within our own circle of influence. Creating a continuous improvement culture and mindset drives efficiencies, challenges the status quo and sets us up for when the tide turns. One way we find this working at Equip2, is a daily challenge to come up with a new idea for improvement. As we implement these ideas, it sets a flywheel effect in motion and we quickly see the effects of constant optimization. Incremental improvements like this can make a big difference over time, and encourages the whole team to be on the lookout for innovation and ways to improve business operations.

Adopting a culture of continuous improvement goes beyond processes and tools. Leadership and company culture are fundamental in fostering this environment. Leaders must

empower teams to collaborate and think creatively, encouraging innovation at every level of the business. It’s about fostering a mindset that embraces change and seeks better ways of doing things.

The resilience to weather through tough times and the drive to build for the future are what separates companies that grow, from those that fall. When we focus on small daily improvements, continuously strive for greater efficiency, and build a culture of innovation and resilience, we ensure that we’re not only surviving today but positioning ourselves for success in the future.

At Equip2, we want to see New Zealand thriving. We want a strong economy, and in turn, stronger industries, businesses and families that rely on it. Our part to play is in building relationships, providing equipment, advice and support that will reduce costs, increase outputs and maximise performance. If we focus on what we can do, we will be on track to a stronger, more resilient New Zealand. Although it’s challenging, now is the time to stay focused on the long-term goals, embrace resilience, and build for tomorrow—one small step at a time.

Bert Hart

PROJECTS ON THE GO!

Tag us on Facebook, Instagram or Linkedin if you are working on a project and using Equip2 equipment.

@equip2solutions

#equip2

New Electric machine induction for customer in the North

Infeed material for CBI 5800 - North Island Customer

ONE OUT THE PARK: KEESTACK R3 DOUBLE DECK

Quarry owners looking for the next move in crushing technology, meet the Keestrack R3e with double deck— the new player on the team.

The Next Level in Crushing

Quarry owners looking for the next move in crushing technology, meet the Keestrack R3e with double deck- the new player on the team.

This machine has been expertly engineered to streamline workflows, reduce carbon footprint, optimize production, and enhance ease of use. It’s not just another impact crusher — it’s a game changer. With double decks, hybrid power options, remote control and enhanced durability, it’s an imperative investment for those serious about performance.

Designed

by Techs, for Techs

Ease of maintenance is a key pillar of the Keestrack philosophy. Kees Hoogendoorn himself was a fitter - he knows what it’s like to work on these machines and you can tell. Everything is built for ease of access, smooth operation and low maintenance, from the open access engine bay with an auto greaser, to the pressurised housing for the electrics.

Even the little things are expertly engineered. For example, their steel piping that dissipates heat more efficiently than typical rubber hosing, the machine doors which have heavy duty handles and gas struts.

As Bert swings open the side doors, we can see the filters in thought out, logical locations, right where you need them for faster maintenance. Its’ simple, smart design that makes the everyday operations easier.

Everything is built for ease of access, smooth operation, and low maintenance.

Easy On

Bert Hart, Equip2, takes us for a closer look, and we’re impressed from the start. Standing at the control panel the first thing we notice is signature Keestrack simplicity - once the ignition is on, you reset the e-stops and the machine is ready to run.

Like all Keestracks, you can also operate the machine entirely from the remote. Operators can auto-start the machine, adjust feeder speed, main belt speed, and even the crusher entry—all without leaving the cab.

Good things come in twos with the R3e— double decks, dual aprons, and hybrid power options.

The Double Advantage

Good things come in twos with the R3e, with double decks, dual aprons and your hybrid power options.

The standout feature that puts the R3e leagues above any other machine, is the new double deck screen box. It’s yet another example of thoughtful design that’s unique to the Keestrack.

Making the switch to the Keestrack family with Equip2 provides you with a massive competitive advantage. Ultimately resulting in more profitable Quarry business.. With two decks you can double output by pulling a mid-fraction product and a main product simultaneously, maximizing your efficiency. Each belt has a stacking height of three meters, increasing stockpiling capability and any returns material is sent back into the machine for an extra innings - no wastage, maximum output.

Speaking of double, this plant also has dual aprons which are all interchangeable, reversible and replaceable. Its just another way you can maximise output, reduce maintenance costs and keep the machine operating for longer.

Hybrid Powerhouse

One of the R3e’s biggest advantages is its hybrid power system, giving you options - either run it off the onboard generator, or plug it straight into the mains. It’s one of the first up to the plate in terms of hybrid crushers, delivering a potential 90 percent reduction in carbon footprint. Running electric means you’ll see significant savings and you’ll also lose the engine noise.

No power? No problem. For sites off the beaten track where you don’t have access to the grid, the onboard diesel Genset will still keep you running. And even then, this efficient player still delivers a 50 percent carbon footprint reduction, compared to a traditional diesel - hydraulic plant.

“It’s one of the first up to the plate in terms of hybrid crushers, delivering a potential

90 percent reduction in carbon footprint.”

Crushing It

We head inside the chamber for a closer look at the R3e’s game changing square rotor design. The shape of the rotor means less grinding and more impact, as material hits the face of the blowbar, launching it up at a perfect 45 degree angle to the dual aprons. The result? Better shape, higher production, and longer wear life.

Its no secret these machines have to take a few hard knocks, and every aspect of the R3e is built with durability in mind. Starting at the top, the hopper is lined with a Hardox steel, reinforcing the already durable Domex parent material. The whole frame is made of Domex, a 350 grade steel that saves on transport weight without sacrificing strength.

While we’re looking at the hopper, Bert points out the unique asymmetric design, which prevents jams and keeps material flowing.

With production rates reaching up to 400 tonnes per hour and a design that excels in processing everything from limestone to greywacke, the R3e is built for high performance. In the below Walkthrough video, Bert tells us that sites with this machine are reporting a 30% increase in production over traditional set ups - that’s a massive contribution to growth and profitability, in an industry where every load counts.

The Keestrack Difference

For Quarry Managers looking for a machine that delivers on efficiency, performance, and ease of use, the Keestrack R3e with a double deck is your star player that consistently gets scores on the board. It’s built by people who understand the game, for people who want results. Keestrack thinks for the Quarry - and that’s what makes these machines stand out.

R3 Double Deck Screens

R3 Double Deck Walkthrough

AN EYE FOR THE BEST: THE EVOLUTION OF CRAWFORD GRAVEL

“Everybody’s keen to sell you something but they’re not keen to fix it when something goes wrong. So that’s why we’ve gone with Equip2. The price was good, the back up service is phenomenal and that’s why we’ve gone that way.”

-Graham Crawford

White Gold Mining

From the outset, things were nothing impressive. “We started off with a small gravel pit over by the duck pond,” says Graham Crawford, pointing across the mounds of pristine white gravel surrounding us. What began as a small-scale farm operation for lane maintenance has transformed into one of the largest concrete aggregate production sites in Southland.

At Crawford Gravel in Edendale, we sat down with Graham to hear the full story—how a simple gravel pit became a major quarry supplying over 200,000 tonnes of top-quality aggregate per year to five concrete plants across Southland and Otago. With strategic investments in land, equipment, and water sustainability, his operation is now poised for even greater expansion, and demand is soaring with new infrastructure projects like wind farms and industrial developments.

For Graham, the key to success has been investing in the right machinery at the right time—and his latest move to the MWS S130 wash plant has completely transformed production, halving diesel costs, slashing maintenance, and doubling output.

Running a highoutput quarry requires efficient, cost-effective machinery. Graham knew the old equipment was costing too much to maintain.

From a Small Step

Graham has worked this land for over 40 years. When he first bought the farm, there was a small gravel pit at one end, mainly used for local farm lane maintenance. Over time, farmers started coming by to grab small loads of gravel, and Graham saw an opportunity.

He expanded the site, and uncovered vast reserves of highquality white stone. Seeing the potential, he purchased neighboring farms, growing the operation to 325 acres with an estimated 7 million cubic meters of gravel reserves.

The site was initially run by just Graham and one staff member screening gravel on weekends—today, it employs four fulltime workers and contracts out heavy earthworks to a team of articulated dumpers.

“We are sitting on a white goldmine,” Graham says with a smile, standing aside a stockpile of premium aggregate. His operation is now a cornerstone of the region’s construction industry, and demand continues to rise.

With quarry consents secured for 15 years and major projects in the pipeline, Crawford Gravel needed to scale up production fast—which meant investing in smarter, more efficient machinery.

To A Giant Leap

Running a high-output quarry requires efficient, cost-effective machinery. Graham knew the old equipment was costing too much to maintain, so he made the leap to a modern MWS S130 wash plant with a sand screw system—a move that has paid off massively.

“We looked at other plants” Graeme explains, but the final decision came down to the service from Equip2. “Everybody’s keen to sell you something but they’re not keen to fix it when something goes wrong. So that’s why we’ve gone with Equip2. The price was good, the back up service is phenomenal and that’s why we’ve gone that way.”

Quick Read: MWS S130

Lower Operating Costs: The old system burned $9,000 a day in fuel just to produce 900 tonnes of product. One engine is now doing the job of two, cutting diesel consumption by 50%.

Dramatically Reduced Maintenance: The old plant was costing up to $5,000 a day in maintenance. The new system has had zero major breakdowns.

Higher Production & Efficiency: The site is now producing 1,500 tonnes per day, with plans to scale up further to 1,800 tonnes per day in the coming months.

Cleaner, More Consistent Product:The sand screw setup eliminates unnecessary processing while still producing the exact specifications concrete plants require.

/// CRAWFORD GRAVEL

Less is More

Local engineering contractor Nigel McCord has nothing but praise for the build quality and design of the MWS S130. "For 15 years, I was a registered welding inspector, and I have to say, the construction of this machine is excellent. Very, very impressed with both the design and the actual welding and construction of it" Nigel adds, “This plant is proven to be a very good piece of kit. It does the job that it's supposed to do. And it pretty much did it from day one.” The efficiency of the new plant has streamlined operations to a single person running the feed and output, with a backup only moving stockpiles when needed. One engine, one loader, and one machine now replace two aging plants and a bucket wheel system.

Back to Basics

Beyond productivity and cost savings, Graham is committed to running an environmentally responsible quarry. His innovative water recycling system is a fundamental part of the operation - “We do not use any spare water, it’s all recycled” Graeme proudly tells us. The site’s spring-fed duck pond he showed us earlier serves as a natural, self-sustaining water source for the wash plant.

After passing through the plant, dirty water flows into a series of sediment catchments, where it is naturally filtered before returning to the main pond. Its a closed-loop system, meaning Graeme isn’t relying on costly water use permits. Its good for Graeme, and good for the environment. In fact, his set up has so impressed local councils that Environment Southland want to showcase it as a model for sustainable water systems. The pond isn’t the only part of the original farm that remains - the site is surrounded by rehabilitated dairy paddocks. Graeme ensures that once a site is finished with, clean fill from excavation work is used to restore the area, seamlessly blending them back into grazing land. Its just another way Graeme has his eye on whats best - for him, for the environment and for the economy.

Graham mentions in the video that a sand screw outperforms a bucket wheel due to its cleaner in-spec material

Wash plant in action as per video of Crawford Gravel

His innovative water recycling system is a fundamental part of the operation - “We do not use any spare water, it’s all recycled” Graeme proudly tells us.

-Graham Crawfors

With the right machinery, strong supplier relationships, and a commitment to efficiency, Crawford Gravel is not just keeping up with demand but staying ahead of the curve. Watch Grahams journey

Future Proofed

As we wrap up our visit, Graham reflects on how far the operation has come—and the massive opportunities ahead.

With the right machinery, strong supplier relationships, and a commitment to efficiency, Crawford Gravel is not just keeping up with demand but staying ahead of the curve.

If you’re serious about quarrying, investing in the right plant makes all the difference. The MWS S130 has cut costs, boosted production, and made life a whole lot easier. It’s a no-brainer.

FROM WASTE TO WEALTH WITH THE KEESTRACK R3:

EVERISS CIVIL

Bill & Sons

Steve Long, director of Everiss Civil and E-Cycle Aggregates, isn’t just another contractor—he’s a pioneer in the Wellington region, leading the way in sustainable concrete recycling. Faced with a growing demand for high-quality aggregate and dwindling landfill space, Steve saw an opportunity to transform waste concrete into a valuable resource.

A family business at heart, Bill and his brother in law John founded the company and built the business foundation. Everiss Civil has long been a respected name in civil contracting, offering a full-service package from drainage to roading and earthworks. Now the baton’s in the hands of Bills sons, Steve and Matthew who are clearly very passionate about their future growth and capability and a key part of that is E-Cycle Aggregates, and how they can reduce waste and turn used concrete into a premium construction material.

Faced with a growing demand for high-quality aggregate and dwindling landfill space, Steve is exploiting the opportunity to transform waste concrete into a valuable resource— turning what was once discarded into a premium construction material.

/// EVERISS CIVIL

Dollars and Sense

For contractors considering concrete recycling, the numbers speak for themselves. Steve and his team at E-Cycle Aggregates have successfully recycled over 35,000 tonnes of concrete, saving significant landfill space and producing a tested and certified GAP 65 equivalent aggregate.

The demand is skyrocketing - not just for their own projects, but from other contractors eager to use this cost-effective, eco-friendly material. It’s a major cost saving, and it just makes sense.

Here’s why civil contractors should seriously consider investing in concrete recycling:

Cost Savings: Recycled aggregate significantly reduces the cost of purchasing virgin material while eliminating hefty landfill fees.

Environmental Benefits: With landfills in Wellington reaching capacity, recycling concrete keeps valuable material in circulation and supports sustainable construction practices.

Market Demand: Contractors and developers are increasingly looking for sustainable building solutions. Using recycled aggregate provides a competitive edge.

Proven Performance: Through lab testing and on-site applications, Everiss Civil demonstrates how recycled concrete performs exceptionally well in road construction, footpath prep, and pavement foundations.

Demand is sky rocketing - not just for their own projects, but from other contractors eager to use this costeffective, eco-friendly material. It’s a major cost saving, and it just makes sense.

“We’ve been able to fine-tune the crusher settings with Equip2’s support to ensure we’re getting the perfect gradation for our GAP 65 equivalent.” -Steve Long

Core Strength

The recycled concrete aggregate produced by Everiss Civil is a certified GAP 65 equivalent, making it an excellent material for a variety of applications.

It packs down exceptionally well, creating a firm, stable base ideal for roading, footpaths, and pavement preparation. Recent beam deflection tests have shown minimal movement, demonstrating its reliability in high-traffic and load-bearing scenarios. This means contractors can confidently use the material knowing it meets stringent engineering standards while also contributing to a more sustainable construction approach.

Steve credits the success of their crushed concrete to the Keestrack R3e impact crusher and Equip2’s expertise. “We’ve been able to fine-tune the crusher settings with Equip2’s support to ensure we’re getting the perfect gradation for our GAP 65 equivalent.

The consistency and performance of the material have been outstanding,” says Steve. “It compacts beautifully and provides a stable base for all types of construction applications. Our engineers have been impressed with the results, and it’s quickly become the go-to choice for many contractors in the region.”

At a glance Keestrack R3h/ R3e

High Productivity: The impact crusher delivers exceptional and superior production rates, ensuring that Everiss Civil can keep up with rising demand.

Optimized Crushing: Adjustments allow for precise control over the final product, ensuring it meets engineering specifications.

Reduced Dust and Noise: The internal sprinkler system minimizes dust, while the quieter operation enables use in more locations.

Transportability: The machine can be moved easily without requiring special permits, offering flexibility across multiple job sites.

Reliable Support: Steve emphasizes the importance of fast service and parts availability—Equip2 has delivered, ensuring minimal downtime.

Ultimate Crushing Solution

After trialing various jaw crushers and struggling with binding issues due to fine concrete material, Steve & Bill knew they needed a better solution, and that’s where the Keestrack R3 impact crusher came to the party, and since then, their whole operation has been a game-changer.

Their recent development, spanning 150,000 square meters of commercial industrial land, is a testament to how recycled materials can be seamlessly integrated into high-profile civil works.

Watch successEveriss story journey here

Formula for the Future

Everiss Civil isn’t just a company; it’s a family legacy. With Steve at the helm and Bill’s experience right at hand, the business continues to expand, taking on major projects that rely on their expertise and innovation in recycling.

Their recent development, spanning 150,000 square meters of commercial industrial land, is a testament to how recycled materials can be seamlessly integrated into high-profile civil works.

For contractors considering concrete recycling, Steve’s story (told in this video) is proof that the right approach—paired with the right equipment—can transform waste into wealth. The Keestrack R3 series isn’t just a well designed crusher; it’s an investment in a smarter, more sustainable future for civil construction.

USED EQUIPMENT

Ex-Demo & Quality Assured

KEESTRACK B3 JAW CRUSHER

Hours:6000

1000x650 Jaw opening

Remote control

45mm CSS

Cummins QSB 6.7 Engine

Asking Price: $790,000 NZD + GST

Hours: 3100

3 Deck Post Screen

Fully Electric Drive

Easy Access Greasing

Metal Detector EGE 3000

Asking Price: $790,000 NZD + GST

KEESTRACK K3 SCALPER

Hours: 400

Plate Apron Feeder

Main conveyor BW 1000mm L: 5000mm

8.3Kw

10 Functions Radio Remote Control Engine: Deutz 55.4kW TCD 2.9 L4_ST3B/ T4f, 24V, with DOC

Asking Price: $360,000 NZD + GST

KEESTRACK B4 JAW

Hours:650

Punch plate top deck 60mm

Prescreen Bottom Deck Woven Mesh

Loading Hopper Wear Plate 6mm

3 Section Hydraulic Foldable Side Belt Conveyor

Asking Price: $830,000 NZD + GST

KEESTRACK R5H IMPACTOR

Hours: 2800

Top deck Prescreen

Prescreen bottom deck woven mesh

Engine Volvo TAD 1354 GE344 kW @ 1800 Stage 3A

Secondary screen unit with overs return

Asking Price: $890,000 NZD + GST

KEESTRACK S5 STACKER

Hours: 550

23 metre belt

1000mm wide

Adjustable Speed Engine, Deutz 44kw Stage 5

Asking Price: $159,000 NZD + GST

KEESTRACK H4E CONE