2024 eFields Report

Ohio State Digital Ag Program

2024 Research Recap

eFields

“connecting science to fields”

eFields is a program at The Ohio State University dedicated to advancing production agriculture through the use of fieldscale research. The 2024 eFields Report is a culmination of the research conducted over the past year on partner farms throughout Ohio. Current research is focused on precision nutrient management strategies and technologies to improve efficiency of fertilizer placement, enable on-farm evaluation, automate machine functionality, enhance placement of pesticides and seed, and to develop analytical tools for digital agriculture.

eFields has expanded from 39 on-farm research sites in 13 counties in 2017, to 95 on-farm research sites covering 25 counties in 2018, 88 on-farm research sites in 30 counties in 2019, 218 on-farm research sites in 39 counties in 2020, 249 on-farm research sites in 45 counties in 2021, 292 trials in 49 counties in 2022, and 184 on-farm research sites in 47 counties in 2023.

2024 Research Recap

New for 2024

• Highlighted Certified Organic Trials

• UAS Cover Crop and Herbicide Applications

3,075 Total Acres

• 1,390 Corn

42 Ohio Counties

260 On-Farm Research Sites

Disclaimer Notice: The information provided in this document is intended for educational purposes only. Mention or use of specific products or services, along with illustrations, does not constitute endorsement by The Ohio State University. The Ohio State University assumes no responsibility for any damages that may occur through adoption of the programs/techniques described in this document.

Soybean Forages Tech

Small Grains Water Quality

Welcome to the 2024 edition of the Ohio State eFields Report.

The 2024 Ohio State eFields report showcases the dedication of our entire Ohio State team and collaborating partners. We extend our heartfelt gratitude to everyone who continues to support the eFields program, making it a resounding success. Special thanks go to our farm partners for their invaluable time, resources, and suggestions for each study. We also want to recognize the OSU Extension Educators, field specialists, faculty, staff, students, industry partners, and many others who contribute their time and resources to these studies. eFields exemplifies the collaborative efforts across all sectors of agricultural production, helping farmers and consultants use the results to enhance crop production in Ohio and the surrounding regions.

The 2024 eFields Report marks its 8th year. Like every growing season, 2024 brought unique challenges and valuable learning opportunities. The weather was the standout story of the year. While weather patterns varied across Ohio, crops generally got off to a good start with rains through July. However, summer turned hot and dry, with most regions experiencing drought conditions in August and September, and limited precipitation until December. Harvest began in early September and wrapped up quickly, with much of the fall work completed well before Thanksgiving. Overall, crop yields varied significantly across Ohio but were near USDA averages for Ohio. Another major concern in 2024 was the decline in commodity prices, which, when adjusted for inflation, hit their lowest levels in years. This issue remains a top priority for the U.S. as we head into the 2025 growing season. The ongoing conflict between Russia and Ukraine, along with the war between Israel and Hamas, dominated headlines throughout the year. Additionally, the agricultural sector faced challenges such as a growing shortage of ag mechanics and an outbreak of avian flu affecting dairy farms. The top concerns going in 2025 are the low commodity prices, high input costs, weather, labor shortages and global market conditions. Despite a grim outlook for crop production in 2025, Ohio farmers remain optimistic, seeking ways to improve efficiency and manage costs effectively.

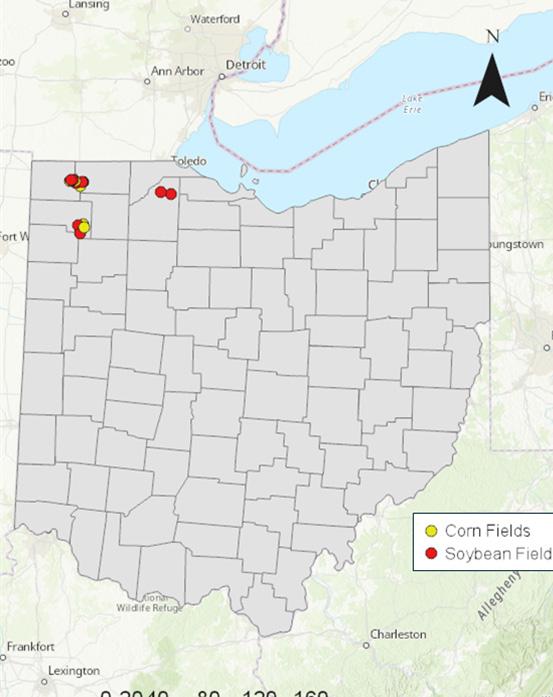

In the 2024 eFields Report, our team conducted 260 studies across 42 counties. We’re thrilled by the growing number and diversity of studies each year. The eFields team eagerly anticipates even more exciting projects in the future. You can access the eFields Reports from 2017-2024 online at go.osu.edu/efieldsreports or delve deeper into the data at kx.osu. edu/efields

We hope you find the 2024 eFields Report both informative and valuable. If you’re interested in collaborating with us in 2025 or have any feedback, please reach out to us at digitalag@osu.edu

Sincerely,

The 2024 eFields Team

Get Involved

Are you interested in contributing to the 2025 eFields Report? If so, visit go.osu.edu/efields to review study implementation plus tips and tricks. See below for details on how to get involved and who to contact. We look forward to working with you!

Growers

Growers interested in hosting on-farm research trials for publication in the annual eFields report should reach out to their county Agriculture and Natural Resources Extension Educator (agcrops.osu.edu/people). To view a list of those educators who are already involved, see page 14. Standard protocols for seeding rates, nitrogen rates, and other management practices have been developed for statewide implementation. Contact us today to find out how to get involved. Additional protocols and topics are being developed and can be customized to fit your questions and needs!

Industry Representatives

We are always looking for new partners to conduct on-farm trials! If you are interested in determining how you can support Ohio State University On-Farm Research, reach out to your county Agriculture and Natural Resources (ANR) Extension Educator, email Dr. Elizabeth Hawkins (hawkins.301@osu.edu), or email the eFields Program Manager, Dara Barclay (barclay.67@osu.edu). We would love to discuss your involvement with the eFields program!

Extension Educators and Field Specialists

If you are a current ANR Educator and are interested in getting involved with eFields, contact the Program Manager, Dara Barclay (barclay.67@osu.edu) to get started.

“ “

On-farm research is incredibly important because it allows me to test and validate practices and products in my own growing environment. This ensures that the results are directly applicable to my operation, rather than relying on generalized recommendations that may not fit my conditions. Pairing with programs like eFields and working with my local extension educator, I can ensure the research is sound and reliable. On-farm research keeps me on the cutting edge while ensuring I’m investing wisely, not just spending for the sake of it.

-Mike Kryling

I appreciate the opportunity to do my part in on-farm research with Ohio State University. Data collaboration is very important to improving any industry, and eFields is a great program to help row crop production farming advance to the next level.

-Doug Yoder

“

We believe that on-farm research is essential to improving agriculture across Ohio and we appreciate the continued efforts of OSU Extension to help us confidently determine what management practices will work best for our farm and determine areas of needed improvement. We would strongly encourage other farmers to get involved with the eFields program, and we look forward to continuing research on our farm in the future.

- Curtis Jones and Travis Newcomb, Sandburr Ridge Farms

Ohio State Digital Ag Program

OHIO STATE

DigitalAg

ABOUT US

The Digital Agriculture Program at The Ohio State University embodies the best of the land grant mission – creation, validation, and dissemination of cutting-edge agricultural production technologies. The central focus of this program is the interaction of automation, sensing, and data analytics to optimize crop production in order to address environmental quality, sustainability, and profitability. Research is focused on execution of site-specific nutrient management practices, development of hand-held devices for in-field data capture, autonomous functionality of machinery, remote sensing solutions, and data analytics to enhance timing, placement and efficacy of inputs within cropping systems.

VISION

The Digital Agriculture Program at The Ohio State University strives to be the premier source of research-based information in the age of digital agriculture.

MISSION

• Uniting the private and public sectors to drive innovation for the benefit of farmers.

• Partnering with farmers to translate innovation into long-term profitability for production agriculture.

• Delivering timely and relevant information for the advancement of digital agriculture technologies.

WHAT IS DIGITAL AGRICULTURE?

The premise of digital agriculture includes the advancement of farm operations through implementation of precision agriculture strategies, prescriptive agriculture and data-based decision making. Digital agriculture is a holistic picture of the data space in agriculture, trends related to services directing input management and the value of data usage for improving productivity and profitability of farm operations.

“Digital Agriculture” combines multiple data sources with advanced crop and environmental analyses to provide support for on-farm decision making.

Quality

Digital Ag Initiatives

“Helping growers make the most of Precision and Digital Ag technologies”

PRECISION SEEDING

Utilizing the latest digital ag technologies to place every seed in an environment optimized for its growth and development.

ON-FARM RESEARCH

Deploying field-scale studies to advance production agriculture through efficiency and profitability using data-driven decisions.

PRECISION CROP MANAGEMENT

Management of crop inputs in a manner that maximizes efficiency and profitability

HARVEST TECHNOLOGIES

Taking advantage of available technologies to improve harvest efficiencies and improve data quality.

SOIL COMPACTION MANAGEMENT

Mitigation of soil compaction to enhance crop health and soil structure.

REMOTE SENSING

Providing the ability to remotely assess field conditions, crop health, nutrient needs, and productivity levels on a sub-field scale.

APPS FOR AGRICULTURE

Embracing the power of smart phones and tablets to utilize mobile applications and farming smarter.

PRECISION NUTRIENT MANAGEMENT

Ensuring that all applied nutrients are in a position to maximize crop uptake. Right source, right rate, right time, right place, right technology.

PRECISION LIVESTOCK

Making use of data and digital tools to manage or automate animal well-being, food safety, pasture sustainability, waste products and more.

DATA ANALYSIS AND MANAGEMENT

Developing a digital strategy and making actionable decisions using data, from operational insights to field execution.

Report Guide

OBJECTIVE

Find study information, objectives, study design, weather graph, and summary on the left page. Find results, summaries, project contact, and statistical summary on the right page.

STUDY INFORMATION

Planting Date 4/30/2024

Harvest Date 10/16/2024

Variety Becks 6076V2P

Population 34,000 sds/ac

Acres 70

Treatments 5

Reps 7

Treatment Width40 ft.

TillageConventional

Management Fertilizer, Herbicide, Insecticide

Previous Crop Soybeans

Row Spacing30 in.

Soil Type Crosby silt loam, 52% Celina silt loam, 48%

STUDY DESIGN

The study design provides a background on the study. This could include a brief history of research, observations that led to the implementation of this study, explanation of the study design, etc.

Location

Box

Look to see the county where the study was conducted.

WEATHER INFORMATION

Here you will find visuals of the study with short descriptions.

OBSERVATIONS

The observations section of the report allows us to provide any relevant information that the researchers noticed throughout the growing season. Observations allow for a deeper understanding of the study results.

RESULTS

Treatments (XXX)

SUMMARY

• The summary section proves results and findings from the study.

• Thank you for taking the time to explore our 2024 eFields Report!

Treatment Means with the same letter are not significantly different according to Fisher’s Protected Least Significant Differences (LSD) test at alpha = 0.1.

TOOLS OF THE TRADE

This section allows us to display the tools and technology used to make each study possible.

PROJECT CONTACT

The Project Contact section provides the name of the researcher along with their email address. We encourage you to contact them if you have questions about an indvidual study.

Calculations and Statistics

To effectively collect, analyze, and interpret data, statistical calculations were made for each eFields study when possible. All statistical calculations were conducted using the OSU PLOTS Research App or calculated using the ANOVA spreadsheet, using Fisher’s Protected Least Significant Differences (LSD, alpha = 0.1) method to determine if treatment differences are statistically significant.

Stand Counts and Harvest Data:

All stand counts were conducted for individual plots by counting the number of plants in 30 linear feet along two adjacent rows. All yield data was collected using calibrated yield monitors or weigh wagons. Data was processed and cleaned to ensure accuracy with yields adjusted to a standard moisture prior to analysis.

Take a look at this example from a

study:

Replication

• Allows one to estimate the error associated with carrying out the experiment itself.

• Without replication, it would be impossible to determine what factor contributed to any treatment differences.

• A minimum of 3 replications is required for a proper evaluation, with 4 or more recommended for field-scale research.

Randomization

• Randomization is as important as replication to help account for any variations in production practices and field conditions.

• Even if treatments are replicated, the conclusions you reach may not be correct if a treatment was always applied to the same part of the field.

• Randomization prevents data from being biased due to its field location.

Explanation:

Treatments

Results show the average of the response variable (i.e. yield) for each treatment.

a

a

ab

b

LSD

Least Significant Difference (LSD) is used to compare means of different treatments that have an equal number of replications. For this report, a significance level of 0.1 (or 10%) was used, which means when a treatment is statistically significant, a 90% confidence is attributed to that treatment actually being different from the comparisons.

• For treatment A to be statistically significant from treatment B, they must differ by at least 3 bu/ac. (They do not, so they are not statistically different and are marked using the same letter).

• For treatment D to be statistically different from treatment A, they must differ by at least 3 bu/ac (here they differ by 5 bu/ac, so they are statistically significant and are marked using different letters).

Defined as the coefficient of variation (CV) is a measure of the variability between treatments (i.e. yields) reported as a percentage (%). CV is an indicator of data uniformity. Higher CV’s indicate more treatment or environmental variability.

In this example, since treatment A is different from treatment D by 5 bu/ac, there is 90% certainity that the results of the treatments were indeed different. Treatment differences are represented by using a letter beside the reported value. Since the averages for treatment A and treatment B differ by less than 3, it cannot be concluded that the treatments are different from each other, so the same letter (e.g. “a”) is used to indicate they are the same.

For more information and examples on statistics and experimental setup, visit go.osu.edu/efieldsinvolved.

Return above analysis allows farmers to consider not only yield increase, but also economic return which ultimately impacts the farm’s bottom line. For studies where economics were calculated, return above is labeled in the right-most column of the results table. To standardize return above calculations state-wide, the OSU Extension budgets were used for a partial profit calculation, farmoffice.osu.edu.

Seed Costs:

For the seeding rate studies, a uniform corn seed cost of $3.75/1,000 seeds was used. Soybean seed cost was $0.452/1,000 seeds. These are based on the Ohio Crop Enterprise Budgets developed by Barry Ward, OSU Extension. Learn more about the budgets on page 26.

Commodity Prices:

Price received was determined by the Chicago price at planting and adjusted with a historical basis to represent an Ohio price. The corn price used in the 2024 report is $4.20/bu and the soybean price is $10.00/bu. We then calculated a 10% price increase and decrease to reflect price variability.

Nitrogen Costs:

A nitrogen cost of $0.43/lb used in this report is from the 2025 Corn Production Budget. For the nitrogen timing studies, application costs were also considered. The average costs of application the report uses are from the 2024 Ohio Custom Farm Rates. Learn more about the 2024 custom rates on page 28.

Example economic calculator for corn seeding rate studies:

The “Return above” line includes only the input expense of what was being studied (i.e. seed cost) to provide a clear indication of economic return. To calculate your own economic return, you can access the eFields Economic Calculators at: go.osu.edu/econcalculator.

eFields Contributors

Glen Arnold Professor Field Specialist

OSU Extension

Tim Barnes Extension Educator

Marion County

OSU Extension

Mark Badertscher

Extension Educator

Hardin County

OSU Extension

Nic Baumer

Extension Educator

Hardin County

OSU Extension

Dara Barclay Program Manager, eFields & eBarns

OSU Extension

Frank Becker Extension Educator Wayne County

OSU Extension

JT Benitez

Extension Educator

Butler County

OSU Extension

Amanda Bennett

Extension Educator

Miami County

OSU Extension

Jocelyn Birt

Water Quality Extension Associate

OSU Extension

John Barker Extension Educator Knox County OSU Extension

Lee Beers Extension Educator Trumbull County

OSU Extension

Maddie Brillhart

Student Assistant Department of Entomology

Soybean Forages Tech Other Small Grains

Quality

Bridget Britton Field Specialist OSU Extension

Brady Campbell Assistant Professor Department of Animal Sciences

Grant Davis Extension Educator Champaign County OSU Extension

Cassandra Brown Program Manager School of Environment and Natural Resources

Caden Buschur Extension Educator Darke County OSU Extension

Marilia Chiavegato Assistant Professor Department of Horticulture and Crop Science & Department of Animal Sciences

Rachel Cochran Water Quality Extension Associate OSU Extension

Wayne Dellinger Extension Educator Union County OSU Extension

Amanda Douridas Extension Educator Madison County OSU Extension

Pressley Buurma Extension Educator Seneca County OSU Extension

Trevor Corboy Extension Educator Brown County OSU Extension

Nate Douridas Farm Manager Molly Caren Agricultural Center

eFields Contributors

Nick Eckel Extension Educator Wood County OSU Extension

Amber Emmons

Water Quality Extension Associate OSU Extension

Louceline Fleuridor

Post Doctoral Scholar School of Environment and Natural Resources

Ken Ford Extension Educator Fayette County OSU Extension

Alyssa Essman Assistant Professor Department of Horticulture and Crop Science

John Fulton Professor Department of Food, Agricultural and Biological Engineering

Paige Garrabrant

Water Quality Extension Associate

OSU Extension

Christine Gelley Extension Educator Noble County OSU Extension

Yang Geng Post Doctoral Scholar Department of Food, Agricultural and Biological Engineering

Mike Estadt Extension Educator Pickaway County OSU Extension

Allen Gahler Extension Educator Sandusky County OSU Extension

Ryan Haden Associate Professor Ohio State ATI

Soybean Forages Tech Other Small Grains

Quality

Jason Hartschuh Assistant Professor, Field Specialist OSU Extension

Dee Jepsen Professor Department of Food, Agricultural and Biological Engineering

Andrew Klopfenstein Sr. Research Associate Engineer

Department of Food, Agricultural and Biological Engineering

Elizabeth Hawkins Associate Professor, Field Specialist OSU Extension

Douglas JacksonSmith Professor and Kellogg Endowed Chair School of Environment and Natural Resources

Seth Kannberg Extension Educator Portage County OSU Extension

Grace Koppelman Student Assistant Department of Food, Agricultural and Biological Engineering

Stephanie Karhoff Assistant Professor, Field Specialist OSU Extension

Carri Jagger Extension Educator Morrow County OSU Extension

Sami Khanal Assistant Professor Department of Food, Agricultural and Biological Engineering

Greg LaBarge Professor, Field Specialist OSU Extension

Abby Leatherman Summer Student Assistant

Department of Food, Agricultural and Biological Engineering

eFields Contributors

Rob Leeds

Extension Educator

Delaware County

OSU Extension

Alan Leininger Extension Educator

Henry County

OSU Extension

Clif Little

Extension Educator

Guernsey County

OSU Extension

Horacio LopezNicora Assistant Professor Department of Plant Pathology

Clifton Martin

Extension Educator

Muskingum County

OSU Extension

Ryan McMichael

Extension Educator

Mercer County

OSU Extension

Ed Lentz

Extension Educator

Hancock County

OSU Extension

Kendall Lovejoy Extension Educator

Fulton County

OSU Extension

Laura Lindsey Associate Professor Department of Horticulture and Crop Science

Steve Lyon Professor, Assistant Director Wooster Operations School of Environment and Natural Resources

Logan Minter Associate Professor, Field Specialist

OSU Extension

Richard Minyo Research Specialist Department of Horticulture and Crop Science

Soybean Forages Tech Other Small Grains

Quality

Marina Miquilini Extension Educator Greene County OSU Extension

Asmita Murumkar Assistant Professor, Field Specialist OSU Extension

Osler Ortez Assistant Professor Department of Horticulture and Crop Science

Ricardo Ribeiro Visiting Scholar Department of Horticulture and Crop Science

Erdal Ozkan Professor Department of Food, Agricultural and Biological Engineering

Eric Richer Associate Professor, Field Specialist Farm Management

Gigi Neal Extension Educator Clermont County OSU Extension

Stephanie Pflaum Student Assistant Department of Entomology

Sarah Noggle Extension Educator Paulding County OSU Extension

Amy Raudenbush Researcher Department of Entomology

Eric Romich Professor, Field Specialist Energy Development

Beth Scheckelhoff Extension Educator Putnam County OSU Extension

eFields Contributors

Clint Schroeder Program Manager Ohio Farm Business Analysis

Ajay Shah Professor Department of Food, Agricultural and Biological Engineering

Scott Shearer Professor and Chair Department of Food, Agricultural and Biological Engineering

Vinayak Shedekar Assistant Professor Department of Food, Agricultural and Biological Engineering

Haley Shoemaker Extension Educator Columbiana and Mahoning County OSU Extension

Kendra Stahl Extension Educator Crawford County

OSU Extension

Ryan Slaughter Extension Educator Ross County OSU Extension

Ambria Small Student Associate Department of Plant Pathology

Jenny Stoneking Extension Educator Adams County OSU Extension

Alan Sundermeier Professor Emeritus, OSU Extension (Conservation Action Project Coordinator)

Jacci Smith Extension Educator Delaware County OSU Extension

Alex Thomas Graduate Research Associate, Department of Food, Agricultural and Biological Engineering

Soybean Forages Tech Other Small Grains

Quality

Kelley Tilmon Professor Department of Entomology

Brooks Warner Extension Educator Clinton County OSU Extension

Amit Prasad Timilsina Post Doctoral Scholar Department of Food, Agricultural and Biological Engineering

Aaron Wilson Assistant Professor, Field Specialist OSU Extension

Tiffany Woods Graduate Research Associate School of Environment and Natural Resources

Kayla Wyse Extension Educator Williams County OSU Extension

Kyle Verhoff Extension Educator Defiance County OSU Extension

Dena Wilson Student Assistant Department of Food, Agricultural and Biological Engineering

Barry Ward Leader, Production Business Management OSU Extension

John Yost Extension Educator Wayne County OSU Extension

Jacob Winters Extension Educator Auglaize County OSU Extension

Chris Zoller Extension Educator Tuscarawas County OSU Extension

2024 Growing Season Weather

The weather of 2024 brought yet another challenging year for producers across Ohio in the name of drought. Ohio experienced one of its historically most intense droughts on record, especially across central and southern counties, while temperatures also averaged well above normal. After ample spring moisture and decent planting conditions in May, extreme heat ensued in June followed by very dry conditions for the bulk of the growing season. Compared to our longterm average (1991-2020), growing season temperatures (March – November) were 2-5°F above normal (Fig. 1). Most counties received less than 30 inches over this nine-month period, with southeastern counties particularly hard hit (5075% of normal; much less if March is not included). Through November, 2024 ranks as the warmest and 40th driest on record (1895-present) for Ohio according the National Centers for Environmental Information. For more inseason climate analysis, please visit the State Climate Office of Ohio. The following is a summary of the growing season and seasonal breakdown of 2024.

Figure 1: (Left) Temperature departures (°F), (Middle) Precipitation departures (inches), and (Right) Precipitation departures (percent of normal) from the long-term (1991-2020) normal for March-November 2024. Figure courtesy of the Midwestern Regional Climate Center.

Spring (March – May)

Following the second warmest winter on record for Ohio, warmer than normal conditions persisted throughout spring. All three months ranked near or in the top ten warmest all time. The last spring freeze (32°F) occurred between April 21-30, with a few spots seeing their last spring freeze before April 10. Overall, precipitation was above average for spring (Figure 2), especially across northwestern and eastern Ohio. This was primarily due to a wet April, while March and May precipitation was close to average. Severe weather was a big story before the summer’s drought, as historic tornado numbers accumulated for the season. Six days with five or more confirmed tornadoes occurred in 2024, including March 14, April 2, and April 17, among others. Ohio’s largest tornado outbreak for the year occurred on May 7-8, with twenty tornadoes confirmed across the state. This led to planting delays and interruptions in spring activities in affected areas. Spring 2024 ranks as the 2nd warmest and 28th wettest for Ohio.

Figure 2. County precipitation ranks for Ohio for spring 2024 (March – May). White shading indicates near normal conditions, while the top third (lighter colors) and top ten (darker colors) of the record are depicted for both dry (brown) and wet (green) conditions. Figure courtesy NOAA

Summer (June – August)

June got off to a hot start as temperatures across the state frequently soared well into the 90s. Stations throughout the state recorded seven to nine consecutive days of at least 90°F during the middle of the month, as June 2024 ranks as the 15th warmest June on record. Both July and August were also warmer than normal. Drought conditions initiated in June then intensified throughout the three-month period. Total summer precipitation for central and southeastern Ohio was less than 7.5 inches, 6-8 inches below normal (50% of normal; Figure 3). This caused significant stress on livestock producers in southeast Ohio, with very little hay production and widespread intensive water hauling. Soil moisture, rivers, and streams were well below average all summer, and crops in the driest areas of the state suffered yield loss. Summer 2024 ranks as the 25th warmest and 7th driest on record.

Figure 3. Accumulated precipitation (inches) for June-August 2024. Figure courtesy of the Midwestern Regional Climate Center.

Fall (September – November)

Drought conditions persisted throughout much of fall as well, peaking in both intensity and areal covereage on September 24, 2024 (Figure 4). This year was the first time in the U.S. Drought Monitor’s inception that D4 (Exceptional Drought) conditions have been designated in Ohio. This year also set records for the greatest coverage of D2-D4 drought conditions. The only relief in September and October came in the form of the remnants from Hurricane Helene in late September, which mainly struck the southern counties of Ohio. Some areas that had expericenced significant drought conditions received 6-10” of rain from this system (e.g., Fayette, Ross, Pike, and Scioto Counties), along with strong winds that caused additional lodging and sprouting issues in row crops. Prior to this system, producers in southern Ohio reported 6% moisture in some soybeans, as harvest activies ran two to three weeks early across the state. The large amount of pod shatter to emergence of fall soybeans when moisture returned a few weeks later. Depite Helen’s moisture, October reverted to very dry and warm conditions, ranking as the 7th driest for the state. All three fall months rank near or in the top 10 warmest on record. As November ended, early season cold swept across Ohio with a major lake snow event across Lake and Ashtabula Counties, where more than five feet of snow fell in some locations into the first week of December. Overall, Fall 2024 ranks as the 3rd warmest and 38th driest on record.

TOOLS OF THE TRADE

FARM (Field Application Resource Monitor)

This tool (farm.bpcrc.osu.edu) allows users to define their locations of interest and receive 12- and 24-hour precipitation forecasts (current and historical) to aid in the application of fertilizer, manure, and/or pesticides.

Figure 4: Drought conditions in Ohio on September 24, 2024. Figure courtesy of the U.S. Drought Monitor.

PROJECT CONTACT

For inquiries about this project, contact Dr. Aaron B. Wilson (wilson.1010@osu.edu).

Crop Progress and Suitable Days

OBJECTIVE

Summarize Ohio planting progress and days suitable for fieldwork reported each year the National Agricultural Statistics Service (USDA-NASS).

Corn Planting Progress

eFields Collaborating Farm

OSU Extension Statewide

Corn planting pace was split across the state with the southern counties having great stretches of dry weather and the northwestern counties having a wet and delayed start. In 2024, Ohio farmers reached the 50% planted mark for corn on May 19th and completed planting by June 16th. Figure 1 illustrates Ohio’s corn planting progress for all years between 1979 and 2024. This is the seventh latest finish recorded. This continues the recent trend of continuing to push corn planting dates later towards the end of spring.

Soybean Planting Progress

Figure 1. Ohio corn planting progress reported by USDA NASS from 1979 –2024. 2024 progress is shown by the scarlet dashed line. Data source: USDA NASS

Soybean planting progress in 2024 was typical for Ohio. Figure 2 shows Ohio’s soybean planting progress for all years between 1979 and 2024. Ohio reached 50% planted by May 26th and soybean planting was reported completed on June 30th. The 2024 soybean crop was ties with 1985 for the seventh latest finish recorded by USDA NASS.

Figure 2. Ohio soybean planting progress reported by USDA NASS from 1979 –2024. 2024 progress is shown by the scarlet dashed line. Data source: USDA NASS

Soybean Forages Tech

Days Suitable for Fieldwork

The 2024 season was a great season for getting work done in the field. The weather provided more favorable conditions for fieldwork with all months after May having more than average days suitable for fieldwork except July (Figure 3). Unfortunately, this increase in days suitable was a reflection of the drought conditions being experienced across much of the state. The dry summer led to an early start to harvest and the dry fall enabled consistent progress throughout the fall.

Harvest Progress

Figure 3. Monthly days suitable for fieldwork. The average number of days per month from 1995 to 2023 (scarlet squares) compared to the number of days available for fieldwork per month in 2024 (gray circles). Monthly totals are calculated based on weekly reports. Data source: USDA NASS

Persistent drought conditions throughout much of Ohio led to quicker than normal crop maturity and an early start to harvest. Figure 4 shows the reported harvest progress dating back to 1981. While both corn and soybean harvests started earlier than normal, the start to soybean harvest was notably early. 2024 was just the fifth earliest soybean harvest start on record, beat by memorable seasons like 1987, 1998, 1999, and 2012. Average reported soybean moistures were the lowest every recorded, nearly 2% lower than the all-time average of 13%.

4. Reported crop hrvest completion dates for corn (left) and soybean (right) in Ohio reported by USDA NASS from 1979 – 2024. 2024 progress is shown by the scarlet dashed line. Data source: USDA NASS

SUMMARY

The 2024 spring planting season was slower than normal for the corn crop and near normal for the soybean crop. Later planting, especially for corn, is becoming a common occurence as weather conditions pose challenges in Ohio and across the country. Dry conditions most of the summer led to higher than average days suitable for fieldwork. Harvest started earlier than typically, especially soybeans due to drought conditions and early maturation.

PROJECT CONTACT

For inquiries about this project, contact Elizabeth Hawkins (hawkins.301@osu.edu), or Aaron Wilson (wilson.1010@osu.edu).

Figure

Ohio Crop Enterprise Budgets

What are Enterprise Budgets?

Enterprise Budgets have been developed by faculty of the College of Food, Agricultural, and Environmental Sciences (CFAES) for several decades. The 2025 Ohio Crop Enterprise Budgets were developed by Barry Ward, Leader, Production Business Management at Ohio State. The budgets are tools that growers can use to examine different scenarios on their operation to help in decision making. The Enterprise Budgets can be found on Excel spreadsheets that users can download. Growers can then input their own production and price levels to calculate their own outputs. As seen below, the budgets have color coded cells that will allow users to plug in their own numbers and calculate bottom lines for different scenarios.

PRODUCTION BUDGET -

No-Tillage Practices*

Cell Color Key:

Gold: Values may be changed to assist in computing the “Your Budget” Column using macros embedded within the spreadsheet.

Light Blue: Values will be calculated for the user based on data entered. These cells may be input manually, but macros will be overwritten!

Gray: Values are stand-alone cells that require direct input from the user.

Soybean Forages Tech

Key points to remember when utilizing the budget sheets:

• The budgets represent common, workable, combinations of inputs that can achieve a given output.

• Amounts of seed, types and quantities of fertilizer, chemicals, and other items reflect University recommendations and the experience of many Ohio farmers.

• The combinations of inputs and prices presented will not likely precisely reflect any given farm.

• In practice, actual costs will be higher or lower than shown. Thus the most important column is “Your Budget”.

Characteristics of an Enterprise Budget:

• Estimates the costs and returns expected for a single enterprise.

• Represents one combination (from among hundreds available) of inputs such as seed, chemicals, and fertilizer to produce some level of output.

• A written plan for a future course of action including estimated costs and returns for that particular enterprise.

• Provides a format and a basis for developing enterprise budgets appropriate for a given farm situation.

Things not implied by an Enterprise Budget:

• It is not the only combination of inputs that can be used to produce this crop.

• It does not imply that anyone whose costs are different from this must have incorrect data or poor records.

• It does not imply that all producers can achieve these costs and yields. Different soil types, different ways in which the soil has been utilized and cared for in the past, and different weather in a given season all can cause the actual results to vary greatly from what is presented.

Yield Levels

Three yields are provided in each budget sheet. The middle yield is the long term trend yield for Ohio. The other two yields are 20% lower and higher than the middle yield. These yields levels reflect differing yield potential.

Variable Costs

Seed, fertilizer, and chemical requirements are based on agronomists’ recommendations. Fertilizer amounts vary by yield level to reflect crop removal, based on typical soil test values for P2O5 and K2O. These quantities and prices can changed to reflect your soil tests and local prices to provide a more accurate estimate of your costs of production.

Fixed Costs

Five items are included as fixed costs, some of which may or may not be fixed for a particular operation. These items include labor, management, machinery and equipment, land, and miscellaneous charges.

Costing Methods

The budgets report all costs including cash, depreciation, and opportunity costs. Cash costs likely include categories such as seed, fertilizer, and chemical costs. Depreciation on machinery is included in the “Machinery and Equipment Charge.” Some items may contain opportunity costs, which reflect returns to a producer’s labor, capital, and managerial resources. Opportunity costs should be included in budgeting because they account for the use of a producer’s resources.

Interpretation of Returns

All budgets report “return above variable costs” and “return above total costs”. Return above variable costs is useful in examining decisions that must be made within a year. Return above total costs would be used to examine “long-run” decisions.

Pricing Methods

Prices for crops and inputs reflect estimates for the given year. Crop prices are estimates of harvest prices. No costs are included for grain storage. If an improved price is acheived by your farm due to storage or marketing strategies, then any increased costs to achieve that price should either be netted out of returns or added to costs.

PROJECT CONTACT TOOLS OF THE TRADE

Enterprise Budgets

Access the Ohio Crop Enterprise Budgets by visiting go.osu.edu/enterprise_budgets or by using the QR code to the right.

For inquiries about this information, contact Barry Ward (ward.8@osu.edu).

Ohio Farm Custom Rates

This publication reports custom rates based on a statewide survey. Surveys were mailed/emailed to past respondents and distributed at various Extension programs through the winter of 2024. The summary information included in this publication is based on the responses of 333 farmers, custom operators, farm managers, and landowners conducted in 2024. These rates, except where noted, include the implement and tractor if required, all variable machinery costs such as fuel, oil, lube, twine, etc., and labor for the operation.

Some custom rates published in this study vary widely, possibly influenced by:

• Type or size of equipment used

• Size and shape of fields

• Condition of the crop

• Skill level of labor

• Amount of labor needed in relation to the equipment capabilities

• Cost margin differences for full-time custom operators compared to farmers supplementing current income

• Region of Ohio with different custom services supply and demand characteristics

Some custom rates reflect discounted rates as the parties involved have family or community relationships. Discounted rates may also occur when the custom work provider is attempting to strengthen a relationship to help secure the custom farmed land in a future purchase, cash rental or other rental agreement. Some providers charge differently because they are simply attempting to spread their fixed costs over more acreage to decrease fixed costs per acre and are willing to forgo complete cost recovery. Charges may be added if the custom provider considers a job abnormal such as distance from the operator’s base location, difficulty of terrain, amount of product or labor involved with the operation, or other special requirements of the custom work customer.

The eFields nitrogen studies utilize the Ohio Farm Custom Rates to calculate return above total N. As you read through our nitrogen studies, you can reference these rates to better understand our calculations. Below is a sample of how we utilize these rates for our return above N calculations. The treatment data below is from an eFields Late Season Nitrogen study. The total nitrogen rate and yield were inputted in the Nitrogen Timing Calculator that is found in a downloadable Excel file at go.osu.edu/econcalculator.

Treatment: Rate 1

In this example, the “Late Season N ApplicationCoulters/Acre” rate of $14.60 was used to calculate the return above N. After inputting the application rate, yield, and total N rate into the calculator, the Return Above N for this treatment is $997.00 per acre.

TOOLS OF THE TRADE

PROJECT CONTACT

Quarterly Fertilizer Price Summary

To better understand local fertilizer prices across Ohio, OSU Extension personnel initiated a fertilizer pricing survey of retailers across Ohio beginning in December 2023. Respondents were asked to quote spot prices as of the first day of the quarter. Sale types included pickup (ie. freight on board or FOB) at the plant (any quantity), direct-to-farm delivery (truckloads), or delivered and applied (poultry litter only). No blending or application charges were to be included in the spot price. Results from the survey data can be used to gauge pricing trends and compare Ohio prices to the national average. We recognize that many factors influence a company’s spot price for fertilizer including but not limited to availability, geography, volume, cost of freight, competition, regulation, etc.

The summary report each quarter contains a chart (Table 1) which includes the number of responses for each fertilizer product. The minimum and maximum values are also reported, as well as a simple average of all responses for each product. The spring quarter (April 1st) summary had the greatest participation with 32 retailers from 19 counties completing the survey. In general, when comparing the results from this survey with national average prices, Ohio’s prices were slightly lower.

With a year of completed results we can begin to see pricing trends over the 2024 calendar year.

Results from the quarterly survey are shared through the Ohio Ag Manager blog : u.osu.edu/ohioagmanager

A summary of those reports can also be found under the Farm Management tab of the Farm Office site: farmoffice.osu.edu

Figure 1: Nitrogen Products 2024 Price Trend

Figure 2: Phosphate Products 2024 Price Trend

PROJECT CONTACT

For inquiries about this project, contact: Clint Schroeder (schroeder.307@osu.edu), Amanda Bennett (bennett.709@osu.edu), or Eric Richer (richer.5@osu.edu)

Table 1: Quarterly Fertilizer Prices go.osu.edu/fertilizersummary

Access the Ohio Quarterly Fertilizer Price Summaries:

Figure 3: Potash 2024 Price Trend

Figure 4. Ammonium Sulfate 2024 Price Trend

Reducing Dust Exposure

In the fields or around the grain storage bins, dust exposure was a significant factor for the 2024 harvest season. In a study funded by Ohio Bureau of Workers Compensation, respirable dust measurements were taken at 14 on-farm grain storage facilities in Ohio during the time that workers were cleaning their bins. Workers wore an N-95 mask during the cleaning process, and calculations were made on the mask’s protective factors. In each case, the N-95 performed well, meeting the OSHA assigned protection factor for a half-mask respirator. However, fit tests and seal checks were not conducted by the farmer prior to N-95 mask use, so it is possible that implementing these two practices could have increased respirator effectiveness.

Humans can suffer significant and irreversible health effects from grain dust exposure. Working in an enclosed tractor or combine cab while in the fields can reduce worker exposure to the generated dust, but additional protection from a properly fitted respirator ensures a safer working environment while unloading grain and working around the grain bin facilities.

On large farms with over 11 non-family employees or commercial grain facilities, workers undergo a fit test procedure to comply with OSHA’s Respiratory Protection Standard, 1910.134(e). On private farms, few regulations are in place for fit testing. However, wearing a proper fitted respirator is a good practice to follow. Medical centers can perform fit tests for a small fee. The Ohio Bureau of Workers’ Compensation also offers fit test training. Just as tractors have specifications for the most effective air filter for their specific make/model, respirators should also fit the specific size and shape of the worker’s face.

STEPS FOR RESPIRATOR FIT TESTING

1. CONDUCT A RESPIRATOR FIT TEST EVERY YEAR

Medical Evaluation

Before wearing a respirator, it is good to know if the worker has the physical ability to wear a respirator. This can be determined through a Respirator Medical Evaluation Questionnaire completed by the worker The answers are reviewed by a physician or licensed health care professional. A positive response to any of the questions 1-8 on the Medical Evaluation questionnaire requires a follow-up medical examination. An OSHA Info Sheet can be accessed at: osha.gov/sites/default/files/publications/OSHA3790.pdf

Qualitative Fit Test

Qualitative fit testing is a pass/fail test that uses the wearer’s sense of taste or smell, or their reaction to an irritant to detect leakage into the respirator facepiece.

In this test, the worker wears his or her respirator inside a tent or hood into which the substance is piped (Figure 1), and the worker indicates the ability to sense the irritant. Air leaks around the respirator allows the contaminant to be detected. There are four qualitative fit test substances accepted by OSHA: Isoamyl acetate, which smells like bananas; Saccharin, which leaves a sweet taste in the mouth; Bitrex, which leaves a bitter taste in the mouth; and Irritant smoke — which is only seldom used because of the specific training needed to administer the OSHA Irritant Smoke Protocol.

Once a worker finds a respirator that is effective against smelling the substances used in their fit test, this respirator becomes “the assigned respirator” for the worker. The worker should only wear this make/model and size of respirator for the entire year. An annual fit test and training is done each year to ensure the worker is in the correct size of respirator.

Figure 1. A qualitative fit test, showing the hood where substances are piped into for detection.

For additional information or to find a fit testing facility, contact the Ohio Bureau of Workers Compensation office (focusing on their virtual or in-person fit testing training event) or the Ohio Pesticide Program: pested.osu.edu/resources/wps/respiratorrequirements

2. CONDUCT A USER SEAL CHECK EACH TIME A RESPIRATOR IS WORN

Each time a respirator is used, the worker should conduct a positive- and negative-pressure seal test. This quick check determines if the respirator has a good seal.

How to complete a positive user seal check:

1. Put on the respirator:

Make sure the respirator is properly positioned on your face, covering both your nose and mouth. Ensure the straps are in place, with one strap above the ears and one below.

2. Cover the respirator surface: For respirators with an exhalation valve, cover the valve with your hand. For respirators without an exhalation valve, gently cover the respirator’s surface with both hands to avoid shifting the mask position.

3. Exhale gently:

Breathe out gently and feel for air escaping from around the edges of the respirator.

4. Check for leaks:

If you feel air leaking around the edges, adjust the straps or re-position the respirator and repeat the check.

SUMMARY

Figure 2. A user seal check for disposable respirators.

How to complete a negative user seal check:

1. Put on the respirator:

Make sure the respirator is properly positioned on your face, covering both your nose and mouth. Ensure the straps are in place, with one strap above the ears and one below.

2. Cover the respirator inlets: For respirators with cartridges or filters, cover the air inlets (filters or cartridges) with your hands. For other respirator types, use your hands to cover the surface of the mask, being careful not to disturb the fit.

3. Inhale gently:

Breathe in gently and the respirator should collapse slightly against your face due to the lack of air entering.

4. Check for leaks: If the respirator collapses and you don’t feel air entering through the sides, the seal is adequate. If you feel air coming in at the edges, adjust the straps or re-position the respirator and try again.

Always wear an N95 or P100 respirator when working in high dust, agricultural environments. A disposable face mask respirator is best when replaced each day, and when a user seal check is performed every time it is worn. Facial hair limits the effectiveness of the seal, as does certain eyeglasses and other personal protective equipment (PPE). However, wearing a properly-sized and fitted respirator protects against organic dusts that can deposit deep in the lungs, and promotes better worker health.

Figure 3. Research participant cleaning a grain bin while wearing a backpack of respiratory monitoring equipment.

PROJECT CONTACT

For inquiries about this project, contact the Agricultural Safety & Health Program: Dee Jepsen, Professor (jepsen.4@osu.edu) or Yang Geng (geng.83@osu.edu)

Digital Ag Download (DAD)

In an effort to bring you the latest news and research related to Digital Agriculture, The Ohio State Digital Ag Team has a newsletter. Special updates are sent out periodically for breaking news, important events, and research updates. The newsletter features articles, podcasts, videos, studies, and publications from our team to provide you with relevant information from the industry.

From tips for fine-tuning your planter, to protecting your harvest data, the Digital Ag Download covers it all and keeps you informed throughout each season. By joining our email list, you never have to worry about missing an update from our team.

GET UPDATES

Help grow the popularity of “The Digital Ag Download” by joining our email list and sharing with growers, industry professionals, and anyone interested in your neck of the woods! To sign-up, scan the QR Code or visit go.osu.edu/DigitalAgDownload.

VIDEOS

If you are looking for more information on eFields studies, Precision University, or other demonstrations, the Digital Ag Download regularly features videos from across the state. Find information on the Knowledge Exchange, spray drone application demonstrations, and interviews with eFields partner farms there.

PODCASTS

From the Agronomy and Farm Management podcast, to Precision Ag Reviews, and Precision Farming Dealer, our team has been featured on more than a podcast or two. Whether you are in the office or on the go, find their most recent podcasts with indsutry updates from the Digital Ag Download.

PUBLICATIONS

The Digital Ag website features seven different research focuses from precision seeding to remote sensing. Get timely updates right your inbox to help keep your operation running smoothly with the most recent work from our team with their research publications, quick start guides, and presentations.

Farm Stress Resources

Mental health plays a vital role in overall health and farm success. Agriculture can become stressful with numerous demands and challenges out of our control. There are many resources available to help you cope through difficult times. If you have additional questions or want help, please reach out.

For information on programs and factsheets on Rural and Mental Health Resources, contact our Farm Stress Team at:

go.osu.edu/farmstress (using the “About” tab)

Ohio Resources and Handouts

• The Ohio Crisis Text Line and Call Line provides confidential, 24/7 support for anyone experiencing a mental health crisis, substance use concerns, or suicidal thoughts. It connects individuals to trained crisis counselors who offer emotional support, guidance, and resources. Both services below are free and available for anyone in need of immediate support or guidance.

• Call or Text 988 to connect with a trained counselor for support with a mental health challenge, substance use issue, or thoughts of suicide—whether for yourself or a loved one.

• Text “4HOPE” to 741741: This service is specific to Ohio and links individuals to crisis counselors who can assist with stress, anxiety, depression, and other emotional challenges.

• Resources relating to Rural and Farm economics, Workforce Development, and Personal Stress Management: extension.osu.edu/about/resources/extension-task-forces/rural-and-farm-stress

• Ohio Mental Health Resource Guides by County: u.osu.edu/cphp/ohio-mental-health-resource-guides/

• Ohio Department of Agriculture Farm Stress: gotyourbackohio.org

Now available - Farm Stress Certified Providers!

A new certification for mental health professionals was introduced in 2024. This three-module program is designed to give mental health professionals the understanding and resources needed to assist the agricultural community.

Find a Certified Farm Stress Provider: go.osu.edu/FarmStressProfessionals

Listen to the “Now at Ohio State” Podcast

Hear from Bridget Britton (Behavioral Health Field Specialist) and Aaron Wilson (Extension Field Specialist - Ag Weather and Climate) on the Ohio State podcast where they discuss the growing mental health crisis in farming communities: go.osu.edu/OSUAgMentalHealth

A Farm Stressor in 2024: Drought

See more on the response to the 2024 drought, here kx.osu.edu/page/early-drought-response

Additional Resources:

• Center for Rural Affairs - 10 Helpful Resources for Farmers: cfra.org/news/180130/10-helpful-resources-farmers

• Iowa State University - Iowa Concern 24-hour hotline: 1-800-447-1985

• National Suicide Prevention Lifeline: 1-800- 273-TALK (8255)

• National Suicide Prevention Lifeline Crisis Chat: suicidepreventionlifeline.org/talk-to-someone-now/ Call or Text 988 to connect with a trained licensed professional counselor within five minutes. Free, confidential, anonymous, and secure 24/7. Features active rescue where trained counselors connect with emergency services to save texters from immediate self-harm.

• Veterans Crisis Line: 1-800-273-8255, Press 1 (website also has a chat option) veteranscrisisline.net/

• My Coping Strategies Plan, Kansas State: bookstore.ksre.ksu.edu/pubs/MF3418.pdf

• Responding to Distressed People, NDSU: ag.ndsu.edu/publications/kids-family/responding-to-distressed-people/fs1805.pdf

PROJECT CONTACT

For inquiries about this project contact Sarah Noggle (noggle.17@osu.edu) or Chris Zoller (zoller.1@osu.edu).

2024 Preharvest Weed Escape Survey

PREHARVEST SURVEY

Just prior to harvest each year, the weed science program at Ohio State evaluates the frequency and distribution of problematic weed species by conducting a survey late-season in soybean fields throughout Ohio. Transects are driven through the top soybean producing counties, and information is collected on weed escapes in each field encountered. A rating scale of 0 to 3 is used to classify population level of each weed, with 0 being no weed present to 3 being dense, widespread infestations. Each field is given these ratings for ten weed species, namely: marestail, giant ragweed, common ragweed, waterhemp, Palmer amaranth, redroot pigweed, volunteer corn, common lambsquarters, giant foxtail/grass, and velvetleaf. Performing the survey at this time provides results that reflect the effect of control measures during the season. Conducting this survey on an annual basis allows for the monitoring of weed species shifts, evaluation of weed management program efficacy, and forecasting of potential issues and threats for the following growing season.

In 2024, 62% of fields encountered on the survey were clean, or at least free of the 10 weeds being evaluated.

The most commonly encountered weeds during the 2024 preharvest survey – percent of total fields with weeds present summed across rating levels:

1. Waterhemp - 11%

2. Giant ragweed - 10%

3. Grass/foxtail spp. - 8%

4. Volunteer corn - 8%

5. Marestail - 7%

The most concerning outcome was that waterhemp was encountered at a higher frequency than in previous years, based on percent of fields surveyed with waterhemp present (Figure 1).

• In 2024, waterhemp was the #1 most encountered weed, found in 91% of the counties surveyed and 11% of the 4,100 fields evaluated.

• In 2023, waterhemp was the #3 most encountered weed in the 4,000 fields evaluated, where waterhemp was found in 89% of surveyed counties and 13% of fields.

• In 2022, waterhemp was the #2 most encountered weed, found in 94% of the counties surveyed, and 11% of the 4,200 fields evaluated.

Figure 1. Results of the waterhemp distribution from the 2022, 2023, and 2024 preharvest surveys evaluating weed escapes in soybean. A county labeled with 0% does not mean no waterhemp exists in the county, but that it was not encountered on the survey.

WATERHEMP DISTRIBUTION

The migration of waterhemp and Palmer amaranth into and around the state of Ohio has been closely monitored. These weeds are especially difficult to control and pose a serious threat to crop yields. Palmer amaranth has been reported in various regions around Ohio. Upon discovery, it has generally been confined to the areas of introduction or eradicated. In the years conducting this survey, it has been uncommon to spontaneously encounter Palmer amaranth. Waterhemp has become increasingly common and is now found in crop fields across Ohio, largely across the western portion of the state.

WATERHEMP BIOLOGY

The following biological characteristics give waterhemp a competitive edge:

• Immense seed production – from 100,000 seeds in competitive situations to over 1 million in noncompetitive situations

• Fast growth rate – approximately 1 to 1 ¼ inches per day

• Prolonged emergence window – can emerge later in the growing season than other weed species

• High genetic diversity – male and female flowers are on separate plants and must outcross to reproduce

• Herbicide resistance – due in part to high genetic diversity, waterhemp populations in the Midwest have developed resistance to several herbicides and even multiple resistance to two or more sites of action

WATERHEMP CONTROL

Waterhemp produces a tremendous number of seeds, but the seeds are relatively short lived in the soil. Excellent control over 3-5 years can help eradicate this weed. Successful waterhemp control programs include:

• Prevention – evaluate potential sources of seed. Waterhemp can be introduced to and spread within an operation via contaminated equipment, livestock feed or manure, or seed for CREP or cover crops.

• Control – start clean with a burndown application or tillage. Use a full rate of an effective preemergence herbicide with residual control. A timely POST application, before waterhemp reaches three inches in height, and an overlapping residual can facilitate season long control. See the Weed Control Guide for Ohio, Indiana, Illinois, and Missouri for product and application recommendations [ANR-789].

• Monitoring – late-season escapes are always a risk. Being able to identify waterhemp, scouting late-season, and removing plants before they set seed will greatly reduce contributions to the soil seedbank.

• Mechanical – deep tillage in fields with large seedbanks can bury seed to prevent emergence.

• Cultural – control can be improved with the use of narrow row spacing or fall-seeded cover crops.

TOOLS OF THE TRADE

Waterhemp Identification and Control

You can find more information on the identification and control of problematic pigweed species like waterhemp at: u.osu.edu/osuweeds/super-weeds/pigweeds/ (or use the QR code to the right)

PROJECT CONTACT

For inquiries about this project, contact Alyssa Essman (essman.42@osu.edu).

Figure 2. Waterhemp in a field in Mercer County, Ohio.

Follow us on Social Media

Follow us on Facebook, X, and Instagram to get instant updates and special relseases from our team! Posts feature students, eFields contributors, helpful resources, and research completed by faculty in the department. Connect with us @OhioStatePA on each platform to ensure you are informed about trending topics and events in agriculutre.

Subscribe to our YouTube page @ohiostateprecisionag9203 or @OSUAgronomicCrops to view past presentations, learn more about current research, and gain valuable insight for innovative farming strategies!

Your Checkoff Dollars at Work

Many eFields projects are made possible by the generous support of our commodity partners, Ohio Corn and Wheat and Ohio Soybean Council. Funding provided by their farmer-led boards make it possible for us to focus research on emerging and critical needs for Ohio farmers.

The Ohio Corn Checkoff and the Ohio Small Grains Checkoffs work on behalf of growers, promoting the use of Ohio-grown corn and wheat. Our partnership with national and state organizations is helping to expand trade markets, grow domestic demand, and work with state and national partners to provide education and research that lead to solutions to issues like vomitoxin in corn and increasing the profitability of wheat. Learn more about what we do at ohiocornandwheat.org.

The Ohio Soybean Council invests in research that provides technologies and information that will increase profit opportunities for Ohio farmers. Through basic and applied soybean research the long-term goals are to protect and increase yield, to provide understandable and usable data to farmers, and to inform them of best management practices to ensure the economic well-being of their operations. The Council’s investment helps develop the next generation of soybean researchers to help Ohio farmers realize their future potential. Learn more at soyohio.org

The 2024 eFields Report is proud to share the results from six projects funded by Ohio Corn and Wheat and Ohio Soybean Council. Thank you for helping drive research and innovation to support Ohio farmers.

Preharvest Weed Survey, page 38

Vomitoxin, DON, Management, page 110

Fungicide for White Mold, page 142

Soybean Cyst Nemotode in Ohio, page 160

Cover Crop Population, Planting Date, page 204

Soil Health Survey across Ohio Farms, page 210

Ohio State Corn Research

For 2024, eFields corn research was focused on improving the production and profitability of corn in the greater Ohio area. Some exciting and innovating projects were conducted this year, with 34 unique studies implemented across the state. 2024 eFields corn research investigated many of the topics listed in the eFields focus areas. Highlights include biologicals, fungicide, nitrogen rate, and many other innovative practices. Here is the 2024 eFields corn research by the numbers:

1390 acres

34 corn studies

For more corn research from Ohio State University Extension, explore the following resources:

2024 Ohio Corn Performance Tests

The purpose of the Ohio Corn Performance Trials is to evaluate corn varieties for yield and other agronomic characteristics. This evaluation gives corn producers comparative information for selecting the best varieties for their unique production systems. For more information visit: go.osu.edu/corntrials

Agronomic Crops Team - Corn Research

The Agronomic Crops Team performs interesting research studies on a yearly basis. Resources, fact sheets, and articles on corn research can be found here on the Agronomic Crops Team website: go.osu.edu/ CropsTeamCorn.

The Ohio State Digital Ag Program

The Ohio State Digital Ag Program conducts studies related to all aspects of corn production. Research related to planting, inputs, and harvesting technology can be found on the Digital Ag website: digitalag.osu.edu.

Growth Stages - Corn

For all corn studies in this eFields report, we define corn growth stages as the following:

VE - Emergence - coleoptile is fully visible, yet no leaves are fully developed.

V1 - Full development of the first (flag) leaf, achieved when the collar of the leaf is fully visible.

VN - N fully developed leaves with collars visible.

VT - Tassels fully visible and silks will emerge in 2-3 days.

R1 - Silking - silks are visible and pollination begins.

R2 - Blister - silks darken and dry out, kernels are white and form a blister containing clear fluid.

R3 - Milk - kernels are yellow and clear fluid turns milky white as starch accumulates, kernels contain 80% moisture.

R4 - Dough - starchy liquid inside kernels has dough-like consistency, kernels contain 70% moisture and begin to dent at the top.

R5 - Dent - nearly all kernels are dented and contain about 55% moisture.

R6 - Black layer - physiological maturity is reached and kernels have attained maximum dry weight at 30-35% moisture.

Image Source: University of Illinois Agronomy Guide, 1999.

Biologicals - Beauveria Bassiana

OBJECTIVE

Determine if seed treated with Beauveria bassiana (Bb) reduces ear mold in organic corn.

STUDY INFORMATION

Planting Date 5/21/2024

Harvest Date 10/23/2024

HybridPrairie 5883

Population 32,500 sds/ac

Acres20

Treatments2

Reps4

Treatment Width 60 ft.

TillageConventional

Management Fertilizer

Previous CropClover

Row Spacing30 in.

Soil Type Crosby-lewisburg silt loams, 76% Kokomo silty clay loam, 24%

STUDY DESIGN

This project used a split planter layout. Half of the planter was loaded with treated seed and half was untreated. The treatments were replicated four times but were not randomized. The fourth block was unable to be analyzed so three replications were used to determine the statistical analysis.

eFields Collaborating Farm

OSU Extension

Madison County

WEATHER INFORMATION

Corn was scouted for leaf disease.

OBSERVATIONS

There was minimal insect and weed pressure in this field. The corn was scouted for leaf disease at R5 and no difference between treated or untreated was seen. This was organic corn with a decent yield given drought conditions.

RESULTS

SUMMARY

• No statistical yield difference was observed.

• Only one sample was positive for DON (vomitoxin). All other samples were clean of the 13 toxins that were tested. Considering drought conditions, which are unfavorable for toxin development, this result was not surprising.

• Due to low toxin presence, it is impossible to determine if Bb can reduce levels. Treating again in a high toxin year would be more ideal but impossible to predict.

Treatment Means with the same letter are not significantly different according to Fisher’s Protected Least Significant Differences (LSD) test at alpha = 0.1.

TOOLS OF THE TRADE

Beauveria bassiana (Bb) is a soil-borne fungus that has been used widely to control various insect species. Recent research has documented growth enhancement and control of ear mold diseases in corn. We utilized the seed treatment product SPE 120 from JABB of the Carolinas.

PROJECT CONTACT

For inquiries about this project, contact Amanda Douridas (douridas.9@osu.edu).

Biologicals - Beauveria Bassiana

OBJECTIVE

Assess the effect of biological seed treatment (Beauveria bassiana, Bb) in corn growth and yield.

STUDY INFORMATION

Planting Date 5/7/2024

Harvest Date 10/8/2024

HybridPioneer P0035AM

Population 34,800 sds/ac

Acres 6

Treatments2

Reps4

Treatment Width30 ft.

Tillage Strip-Till

Management Fertilizer, Herbicide, Insecticide

Previous Crop Soybeans

Row Spacing30 in.

Soil Type Kibbie fine sandly loam, 78%

Gilford fine sandy loam, 17%

Hoytville clay loam, 5%

STUDY DESIGN

This project was laid out in Randomized Complete Block Design (RCBD) with four replications. Each replication consists of one large strip of Bb treated and one large strip of untreated. Bb treatment was applied as seed treatment before corn planting, following product label rate. Beauveria bassiana, is a natural, beneficial fungus that forms a symbiotic relationship with plants. JABB strains are isolated.

eFields Collaborating Farm

OSU Extension

Sandusky County

WEATHER INFORMATION

OBSERVATIONS

There was better growth of corn in treated strips relative to non-treated (control) strips for multiple variables, including more biomass production in the treated strips. Statistical analyses used p-value of 0.1.

RESULTS

SUMMARY

• There was no significant difference between the treated and control strips in stand count and brix concentration across different stages of data collection.

• The chlorophyll content was higher in treated than control strips at the V6 stage (6 collared leaves).

• The biomass production was higher in treated than control strips across different growth stages.

• Follow-up experiments are being conducted in the field and greenhouse.

Bassiana Treated

Treatment Means with the same letter are not significantly different according to Fisher’s Protected Least Significant Differences (LSD) test at alpha = 0.1.

TOOLS OF THE TRADE

Beauveria bassiana (Bb) is a soil-borne fungus that has been used as a biopesticide. Recent research has documented biostimulant benefits of Bb and helping plant growth enhancement in several crop species. We utilized the powdered seed treatment product with Bb as active ingredient from JABB of the Carolinas.

PROJECT CONTACT

For inquiries about this project, contact Allen Gahler (gahler.2@osu.edu) or Osler Ortez (ortez.5@osu.edu).

Biologicals - Bioreactor Extract

OBJECTIVE

Determine the effect of Johnson-Su compost bioreactor extract on corn production.

STUDY INFORMATION

Planting Date 5/25/2024

Harvest Date 10/29/2024

HybridPioneer P04511 AM

Population 32,000 sds/ac

Acres 15

Treatments2

Reps4

Treatment Width300 ft.

Tillage No-Till

Management Fertilizer, Herbicide

Previous CropWheat

Row Spacing30 in.

Soil Type Blount silt loam, 72%

Pandora silt loam, 25% Haskins loam, 4%

STUDY DESIGN

Randomized complete block design with two treatments. Liquid extract was applied at planting at 6 gal/ac as pop-up on the corn seed. Extract treatments were reduced 5 gal/ ac sidedress UAN nitrogen compared to no extract.

eFields Collaborating Farm

OSU Extension

Seneca County

WEATHER INFORMATION

Corn growing through thick mixed cover crop residue.

OBSERVATIONS

Corn was planted green into a thick stand of mix cover crop. Wet spring conditions were followed by drought mid-summer to fall. No visual difference between treatments.

RESULTS

SUMMARY

• No extract treatments received a total of 67 gal/ ac 28% N compared to extract treaments with 62 gal/ac 28% N.

• Fall application of 2 ton/ac poultry litter on entire plot.

• Extract treatments were not significantly different in yield compared to no extract.

Treatment Means with the same letter are not significantly different according to Fisher’s Protected Least Significant Differences (LSD) test at alpha = 0.1.

TOOLS OF THE TRADE

Johnson-Su compost extract is a liquid made by diluting Johnson-Su compost in water to create a soil amendment that is rich in beneficial microbes, especially fungi.

PROJECT CONTACT

For inquiries about this project, contact Pressley Buurma (buurma.20@osu.edu) or Alan Sundermeier (sundermeier.5@osu.edu).

Biologicals - HopperThrottle

OBJECTIVE

Evaluate the use of Meristem HopperThrottle on-seed biological product in the place of conventional graphite seed lubricant.

STUDY INFORMATION

Planting Date 5/24/2024

Harvest Date 11/1/2024

HybridAxis 59A25VT2PRIB

Population 33,000 sds/ac

Acres20

Treatments2

Reps 12

Treatment Width 15 ft.

Tillage No-Till

Management Fertilizer, Fungicide, Herbicide, Insecticide

Previous Crop Soybeans

Row Spacing30 in.

Soil Type Crosby silt loam, 27% Miamian silt loam, 26% Celina silt loam, 22%

STUDY DESIGN

This study was conducted with a 12-row planter, using the HopperThrottle product in the left 6 rows and conventional graphite in the right 6 rows. Application was made at planting. All other product applications were done uniformly over the field. The field was then harvested with a 6-row combine head. Final analysis was done using yield data from the calibrated combine yield monitor.

eFields Collaborating Farm OSU

Extension

Champaign County

WEATHER INFORMATION

Growing Season Weather Summary

Corn was planted at 30-inch row spacing.

OBSERVATIONS

It did seem that the treated rows had a slight growth advantage to the untreated rows, but it was slight and difficult to measure or document. The treated rows also did seem to flower slightly earlier than the untreated rows. Though this did not seem to last through the season, or result in a difference in yield.

RESULTS

SUMMARY

• This study evaluated the use of Meristem RevLine HopperThrottle graphite replacement product. This product is a 80/20 talc/graphite and micronutrient blend, that also features a biological product that is mixed at the time of use.

• This product is used in the place of conventional seed lubricants, while supplying the micronutrients and biological product right on the seed.

• While some differences in growth rate and plant size were observed, it did not make a difference in yield. Although a greater yield advantage could be possible in a lower yield environment, it was captured in the data.

Treatment Means with the same letter are not significantly different according to Fisher’s Protected Least Significant Differences (LSD) test at alpha = 0.1.

TOOLS OF THE TRADE

REVLINE® HOPPER THROTTLE™ CORN is a best-in-class 80/20 talc/graphite and micronutrient blend that ensures optimum planting performance. It can replace any seed fluency agent.

PROJECT CONTACT

For inquiries about this project, contact Grant Davis (davis.1902@osu.edu).

Biologicals - HopperThrottle

OBJECTIVE

Evaluate the use of Meristem HopperThrottle on-seed biological product in the place of conventional graphite seed lubricant.

STUDY INFORMATION

Planting Date 5/21/2024

Harvest Date 10/24/2024

HybridAxis 61A66PCE

Population 34,000 sds/ac

Acres 26

Treatments2

Reps 11

Treatment Width 15 ft.

Tillage No-Till

Management Fertilizer, Fungicide, Herbicide, Insecticide

Previous Crop Soybeans

Row Spacing30 in.

Soil Type Crosby silt loam, 46% Brookston silty clay loam, 39% Celina silt loam, 15%

STUDY DESIGN

This study was conducted with a 12-row planter, using the HopperThrottle product in the left 6 rows and conventional graphite in the right 6 rows. Application was made at planting. All other product applications were done uniformly over the field. The field was then harvested with a 6-row combine head. Final analysis was done using yield data from the calibrated combine yield monitor.

eFields Collaborating Farm

OSU Extension

Champaign County

WEATHER INFORMATION

Corn was harvested in October.

OBSERVATIONS

It did seem that the treated rows had a slight growth advantage to the untreated rows, but it was slight and difficult to measure or document. The treated rows also did seem to flower slightly earlier than the untreated rows. Though this did not seem to last through the season, or result in a difference in yield.

RESULTS

SUMMARY

• This study evaluated the use of Meristem RevLine HopperThrottle graphite replacement product. This product is a 80/20 talc/graphite and micronutrient blend, that also features a biological product that is mixed at the time of use.

• This product is used in the place of conventional seed lubricants, while supplying the micronutrients and biological product right on the seed.