PREMIUM PARTNERSHIPS

Our transportation services are some of the most comprehensive in the business and have been serving the U.S., Mexico and portions of Canada since 1996. We understand that in the transportation industry, time is of the essence. When you partner with our business, we strive to surpass even the most rigorous of customer expectations. Our mission is to be the single source supply-chain partner of choice and to provide premium services that exceed our customer’s expectations. The heart of our operations begins with our experienced, professional staff. The expertise of our employees, coupled with our innovative technologies, gives our clients the resources and tools to run their transportation operations at an optimal level. Unlike many of our competitors, we aren’t in business for ourselves. We are the best at what we do because we are a vital part of each individual customer’s supply chain. That is “The Logicorp Difference.”

As part of our commitment to our customers, we offer tailored options to meet the unique needs of every business organization we partner with and allow you to centralize your transportation operations and track your freight’s progress across our entire network thanks to our state of the art technology. Some of our services include:

• Door to door service in the U.S., Mexico and portions of Canada

• Dedicated Carrier Service

• Team Drivers Service

• “Live” Cargo tracking

• Direct coverage nationwide for the U.S., Mexico and Canada

• Dedicated Customer Service Representative

• Late model equipment

• Highly productive professional drivers with distinguished on-time service

Efficient transportation processes are very complex and require highly sophisticated logistics when you’re hauling just-in-time, build-to-order products. When trucking becomes a vital part of your supply chain, our processes must be deeply integrated into our customer’s processes. That’s the kind of bond that is vital for us to have with any of our customers. Partnerships offer a wealth of opportunities for growth... when they occur between the right businesses.

Logicorp Transportation, LLC 3101 W Military Hwy McAllen, TX 78503 Phone: 956-661-6540 / Fax: 956-661-5998 / Toll Free:

/ www.logicorpllc.com

1-888-353-1716

Publisher’s Letter

As a woman-owned business, we at Industry Today have a particular interest in encouraging greater female participation in the sciences and industry. Alas, as noted in this issue’s feature store, Lab Coats to Leadership: A Celebration of Women in Stem, “Despite the progress we’ve made in women’s education, there’s still a noticeable gap in STEM fields. Women are still underrepresented, and that’s a big deal because we need diverse perspectives to solve the complex challenges we face today.” The good news, however, is that more women than ever are pursuing STEM careers. The article polls a few of these trailblazers about their thoughts on opportunities and challenges for women in STEM careers.

More broadly, we look at several other issues confronting manufacturing today. Overcoming Top Manufacturing and Facility Management Challenges explores top strategies to address workforce issues, aging infrastructure, and downtime. As smart manufacturing technologies continue to transform business processes, industry is also increasingly more vulnerable to cyberattack. NIST 2.0: Safeguarding Manufacturing’s Future examines proposed changes to the National Institute of Standards and Technology (NIST) framework for safeguarding against cyberattack. The core elements provide steps for manufacturers to protect their organizations before, during and after a potential attack.

Supply chain issues continue to confront manufacturers. As we write this, conflict between Israel and Hamas has caused some difficulties in the Red Sea trade routes, but nothing approaching a crisis that might otherwise have arisen. In Supply Chain Reacts to the Red Sea, global transportation data collected from the Infor Nexus supply chain network technology sheds light on the ripple effects of rapidly changing conditions in the Mideast and how they are being addressed.

More generally, supply chains are prone to a number of pressing challenges, stemming in part both from the after effects of the pandemic and geopolitical uncertainties. Supply Chain Disruption Continues to Steer M&A examines how markets and businesses build supply chain resiliency in response to continuing disruptions.

The Biden administration continues to announce initiatives to advance transition to madein-America electric vehicles and build out a national EV charging network infrastructure. This transition cannot happen without critical minerals required for EV batteries. Critical Mineral Independence Must Be Made in the USA discusses how we can reduce our reliance on China supply chain dominance.

Elsewhere, we look at a region of the U.S. in the forefront of industrial innovation in The Manufacturing Renaissance in Lehigh Valley, PA. More than 700 manufacturers in the Lehigh Valley generate $8 billion in economic output and employ 37,000 people. Manufacturing jobs have grown by 22 percent in the last 10 years, while average annual wages have increased by more than $20,000. Read about why companies are drawn to the area.

We hope you enjoy this issue of Industry Today. Look for the same extensive timely coverage on a weekly basis at industrytoday.com.

Project Managers: Jonathan Listig

Industry Today is published by Industry Today LLC, 164 Market Street, Suite 176, Charleston, SC 29401. Copyright © Industry Today 2024. All rights reserved. No part of this publication may be reproduced in any form or for any purpose without prior written consent from the publisher and payment of the agreed fee. ISSN # 1521-8058 www.industrytoday.com spoeton@industrytoday.com 164 Market Street, Suite 176, Charleston, SC 29401 Ph. 973.218.0310 Publisher:

G. Poeton

Susan

Project Director: Brian McMillan

Production: Melissa S. Burge Art Director: Seema Mazhar

Profile Editor:

Contributing Designers: Jorge Leandro Rodrigues

David Soyka

INDUSTRY TODAY 1

38 CRITICAL MINERALS 54 INTERNATIONAL DAY OF WOMEN & GIRLS IN SCIENCE 20 FIMBEL Contents Table of 2 INDUSTRY TODAY 30 GLOBAL M&A TRENDS AND RISKS REPORT ARROW TRU-LINE NEW ANGLE BEVELING PANA-PACIFIC VERSATEX BUILDING PRODUCTS Sponsors

INDUSTRY TODAY 3

NIST 2.0 CYBERSECURITY FRAMEWORK 04 LEHIGH VALLEY, PA VOLUME 27 • ISSUE 1 46 KENWORTH 12 RED SEA CRISIS 64 STATE OF MANUFACTURING AND FACILITIES MAINTENANCE REPORT

74

THE MANUFACTURING RENAISSANCE IN VALLEY, PA

4 INDUSTRY TODAY FEATURE - LEHIGH VALLEY, PA MANUFACTURING RENAISSANCE

MANUFACTURING LEHIGH

What regions are at the forefront of innovation as the U.S. enters the fourth industrial revolution?

The Lehigh Valley, a two-county region in eastern Pennsylvania, has been a manufacturing hub since before the American Revolution. In the 19th and 20th centuries, heavy industry dominated the region’s economy. Products made in the Lehigh Valley helped the United States win two world wars and emerge as a global manufacturing powerhouse.

By the end of the 20th century, the Lehigh Valley found itself at an economic crossroads as manufacturing increasingly moved offshore and mainstays of the region’s economy, including steel and textiles, went into decline. Business and community leaders had the foresight to realize that the Lehigh Valley needed to reinvent itself economically to avoid a downward spiral.

Thanks to the advanced manufacturers, food and beverage producers, and technology and life science companies that have established and expanded the Lehigh Valley operations in the last 25 years, the region is today at the center of what’s being called the Fourth Industrial Revolution.

INDUSTRY TODAY 5 FEATURE - LEHIGH VALLEY, PA MANUFACTURING RENAISSANCE

Situated on the border of Pennsylvania and New Jersey, the Lehigh Valley (and its three primary cities of Allentown, Bethlehem, and Easton) is a short drive from Philadelphia and New York City. With a population of 695,000, the Lehigh Valley is the third largest region in Pennsylvania, and one of the state’s fastest growing regions, most notably among the 18-to-34 age group.

As the population has grown, so too has the economy, with a GDP that exceeds $50 billion, and has grown by $10 billion in just the last five years, driven by manufacturing.

A big part of the Lehigh Valley’s econom-

ic reinvention is rooted in its manufacturing tradition. We still make things: internationally recognized brands like Crayola crayons, Martin Guitars, and Mack Trucks, and cutting-edge products like optical semiconductors, energy-efficient lighting controls, and in-home diagnostic tests.

Pictured previous spread: Lehigh Valley – which includes Allentown, Bethlehem and Easton – has a GDP that exceeds $50 billion and an $8 billion manufacturing sector;

above: Lehigh Valley is home to several trade education programs including iTEC, an apprenticeship program for careers in advanced manufacturing.

6 INDUSTRY TODAY FEATURE - LEHIGH VALLEY, PA MANUFACTURING RENAISSANCE

More than 700 manufacturers in the Lehigh Valley generate $8 billion in economic output and employ 37,000 people. Manufacturing jobs have grown by 22 percent in the last 10 years, while average annual wages have increased by more than $20,000, contributing to a median household income for the Lehigh Valley that is greater than the national median.

Why are companies drawn to a mid-sized region like the Lehigh Valley? The number one reason is location: 50 million people live within 200 miles of the Lehigh Valley and companies can reach one-third of the U.S. population within a one-day drive. The Lehigh Valley is

convenient not only to U.S. consumers, but provides global access, too, with multiple international airports and seaports close by. In addition, the Lehigh Valley offers economic advantages over larger metro areas in the Northeast, including lower operating costs, lower real estate costs, and a more affordable cost of living. The mid-market scale of Lehigh Valley has enabled us to cultivate and sustain strong coalitions among businesses, local and state government, educational institutions, banks, and workforce organizations that contribute to a thriving business environment.

Because of these collaborations, the Lehigh

Don Cunningham is President and CEO of the Lehigh Valley Economic Development Corporation (LVEDC). Prior to leading the region’s economic development organization, Cunningham served in a variety of key public and private positions for three decades in the Lehigh Valley and Pennsylvania.

He was twice-elected Mayor of Bethlehem, twice-elected Lehigh County Executive, and the appointed Pennsylvania Secretary of the Department of General Services in Governor Ed Rendell’s administration. He also served as President of the Pennsylvania League of Cities and as a member of Bethlehem City Council. Prior to his public sector career, Cunningham worked for the Fortune 500-company, PPL, in Allentown and served in the Moravian College administration in Bethlehem. He started his career as a newspaper reporter in Bethlehem and Philadelphia and contributes a monthly column on business and economics to The Morning Call newspaper in Allentown.

INDUSTRY TODAY 7 FEATURE - LEHIGH VALLEY, PA MANUFACTURING RENAISSANCE

Valley has seen significant manufacturing expansion projects completed in the last five years, including:

• An $84 million expansion of Mack Trucks’ 1 million-square-foot plant, where every Mack product for the North American market is assembled, including its first fully electric heavy-duty truck.

• A $200 million expansion of B.Braun’s medical device manufacturing plant that adds 310,000 square feet of production space that will enable the German company to add 200 new jobs.

• A new innovation hub developed by Evonik, a world leader in specialty chemicals, that comprises more than 60 state-of-the-art testing and processing labs and a pilot plant and creat-

ed 50 high-paying jobs for scientists, engineers, and lab technicians.

• A 139,000 square-foot manufacturing and distribution center that will enable OraSure Technologies, a Lehigh Valley startup that has become a global leader in point-of-care testing for COVID-19, HIV, and other diseases, to produce 2 million in-home COVID-19 tests per week.

• A 200,000 square-foot distribution center built by guitar manufacturer CF Martin & Co., to keep up with demand for its world-famous instruments that have been the choice for generations of music icons such as Bob Dylan, Neil Young, Elvis Presley, Hank Williams and Willie Nelson.

8 INDUSTRY TODAY FEATURE - LEHIGH VALLEY, PA MANUFACTURING RENAISSANCE

Educational Institutions Fueling Innovation

The Lehigh Valley’s economic transformation has also been driven by a talented workforce with skills employers are seeking to be successful in a 21st century economy. As the region grows, its commitment to education and workforce development remains a cornerstone. Its talent strategies are directed by a strong partnership between employers and educators that has earned recognition nationally as a best practice in economic development.

The Lehigh Valley is home to 11 colleges and universities – public and private, 2-year and

INDUSTRY TODAY 9 FEATURE - LEHIGH VALLEY, PA MANUFACTURING RENAISSANCE

4-year – that award more than 10,000 degrees each year in a variety of fields that contribute to the region’s talent pool.

Three technical education schools prepare students for a variety of career paths. Lehigh Career & Technical Institute (LCTI) is Pennsylvania’s largest vo-tech school, offer-

ing over 45 skills-based programs catering to approximately 2,700 students. Bethlehem Area Vo-Tech School (BAVTS) serves around 1,300 students across 26 programs of study., The Career Institute of Technology (CIT) has 20 programs covering construction, engineering, information technology, health & human

10 INDUSTRY TODAY FEATURE - LEHIGH VALLEY, PA MANUFACTURING RENAISSANCE

services, and manufacturing.

Most recently, a unique new apprenticeship program – Industrial Training and Education Consortium of the Lehigh Valley (iTEC) launched as a partnership of industry, education, government, and community organizations to promote careers in advanced manufacturing.

iTEC offers state-registered apprenticeship programs in mechatronics and industrial manufacturing technician career paths. Additional programs for machinists and chemistry lab technicians will be available soon.

Looking ahead

The evolution of the Lehigh Valley into a 21st-century manufacturing hub has transformed our community. The population is growing. Job opportunities are increasing for people of all education levels. Regional prosperity is on the rise. The outcomes produced by the Lehigh Valley’s partnership approach motivate us to persist on this trajectory, aiming for sustained economic growth that benefits every person who lives here and attracts new talent seeking opportunity and an exceptional quality of life.

INDUSTRY TODAY 11 FEATURE - LEHIGH VALLEY, PA MANUFACTURING RENAISSANCE

SUPPLY CHAIN REACTS TO THE RED SEA

As the Israel–Hamas war continues to cause a reshuffling of Red Sea trade routes and port preferences, the shortterm impact on the global supply chain seems to—surprisingly—fall short of “crises” level. Shippers are coping with the challenges despite uncertainty on how long the hostilities

will last or how far reaching the ripple effects will be.

The global transportation data that flows through the Infor Nexus supply chain network technology offers interesting insights about the situation, pointing to the need for continued vigilance and scrutiny.

12 INDUSTRY TODAY FEATURE - RED SEA CRISIS

Modern supply chain technology helps shippers adapt to Red Sea bottlenecks.

REACTS SEA

Ripple Effects Across Oceans

The Bab el-Mandeb Strait is a narrow passage connecting the Red Sea to the Gulf of Aden and a vital artery for global trade. About 15 percent of global trade and an estimated 30 percent of global container traffic passes through its waters. With the outbreak of war, the strategic

value of the Red Sea came into sharp focus.

Overnight, the strait became a chokepoint. Major shipping companies suspended operations in the Red Sea fearing for the safety of crews and cargo. But rerouting vessels around the Cape of Good Hope to bypass the Bab el-Mandeb Strait brings major increases

INDUSTRY TODAY 13 FEATURE - RED SEA CRISIS

in transit times, increases fuel costs, and puts strains on other ports.

Making sense of the interconnected issues can be a challenge as the conditions change rapidly and one delay often leads to another, causing cascading responses. Fortunately, modern software can help monitor and track situations as they evolve.

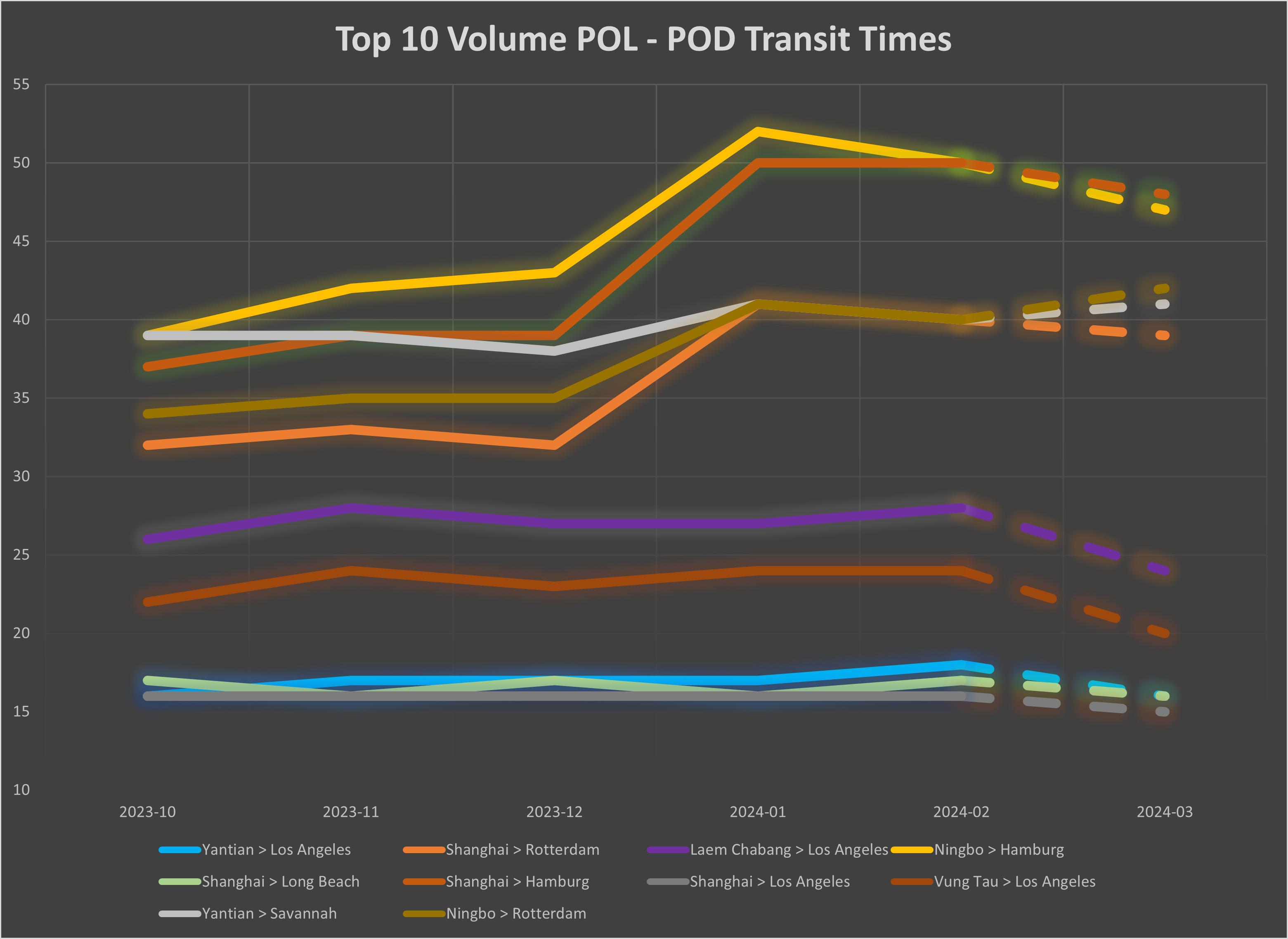

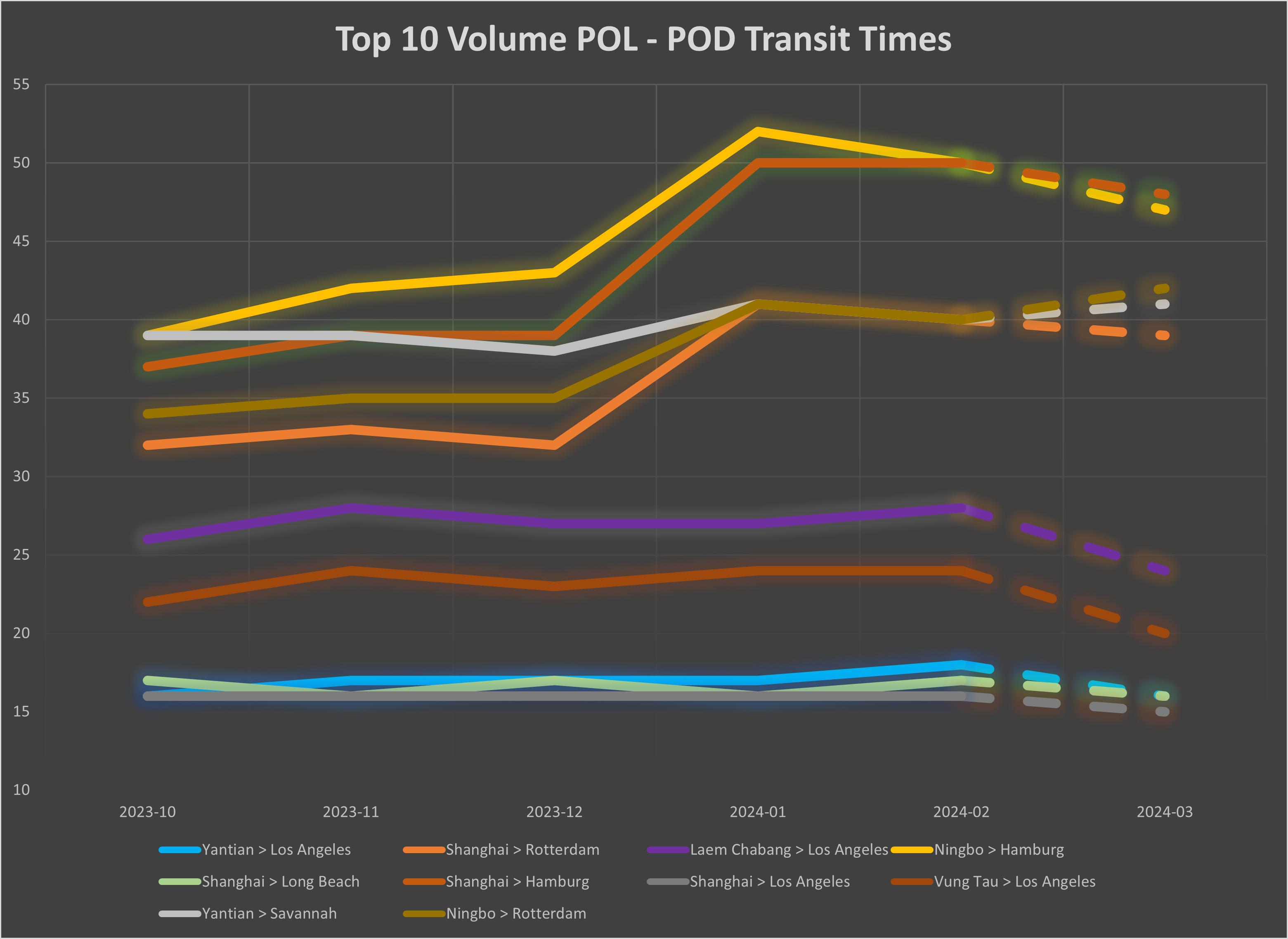

Data can provide some interesting insights and unexpected trends. For example, data flowing through Infor Nexus shows a mix of transit delays, longer dwell times, and yet some projected delivery times for March are close to 2023 timeframes.

Here are recent Infor Nexus observations:

• Rerouting continues to impact transit times for shippers throughout Europe and North America. Many shipping companies continue to travel the longer but safer route around the Cape of Good Hope, South Africa, leading to a heightened level of transit times on shipments from Asia.

• Western European ports such as Felixstowe, Rotterdam and Hamburg continue to be hit the hardest by these longer transit times, resulting in delays of 6-16 days.

• Similarly, shipments destined for key ports in North America, including New York, face delays of up to 10 days. The most significant impact appears to be the Indonesia to Montreal

14 INDUSTRY TODAY FEATURE - RED SEA CRISIS

Pictured: Close up of the Bab el-Mandeb Strait that connects the Gulf of Aden to the Red Sea.

route, now experiencing a 24 percent increase in transit times over typical 2023 times.

• Up to 20 percent of Canadian shipments appear to be shifting from Eastern to Western Canadian ports as shippers try to avoid both the Red Sea and the Panama Canal.

More observations:

Increased Dwell Times expected. In addition to shifts in transit time, dwell times at a number of the larger transshipment ports have extended;

particularly those in Asia due to the extended return times to ports of origin. Particularly hard-hit is the Port of Colombo, Sri Lanka, where dwell times have doubled from four days to eight.

Cautious optimism for March. Contrary to the evidence of extended transit times, carriers are still reporting that they expect transit time levels for March to fall back to rates during November 2023 and the outbreak of the IsraelHamas war. While the rate is still unnaturally

INDUSTRY TODAY 15 FEATURE - RED SEA CRISIS

high, the downward shift is positive news for businesses. Of the top 25 routes (by volume), only 6 show an expected increase in transit times. The China to Rotterdam route is the most heavily affected with 11 percent above the levels they were before December 2023.

The ripple effects of these disruptions are felt throughout global supply chains, proving the interconnectedness and vulnerability of the maritime trade network.

Lessons learned

Although the long-term repercussions are yet to be tallied, we can see that the impact of the Red Sea crisis may be under control and not quite ratcheted up to crises status of infamous COVID proportions. The situation, although complex, is understandable and manageable.

16 INDUSTRY TODAY FEATURE - RED SEA CRISIS

Organizations are able to make strategic decisions to observe, collect facts, evaluate risks, adapt, and monitor results. Technology has helped global shippers to quickly pivot in new directions. Although most industries have likely felt the ripples of disruption that originated at the Red Sea, we have not seen Pandemic-era devastating shortages, plant shutdowns, or consumer buying panics.

The “new norm” of ongoing disruptions has caused supply chain professionals to be more alert, proactive, and ready to make timely decisions, rather than take a “hope it resolves it itself” approach to response planning. Professionals in

the industry have also learned the value of modern software solutions and process improvements. Here are some ways these best practices have helped mitigate the recent supply chain complications:

Emphasis on resilience. More aware of their vulnerabilities, companies are now prioritizing building robust and flexible supply chains capable of withstanding disruptions, whether from geopolitical tensions, natural disasters, or other unforeseen events.

Improved visibility. Improved visibility and predictive alerts help users get ahead of issues while there is still time to intervene and improve

INDUSTRY TODAY 17

outcomes. Plus, network-wide views of inventory give organizations flexibility to move goods between warehouses or ship earlier from suppliers to help meet shortages.

Accelerated digital adoption. Organizations are seeing the value of digital technologies and modernizing solutions. From predictive analytics and AI-driven forecasting to supply chain mapping for traceability and automated

procurement processes, companies are turning to technology to help them enhance responsiveness to disruptions and their ability to meet changing market demands.

Shift to localized sourcing. Heightened awareness of the risks associated with long and complex supply chains has led many companies to reconsider their sourcing strategies. Reshoring, nearshoring, and regionalized hubs

18 INDUSTRY TODAY FEATURE - RED SEA CRISIS

Pictured: Infor Nexus data showing an increase in Ocean transit times and Predicted Transit Times (dotted lines) for the Top 10 lanes (by volume) from POL in Asia to POD in Europe (by lane by month); right: European Bound Container Ships (Under Way Using Engine) travelling around the Cape of Good Hope to avoid the Bab el-Mandeb Strait according to Infor Nexus data.

are being adopted as companies strive to bring production closer to end markets, reduce lead times, cut transportation costs, and minimize risks associated with distant suppliers.

Interconnected ties. In an interconnected global economy, collaboration and data sharing are important. Suppliers, logistics providers, and other stakeholders are recognizing the value of transparency, communication, and risk mitigation. Enhanced visibility into inventory levels, production capacities, transportation routes, and market demand also helps organizations to be better prepared, ultimately leading to more resilient and responsive supply chains.

Not out of the woods yet

No one can accurately predict how long the conflict between Israel-Hamas may continue or what other volatile situations may arise. By being alert to global economic shifts as well as supply chain disruptions, organizations can make well-informed decisions based on facts, not fears or rumors. With smart strategies in place, no matter what disruption may be around the corner— or beyond the strait—the modern supply chain organization can respond with agility.

Heidi Benko, global supply chain expert, is VP of Strategy for Infor Nexus.

INDUSTRY TODAY 19 FEATURE - RED SEA CRISIS

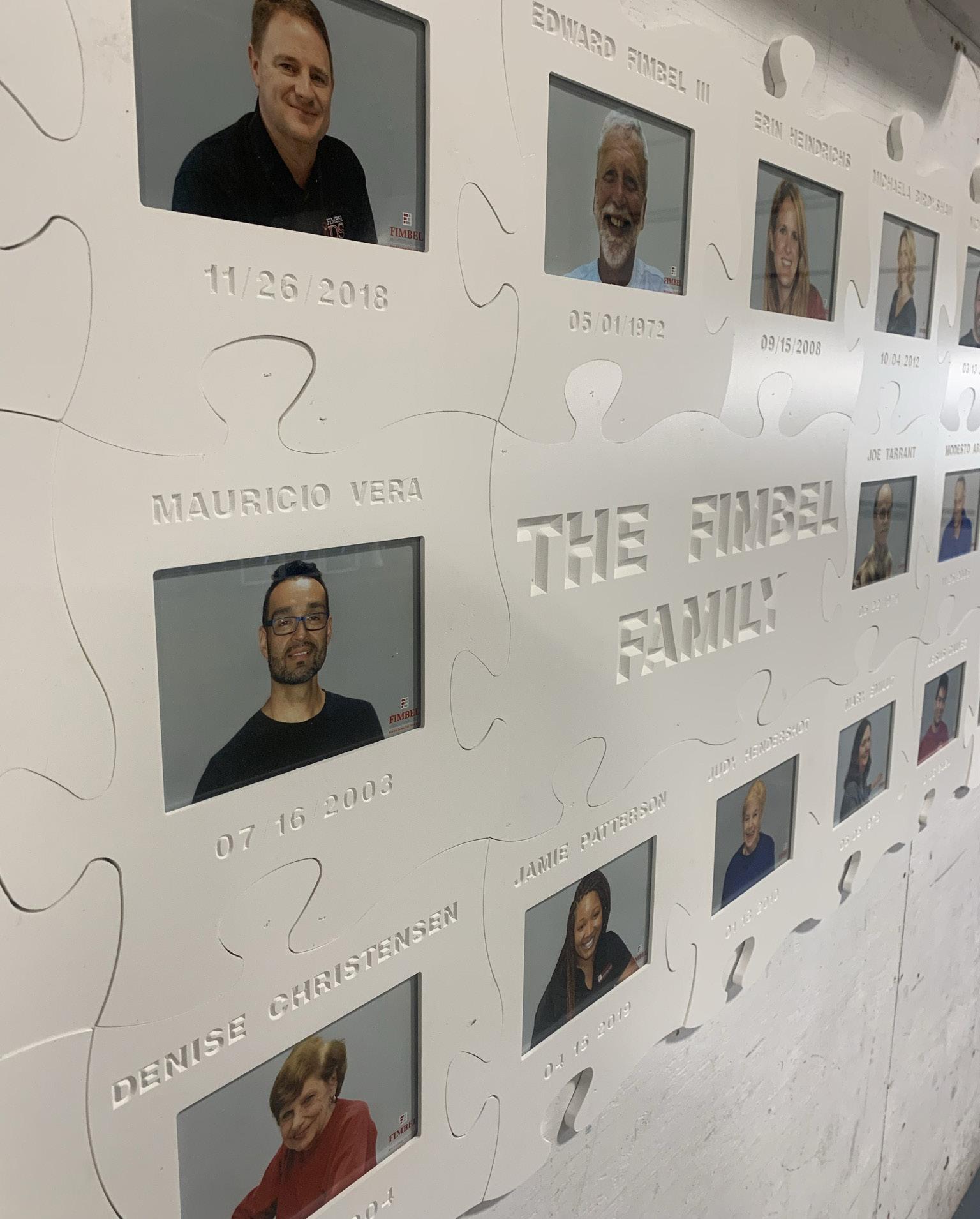

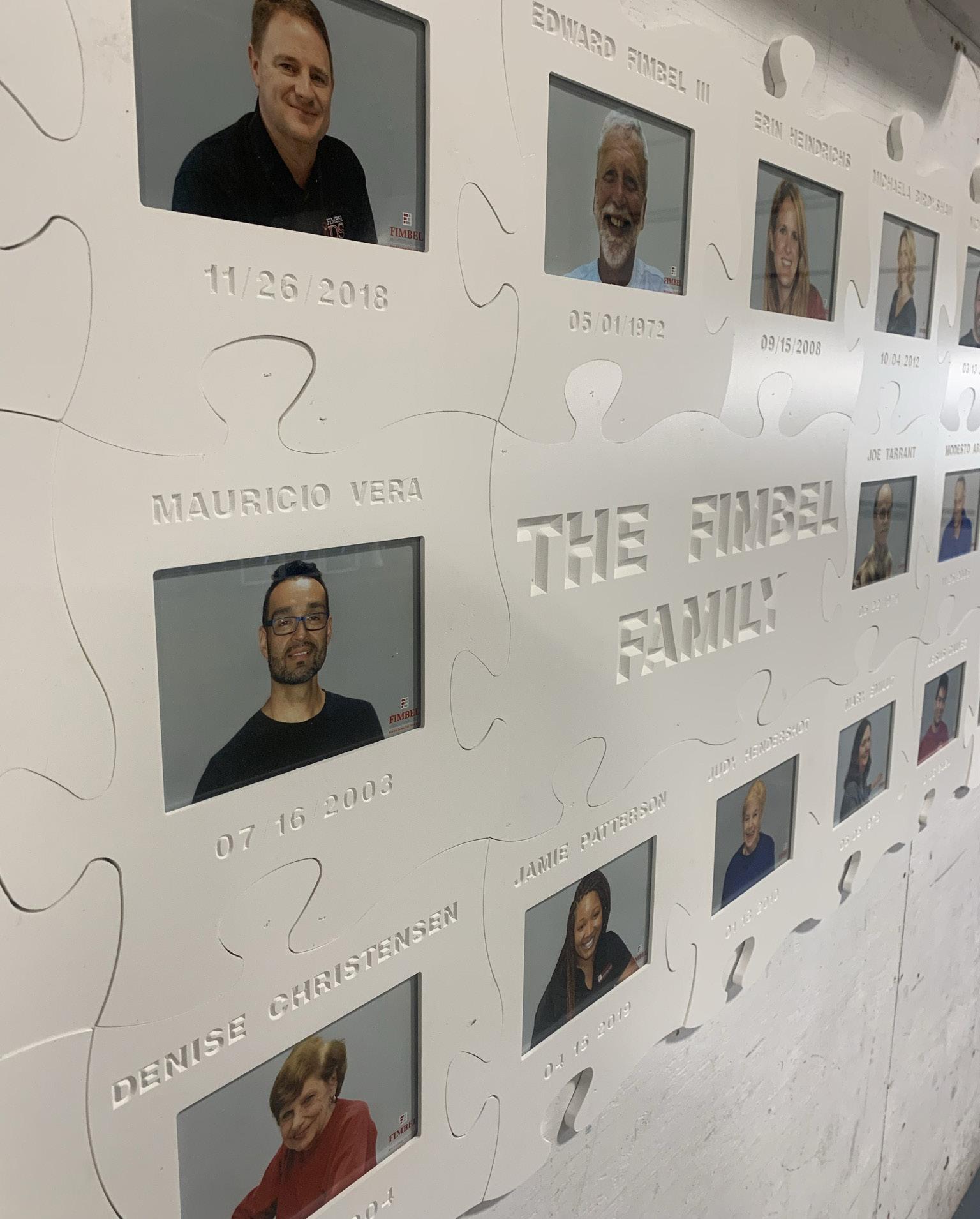

FAMILY OPENINGS

20 INDUSTRY TODAY PROFILE | FIMBEL

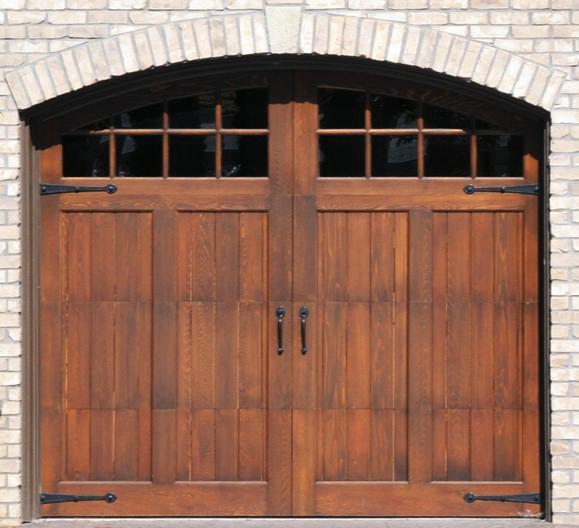

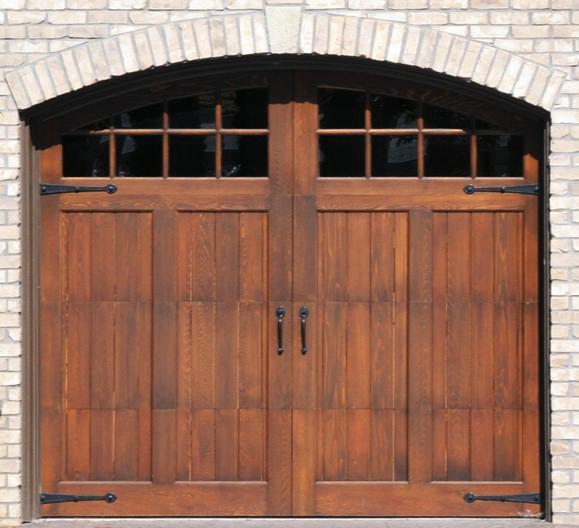

Fimbel Architectural Door Specialties is the oldest manufacturer of sectional garage doors owned and operated continuously by the founding family.

There’s an old saying that when one door closes, another opens.

For Fimbel Architectural Door Specialties (Fimbel ADS), that saying defines a fourth generation family business focused on opening and closing doors.

Celebrating its 100th anniversary in 2024, Fimbel ADS is the world’s oldest manufacturer

INDUSTRY TODAY 21 FIMBEL | PROFILE

of sectional garage doors owned and operated continuously by the founding family. The company’s origins date back to 1924, when master carpenter Edward Fimbel Sr. signed the first franchise with the Overhead Door Corporation to manufacture, distribute, and install wood sectional garage doors from its original Hillside, NJ location.

Edward Fimbel Sr. passed away at the age of 94, passing his legacy to Edward Fimbel Jr. who became president of Fimbel Door Corporation. In 1991 he acquired and setup an automated roll forming line to manufacture foamed-inplace residential and commercial insulated steel doors at their Whitehouse, NJ factory.

XCEED Siding Trimboard & Stealth Sheet T&G Profiles VERSAWRAP Canvas Corners Soffit System Mouldings Skirtboard Finishing ·Lightweight ·Easy to install ·Resists Moisture ·Resists Insects ·Install at Grade versatex.com 22 INDUSTRY TODAY PROFILE | FIMBEL

Fast forward to 2004, when Ed Fimbel III recognized that the market was shifting to doors with a carriage style look. So the company transitioned from producing stamped steel doors as Fimbel Door Corporation to become Fimbel ADS, employing CNC manufacturing utilizing composite materials to provide the look of real wood sectional carriage doors without the maintenance.

Today, Fimbel ADS, under the fourth-generation leadership of President Erin Fimbel, continues to set the standard for design, manufacturing, and quality as a recognized industry leader. Operating under the guiding principle, “More in a garage door,” the Whitehouse, NJ

INDUSTRY TODAY 23 FIMBEL | PROFILE

Pictured left: Firehouse WI Ghostbusters Sign-Hook+Ladder; American Legends Model 13 Wright Factory Painted Evergreen; Engine 55 New York City Fire Department (FDNY).

24 INDUSTRY TODAY PROFILE | FIMBEL

headquartered company’s advanced materials, patented manufacturing techniques, and advanced quality systems, combined with high attention to detail and a customer service experience that is unsurpassed.

“We make garage doors that look like wood, but without the maintenance,” Fimbel says. Vinyl coated steel and solid vinyl and composite

doors treated with composite overlays create a classic wood door appearance, particularly in comparison to embossed fake wood grains in other products, without the drawbacks of real wood that is susceptible to rotting over time.

Fimbel ADS provides residential and commercial garage door solutions for everything from new construction to period-authentic historic preservations. Every door is produced to strict manufacturing specifications, driven by a

INDUSTRY TODAY 25 FIMBEL | PROFILE

Pictured: 4 Generations; below: Fimbel Family 50th Anniversary.

culture of continuous improvement combined with sustainable and environmentally responsible best practices.

Among the various styles of low maintenance residential and commercial garage doors currently available are traditional, carriage style, modern, and custom designs. “Our CNC manufacturing capabilities allow us to provide complete customization without the added expense,” Fimbel says.

Who You Gonna Call? Fimbel ADS

Case in point is the replacement of deteriorating wood carriage doors for the New York City Fire Department. “Our designers worked closely with the city’s historical society to ensure we accurately duplicated the look of the doors, particularly the wrought iron transoms as well as the windows. If you’ve seen any of the Ghostbuster movies, the Tribeca firehouse shown in the film, which dates back to 1903, features one of our doors.”

Fimbel ADS maintains a 60,000 square foot facility in McAdoo, Penn for most of its

26 INDUSTRY TODAY PROFILE | FIMBEL

Pictured: Roaring Twenties Model II Detroit Natural White.

sectional garage door manufacturing. A 30,000 square foot facility in Whitehouse is devoted to office space and production of more specialized custom doors. Fimbel emphasizes that the company’s commitment to quality and safety is not just about its manufacturing processes, but also to its 48 employees and local community.

“Our facilities run on solar power and we pass along our unused power back to the grid,” she says. “Fimbel’s recycling program utilizes engineering practices to consume production waste, aiming to achieve zero landfill”. In addition, Fimbel partners with One Tree Planted (501c3)

to do our part to restore generous forests. On top of that, our products are designed to minimize environmental impact, both during their construction and throughout their lifetime.”

Patented Performance

Numerous U.S patents have been awarded to Fimbel ADS for its unique processes and product performance. All product lines are engineered for outstanding reliability and longevity. Of particular note are the inlaid door panel overlays that prevent water from seeping behind an overlay and loosening the

INDUSTRY TODAY 27 FIMBEL | PROFILE

panels over time. By eliminating gaps between the face and overlay, this feature also produces an aesthetically superior appearance.

Additionally, Fimbel has multiple patients to utilize computer-controlled machinery to carve a design into the solid face of the door and win-

dow section. This allows for the look of multipiece construction without the drawbacks and allows for flexibility of design.

Fimbel ADS sells through distributors primarily throughout the northeast who work with homeowners, developers, and architects to deliver garage doors with exceptional curb appeal. While the company is looking to expand, Fimbel emphasizes that any potential future partners must live up to the company’s high quality standards. “We don’t sell to just anybody,” she says. “We’re continually looking to evolve the company and our products, but we’re never going to do that at the expense of our commitment to our customers and team.

Fimbel acknowledges that a garage door is not the first thing that comes to mind to every homeowner or builder when thinking about design aesthetics. “Yet in many situations garage door(s) make up 30% or more of a home’s exterior. The right garage door can have a huge impact on a home’s curb appeal and currently has a 103% ROI”.

28 INDUSTRY TODAY PROFILE | FIMBEL

Pictured above: Bill Rasely, Vice President; below: Erin Fimbel, President.

Unique Manufacturing

She adds, “Our manufacturing methods enable us to construct door sections in one-inch increments. Combined with single sheet construction and handmade frames, we can make a door just about any way a customer wants. Even if it is the most odd-sized opening, we can make a beautifully built-to-size door. This makes a huge difference in the look, fit and functionality of the door. Premium features and custom options are available for a door’s design, finish, application and more. Most of which come at minimal or no additional charge. Additionally, all products can be factory stained and painted, and Fimbel offers custom colors to complement any home or project.

Interlocking tongue and groove vinyl-clad section joints allow for a door that meets not only durability, but attractiveness. Glass sections are a solid one-piece grille made from durable Versatex®, or Tricoya®. There are no seams in the window muntins for a clean look that does not crack, warp, or gap. There’s an energy insulated glass package and UV resistant materials to prevent yellowing. Hardware attachment points are pre-drilled to ensure a secure and long-lasting installation. All Fimbel ADS

doors are encased with high quality materials to prevent water damage and allow for a limited lifetime warranty.

“We are excited with possibilities that exist for Fimbel ADS as we move forward into our second century,” Fimbel says. “New materials, emerging technologies, and a renewed commitment to excellence offers unlimited opportunities for us to create the future generations of high performance, industry-leading doors.”

INDUSTRY TODAY 29 FIMBEL | PROFILE

SUPPLY CHAIN DISRUPTION CONTINUES TO STEER

Following the COVID-19 pandemic and recent geopolitical uncertainties, the supply chain has become prone to more challenges, calling for markets and businesses to build supply chain resilience and reliability. This article explores current issues relating to supply chain disruption and the impact on dealmaking.

FEATURE - GLOBAL M&A TRENDS AND RISKS REPORT

DISRUPTION STEER M&A

The supply chain is a critical component of any business that drives the production and distribution of products and services. Any level of disruption has the risk of significantly impacting the performance of the business. The COVID-19 pandemic led to a series of border shutdowns, resulting in

FEATURE - GLOBAL M&A TRENDS AND RISKS REPORT

challenges for markets heavily reliant on imports and exports of materials and products. As the global economy slowly began to recover from the after-effects of the pandemic, geopolitical tensions loomed in some regions, resulting in businesses grappling with severe supply chain issues.

Some businesses witnessed a steep downfall in their operations and economic performance, exposing deficiencies in their supply chain networks. Manufacturing processes slowed due to a shortage of materials, and distribution was significantly impacted. Supply chain availability became far more valuable, spurring deal activity. In the Global M&A Trends and Risks (2024)

report released by Norton Rose Fulbright which highlights the takeaways about market trends after surveying more than 200 senior executives across multinational corporations, large private equity firms and major investment banks, supply chain came up as a key driver for M&A activity worldwide.

Government policy in the U.S. impacting supply chain

Due to the geopolitical friction between the United States and China, supply chain networks were disrupted. The supply chain was already undergoing challenges when China adopted its zero-COVID policies, partially influenced

32 INDUSTRY TODAY FEATURE - GLOBAL M&A TRENDS AND RISKS REPORT

by political pressure. The situation worsened when the United States, in addition to the EU, increased tariffs on imports from China. As things escalated, panic set off among businesses heavily reliant on Chinese imports.

The world saw another conflict that changed the course of supply chain. In response to the Russia-Ukraine conflict, Russia also faced economic sanctions from the United States. These measures have led to supply shortages, especially in the oil and gas trade. With a similar response from the European Union, supply of oil and gas has been a challenge for both markets, but especially the European Union.

The U.S. government introduced specific initiatives aimed at boosting supply chain resil-

ience. Most were in response to the pandemic and meant to address manufacturing and delivery challenges. The Congressional Supply Chain Caucus, the Chips and Science Act which is specifically focused on semiconductor chips, and the Supply Chain Disruption Task Force. These are some of the initiatives as a result of the United States’ shift in approaching supply chain. It is too early to assess how much positive impact these initiatives have had.

Sectors and regions most impacted by supply chain disruption

The problems with the global supply chain have severely disrupted businesses in the

INDUSTRY TODAY 33 FEATURE - GLOBAL M&A TRENDS AND RISKS REPORT

automotive and transportation sectors. In addition to the automotive sector, the United States and Canada witnessed disrupted in the electronics sector too. Europe saw a downturn in industries such as automotive and manufacturing.

Due to shortages in computer chips, automakers have found it challenging to meet the already pent-up demand for vehicles driven by labor shortages. The impact on manufacturers within the semiconductor sector has had ripple effects in the technology industry, due

34 INDUSTRY TODAY FEATURE - GLOBAL M&A TRENDS AND RISKS REPORT

to shortages in raw materials and production slowdowns. Other sectors, such as healthcare and retail, have also felt a substantial impact, leading to a slowdown.

The impact of supply chain issues is prevalent across the globe. The emerging crisis in the Red

Sea and the resulting increase in shipping costs and delays have further exacerbated supply chain concerns. Countries in Asia suffered an economic downturn due to a slower pace in the manufacturing and logistics sectors.

Businesses leaning towards strategic changes and M&A deals to mitigate effects of supply chain disruption

The U.S. policy, in response to geopolitical tensions, has forced businesses to explore options for securing reliant supply chain networks. With limited external solutions, most businesses are considering operational over-haul, reshoring, and near-shoring. Companies are engaged in reshoring by finding logistics solutions within the domestic market. Near-shoring, on the other hand, is an approach to finding solutions within the geographic area where most of the consumer demographic is concentrated.

INDUSTRY TODAY 35 FEATURE - GLOBAL M&A TRENDS AND RISKS REPORT

Recently, businesses have also turned towards embracing digital transformation. Increased investment in the automation of warehousing and supply-chain planning is trending. As the respondents in the report indicated, the ongoing pursuit of digital transformation and the increased demand for deals are among the key drivers of M&A activity.

Businesses are more inclined to acquire or merge with players in transportation and logistics industry to support their vertical integration goals. Not many businesses are inclined towards working with third parties to facilitate supply

chain. The urgent need for maintaining a resilient and reliable supply chain process is driving the deal market.

As the report notes, businesses are looking to boost supply chain and attain inorganic growth through vertical acquisitions. This trend will bolster supply chain resilience amid geopolitical friction and world-shifting pandemics. The benefits of such deals include improved sustainability and the ability to drive faster growth.

Companies that are not actively considering vertical deals as a solution to address supply chain disruption are looking to build capability and transform their supply chain designs so that they have more ownership over the different phases of production. More businesses are relying on artificial intelligence to design sophis-

36 INDUSTRY TODAY FEATURE - GLOBAL M&A TRENDS AND RISKS REPORT

Aara Tomar provides corporate advice to business owners and entities in mergers and acquisitions and private equity transactions.

Ayşe Yüksel Mahfoud is Norton Rose Fulbright’s Global Head of Corporate, M&A and Securities.

ticated channels for foolproof supply chain process.

Vertical Deals Triggering Government Scrutiny

Vertical deals are not without their own problems; they are drawing regulators’ attention globally. As indicated in the report, national security and antitrust regulations have tightened. Antitrust agencies are scrutinizing the potential of vertical deals to limit the market for participants operating in the logistics sector. Big-scale businesses in different levels of the supply chain that are parties to such deals are seen to harm other businesses’ ability to compete. In the U.S., for example, the merger

guidelines 2023 expressly target vertical transactions, raising the probability of lengthy deal closings. In addition, antitrust agencies across countries are initiating cooperation with each other, posing the risk of an increased review period for deals, including vertical deals. The European Commission, for example, recently indicated that it is working with competition authorities worldwide.

Despite the evolving regulatory landscape concerning vertical deals, the deal market continues to feature strategic moves by businesses looking to develop supply chain resilience. This trend will likely dominate the first half of 2024, resulting in more deals in response to supply-chain disruption.

INDUSTRY TODAY 37 FEATURE - GLOBAL M&A TRENDS AND RISKS REPORT

38 INDUSTRY TODAY FEATURE - CRITICAL MINERALS

CRITICAL MINERAL MUST BE MADE IN

Onshoring production would unlock local value chains for industry.

The clean energy transition cannot happen without critical minerals. The United States needs to address three key supply chain challenges to meet its ambitions for industry, citizens, and the economy as a whole. These are:

1. China’s supply chain dominance – how can the US reduce this dependence and create national value chains?

2. Shortfalls in supply – with demand rapidly growing, how can this shortfall be filled?

3. The negative environmental impact of incumbent technologies and supply chains –can America show the world that there is a better way of doing business?

Failing to address these challenges risks allowing China to dictate the pace of electrification and net zero efforts and thus, the opportunities that they provide US industry. Additionally, failure to achieve critical mineral independence

MINERAL INDEPENDENCE

INDUSTRY TODAY 39 FEATURE - CRITICAL MINERALS

IN

THE USA

risks driving big players in the American automotive industry out of business due to reduced access, supply constraints, and the unfair advantages enjoyed by overseas competitors.

Further, the International Energy Agency predicts that future demand for the critical minerals required to manufacture batteries will far outstrip supply. This would slow the deployment of electric vehicles (EVs) and energy storage and thus, renewable energy – harming key industries, as well as the country’s economic growth and energy security.

The US government and industry has already become aware that the clean energy transition

is contingent upon critical mineral supply chains. Enabling the electrification of transport and decarbonization of energy systems through onshoring critical mineral supply chains will play a pivotal role in helping America achieve its future economic and environmental goals in tandem.

Crucially, threats to these supply chains also represent threats to US security – as revealed by Assistant Secretary Pyatt’s centering his engagements on critical minerals at the recent Munich Security Conference.

But words alone will not suffice. They need to be backed up with urgent action, from

40 INDUSTRY TODAY FEATURE - CRITICAL MINERALS

policymakers and industry.

Critical minerals like graphite – which comprises half the weight of lithium-ion batteries – are integral components of the technologies powering the clean energy transition.

The US government maintains three lists of critical strategic materials. Graphite is on all three.

Addressing China’s supply chain dominance

China is a dominant, disruptive player in global critical mineral supply chains, particularly when it comes to graphite – the country currently controls over 90% of the world’s supply.

This dominance entails the risk of weap-

onization for political leverage and potential disruption of supply to the US’s clean technology industry. China has already shown itself willing to do so, with graphite exports dropping by 91% in December 2023 after it imposed controls. This move resulted in widespread uncertainty in American industries and markets while providing an unfair advantage for China’s homegrown EV manufacturers, which

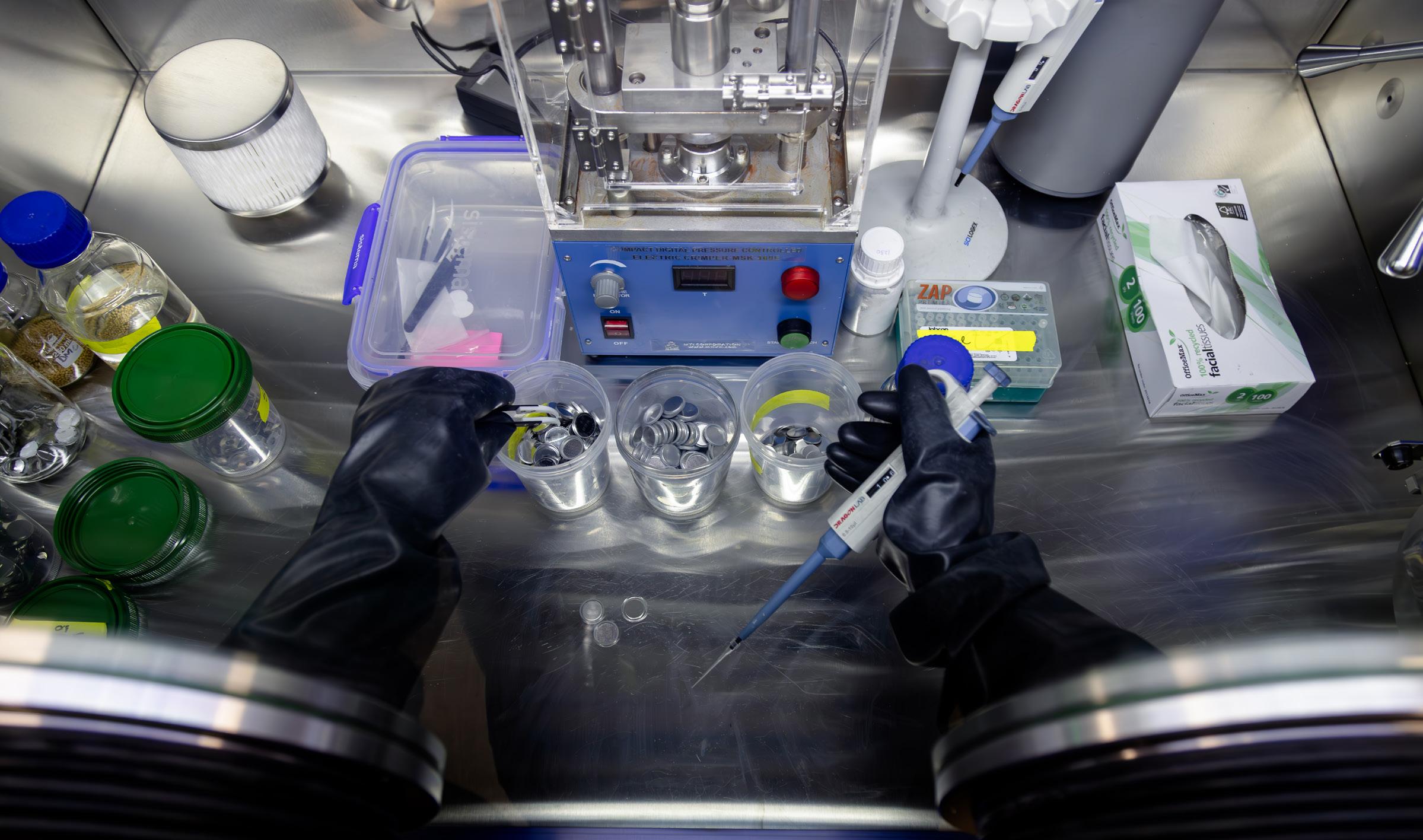

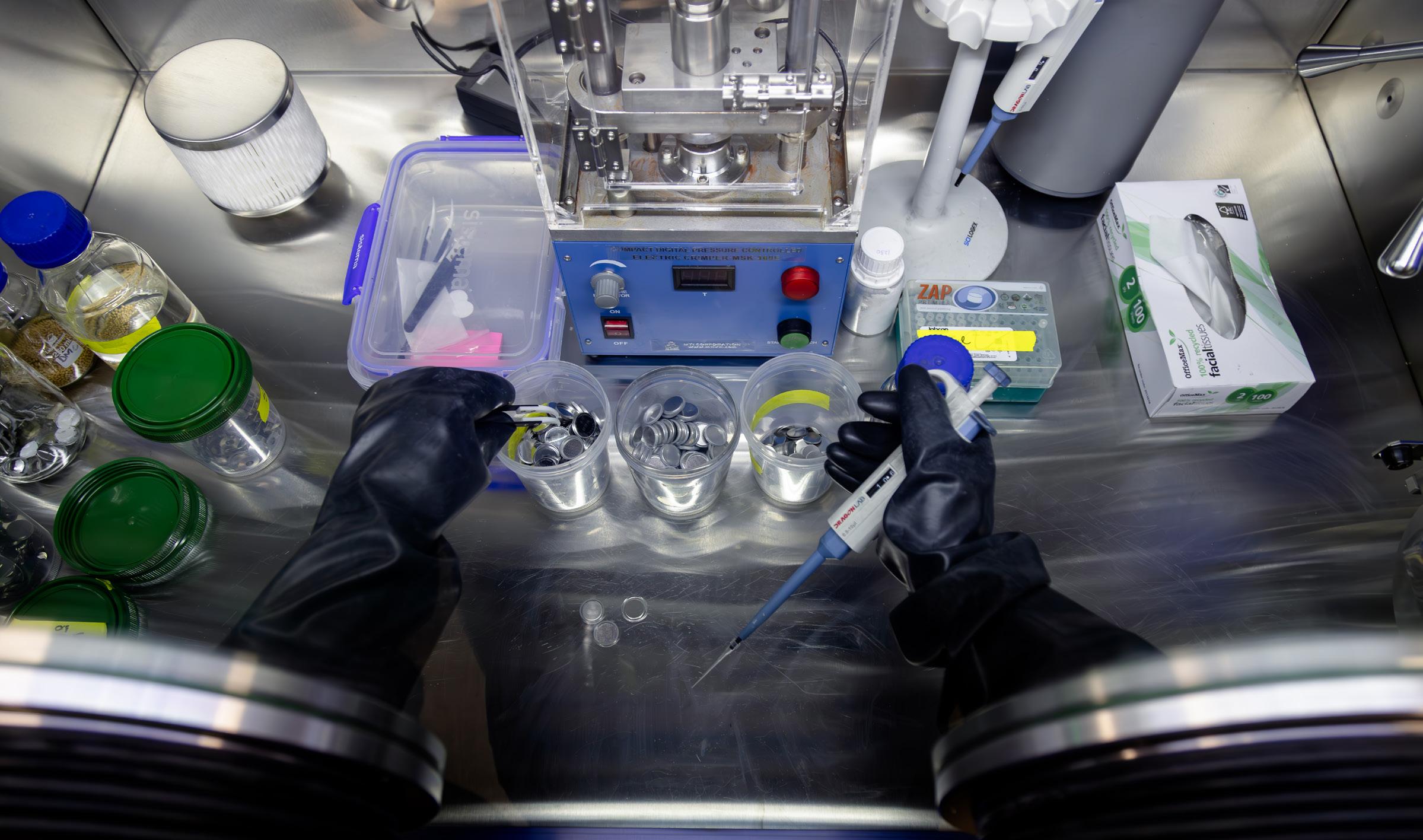

Pictured left: Sustainable and renewable waste woodchip from forestry is the feedstock for the production of CarbonScape’s innovative biographite;

below: A state-of-the-art battery laboratory ensures optimal performance of biographite against our OEM battery clients’ unique specifications.

INDUSTRY TODAY 41 FEATURE - CRITICAL MINERALS

are growing at a remarkable pace.

To date, the US has made little headway in breaking its dependence on China for the types of minerals and metals that are critical to the nation’s clean energy ambitions, economic well-being, and defense. The 2024 edition of the US Geological Survey’s annual Mineral Commodity Summaries found that America is 100% dependent on imports for graphite.

That said, there is growing consensus among US policymakers around the need to address this challenge, as demonstrated by making it a focus of their engagement at the Munich Security Conference. Policy now needs to be put into place, to help the US achieve critical mineral independence by strengthening national supply chains.

Onshoring is the future

right: Ivan Williams, CEO – CarbonScape stands beside woodchip and the biographite produced from it (actual yield 7:1 – dry woodchip: biographite).

Onshoring the production of these critical minerals – a key part of the automotive industry’s value chain – is the best way to address the challenge. Not only will this enhance supply chain security, but it will also catalyze

Pictured: Sustainable forestry byproduct is pyrolysed, then milled for optimal proprietary catalytic graphitisation;

42 INDUSTRY TODAY FEATURE - CRITICAL MINERALS

economic growth, cr ate new jobs, and enable local control of the electrification economy.

Through initiating domestic production, the US can protect itself against potential supply chain disruptions and free itself from the uncertainty of geopolitics.

However, neither of the incumbent forms of graphite offer long-term security.

The production of ‘traditional’ synthetic graphite is dependent upon dwindling stocks of fossil-fuel based feedstocks (coal tar or petroleum coke) and highly polluting manufacturing processes. Each metric ton of this form of graphite can be responsible for as much as 50 metric tons of carbon emissions.

For synthetic graphite, which is produced

using petroleum needle coke or coal tar pitch, this would require vast new plants to be built across the country by 2030. Meeting demand for graphite with only synthetic graphite would make the country fully dependent on finite resources i.e. fossil fuels, and high-emission processes.

Natural graphite is mined from the earth, exacting a heavy toll on nearby communities, animals, and the environment – every metric ton produces as much as 15 metric tons of carbon emissions. Graphite mines are also confined to certain geographies and could quickly cease to be economically viable, leaving stranded assets and scarred earth in their wake.

Fulfilling demand with mined graphite would

INDUSTRY TODAY 43 FEATURE - CRITICAL MINERALS

require extensive new mines to be commissioned and built throughout the country by 2030. With some mines taking up to 7 years to come onstream, this represents a particularly huge challenge. This solution would also cost taxpayers hundreds of millions of dollars and entail enormous social and environmental costs while making the country fully dependent on finite resources.

A sustainable graphite solution

One alternative to unsustainable graphite production is biographite, a new high performing, cost competitive and climate positive form of synthetic graphite that can be produced from low cost, sustainable forestry by-products (such

as wood chips), using renewable energy.

Biographite acts as a ‘drop-in’ replacement for costly traditional synthetic graphite and can be produced locally using widely available, sustainable feedstock. This key distinction means that production can be rapidly scaled to meet skyrocketing demand. It also means biographite plants can be located near cell and battery manufacturers and OEMs – shortening supply chains, driving economic efficiencies, and

Pictured: CarbonSpace’s end-to-end proprietary technology takes wood-chip raw material through to fully functioning high-grade anode material; right: An international team of over 12 nationalities, all committed to a world where sustainable biographite empowers a greener future for all.

44 INDUSTRY TODAY FEATURE - CRITICAL MINERALS

providing additional environmental benefits.

Critically, biographite can be produced in mere hours, as opposed to the months currently required to manufacture anode-grade synthetic graphite. In addition, the creation of biographite saves up to 55 metric tons of carbon emissions per metric ton when compared to traditional synthetic graphite.

Using only a small fraction of the US’s forestry industry by-products that are generated annually, enough biographite could be produced to meet the country’s projected graphite demand by 2030, a giant leap towards critical mineral independence that will onshore new, high-skilled jobs.

Rolling out commercial scale biographite

plants across America will accelerate electrification and net zero efforts, unlocking new opportunities for a wide range of American industries while transforming the battery material supply chain. By supporting the onshoring of this critical mineral, US policymakers and industry can play a vital role in shaping a future where America regains control of its critical mineral supply chains and elevates the country’s global leadership credentials in clean energy.

Biographite can help transform America’s electrification economy and enable it to outmaneuver its overseas competitors as the world transitions to a climate positive future, but only if we act now.

INDUSTRY TODAY 45 FEATURE - CRITICAL MINERALS

KEEP ON TRUCKIN’

Kenworth Trucks builds innovative transportation solutions employing the latest technologies that improve truck performance and energy efficiency.

46 INDUSTRY TODAY PROFILE | KENWORTH

In 1924, Harry Kent and Edgar K. Worthington started a business to build customized trucks capable of carrying heavy loads over difficult muddy logging roads in the Pacific Northwest. The new business headquartered in Seattle, Wash. combined

their names to form the trucking company Kenworth.

The partners manufactured 80 trucks in the first year of operation. By 1925 production upped to nearly two customized trucks per week.

INDUSTRY TODAY 47 KENWORTH | PROFILE

Fast forward to its centennial celebration in 2024, Kenworth is launching two Special Edition trucks, the T680 Signature, available in mid- and high-roof configurations, and the Wool 900L Limited, available in extended day cab, flat-top or studio sleeper options.

Both Special Edition models feature signature seats, serialized badging, unique trims, and paint options, as well as Kenworth advanced technologies and manufacturing processes that

deliver higher fuel efficiency and lower cost of ownership. The Wool 900L, one of the longest of long-nosed conventionals at 130 inches from bumper to back-of-cab, as the name implies is limited to 900 production models.

All Kenworth trucks offer a suite of driver-optimized technologies:

• Digital Mirror System enhances visibility around the truck in all kinds of weather conditions; improved handling results in better fuel

48 INDUSTRY TODAY PROFILE | KENWORTH

economy by up to 1.5 percent.

• Smartwheel provides tactile, eyes-on-theroad function choices.

• Adaptive cruise control with stop and auto go modulates the throttle and brakes to keep truck at pre-set distance from the vehicle in front of it.

• Collision Mitigation detects when truck may be about to collide with another vehicle and alerts drier to take pre-emptive braking action.

• Side Object Detection visual and audible alerts of vehicles or objects entering the truck’s blind spots.

• Lane Departure Warning alerts driver of any unsignaled lane change for driver to make appropriate correction.

• Highway Detection Braking to Zero provides

INDUSTRY TODAY 49 KENWORTH | PROFILE

Pictured: The Kenworth T680 includes a world-class cabin reminiscent of the finest automobiles whilst the 900L combines ready-foranything functionality with aesthetic design.

audible chime and braking when

roadway.

• Lane Keeping Assist helps ensure driver has hands on wheel and is staying within lane markings.

• Torque Assisted Steering adjusts torque based on truck speed to improve driving experience.

Cleaner Trucks, Inside and Out

The first truck manufacturer to receive the EPA’s Clean Air Excellence Award, Kenworth is also at the forefront of truck electrification. Built on proven platforms, with superior visibility, reliability, maneuverability and driver comfort, the T680E Class 8 and K270E/K370E

truck departs

50 INDUSTRY TODAY PROFILE | KENWORTH

Pictured: For 100 years, Kenworth’s customers have counted on them to deliver in the harshest conditions, on the toughest roads, with the heaviest loads.

Medium

Duty models

combine state-of-the-art zero emission powertrains with comprehensive charging solutions and infrastructure support.

To further push the envelope for zero emissions trucking, Kenworth has embarked on a pilot hydrogen fuel cell class 8 tractor. Kenworth integrated Toyota’s latest advancements in hydrogen fuel cell technology into its flagship T680 on-highway truck. The T680 FCEV has a range of up to 450 miles at a top speed of 70

miles per hour, an ideal solution for weight-sensitive operators with short-distance deliveries.

Kenworth also aims to make traditional truck’s more energy efficient and sustainable, while also improving performance. One example is the recent introduction of new PACCAR TX-12 PRO automated transmission, available on select models, which promises higher performance and efficiency.

Kenworth also delivered the industry’s first

INDUSTRY TODAY 51 KENWORTH | PROFILE

15-liter compressed natural gas (CNC) powered truck to UPS. The Cummins X15N meets both upcoming 2027 EPA emission requirements and CARB 2024 Low NOx standards; Kenworth is the first major truck manufacturer to offer an engine that meets CARB’s NOx emission standards. At the same time, the CNC truck offers diesel-like power and performance,

making it appealing for regional and long-haul operations.

Just as Kenworth commemorates its 100th anniversary as a company, Kenworth’s Chillicothe, Ohio manufacturing plant celebrates 50 years since a Kenworth truck rolled off its assembly line.

The Kenworth Chillicothe plant is located

52 INDUSTRY TODAY PROFILE | KENWORTH

on a 120-acre site, some 50 miles south of Columbus, Ohio. Beginning in 2018, Kenworth invested $300 million in the 622,000-squarefoot facility that features a number of advanced manuacturing technologies, including robotic assembly and a state-of-the-art paint facility. The plant received an Encouraging Environmental Excellence “E3” Gold Award from the Ohio Environmental Protection Agency (EPA) for going beyond regulatory compliance require-

ments for environmental stewardship activities.

As a leader in the development of advanced diesel powertrains, zero emissions vehicles, connected truck technologies and advanced driver assistance systems, Kenworth is creating transportation solutions to drive a better world.

INDUSTRY TODAY 53 KENWORTH | PROFILE

Pictured: Kenworth has seen a lot of change in the transportation industry but they stand by their pledge to continue driving the next 100 years of innovation.

LAB COATS TO LEADERSHIP:

CELEBRATION OF

54 INDUSTRY TODAY FEATURE - INTERNATIONAL DAY OF WOMEN & GIRLS IN SCIENCE

Explore the impact and challenges for women in STEM this International Day of Women and Girls in Science with insights from industry leaders.

Ever heard of the International Day of Women and Girls in Science? It’s a day dedicated to celebrating the remarkable contributions of women and girls in the world of science and technology. This special day was established back in 2015 by the United Nations General Assembly to shine a light on the essential role of women in scientific fields. Since then, every February 11th, we’ve been honoring these trailblazers.

Despite the progress we’ve made in women’s education, there’s still a noticeable gap in STEM fields. Women are still underrepresented, and that’s a big deal because we need diverse perspectives to solve the complex challenges we face today. Think about it - from cli-

LEADERSHIP: A WOMEN IN STEM

INDUSTRY TODAY 55 FEATURE - INTERNATIONAL DAY OF WOMEN & GIRLS IN SCIENCE

mate change to medical breakthroughs, we need everyone on board.

Now, let’s talk numbers. Globally, women make up only about 28 percent of researchers, and less than 30 percent choose STEM fields in higher education. And when it comes to STEM jobs, women hold just 24 percent of them worldwide. Plus, there’s still this pesky gender pay gap in STEM careers. It’s clear we’ve got some work to do.

But hey, here’s the good news - more and more women are stepping up and pursuing careers in

STEM. That’s something worth celebrating! We just need to make sure we’re giving them the support they need to succeed. Because when we empower women and girls in science, we’re not just changing lives - we’re shaping the future.

And you know what’s really cool? Experts agree. They’re all about championing women and girls in science because they know that when we do, everyone wins. So let’s keep cheering on these STEM superstars and creating a world where everyone’s talents are recognized and valued.

56 INDUSTRY TODAY FEATURE - INTERNATIONAL DAY OF WOMEN & GIRLS IN SCIENCE

Sara Faatz, Director, Technology Community Relations, Progress

“Though incredible strides have been made in recent years, the hard work of breaking down the barriers for women in STEM is really just beginning. Women still only make up less than one-third of STEM employees despite earning the majority of all undergraduate and advanced degrees. This year’s International Day of Women and Girls in Science is an opportunity to celebrate the contributions of women in STEM—but it’s also a chance to

INDUSTRY TODAY 57 FEATURE - INTERNATIONAL DAY OF WOMEN & GIRLS IN SCIENCE

Pictured: Sara Faatz is the director of technology community relations at Progress.

think deeply about the obstacles that prevent so many young women from realizing their potential in these fields. Working to combat discrimination is one component of this program, but it’s just as important to create the actual material conditions for tomorrow’s women in STEM to thrive. Progress’ global Women in STEM Scholarship series aims to do just that and was established to support women studying computer science, software engineering, IT and/or computer information systems.”

Sheena Blanco, Head of Customer Experience at Next DLP

“The opportunities for women to work in STEM these days are myriad. Back when I was at school, Information Technology wasn’t even on the curriculum, but during my first year at Stirling University, I discovered computer science. It was through my interest in learning

computer languages that I found my true calling and embarked on a stimulating and rewarding career in technology. What is clear from my journey is that there is something in STEM for everyone.

Throughout my career, I’ve developed and refined a diverse set of skills crucial to my current role, blending my technical skills in computing science with my proficiency in languages and communication. Achieving this level of expertise required not only hard work and dedication but also resilience in overcoming the gender biases that unfortunately existed in the field of technology. The landscape is now changing for the better, and it’s crucial for women to hold firm in their self-belief and know they have a very rightful place within STEM fields. Our growing presence and achievements underscore a pivotal point: capability and skill transcend any bias.

My advice for any girls or women taking up studies, or considering a career, in STEM is to go for it. On this day, we must remember that women have already contributed to STEM in some extraordinary ways, and this is only the beginning.”

58 INDUSTRY TODAY FEATURE - INTERNATIONAL DAY OF WOMEN & GIRLS IN SCIENCE

Pictured: Sheena Blanco serves as head of customer experience at Next DLP; right above: Sylvia Zachary serves as cybersecurity & software director – Secure Communications (SCOM) at Cubic Defense; right below: Arti Raman is the CEO and founder of Portal26.

Sylvia Zachary, Cybersecurity & Software Director – Secure Communications (SCOM), Cubic Defense

“In my current role at Cubic Defense, I am proud to say Human Capital is a priority in all business strategies. Over my career, I have seen incredible changes for the better, such as critical breakthroughs past the infamous glass ceiling. Companies have created significant momentum and progress in developing environments that cultivate diversity, inclusion and equity –especially in critical industries like technology, security and public safety. However, there is always more work to be done.

Organizational leaders today are more open to constructive feedback and wish to foster workplaces that invite talent regardless of gender. This openness to formulating cultures created to understand and promote diversity drives

innovation in business solution-making. I have seen teams with this structure overwhelmingly succeed.

And for the women still looking for their chance to break through, I encourage each of you to remember and value your contributions and accomplishments. Hold faith in your abilities, seek support systems that uplift you and help you achieve your career goals, and be open to embracing constructive criticisms that will help you succeed in the long term.

Heading into two incredibly important occasions (Engineers Week and International Day of Women and Girls in STEM), I want women to come together and take the steps towards building these ecosystems, safe spaces, and their strengths that make them formidable.”

Arti Raman, CEO and founder, Portal26 (She/Her)

“Encouraging women to persist in STEM

INDUSTRY TODAY 59 FEATURE - INTERNATIONAL DAY OF WOMEN & GIRLS IN SCIENCE

International Day of Women and Girls in Science, established by the UN General Assembly in 2015, celebrates women’s contributions to STEM. Despite progress, women remain underrepresented, holding only 24 percent of STEM jobs globally. They comprise just 28 percent of researchers and less than 30 percent of STEM students in higher education. Challenges persist, including gender biases and a gender pay gap. However, initiatives like Progress’ Women in STEM Scholarship series, as advocated by Sara Faatz, aim to support women in computer science and related fields. Female leaders in technology like Sheena Blanco, Sylvia Zachary, Arti Raman, and Deepika Gajaria stress the importance of representation and support systems for women pursuing STEM careers.

60 INDUSTRY TODAY FEATURE - INTERNATIONAL DAY OF WOMEN & GIRLS IN SCIENCE

careers requires ongoing representation in these roles. Unfortunately, girls often divert from STEM paths due to disparities in treatment, both in educational settings and professional fields. Recent statistics highlight a concerning 50 percent drop in women holding tech roles by the age of 35, signaling issues like insufficient support and undervaluation of their capabilities. While progress has been made, there’s more work ahead, starting with enhancing visibility and representation.

As a minority tech entrepreneur, I’m acutely aware of the diversity gap. It’s time to boldly fill this gap in the tech landscape by fostering trust and collaborating for increased representation. Striking a balance between personal growth and shaping the next generation of female entrepreneurs is our responsibility. We can help close this gap by applauding achievements, creating growth opportunities, and consistently reminding all girls and women of their boundless potential.

INDUSTRY TODAY 61 FEATURE - INTERNATIONAL DAY OF WOMEN & GIRLS IN SCIENCE

On this International Day of Women and Girls in STEM, it’s crucial to recognize that educating our sons is equally pivotal for achieving gender equality. Men play a vital role in advancing this cause, and it begins by instilling the right values from an early age.”

Deepika Gajaria, VP of GTM and Strategy, Securin

“Looking ahead, the landscape of STEM fields is evolving, and there is an exciting opportunity to create a more inclusive and diverse future. My vision is to witness a flourishing of talent, where girls, women, and individuals from various backgrounds can fully embrace their passions in STEM and find their path in dynamic fields like cybersecurity. To pave the way for the next generation of STEM professionals, I recognize the importance of starting early in their educational journey. Organizations can play a pivotal role by investing time, resources, and enthusiasm in providing hands-on security

62 INDUSTRY TODAY FEATURE - INTERNATIONAL DAY OF WOMEN & GIRLS IN SCIENCE

Pictured: Deepika Gajaria is the vice president of go-to-market strategy at Securin.

and research experiences for students.

I am a staunch supporter of initiatives like the Living Classroom and the Sierra Club, which play a crucial role in leveling the playing field for those who may not have had the privilege to access similar resources. By empowering young minds, particularly girls, to explore their inter-

ests in STEM, we are actively dismantling the barriers that once hindered people from pursuing fulfilling careers in these fields. Together, we can foster an environment where every aspiring voice is not only heard but celebrated, contributing to a brighter and more inclusive future in STEM.”

INDUSTRY TODAY 63 FEATURE - INTERNATIONAL DAY OF WOMEN & GIRLS IN SCIENCE

OVERCOMING TOP MANUFACTURING FACILITY MAINTENANCE

64 INDUSTRY TODAY FEATURE - STATE OF MANUFACTURING AND FACILITIES MAINTENANCE REPORT

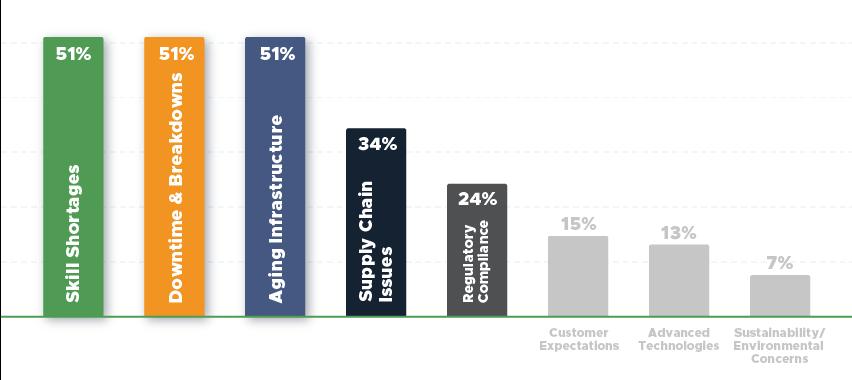

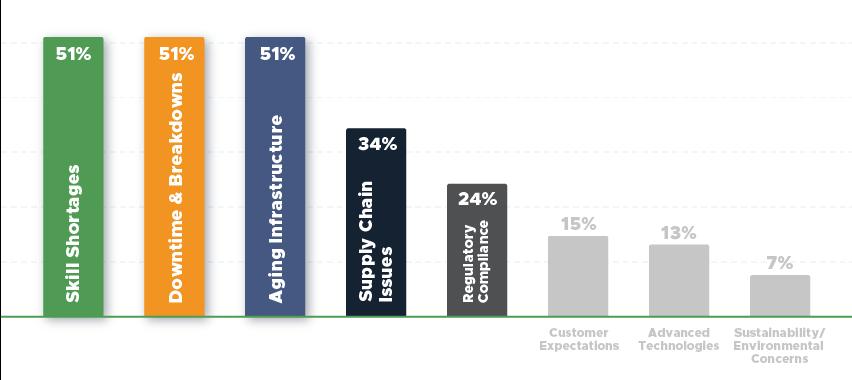

Report reveals top strategies manufacturing and maintenance professionals are embracing to address downtime, workforce issues, and aging infrastructure

In recent years, the world of manufacturing and facilities maintenance has evolved at a rapid pace with the introduction of AI and other advancing technologies. While it may be tempting to look out for the “next big thing”, a recent report showed that many maintenance teams are actually focusing on more foundational elements that will pave the way for future innovation. Limble’s State of Maintenance in Manufacturing and Facilities report surveyed over 250 maintenance professionals and found that more than half of them identified downtime, skilled workforce shortages, or aging infrastructure as one of their top three challenges. Most maintenance teams are

MANUFACTURING AND MAINTENANCE CHALLENGES

INDUSTRY TODAY 65 FEATURE - STATE OF MANUFACTURING AND FACILITIES MAINTENANCE REPORT

less concerned with emerging technologies and more interested in the fundamental strategies they can employ to solve today’s most pressing challenges while also preparing themselves to embrace future innovations.

Equipment Downtime and Reliability

Minimizing equipment downtime stands as one of the most prevalent challenges for manufacturing and facility professionals, with 51.2 percent of respondents listing it as a top challenge, according to Limble’s research.

Maintenance professionals have struggled with this issue for as long as the industry has existed, and the reason is quite simple: when machines are down, operations and production are halted, which directly impacts revenue. Unplanned downtime costs the manufacturing industry billions of dollars each year. Downtime can also put a strain on relationships and contracts with partnering companies due to the obstructed flow of input and output.

Equipment downtime can be a result of operator errors, insufficient employee training, or old, faulty equipment. Most commonly, however, a

66 INDUSTRY TODAY FEATURE - STATE OF MANUFACTURING AND FACILITIES MAINTENANCE REPORT

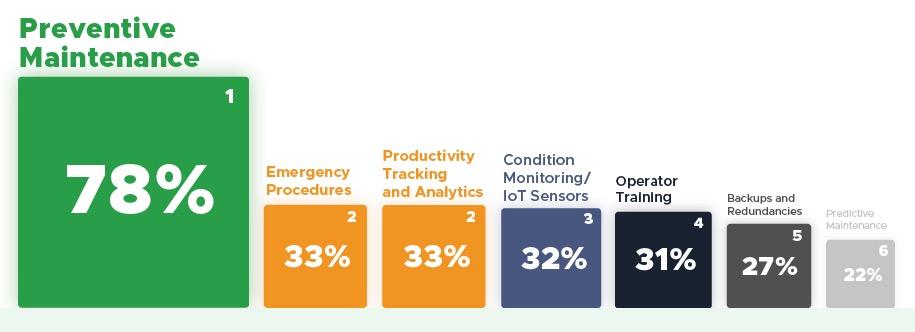

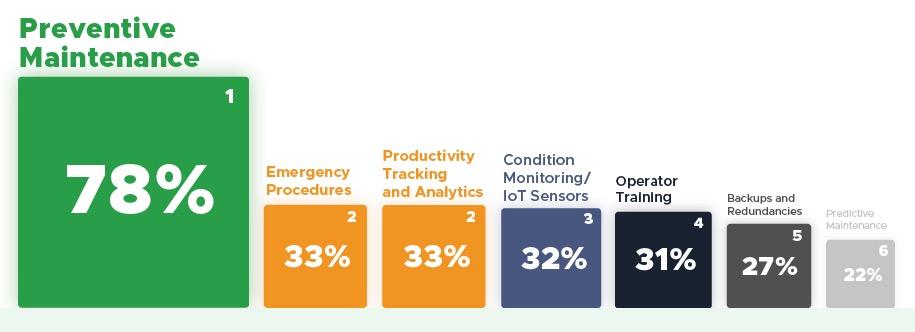

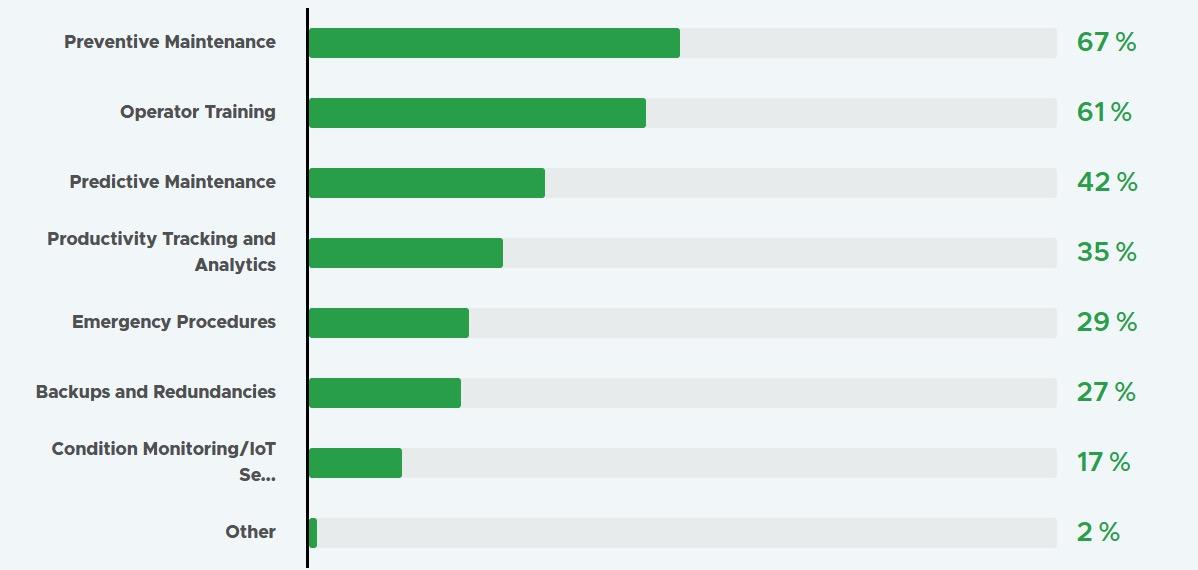

fully reactive maintenance strategy is causing avoidable unplanned downtime. This explains why 78 percent of the companies surveyed that are looking to reduce downtime are leveraging preventive maintenance as a top strategy. Preventive maintenance involves inspecting and repairing assets before issues arise to keep them in optimal working condition. The U.S Department of Energy estimates that preventive maintenance measures can result in up to 30 percent reduction in maintenance costs, 45 percent fewer malfunctions, and up to 75 percent increase in uptime. Common preven-

tive maintenance tasks, such as cleaning, inspections, and lubrication are essential for maximizing equipment performance and extending its lifecycle.

While those tasks may seem simple, it can be difficult to manually implement a preventive maintenance program. From documenting procedures, checklists, parts, and tools, to prioritizing preventive maintenance tasks against unplanned Work Orders, to scheduling and assigning the tasks and tracking completion, a preventive maintenance program may seem daunting. This is where the technology comes

INDUSTRY TODAY 67 FEATURE - STATE OF MANUFACTURING AND FACILITIES MAINTENANCE REPORT

in to introduce automation and streamline processes. Tools such as computerized maintenance management systems (CMMS), can automate PM scheduling, offer customizable PM templates, and keep detailed logs of all asset and maintenance history. This eliminates the administrative burden of manually implementing or optimizing a preventive maintenance program while helping to ensure proper equipment maintenance and, ultimately, reduce downtime. In the event unplanned downtime does occur, it is also important to have emergency maintenance procedures and backup equipment in place to help drive speedy responses to critical issues and get equipment back up and running as quickly as possible.

Skilled Workforce Shortages

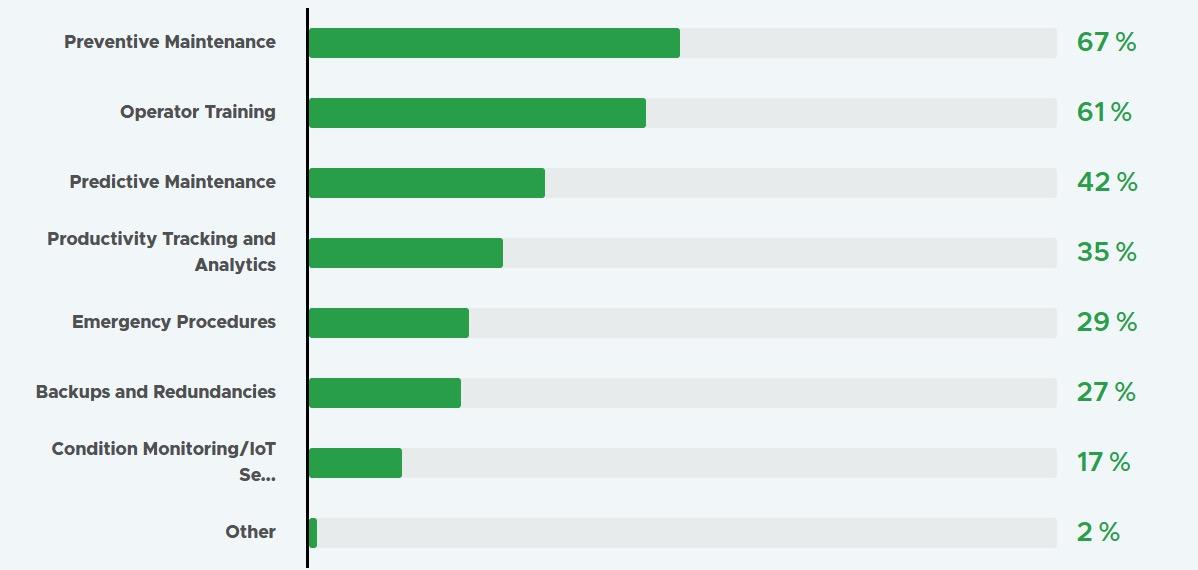

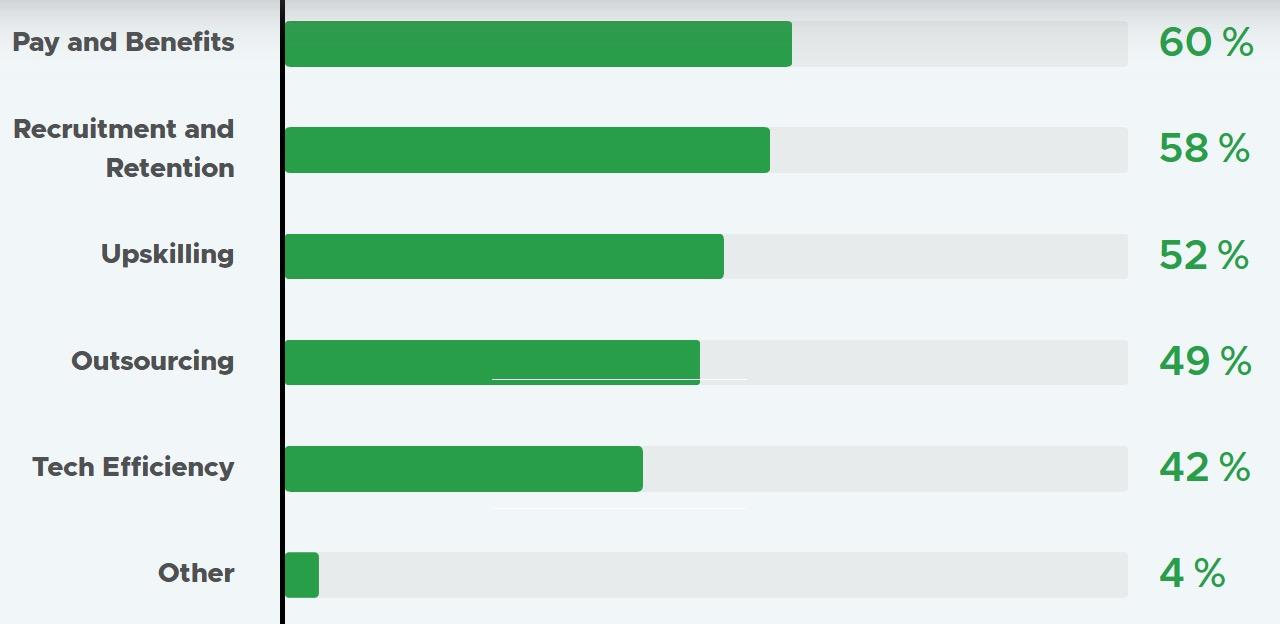

Workforce shortages continue to pose a significant challenge for many industries, including manufacturing and facilities management. The research showed that more than 50 percent of maintenance professionals surveyed considered workforce shortages as one of their top three challenges. A lack of qualified staff not only impacts essential daily tasks, but also compromises product quality and service delivery. Organizations also may see increases in overtime labor costs as limited team members are required to work additional hours. Labor shortages and worker turnover can result in limited internal knowledge and familiarity with equipment, standard operating procedures, and digital tools. This can impact the teams

Charts:

1. More than half of respondents chose downtime, aging infrastructure, or workforce issues as one of their top three challenges;

2. Majority of organizations that listed downtime as one of their top challenges have already shifted their focus to preventative maintenance;

3. Manufacturing companies specifically are focused on preventative maintenance, and most are doing so by implementing predictive maintenance technologies. Many are also strategically leveraging machine operators to reduce downtime.

68 INDUSTRY TODAY FEATURE - STATE OF MANUFACTURING AND FACILITIES MAINTENANCE REPORT

1

productivity, efficiency, and the organization’s ability to maintain a competitive edge in their industry.

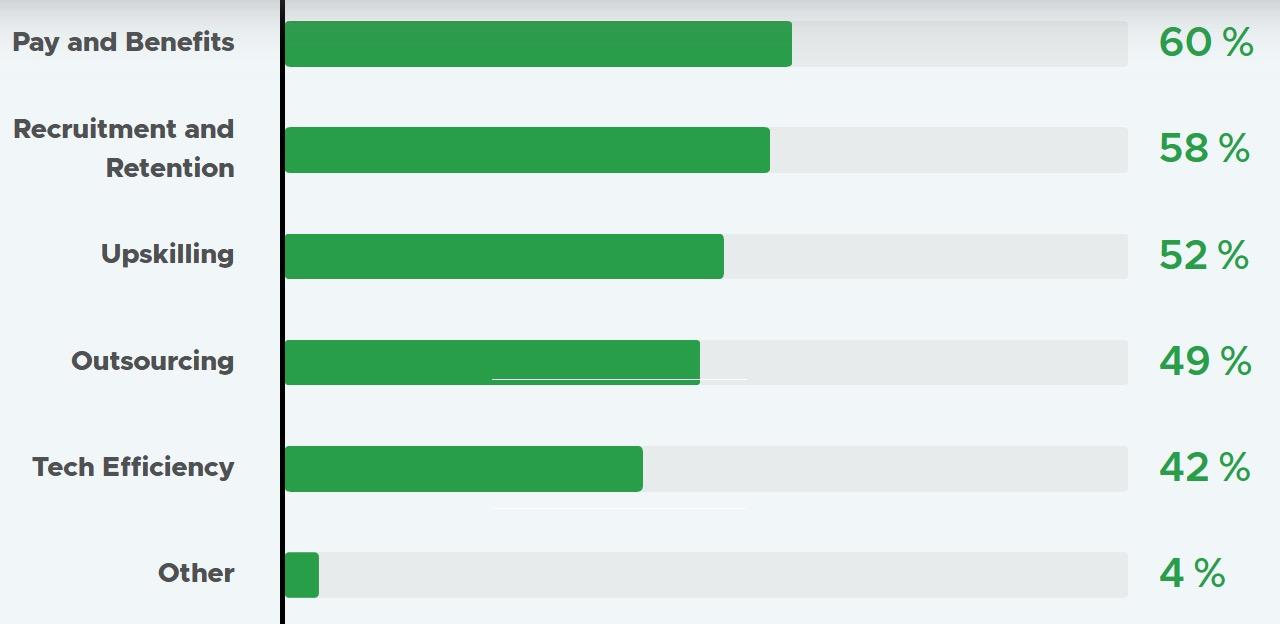

To address the workforce issue, companies are ramping up their recruitment and retention efforts, and offering more competitive compensation and benefits to attract new talent.

Recognizing the value of skilled workers in driving operational excellence and fostering innovation, maintenance teams are also looking to upskill their current personnel by providing opportunities such as training sessions and mentorship programs. Through these strategic

initiatives, manufacturing and facilities teams can overcome the skilled workforce shortages and equip their workers with the knowledge they need to increase their impact.

Companies can also address this issue by investing in tools that help maintenance teams do their jobs more efficiently. For example, the survey showed current CMMS users were 32 percent less likely to cite workforce shortages as a top challenge compared to those not using a CMMS. This is because CMMS platforms boost productivity by 41 percent, helping maintenance teams accomplish more with less,

INDUSTRY TODAY 69 FEATURE - STATE OF MANUFACTURING AND FACILITIES MAINTENANCE REPORT 2 3

ultimately reducing the pain of workforce shortages.

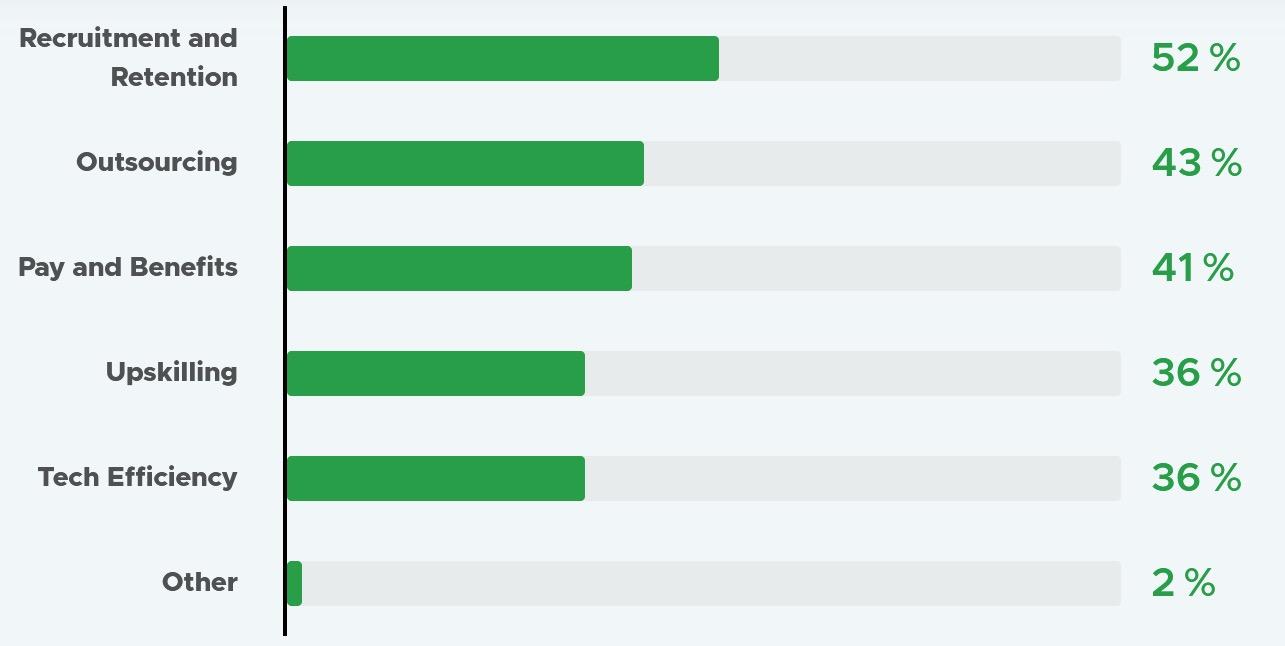

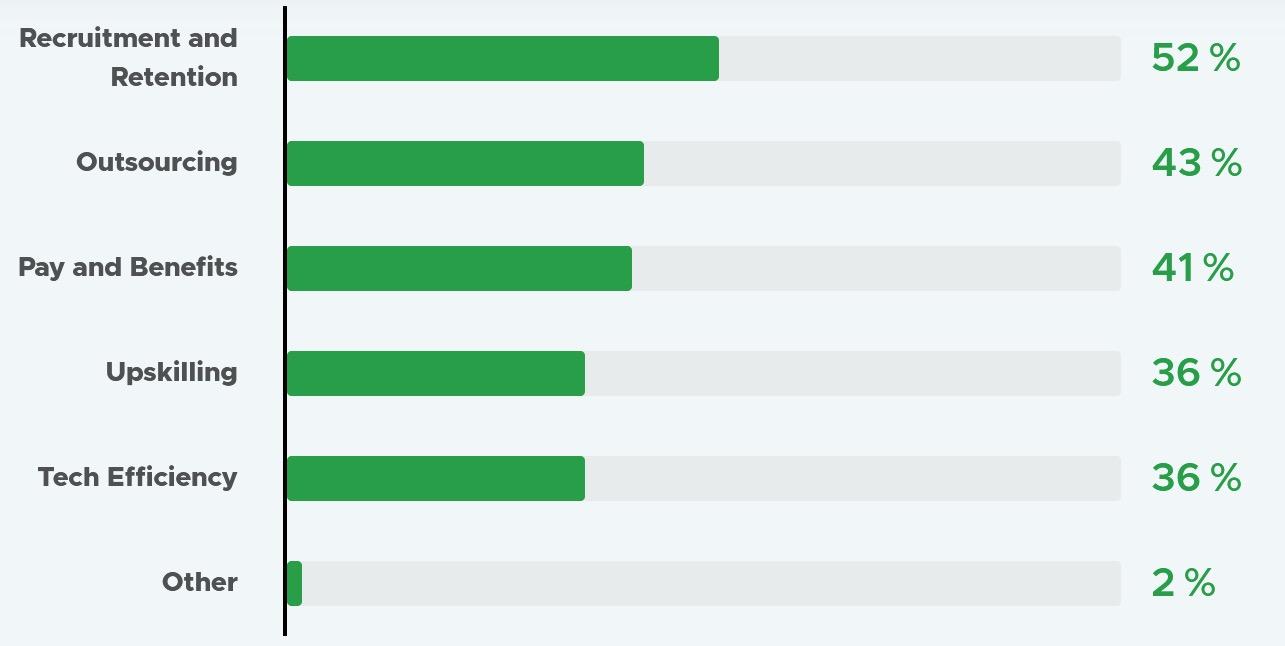

Aging Infrastructure

The research also found aging infrastructure to be a top challenge for more than half of the maintenance professionals surveyed. Upgrading infrastructure in a financially strategic and responsible manner can be challenging but is necessary for organizations to sustain reliable operations, alleviate logistical strains, ensure regulatory compliance, and uphold worker safety. Strategically investmenting in upgrad-

ing or replacing aging infrastructure can also help organizations save money in the long run. Depending on the piece of equipment, it may cost more to maintain it between labor hours and consumable parts usage than to replace the equipment entirely.

Proactive maintenance and strategic investments in upgrades were the favored strategies among manufacturing professionals to address aging infrastructure challenges. To make the most of these investments, strategic maintenance strategies supported by technology and data insights will take on an even more critical role.

Charts: 4. Alternatively, facility managers almost universally agreed that preventive maintenance was their chosen strategy to reduce downtime;

5. To address the workforce shortage, companies are increasing and intensifying their recruitment and retention efforts, and investing more heavily in compensation, recognizing the value of skilled workers in driving operational excellence and fostering innovation;

6. Manufacturing companies specifically are investing more in compensation and recruitment efforts to grow and retain their teams, as well as building the skillset of their existing teams by offering upskilling opportunities.

70 INDUSTRY TODAY FEATURE - STATE OF MANUFACTURING AND FACILITIES MAINTENANCE REPORT 4

For example, technologies like CMMS can collect asset performance data, record maintenance activity history, and forecast future costs.

Understanding time and budget allocation by asset, and identifying equipment that is requiring excessive man hours and parts inventory, can help maintenance teams make informed ‘repair vs. replace’ decisions. CMMS plat-

forms also enable maintenance teams to automate PM scheduling and easily leverage proactive maintenance to get the most out of their existing infrastructure.

Looking Ahead

Embracing digital transformation is vital for organizations to remain competitive in today’s

INDUSTRY TODAY 71 FEATURE - STATE OF MANUFACTURING AND FACILITIES MAINTENANCE REPORT 5 6

manufacturing and facility maintenance landscape. While the top challenges facing manufacturing and facility maintenance professionals have existed for many years, embracing foundational technologies like CMMS can play

a critical role in solving them. Organizations should adopt a proactive, holistic approach that combines technological investment with a focus on fundamental preventative maintenance principles and workforce development. This shift

Charts: 7. Alternatively, when looking specifically at facilities managers, the majority of respondents noted they are more likely to resolve workforce shortages by bringing in new workers through expanded recruitment efforts and outsourcing of maintenance work;

8. Proactive maintenance and strategic investments in upgrades were the favored strategies among respondents to address aging infrastructure challenges;

9. Manufacturing teams specifically indicated that they are hoping to leverage proactive maintenance to get the most out of their infrastructure, while strategically investing in upgrades.

Bryan Christiansen is a self taught full stack developer turned marketer turned entrepreneur. Bryan is the founder and CEO of Limble CMMS, the leader in CMMS software which empowers the unsung heroes that support the world. Limble has grown to having thousands of users in just a few short years.

Website: https://limblecmms.com/

Email: limble@luminapr.com

72 INDUSTRY TODAY FEATURE - STATE OF MANUFACTURING AND FACILITIES MAINTENANCE REPORT

7

will allow manufacturing and facilities management organizations to overcome the day-to-day challenges they are facing, and remain competitive in the ever-evolving industry landscape.

Three Key Focus Areas/Phrases

1. Implementing tools such as computerized maintenance management systems (CMMS) can streamline maintenance workflows, schedule preventive tasks, and track equipment per-

formance in real-time to improve equipment maintenance and reduce downtime.

2. Common preventive maintenance tasks, such as cleaning, inspections, and lubrication, are essential for maximizing equipment performance and extending its lifecycle.

3. Current CMMS users surveyed were 32 percent less likely to cite workforce shortages as a top challenge, because CMMS tools allow maintenance teams to work more efficiently.

INDUSTRY TODAY 73 FEATURE - STATE OF MANUFACTURING AND FACILITIES MAINTENANCE REPORT 9 8

74 INDUSTRY TODAY FEATURE - NIST NIST 2.0: SAFEGUARDING

FUTURE

MANUFACTURING’S

SAFEGUARDING MANUFACTURING’S FUTURE

Understand how manufacturers can embrace the NIST 2.0 Cybersecurity Framework to safeguard operations in the evolving cyber landscape.

The manufacturing industry is undergoing a digital transformation, driven by the adoption of smart manufacturing technologies such as the Industrial Internet of Things (IIoT), cloud computing and AI. The rise of connected devices and the convergence of IT and OT have expanded the attack surface for cybercriminals, making manufacturers prime targets for cyberattacks from inside and outside of their organizations. For OT environments, more than 80% of threats come from outside the organization, while internal personnel unintentionally open the door for threat actors in 33% of incidents.