Issue | Putanga 28/2024

Towards an age-inclusive Aotearoa Engineers innovating as the world ages

AI in practice: engineering examples Kiwi engineers applying AI in their work

Issue | Putanga 28/2024

Towards an age-inclusive Aotearoa Engineers innovating as the world ages

AI in practice: engineering examples Kiwi engineers applying AI in their work

A port upgrade with people in mind

Capital works

Significant transport-related projects worth celebrating

The smart alternative to steel, the PLX Portal is a structural timber bracing solution for buildings within the scope of NZS3604:2011.

Strong support

Steel-reinforced glulam timber beam for increased load bearing and spanning capability.

Superior bracing

Easy to specify

Pre-engineered for simple specification with PS1 Certificate using the Prolam Specifier.

Complete portal system with custom brackets and tightening rods for next level bracing capacity. A sustainable choice

Made from renewable NZ plantation timber with far better thermal properties than steel. FSC certified timber options available.

Building better together

“It’s like having a pair of eyes looking out for safety issues, but they don’t get tired and they’re picking up everything.”

“Our aim is to allow residents to live as normal a life as possible in a safe and secure village.”

“I just thought it was so interesting and that there were so many opportunities applying engineering and mathematical approaches to biology...”

“Local stakeholders, including skilled Tongans returning from abroad, bridge language gaps and explain what’s required in a Tongan context.”

PO Box 12 241, Wellington 6144 New Zealand 04 473 9444

hello@engineeringnz.org engineeringnz.org

Editor Jennifer Black editor@engineeringnz.org

Designers

Angeli Winthrop Karlos Tui

Advertising sales advertising@engineeringnz.org 04 473 9444

Subscriptions hello@engineeringnz.org

Circulation

Magazine 360° Circulation for the 12 months ended 31 March 2022.

New Zealand 13,749 Print ISSN 2537-9097 Online ISSN 2537-9100

EG online

EG is available digitally for members on our website or through your EN.CORE app.

Printing

Your cover is printed on Forest Stewardship Council (FSC) approved and elemental chlorine free (ECF) paper. The inside pages are Programme for the Endorsement of Forest Certification (PEFC) approved and elemental chlorine free (ECF). EG is printed using vegetable-based inks made from renewable sources. Printing and fulfilment by Bluestar.

Please recycle your paper envelope – it’s 100% recyclable and made from PEFC accredited paper.

Disclaimer

Advertising statements and editorial opinions expressed in EG do not reflect the views of Engineering New Zealand Te Ao Rangahau, its members, staff, or affiliated organisations unless expressly stated.

This issue of EG was published in September 2024.

8

AI in practice: engineering examples As AI continues to grow in scale and scope, we look at some practical ways it’s being applied by engineers in Aotearoa.

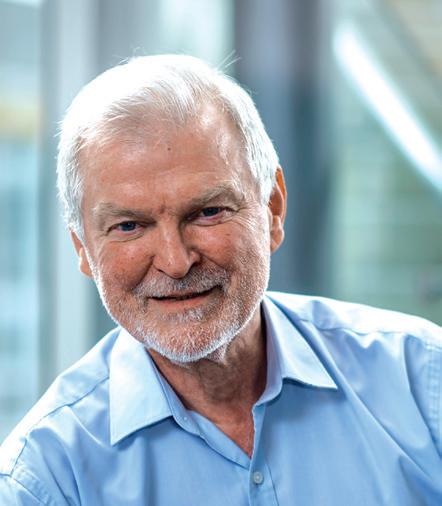

14 Success and succession The 2011 Canterbury earthquake continues to drive the work of two engineers who founded a company together, despite being at different ends of the career spectrum.

18 Towards an age-inclusive Aotearoa How engineers are working on a range of innovations to make Aotearoa more age inclusive.

24 Capital works Despite Wellington being hit by public sector job cuts and the temporary closure of some major civic buildings, the city has some significant transport-related projects to celebrate.

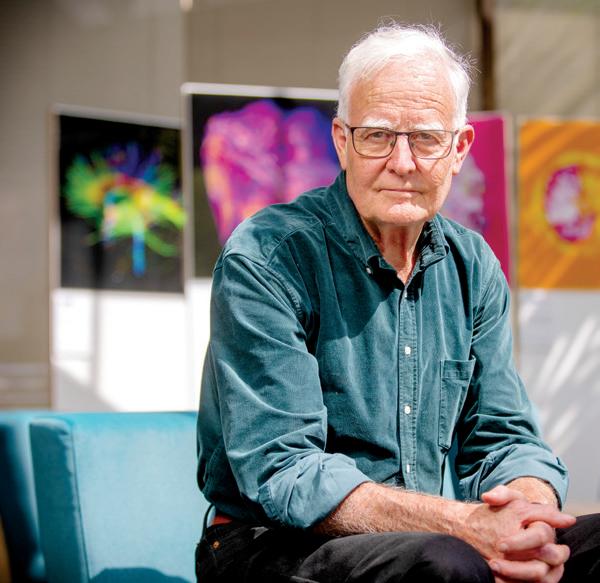

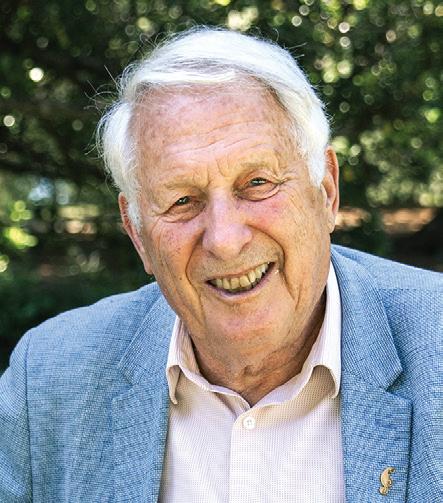

30 A model Knight Celebrating Sir Peter Hunter HonFEngNZ, who has helped put Aotearoa on the map through bioengineering.

32 Strengthening a lifeline for Tonga How a port upgrade strengthens a lifeline for the Tongan people, helps mitigate the effects of climate change and provides local jobs.

40 Women in engineering: dreams and realities An oral history project reveals that women engineers in Aotearoa through the years all have one thing in common.

42 From engineer to business owner Transitioning from a technical role to business ownership can be both challenging and rewarding.

43 Concrete goals Aotearoa’s cement and concrete industry’s journey to net-zero carbon by 2050.

44 Bridges to span generations How can we address the ever-rising demands on our bridges and road structures?

46 Keep your career on course How taking a strategic, proactive approach to professional development helps both individual engineers and the industry more broadly.

47 Proactively addressing privacy in the age of AI As AI continues to evolve rapidly, privacy and data protection are crucial factors that engineers must address in their work.

48 Intersection

Chosen by Te Ao Rangahau staff

Fortunately, there’s no sunset clause in the build contract of one of Barcelona’s most “familia” icons – Basilica de la Sagrada Familia. Designed by Catalan architect Antoni Gaudí, construction began in 1882. There’s crafty engineering behind the breathtaking visual experience that drew more than 4.7 million visitors in 2023, which took inspiration from the natural forms Gaudí found around him. The intricate, complex shapes provide inherent strength, allowing for a slender framework that belies a building of its size. With 13 of the 18 planned spires finished, the basilica’s completion is scheduled for 2026 – 100 years since Gaudí’s death – after more than 140 years of construction.

I visited in 2005 and was amazed by its breathtaking grandeur and multigenerational construction. I can't wait for Gaudí's visions from over a century ago to be fully realised.

Suzanne Roff – Marketing Manager

I was delighted to have the opportunity for this introduction to be presented in the two official spoken languages of New Zealand – te reo Māori and English –to contribute to Te Wiki o te reo Māori 2024. Te wiki reminds us that we are partners with our communities in everything we do to engineer a better and safer society in New Zealand and beyond.

This issue of EG magazine focuses on celebrations, together with engineering work that benefits society. It is a tribute to our profession that five engineers were recognised in the 2024 King’s Birthday Honours list, including a knighthood for Sir Peter Hunter HonFEngNZ, founder of the Auckland Bioengineering Institute, who is profiled in this issue.

Also in these pages we showcase Ben Exton CMEngNZ CPEng IntPE(NZ) who received the Ivan Skinner Award for Earthquake Engineering, Climate Scientist and New Zealander of the Year Dr Jim Salinger, and Clive Davies FEngNZ who was awarded the Chemeca Medal, the most prestigious award in the chemical engineering profession in New Zealand and Australia.

There are many other examples of people and projects worthy of celebration in this edition, including a new concept in dementia care living, practical examples of how Artificial Intelligence is being used in engineering, and large projects addressing sustainability.

Jan Evans-Freeman DistFEngNZ President, Engineering New Zealand Te Ao Rangahau

Ka nui taku hari ki te tāpae i ēnei kupu whakataki ki ngā reo kōrero whai mana e rua o Aotearoa – te reo Māori me Te Reo Ingarihi – hei tautoko i Te Wiki o te reo Māori 2024. Tā te wiki o te reo he whakamahara i a tātou he hoa kōtui tātou mō ō tātou hapori, i a tātou e mahi nei ki te hanga pāpori pai ake, haumaru kē ake mō Aotearoa, otirā mō te ao.

E aro nui ana tēnei putanga o te moheni EG ki ngā mahi whakanui, waihoki ngā mahi pūhanga ka noho hei painga mō te porihanga. He aumihi nui ki tō tātou umanga te tohutanga o ētahi kaipūhanga tokorima i te Rārangi Tohu Whakanui a Te Kīngi 2024, tae atu ki te tānga o Tā Peter Hunter HonFEngNZ, te kaiwhakatū o te Auckland Bioengineering Institute, e kitea nei he tuhinga mōna i tēnei putanga.

Waihoki, kei ēnei whārangi ka whakanuia e mātou a Ben Exton CMEngNZ CPEng IntPE(NZ), i whakawhiwhia rā ki te Tohu o Ivan Skinner Award mō te Pūhanga Rū Whenua; te Kaipūtaiao Āhuarangi, Tangata o Aotearoa mō te Tau, a Tākuta Jim Salinger, me Clive Davies FEngNZ i whakawhiwhia rā ki te Mētara Chemeca, te tohu whai mana tiketike rawa i te umanga pūhanga matū i Aotearoa me Āhitereiria.

He maha atu anō ngā tauira o ētahi tāngata, kaupapa hoki e tika ana kia whakanuia i tēnei putanga, tae atu ki tētahi ariā hou mō te noho o te hunga mate wareware, ētahi tauira whai tikanga mō te whakamahi i te Atamai Hangahanga i te ao pūhanga, me ētahi kaupapa rahi e hāngai ana ki te toitū.

Nā Jan Evans-Freeman DistFEngNZ Amokapua, Engineering New Zealand Te Ao Rangahau

“Elena Trout is an experienced independent director and chair… she has a wealth of governance experience and brings a strong knowledge of public accountability to the board.”

Workplace Relations and Safety Minister, Brooke van Velden, appoints Elena Trout DistFEngNZ to the WorkSafe board.

“More than 120 teams from 20 countries participated in Spaceport America Cup, with the team from Canterbury University winning in their ‘30,000 Foot’ category against 28 other teams, using off-the-shelf components,”

Space Minister Judith Collins applauds students from the University of Canterbury’s Aerospace Club on their success at the world’s largest inter-collegiate rocket engineering competition.

“I shed my inhibitions the moment I first stepped into a pole dance studio. There, I found doctors, nurses, engineers — people from all walks of life and with diverse body types — all eager to learn this art form.”

Kiwi-Indian software engineer and pole dance instructor, Ajay Chhibber.

As Artificial intelligence (AI) continues to grow in scale and scope, it is affecting every industry, including engineering. Here’s a round-up of some practical ways engineers in Aotearoa are applying AI.

Engineering consultancy firm Beca is harnessing AI to help evaluate bridge conditions, specifically the 100-yearold Purewa Bridge in Tāmakai Makaurau’s Ōrākei suburb. The project was a finalist for the innovation category at the 2024 New Zealand Workplace Health and Safety Awards.

AI-enabled drones equipped with high-definition cameras captured a total of 15,000 high-resolution images and acoustic soundings from various heights and angles of the bridge’s longitudinal beams, piers and underdeck, with Niricson providing the AI tools and software. Computer vision and machine learning were then used to analyse the data and conduct a digital condition assessment.

“It’s faster, more accurate and eliminates subjectivity,” says Jack Donaghy, Digital Innovation Leader –Transportation & Infrastructure NZ at Beca.

“It also reduces the need for traffic management and is much safer as the drones are often able to get to areas inaccessible by humans.”

Beca is also looking into other uses for AI. For instance, they’ve built PIPE-i, a robotic survey vehicle that captures detailed spatial information of challenging and hazardous confined spaces, such as culverts and tunnels, through images, Lidar and videos.

“We’re developing functionality into it where once it captures the images of the inside of the culverts, AI will be able to pick up the condition of the culverts as well,” Jack says.

In the past year or so, Jack has observed that clients are becoming more open to the possibilities of AI. “With some of our public sector clients, they are advocating for the use of AI. They want to do more but faster and cheaper by leveraging technology.”

However, AI still has a long way to go for it to become mainstream. The adoption of AI is “… not as fast as I thought it would be”, says Jack.

“But I’m seeing that changing. A lot of clients are beginning to ask the right questions and starting to trial AI and see its benefits. It may take a few years, but anything that’s repeatable with big data, especially in asset management, is ripe for AI and is a big opportunity.”

At integrated services provider Downer, health and safety is a prime consideration. Downer’s Transport and Infrastructure team has partnered with design and technology company RUSH to make roadworks safer for both workers and road users through R/VISION, a cloud-based, AI-driven workflow automation platform.

Images and videos from mobile camera units are transmitted to R/VISION, which runs computer vision models for image, object and action recognition. Based on what the models are trained to recognise, the platform triggers actions, such as text and email alerts.

“We needed a mobile solution, especially for road maintenance sites where roads are getting resurfaced and chip sealed, or new kerbs and channels are laid

Left: Beca's AI-enabled drones captured thousands of images of Purewa Bridge’s structure in order to conduct a digital condition assessment. Photo: Beca

Above: Beca's PIPE-i, a robotic survey vehicle, reduces the need for traffic management.

Photo: Beca

Opposite: Mobile camera units send images and videos to R/VISION, RUSH's AI-driven workflow automation platform. Photo: RUSH

down,” says Cameron Hyndman, National Digital Engineering Lead at Downer.

He adds that R/VISION can be used to capture information about traffic speed, traffic encroaching into live sites and whether workers are wearing their personal protective equipment. Also, whether people are walking into a no-go zone, among other hazards and safety practices.

“We can use it as a risk management tool,” says Oliver Fradley, Maintenance Manager at Downer.

“It’s about being able to visually represent to the teams when they’re breaching safety zones and the like. There’s a huge amount of worth at ground level for the people actually working on the sites.”

Danu Abeysuriya, Founder and Chief Technology Officer at RUSH, adds that the system “… allows you to get information quickly and disseminate it to the right people to make good decisions much faster. What that means is that your risk changes in days or hours rather than months”.

As with other visual AI technologies, privacy presents the biggest challenge. Both Downer and RUSH ensure they comply with the Privacy Act, distributing information brochures to teams and putting safeguards in place, such as blurring faces and front yards, and anonymising and aggregating data and statistics so people aren’t individually identifiable.

It’s like having a pair of eyes looking out for safety issues, but they don’t get tired and they’re picking up everything.

– Cameron Hyndman

“The feedback we got from the teams on site – who can often be wary of new technology, especially if it’s something with cameras – was positive,” says Oliver.

“They understood the benefit it was bringing them in the safety space. And from an operational point of view, if you can get your teams on the ground to embrace something that brings safety benefits, it’s an easy sell.”

Data from R/VISION can also be used during safety audits to create better safety practices in the future.

“It’s like having a pair of eyes looking out for safety issues, but they don’t get tired and they’re picking up everything,” Cameron says.

Engineering, planning and surveying consultancy Civix has been using AI for eight years and has built its own cloud-based, AI-powered design software for land development projects, Allsite.ai.

Instead of manual inputs for every aspect of the surface design, Allsite.ai automatically generates 3D models from 2D layouts, local design standards and other parameters.

“Our system comes up with the solution and then the engineer reviews it,” says Sam Blackbourn CMEngNZ CPEng, Civil Engineer and Director at Civix.

“For specific site constraints, engineers still have the ability to override and lock different parts of the design that the AI produces, and the system will optimise around those results.”

For Sam, the benefits of AI boil down to quality and speed, especially for large-scale developments.

“We’re producing 3D designs for sites in around three days that would typically take two months. It’s less time manually laying out designs and coming up with a spreadsheet for calculations. It’s more around reviewing, correcting, and spending time on the difficult facets that a piece of software just can’t do.”

Training is still needed to understand how the system works. And falling back on manual methods remains an option, particularly for edge cases and other scenarios where the AI system just doesn’t have enough examples to follow.

Sam believes a key factor when applying AI in engineering is a mindset change.

“A lot of engineers are used to doing it all themselves, but now they get a full solution that they review and correct,” Sam says.

A lot of engineers are used to doing it all themselves, but now they get a full solution that they review and correct.

– Sam Blackbourn

“There’s an element of building trust with an automated AI system. And once AI does all the easy parts, what’s left is the complex problem-solving. That is the core of what engineering is, and I don’t think that’s going away.”

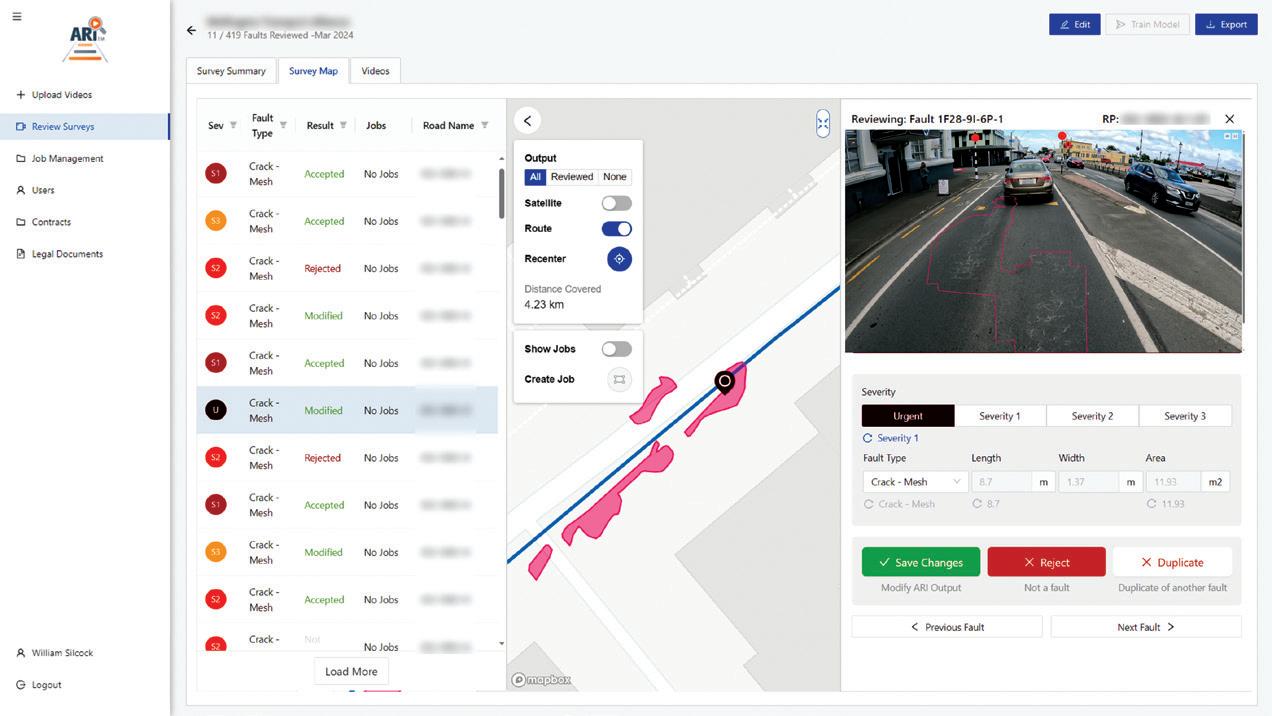

After researching AI for the past five years, Fulton Hogan has started employing the technology more widely since 2022. The construction firm has been using AI for its maintenance contracts, assisting with the assessment of road condition, which includes identifying pavement and surfacing failures such as potholes, cracking and flushing, among others.

“Our primary driver was safety,” says Willy Silcock MEngNZ, an engineer within Fulton Hogan’s Engineering Solutions team.

“Our teams are out there collecting data on the size, severity and type of defect. We want to take them off the road, which also means we won’t be affecting road users while doing our checks.”

Videos of road networks are analysed by AI, which “… acts as our first cut of information”, Willy says. He adds that well-trained AI models avoid missing defects and provide an objective view of how the road is looking.

AI models can also detect early warning signs, which can be valuable for long-term asset management.

“We might have been considering road rehabilitation in eight years, but that might be extended out to beyond 10 years by proactively ‘patching’ any isolated early warning signs of cracking, allowing us to protect the asset at the right time and optimise investment levels,” says Willy.

Yet machine-assisted fault identification can be prone to generating false positive results. For example, the system might pick up a dark spot on an image or video frame as cracking when it’s just a shadow.

“We need to take people on a change management journey to show them the strengths and also limitations of the data,” Willy says.

“The technology has come a long way in the last few years and the accuracy of AI outputs is improving all the time – some of the raw outputs don't require a review due to a high historic acceptence rate.”

Moreover, aggregation tools are essential to understand what’s happening at a higher level.

“One of the things we find with AI is that data-rich isn’t necessarily easy to understand,” says Willy.

“We need to aggregate that data, slice and dice it, and join it all together so we can tell a story.”

Ultimately, Willy envisions AI helping advance the engineering sector.

“The big benefits lie in the data-driven analytics and evidence-based decision-making that AI can offer.”

WRITER | KAITUHI ALEXANDRA JOHNSON

The 2011 Canterbury earthquake had a massive impact on all who were involved, and for two engineers who founded a company together despite being at different ends of the career spectrum, it continues to be a central driver of their work.

Structural engineers Ben Exton CMEngNZ CPEng IntPE(NZ) and Geoff Banks CMEngNZ IntPE(NZ) are at opposite ends of their careers. In 2016, new graduate Ben completed his internship at Geoff’s structural engineering company, Structex, which he founded 21 years ago. The pair have been working together ever since and in 2022, co-founded Seismic Shift. It’s an earthquake resilience research and development company intent on revolutionising how to protect homes from future earthquake damage.

“There is still a view in the profession that the housing stock stood up really well in Canterbury,” says Ben. “And while they are correct that there were no lives lost due to structure damage, if you spoke to anyone who was turfed out of homes or who didn’t have showers or toilets for many months, they might have a different view,” he says, adding that they are challenging the engineering profession to do better for communities.

He explains that at Structex, a spinoff company created a product to avoid

wine tanks from being disturbed in earthquakes, but it only acted in one direction.

“I felt there must be a way to apply these same principles, and what’s in a large building such as Te Papa, to residential homes in a way that was cost effective.”

The engineers have developed FrontFoot, a base dissipation system for residential dwellings. Ben says FrontFoot was born of a 3am brainwave.

“One night I sketched an idea down and had it 3D printed at the library. Then, with a scalpel, my wife and I shaved little bits out and fitted it together, and it moved as I had thought it might do.”

It seems bizarre that in New Zealand we continue to build houses the way we have for decades and expect something different to happen next time.

– Ben Exton

The system utilises friction to dampen the effects of an earthquake and allows some of the movement that would otherwise damage the walls to occur at floor level.

“There’s a slip layer under a house and FrontFoot sits within the floor slab, allowing the house to move around within a constrained zone of movement, up to 20 millimetres,” he explains.

He says the system is generating more interest offshore than it is at home, in places such as Japan and California, where there are insurance discounts available for those who include resilience in structures.

“It seems bizarre that in New Zealand we continue to build houses the way we have for decades and expect something different to happen next time.”

Ben says most developers ask whether installing FrontFoot means they can reduce the cost of construction.

“But installation and end-product cost is sitting around two percent of the price of a house, and that’s pretty small considering the damage reduction after an event.”

The pair are currently in conversation with the Natural Hazards Commission Toka Tū Ake, “… to consider whether in future they can incentivise resilience, similar to what’s done overseas”, Ben says.

This year, Ben won the Ivan Skinner Award at the New Zealand Society for Earthquake Engineering annual conference for the FrontFoot system, and to support him in developing and commercialising cost-effective engineering solutions.

“That is an acknowledgement for both myself and the Seismic Shift team because we believe in the power of taking engineering principles and leveraging those to create impact on mass outcomes.”

He says consulting engineers have a massive impact on a project-by-project basis, “… but you’re always focused on moving on to the next project and don’t often get a chance to leverage what you’ve learned, and that’s what needs to change”.

Geoff believes engineers are perfectly positioned to solve the world’s problems.

“Engineers are capable of coming up with a solution to a problem that people aren’t yet asking us to solve, but we

know is there. For example, until you’ve experienced it, people don’t realise the impact an earthquake can have on your family home, the impact it can have on your kids when they go to school, or even the health impacts 10 years later when those same kids are teenagers.”

Geoff adds: “I come at this [Seismic Shift] from a high level. It’s been an eye opener for me towards the end of my career that whilst I’ve been designing things to stand up for decades, it’s actually just as important for people to be able to occupy their homes after a disaster.”

He says when people approach the end of their career it’s important not only to recognise the skills you have, but also to recognise those you don’t have.

“A graduate starting out probably knows more about the latest engineering technologies because they’ve been consuming the current information. But what you learn with experience is what can

go wrong, the human factors.”

So, given their age difference, have Geoff and Ben established the ultimate succession plan built into Seismic Shift?

“I feel that succession planning should be continuous for engineers – you’re mentoring upwards and downwards, or you’re being mentored,” Geoff says. “If you don’t share what you’ve learned over your career, then others are going to make the same mistakes you have. Succession is just a mindset of making sure that there’s always someone who can step into your role.”

Ben says he enjoys the way he and Geoff challenge each other’s thinking and push the business forward for better outcomes.

“From day one the company has had the ability to make decisions on the triple bottom line principles; profit, people and planet. We’re just working towards those positive outcomes. It's been a pretty fun ride to date.”

The nnounce ecosystem gives you:

Unrivaled security

Crystal-clear announcements

Robust reliability

Advanced audio processing

Seamless integration

Let us find the perfect solution for your needs.

P: 09 373 2416

E: Info@bartonsound.co.nz

WRITER | KAITUHI RACHEL HELYER DONALDSON

As overall population growth slows, the most formidable demographic challenge facing the world is ageing.

New Zealand is likely to have 1.2 million people aged 65 and over by 2034. This means many health, social and economic challenges, all requiring adaptations to the way society is structured. Engineers are working on a range of innovations to make Aotearoa more age inclusive.

The World Health Organisation (WHO) says more than 55 million people worldwide are living with dementia, with 10 million new cases every year. Dementia is not a normal part of ageing, but age is the strongest known risk. Despite its prevalence, WHO states there remains a lack of awareness and understanding of dementia, resulting in stigmatisation, and barriers to diagnosis and care.

But there is a different way, says Invercargill-based Frank O’Boyle CMEngNZ CPEng.

Originally from Ireland, Frank is South Port New Zealand’s Infrastructure and Environmental Manager. He is also the Chair of the Hawthorndale Care Village, a not-for-profit organisation building a “dementia village” which is set to open in Invercargill in May 2025.

Hawthorndale is based on the groundbreaking Hogeweyk Dementia Village which opened in Amsterdam in 2009. There, the primarily government-funded community resembles a typical Dutch town with a shop, restaurant, theatre and pub, and 27 houses. The 188 residents all suffer from severe dementia, yet they move about the village freely and interact with fellow patients and plainclothes care staff.

Back in Southland, construction of the $39m project started in October 2022 after a decade of planning and years of fundraising. On completion, it will house 86 residents, including 74 transferring from another aged care facility that is closing.

Instead of a segregated wing for dementia patients, Hawthorndale’s residents will live in 13 houses, each with six or seven bedrooms and a shared living space. Caregivers will be on hand to monitor and help with showers and cook meals, although residents will be encouraged to participate in everyday household chores.

Our aim is to allow residents to live as normal a life as possible in a safe and secure village.

– Frank O’Boyle

site

Right: Artist's render of the main entrance. Image: Foley Group

For Hawthorndale, having a “town centre” was a non-negotiable to replicate everyday living, says Frank. Amenities will include a theatre, hairdresser, library, gym, cafe, dairy, chapel, travel agent and a workshop. “Our aim is to allow residents to live as normal a life as possible in a safe and secure village.”

Residents are not locked in their rooms at night and there are no security cameras in bedrooms or bathrooms. Instead, hi-tech wristbands connected to security sensors will track residents, for example alerting staff if a resident gets out of bed.

The “main street” will be enclosed in an all-weather atrium, but each business will be distinctive. Other design features such as landscaping and colour schemes for each home will also help residents find their way around.

Like the former school whose site it’s built on, Hawthorndale will be part of the community. The cafe and playground will be open to the public. Frank describes the community support as “phenomenal” with more than $10m raised towards the project.

Frank, who has family members who have suffered from dementia, says learning about the Hogeweyk model was a “lightbulb moment”.

“It aligned nicely with the decision to move to a new site and invest in a new model of care. As an engineer, it is exciting and hugely satisfying to be involved with such a groundbreaking project.”

WorkSafe says healthcare workers who move and handle patients have one of the highest rates of musculoskeletal disorders among all occupational groups. HT Systems, a Christchurch start-up run by two engineers, aims to solve this with the Kera sit2sit. It’s an innovative way of transferring someone with limited or no mobility from chair to chair – such as wheelchair, armchair or toilet –a major proportion of the transfers of elderly or disabled people in homes or hospitals.

The University of Canterbury Mechanical Engineering Department’s Professor Emeritus Keith Alexander FEngNZ is perhaps better known as the inventor of the Springfree Trampoline, and for his work on jet boats, jetpacks and an amphibious car. But he realised there was a growing need for a low-force transfer device for elderly people and their caregivers.

The essential idea is a pivot system based on the natural motion people use to get out of a chair.

“The transfer aid has no electronics, requires minimal physical effort and, crucially, can be operated by one person,” Keith says.

Several patents have been taken out for the Kera sit2sit, with “Kera” a play on the Kiwi pronunciation of “carer”.

Mechanical engineer Alex O’Keefe, whose sister has spina bifida and uses a wheelchair, played a key role in rethinking and refining the design for market.

Keith says the Kera sit2sit may look simple, but it’s not.

“A lot of transfer devices out there are not very well thought-out, but look as if they will work. But there’s a lot of subtlety in working with people, and matching the engineering with their needs is really unique.

“I found it quite challenging to engineer around people’s bodies. They don’t fold up the way you might expect and sometimes the hinges are frozen. People are soft and spongy and you can’t kind of measure things very accurately. Getting good data is hard.”

Keith says: “Ten protoypes later we got to the point where you could lift somebody of 70 kilograms comfortably, gently and safely, with just two fingers.”

An advantage of the Kera sit2sit is that it only needs one caregiver to move a person.

The Kera sit2sit won Best New Product of the Year at the Assistive Technologies Suppliers Australia (ATSA) expo in Perth in 2023 and was nominated as a finalist in the 2024 NZ Hi-Tech awards.

HT Systems is also developing a novel holding and raising system to help people to stand, regardless of weight-bearing ability.

Engineering, in particular, automation and artificial intelligence (AI), can help support senior workers.

University of Auckland Professor of Smart Manufacturing Dr Xun Xu FEngNZ runs the Laboratory for Industry 4.0 Smart Manufacturing Systems (LISMS). The lab is a partner of the European Union’s (EU’s) Research and Innovation Staff Exchange programme Models and Methods for an Active Ageing Workforce, looking at the needs of the ageing workforce in manufacturing and seeking solutions. In Auckland, that work is being led by Dr Yuqian Lu, with students from the University of Auckland and those in the team from the EU, investigating the fatigue level and ergonomic postural risk in manufacturing and seeking solutions via empathetic human-robot collaborations.

The ageing world population will be one of the defining “mega-trends” of this century, notes Arup’s 2019 report Cities Alive: Designing for ageing communities. This shift in demographics, it says, will be most keenly felt in our cities, with enormous implications for public services, infrastructure and housing. Arup Principal and New Zealand leader Mayurie Gunatilaka says it’s crucial to prepare. Cities should be inclusive to all by supporting everyone’s diverse needs, she says.

“However, age is a really important lens to think about inclusive designs.”

With issues for older people including social isolation, accessing support and affordability, Mayurie says age-friendly cities offer people an enhanced sense of belonging.

“They address how the environment supports social interaction and they promote a healthy and active lifestyle and support physical and mental wellbeing with well-designed spaces that help mobility and accesibility, while feeling safe.”

Mayurie says Singapore’s Kampung Admiralty MixedUse Development is a great example of a residential development for older people. Built in 2018, it aims to support residents’ health and community involvement. It boasts a medical centre, fitness centre, a bank, supermarket and other shops, and green spaces.

Xun says automation can help support older workers physically and mentally.

“They may not be able to do the work they have been doing because of their physical capabilities, but their knowledge, expertise and experiences are still very important and bring value to businesses.”

Automation tools can assist senior workers, in a factory for example, by taking on the heavy lifting. Xun says advances in technologies such as those of teleoperation enable the operation of a machine, system or robot from a distance. For example, Xun says, in the forestry sector, an operator could work from a virtual environment with live video and audio feedback from a tree-felling machine.

Xun says certain sectors, such as manufacturing, are experiencing “perception issues” – not enough young people are attracted to the profession, hence there is a need to prolong the working life of the existing workforce. Equally important is capturing their knowledge and expertise before they exit the workforce. Typically, the senior workers are happy to share their expertise, he says.

At LISMS, Yuqian has developed advanced machine learning tools to analyse videos of factory workers involved in human-robot collaborative assembly. Domain-specific

An “inter-generational approach” to planning, designing, funding and delivering infrastructure is critical, Mayurie says. This involves thinking holistically and looking beyond an asset, such as roading, to consider the opportunity to adapt, enhance and imagine how it might service people and the environment in the future.

Above: Views of the landscaped terraces and community park at Singapore's Kampung Admiralty development help residents feel connected to nature and their community. Image: Patrick Bingham-Hall

knowledge can be captured and coherent assembly action sequences can be generated for assisting workers and training new employees – and even for training robots to be more skilled at working with humans.

Xun predicts factories will increasingly become a “society” where machines and human coexist in harmony. “This society will have more and more senior members and, for it to remain resilient, their wellbeing has become a new focus of the employers and researchers.”

Wellington is feeling the pinch, hit by public sector job cuts and the temporary closure of some civic buildings for earthquake-strengthening work. But the city has not stalled. In fact, it’s currently undergoing a major transport-related overhaul, with several significant projects underway or recently completed.

On an afternoon in March 2023, the team overseeing train movements around most of Aotearoa quietly handed over to colleagues sitting in front of a sea of monitors in a building 30-odd kilometres away. From seismically vulnerable Wellington Railway Station, national rail traffic control was re-routed in an instant to a purpose-built new centre in an Upper Hutt business campus.

“We went live very easily and very smoothly,” says KiwiRail Control Systems Integration Project Director Carl Mills. He led the project in Wellington as well as a second, more recently completed operation to build a new control centre in Ellerslie to oversee Auckland’s commuter rail network.

The spur for the change was the 2016 Kaikōura earthquake. By virtue of its new location, KiwiRail’s critical national nerve centre will now be less at risk from the tsunamis, slips, liquefaction and other hazards that could shut down train movements around the country. In addition, the 900-square-metre single-level structure has been designed to be highly resilient – and not only in

terms of seismic performance. To safeguard power, data and communications continuity in a disaster, all workstations have been set up so that, at worst, the centre would only lose half of them and never an entire function. Also, data routes have been effectively “twinned”, with multiple fibre pathways into the building using separate ducts.

The other standout feature of the project is the acoustic engineering. Noise is the enemy in a rail control centre, where a distraction or misheard communication over radio could prove disastrous. Previously, acoustic separation was achieved by putting everyone in separate offices, behind closed doors. The new centre achieves the same level of quiet through a combination of headsets and room acoustics – sound-absorbing timber ceilings, soft acoustic panels wrapped around workstations, and acoustic “clouds”.

“It is like a TV recording studio,” says Carl, adding that the new open-plan workplace is proving more collaborative, effective and enjoyable.

Like a house built facing away from the view, Lower Hutt turns its back on its most appealing natural asset, the river. Among multiple objectives, Te Wai Takamori o Te Awa Kairangi programme is partly about correcting that historical misstep by creating improved walking and cycling links to and over the river, and the addition of new riverside development sites.

There’s more. The five-year programme of works will step up protection for Aotearoa’s most densely populated flood plain – Lower Hutt has a population of 110,000 and rising – and tackle unsafe traffic congestion around the Melling/State Highway 2 intersection, while forging better public transport links.

It’s an ambitious programme, gifted a suitably consequential name. Te Wai Takamori o Te Awa Kairangi means “The Soothing Waters of Te Awa Kairangi” and refers to the story of how the ancient tupua Ngake created the river as he strived to escape a land-locked lake.

The five partners involved include iwi Taranaki Whānui ki Te Upoko o Te Ika and Ngāti Toa Rangatira, Greater Wellington, Hutt City Council and NZ Transport Agency Waka Kotahi (NZTA). Through an alliance with AECOM and Fletcher Construction, NZTA will deliver the Melling transport improvements (including a new gradeseparated SH2 Melling interchange and bridge over Te Awa Kairangi/Hutt River, relocation of the Melling train station and improved walking and cycling paths). The Alliance team is also working with Hutt City Council to deliver the City LInk Bridge that links the railway station with the city centre. Outside the Alliance, Greater Wellington will handle

river works and stopbanks while Hutt City Council will tackle improvements to local roads and streetscapes.

Given the devastation caused by storm events around Aotearoa in the past few years, and with more extreme weather events, arguably the programme's most pressing order of business is flood protection. Graeme Campbell, Greater Wellington’s Strategic Advisor for Flood Resilience, says the goal is to upgrade Lower Hutt’s stopbank system to withstand a one-in-440-year flood event, which has a 0.23 percent chance in any year. This includes an allowance for climate change. To achieve it, the existing Melling Link Bridge, which forms a chokepoint in the river, will go, and the stopbanks will be raised and widened. Providing a bigger stopbank while giving the river as much room as possible and removing existing services is part of the challenge.

Transport? Currently, the Melling interchange is congested and unsafe. Transport improvements here will remove the dangerous right-hand turns to and from the state highway by building a grade-separated interchange. But fitting a solution between the river and the western hills is challenging. The grade-separated interchange will operate more safely and efficiently. Meanwhile, the Melling train station will be relocated and linked to an all-new pedestrian and cycle bridge. This programme of works will help turn Lower Hutt into a better-connected city, with better access to the state highway, public transport, walking and cycling, and a healthier river.

According to the traditional Māori creation story, the battle between the tupua Whātaitai and Ngake was earth-shattering, but it gave us Te Whanganui-a-Tara/Wellington Harbour. Now a $311.9m project named in reference to those two tupua is under construction. A key goal: to give the harbour’s western edge the resilience it will need to withstand whatever climate change and seismic upheaval can throw at it.

Te Ara Tupua, gifted by Kura Moeahu, one of the mana whenua leaders, is about more than resilience. When completed in 2026, it will also provide cyclists and walkers with a safe coastal pathway between Wellington and Lower Hutt, complete with six ūranga (landings) to take in the view.

“Not only will it make it safer, but it will open up demand,” says Project Director Ulvi Salayev FEngNZ CPEng, citing official forecasts of 2,100 cycle trips per day, 360 walking or running, and 290 on e-scooters and similar.

The same five partners on Te Awa Kairangi are involved here, along with Wellington City Council, and the project has been divided into two sections. The first is a five-metrewide, 4.5-kilometre shared path between the Ngā Ūranga interchange and Pito-One. It includes boulder and concrete revetments (plus six seawalls in places with high value habitats) designed to protect the pathway and neighbouring rail line and highway from erosion by waves, as well as a rail overbridge at the Ngā Ūranga end. It’s being delivered by alliance partners Tonkin + Taylor, Downer and HEB Construction, and is well underway, with a targeted completion of 2026. The second section, a 3.5km cycleway from Pito-One to Melling at Lower Hutt, was delivered by Fulton Hogan and opened in October.

Ulvi highlights the critical nature of the corridor, which as well as a state highway and a rail line incorporates the pipes that provide up to 70 percent of Wellington’s water. In 2013, a storm washed out part of the seawall between Ngā Ūranga and Pito-One and

We have flora and fauna there, we have KiwiRail next to us, so how do we balance all of that while moving fast to deliver the project on time and budget?

– Ulvi Salayev

disrupted rail services for a week. On that evidence, the decades-old revetments won’t withstand the impact of climate change. Their replacements will be composed of 144,000 tonnes of boulders, supplemented with precast concrete X-shaped blocks, each 2.6 tonnes, that interlock like Lego to provide armour against storms and wave-action. Both the revetments and sea walls have been designed so they can be raised to accommodate future sea level rise at reduced cost.

Constructing this section of Te Ara Tupua will be difficult. As Ulvi points out, they’re operating between a rail line and the water, cheek by jowl with a major faultline.

“We have flora and fauna there, we have KiwiRail next to us, so how do we balance all of that while moving fast to deliver the project on time and budget?”

The concrete blocks are part of the answer, being more cost-effective and quicker to deliver than boulders. Another cost- and labour-saving innovation on the project is the use of GPS-enabled “digital shield” technology to manage the movement of heavy machinery around the rail line. As for mitigating the impact on flora and fauna, two rocky habitats have been constructed 40m offshore to accommodate birds disrupted by the project, and 56 artificial reefs have been placed to provide habitat for seaweeds, algae, crayfish and shellfish.

Stricter seismic standards have put some of Wellington’s key civic buildings temporarily out of action. How are things progressing?

Demolition work was to begin in late June and conclude in December.

As of June, seismic work was largely complete, and the focus had shifted to completing the new auditorium basement and reinstatement works.

Strengthening and modernising Te Matapihi began in 2022, with a predicted completion in 2026. In 2023, new piles and base isolation were installed; earlier this year a “rattle zone” was created and a ground concrete slab poured.

Above: Rock and XblocPlus units are stored on the Te Ara Tupua project site before being transported to work areas.

Photo: NZTA

Opposite: Construction of the Mills St stopbank is progressing well. Photo: Greater Wellington

WRITER | KAITUHI ALEXANDRA JOHNSON

From building transistor radios as a child in the 1950s to becoming a global leader in computational physiology is quite a journey. But that’s the path newly-Knighted Sir Peter Hunter HonFEngNZ has taken as he’s helped put Aotearoa on the map through bioengineering.

Recently appointed a Knight Companion of the New Zealand Order of Merit for services to medical science, Sir Peter Hunter HonFEngNZ has always been a problem solver. He’s the Founder of the Auckland Bioengineering Institute (ABI) at the University of Auckland, and a founding member and Co-Chair of the International Physiome Project, which aims to build sophisticated models of human organs by integrating mathematics and physics with human biology. This will ultimately result in a complete virtual physiological human and could eventually revolutionise patientspecific diagnosis and treatment.

Sir Peter grew up in an engineeringdominated family. His father, an electrical engineer, was commissioned by the Broadcasting Commission to build New Zealand’s first closed circuit television, which he did in his garden shed with a young Sir Peter looking on.

“My brothers and I had our own workbench and tools in our bedroom. In those days you spent your childhood building things, pulling things apart and putting them back together.”

Sir Peter completed an engineering degree in Theoretical and Applied

Mechanics at the University of Auckland in 1971, followed by a Master of Engineering focused on solving the equations of arterial blood flow.

“When I finished my undergrad degree, an inspirational lecturer, Mike O'Sullivan senior, offered a topic in blood flow, how to understand it using a mathematical approach,” he says.

“I’d done no biology at school, knew nothing about it,” he says. “But that opened the door. I just thought it was so interesting and that there were so many opportunities applying engineering and mathematical approaches to biology, that I never wanted to do anything else from that moment on.”

Following his master’s degree, he was granted a Commonwealth Scholarship at the University of Oxford in England.

“I decided I wanted to jump in boots and all and did my PhD in the physiology department.”

He joined a group intent on building a model of the heart using very simplistic methods.

“That’s when I really began to delve into how you could understand heart anatomy using mathematical techniques to build models.”

He adds: “I was, in a sense, taking a punt on computing power increasing. And it did, thank goodness.”

Since then, Sir Peter’s vision of a digital model of the heart has grown into a programme called The 12 Labours, which aims to map 12 organ systems. The project

is led by the ABI in collaboration with numerous international partners.

Where did such foresight stem from?

“Naivety. I didn’t know what I didn’t know,” he says simply.

“Everything is based on the laws of physics. That’s the case right across all areas of human endeavour, except for, at that stage, biology. It was felt that biology was just too complex. But biology has to satisfy the laws of physics as well and bioengineering brings that framework, that ability to use maths, physics and engineering to bear on physiology, anatomy and biology.”

While it’s still early days, he says bioengineering is going to play a key part in understanding the complexity of health and medicine, “... particularly as we get

more measurements on a given individual, such a genes, blood biomarkers, wholebody physiological testing”.

While working on this ambitious project, the ABI has spun out approximately 25 companies in the past 15 years.

“You can’t ask for public money to fund a very long-term goal without delivering in the interim. You need the long-term goal but also the capacity to spin out opportunities for application and employment along the way.”

Peter says medical technology, or medtech, has got huge potential to create both economic opportunities for Aotearoa and positive healthcare outcomes.

“New Zealand is a very good place to be trialling new approaches to healthcare

– we’re a small, well-connected, welleducated population with electronic health records.”

Peter says there’s a huge focus on health equity within the ABI.

“It’s about trying to move healthcare into the home environment. It’s a long-term solution to keep people out of hospitals and reduce the cost of healthcare.”

Throughout his career Peter has received a cornucopia of national and international accolades and awards, but says the most significant was becoming a Fellow of the Royal Society (United Kingdom), which recognises many of the world’s most eminent scientists. The second, he says, is the Rutherford Medal, New Zealand’s most prestigious science award.

My brothers and I had our own workbench and tools in our bedroom.

He sees his most lasting legacy in the establishment of the ABI, “... building a collegial working environment that has critical mass and is very strongly internationally connected. It has over 120 PhD students and shows that New Zealand can be an international player in science”.

What advice does such a highachieving scientist give to engineers starting out?

“While you have to delve deeply to make a contribution in your field, it’s really important to be reading across a broad area, not only in science, but outside of it.” He adds: “In my career, I was probably pretty naive in a number of areas, but the more you read and delve into new areas, the more opportunities open up.”

Engineering

Construction underway on Stage One of the project in Nuku’alofa, Tonga.

Stage 1 (of 3) was completed in June 2024

180 people employed from McConnell Dowell

80 percent of the project team are local employees

Approximately 950m3 of old concrete recycled into 249 rock bags of crushed concrete to form the new seawall

More than 8,000m3 of concrete produced on-site using local aggregates to reduce shipping impact

165 tonnes of scrap steel recycled to New Zealand

| KAITUHI KATHY CATTON

Upgrading and expanding Tonga’s main port not only strengthens a lifeline for the Tongan people – given an estimated 98 percent of the nation’s imports arrive here –but it also helps mitigate the effects of climate change and provides employment for more than 140 local people.

The port of Nuku’alofa on Tonga’s main island of Tongatapu is midway through a large-scale transformation of its maritime infrastructure at the Queen Sālote International Wharf. Bolstered by smart engineering solutions, a focus on environmental sustainability, and a desire to work with and for the local people, this project marks a significant milestone in Tonga’s economic development and resilience against cyclones, earthquakes and rising sea levels.

The upgrade has been designed by engineering company Royal HaskoningDHV and is being delivered by multidisciplinary construction company McConnell Dowell. The aim is for the port to receive larger vessels and hence reduce operational expenses. Lowering the cost of importing and exporting goods will support the country’s economic growth.

David Perbey, Principal Engineer and Team Leader from Royal HaskoningDHV, is responsible for the overall delivery of the design, procurement, site supervision and contract management of the upgrade of the two wharves and surrounding infrastructure. He has been involved in the project since initial feasibility back in 2019.

“Using insights from the local people, we conducted a climate and disaster risk assessment,” says David.

“We also projected exposure to climate and disaster hazards, identified appropriate resilience measures, calculated investment costs and explored any residual risk as part of the assessment.”

As a result of this research, David and his team proposed to demolish and rebuild Wharf 1, extend Wharf 2 by 45m, build four additional mooring dolphins, refurbish four cargo docks, build a new revetment and new seawall, and lift the entire pavement by 400–600mm. The US$75m project also includes significant updates to lighting, waste management, fire protection and stormwater drainage. While one-half of the yard is upgraded, the other half remains fully operational.

Using insights from the local people, we conducted a climate and disaster risk assessment.

– David Perbey

The work is upskilling the local workforce using training programmes on port operations, maintenance, environmental working practices, HSE (health, safety and environment) and gender equality.

Frank Schubert is the Senior Project Manager from McConnell Dowell, managing the mix of marine and onshore works. He is very aware of the importance of social safeguards and community involvement in the project.

“We have 16 engineers on site, out of a total crew of 180. Of these 16 engineers, 10 are Tongan,” says Frank.

“Although there isn’t an engineering school here, we train them and they work with our expert project engineers to deliver the field work, ensure quality control and act as a vital link to the Tongan workforce.”

On the quality control side, for example, two Tongan engineers work in the on-site concrete batch plant.

“They are testing, sampling, crushing our concrete to ensure it is of an exceptionally high quality,” says Frank.

With the requirement to locally source as much as

possible, the concrete is produced out of the local coral aggregates. Although in Tonga the coral limestone is soft – not ideal for making concrete – the team is pleased with the solution.

“The limestone absorbs too much water, which is not good when we’re building new foundations under water. We’ve had to create a very sophisticated concrete mix,” Frank says.

The construction of the foundation for the marine structure in the Holocene limestone layer is critical in term of resilience. David explains further: “As part of the piling, we’ve put large concrete rock sockets within the limestone to ensure it withstands large cyclone uplift and earthquake kinematic loads.”

Through on-site training, the local workforce gains certificates and qualifications that are recognised in New Zealand. Frank says the project is the largest employer in Tonga and workers are supported with measures such as shuttle buses to and from work.

Frank and David are particularly proud of the “client-design-contractor communication” and the team spirit that exists on this project.

Frank says: “We started on the back foot due to Covidinduced delays, inflation, the general economic downturn linked to the Ukraine–Russia conflict, and there was the impact on the site from the volcanic eruption in January 2022 and the following tsunami.

“But we managed to keep communicating and finding a team spirit through all of this.”

David adds that the project is seen as “one of the best-performing projects in the Pacific to date”.

Environmental considerations include using a marine spotter (for marine mammals) during piling, and using non-impact techniques, David says. At the design phase, environmentally friendly features included oil separators in the stormwater system and an automated fuel tank system to prevent release of oil into the sea.

The project is set for completion in 2025 and is expected to bring a 50 percent increase in throughput and a reduced carbon footprint and provide safer working spaces for local operators and shipping companies.

Based in Tonga, Ana Bing Fonua is the Consultant Project Coordinator, leading the Project Management Unit. The team of three assists the Ministry of Infrastructure in implementing the project.

“For us, this project has been hugely important for the people of Tonga,” Ana says.

“Local stakeholders, including skilled Tongans returning from abroad, bridge language gaps and explain what’s required in a Tongan context.”

This collaboration has improved work practices and boosted local employment, aligning with Tonga’s strategic priorities and cultural values.

“It’s really special seeing Tongans give back to their community.”

Above:

Snapshot When Spain’s new look Spotify Camp Nou stadium is set to open at 60 percent capacity in December, the home of FC Barcelona will show off a range of sustainability credentials. Up to 90 percent of the materials from the predecessor structure will be recycled or reused. The new stadium, which will hold almost 105,000 spectators –making it Europe’s largest –will also utilise solar panels and a rainwater collection system. The stadium is due to be fully operational for the start of the 2026–2027 season. Image: FC Barcelona

Mainmark

40 Women in engineering: dreams and realities

42 From engineer to business owner

43 Concrete goals

44 Bridges to span generations

46 Keep your career on course

47 Proactively addressing privacy in the age of AI

48 Intersection

CINDY JEMMETT

All the participants in an oral history project canvassing women’s experiences in engineering in Aotearoa over the years have one thing in common.

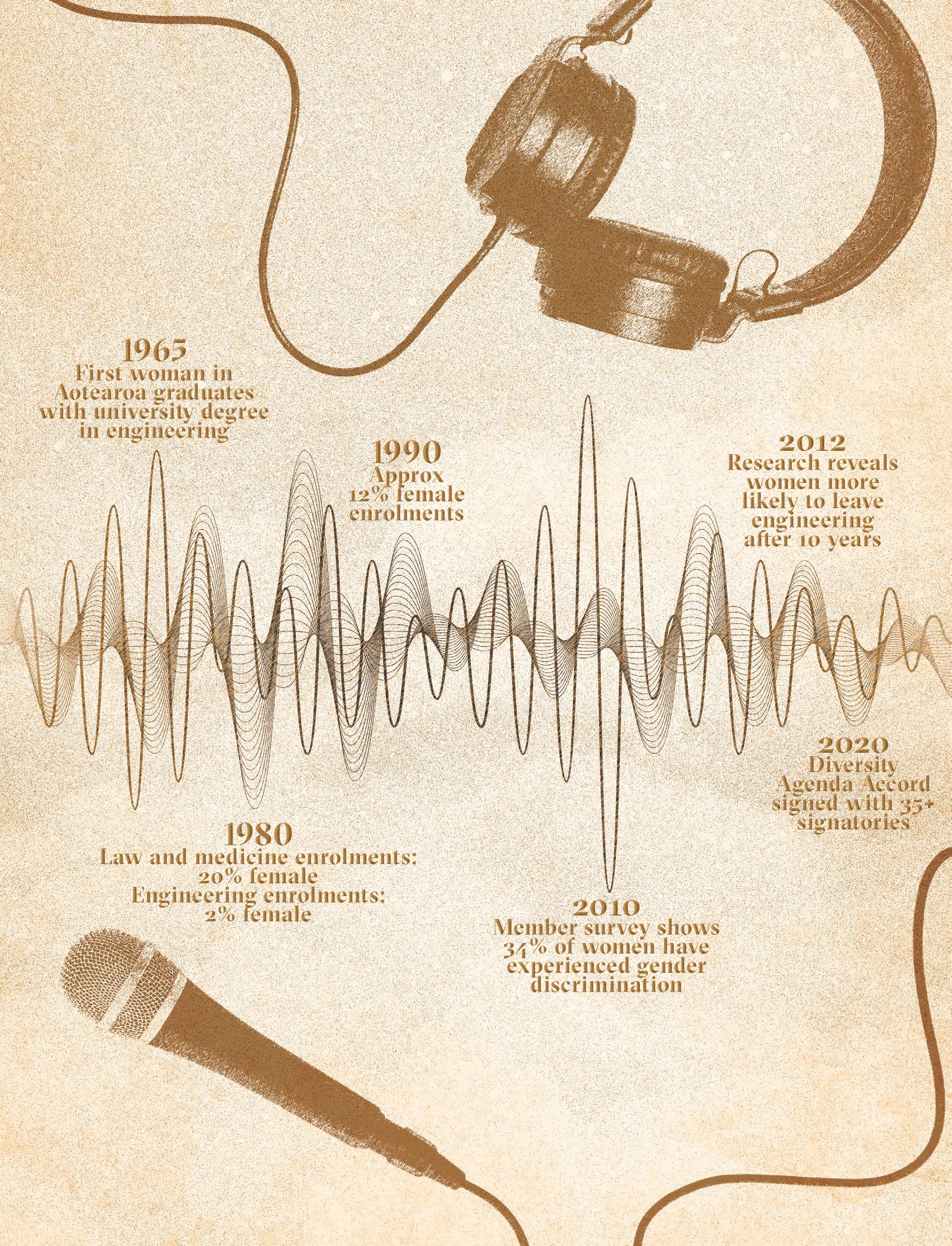

In September, Te Ao Rangahau launches an oral history project exploring the history of women entering the engineering profession in Aotearoa. It's a history that's relatively recent. Women currently make up only 18 percent of Te Ao Rangahau members. While there is still work to do, we’re excited to be working on it with industry and partners to welcome in the next chapter.

The project features the voices and stories of 20 women engineers from a range of career stages and backgrounds. They discuss how they first became interested in engineering, their experiences at university and in the workplace, and their hopes for the future. While their stories and experiences are diverse, they’re united by a love of engineering and a dream that everyone can feel welcomed and valued in this profession.

It was not until 1965 that the first woman graduated from a New Zealand university with a degree in engineering. By 1970, there were only a handful of female engineering graduates. By 1980 law and medicine were attracting around 20 percent women enrolments, while engineering trailed behind at 2 percent. Engineers have often been in short supply in Aotearoa. In the 1980s, the profession began to look to women as a previously untapped supply of engineering

talent to make up this shortfall. Why, the profession and universities asked, were so few women pursuing an engineering career? The answers they found focused on the lack of information available for high school students. Campaigns to encourage girls to enrol in engineering included brochures, posters and videos, along with activities such as talks, workshops and faculty open days. Much of this work relied heavily on women’s participation as advocates and role models.

These efforts in the 1980s had some success, and enrolment numbers climbed to around 12 percent by 1990. But would these graduates choose to stay in the profession? In the early 1990s women still only made up around two percent of the country’s professional engineers. It was not until the late 1990s that the conversations around women in engineering broadened to consider women’s experiences in the workplace and to discuss organisational culture, parental leave policies, part-time work and promotion. While many workplaces had equal opportunities policies in place by the late 1990s, there was sometimes a gap between policy and practice. An engineering career still very much demanded full-time commitment with little tolerance for career breaks. Taking part-time hours meant being assigned less-interesting or less-challenging roles and limited career progression.

These issues were still common through the 2000s and 2010s. Research published

in 2012 revealed that women were more likely than men to leave the profession within 10 years of graduating, due to not enjoying engineering or the workplace culture, or moving into different areas such as corporate finance, business analysis or research. A 2010 survey of our members showed women were far more likely than men to have experienced sexual harassment and gender discrimination at work – 18.8 percent of women compared with 1.4 percent of men, and 34.5 percent of women and 3 percent of men, respectively.

But also, from the 2000s it is possible to trace a growing appreciation and a deeper understanding of the value of diversity –for women’s contribution to the profession to be valued for the different skills and lived experience they bring.

Understanding this history has informed current initiatives to champion diversity and inclusion and to address our skills shortage. Te Ao Rangahau is a founding member of the Diversity Agenda and an Accord signatory. Our schools programme, the Wonder Project, continues to inspire Years 5–13 students and to grow their interest in STEM. We are also collaborating with ACE New Zealand and Waihanga Ara Rau to develop an action plan to better understand and address the country’s current engineering skills shortage.

Cindy Jemmett is Heritage Advisor at Te Ao Rangahau.

Transitioning from a technical role to business ownership is challenging and rewarding. I recently started my own structural engineering business to stay current as an engineer and maintain an understanding of our members’ needs.

Initially, I expected to be primarily an engineer with added business responsibilities. The reality, however, is I'm now a business owner, with engineering expertise woven into my work. This shift demands a diverse skill set, including project management, financial acumen and strong decision-making capabilities. You need a business plan and a marketing plan. You can make use of resources available from banks and the government. Balancing technical tasks with business operations requires adaptability and a willingness to continuously learn and evolve.

Unexpected costs and fluctuating income are inherent in running a business. Even with a reliable source of work, external factors such as economic downturns and policy changes can affect financial stability. For example, a change in government led to public service redundancies and a slowdown in the Wellington economy, significantly affecting my revenue. Building financial reserves and diversifying your services are essential strategies for maintaining stability. It's crucial to prepare for worstcase scenarios by having a financial cushion and alternative revenue streams.

One of my early mistakes was underestimating the importance of financial management. Engaging an accounting firm from the beginning and mastering tools like Xero could have saved considerable time and stress. Financial literacy is vital for managing cash flow, making informed decisions, and ensuring tax compliance. Prioritising your business’s financial health and seeking resources and training on financial management can provide a clearer understanding of your financial position and inform strategic decisions. There are a lot of tools out there and many of them are free. Use them and learn the skills before you need them.

In a competitive market, differentiating yourself doesn’t require grand gestures. Consistently delivering on the basics –promptly answering calls and emails, communicating clearly, and meeting client expectations – can set you apart. Ensuring that clients feel valued and maintaining open lines of communication builds trust and fosters long-term relationships, leading to repeat business and referrals.

Developing a robust quality assurance system from the start ensures consistent, efficient project delivery. Whether it’s a comprehensive project assessment tool or a simple checklist for routine tasks, these systems help prevent errors,

streamline processes, and enhance client satisfaction. One I developed is available at engineeringnz.org on the “Guidelines” page, along with a downloadable checklist for members. Although tailored to structural work, this can be adapted for other disciplines. These tools help avoid common pitfalls, reduce requests for information and improve overall efficiency. Prioritising quality assurance demonstrates a commitment to excellence and reliability. It also shows Chartered Professional Engineer assessors that you have a quality plan and understand the importance of processes.

Leverage AI – with caution

AI can be a valuable tool when used effectively. Use the AI resources available through Te Ao Rangahau but approach their output with the same scrutiny you would apply to a graduate engineer’s work. AI is particularly useful for tasks such as rephrasing difficult emails and conducting basic research. However, always verify the accuracy and relevance of AI-generated information to ensure it meets your standards and those of your clients. Thoughtfully leveraging AI can enhance efficiency and allow you to focus on more complex tasks and strategic decisions.

This article was written by Martin Pratchett CMEngNZ CPEng, Engineering Practice Manager at Te Ao Rangahau, and generative AI tools ChatGPT-4o and Google’s Gemini Pro.

ROB GAIMSTER

Aotearoa’s cement and concrete industry’s journey to net-zero carbon by 2050.

Demand for the world’s most widely used construction material will only increase as tomorrow’s built environment responds to climate change mitigation and adaptation requirements. For instance, shifting to clean and renewable energy, such as extended wind and hydro capacity, will require more concrete, not less, as will building resilient infrastructure in general. Steps have already been taken to ensure that the concrete used will be low-carbon, and ultimately net-zero carbon by 2050.

In late 2023, the country’s concrete industry released A Net-Zero Carbon Concrete Industry for Aotearoa New Zealand: Roadmap to 2050. This plan reflects a commitment to the Climate Change Response (Zero Carbon) Amendment Act 2019 and its aim to meet the greenhouse gas reduction targets under The Paris Agreement. The Roadmap identifies ways to reduce the direct (Scope 1) and electricity-related (Scope 2) emissions by 44 percent from 2020 levels by 2030, and 100 percent by 2050. The 2020 reference year was chosen to align with the Global Cement and Concrete Association’s roadmap. Manufacturing cement clinker releases CO2 from burning fuel to heat the kiln, and also through a chemical reaction as the raw materials reach temperature. As this constitutes a significant portion of the industry’s emissions, the pathways that will be taken to achieve net-zero emissions

by 2030 and 2050 have a focus in this area. By 2030, the industry plans to reduce emissions by using alternative fuels in cement clinker production. Golden Bay’s facility near Whāngarei has reduced its dependence on fossil fuel by replacing more than 50 percent of coal with waste tyres and construction wood waste, with the intention to be coal-free by 2030. Using less cement by replacing it partly with low-carbon supplementary cementitious materials (SCMs) and mineral additions is another major step in decarbonising concrete. SCMs can be naturally occurring materials, industrial byproducts, or manufactured products. Examples include ground granulated blast-furnace slag (GGBS), fly ash, silica fume, calcined clays and natural pozzolans (volcanic ash and pumice). Currently our uptake of SCMs is low, meaning there is potential for greater volumes to be used. All domestic cement suppliers are incorporating SCMs into their products, including Mount Maunganui-based HR Cement, which uses GGBS, while Holcim New Zealand recently opened a low-carbon cement replacement facility in Auckland. This use of low-carbon waste materials as alternative kiln fuel and as a partial cement replacement demonstrates concrete’s strong position within the circular economy. Another example is repurposing concrete structures at the end of their useful life, or crushing them to replace primary aggregates.

Another pathway is accounting for concrete’s ability to absorb CO2 over time,

a natural process officially recognised by the United Nation’s Intergovernmental Panel on Climate Change. Improving efficiency in design and construction will also contribute to emissions reduction.

Between 2030 and 2050, the industry will focus on Carbon Capture, Utilisation and Storage (CCUS) of remaining emissions to prevent them from entering the atmosphere. In Europe and the United States, Holcim has flagship scoping projects which will contribute to capturing more than five million tons of CO2 annually by 2030. CCUS is gaining particular traction in the United States, where the Inflation Reduction Act incentivises its adoption.

Other potential policy instruments include specifying low-carbon concrete, creating the infrastructure needed for a circular and net-zero manufacturing environment, and using appropriate carbon pricing mechanisms to ensure a level playing field on carbon costs and to avoid carbon leakage.

The industry has begun its decarbonisation journey on a strong footing, with sustainability firm thinkstepanz confirming emissions from cement fell by 15 percent between 2005 and 2018. Ongoing commitment from government, researchers and concrete stakeholders is crucial for further progress. Carbon reduction data will be reported every five years to ensure new technologies and regulatory changes are incorporated.

Rob Gaimster is Chief Executive of Concrete NZ.

ANDREW BALL CMEngNZ CPEng IntPE(NZ)

The demands on Aotearoa’s bridges and road structures are ever rising, with increased vehicle weights, extreme weather and climatic events, and heightened expectations of resilience under accidental loadings such as vessel and vehicle impacts.

While modern design standards have made infrastructure more resilient with minimal instances of failure, a large portion of our ageing bridges stem from the late 1930s construction boom. In benign environments with low traffic use, these bridges have performed well. Yet those subjected to harsh environmental conditions, increased loadings and perennial deferred maintenance are fast approaching the end of their service life, or are no longer able to meet expected levels of service and resilience. Most of these aged assets fall short of today’s design standards, having been designed for hazards and loads much lighter than current demands. These factors of aged asset portfolios and increasing demands put the country’s road structures at a critical junction.

Long-life assets such as bridges have for many years been an easy target for “sweating the asset” strategies. Unlike potholes, which are conspicuous in the road surface, structural deterioration generally occurs out of the public view. Relatively benign effects such as corrosion

of reinforcing and structural steel, or waterway degradation, if left unattended progressively consume asset life and increase vulnerability. This can lead to life-safety threats, early asset replacement or costly unplanned interventions. Unfortunately, this scenario has become increasingly common among asset owners.

Rising freight loads, traffic volumes and major weather events are exposing the deteriorating conditions and inherent vulnerabilities in our existing structures. Addressing the vulnerabilities that have reached a critical state is consuming an increasing portion of investment in network operations, often at the expense of proactive and preventative maintenance.

Asset managers serve as the safety net for the general public, entrusted with identifying threats to asset performance, managing these vulnerabilities and prioritising necessary interventions for the lowest whole-of-life cost. The ethos of maximising the use of existing assets resonates strongly within the asset management community, promoting sustainable resource use and efficient use of taxpayer and ratepayer contributions. Leading asset owners of Aotearoa’s transport structures, in collaboration with diligent structures managers, have proactively screened their asset portfolios

for failure risks not normally captured during condition inspections. Instances like load-deficient bridge halving joints, exposed truss members above deck, or bridges susceptible to vessel impact have been pinpointed through meticulous scrutiny. Through proactive and strategic interventions to address these vulnerabilities, the integrity and safety of critical transport infrastructure can still be protected. However, the growing cost of delivering these treatments presents a barrier to progress.

The role of asset managers grows increasingly pivotal, albeit with their safety nets wearing thin with growing backlogs of deferred maintenance, arising from decades of insufficient maintenance or asset renewals to maintain a steady state. On top of this, uncertain climate change dynamics, eco-conscious road network operations and enduring fiscal limitations magnify the challenges faced.

Embracing proactive maintenance and targeted improvements is essential for aged assets to achieve their design life, or better still, remain in service indefinitely. This approach requires that asset owners have a thorough understanding of their portfolios, built up on individual asset condition, vulnerabilities and documented management strategies that make best use of these assets. Decisions made on a whole-of-life optimisation approach would

put an end to a “throwaway” era. It would also allow the delivery of greater financial and resource operational efficiency through reduced premature asset renewal and reduced need for emergency works. Reducing levels of service may provide relief where the funding constraints prevent intervention. This trade-off of efficiency for reliability is a necessary consideration for communities residing in sparsely populated regions.

The good news is that good asset managers already have a thorough understanding of the condition, threats and vulnerabilities of the portfolios that they manage. Our design standards have continued to evolve to enable justified replacements to be longer lasting and more resilient now. We must work together to ensure the urgent threats facing the country’s bridges are well understood, and to emphasise the importance of adequate funding and investment to keep these critical community assets safe and serviceable into the future.

Andrew Ball CMEngNZ CPEng IntPE(NZ) is the Transport Structures Asset Management Director at Beca, with more than 20 years’ experience in the life cycle of transport structures from concept design through to end-of-life planning and everything in between.

Taking a strategic and proactive approach to professional development helps not only individual engineers, but the industry more broadly.

While the words “contracts” and “exciting” might not typically go together, with the right combination of course material and presenter, it can happen.

“The course was engaging and showcased a real-life example that was exciting and related to what we do.” This feedback is from an engineer who recently participated in a course exploring the practical applications of the role and responsibilities of the Engineer to the Contract and the Engineer’s Representative under NZS3910 Conditions of Contract for building and civil engineering works. Other feedback includes: “Couldn’t recommend more” and “Course material relevant. Discussions very informative.” Further testimonials specifically praise presenter Gavin Shaw MEngNZ: “Gavin kept it interesting with relevant examples and kept everyone engaged.” Founder of Navig8 Construction Advisory and Chair of the recently-established Society of Construction Contract Practitioners (SCCP), Gavin believes these courses are popular because they bring 3910 to life as a foundation document that sets the rules of engagement in construction contracts.

“All engineers benefit from a sound understanding of the part they play supporting 3910 contracts,” he says.

As for his presenter style, in part he

uses storytelling to engage and educate participants in his interactive workshops.

“It’s about using examples people can relate to, delivered in a relaxed and enjoyable manner, which is essential to bring 90 pages of 536 legal clauses to life in a way that resonates.”

While these courses are Te Ao Rangahau’s most popular continuing professional development (CPD) offering, Learning Partnerships Manager Nick Kimber says the development opportunities on offer are broad, from communication skills to specialist technical areas, and CPD plays a pivotal role in supporting members on their professional journeys.