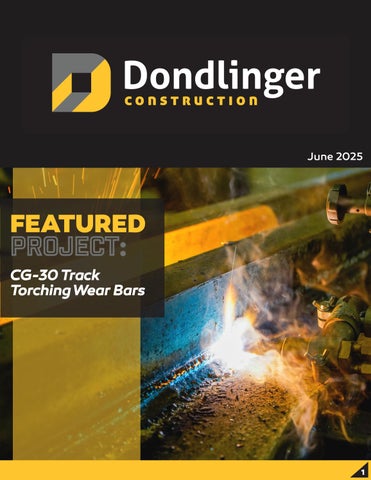

FEATURED PROJECT:

CG-30 Track

CG-30 Track

MAXIMIZING PRECISION & EFFICIENCY WITH THE CG-30 GAS CUTTING TRACK TORCH

In the demanding environment of industrial welding and heavy equipment maintenance, efficiency, precision, and reliability are critical. One tool that’s proven to be a game-changer in our weld shop is the CG30 Gas Cutting Track Torch—a versatile and dependable piece of equipment ideal for both long, straight cuts and curved profiles. Recently, the CG-30 was utilized in a project involving the removal and replacement of wear bars on crane tracks.

The CG-30 is designed for multi-use applications, making it ideal for a variety of cutting tasks; not only for long, straight cuts, but also for complex round cuts, offering flexibility that would be hard to achieve with manual cutting methods. This torch rides along a rigid track system, ensuring clean, precise lines with minimal operator input, which is essential when working with thick and hardened industrial steel components, such as crane track wear bars.

Before any cutting could begin, the 2-inchthick wear bars required a two-hour preheat process. This “down and back” pass was critical to bringing the material up to temperature and preventing cracking or warping during the high-temperature cut. The CG-30 track torch operated at an estimated 1,600°F during the cutting phase—hot enough to slice through the wear bars with consistency and accuracy.

Following removal, the wear bars were reinstalled using a hollow wire arc spray transfer weld—a modern and efficient welding technique. This method involves the transfer of fine, molten droplets across a stable arc in a controlled spray pattern. Unlike traditional stick welding, arc spray transfer produces minimal spatter and

However, it’s worth noting that the CG30 has a maximum cutting temperature capability of up to 6,000°F, giving it the ability to handle a wide range of materials and thicknesses. From start to finish, the full removal process of the wear bars took approximately four hours, showcasing both the speed and power of the CG-30 in handling heavy-duty materials.

results in a cleaner, more uniform weld. The choice to use arc spray transfer was driven by its speed and consistency. Compared to the slower, more labor-intensive rod welding technique, this method allowed the team to complete the re-installation in about one day, significantly reducing downtime and increasing shop productivity.