PINCH yourself, grasp the smelling salts and rub your eyes in the style of a Tex Avery cartoon. There has been “a significant improvement to the whole [UK cycling] market”. That’s according to the latest statistics from the Bicycle Association, which notes total sales are up 12% and – you may need to sit down – there has been a value rise of 13% for mechanical bikes. Proof-positive that the channel is finally clearing overstocks and is firmly “on the mend”? It would appear so.

We sincerely hope that your till receipts, bookings and order numbers reflect these findings from the BA. Maybe they will also mean money is more forthcoming when you’re chasing invoices and payments.

These positive market results coincide – and are doubtless partially at least due to – a significant upturn in the UK’s meteorological fortunes, with large swathes of the UK enjoying a warm and dry spring so far. It’s perhaps helpful to be reminded that last year was pretty wet (particularly in England’s populous South) and that damp weather came (in ’24) as the industry was direly in need of tailwinds to help it get through tricky times.

Back to those BA stats: Sales were up 14% for eBikes, 9% for PAC and 14% for services, in March 2025. Positive signs indeed and while many of us will be watching them with caution, there’s a fair chance they are a genuine sign of the recovery. It would be remiss not to at least mention that many market challenges remain, but let’s have our moment.

However, if recent years have taught us anything, it is that the market (and weather) changes. Just like the lockdown boom, these things do not last forever. If we are in line for a long-awaited upturn in fortunes, we can’t squander this opportunity to make the industry, and the businesses within it, more robust, nimble and – wherever possible – not put all our eggs in one basket. The industry needs to be sustainable, in all senses of the word. We all want to be able to pay our mortgages and rent not just when things are looking up, but also when things inevitably get a bit leaner again at some point further in the future. It is now that the pressure is really on the business leaders, owners and CEOs: to ensure a robust future for themselves, their brands, employees and local business ecosystems.

jon@cyclingindustr y.news

Publisher

Jerr y Ramsdale jerr y@cyclingindustr y.news

Editor Jonathon Harker jon@cyclingindustr y.news

Sales Manager Lloyd Ramsdale Lloyd@cyclingindustr y.news

Head of Produc tion Luke Wikner production@cyclingindustr y.news

Designers

Dan Bennett Victoria Arellano

cyclingindustr y.news

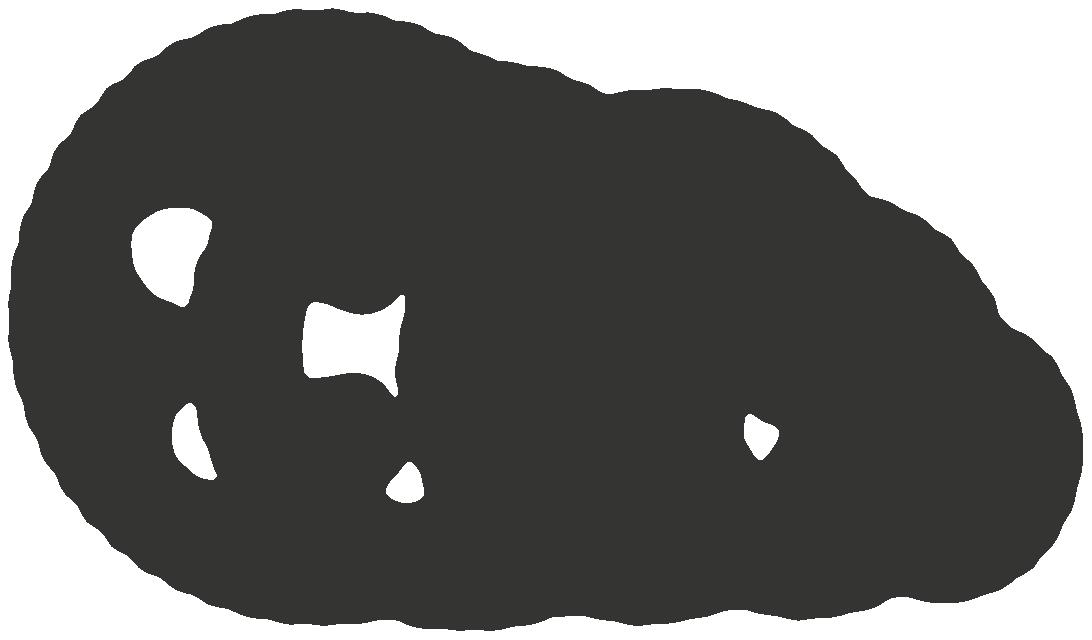

With the full Cycling Industry News 2025 Market Data report set to appear in retailer inboxes shortly, CIN digs into some of the insights, including bike shop views on current trading challenges and some of the policies the industry could be pushing for...

Overheadcostsrisingareof

signi�cant concern to ability to trade

I have had an enquiry about the sale of my business to a bike brand

I have struggled to �nd or keep sta�

I have given sta� pay rises

I have given sta� pay rises in line with or above in�ation

I have been unable to give sta� a rise

I am holding cash back

If available, I would join a buying group

Ihaveturnedtosecond hand renovation and sales

I have adjusted my main suppliers year on year to source goods

I am concerned by brands cuttingstoresinfavourofB2C

I see a degree of inevitability competing with brand-owned stores in future

I may sell my business

I am planning to attendtradeevents

Consumers are spending freely on bike goods

Consumers are holding on to their cash, or remain discount orientated

I have hired or will hire addition workshop sta�

WITH PROLONGED CHALLENGING TRADING CONTINUING, WHICH APPLY HEADING INTO 2025?

ANALYSIS

Clearly, the economy is due a turnaround and the cycling industry, like many others, has been gritting its teeth and awaiting this for what seems like an awfully long time.

Last year, the chief concern in our list of trading challenges was “consumers holding onto their cash or remain discount orientated”. This year too, there is consensus that this is the biggest challenge that the trade has to contend with. Likewise, the rise of overhead costs that are a significant concern on ability to trade is factoring high among concerns. Perhaps that is no surprise with a number of tax rises arriving in the current financial year adding costs to business. We’re not qualified to provide future economic insights, but with interest rates lowering and the Bank of England signposting that further cuts are on the way, there does at last seem to be some relief on the way in cutting borrowing costs and indeed freeing up consumer budgets slightly. But the gains have been slow paced, with the economic ship taking its sweet time to set a course for growth.

A further indicator is the moderate increase in shops giving staff pay rises to cope with inflation.

Aside from those economic-related concerns, there is evergreen concern over brands cutting stores in favour of B2C. There is, in 2025, an awful lot of nuance in a brand’s route to market, with some successfully combining B2C with the traditional shop model and various variations of that. There is undoubtedly still an image problem for such multi modal approaches, however.

You can see some positive points in the results, if you look closely enough. Compared to the previous year, there has been a slight increase in the number of shops who have found that their customers are “spending freely on bike goods”. Other stubbornly stable numbers can be seen as positives too, with similar numbers of bike shops looking to hire additional workshop staff in 2025, despite endurance of the prolonged economic woes.

There’s a slight drop in the number of respondents that are adjusting their main suppliers year-on-year to source goods. Itself not a huge surprise but a reminder that the big administrations within the industry appear to be in the past and there is market stabilisation. Perhaps not time to crack open the bubbly yet, but a positive indicator of the market, nevertheless.

OF

We’ve dedicated a bit of time in recent months to contemplating the kind of policies and options that would make a big difference to the cycling industry. Last issue, regular columnist Mark Sutton committed himself to a cycling manifesto for the next five years and elsewhere in the same issue we made the case for the trade to switch from defence to attack: that despite the market challenges facing it (and there are many), the industry must continue to push hard for support, not least because it facilitates the improved wellbeing, health and economy of the nation.

With that in mind, what are the kinds of things that the UK’s independent bicycle retailers believe are worth pursuing and the policies that would make the difference to the industry and therefore the nation?

Here, we limited shops in the survey down to three options, and chief in popularity of those was as a national UK eBike subsidy scheme, with over half of respondents believing such a thing would have a favourable impact on their business.

We’ve seen such subsidy schemes have a profoundly positive impact on other northern European nations, like France. There, an electric bike subsidy scheme grew the market from around 150,000 units – akin to the size of the UK’s electric sector – to a whopping 750,000 units in just over five years.

There’s a precedent too – the UK has already used an overseaspioneered initiative (from France, no less) in recent years – namely the bike repair voucher scheme enacted during the lockdown –which proved wildly popular. Doubtless the powers that be would

point to the fact that the UK already has the cycle to work initiative to help the public (those employed in stable roles) to buy a bicycle, but with reform on the agenda there, this eBike subsidy might have a look in.

Likewise though, the government might point to the relaxation of tariffs on eBikes from China as a policy change to boost eBike numbers in this nation. In fact, this could be the year of the eBike, if you were feeling argumentative. But how the UK cycle trade will benefit from that relaxation of tariffs, other than presumably more eBike users, remains to be seen. Going back to the French approach, there was an effort to make sure ‘professional and identified’ retailers or bodies benefitted from its eBike subsidy scheme.

Should further policies be enacted to boost eBike ownership in the UK, we can surely expect eBikes to make good on their promise to take a larger share of the market. Something that is taking place (ironically) slowly here compared with other European nations.

The trade is also keen on the idea of funding UK cycle innovation to grow jobs. That’s a potentially interesting area that deserves fleshing out further. The UK is not short of forward thinking innovators, with manufacturing on British shores tending to focus on high value, intricate production, with mass production of products seen as largely unviable. We’ve yet to see a UK version of say, Portugal’s bike valley, emerge. But the jobs market is a politically important area and perhaps the right argument, posed in the right way might be used to boost the industry.

VAT removal on childrens’ cycles was a less popular option, possibly because this part of the market is traditionally less popular with independent bike shops, being a heavily competitive area dominated by online and high street names like Halfords, Smyths and others.

Bicycle frames have been welded together since the first metal models got off the drawing board in the 1800s. So, LOCTITE and Faction Bike Studio’s claim to have “redefined frame construction” by eschewing welding my well be judged to have ripped up the bike production rule book…

Innovation continues, as has been noted many times, despite the cycle market itself operating in sub-optimal conditions. Elsewhere in these pages CIN’s correspondent points out this finding in industry heartland show Taipei Cycle (pages eight onwards). Sometimes innovations get to the core of bicycle construction –even to how bikes are put together.

Faction Bike Studio and Frameworks teamed up with adhesives specialist LOCTITE to evolve bicycle frame construction and assembly beyond traditional welding techniques. The collaboration embraced cutting-edge adhesive bonding, delivering enhanced durability, precision and weight reduction.

Bicycle frames have traditionally been welded together, a process that presents several challenges, including alignment difficulties, increased weight and potential structural inconsistencies. Frameworks, a company owned by USA National Cycling Champion Neko Mulally, sought a solution that would streamline production while enhancing frame accuracy and performance.

Through close collaboration with LOCTITE’s application engineering

team, Faction Bike Studio introduced LOCTITE’s advanced adhesive bonding technology to replace welding in the construction process. LOCTITE provided material data properties and technical support to ensure the bonded frames could withstand the rigorous stresses and loads experienced in highperformance cycling.

Michael Feeney, Application Engineer at Loctite, says: “Our team worked closely with Faction Bike Studio and Frameworks to ensure the adhesive bonding process met their performance needs. By combining their expertise in bike design with our deep knowledge of adhesives, we’ve created a solution that enhances precision, reduces weight, and simplifies assembly, without compromising strength or durability.”

The adoption of LOCTITE’s bonding technology delivered a range of advantages for Frameworks and Faction Bike Studio:

• Improved production efficiency –Adhesive bonding speeds up and simplifies assembly, reducing the complexity and time required to manufacture each frame.

• Enhanced accuracy – Unlike welded

frames, where alignment can be a challenge, bonded frames maintain precise pivot locations and design specifications.

• Weight reduction – Eliminating welds enabled Frameworks to reduce overall frame weight, a critical factor in high-performance cycling.

• Increased durability and performance

– The bonded construction method resulted in a frame that is not only lighter but also more resilient and responsive on challenging terrains.

For Neko Mulally and his team at Frameworks, the transition to LOCTITE’s adhesive bonding has been a game changer. The precision of the bonded frames has transformed the assembly process into a seamless operation, eliminating previous headaches associated with welding.

“The benefits we were chasing were really in the ease of construction and accuracy of the frame. Bonding has not only simplified the process but also allowed us to take weight out of the frame, which is a major advantage,” said Mulally. “Working with LOCTITE has been so refreshing. Their engineers collaborated closely with us to develop the best possible solution for making the strongest and most precise bicycle frames.”

www.henkel.com

For more on LOCTITE’s partnership with Frameworks and Faction Bike Studios, visit:

Taipei Cycle Show

As the first major global event on the bicycle calendar, Taipei Cycle 2025 set the tone for the months ahead. Though the threatened tariffs had not yet come into force, their mere presence already signalled new challenges on the horizon. Despite this, the show also offered reasons for cautious optimism – from returning international buyers to signs of a slow recovery in demand. Cycling Industry News reporter Werner Müller-Schell was on the ground to capture the shifting dynamics at the heart of the cycling world

The phrase “back in the saddle” is well known in the cycling world. Often used after a professional rider comes back from injury, a dip in form, or a lengthy absence from competition, it signals a tentative return to rhythm, stability and purpose. But the expression isn’t limited to sport – the global cycling industry, too, is hoping it holds true in 2025. Following more than two years of painful correction after the COVID-19 boom, the sector is trying to find its footing once more. Warehouses remain overstocked, sales are still unpredictable and the optimism of the pandemic era feels like a distant memory. For this very reason, the industry is keeping a close eye on the earliest signs of recovery – no matter how faint. In this

context, this year’s Taipei Cycle Show, held 26-29 March, carried extra significance. More than just a trade show, it became a litmus test for the mood and direction of the industry.

There were good reasons to be hopeful. In the run-up to Taipei Cycle 2025, signs of recovery had become more common. Big Taiwanese manufacturers like Giant, Merida and KMC reported falling inventory levels and a slow but steady return to normal order volumes. But on the opening day of the show, fresh export data revealed the ongoing fragility of Taiwan’s bicycle industry. According to the Taiwan Bicycle Association (TBA), overall bike exports dropped by 31.3% in 2024 – falling below the symbolic

On the floor: Once again, the economy was the main talking point – just as it was in 2023 and 2024

mark of one million units. eBike exports, once a key growth driver, fell by 47%. The value of these exports dropped too: down 25.7% for regular bikes and 44.6% for eBikes. These aren’t small changes. They show that the industry is still dealing with the fallout from the pandemic boom. Even parts suppliers – usually more stable – saw a 17.5% drop in export value. The message of these numbers was clear: oversupply has hit every part of the supply chain, from OEMs to small suppliers. Therefore, it was no surprise that, once again, the economy was the main talking point at Taipei Cycle – just as it was in 2023 and 2024.

Against this backdrop of economic uncertainty, Taipei Cycle 2025 managed to strike a surprisingly constructive tone. While no one expected miracles, there was a marked shift in energy and engagement compared to previous editions. With 980 exhibitors from 35 countries, and nearly 17,000 visitors from around the globe, the show reaffirmed its role as the industry’s most important early-year gathering – particularly for Asian and European B2B markets. The show’s four official themes – Smart Cycling, Innovation Drive, Green Forward and Cycling Ecosystem – signalled an industry in search of direction, but not short on ideas. On the floor, there were fewer grand unveilings than in precrisis years, but a clear focus on incremental innovation and product refinement was evident. The message

“between the booths”: for many brands, 2025 is not about revolution but recovery. That became clear during conversations with show participants. “From what I’ve seen, the eBike market is slowly finding its way back to steady growth in 2025 – just at a more cautious pace,” said Shawn Lin, Marketing Manager at Taiwanese drive-unit specialist Hyena E-Bike Systems. “Brands are already talking about, or even working on, new projects for 2026 and 2027, but they’re being careful – launching small production runs to test how the market reacts before deciding on their next move. “This cautious strategy is particularly tough on suppliers who are used to managing large OEM/ODM orders. Now they need to adapt by offering more standardised products, quicker turnaround times, and support for smaller volumes – to match the needs of brands that are working with tighter budgets. “So in my view, it’s too soon to call this a recovery. The market still needs time to settle after such a major shake-up,” he concluded.

Min Chou, Sales Manager at Taiwanese manufacturer Yota Cycles, has noticed a clear shift among many brands towards value-driven innovation. “Instead of launching lots of new SKUs, brands are focusing on improving their existing platforms,” she said. Despite the export difficulties in 2024, she believes the Taiwanese bicycle industry is on the rebound. “Premium models and strong US demand for mid-range bikes are signs of a recovery in 2025 –helped by Taiwan’s tariff advantages over China. We’re expecting 2026 to be even better, as global markets stabilise and new product cycles drive growth,” she added.

One of the most noticeable trends on the show floor was the sheer number of eBike brands and component suppliers competing for attention. What started as a small niche led by a few high-end names has now become a fiercely competitive market. “E is the new normal – and not just for eBikes,” said industry consultant Nicolas Le Carré. “It’s everything electronic now – drivetrains, dropper posts, you name it. And it’s not just the premium brands anymore. New players, including many from China, are really stirring things up. “The number of companies offering eBike motors is astonishing. Everyone wants a slice of the market – but the big question is: how many of them will still be here in a few years?”

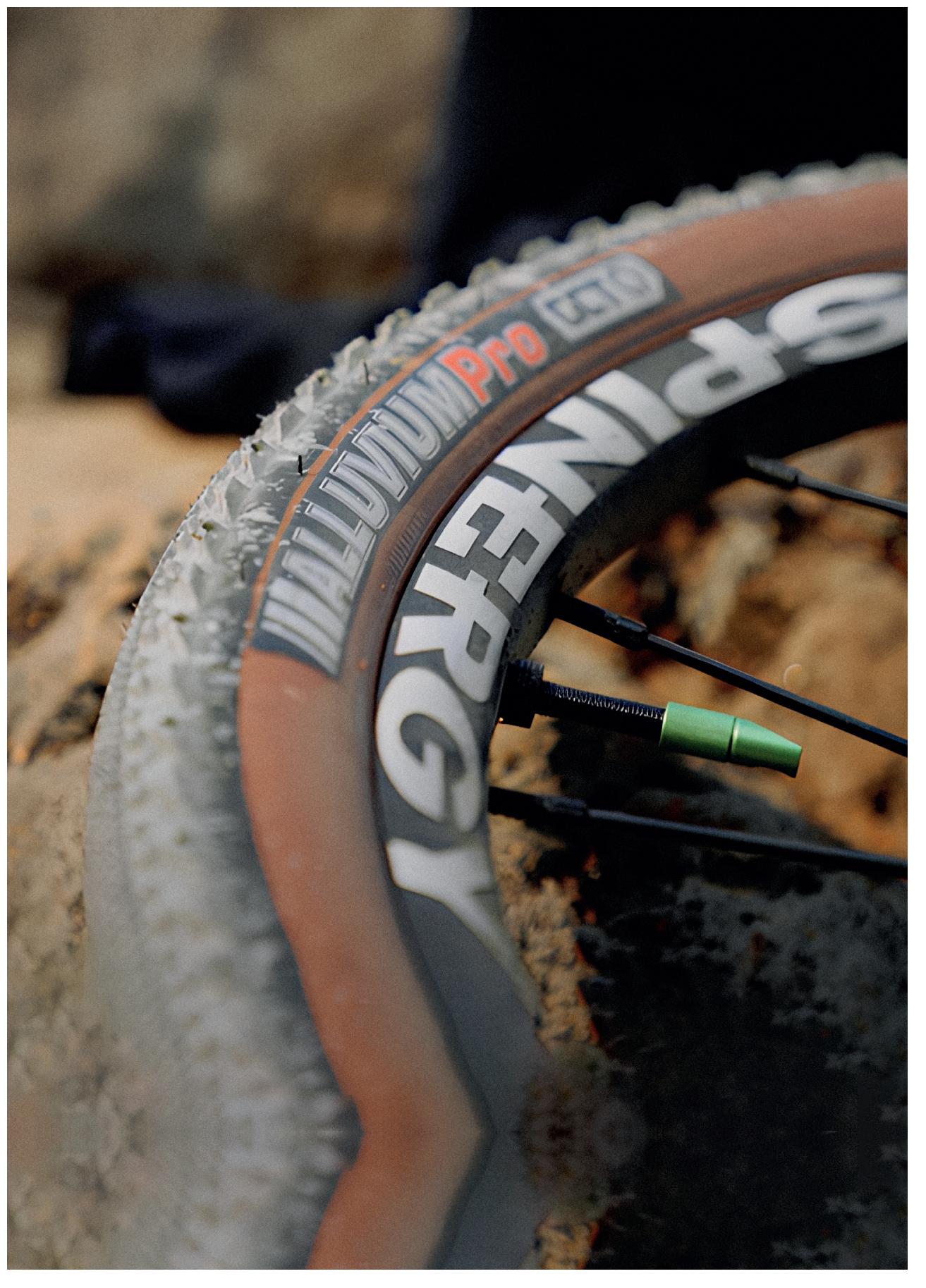

A subtle but intriguing reveal at Taipei Cycle 2025 on the product side was the introduction of 32-inch products for MTB applications. Formula presented a prototype carbon MTB rim built for 32-inch wheels — a potential new standard for mountain biking. Paired with matching 32-inch tyres from Maxxis, this oversized setup hints at future trends in geometry, speed and performance. While still in the early stages, the idea of a 32-inch MTB stirred curiosity among both media and product managers. Whether this gains traction or not, it showed that innovation in bike formats isn’t slowing down — even in a year full of challenges.

Very noticeable in Taipei was the growing importance of ESG (Environmental, Social and Governance) as a key factor in design and procurement. What used to be

confined to sustainability reports is now shaping how products are developed and how suppliers are chosen.

“Customers are taking ESG more seriously – designing with circularity, recyclability and supply chain transparency in mind,” said Amy Shih, Marketing Manager at component maker Nuvo. “Our fully recyclable booth wasn’t just for show – it reflects how we operate, from trade fairs to production,” she added. There were plenty of examples. Exhibitors like Schwalbe, Vittoria and reTyre showcased tyres made from alternative materials, while Giant presented a balance bike made mainly from recycled carbon fibre. “We saw real interest – customers asked about recyclability, packaging, and energy use. Sustainability isn’t just a talking point anymore; it’s becoming part of the product spec,” Shih said.

The shift towards ESG was also formalised through the growing influence of the Bicycling Alliance for Sustainability (BAS) – an alliance of leading Taiwanese bicycle manufacturers committed to promoting sustainability in the cycling industry. Its ESG Global Initiative Forum, held during the show, brought together over 150 delegates and showcased the sector’s increasing alignment on environmental and social goals. BAS now has 82 member companies, 88% of which are actively tracking their carbon emissions. A key milestone was the introduction of a new Human Rights Code of Conduct, offering a framework for responsible business practices. As Giant Group Chairman Young Liu put it: “We’ve moved beyond commitments – now we focus on implementation.” “The goal for the Taiwanese bicycle industry is clear,” said BAS Chairman Charlie Liu. “To lead the global bicycle

On the floor, there were fewer grand unveilings than in pre-crisis years, but a clear focus on incremental innovation and product refinement was evident

industry towards true sustainability – especially in the area of green bike production.”

While stabilising inventories and cautious innovation gave reasons to be hopeful at Taipei Cycle 2025, geopolitics served as a stark reminder that external shocks could still derail the industry's fragile recovery. Chief among these concerns was the threat of renewed US tariffs. Trade measures linked to the administration of Donald Trump loomed large over the show, creating a sense of uncertainty that many exhibitors found unsettling. Although the full details remained unclear at the time, the anticipation alone had already influenced behaviour. Several US buyers reportedly cancelled their flights to Taipei last-minute. “Agreements made today for MY 2026 orders might be worthless in two months if the USChina trade war flares up again,” one exhibitor said. “In today’s geopolitical climate, trade policy could reshape supply chains and pricing strategies in ways that affect the entire industry,” added Nicolas Le Carré.

Taiwanese investment strategist Elisa Chiu echoed these concerns, calling the new tariff regime “a direct challenge not only to operations but to long-term strategy.” While Taiwan currently enjoys a lower base tariff than Vietnam –32% compared to 46% – the situation is far from straightforward. “Vietnam has become a major production base for many Taiwanese suppliers,” Chiu pointed out, “and the new tariffs further complicate an already fragmented and interdependent supply chain.” For manufacturers still setting up

or expanding production overseas, choosing the right location has become a critical issue. “Margins are usually too tight to absorb tariff-driven cost increases,” she warned. “Very few companies can manage this on their own – and it remains unclear whether Western brands will share the burden or simply pass the cost on to consumers.” She believes that the months ahead will focus less on growth and more on contingency planning. “A cautious, wait-andsee approach is the only sensible strategy for now.”

Taipei Cycle 2025 showed that the global bicycle industry remains in a state of uncertainty. Stabilising inventory levels and cautious signs of innovation offer some reason for optimism, but structural pressures, shifting demand and renewed geopolitical risks continue to weigh heavily. While some brands are seeing early signs of recovery, others are still struggling with excess stock and subdued consumer confidence. Regulatory changes in key markets and the potential impact of new tariffs have added further complexity. At the same time, the industry is beginning to respond. Manufacturers are rethinking product development timelines, ESG criteria are becoming part of procurement processes, and investor interest – though selective – is slowly returning. It is still far too early to talk about a full recovery. But there are signs that the industry is beginning to reposition itself. The ride ahead will be uneven, but for the first time in many months, the path toward getting back in the saddle is visible.

Our exciting new range of KX Wheels are produced right here at Bob Elliot HQ Utilising our specialist machinery, we prepare the hubs using reliable, economical, high quality componentry and lace the wheels before finishing them to precise tolerances with the use of a robot which are then quality checked to deliver the perfect wheel every time. Competitively priced replacement wheels offering a wide selection for 700C and all MTB disciplines.

Built here at Bob Elliot HQ IN THE UK

All wheels FInished to exacting tolerances Comprehensive range, PRICED competitively

Quality componentry from all around the World

Over 50 years combined wheel building experience

Next day delivery available

BELL’S BICYCLES

Everyone involved in cycle retailing knows the industry is changing but how to adapt to those changes is the challenge that the trade is facing. For Bell’s Bicycles it has meant closing a high street store and moving to an industrial unit to concentrate on online sales and bicycle restorations. Duncan Moore investigates…

Big chains offering discounts, online retailers providing next delivery on the most obscure of items and the ever-increasing cost of living making many people feel that new bicycles are unaffordable are the main challenges the independent bike trading is currently facing but why try and face them head-on when you can go your own way and do something different? Closing a high street store in a seaside town to move to a nondescript unit on an industrial estate is how Megan Williams, the owner and founder of Bell’s Bicycles is dealing with the challenge of running an independent bike shop in today’s environment.

Up until late last year, a walk through the Old Town area of the Southeastern seaside town of Hastings would have taken you past Bell’s Bicycles. You couldn’t miss it with its rack of rental bikes outside and carefully dressed window displays showing the selection of traditional-styled bikes available for sale alongside a range of carefully curated parts and accessories to match. It was less of a bike shop and more of a boutique and that is just what Megan (Meg) Williams the shop’s founder and owner wanted.

“We’ve always been quite specialist really,” Meg explains. “It comes from the viewpoint of gender inequality. I’m a girl who’s always loved bikes, yet I always felt intimidated around other bike people, especially going into that all-male environment of the regular bike shops. Still, to this day, I find it intimidating, it’s so silly, isn’t it? I mean, why? It’s just a load of boys in Lycra, but

“WE’VE ALWAYS BEEN QUITE SPECIALIST REALLY... A REALLY BIG PART OF BELL’S WAS THAT I WANTED TO MAKE A SPACE THAT WOMEN WOULD FEEL COMFORTABLE IN AND THAT FOLLOWED MORE

OF A TRADITIONAL REGULAR SHOP FEEL”

it’s still there. So, a really big part of Bell’s was that I wanted to make a space that women would feel comfortable in and that followed more of a traditional regular shop feel. I wasn’t reinventing the wheel, just thinking about retail and making buying a bike a nice and approachable experience.”

Meg grew up with a love of bikes and cycling, and it was this love of old bikes that saw the creation of Bell’s. Despite landing a job in the arts industry after completing university, Meg wanted to earn a little extra money and with an ever-increasing collection of older bikes taking up every spare inch

of space at home the answer was obvious – sell some of the bikes.

A weekend-only pop-up shop was the first incarnation of Bell’s Bicycles. “I opened one [a pop-up shop] around 20 years ago and sold every single bike I had in the shop and I’ve not stopped since,” Meg explains. The stock at that time was older Raleighs, Claude Butlers, Carltons and the like, steelframed road bikes and roadsters, the type of bikes at that time that were considered unfashionable and which Meg bought cheaply at car boot sales, as job lots on eBay and in some cases found in skips.

By working on rebuilding and restoring those old bikes to create fresh stock as stock for the pop-up store Meg quickly taught herself the basics of cycle maintenance and repair. Not bad for someone who freely admits: “When I started, I didn’t even know how you would take a brake apart. It was just picking skills up along the way. The business started with restoration, but then became a much more commercial, actual bike shop, still with that kind of feeling of a kind of classic bicycle aesthetic.”

“THE BUSINESS STARTED WITH RESTORATION, BUT THEN BECAME A MUCH MORE COMMERCIAL, ACTUAL BIKE SHOP, STILL WITH THAT KIND OF FEELING OF A KIND OF CLASSIC BICYCLE AESTHETIC”

It was this focus on the aesthetic of bicycle design that played a key role in the brands Meg chose to stock in the Hastings shop when she made the move from operating a semi-regular pop-up style store to a regular retail outlet. The decision to go full-time with bike retailing was helped by the fact that despite her increasing the price of the second-hand and lightly restored bikes she was selling she kept selling all of her stock each weekend she opened the pop-up.

It was the distinctly old-school and yet practical style of bike that she had been restoring and selling that set the theme for the brands that Meg has stocked in Bell’s Bicycles over the years and has included Tokyo Bike, Temple, Genesis, Pashley and Gazelle. The last two have always been the mainstay of the retail side of the business with the classic styling the two brands offer fitting with the founding ethos of Bell’s and the regular selection of bikes passing through the workshop for restoration.

The choice of brands stocked as accessories too has always been equally carefully considered and nothing as

regular as trade team Lycra has ever been in favour or on the shelves. Meg’s choices have always been a carefully curated choice of ‘lifestyle’ brands; the type of accessories that hark back to an older, and some might say simpler and more elegant time. The type of equipment people who simply ride bicycles want rather than what ‘cyclists’ might desire.

There was also a third revenue stream alongside retail and bicycle restoration, during Bell’s time in Hastings. Bike hire was a useful additional source of income, albeit a rather seasonal one. Therein lies part of the issue with running an IBD in a small seaside town. Unlike its near neighbour Brighton, Hastings has never been an affluent town and passing trade was limited. Fortunately, for many years the lack of local trade was not too much of an issue for Bell’s due to the brands and highly curated brands stocked many people from farther afield were happy to shop with the business online, indeed the sales breakdown in recent years saw almost 90% of sales being online. Meg says of the last few years in Hastings: “There’s

no logical sense other than the fact that it was quite cheap to rent.”

With home life changes causing Meg to relocate to London and then having to travel to Hastings every week, decisions about radically changing the business began to form. As Meg explains: “The restoration was just growing more and more and more to the point where we ended up having, like, an eight-month waiting list, and just didn’t have the space, couldn’t fulfil everything, and yet, that’s the side that we just love.”

And so it was that the high street shop front in Hastings was swapped at the start of this year for an anonymous unit in an industrial estate in Southeast London. Online sales remain as buoyant as ever: “Our online stuff is still exactly the same as it was before. We’ve just got more time to dedicate to actually being able to do it,” Meg notes, “and the restoration side of the business is continuing to grow.

“The idea is to fully commercialise bike restoration, which is something

BELL’S

that really doesn’t currently exist on a commercial basis. There are plenty of people doing it at home as a hobby in an informal way. But it does not exist in the same way as it does in the classic car world, where you’ve got professional workshops who can fully restore something even though the cost will far exceed the value.”

In the short time since the business moved from Hastings to London the restoration requests are proving enough to keep two on-site mechanics and an off-site painter busy. The current job list stands at around 40 bikes ranging from examples of classic Raleigh Roadsters that Bell’s is known for restoring through Moultons and Raleigh Choppers and Grifter and on to more modern machinery with a mid-’90s GT Zaskar dripping anodised trinkets, that will soon be wearing a full period correct XTR groupset, being the latest bike through the door.

Given that one recent Raleigh Roadster restoration that is nearing completion will have cost the customer close

“THE IDEA IS TO FULLY COMMERCIALISE BIKE RESTORATION, WHICH IS SOMETHING THAT REALLY DOESN’T CURRENTLY EXIST ON A COMMERCIAL BASIS”

to £4,000 it is clear to see what the potential for this aspect of Bell’s to develop given the move to a dedicated restoration workshop space.

However, despite the long wait list of restoration jobs, Meg has not forgotten the importance of retail and already has plans on that front. “My kind of plan for this year is, to keep this unit fully dedicated to restoration and then soon, we’re going to be taking on another space next door, and we’ll have that as much more of a showroom space. We will only be opening that on an appointment-only basis for people who want to come and look at a particular model and perhaps have a test ride before buying a new bike.

“We’ve already had so many people getting in touch and saying, ‘Can I come down see you? I’m just really glad you’re now in South London, you’re much more accessible than in Hastings.’ Which is an additional benefit of the move.”

www.bellsbicycles.co.uk

Experiential retail, ‘retailtainment’, events… the retailer/customer interaction may once have just been limited to over-the-counter exchanges, but now there are a myriad of options for shops to create and solidify their all-important customer relationships. Shops rides are probably one of the longest established in the genre and these also serve as chance for brands and distributors to cement their shop relationships, and of course get brands firmly lodged in the minds of consumers.

That lengthy preamble leads us to Brooks on Tour, a fairly new programme of UK rides that Brooks is hosting alongside local Brooks dealers and their communities, also supported by Retail Specialists from Extra UK – Dean Teifel and Stu Prentice.

Rides so far this year have included a 50km New Forest loop with pauses for ice creams and loaded scones, as well as a Manchester-set canalway and football stadium linked ride, with stops for cider and apple cake.

“The focus is to support our shops,” Brooks Events and Activation Lead Stefan Amato tells CIN. “But it’s key for Brooks to be riding again: hosting ace, accessible – we’re calling them ‘picnic-paced’ –experiences for the cycling community.”

The cycle enthusiast is welcome, as is the Brooks enthusiast. Will there be a broader demographic attracted at the thought of a picnic-paced ride that may include scones and/or cider? Those kinds of riders are viewed as an absolute bonus.

“By tweaking and tailoring the rides to each shop’s wants and needs, we can hopefully cater (literally) for a wide range of ‘cyclists’, the Brooks way. We of course, have test saddles available for fitting at the rides for folk to experience the comfort and craft of a Brooks or, if they are already acquainted, the difference between a C15 and C17 Carved for example. Brooks on Tour means escaping by bike, together.”

Brooks Events and Activation Lead Stefan Amato takes CIN through Brooks’ quintessentially British version of a shop ride programme…

Local bike shops are an essential ingredient in these Brooks on Tour rides, as Stefan explains: “This is the first season of the Brooks on Tour programme, for which we’ve started close to home in England with five stops scheduled in the New Forest (Woods Cyclery), Manchester (Keep Pedalling), Cambridge (Bicycle Ambulance) Bicycle Ambulance (Cambridge), Ascot (Brilliant Bikes), and Ripon (Bikemonger).

“We’re soon to release the next few

“IF WE CAN HELP SHOPS HOST SOMETHING SPECIAL FOR THEIR COMMUNITIES, THEN IT’S A WIN FOR ALL”

• WOODS CYCLERY NEW FOREST - (23 MARCH 2025)

• KEEP PEDALLING MANCHESTER - (30 MARCH 2025)

• BICYCLE AMBULANCE CAMBRIDGE - 25 MAY 2025

stops in Sheffield, London, Ambleside and Edinburgh throughout the remainder of 2025, and then will be looking to ride into 2026 so shops are very welcome to get in touch –stefan.amato@selleroyalgroup.com – if you’d be keen for us to bring Brooks to you in the UK, or further afield.”

At time of writing, the Picnic Rides are only just beginning to get rolling. As noted above, the first two occurred in the New Forest and Manchester with Tom and team at Woods Cyclery, and Shona and Rich at Keep Pedalling, respectively: “These were both super days out not least because they were so (purposefully) unique and quintessentially British. The reaction has been positive so far – for some, the routes are shop rides they might do regularly but with Brooks touches throughout; for others that are new to the shops and locations it’s a super way of discovering a new riding destination, with a group of likeminds.

“In the New Forest, after Woods’ cafe brews, around 40 of us headed out on a 50KM loop of the National Park’s expansive moorlands and wonderfully disorientating forest tracks, pausing for natters, ice creams, loaded scones and drinks at a local brewery tucked away.

“In Manchester, 40 of us escaped out

• BRILLIANT BIKES ASCOT - 31 MAY 2025

• BIKEMONGER RIPON - 8 JUNE 2025

• A DIFFERENT GEAR SHEFFIELD - TBC

west into the suburban countryside, via the canalways and football stadiums, to an Orchard for juices, ciders and apple cake. Both different experiences; both great groups of people meeting up and riding bikes together. We finished up the Manchester ride at Balance Brewery, where Will had bottled up some of his speciality ‘Picnic Saison’ beer for us to enjoy. Age-old processes. Simple, quality ingredients. Craftsmanship. Time. The Brooks way, and the case for Balance’s Beers too. Cheers!”

“A win for all”

Niceties of picnics and leisurely rides aside, there’s a solid commercial princi-

• GHYLLSIDE CYCLES AMBLESIDE - TBC

• SEABASS CYCLES LONDON - TBC

• PROJEKTRIDE EDINBURGH - TBC

ple at stake here: even when your brand has been around for over one and a half centuries, outreach to consumers and new generations is essential. And a clever way of reaching out is through events and leveraging your retail network, while benefitting them too.

“I’m not sure you could find a bigger advocate for real-world events and activations,” says Stefan. “Shared kilometres and picnic-stop connection is so important in creating memorable experiences. Having been around for 150-plus years, Brooks is on a certain level of trust and awareness, but we can’t be complacent – it’s equally invaluable for us to be out there meeting riders and our shops, as it is for riders and shops to be connecting with people behind Brooks.

“And, riding back to the main rationale of the Brooks On Tour programme – if we can help shops host something special for their communities, then it’s a win for all,” Stefan adds.

While the Tour programme progresses, we’re also told to keep an eye out for “the next big activation from Brooks” coming on 14 June 2025.

Brooks England is distributed in the UK and Ireland by Extra UK.

www.extrauk.co.uk

Cycling manufacturers are harnessing 3D printing technology to significantly revamp the design and manufacturing of saddles. Andrew Sink, Staff Applications Engineer at Carbon, explains how 3D printing is becoming a cornerstone element of the saddle business…

For a long time, when it came to designing saddles for bikes, striking a balance between comfort, performance and durability has been the goal. However, meeting these objectives has come with limitations, mainly insofar as the materials used.

Specialized is among those leveraging 3D printing to reimagine the way saddles are designed and produced

"3D PRINTING AND ADDITIVE MANUFACTURING IS OFFERING NEW POSSIBILITIES OF CUSTOMISATION, EFFICIENCY AND INNOVATION WHICH WERE NOT PREVIOUSLY ATTAINABLE"

Foam and moulded materials for saddles, such as plastic, were widely used for their durability and affordability but often failed to deliver personalised support and long-term resilience. Poorly designed saddles can lead to discomfort, numbness, poor posture, lower back pain and even potential injury due to bad pressure distribution on sensitive areas, driving the demand for seating that is comfortable, durable and increasingly personalised to the individual.

3D printing/additive manufacturing is disrupting this application area, offering new possibilities of customisation, efficiency and innovation which were not previously attainable. By designing lattice structures that offer precise pressure distribution, brands are demonstrating that the future of saddles includes 3D printing technology.

Leading brands are taking to 3D printing to reimagine their saddle designs. These companies include the likes of US bicycle manufacturer Specialized, whose award-winning S-Works Power with Mirror Technology has received rave reviews from cycling enthusiasts.

Demonstrating the capabilities of Digital Light Synthesis™ (DLS) 3D printing

technology, the S-Works Power Saddle with Mirror comprises a complex multizonal lattice structure designed for optimal pressure relief and comfort. Proving the scalability of the technology, that particular saddle has since paved the way for the introduction of the S-Works Romin Evo with Mirror, which was specially developed for the performance cycling market. Thanks to the flexibility of the DLS technology deployed to develop this saddle, the project took just six months from prototype to commercialisation.

Similarly, Italian biking accessory brand, Fizik has a solid track record of using technology and data to create revolutionary products that elevate the rider experience.

Having successfully leveraged elastomeric materials, lattice design software and DLS 3D printing technology, the company recently set itself the challenge of harnessing the same technology to develop a fully customised 3D printed saddle topper that would provide maximum support, stability, and comfort, minimising pressure points and enhancing aerodynamic efficiency.

Collaborating with pressure map data experts at gebioMized, Fizik engineered a system for collecting pressure map data (specifically the body force transferred to the saddle as well as how that force is distributed across the saddle’s surface) from riders to customise a saddle design with distinctive zonal cushioning tuned to adapt specifically to the rider’s body. This data is subsequently translated into the

“BY CAPITALISING ON THE FLEXIBILITY OF 3D PRINTING, THE COMPANY WAS GRANTED THE MEANS TO VERY QUICKLY AND EFFECTIVELY DEVELOP INDIVIDUALLY DESIGNED ONE-OFF SADDLE PADDINGS”

3D printed lattice structure using Carbon Custom Production Software, resulting in a highly personalised supportive saddle optimised for comfort and performance.

By capitalising on the flexibility of 3D printing, the company was granted the means to very quickly and cost-effectively develop individually designed one-off saddle paddings. The result is Fizik’s recently launched, fully customised, 3D printed One-to-One saddle, now in use by professional riders like Tadej Pogačar who, in February this year, rode his personalised Aeris LD One-to-One saddle as he sealed victory on the 2025 UAE Tour. Another brand to have firmly embraced 3D printing technology to revolutionise its design to production workflow is saddle manufacturer Selle Italia. To meet the highest levels of performance that its elite

cyclists required, Selle Italia wanted to find a material that was not only supportive for riders but was also breathable and ultimately provided a more comfortable ride. Requirements included:

Multiple zones within the saddle space to optimise performance and comfort

Energy-returning elastomeric material that was both soft and grippy

High breathability

Increased comfort for the rider

Ease of printability with difficult shapes

Working closely with Carbon production partner, Prototek, Selle Italia was recommended EPU 41 material – a durable, highly elastomeric, energy-returning material that offers cushioning and gripping for the rider. This particular material also lends itself to multi-zonal lattice

designs that are extremely breathable and can be tuned precisely to offer a variety of mechanical responses for an overall better ride.

The company has since expanded its 3D printed line to include those for performance cycling, comfort cycling, and triathlons – the first ever made with 3D printing and developed in partnership with reigning men’s IRONMAN World Champion Patrick Lange.

The utilisation of 3D printing by brands such as Specialized, Fizik and Selle Italia, and the revolutionary saddle designs that they are able to realise, is indicative of the transformative nature of this technology. Not only does it successfully address long-standing challenges in rider comfort but also sets the standard for future innovations and increased customisation to suit the individual. As companies like Carbon continue to innovate their technology offering, it paves the way for even greater product design innovation among brands like these and many others.

www.carbon3d.com

ANDREW SINK: A Staff Applications Engineer at Carbon, a product development and manufacturing technology company whose technologies portfolio enable brands to design, develop, and manufacture datadriven, high-performance comfort and protection products that are breezy, aesthetic and custom.

“AS COMPANIES LIKE CARBON CONTINUE TO INNOVATE THEIR TECHNOLOGY OFFERING, IT PAVES THE WAY FOR EVEN GREATER PRODUCT DESIGN INNOVATION AMONG BRANDS”

Join the global platform for cycling and ecomobility

June 25 – 29, 2025 Messe

EUROBIKE Festival: June 28 – 29

Kicking off a series of articles from knowledgeable cycle sales veteran John Styles, ‘Bike Trade Sales Secrets’ gets underway with some straightforward pointers on body language and breaking down barriers with bike shop customers…

n my 20-plus years as a sales rep in the industry, I’ve been lucky enough to set foot in over 600 stores across seen countries. I’ve listened to (literally) thousands of sales conversations. And I’ve noticed some great habits and techniques along the way. Though oftentimes I notice only a minority of salespeople practice these techniques.

So, here’s a simple tip I spotted in a few stores. If we wanted to give this one a name, perhaps we just call it “The Triangle.” And it’s simple: try to start by positioning you, the consumer, and the bike, in a triangle. Stand the bike up so you can both observe it, shoulder to shoulder.

What often happens instead is the salesperson takes the bike from the rack, holds it by the stem and saddle, and presents it face-to-face, between them and the consumer. Sometimes the body language is even dominant or a little possessive, standing over the bike.

Now this isn’t completely ‘wrong’, but it can set the conversation up to be a little combative or competitive. Talking to someone face-to-face is inher-

“I’VE LISTENED TO (LITERALLY) THOUSANDS OF SALES CONVERSATIONS. AND I’VE NOTICED SOME GREAT HABITS AND TECHNIQUES ALONG THE WAY. THOUGH OFTENTIMES I NOTICE ONLY A MINORITY OF SALESPEOPLE PRACTICE THESE TECHNIQUES”

ently more confrontational. And holding the bike looks like a bit like a tugof-war. I’ve also observed consumers (literally) backing up to create space, because they don’t want to stand “eyeto-eye” and need to step back to see the bike – this creates distance.

All-too-often, the bike then becomes the focus for the salesperson, who starts talking about the bike, instead of to the person. Many consumers are anxious about shopping in store and interacting with other people (especially salespeople). With just a simple change in body language, we can set them more at ease. So how does a triangle help us?

Help your consumer feel at ease

Well first off it sends a very different message about what’s happening in our conversation. It means we can stand together, shoulder to shoulder with our consumer. This reduces stress for your consumer because they don’t have to focus on you, your expression and your words. They can focus on the bike and it’s non-threatening, creating more of a feeling of closeness between you.

“TRIANGLE POSITIONING HELPS YOU BECOME MORE PEOPLE FOCUSED INSTEAD OF PRODUCT FOCUSED. BECAUSE THEY ARE NEXT TO YOU, YOUR FOCUS CAN BE TOWARDS THEM, WITHOUT IT BEING CONFRONTATIONAL”

Focus, focus, focus. Second, it helps you focus on the consumer instead of the bike. Looking at the bike and rattling off all its features is something we want to avoid. Features may impress you, but they don’t always impress your consumer, sometimes making them feel stressed and overwhelmed. Our job is to simplify, not complicate. Instead, perhaps try to focus your attention on the consumer and understanding their needs. Triangle positioning helps you become more people focused instead of product

shoulder to shoulder with the consumer can help put them at ease

focused. Because they are next to you, your focus can be towards them, without it being confrontational.

Take your time

Third, it seems to take the heat and hurry out of the conversation, giving both parties more time to think. All too often I’ve seen salespeople rush through a conversation. Sometimes by asking just the consumers budget and type of bike. I suspect that holding the bike up adds an urgency too – it kind of implies a bit of a question “are you

Tug-of-war: Having the bike between sales staff and customer can be confrontational or combative.... so is ideally avoided

going to take this or shall I put it back in the rack?”. The triangle helps you slow down, so you don’t ask for the sale too early, before really understanding the consumer’s needs.

thought

Any sales conversation can seem complex with all the different questions and concerns the consumer may bring. Plus the technicalities of a bike, with its different materials, geometry and features that you may need to interpret for them. All these things can be better managed when you start by placing you, your consumer, and the bike, in a triangle. This sets you up for the key fundamental of selling, to focus on the consumer, not the product.

John Styles is a veteran of the cycling industry, having worked with leading distributors and brands across the sector. With a well-rounded perspective on the opportunities and challenges facing the sector, backed by a Bachelors Degree in Economics, John Styles is an expert consultant for the bike trade and will be speaking at the forthcoming CIN Live, 14-15 September 2025.

Emma Karslake has embarked on a mission to glean opinions from women cycle consumers and their views on bike shops. While we may already think we know the broad strokes overview (spoiler: there are reports of patronising behaviour), this ad hoc survey delves deeper into the topic, with specific experiences and notes on the implications, hereby shared with CIN readers…

Ten years ago, I went to a bike shop to get my front derailleur adjusted. I looked at what the mechanic was doing, hoping to learn. After a couple of minutes, he said he was done.

“You haven’t checked whether it shifts to the big ring,” I remarked, slightly confused.

He sneered back at me: “Do you ever use that one?”

I wondered whether he would ever behave this way towards a male customer. I vowed to never go back to him even though there was no other bike shop within a 15km radius.

For me, this became one of many examples. My motivation to learn mechanics was thus part guided by curiosity, part guided by the expecta-

tion of a less-than-pleasant encounter every time I entered a bike shop. I freed myself from bike shops entirely and bought parts exclusively online. I would gladly spend a whole afternoon struggling on my own rather than paying a mechanic £20 to change a cable.

Fast forward 10 years, I still don’t personally frequent many bike shops, or rather, only one. I made my reappearance in the shape of a professional mechanic. Hearing my female road cycling clubmates complain about their bad customer experiences in workshops, I started to wonder whether anything had changed.

I surveyed 93 individuals to try to get a picture of how people feel received by bike shops. Out of the total, 47 were women, 45 were men, and two

preferred not to say. While this is not a representative sample, the consistency and depth of responses suggest clear trends that deserve attention.

My hunch was confirmed when women overwhelmingly reported feeling talked down to and wanting to learn bike maintenance to avoid interacting with male mechanics. A slightly more surprising outcome was that most men also reported that they had experienced patronising behaviour in bike shops.

The questionnaire was circulated on LinkedIn and to a range of cycling clubs around the UK. Additionally, the last line of the survey encouraged participants to share the link with others. The pool is thus likely dominated by people who cycle as a sport or hobby, as opposed to commuters (although they can be both).

“I HAVE A TOP-OF-THE LINE, CUSTOM-BUILT ROAD BIKE AND MEN ARE QUITE PATRONISING TOWARDS ME, IMPLYING THAT I HAVE NO IDEA WHAT I’M TALKING ABOUT AND HAVE JUST SPENT A LOT OF MONEY ON A BIKE THAT I DON’T RIDE, WHEN IN FACT I RACED INTERNATIONALLY AS A JUNIOR AND HAVE BEEN CYCLING FOR CLOSE TO 20 YEARS”

It contained 15 questions to gauge the level of mechanical knowledge of respondents, the frequency of their visits to bike shops, their reasoning in choosing bike shops, and a series of questions about how they have felt received in bike shops, encouraging them to share both positive and negative experiences.

From this sample of respondents, the key takeaway was that most people (68%) reported they had felt talked down to in a bike shop. The share rose to 82% for women.

On the bright side, the vast majority of people (70%) could recall a particularly positive experience with a bike shop, and surprisingly, this share was

slightly higher (76%) in women.

This paints a picture of women as an overlooked segment of the market, one that often feels unwelcome in bike shops but that might also be more likely to remember a good experience.

Increasing confidence on bike rides and lowering costs often came up for both men and women as a reason to try to maintain their bike themselves. In addition to these, many women also listed avoiding unpleasant interactions with mechanics.

The quality of the work came out as respondents’ main consideration when choosing to return to a bike shop, followed by friendliness of staff. Price only came in third, closely followed by location. The free-text field yielded a variety of unique

answers such as ease of parking and opening hours, but for women, an answer that appeared repeatedly was the willingness of staff to give further explanation about repairs in a nonpatronising way.

Finally, despite an almost equal representation of men and women filling out the survey, many more women shared particularly poor experiences. Feeling that they had to demonstrate their level of understanding and still being talked down to came up multiple times. A few also reported shop keepers addressing their male friend or partner instead of them, or being ignored while male customers were being taken care of. The third recurring complaint was being secondguessed when asking for specific parts.

“MEN ALWAYS ASSUME I KNOW NOTHING ABOUT BIKES BECAUSE I'M FEMALE… OR TALK TO THE MALE I'M WITH INSTEAD OF ME, DESPITE ME BEING THE CUSTOMER”

“A SHOP WOULDN’T LET ME JOIN THE SHOP MTB RIDE BECAUSE I WAS A WOMAN”

In contrast, men’s negative experiences were more varied, ranging from incorrect components being fitted to perceived rudeness; although two men did mention feeling talked down to.

The women’s cycling market in the UK has shown notable growth in recent years. During the Covid-19 pandemic in 2020, the number of cycling trips made by women in England increased by more than 50%, compared to a 12% rise among men. This significant and growing demographic within the cycling market presents substantial opportunities for bike shops to broaden their

customer base and cater more effectively to female cyclists.

While the vast majority of respondents could change an inner tube themselves regardless of gender, only 25% of women felt comfortable replacing cables, against over 50% of men, making women more likely to require regular in-shop services.

While down-selling affected very few men, 39% of women reported having been directed towards cheaper products than what they had come in to purchase or being offered an ‘allrounder’ product after asking for a specialised one. One woman recalled being mostly shown £1,000 to £2,000 bikes by shopkeepers after stating her

budget was around £3,000. Another said the shop assistant kept suggesting flat handlebar bikes with a front basket despite repeated requests for a road bike, saying she couldn’t handle the skinny wheels of a road bike.

The question that yielded the most different responses by gender was the following: ‘All other things being equal, would you be more likely to visit a bike shop that actively promoted inclusivity? Examples include having diverse staff (gender and/or ethnicity), womenspecific workshops, welcoming signage, etc.’ Just over half of men said that it would make a difference to them, against a whopping 90% of women.

The theme of mechanics taking time to explain things if relevant in a neutral manner cropped up in many women’s responses to three free-text questions. Negative experiences in this area seem to drive women away, while positive ones constitute a main reason to visit the shop again.

Women also reported that being explained basic principles at length after demonstrating a decent level of mechanical knowledge (commonly known as mansplaining) was a recurring source of annoyance and a reason to cross off a shop from their list.

Another issue is that many women are so used to being talked down to on technical topics that they may be more likely to dislike a basic and long explanation even if the member of staff gives the same explanation to everyone. Being aware of this when having technical discussions with women can avoid any such misunderstanding.

YOUR PARTNER TO HELP YOU BUILD YOUR BUSINESS

√ 24 years of experience √ Customer & sales support

√ Customized marketing activities √ Delivery from stock

√ Place orders 24 hours a day 7 days per week

For more info about our brands, send a message to sales@onewaybike.nl or give us a call: +44 1527 958331

Website: shop.oneway.bike

Have you ever felt like a bike shop employee was condescending or patronising to you?

Conclusion

From over a decade of personal experience as a female cyclist riding in groups, I can say that word of mouth among women goes a long way. In the male-dominated sport of cycling, women’s groups often serve as a way for women to enter the scene, gain confidence and create a network. In an environment where many women feel intimidated and marginalised, peer recommendations of good bike shops are highly valued.

Every bike shop employee knows it can be tricky to figure out someone’s level of knowledge without being patronising in order to best advise them. But at least, we can try. Being

aware of the issue and of how our comments might be perceived constitutes a good first step in making people feel more at ease, willing to trust us, and become regulars.

In a market recovering from recent downturns, the rising number of women taking up cycling presents a significant opportunity for bike shops. By creating welcoming and respectful environments, retailers can not only tap into this growing demographic, but also foster long-term customer loyalty. As the industry seeks avenues for growth, embracing inclusivity and addressing the specific needs of female cyclists could be a pivotal strategy for success.

In a bike shop, have you ever felt like sta� was down-selling to you?

“EVERY

TIME I TRY TO BUY SOMETHING FOR MY ROAD BIKE, I GET A GRILLING ABOUT ‘AM I SURE THIS IS THE RIGHT COMPONENT’. I'M EITHER PATRONISED WHEN I DON'T KNOW EXACTLY WHAT I NEED OR CONDESCENDED TO WHEN I DO KNOW WHAT I NEED”

bob-elliot.co.uk

bob-elliot.co.uk/twitter

bob-elliot.co.uk/facebook

bobelliot-online

Has the time come to turn our backs on the electric bike conversion kit for the greater good until the Government catches up? Mark Sutton takes a pragmatic view despite fearing that if collective action is not strengthened then trouble awaits…

This is an article I’ve had in the back of my mind for a year or more now. I don’t think I can sit on it any longer, given that today alone I have seen a handful of new ‘eBike fire’ headlines.

For anyone plugged into this fractious subject on a level that is to be considered ‘invested,’ you probably already know the facts, or as close to the facts as we reliably have. The Office for Product Safety Standards, on behalf of the Government and in collaboration with the engineers at the Warwick Manufacturing Group, reached the conclusion that “abuse testing has shown a clear correlation between the price-per-unit-of-energy of PLEV batteries and the safety outcomes” and “Where an unsuitable charger or a modified PLEV drive motor is used, the risk of the batteries being electrically or thermally abused is far higher.”

In plain language, you get what you pay for when it comes to the quality of the batteries and fail safes provided in various forms of assisted mobility. That, unfortunately, has cost people their lives, whether it was their kit or not.

In reaching out to a London firefighter friend of mine to discuss this piece, his first line of response was “I’ve just come back from one”, referencing a fire incident attributable, he says, to a kit bike.

This is a hard trend to argue against because it is so full of raw emotion, and I have written again and again in defence of the electric bike because I know that facts should always get out in front of misdirection, regardless of what often feels like fighting a minority corner may sometimes feel like.

Anybody who looks out across a showroom floor packed out with Bosch-standard electric bikes knows that there is next to no chance any of these bikes will ever provoke a headline, whether it be to do with fires or the kind of throttle-based ‘speed’ stories that equally damage the reputation of what are, in a legal sense, cyclists and of course bike shops too.

Truth be told, there are conversion kit manufacturers that I know take the subject of safety very seriously. For anybody who has met Nick Bailey in person, there’s an equal chance that he was wearing his BatteryIQ hat to his Boost conversion kit hat. For the uninitiated, BatteryIQ seeks to become a global standard in quality assurance, offering traceability and a safety benchmark that will be good enough for employer recognition and prove as much in real time via a dashboard that can plug in to an employer’s IT systems, if they insist. With businesses like the More London Group, Canary Wharf and, rumour has it, Morrisons banning staff from riding eBikes to

their buildings, this is direly needed. I commend Nick’s efforts to produce a conversion kit product that is adhering to standards and is in demand, up 30% year-on-year in Q1, he tells me, all the while putting in the required legwork on safety standards. He’s on the frontline of the fury against conversion kits and is keeping a cool head. He says that the adverse headlines are not affecting his business, but others in the wider electric bike business are starting to disagree.

Retailers have to tread a very careful path when it comes to conversion kits, as if they indulge them in stores they essentially become the manufacturer and with that assume a lot of new liability. That can apply even if you have the kitted bikes in store, but do not work on the motor. That said, if you are a London retailer, for example, how can you avoid them nowadays?

Gavin Hudson is one such retailer. As the owner of Butternut Bikes, which is primarily a workshop but does also sell a handful of Terns and Estarlis, his stance is to permit the quite deliberately road legal systems like Boost, Swytch and Skarper, turning away anything that does not seem recognisable.

He says: “We usually insist on doing a full service along with the fitting. The problem is that then we at Butternut Bikes become the point of warranty for any problems with the electrics,

“A KEY FACTOR ON WHETHER WE WOULD FIT A KIT IS THE CONDITION OF THE DONOR BIKE, WHICH MATTERS”

which happens more often than we'd like – faulty sensors, battery failure, etc. Customers come back to us, understandably, and we have to build something into our fees to take account of that, and there often isn't much that we can do. They definitely fall under the more trouble than they are worth category, but we take a view on them on a case-by-case basis.”

Gavin has a bigger reluctance playing on his mind, however. He adds: “From an emotional level, the thing I don't like about these kits is that they probably delay the purchase of a decent electric bike, as much as they inspire one, and are quite likely to make people think that eBikes are not all they are cracked up to be.”

As the latest Bicycle Association data shows, 2024 was another year of stagnation for electric bikes, which again came in just under 150,000 units sold. Without Government intervention to encourage cycling, and indeed the electric bike’s role within that, it’s hard

to see a sudden lift like that seen in France or Germany happening in 2025.

As the latest Department for Transport statistics revealed to little fanfare for the year ending June 2024, there were 51 cycling miles per person, similar to 2023 levels at 53 miles per person, but a full 6% lower than in 2019, where 54 miles per person was cycled.

This data, while easy to gloss over, is plainly showing us that despite cycling to work being made infinitely more accessible to the masses, the revolution is stuttering, and it’s hard not to join the dots between reactionary policy and the cycling rates that are stubbornly flat. Another retailer told me that in one London building alone of the major employer, they had 50 customers, all of which have been told not to eBike to work. That’s potentially another 50 bikes on an inflated second-hand sales market. Moreover, it is no doubt lost sales potential for brand new eBikes.

In a somewhat awkward viewing of the second-hand market, soon to be

seen in a Channel 5 documentary on this very subject, I have been led to question what the necessary next steps are for the bike industry and the Government when it comes to conversion kits. In the same way that I hate the way that eBikes are lumped in with e-bicycle-shaped objects, I want to be careful not to conflate the engineering of companies like Boost with some of the patently unsafe direct-market conversion kits that have been causing problems. To do so would be casting similar stones that I’ve been putting shields up against for the past year. A pragmatic view is required, but in having my eyes opened to just how cheap and widely available demonstrably unsafe ‘c-bikes’ (conversion kit bikes) have become, I reluctantly want to dive deeper on whether emergency legislation is required. It’s unlikely, of course. The Government has other priorities, but then again, it’s a very real possibility that the next Grenfell is around the corner, and the headlines

won’t be kind to all forms of e-mobility, regardless of what lights the fuse.

To recap on my personal experience, as part of the upcoming Channel 5 segment, a converted bike was chosen at random from Facebook’s marketplace. I’m told that the seller immediately asked the film crew if the buyer was a food delivery worker, that’s the assumption for this kind of vehicle in London and clearly where the majority of demand comes from. In any case, for something like £450, a converted Cannondale hardtail was acquired. Upon inspection, the bike had been sold with unknown burn marks on an insulated case housing a taped-up bunch of battery cells. They could have been scorched to route cables, but none were protruding, so it’s hard to be sure. Encouragingly, the brakes had been upgraded, but everything else was, mechanically speaking, not ready for the 40mph I later witnessed that hardtail do. I strongly advised a safe disposal to the film crew post demonstration.

In speaking to Nick at Boost, he told me that he tracks sales of cells on various marketplaces and has seen “batches

“I WANT TO BE CAREFUL NOT TO CONFLATE THE ENGINEERING OF COMPANIES LIKE BOOST WITH SOME OF THE PATENTLY UNSAFE DIRECT-MARKET CONVERSION KITS THAT HAVE BEEN CAUSING PROBLEMS. TO DO SO WOULD BE CASTING SIMILAR STONES THAT I’VE BEEN PUTTING SHIELDS UP AGAINST FOR THE PAST YEAR”

of 100 cells sold for as low as £45” for DIY kits. Several Facebook forums badged as ‘eBike’ groups would tend to reveal these claims to be fairly accurate.

In browsing the same marketplace earlier, there were similar examples of Frankenbikes advertised for a third of that cost. Prices are so low that I wonder whether people are cottoning on and cutting their losses. Unfortunately, these are the kinds of prices that are affordable to bored teenagers, and I’ve spoken to a group this spring that followed this exact path to ownership of bikes that they were happy to ride to destruction, with no intention to repair or maintain. If those kids are anything like I was at that age, the bikes will be taking a beating. Worse, they will become adults whose only opinion of the eBike is that they’re throwaway items, or toys, not a future transport form.

This is the reality of the danger. It’s ubiquitous, available cheaply and terribly maintained. The demand is not just naturally high, but actively driven by a gig economy that draws a line in the sand between company responsibility and worker protection.

The business model encourages unsafe practices. Paid on a price per drop model, agility and speed are set against miniscule wages, which in turn means cut corners on equipment.

Even if delivery giants were not arguably driving the market for dangerous goods, researchers at McKinsey recently wrote in a report about current mega trends a profile of the ‘value consumer’, a demographic that’s growing exponentially.

They wrote: “It appears we have entered a new chapter in consumer behaviour: the era of the ‘value now’ consumer. The value now consumer copes with relatively downbeat feelings about the economy by optimising their purchases, spending money in ways they think will yield the greatest value, and ascribing value to purchases in new ways. This also involves oscillating between trade-offs and splurges. So, while consumers may not want to overspend, they still have the means to spend and will splurge in things that ‘inspire’ them.”

A quality electric bike is, to many, an aspirational product. In the psyche of the UK consumer, the “I could buy a

THE NEXT 10 YEARS | PART 6

car for that” anecdote is sticky when it comes to bikes. People understand that a bike can be transport, but they expect it to be far cheaper than motoring, despite the difference in experience and potential. In the context of transport costs, a brand new eBike can be very cost-effective, but a secondhand special from an online marketplace is all the more appealing to the unsavvy shopper. No thanks to our press at large, consumer education is not starting from zero, but rather somewhere in the minus ranks. You’ll know it as well as I, the sales process starts with many more questions than is typical of a bike sale.

I asked my local Hertfordshire retailer, Highway Cycles, about their experience with the customer when they land in store, fresh and full of ideas. Owner, Len Simmons, tells me:

“The interest in our shop for conversion kits is small, maybe one to 20 enquiries versus a standard eBike. A key factor on whether we would fit a kit is the condition of the donor bike, which matters. The subject of speed restriction does come up, but it rarely stops a sale. I’d wager that if we had the American 20mph benchmark the subject would disappear entirely.”

Adjusting the legal regulations is another conversation entirely, but it’s interesting to note the take of European umbrella organisations like ZIV and CONEBI lately. In getting their heads together, they feel that the European industry of the future should settle on the following regulations across the board, perhaps with the exception of multi-track cargo bikes:

Support ratio of 1:4 and Support ratio of 1:6 possible up to max. 15 km/h and Max. assistance power of 750 W at the drive wheel and Max. (loaded) weight of 250 kg for single-track EPAC (like a Tern GSD) Max. (loaded) weight of 300 kg for multi-track EPAC (like some fourwheel cargo builds)

A Separate framework conditions and parameters must be defined for cargo bikes weighing more than 300 kg (see EN 17860-4:2025

Getting our ducks in a row is especially timely given the unsettling side effects that global tariff wars will bring. One might reasonably expect that a lot of eBikes set for the USA will now be

“THERE’S AN ASSUMPTION THAT FOR THIS KIND OF VEHICLE IN LONDON, THE MAJORITY OF DEMAND COMES FROM THE FOOD DELIVERY WORKER”

diverted, and they will be tuned to US regulations. With anti-dumping duties on Chinese electric bikes removed only by the UK Government, but held in Europe, it’s fair to assume that what was already set to be a flood of eBikes landing with now come in significantly more unsuitable and larger volume.

This subject was already due urgent attention, and for some critical thinking to be applied rather than the kneejerk bans that we are now enduring, like that delivered by TfL in response to yet another conversion kit fire, plus pressure from the ASLEF trade union. Fairly, its members have become concerned by what they have seen on station platforms and, as fire tends to provoke, an ask questions later

approach to avoidance was dished out to the bike shop’s detriment.

The Product Safety and Metrology Bill is, presently, the one to watch, to see what the final draft has to say about the future of conversion kits in this country. The evidence now exists to make an informed decision, rather than to punish anyone and everyone involved in pedal-assisted cycling.

All things considered, this will only get more urgent, be that for the Government, the food delivery worker, the bike shop, distributor or manufacturer, even the public at large, but also for all of those that had high hopes that the electric bike could represent a real shot at increasing cycling rates and reducing our nation’s car dependency.

With momentum building and some of the biggest names in the business signed up, CIN Live will debut in Stoneleigh, combining product, seminars and networking…

The inaugural CIN Live is taking place this year, running over two days – Sunday 14 September and Monday 15 September 2025 –promising a combination of education and training, new products and quality face-to-face time with the trade, at NAEC Stoneleigh, Warwickshire.

CIN Live 2025 is for bike shops, workshops and mobile mechanics as well as distributors, brands, importers and service providers for the industry.

“We have been bowled over by the response and support from the trade, with some great names signed up to exhibit with us this September,” said Show Director Jerry Ramsdale. “We’ve long been aware that we had chance to do something a bit different with a Cycling Industry News show and have been waiting for the right opportunity to launch it into the market. Everything is coming together and we can’t wait until September.”

CIN Live 2025 arrives as the market

has endured a roller coaster few years, post-Covid and Brexit. Much has shifted, and the need for the trade to take the opportunity to come together has perhaps become more essential than ever. CIN Live is a platform to welcome the whole industry in one place, at this important time of the year.

CIN Editor Jonathon Harker says: “We’ve seen that UK cycle trade events have been consistently popular in recent times. There’s a clear appetite to meet face-to-face with suppliers and fellow retailers – whether that’s because of challenging market conditions or because we’re seeing glimpses of green shoots, or a combination of the two. What there isn’t, currently, is a single event where the trade can come together and see a whole range of brands in one go, or meet with a wider range of retailers, which is where CIN Live comes in.”

live.cyclingindustry.news

Tune into the CIN Live site to see the latest exhibitors and brands signed up, which include big names like:

Madison

ZyroFisher

Muc-Off

Oxford Products

Chicken Cyclekit

Ison Distribution

Bob Elliot

Citrus-Lime

Ananda

Kenda

Activate Learning

Bike Trac, the ACT and more...

New companies are signing up joining CIN Live every day. To see the full list of exhibitors go to the website...