Issue | Putanga 27/2024

Home truths: resettling in New Zealand What’s it really like being an immigrant engineer in Aotearoa?

Go fourth and prosper Engineering and the fourth industrial revolution

From words to meaningful outcomes

What incorporating Te Ao Māori into engineering means in practice

Powering up

Addressing the energy trilemma: security, affordability and sustainability

Experience

Unparalleled

Enhanced

Effortless

stability, and

PLX20 ® by Prolam redefines innovation, offering unmatched strength, durability, and eco-friendliness. From garage lintels to ridge and floor beams, our steel-reinforced laminated timber beam sets new standards across the board.

Upgrade your projects with superior strength,

sustainability.

the benefits:

lighter

40%

strength and durability

spanning capability

installation, saving you time and hassle. Building better together PLX20® Lighter. Stronger. Smarter. prolamnz.com NZ designed & made

to PLX20® for projects that demand the best. Experience PLX20®

Upgrade

In this issue

I roto i tēnei putanga

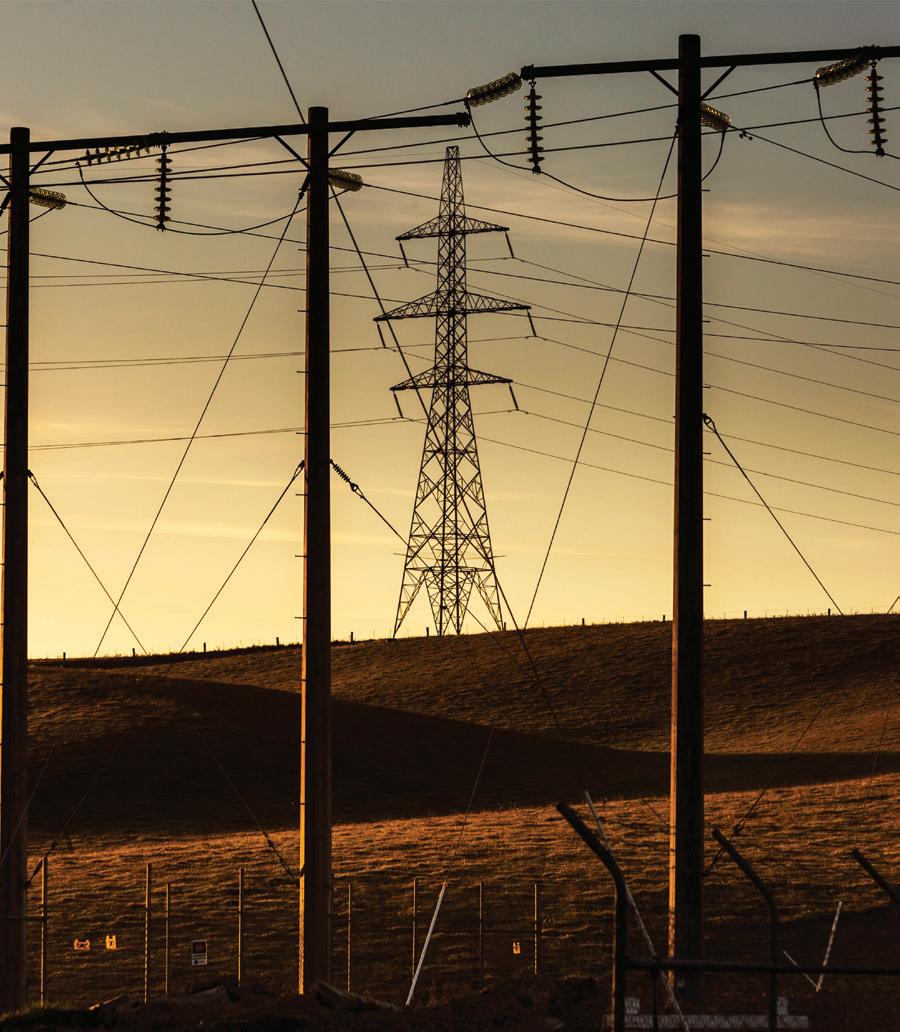

08 Powering up We're at a tricky transitionary point with our broader energy system, trying to balance affordability, sustainability and reliability.

14 Home truths: resettling in New Zealand What’s it really like being an immigrant engineer and what could improve the experience?

52 Inside job Why a machine safety engineer feels like on a typical workday.

60 Engineering genius

52 08 14 60

PO Box 12 241, Wellington 6144 New Zealand 04 473 9444 hello@engineeringnz.org engineeringnz.org

Editor Jennifer Black editor@engineeringnz.org

Designers

Angeli Winthrop Karlos Tui

Advertising sales advertising@engineeringnz.org 04 473 9444

Subscriptions hello@engineeringnz.org

Circulation

Magazine 360° Circulation for the 12 months ended 31 March 2022.

New Zealand 13,749

Print ISSN 2537-9097 Online ISSN 2537-9100

EG online

EG is available digitally for members on our website or through your EN.CORE app.

Printing

Your cover is printed on Forest Stewardship Council (FSC) approved and elemental chlorine free (ECF) paper. The inside pages are Programme for the Endorsement of Forest Certification (PEFC) approved and elemental chlorine free (ECF). EG is printed using vegetable-based inks made from renewable sources. Printing and fulfilment by Bluestar.

Please recycle your paper envelope – it’s 100% recyclable and made from PEFC accredited paper.

Disclaimer

Advertising statements and editorial opinions expressed in EG do not reflect the views of Engineering New Zealand Te Ao Rangahau, its members, staff, or affiliated organisations unless expressly stated.

This issue of EG was published in June 2024.

Features

Ngā āhuatanga

08 Powering up We're at a tricky transitionary point with our broader energy system, trying to balance affordability, sustainability and reliability.

14 Home truths: resettling in New Zealand What’s it really like being an immigrant engineer and what could improve the experience?

20 Go fourth and prosper How can Industry 4.0 technologies help manufacturers to work smarter, and is there a flow-on benefit for the way people view engineers?

28 “I want us to be part of the solution…” Dr Owen Catchpole FEngNZ on innovation and sustainability in the primary sector; AI and governance.

30 Healthy career goals The dual focuses of a bioengineer investigating the long-term effects of vaping and working to improve health equity for wāhine.

32 “We’re changing a city forever” Why the Central Interceptor project is more than just a tunnel.

Best practice

Ngā mahi papai rawai

40 A truckload of training tools How a new, award-winning training package could help bolster the number of Heavy Vehicle Specialist Certifiers.

41 Addressing complaints about complaints We've reviewed and improved complaints and disciplinary processes.

42 From words to meaningful outcomes What incorporating Te Ao Māori into engineering means in practice.

45 Elevating construction standards An updated construction contract and a new professional group hope to help drive lasting change in the construction sector.

46 Powerhouse for environmental action Why the Manapōuri hydro power station is significant for its engineering achievement and its social history.

48 Intersection

49 Common issues with producer statement PS4 Top queries about completing the producer statement PS4 – Construction Review

52 Inside job

54 Bedside table

55 Preview

56 Secret life of engineers

58 Leading questions

59 Obituaries

60 Engineering genius

Shorts Ngā tūhinga poto me ngā pito kōrero

Engineering Envy #136

Chosen by Te Ao Rangahau staff

Gore-Tex: United States

The simplicity of the diamond Gore-Tex tag attached to premium recreational wear since the mid-1970s belies the ingenious engineering behind the fabric. The use cases for Gore-Tex fabric include some of the most extreme conditions in all corners of the world, making the claim of “guaranteed to keep you dry” all the more bold. It’s no surprise, then, that Gore-Tex is one of the most sought-after features in gear that has to perform every day.

In 1958, Bill and Vieve Gore launched Gore in the basement of their Delaware home in the USA, where happenstance when experimenting with polytetrafluoroethylene (PTFE) led to the creation of Gore-Tex, the first breathable, waterproof and windproof fabric on the market.

It’s hard to top endorsements from NASA astronauts and Antarctic explorers. Despite this, Gore-Tex has continued to innovate and develop its product offering, while the well-proven engineering of their original fabric continues to be put to the test by extreme adventurers and everyday users alike.

I see Gore-Tex as a fusion of style and weatherdefying innovation. I love how their collaborations with streetwear brands keep you protected from the elements in style.

Karlos Tui – Graphic Designer

03

Photo: Gore-Tex/Christoph Siegert

The most wonder-ful way to future-proof the STEM industry

Foster the next generation of innovators in Aotearoa.

Partnering with the Wonder Project is a direct investment into New Zealand’s STEM future. Over 100,000 ākonga have been inspired with STEM through Engineering New Zealand’s free schools programme – and with your help, our impact can be even greater.

• Inspire thousands of ākonga with STEM each year.

• Secure the future pipeline of STEM professionals.

• Build confidence in kaiako and ākonga.

• Foster purpose and engagement with employees.

• Create social good across Aotearoa.

Let’s create the change that matters for your organisation, together.

Feed your wonder wonderproject.nz

Join the rōpū of organisations committed to inspiring the next generation with STEM.

@WonderProjectNZ

A rātou kōrero What they said Working for the profession

“It is almost impossible to design a bridge pier to withstand this kind of impact.”

Ian Firth, independent engineering consultant and past President of the United States’ Institution of Structural Engineers on the Francis Scott Key Bridge collapse in Baltimore, Maryland, USA.

“I thought no way is some girl from New Zealand going to win this award.”

University of Canterbury engineering graduate Alicia Smith is surprised to win a Distinguished Undergraduate Award from the Universities Space Research Association (USRA), becoming just the second non-American student to do so.

“I got a text in the morning saying, ‘You’re going to be working on Sophie’s leg’… It was the coolest second day of work ever.”

Goldmine mechanical engineer

Bex Lilley recalls being asked to fix Paralympic swimming champion Dame Sophie Pascoe’s prosthetic leg.

“Dael is an exceptional engineer and what was a concept he developed is now an operational system that we are deploying across the region.”

Tairāwhiti Emergency Management Group Manager Ben Green on Australian engineer and inventor Dael Liddicoat’s water desalination purification systems.

As I write my first EG column as President, I’m aware that when you read this, half of 2024 will have passed. Our new Board met for the first time in April and, in May, we reviewed progress and continued planning towards our goals.

The Te Ao Rangahau team has been busy meeting new Ministers, reviewing the complaints process, thinking about regulation, planning the budget process, and working on future plans for the Wonder Project – among other things. These items alone give you an idea of just how diverse the work of your members organisation is, and the articles in this edition of EG reflect that diversity.

In my work at the University of Canterbury we’re committed to Te Tiriti o Waitangi, aiming to embed what we can into our everyday work. See p42 for a thought-provoking article on incorporating a Māori world view into engineering practice. Te Ao Rangahau is committed to this, having released the Kimihia Rangahaua strategy in February, with the goal of embedding Te Ao Māori into the organisation and the engineering profession. Then on p48, a Q&A with New Year Honours recipient Naomi Manu looks at leveraging the untapped potential of mātaurangi Māori into working with engineers.

It gave me great pleasure when Te Ao Rangahau set up the Special Interest Group for Immigrant Engineers. I was once an immigrant, and while perhaps it was easy for me to settle in, that’s not necessarily the case for many immigrants. The article on p14 examines how we, collectively, could do better with integrating immigrant engineers, and valuing skills and differences.

Also in this edition, there’s an update on the improved complaints process with data to show that it is successful, and a look at the engineering complexities of addressing 150 years of environmental issues while future-proofing some of Auckland’s ageing infrastructure with the Central Interceptor project.

Finally, not everything we invent for the human race is for human good. Who could have seen that vaping would turn into an international problem when it was touted as solving the issue of smoking tobacco?

Bioengineer Kelly Burrowes explains how and why she’s looking to find definitive signs that vaping causes long-term harm.

I wish you all a peaceful Matariki and health and happiness in the months ahead.

Jan Evans-Freeman DistFEngNZ President, Te Ao Rangahau

06 EG 27/2024

8 Powering up 14 Home truths: resettling in New Zealand 20 Go fourth and prosper 28 “I want us to be part of the solution…” 30 Healthy career goals 32 “We’re changing a city forever” Features Ngā āhuatanga

Powering

WRITER | KAITUHI MATT PHILP

UP

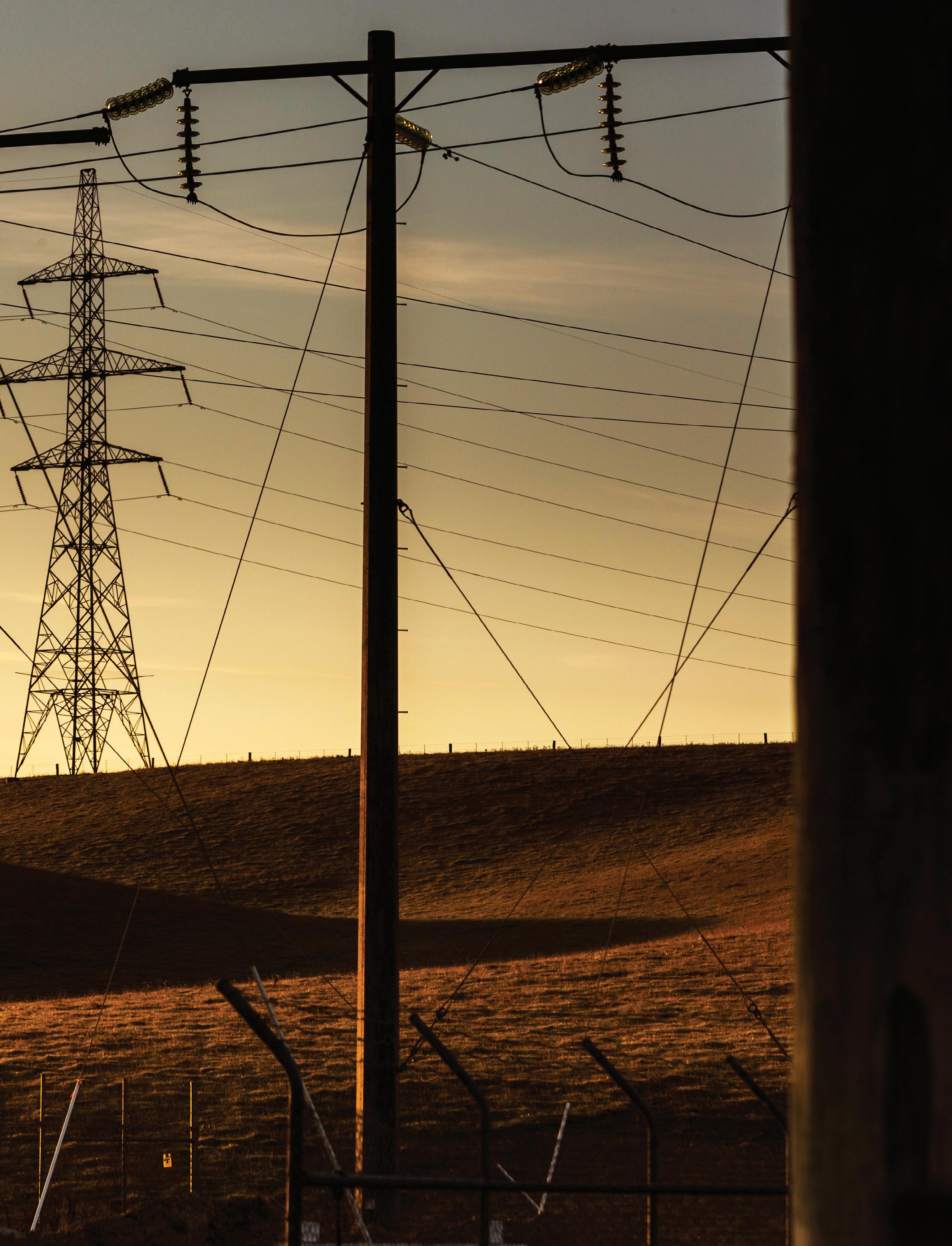

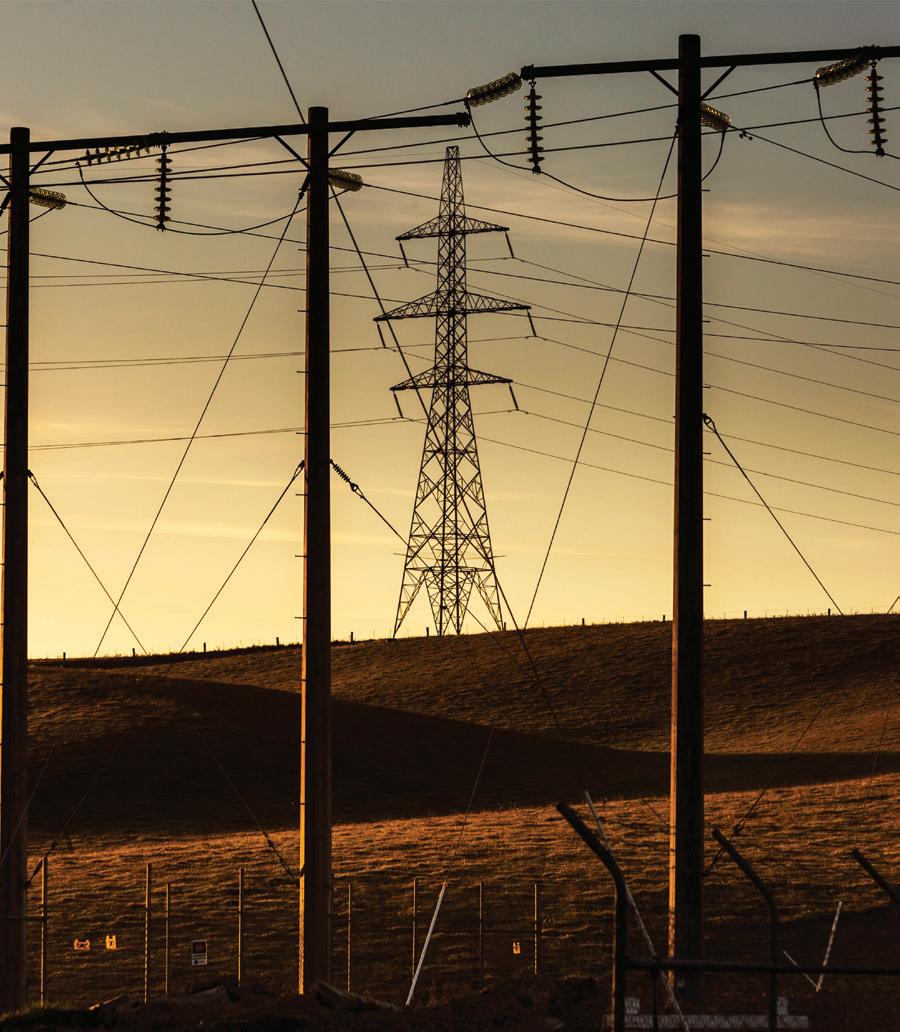

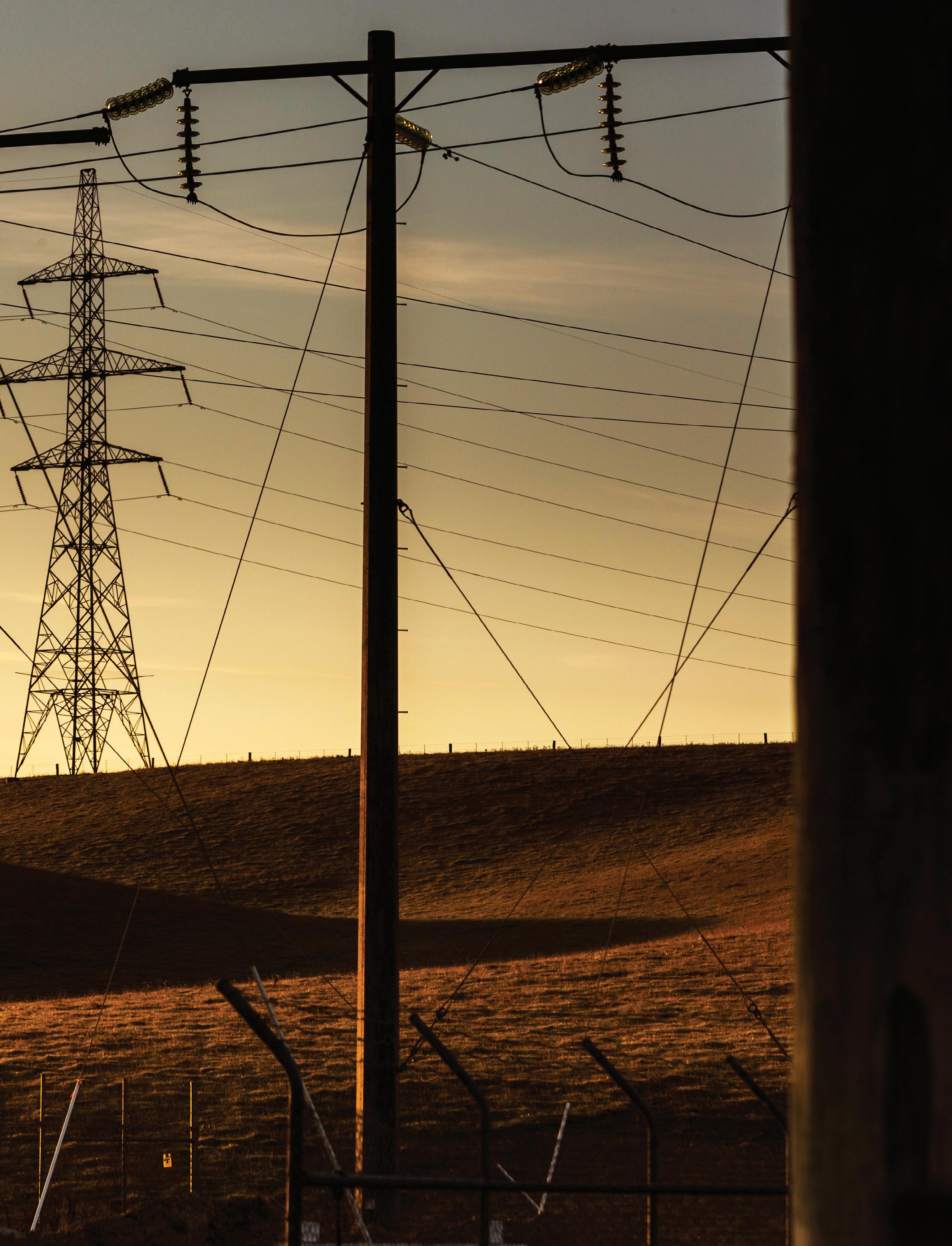

Timaru substation at sunset.

08 EG 27/2024

Photo: Transpower

Our future is electric, but getting there will be no picnic – in fact, there’s no guarantee we’ll be able to keep the lights on without interruption this winter. In its recent “Winter 2024 Outlook”, system operator Transpower identified a heightened risk of going short at times, warning that Aotearoa needs to accelerate investment in more “flexible” sources in our electricity system to cover peak winter demand.

09 Feature | Āhuatanga

We are in a tricky transitionary moment with our broader energy system, trying to balance security, affordability and sustainability – the so-called “energy trilemma”. According to the Climate Change Commission, by 2050 New Zealand needs to achieve 60 percent of energy needs from electricity (it’s currently around 40 percent). Renewable sources such as wind and solar will be key, but they are limited, and potentially put security of supply at risk due to their intermittency. Having enough thermal generation to bridge the gap – both for “firming” (maintaining output from variable intermittent supply) and “peaking” (managing peak demand) – looks increasingly problematic. Adding to the complexity, energy affordability is heading in the wrong direction, and we have a new government with a different take on how to meet the energy challenge, demonstrated by its rapid axing of the Lake Onslow pumped hydro scheme.

Factoring in risk

John Kidd, Director and Head of Research for research house Enerlytica, distinguishes electricity and gas from the rest of the energy system – electricity and gas being indigenous, with most of the balance being imported liquid fuels. Both are “tense”, but it’s electricity and gas that are the most stressed.

“The market is pricing a substantial level of risk into the next few years of supply,” he says.

Why the angst? That predicted dry winter for one thing. John points out that the past two winters have been unusually wet, which has meant less demand for gas and coal for firming. As a result, we were cushioned from the worst effects when Genesis Energy suffered a prolonged outage at its combined cycle gas plant at Huntly last July, followed by one of Contact Energy’s fast-start gas peakers in Taranaki being damaged. Both incidents underscored the system’s vulnerability to unanticipated outages, particularly at a time when demand growth in the upper North Island is exacerbating concern about having sufficient dispatchable generation capacity.

“We didn’t get the level of investment we needed at the right time to remove some of the stress we’re now seeing,” he says, citing the previous government’s offshore oil and gas ban, its targeting of 100 percent renewable electricity by 2030, and the Lake Onslow scheme as having a chilling effect.

Identifying vulnerabilities

Where are we most vulnerable? Transpower Executive General Manager Grid Development John Clarke FEngNZ says two things are in play. One is the dry year concern of not having enough energy in the system and suffering another 2008, when desperately low hydro lakes precipitated a national electricity conservation campaign.

10 EG 27/2024

The market is pricing a substantial level of risk into the next few years of supply.

– John Kidd

Opposite: Genesis Energy's Huntly Power Station has capacity of 1,200 MW.

Left: Genesis Energy plans to install up to 400 MW (800 MWh) of battery capacity at Huntly Power Station.

Photos: Genesis Energy

That crisis led to changes for Transpower – among other things it began publishing an annual security of supply assessment – and to the market to better manage this risk. John believes those reforms make a repeat of 2008 unlikely while our large gas- and coal-fired thermal generators in the North Island are still in service.

More concerning for Transpower is the risk of coming up short when demand spikes and perhaps wind suddenly falls away or there’s an equipment failure somewhere. It’s a short-lived problem and may involve only a handful of mid-winter nights and mornings, “… but the consequences are serious if you have to turn off people’s power because you run out of capacity”.

We shouldn’t underestimate the effect of the intermittency of wind and solar on the system. Across a fortnight in March, the capacity factor of wind averaged

17 percent in the first week and 50 percent the next –“which is a massive swing” says John Kidd. Part of the answer is to build more flexible, rapidly dispatchable electricity for “peaking” – juice the system can call on immediately at times of particularly high demand. That’s not necessarily gas-fired – John Clarke cites resources such as grid-scale batteries, and John Kidd says Mercury Energy’s Waikato River hydro system could operate more as a peaking plant, assuming there was additional generation to cover baseload.

Batteries or gas to the rescue?

The batteries are coming – for example, Meridian Energy is building a 100 MW system at its Ruakākā Energy Park near Marsden Point. And there have been recent demand-side developments, including an agreement between Meridian and Tiwai Point, as well as Contact Energy’s deal to supply flexible off-peak power to New Zealand Steel at Glenbrook. But gas-fired peaking is going to be vital for at least another decade.

In fact, there’s a school of thought that we need to build more of it. But that’s not going to be an easy ask. Gas fields are in sharp decline, and investors aren’t exactly queuing up to finance thermal power plants.

“The capital markets in New Zealand have started applying significant ESG [environmental, social and

11 Feature | Āhuatanga

governance] factor discounts to share prices where companies are investing in assets and fuels with a heavy carbon footprint, which means no one is investing in the generation needed to deliver reliability,” says Genesis Chief Executive Malcolm Johns.

“That’s not a 2024 and 2025 winter problem, it’s an ongoing 25-year problem for the system because we’re relying heavily on intermittent solar and wind to get us to that 60 percent target.”

He notes that his company’s Rankine units at Huntly, which have a combined capacity of 750 MW, can’t respond quickly to sudden need. “Is there enough generation to cover off winter peaks at the moment? Yes. Do we have the market mechanisms to utilise that generation? No, we don’t. Do we have enough firming capacity in the system for what we need to do over the next 25 years? Doesn’t look like it. Those are the challenges in front of us.”

The key targets, he argues, are 60 percent electrified and 100 percent reliable, and we should accept that the last three to five percent will come from non-renewable sources, at least during this transitionary phase. In May, Genesis announced it expects to be buying coal again by the end of the year “to keep the lights on” for customers in the light of reduced gas supplies and increasing demand.

Increasing generation capacity

Beyond the peaking and firming question, we simply need to build more generating capacity, adds John Kidd, who likes the Government’s talk of fast-track consenting.

“You need to enable as much generation of any format as you can to come into the system as quickly as you can, because that takes away the burden of peaking.”

It is happening, albeit slower than many would like. Genesis, which is targeting 95 percent renewable generation by 2035, will spend $1.1b over the next seven

Improving security of supply

The Electricity Authority is as concerned as anyone about the capacity issue heading into this winter, particularly short-term challenges due to equipment failure or wind dropping away during peak demand. But it is also engaged in planning to mitigate risk as we add more wind and solar. Among its solutions to improve security of supply in the near term are improved wind forecasting and enhanced dispatch notification. Looking further ahead, “Incentivising flexible resources such as battery energy storage systems, demand response and new commercial markets will play a critical role in meeting the flexibility challenge,” says Manager Operations Policy Chris Otton, adding that the Authority has ongoing work programmes focused on the evolution of the wholesale market and the future operation of the system.

years to build solar and wind plants, and plans a gridscale battery at Huntly. It’s also investigating the case for running the Rankines on biomass, with an answer expected this year.

Meanwhile, Contact Energy has invested more than $1.2b in its new Tauhara geothermal power station at Taupō and to extend its Te Huka plant, for a combined 225 MW of additional baseline electricity. The company is contemplating a similar investment to replace its original Wairakei geothermal plant, says CEO Mike Fuge CMEngNZ, “… and we have further geothermal opportunities beyond that, as well as a pipeline of potential wind, solar and battery plants”.

Resilience and affordability

Achieving a reliable power system isn’t only about generation capacity, however. The network is vulnerable to natural disasters, and much of the infrastructure dates to the 1970s, 1980s and 1990s. Transpower has sought $40m per year to “harden” critical older sites, and is focused on resilience in planning for the grid’s expansion through the 2030s and beyond.

“Particularly in the central North Island, when building new transmission routes you have an opportunity to make sure there’s a diversified network,” Transpower’s John Clarke says.

As for the affordability question, Genesis’ Malcolm Johns reckons the key is efficient delivery.

“Getting the right capital deployed at the right time over the next 25 years will be the most impactful thing we can do for electricity prices,” he remarks. He adds there will also be a greater role for demand response as businesses and homes electrify.

We will support our customers to contribute to affordable grid security in ways that work for them.”

12 EG 27/2024

Chris Otton. Photo: Supplied

Left: First steam at Contact’s Tauhara geothermal power station in Taupō.

Above: Mike Fuge CMEngNZ, Contact CEO.

Below: Tauhara will house the world’s largest single shaft geothermal steam turbine.

Left: First steam at Contact’s Tauhara geothermal power station in Taupō.

Above: Mike Fuge CMEngNZ, Contact CEO.

Below: Tauhara will house the world’s largest single shaft geothermal steam turbine.

13 Feature | Āhuatanga

Photos: Contact

Home truths: resettling in New Zealand

14 EG 27/2024

What’s it really like being an immigrant engineer in Aotearoa and what could improve the experience?

WRITER | KAITUHI RINA DIANE CABALLAR

15 Feature | Āhuatanga

Aotearoa’s engineering skills shortages are a perennial issue. The industry is working to fill the gap, with some companies searching offshore to attract migrant engineers. The government is doing the same, listing engineers amongst the highly skilled in-demand roles for immigration into New Zealand.

Yet migrant workers can confront barriers to living and working in Aotearoa, including housing overcrowding, scam job offers and exploitation. They also often encounter hurdles when searching for jobs, from downgraded qualifications and positions, to employers failing to recognise their overseas work experience and highlighting their lack of local experience.

Hailing from Sri Lanka, Dr Rajika Jayaratne FEngNZ CPEng IntPE(NZ) arrived in Aotearoa in 2000 armed with a scholarship for a PhD in civil engineering at the University of Auckland. Soon after completing her doctorate in 2003, she was hired – but only as a graduate engineer.

“It was disheartening and felt like a step backward,” Rajika says. Yet she decided to demonstrate her ability through hard work, routinely clocking 50-to-60-hour weeks. It was a conscious strategy to prove her potential and commitment.

Throughout the following decade, Rajika brought her strong work ethic to every position, steadily building up her reputation. While some colleagues offered support, others revelled in pointing out her differences – her accent, her attire and even her cultural mannerisms.

But Rajika forged on. In 2012, she transitioned to consultancy, establishing her own water resources engineering consultancy firm. Breaking into the field proved difficult.

“The big players had a lock on the good clients, and everything revolved around connections, which I simply didn’t have.”

Landing her first project opened doors, and Rajika’s clients hired her for her expertise in strategic planning, hydraulic modelling, water infrastructure design and environmental problem-solving. Gradually, she carved a niche for herself in the industry.

Just as her company was gaining momentum, the Covid-19 pandemic struck. Clients dwindled and Rajika made the tough decision to shift gears, taking a full-time position as a stormwater engineer at NZ Transport Agency Waka Kotahi (NZTA).

16 EG 27/2024

Dr Rajika Jayaratne FEngNZ CPEng IntPE(NZ). Photo: Tim Hamilton/VisionWorks Photography

Rajika says she would have found it helpful if there had been a community for immigrant engineers when she was a new migrant about 25 years ago.

“We have to help each other – it’s the only way to overcome all these struggles and barriers.”

Helping immigrant engineers settle in

That community now exists through the Special Interest Group for Immigrant Engineers (SIGIE), a Te Ao Rangahau initiative that spun out of efforts to provide training courses for immigrant engineers. With more than 1,000 members including Life Members Zaid Essa MEngNZ and Remi Cruz CMEngNZ CPEng IntPE(NZ), it provides a networking opportunity for immigrant engineers, and offers professional development, employment and career counselling, and a range of other support, including a conference.

“We’re from all over the world, and it just goes to show that New Zealand is attractive for talent around the globe,” says Steven Wang CMEngNZ CPEng IntPE(NZ), Building Services Team Leader at GHD and Chair of SIGIE, who moved to New Zealand at a young age.

I learned how to navigate cultural nuances and overcome biases. I learned a lot not only as an engineer but as a human being.

– Dr Rajika Jayaratne

“Having been through the same experiences ourselves, we’re passionate about giving back to the community. The sooner we get immigrant engineers onto their feet, the sooner they can make contributions to New Zealand, and we all benefit from that.”

Steven encourages immigrant engineers to join SIGIE, which is free, even before they arrive in Aotearoa.

Enhancing the immigrant experience

Both employers and other engineers in Aotearoa play a key role in helping improve the immigrant engineer experience.

“By embracing diversity, they understand the value and contributions that immigrant engineers can bring,” says Steven.

For Rajika, it’s about acknowledging and taking into account qualifications, knowledge, skills and expertise, even if these were gained abroad.

Above: Steven Wang CMEngNZ CPEng IntPE(NZ), Chair of the Special Interest Group for Immigrant Engineers. Photo: Tim Hamilton/VisionWorks Photography

Above: Steven Wang CMEngNZ CPEng IntPE(NZ), Chair of the Special Interest Group for Immigrant Engineers. Photo: Tim Hamilton/VisionWorks Photography

17 Feature | Āhuatanga

Below: SIGIE Conference 2022 presenters. Photo: Supplied

“Immigrant engineers bring a wealth of experience and expertise and it’s crucial for employers and fellow engineers to acknowledge and respect this,” Rajika says.

“We possess not only technical skills but also valuable interpersonal and teamwork abilities cultivated through our professional journeys. While our prior experiences may differ from those in New Zealand, we are quick learners and adept at adapting to new environments. Despite not having identical backgrounds, we are far from being novices in our field. Instead, we offer a diverse perspective and a rich blend of skills acquired from various contexts. By recognising and embracing the contributions of immigrant engineers, New Zealand can harness the full potential of its engineering workforce and foster a more inclusive and innovative industry."

Arno Nothnagel, Immigration Director – New Zealand at the Absolute Immigration agency, notes that having a detailed induction plan and training process in place sets the tone for employing immigrants. Providing feedback mechanisms via employee surveys and one-on-one chats can also help employers better understand staff, leading to increased retention.

Arno advises employers to supply certain helpful information before the immigrant employee arrives in the country. This means things like links to websites or guides on living in Aotearoa and the cities they’ll be staying in, as well as details about the basics of settling in, including how to get an IRD number, set up a bank account, find a rental property and access healthcare.

A buddy system also helps familiarise immigrants with New Zealand culture and how the workplace functions. “Link them up to a staff member from the same country or region, and even community groups for their country or region.” He adds that English assistance can help with language barriers and learning the nuances specific to New Zealand, such as the Kiwi accent, the speed of speaking and common slang words.

“Hiring people from other countries brings different ways of thinking and doing,” says Arno. “It brings overseas knowledge and skills that can contribute to the workplace in New Zealand and create connections.”

While Rajika compares her journey to a roller coaster ride, she still views her career path as fulfilling.

“I learned how to navigate cultural nuances and overcome biases. I learned a lot not only as an engineer but as a human being.”

When she became a Fellow of Te Ao Rangahau in 2023, Rajika considered it a huge honour.

“I feel proud as a brown woman getting to this level, and I want to do the same for the next generation of immigrant engineers, guiding them to attain the same achievements I have.”

18 EG 27/2024

Opposite: Structural drafter Mohammad Fahim Mazuri (left) was introduced to mentor Alex Leo MEngNZ (right) through the New Zealand Red Cross Pathways programme. Photos: Supplied

Supporting former refugees

Mohammad Fahim Mazuri worked as a structural engineer and drafter in Kabul, Afghanistan, after graduating with a bachelor’s degree in civil engineering in 2016. But six years later, he arrived in Aotearoa after fleeing Afghanistan following the Taliban’s government takeover.

“It is so difficult to leave everything behind – the place you grew up in, the people you love,” Fahim says.

“But I had hope that I will find a new life and opportunities in a new environment.”

Through the New Zealand Red Cross Pathways to Employment scheme, Fahim was introduced to Alex Leo MEngNZ, Senior Associate – Civil Engineer at Beca. Alex mentored Fahim, showing him how to update his CV and write his cover letters, and coaching him during mock interviews. “He told me so much about New Zealand work culture, and it was so helpful for me. He’s a great mentor and a great person,” Fahim says.

The Pathways to Employment scheme started in 2011 as a service designed to provide specialist advice and support to former refugees and those with a refugeelike background, helping them gain sustainable and meaningful employment.

“One of the major markers of successful resettlement is employment, and for people to rebuild their lives in a new country, they need to be economically independent,” says Samantha Jones, New Zealand Red Cross Manager Migration Employment.

“Even though former refugees come with high motivation and lots of work experience offshore, it can be difficult for them to break into employment because their

qualifications may not be recognised,” Samantha says.

Beca has been part of the Pathways to Employment scheme for the past seven years, with Alex at the helm.

“As an employer and company, we want to contribute to our communities beyond just engineering,” he says. “And for me, it’s a way to give back. It’s rewarding to help and watch people go from being nervous to confident. There’s this myth that people who come here as refugees are a burden on the country, but they’re incredibly driven and want to contribute to the country they are part of.”

Aside from helping former refugees in the scheme through the employment process, Beca also advises young former refugees or those born in New Zealand with former refugee parents in charting a path towards engineering.

“It’s that kind of specialist insight that they can provide us and that we want to tap into,” Samantha says. New Zealand Red Cross is looking to widen its pool of partnering engineering firms.

“We can help match people with available roles –from an internship to full-time permanent employment,” says Samantha.

“We provide support to employers and help bridge the cultural gap. Employers just need a willingness to work with people from culturally diverse backgrounds.”

Fahim now works as a structural drafter at Kordia, a technology solutions provider.

“I’ve started a new life in New Zealand, and professionally, I want to become a Chartered Professional Engineer,” he says. “I also want to be a mentor just like Alex, helping my community of migrants and refugees.”

19 Feature | Āhuatanga

fourth and prosper Go

20 EG 27/2024

How can Industry 4.0 technologies help Aotearoa’s manufacturers to work smarter, not harder, and is there a flow-on benefit for the way people view engineers?

WRITER | KAITUHI RACHEL HELYER DONALDSON

21 Feature | Āhuatanga

From making chocolate chips to computer chips, Aotearoa’s diverse manufacturing sector contributes $23.28b to our gross domestic product. It directly employs 222,400 people and accounts for more than 60 percent of the country’s total export value, according to the Technology Investment Network’s (TIN) New Zealand Advanced Manufacturing Report 2023. The sector includes household names like Fisher & Paykel Healthcare, large firms such as precision manufacturer Buckley Systems, Red Stag Timber and smaller operations such as iwi-owned milk processing company Miraka and sustainable knitwear brand Untouched World.

The country’s top-earning manufacturers are “working smarter not harder” by deploying Industry 4.0 technologies, the TIN report notes. Industry 4.0 – or the fourth industrial revolution – involves greater automation, with smart technologies (for example robotics, digital twins and artificial intelligence [AI]) and data combining to monitor and control processes in real time. As well as increasing productivity by as much as 30 percent, advanced technologies can help overcome geographical disadvantages, boost profitability, enhance competitiveness, reduce carbon emissions and help to generate higher-value jobs by automating lower-level tasks.

There’s still a perception in New Zealand that manufacturing is a dirty, basic industry and it’s all men.

– Sarah Ramsay

But industry observers warn New Zealand is 10 years behind Europe in adopting these technologies. The nowdefunct Productivity Commission found local companies are working harder than many overseas rivals, yet creating less value.

Industry undergoing “a fundamental shift”

Those who fail to embrace smart processes and products will get left behind, says Advanced Manufacturing Aotearoa (AMA) Chief Executive Catherine Lye.

“It is a concern. Industry is undergoing a fundamental shift with the application of these advanced technologies, but New Zealand manufacturers are a laggard.”

Left: New Zealand's manufacturing industry accounts for more than 60 percent of the country’s total export value.

Above: Advanced Manufacturing Aotearoa Chief Executive Catherine Lye. Photo: Supplied

Opposite: CNC Machinist Matt Topping proves out a component on the Mazak VARIAXIS fully automated machining centre.

Photo: United Machinists/ Graham Warman

Photo: New Zealand Story

22 EG 27/2024

Catherine says the key is to support manufacturers by raising awareness and understanding of these technologies and then accelerating investment and adoption.

She admits significant investment is required while it can also be “… overwhelming, particularly for smaller firms, to wrap their heads around all the different options”. Catherine says the AMA will play a key role in strengthening the country’s manufacturing network. The aim is to support the adoption of smart, modern technologies and processes that enable a more productive, sustainable and globally competitive sector.

“...we need to make engineering sexy again”

Meanwhile, the Minister for Small Business and Manufacturing, Andrew Bayly, has set up a Manufacturing Productivity Advisory Group (MPAG) comprising industry people and strategic thinkers to look at funding opportunities. A key priority is addressing the way the industry is viewed.

MPAG is chaired by United Machinists Chief Executive Sarah Ramsay, who says it has become rapidly apparent that manufacturing “is not a sector in itself but a function that underpins all of New Zealand’s major export sectors”.

“There’s still a perception in New Zealand that manufacturing is a dirty, basic industry and it’s all men. We don’t associate it with making rockets or pharmaceuticals or healthcare – all industries where there’s so much innovation and opportunity.”

She says the out-of-date stereotype affects how the sector is seen by students and schools, as well as investors.

“We need to directly address this: we need to make engineering sexy again.”

Sarah says this doesn’t need to be costly, citing Engineering New Zealand’s Wonder Project, the schools programme which aims to inspire rangatahi with science, technology, engineering and maths, as an example of a “fantastic” initiative.

She adds that micro-credentials, obtained via shortburst training, offer qualifications in new technology that can help the existing workforce upskill.

23 Feature | Āhuatanga

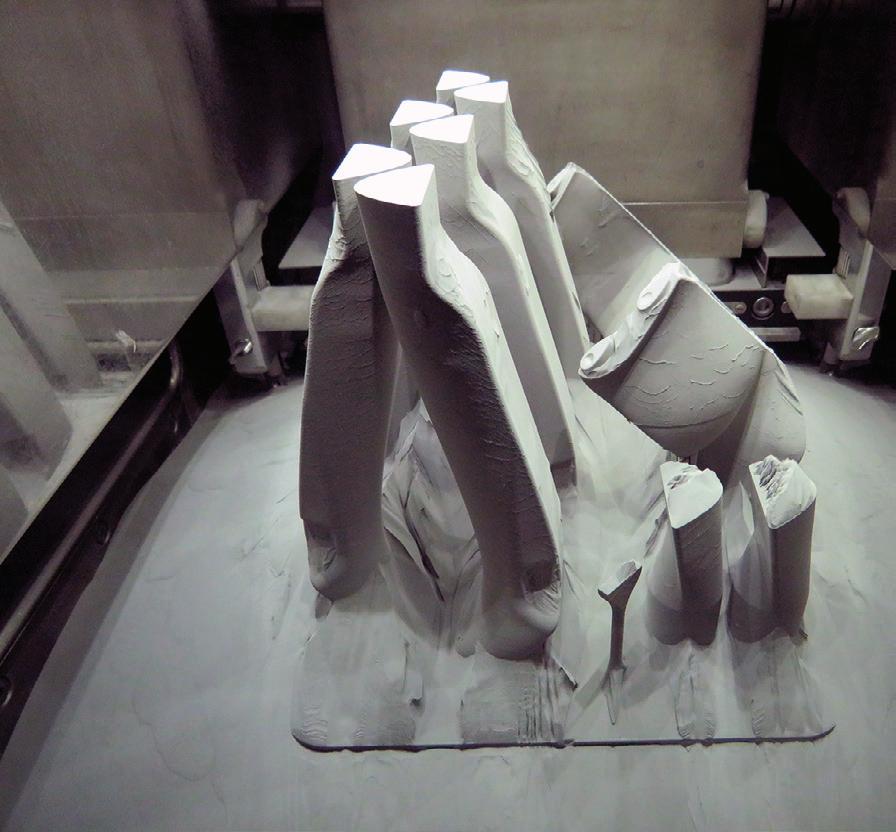

A “learning factory” for students and industry

Professor of Smart Manufacturing Dr Xun Xu FEngNZ is the only non-industry person invited to be part of MPAG.

In 2016 Xun, hailed as one of the world’s most influential professors in smart manufacturing by Smart Manufacturing magazine, set up Aotearoa’s first and only Industry 4.0 laboratory at the University of Auckland’s Department of Mechanical and Mechatronics Engineering.

He wanted to create a “learning factory” for both future engineers (students and postgraduates) and industry. Unlike most research labs, Laboratory for Industry 4.0 Smart Manufacturing Systems (LISMS) is like a miniaturised factory. Conveyor systems and machine tools whir away as robots direct parts.

“It provides a unique setup to learn about advanced manufacturing technologies, and it also serves as a ‘testbed’ for companies to come and try out different

industry 4.0 technological solutions in an environment that is akin to their own.”

Up to 30 companies annually visit the lab, which often results in collaborative projects. LISMS’s clients include ABB, Air New Zealand, Ports of Auckland and Fletcher Steel.

An example of such an industry-based project is developing an inspection system for ABB in Napier, which wanted to automate its inspection processes of a uninterruptable power supply (UPS) chassis to avoid errors and repeats. The students developed a bespoke, low-cost, easy-to-operate solution – and trained staff –after an earlier foray into robotics proved too expensive.

Xun says robots are good, as long as companies can afford them, train their staff and use them to their full potential. But many New Zealand businesses are “small to micro-sized” with very low capital intensity. A low-cost digital solution is often more fit for purpose.

When one job is automated, another job is often created. It may not be in a similar area, so factories need good re-skilling programmes.

– Xun Xu

LISMS is also looking into how technologies can be developed for sustainable manufacturing, particularly considering workers’ welfare. For example, human-centric automation is demonstrated by operators working with, and supported by, collaborative robots, or co-bots.

Xun says humans are still needed for some more complex and highly dexterous tasks.

Automation could mean that fewer people would be needed to perform some repetitive jobs in a factory, but businesses need to look after their workers.

“When one job is automated, another job is often created. It may not be in a similar area, so factories need good re-skilling programmes.”

Starting “... before Industry 4.0 was a term”

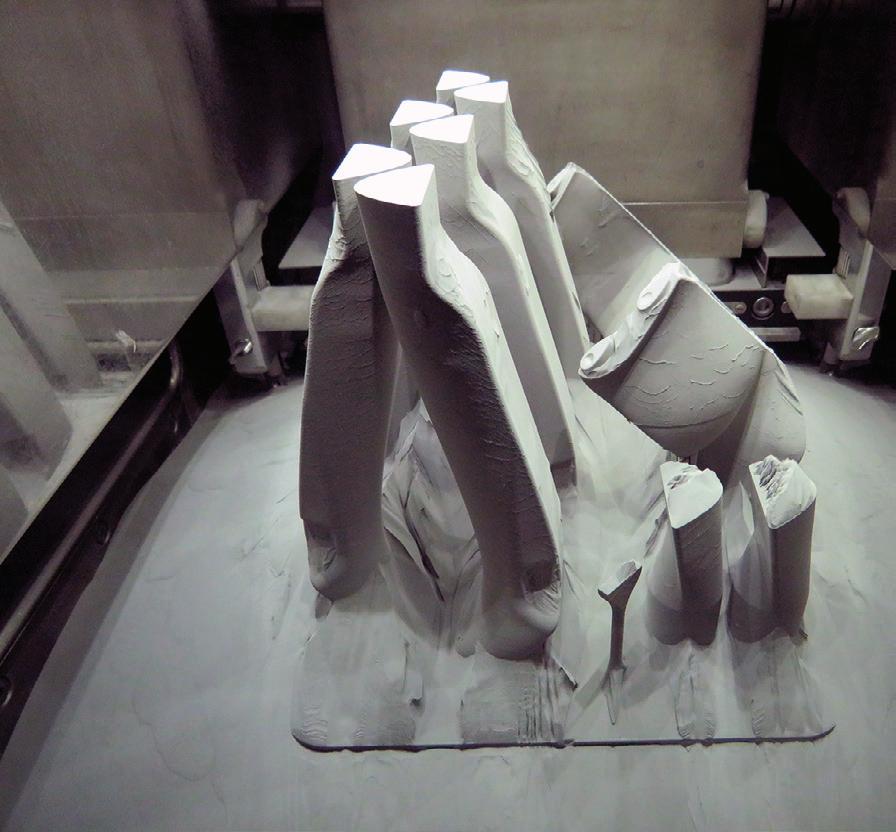

Tauranga’s RAM3D (Rapid Advanced Manufacturing 3D), a large provider of additive manufacturing, was a pioneering Australasian firm when it began developing metal 3D printing in 2009.

“It was exceptionally early days. We started well before Industry 4.0 was a term,” says Director Warwick Downing.

Additive manufacturing offers a more agile and efficient way to produce complex metal parts that are lighter and stronger, and cost less.

The next few years were “a big learning curve” for both the start-up and prospective customers.

“After a number of years building our knowledge and a customer base, we started RAM3D in 2013 to take the technology to market.”

More than a decade later, RAM3D has 11 staff and 13 machines. Around 80 percent of its work is offshore. It includes projects in aerospace, cycling and defence.

Some 8,000 RAM3D-manufactured components have been launched into space, including a current project which put sensors on the moon. Meanwhile, its bespoke handlebar extensions are used by many Tour de France cyclists as well as the New Zealand track-cycling team.

Design and analysis are key to creating leading-edge components. Humans still need to have an input “to maximise effectiveness” in manufacturing, says Warwick.

“New technologies are enabling new performance standards, but if you don’t understand what you’re trying to achieve, you won’t get there.”

24 EG 27/2024

Above: The “learning factory” inside the Laboratory for Industry 4.0 Smart Manufacturing Systems.

Far

Titanium handlebar extensions being removed from the machine after laser powder bed fusion printing.

Full strength titanium components ready for action in top cycling events.

Photo: ©University of Auckland

left:

25 Feature | Āhuatanga

Left:

Photos: RAM3D

Creating the “Machine shop of the Future”

Sarah and Alex Ramsay are second-generation owneroperators who bought their Dunedin-based precision machining company United Machinists from Alex’s parents in 2016, with the aim of creating the “Machine shop of the Future”.

It’s a thriving example of why companies need to combine engineering skill with strategic leadership.

Sarah says Chief Technical Officer Alex is an “incredible tradesperson” who started helping in the workshop as a four-year-old.

Meanwhile, Chief Executive Sarah brings the commercial nous as a former business consultant who previously owned a marketing agency.

A self-described “high school drop-out with no formal education”, Sarah is now an award-winning business leader who holds numerous governance positions and writes a fortnightly column for the Otago Daily Times But, she says, her most unusual achievement is applying things that are common practice in other sectors to manufacturing.

In 2018, she set about establishing the company’s brand. A year later the firm started on its Industry 4.0 journey by moving to a fully automated, digital scheduling system using Enterprise Resource Planning software.

Having better control of data and greater visibility of workflow has boosting earnings substantially.

“In the first month we realised we were losing money

on 45 percent of our jobs, and now it’s about three percent.

“We were under-estimating. Engineers constantly undervalue how brilliant they are.”

The money saved helped fund a new workshop in 2020, with a lights out 24/7 manufacturing facility, whereby robot and automation systems operate on their own.

It also allows the company to keep investing to grow their precision machine capabilities, automating wherever possible. United Machinists has started to move into processes like 3D printing, engraving and anodising.

Clients include Shotover, which designs high-performance camera systems used on the likes of the X-Men movies. Automation has opened it up to new sectors such as aerospace, defence and medical technology.

Sarah says the team is “no longer suspicious about AI taking their jobs, but excited” AI will do the bulk of the “grunt” quoting and programming work while they upskill and move into more challenging roles.

United Machinists has grown “significantly” on the back of its investment in Industry 4.0: it has increased staff by 50 percent, while more than doubling revenue and profitability.

“That’s a pretty good metric. We never could have done that without automation.”

Nor, she adds, do staff need to work overtime.

“What I see go wrong in industry so often is that these programmes and implementations aren’t being done to bring everybody along for the ride.”

26 EG 27/2024

Right: Alex and Sarah Ramsay, owner-operators of United Machinists. Photo: Supplied

HIGH SPEC IMPORTED FIBREGLASS & VINYL SHEET PILES

In addition to our core product, steel sheet piles, we are now importing top quality, high spec Fibreglass FRP (fibre reinforced polymer) and Vinyl sheet piles from the US – the first NZ company to stock these on a consistent basis.

• Imported from USA

• Free CAD files available on our website

• Highest spec fibreglass

• Zero corrosion

Find out more and register at www.sheetpile.co.nz/for-engineers or email us at sales@sheetpile.co.nz

“I want us to be part of the solution…”

WRITER

| KAITUHI ALEXANDRA JOHNSON

Chemical engineer Dr Owen Catchpole FEngNZ on innovation and sustainability in the primary sector; artificial intelligence, and why more engineers should go into governance.

Early on in his adult life, Dr Owen Catchpole FEngNZ knew he wanted to become a chemical engineer.

“I took chemical engineering at university because I wanted to do chemistry at a large scale and for my work to be of benefit to New Zealand,” he says.

After several decades in the profession, it is clear he has done just that. Team leader in the Food Processing Technology team within the Biotechnologies research group at Callaghan Innovation, where he is also Chief Engineer, last year he was awarded the Scott Medal by Royal Society Te Apārangi for being a world leader in the development of processes to extract highvalue bioactive chemicals from biological materials. In 2022, he was made a Fellow of the Royal Society, the first scientist from Callaghan Innovation to receive the honour.

Following the completion of his Bachelor of Chemical Engineering at the University of Canterbury, Owen says he had to complete some practical projects, which he did at the Department of Scientific and Industrial Research (DSIR).

“When my academic results came out, serendipitously, two chemical engineers were leaving, and I was offered a job. We had a client at the time who had a vision of making low-fat, low-cholesterol meat,

and also a cholesterol-free butter, and he thought that supercritical extraction might be a way to do that.”

He continues: “We were seeing a number of R&D articles emerge on supercritical extraction and companies that were pioneering it in Europe and the US. My job was to design and build some lab-scale equipment from scratch, to learn out how to apply this technology.”

I took chemical engineering at university because I wanted to do chemistry at a large scale and for my work to be of benefit to New Zealand.

Supercritical extraction is a process that uses carbon dioxide at high pressure to extract natural products from biological materials. Because any residual carbon dioxide evaporates after processing, there is no contamination in the finished product, unlike with traditional petrochemical solvents.

Realising the potential of the technology, the DSIR funded Owen to complete a PhD in supercritical extraction at the University of Birmingham, “to learn from experts in

Europe and bring that knowledge back to New Zealand”.

On his return, Owen began to make larger-scale equipment, followed by a commercial-scale extraction plant hired to a start-up called Supercritical Extraction New Zealand Limited.

“There was a range of high-value seed oils we helped them make in those early days, such as evening primrose and borage seed oil. We also helped them make an extract from totara heart wood that was used in cosmetics, which we actually made from old fence posts.”

Owen says the technology has greatly expanded since then.

“There’s a large supercritical extraction plant in Nelson. One of its main products is oil from green-lipped mussel powder, but it also produces hop extracts for making beer and other extracts for nutraceutical and functional food applications.”

He adds: “The great advantage of CO2 extraction is that it’s solvent-residue-free and these high-value extracts now make millions of dollars of revenue for New Zealand per annum.”

More recently, the process has been applied to extracting cannabinoids from cannabis and hemp.

From the micro to the macro, Owen has widened his focus on the primary industry as a whole, as he helped initiate the Bioresource Processing Alliance to create a best-team, best-equipment approach to solving byproduct problems for industry.

“Our main goal is to recover more value out of byproduct streams from

28 EG 27/2024

primary industry – byproducts that would otherwise end in very low value applications or in a landfill. We also want to reduce the use of fossil fuels and water.”

He says one outcome by SCION, a partner in the alliance, was making biomethane out of food scraps.

“And more recently, we have worked with a company to turn second-grade avocados into a freeze-dried avocado powder.”

Creating innovations that result in sustainable outcomes is a key focus.

“Sustainability was a big driver for the avocado project, as it turned something from a problem into a solution.”

Owen is now venturing into a new area entirely – artificial intelligence (AI).

“I’m part of a project called CyberMarine, led by Plant & Food Research in Nelson, and its grand aim is to create the fish processing factory of the future.”

He says AI will be used to analyse the marine biomass entering the factory to determine what type of advanced processing technologies should be applied to give the optimum set of high- value products.

“These might be oils or protein-based products or whatever is most appropriate. This could transform our seafood industry and create a much more sustainable method of utilising marine biomass and create less reliance on wild-catch.”

Looking to the future, Owen is eager to see New Zealand become a more innovative and high-value economy.

“I want to see that’s done in a sustainable way and help to mitigate some of the effects of climate change. I want us to be part of the solution rather than the problem.”

He’s a strong advocate for engineers and scientists having governance roles on boards, saying that, to their detriment, many boards in Aotearoa lack technical expertise in these areas.

“If you look at the big tech companies in the US and Europe, the CEO has often got some form of engineering background and the boards usually have engineers on them as well.”

He says engineers bring valuable expertise to boards, “... particularly with regard to problem-solving, strategy and economic viability”.

Photo: Callaghan Innovation

29 Profile | Kiwhaiaro

Healthy career goals

The dual focuses of a bioengineer with a passion for health and wellbeing aim to find definitive signs that vaping causes long-term harm, and to improve health equity for wāhine.

When Kelly Burrowes first heard of vaping, she did not anticipate it would be the focus of thousands of hours of research, several research grants, and a passionate ambition to elucidate the impact of a harmful trend that has taken our youth by storm.

A New Zealand health survey in 2021/22 found that 8.4 percent of people aged 15 or older were daily vapers, and 22.9 percent of people aged 18–24 vaped daily.

Kelly, who holds a PhD in bioengineering and has spent many years researching the impact of smoking on the respiratory system, studied chemical and materials engineering at the University of Auckland followed by 10 years as a researcher at the University of Oxford in England.

“I initially presumed vapes involved harmless water vapour. But in 2018 I went to an Asthma and Respiratory Foundation Conference and saw [The University of Adelaide Professor] Sandra Hodge speak about e-cigarettes and the evidence they had on the damage of vaping on cells, and I became intrigued by it.”

While the risks associated with longterm vaping are unknown, it has been established that they contain a range of chemicals, including heavy metals and flavouring compounds with unknown

health effects; cause nicotine addiction; trigger inflammation; and can lead to increased risk of cardiovascular disease. Kelly’s research aims to find a definitive sign that vaping causes harm in the long term.

The recipient of both a Marsden Fund grant and a James Cook Research Fellowship to conduct her studies, Kelly says her first project aimed to find out what was in the aerosol, “where it goes, how it affects the cells and lungs, and then to bring this together using computational tools”.

She says new projects are aiming to look for early biomarkers of changes in the lungs and blood vessels.

She says: “Because vaping has only been around for about 20 years, and it’s likely that long-term effects will take another 10 or 20 years to see, what I’m hoping to do is find some early warning signs so we can get some definitive answers on the health effects of vaping – which could potentially be similar to smoking.”

Just as early lung damage can be detected in smokers before any clear evidence of disease, she and her research team will be taking CT scans and other measurements of vapers’ lungs and blood vessels to see if there are any changes and biomarkers present, such as changes to lung tissue or blood vessel rigidity.

“We will also be measuring signs of inflammation, which is thought to be one of the disease-driving processes.”

Kelly and her team have created a

device to which an e-cigarette is attached to mimic a puff of aerosol.

“We can grow lung cells and expose them to the aerosol and try and replicate a normal puff.”

Kelly is clear about her goal.

“My greatest wish is that we can establish the impact of vaping now, before it actually manifests in millions of kids.”

In addition to lung health, she's passionate about women’s health and wellbeing. During the Covid-19 lockdowns she established The FemTech Revolution, an online business selling tech products to support women’s health, from fitness trackers and pelvic floor trainers to hightech fertility tools.

“There is a huge range of FemTech products being developed overseas but not many have made it to New Zealand.”

Kelly says medicine has largely been developed under the assumption that men and women are the same and young white males are still seen as the ”average” human being in healthcare research.

“But women’s bodies respond differently to both health conditions and medications.”

She adds: "New drugs should be tested equally on men and women – even now some studies test only on men.”

Sex-based health equity is one reason she established a health tech business specifically for wāhine.

“Women need to know about their bodies and their symptoms so we can advocate for our own health. Our bodies are just different.”

30 EG 27/2024

WRITER | KAITUHI ALEXANDRA JOHNSON

My greatest wish is that we can establish the impact of vaping now before it actually manifests in millions of kids.

Photo: Elise Manahan

31 Profile | Kiwhaiaro

“We’re changing a city forever”

WRITER | KAITUHI KATHY CATTON

Aerial view of shafts at Keith Hay Park, June 2023. Photo: Watercare

Engineering resilience

A w(hole) lot of numbers

Project build 2019 to early 2026

Tunnel length 14.7km (longest wastewater tunnel in New Zealand)

Tunnel diameter 4.5m

Tunnel capacity 226,000m3

Tunnel lies Between 15 and 110m below the surface

Construction sites 16

Size of workforce Approx 600 workers

The Central Interceptor project – Aotearoa’s largest bored wastewater tunnel – has been designed to improve the health of waterways and meet the demands of ageing infrastructure, population growth and housing intensification in Tāmaki Makaurau Auckland.

“We’re not just building a tunnel; we’re changing a city forever,” says Shayne Cunis FEngNZ, Watercare Central Interceptor Executive Programme Director.

Ageing infrastructure coupled with increasing demands necessitated a visionary solution. The main tunnel and network of smaller tunnels significantly reduces wet weather overflows into Central Auckland waterways and beaches, leading to an improvement in regional water quality. It also provides resilience for ageing assets and ensures sufficient capacity for Auckland’s wastewater, given the city’s projected population growth and intensification.

33

“We’re fixing 150 years of environmental issues, future-proofing the infrastructure for our children and grandchildren, and doing so safely while engaging with our stakeholders and local communities,” says Shayne.

Planning and concept design for the tunnel (running between Pt Erin, Herne Bay and the Māngere Wastewater Treatment Plant) began in 2009. In 2019, Watercare awarded the construction contract to Ghella Abergeldie JV. Work began in 2019 and is due for completion by early 2026. This year Watercare expects completion of sites at Blockhouse Bay, Lynfield and Avondale, with section one of the southern tunnel (May Road, Mt Roskill south) going live by the end of the year.

While the main tunnel (and its state-of-the-art tunnel boring machine (TBM) Hiwa-i-te-Rangi) receives plenty of interest, there has also been some innovative engineering work underway at one of Auckland’s busiest hubs for sport and recreation, Keith Hay Park. Situated next to State Highway 20 in Mt Roskill, it has remained open to the public and sports clubs despite the Central Interceptor site occupying a large section of the park.

Shayne explains that wastewater creates a corrosive environment that eats away at the concrete.

“So in the design stage we looked at various strategies to achieve this tunnel’s design life, from sacrificial concrete to acid-resistant concrete,” he says.

“We came across these innovative Australian-designed fibreglass-reinforced polymer (FRP) shafts, whereby the material is impermeable to the corrosive environment.”

These shafts allow wastewater from the shallow existing sewer pipes (typically a couple of metres underground) to reach the main tunnel 78m below. The challenge of digging and installing these shafts lay in the fact that they are made up of very large pieces (12m long, 5.5m in diameter and 25 tonnes) and had to be shipped from manufacturers in Indonesia and Australia.

“The FRP shafts consist of a series of cascade shelves, which creates a series of cascading mini waterfalls, rather than a 78m single waterfall,” says Chris McCarthny CPEng, Watercare Central Interceptor Delivery Manager.

We’re fixing 150 years of environmental issues, futureproofing the infrastructure for our children and grandchildren, and doing so safely while engaging with our stakeholders and local communities.

– Shayne Cunis

Left: Fibreglass reinforced polymer shaft liner being lifted into place at Keith Hay Park.

Above: Directional drilling under SH20.

Opposite: Emma Hyde, Ghella Abergeldie JV Site Engineer, Shafts and Microtunnels.

Left: Fibreglass reinforced polymer shaft liner being lifted into place at Keith Hay Park.

Above: Directional drilling under SH20.

Opposite: Emma Hyde, Ghella Abergeldie JV Site Engineer, Shafts and Microtunnels.

34 EG 27/2024

Photos: Watercare

Staff spotlight

Emma Hyde, Ghella Abergeldie JV Site Engineer, Shafts and Microtunnels, graduated from Te Herenga Waka Victoria University of Wellington at the start of 2019 with a double major degree in Building Science, Project Management and Sustainable Engineering Systems. She joined the Central Interceptor project in May 2019, initially in a risk management role, then as a Quality Engineer, before reaching her goal of being a Site Engineer. “I knew from primary school that I wanted to be in construction,” she says. “I come from a long line of civil engineers… and I enjoy the problem-solving and the sequencing of works – you have to think 100 steps ahead here.”

Emma works with Victoria, the “nano” micro TBM (925 mm diameter), designed to connect the main Central Interceptor tunnel to the local wastewater network. This new infrastructure will improve water quality in tributaries to Oakley Creek as well as allowing for future Kāinga Ora housing developments in the area.

Chris adds: “This is really important as it takes the energy out of the falling wastewater and stops the tunnel from being battered and eroded. It also helps reduce the aeration of the wastewater, which reduces the release of harmful gases,”

Although cascades aren’t new technology, the large scale is what makes these different.

“There was no rule book for how to do this at scale,” says Chris. “So, there was ingenuity in not only the way we did the digging, but also in how we got the dirt out.”

He continues: “First we drilled a 76-metre-deep pilot hole, 0.9m in diameter, which we 3D- scanned to make sure we were completely vertical.

“Then we drilled five holes approximately 1.5m deep and used a custom-made 4.2m diameter flat reaming tool that was centralised by the pilot hole, to scrape the rock into five 1.2m diameter holes.

“Once the holes were filled with rocks, we picked them up using a traditional auger bucket. We repeated this process under bentonite support fluid until we reached a final depth of 76m, and all without a single person going below the ground surface,” says Chris.

“The next challenge was installing all of the 25-tonne FRP modules with tight clearances and strict verticality requirements. This was done by filling each of the FRP modules with a predetermined volume of water to take advantage of the natural buoyancy of the modules in

the bentonite support fluid, slowly sinking each module, bolting on the next one, and repeating the process until all of them were in the ground, then carefully grouting them in place bottom up after a final 3D scan to confirm we had met the 1 in 300 verticality requirement.”

Engineering teams are also connecting the main Central Interceptor tunnel to the local wastewater network. Victoria, a “nano” micro TBM, is creating two new sewer lines (Branch 9B Diversion and Collector Sewer 9).

Putting in new connections also involved directional pilot drilling underneath the motorway and dodging buried trees in a former swamp.

“We had a couple of goes to complete the drilling and it was hair-raising stuff, tunnelling under the motorway, but it was successful and a big one to tick off the list,” says Chris.

Both Shayne and Chris acknowledge the power of the teams involved in executing this large-scale, complex project.

“I’ve worked on a lot of projects, and this one has certainly shown the benefits of investing in the basics –consulting with stakeholders, caring for the environment and caring for the people,” Chris says, while Shayne recognises the rarity of such a vast project on home turf: “It’s not often you get to work on such a multidimensional project. We really are building a better future for Aucklanders and New Zealand.”

35 Feature | Āhuatanga

Powered by Fantic, the bike has four levels of electrical assistance. The estimated battery range is 20–150km, depending on terrain, rider weight and amount of assist used.

Snapshot It's World Bicycle Day on 3 June and this year’s theme is “Promoting health, equity and sustainability through cycling.” According to Aotearoa’s Cycling Action Network, roughly 30 percent of Kiwis ride bikes. And while it’s better known for its four-wheel products, automotive manufacturer Audi continues to expand its e-mobility products, with the range including two-wheel offerings such as the Audi eMTB. The livery is inspired by the design of Audi’s electrified Dakar Rally-winning RS Q e-tron racecar.

Photo: Audi of America

Tray-dec 09 820 9133 info@traydec.co.nz

Nelson Stud Welding 09 820 9133 sales@nelsonstud.co.nz

rinnai.co.nz Maximising efficiency for commercial hot water needs. Heavy Duty Electric Cylinders NZ building code energy efficiency compliant Quick recovery with up to 16.5kW input High flow rates

32mm connections 60L

small to large applications Four Hours of Fire Testing and the Tray-dec floor is still intact Contact

get our updated BRANZ Appraised design software incorporating our latest fire and structural updates

with

& 340L for

us to

www.traydec.co.nz

40 A truckload of training tools

41 Addressing complaints about complaints

42 From words to meaningful outcomes

45 Elevating construction standards

46 Powerhouse for environmental action

48 Intersection

49 Common issues with producer statement PS4

practiceBest

rawai

Ngā mahi papai

A truckload of training tools

From supermarket goods to concrete for a new driveway, around 200,000 heavy vehicles transport almost everything people buy or use across the motu. And while there’s currently a shortage of Heavy Vehicle Specialist Certifiers to ensure critical vehicle components like towbars meet required standards, it’s hoped a new, award-winning training package will help bolster the sector.

The Heavy Vehicle Specialist Certifier industry is small but vital, made up of nearly 200 certifying engineers and manufacturers who help keep freight, and in turn the economy, moving.

Several years ago, it was widely publicised that industry compliance was lacking (including potentially dangerous towing connection failures), regulation needed attention, and many experienced certifiers were nearing retirement. There was also no vocational pathway for people joining the industry and serious intervention and support were needed.

Enter the Heavy Vehicle Training Design and Development Project. A group of engineering certifiers joined forces with Te Ao Rangahau and the regulator, NZ Transport Agency Waka Kotahi (NZTA) to create a training programme based on recommended practice to achieve consistent certification compliance.

Supported by the Heavy Vehicle Engineers Group, input was gathered from many subject matter experts to understand the critical gaps in knowledge, the fundamental topics that build basic engineering practices, and to develop

real-life scenarios and model answers.

Fast forward two years and the result is a unique training package, comprising eight Fundamental modules and two programmes targeting Towing Connection and Load Anchorage certifications. In March, the Heavy Vehicle Training Design and Development Project was awarded the Fulton-Downer Gold Medal, one of the highest accolades presented by the President of Te Ao Rangahau.

Developing the training programme wasn’t without its trials. Ask any of the engineers involved and they’ll tell you that finding agreement was one of their biggest challenges. While they all had different approaches to tackling a job, they put the focus on good practice, looking at the essentials someone joining or moving through the industry needed to know.

With the guidance of Te Ao Rangahau, bringing industry and NZTA together to achieve agreement was key to producing results. Having the right people in the room broke down barriers and has resulted in a healthier, mature relationship. This is a win for industry and NZTA and will result in further successes beyond this initial training programme.

The Project had a soft launch in March, with the first two of 18 modules open to those in the industry. With more than 40 participants, the successful training laid the platform for the recent full programme launch in mid-2024.

This is great news for anyone entering the industry. For a mechanical engineering graduate with a passion for vehicles, the

Fundamental modules are the first step. Then, with support from an industry mentor, the Towing Connection and Load Anchorage programmes will help set them up for success to achieve appointment and establish a career as a Heavy Vehicle Specialist Certifier. For existing Heavy Vehicle Specialist Certifiers, the training is an opportunity to upskill and refresh knowledge.

Providing consistent learning methods across industry will help to ensure that regulatory requirements are met, resulting in safer vehicles on our roads.

Looking beyond the heavy vehicle industry, the Fundamental modules can apply across a broad spectrum of engineering practices. Engineers can delve into a module on “Materials” or take a refresher course on “General mechanical analysis”.

Completion of the Project represents a huge win for engineering in Aotearoa and particularly for those in the industry. With new Heavy Vehicle Specialist Certifiers already adopting the training, this is a significant step towards growing and future-proofing the industry. It also provides the regulator with a baseline to focus on, measuring compliance expectations against the training.

The Project is designed to evolve over time, moving in line with new technology and legislative change.

Rebecca Bohnen is Engagement Manager for the Sector Programmes team at Te Ao Rangahau.

REBECCA BOHNEN

40 EG 27/2024

Addressing complaints about complaints

IZAAC SUGRUE

In response to member feedback, we've reviewed and improved our complaints and disciplinary processes.

One of Te Ao Rangahau’s many responsibilities is acting as “The Registration Authority”, a title granted by Parliament under the Chartered Professional Engineers of New Zealand Act 2002. This means we maintain the Register of Chartered Professional Engineers (CPEng), manage CPEng applications and assessments, investigate complaints made against CPEngs and, if necessary, make disciplinary findings.

Those latter functions, complaints and discipline, have been the subject of much feedback in the past few years, which prompted us to review related processes. Now in 2024, with an almost entirely new legal and complaints team, we have begun to roll out our new and improved complaints and disciplinary process.

Speeding up the process

One of the key messages in the feedback was that our complaints process takes too long. Naturally, Te Ao Rangahau complaints frequently involve complex technical and professional issues which take time to work through. Plus, the principles of natural justice require that complainants and respondents are given adequate opportunity to make their case and respond to one another, which can also take time. Taken together with opportunities to appeal disciplinary decisions to the Chartered Professional

Engineers Council, it is not surprising that complaints can be slow to make their way through our system. Still, there was room for improvement.

An important thing to note about the complaints we receive is how often they are resolved at an early stage, either through mediation between the parties, the dismissal of commercial disputes for want of jurisdiction, or resolution by other means. Two-thirds of current complaints are at the initial investigation stage and a large majority of complaints never make it further than that.

A dedicated Complaints Officer

As a first step, in October 2023 we hired a dedicated Complaints Officer responsible for handling complaints at the initial investigation stage. The complaints process is run by Te Ao Rangahau’s in-house legal team, and until the Complaints Officer started, each legal advisor (on top of their usual mahi as in-house counsel) was responsible for a share of all cases received, managing each complaint through to conclusion. At first glance, this is sensible. Complaints, especially ones that reach the latter stages of the process, often involve many tricky legal issues which decision-makers need advice on. However, these issues don’t usually materialise until later down the track, and because of the amount of cases at the earlier stages, the legal advisors were getting bogged down in difficult, time-consuming work that frequently did not require legal expertise. With the introduction of the Complaints

Officer, who is not a legal expert but an expert in handling complaints, we were on track to a more efficient process.

The Complaints Officer immediately got to work, not only handling early stage complaints with speed and expertise, but also playing a key part in refining the initial investigation process. Since bringing the Complaints Officer on board we have removed procedural obstacles; streamlined information gathering, advising and report writing; and introduced a framework for communication timelines and a new template for written decisions. These changes have already had a measurable impact. From February to April 2024, the average time to resolve a complaint has dropped by nearly 10 percent and the number of complaints resolved between the start of 2024 and 2 April 2024 is more than half of all complaints resolved in 2023.

Continuing improvement

We are thrilled with the results so far, but this is not the end of the matter. We'll continue to investigate and implement efficiency gains at the latter stages of the complaints process. We'll also seek to address other issues with the complaints process, including through the possibility of changing the Chartered Professional Engineers of New Zealand Rules (No 2) 2002, which govern the complaints process.

Izaac Sugrue is Legal Team Leader at Te Ao Rangahau.

41 Best practice | Ngā mahi papai rawai

From words to meaningful outcomes

PAUL MORGAN FEngNZ CPEng

What does it mean in practice to incorporate Te Ao Māori into engineering?

I have been working with the Pou Ārahi (Māori Advisors) and Stantec’s Water Resources leadership team on how to better integrate Te Ao Māori within our work. As an engineer with whakapapa to Kāti Mamoe, Kāi Tahu and Waitaha, this gives me an understanding of both worlds. But it does not mean it makes this easy. In many ways, we are all at the early stages of finding better ways of doing this.

In February, Te Ao Rangahau released the Kimihia Rangahaua strategy with the goal of embedding Te Ao Māori into the organisation and the engineering profession. This follows a formal recognition in 2019 of Te Tiriti o Waitangi and commitment to promoting principles of partnership, protection and participation.

The recognition of Te Tiriti and Te Ao Māori is the foundation for significant change occurring across many organisations and within recent legislation. In particular Te Mana o te Taiao (Aotearoa New Zealand Biodiversity Strategy 2020) and the National Policy Statement for Freshwater Management 2020 (NPSFM). Even with current and proposed changes coming from the Government, the principles of this change will continue. There is growing momentum in the willingness to find meaningful ways to meet the obligations of Te Tiriti and better incorporate Te Ao Māori into the work we do.

The challenge for those who work in engineering is how to turn the words and meaning behind the strategy into tangible and meaningful outcomes within our practice. This is a much bigger hurdle than those we face due to common changes, like changes to regulations. Instead, it requires a more holistic shift in our thinking and approach to our projects. I work in the water sector where the fundamental concept of the NPSFM is Te Mana o te Wai. This acts as a framework for the integration of Te Ao Māori into water engineering projects, though many of these processes can apply to any sector. It provides an approach to lift the health of natural water environments and cultural values linked to it.

Engagement

with mana whenua and māturanga Māori

Engagement with mana whenua is the first step, where we begin the process of understanding mātauranga Māori (Māori knowledge originating from ancestors, including world view, values, creativity and cultural practices) as it relates to the project and surrounding area.

Mātauranga Māori can only be provided by mana whenua. By building a relationship based upon respect and trust, we have the opportunity to listen to mana whenua and thus grow our understanding. Often, engagement processes with mana whenua are undertaken by the client, project managers and planners. Integrating the varied and complex mātuaranga Māori that comes out of

… it requires a more holistic shift in our thinking and approach to our projects.

this engagement into the project is a challenging process, and the engineers are central to this being successful. Therefore, it is very important that engineers engage directly with mana whenua throughout all stages of a project so we can collaboratively develop meaningful solutions that achieve the outcomes required.

Iwi as a partner not a stakeholder

Iwi have often been viewed as a stakeholder, meaning they get informed of our plans and their feedback is used to consider how we can account for their values. However, Te Tiriti is about partnership. Through legislation such as the Resource Management Act and NPSFM, there has been growing recognition of iwi as a partner. This approach is fundamental to successfully integrating Te Ao Māori into a project. Māori have significant contribution to make as kaitiaki (guardians) of our natural world.

42 EG 27/2024

Integrating mātauranga Māori with Western engineering Engineers, by nature and training, are used to immediately considering solutions to problems. This approach is very focused on the technical and economic issues and led by principles of engineering practice and experience from other projects. Integrating Te Ao Māori into a project requires a change in approach. In the first stage of a project, we must develop an understanding of the issues. This is the time for listening, asking questions and digging into the environmental, cultural and social elements of the project. In turn, this enables engineers to approach the project not just with our existing technical knowledge and skills, but considering ways we can include mātauranga Māori in the processes and outcomes of the work we undertake.