— WORLDWIDE LOCATIONS

TEKNA, WORLDWIDE DISTRIBUTION OVER 60 COUNTRIES

The presence of Tekna on the territory is organised through a radial system. The same principle used by airlines to optimise coverage of all routes.

A HUB routes toward itself all the activities within a certain zone whose area is determined based on the type of market. The various units operating within the area therefore refer to the reference HUB, which organises and coordinates the commercial flows and is in charge of the results within its zone.

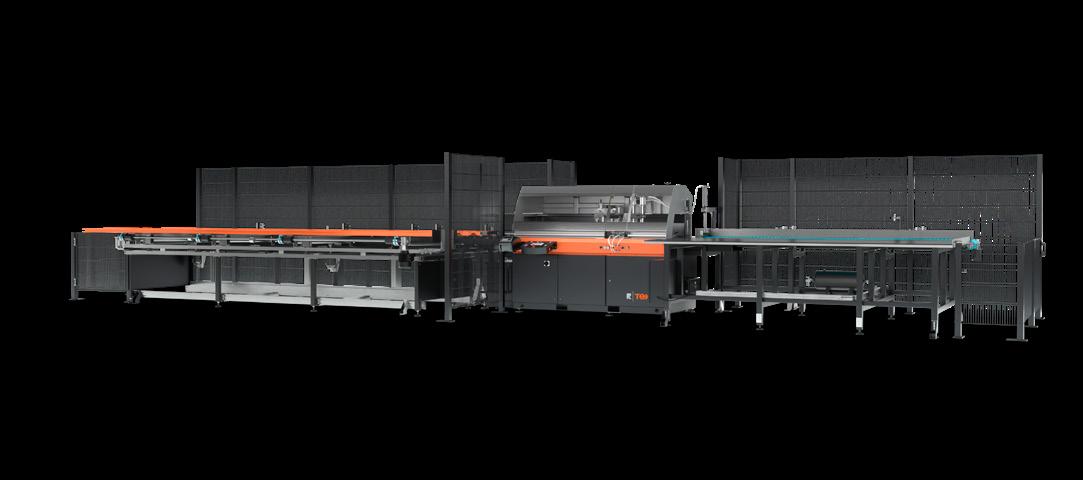

TKE 955

5-axis CNC mobile gantry machining centre for drilling, milling and tapping, at any angle from -90° to +90°, on bars or workpieces in aluminium, PVC and steel up to a thickness of 2 mm. The local safety cabinet combines top functionality, accessibility, soundproofing and lighting with safety and ergonomic requirements. The 11 kW electrospindle is able to perform heavy-duty machining. Tool magazine with 10 tools; a second magazine features two positions for a 400 mm blade and a second blade with 180 mm diameter. TKE 955 has two different operating modes: single-area mode, allows machining entire bars having a maximum length of 7 m in a single work area; double machining mode, allows machining several workpieces in the two different work areas. In HP version, it is possible to use the machine in dynamic double operation. TKE 955 features a laser scanner for more precise and advanced access control to the machine. Industry 4.0 ready.

Gantry positioning speed

125 m/min

TWO PROFILES

5 axis CNC functional, accessible, soundproofing cabin

with moving gantry in parallel machining

INDEPENDENT

H and P AXES Vice positioning through

7 m version

9 m version

TKE 954

4-axis CNC mobile gantry machining centre, designed for drilling, milling and threading at any angle from -90° to +90° on bars or pieces in aluminium, PVC and steel up to 2 mm thickness. The local safety cabinet was designed to combine top functionality, accessibility, soundproofing and lighting with safety and ergonomic requirements. The 8.5 kW electrospindle is able to perform even heavy-duty machining. 12-place tool magazine with positions for a 250 mm blade and an angular

machining unit. TKE 954 has two operating modes: the first one, in single-zone mode, for machining whole bars in a single working area; the second one, in double operation, for working on multiple workpieces in the two separate working areas. In version with clamp handling system on H and P axes, the machine can be used in dynamic double operation. TKE 954 features a laser scanner for more precise and advanced access control to the machine. Industry 4.0 ready.

Gantry positioning speed

125 m/min

TWO PROFILES

4 axis CNC functional, accessible, soundproofing cabin

with moving gantry in parallel machining

INDEPENDENT H and P AXES Vice positioning through

7 m version

9 m version

TKE 954 F

CNC 4-axis machining centre with mobile gantry, built for drilling, milling and threading from -90° to +90°, on bars or workpieces in aluminium, PVC and steel. The local guarding cabin has been designed to offer optimal functionality, accessibility, soundproofing and lighting while fulfilling safety and ergonomics requirements. The 11 kW electrospindle allows performing machining operations, even heavy-duty ones, with optimal results. The 13-place tool magazine, integrated into

the mobile gantry, features two special positions, one for a blade with a maximum diameter of 250 mm and the other for the angle machining head. TKE 954F features two operating modes: single-area mode to machine entire bars having a maximum length of 7 m in a single work area; double operation mode to machine several workpieces in the two different work areas. Ready for Industry 4.0.

Mobile gantry positioning speed

125 m/min

PROGRAMMING

4 axis CNC with moving gantry

Automatic clamp positioning through

INDEPENDENT

CNC FANUC 7 m version

H and P AXES

944 TKE 943

4-axis CNC machining centre with moving gantry structure, designed for drilling, milling, thread cutting and cutting at angle any from -90° to +90° on bars or workpieces of aluminium, PVC, light alloys in general and steel. The gantry is provided with a guard which reduces the noise impact on the environment. Industry 4.0 ready.

3-axis CNC machining centre with moving gantry structure, designed for drilling, milling and threading on bars or workpieces of aluminium, PVC, light alloys in general and steel. The gantry is provided with a guard which reduces the noise impact on the environment. Industry 4.0 ready.

8,5 KW AIR-COOLING ELECTROSPINDLE

12 PLACES AUTOMATIC TOOL MAGAZINE UP TO 16 PNEUMATIC VICES

4 m VERSION; 7 m VERSION

5,5 KW AIR-COOLING ELECTROSPINDLE

12 PLACES AUTOMATIC TOOL MAGAZINE

UP TO 16 PNEUMATIC VICES

4 m VERSION; 7 m VERSION

4-axis CNC machining centre for aluminium, PVC or steel up to 2 mm. Manual 9-places tool magazine and an automatic 4-station tool magazine located on the left side. An optional second automatic 4-station tool magazine can be installed on the right side. Mobile work surface that facilitates loading/unloading operations and increases the workable section. Industry 4.0 ready.

4-AXIS CNC CABINET

4 KW ELECTROSPINDLE

AUTOMATIC TOOL STORE UP TO 8 PLACES

ERGONOMIC BAR LOADING

TKE 783

3-axis CNC vertical machining center featured with a clamping system made up of vacuum tables. The machining center is equipped with a series of valves that turn on/off different areas of the table. It is designed for drilling and interpolated milling operations on composite panels, panels and plates in aluminum and steel. Industry 4.0 ready.

10 KW ELECTROSPINDLE

19 PLACES ON-BOARD TOOL MAGAZINE OR CARRIAGE-MOUNTED 10 PLACES REVOLVER TYPE TOOL MAGAZINE

X=4140; 6440 mm; Y=2000 mm

5 FACES MACHINING WITH ANGULAR UNIT

TKE 743

3-axis CNC vertical machining center featured with a clamping system made up of vacuum tables; The machining center is equipped with a series of valves that turn on/off different areas of the table. It is designed for drilling and interpolated milling operations on composite panels, panels and plates in aluminum and steel. Industry 4.0 ready.

10 KW ELECTROSPINDLE

12 PLACES FIXED TOOL MAGAZINE

X=4000; 5000 mm; Y=1600 mm

TKE 800

2-axis semi-automatic CNC cutting-off centre with horizontal blade feed designed for cutting profiles made of aluminium, PVC, light alloys in general. The machine is intended to perform cutting at an angle from 45° to 135° or from 22°30’ to 157°30’. It can be fitted with customised horizontal and vertical drilling units. Industry 4.0 ready.

2-AXIS CNC CUTTING CENTRE

550 mm HORIZONTAL BLADE

AUTOMATIC SETTING OF THE CUTTING ANGLE

INTEGRAL PROTECTION OF THE CUTTING AREA

TKE 801

3-axis automatic CNC cutting-off centre with horizontal blade feed designed for cutting aluminium, PVC, light alloys. It performs automatic cutting according to cutting lists and beveled cut on both sides of the profile. Cutting from 45° to 135° or from 22°30’ to 157°30. Automatic unloading magazine on the opposite side. Industry 4.0 ready.

3-AXIS CNC CUTTING CENTRE

550 mm HORIZONTAL BLADE

AUTOMATIC STORAGE UNLOADING

INTEGRAL PROTECTION OF THE CUTTING AREA

TKE 802

3-axis automatic CNC cutting-off centre with horizontal blade feed designed for cutting aluminium, PVC, light alloys. It performs automatic cutting according to cutting lists and beveled cut on both sides of the profile. Cutting from 45° to 135° or from 22°30’ to 157°30’. Automatic unloading magazine. Industry 4.0 ready.

3-AXIS CNC CUTTING CENTRE

550 mm HORIZONTAL BLADE

AUTOMATIC BAR FEEDER

AUTOMATIC STORAGE UNLOADING

INTEGRAL PROTECTION OF THE CUTTING AREA

TKE 554

Twin-head cutting-off machine with 3 controlled axes with automatic movement of the mobile head and electronic management of all 45 ° (internal) to 22°30’ (external) angles. Blades feed driven by hydro-pneumatic cylinders. 550 mmblade. Available with a useful cut of 5 m in length. Industry 4.0 ready.

3-AXIS CNC

550 mm BLADE

AUTOMATIC LOCAL PROTECTION

ERGONOMIC LOADING

7” TOUCH-SCREEN USER INTERFACE

TKE 553

Twin-head cutting-off machine with 3 controlled axes with automatic movement of the mobile head and electronic management of all 45 ° (internal) to 15° (external) angles. Blades feed driven by hydro-pneumatic cylinders. 550 mmblade. Available with a useful cut of 5 m or 6 m in length. Industry 4.0 ready.

3-AXIS CNC

550 mm BLADE

AUTOMATIC LOCAL PROTECTION

INTUITIVE TOUCH-SCREEN INTERFACE

STURDY DESIGN

TKE 552

Twin-head cutting-off machine with automatic mobile head movement driven by an NC-controlled brushless motor.

Pneumatic tilting of cutting units from 90° to 22°30’ (outward) in two fixed positions or with optional mechanical adjustment system for intermediate angles. Hydro-pneumatic blade feed.

Available with a useful cut of 5 m in length. Industry 4.0 ready.

1-AXIS CNC

550 mm BLADE

AUTOMATIC LOCAL PROTECTION

ERGONOMIC LOADING

7” TOUCH-SCREEN USER INTERFACE

TKE 305 EA

Single head rising blade machine for 90° cutting. It can be set up with four different diameter blades, the blade feed is N/C electrical driven. It can be provided with inverter, to control the blade rotation speed for the best adjustment. It can be equipped with an automatic bar loading magazine and with custom drilling units. Industry 4.0 ready.

IDEAL FOR INDUSTRIAL APPLICATION

350, 450, 550, 650 mm BLADE

REPEATABLE AND RELIABLE CUT

AUTOMATIC BAR LOADING

AUTOMATIC UNLOADING OF CUT WORKPIECES

TKE 365 EA

Single-head, rising blade cutting-off machine, with N/C automatic rotation of the vertical axis and hydraulic tilting of the horizontal axis. Cutting with angular settings from 90° to 22°30’ (left and right) on the vertical axis and from 90° to 35° (right only) on the horizontal axis. Equipped with digital position display for the horizontal axis.

650 mm BLADE

COMPOUND CUT

WIDE CUTTING DIAGRAM

STURDY AND ERGONOMIC DESIGN

TKE 355 PA - 350 PA -

345 PA

Single-head, rising blade cutting-off machine, with left loading side, able to perform cuts from 20° left to 20° right and intermediate angles.

450, 500, 550 mm BLADE

ADJUSTABLE BLADE SPEED ROTATION

COMPATIBLE WITH ELECTRONIC STOP GAUGE SYSTEM

USER-FRIENDLY AND INTUITIVE CONTROL

TKE 340 PA

Single-head, rising blade cutting-off machine, with left loading side, able to perform cuts from 15° left to 15° right and intermediate angles.

400 mm BLADE

ADJUSTABLE BLADE SPEED ROTATION

COMPATIBLE WITH ELECTRONIC STOP GAUGE SYSTEM

USER-FRIENDLY AND INTUITIVE CONTROL

TKE 355 PF - 345 PF

Single-head cutting-off machine with horizontal blade feed and left loading side, pneumatic double side tilting of the cutting head in fixed positions: 45° to the left, 90°, 45° and 22°30’ to the right. A special positive stop also allows cutting at intermediate angles.

TKE 340 SD

Single-head, descending blade cutting-off machine with left loading side,rotation of the cutting head to 45° (left and right) and manual tilting by 45° referred to the horizontal axis.

450 OR 550 mm BLADE

INTERMEDIATE ANGLES MECHANICAL STOPS

HORIZONTAL CLAMPING SYSTEM

400 mm BLADE

MANUAL CUTTING

ERGONOMIC DESIGN

TKE 330 SA - 330 MA

Single-head, rising blade cutting-off machine designed for cuts at 90°, 45° left and right and intermediate angles.

TKE 335 R

Single-head trimming machine with rising blade, for extruded profiles and flat sheets of aluminium. The especially rugged structure allows well defined and accurate cutting and ensures perfect parallelism between the profiles faces. Furthermore it can be equipped with profile support roller conveyors to increase its versatility. The blade guard is designed and built to work under the best safety conditions.

300 mm BLADE

MANUAL CUTTING

VERTICAL AND HORIZONTAL VICES

350 mm BLADE

ADJUSTABLE STOP

MAX TRIMMING HEIGTH 120 mm

MICROBO

Measurement and profile support verification system with movement of the lock through C.C. motor and electronic encoder reading. Measurement repeatability tolerance ± 0.3 mm.

FERMOSTOP

Measurement and profile support verification system with movement of the lock NC axis and electronic reading through absolute magnetic band. Equipped with electronic measurement system that allows saving data on internal memory or transferring them in real time to a PC or the control unit of a cutting-off machine via Bluetooth.

CUTTING LISTS MANAGEMENT

PNEUMATIC LIFTING WORKPIECE STOP

2 LENGTHS VERSIONS AVAILABLE (7.200 - 4.200 mm)

USB-PORT AND LAN RJ45

MANAGEMENT OF CUTTING LISTS

CONNECTION WITH BLUETOOTH MEASURING GAUGE

LENGTH 3,000 MM

SMART MANAGEMENT OF GLAZING BEAD CUT

FERMO VIS

Measurement and profile support verification system with positioning of the end stop using a handwheel and reading of the quota on the digital display screen. Positioning tolerance ± 0.5 mm.

INFEED ROLLEROUTFEED ROLLER

Structure in steel tubular con adjustable feet and PVC-coated steel rollers. 3,500 mm long roller conveyors with 240 mm rollers, or 4,000 mm-long with 440 mm rollers. Unloading roller conveyors equipped with metric rod and measuring lock.

AVAILABLE IN RH AND LH VERSION

VIS DIGITAL READER ALLOWS REPROGRAMMING POSITIONING

2 LENGTHS VERSIONS AVAILABLE (5.780 - 3.780 mm)

SUITABLE TO BE CONNECTED TO ALL MT MACHINES

EASY INSTALLATION

STURDY DESIGN

TKE 158 N TKE 158 S

Single-head copy router with 2 NC axes, ideal for machining aluminium profiles, PVC and steel up to 2 mm, possibility of machining stainless steel (optional). The 4-faced rotary work table allows increasing working speed and precision. Quick tool change ISO 30. Work area with pneumatic control protection.

2-AXIS CNC

WORKPIECE ROTATION IN 4 PRESET POSITIONS

MANUALLY-REGULATED STOP DEVICES

PNEUMATICALLY-CONTROLLED VICES

FOR ALU AND STEEL APPLICATIONS

Single-head manual-control copy router with pneumatic locking system and head traversing movement controlled by an indirect lever. Ability to work steel up to 2 mm and stainless steel (optional) up to 2 mm. Equipped with a rotating surface vice table system, the machine works 4 profile faces performing a rotation of 270° to 90° sectors.

1,1 KW MOTOR WITH INVERTER

WORKPIECE ROTATION

RAPID TOOL CHANGE

FOR ALU AND STEEL APPLICATIONS

TKE 158

Manually controlled single-head copy router with pneumatic vices and traverse of the cutting head with indirect lever. The tool rotation speed can be modified with electronic variable speed drive to allow machining on steel up to 2 mm, as well as to improve quality of milling and longer tool life. Scratch-proof work table.

TKE 151 S

Single-head copy router with manual downfeed. Manually controlled single-head copy router with pneumatic clamping and traverse of the cutting head with indirect lever. Predisposition for performing through machining operations on aluminium without turning the workpiece and for working steel up to 2 mm. Scratch-proof work table. Pneumatic stylus with control on the handle.

1,1 KW MOTOR WITH INVERTER

FIXED WORKPIECE POSITION RAPID TOOL CHANGE FOR ALU AND STEEL APPLICATIONS

0,75 KW MOTOR POWER

FIXED WORKPIECE POSITION HORIZONTAL VICES ONLY FOR ALU APPLICATIONS

TKE 162 M

Horizontal end milling machine with manual feed. Milling of intermediate angles, +45° / 90° / -45°. High speed of tool rotation for improved quality machining on painted profiles and at intermediate angles. Quick cutter change with pneumatic control. Scratch-proof work table. Fully guarded work zone with high internal visibility.

TKE 160 M

Horizontal end milling machine with manual feed. Mitre milling at 90°. Quick cutter change with manual control. Scratch-proof work table. Full guarding of work zone.

1,5 KW BRAKE MOTOR

320 mm STROKE

SUPPORT ROLLER CONVEYOR

FEED 1,1 KW BRAKE MOTOR

290 mm STROKE

TKE 124

Corner crimping machine for corner closing that can be used for many types of profiles, such as windows, doors, frames or mosquito nets. Thanks to its high corner crimping force, it is also ideal for use of large profiles where the maximum quality requirements are needed. Distinguishing features of TKE 124 are its stability and long service life.

CORNER CRIMPING OF LARGE PROFILES

EASY CONFIGURATION AND USE

ROBUST AND ERGONOMIC DESIGN

PRODUCT TESTED AND RELIABLE

ITACA SOLUTION

Crimping machine for closing corners of aluminium profiles for doors, windows and facades. The machine is controlled by an electronic system capable of storing the crimping coordinates. This information is required by the management system for the automatic positioning of the profile reference fork and crimping tools. The fork and tools position themselves automatically.

SUITABLE FOR DOORS, WINDOWS AND FACADES

AUTOMATIC FORK AND TOOLS POSITIONING

STURDY AND RELIABLE DESIGN

TKE 259

Machine to apply sealant on the profiles prior the assembling with corner cleats. With this machine, the quality of the window/door remarkably improves in the meaning of a better aspect of the window/door, a protection against corrosion initiation and a protection against air, water, noise and high/ low outside temperature.

PNEUMATIC FEED

SEALANT PLATE SIZE 150X130 mm

HIGHLY RESISTANT TO AGEING SEALANT

PEDAL CONTROLLED

TKE EXHAUSTERS

Exhauster for aluminium, steel and PVC swarf and chips, designed for cleaning machines and the work environment or extract swarf from work units that require high vacuum values. The use of a high-depression side duct turbine/venting system makes this products suitable for various extraction requirements. Equipped with an anti-static filter, they can manage the extraction of aluminium, steel and PVC swarf and comes complete with a wheel mounted, quick release collection tank.

MG2-T

2,2 KW MOTOR POWER

TURBINE VERSION WITH SILENCER

N.1 SUCTION INLETS

ANTI-STATIC BAG FILTER

MG2-V

1,5 KW MOTOR POWER

VENTING VERSION WITH SILENCER

N.1 SUCTION INLETS

ANTI-STATIC BAG FILTER

AUTOMATIC START BY ELECTRICAL CONNECTION TO MACHINE

MG4-V MG8-T

5,5 KW MOTOR POWER

TURBINE VERSION WITH SILENCER

N.2 SUCTION INLETS

ANTI-STATIC CARTRIDGE FILTER

MG4-VP MG2-TP

4 KW MOTOR POWER

SUITABLE FOR PANELS WORKING CENTRES

N.1 SUCTION INLETS

ANTI-STATIC BAG FILTER

AUTOMATIC START BY MACHINE

2,2 KW MOTOR POWER

VENTING VERSION WITH SILENCER

N.2 SUCTION INLETS

ANTI-STATIC BAG FILTER

AUTOMATIC START BY ELECTRICAL CONNECTION TO MACHINE

2,2 KW MOTOR POWER

VENTING VERSION WITH SILENCER

N.2 SUCTION INLETS

ANTI-STATIC BAG FILTER

AUTOMATIC START BY MACHINE

SOFTWARE FOR MACHINING AND CUTTING CENTRES

For Tekna Machining Centres management, Emmegi has a broad range of software: CAMplus, Shape, DriverCL, DriverCAD, Time-X, Mac-X; complementary and integrated with each other. The software listed above allow you to quickly define all machining that needs to be carried out on the workpiece and move on to the production phase in just a few minutes and in a simple and intuitive manner thanks to a userfriendly interface. More specifically, CAMplus allows you to program machining graphically in 3D, visualising the profile and the tool. The software includes the most recurrent figures (holes, slots, rectangles, etc.) that can be broadened with Shape, which allows defining any tool path. For those who work in the door and window frames field, CAMplus is fully integrated with the FP Pro program by Emmegisoft and is interfaced with the most common software on the market by means of DriverCL. For designers who use CAD 3D programs (Autodesk Inventor, SolidWorks, etc.). DriverCAD allows recognizing the machining automatically, with a significant reduction of the programming time and the error rate. CAMplus, DriverCL and DriverCAD additional modules simplify the connection between office and workshop. SolidCut is a specific driver CAD for cutting machines; with this office software we can import single, multiple or assembled step files. The profile code and other informations like length and cut angles can be automatically recognized generating a cutting list to send at the machine. Suitable for TKE 554 and 553. Time-X is the tool proposed for estimation and allows calculating in advance the workpiece machining time. MAC-X is a web-based software that allows viewing and monitoring the production activities carried out by one or more automatic machines and/or manual stations in real time and getting a complete reporting of the production cycle. All these software are then completed, on the machine, by the operator interface, HDrill, simple and clear, which provide, in an immediate and efficient way, all the information necessary to use the machine.

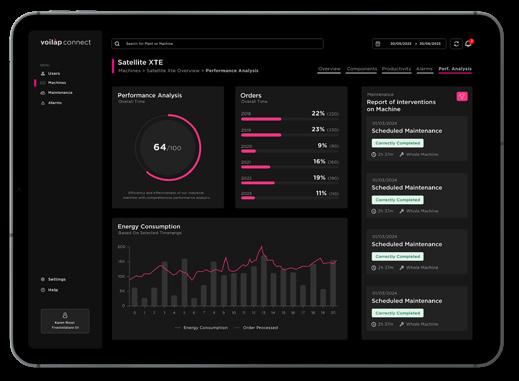

Evolve your production

Voilàp Connect is a cloud-based IoT (Internet of Things) platform which allows machines, their energy and pneumatic consumption, as well as production status to be monitored from anywhere in real time. Its control panel provides access to the machine’s data history, facilitating analysis of productivity, compliance, alarms and downtime. This enables swift measurement and enhancement of production capacity, reduction of consumption and waster as well as prediction of maintenance requirements.

REMOTE CONTROL DATA SECURITY

Real-time overview of the overall condition of every machine within the company

Machine status in real time: uptime, working time, idle time, alarms, etc

Remote display of the alarms on the machines

Can be viewed on tablets and smartphones

Dedicated 4G/LTE network: connectivity via a dedicated sim excludes the need to connect to the corporate network

Adoption of advanced security measures with state-ofthe-art encryption

All data collected is protected according to the strictest privacy regulations

Cloud service provided by main providers

PRODUCTION EFFICIENCY

Trend creation and display of machine production efficiency

Cloud access to basic production status information of orders

Creation and display of cloud-based production reports

ENERGY AND PNEUMATIC CONSUMPTION MEASUREMENT

Analysis of consumption trends over time

Analysis of consumption peaks

SLW SELF-LEARNING

HDRILL

The Numerical Control basic software, which controls all the functions of the Working Centre through a window-based interface, includes: The operator graphic interface that displays all the variables of the Centre, related both to programming and user.

CN6 SHAPE SHAPE 3D CAMPLUS

Specific 3D CAD/CAM system for programming Emmegi machining centres, it is characterised by extremely high performance integrated in a user-friendly interface. The programming of the machining operations is based on a graphic environment with 3D visualisation.

SLW (Self Learning for Windows) software license, complete with additional macro libraries, for creating machining programs from the office.

Next-generation operator interface, specifically designed for large, vertically-oriented monitors, optimised for use with touch screens.

Born as a tool for the programming of special shapes, today Shape has evolved adding to the basic performance the management of special tools such as flow drill, creator, thriller, screw tap bit.

Available for 5-axis machining centres, Shape 3D adds to Shape’s features the ability to work on curved profile faces, using 5-axis continuous milling functions.

The software to import “STEP” and “ACISSAT” formats from CAD-3D programs, such as Autodesk Inventor, Solidworks, etc.

DRIVER CL MAC-X DRIVER CAD

Web software for displaying in real-time and monitoring the production activities carried out by one or more automatic machines and/or manual work stations.

The software that interfaces with window/door software, management software and CAD/CAM software.

SOLID CUT

Driver CAD for cutting machines to import multiple or single step files.

TIME-X

TIME-X is the estimation tool, available in the CAMPLUS suite, to calculate the piece machining time in advance. For machines that work with pre-cut pieces, TIME-X will estimate the machining time of the piece or pieces loaded in a work zone.

The product data, descriptions and illustrations appearing in this catalogue are shown for advertising purposes; they are given as examples only, and shall not be binding on the manufacturer or the vendor under any circumstances. For marketing reasons, products may be reproduced or portrayed with non-standard configurations, colours or optional extras, in older versions or withspecial customisations or different technical characteristics, possibly for supervening manufacturing reasons. The manufacturer and the vendor reserve the right to make any modification whatsoever to the products. Please contact the sales personnel if you have any queries.