BIOFUELSAND BIOREFINING

Volume2:Intensification ProcessesandBiorefineries

Editedby

CLAUDIAGUTIERREZ-ANTONIO

FERNANDOISRAELGÓMEZCASTRO

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2022ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicormechanical, includingphotocopying,recording,oranyinformationstorageandretrievalsystem,withoutpermissioninwriting fromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthePublisher’spermissionspolicies andourarrangementswithorganizationssuchastheCopyrightClearanceCenterandtheCopyrightLicensingAgency, canbefoundatourwebsite: www.elsevier.com/permissions.

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher(otherthanas maybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenour understanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusingany information,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethodsthey shouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhaveaprofessional responsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliabilityfor anyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,orfromany useoroperationofanymethods,products,instructions,orideascontainedinthematerialherein.

ISBN:978-0-12-824117-2

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: CharlotteCockle

AcquisitionsEditor: PeterAdamson

EditorialProjectManager: JaiMarieJose

ProductionProjectManager: SojanP.Pazhayattil

CoverDesigner: GregHarris

Contributors

SairaAsif

SustainableProcessIntegrationLaboratory,SPIL,NETMECentre,FacultyofMechanical Engineering,BrnoUniversityofTechnology,VUTBrno,Brno,CzechRepublic;Facultyof Sciences,DepartmentofBotany,PMASAridAgricultureUniversity,Rawalpindi,Punjab, Pakistan

AlexandraBarron

DepartmentofChemicalEngineering,TexasA&MUniversity;GasandFuelsResearchCenter, TexasA&MEngineeringExperimentStation,CollegeStation,TX,UnitedStates

AwaisBokhari

SustainableProcessIntegrationLaboratory,SPIL,NETMECentre,FacultyofMechanical Engineering,BrnoUniversityofTechnology,VUTBrno,Brno,CzechRepublic; ChemicalEngineeringDepartment,COMSATSUniversityIslamabad(CUI),Punjab, Lahore,Pakistan

P.Champagne

Institutnationaldelarecherchescientifique,QuebecCity,QC,Canada

YokeWangCheng

DepartmentofChemicalEngineering,SchoolofEngineeringandComputing,Manipal InternationalUniversity,NegeriSembilan,Malaysia

ChiChengChong

DepartmentofChemicalEngineering,SchoolofEngineeringandComputing,Manipal InternationalUniversity,NegeriSembilan,Malaysia

NatashaChrisandina

DepartmentofChemicalEngineering,TexasA&MUniversity;GasandFuelsResearchCenter, TexasA&MEngineeringExperimentStation,CollegeStation,TX,UnitedStates

LaiFattChuah

FacultyofMaritimeStudies,UniversitiMalaysiaTerengganu,KualaTerengganu,Terengganu, Malaysia

M.Collotta

DIMI,DepartmentofMechanicalandIndustrialEngineering,UniversityofBrescia,Brescia,Italy

GabrielContreras-Zarazu ´ a ChemicalEngineeringDepartment,UniversityofGuanajuato,Guanajuato,Mexico

JulioArmandodeLira-Flores

FacultaddeQuı´mica,UniversidadAuto ´ nomadeQueretaro,CentroUniversitario,Queretaro, Mexico

MarcosR.P.deSousa

UniversityofCampinas,SchoolofChemicalEngineering,Campinas,SP,Brazil

ThiagoEdwiges

DepartmentofBiologicalandEnvironmentalSciences,FederalUniversityofTechnology, Medianeira,Parana,Brazil

MahmoudM.El-Halwagi

DepartmentofChemicalEngineering,TexasA&MUniversity;GasandFuelsResearchCenter, TexasA&MEngineeringExperimentStation,CollegeStation,TX,UnitedStates

MassimilianoErrico

FacultyofEngineering,DepartmentofGreenTechnology,UniversityofSouthernDenmark, Odense,Denmark

YulissaMercedesEspinoza-Va ´ zquez

DepartamentodeIngenierı´aQuı´mica,Divisio ´ ndeCienciasNaturalesyExactas,Universidadde Guanajuato,Guanajuato,Guanajuato,Mexico

ErnestoFlores-Cordero

BiotechnologyEngineeringDepartment,UniversityofGuanajuato,CampusCelaya-Salvatierra, Guanajuato,Gto.,Mexico

JuanFernandoGarcı´a-Trejo

FacultaddeIngenierı´a,UniversidadAuto ´ nomadeQueretaro,Amazcala,Queretaro,Mexico

FernandoIsraelGo ´ mez-Castro

DepartamentodeIngenierı´aQuı´mica,Divisio ´ ndeCienciasNaturalesyExactas,Universidadde Guanajuato,Guanajuato,Guanajuato,Mexico

ClaudiaGutierrez-Antonio

FacultaddeIngenierı´a,UniversidadAuto ´ nomadeQueretaro,Amazcala,Queretaro,Mexico

JunaidHaider

SustainableProcessAnalysis,Design,andEngineeringLaboratory,EnergyandChemical EngineeringDepartment,UlsanNationalInstituteofScienceandTechnology(UNIST),Ulsan, SouthKorea

SalvadorHerna ´ ndez

DepartamentodeIngenierı´aQuı´mica,Divisio ´ ndeCienciasNaturalesyExactas,Universidadde Guanajuato,Guanajuato,Mexico

Noemı ´ Herna ´ ndez-Neri

FacultaddeIngenierı´a,UniversidadAuto ´ nomadeQueretaro,Amazcala,Queretaro,Mexico

Jirı ´ Jaromı´rKlemes ˇ

SustainableProcessIntegrationLaboratory,SPIL,NETMECentre,FacultyofMechanical Engineering,BrnoUniversityofTechnology,VUTBrno,Brno,CzechRepublic

MoonyongLee

SchoolofChemicalEngineering,YeungnamUniversity,Gyeongsan,SouthKorea

NguyenVanDucLong

SchoolofEngineering,UniversityofWarwick,Coventry,UnitedKingdom;SchoolofChemical EngineeringandAdvancedMaterials,UniversityofAdelaide,Adelaide,SA,Australia

AntiocoLo ´ pez-Molina

UniversidadJua ´ rezAuto ´ nomadeTabasco,JalpadeMendez,Mexico

W.Mabee

Queen’sUniversity,DepartmentofGeographyandPlanning,Mackintosh-CorryHall,Kingston, ON,Canada

SergioIva ´ nMartı´nez-Guido

FacultaddeIngenierı´a,UniversidadAuto ´ nomadeQueretaro,Amazcala,Queretaro,Mexico

LeCaoNhien

SchoolofChemicalEngineering,YeungnamUniversity,Gyeongsan,SouthKorea

AlvaroOrjuela

DepartmentofChemicalandEnvironmentalEngineering,UniversidadNacionaldeColombia, Bogota ´ D.C.,Colombia

AndreadelPilarOrjuela

ProcessSolutionsandEquipmentSAS,EngineeringDivision,Bogota ´ D.C.,Colombia

JoseMarı´aPonce-Ortega

FacultaddeIngenierı´aQuı´mica,Divisio ´ ndeEstudiosdePosgrado,UniversidadMichoacanade SanNicola ´ sdeHidalgo,Morelia,Michoaca ´ n,Mexico

CesarRamı´rez-Ma ´ rquez

ChemicalEngineeringDepartment,UniversityofGuanajuato,Guanajuato,Mexico

MariaCintaRoda-Serrat

FacultyofEngineering,DepartmentofGreenTechnology,UniversityofSouthernDenmark, Odense,Denmark

AraceliGuadalupeRomero-Izquierdo

FacultaddeIngenierı´a,UniversidadAuto ´ nomadeQueretaro,Amazcala,Queretaro,Mexico

EduardoSa ´ nchez-Ramı ´ rez

ChemicalEngineeringDepartment,UniversityofGuanajuato,Guanajuato,Mexico

HarrsonS.Santana

UniversityofCampinas,SchoolofChemicalEngineering,Campinas,SP,Brazil

JuanGabrielSegovia-Herna ´ ndez ChemicalEngineeringDepartment,UniversityofGuanajuato,Guanajuato,Mexico

DebalinaSengupta

GasandFuelsResearchCenter,TexasA&MEngineeringExperimentStation,CollegeStation, TX,UnitedStates

ClaireShi

DepartmentofChemistry,RiceUniversity,Houston,TX,UnitedStates

PauLokeShow

DepartmentofChemicalandEnvironmentalEngineering,UniversityofNottingham—Malaysia Campus,Semenyih,Malaysia

Joa˜oL.SilvaJu ´ nior

FederalUniversityofABC,CECS—CenterforEngineering,ModelingandAppliedSocial Sciences,AlamedadaUniversidade,Sa ˜ oBernardodoCampo,SP,Brazil

G.Tomasoni

DIMI,DepartmentofMechanicalandIndustrialEngineering,UniversityofBrescia,Brescia,Italy

StefaniaTronci

DipartimentodiIngegneriaMeccanica,ChimicaedeiMateriali,Universita ´ degliStudidi Cagliari,Cagliari,Italy

Processintensificationinbiofuels production

SalvadorHernández DepartamentodeIngenierı´aQuı´mica,Divisio ´ ndeCienciasNaturalesyExactas,UniversidaddeGuanajuato,Guanajuato,Mexico

1.1Introduction

Throughhistory,thesocietyhasevolvedduetotheresearchandtechnologicaladvances inalltheknowledgeareas.Theseadvanceshaveallowedbetterqualitylifeofthesociety, throughthemedicaladvances,transportationmeans,homecomforts,education,aswell asrecreationalactivities.Eveninthelastdecades,theglobalizationhasmadepossiblethe contactbetweenpeoplelocatedindifferentpartsoftheworld,whichcaninterchange experiences,culture,goods,news,andevenreal-timeeventswithjustaclickonacomputerwithinternetaccess.Alltheseimprovementsandbenefitstothesocietyhasone commonfactor:energy.

In2019,theworldwideenergyconsumptionwas14,406Mtoe(IEA,2020a);this amountofenergyproceedsfromoil(31%),coal(26%),naturalgas(23%),renewables (14%),andnuclear(6%)(IEA,2020a,2020b).Theforecastsindicatedthatthisamount ofenergywouldhaveincreasedin10%for2028(IEA,2020c).However,theforecasts changedduetotheappearanceandspreadoftheSars-CoV-2,whohasmodifiedthe knownworld’sdynamics.Potentialnewpracticesandsocialformsbeingfacilitatedby thepandemicsarehavingimpactsonenergydemandandconsumption,whichhas,in general,declined( Jiang,VanFan,&Klemesˇ,2021).Inspiteoftwovaccineshavebeen successfullydevelopedatanunprecedentedspeed(Huang,Zeng,&Yan,2021),itslargescaleproductionisnowthebottleneck.Nowadays,notalltheworldpopulationhas receivedthevaccine;thereforetherearestillmanyeconomicsectorsthataredetained orwithlowactivity,suchastheaviationsectorwhichrecoveryprocessseemsmuch slowerthananticipated(Dube,Nhamo,&Chikodzi,2021).Itisimportanttomention thatthepandemicsituation,aswellasitseffects,isaconstantlychangingsituation.

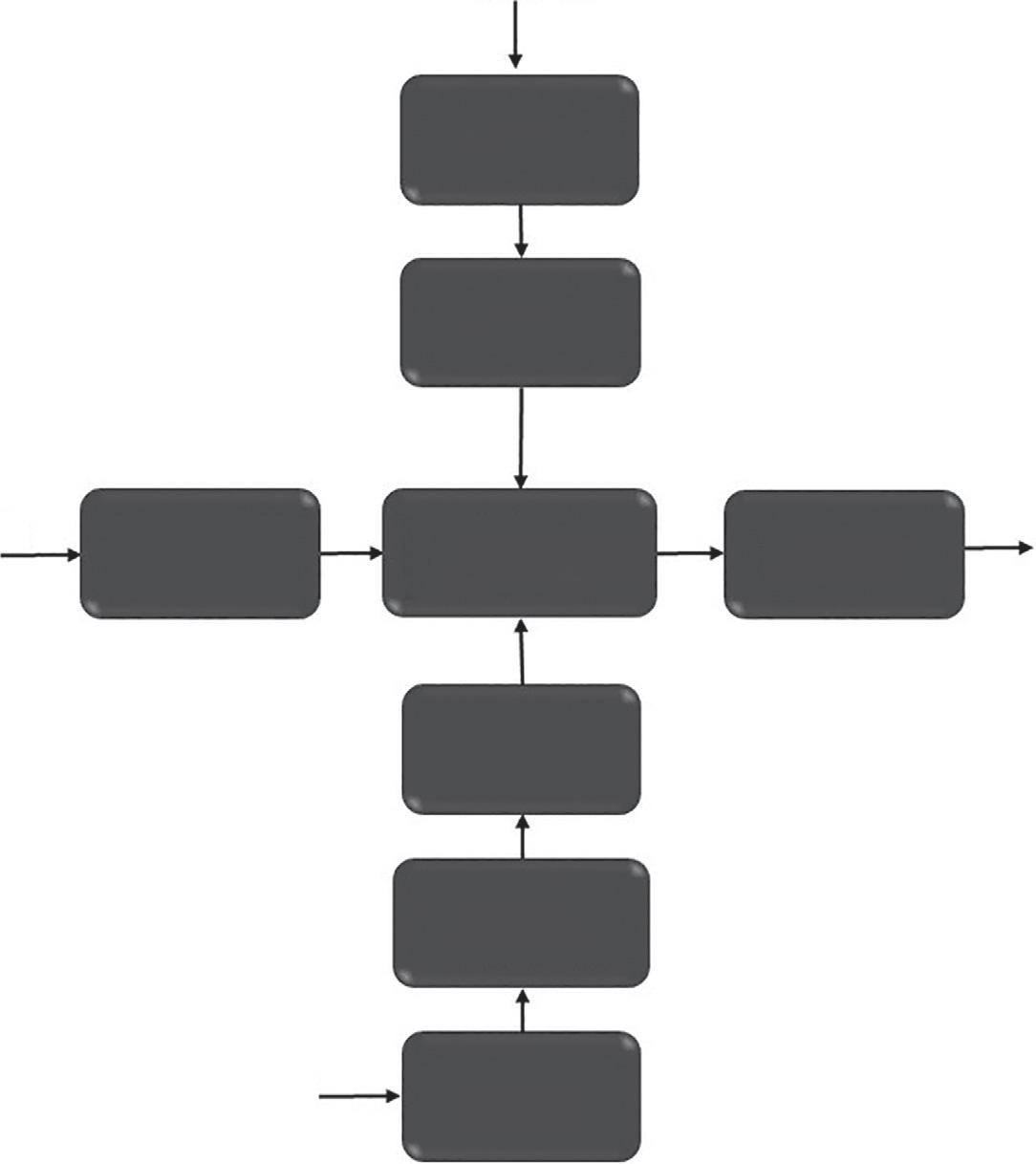

Inthiscontext,theInternationalEnergyAgencyhasproposed,incollaborationwith theInternationalMonetaryFund,aSustainableRecoveryPlan(IEA,2020d).Thisplanis focusedonboostingtheeconomicgrowth,creatingjobs,andbuildingmoreresilientand cleanerenergysystems;itisimportanttomentionthatthisplanisintendedtobeimplementedintheperiod2021–23.Theplanincludespolicies,investments,andmeasuresto acceleratethedeploymentofsixkeyareas(IEA,2020d),whichareshownin Fig.1.1.

BiofuelsandBiorefining Copyright © 2022ElsevierInc. https://doi.org/10.1016/B978-0-12-824117-2.00001-6

Boost innovation in technological areas

Development of sustainable biofuels

Enhance efficiency of industrial equipment

Recovery Plan

Accelerate low carbon electricity

Spread cleaner transport

Increase energy efficiency of buildings and appliances

Fig.1.1 SustainablerecoveryplanproposedbytheInternationalEnergyAgencyincollaborationwith theInternationalMonetaryFund.

Fig.1.2 Classificationofbiomassbasedonitschemicalnature.

From Fig.1.1,itcanbeseenthatthedevelopmentofbiofuelsplaysakeyroleinthis SustainableRecoveryPlan.

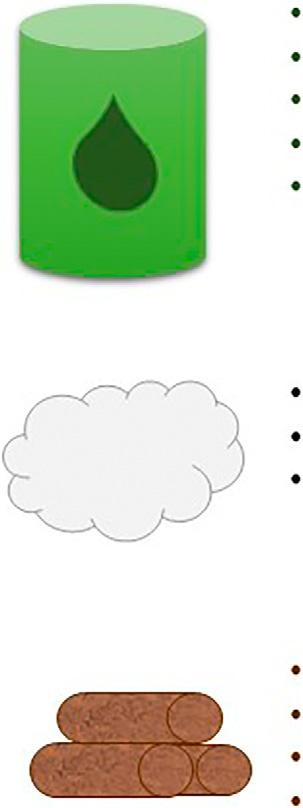

Biofuelsaredefinedasthosefuelsthataregeneratedfromtheconversionofbiomass, whichisacomplexnaturalrenewablematerialwithenormouschemicalvariability (Bonechietal.,2017).Thebiomassisdefinedasalltheorganicmatteroriginatingfrom livingplants,organisms,aswellassometypesofresiduesfromagricultural,agroindustrial, food,domestic,andothersectors(Pang,2016; Soria-Ornelas,Gutierrez-Antonio,& Rodrı´guez,2016).Biomassisconsideredasuitablesourceforrenewableenergyandbiobasedproductsduetoitsorganicnature,carbonstability,andabundantsupply(Gent, Twedt,Gerometta,&Almberg,2017).Thebiomasscanbeclassifiedaccordingtoseveral criteria,suchasarable,edible,residual,amongothers.Aninterestingclassificationconsideringthechemicalnatureofthebiomassisasfollows:triglyceride,lignocellulosic, sugar,andstarch(Maity,2015)(Fig.1.2).

Bioethanol

Biogasoline

Biodiesel

Green diesel

Biojet fuel

Biogas

Syngas

Biohydrogen

Fuel pellets

Briquettes

Pales

Cubes

Thetriglyceridebiomasscontainsfattyacids(palmiticacid,linoleicacid,ricinoleic acid)andtriglycerides(palmitin,linolein,ricinolein);thistypeofbiomassincludesoils fromsoybean,castorbeanormicroalgae,aswellasfatsfrompoultry,fish,beef.On theotherhand,thelignocellulosicbiomasscontainslignin,cellulose,andhemicellulose asmaincomponents;thistypeofbiomassincludesalltheagriculturalresidues,leaves, wood,grass,aswellasenergeticcrops.Finally,asthenamesuggest,thesugarandstarch biomasscontainpentose,hexose,glucose,amylose,andamylopectin;thistypeofbiomass includessugarcane,potatoes,apples,aswellasotherediblecrops.Thisclassification allowstogroupallthebiofuelconversionprocessesbasedonthechemicalnatureof thebiomass,inspiteofitisedible,nonedible,orresidual.

Thebiomasscanbeconvertedintobiofuelsinliquid,gaseous,orsolidstate(Fig.1.3). Amongliquidbiofuels,thosedestinedmainlyfortransportsectorarefound,suchasbiogasoline,greendiesel,andbiojetfuel;however,theyalsocanbeusedtogenerateelectricityorheat.Regardthesolidbiofuels,themostpopulararethefuelpellets,whichcan beusedtoproduceelectricalorthermalenergy,similartothegaseousbiofuels,among whichbiogasisthemostpopular.

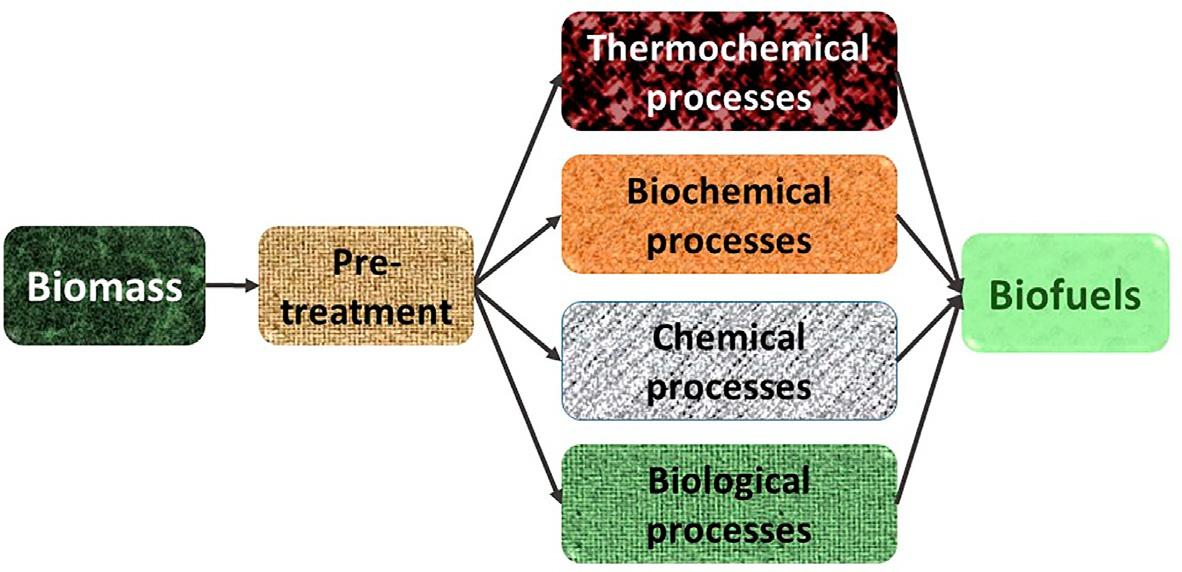

Thebiofuelsareobtainedfromtheconversionofbiomassthroughchemical,biochemical,thermochemical,andbiologicalprocesses(Fig.1.4).Inthechemicalprocesses, thebiomass(orafractionofit)isconvertedthroughasetofchemicalreactions,which wouldrequireadditionalreactants,solvents,catalysts,andmoderatetohightemperature andpressure;examplesofthistypeofprocessaretransesterification,hydrodeoxygenation,hydrocracking,andoligomerization,amongothers.Ontheotherhand,inthe

Fig.1.3 Classificationofbiofuelsaccordingtoitsphysicalstate.

biochemicalprocesses,thelargemoleculesthatconstitutethebiomass(orafractionofit) areconvertedinsmalleronesthroughtheactionofmicroorganisms;thistypeofprocess usuallyrequireswaterandlowtemperatureandpressure.Thefermentation,hydrolysis,as wellasdigestion,arebiochemicalprocesses.

Ontheotherhand,inthethermochemicalprocesses,themainobjectiveisconverting thebiomass(orafractionofit)intogases,liquids,orevensolidcompounds,releasingthe energycontainedinthemasheat.Theheatcanbeuseddirectlyoremployedtoproduce electricity;atthesametime,thecompoundsgeneratedcanbetransformedinothervaluableproducts.Inthermochemicalprocessisrequiredairorinertatmospheresaswellas hightemperatureandpressure.Thepyrolysis,gasification,andcombustionareexamples ofthistypeofprocesses.Finally,thebiomass(orafractionofit)canalsobeconverted throughbiologicalprocesses;inthiscase,thebiomassisusedasfeedfortheorganisms, whichgeneratednewcompoundsasresultsofthedigestionorneworganismswhichcan befurtherprocessedtogenerateothervaluableproducts.Inthiscategory,wecanmentionthecultureofblacksoldierflyaswellasworms.

Itisimportanttomentionthatallbiofuelsarerenewables,sincetheyaregenerated frombiomass;however,theydonotnecessarilyaresustainable,sincethisdependson thekindofbiomassandprocessingroute.Eachoneoftheseprocesseshavedifferentenergeticefficiencies,obtainedproducts,yieldsaswellasoperationandinvestmentcosts.To havebiofuelsthatarerenewableandsustainable,itmustbeensuredthatthewholesupply chainhasreducedcarbonfootprint,withspecialemphasisontheconversionprocesses.

Inthelastyears,researchershavefocusedtheireffortsonthedevelopmentofproductionprocessesfortheproductionofbiofuels.Intheliterature,therearestudiesforthe productionofbioethanol(Ayodele,Alsaffar,&Mustapa,2020; Greetham,Zaky, Makanjuola,&Du,2018; MohdAzharetal.,2017; Sharma,Larroche,&Dussap, 2020),biobutanol(Huziretal.,2018; Ibrahim,Kim,&Abd-Aziz,2018; Wangetal., 2017; Yeongetal.,2018),biogasoline(Hassan,Sani,AbdulAziz,Sulaiman,&Daud,

Fig.1.4 Conversionprocessesfortheproductionofbiofuels.

2015; Mascal&Dutta,2020; Shamsul,Kamarudin,&Rahman,2017),greendiesel (Ameen,Azizan,Yusup,Ramli,&Yasir,2017; Amin,2019; Arun,Sharma,&Dalai, 2015; Kordulis,Bourikas,Gousi,Kordouli,&Lycourghiotis,2016),biojetfuel (Galadima&Muraza,2015; Gutierrez-Antonio,Go ´ mez-Castro,deLira-Flores,& Herna ´ ndez,2017; KandaramathHari,Yaakob,&Binitha,2015; Va ´ squez,Silva,& Castillo,2017),biogas(Pramanik,Suja,Zain,&Pramanik,2019; Alavi-Borazjani, Capela,&Tarelho,2020; Kovacicetal.,2021; Liu,Ren,Yang,Liu,&Sun,2021; Liu,Wei,&Leng,2021),syngas(Aziz,Setiabudi,Teh,Annuar,&Jalil,2019; Leonzio,2018; Ren,Cao,Zhao,Yang,&Wei,2019; Yeo,Ashok,&Kawi,2019),biohydrogen(Fagbohungbe,Komolafe,&Okere,2019; Chen,Wei,&Ni,2021; Dahiya, Chatterjee,Sarkar,&Mohan,2021; Fajı´n&Cordeiro,2021),fuelpellets(Bajwa, Peterson,Sharma,Shojaeiarani,&Bajwa,2018; Heetal.,2018; Mamvura&Danha, 2020; Pradhan,Mahajani,&Arora,2018),andbriquettes(Bajwaetal.,2018; Kaliyan&VanceMorey,2009; Zhang,Sun,&Xu,2018).Inthesestudies,severalbiomassesareanalyzedaswellasdifferentconversionpathways,withthemainobjectiveof obtainingfeasibleprocesseswithhighyields.Nevertheless,biofuelsmustalsobecompetitivefromtheeconomicpointofviewwithitsfossilcounterparts;thisimpliesthatthe productioncostsofbiofuelsmustbeassmallaspossible.Inthiscontext,processintensificationplaysakeyrole,sinceitcouldhelptohavecompactprocess,withreduced energyconsumption,safer,andenvironmentallyfriendly.

Therefore,inthischapterthepotentialadvantagesonusingprocessintensificationin thebiofuelproductionprocesseswillbeexplored.Forthis,itwillbepresentedthegeneralitiesoftheconventionalproductionprocessesforbiofuels,aswellastheconceptof processintensification.Basedontheseconcepts,thenecessityofapplyingprocessintensificationintheproductionprocessesforbiofuelswillbeexposed.Finally,thecurrent stateoftheintensifiedbiofuelproductionprocesseswillbedescribed.

1.2Basicconceptsonprocessintensification

Theproductionprocessescanbedefinedasasuccessionofunitoperations,wheretheraw materialsareadequated,transformed,andpurifiedtoobtaintheproductofinterest;this typeofproductionprocessesareusuallyknownasconventionalones.Mostoftheconventionalequipmenthasasmaintroublesomethepresenceofdeadzones,shortcutsinthe processing,orlimitedheatandmasstransfers;asconsequence,theyareusuallyoversized, whichdirectlyimpactsitsinvestmentandoperationcosts.Inthiscontext,processintensificationarisesinordertoovercometheselimitations.

Processintensificationisdefinedasanychemicalengineeringdevelopmentthatleads toasubstantiallysmaller,cleaner,andmoreenergy-efficienttechnology(Stankiewicz& Moulijn,2000).Theintensificationofaprocessconsiderstwomainstrategies:theuseof highlyefficientequipmentorthecombinationoftwo,ormore,unitoperations.Inthe

firstcase,newequipmenthasbeenproposed,whosemaincharacteristicisthehighrateof heatand/ormasstransfer;asconsequence,itssizeissmallincomparisonwithitsconventionalcounterpart.Inthesecondcase,thethermodynamicsynergyisusedinorderto carryouttwo,ormore,unitoperationsinthesamevessel,whichareusuallycalledas hybridequipment;asconsequence,theinvestmentandoperationcostsarereduced.

Theapplicationofprocessintensificationstrategyhasmanyadvantages.Thefirstone isthatthistypeofprocessareinherentlysafer;sincetheequipmentaresmallerorhybrid, theamountofreactants,solvents,aswellasenergyarelower.Thusincaseofanaccident, thepotentialconsequencescanbemanagedmoreeasily.Thesecondoneisthattheplants aresmaller,respecttotheconventionalones,sincehigherratesofheatand/ormasstransferareobserved;inconsequence,minorareasfortheconstructionoftheplantare required,andinsomecases,lesspipesandadditionalequipment(likepumps).Thethird oneisthattheintensifiedprocessesaremorecompetitivefromtheeconomicpointof view,duetotheefficientuseofenergyandrawmaterials.Finally,theintensifiedprocess hasareducedcarbonfootprintwithoutloseproductivity.Ontheotherhand,process intensificationhastwomaindisadvantages.Themaindisadvantageisthatnotall processintensificationalternativeshaveabetterperformanceinalltypeofprocess,in comparisonwiththeconventionalone;thusthealternativesmustbeevaluated.Theseconddisadvantageisthatprocessintensificationimpliesthereplacementoftheequipment, forasmalleroneorforahybridtechnology.

Untilnow,severaladvanceshavebeenreportedintheliteratureinrelationtothe proposalofintensifiedequipmentforreaction,separation,andconditioningtasks.These alternativeswillbepresentednext.

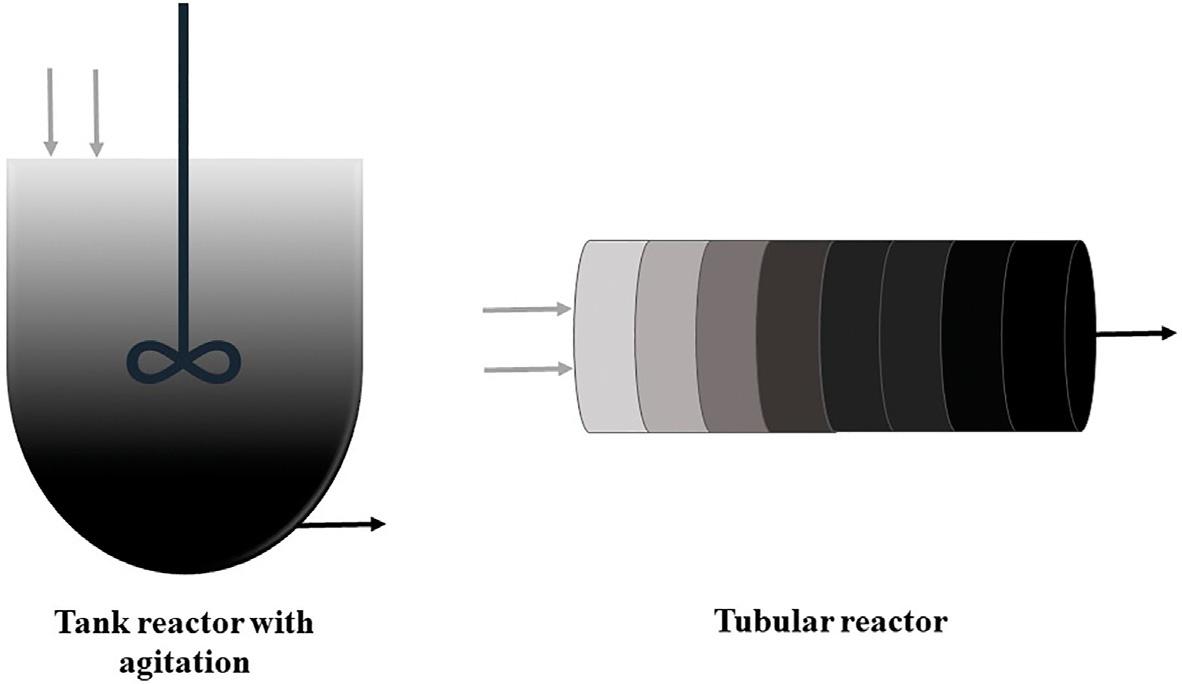

1.2.1Reactionequipment

Areactorisavesselwhereachemicalreactioniscarriedout.Thereactorscanbeclassified basedonthenumberofphasesinteractingonit.Thehomogeneousreactorsarethose wherethereactants,products,andcatalystsareinthesamephase;ontheotherhand, theheterogeneousreactorsarethosewherethereactants,products,andcatalystsarein atleasttwodifferentphases.Thereactorscanalsobeclassifiedbasedonitsform:tank withagitationandtubular(Fig.1.5).

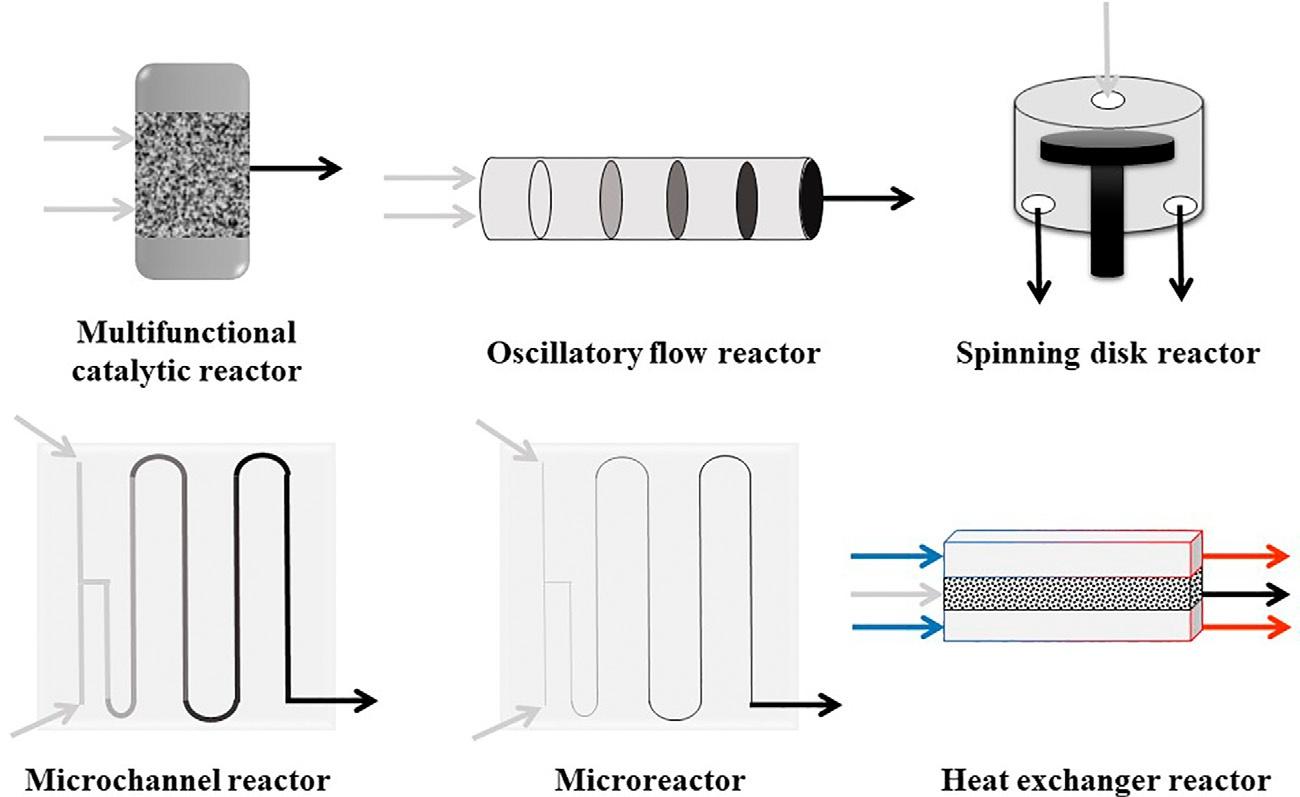

Inspiteofitsformorthenumberofphasespresent,thesetypesofconventionalreactorspresentdeadzones,shortcuts,anditisnecessarytointroducethereactantsinexcess inordertoobtainhighconversionrates.Inordertoovercometheselimitations,new reactorequipmenthasbeenproposed,amongwhichcanmentionmultifunctionalreactors,microreactors,microchannelreactors,spinningdiskreactor,heatexchangerreactor, oscillatoryflowreactor(Fig.1.6).

Themultifunctionalreactorsallowtocarryonseveralreactionsinthesamevessel, whichfavorsthegenerationofsomeproductsofinterest.Inthistypeofreactor,the

Intensifiedreactors.

intensificationallowsperformingseveralreactionsinthesamevessel;however,thetype ofreactorisconventional.Forinstance,thehydroprocessingofonestepfortheconversionofoilintohydrocarbonsisanexampleofthistypeofmultifunctionalreactor (Gutierrez-Antonioetal.,2017).

Ontheotherhand,theotherequipmentshowedin Fig.1.6 arenewdesigns, wheretheheatandmasstransferareintensifiedinsuchawaythatthesizeoftheequipmentissmall.

Fig.1.5 Conventionalreactors.

Fig.1.6

Microreactorsaredevicesconsistingofsingleormultiplesmall-diameterchannels, typicallybetween10and1000 μm(Moulijn&Stankiewicz,2017).Someofthereactions thathavebeenstudyinmicroreactorsincludehydrogenproductionandethylenepartial oxidation(Keiski,Ojala,Huuhtanen,Kolli,&Leivisk€a,2011).Themaindifference betweenmicroreactorsandmicrochannelreactorsisthesizeofthechannels.Microchannelreactorscanbedefinedasreactorsconsistingofchannelswithahydraulicdiameter (Dh)morethan3mm,whilemini-channelscanbeconsideredasreactorswithchannels withahydraulicdiameterintherangeof200 μm–3mmandmicrochannelswitha hydraulicdiameterintherangeof10–200 μm(Kiani,Makarem,Farsi,&Rahimpour, 2020).Microchannelreactorshavebeenusedfortheconversionofsyngastoalcohols (Reay,Ramshaw,&Harvey,2013a).Theoscillatoryflowreactorssuperimposeanoscillatoryflowtothenetmovementthroughaflowreactor,withtheaimtoeffectivelyhavea plugflow(Bianchi,Williams,&Kappe,2020);thistypeofreactorshasbeenusedforthe conversionofjatrophaoiltobiodiesel(Ghazi,Resul,Yunus,&Yaw,2008).Theheat exchangerreactorallowsthecombinationofthereactionandheatexchange,which increasestheselectivityandpreventrunawayreactions(Hesselgreaves,Law,&Reay, 2017a,2017b);thistypeofequipmenthasbeenusedforthesteamreformingofLPG, ethanol,andmethanolandcatalyticcombustionofLPGandmethanol(Kolbetal., 2007).Finally,thespinningdiskreactorhashighfluiddynamicintensity,which favorstherapidtransmissionofheat,mass,andmomentum(Reay,Ramshaw,& Harvey,2013b),therebymakingitanidealvehicleforperformingfastendothermicreactionssuchascatalyticisomerizationof α-pineneoxidetocampholenicaldehyde(Reay etal.,2013a,2013b).

Theintensifiedreactorsofferhighertransferratesofheatandmass,whichreducedead zonesand,asconsequence,thesizeoftheequipmentdecreases.Animportantfactisthat inthistypeofequipmenttheconversionishigher,andtherunawayreactionsarebetter controlled.

1.2.2Separationequipment

Oncetherawmaterialshavebeentransformedintoproducts,thepurificationofthem mustbemade.Usually,thepurificationimpliestheseparationofunreactedcompounds aswellasbyproductsgenerated.Thereareseveralunitoperationsthatcanbeusedto separatetheproductsofinterest,suchasliquid-liquidextraction,adsorption,absorption, membranes,evaporation,anddistillation;nevertheless,distillationisthemostcommon methodfortheseparationoffluidmixtures.Thusinthissection,thefocuswillbegiven onthisunitoperation.

Distillationisaunitoperationthatallowsthepurificationofhomogeneousmixtures offluids,throughthetransferofmassbetweenliquidandvaporstreams;theselastonesare createdwithareboilerandacondenser,locatedinthebottomandtopofthedistillation

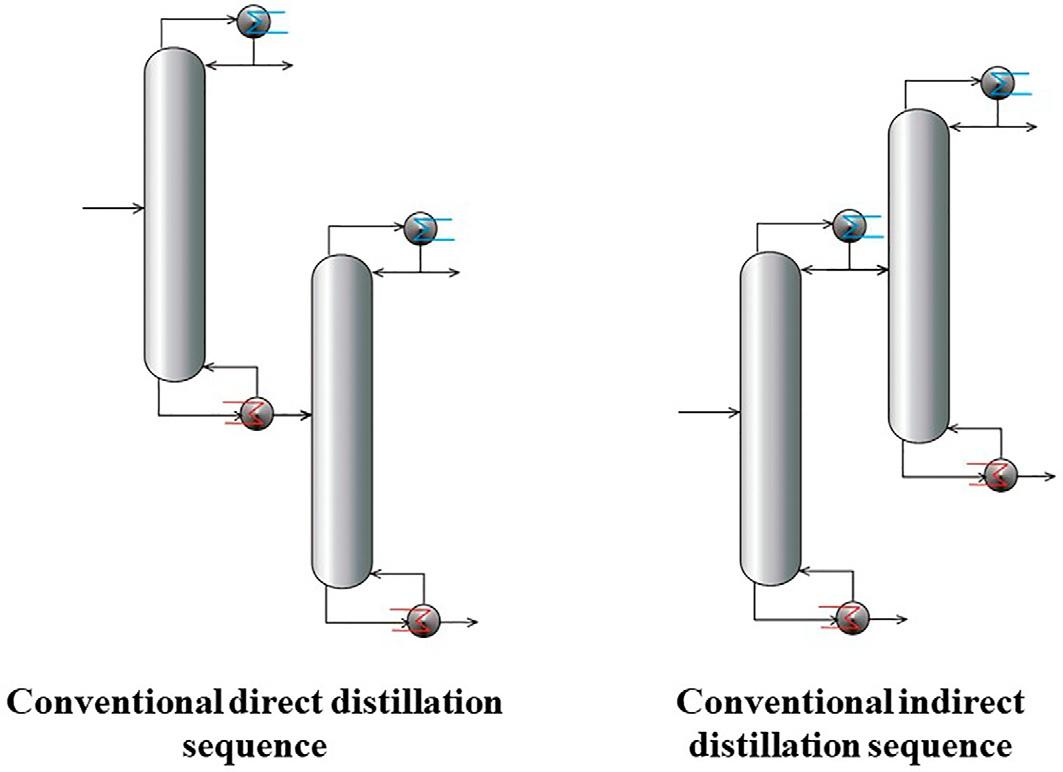

columns,respectively.Aconventionaldistillationcolumncanseparateoneproductatthe time,bytoporbottom;thususuallyatrainofdistillationcolumnsisrequired.Thesedistillationtrainsareconsideredasconventionalones,andthetwomoreknownsequences arethedirect(wherethemostoftheproductsareobtainedatthetopofthecolumn)and theindirect(wherethemostoftheproductsareobtainedatthebottomofthecolumn); theconventionaldistillationtrainsarepresentedin Fig.1.7 forthepurificationofaternarymixture.

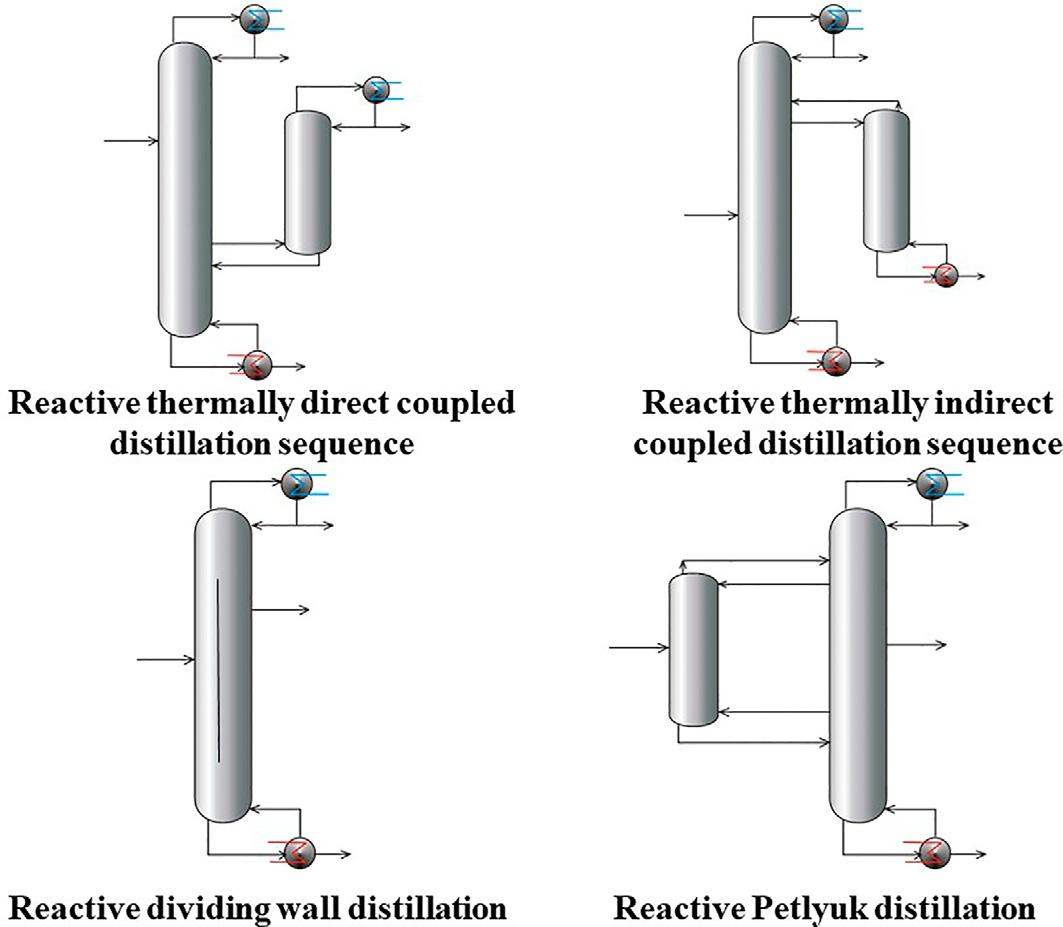

Thedistillationcolumnsareveryflexibleintheirdesignfortheseparationofmixtures ofdifferentcharacteristics;theirmaindisadvantageistheirlowthermodynamicefficiency,duetotheremixingeffect.Toovercomethisweakness,newdistillationconfigurationshavebeenproposed,andtheyareknownasthermallycoupleddistillation sequences(Fig.1.8).

Thethermallycoupleddistillationschemesconsistofdistillationcolumnslinked betweenthemthroughliquidandvaporinterconnectionflows.Sincethesupplyofliquid andvaporrequirementsissatisfiedwiththeinterconnectionflows,itispossibletoeliminateacondenserand/orareboiler;thishelpstodecreasetheinvestmentcostforthe separationofthemixture.Moreover,intypeofschemes,itispossibletoreducethe energyrequirementssincetheinterconnectionflowsarelocatedtoavoidtheremixed effect.Accordingtotheliterature,thermallycoupleddistillationsequencescanreduce theenergyrequirementsbetween30%and50%,incomparisonwithconventionaldistillationsequences(Caballero,2009; Dejanovic,Matijasˇevic,&Olujic,2010; Go ´ mezCastroetal.,2016; Yildirim,Kiss,&Kenig,2011).Thereareseveraltypesofthermally coupleddistillationsequencessuchasthedirectandindirectones,aswellasthePetlyuk

Fig.1.7 Conventionaldistillationsequences.

distillationcolumnandthedividingwalldistillationcolumn.Inparticular,thedividing walldistillationcolumnisaverypromisingtechnologyallowingasignificantenergy requirementreduction(Yildirimetal.,2011),aswellasreductioninspacerequirements andpipingandinstallationcosts.

Moreover,thermallycoupleddistillationcolumnshavebeenusedfortheseparation ofmulticomponentmixtures(Avendano,Pinzo ´ n,&Orjuela,2020; Kiss,Ignat,Flores Landaeta,&deHaan,2013; Rong,2011; Vazquez-Castilloetal.,2009),azeotropic (Waltermann,M € unchrath,&Skiborowski,2017; Yangetal.,2019; Zhangetal., 2020),extractivemixtures(Aniya,De,Singh,&Satyavathi,2018; Murrieta-Duen ˜ as, Gutierrez-Guerra,Segovia-Herna ´ ndez,&Herna ´ ndez,2011; Staak&Gr€ utzner,2017; Yangetal.,2020)aswellasreactiveprocesses(Murrieta-Duenasetal.,2011; Weinfeld,Owens,&Eldridge,2018).

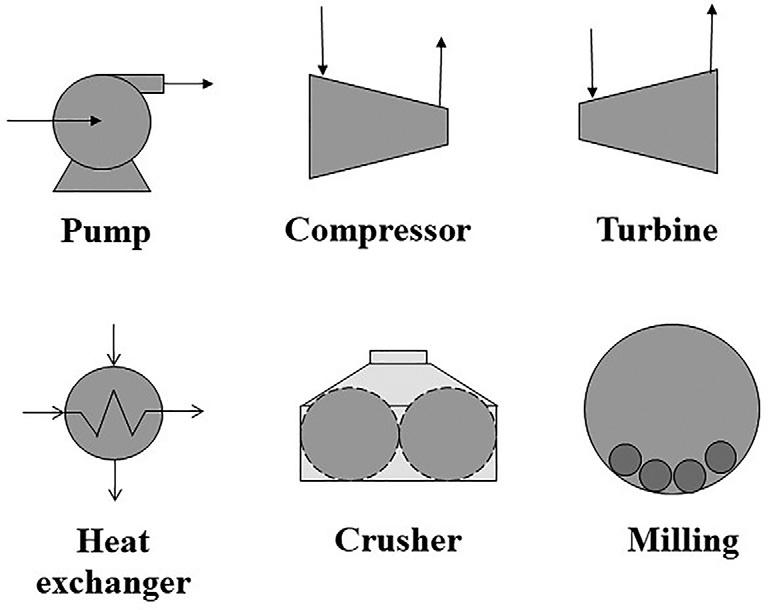

1.2.3Conditioningequipment

Inallconversionprocess,reactionandpurificationzones,aswellastheconditioning equipment,areessentials.Usually,theconditioningequipmentisusedtomodifythe temperature,pressure,orsizeoftherawmaterials;thusinthiscategoryofequipment, heatexchangers,pumps,compressors,turbines,grinders,andcrusherscanbefound (Fig.1.9).Amongtheseequipment,thedesignofheatexchangershasbeenstudied

Fig.1.8 Thermallycoupleddistillationsequences.

Fig.1.9 Conventionalconditioningequipment.

Fig.1.10 Intensifiedconditioningequipment.

andimprovedthroughdifferentstrategies(Awais&Bhuiyan,2018; Dixit&Ghosh, 2015; Klemes ˇ etal.,2020).

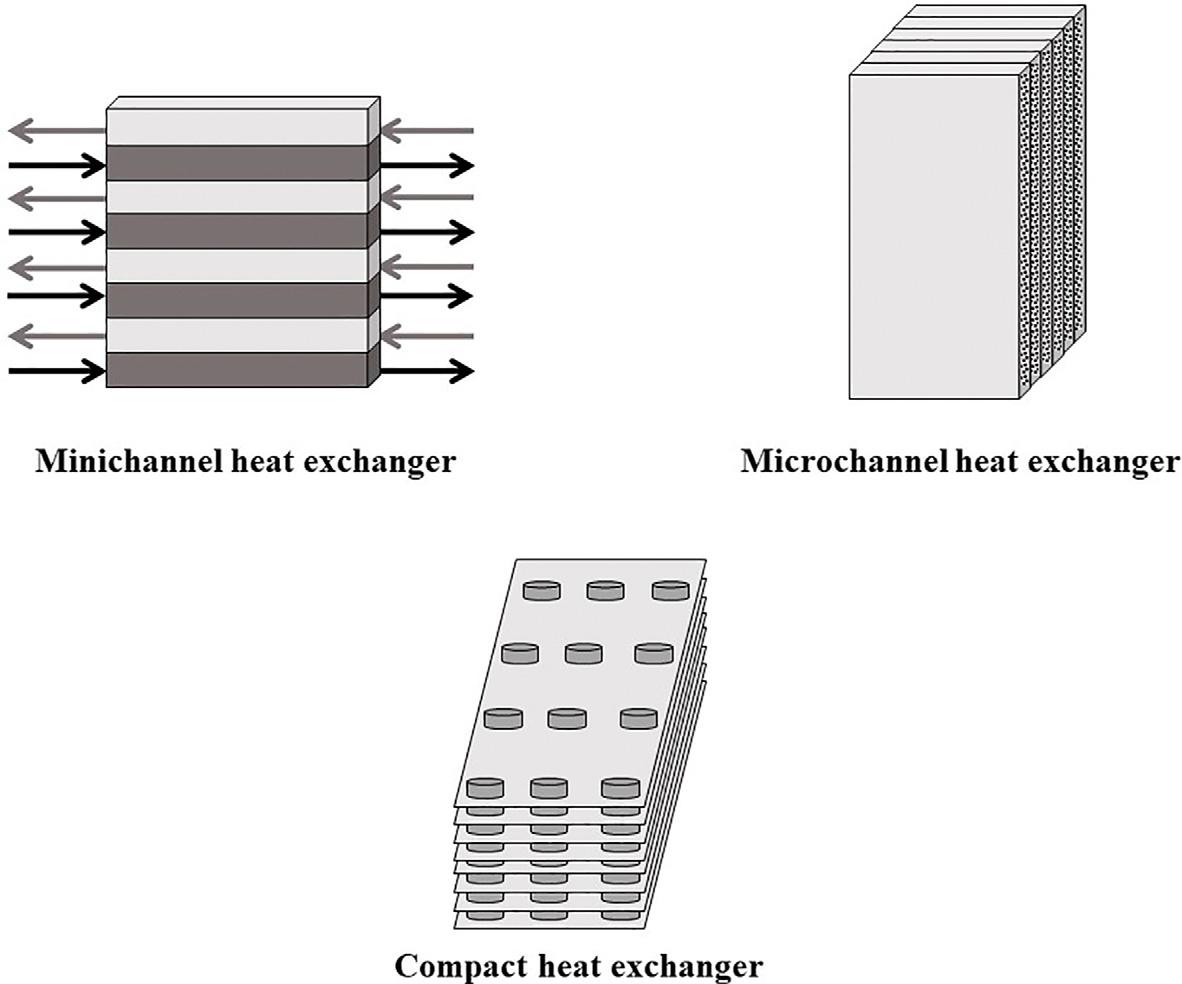

Thetraditionalheatexchangersemployconventionaltubes( 6mm)withvarious cross-sectionsandorientations;eveninthosewithenhancedsurfacetextures,thistechnologyisnearingitslimits(Khan&Fartaj,2011).Incontrast,intensifiedequipmentfor heatexchangerisofsmallersizerespecttoconventionaltechnology(Fig.1.10).

Microchannelheatexchangers( 1mm)representanimprovedalternativedueto theirhigherheattransferandreducedbothweightandspacerequirements(Khan& Fartaj,2011).Therearealsominichannelheatexchangerswithdiametersgreaterthan 200 μmbutminorsorequalthan3mm(Dhar,2017).Othertypeofintensifiedequipmentisthecompactheatexchanger,whichisformedoflayersofplatesorfinnedchannels offixedlengthandwidth(Hesselgreavesetal.,2017a,2017b);amongthiskindofheat exchangers,thefollowingareincluded:theplateheatexchangers,theprintedcircuit heatexchanger,theChart-flowunitofchartheatexchangers,andthepolymerfilmheat exchanger(Reay,Ramshaw,&Harvey,2008).

1.2.4Designmethodologiesforintensifiedequipment

Thedesignofintensifiedequipmentcanbeaddressedwiththreedifferentapproaches: shortcutmethodologies,optimizationstrategies,andtheuseofcomputationalfluid dynamics.Shortcutmethodologiesaredefinedasdesignproceduresthatemploymainly materialbalancesandsimpleequationsforthemodelingofthethermodynamicbehavior ofthecomponentsinvolved.Forinstance,inthedesignofidealconventionalreactors, massbalancealongwiththekineticmodelisemployed(Smith,1981),whileinconventionaldistillationsequences,theFensk-Underwood-Gillilandequationsareused (Henley&Seader,1981).Ontheotherhand,optimizationprocedurescanbeusedas adesigntool;usuallytheobjectivesconsideredaretheyield,energyconsumption,or volume.Theoptimizationprocedurescanincludemathematicalprogrammingaswell asmetaheuristicstrategies,andevencanbelinkedtoprocesssimulators(Modak, Lobos,Merigo ´ ,Gabrys,&Lee,2020; Pistikopoulosetal.,2021).Finally,computational fluiddynamicsisanefficientcomputerizedmethodofstudyingfluidmechanicsbasedon numericalanalysis( Junka,Daly,&Yu,2013).Thuscomputationalfluiddynamicsisa powerfultoolforthesimulationanddesignofintensifiedequipment,especiallythose whichareminiaturized.

Regardthedesignofintensifiedequipmentforchemicalreactions,optimizationproceduresaswellascomputationalfluiddynamicsarethemostcommontools.According totheliterature,optimizationprocedureshavebeenappliedtoobtaintheoptimaldesign oftailor-madereactors(Freund,Maußner,Kaiser,&Xie,2019),amultitubularreactor forethyleneproduction(Ovchinnikova,Banzaraktsaeva,&Chumachenko,2019),and capillary-basedLSC-photomicroreactors(Zhaoetal.,2020).Ontheotherhand,computationalfluiddynamicsmethodologieshavebeenusedtodesignamicrochannelreactorheat exchanger(Engelbrecht,Everson,Bessarabov,&Kolb,2020),gas-solidvortexreactorfor oxidativecouplingofmethane(Vandewalle,Marin,&VanGeem,2021),photocatalytic reactorsinthegasphase(OliveiradeBritoLira,Riella,Padoin,&Soares,2021),microwave heatinginheterogeneouscatalysis(Yan,Stankiewicz,EghbalSarabi,&Nigar,2021),aswell aspneumaticallyagitatedslurryreactors(Geng,Mao,Huang,&Yang,2021).

Thedesignofintensifieddistillationschemescanbemadewithshortcutmethodsaswell asoptimizationprocedures.Amongtheshortcutmethodologies,thosecanbecitedarethe onesproposedforthedesignofthermallycoupleddistillation(Herna ´ ndez&Jimenez, 1996),thesynthesisofintensifiednonsharpdistillationsystems(Rong,2014),andsimple columnconfigurationsformulticomponentdistillation(Rong&Errico,2012).Onthe otherhand,thegenerationofoptimaldesignsthroughoptimizationstrategiesisreported throughtheuseofmulticomponentintensifieddistillationsystems(Errico,Pirellas, Torres-Ortega,Rong,&Segovia-Hernandez,2014),intensifiednonsharpdistillationconfigurations(Torres-Ortega,Strieker,Errico,&Rong,2015),intensifiedthermallycoupled distillationsequences(Caballero&Reyes-Labarta,2016),synthesisofintensifiedsequences formulticomponentzeotropicmixtures(Li,Demirel,&Hasan,2019),dividingwallcolumnsforextractiveseparations(Lietal.,2021),separatingnormalalkanesviamultiobjectiveoptimization(Liu,Ren,etal.,2021; Liu,Wei,&Leng,2021).Forthedesign ofreactivedistillation,thereareshortcutmethodologiesaswellasoptimizationstrategies. Regardtheshortcutmethodologies,theworksof BarbosaandDoherty(1988), Dragomir andJobson(2004), Carrera-Rodrı´guez,Segovia-Herna ´ ndez,andBonilla-Petriciolet (2011), Flores-EstrellaandIglesias-Silva(2016) canbecited.Inaddition,optimizationstrategieshavebeendevelopedfortheoptimaldesignofreactivedistillation,asitcanbeseenin theworksof CiricandGumus(2009), Tsatse,Oudenhoven,tenKate,andSorensen(2021), and Tian,Pappas,Burnak,Katz,andPistikopoulos(2021)

Regardtheintensifiedheatexchangers,mostofthereportedworksareexperimental; thestudiesonthedesignofintensifiedheatexchangersarescarce,andtheyemployed computationalfluiddynamicsasdesigntool(Alimoradi,Olfati,&Maghareh,2017; Bahiraei,Mazaheri,&Hanooni,2021; Jamshidmofid,Abbassi,&Bahiraei,2021; Piriyarungrodetal.,2018).

1.3Conventionalprocessesfortheproductionofbiofuels

Asitwasmentionedbefore,thebiomasscanbeconvertedintobiofuelsinliquid,gaseous orsolidstate.Inthissection,thedefinition,mainuses,aswellastheconventionalprocess foritsproductionwillbepresented.

1.3.1Liquidbiofuels

Amongliquidbiofuels,wecanmentionbioethanol,biobutanol,biogasoline,biodiesel, greendiesel,andrenewableaviationfuel.

Bioethanol,aswellasbiobutanol,isanalcohol,whosechemicalcompositionis exactlythesameofitsfossilcounterpart;themaindifferenceisthatbioethanolandbiobutanolarenotgeneratedfrompetroleum(Alam&Tanveer,2020).Bioethanolcanbe usedasanadditiveininternalcombustionenginesthatoperatewithgasolineorasafuelin enginesspecificallydesignedforit.Inaddition,bioethanolcanbeusedinthebeverage

Fig.1.11 Mainstepsintheconventionalprocessfortheproductionofbioethanol.

industryaswellasrawmaterialforthegenerationofethyleneandderivativecompounds (Ferreira,Agnihotri,&Taherzadeh,2019).Ontheotherhand,biobutanolhascaptured theattentionforitspotentialuseasgasolinereplacement(Roberts&Patterson,2014). Biobutanolcanbeusedasanadditiveininternalcombustionenginesthatoperateswith gasoline,until12.5%volumeaccordingtothestandardASTMD7862-19(ASTM, 2019).Inaddition,biobutanolisusedasasolventincosmetics,hydraulicfluids,detergent formulations,drugs,antibiotics,hormones,andvitamins,asanintermediateinchemical synthesis,andalsoasanextractantinthemanufacturingofpharmaceuticals(Isom€aki, Pitk€aaho,Niemist € o,&Keiski,2017).

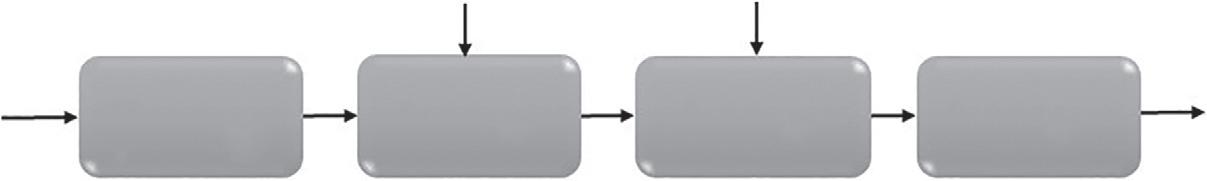

Bioethanolandbiobutanolcanbeproducedthroughfermentationofsugars,which canbeobtainedforcultivatedorresidualbiomass. Fig.1.11 showsthemainprocessinthe productionofbioethanol.

Asitcanbeseenin Fig.1.11,bioethanolcanbeproducedfromlignocellulosic,sugar, andstarchfeedstock.Inallcases,itisnecessarytogrindthefeedstockinordertoincrease theavailableareaforthereleaseofthesugarscontainedintherawmaterial.Inthecaseof sugarfeedstock,itisusuallyrequiredtoperformasolid–liquidextraction,whilehydrolysisisusedforstarchfeedstock;inthecaseoflignocellulosicfeedstock,pretreatmentsare carriedontoseparatecelluloseandhemicellulosefrombiomassfollowedbyhydrolysis andsaccharification.Later,thereleasedsugarsarefermentedusuallywith Saccharomyses cerevisiae inordertogeneratebioethanol(Ciani,Comitini,&Mannazzu,2008).Typical yieldstobioethanolareintheorderof5%–12%,sinceatmajorconcentrationsthemicroorganismsareinactivated(Dimian,Bildea,&Kiss,2014).Duetothis,theseparationis necessaryinordertoobtainanhydrousbioethanol.Typically,distillationhasbeenused forthepurificationofbioethanol,forwhichtheazeotropicpointmustbeoverpass;this usuallyrequirestheuseofasolvent,suchasethyleneglycol(Pacheco-Basultoetal., 2012).Intheconventionalprocessfortheproductionofbioethanol,itspurificationis theoperationwithhigher-energyconsumption.

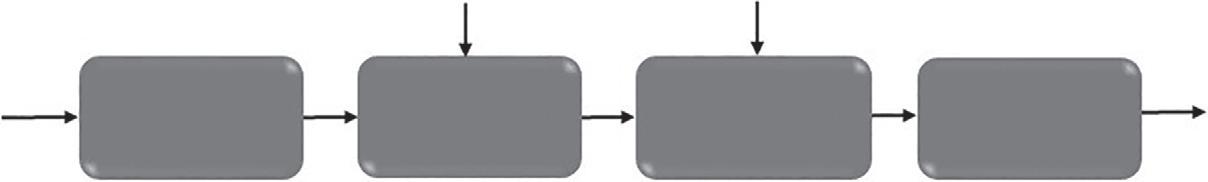

Ontheotherhand,themainstepsinvolvedintheproductionprocessofbiobutanol areshownin Fig.1.12.

From Fig.1.12,itisimportanttomentionthatthepretreatmentandhydrolysissteps areexactlythesamepreviouslydescribedforbioethanolproduction.Themaindifference reliesonthefermentationanddistillationsteps.Thereleasedsugarsareconverted

feedstock

throughacetone-butanol-ethanol(ABE)fermentation,whosenameindicatesthatthese productsaregenerated.Theconcentrationsofbutanolrangefrom2.75to12g/L, obtainedwith Clostridiumacetobutylicum ATCC824(Sindhuetal.,2019).Duetothe lowyields,theseparationisnecessaryinordertoobtainbiobutanol;accordingtotheliterature,distillationandliquid-liquidextractionhavebeenusedforthepurificationofthe productsofABEfermentation(Kaymak,2018; Sa ´ nchez-Ramı´rez,Quiroz-Ramı´rez, Segovia-Herna ´ ndez,Herna ´ ndez,&Ponce-Ortega,2016).Intheconventionalprocess fortheproductionofbiobutanol,itspurificationistheoperationwithhigher-energy consumption.

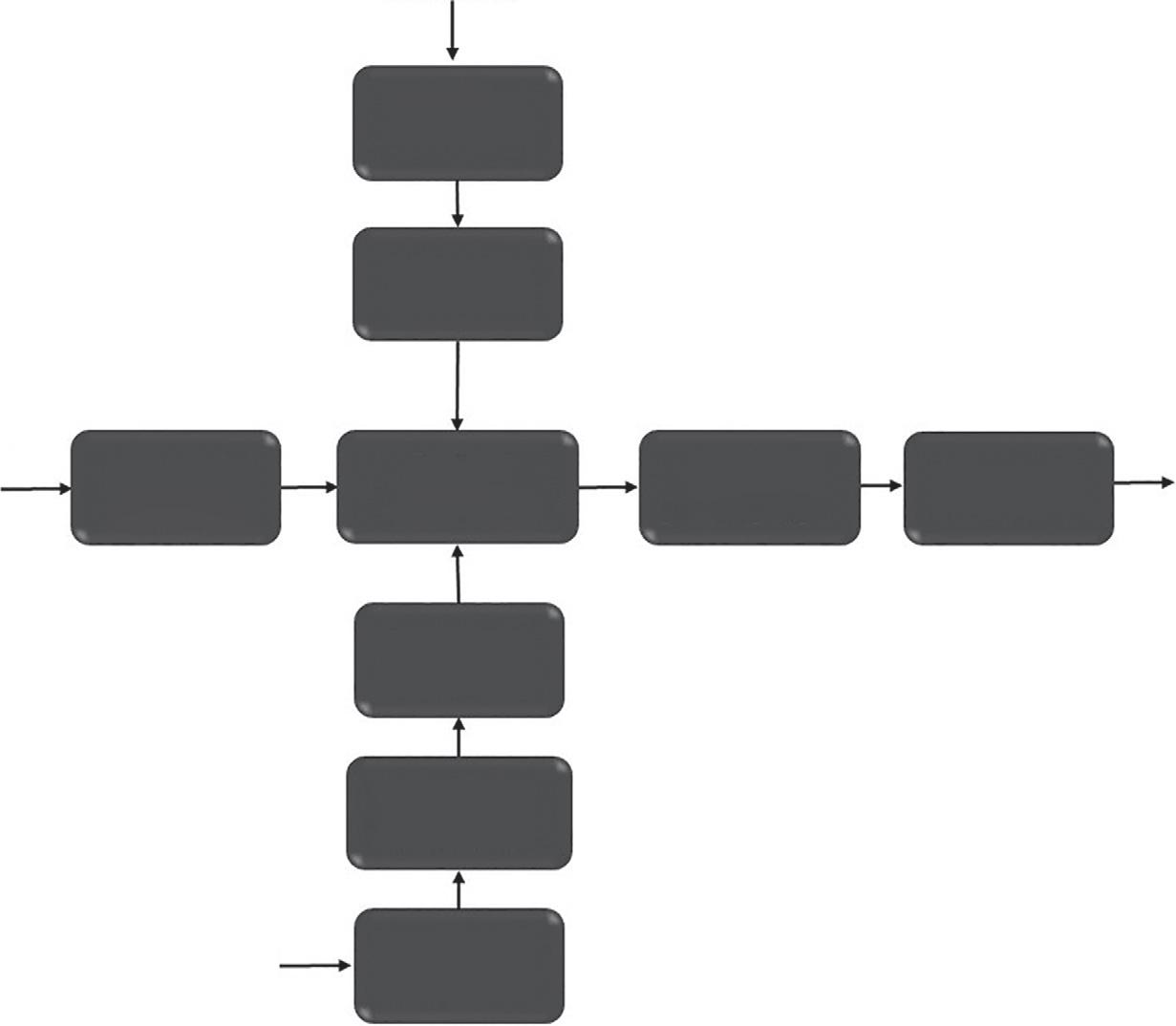

Ontheotherhand,renewablegasolineorbiogasolineconsistsofhydrocarbonsinthe rangeofC4–C12,generatedfrombiomass;inastrictsense,biogasolinewouldexclude thealcoholssincealcoholsaretypicallyoxygenated,incontrastwithoil-derivedfuels (Pagliuso,2010).Thusthecompositionofbiogasolineandgasolinearethesame,aswell asitsproperties(ASTM,2021).Thusthebiogasolinecanbeusedinmixtureswithfossil gasolineorat100%ininternalcombustionenginesthatoperatewithfossilgasoline.In addition,biogasolinecanbeusedtoproducesteaminboilers,ortogenerateelectricityin smallpowerplants. Fig.1.13 showstheroutestoproducebiogasoline.

Asitcanbeobservedfrom Fig.1.13,biogasolinecanbeproducedfromtriglyceride, lignocellulosic,sugar,andstarchfeedstocktodifferentprocessingpathways.Iftriglyceridefeedstockisused,itmustbehydroprocessedinordertogeneratebiogasoline,aswell aslightgasesanddieselfuel;inaddition,biooilderivedfromthepyrolysisoflignocellulosicfeedstockcanalsobehydroprocessedtogeneraterenewablegasoline.Ontheother hand,itispossibletoproducebiogasolinefromsugarandstarchfeedstock,throughits conversiontoalcoholandlateroligomerizated.Inspiteofthetypeofrawmaterialused, distillationisincludedforthepurificationofthehydrocarbonsgenerated.Thereported selectivitiesforrenewablegasolineare90%orhigher(Duanetal.,2020; OhayonDahan, Porgador,Landau,&Herskowitz,2020).Intheseconversionpathways,thepyrolysis, hydrodeoxygenation,aswellasdistillationarethemostenergy-intensiveprocesses.

Bioethanolandbiobutanolhavebeenproposedasreplacementsoradditivesforgasoline,whilebiodieselandgreendieselhavebeendevelopedforfossildiesel.Inparticular, biodieselisamixtureoflongchainfattyacidestersthataregeneratedthroughatransesterificationreaction(Du,Kamal,&Zhao,2019);biodieseldiffersfromfossildieselin composition,sincethelastoneconsistsofhydrocarbonsintherangeofC17–C28.

Starch feedstock Sugar feedstock

Acetone Biobutanol Bioethanol

Lignocellulosic feedstock Pretreatment HydrolysisFermentationDistillation

Fig.1.12 Mainstepsintheconventionalprocessforbiobutanolproduction.

Biodieselcanbeusedinmixturesininternalcombustionenginesthatoperatewithfossil dieselorat100%inenginesspecificallydesignedforthisbiofuel(ASTM,2020a).Inaddition,itcanbeusedasfuelinboilerstogeneratesteamorinsmall-generationpower plants. Fig.1.14 showsthemainstepsintheconventionalprocessfortheproduction ofbiodiesel.

Biodieselcanbeproducedfromtriglyceridefeedstock,whichmayrequireapretreatmentespeciallyiftherawmaterialisresidual.Thetriglyceridesareconvertedintofatty acidestersandglycerol,throughtransesterificationandesterificationreactions;these productsmustbeseparatedbydecantation.Finally,thebiodieselispurifiedtoeliminate theimpuritiesandreachthepurityrequiredforitsuseasfuel.Themostusedprocess involvesthehomogeneouscatalysis,whichcanbeacidorbasic;theconversionsare 98%orgreater(BritoCruz,Souza,&BarbosaCortez,2014).Intheconventionalprocess

Fig.1.13 Mainstepsintheconventionalprocessforbiogasolineproduction.

Fig.1.14 Mainstepsintheconventionalprocessforbiodieselproduction.

Fig.1.15 Mainstepsintheconventionalprocessesforgreendieselproduction.

fortheproductionofbiodiesel,itspurificationistheoperationwithhigher-energyconsumptionandalsowiththegreaterhydricfootprint.

Ontheotherhand,greendieselconsistsofhydrocarbonsintherangeofC17–C28, whichcorrespondtothesamecompositionoffossildiesel.Greendieselcanbeusedin mixturesininternalcombustionenginesthatoperatewithfossildieselorat100%in enginesdesignedtooperatewithfossildiesel(ASTM,2020a).Moreover,greendiesel canbeusedasfuelinboilerstogeneratesteamorinsmallgenerationpowerplants.

Fig.1.15 showsthemainstepsintheconventionalprocessfortheproductionofgreen diesel.Similartotheproductionofbiogasoline,greendieselcanbegeneratedfromsugar, starch,triglyceride,orlignocellulosicfeedstockfordifferentconversionpathways;in spiteoftheprocessingpathway,thepurificationofthegeneratedhydrocarbonsiscarried outthroughdistillation.Thereportedselectivitiesfortheproductionofgreendiesel rangefrom80%to94%(Ameenetal.,2020; Papanikolaouetal.,2020).Inthese