08 World-leading earthquake safety Why a seismic engineer who travels the world working in disaster recovery describes Aotearoa as a world leader in earthquake safety.

16 A “massive paradigm change” Artificial intelligence –what do engineers in New Zealand need to know?

30 Good evening gentlemen, and Kathryn A new Fellow sheds light on how the high voltage power systems industry has changed during her career.

32 Elevated training This specialised facility for guide dog and white cane training has real-world situations from escalators to aeroplanes.

PO Box 12 241

Wellington 6144 New Zealand

04 473 9444 hello@engineeringnz.org engineeringnz.org

Editor Jennifer Black editor@engineeringnz.org

Designers

Angeli Winthrop

Karlos Tui

Advertising sales advertising@engineeringnz.org

04 473 9444

Subscriptions hello@engineeringnz.org

Circulation

Magazine 360° Circulation for the 12 months ended 31 March 2022.

New Zealand 13,749

Print ISSN 2537-9097

Online ISSN 2537-9100

EG online

PDF versions of EG are available for members on our website or through our EN.CORE app.

Printing

Your cover is printed on Forest Stewardship Council (FSC) approved and elemental chlorine free (ECF) paper. The inside pages are Programme for the Endorsement of Forest Certification (PEFC) approved and elemental chlorine free (ECF). EG is printed using vegetable-based inks made from renewable sources. Printing and fulfilment by Bluestar.

Please recycle your paper envelope – it’s 100% recyclable and made from PEFC accredited paper.

Disclaimer

Advertising statements and editorial opinions expressed in EG do not reflect the views of Engineering New Zealand Te Ao Rangahau, its members, staff, or affiliated organisations unless expressly stated.

This issue of EG was published in September 2023.

8 World-leading earthquake safety

Why a seismic engineer who travels the world working in disaster recovery describes Aotearoa as a world leader in earthquake safety.

16 A “massive paradigm change” Artificial intelligence – what do engineers in New Zealand need to know, what can they harness, what should they avoid and what might be coming next?

22 A soaring career How – and why –Professor Rod Badcock is propelling aviation into a sustainable future.

24 Founders keepers From idea to reality, what does it take for engineers to launch a successful startup and what help is available?

30 Good evening gentlemen, and Kathryn New Fellow Kathryn Ward sheds light on how the high voltage power systems industry has changed during her career.

32 Elevated training How a rundown swimming pool complex became a specialised facility for guide dog and white cane training with real-world situations from escalators to aeroplanes.

41 New Act helps reduce risk Act’s amendment aims to provide certainty about where retention money will be held, and to protect subcontractors in their engagements.

42 “Engineers have feelings too” What impact does working in disaster areas have on engineers and how can they look after themselves in tough situations?

43 Learning: to be continued Addressing some common questions about continuing professional development.

44 Cornerstone of engineering education

As the University of Canterbury celebrates turning 150, we look at the origins – and growth –of its engineering school.

47 Growing pains Green growth, degrowth and engineering.

48 Making transport more accessible

The importance of all people having their voices heard and their needs met.

49 Intersection Crossing paths with engineers.

Bailey bridges, developed for use during World War II and named for inventor Sir Donald Coleman Bailey, were originally designed to facilitate the movement of troops and equipment across otherwise-impassable spans – fast. The prefabricated, temporary bridges are versatile and can be assembled relatively quickly. This unsung hero of the Allies’ war effort is still in use today. The engineering underpinning the humble Bailey bridge has stood the test of time, featuring prominently in the recovery effort after extreme weather events in New Zealand earlier this year. Waka Kotahi is quick to deploy its stock of Bailey bridges when severe weather events damage and destroy important bridges, reconnecting communities and re-establishing critical transport links.

time taken to complete a 91m bridge over Italy’s Trigno River in World War II

20

Bailey bridges available for immediate deployment in New Zealand at start of 2023

3m

length of the basic truss panel

3,000 tonnes

weight of Bailey bridge components owned by Waka Kotahi (in 2012)

Engineering Envy #172A Bailey bridge is rapid, cost-effective and versatile engineering at its finest. I grew up in Hawke’s Bay, so the reconnection they provide to isolated communities is important to me.Laura Sturch – Legal Advisor

Do you recognise the power of innovation to generate even more innovation? We do.

The ones that can help us make Aotearoa New Zealand a place where innovation thrives. If you’ve got a game changing idea and you need help getting it to market, the new Ārohia Innovation Trailblazer Grant is here to help you go far — then take innovation further.

You bring the belief, we’ll bring the backing.

Apply now at arohia.govt.nz

“We worked incredibly hard for six months building the rocket, testing all the subsystems, and doing test launches to validate everything. It was awesome to watch it launch in the New Mexico desert and to have everything work so well.”

Engineering student Alicia Smith from the University of Canterbury’s UC Aerospace club on winning their category and placing third overall at the 2023 Spaceport America Cup in the United States.

“They had to be the best stairs in a company that has about 400 structural engineers here and in Australia. It needed to be an impressive staircase.”

Matt Capon CMEngNZ IntPE(NZ) on the engineered timber internal staircase in Aurecon’s new Newmarket office block.

“Our technology will unleash the huge potential of using waste plastics as an energy-dense source, offering a solution to the global landfill pile-up.”

University of Canterbury Chemical and Process Engineer, Professor Alex Yip, is leading a research team aiming to turn medical plastic waste into energy.

Like many engineers, I’m struck by the speed of the advances in artificial intelligence (AI) and wondering what it’ll mean for individuals, organisations and our wider industry. While we mightn’t yet know the extent to which AI will change the face of engineering, as an industry we do need to look at what it might mean, and be aware of both the opportunities and some of the risks, as covered here by a range of experts, including Professor Dale Carnegie MEngNZ, on p16.

September sees the 13th anniversary of the 2010 Canterbury earthquake, and in this edition of EG we look at earthquake resilience and talk to engineers whose post-disaster expertise is sought around the world. Also in September, it’s Te Wiki o te Reo Māori, with this year’s theme: Kia Kaha Te Reo Māori – making the language stronger. I encourage members to embrace, celebrate and use te reo during this week, and on an ongoing basis.

I’ve been privileged to attend a number of Member Connect events as these continue around the country. It’s been great engaging with a diverse range of people on matters including Engineering Climate Action, occupational regulation and our governance review. Thanks to

everyone who provided a response to the consultation. The Governing Board is considering feedback and next steps and we’ll communicate what’s coming next, soon.

Congratulations to all finalists and winners at the recent ENVI Awards. It was great to see the quality of the projects, innovations and work programmes, and the calibre of engineers who topped categories on the night.

Finally, I acknowledge the potentially significant impact on home and building owners around the country due to recent concerns about the ethics and competence of one of our members, and the considerable demands this is placing on other engineers and many councils. This ongoing matter impacts the integrity of, and public confidence in, our profession. It also highlights the importance of Chartered Professional Engineers being mindful when undertaking designs and signing-off peer reviews, especially being mindful of all signoff processes and responsibilities, including the Code of Ethics. We’ll continue to keep you updated about this case.

Glen Cornelius FEngNZ CPEng President Engineering New Zealand Te Ao Rangahau Nau mai koutou katoa.

One New Zealand-based seismic engineer who travels the world working in disaster recovery describes Aotearoa as a world leader in earthquake safety. With the anniversary of the September 2010 Canterbury earthquake, we look at what the country is doing well and how our expertise is valued overseas.

WRITER | KAITUHI RACHEL HELYER DONALDSON

WRITER | KAITUHI RACHEL HELYER DONALDSON

On 6 February 2023, two catastrophic earthquakes rocked southern Turkey and northern Syria. The 7.8 and 7.7 magnitude quakes killed more than 55,000 people, injured more than 100,000 and caused widespread destruction.

When they struck, Christchuch-based engineer Jitendra Bothara FEngNZ IntPE(NZ) was preparing to visit Pakistan, to advise the World Bank on the reconstruction and recovery of 2.1 million homes, following cataclysmic floods and landslides during the 2022 monsoon.

Jitendra, who has spent three decades working in earthquake engineering, disaster risk management and post-earthquake response, was asked by the United Nations Development Programme (UNDP) to help in Syria. Up to 5 million people there are estimated to be homeless, many already displaced after 12 years of internal conflict. He began advising remotely, but arrived in Damascus, where UNDP is based, in March.

Jitendra has worked on 10 major earthquakes and was heavily involved in the 2005 Kashmir (Pakistan), 2011 Christchurch and 2015 Gorkha (Nepal) rebuilds. Syria is proving the most difficult and complex, due to the ongoing political crisis. This affects many aspects of recovery, from

accessibility to funding, and travel – including working 300km from the disaster zone, often relying on secondary information and travel in an armoured vehicle while in the earthquake affected areas. He has been helping Syrian engineers to assess damaged buildings, developing systems for housing recovery and working on capacity building (training local engineers and building artisans, and orienting policy makers) for safer construction. Capacity building, he says, is crucial to improving a country’s earthquake resilience.

Speaking to EG from Syria by video call, four months after the quakes, Jitendra says he’s also been developing a strategic plan to enable the UNDP to intervene in the recovery process.

“That way people can finally start working on their homes.”

Jitendra says New Zealand is a world leader in earthquake safety. Aotearoa’s engineers working in disaster-hit countries promote safety culture, protocols and “cutting-edge” technology. Their “softer approach” with local communities makes a big difference, he says. “It’s ‘we are here to help you, tell us how we can help you, and here is how we help you’.”

Left: Public consultation with flood-affected communities in Sindh, Pakistan, 2022.

Above left: Destruction of a village in Pakistan from 2005 earthquake.

Above: Destruction of a heritage site in Aleppo, Syria, from 2023 Turkey-Syria earthquake.

Right: Shock table testing of seismic retrofitting of stone masonry buildings, Nepal.

Left: Public consultation with flood-affected communities in Sindh, Pakistan, 2022.

Above left: Destruction of a village in Pakistan from 2005 earthquake.

Above: Destruction of a heritage site in Aleppo, Syria, from 2023 Turkey-Syria earthquake.

Right: Shock table testing of seismic retrofitting of stone masonry buildings, Nepal.

New Zealand engineers also help affected countries with long-term recovery. Originally from Nepal, Jitendra was a graduate engineer when, in 1993, he joined a project to develop Nepal’s building codes and worked with two New Zealand seismic experts, Dr Richard Sharpe DistFEngNZ IntPE(NZ) and Rob Jury FEngNZ, from Beca. The pair became Jitendra’s mentors, and changed the course of his life. In 2006, Jitendra moved to Aotearoa to join Beca. “They gave me the whole concept of earthquake safety.”

Now Jitendra travels the world, working in earthquake, flood and war recovery. He says the international disaster community is small and closely connected. He works frequently for the UNDP but he also advises governments and multinational organisations such as World Bank and Asian Development Bank. Working in different countries and cultures has given him “a deeper understanding of how culture, society, politics and safety are interlinked”.

In some countries, people see earthquakes as God’s will. It’s a frequent stumbling block to improving safety culture. But Kiwis’ reliance on insurance – thinking if they’re insured that an earthquake is wholly the insurer’s problem – can be “just as fatalistic” as religion.

Jitendra says the biggest challenge working in disaster areas is avoiding psychological trauma. “I connect with people, but I take care of myself. I keep engaged in work, and stay in regular communication with family and friends.” In Syria, people are still mourning loved ones. There are many orphaned children. Yet despite the country’s crises, people have been welcoming.

“It can be painful. But it is very fulfilling work. Coming here and supporting people gives my life a greater purpose.”

It can be painful. But it is very fulfilling work. Coming here and supporting people gives my life a greater purpose.

– Jitendra Bothara FEngNZ IntPE(NZ)

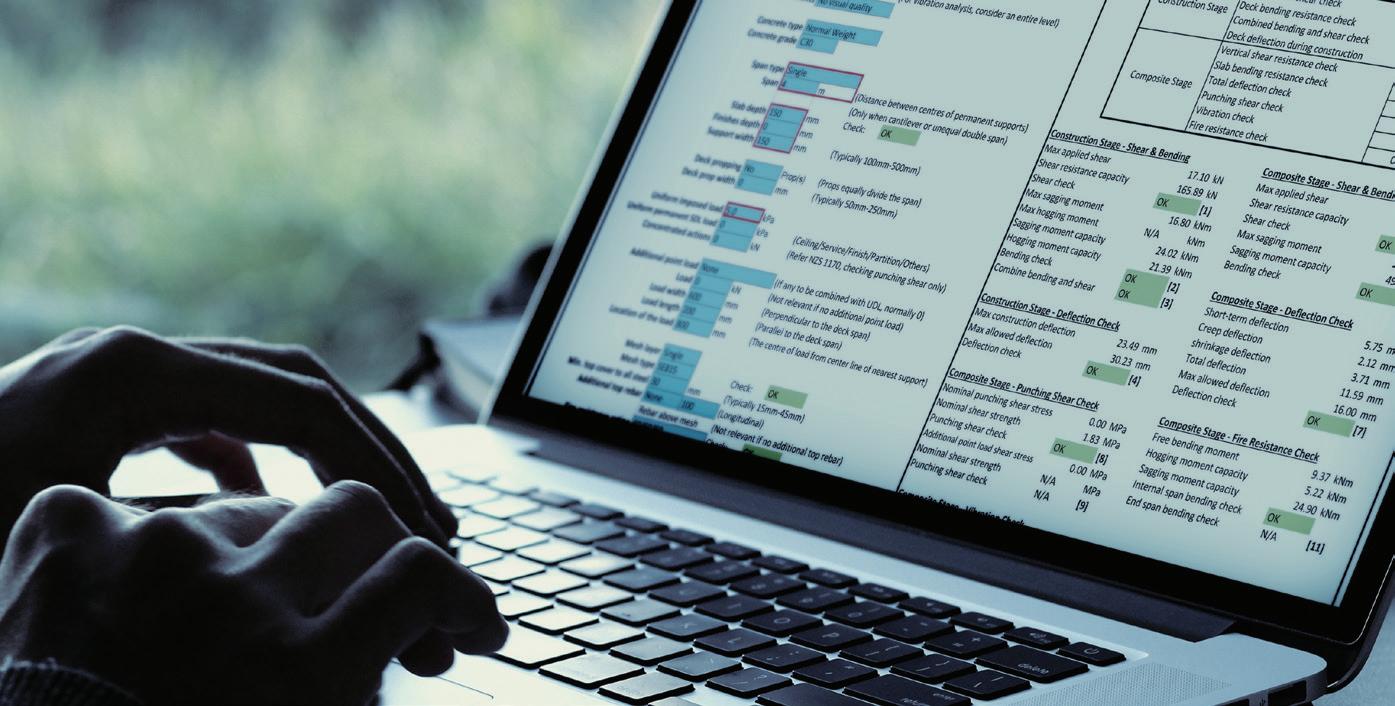

University of Auckland structural engineering lecturer

Dr Lucas Hogan’s research into natural hazards is improving building practices here and overseas. He’s the 2023 winner of the Toka Tū Ake EQC/NZ Society for Earthquake Engineering Ivan Skinner Award for his work in understanding the earthquake risk to buildings and bridges in New Zealand, and for helping to change building codes. He says his work with precast concrete has had the biggest impact on earthquake engineering practices.

walls are connected to the foundations and has helped provide assessment guidelines.

Meanwhile, his work as a team member on the ReCast project (funded by BRANZ, EQC and ConcreteNZ) has led to improved assessment and strengthening of hollowcore precast concrete floors. These floors were commonly used in multi-storey buildings in the 1980s and 1990s. ReCast’s research showed they would not hold up in an earthquake. Changes have been made to the building code, and these floors are no longer put into buildings.

Originally from Ohio, Lucas is a member of the American Concrete Institute. He plans to use his $10,000 award prize money to share his expertise with peers to improve building guidelines in the United States as well as New Zealand. There’s a strong desire for collaboration among the international earthquake engineering community. “We all have the same mission – to keep people safe.”

Precast concrete wall panels perform poorly, yet much of New Zealand’s building stock is assembled this way, including commercial buildings housing big box retailers. Lucas’s work highlighted vulnerabilities in the way the

One reason he loves working in Aotearoa is the impact his research can have on industry. “The feedback loop is tighter. If you have good work, you can see it get implemented and make positive change.”

Lucas hopes to make buildings more robust, to either withstand earthquakes or be built back faster.

We all have the same mission – to keep people safe.

– Dr Lucas HoganAbove: Dr Lucas Hogan during precast wall testing. Right: The ReCast project team, whose work has led to improved assessment and strengthening of hollow-core precast concrete floors. Photos: Supplied

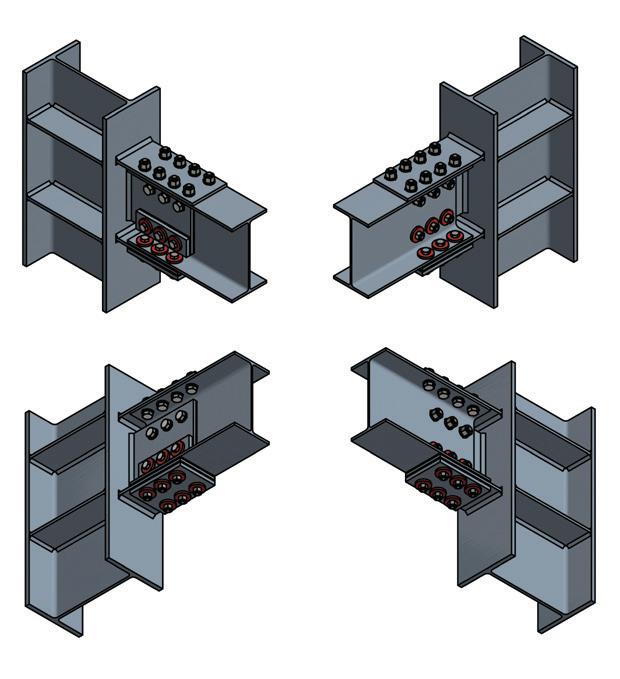

A low-cost and low- to no-damage seismic engineering system developed in New Zealand could be a game changer for the global construction industry. Dr Shahab Ramhormozian MEngNZ, a senior lecturer in structural and eathquake engineering at Auckland University of Technology (AUT), developed the Optimised Sliding Hinge Joint (OSHJ) for his PhD. Shahab’s work improved and finetuned sliding hinge joint technology conceived by his PhD supervisor, Dr Charles Clifton DistFEngNZ, in the late 1990s.

The system allows buildings to withstand stronger-thanexpected earthquakes, by dissipating seismic energy and limiting the earthquake-induced forces, acting like a fuse in electrical wiring.

Shahab says the original system was “groundbreaking, but had some shortcomings”. These include design and construction accuracy and precision issues, and postearthquake loss of strength.

For his work, the Iranian-born engineer, who moved to New Zealand in 2012, won the 2022 Ivan Skinner Award. Late last year his research group’s $9.47 million proposal to the Ministry of Business, Innovation and Employment’s (MBIE) Endeavour Fund was successful, with funding for five years.

The aim is to show that the innovation can be used within a wide range of building types, with the longterm objective to have it adopted into building codes. Retrofitting is also in Shahab’s sights.

So far five major construction projects are using OSHJs, including three buildings for ACC in Hamilton.

Engineers and academics around the world are keen to explore the technology, including a major project to construct the first building w ith OSHJs in Europe, plus research at Tongji University in China. For their own MBIEfunded project, Shahab’s team are collaborating with international researchers, and an American manufacturer who is a NASA partner and supplies Belleville Springs (an important component of the OSHJ system).

Shahab says New Zealand is “the world leader, and one of the pioneers” in this research area. “If we are the first country to codify these systems, I’m sure other countries will follow.”

Above: 3D drawing of the Optimised Sliding Hinge Joint system.

Image: Shahab Ramhormozian

Below: Optimised Sliding Hinge Joint system in action at an ACC building in Hamilton CBD. Photo: Tainui Group Holdings/Beca/

If we are the first country to codify these systems, I’m sure other countries will follow.

Ramhormozian MEngNZ

An ancient Māori building technique that involved tightly lashing and tying interlocked structural supports was able to withstand big earthquakes. Architect and researcher Professor Anthony Hoete and his team from the University of Auckland put the practice, known as mīmiro, to the test in April. They built a prototype, and testing was carried out with the help of the University’s School of Engineering. A snap test was undertaken as well as various vertical, horizontal and combined loadings. The prototype withstood three tonnes of lateral load, oscillating for just nine seconds afterwards.

Anthony, a Professor of Architecture and Planning at the University, and his team plan to rebuild a wharenui near Opōtiki that was destroyed in the 1931 Hawke's Bay earthquake. He says the technology, lost when Europeans arrived, could “absolutely” be widely used in earthquakeprone buildings.

“This research will increase seismic resilience through post-tensioning of structures both before and after an event. To do this, designers must seek to increasingly deploy post-tensioning as a means of resilience to mass timber-engineered (and architecturally designed) structures.”

Strengthening weak spots in concrete structures with carbon-fibre strips can strengthen earthquake-prone high-rise buildings, engineering researchers from the University of Auckland have found.

“Hundreds or even thousands” of buildings are at risk during an earthquake in New Zealand, says senior lecturer Dr Enrique del Rey Castillo CMEngNZ IntPE(NZ). Many of these are concrete, with a prevalence in Wellington.

“Using carbon fibre reinforcement polymers (CFRP) is a very attractive solution for owners and tenants as it’s often more cost-effective and less disruptive.”

Unfortunately, he says, the guidance for engineers to design these seismic strengthening techniques is limited. Despite this, CFRP is widely used, sometimes in a substandard manner.

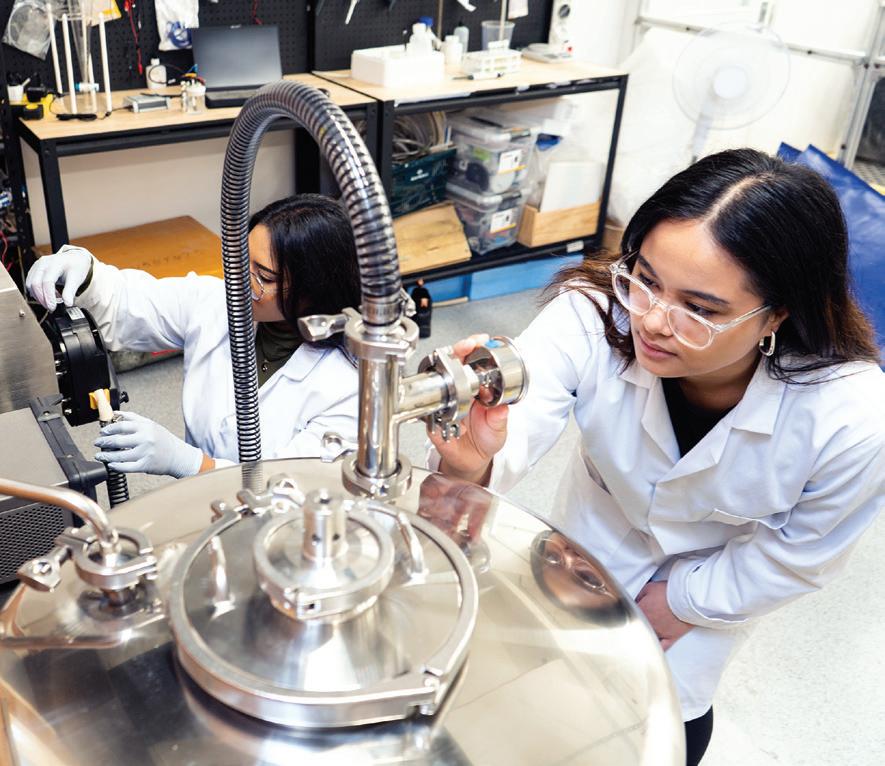

The research, led by Enrique and with a large team of PhD candidates and academics from Aotearoa and the United States, involves funding from MBIE and Toka Tū Ake EQC, and collaboration with industry to complete experimental work using state-of-the-art methodology.

“Comprehensive experimental testing, complemented by computer modelling will give insight into the effect of these strengthening interventions in the global behaviour of the building, allowing the team to produce design guidance for engineers to use CFRP confidently and reliably.”

Top: Architect and researcher Professor Anthony Hoete demonstrates the traditional Māori building technique mīmiro. Photo: Toka Tū Ake EQC

Above: Dr Enrique del Rey Castillo CMEngNZ IntPE(NZ) and student Zhibin (Victor) Li inspect cracking patterns and wall behaviour during testing.

Top: Architect and researcher Professor Anthony Hoete demonstrates the traditional Māori building technique mīmiro. Photo: Toka Tū Ake EQC

Above: Dr Enrique del Rey Castillo CMEngNZ IntPE(NZ) and student Zhibin (Victor) Li inspect cracking patterns and wall behaviour during testing.

With one engineer well versed in artificial intelligence saying he’s “never seen a step change in technology as rapid as this”, what do engineers in Aotearoa need to know, what can they harness, and what should they avoid? >>

Artificial intelligence (AI) has been around for decades, but was again thrust into the spotlight with the release of ChatGPT in November 2022.

“We’ve had AI in the background for a long time, but it was more in the realm of experts. It’s now suddenly moved into the public domain and has become vastly more accessible,” says Dale Carnegie MEngNZ, Professor and Dean of Engineering in the School of Engineering and Computer Science at Te Herenga Waka—Victoria University of Wellington.

“I have never seen a step change in technology as rapid as this. We’re in a massive paradigm change.”

Aotearoa’s infrastructure can benefit from AI. Engineering consultancy Beca is harnessing AI to help manage assets and infrastructure including roads, bridges and utilities. They’re employing computer vision and machine learning to detect, identify and classify

problems – including bridge cracks, wastewater pipe defects and roadside kerb and channel defects – from images and videos captured via high-resolution cameras, scanners on vehicles and AI-enabled drones.

“We draw on the big datasets of assets that we have and use our engineers familiar with those assets to test and train models to spot issues with the assets,” says Jack Donaghy, Digital Innovation Leader – Transportation & Infrastructure NZ at Beca.

Benefits from AI-driven solutions here include improved safety, less traffic disruption and savings in time, money and resources.

“It can lead to a lot of predictive maintenance, and we can have better asset management systems and do better forward work planning for assets,” Jack says.

“It’s more accurate as well. It’s not subjective and it’s a consistent output.”

Yet the proliferation of AI technologies is sowing seeds of doubt, leading engineers to question if they could lose their jobs to AI. Dale Carnegie has reassurance.

Professor“The jobs won’t go away. AI will need a huge industry behind it, so there will be a large number of jobs required to support it. We’re going to see a further movement into the high-tech side, and it’s going to increase the return on value that we have,” he says.

I have never seen a step change in technology as rapid as this. We’re in a massive paradigm change.

–

Dale Carnegie MEngNZ

Opposite: Typical machine learning workflow for image detection and classification.

Image: Beca

Right: Example of a machine learning image detection scenario for a bus shelter project. Image: Beca

Below right: Māori Data and Emerging Technologies Ethicist and Kaupapa Māori Researcher Dr Karaitiana Taiuru. Photo: Supplied

Below: Jack Donaghy, Digital Innovation Leader –Transportation & Infrastructure NZ at Beca. Photo: Supplied

And rather than a loss, it would likely be a shift, with AI enabling engineers to do their work more efficiently, resulting in a step up to higher-level roles.

“Engineers will move on to higher-value tasks as well,” says Jack. “Many are using their skills and knowledge to train the models and use good data to manage assets better. They won’t be doing boring, repetitive tasks — their time will be better spent looking at the bigger picture and getting more done in the industry.”

Even junior engineers can add more value. Jack says, “What we’re finding with our young engineers coming out of university is that they have digital backgrounds. AI can empower them and it can accelerate their development and allow them to focus on higher value activities that benefit the community.”

Despite its advantages, AI does come with risks. Earlier this year, Geoffrey Hinton, touted as the “godfather of AI”, stepped down from his post at Google over concerns of bad actors possibly exploiting AI, as well the existential risk it poses. Alongside other AI experts, he also warned that artificial intelligence could lead to extinction. Privacy and bias are also of concern.

“If you’re Māori, a person of colour or part of a minority group, you will be discriminated against with these systems,” says Dr Karaitiana Taiuru, a Māori Data and

Emerging Technologies Ethicist and Kaupapa Māori Researcher.

Avoiding bias requires involving Māori in decisionmaking processes.

“It’s important that we have Māori developers and ethicists and Māori in governance and management,” Karaitiana says.

“We are at a crossroads right now. We can go left and keep the status quo of colonisation and discrimination. Or, we can turn right and harness the power of AI to empower Māori and minorities and decolonise the biased data we already have, but it’s not possible at this stage because of the lack of engagement.”

Engineers working with iwi on projects that use AI, must include and partner with iwi and Māori and understand mātauranga Māori, Karaitiana advises, as well as honour the Māori view of data as a living tāonga with immense value. >>

“We have traditional knowledge, but a lot of iwi and Māori aren’t going to just want to share all their knowledge straightaway,” he adds.

“You’ll need to build up trust, and don’t think that your ideas are more superior than iwi ideas — there needs to be a good balance for everybody.”

Additionally, AI chatbots such as OpenAI’s ChatGPT, Google’s Bard and Microsoft’s Bing search engine are prone to “hallucinations” which occur when they produce false or incorrect outputs.

“Where it’s really dangerous for engineers and the industry is if they are relying on AI tools and just accepting the outcome from that. AI can be wrong — don’t blindly trust it,” emphasises Dale.

To mitigate this risk of inaccuracy, he advises embedding fundamental knowledge in engineers so they have the capacity to reason about, make sense of, question and critically challenge the decisions and results coming out of AI. Establishing engineering standards and regulating engineers are also crucial.

“That tells me that a company is not going to blindly employ AI to do something if the company can then be found liable for a defective construction. And we’ve got very strict building codes, so we know that regardless of whether we’re using AI as a tool, in the end it’s going to have to satisfy those requirements,” Dale says.

Technical upscaling and regular training can also help increase awareness of these risks and enable engineers to keep up with advances in AI.

“We often have domain-specific workshops but we have fewer about the risks involved in AI. That’s something we need to have with ongoing education for our engineers,” says Dale.

While the Privacy Commissioner has issued guidance on the use of generative AI for agencies and businesses, the country currently lacks AI-specific legislation.

“I’d like to see the New Zealand Bill of Rights Act, Human Rights Act, Privacy Act and intellectual property legislation all updated to include AI and ensure it won’t do harm to communities,” Karaitiana says.

“We need Māori at the table legislating. This is a real opportunity for our country to be more equitable for all minorities.”

The challenge, however, is the swift pace of developments in AI.

“Regulation is lagging far behind because the technology is outstripping people’s ability to create the policies around it,” explains Dale. This means that the responsibility falls on engineers to ensure they’re using AI safely.

“The onus is on people in engineering domains to really know what their state of the art is,” he says.

“And it’s not new territory – we’re always developing and testing models, so we have the ability to do that critical analysis. We just have to be careful about how much confidence and faith we’re putting in AI.”

How has your work contributed to the development of AI in Aotearoa?

Dr Yi Mei: My research mainly focuses on using AI to assist complex decision-making processes. An example is a project we are working on with Wellington Free Ambulance, which uses AI to help dispatchers make real-time ambulance dispatching decisions. Our preliminary approach, implemented with a controlled test environment utilising simulated dispatch scenarios, suggests we may be able to significantly reduce real-world response times.

Professor Bing Xue: My work contributes mainly to fundamental research and real-world applications of AI in various areas of New Zealand’s primary industry, in collaboration with Cawthron, Plant & Food Research and other organisations. As the Programme Director and Deputy Head of School, I co-led the AI group to establish the first postgraduate qualification and undergraduate major in AI in Aotearoa.

How can Kiwi engineers keep up with developments in AI?

Dr Yi Mei: The current AI development is happening so fast for people to keep up with. But the good news is that the latest AI tools are user-friendly for engineers. You don’t even need to know programming to use AI as tools (for example, the latest Windows has embedded ChatGPT in many of their products). I think the latest trend in AI is large language models and generative AI, which will enable AI to “create” instead of just “mimic” humans, with the corresponding ethical issues raised to be addressed. Attending AI events and workshops will be very helpful.

Professor Bing Xue: Stay connected and collaborate with each other. New Zealand is a small country but has a group of excellent AI researchers and practitioners. The Artificial Intelligence Researchers Association, AI Forum of New Zealand and annual AI workshops provide good opportunities for people to exchange ideas and create opportunities for AI in engineering. Being aware of the ethical considerations and challenges surrounding AI development, deployment and governance is another critical point, which is probably as important as the AI solutions themselves.

What do you think we’ll be doing with AI in five years’ time?

Dr Yi Mei: We are currently at a crossroads. On one hand, we can expect AI to make a dramatic change in our work and lifestyle, as ChatGPT is doing. On the other hand, there could be serious ethical issues if AI is misused. For example, in five years’ time, you may have a personal AI assistant that learns from your past decisions and make your favourite work and life recommendations. However, this might not be ethical if past decisions are biased, so AI ethics and regulations are becoming increasingly important.

Professor Bing Xue: I’m positive about the potential of AI and how it can help society. Last year, most people did not know ChatGPT would affect the work and lives of so many people. I’m sure there will be new AI tools appearing in the next five years that could change the way we are doing things as much as what ChatGPT is doing.

Photo: Wellington Free AmbulanceHow – and why – Professor Rod Badcock is propelling aviation into a sustainable future.

Launching rockets into space, high performance motorsport engines, and leading the world into sustainable aviation – New Zealand punches far above its weight, says Paihau—Robinson Research Institute Te Herenga Waka—Victoria University of Wellington Professor Rod Badcock. He leads a team developing superconductive motors to enable all-electric aircraft and, ultimately, sustainable aviation.

“There’s so much engineering capability around Wellington, Christchurch, and up and down the country,” he says.

“That’s partly due to the agility you find here. When you’re developing technology, you need people who can work at the highest precision and quality but be agile enough to make one-offs. New Zealand has that capability. It also has a history of very good education and a willingness to try something new.”

Another reason for this engineering global excellence, Rod says, is that in the 1980s, a team at the then Department of Scientific and Industrial Research was the discoverer and patent inventor of a high-temperature superconductor.

At the Institute and almost 40 years on, he continues this work by developing superconducting technologies for use in aviation.

“While there are some fantastic conventional electric motors that have been developed, with power densities

of 5 kW/kg, for aviation to operate with economic payloads then motor systems must deliver 25 kW/kg,” Rod says.

Currently, an electric motor required to power a long-haul flight is too heavy, and this is where superconductors will take the stage. A superconductor can carry hundreds of times more current than conventional systems and overcome the power-to-weight limit.

“These high-temperature superconductors are so critical because they allow windings with hundreds of amps. They enable electric motors and generators to deliver 5 to 10 times the power output per kg of the current stateof-art electric machines and solve this critical challenge.”

To meet climate emission reduction targets, jet engines need to be significantly more efficient, and superconducting electric motors are expected to be a critical system that enables an increase in aeroplane fuel efficiency by 70 percent. This, however, will take time. Technology readiness levels (TRLs), a NASA method for understanding the technical maturity of a technology, is a necessary but lengthy process that documents all development stages, and Rod says their biggest challenge is to raise the TRLs of superconducting motors fast enough. To bridge the gap, sustainable aviation fuel and hydrogen have roles to play. New Zealand's already instrumental in accelerating electric hybrid technology, commercially and in research.

“The country has a history of ground-

breaking engineering partnership centres, such as the Christchurch Engine Centre, and is seeking to establish, along with Air New Zealand and big international players such as Airbus and Pratt & Whitney, a full test facility that could run and test zeroemission propulsion systems.”

He adds: “The facility will look at both hydrogen and electric propulsion and the other zero-emission fuel systems.”

Within 10 years, Rod anticipates Aotearoa will have hybrid propulsion regional flights, “with smaller, turbine engines on board and electrical assist, so they will take off with electric power, which is where most of the power is needed”.

“You’ll see smaller hybrid aircraft and more frequent services, and the fuel burn will drop by at least 40 percent, which of course means 40 percent less emissions.”

Over the past decade, Rod has been showered with awards and accolades for his work, including the 2022 Pickering Medal from the Royal Society Te Apārangi. He says while they’ve all been an honour to receive, his greatest achievement is seeing many of his students hone their entrepreneurial skills at the Institute and go on to have commercial success in emerging deep tech and clean tech.

Outside of work, Rod can be found on a bike, cycling to work or on spectacular trails all over the Wellington region.

“Cycling is the most efficient form of transport there is, and an engineer can maintain a bicycle far better than anyone –I like the synergy of engineering delivering efficient sustainability.”

From idea to reality, what does it take for engineers to launch a successful startup and what help is available?

Levi Fawcett started three companies during his time at the University of Canterbury. Alongside completing his Mechatronics Engineering degree, he had big business ideas.

“My primary goal at university was just to understand the fundamental concepts and not worry too much about grades,” he says.

“Once you understand the concepts and principles of engineering, you can apply these to real-world, complex problems.”

When he was asked to join Rocket Lab during his fourth year at university, he jumped at the opportunity.

“Rocket Lab embodied ambition to me,” says Levi. “At the time, there were 130 of us working very hard to launch the first rocket. So that raised my bar in terms of what was possible.”

Such was the level of dedication, Levi slept in his Toyota Corolla in the Rocket Lab carpark in Auckland, working 7am until midnight Monday to Wednesday, then flying back to Christchurch to run AllGoods, an e-commerce company he’d set up in 2017, from Thursday to Sunday.

Working with AllGoods, Levi realised it wasn’t going to be a “wildly successful business”.

“AllGoods was like our MBA. We were strong technically, but made a lot of mistakes on the business model side,” he says.

“After three years we decided to shut the business down and start Partly in 2020.”

With Partly, Levi had unearthed a genuine global problem that hadn’t been solved. It turns raw car parts data into usable information using multiple bleedingedge data sets and software configurations. Car parts manufacturers, retailers and marketplaces, such as eBay and Amazon, now offer customers a quick, easy way to

It’s all very well having an idea and executing it, but you need to be able to sell it and continually re-evaluate the solutions and the value your company provides.

– Levi Fawcett

find the right car parts from a licence plate, thanks to Partly.

The company now works with large retailers including Walmart, transforming their data infrastructure. Staff numbers have grown from five to 60 full-timers in less than three years, and the business now has offices in Christchurch, Auckland and London.

But as Levi sees it, that’s only the tip of the iceberg.

“The size of the problem we’re tackling is nearly US$2 trillion spent annually on parts. Our goal is to make it really easy for buyers to find the right part – across all countries, and billions of car parts in the world. We’re building that tech infrastructure, but there’s still a long way to go.”

Along the way, Levi has had to upskill and find ways to fund the business. After initially funding the company himself, at a pre-seed round of investment he raised NZ$1.7 million from Blackbird Ventures as the principal investor.

“Twelve months later, we raised $3.5 million, and in December 2022, we raised $37 million at Series A.”

Levi credits several people with his success, including Peter Beck from Rocket Lab, who helped Levi review the early funding options.

Aidan Smith and Connor Read crossed paths while pursuing their mechanical engineering degrees at the University of Canterbury. After graduating, they joined forces at Holmes Solutions, developing and designing electric adventure recreational rides and transportation. They identified an untapped market opportunity: providing e-bikes to commuters via a subscription model.

“We realised that the main hurdle for most people was the upfront cost. To tackle this, we introduced Shutl, an all-inclusive electric bike subscription service for both businesses and individuals,” Aidan explains.

The pair secured an innovation grant from Waka Kotahi to pilot a community-based e-bike programme.

Aidan says in the world of startups, change is a constant. “It’s about constantly evolving and staying open to new opportunities.”

He attributes his achievements to his engineering background. “A logical and rational approach to problem-solving assures me that there’s always a solution out there. With Shutl, we get to utilise our engineering skills in a meaningful way that not only creates value for others but is also scalable.”

“Although I’ve never had a formal mentor, I’ve valued many people’s input. It’s all very well having an idea and executing it, but you need to be able to sell it and continually re-evaluate the solutions and the value your company provides.”

Callaghan Innovation is one grant provider offering a potential source of funding for engineering startups. Student Grants fund a student into a business active in the research and development (R&D) space. The New to R&D Grants focus on startups with an embryonic idea.

“Perhaps a pair of engineers have spent $2,000 on a prototype and they need to test out the idea with further research,” says Spencer Willis, Group Manager Funding and Engagement at Callaghan Innovation.

Opposite: Entrepreneur and CEO of Partly, Levi Fawcett. Photo: Partly“It’s a co-funded grant, whereby Callaghan contributes 20 percent, and the applicant contributes 80 percent. The advantage of this grant is that Callaghan also funds the grantee to upskill in areas outside their core capabilities. That may be regulation and compliance knowledge, working with IP [intellectual property], adopted lean behaviours and so on,” says Spencer. There’s up to $400,000 available, with half to be spent on R&D and half on capability development.

Ārohia Innovation Trailblazer Grants focus on pushing boundaries and funding ground-breaking and novel ideas, while fuelling the innovation ecosystem. “Callaghan grants have been used by some of the country's bestknown organisations, for example Rocket Lab, who have not only gone on to great things, but also influenced other innovators to create, grow and succeed.”

With the philosophy of “fail fast, succeed quick” the grant application process has stage gates and applications are processed quickly. And Spencer’s advice for applicants? “By getting clear on the eligibility and funding criteria, you can get a good steer on whether your idea will fit the requirements. And focus on the technical and commercial side of the organisation.”

Callaghan Innovation funds various providers around New Zealand to deliver its Founder and Startup Support programme, wrapping commercialisation support around co-founders to get them investor-ready. Nathan Stantiall, Group Leader of Product Ownership at Callaghan Innovation, says, “We help founders establish whether there is a genuine problem to solve, whether their solution is going to solve it and whether customers are willing to pay for it.”

The Ministry of Awesome (MoA) runs capabilitybuilding programmes nationwide for Callaghan.

By getting clear on the eligibility and funding criteria, you can get a good steer on whether your idea will fit the requirements.

– Spencer WillisAbove: The Electrify Accelerator, powered by the Ministry of Awesome (MoA), supports women and nonbinary high-growth startup founders. Above right: MoA's Orion Energy Accelerator gives startups five minutes to pitch to a panel of expert judges. Right: Zach Warder-Gabaldón, Head of Programmes at MoA. Photos: Ministry of Awesome Opposite left: Imche Veiga, co-founder of Outset Ventures. Photo: Supplied

Zach Warder-Gabaldón, Head of Programmes at MoA, himself an engineering graduate from Stanford University, operates three accelerators and one continuous incubator programme, Founder Catalyst, per year. “We run the six-month Founder Catalyst programme four times a year with cohorts of 15 to 20 companies, focusing on building market, globalisation and fundraising capability.”

MoA also partners with Te Pūkenga (Ara Institute of Canterbury) to provide Research Hub, a collaborative programme where founders can pair with professional staff when R&D is heavily needed.

Outset Ventures is an early-stage investment fund, community hub and incubator aimed at the science and engineering sectors. Founded by Imche Veiga and Mat Rowe, it’s home to more than 30 deep technology startups.

“We back startups with highly technical solutions to big market problems such as reducing carbon emissions, increasing food security and generating clean energy,” says Imche. “We have 5,000m2 of laboratory and workshop space in Auckland for our startups. This means they instantly join a community of fellow venture builders who we can support through coaching, capability-building workshops and facilitating connections to other investors and experts.”

With an initial fund of more than $11 million, Outset Ventures has helped ground-breaking engineering solutions such as OpenStar, Vertus Energy and Foundry Lab.

Engineering New Zealand’s Young Engineer of the Year 2019, Eight360 founder Terry Miller, has since taken his NOVA immersive motion simulator to the world stage. The same day he won the Engineering New Zealand ENVI Award, his company signed a contract with the New Zealand Defence Force to trial NOVA for safety-critical vehicle training. They’ve since been focusing on the defence sector internationally. The company's built more than 12 units and raised more than $3 million in funding to date.

“We have raised funds from angel investor groups mainly within New Zealand but also Australia.”

In addition, Eight360 was a resident of the First Assembly Hardware Incubator in Lower Hutt for several years. Since the programme’s closure in 2019, Terry has been campaigning for a new incubator space in the Hutt Valley to seed the next generation of tech hardware product startups.

Alongside the international defence sector, Terry is seeing interest from the aerospace and academic research sectors. “Using VR [virtual reality] means we can create situations that would otherwise be impossible. There are so many training, science and engineering applications. We’re excited to see where this technology can go.”

When new Fellow Kathryn Ward embarked on her engineering career in the 1980s, women were such an anomaly she was often addressed personally at industry presentations. She tells EG how the industry has changed, and about her range of contributions to the high voltage power systems industry and the profession.

An aptitude for mathematics and the sciences, coupled with an interest in her father’s work at the New Zealand Electricity Department, led Kathryn Ward FEngNZ CMEngNZ IntPE(NZ) to study electrical engineering. While at the University of Canterbury, she was a cadet with the Department, and on graduating, became an Assistant Engineer.

“I was rotated through the three main areas of operations, design and construction, and technical services, and in the latter area, I found my place in high voltage power systems protection. I knew I had found my dream career path.”

As a woman in a male-dominated industry, Kathryn found she would only be recognised as an equal if she excelled.

“So, I listened to feedback, learnt from the gurus in high voltage power systems protection, and grew my technical skills.”

The Specialist Protection and Automation Consultant Engineer at Beca says the industry has changed significantly since she started out, and she has spent her career actively encouraging and upskilling women in the industry.

“Females working in engineering is now BAU [business as usual]; there is a big

emphasis to increase the female to male ratio, along with the rainbow community and ethnic diversity. What matters is your contribution to both the industry and our local communities.”

Sustainability has long been a focus. “I’ve always been interested in helping clients think about the whole life of the substation and not just the project requirements. Future-proofing asset upgrades helps reduce replacement of equipment prior to the end of its serviceable life.”

She thrives on technically challenging projects and the ongoing change in protection relays.

“I have been fortunate to have worked with all four generations of them. The latest generation relays now do so much more than just provide protection for faults on the power system.”

Change is afoot with the adoption of artificial intelligence (AI) into power systems, and while it will play a significant role in the future, Kathryn says it doesn’t yet find complex solutions to unique problems.

“But when they have developed true AI self-learning skills, quite a bit of what I do now will be done by technology.”

She has always been passionate about giving back to the industry, through training and mentoring. She says there's still work to be done increasing the number of women in the profession at higher career levels.

“One of the harder barriers for females to overcome is their personal choice to

have children. From my own experience, it's so much harder juggling family and work responsibilities for a female than a male. Even today, parts of society expect the male to be the principal breadwinner and the female to be juggling work commitments around children and running the household. Often this results in the female working part time, which usually means a female’s career path hits a plateau.”

Kathryn has been at Beca for 25 years. “It is here I have learnt teams are stronger than individuals, that giving back to the industry by training the next generation of engineers is so important, as is sharing company success with employees, as they are the ones that make it a great company.”

When not at work, or lecturing on power systems protection at the University of Canterbury, Kathryn is a keen cyclist, speaking to EG from a cycle tour in Portugal. As for career advice for engineers new to the profession, she says.

“Be yourself and treat your mistakes as learning opportunities; take on every opportunity offered, even if it takes you out of your comfort zone. You don’t know what you can do if you aren’t prepared to try.”

Airbridge and Airbus interior

Train platform and train carriage with functioning doors

Bus Café Lift

Mall with stairs and escalator

Street with multiple road and footpath surfaces

Multiple road crossing types

Amazon Alexa speakers to create real-world sound

A rundown swimming pool complex in Auckland underwent a unique retrofit to become a specialised facility for guide dog and white cane training, offering a range of real-world situations, from escalators to aeroplanes.

Based at Blind Low Vision NZ’s South Auckland complex, the Mobility Centre provides real-world simulations –including mock buses, trains and planes – to create a training environment for guide dogs, their handlers, and people learning how to use white canes. Smart speakers echo with traffic noise and the hum of bus doors opening, offering a 360-degree immersion into the real-world scenarios these guides and their handlers will navigate daily.

“Our aim was to create a space that gives people who are blind, deafblind or have low vision, the best possible chance to learn, for example, how to work with their new guide dog, in a real-life environment,” says Blind Low Vision NZ Chief Executive John Mulka.

“Our centre’s replication of roads, stairs and escalators allows guide dogs to acclimatise to these elements, preparing them to assist individuals with visual impairments effectively. This invaluable training opportunity elevates the standard of guide dog assistance.”

Opened in March 2023, the Mobility Centre houses the simulated training environment for guide dogs along with Blind Low Vision NZ’s offices and an indoor football pitch that’s used for training purposes.

Hauraki Design was the architect for the project, while Cape Construction, along with various subcontractors, brought the design to fruition.

John says the build faced considerable design challenges from the outset.

“Transforming a dilapidated, yet cherished, former swimming pool complex into a state-of-the-art facility demanded ingenuity and resourcefulness.

“The limited space and existing infrastructure led us to think beyond the square. Drawing inspiration from Australia’s centre, we pushed the envelope to incorporate additional elements like a lift and even an aeroplane layout.

“In the end, it was meticulous planning that allowed the team to optimise the space, resulting in a truly remarkable achievement.”

During initial investigations, the building was found to be earthquake prone, while some of the portal frames were significantly rusted due to chlorination from the pool.

Rak Natesh, a structural engineer at EQSTRUC, worked on the building’s seismic retrofit and alterations.

“When we started out, we did heavy investigations throughout the building. There was no property file, so we needed to do as much detailed investigation as we could,” says Rak.

“We did soil analysis and cone penetration tests to work out the state of the foundations. We also scanned the walls and found out they were unreinforced. After all these investigations we came back to the drawing board and went from there to understand what parts of the building could be reused and what needed remediation.

“To remediate the rusted structural elements, we inspected each portal frame and tried to figure out what parts the chlorination had had an effect [on]. During inspection, we’d start from one corner of the portal frame

and focused on areas where there was bubbling or significant rust build up.

“The contractors used wire brushing to remove the rust to figure out the steel thickness. We used that in our calculations to modify the strengths of the existing beams and from that we knew how to alter it to get the strength required for the seismic retrofit.”

To address the seismic issues, strengthening unreinforced masonry was needed.

“The office block area was supported by mainly unreinforced masonry – there was no actual lateral system in the area. So we used portal frames and roof bracing to strengthen the structure."

Rak adds: “The swimming pool area also needed to be filled up and compacted. We did a lot of geotechnical

work on that portion. We worked with the geotechnical engineers quite closely to design a slab in the middle for the football pitch. It was built up using compacted soil and geofoam blocks.”

Disruption from Covid-19 added to the mix, affecting the availability of shipping materials and subcontractors. This meant revising material choices, adjusting schedules and working more closely across trades to find viable alternatives.

Terra Firma Group, the project managers, worked to keep the various elements of the project together, despite the delays the pandemic caused.

John says collaboration with the “exceptional” team of architects and engineers was pivotal in bringing the vision to life.

“Working closely with industry experts, we landed on a design brief that met all the objectives. Throughout the tightknit partnership with the Guide Dog Services team, we refined every aspect of the centre to ensure seamless integration within our community.”

John adds: “The Mobility Centre is a truly unique construction, so we are proud to see this ground-breaking initiative come to life.”

blindlowvision.org.nz/resources

Transforming a dilapidated, yet cherished, former swimming pool complex into a state-of-the-art facility demanded ingenuity and resourcefulness.

Blind Low Vision NZ has a range of guidelines to help increase accessibility for people who are blind, deafblind or have low vision.

the Asset Management Excellence Supreme Award.

stormwater network. The project won three awards at the Institute of Public Works Engineering

Australasia (IPWEA) NZ 2023 Asset Management Excellence Awards, including

underground for more than 70 years, is now a place where wildlife can flourish, children can play and the community can connect. It’s now also an integral part of Northcote’s

The new, 1.5km blue-green corridor Te Ara Awataha in Auckland’s

Northcote links parks, the town centre, schools and homes. The Awataha stream, piped

Photo: David St George

Amendment aims to provide certainty about where retention money will be held, and to protect subcontractors in their engagements.

The collapse of Ebert Construction in 2018 has led to changes to the Construction Contracts Act 2002 (the Act). The changes, introduced through the Construction Contracts (Retention Money) Amendment Act 2023 (CCA), mean retention money will now be automatically held in trust, reducing the risk of the money being used for other purposes and providing more security for contractors when engaging in construction work. The changes will be in force from 5 October 2023.

This is an integral change to commercial construction contracts and will require the client, who is the principal, to hold money on retention on behalf of the contractor. Retention money will be held in a bank account or by alternative financial means such as insurance or a payment bond by the principal.

In circumstances where there are subcontractors involved, the head contractor will act as principal (in the contract between it and the subcontractor) and holds the retention money on behalf of the subcontractors. If those subcontractors then further subcontract out work, they become the principals of those subcontracts, and must also hold retention money, and so on. This means multiple contracting parties may hold retention money. The principal in each contract will hold retention on behalf the

other party, the contractor.

The changes mean sums of money will be automatically held as retention money, regardless of whether a portion of the fee has already been paid to the contractor. This means a contractor who has been partially paid should no longer be in a better position than one who has not if the principal becomes insolvent.

For retention money held in a bank account, the account must be used for the purpose of holding the retention money and the principal must advise the bank that it is a trust account to be used for holding the retention money only.

The principal is required to give the contractor information about the money, including the sum held, the contract which it relates to, the date of its retention, and details about the bank account the money is held in. If the retention money is held by an alternative financial instrument, the principal must advise the name of the issuer and any relevant information for identifying the instrument, and the amount protected. The information should be provided from when the money is first held on retention, and every three months thereafter. If the information given by the principal is false or misleading in any way, there will be the ability to issue a penalty.

Penalties will apply if provisions are not followed, including fines of up to $200,000. If the principal is a company, and it fails to hold retention money per the CCA, liability will fall on the director personally. The Ministry of Business, Innovation and Employment (MBIE) reserves the right

to investigate and enforce retention regulations, with further penalties if principals fail to provide MBIE with information to assist with investigations into breaches of the Act.

Some readers familiar with NZS 3910 construction contracts may wonder about the role of the Engineer to the Contract in relation to retention money. As with the Act, NZS 3910 is also in a period of change. The Review Committee is now considering submissions from the public consultation to the revised version of the standard (which takes into account the changes to the Act). Under the current draft of the new standard, the Engineer to the Contract role is now called the Independent Certifier, and the role of Engineer’s Representative has been renamed Contract Administrator, with more clearly defined, and changed, responsibilities. In terms of their role as to retention money, before retention money can be released to the contractor the Independent Certifier will need to have assessed the cost to the principal of completing any outstanding contract works or making good any omission or defects. Additionally, the Independent Certifier will be responsible for issuing payment schedules in relation to retention monies. The new standard is expected to be finalised and published in October 2023, and the above information in respect of it subject to change.

What impact does working in disaster areas have on engineers; what should they be aware of and how can they look after themselves, and their mental health, in tough situations?

Resilience in engineering usually refers to resilient infrastructure. But, says Regan Potangaroa CMEngNZ (Ngāti Kahungunu ki Wairarapa), “there is another side to the resilience conversation”. Professor of Resilient and Sustainable Built Environment (Māori Engagement) at Massey University, Regan says resilience is crucial for engineers, both in the way they protect their mental health and work with communities.

“Engineers have feelings, too,” he says. “We’re not solely concerned with cost-benefit analysis, but we also care about the environment and the long-term sustainability of the infrastructure we build.”

Engineers, particularly those working in disaster areas, are expected to bridge that gap themselves, he says.

“Acknowledging the emotional impacts experienced by engineers in disaster zones humanises their role and recognises their need for support.”

Regan is a structural engineer with more than 25 years’ experience in design and construction. Since 1996, he has also completed more than 200 humanitarian missions in 22 countries, working with the United Nations High Commissioner for Refugees (UNHCR) and international non-governmental organisations like

RedR and CARE (Cooperative for Assistance and Relief Everywhere). He’s been shot at numerous times and taken hostage twice, in Haiti and Pakistan.

Regan’s first deployment was in East Timor, during the massacres. “We were dumped straight in. There were dead bodies everywhere, they were killing nuns and priests. It was really, really bad.” Regan worked with UNHCR setting up refugee camps. For the next few years he worked with refugees in disaster zones around the world. The 2004 Indian Ocean earthquake and tsunami (which killed nearly 230,000 people) saw him go to Banda Aceh in Indonesia, to work with internally displaced people for the first time, and help them rebuild their communities. He’s worked in the Philippines and Gaza, plus the 2005 Pakistan, 2011 Christchurch and 2016 Kaikōura earthquakes.

These days he’s more likely to be in the field in Aotearoa, while training people overseas. Currently he’s working on assessing buildings and communities affected by the February flooding on the East Coast, and a bridge collapse and flooding on Aohanga Incorporation, a Māori farm near Dannevirke. Last year he trained soldiers in Thailand’s military, teaching them how to react in a hostage situation. In June, Regan took part in a review of Fukushima, the site of Japan’s 2011 nuclear power plant accident, following the earthquake and tsunami.

Regan says he’s seen colleagues “go AWOL” after being shot at, but he’s managed to keep himself safe.

“The support and emotional resilience that you need is based on awareness and education, pre-deployment training, post-deployment debriefing, access to mental health professionals, friends and colleagues, cultural sensitivity, and your own ongoing monitoring.”

His experiences have taught him adaptability and he's “hellishly flexible”. He has incorporated much of what he has learned and experienced in the field into his knowledge and teaching, including case studies and ethical discussions.

What is an engineer’s number one role in a disaster situation?

“Anything you can do immediately is good. It might be fixing roads, the water, housing, making temporary shelter.”

However, research shows that what engineers do in the field in a disaster zone is often not well-connected to a community’s needs, he says.

“We’ve got to better connect the work we do to strategic outcomes. You can build a house, but what people really need is a home.”

He says training is vital for ensuring engineers’ wellbeing, particularly simulation training based on real-world situations. And he believes that when possible, engineering firms should give employees the chance to do humanitarian work.

“The person who returns will be much more motivated.”

And it gives the profession meaning. “It makes engineering seem worthwhile.”

WRITER | KAITUHI RACHEL HELYER DONALDSONContinual learning is the most effective way to stay current and on top of our game as engineers. Here, some common member questions about continuing professional development (CPD) are addressed.

Committing to continual learning benefits members, the engineering profession, employers and wider society. CPD is an ongoing requirement to undertake education, maintain a current knowledge base and improve skills and knowledge.

Why are the Engineering New Zealand and Chartered Professional Engineer (CPEng) CPD requirements different?

Working members of Engineering New Zealand must complete 40 CPD hours each year, with a loosely defined mix of business and technical topics. The CPEng Competency Assessment Board requires a more closely defined mix of topics. An applicant with one field of engineering must complete at least 15 hours of technical CPD and another 25 hours of general studies – a minimum of 40 hours. An applicant with two fields of engineering must complete at least 15 hours for each field, plus another 25 hours of general studies – a minimum total of 55 hours.

We encourage you to record your CPD activities in the member area of engineeringnz.org, which can provide a career-long record of all your CPD activities. It is also the portal through which Chartered Members must submit

CPD records when requested for the purpose of a Practice Review. Also, it provides you with the facility to upload supporting information to verify your participation in CPD activities.

If you're an Emerging Professional Member following a Professional Development Partner (PDP) programme, the PDP will oversee the recording and signoff of CPD requirements. They will provide a declaration to Engineering New Zealand that you have met the requirements of our accredited programme.

You can also download a spreadsheet from the guidelines page of our website, under Engineer Tools then Engineering Documents/guidelines.

I have a limited CPD budget. How can I get at least 40 CPD hours?

Your CPD records could include formal education, formal courses and online modules, workshops, conferences and networking events, Engineering New Zealand branch or group activities, mentoring or volunteering, reading (including EG magazine), and on-the-job training. Completing a mix of learning activities each year covering business and technical skills will ensure you stay relevant and up to date. These all provide evidence of your ongoing professional development and count towards the requirement to complete 40 hours of CPD each year.

We have free online courses on core skills like Te Tiriti o Waitangi, diversity and inclusion, and personal

stress management. There are free specialist courses from the Earthquake Commission (EQC) including geotechnical assessments of residential land, how to write a geotechnical report, and complex EQC assessments. There is a free webinar on ethics. See the course calendar on the website under Learning and Events.

Events such as seminars on ethics or new developments in physics run by other learned societies may also count. Engineers must reflect, articulate and record how the activity developed their professional engineering knowledge and skills. In addition, YouTube videos on relevant technical topics may count. The key is to record the learnings from the videos.

Self-learning, such as reading and watching videos, should comprise no more than 50 percent of your CPD activities each year.

Does all my CPD need to be done in New Zealand, or can some be done overseas? Overseas conferences count. On-thejob training overseas counts. Overseas experiences that highlight ethical dilemmas count, with the “hours” required to reflect on and record the development of your understanding of professional ethics.

Cameron Smart CMEngNZ (Ret.)’s career has included a focus on earthquake defence by base isolation, finite element analysis, aircraft engineering and wind and ice loads on tall towers.

CAMERON SMART CMEngNZ (Ret.)As the University of Canterbury celebrates its 150th birthday this year, we look at the origins – and growth – of its engineering school.

The engineering school at Canterbury College provided New Zealand’s first formal engineering training. The school’s beginnings were humble and at its foundation in 1887, its future was uncertain.

In the 1880s, Christchurch was calling out for trained engineers to grow the city’s infrastructure. Concern over a lack of technical education for apprentices, engineering and industrial firms pushed for the establishment of an engineering school. Funding, however, was not forthcoming. The school's beginnings were modest, with no dedicated buildings or facilities and a staff of two part-time lecturers.

The first of these was Edward Dobson, a highly respected civil engineer who had played a key role in many of the city’s early infrastructure projects, including the Lyttelton Rail Tunnel and the Ōtira Gorge road. Edward was a reserved and modest man and, at the time of his appointment, was already in his early 70s.

The second was Robert Julian Scott, aged 26, ambitious and self-assured. Tall and broad, his personality was equally forthright. At the time of the school’s foundation, he was General Manager at Addington Railway Workshops in Christchurch and had several engineering achievements to his name. These

included the design of a 35-horsepower steam buggy – Australasia’s first motor car; a prototype insulated frozen-meat wagon; and designs for both the first New Zealand-built locomotive and oil engine. Robert was single-minded in his advocacy for the fledgling school and employed his personality, presence and connections to win support and funding. In 1890, he accepted the full-time position of lecturer in charge and until his retirement in 1923, drove the development of “his” engineering school with dedication and dictatorial verve.

The first courses the school offered were technical evening classes in mechanical and civil engineering. It was not until 1892 that students were able to enrol in a BSc(Eng) and take engineering papers as part of a degree-level course. The school continued to offer evening classes and for the next few decades, these were still the main classes taught. Engineering degree students would not exceed technical students until the late 1930s.

From its small beginnings, Robert pushed for further resources and recognition for the school. A mechanical laboratory was completed in 1891, although delays getting apparatus dragged until 1894. An electrical laboratory followed in 1902, and a hydraulics laboratory in 1914. A new wing with three laboratories plus a large drawing office was completed, equipped and opened in 1923, the year of Robert’s retirement.

His departure left a leadership vacuum and with no money for new equipment,

facilities or research, the school stagnated through the Great Depression and World War II. Even after his death in 1930, some staff were still using Robert’s notes to teach classes. The appointment of new staff in the late 1940s and early 1950s injected new energy, and student numbers increased greatly in the post-War period. Grants were received for a concrete laboratory and an extension to the soils and structures laboratories, but the school had long outgrown its city site and the next chapter in its development would begin at Ilam.

As early as 1945, the engineering school had begun looking at options for expansion. In 1947, the university council rejected the idea of moving the whole university to a new site, but changed its tune two years later after an engineering school staff member suggested acquiring land at Ilam. The Engineering School was the first to move and students attended classes at Ilam from 1960. The new buildings were designed to accommodate 450 students, but even as they opened, were already too small. Extensions were completed between 1965 and 1969. By 1987, the year of the school’s centenary, student numbers exceeded 900.

From uncertain beginnings, the school grew, adapted and diversified to become an integral part of the university and a cornerstone of engineering education in New Zealand.

Cindy Jemmett is Heritage Advisor at Te Ao Rangahau. Aerial view, Canterbury University College (c.1930).

Aerial view, Canterbury University College (c.1930).

In addition to our core product, steel sheet piles, we are now importing top quality, high spec Fibreglass FRP (fibre reinforced polymer) and Vinyl sheet piles from the US – the first NZ company to stock these on a consistent basis.

• Imported from USA

• Free CAD files available on our website

• Highest spec fibreglass

• Zero corrosion

Find out more and register at www.sheetpile.co.nz/for-engineers or email us at sales@sheetpile.co.nz

Last year saw the 50th anniversary of the influential Club of Rome publication The Limits to Growth, which analysed the potential consequences of exponential population growth and resource consumption within a finite world. It was revisited in the 1992 follow-up Beyond the Limits, which addressed criticisms and refined some of the modelling assumptions in the original publication. But the message was the same: we cannot continue on a business-as-usual basis. Yet we did, driven by our usual economic metrics.

In the face of worsening environmental outcomes, the concept of green growth gained prominence in the 2000s, culminating in the 2011 OECD report Towards Green Growth. It emphasised the need for economic growth to be compatible with environmental sustainability, and highlighted policy approaches that could promote both objectives. The key idea was we could still have economic growth as long as it was within ecological limits and we addressed environmental challenges.

The notions of a green economy and decoupling were specifically introduced by the United Nations Environment Programme, also in 2011. Decoupling refers to a relative reduction of resource use and an absolute reduction of environmental impacts while maintaining growth and improving human wellbeing.

Our engineering practices contribute to economic growth, but we need to have a holistic, systems perspective of the implications of those practices. It is not only about reducing the environmental impacts and resource use of our operations or the project that we undertake. We need to think about upstream and downstream

effects. How can we reduce environmental and social impacts in our supply chains, including outside our borders? What are the end-of-life impacts of our projects, of our assets, and of the derived products and services?

These considerations are implied in our code of ethics, and we’re responsible for weighing up options and making the right decisions from an overall sustainability perspective.

The global transition of the energy sector is a clear example of green growth. For Aotearoa, it’s projected the demand for electricity will increase significantly as we electrify the industrial and transportation sectors and produce new fuels such as green hydrogen. And our target of a net zero carbon emissions economy means we need to meet the demand with renewable energy sources and sufficient storage to deal with variability of supply and balance the power system. The next three decades will require significant investment in infrastructure, which implies economic growth. Our challenge, from a systems thinking perspective, is to ensure those investments are sustainable.

As green growth emerged, the concept of degrowth also gained traction. Coined in 1972, degrowth has been further developed with attempts to reimagine economic systems based on principles of sustainability, social equity and wellbeing, rather than perpetual growth. The argument is that green growth as a sole strategy for sustainability is simply not enough. Advocates point to research showing efforts to decouple economic growth have not succeeded and are unlikely to succeed. Degrowth is not favoured by politicians or industrialists. It means living better with less: reducing

consumption and resource throughput in the economic system by putting wellbeing ahead of profit.

Engineering practice includes strategic analyses and planning. We need to be proactive and inform the various sectors and organisations we work in, and society more broadly. Questions to consider include: what are the sunset and upcoming industries, technologies, processes, products and services? How can we transform some of those to reduce production and consumption? And how do we change our engineering practices accordingly? For example, planned obsolescence — techniques manufacturers use to reduce the life of a product — has been outlawed in France with the rest of Europe following suit.

We need to stay ahead of the law, consider what's ethically right, and make society and environmental wellbeing the metric that drives engineering decisions.