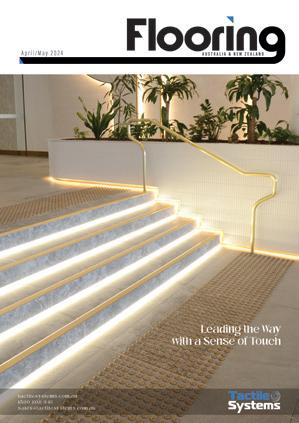

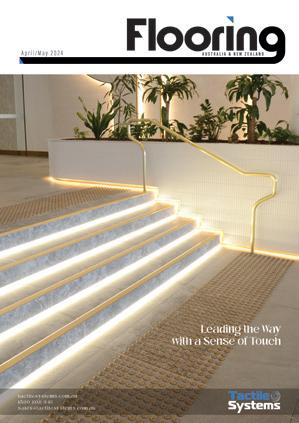

AUSTRALIA & NEW ZEALAND April/May 2024 Leading the Way with a Sense of Touch tactilesystems.com.au 1300 808 946 sales@tactilesystems.com.au

step® safety flooring

The new Step safety flooring collection combines modern aesthetics without compromising on performance. The refreshed offer features 63 new colourways, including the addition of new contemporary wood and stone designs alongside a new dementia-friendly range. R10, R11, R12 and barefoot areas are covered.

Discover Forbo’s newest safety flooring range

creating better environments

Editor’s Note

Welcome to the April / May 2024 issue of Flooring Magazine. Inside this issue you will find our Australian Made feature where the team behind the eponymous Australian Made Campaign explain how businesses can certify their products with the unmistakable green and gold kangaroo label, the quickest and easiest way to communicate your genuine Australian credentials.

Our Company Profile in this issue is Beare Flooring. A fresh concept in flooring, Beare are pushing the industry forward with their own newly developed software technologies and specialising in mobile showrooms.

If you have any industry news, company events and or new products you would like to showcase please feel free to contact me directly at –michelle@elitepublishing.com.au

Until next time, enjoy your read.

Michelle Cammiade Editor

3 Flooring April/May 2024 www.flooringmagazine.com.au Contents

Front Cover Tactile Systems www.tactilesystems.com.au vol 42 no 2 Flooring Magazine is on: @flooringmagazineaustralia @flooringmagazineaustralia News 4 FCIA Gala Ball Product Update 12 Transforming urban accessibility Feature 14 Australian Made Focus On 28 QEP – Now completely Australian owned Company Profile 32 Team Beare – A new standard Software 36 Improve your business – Embrace follow-up Design & Trends 42 An interior trend report by Feltex Spotlight On a Franchisee 48 Down to earth at Andersens Stanthorpe

FCIA Gala Ball – Our industry night of nights

On Saturday, the 2nd of March 2024, the FCIA hosted its second Gala Ball building upon the success of the Inaugural Gala held in 2023. With a guest list of over 448 attendees, the Plaza Ballroom was nearly at capacity and alive with anticipation.

The opening comments from the FCIA’s Chairman, Brett Sturgess were, “Thank You” and “Amazing” as he welcomed the who’s who of the Floor Covering Industry.

A highlight of the evening was the announcement that the FCIA was actively seeking Alliance Partnerships with other associations in the floorcovering industry, who offered unique advancements and benefits, from each other, for the benefit of our industry. Simply put, under the Alliance Partnership industry associations would

collaborate and work together developing projects that made sense for each other for the benefit of our industry. Brett confirmed that FCIA had already formed Alliance Partnerships with both the Australian Resilient Flooring Association (ARFA) and the Floorcovering Education Foundation of America (FCEF), partnerships which will benefit our industry moving forward.

Brett further acknowledged that the primary concerns and frustrations of our skilled labour shortage has plagued our industry for more than a lifetime and we therefore, as an industry, need to change the way we try and solve these issues, from the current singular level to a full industry level, with everyone represented in the room committed to the design and support of one industry road map moving forward. It is very much the old adage,“Many hands make light work,” if we all commit, we all end up in a better place sooner-it’s as simple as that.

Following his remarks, Fiona Wischnewski, CEO of the FCIA Group, highlighted the organisation's achievements over the past year and future plans for this year. These included:

• RTO – now operating and funded in NSW, SA, TAS and ACT

• Attracting new learners into the flooring trade by attending career days, talking to schools etc.

• Specific welcome packs for apprentices

• Insurance program with Flooring Protect

• Creation of FCIA’s Underfoot Newsletter

• Creation of a Females in Flooring group → 6

4 Flooring April/May 2024 www.flooringmagazine.com.au News

• Short courses due to be released in June/ July 2024

• Self-regulated license

To enable FCIA members to participate in the award segment of the evening, this year's awards were sponsored. Additionally, a new award was introduced for the FCIA Supplier of the Year and Commercial Contractor of the Year, to once again acknowledge and honor some of the industry's top talent. The winners of these awards included:

• Apprentice of the year – first year Max Cheetham, Warilla Carpet Court

• Apprentice of the year – second year Caleb Jacoby, ISA Street Carpets

• Apprentice of the year – third year Bear Payne, ISA Street Carpets

• Apprentice of the year – fourth year Ben Townsend, Devonport Floorworld

• Apprentice Achievement Award Cooper Morrison, Terry Bros Carpet Court Young

• Employer of the year Mascot Carpet Court

• Supplier of the year Mapei

• Commercial Contactor of the year Lockwood Flooring

• Flooring Industry Achievement Award Don Considine, ATTAR

The Gala provided a platform for professionals from all sectors of the industry to network and engage in discussions

regarding the significant challenges and risks facing the flooring sector. It was inspiring to watch representatives from a range of different flooring organisations come together to celebrate the Australian Flooring Industry.

In a post-Gala survey, many attendees shared their positive experiences and discussed their excitement for next year’s event. The team at FCIA are passionate about making sure that each year’s event is a better experience for those who attend, and they are already hard at work on planning the 2025 Annual Gala.

If you would like to understand more about what the dedicated team at FCIA do and how you can partner with them to create a better future for the flooring industry, then visit www.fcia.org.au s

6 Flooring April/May 2024 www.flooringmagazine.com.au News

Big River Group unveils strategic rebranding initiative

Big River Group, a leading supplier of building materials and panels across ANZ, proudly announces a strategic rebranding initiative aimed at fortifying its market position by unifying the company’s diverse portfolio of brands to foster synergies and coherence across its business operations.

John Lorente, CEO of Big River Group, emphasised the rebranding is a proactive step to streamline operations, create unity across the business and unlock new opportunities for growth. "By aligning our local service excellence with our national scale, we aim to enhance our operational efficiencies while driving excellence and innovation in our solutions to better serve our customers, suppliers, and shareholders," stated Lorente.

With a legacy spanning over 120 years, Big River Group is positioned for future growth while remaining steadfast in its commitment to stakeholders. "We understand the importance of clarity and consistency in how we represent ourselves to the market. Our rebranding effort signifies more than just a visual transformation; it leverages our extensive experience and service autonomy across the group, empowering the company to adapt swiftly to evolving market dynamics

while maintaining a steadfast focus on customer satisfaction. By consolidating our resources and expertise under a cohesive brand identity, Big River Group is poised to capitalise on synergies and drive sustained growth in the years to come,” Lorente added.

“There is a need to be representing ourselves as one Big River team showcasing our capability for our customers and suppliers. Our mission, ‘Committed to doing good business with good people to build better projects,’ serves as a testament to our commitment to operating as one team, delivering exceptional value and product solutions to the market," said Lorente.

Key highlights of the rebranding initiative:

• Brand Architecture: Big River Group's brand structure will adopt a hybrid approach featuring five key brands: Big River Group as the Masterbrand, with Big River Commercial and Big River Trade Centre as sub-brands, and Timberwood Panels and Plytech Panels as endorsed brands.

• Unified Values: The rebranding initiative will align all Big River Group brands

under shared common values, ensuring consistency in delivering exceptional products and services. This unified approach will reinforce the company's dedication to quality and customer satisfaction.

• Visual Identity: The rebrand encompasses a new logo, website design, and name changes to existing brands, maintaining visual coherence to the Masterbrand, while reflecting the company's renewed focus on synergy and cohesiveness.

As Big River Group embarks on this journey, daily operations will not be affected, its wide product range, services and exceptional team remain unaffected, ensuring a seamless transition for customers and stakeholders. Big River Group remains committed to delivering innovative products and services without interruption.

The phased roll-out of the rebranding initiative will commence with the introduction of the new logo, followed by subsequent brand assets throughout the year.

For further information, visit https://www. bigrivergroup.com.au/ s

7 Flooring April/May 2024 www.flooringmagazine.com.au News

Product Update

Exploring the new possibilities of custom flooring design

More and more we are seeing the request for custom design flooring that turns a mundane space and floor into a unique feature. Thanks to technology and considered design, floors are moving beyond functional finishes and becoming tools that communicate and set the interior mood and feel.

With Forbo's extended digital printing capabilities, the possibilities are now endless. From vibrant abstracts to lifelike natural scenes, create a floor that reflects a unique style on both vinyl sheet and Flotex resilient textile. Digital libraries are expansive, offering hundreds of designs ranging from floral elegance to geometric precision and many designs can be tailored to a client’s preferred colour scheme.

One example shown is drawn from the transformation of Loxton Lutheran School, where Eternal custom HD digitally printed floor transformed classrooms into vibrant reflections of local culture and landscape. Designed by Hodgkison Architecture, they collaborated closely with the school to capture the essence of the local area and culture with its design of the winding Murray River and the creatures that inhabit the area, incorporated into the classroom floors.

It is a testament to the power of personalised flooring in creating truly inspiring spaces. From educational facilities to commercial offices, the Forbo Custom Flooring offer is revolutionising interior design.

Coming soon: The Next Step in adhesive-free HD flocked flooring Forbo are constantly pushing the boundaries of what is possible in flooring technology. That is why they are thrilled to announce the upcoming launch of Flotex Next, the industry's first fully adhesive-free textile flocked flooring.

The new engineered backing combines Flotex's unbeatable performance with the ease of loose-lay installation for high-traffic areas. No more installation hassles with adhesives—just seamless flooring that is ready to walk on right away and can be removed and replaced with ease. Perfect for environments that need fast and flexible design solutions.

About Flotex

Flotex flocked flooring is a unique textile flooring that combines the hard-wearing and durable characteristics of a resilient floor with the quality, warmth and comfort of a carpet. Flotex is available in sheet, tiles and planks.

• Easy to clean and maintain year after year

• Hygienic: nylon fibres capture allergens and fine dust from the air, which they effortlessly release with every cleaning action

• Allergy and asthma-friendly

• R12/P5 slip rating minimises the risk of slips and falls in the wet and dry. Fast drying.

• Great sound absorption properties and low-impact sound transmission

The Flotex Next construction will be made available for Forbo Flotex Naturals, Hospitality and Leisure and ‘Created by’ sheet collections and for all Flotex sheet items in the digital library. The floor covering is a sustainable solution, with excellent circularity benefits thanks to the easy reusability of the product.

Trust Forbo Flooring Systems to bring your vision to life, blending creativity to deliver flooring solutions that inspire. With their Custom Flooring offer, the only limit is your imagination. To learn more visit www.forboflooring.com.au/custom-flooring s

8 Flooring April/May 2024 www.flooringmagazine.com.au

Product Update

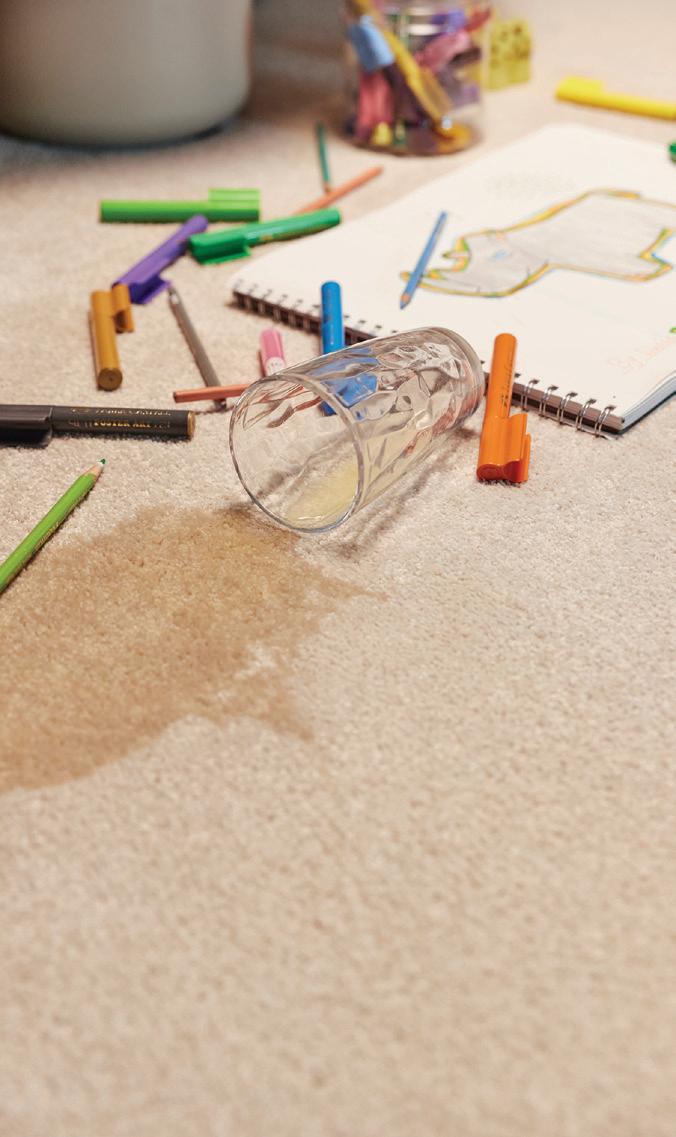

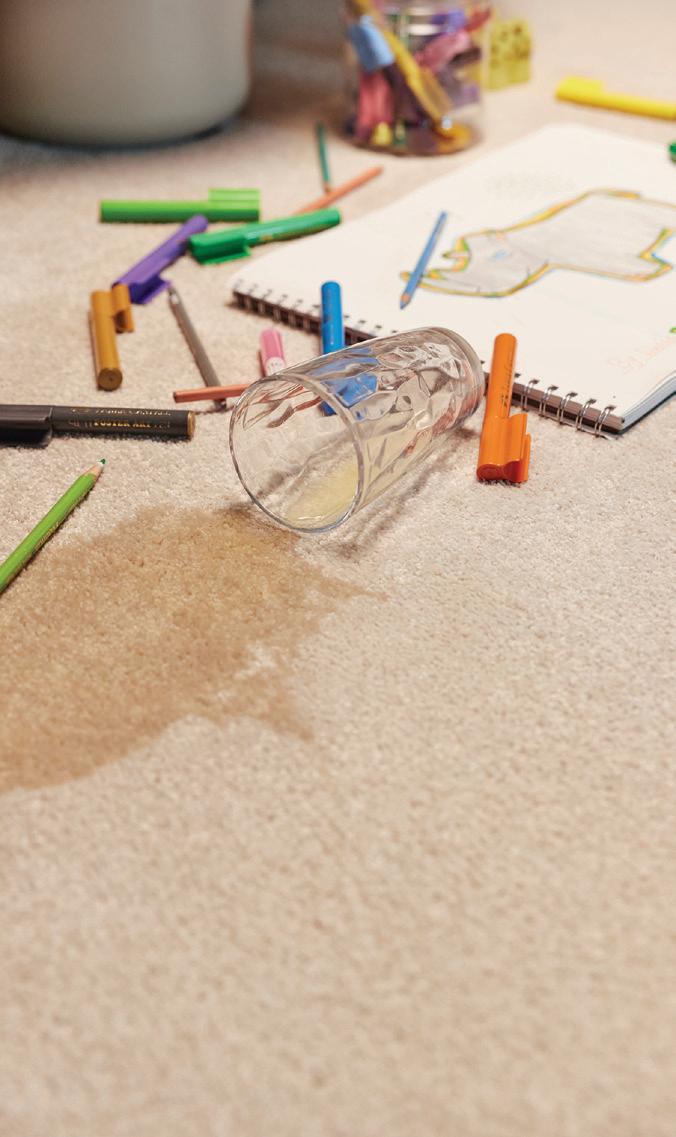

The Godfrey Hirst triexta story

Carpet your kingdom

First released by Godfrey Hirst in 2010 under the brand name eco+, triexta carpet has quickly gained a place in many Australian and New Zealand homes thanks to the unique partly plant based fibre that is durable, cleans with just water and pet friendly, yet still soft and luxurious underfoot.

The fibre was first launched globally in the US market by Godfrey Hirst parent company Mohawk. In 2009 Mohawk put triexta carpet to the test, carpeting the enclosure of Ricko the Rhino, but he could not outmatch the durability and performance of triexta carpet. Mohawk continued to challenge triexta carpet over the next decade+ including the messiest kid competition in 2012, Puppy Bowl X in 2014 and Tough Mudder in 2015.

Here at Godfrey Hirst in Australia, we also challenged triexta with the Ultimate Carpet Test in Sydney in 2016 where four families battled it out on a giant carpet twister with food spills. Triexta yet again proved to be easily cleaned with just water after all the thrills and spills.

The original Ricko the Rhino challenge has remained at the top of hearts and minds in the industry, so in 2024 we are bringing the Rhino back.

The branding is also being simplified for 2024, removing the eco+ sub brand and simply referring to the range as Godfrey Hirst triexta carpets. This is because of many features and benefits of this premium carpet range extend far beyond the just eco credentials. It is cleanable and durable partly plant base fibre that is pet friendly, Australian Made and Red List Free Certified.

Godfrey Hirst triexta carpet cleans with just water because it is made of a unique plantbased fibre with built-in stain resistance and durability to suit even the wildest family. Check out the new Godfrey Hirst ‘Carpet your Kingdom’ video and latest triexta carpets in the biggest range of colours at www. godfreyhirst.com s

10 Flooring April/May 2024 www.flooringmagazine.com.au

Product Update

Transforming urban accessibility

In the dynamic realm of urban design and construction, every element plays a crucial role in shaping the accessibility and inclusivity of our built environment. Tactile Systems emerges as a trailblazer, dedicated to revolutionising urban accessibility through innovative solutions and unwavering commitment to excellence.

At the heart of their mission is the implementation of Tactile Ground Surface Indicators (TGSI), strategically positioned across platforms, crossings, ramps, escalators, and stairs. These indicators serve as vital aids for individuals with visual impairments, offering tactile cues that enhance safety and independence. What sets Tactile Systems apart is their meticulous attention to detail, ensuring precision in every aspect—from the location and colour of tactiles to their size, slip resistance, and luminance contrast. These considerations are not just about meeting standards but about creating a seamless and reliable experience for all users, regardless of ability.

With a rich history dating back to 1999, Tactile Systems has amassed a wealth of experience and expertise, having contributed to a diverse array of projects that have become landmarks in their own right. From the iconic Star Casino on the Gold Coast to the modern architectural marvels like 300 Queen Street in Brisbane, Tactile Systems has left an indelible mark on the urban landscape.

Their product range extends beyond TGSI to encompass a comprehensive suite of solutions, including Stair Nosing, Braille Signs, Bollards, Skate Deterrents, Bike Racks, Wheel Stops, and more. This expansive portfolio reflects their deep understanding of the multifaceted needs of urban environments and their commitment to providing holistic solutions.

What sets Tactile Systems apart is not just their product range but also their approach to service delivery. They go beyond mere supply, offering professional installation services using a fleet of skilled mobile installers. This ensures that their products are not only

12 Flooring April/May 2024 www.flooringmagazine.com.au

Product Update

of the highest quality but are also installed with precision and efficiency, adhering to the strictest standards. Additionally, their line marking team adds another layer of functionality and safety to urban spaces, providing services such as car park design and layout, logo marking, loading zones, disabled zones, walkways, emergency zones, and painted stair nosing. This comprehensive suite of services positions Tactile Systems as a one-stop destination for architects, builders, and project managers seeking to enhance accessibility and safety in their projects.

Looking ahead, Tactile Systems is poised for expansion, with immediate plans to establish operations in Sydney, Western Australia, and future plans for beyond. This strategic growth reflects their ambition to extend their reach and impact, making their innovative solutions

accessible to communities across Australia and New Zealand. Their vision goes beyond mere compliance with regulations; it is about creating secure, inclusive, and user-centric urban environments that enrich the lives of all inhabitants.

Central to Tactile Systems' ethos is their unwavering commitment to quality and compliance. Their products are designed and manufactured to meet Australian Standards, the National Construction Code, and other relevant regulations, ensuring that clients receive solutions that are not just reliable but also compliant with industry standards.

commitment to excellence extends to their testing and consultancy services, where they collaborate with builders and architects to ensure that projects meet all regulatory requirements.

In addition to their core products and services, Tactile Systems has diversified their offerings to include Trolley Bays, Safety Railing and Threshold Ramps, and specialised adhesives, among others. This diverse range underscores their versatility and adaptability, allowing them to cater to a wide range of project needs and specifications. Their continuous innovation and dedication to meeting evolving market demands position them as a leader in the industry, trusted by clients and partners alike.

Tactile Systems' impact goes beyond the tangible products they provide; it is about fostering a culture of accessibility, inclusivity, and innovation in the built environment. Their products not only enhance safety and functionality but also add value to architectural design, contributing to the creation of vibrant, accessible, and userfriendly urban spaces. As they embark on their expansion journey, Tactile Systems remains steadfast in their commitment to transforming urban accessibility and setting new standards of excellence in both the industry and meeting client expectations. s

13 Flooring April/May 2024 www.flooringmagazine.com.au

This

Feature

Australian Made

A true mark of Aussie authenticity

“Buying Australian is an important way we can support each other and ensure all Australians prosper. So let’s make some noise for supporting Aussie businesses.”

JESSICA MAUBOY, AUSTRALIAN MADE WEEK EMBASSADOR

Kicking off on the 20th of May, Australian Made Week is a time to highlight the importance of local manufacturing and its many benefits.

Now in its fourth year, the campaign is hitting the high notes with Australian singer-songwriter Jess Mauboy as this year’s Australian Made Week Ambassador.

An enthusiastic supporter of Australian manufacturing and locally made products, Jess Mauboy is encouraging Australian shoppers and businesses to support their fellow Aussies by choosing Australian Made. The campaign aims to promote Australian Made products as they contribute to boosting our economy, supporting high quality manufacturing, sustainable practices, and most importantly – Australian jobs and workers.

Running from the 20th to the 26th of May, the annual event aims to celebrate all that Australians create, with the homegrown singer songwriter encouraging us to prioritise buying products bearing the iconic Australian Made green and gold kangaroo logo.

“I couldn’t be more proud to be Australian and come from this beautiful country where we have such an abundance of clever makers and growers who work so hard to produce for us and the rest of the world.”

“Buying Australian is an important way we can support each other and ensure all Australians prosper. So let’s make some noise for supporting Aussie businesses,” Mauboy said.

14 Flooring April/May 2024 www.flooringmagazine.com.au

Feature Australian Made

Australian Made Chief Executive Ben Lazzaro was thrilled to welcome Jess aboard as the face… and voice of the campaign.

“With her infectious optimism, incredible work ethic and connection to Country, Jess embodies the very spirit of Australian Made Week which has become an annual celebration of our local creators.

“She is a true trailblazer, and we are absolutely delighted that Jess will headline our campaign to raise awareness of the importance of buying products bearing the Australian Made brandmark,” Lazzaro said.

For more than 35 years, the trusted Australian Made, Australian Grown green-and-gold logo featuring the outline of a kangaroo has identified products as authentically Australian.

From automotive to arts, beauty to boating, clothing to cleaning products and many, many more, every single purchase of products bearing our unique country-of-origin certification helps create and support local

jobs and boost the economies of the cities, towns and regions where the goods are produced.

The quickest and easiest way to communicate your genuine Australian credentials is to certify your products with the green and gold kangaroo logo. Recognised by 99% and trusted by 93% of Australians, the Australian Made logo is the true mark of Aussie authenticity.

Businesses that carry the Australian Made certification are encouraged to join in the Australian Made Week celebrations and share their authentic Australian stories.

Learn more about Australian Made Week at - australianmadeweek.com.au s

15

60 years of elevating comfort to Australian homes.

It was humble beginnings back in 1963 for Edwardstown Carpets. Located, eponymously, in Edwardstown, South Australia, the company has seen a journey of growth that few others can lay claim to.

After what has now been 60 years of creating innovative, loop pile carpets, the company undertook a re-brand in 2023 to demonstrate its evolution, becoming simply, EC. A nod to the past but with a view to the future, which is an ethos that has carried them through over half a century of production and growth.

Now, EC remains the only fully Australianowned and operated producer of highquality, innovative loop pile carpets. Due to considerable investment and a progressive disposition, the over 100-person staff now designs, manufactures, and delivers their carpets from their new 14,0000 sqm stateof-the-art facility in Lonsdale, SA. This new factory and head office bring all operations under one roof with new carpet backing line, tufting, enhanced warehousing capabilities and a modernised innovation hub.

Standing the test of time

The decision to build their new premises wasn’t simply a means for production expansion, but rather a dedication to their ethos of innovation and a commitment to sustainability.

This level of advocacy means that sustainability couldn’t just become a tick-box exercise for the business. EC transformed its operations, products, and internal policies to ensure this key driver was at the forefront for the organisation. This meant taking control of many of the moving pieces required to create exceptional flooring solutions.

The new space brought together things such as an in-house compounding glue facility, reducing their carbon footprint by over 40 tonnes of CO2 per year. The 75,000L rainwater tanks they have installed minimise dependency on the reticulated water supply.

The dynamic nature of being fully owned and operated under one roof also leaves room for further innovation in product and design. In 2021 the business was able to launch it’s first public-facing commitment to a sustainable carpet solution with the

ECONYL EC Carpet collection. This range utilises ECONYL regenerated nylon, which is made from salvaged items that can be extremely polluting and hard to break down, such as fishing nets and industrial plastic. The regeneration and purification process recycles the nylon waste right back to its original purity. It’s exactly the same as fossil-based nylon but with a far more sustainable future. It is then processed into yarns and polymers, which EC use to create the ECONYL EC Carpet collection.

“Our heritage has allowed us to gain extensive industry knowledge over the last 60 years. This allows us to learn from the past, but be nimble in how we approach the future. To be able to say we’re 100% Aussie-owned and operated. It’s something we’ve always been passionate about, and now we get to see the benefits of that reality.” says EC Director, Colin Grace.

Flooring April/May 2024 www.flooringmagazine.com.au Feature Australian

Made

web www.eccarpets.com.au s

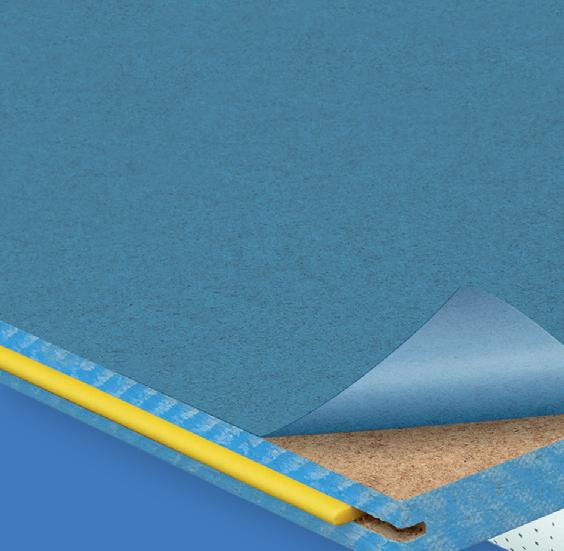

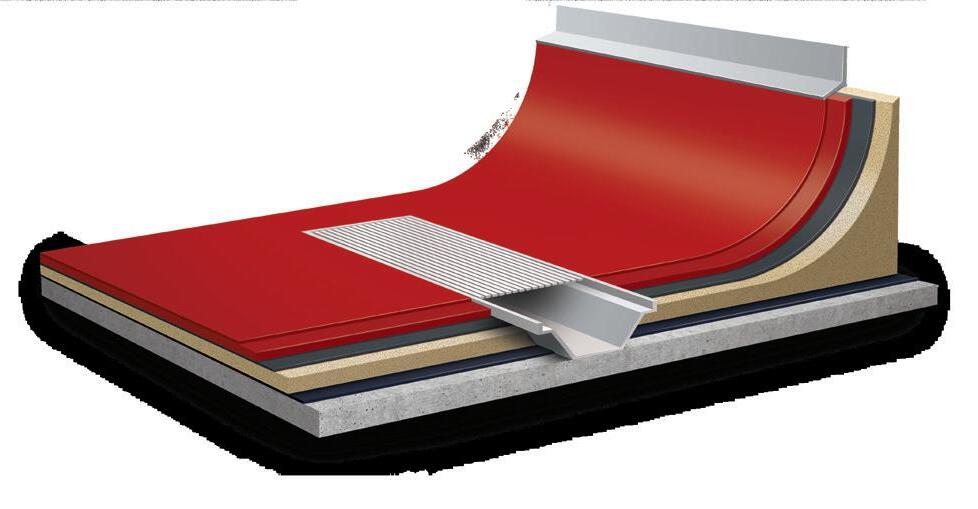

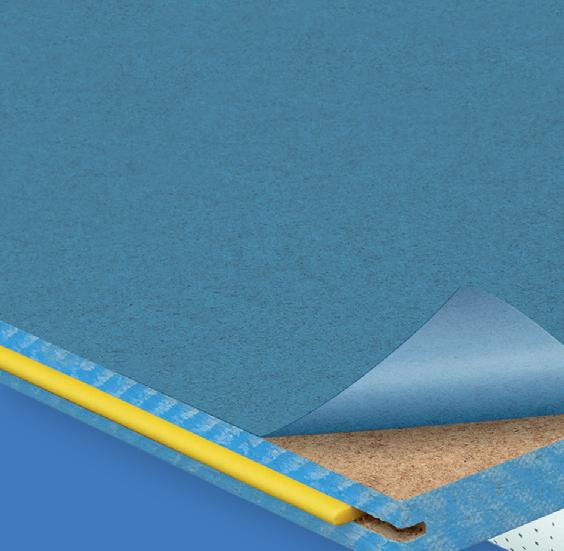

Australian Made for Australian conditions

Designed with the specific needs of Australian builders, architects, and homeowners in mind, STRUCTAflor R-flor Radiant Barrier Flooring is a revolutionary product designed to offer a comprehensive flooring solution specifically tailored for platform construction scenarios where the floor is laid before erecting walls. STRUCTAflor R-flor is manufactured in Australia from sustainably grown Australian plantation pine. The precision-milled wood flakes are bonded together using moistureresistant resin. The key distinguishing feature of STRUCTAflor R-flor lies in its foil laminated underside, comprising a low emittance (high reflectance) metallised foil surface. This feature plays a pivotal role in significantly reducing radiative heat transfer, making it an ideal choice for Australia’s extreme climatic conditions.

The upper surface of is enriched with resin, making it highly resistant to moisture and weather exposure during construction for up to five months. This protective layer safeguards the integrity of the flooring material, even when subjected to the challenges posed by the diverse and varying weather conditions in Australia.

Termites pose a significant threat to Australian homes, causing more damage than fire, floods and storms combined.

STRUCTAflor R-flor is H2 treated, providing cost-effective long-term defence against destructive termite damage, preventing costly repairs and replacements, and ensuring the sustained durability and stability of the structure.

Inappropriately insulated properties have a lower thermal efficiency creating greater energy requirements to heat and cool. The floor makes up a large part of the external envelope of any construction, and by properly insulating, you can greatly reduce the temperature variation inside the conditioned space caused by the transfer of heat through the floor. The low emittance foil surface of STRUCTAflor R-flor contributes to energy efficiency

within structures by minimising radiative heat transfer thus reducing the reliance on artificial heating and cooling systems. This feature is especially beneficial in regions with extreme temperatures, helping to create a comfortable indoor environment.

In a country prone to bushfires, safety standards are paramount. STRUCTAflor R-flor features an increased Bushfire Attack Level rating (BAL) compared to standard particleboard flooring. Whether the subfloor is enclosed or unenclosed, STRUCTAflor Premium can be utilised for the highest BAL rating of BAL – FZ or up to a BAL 29, respectively, ensuring robust protection against the threat of bushfires.

STRUCTAflor R-flor boasts an impressive 80% less moisture uptake through the bottom surface compared to other common wood subfloor products. This characteristic ensures better overall subfloor and floor covering performance, especially when constructing close to the ground. Reduced moisture uptake also translates to fewer issues with expansion, cupping, and other moisture-related problems and contributes to a substantial decrease in mould growth potential on both the top and bottom surfaces during and after construction.

STRUCTAflor R-flor is a testament to Australian ingenuity, offering a versatile, resilient, and durable flooring solution that adapts harmoniously to the diverse conditions of the country. With its innovative features, commitment to sustainability, and functionality, this proudly Australian Made product is the preferred choice for builders, architects, and homeowners seeking excellence in flooring solutions.

web www.australianpanels.com.au s

18 Flooring April/May 2024 www.flooringmagazine.com.au Feature Australian Made

The ULTIMATE Sub-floor Solution

Bushre Attack Level (BAL)

• If sub- oor is enclosed then R- or can be used for the highest BAL rating of BAL – FZ

• If sub- oor is unenclosed then R- or can be used up to a BAL 29

Increased R Value (Insulation)

R- or provides a signicant insulation R-value increase compared to normal STRUCTAor YELLOWtongue ooring.

Reduced Moisture Uptake

80% less moisture uptake through the bottom surface compared to other common wood sub- oor products.

Termite Resistant H2

R-or H2 is deemed to be a termite resistant building material under the Building Code of Australia and AS 3660.1.

Load Carrying Capability

R- or comes in three thicknesses based upon what load factor is required:

• 19mm YELLOWtongue, 3600mm x 800mm

• 22mm REDtongue, 3600mm x 800mm

FREE SAMPLE

Order your free STRUCTAor R- or sample today by scanning the QR code or by visiting www.australianpanels.com.au/ ranges/structaor-r- or/

Reflective foil underneath

Radiant barrier –Keeps winter warmth in and summer heat out

Moisture barrier - Minimises moisture ingress

www.australianpanels.com.au

Protective film

STRUCTAflor H2

Blue edge

wax coating

Feature Australian Made

Can a floor be more than a floor?

The team at Interface, believe in flooring that is made with purpose and without compromise. That’s why they say their flooring is made for more — it means their customers don’t have to choose between sophisticated patterns and durability or between ease of maintenance and low carbon impact. With Interface, there’s no ‘either’ — only ‘more.’ More beautiful design. More innovation. More performance. More sustainability.

Made for more

That’s because inside every colour, pattern, texture and detail is a whole lot of innovation, design thinking and pioneering sustainability. Interface flooring is made with purpose and without compromise — it does more, means more, for more.

In 1973, their founder, Ray Anderson introduced a European carpet tile concept to America, starting a commercial flooring revolution that would spread around the world. Now, Interface is a global leader in modular flooring, offering an integrated collection of carpet tile and resilient flooring.

Interface, made for more

Made for more than 50 years of local manufacturing Interface has manufactured modular carpet tiles locally in south-west Sydney NSW since 1971.

Investing in a purpose built, state of the art manufacturing facility producing carpet tiles, their global reach combined with local knowledge helps to build customer relationships that are collaborative, committed, and productive.

For over 50 years their customers and team have been the thread that connects and commits to be better together. With the notion that - you have supported our growth; we have supported your ideas.

Encouraging customers to buy local, for Interface, means not only supporting our own people, but in turn, the wider community and economy. Their company’s investment in the local community began back in the 1970s, when Heuga, which eventually became the Interface that we know today, opened its first manufacturing plant in Picton, NSW. After growing and prospering there for 40 years, they experienced a significantly damaging factory fire in 2012 and were forced to shut down local operations.

Faced with a critical decision for the future of the company, Interface chose to reinvest in Australia. Relocating to Minto in 2014, they were able to continue their local manufacturing capabilities, thanks to the confidence and support of their community. → 22

20 Flooring April/May 2024 www.flooringmagazine.com.au

MADE FOR

Can a floor be more than a floor? Flooring made for more inspiration, more climate progress, more performance, and more ways for you to create remarkably good spaces. It’s flooring—and then some. Discover more. interface.com/madeformore

Feature Australian Made

Interface will continue to care for our planet, connect to community and build opportunities here in Australia.

Made for sustainability

Interface is committed to becoming a restorative business. From their original industry-defining goal to make zero negative impact, to realising zero wasn’t enough, to designing with circularity across everything they do, they have continued to show change is possible no matter how improbable.

By working together, setting ambitious science-based targets and investing resources into reducing their carbon impact, they will do more than just less harm – they will do good.

Made for more than offsets

Recently, Interface announced that they are focusing on direct carbon reduction and carbon storage to meet the urgency of the climate crisis. The company is aligning their strategy to meet climate commitments, which do not allow for carbon offsets.

The planet is at an inflection point and absolute emission reductions are critical to solving the climate crisis. From 2025, Interface will repurpose former offset investments to accelerate innovation projects that will result in direct carbon reductions and carbon storage both internally and in their supply chain.

Interface is all in on solving the climate crisis.

Making incredible progress in their 30-year sustainability journey, and a commitment to achieving ambitious environmental sustainability goals without carbon offsets.

Made for design

Designed to stand up, stand out and stand for something, Interface’s innovative modular flooring is more than just something you can walk on. Inspired by everything from the restorative nature of biophilic design to science, art and a rich heritage, Interface push trends for more ideas, more inspiration and more leading the way.

With an ambition to create products that are beautifully designed, innovative, and made to transform spaces beyond just the aesthetic to environments that can enrich people’s lives. Interface’s team of designers continuously explore trends, textures, colours, and materials to ensure every pattern and detail is thoughtfully crafted.

Made for innovation

Interface invest in the latest technology and materials science to make groundbreaking flooring – like the world’s first carbon negative carpet tile – that reshapes the industry. Made with purpose and without compromise. It’s flooring – and then some.

web www.interface.com s

22 Flooring April/May 2024

Revolutionising air scrubbers for the construction industry

In the quest for clean and safe workspaces, the DustMaster Air Scrubber 1000 G2 emerges as a game-changer. Developed and manufactured in Australia by Floorex, this innovative in-room air purifier redefines standards with its advanced features and unparalleled efficiency.

At the heart of its design lies a sophisticated four-stage filtration system, meticulously engineered to deliver optimal air quality. From stainless mesh gauze to H14-rated filters, each stage is carefully crafted to capture particles and impurities, ensuring that the air circulating within your space meets the highest standards of purity.

One standout feature of the DustMaster Air Scrubber 1000 G2 is its stackable design, allowing for space-saving convenience without compromising performance. Coupled with a German engineered centrifugal fan, this unit offers exceptional airflow capabilities while maintaining whisper quiet operation—a true testament to its engineering excellence.

Versatility is another hallmark of the DustMaster Air Scrubber 1000 G2. With variable fan speed control, users can adjust airflow and noise levels to suit diverse environments, whether it is a small or large work site area.

This air scrubber boasts remarkable energy efficiency, consuming just over one amp of power. Its lightweight yet durable construction, complete with built-in handles and locking castors, ensures effortless mobility and stability.

web www.floorex.com.au s

23 DustMaster Air Scrubber 1800 356 673 Australia-Wide www.floorex.com.au Your Key To Floor Preparation Success WHAT EVERY CONSTRUCTION SITE NEEDS.......... P Safe working space P Excellent control of airborne dust P 3 stages of air filtration up to H14 P Very low noise in operation Over 1000 m3/hr performance Variable speed Low power consumption Easy Change Filters Filters dust from: Concrete, Stone & Timber Feature Australian Made

Polivac - In it for the long haul

Polivac International was formed in 1949 and is now recognised as Australia’s leading manufacturer of commercial cleaning equipment and a major exporter of advanced cleaning technology worldwide. The company produces a wide range of commercial cleaning equipment, including burnishers, scrubbers, polishers, sanders and carpet extractors from its state-of-the-art manufacturing facility in Kensington, Victoria.

Over half a century ago, Polivac was responsible for the development of the world’s first suction polisher, the PV25. This remarkable machine, with refinements madeover the years, remains one of Polivac’s flagship models, with an outstanding reputation in the marketplace.

The Polivac range has electric, gas and battery-powered models suitable for a wide range of cleaning environments and applications. The company strives to achieve best practice in floor maintenance and cleaning, by designing machinery which produces high quality, highly durable floor finishes and deep cleaning.

Polivac was originally involved in the production of both cleaning equipment and cleaning chemicals. However, under owner and Managing Director Tony Antonious, it was decided to end its association with chemicals and focus solely on the manufacture of high quality and user-friendly cleaning models. Machine components are outsourced to both local and international vendors, the company continues to engage with local suppliers, with over 80% of its raw material and spare parts are sourced locally. Polivac maintains a complete product inventory to ensure high levels of product availability and responsive customer service for machinery and spare parts.

The Polivac range includes machines for stripping polish from hard floors; laying new polishes and sealers; high speed and ultra high-speed polishing of all floors; scrubbing of floors to maintain hygiene and floor life; concrete grinding and finishing, timber sanding and vacuuming and shampooing of carpets for large or small area operations.

Recently, the company has entered into the stick vac market.

Today, Polivac sells its products via a network of over 120 distributors within Australia, as well as to several international destinations, including the Pacific region Asia, Europe, USA and the Middle East.

Owner Tony Antonious firmly believes in the axiom that an organisation’s number one asset is its staff. It follows, then, that Polivac employees receive the best training and support possible, to allow them to operate at their full potential. The small team of technicians at the Kensington plant are highly skilled and are integral in maintaining Polivac’s reputation as a producer of quality equipment, as well as pushing the boundaries in innovation and product development.

Such research has resulted in the introduction of specialised equipment such as the ‘Shark’ long nose scrubber. It has also seen refinements to gas-powered machinery,

24 Flooring April/May 2024 www.flooringmagazine.com.au Feature Australian Made

Above: Some of the Polivac range

Above: Machine assembly in the Kensington factory

to reduce emissions while increasing productivity rates, as well as develop significant improvements in ergonomics to increase operator comfort and safety.

Traditionally, commercial cleaning equipment has been operated via gas or mains-powered electricity, but increasingly, the market is looking towards battery-powered operation, even for the largest machines. Polivac is currently investing significant research and development effort into producing environmentally friendly machines which can operate for extended lengths of time under battery power. A continuous field-testing program is also in place to continually monitor product performance for further development.

Another philosophy entrenched in the Polivac ethos is the need to fulfil orders quickly. Through state-of-the-art inventory control and just in time manufacturing practices, Polivac aims to fulfil 95% of orders within 24 hours. Distributors and their customers are therefore confident that they will receive their orders in the shortest possible time.

Polivac acquired its ISO9001 quality accreditation back in 1997 and has maintained this certification ever since - evidence of the strength, and quality of its processes and practices. Products are extensively tested under specified QA processes during manufacture and after product completion. This ensures exceptional product quality and high reliability.

As Tony Antonious says: “We are in it for the long haul—for our customers and for our world. We strive to provide increased productivity through the intelligent design of our machines. Our customers can be found in virtually every corner of the earth, and we realize our success comes directly from helping our customers be successful.”

web www.polivac.com.au s

Flooring April/May 2024

Feature Australian Made

Above: Polivac owner Tony Antonious

The best flooring for your commercial kitchen

Anyone who has spent time in the commercial food industry would understand the crucial role of kitchen flooring. There are unique needs that reach far beyond those of typical flooring. The key reasons that make this especially demanding are:

Visual Appeal – Kitchen flooring can’t be hidden or lacklustre. Often with new open designs in clubs and restaurants the kitchen is partially exposed to customers. Although this helps the ambience and reassure customers that the food production and space is clean it is critical the floor performs to a very high standard hygienically.

Heavy Traffic – Commercial kitchen floors take a beating. They need to stay strong beneath heavy foot traffic and trolley movement. At the same time shrug off spills and avoid damage from high heat or cold.

Safety Requirements – Flooring should help employees keep safe and be productive. That means a high level of slip resistance to protect from grease and trip hazards.

Sanitation Regulations – In Australia most commercial food facilities, hotels and restaurants have strict Food Safety Compliance standards. These facilities are audited on a regular basis to meet HACCP Certification. The Epoxy floor coating is ideal, it is an impervious seamless finish minimising any bacteria build up.

ROXSET HACCP Flooring is a premium supplier of food and beverage compliant floor coatings for over 30 Years across Australia. They service commercial kitchens, bars, food processing and production areas.

web www.roxset.com.au s

Stylish, Seamless & Safe

The ROXSET range of epoxy floor coatings offer an aesthetically pleasing fresh and bright look. They can be customised with varying degrees of slip-resistance for extra safety and provide long lasting durability even in a heavy traffic environment. All coatings are non-toxic (VOC fee) with antimicrobial properties making them perfect for any retail or commercial environment where safety and style are paramount.

Durable with superior long lasting protection for any environment.

26 Feature Australian Made

View our range now

Australian Made

QEP is a world class, worldwide provider of innovative, quality and value-driven flooring and industrial solutions for the professional tradie as well as the DIY market.

As a leading worldwide manufacturer and distributor, QEP delivers a comprehensive line of building products, engineered wood flooring, flooring installation tools, adhesives and flooring related products.

QEP is now a completely Australian owned and operated business. Flooring Magazine recently sat down with Bruce Maclaren, Managing Director to discuss all things business.

1. In March this year QEP announced the formation of QEP Australasia. Talk us through this announcement and the change of ownership.

Although a public company in the US, QEP has been controlled by the Gould family for over 40 years and the Founder Lewis

Focus on QEP

Gold is now 84. As recognition for my long involvement with the Australasian operations and realising it was time for him to step away, he approached me about 12 months ago to see if I would be interested in acquiring the local business here as part of a re-set of the global operations.

Obviously, I jumped at the opportunity, and it has been a completely friendly and amicable process since that time until we settled on the 29th of February. It was very important to ensure continuity for employees, suppliers and customers and as far as possible we have managed a seamless transition.

The QEP name, brands and trademarks will continue on, and we will remain closely connected with the global QEP organisation through cooperation on product development, marketing etc.

2. QEP Australasia is a family owned and operated business. What does this mean for business moving forward?

From a personal perspective, ending the corporate reporting and managing requirements of a public company, allows me to focus much more on the day-to-day operations of our business in Australia and New Zealand.

This will enable us to make more immediate decisions and implement strategies more efficiently than previous, which will see us deliver initiatives to market quickly in support of our customer needs.

My son Fraser has re-joined QEP after time working elsewhere in the industry and he has some very progressive ideas for growing our business into the future.

3. AFS is a well-known part of the QEP structure in Australia. Will this continue?

Absolutely!

Australian Flooring Supplies (AFS) is a highly regarded and long-established network supplying accessories and flooring to the trade. We have 22 trade centres up the Eastern Seaboard, and I have had the pleasure of visiting with all the team in the weeks since the acquisition and I am reminded how committed they are to continue our clear strategy to provide great service and products to the flooring industry.

28 Flooring April/May 2024 www.flooringmagazine.com.au

Feature

Feature Australian Made

The QEP name, brands and trademarks will continue on, and we will remain closely connected with the global QEP organisation through cooperation on product development, marketing etc.

4. Discuss some of QEP’s milestone moments.

After 24 years in Australia and New Zealand there have been many, including the acquisition of six of our independent distributor customers to form the countrywide Australian Flooring Supplies business.

Perhaps the most memorable milestone was on 13th September 2013 when we suffered a catastrophic fire which completely destroyed our Dandenong headquarters.

In looking back, I am still incredibly grateful to the QEP team who helped us to rebuild in an amazing timeframe, but I am always reminded of what a great industry this is after I received so much support through a very challenging time from customer, suppliers and competitors alike.

5. When it comes to flooring QEP continues to develop and introduce trailblazing ideas and products including high performing and competitively priced ranges for both domestic and commercial projects across laminate, LVT, carpet, carpet tiles and sheet vinyl. Discuss the latest QEP product offering.

All our current products remain as a part of the transition to the new ownership. They include high quality water resistant laminate from Germany, leading edge sheet vinyl from Europe’s major manufacturer as well as our Xpress ranges of LVT and Carpet Tiles where

we hold excellent stocks in multiple locations to provide an immediate supply solution for our customers.

We also have several new product categories which QEP and AFS will be launching in the second half of this year which will see us further establish ourselves as a key provider to the flooring trade…..watch this space!

6. Looking ahead, what plans have you got for the future of QEP Australasia?

We already have a great experienced team in place, many of whom have worked with me and my wife Sue (who is a 16 year veteran at QEP) for a long time.

The change in ownership to the Maclaren family will provide certainty on our direction and despite the current challenging market conditions, we intend to drive the continued growth of the QEP and AFS business units.

We have a number of new initiatives lined up for this year and the involvement of Fraser Maclaren alongside these, confirms the commitment we have to the future and the next generation of passionate flooring people.

web www.qep-aust.com.au s

29 Flooring April/May 2024 www.flooringmagazine.com.au

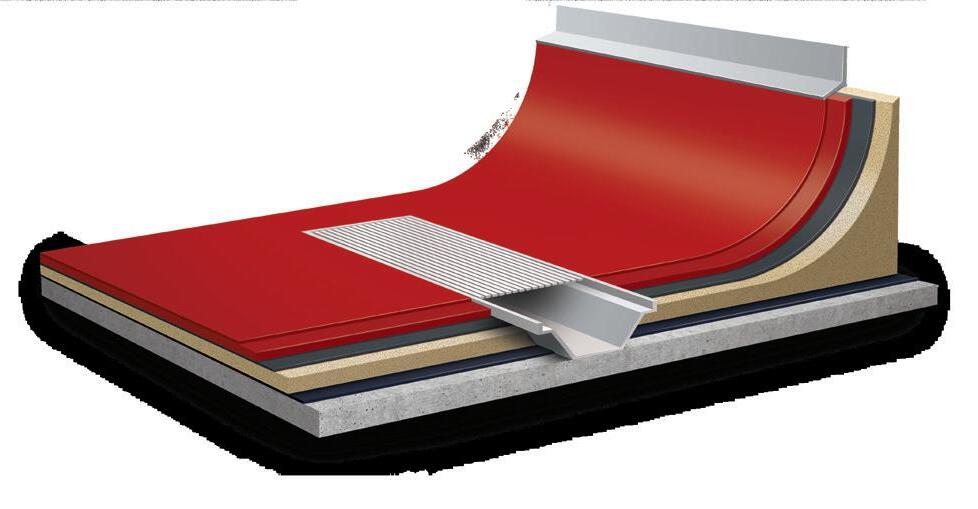

ARDEX K 125 TAKES YOU TO THE NEXT LEVEL!

Thin profile application: 2.5mm to 15mm depth

Heated floor compatible: Can be used with Ardex E25 for heated floors

Fast track flooring: ready for tile in 4 hours and floor coverings in 18 hours

Pumped applied: ARDEX K125 can be pumped for efficient application

ARDEX K 275 WHERE INNOVATION MEETS PERFORMANCE!

Thin and versatile: Application depth of 2mm to 25mm

Fast setting: Tile ready in 4 hours, floor coverings in 16 hours

Easy application: ARDEX K275 can be pumped for efficient application

Bulk for additional depth: Can be bulked out to a maximum depth of 40mm

SCAN HERE FOR ARDEX K 125 SCAN HERE FOR ARDEX K 275 INTRODUCING

VISIT ARDEXAUSTRALIA.COM TO LEARN MORE OR CONTACT YOUR NEAREST FLOORING STOCKISTS

THE NEWEST INNOVATIONS IN FLOOR LEVELLING

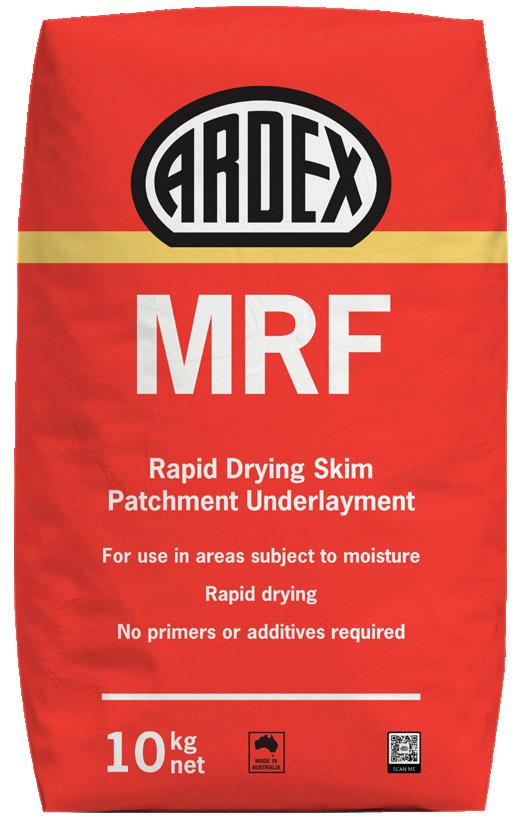

ARDEX MRF

ARDEX K 60

MOISTURE RESISTANCE FINISH: THE MOISTURE SHIELD FOR YOUR FLOOR

Highly Durable: Withstands up to 100% RH for internal & external applications

Walk ready in minutes: Install floor coverings in 30 minutes

Versatile Application: Up to 6mm on concrete and 3mm on internal timber

Advanced Compatibility: Use ARDEX MRF before installing moisture barriers and waterproof membranes

STRONG, FLEXIBLE, FAST - A PERFECT FLOORING LEVELLING COMPOUND

Easy to use: No need for priming in most applications

Superior Bonding: Excellent adhesion with high water resistance

Convenient mixing: Two-part liquid & powder formula – simply mix and apply. No need for site water.

Verastile application: Suitable for a feather edge to 12mm depths

SCAN HERE FOR ARDEX MRF SCAN HERE FOR ARDEX K 60

Company Profile

Article by Philip Ashley

Team Beare – A New Standard

Beare Flooring is a new age flooring business offering clients a fresh and exciting option when purchasing flooring products. In tune with consumer demands of the times, Beare Flooring are pushing the industry forward in leaps and bounds with their own newly developed software technologies and specialising in mobile showrooms.

Beare Flooring is based on the Gold Coast and currently services Brisbane, the Gold Coast, and Northern New South Wales. Their focus is on a mobile service that meets the specific needs of the consumer, in their home under the space and lighting conditions where their new flooring will be installed.

The customer sees the product in the natural light of their homes, a key factor in choosing the best flooring for any space. Beare Flooring quotes are creating a new standard for the industry. Being itemised, they contain the specific information customers need to help them make an informed decision about their purchase.

Beare Flooring began trading at the beginning of 2021. Founded by William Beare, at home with a laptop and a dream. Will has a passion to transform the Flooring industry first in Queensland, followed by the rest of Australia. Team Beare now have four

company owned locations. Franchises are currently available to join Team Beare and existing franchisees; already taking advantage of the unique business opportunities a mobile service brings.

Family Values

Beare Flooring is operated by Will as Director and his sister, Aleisha Martin as Business Manager. It’s a family owned, and locally operated business built on family values and a younger, fresher look at an industry that Will says is, “Wide open for change.” Feedback from customers about the mobile van service is very encouraging. The vast expanses of Australia are certain to benefit from a different approach to purchasing flooring products.

Aleisha brings with her an extensive knowledge of the textile and interior design industry. Having worked with some of the

country's leading Hoteliers in her previous career, she knows how important it is for products to not only be aesthetically pleasing but that they perform under the conditions they are specified for. A new Mum, her focus has shifted from the fast-paced commercial world she thrived in, to working alongside her brother Will at Beare Flooring, creating a work life balance that sees her able to enjoy quality time with her family.

Aleisha brings the knowledge from her previous career to her role as Business Manager sourcing stylish and hard-wearing products from Australian suppliers that suit Beare Floorings core values of delivering the best possible products to their customers. A creative person at heart, her passion for all things beautiful has easily transpired to her transforming Beare Floorings website and heading up their social and marketing teams.

→ 34

32 Flooring April/May 2024 www.flooringmagazine.com.au

Franchise Owner Franchise Owner

No showroom or warehouse required Lowest cost entry available in the flooring industry Minimal overheads Finance options available Benefit from our fantastic 5 Star customer rating 100% Mobile Retail Showroom 100% Mobile Retail Showroom Geoff McDonnell 0434690275 franchising@beareflooring.com.au AUSTRALIA’S FIRST AND ONLY AUSTRALIA’S FIRST AND ONLY

Flooring has experienced exponential growth since establishing in Australia. Due to this proven success we are looking for like minded individuals to join our rapidly expanding family business! portunities available Australia wide portunities available Australia wide For a confidential obligation free enquiry, speak with our Franchise expert beareflooring.com.au BECOME A BEARE FLOORING BECOME A BEARE FLOORING ENTERING THE RETAIL FLOORING INDUSTRY HAS NEVER BEEN EASIER ENTERING THE RETAIL FLOORING INDUSTRY HAS NEVER BEEN EASIER ! WHAT ARE YOU WAITING FOR? ! WHAT ARE YOU WAITING FOR?

Beare

Company Profile

A Fresh Approach

For over a decade, Will has supported local families and businesses providing the perfect flooring solution for their space. He’s approachable, knowledgeable, and trustworthy, and prides himself on his fivestar reputation for service. He is passionate about the product selection process and prides himself on his diligent organisation skills, ensuring every project is managed to the highest standard. To this end Will and a team of software engineers have developed custom software that streamlines every aspect of the Beare Flooring business. In time, “Beare Central” software will be made available to the wider industry.

Beare Central is Aleisha and Will’s internal custom software and has been built to streamline essential flooring industry business tasks such as, quoting, invoicing, ordering, appointment scheduling, installation scheduling combined with aftersales and internal communication, making the day to day running cleaner and simpler than ever before for their teams. The software is essential for personalized in-house sales and quoting and enhances the customer experience. Will says the software, “Will be of great benefit to an industry that at times can be archaic, unorganised, lacking in technology and innovation, and in need of a shakeup.”

Built on Performance

Will has worked on large development projects, commercial fit-outs, to residential homes. Originally starting his flooring carer in New Zealand in warehousing within a family run flooring business, Will gained invaluable skills that helped him to understand how a business operates from top to bottom. He was able to identify very quickly how he could streamline processes which would improve the day-to-day functions. Will was soon promoted to Sales and quickly progressed to Sales Manager then onto General Manager.

34 Flooring April/May 2024 www.flooringmagazine.com.au

Company Profile

Will comments,“At Beare we’re experiencing rapid growth, every month is better than the last. When I first opened the business, it was just myself and one van with minimal product offerings. We now work from Northern Rivers in NSW, inland to Toowoomba, Gold Coast, Brisbane, Sunshine Coast, and we’ve just begun looking into our Sydney expansion. We deal mainly with residential owner occupier consumers; we do everything from entry level to very high-end solid timbers & woolen carpets. We also do group housing builders and commercial projects.”

A recent commercial project ‘Sovereign on The Gold Coast’ involved transforming the entire ground level with Beare’s exclusive ‘Forest’ commercial vinyl planking range. The areas included the main entry foyer and all the corridors spanning to the rooms on the ground level. The project involved lifting and removing the old ceramic floor tiles and skirting, grinding the substrate, and applying a flood coat. The result was a transformation worth its weight in gold! Team Beare offer a complete flooring service from start to finish including project management.

Beare Philosophy

Aleisha says, “At Team Beare we are committed to revolutionizing the flooring industry with our never before seen 100% Mobile Retail Flooring Showrooms. We are changing the way consumers purchase

flooring ‘in home’ rather than the standard bricks and mortar retail stores. Our mission is to be the helping hand of middle management. We believe experienced flooring sales representatives should get into business ownership through our redefined, easily accessible, and affordable flooring franchise model. Will said, “Our cost to entry is by far the lowest in the industry, our model requires no physical showroom, no warehouse, no staff, and minimal overheads. Our custom built Beare Central software is light years beyond anything else available to the flooring industry, which results in high levels of organization and automation.”

Will continues, “Our goal is to become a national franchise that is focused on the franchisee. We aim to expand rapidly, assisting and mentoring as many flooring professionals as we can into successful business ownership. Our franchisees are designed as a lifestyle business, work from home, set your own hours, it is what you make it.” Will relocated to Queensland to be closer to his sister Aleisha and her family. He enjoys spending his free time being a doting Uncle to his little niece Nessa and spending the weekends on the water enjoying the idyllic Gold Coast lifestyle. If Will and Aleisha’s success and lifestyle is anything to go by, Beare Flooring is a winner.

web www.beareflooring.com.au s

get what

to… every time.

For more, call 1800 607 204 or visit floorinsure.com.au FloorInsure offers the benefit of large insurance firms with our superior capacity to manage complex insurance claims while retaining personal, flexible and tailored service. We are dedicated to ensuring you

you’re entitled

a dedicated industry insurance broker? now that’s something to smile about… Tailored insurance for Flooring & Carpet Retailers

Flooring April/May 2024

Software

Improve Your Business-Embrace Follow-up Part 1

Article by Chris Ogden

Idiscussed the importance of implementing an effective sales process in the previous issue. I finished the article with the following statement:

Sales is the engine room of our business; when it stalls, our business stalls. In my experience, the most significant change for good that can be made in a flooring business is controlling, understanding and fine-tuning the sales engine.

I know. Easier said than done.

We will start with maybe the most challenging aspect of sales: follow-up, the best way to increase our conversion rate yet the most overlooked. More accurately, the most avoided. We need to understand why our salespeople avoid follow-up, so we will look at that in another article.

I will restate something else from my previous article. Many salespeople believe their conversion rate is 75-80%. In fact, despite what they think, most salespeople have conversion rates of less than 50%— some even less than that.

We will start with maybe the most challenging aspect of sales: follow-up, the best way to increase our conversion rate yet the most overlooked. More accurately, the most avoided.

So, a mind experiment.

Imagine we live in a world where we can only make a sale if we make four follow-up calls. In this imaginary world, our conversion rate would be guaranteed to be 75%, but only if every opportunity is followed up four times. What would our store's sales process look like if this was the world we lived in? Would we be happy for our salespeople to choose not to make those four follow-up calls? No, sales would become a process; quote the job, follow up four times and win 75% of all quotes. You would require your salespeople to make those four follow-ups to remain employed.

You might be surprised that this imaginary world is, potentially, our world. I won’t guarantee a 75% conversion rate, but it will be significantly higher than current conversion rates if you improve the frequency, number, and quality of your follow-up calls. Also, some opportunities will need less than four followups, while others will require more.

My point is that we lose sales because our salespeople don’t adequately follow up on opportunities.

This leads us to the next question. If you were to ask your salespeople what the correct number of follow-up calls is, you would likely get answers ranging from two to four. The actual answer is that there is no fixed number of follow-ups that we make before we stop; we continue the follow-up process until we either close the sale or learn that we have lost the opportunity.

From my experience in retail flooring and software, I know how powerful follow-up is, but it doesn’t happen in a vacuum. It happens in a managed structure. The elements of this structure are:

• Visibility of sales opportunities, actions, and outcomes.

• Monitoring, measuring, and coaching.

• Reliable and timely reporting on which to base monitoring and coaching.

• Sales budgets.

• Recognition for achievement.

There is some heavy lifting to create and keep this environment up to date. It can be accomplished within the systems retailers use today, but realistically, most flooring stores have the systems that make it challenging.

36 Flooring April/May 2024 www.flooringmagazine.com.au

→ 38

Layers Diary Mobile Sales Financials Measuring Debtors Reporting Quotes Projects Australia: 1800 229 427 New Zealand: 0800 643 012 www.rfmsanz.com salesau@rfmsanz.com YOUR BUSINESS MANAGEMENT SOFTWARE SOLUTIONS FOR YOUR FLOORING BUSINESS Integration with Customer Relationship Management App Every sales team needs a way to manage the relationship with past, current, and potential customers. CRM provides an efficient and mobile tool to focus on retaining existing customers and gaining new customers with lead workflow and customer communication to drive sales growth. Scan this QR Code to view a video about CRM ✓ Lead Management + Workflow ✓ Communication ✓ Visibility

Software

RFMS, on the other hand, has all the tools needed to create a sales structure and environment in which your salespeople will be effective. Many people in our industry connect computers and software with office functions, such as invoicing and

financial reporting. RFMS, on the other hand, manages all the operational aspects of your business, including sales. If you would like to see what RFMS might offer your flooring business, we would be happy to show you. s

There is no fixed number of follow-ups that we make before we stop; we continue the follow-up process until we either close the sale or learn that we have lost the opportunity.

Chris Ogden is a consultant and Managing Director of RFMS Australasia (RFMSanz.com), a supplier of IT solutions for the flooring industry. Chris has an extensive background in all aspects of the flooring industry, and he can be contacted at cogden@rfmsanz.com.

38

BE ACCURATE | BE EFFICIENT | BE PROFITABLE MEASURE MOBILE • Draw Scale Plans • Add, Delete and Move Seams • Include Doorways and Stairs • Calculate Material Quantities • Create and Email Quotes • Take Signed Acceptance on Tablet • Take Payments Australia: 1800 229 427 New Zealand: 0800 643 012 www.rfmsanz.com salesau@rfmsanz.com

Improve Your Business-Embrace Follow-up Part 2

Article by Chris Ogden

If you read my articles, you will know I am passionate about follow-up as the best way to maximise sales. In fact, salespeople who don’t have a robust followup process are not salespeople. At best, they are order takers; rather than building relationships, they rely on price to make sales.

A salesperson who doesn’t follow up is not a salesperson, just as a pilot who can’t land a plane is not a pilot.

The flooring industry doesn’t have this problem alone. Over the years, I have had quotes from many different businesses, and I can’t think of any that made more than a single cursory call to follow up and get my business.

Salespeople who don’t have a robust follow-up process are not salespeople. At best, they are order takers; rather than building relationships, they rely on price to make sales.

Robust follow-up is the only way to get more than our fair share of business.

Follow-up looks different from project to project, but to make sure we are on the same page, let’s take the example of a simple residential renovation. As a salesperson, I would follow up multiple times in a short period until I had won the job or was told I had been unsuccessful. At this point, salespeople will say to me I’m being pushy.

40 Flooring April/May 2024 www.flooringmagazine.com.au

Software

No, I’m not. I am letting the prospective customer know I want to work with them.

If the prospective customer is unhappy with hearing from me, they can tell me not to call again. Thirty-four years in sales is a long time, so I won’t be adamant that I have never been told not to call back, but I can’t recall it. Along the way, I have made more sales than I would have without those calls. Of course, I have been told that I missed out to a competitor. This is the nature of sales. It hurts, but I thank them for the opportunity, and the good news is I have one less quote to follow up on.

As a salesperson, I can tell you with absolute certainty that we have time to call our prospective clients, but we don’t because we fear rejection.

If follow-up is a silver bullet, why do salespeople not do it? Salespeople will tell you they don’t have time and don’t want to be “pushy”.

As a salesperson, I can tell you with absolute certainty that we have time to call our

prospective clients, but we don’t because we fear rejection. It’s the obstacle I must overcome before every follow-up call. Even as I write this, I know there are follow-up calls that I have been putting off. None of us like hearing that we have been unsuccessful, and we avoid it by not making the calls.

Salespeople will perform to the level they are permitted to perform. As business owners, we must control how our salespeople do their jobs. As a business owner, an excellent way to focus our mind is to total all the overhead costs associated with our showroom space for a month: rent, electricity, sales salaries, and vehicle costs, and then divide that total by the number of quotes we do in a month. The result is how much each quote is costing you. It’s likely hundreds of dollars. How happy are you that you miss out on maybe more than half of these opportunities through lack of follow-up?

It comes back to our expectations as business owners. When it comes to expectations, salespeople usually have it easiest; when the economy is good, they make satisfactory numbers by being ordertakers. When things slow down, they don’t make their numbers and they blame the economy.

Salespeople

will perform to the level they are permitted to perform. As business owners, we must control how our salespeople do their jobs.

Creating a sales environment driven by robust follow-up is the single most significant opportunity for growth in 95% of flooring businesses and not something we can leave to our salespeople. It starts with us as business owners. We will look at how we do this in the next issue, but in the meantime, you might wonder how you can capture the sales information to help your salespeople be more effective. If you would like to see how RFMS can assist you, we will be happy to join you in an online meeting to show you. s

Chris Ogden is a consultant and Managing Director of RFMS Australasia (RFMSanz.com), a supplier of IT solutions for the flooring industry. Chris has an extensive background in all aspects of the flooring industry, and he can be contacted at cogden@rfmsanz.com.

Gain

Receive

PVC use Fight

41 Software

recognition for contributing to the circular economy

reputable, third-party authentication of recycled

greenwashing For more information, visit vinyl.org.au/vinylcycle

Design & Trends

Introducing Soothing Tactility - An interior trend report by Feltex

Explore the latest trend report from Feltex to help guide your customers in complementary flooring. The team at Feltex Carpets are designers and technical specialists armed with a passion for interiors. These experts are at the forefront of cuttingedge designs, bringing the latest colour and style trends to floors all over the world.

Feltex’s carefully curated Interior Trends highlight new and emerging trends, and how these can be bought to life in the home with Feltex carpets. The desire to introduce a sense of restfulness and soothing aura in the home has been apparent recently. Recent interior design has proven a significant shift towards spaces that prioritise comfort and a connection to the natural world through textured décor and neutral colours.

Well-being and comfort

The worldwide emphasis on mental health and well-being is a major catalyst for this trend. Environments crafted with a neutral, textured palette are regarded as more soothing and effective at reducing stress, making them perfectly suited for residential settings and commercial spaces centred on wellness.

Digital detox

In an age dominated by technology, natural tactility offers a counterpoint that encourages physical engagement and a break from digital saturation. Interiors designed with this trend in mind serve as sanctuaries from the highpaced, screen-focused lifestyle.

How to create a soothing tactility in your space

Our homes are quickly becoming havens of serenity, with living rooms, bedrooms, and bathrooms adopting tactility to create a cosy, restorative ambience. Soft furnishings, plush carpets, and textured walls invite interaction and relaxation.

The selection of flooring plays a pivotal role in enhancing this trend by adding textural depth, dimension, and visual allure to interior environments. The tactile experience of textured carpets enriches the sensory appeal of minimalist designs, while the use of natural wool materials reflects an affinity with the external natural world. To order samples, please head to www.feltex. com and stay up to date with the

42 Flooring April/May 2024 www.flooringmagazine.com.au

Above: Stylist: Bree Leech. Photographer: Mike Baker

@feltexcarpets on Instagram.

latest by following

s

Design & Trends

Design duo Oak & Orange on what’s trending in 2024

Whether you are embarking on a ground-up build or giving your current home a facelift, reimagining our living spaces with innovative design concepts presents an ideal chance to craft environments that are not just visually stunning but also eco-friendly. Sarah Jobse, a visionary behind the design powerhouse Oak & Orange and a trusted partner of Andersens, shares her insights on cutting-edge interior design trends. Enjoy a world of vibrant colour palettes, luxurious textures, exquisite flooring options, and stylish window treatments. With savvy selections, Sarah demonstrates how you can effortlessly transform your house into a haven.

According to Sarah, this year sees a focus on organic and sustainable design choices. “It's really great to see Aussies getting more tuned into this trend. People are all about crafting interiors that reflect nature while still their own personal style. It's like mixing ecofriendly vibes with your own flair.” Biophilic design, which integrates natural elements into indoor spaces, is at the forefront, using raw and organic materials that connect us to nature. Sarah says, “We’re not just thinking about aesthetics; it’s about making sure these spaces are as unique as you are, blending ecofriendliness with your own personal touch.”

Flooring trends: Light, natural and eco-conscious

Flooring is often the first element that physically connects people to a room, and therefore plays a vital role in interior design. “Flooring is a crucial element that can really make or break a space. It's like the foundation of a great outfit—it sets the tone for the whole home,” says Sarah. “There’s a strong preference

for natural materials like timber, natural stone and bamboo that are known for their eco-friendliness and ability to work for most architectural styles. We are continuing to see these materials being used in both new builds and renovations.”

In terms of colour, wooden flooring in bleached, light, and white oak is gaining

44 Flooring April/May 2024 www.flooringmagazine.com.au

Design & Trends

popularity. “These subtle sand-coloured tones provide a flexible base for homeowners to incorporate other furnishings and design elements around them. Andersens’ Timbre range of engineered timber flooring in the Ash Oak colour aligns perfectly with this trend offering both sustainability and touch of everyday luxury. We are seeing favouritism towards wider floorboards, lending a sense of expansiveness to spaces. Matte finishes on wooden floors are gaining traction, offering durability and a natural aesthetic that mimics the outdoor textures.”

Moving from wooden flooring to carpet, the timeless appeal of light earth-toned hues will continue their reign in creating harmonious and serene interiors. “We'll see a continued affection for earth-toned hues. These colours are versatile and blend seamlessly with various interior styles,” remarks Sarah. “Especially in bedrooms, there's nothing that rivals the tranquillity brought by a luxurious, neutral-toned carpet.”

The paler earth-toned carpets provide a perfect backdrop, acting as a blank canvas,

and allowing homeowners to experiment with vibrant wall colours and patterned furnishings, enabling diverse interior expressions. “Textured carpets are also on the rise, adding depth and interest to living spaces. Combining natural materials like sisal, jute, bamboo, and wool creates visually appealing effects. Yet you can achieve a similar look and feel with manmade carpets similar to the effect we created in our Dream Home 8 using

Andersens’ twist pile carpet Byng in Wheat. These are often found in soft, warm colours like beige, sand, cream, and light straw, which are perfect for rugs and carpets,” Sarah added.

Beyond aesthetics, sustainability in carpet choices is gaining momentum. “As designers, we prioritise being kind to the earth, and that's reflected in our enthusiasm for carpets like Andersens’ Feltex Salisbury.

46 Flooring April/May 2024 www.flooringmagazine.com.au

Design & Trends

This shift towards sustainable materials is seen in its composition – crafted entirely from wool and naturally dyed in shades like the tranquil Druid Stone. Its unmatched durability pairs with a unique aesthetic, enhancing the beauty of any space,” says Sarah.

Window treatment trends: Natural textures and earthy tones