Grandpa Sol’s Legacy Carries On at Rexius

By P.J. Heller

Nine decades after “Grandpa Sol” started his business by repurposing wood waste materials, his legacy lives on.

“We’re doing the same thing 90 years later that grandpa did in the ’30s,” says his grandson, Rusty Rexius.

Grandpa Sol’s business – Rexius Fuel Service – initially involved going to Oregon sawmills to collect sawdust, which would normally be burned as waste, and delivering it to homes and other establishments to use to fuel their furnaces in the winter.

“He’s seeing all this waste material being burned up and thought there had to be a better way,” Rexius says.

In the summer, the thousands and thousands of cubic yards of sawdust that was collected would pile up, rot and turn black but could then be sold for landscaping and decoration. Bark from logs was also collected from the sawmills and used for mulch. Wood shavings were collected and sold for animal bedding.

Over the decades, the company morphed and expanded and in 1986 became Rexius Forest By-Products. It remains a family-owned and operated business, recycling and processing organic waste and wood residual materials for the landscape, agricultural, and environmental industries.

The company has remained true to Grandpa Sol’s vision.

“We’re trying to make something out of nothing,” Rexius says. “We’re interested in making stuff and inventing things and trying to make a business model out of something that nobody had tried before.”

on a 157-acre site in Eugene, OR, the company has nine divisions including landscape and irrigation services, landscape maintenance, environmental restoration services, organic erosion control systems, and conveyed delivery systems manufacturing. It markets mulch, bark, compost, aggregates and regular and certified organic potting soils, as well as planting mixes and soil amendments. It provides bagged products under about three dozen different labels for retail and garden centers and wholesale distributors.

It also sells bulk super sacks (2 cubic yard totes are the most popular size among growers) and semi loads. The company’s products are sold worldwide.

“We ship millions of bags every season,” notes Arlen Rexius, who is also a grandson of Sol Rexius and who serves as copresident with his cousin Rusty Rexius.

As a youngster, Arlen Rexius worked on the bagging line, earning 8 cents for every filled bag.

“I could make $5.60 an hour if I

was really fast,” he laughs.

With a degree in diesel technology, he developed an automated bagging machine to meet a request from a chain store customer that wanted more than a million bags a year of bark, mulch and steer manure.

He later went on to run the bagging operation for about two years.

Rusty Rexius recalls working after school at the company when he was 11 years old.

What probably ranks as one of the more unique sales for the company was the shipment of 70 semi loads of soil to New York City, where it was put on the roof of a Manhattan skyscraper to grow blueberries.

Rexius also markets a variety of premium Opus Grows soils, one of which is prized by the cannabis industry, although some growers prefer to mix their own blends.

“They (cannabis growers) think they have their own secret recipe, so we sell them the components,” Arlen Rexius notes.

Other customers can also take advantage of custom mixes.

“If you prefer to opt for a custom mix, we have a wide variety of base ingredients and organic amendments to choose from to create just the right mix for your needs,” the company tells its customers.

Rexius has grown to 350 people (it had fewer than 100 employees 20 years ago).

“With 350 employees, we’re a force to be

Continued on page 3 NEWS

Vol. XVI No. 6 November / December 2022 www.SoilandMulchProducerNews.com

Serving Soil, Mulch, Compost & Wood Pellet Producers

Headquartered

Aerial view of Rexius’ main bark and soil producing plant located outside of Eugene, OR. Photos courtesy of Rexius Forest By Products (Rexius.com).

Co-president, Rusty Rexius, holding his young grandson. Rusty is flanked by his sons Trevor (L) and Tyler (R), who also work for the company. The two sons represent the 4th generation of the Rexius family.

Goodbye, guesswork.

And hello, GEM Studiov4 Thanks to this do-it-all interface, the all-new Sahara® XP coloring system is as simple as push to start. Plenty smart enough to follow the flow of material and find hidden dollars in every drop. Get to know the new GEM at SaharaXP.com.

2 Soil & Mulch Producer News November / December 2022

The Sahara® XP comes equipped with GEM Studiov4 Colorbiotics and Sahara are registered trademarks of MBCC Group. © 2022 MBCC Group. All rights reserved.

Grandpa Sol’s Legacy

reckoned with,” Arlen Rexius says.

Some of those employees have been with the company for 40 to 50 years. Arlen Rexius has worked full-time at the company for 50 years.

“It’s the only job I’ve ever had,” he says.

All manufacturing is done in Eugene but the company also has facilities in Portland and Bend. The Portland location has a fleet of blower trucks while Bend, as well as Eugene, offers landscaping services.

“We’re a unique company because we have so many things going on,” Arlen Rexius says. “We’re not just one thing. We don’t do just landscaping. We don’t just do soil.”

It also gives back to the community, through its involvement with charitable organizations and its annual Earth Day promotion, when it gives a free half yard of compost to anybody who stops by.

“We take their yard waste and turn it into something they can use and we give it back to them,” Arlen Rexius says.

Co-president, Arlen Rexius, with his grandson, Colton Arlen Rexius. Colton represents the 5th generation of the

Among its many offerings is design and installation of outdoor kitchen and living spaces, outdoor water features and outdoor fire features.

The Eugene site takes in thousands of yards of green waste as well as food scraps from restaurants and grocery stores.

In 1950, Sol Rexius invented what his grandson describes as a “very primitive” blower truck that could blow sawdust into the bins in homes for their furnaces. Arlen Rexius subsequently developed an automated blower truck and holds numerous patents on those Express Blower vehicles. Although that part of the company was sold in 2002 to FINN Corp. of Ohio, Rexius still builds Express Blower trucks for FINN and provides sales and services from its Eugene location.

“The blower truck spreads the same amount of mulch as 20 workers,” Arlen Rexius says. “When companies get short of workers, people buy blower trucks.”

Even so, it’s not always the solution to labor issues as Rexius well knows.

PUBLICATION STAFF

Contributing Editors / Writers

P.J. Heller • Robert L. LaGasse

Sandy Woodthorpe Production & Layout Christine Mantush Advertising Sales

Rick Downing

Subscription / Circulation

Donna Downing

Editorial, Circulation & Advertising Office

6075 Hopkins Road, Mentor, OH 44060

Ph: 440-257-6453 • Fax: 440-257-6459

Email: downassoc2@oh.rr.com

Subscription information, call 440-257-6453.

Soil & Mulch Producer News is published bimonthly by Downing & Associates. Reproductions or transmission in whole or in part, without written permission of the publisher, is prohibited.

Annual subscription rate U.S. is $19.95. Outside of the U.S. add $10 ($29.95). Contact our main office, or mail-in the subscription form with payment.

©Copyright 2022 by Downing & Associates

Printed on Post-Consumer Recycled Paper

“When I’m trying to do a landscape job, I need 20 workers to put in the plants and the irrigation system,” he says. “We’re looking (for people) all the time.”

Some of the jobs to be filled are listed on the company’s website.

Beside labor shortages, problems getting equipment and parts to make equipment have become more difficult as companies nationwide continue to face supply chain issues.

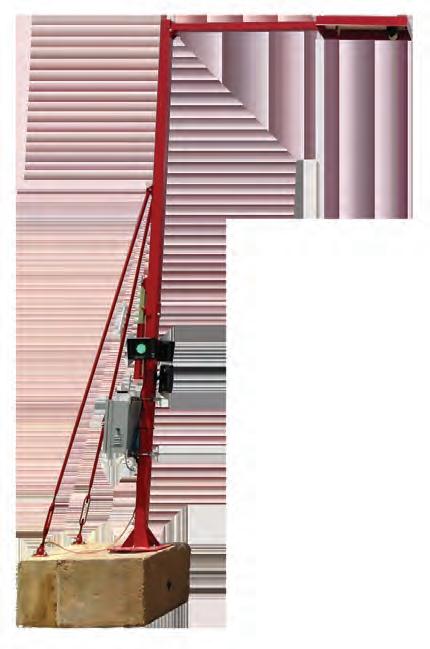

Another Rexius division is Conveyor Application Systems (CAS), which manufactures Slinger trucks which can place stone, sand, soil, mulch, and other aggregates at a distance of 150 feet.

“We’re a leader in blower trucks and slingers,” Arlen Rexius says.

Despite the growth over the decades, Rusty Rexius insists that “bigger is not better.”

“Bigger to me is not better,” he says. “Better is better. I bristle at the whole idea that success is equal to the size of your company. I don’t think that’s true at all.

‘It’s important to me and it’s important to my family that whatever we do we’re doing it better all the time, as best as we know how. It’s certainly not perfect but we’re working on better all the time. That’s just a really important part of this company and what our family has tried to adopt as why we do what we do. So bigger is not better, better is better,” he says.

on page 11

3 November / December 2022 Soil & Mulch Producer News Soil & Mulch Producer NEWS

Continued from page 1

Publisher / Editor Rick Downing

www.SoilandMulchProducerNews.com

P.O. Box 412 • 223 Marginal Road New Stanton, PA 15672 PHONE: (724) 925-8500 FAX: (724) 925-6421 800-348-0765 Email: dsmalis@mac.com Web site: www.radialstackers.com CONVEYOR REPLACEMENT PARTS • Pulleys • Belts • Idlers • Motors • Gearboxes • Hood Covers • Fasteners Nationwide Availability Reasonable Prices CONVEYORS RADIAL STACKERS CONVEYOR PARTS

Continued

News From The Mulch & Soil Council

By RoBeRt LaGasse, executive DiRectoR

By RoBeRt LaGasse, executive DiRectoR

Legislative & Regulatory News

The U.S. Environmental Protection Agency (EPA), in collaboration with the California Department of Pesticide Regulation and the U.S. Geological Survey, has released an updated version of the Aquatic Life Benchmarks. These benchmarks are estimates of the concentrations below which pesticides (including conventional pesticides and antimicrobial chemicals) are not expected to present a risk of concern for freshwater organisms.

The updated Aquatic Life Benchmarks represent 759 chemicals (parent compounds or degradates) including newly registered pesticides or new values for previously registered pesticides and selected degradates. The updates include:

• Benchmarks for 27 new chemicals (i.e., 16 new active ingredients and 11 of their degradates).

• Additional benchmarks for 10 degradates of chemicals with existing benchmarks.

• Revised benchmarks for 72 existing chemicals (i.e., 57 registration review chemicals and 15 degradates).

EPA based these benchmarks on toxicity values from scientific studies that the Agency has reviewed and used in publicly accessible ecological risk assessments in support of regulatory decisions for pesticides. For each of the chemicals listed in the Aquatic Life Benchmarks table, the table provides a link to the source documents for the benchmarks.

State, tribal and local governments use these benchmarks in their

interpretation of water quality monitoring data. Comparing a measured concentration of a pesticide in water to its Aquatic Life Benchmarks can be helpful in interpreting monitoring data and in identifying and prioritizing monitoring sites that may require further investigation. International regulatory authorities and researchers also use these data in their work.

This update supersedes the previous version published Aug. 31, 2021. EPA intends to continue updating these benchmarks yearly. Read the summary of updated benchmarks or see the complete Aquatic Life Benchmarks table.

EPA Withdraws Glyphosate Interim Decision

The U.S Environmental Protection Agency (EPA) is announcing its withdrawal of all remaining portions of the interim registration review decision for glyphosate. Pesticide products containing glyphosate continue to remain on the market and be used according to the product label and are unaffected by this action.

Glyphosate is undergoing registration review, a periodic reevaluation of pesticide registrations to ensure that existing pesticide products continue to perform their intended function without unreasonable adverse effects on human health or the environment. Under the Federal Insecticide, Fungicide and Rodenticide Act (FIFRA), each pesticide must be reviewed every 15 years.

On Feb. 3, 2020, EPA published the Glyphosate Interim Registration Review Decision (ID). The ID did not identify any human health risks of

Continued on page 6

H4 Soil & Mulch Producer News November / December 2022 Soil & Mulch Producer NEWS

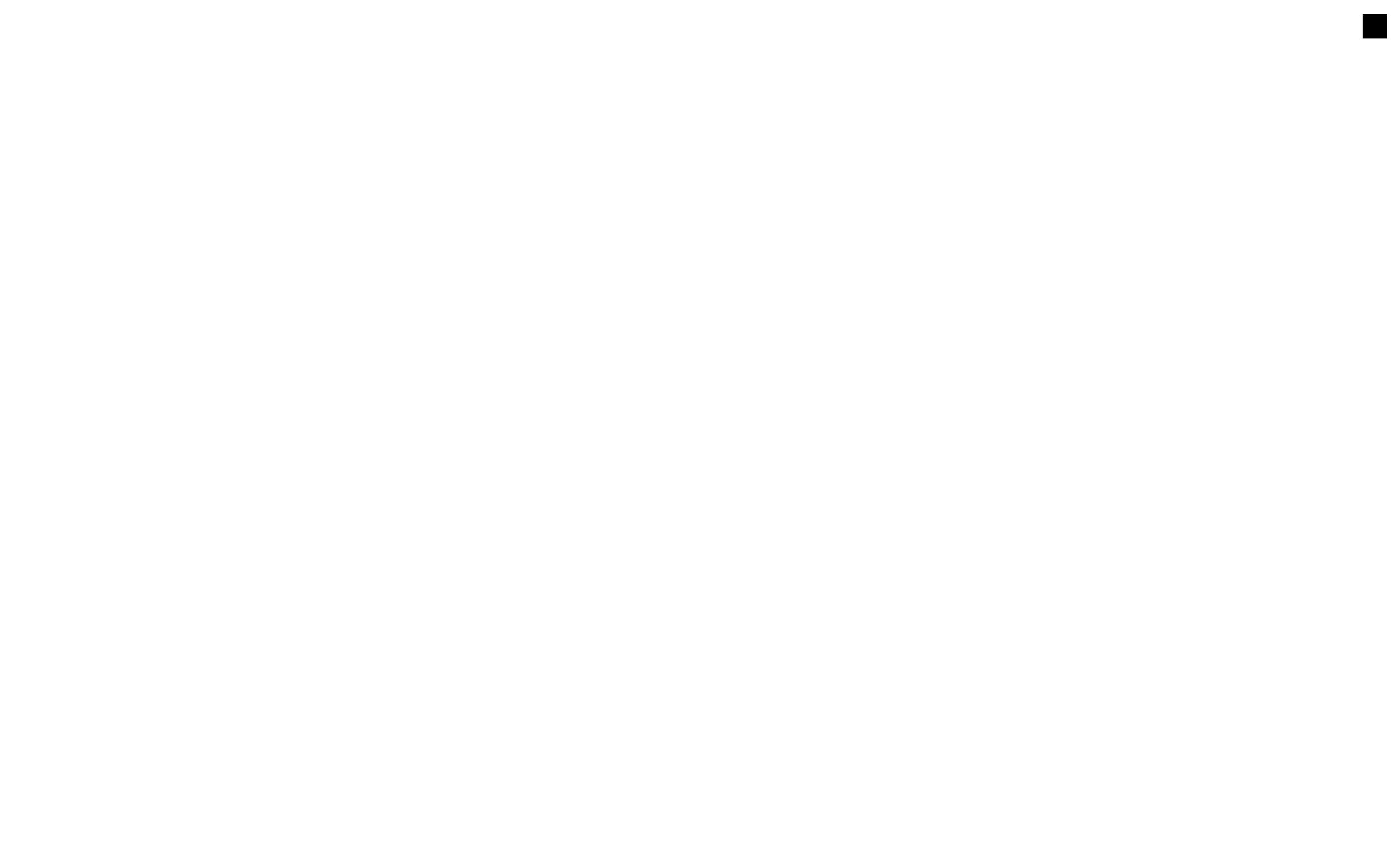

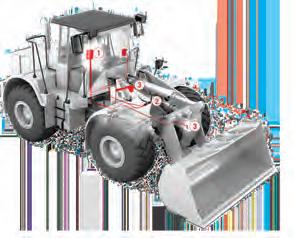

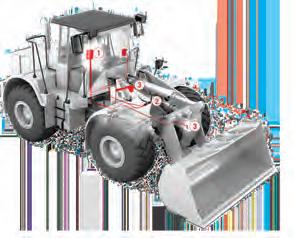

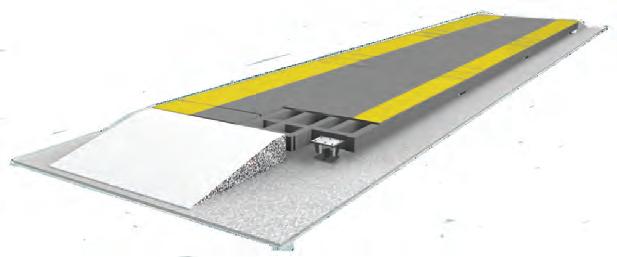

5 November / December 2022 Soil & Mulch Producer News SAVE MONEY MEASURE YOUR VOLUME! WA LZ S C A L E • S C A N N E R (800) 747-0701 656 High Point Ln., East Peoria, IL 61611-9369 www.walzscale.com Volumetric Belt Scanner / Volumetric Truck Scanner Axle Scales/Truck Scales Starting @ $23,600.00 Starting @ $1,620.00 Skid Steer / Lift Truck Scales Starting @ $995.00 Wheel Loader Scales Starting @ $3,250.00

News From The MSC

concern from exposure to glyphosate but did identify potential ecological risks. The ID included interim risk mitigation measures in the form of label changes, including labeling to manage spray drift and herbicide resistance. It concluded that the benefits of glyphosate outweigh the potential ecological risks when glyphosate is used in accordance with the labels.

On March 20, 2020, the glyphosate ID was challenged in the U.S. Court of Appeals for the Ninth Circuit. Petitioners challenged EPA’s analysis of human health and ecological risk, the weighing of such risks against the benefits of glyphosate and the interim risk mitigation measures and alleged that EPA violated the Endangered Species Act (ESA).

On May 18, 2021, EPA sought partial voluntary remand without vacatur of the ecological portion of the ID so the Agency could revisit aspects of its analysis in light of EPA’s November 2020 draft biological evaluation for glyphosate and recent court decisions for other herbicides, among other reasons.

On June 17, 2022, the U.S. Court of Appeals for the Ninth Circuit vacated the human health portion of the glyphosate ID and held that EPA’s registration review decision under FIFRA was an ‘action’ that triggered ESA obligations. The court also granted EPA’s request for voluntary remand, without vacatur, of the ecological portion of the ID but imposed an Oct. 1, 2022 deadline for EPA to issue a new ecological portion. EPA sought relief from this deadline, which the court denied on Aug. 5, 2022.

EPA has determined that withdrawal of the glyphosate ID is appropriate in consideration of the Ninth Circuit’s June 17, 2022 decision. The Agency was unable to finalize a new ecological portion in a registration review decision for glyphosate by the court-imposed Oct. 1, 2022 deadline because of the time needed to address the issues for which EPA sought remand of the ecological portion and satisfy ESA requirements. EPA initiated formal ESA consultation with the U.S. Fish and Wildlife Service

and the National Marine Fisheries Service (the Services) for glyphosate in November 2021, and consultation is ongoing. Moreover, before issuing any decision, EPA must first prepare a proposed decision, publish for a 60-day public comment period, and consider any comments received. EPA could not complete this process by the court-imposed deadline.

EPA’s underlying scientific findings regarding glyphosate, including its finding that glyphosate is not likely to be carcinogenic to humans, remain the same. In accordance with the court’s decision, the Agency intends to revisit and better explain its evaluation of the carcinogenic potential of glyphosate and to consider whether to do so for other aspects of its human health analysis. For the ecological portion, EPA intends to address the issues for which it sought remand, including: to consider whether additional or different risk mitigation may be necessary based on the outcome of ESA consultation for glyphosate, prepare an analysis of in-field effects of glyphosate on monarch butterfly habitat, consider whether there are other aspects of its analysis of ecological risks and costs to revisit, and consider what risk mitigation measures may be necessary to reduce potential risk following completion of analyses left outstanding in the ID. EPA also intends to complete ESA consultation with the Services, make a determination under the Endocrine Disruptor Screening Program, and respond to an administrative petition regarding glyphosate before issuing a final registration review decision.

Court Rules in Favor of Organic Hydroponic Producers

The Coalition for Sustainable Organics (CSO) has reported that a three-judge panel of the U.S. District Court in San Francisco affirmed the legality of the U.S. Department of Agriculture to have the authority to recognize and certify growers using hydroponic organic production methods in a ruling issued last month.

Lee Frankel, the executive director of the CSO, stated, “The court stood up for our efforts to make organics more accessible to consumers

on page 8

6 Soil & Mulch Producer News November / December 2022 Soil & Mulch Producer NEWS

Continued

page 4

Continued

from

7 November / December 2022 Soil & Mulch Producer News

Continued from page 6

and not limit them to only the wealthy. Inflation is hitting consumers hard, and innovative and highly productive organic production systems should not be excluded from the market just because a group of growers wants higher profits for themselves.

The decision by the court preserves historically important supplies of berries, tomatoes, cucumbers, peppers, mushrooms, leafy greens, herbs, sprouts and microgreens that are frequently grown using containers or other hydroponic organic systems. In addition, the lawsuit threatened the nursery industry that provides many of the seedlings used by organic growers planting both in open fields as well as greenhouses.”

Frankel was pleased that the court ruling clearly affirmed the legitimacy of hydroponic and container production systems under the Organic Foods Production Act that established the USDA National Organic Program. In addition, the ruling also confirmed that USDA was fully within its rights to reject the petition to ban the certification of operations and correctly followed procedures in its handling of the petition.

The Mulch & Soil Council began in 1972 and is the national association of producers of horticultural mulches, consumer potting soils and commercial growing media. Its mission is to define quality products and promote an open market and fair competition. To learn more about The Mulch & Soil Council, visit mulchandsoilcouncil.org or call 806-832-1810.

8 Soil & Mulch Producer News November / December 2022 Soil & Mulch Producer NEWS

From The MSC Reach More Than 5,000 Mulch, Soil & Compost Producers & Resellers ... Advertise in Soil & Mulch Producer News! Contact Rick or Donna Downing at 440-257-6453

News

9 November / December 2022 Soil & Mulch Producer News www.chromascape.com service@chromascape.com

Mulch & Soil Council Reports Record Attendance

By P.J. Heller

By P.J. Heller

Arecord number of people attended the 51st annual Mulch and Soil Council meeting in Charlotte, NC, which featured programs ranging from women in the industry to new ways to recruit and retain the next generation of employees.

The meeting, held Oct. 4-6 at the Hilton Uptown Hotel, attracted 205 participants, up 18 percent from the previous record of 174 set the previous year.

The meeting came after a tough year for the industry, with sales down as much as 15 percent in the late first quarter and early second quarter of 2022 compared to growth in 2021, a council survey reported.

“The market’s not down, it’s returning to normal,” explained Robert C. LaGasse, noting that sales jumped a whopping 50 percent in 2020 and 2021 combined.

A marginal sales increase of 12 percent in 2021 came on top of a “massive increase” in 2020, when sales jumped by 30 percent to 45 percent.

“Now you’re starting to see a decline” after that 50 percent increase in sales over 2019, said

LaGasse, executive director of the council.

“We take that as an indicator that the market is returning to normal” he said. “2020 and 2021 were abnormal.”

That decline was mainly attributed to softening consumer demand as people resumed other activities as concerns faded about the coronavirus pandemic, LaGasse said.

“A lot of consumers found other things to do with their time as the pandemic receded,” he said. “They got back to normal. They got back to travel. They found more things to with their time and their discretionary spending.

“We think it was a decrease in consumer demand [for mulch and soil products] compared to the pandemic where everyone was held captive and the increase [in sales] went up due to the need to do something while you’re home, the need to occupy your time, the need to grow food,” he said.

The survey of members included sales of bagged and bulk soils and bagged and bulk mulches. The council was still analyzing the data; about 23 percent of respondents reported

Continued on next page

10 Soil & Mulch Producer News November / December 2022 Soil & Mulch Producer NEWS EDGE COLORPRO With unmatched production rates of 500 yards³/hr and high efficiency; the EDGE ColorPRO offers operators the highest return of any coloring system available on the market. 1. INTELLIGENT LOAD MANAGEMENT SYSTEM 2. UNIQUE MATERIAL DETECTION SYSTEM 3. 500 YARD³/HR PRODUCTION CAPACITY PORTABLE COLORING SYSTEM HIGH CAPACITY #UNMATCHEDPRODUTION www.edgeinnovate.com info@edgeinnovate.com +44(0)2887 740525 COLORING

Continued from previous page

a “significant decrease” in sales and 20 percent reported a “somewhat decrease” in sales.

There was also an unusually large number of women from the industry attending the meeting, LaGasse reported. Some of that may have been due to a panel discussion about women in the industry.

“We are seeing more women in the industry, everything from heavy-equipment operators to line managers,” LaGasse said “It’s not just bagging-line people anymore. It’s all up and down the line.

“They are half the population,” he noted.

“We need to explore the unexplored option of bringing more women into the manufacturing process,” he said, adding that women in school typically “don’t think of a manufacturing job in the mulch industry as being a key option, but it is.”

To reach more women, the council is considering putting together a video to show women as young as high school age that a career in the mulch industry is a viable option.

“We [also] hope to make that video available to all the members so when they do job fairs, etcetera, it will show not only the traditional male roles but women in traditional male roles,” LaGasse said.

Another topic at the meeting was a discussion about the “double hazard” of fire.

“Fire has a double hazard these days,” LaGasse explained. “You not only lose your equipment, but you lose production time because you can’t replace it. The wait time for new equipment is ridiculously long just because of supply chain availability. Even if you just need to repair equipment, parts can take forever. It’s more than the traditional loss you would experience from fire. It’s exacerbated by the supply chain interruptions that increase the amount of downtime or loss time that you experience.

“So a minor fire can be a major problem,” he said, adding that supply chain issues were expected to continue for the next two years.

Other topics discussed during the conference included taking charge of business insurance programs and costs. The keynote speaker was Brian Jackson, professor and director of the horticultural substrates lab at North Carolina State University. He discussed current challenges and opportunities in the growing media industry.

Among the challenges he cited was competition from other industries, such as wood pellets and biofuels, and environmental impacts. He also discussed using shredded wood as a replacement or augmentation for today’s hard to obtain peat moss.

“Our industry is on the forefront of global change,” he said. “Global trends based on perceptions, social media, political platforms are helping to steer the future of our industry. Ecological awareness of consumers is increasing, and we now face the challenge of responding to this demand. We must remain both proactive and reactive.”

The council’s 2023 annual meeting is scheduled for Oct. 10-12 in Savannah, Ga.

Grandpa Sol’s Legacy

Dan Sutton, a third grandson of Sol Rexius, serves as senior vice president of the company. He started part-time at the company in September 1978 while he was attending college.

“As a very young child, I always wanted to come back and work for the company,” he says. “It was something I always thought I would do. I didn’t know how or when or what. I knew at some point in time I would like to come to work [here].”

His mother, June Rexius Sutton, was one of three children of Sol and Lillian Rexius. The other two Rexius children were Ray (father of Arlen Rexius) and Marv (father of Rusty Rexius).

In 1959, the three Rexius siblings – Marv, Ray and June -- became partners in the company along with their father. After Sol Rexius died, the company was run by Ray and Marv Rexius and June Rexius Sutton was a limited partner.

“The company started off just as a fuel company and developed over the years,” Arlen Rexius says. “Everybody was using sawdust for fuel. When that went away, we had to invent new things. We kept developing other uses, other soils.

“Twenty years from now, maybe we’ll be making spaceships so people are going to Mars . . . We might be using fumes from composting to power all these electric vehicles and to generate electricity. We’re nimble enough. We’ll keep an eye on the next great thing.”

11 November / December 2022 Soil & Mulch Producer News Soil & Mulch Producer NEWS

Continued

3

from page

EQUIPMENT & PRODUCT SHOWCASE

B.C. Scientists and Wet’suwet’en

First Nation Create Decomposable “Biofoam” Packing Material

Vancouver, B.C. – Thanks to a breakthrough in wood waste research, scientists have developed an alternative packing material that degrades naturally within weeks, according to University of British Columbia (UBC) News

Called biofoam, the material requires little heat and few chemicals to make and can be used as substitute for packaging foams, packing peanuts and even thermal insulation boards. The material is made of forestry waste, much of which has been sourced for the study from trees damaged by wildfires and pine bark beetle infestations.

Styrofoam, the trademarked material commonly used in many products from building supplies to food containers, and as cushioning material in packaging, has been manufactured in the U.S. since the 1940s. The material currently fills up to 30 percent of landfills and can take 500 years to decompose, say the UBC scientists who have shown that biofoam can degrade completely within two months.

The biofoam study went into high gear several years ago when the B.C. Forests Ministry connected the Wet’suwet’en First Nation in central B.C. with University of B.C. researchers. The First Nation’s Yinka Dene Economic Development Limited Partnership saw the value of working with the university team to identify ways of utilizing the wood waste from their tribal lands in Earthfriendly ways. The Yinka Dene group helped to secure provincial government funding and provided raw materials from tribal land forests, located near Burns Lake, B.C. for the research.

With the demonstration phase completed, plans are in the works to open a pilot plant in B.C. There is optimism for future expansion globally one day, too. Under an agreement between the research team and Yinka Dene, the Wet’suiwet’en share intellectual property rights. The pilot project is hoped to begin regenerating First Nations jobs that were lost when the pine beetle epidemic swept through their timber industry. Visit

12 Soil & Mulch Producer News November / December 2022 Soil & Mulch Producer NEWS

www.keithwalkingfloor.com/j-max

us

at

online

www.soilandmulchproducernews.com.

BORN TO GRIND.

Precision Husky Corporation leads the forest products industry, building the most rugged equipment available.

Our horizontal and tub grinders are the most powerful, easiest to use grinders in the industry. They are designed with innovative features and advanced technologies to give you the power and production needed

to tackle the most demanding grinding operations.

We are a family-owned, family-operated company, and we’ve earned our position in the industry by building the highest-quality, most reliable equipment since 1964. Contact us to learn more about our products and to discuss your needs.

13 November / December 2022 Soil & Mulch Producer News P.O. Drawer 507, Leeds, AL 35094 • 205-640-5181 • www.precisionhusky.com • sales@precisionhusky.com

H3060 Horizontal Grinder

MAY WE INTRODUCE SOME OTHER MEMBERS OF OUR FAMILY... Precision Husky PG-5200 / Horizontal FP S&M Producer News Mar-Apr 2022.indd 1 3/14/22 9:37 AM

East Texas Forests Growing and Thriving

Marshall, TX – The forests of East Texas are thriving, thanks to modern forestry practices and a strong forest-products economy, reports Texas A&M Forest Service

Today’s forest health can be attributed to focus on growing higher-quality trees over the past 20-30 years, according to Dr. Aaron Stottlemyer, Texas A&M Forest Service Forest Analytics Department Head.

Dr. Stottlemyer says the trees are better quality and growing faster and faster. That, in turn, translates to a robust forest with benefits for the Texas economy.

In 2021, the state’s forest sector had a total economic impact of $41.6 billion while supporting over 170,000 jobs. The forest-based industry was one of the top 10 manufacturing sectors in the state, and timber ranked seventh among Texas’ agricultural commodities.

An abundance of harvest-ready trees spells investment opportunities leading to increased development and utilization of the resource.

Annually collected information on forest conditions and tree numbers, size and condition helps the Forest Service keep tabs on how much timber is growing versus how much is harvested.

The data collected since 2016 show the growth of commercial timber in Texas outpacing the amount being removed. In fact, figures from forest inventory reports show that enough wood grows in East Texas to fill a logging truck every 19 seconds.

A combination of factors has contributed to the recovery of Texas’ forests over the past several decades: genetic gains from tree improvement programs, the modernization of sawmills that has maximized the amount of lumber produced from logs, stronger markets for smaller-diameter logs, and the recent absence of natural disasters and pest infestations in the forest.

Assessments following Hurricane Rita in 2005 estimated damage to 770,000 acres of East Texas forests, accounting for about six percent of growing stock. Hurricane Ike in 2008 damaged about 450,000 acres of

forestland. The recession in 2008 and drought in 2011 also took a toll on the timber industry.

Since then, the region has not had an event causing major forest damage, which Stottlemyer credits to how well the forests are managed. The right amount of density is protection against high winds and hungry insects, he believes.

The effort to improve tree genetics to meet specific needs such as fast growth, drought and disease resistance and regional adaptability has played a major role in contributing to a robust forest economy.

“We’re able to get more wood — more volume per acre — and we’re able to get that volume sooner,” said Fred Raley, Texas A&M Forest Service Tree Improvement Coordinator and Director of the Western Gulf Tree Improvement Program. “We’ve enhanced forest productivity in terms of both time and quantity. We’re getting product to the market quicker, and we’re getting more tonnage per acre.”

The ability to get higher yield on less land allows timber owners to focus on acreage that is more productive, making way for restoration-based activities elsewhere.

More than 90 percent of the state’s 12 million acres of productive timberland is privately owned. Those landowners rely on the forest industry to support their land management activities.

Texas A&M Forest Service experts work with landowners to assess the risks of wildfires, pest infestations and other threats. A robust forest industry that turns timber into forest products generates the return needed to offset some of the costs of risk management, as well as replanting.

The forest economy is not without challenges, including an ongoing labor shortage that has contributed to a downward trend in harvesting.

According to a Texas Forestry Association spokesperson, an oversupply of timber could lead to a changing landscape in the forestry industry, with some landowners opting to move into livestock or hay production in an effort to make a return on their land investment.

14 Soil & Mulch Producer News November / December 2022 Soil & Mulch Producer NEWS LEADING EDGE SCREENING SOLUTIONS MADE IN THE USA www.spaleck-us.com 412-294-2494 COMPOST BIOMASS GREEN WASTE ORGANICS

Blah...Blah...Blah...

15 November / December 2022 Soil & Mulch Producer News Our Vision Colors Yours! 615-443-0345 Ext 103 OHIO | TENNESSEE | TEXAS | info@agricoatings.com | www.agricoatings.com All the mulch colorant companies are saying the same thing: Ours has better coverage, Ours has better weatherability, Ours is more brilliant, looks better...blah..blah..blah We at Truly believe WE make THE Best High Performance Mulch Colorant! Prove it to yourself. Contact us to set-up a trial run.

Hurricane and Human Waste Become a Soil Booster for Citrus Orchards

Tampa, FL – Composted human waste and hurricane debris can make a potent fertilizer for ailing citrus trees, reports Fox Channel 13 News The Category 4 Hurricane Ian made landfall Sept. 28 on Florida’s Gulf Coast before crossing the state, leaving huge amounts of trees, brush, and stumps in its wake. Hillsborough County Solid Waste has been taking in the wood debris and other organic matter, grinding it, and sending the material to the county’s Biosolids Composting Facility where it is processed with human waste.

A Newberry, Florida-based Life Soils is turning the compost into a potent fertilizer that can be used in citrus orchards. A company spokesperson said the product can improve soil properties to help the trees resist disease.

For close to 20 years, citrus groves in the U.S. have been severely hurt by Huanglongbing (HLB), also known as citrus greening disease. The disease is among the biggest threats to the U.S. citrus industry because infected trees produce fruits that are green, misshapen, and bitter tasting, though harmless to humans. Eventually, the infected trees die.

According to the Life Soils website, the compost product adds organic matter that improves soil moisture holding capability, cation, and pH balance. It also can be used as part of soil remediation process for land that has been stripped of its nutrients.

Meanwhile, there’s another approach in the works to bring an end to citrus greening. A Purdue University researcher has received a $1 million grant from the U.S. Department of Agriculture’s National Institute of Food and Agriculture to support developing nanocarriers as an antibiotic delivery system to help plants fend off the disease.

16 Soil & Mulch Producer News November / December 2022 Soil & Mulch Producer NEWS

Spring time is mulch time, and all about productivity. You need to produce tonnage and you need to produce it now. That’s what the Diamond Z DZH4000TK is designed for ... and does.

The DZH4000TK will out grind competitor’s comparably sized machines. The C18 Caterpillar engine combined with our aggressive down-cut mill delivers production rates up to 120 tons per hour. The smaller stature offers easy transportability. Friendly operation, ease of maintenance and attention to detail are throughout ... hallmark traits for all Diamond Z grinders.

As a track-mounted horizontal grinder, the DZH4000TK allows you to operate just about anywhere a portable grinder cannot. With up to 755 horsepower, production capacities up to 120 tons per hour, and an innovative, operator-friendly design, the DZH4000TK is the simple horizontal-tracked choice for your most difficult jobs.

DZH4000TK-THEMULCHMASTER GRINDINGSIMPLIFIED

17 November / December 2022 Soil & Mulch Producer News

Caldwell,

208.585.2929 www.diamondz.com Visit www.diamondz.com to see these tub and horizontal grinders and our complete line: 1352B 1463B DZH3000 1248BTK DZ800TKT DZH6000 ® ™ Soil Producer.indd 1 1/29/2020 2:00:45 PM

DIAMOND Z GRINDERS

Idaho

California State-mandated Food Waste Recycling is Yielding Results

Santa Cruz County, CA – Since beginning a composting program last January, Northern California communities in Santa Cruz County have diverted close to 50,000 tons of food scraps from landfill, according to a Pajaronian.com article.

Historically, as much as 44% of material hauled to the countyrun Buena Vista Landfill has been food, according to a Santa Cruz County Recycling & Solid Waste Services spokesperson. The landfill is slated to close in about eight years.

In effect since January 1, 2022, California law (SB 1383) targets a 50 percent reduction in the landfilling of organic waste in 2022. By 2025, that reduction target is 75 percent. The law requires every jurisdiction in the state to divert food waste from landfill to organics recycling.

The law requires jurisdictions to provide organic waste collection services to all single-family and multifamily residences of all sizes and businesses that generate organic waste. Single-family and multifamily complexes are required to recycle both green waste and food waste, as well as other organic waste materials.

Santa Cruz County began collecting food scraps from a handful of restaurants and businesses for a small-scale composting operation at the landfill in 2008. Today, the largest volume of food waste collected is trucked to Monterey Regional Waste Management District, where it is processed. From there, Salinas-based Keith Day Company sells the compost to commercial agriculture and retail landscape businesses.

While most cities and the entirety of the County’s unincorporated region is participating in that program, the City of Santa Cruz—with its own landfill and recycling center—has taken a different approach.

Food waste collected through its curbside recycling program is hauled to the City of Santa Cruz Resource Recovery Facility where it is screened for contaminants and pre-processed. The resulting ground food mash—food scraps including vegetables, fruits, meat scraps, dairy products, seafood, and solid fats – is then transferred to either of two facilities in Santa Clara where it is made into pellets for pig feed, biogas and fertilizer.

UMass Researchers Receive $2.36 Million Federal Grant to Investigate Necromass

Amherst, MA – A $2,358,722 million grant from the U.S. Department of Energy (DOE) will support an interdisciplinary team of researchers to investigate a poorly understood, yet crucial, ingredient of the Earth’s soil: necromass.

Necromass, the once-living decrepit organic matter that gives soil much of its fertility, is absolutely essential for life on earth because it decays into the carbon that new plant life needs to thrive.

The grant was awarded to Kristen DeAngelis, a University of Massachusetts Amherst microbiologist who is leading the investigation.

Until recently, necromass was thought to have come exclusively from dead leaves, rotting bark, decaying grasses and the litany of things that we can observe rotting on the ground.

Dr. DeAngelis says that soil chemists found something else in the soil: the chemical signatures of microbes. In fact, soil is alive with billions of microbes. And since death follows life, it turns out that the soil is also composed of uncountable masses of dead microbe bodies—so many that microbial necromass accounts for about half of the total necromass content in our soils.

However, microbial necromass is extremely sensitive to further decay and loss from the soil as carbon dioxide. Why, and how to stabilize microbial necromass so that it isn’t lost, remains a mystery.

DeAngelis is leading an interdisciplinary team that will embark on a series of experiments over the next three years to determine the role that soil minerals play in the persistence of microbial necromass.

The experiments will first focus on identifying which living microbes convert the four basic necromass biomolecules—carbohydrates, lipids, nucleic acids and proteins—into soil elements. Next, the team will define what combinations of microbes and minerals drive necromass decomposition. From there, the team will trace the food webs that necromass molecules travel as they support the Earth’s various life systems. The combined study results will be used to refine a series of models that will help the scientific community to better understand how soils form, persist and decay.

The idea for the investigation developed when UMass microbiology graduate student, Melissa Shinfuku, began her research on global climate change and necromass. It was then that Shinfuku and DeAngelis realized that dead microbes are fundamental to the Earth’s carbon cycle

Product / Equipment Profiles

U.S. Pride Products Releases Two New Portable Trommel Screens

Hammond, WI - U.S. Pride Products, a manufacturer of cone screw log splitters, is proud to announce the release of two new portable trommel screens built for the HF-300 and HF-800 cone screw powerheads. The new trommel screens expand the capabilities of both HF splitters to provide a low-cost screening solution that customers have been asking for. These new trommel screen attachments allow bulk material like mulch, compost, sand and topsoil to be separated efficiently by a trommel that is easily transported between jobs.

U.S. Pride trommel screens are built with all steel construction and simply bolt to their respective HF powerheads. Screens are easily replaceable and are available in a range of hole sizes to separate bulk material. Like all equipment from U.S. Pride Products, both trommels are made in the U.S.A.

TR-300 Trommel Screen: The TR-300 is the smaller of the two trommel attachments and mounts on the HF-300 cone splitter powerhead. With a capacity of one yard, the TR-300 was designed and

built to screen smaller volumes of material. This unit typically runs on a mid-sized skid loader, or smaller wheel loader.

TR-800 Trommel Screen: Stepping up in size to a total capacity of 3-1/2 yards, the TR-800 is built to screen larger material volumes. TR-800 trommels mount on either of the HF-800 cone splitter powerheads which are usually run on large skid loaders, excavators and wheel loaders.

For more information on U.S. Pride Products trommel screens or cone screw splitters, please visit: www.USPrideProducts.com.

18 Soil & Mulch Producer News November / December 2022 Soil & Mulch Producer NEWS

With time being so valuable, it is more important than ever to invest in equipment that will save time and money. At Bandit, we pride ourselves by producing tough, reliable, easy to maintain equipment that will serve you on a consistent basis reducing manual labor and unnecessary downtime. Therefore, allowing you to move on to the next job quicker or enjoy some well-deserved time off. If

19 November / December 2022 Soil & Mulch Producer News

you

tried a Bandit unit for your operation, please contact

Bandit dealer

or

our

we

assist you!

sales,

service

THE BEAST® 2460XP 24” Capacity Horizontal Grinder

haven’t

a local

, email marketing@banditchippers.com

visit

website www.banditchippers.com and

will be happy to

A highly trained dealer network with dedicated parts,

and

personnel are committed to providing top notch support from the initial purchase through the entire life cycle of the machine increasing uptime and reducing downtime.

Ins I de Th I s Issue PRSRT STD U.S. Postage PAID Cleveland, OH PeRmIT #1737 6075 Hopkins Road • Mentor, OH 44060 Ph: 440-257-6453 • Fax: 440-257-6459 Email: downassoc2@oh.rr.com VOL. XVI NO. 6 NOV / DEC 2022 www.SoilandMulchProducerNews.com Grandpa Sol’s Legacy Carries On at Rexius PAGe 1 News From The Mulch & Soil Council PAGe 4 Mulch & Soil Council Reports Record Attendance PAGe 10 B.C. Scientists and Wet’suwet’en First Nation Create Decomposable “Biofoam” Packing Material PAGe 12 East Texas Forests Growing and Thriving PAGe 14 Hurricane and Human Waste Become a Soil Booster for Citrus Orchards PAGe 16 UMass Researchers Receive $2.36 Million Federal Grant to Investigate Necromass PAGe 18