McPherson College takes their automotive preservation to the air...literally. With the help of a meticulously designed automobile rigging system, vehicles can be suspended with precision & safety, creating a stunning

overhead display with not one, but two vehicles hanging mid-air in the facility for many onlookers to pass underneath. This process combines mechanical ingenuity with rigorous safety standards and here is how it works.

Before a single bolt is tightened, safety is paramount. The system is designed for vehicles up to 5,500 lbs., and only qualified operators are authorized to use it. Annual inspections, attention to OSHA standards, and an absolute ban on lifting people or modifying the rig are foundational rules. Tire pressure checks and hardware integrity are non-negotiables.

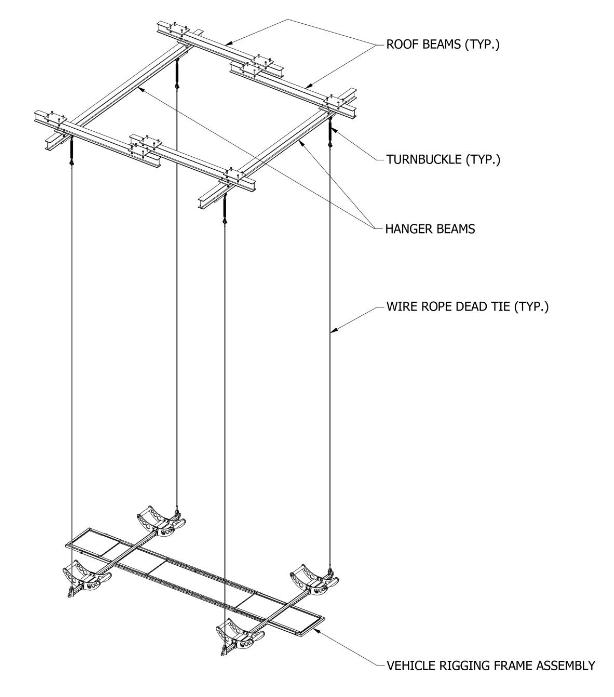

Everything starts from above. The rigging process begins by measuring the vehicle’s wheel base and adjusting the hanger beams, attached to fixed roof beams, to match that dimension. Chain hoists and safety “deadties” are installed next, forming the literal backbone of the lift. These components work together to support the vehicle from the atrium’s overhead structure.

With the hanger beams in place, the vehicle is prepped. It’s shifted into gear or park, the parking brake is engaged, and floor jacks lift the car about a foot off the ground onto jack stands. From here, a telescoping frame is aligned under the wheels, rear frame first, followed by the front. Wheel saddles are secured to hold each tire in place. Then,

Now comes the big lift. Chain hoists raise the vehicle until the dead-ties can be pinned securely to the rigging frame. Once locked in, the weight is shifted off the chain hoists and onto the static dead-tie system, which is then leveled using adjustable turnbuckles. The final touch: safety wiring to prevent any slippage. The vehicle now floats above the floor, safely, securely, and displayed.

using chain hoists, the rigging frame is raised to gently press against the tires, not to lift them...yet. High-strength ratchet straps are then wrapped tightly around each wheel and saddle, locking the tires in place. After tightening all bolts and (optionally) installing drip trays, the vehicle is ready to rise.

*Video Credits to McPherson College

McPherson wanted the cars to be titled for a more dynamic look, this system allows for angles up to 10 degrees. This requires precise adjustment (or fabrication) of dead-tie lengths and an understanding that each wheel’s

Lowering the car is a simple reversal of the process. Unfasten, lower, unbolt, and roll away. The rigging system is as much about seamless removal as it is about elevation. It won’t be lowered unless McPherson is wanting to swap out their chandelier display, but I think they chose two magnificent cars that compliment each other. They don’t foresee changing them often if they do.

suspension compression will vary; meaning, the car won’t sit as it does on the ground. But when done correctly, it adds a whole new dimension to automotive display.

The team effort on this project was exemplary and the display system shows what happens when excellence meets historical preservation. This custom-built solution allows vintage vehicles to be suspended securely and artistically, transforming static cars into airborne works of art. It’s not just about lifting a load; it’s about elevating the experience of automotive storytelling. Every detail, from the precision-aligned beams to the calculated dead-tie angles, speaks to Dondlinger’s craftsmanship and dedication to safety.

The system ensures that each suspended vehicle is not only visually stunning but also rigged to the highest structural standards. More than a display system, it’s a showcase of our ability to take on unique challenges and deliver solutions that go beyond the expected. In suspending these classic cars, we aren’t just lifting vehicles... we are lifting the possibilities of what construction can do for museums, institutions, and experiences that demand something extraordinary.