https://ebookmass.com/product/artificial-intelligence-and-

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Computational and Data-Driven Chemistry Using Artificial Intelligence: Fundamentals, Methods and Applications

Takashiro Akitsu

https://ebookmass.com/product/computational-and-data-driven-chemistryusing-artificial-intelligence-fundamentals-methods-and-applicationstakashiro-akitsu/ ebookmass.com

Artificial Intelligence and Credit Risk: The Use of Alternative Data and Methods in Internal Credit Rating

Rossella

Locatelli

https://ebookmass.com/product/artificial-intelligence-and-credit-riskthe-use-of-alternative-data-and-methods-in-internal-credit-ratingrossella-locatelli/

ebookmass.com

NOx Emission Control Technologies in Stationary and Automotive Internal Combustion Engines: Approaches Toward NOx Free Automobiles B. Ashok

https://ebookmass.com/product/nox-emission-control-technologies-instationary-and-automotive-internal-combustion-engines-approachestoward-nox-free-automobiles-b-ashok/ ebookmass.com

The Body in the Dumb River George Bellairs

https://ebookmass.com/product/the-body-in-the-dumb-river-georgebellairs/

ebookmass.com

School and Society: Historical and Contemporary Perspectives 7th Edition, (Ebook PDF)

https://ebookmass.com/product/school-and-society-historical-andcontemporary-perspectives-7th-edition-ebook-pdf/

ebookmass.com

Auctioned Surrender: A Dark Mafia Romance (Sinful Duets Book 2) Mari

https://ebookmass.com/product/auctioned-surrender-a-dark-mafiaromance-sinful-duets-book-2-mari/

ebookmass.com

Saving Finley: Military Hero, Heroine Romance (Safe and Secure Book 8) Alyssa Bailey

https://ebookmass.com/product/saving-finley-military-hero-heroineromance-safe-and-secure-book-8-alyssa-bailey/

ebookmass.com

Human Evolution: Bones, Cultures, and Genes John H. Langdon

https://ebookmass.com/product/human-evolution-bones-cultures-andgenes-john-h-langdon/

ebookmass.com

Come Dance With Me: Elladine Fire Steamy Romance Series Finley Daniels

https://ebookmass.com/product/come-dance-with-me-elladine-fire-steamyromance-series-finley-daniels/

ebookmass.com

Paradigms in India Indranil De

https://ebookmass.com/product/social-norms-gender-and-collectivebehaviour-development-paradigms-in-india-indranil-de/

ebookmass.com

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright © 2022ElsevierINC.Allrightsreserved.UChicagoArgonne,LLC,Contract No:DE-AC02-06CH11357.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyany means,electronicormechanical,includingphotocopying,recording,orany informationstorageandretrievalsystem,withoutpermissioninwritingfromthe publisher.Detailsonhowtoseekpermission,furtherinformationaboutthe Publisher’spermissionspoliciesandourarrangementswithorganizationssuchas theCopyrightClearanceCenterandtheCopyrightLicensingAgency,canbefoundat ourwebsite: www.elsevier.com/permissions.

Thisbookandtheindividualcontributionscontainedinitareprotectedunder copyrightbythePublisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthis fieldareconstantlychanging.Asnewresearch andexperiencebroadenourunderstanding,changesinresearchmethods,professional practices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledge inevaluatingandusinganyinformation,methods,compounds,orexperiments describedherein.Inusingsuchinformationormethodstheyshouldbemindfulof theirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhavea professionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,or editors,assumeanyliabilityforanyinjuryand/ordamagetopersonsorpropertyasa matterofproductsliability,negligenceorotherwise,orfromanyuseoroperationof anymethods,products,instructions,orideascontainedinthematerialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

ISBN:978-0-323-88457-0

ForinformationonallElsevierpublicationsvisitourwebsite at https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionsEditor: CarrieBolger

EditorialProjectManager: MarianaKuhl

ProductionProjectManager: PoulouseJoseph

CoverDesigner: GregHarris

TypesetbyTNQTechnologies

Contributorsix

Forewordxi

Preface xv

1.Introduction1

BalajiMohan,PinakiPal,JihadBadra,YuanjiangPeiandSibenduSom

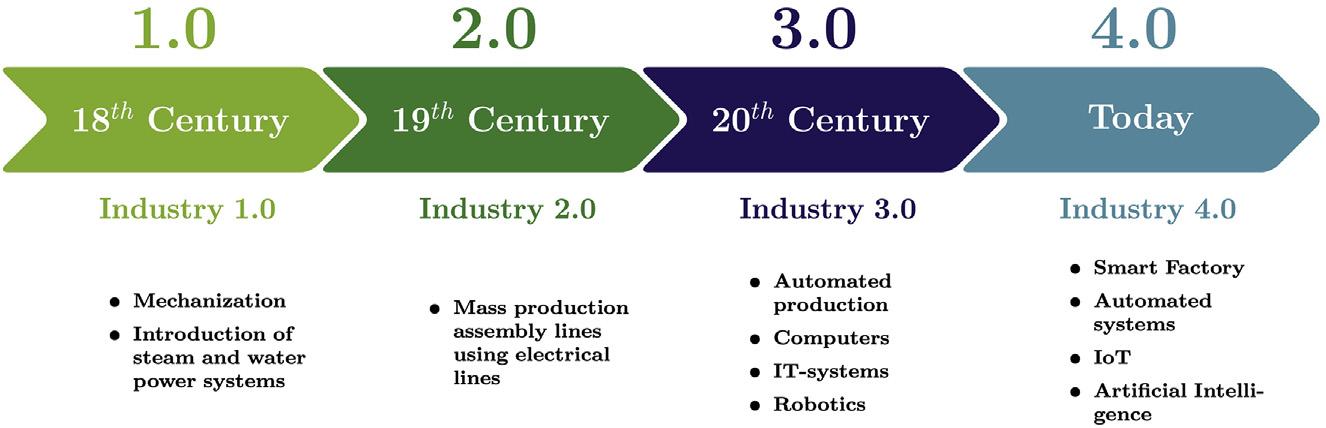

1. Industrialrevolution1

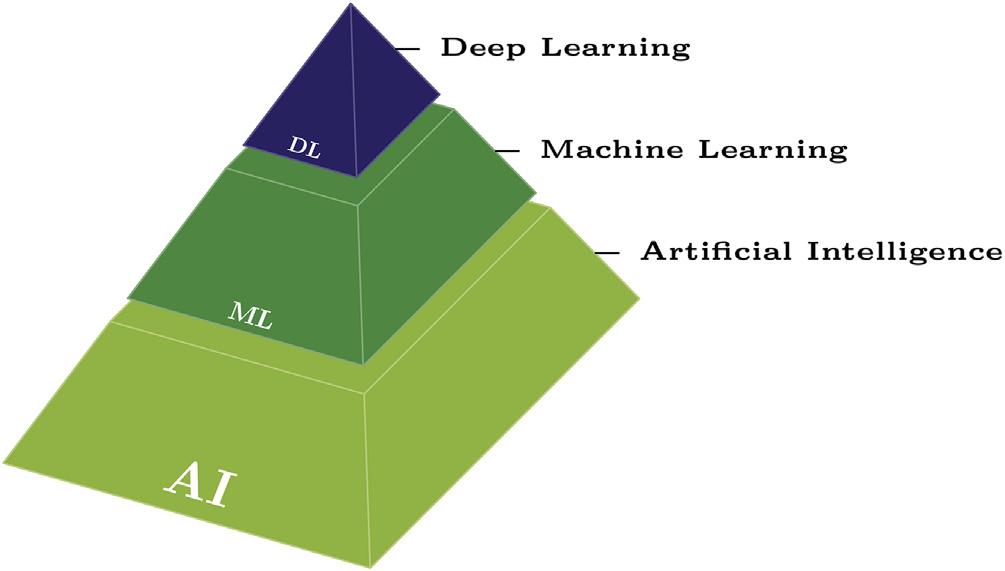

2. Artificialintelligence,machinelearning,anddeeplearning2

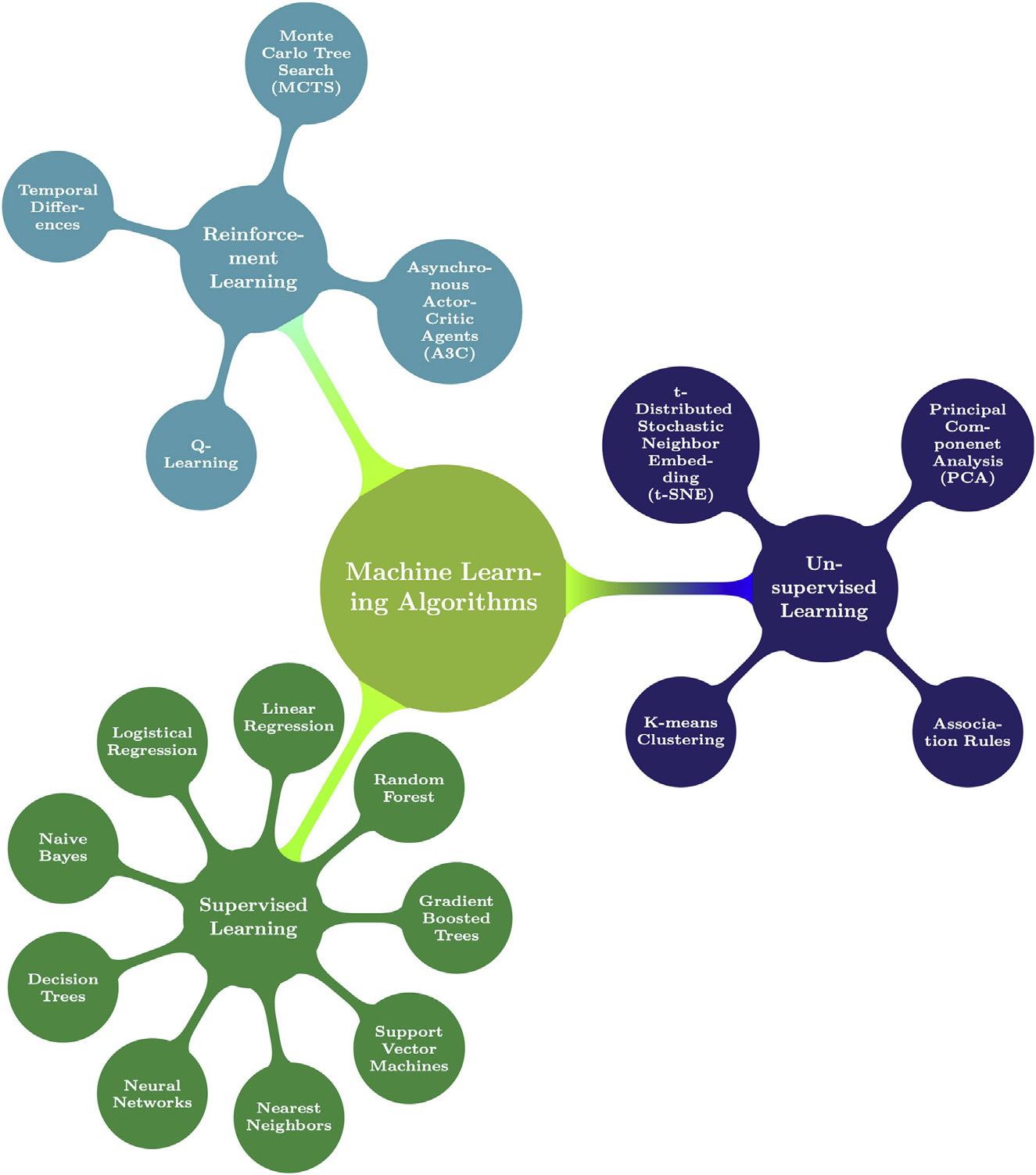

3. Machinelearningalgorithms3

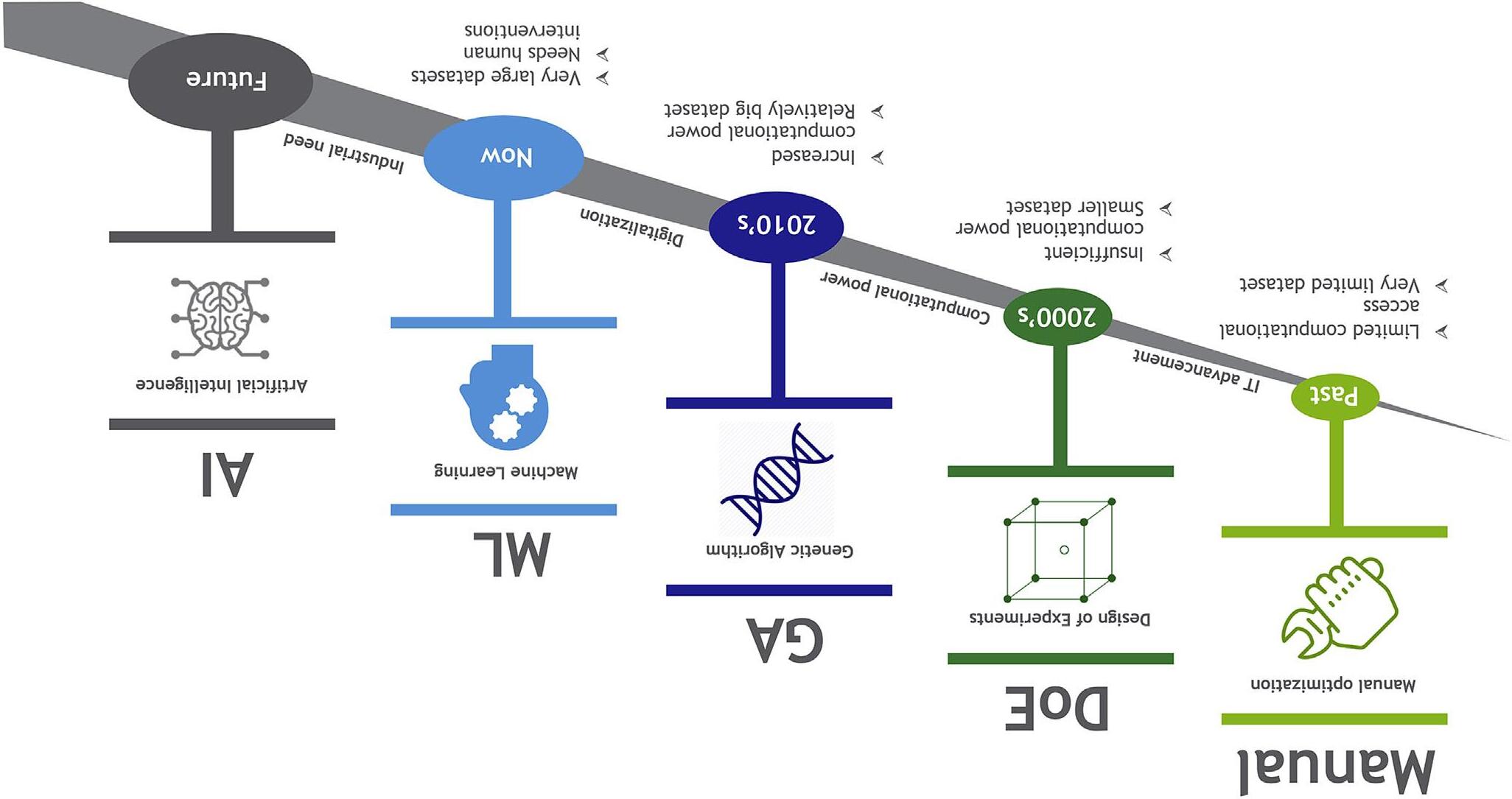

4. Artificialintelligence basedfuel-engineco-optimization4

5. Summary16 References16

SECTION1ArtificialIntelligencetooptimizefuelformulation

2.Optimizationoffuelformulationusingadaptivelearningand artificialintelligence27

JulianeMueller,NamhoKim,SimonLapointe,MatthewJ.McNenly, MagnusSjöbergandRussellWhitesides

1. Introductionandmotivation27

2. Mixed-modecombustionandfuelperformancemetrics28

3. Aneuralnetworkmodeltopredictfuelresearchoctanenumbers31

4. Optimizationproblemformulationanddescriptionofsolutionapproaches32

5. Numericalexperimentsandresults37

6. Discussion40

7. Summaryandconcludingremarks42 Acknowledgments43 References43

3.Artificialintelligence enabledfueldesign47

KiranK.Yalamanchi,AndreNicolleandS.ManiSarathy

1. Transportationfuels47

2. Applicationofartificialintelligencetofuelformulation52

3. Conclusionsandperspectives58 Acknowledgments60 References60 v

SECTION2ArtificialIntelligenceandcomputational fluid dynamicstooptimizeinternalcombustion engines

4.Engineoptimizationusingcomputational fluiddynamics andgeneticalgorithms71

AlbertoBroatch,RicardoNovella,JoséM.Pastor,JosepGomez-Soriano andPeterKellySenecal

1. Introduction71

2. Modelingframeworkandaccelerationstrategies74

3. Optimizationmethods79

4. Summaryandconcludingremarks97 References98

5.Computational fluiddynamics guidedenginecombustion systemdesignoptimizationusingdesignofexperiments103

YuanjiangPei,AnqiZhang,PinakiPal,LeZhao,YuZhangand SibenduSom

1. Introduction103

2. Methodologies106

3. Arecentapplication113

4. Recommendationsforbestpractice118

5. Conclusionsandperspectives120 Acknowledgments121 References121

6.Amachinelearning-geneticalgorithmapproachfor rapidoptimizationofinternalcombustionengines125

JihadBadra,OpeoluwaOwoyele,PinakiPalandSibenduSom

1. Introduction125

2. Engineoptimizationproblemsetup127

3. Traininganddataexamination129

4. Machinelearning-geneticalgorithmapproach132

5. Automatedmachinelearning-geneticalgorithm141

6. Summary156 Acknowledgments156 References156

7.Machinelearning drivensequentialoptimizationusing dynamicexplorationandexploitation159

OpeoluwaOwoyeleandPinakiPal

1. Introduction159

2. ActiveMLoptimization(ActivO)160

3. Casestudy1:two-dimensionalcosinemixturefunction165

4. Casestudy2:computational fluiddynamics(CFD)-basedengine optimization171

5. Conclusions179 Acknowledgments180 References180

SECTION3ArtificialIntelligencetopredictabnormal enginephenomena

8.Artificial-intelligence-basedpredictionandcontrolof combustioninstabilitiesinspark-ignitionengines185

BryanMaldonado,AnnaStefanopoulouandBrianKaul

1. Introduction185

2. Casestudy:artificial-intelligence-enhancedmodelingofdilute spark-ignitioncycle-to-cyclevariability189

3. Casestudy:neuralnetworksforcombustionstabilitycontrol193

4. Casestudy:learningreferencegovernorformodel-freedilute limitidentificationandavoidance199

5. Summary204 References205

9.Usingdeeplearningtodiagnosepreignitioninturbocharged spark-ignitedengines213

EshanSingh,NursuluKuzhagaliyevaandS.ManiSarathy

1. Introduction213

2. Preignitiondetectionusingmachinelearningalgorithm215

3. Activationfunctions221

4. Experimentsanddataextraction222

5. Machinelearningmethodology224

6. Model1:Inputfromprincipalcomponentanalysis230

7. Model2:Timeseriesinput231

Contributors

JihadBadra

TransportTechnologiesDivision,ResearchandDevelopmentCenter,SaudiAramco, Dhahran,EasternProvince,SaudiArabia

AlbertoBroatch

CMT ThermalMotors,PolytechnicUniversityofValencia,CaminodeVera,Valencia, Spain

JosepGomez-Soriano

CMT ThermalMotors,PolytechnicUniversityofValencia,CaminodeVera,Valencia, Spain

BrianKaul

OakRidgeNationalLaboratory,Knoxville,TN,UnitedStates

NamhoKim

SandiaNationalLaboratories,Livermore,CA,UnitedStates

NursuluKuzhagaliyeva

CleanCombustionResearchCenter(CCRC),KingAbdullahUniversityofScienceand Technology,Thuwal,WesternProvince,SaudiArabia

SimonLapointe

LawrenceLivermoreNationalLaboratory,Livermore,CA,UnitedStates

BryanMaldonado

OakRidgeNationalLaboratory,Knoxville,TN,UnitedStates

MatthewJ.McNenly

LawrenceLivermoreNationalLaboratory,Livermore,CA,UnitedStates

BalajiMohan

TransportTechnologiesDivision,ResearchandDevelopmentCenter,SaudiAramco, Dhahran,EasternProvince,SaudiArabia

JulianeMueller

LawrenceBerkeleyNationalLaboratory,Berkeley,CA,UnitedStates

AndreNicolle

AramcoFuelResearchCenter,AramcoOverseas,Rueil-Malmaison,Paris,France

RicardoNovella

CMT ThermalMotors,PolytechnicUniversityofValencia,CaminodeVera,Valencia, Spain

OpeoluwaOwoyele

EnergySystemsDivision,ArgonneNationalLaboratory,Lemont,IL,UnitedStates

PinakiPal

EnergySystemsDivision,ArgonneNationalLaboratory,Lemont,IL,UnitedStates

JoséM.Pastor

CMT ThermalMotors,PolytechnicUniversityofValencia,CaminodeVera,Valencia, Spain

YuanjiangPei

AramcoAmericas:AramcoResearchCenter Detroit,Novi,MI,UnitedStates

S.ManiSarathy

CleanCombustionResearchCenter(CCRC),KingAbdullahUniversityofScienceand Technology,Thuwal,WesternProvince,SaudiArabia

PeterKellySenecal

ConvergentScience,Inc.,Madison,WI,UnitedStates

EshanSingh

CleanCombustionResearchCenter(CCRC),KingAbdullahUniversityofScienceand Technology,Thuwal,WesternProvince,SaudiArabia

MagnusSjöberg

SandiaNationalLaboratories,Livermore,CA,UnitedStates

SibenduSom

EnergySystemsDivision,ArgonneNationalLaboratory,Lemont,IL,UnitedStates

AnnaStefanopoulou

DepartmentofMechanicalEngineering,UniversityofMichigan,AnnArbor,MI, UnitedStates

RussellWhitesides

LawrenceLivermoreNationalLaboratory,Livermore,CA,UnitedStates

KiranK.Yalamanchi

CleanCombustionResearchCenter(CCRC),KingAbdullahUniversityofScienceand Technology,Thuwal,WesternProvince,SaudiArabia

AnqiZhang

AramcoAmericas:AramcoResearchCenter Detroit,Novi,MI,UnitedStates

YuZhang

AramcoAmericas:AramcoResearchCenter Detroit,Novi,MI,UnitedStates

LeZhao

EnergySystemsDivision,ArgonneNationalLaboratory,Lemont,IL,UnitedStates

Foreword

Theinternalcombustionengine(ICE)powersourworld.Fromcarsand long-haultruckstoagriculturalandconstructionequipments,liquid-and gaseous-fueledenginestouchpracticallyeveryaspectofourlives.ICEshave beenaroundfortwohundredyears,andthevehiclestheypowerpermeated themassesmorethanacenturyago.Thesemachineshaveimprovedour livesbyliftingpeopleoutofpovertyandgivingusthefreedomtoliveand workwhereweplease.

Today’sICElooksvastlydifferentfroman1800s-eraengine.Significant advancesinairdelivery,fueldelivery,andemissionscontrolsystemshave madethemodernengineamuchcleanerandmoreefficientmachine.Even withtheseadvances,however,thecombustionengineisnotsustainablein itscurrentform.Thereisnowaglobalracefordecarbonization,whichis leadingtothedevelopmentofnewinnovationsatanunprecedentedpace.

TheICEnolongerhastogoalone.Technologiessuchasbattery electricandhydrogenfuelcellvehiclesholdgreatpromiseforhelpingus achieveacleaner,greener,andmorediversemobilityfuture.Practically, though,thesetechnologiescanbeonly part ofthesolution.Westillneed engines alotofthem buttheengineoftomorrowmustbedifferent fromtoday’smachines;theengineoftomorrowmustbedecarbonized. Achievingafullydecarbonizedenginerequiresimprovementsinengine technologies,hybridization,andlow-orno-carbonfuels.

Howdowegetthere?Thepathforwardwillbeacombinationof improvedsimulationthroughtechniquessuchascomputational fluiddynamicsandadvancesinenginehardwareandcontrols.Virtualization throughsimulationhasbeen,andcontinuestobe,powerfulforoptimizing newenginetechnologies.Asanexample,theMazdaSKYACTIV-Xwas developedvirtuallybeforeanyphysicalprototypeswerebuilt,andthis successisjustthestartofwhatistocome.Butsimulationmethodsaloneare notenoughtogetuswhereweneedtogo,atleastnotintheshortamount oftimewehavetogetthere.

Theenginerepresentsalargeandcomplicateddesignspace,encompassingfuels,combustionchamberdesign,fuelinjection,ignitionstrategies, andmore.Thisisamassive,multi-objectiveoptimizationproblemwithnot justone,butacollectionofoptima.Makingthemostofthisparameter spacewillrequirecontinuedadvancesinenginecontroltechnologies,

sensors,andonboardcomputers.Theseadvancesarealreadyleadingto unprecedentedopportunity,butalsotoanever-expandingandunmanageabledesignspaceformodernengines.Currenttrendsareshowingan exponentialincreaseintheparameterspace,andthistrendisexpectedto continuefortheforeseeablefuture.Howcanwepossiblyevaluateand implementeverydesigncombinationto findthebestsolution?Thecurrent inabilitytorealizethepotentialofthisparameterspaceefficientlyand effectivelyisleadingtosuboptimalenginesinthemarket.

Fortunately, “bigscience” toolshaveevolvedalongsidetheengineitself. Supercomputing,advancednumericalmethods,andevenartificialintelligence(AI)arenowatourdisposal.Aswithsomanydisciplinestoday, machinelearning(ML)hasopenedanewrealmofpossibilitiesfor advancingengines.Bymarryingbigscience/datasciencewithvirtualrepresentationsoftheengine,wecan(andwill!)achievetheultimateICE design.AI/MLwillbridgeatomisticmodelingbreakthroughswithengineeringsimulations,andAI/MLcontrolswillalsoenableautonomous, intelligentsystemscontrols.Thesesystemswillhavetheabilitytolearn, adapt,andmanipulateenginecontrolstooperateattheedgeofstabilityto maximizeefficiencyandminimizeemissionsunderever-changingvehicle demands.

ThisbookdoesanexcellentjobcoveringtherelativelynewtopicofAI appliedtoenginesimulationandexperimentation.Insteadoftryingto covertheentiredesignspaceatonce,theauthorsofeachchapterfocusona singleaspect,suchasfuelformulation,enginecalibrationparameters, combustionchamberdesign,detectingabnormalenginephenomena(e.g., lowpressureignition),andmore.Furthermore,theauthorsdonotfocus solelyonthecurrentlearningalgorithms theyalsoprovideahistorical perspectiveandcoveroptimizationmethodsbasedontheprinciplesof evolution,forexample,geneticalgorithms.

Thisbookprovidesathoroughandtimelyoverviewofwhere AI-assistedengineoptimizationstandstoday,makingitavaluablereference fornewresearchersandseasonedenginedesignersalike.Theeditorshave succeededinchoosingnotonlytherighttopicstocoverbutalsotheright expertstowriteaboutthem.

WeareenteringabravenewworldfortheICE.Ourenginesmustbe cleanerandgreenerthanevertostayrelevantintoday’sdecarbonizing society.Thisbooklaysoutthemostpromisingtoolswehaveavailableto

ensuretheICEreachesitsfullpotential.Throughtherightcombinationof humanintelligenceandAI,advancedengineswillhelpusdecarbonize transportation.

Dr.KellySenecal Co-founder,ConvergentScience Madison,WI,UnitedStates

Dr.RobertWagner Director,BuildingsandTransportationScienceDivision, OakRidgeNationalLaboratory Knoxville,TN,UnitedStates

Preface

Internalcombustionenginesarenotgoingtogoawayanytimesoon. Internalcombustionengineiscurrentlytheprincipalprimemoverinthe transportationsector,anditisexpectedtomaintainitsdominancein theforeseeablefuture.Wetherefore,stronglybelievethatimprovingthe efficiencyandreducingtheemissionsfrominternalcombustionenginesare themosteffectivemeasurestohaveanimmediateandprominentimpacton theenvironment.Ouraiminthistextistoprovideanexpositionofvarious engineandfueloptimizationtechniquesandtoshowcasesomeoftheir applications.Specifically,thedesignoptimizationusingadvancedartificial intelligenceanddata-drivenmethodsisthefocusofthistext.Wehopethat thereaderswillenjoyitand,moreimportantly,learnfromit.

Thetextisprimarilyadaptedfrompreviousarchivalpublicationsmade bythevariousactiveresearchgroupsinthisspecificarea.Theauthorslistis acombinationofleading,reputable,andactiveexpertsinthe fieldofinternalcombustionenginesandartificialintelligence.Wearegratefultothe authorsfortheirinvaluablecontributionsandaretrulyhonoredtohave workedwithsuchanelitegroupofworld-renownedresearchers.

JihadBadra,TeamLeader

EngineCombustionTeam,TransportTechnologiesDivision, ResearchandDevelopmentCenter,SaudiAramco,Dhahran, EasternProvince,SaudiArabia

PinakiPal,ResearchScientist EnergySystemsDivision,ArgonneNationalLaboratory, Lemont,IL,UnitedStates

YuanjiangPei,TeamLeader

ComputationalModelingTeam,AramcoAmericas:Aramco ResearchCenter Detroit,Novi,MI,UnitesStates

SibenduSom,Manager

Multi-PhysicsComputationSection,EnergySystemsDivision, ArgonneNationalLaboratory,Lemont,IL,UnitedStates