THE STACK

NAVIGATING SHIFTS IN TECHNOLOGY FOCUS

The future is looking brighter, and attending the 2024 Quarry Conference was a remarkable experience.

One of the most significant takeaways from such events is getting a pulse on industry trends. It’s inspiring to be part of an industry where networking, sharing ideas, and addressing challenges are integral parts of our daily work.

This year’s conference theme, “The Future is Digital: Navigating Shifts in Technology Focus,” was especially relevant for us.

As a company serving this industry, it’s our responsibility to bring innovation to the table and share it broadly. Digital technology isn’t just about following trends; it’s about enhancing operational efficiency, increasing profitability, and ensuring safer workplaces.

As Albert Einstein wisely said, “The definition of insanity is doing the same thing over and over again and expecting different results.” This quote underscores the importance of continuous innovation and seeking better ways to achieve results. We should not be discouraged by failure but rather use it as a stepping stone to success. Many of our customers have achieved significant progress by asking questions and sharing their experiences, reflecting the collaborative spirit of our industry.

Our biannual Equip2 Demo Days are a testament to this collaborative ethos, showcasing what works and providing a platform for idea exchange. code to a video of the event included here.

Check out the 2023 Demo Day

“The definition of insanity is doing the same thing over and over again and expecting different results.”

On the economic front, while some may feel the pinch, I encourage everyone to stay resilient and plan for the future. Historically, the industry has spent about 20% of the time in a downturn and 80% in a high phase.

With the government announcing new roading projects, we anticipate increased pressure on quarries throughout New Zealand. Therefore, it’s becoming critical to not only plan for 3-5 months but to focus on long-term planning, what are we going

SUBSCRIBE THE

to get the Material Processing Magazine delivered every quarter to your door.

Bert Hart General Manager

Tag us on Facebook, Instagram or Linkedin if you are working on a project and using Equip2 equipment.

@equip2solutions

#equip2

Byfords 10,000hr celebration.

R3 Jaw crusher making it’s way to Kimbolton.

XL Slayer showing off at P3 Demo Day.

B5 running at Olivers.

B4 and K4 at the Hillhead show in UK.

SMALL HERO MACHINE SHINES

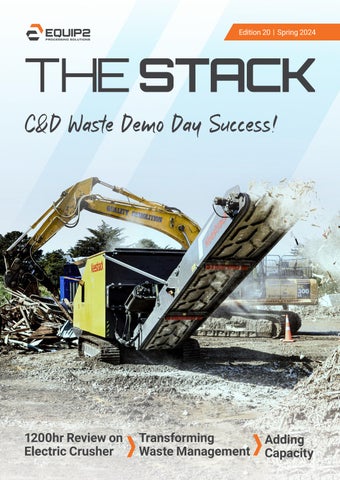

Held at the Equip2 HQ on September 5th and 6th, the C&D Waste Demo Day unfolded as a masterclass in versitility and innovation.

More than just a showcase of cutting-edge machinery; it was a testament to the extraordinary capabilities of the Equip2 team.

The P3 tracked shredder stole the limelight from the start of the event, with its remarkable versatility, particularly in shredding concrete with ease.

Then with timber, old shopping trollies and battered roofing iron amongst the C&D waste. But it wasn’t just about the P3. The C&D waste event also highlighted a range of complementary machines, such as the XL Slayer and 5800 High speed Grinder, illustrating the breadth and depth of Equip2’s product lineup.

‘One great thing about our demo days is it gives our customers hands-on and 1-1 time with our techs to talk around problems they are facing within their applications with their existing machinery along with upcoming projects they are working on’.

The event’s atmosphere expertly combined a friendly, approachable feel with professionalism, showcasing the team’s confidence and expertise.

From their technical skills to their event management prowess, the Equip2 team showcased a broad array of talents. And let’s not forget the culinary highlight—those “famous smokey joe burgers” that added one of the finer touches to the event.

Overall, the demo day offered a comprehensive insight into Equip2’s value proposition. It wasn’t just about showcasing machinery; it was also the team’s adaptability, problem-solving abilities, and exceptional customer support.

For the attending contractors and demolition companies, it was a compelling display of what Equip2 brings to the table beyond their impressive equipment.

Check out the C&D Waste Demo Day Videos

REVOLUTIONIZING ASPHALT RECYCLING THE KEESTRACK R3E AT FULTON HOGAN’S AUCKLAND RAP PLANT

In the evolving landscape of quarrying and recycling, innovative operators are finding ways to enhance productivity while meeting growing sustainability expectations.

Wayne Richardson, overseeing Fulton Hogan’s Auckland RAP (Recycled Asphalt Pavement) plant, has implemented a solution worth noting: the Keestrack R3e electric crusher. This equipment is proving to be a significant asset, offering tangible benefits in efficiency and environmental performance.

For Quarry Owners weighing their equipment options, Wayne’s experience provides valuable insights into how electric crushing technology can address both operational and sustainability challenges in today’s competitive market.

Efficient Recycling for a Circular Economy

The Auckland RAP plant exemplifies the circular economy in action. As Wayne explains, “We take all the leftover asphalt, dig outs, all of that sort of stuff, millings, we recycle it and crush it down first then screen it out... It’s a cool product because it just goes round and round endlessly.”

This 100% recyclable product not only reduces waste but also provides a high-quality material for new asphalt mixes, offering both environmental and economic benefits.

The Electric Advantage

The Keestrack R3e's electric operation brings several key advantages:

• Versatility: "When you're not plugged into the mains, it's diesel-electric. But we mostly run it plugged into mains, so it's running all electric for us," Wayne notes.

• Noise Reduction: "It's super quiet, so you can have a conversation in the yard while the machine's working," improving workplace communication and safety.

• Enhanced Troubleshooting: The quiet operation allows for better problem detection. Wayne shares, "You can hear stuff going through the crusher... we can now tell when there's something wrong, bit of steel gone through, because you can hear it."

“The service and the backup support has been really, really good...Guys know what they’re talking about. Actually fantastic.”

- Wayne Richardson

• Reduced Heat Generation: "Everything being electric, it doesn't generate the same sort of heat as it does with your diesel hydraulic type thing, so that's a real bonus for us dealing with asphalt," Wayne explains.

Impressive Performance

The R3e has exceeded expectations in terms of output and reliability:

• High Production Rates: "On a good day we're getting over 130 ton/hour finished product," Wayne reports.

• Consistent Performance: "If you overload it or surge feed it... it's got all that torque from the electric motor, it doesn't [slow down], it just crushes it," maintaining high productivity even under challenging conditions.

• Adaptability: The machine performs well in various conditions. "Even in those [wet winter] conditions, we're exceeding our expectations. Summertime, the stuff just pours through the plant," Wayne states.

Ease of Maintenance and Support

The R3e's design and Equip2's support make maintenance straightforward:

• Simplified Mechanics: "It's a pleasure to deal with, pleasure to work on, nice and simple... with less stuff to sort of worry about," Wayne notes.

• Quick Repairs: "We've broken the hammer and broken some apron bars - piece of cake to change," demonstrating the machine's serviceability.

• Excellent Support: Wayne praises Equip2's service: "The service and the backup support has been really, really good. Guys know what they're talking about, actually fantastic."

A Sustainable Investment

For quarry owners looking to improve their sustainability profile, the R3e aligns perfectly with environmental goals.

As Wayne puts it, "It fits with what we're doing at Fulton Hogan, trying to reduce our carbon footprint, sustainability and all that stuff. It fits with our whole recycling motto."

In conclusion, the Keestrack R3e electric crusher offers a powerful, efficient, and environmentally friendly solution for asphalt recycling and aggregate production.

Its performance at Fulton Hogan's Auckland RAP plant demonstrates its capability to meet and exceed the demands of modern quarrying operations while contributing to sustainability efforts.

As Wayne succinctly puts it: "Good bit of kit. Really like it."

Check out the 1200hr review video on the R3e

IAN BUTCHER'S JOURNEY WITH THE EDGE XL SLAYER

TRANSFORMING WASTE MANAGEMENT

Ian Butcher, the Managing Director of Central Environmental Limited, faced a significant challenge in managing construction, demolition, and green waste. His journey with the XL Slayer shredder demonstrates how the right relationships revolutionize waste management practices.

The Search for a Solution

Confronted with increasing waste volumes, Ian and his team began their search for an efficient solution. "What we did was we researched online and went out for quotes on equipment that would suit our needs," Ian recalls. This process led them to Equip2, a company they had worked with for nearly 20 years.

Discovering the XL Slayer

The XL Slayer shredder emerged as the ideal solution. Ian highlights its key features: "The features we really like about the XL Slayer are the simplicity of use, the fact that it will reverse itself if you put too much stuff in it, it won't clog itself and produces a great product at the end of it."

Versatility in Action

The XL Slayer proved to be more versatile than initially anticipated. Ian explains, "You'll see the edge shredder behind me, which is the machine we purchased to process construction and demolition waste. But we also found that it

was perfectly suited to produce compost, so green waste and shredding that material and then processing it into a highgrade compost."

Daily Operations

Ian describes a typical day of operation: "A day for the operator on this machine he'll obviously do his checks before starting the machine, especially with green waste we try and blend the material before it goes through the machine itself because we get a different mixture of green waste products coming in." The machine operates three days a week to keep up with the incoming green waste volume.

Environmental Impact

The XL Slayer has significantly reduced landfill volumes. Ian states, "We're reducing landfill volumes obviously and also the need to have more trucks on the road transporting it to the landfills." This reduction in transportation needs has further positive environmental implications.

Cost Considerations

While the initial investment was substantial, Ian sees long-term benefits: "The cost of the machine isn't cheap but eventually it definitely will pay for itself because just in terms of landfill reduction and tip fees is, and basically there's an unquantifiable cost at this stage where we're talking about the environment."

Quality Output

The XL Slayer enables Central Environmental Limited to produce high-quality compost. Ian emphasizes, "Products that we want to produce are a high quality compost product that does not have bulking factors or bulking agents in it. We want to produce the premium end of the compost so that's a very very strong goal."

Future Plans

Looking ahead, Ian and his team are expanding their operations. "The next stage for us is to develop a full picking station and we have on order that comes through from Equip2," he shares. They're also in the early stages of developing their construction and demolition recycling capabilities.

Community Impact

The XL Slayer has enabled Central Environmental Limited to provide valuable services to their community. Ian explains, "In terms of the community the service we're able to provide is not only a green waste but soon a food waste collection and recycling area as well."

Advice for Others

For those considering entering the green waste processing field, Ian offers this advice: "You can't really do it half-heartedly I think you have to be 100% committed to doing it and that's the only way you'll get a good product at the end of the day."

Conclusion

Ian's experience with the XL Slayer shredder demonstrates its effectiveness in transforming waste management practices. His enthusiastic endorsement speaks volumes:

"I could 100% recommend it at this stage the shredder itself has been fantastic it's like I say it's it's a very easy machine to operate it's a high quality piece of machinery you can tell that when you're using it it's got so many good services that run with the machine so yeah I would definitely go for a slayer shredder."

Through Ian Butcher's journey, we see how the XL Slayer has not only improved his business operations but also contributed to more sustainable waste management practices in his community.

Check out the XL Slayer in action

ADDING CAPACITY

Peter Fredricsen of Rotomara Holdings Ltd relies on Equip2's Keestrack machines for concrete recycling and aggregate production at Kiwi Point Quarry.

The partnership began in 2016 and Equip2’s exceptional service and product knowledge have cemented a strong ongoing relationship.

Peter values the flexibility and quality of the Keestrack B3 jaw crusher, R3 impactor, and K3 screen, which have significantly boosted his business’s output and versatility.

Kiwi Point Quarry, to the left of Wellington’s steep Ngauranga Gorge, is very much out of sight and out of mind to most passersby, lying tucked into its hillside quarry site that’s largely unknown to most New Zealanders who are not part of the construction industry.

The hum and roar of processing machines are somewhat

mitigated by the steady flow of traffic along State Highway One, the major arterial route in and out of the capital city. It’s here, between the suburbs of Johnsonville and Khandallah, that Peter Fredricsen has found a home for his business Rotomara Holdings Ltd and is in his element.

Kiwi Point Quarry is owned by the Wellington City Council and is operated by Leach & Co Ltd, which Rotomara Holdings Ltd subcontracts to.

Peter is an authoritative industry figure on rock processing and aggregate production, with decades of

experience crushing aggregates as well as concrete recycling since 1996.

His subcontracting work has given him perspective, insight, learnings, and plenty to ponder on. And he’s far from done. In the near future, he’s hoping to open a new site on the Kāpiti Coast that will continue to recycle and process aggregate.

Machinery fleet

While Peter’s team consists of three valued staff members, it’s the other three members on his team — the yellow machines in his arsenal — that give him the ability to produce a wide array of quality products and the flexibility to meet client-specific needs. All are Keestrack-built: a B3 jaw crusher, an R3 impactor, and a K3 screen. But it wasn’t always this way.

“I had used other crushers when I was up in the Waikato, but it was talking to Bert Hart [Equip2 CEO] that led to getting my first Keestrack in 2016 — the B3 jaw,” says Peter. “Bert really knew what work we were doing and offered me a trade-in. I took some convincing, but it worked very well, and now I have the R3 and K3, too, because they are well-suited to our work.”

Ongoing service

Equip2’s service has cemented Peter’s ongoing relationship with the company. It started right from his first purchase when a transporter incident damaged the B3 crusher and led to its delayed arrival.

“Many people offered to help us get back up and running, but Equip2 really stood up and was the most helpful when I really needed it. The support they gave me at that time was the clincher that made me quite loyal to them,” says Peter. “It was well beyond what anyone else was offering me.”

Beyond service, Peter says it’s the value that Equip2 brings to the client relationship that means the most to him. “Their understanding of an operator’s business and the needs of that business are quite exceptional,” he says.

“The after-sales support and service are very good. Their sales and parts people have all been associated with a business like mine in one way or another, so they already understand the needs of a contractor. That’s extremely helpful for me. Their people are great to deal with and they understand my urgency.”

“Equip2 really stood up and was the most helpful when I really needed it. The support they gave me at that time was the clincher that made me quite loyal to them.”

- Peter Fredricsen

The value of Equip2 ultimately extends into the machines that Peter’s team engages with on a day-to-day basis, and Equip2 takes great care to marry them to the right end user. Getting this right so the machine’s performance can match an owner’s expectations is crucial and something Equip2 prides itself on.

Peter notices it, too. “Machines are horses for courses,” says Peter. “You apply them in the right instance. I was hesitant to get an impactor because they can be high wear, but we ultimately needed more capacity. “Equip2 helped answer my concerns and gave me the assurance to know that I was making the right decision.”

While the B3 jaw crusher enabled large rocks to be broken down three times their initial size — a reduction ratio of 1:3 — Peter decided an R3 impactor would be able to shape material and get it even smaller — a 1:10 reduction ratio. Again, Peter turned to Equip2 who were able to source a used but well-maintained R3 impact crusher.

“It was a game-changer for us and gave the business a whole new level in performance outputs. We could make more products and add them to the recycling operation as well as our quarry work. It more than doubled our output, so it essentially gave us more production capability and versatility in what we could produce.”

“The role Equip2 has played in my business, whether it be in advice or supply of products or parts, to aid me to get to this point has been great”

Expanding operations

Peter replaced his Portafill MR-5 screen, upgrading to the K3 screen, which works well with both his impactor and jaw crusher. The mix of machines allows Peter to make and sell a range of products, and with the K3, he has surety of grading sizes.

“We used to just process concrete, but now we can also recycle asphalt, waste concretes from ready mix plants, and leftover sludge from concrete plants and batch mix it to make premium spec aggregates,” says Peter. “We do all GAPs — 65, 40, and 20. We make three or four sizes of drainage products — some sand and some builders mix products.” Seeing concrete get recycled and given a new life gives Peter huge satisfaction.

“The role Equip2 has played in my business, whether it be in advice or supply of products or parts, to aid me to get to this point has been great. They have excellent product knowledge and are very good at listening.”

Check out the B3, R3 and K3 machines.

KEESTRACK B4 JAW CRUSHER

Hours: 650

Punch plate top deck 60mm

Overband Magnet

Remote Control 10 Function

Hydraulic Foldable Side Belt Conveyor

Asking Price:

$790,000 NZD + GST

KEESTRACK H4e CONE CRUSHER

Hours: 3100

3 Deck Post Screen

Fully Electric Drive

Easy Access Greasing

Metal Detector EGE 3000

Radio Remote Control 10F

Asking Price:

$790,000 NZD + GST

Hours: 100 +/-

Heavy Duty Tracks

Radio Remote Control

Hydraulic Tipping Hopper

Overband Magnet

Asking Price: $740,000 NZD + GST

KEESTRACK K3 SCALPER

Hours: 350

Plate Apron Feeder 10 Functions Radio Remote Control Main conveyor BW 1000mm L: 5000mm 8.3Kw

Asking Price: $360,000 NZD + GST

KEESTRACK B3 JAW CRUSHER

Hours: 6,000

1000x650 Jaw opening

Remote control 45mm CSS

Cummins QSB 6.7 Engine

Overband Magnet

Asking Price: $295,000 NZD + GST

KEESTRACK S5 TRACKED STACKER

Hours: 550

23 metre belt

1000mm wide

Adjustable Speed Engine, Deutz 44kw Stage 5

Asking Price: $212,000 NZD + GST

EDGE SLAYER XL SHREDDER