THE STACK

FROM THE GROUND UP

Case Study: Fulton Hogan Gisborne

THE QUARRY INDUSTRY IN NZ:

Bridging the Gap Between Perception and Reality

To most New Zealanders’, the quarry industry is dust, dirt, and dangerous working conditions. However, once you get involved in the industry, you quickly realize that it’s a vastly different story.

It’s an industry full of friendly, hard working people, committed to supporting their communities - working day in, day out, to supply the materials essential for the country’s growth and development.

Many Kiwis don’t connect the quarry industry with the materials they rely on every day. A statistic I always like to share is that every person in New Zealand consumes, on average, 9 tons of aggregate per year.

This material goes into everything from housing, roads, and concrete, to plasterboard and bricks - and it comes from our quarries. It’s essential to New Zealand’s infrastructure, and yet it often goes unnoticed by the general public.

While public perception is hard to change, I believe it’s important for us to build better relationships with communities and improve their understanding.

Initiatives like quarry open days are one effective way to raise awareness around the importance of quarrying - people can help people see firsthand what goes on behind the scenes. Equip2 is attending the upcoming Wheels at Wanaka show held on 18-20th April, which showcases screening and crushing equipment in action.

With 30-40,000 expected attendees, it’s a great opportunity to introduce the public to the machinery and operations in this vital industry.

Environmental impact is another area where the industry tends to get a bad rap. While the industry has faced challenges with adhering to regulations in the past, it’s fantastic to see an increase in the support from the government in primary infrastructure industries, including quarrying.

Backing from the top means the industry is in a better position to move forward responsibly. The key is to continue to improve practices, embrace innovation, and be transparent about operations. This will help not only maintain the industry’s sustainability, but also increase its acceptance within communities.

Ultimately, it’s crucial for the public to understand that quarrying isn’t just about digging up the earth—it’s about supporting New Zealand’s growth and prosperity.

Through continued dialogue and open days, I believe we can improve perceptions, reduce misconceptions, and deliver a prospering industry and country.

SUBSCRIBE THE

to get the Material Processing Magazine delivered every quarter to your door.

Bert Hart General Manager

Tag us on Facebook, Instagram or Linkedin if you are working on a project and using Equip2 equipment.

@equip2solutions

#equip2

Winestones Belmont.

B3 crushing lime to 160mm.

Herman burning the midnight oil for a customer

K4 screening silt in a 2-way split configuration.

Wakefields Destroyer crushing it.

A QUARRY MANAGER’S UNEXPECTED PATH TO SUCCESS FROM THE GROUND UP:

“It wasn’t part of the grand plan, but a chance decision that turned into a career”.

- Sean McIntyre, Quarry Manager

Sometimes, things don’t go to plan, and that can be a good thing. Other times, planning and preparation is the key to success.

Sean McIntyre, Quarry Manager for Fulton Hogan has definitely experienced both sides of the coin. From the deep drilling sites of Western Australia, to the graywacke peaks of the East Coast, McIntyre talks about how he became a Quarry Manager, and what makes him successful.

Before ending up at Matawai, McIntyre tells us he “was over in Australia, drilling for Western Deep Hole Drilling.” This was exploration drilling in Western Australia, around Perth and south of Kalgoorlie.

On returning to New Zealand, he took up studies in engineering, not knowing that things were about to change - we think, for the better. It was while he was studying, that “somehow, don’t ask me

how, got asked to come into quarries. And he said, yep, I’ll give it a go.” And just like that, plans changed.

Funnily enough, when compared to the intensive nature of his current role, his entry into quarry work was casual, almost dismissive. Just something to do part time while he finished his studies, he recalls, but he found he “actually enjoyed it, and ended up doing it, hence to this day.”[sic].

One moment he was focused on engineering and then – almost by accident – he’s running a critical piece of NZ infrastructure, helping to build, rebuild and connect communities. It wasn’t part of the grand plan, but a chance decision that turned into a career.

R5 Impact Crusher.

Sean McIntyre

We have had this (R5) now for 250 hrs... and we have doubled production.

- Sean McIntyre, Quarry Manager

Early Days

Working on various machines, loaders, dozers, and mobile jaw and cone, Sean learned different aspects of quarry operations, from the ground up, so to speak. But the old equipment struggled.

"We used to have a jaw and a cone, which were really old at the time and we struggled to make M4 because of the weathering" he'd explain. But about eight years ago, everything changed.

"We decided to change to an impactor and we got an R3 … I think it was the first one in New Zealand." It was a bold move that took good planning and it paid off. "With the impactor, we managed to get M4 pretty much straight away." It was the first big improvement of many that Sean implemented at the Fulton Hogan quarry, which had a flywheel effect.

The Matawai quarry became more than just a workplace, Sean was turning it into an efficient production site, building relationships and supporting the local community and industry.

Sean gives us the low down in the video (left) "This quarry is a greywacke quarry," he'd explains, "We produce aggregate mainly for forestry, but we do produce material for the highways and

local council.” In industry spec terms, thats

AP65 and GAP products.

While we’re chatting with Sean and the team, you get a sense of camaraderie - Sean is one of those Managers that puts his team first. He talks about making sure there’s enough people on the ground to do the job, that they are clear on what the days work is, what they are producing, and above all, that they are safe on the job.

Coming Full Circle

When Cyclone Gabrielle tore through the East Coast, leaving a wake of destruction, Sean saw more than just a disaster - he saw an opportunity to help his community rebuild.

“After Gabriel, we had a fair bit of damage around Gisborne, East Coast area,” he recalls with a typical Kiwi understatement. The resources to rebuild and upgrade the roading was going to be massive, and the question was - could Sean and his team keep up?

Having since moved on from the R3 to an alternative supplier, this quarry was struggling for real support, and their current machinery arrangement wasn’t going to cut it. So it became

M4,

“The guys are impressed with how the R5 goes, the ease of operation, and changing blow bars and skirting”.

- Sean McIntyre, Quarry Manager

clear that another step change was required.

This time, Sean left nothing to chance and made sure his move was well-planned, speaking to Quarry Owners up and down the country before deciding to go back to his original relationship with Keestrack from Equip2 - this time purchasing an R5. It’s a decision he clearly hasn’t regretted. “When we first got the first R3, production was good, but this is way better.” Features like hydraulic rams at the back to level the machine out, the split deck and the swing return arm were small innovations that made a big difference on site.

Thanks to the R5, Sean and his team were able to keep up with production for the Gabrielle rebuild - in fact, they had to purchase a stacker to deal with the extra production.

Secrets to Success

Like most successful Quarry Managers, Sean pays attention to more than just the upfront purchase. Safety, production time versus down time and repairs are a huge consideration and this is where Keestrack, Equip2 and the R5 in particular really add value to his quarry.

“One of the main reasons with these guys is production… And every time you’re broken down and you’re not crushing, you’re losing money. So it’s not actually the repair bill, it’s how quick you can get the parts… These guys have been great in supplying us with parts and giving us any help when we needed it.”

Advanced safety features on R5 also impressed Sean, as he mentions “You can just lower the screen down right to the ground, and the guys feel safe working on it.”

Pictured cleaning his glasses is Seans right hand man, who comments how much safer the R5 is compared to the last

“Because of high production we even had to get a stacker to help out.”

- Sean McIntyre, Quarry Manager

machine they ran at the quarry. For him it was the biggest thing, the safety aspect. And he is loving his new R5 Impactor.

Sean, is somehow both gruff and jovial, giving his men a hard time (in a good way), has the nack of running a quarry like a well oiled machine. Time is not wasted but rather efficiency is a key driver, and he mentions the “immense” savings and efficiency of the R5. At a calculated estimate, Sean states the time saved is excess of a week.

Even when repairs are needed, getting parts and service technicians to the remote site doesn’t seem to have posed a problem for Sean, who goes on to say “I’ve been impressed with Equip

They’ve stood by their word, they delivered when they said they were going to deliver, they’ve supplied parts when they said they’d have parts, and they’ve turned up when they’ve said they’ve turned up, every time, on time.” You could tell he appreciates it.

Watch the full interview here

His advice to other professionals was simple and profound: “If you’re looking at buying a Crusher - impact Crusher - I really recommend going to someone that’s got one operating, asking them if you can watch it and get their feedback… The way this one’s been going so far, I’d definitely look at buying another one.”

As we wrap up the interview, we can’t help but notice the men and machines working steadily on, against the backdrop of the blue East Coast sky and the ever changing quarry face.

But Sean sees much more - as he puts it, “ it’s making sure operations are running smoothly. Just get orders coming in, making sure we have the product available and can supply our clients.” and with this plant & support from Equip2, he can focus on that.

Listen to the full interview below for industry insights, Seans’ seasoned advice and how you can help you move your quarry forward.

“Because of the 2-deck, we can scalp out and crush at the same time, so we have saved us getting another plant”.

- Sean McIntyre, Quarry Manager

“This unit’s taking it from raw form and shredding it down to a manageable size.”

- Bert Hart, General Manager

NO STONE UNTURNED HOW TECHNOLOGY IS

REVOLUTIONIZING

CONSTRUCTION WASTE MANAGEMENT

In the changing landscape of the NZ construction and recycling industry, we are witnessing a transformation in waste management.

Cutting-edge separation technology that combines innovation, intelligence, and automation is making precise material recovery possible - and at scale.

It's an integrated approach, not only maximizing recycling efficiency but also creating new revenue streams while significantly reducing landfill waste.

In a recent showcase, Bert Hart from Equip2 puts the spotlight on a plant set up with the Slayer XL, Keestrack K5 and MC 1400, a trio that makes it all possible.

RAW TO REFINED

True to name, the Slayer XL takes in all the C&D waste from the site - thats everything from timber and gib to plastics - and shreds it down to a 150 to 200mm output.

An automated steel extraction pulls steel waste to one side, minimising jams and reducing your downtime. Berts summary - “this unit’s taking it from raw form and shredding it down to a manageable size.”

QUICK READ - SLAYER XL

• Capable for diverse range of waste material

• Reduces site waste to a manageable and uniform size

• Automated steel extraction

PRECISE, INNOVATIVE, UNJAMMABLE

From there, we head over to the Keestrack K5 with its precision screening technology - a machine designed specifically for C&D waste, separating out fines of 0 to 12ml and oversize material of 70ml and above for manual picking.

Waste is processed through the 3D screen box and and as Hart demonstrates in the showcase video, the innovative design prevents rebar from jamming while material is flowing down the apron.

Another standout feature is the circular screen with dynamic tension, which makes this machine almost impossible to block. Its a breakthrough design, preventing critical processing challenges - “it’s built for the job, and to do it right.”

CONSTRUCTION WASTE MANAGEMENT

Quick Read - Keestrack K5

• Separates out fines and large waste

• 3D screen box technology

• Heavy-duty apron feeder

• Circular screening with dynamic tension

• Prevents material blockages

Heavyweight Champion

To complete the process, all mid fraction waste then flows directly into the MC 1400 Density Separator for intelligent sorting into heavy, mid and light weights.

Heavy weights such as stone is stockpiled on one side, lightweight leaves and plastics to the other side, and mid weights like timber pieces flow off the end.

"It's very, very difficult for a human to be able to pick those smaller sizes out," Hart explains about the separation process, but dual cyclone suckers make short work of this precise sorting.

While this particular setup is headed for a C&D waste plant,

these types of separators are also ideally suited to bio waste and compost, where precise sorting of small material is required.

Quick Read - MC 1400

• Dual cyclone suction technology for precise sorting

• Weight-based material classification

• Versatile industrial application

Cutting edge separation technology like this is the next mover and shaker in the New Zealand construction industry, and with Equip2’s experience, expertise and equipment, they are at the fringe of new developments.

All in all, its an impressive line up that leaves no stone unturned in C&D waste Management.

Its design and innovation at its smartest, that reduces your downtime, enhances environmental sustainability and turns your challenges into opportunities.

Interested to see how a set up like this comes together? Send an enquiry to sale@equip2.co.nz

Watch the C & D Waste Walk Through

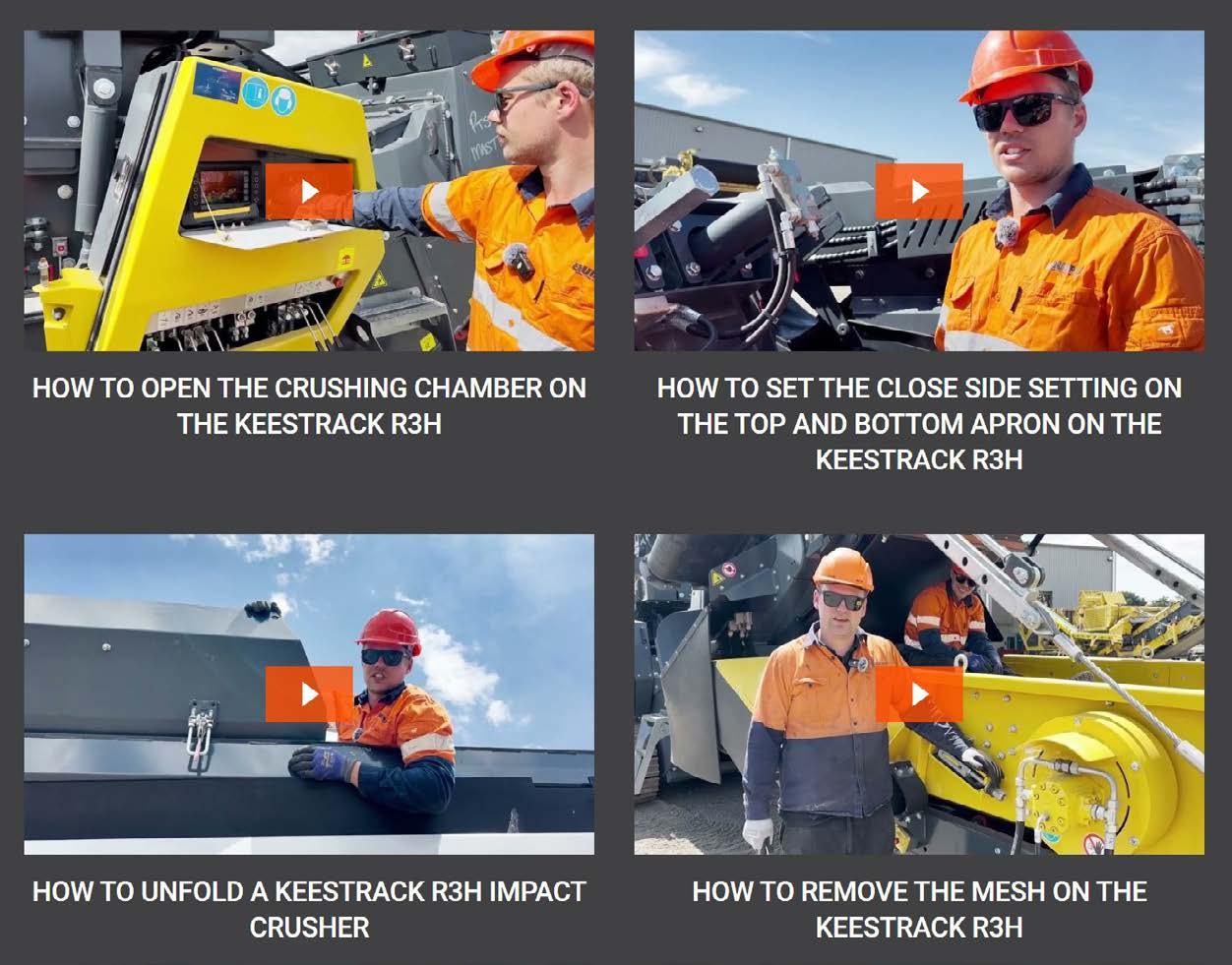

EQUIP2 UNIVERSITY - AN INDUSTRY KNOWLEDGE BANK

In the dynamic and fast-paced world of Quarry operations, efficiency and knowledge are key. Yet, many Quarry Managers and operators face similar and recurring challenges in running their plant at peak performance.

We’ve heard these frustrations right from those on the coal face, and armed with that we’re developing an Equip2 University. This online platform will be giving you access to detail expert advice about your particular machines, any time, from your laptop.

Its designed to help keep you and your machines at peak efficiency, and reduce that dreaded downtime to improve your bottom line.

Real-World Solutions for Real-World Challenges

The concept was born from listening to the struggles of many quarry professionals. We heard the concerns about the limited access to manuals, advice and best practices.

We can give instructions over the phone, and send short instructional videos via email but this back-and-forth style of support has proved to be time consuming, and inadequate, and sometimes led to misinterpretation, which can create further issues.

With Equip2 University, these troubleshooting obstacles are

Coming Soon

This online platform will be giving you access to expert advice about your particular machines, any time, from your laptop.

a thing of the past. The platform provides instant access to a library of instructional videos on your machines, giving operators the knowledge they need, whatever hour they need it.

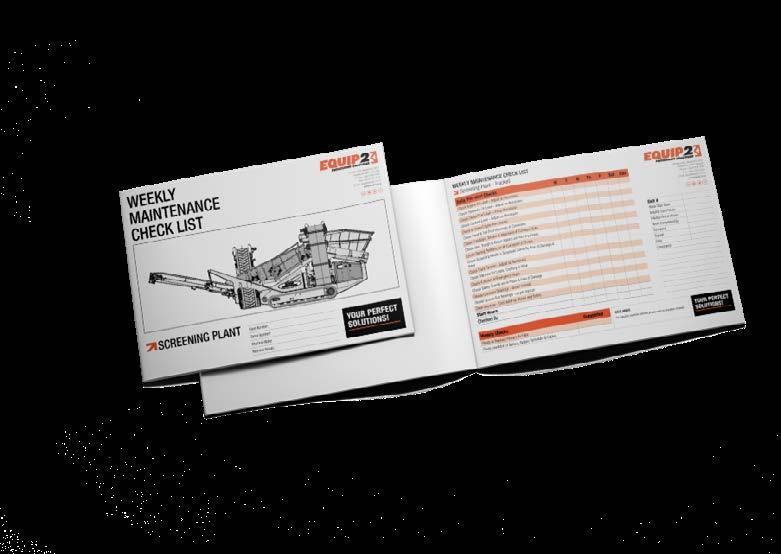

Whether it’s understanding best procedures for blow bar changes or performing daily and weekly checks, the goal is to enhance efficiency and reduce dependence on external support.

Another trend we identified was the lack of awareness around special features on some machines. For example, some Quarries were not aware of the mobility of the Keestrack R5, and how to quickly fold it up for transporting to different locations.

Not utilising this feature due can be a deal breaker, but watching just one how to video on this enables Equip2 customers to win more jobs and maximise profits in a competitive landscape.

Like any business there can be many oversights and inefficiencies at a Quarry which can lead to avoidable delays and missed opportunities to leverage the equipment’s full potential. Equip2 University will also include step-by-step guides

and videos that demonstrate the time saving features, but also simplify the process so everyone on site can be cross trained and upskilled. Armed with this knowledge, quarry operations can become more competitive, saving time and maximizing production.

Empowering Success Through Knowledge

Equip2 University’s mission is clear: to deliver maximum value to customers by sharing in-depth, fast-paced knowledge. The courses are self-paced and interactive, ensuring operators and managers alike can build their expertise at their convenience.

This kind of training for those on the ground is a real need in such a fast paced industry. What was best practice a few years ago has since been replaced, new efficiencies are being realised and new challenges are being faced.

A Vision for the Future

Like the dynamic industry we’re in. Equip2 University will

be constantly evolving. Initially, we will be focusing on core operational and maintenance best practices, and providing general competence reports for Quarry Manager.

Then we plan to see certificates and quarry credits. These certifications will provide an added layer of credibility for operators and managers, ensuring their skills are recognized.

Equip2 University isn’t just a training platform; it’s a movement toward smarter, more efficient quarry operations. By addressing the real challenges faced in the industry and delivering practical, actionable, hands on knowledge.

Driven by the desire to help customers succeed, Equip2 is redefining what it means to support its customers. With this partnership, Quarry Managers can now trust that their teams are equipped with the expertise to excel—every step of the way.

Equip2 University will also include step-by-step guides and videos that demonstrate the time saving features, but also simplify the process so everyone on site can be cross trained and upskilled.

OVERCOMING CHALLENGES IN DESIGNING & ERECTING

A COMPLEX PLANT

Designing and setting up a new plant in the South Island within an existing operational site presents a unique set of challenges.

Our recent project illustrates the complexities involved and highlights the solutions we've implemented to ensure a successful outcome.

Designing Around Existing Infrastructure

The current site already houses significant infrastructure, much of which will remain operational. The new plant will need to integrate closely with the existing setup, including being mounted near and even over some current buildings and equipment.

This has required meticulous planning of footing positions, height adjustments, and chassis modifications to accommodate

South Island

the site’s limitations.

Fortunately, our partners at McCloskey have been instrumental in this process, working closely with both our team and the client to adjust designs and coordinate these changes. Their flexibility and responsiveness have been crucial in overcoming these initial hurdles.

Erection Challenges: Access, Safety, and Timing

Erecting the plant will involve significant logistical coordination. With limited access for cranes and a site bustling with activity, safety is a top priority.

NEW

Timing will also be critical, as the plant components will arrive in nine containers, each containing specific parts needed in sequence.

To manage this, we’ve devised a precise unloading and assembly plan. Containers will arrive in the order of assembly requirements, ensuring that each part is set up before the next arrives. This approach minimizes onsite congestion and ensures smooth progress throughout the project.

Final Setup and Commissioning As the plant nears completion, additional challenges will arise, including:

• Positioning: Ensuring that all components align perfectly within the designated space.

• Utility Integration: Aligning discharge points and securing electrical and water fittings to match supply and waste needs.

• Water Balance: Calibrating water pressures and volumes to optimize the washing solution's effectiveness for the client’s requirements.

None of these tasks are insurmountable but require careful coordination and attention to detail. By prioritizing effective communication and planning, we aim to deliver a longterm solution that meets the client’s needs and exceeds expectations.

A Win-Win Outcome

This project reflects our commitment to overcoming challenges and delivering tailored solutions.

By working closely with partners and maintaining a focus on safety, precision, and client satisfaction, we’re confident that the result will be a plant that operates seamlessly, benefiting all stakeholders for years to come.

USED EQUIPMENT

KEESTRACK B4 JAW CRUSHER

Hours: 650

Punch plate top deck 60mm

Overband Magnet

Remote Control 10 Function

Hydraulic Foldable Side Belt Conveyor

Asking Price:

$790,000 NZD + GST

KEESTRACK H4e CONE CRUSHER

Hours: 3100

3 Deck Post Screen

Fully Electric Drive

Easy Access Greasing

Metal Detector EGE 3000

Radio Remote Control 10F

Asking Price:

$790,000 NZD + GST

EDGE SLAYER XL SHREDDER

Hours: 100 +/-

Heavy Duty Tracks

Radio Remote Control

Hydraulic Tipping Hopper

Overband Magnet

Asking Price:

$740,000 NZD + GST

EX-DEMO BARFORD SM312 SCREENER

Hours: 350

Power unit: CAT 2.2 37kw

High energy Screen box size: 3m x 1.29m on both decks

Screen box on coil springs

Foldable Conveyor

Asking Price:

$97,000 NZD + GST

ROCKSTER R700S IMPACT CRUSHER

Volvo Tier 3 Engine

Belt protection

Magnet belt

Single Deck Post Screen 1800x1000m

Return belt for screen box

40mm Pre-screen Punch Plate

Hardox 450 hopper

Asking Price:

$755,000 NZD + GST

KEESTRACK S5 TRACKED STACKER

Hours: 550

23 metre belt

1000mm wide

Adjustable Speed

Engine, Deutz 44kw Stage 5

Asking Price: 149,000 NZD + GST