BA3 Technologies

Part A+B

Case study: Office Building in Ferrara

Deekshita Viju Nair

Some Kind of Nature

Ecological and Environmental Evaluations

Theory and Strategy

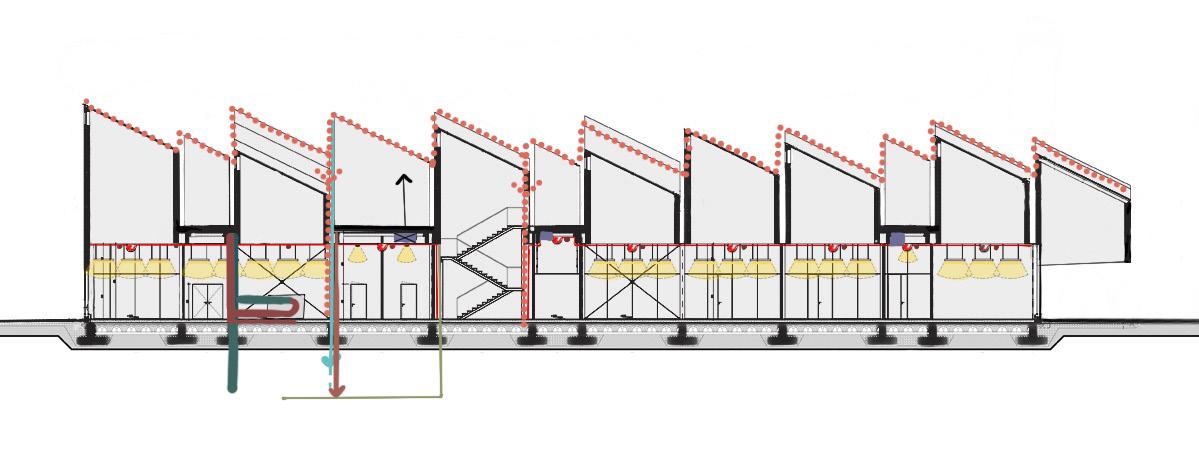

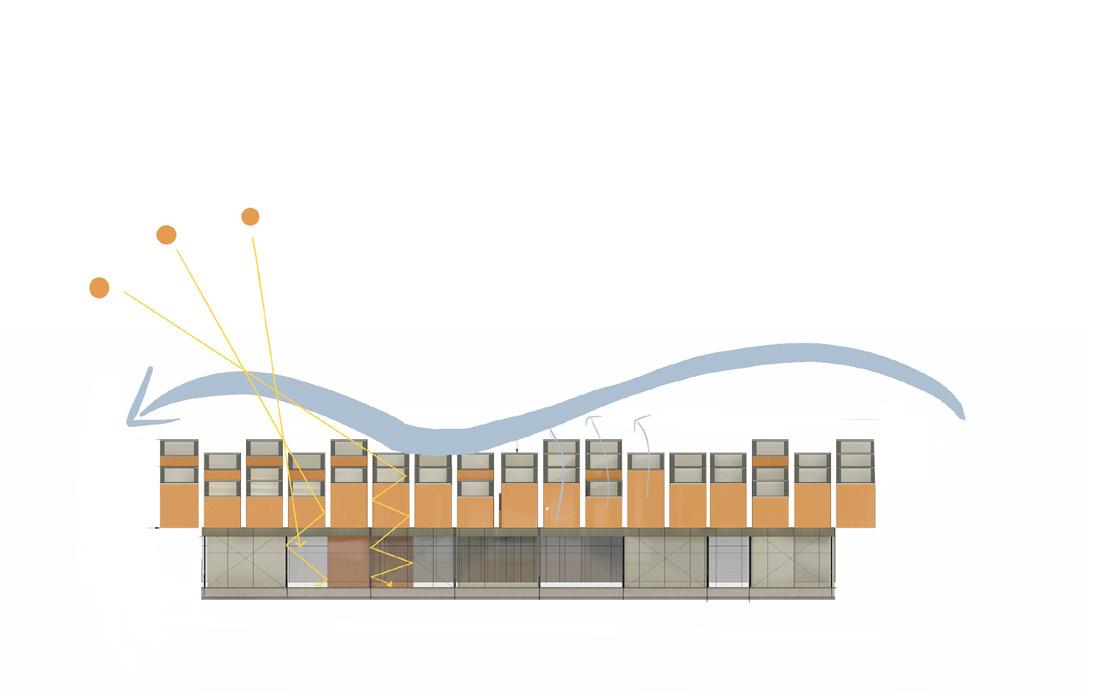

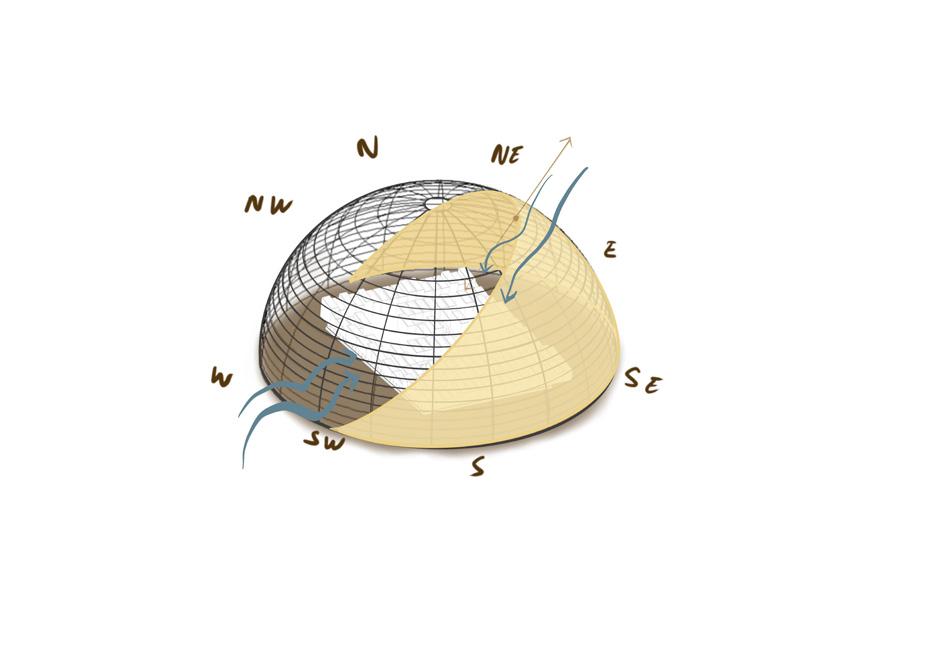

Extensive daylight modelling and solar massing studies were undertaken tp determine the massing of the roof.

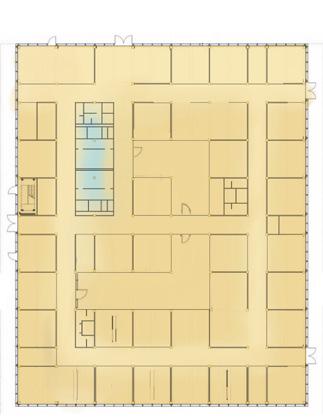

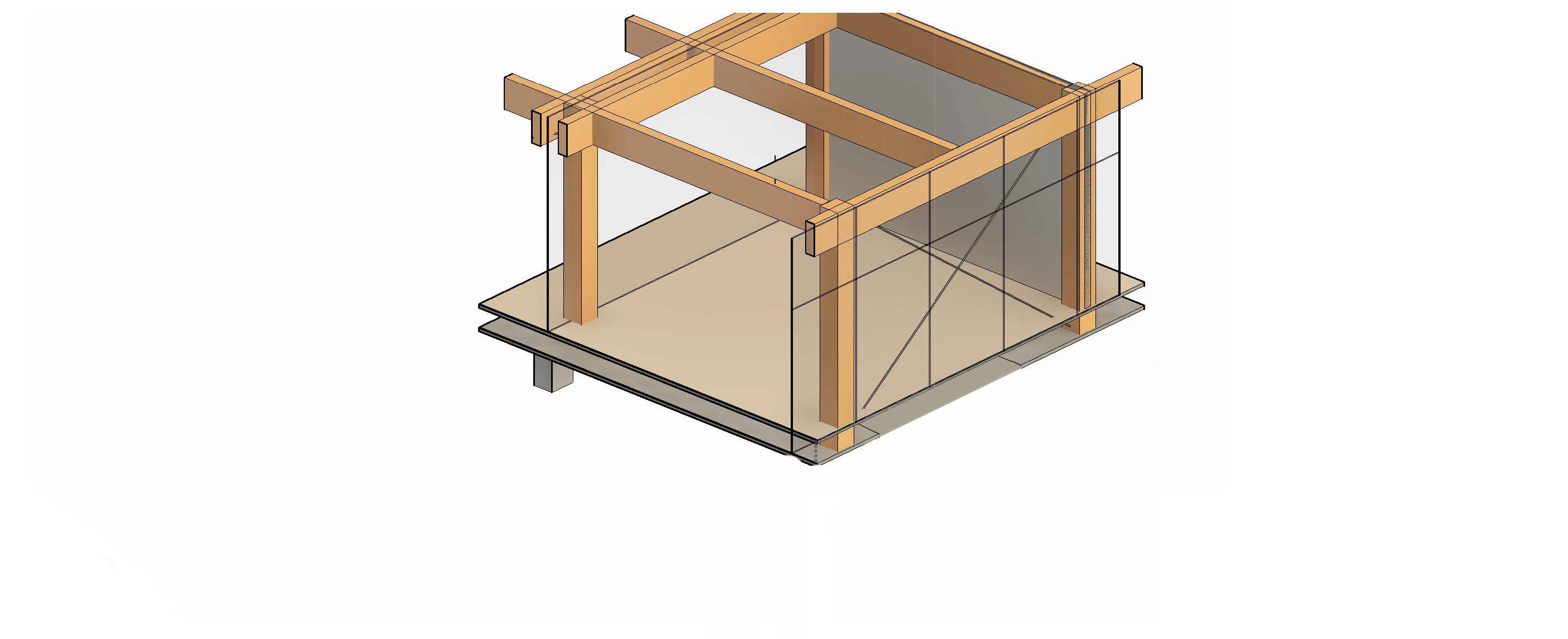

Overall massing form, arrangement

The form of the building is used to drive natural performance. Rectilinear mass of the building oriented to the south east to maximise daylight and solar gains.

Interior Environment Analysis

Summer Goals Provide sunlight without solar gains Mediate High relative humidity and temperatures with natural ventilation

Winter Goals

Harvest solar gains for passive heating

Allow for user designated thermal control in office and laboratory spaces to ensure comfortable working conditions

Iterative wind chimneys with operable glazing and exterior glazing allow for exterior and interior side lighting. The Operable windows and adjustable windows allow users to control their own internal environment. Exterior glazing maintains views to the landscape providing visual relief.

The roof acts as a climatic moderator. The overhangs provide ventilation and light to external circulation paths. The fir batten cladding extends past the roofs on the facade to shade the external glazing and prevent over heating. The Light shafts undulate to avoid shading adjacent monitors and follow the east -west sun path.

Internal Environment

Cucinella describes the building as “Autonomous rooms liked by circulation routes”. Offices and lab spaces organised around two L-shaped courtyards. Views to nature and natural element are consistently maintained. The courtyard also allows the building to function as two long and narrow buildings as that form enhances natural ventilation.

Every room consists of at least one chimney structure. Structure allows for high performance passive environmental control strategies such as stack ventilation, creating a greenhouse effect and filtering natural daylighting.

The passive systems in tandem with the High performance mechanical systems are estimated to provide a carbon reduction of 85%

Evaluations

Sustainable Water Cycle

Provide rainwater and greywater recycling

Both rainwater and grey water recycling have been impemented and solar energy is used to operate the system.

Additionally passive systems hor cooling and heating allow for higher operational water system while maintaining low carbon emissions from the building

Create Sustainable drainage that supports natural aquatic habitats and human amenities: Good drainage system surrounding building and directing waterflow to nearby river.

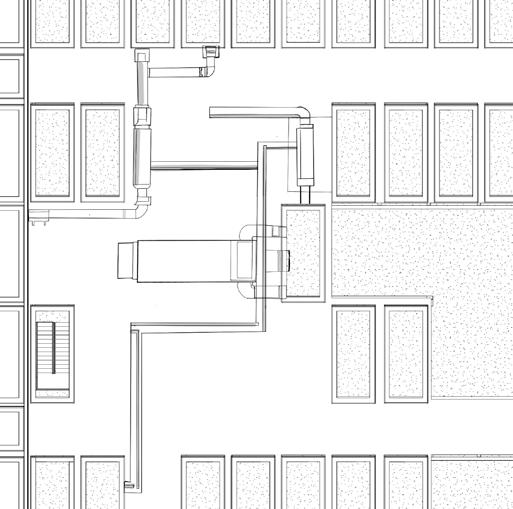

Water systems

The primary water source is the rainwater harvesting and condensate reuse system, which provides water for the GSHPs, greywater, water for toilet flushing and irrigation.

The water flow for the building is speculated.

1. Rainwater - Rainwater is harvested from the roof and directed through the walls of the plant room to an underground filtration system and stored in the water cistern to be used as needed within the building.

2. Grey water once used is recycled to the water filtration system with rainwater and reused as needed.

3. Foul water - Once water is used to flush toilets it is directly discarded into Ferrara’s sewage system.

4. In addition to water from the harvesting system it is speculated that the building is connected to Ferrara’s water supply also. Water stored in the cistern is distributed throughout the building as needed. When the tank overflows water is directed into a soak away before being dispersed into the ground to combat the clay like soil texture in the area.

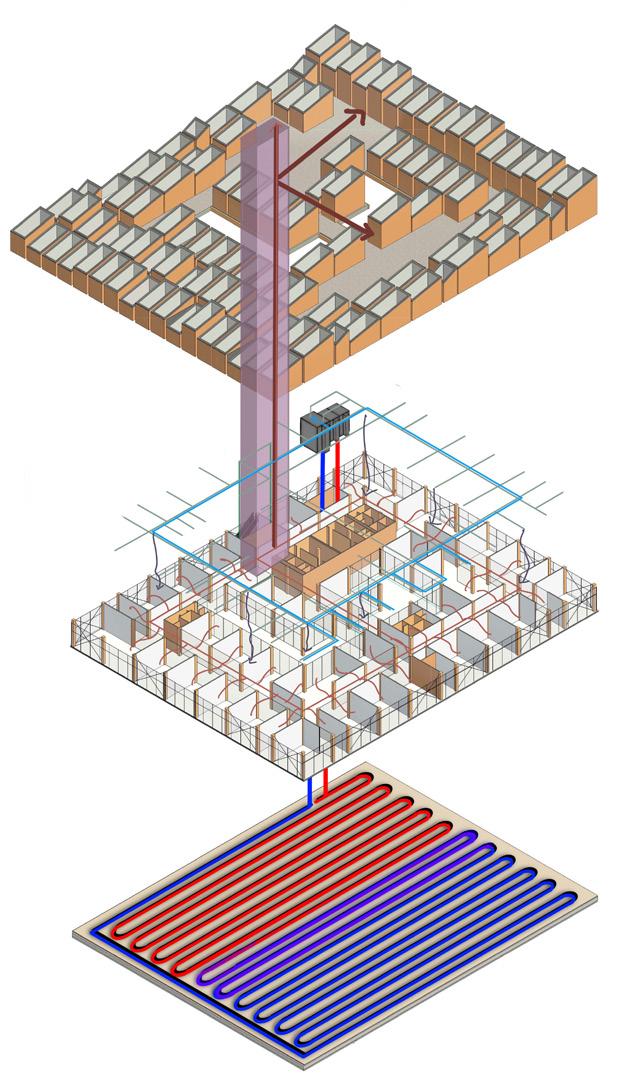

The office building is cooled and heated with the use of a 3 GSHP (ground source heat pumps). Of the three pumps one is reversible and provides cooling needs.

The geothermal pump is connected to a radiant heat distribution and recovery system. The heat and cold enter the building through fan converters placed underneath the primary beam structure (the pipework follows the same distribution as the HVAC system)

These systems aim to reduce the electrical load and operational carbon use of the building.

Energy for water heating and the GSHP system is provided by the photovoltaic cells on the ceiling.

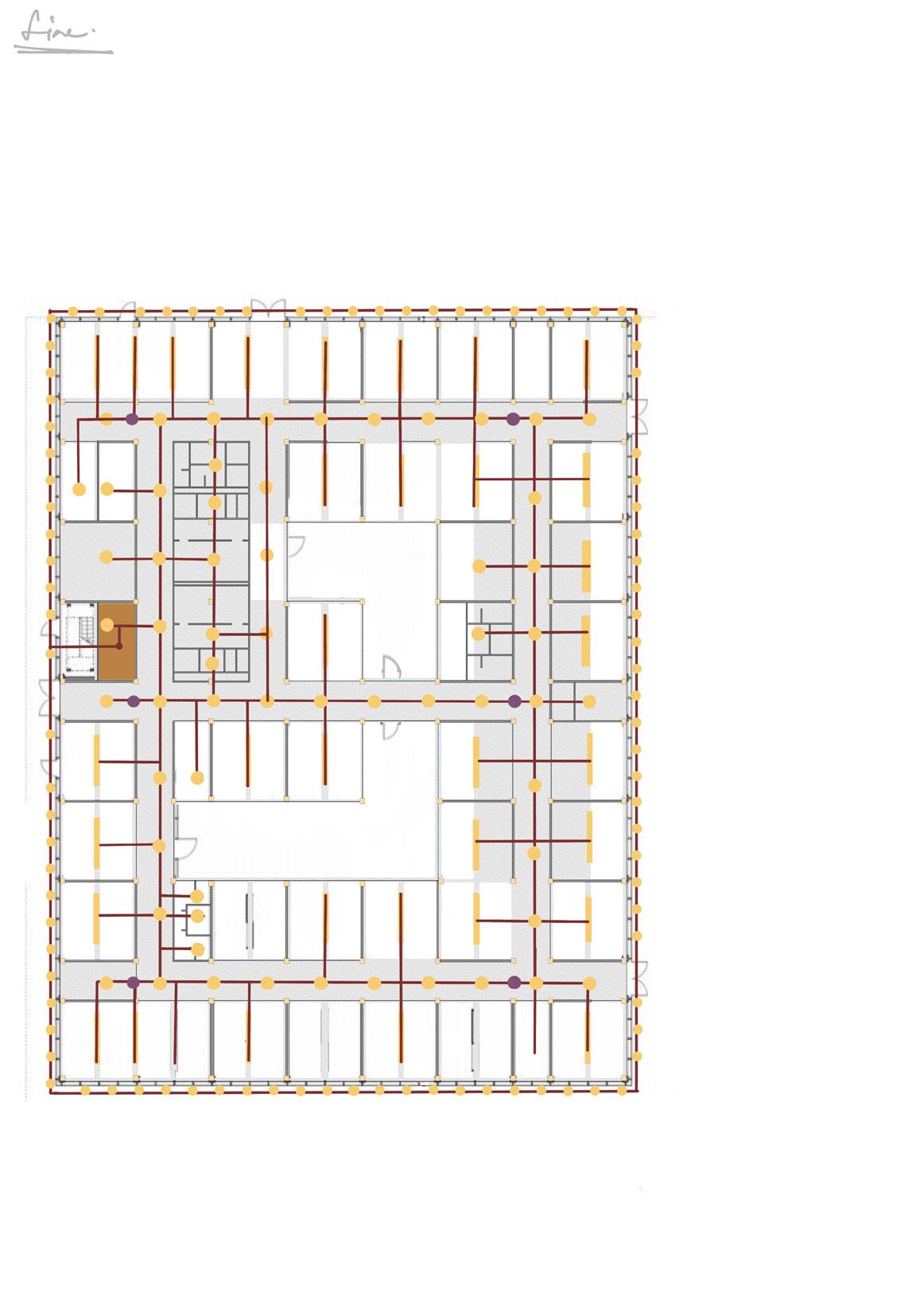

General Arrangement Services Distribution

Provide low flow fittings and appliences:

Building equiped with low flow, high rated appliences to reduce water use. additionally dry construction was used to minimise water loss.

Good Health and Wellbeing

Provide spaces with strong visual connection to outside: Glazed facade preserves views to exterior landscape on all sides

Provide responsive local controls.

Operable ventilation flaps, windows, blinds for roof glazing and HVAC system to ensure user comfort and highly costumisable indoor environment

Design spaces with good indoor, daylighting and glare control:

Multiple passive stratergies such as light shafts to amaximise good quality light.

Additional electrical lighting is provided to all spaces. refer to Interior environment analysis and general arrangement lighting distribution.

Net Zero Operational Carbon

Fine tune internal environment with efficient mechanical systems: HVAC,VAV,GSHP systems to provide maximum internal comfort. refer to environmental design stratergies.

Provide responsive local controls.

Operable ventilation flaps, windows, blinds for roof glazing and HVAC system to ensure user comfort and highly costumisable indoor environment.

Microclimate created by indoor courtyards

Prioritise maximum use of onsite renewables appropriate to context: Water re-use system, solar panels and heat recovery system create an extremely energy efficient building that produces a carbon reduction of 85%. Aprox. 3kg carbon released yearly.

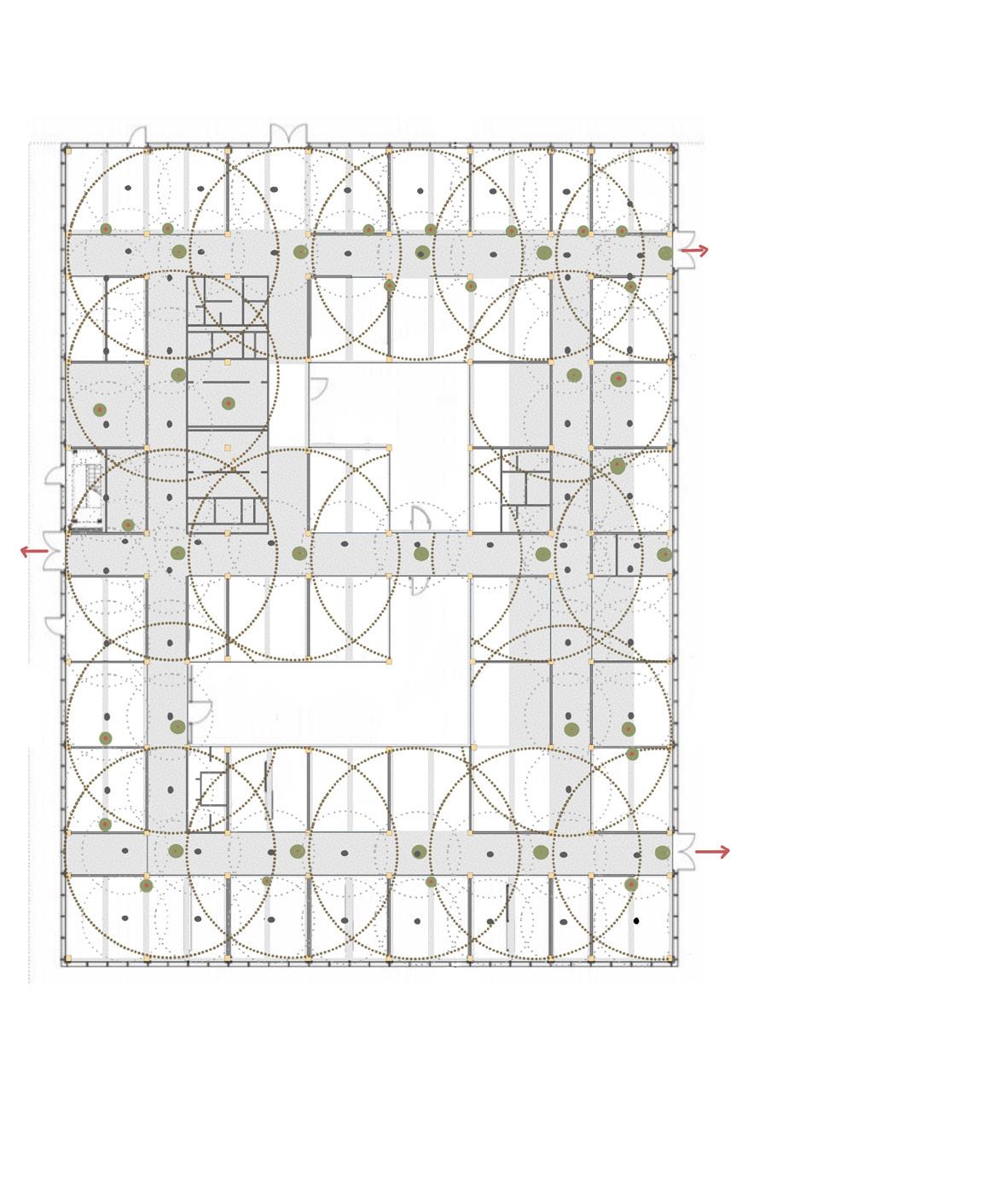

is attached to the base of the shaft in all laboratories and office spaces. Suspended lighting hangs from the corridors and spotlighting is used to illuminate the external path surrounding the building. Wifi amplifiers are placed in the corridor spaces.

Mechanical systems

The water based HVAC system is connected to and powered by the GSHP’s.

In addition to this there is a secondary heating system that meets additional heating needs when there is a lack of solar energy, primarily in the winter months. The HVAC system covers all laboratories, offices and archival spaces.

The Air duct for the HVAC system is on the north west corner on the roof (above the plant rooms). as the area receives the least amount of solar gains. In the laboratory spaces the HVAC spaces are complimented by a VAV (Variable air volume) system which balances the air extracted by the laboratory hoods and maintains the room at a negative pressure to the surrounding areas.

Electrical Systems.

10% of the energy needed by the building is provided by the 201sqm Photovoltaic panels on the roof. The remaining energy needed by the building is 119 kWh/m2 - which is 55% less than the average office building in the area. The electrical systems emanate from the service and maintenance room that sits adjacent to the plant rooms. It is speculated that the electrical wiring run through the insulation of the roof build up. Electrical wiring will also be present in the stud frame walls and to support power sockets and signal amplifiers.

In the summer the natural side lighting from the chimneys and exterior glazing along with the top lighting from the light shafts provide daylight to every aspect of the building. Over hangs on the facade block some of the solar energy to prevent overheating. User controlled operable lighting is also in place. Dedacious trees in the courtyards also provide additional solar shading

Active strategies

Active strategies are secondary to passive strategies. All active strategies are tenant controlled and in use only when needed. It is speculated that in spring and autumn when

In the winter the natural side lighting from the chimneys and exterior glazing along with the top lighting from the light shafts provide daylight to every aspect of the building. White dye in the solar chimneys increase reflectivity of low angled light and therefore increase light entering the building. Over hangs do not stop low angled winter light. Dedacious trees in the courtyard loose their leaves and courtyards provide additional sunlight.

Passive strategies

Exterior side lighting Interior courtyards

High temperatures lead to overheating of the building which was combated by increasing air exchange to move air and remove water vapour caused by high humidity. In the summer the Stack effect is used to achieve this. In the summer hot air rises to the top of the building due to its lower density in comparison to cold air. The operable vents in the air shaft are opened allowing the hot air to escape. This creates air vacuum at the bottom of the building and high pressure sucks in cold air from the outside. The difference in indoor and outdoor air density keep this cycle on a loop. This Courtyards and operable windows are used to help in attracting cold air to the building and increasing cross ventilation. These strategies along with the self-shading significantly reduce cooling the cooling loads of the building. It is estimated that the building reduced energy consumption by 30% in the summer.

User controlled HVAC system and reversible GSHP are also available to enable users to control their own environment.

Qualitative Interior study

Summer Solstice

reduces electrical lighting loads.

GSHP and HVAC system are also used for heating purposes. It is estimated that the building reduced energy consumption by 40% in the winter.

Morning 4am Noon 12 pm Night 8pm

Winter Solstice

Fire Safety

It is speculated that the building complies with category L3 fire system. Fire sensors are placed every 7.5 m in circulation and exit routes. Every room opening onto the rooms are also outfitted with a device. Sprinklers are placed at a ristance of 4.5 m.

HVAC and VAV systems Systems are encased in steel ducts. All ductwork is suspended in the corridor from the ceiling deck and open. HVAC system is user controlled ensuring comfortable indoor environments

Morning 4am Noon 12 pm

The renders do not take into consideration the electrical lighting and focus on the effectiveness of the form in controlling light. As expected the building is dark in the winter and summer noon tends to be overlight even when shaded with the roof operable glazing.

Additionally the interior environment is highly customiseable. other than for the exterior glazing all lighting can be controlled and electrical lighting is avaiable making the interior an enjoyable location. Additionally the trees in the courtyard provide visual and aesthetic relief. The courtyards also break up the plan and the exterior glazing can be viewed from the courtyard. This promotes socialisation but could become a problem when privacy is considered.

summer winter services are in the north west corner as it recieves the least sun and labs are in the South East as it recieves the most sun

Speculative lighting distribution

Technical systems. The electrical, groundwater and HVAC/VAV systems of the building feed into each other and work in tandem to produce the majority of resources required to provide comfort in the building. By working in tandem the services become more efficient than the average office building in Italy.

Ecological and Environmental Evaluations

Evaluations

Net Zero Carbon Emissions

Prioritise building reuse:

The tartan grid of the building, its equilateral floor plan focus on internal comfort make the building easy to repurpose and reuse

Prioritise low embodied carbon and healthy materials: Timber as the primary construction material. Natural material reduces embodied energy and promotes a sense of well being within the building

Consider off site

modular construction systems:

Secondary cladding is orefabricated and transported to site.

Primary structural elements and cladding are also fabricated off site as modular elements. it reduces time of construction while ensureing quality of construction

Sustainable Life Cycle Cost

Measure Management and maintanence cost:

Dry construction makes replacement of elements easy and cost effective. Services need to be maintained every 2-4 years.

Measure added value of occupants health and well being:

Construction ensures year round thermal and lighting comfort without relying on mechanical services. Green spaces and timber construction have positive phycological effects

Measure Energy costs:

Operational energy of building reduced by 30% in the summer and 40% in the winter through passive strtergies. 10% of energy needed by the building is provided by PV panels.

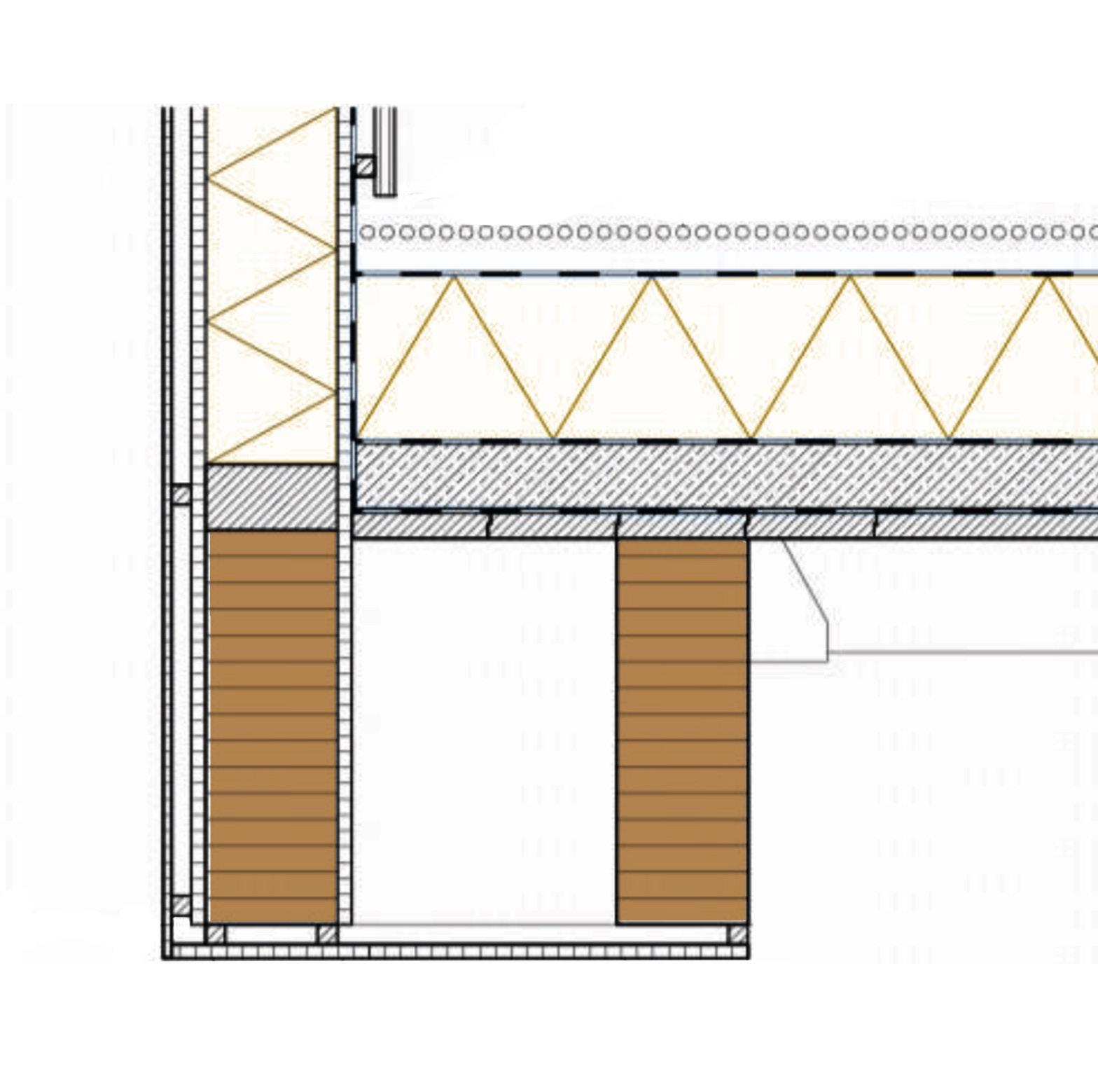

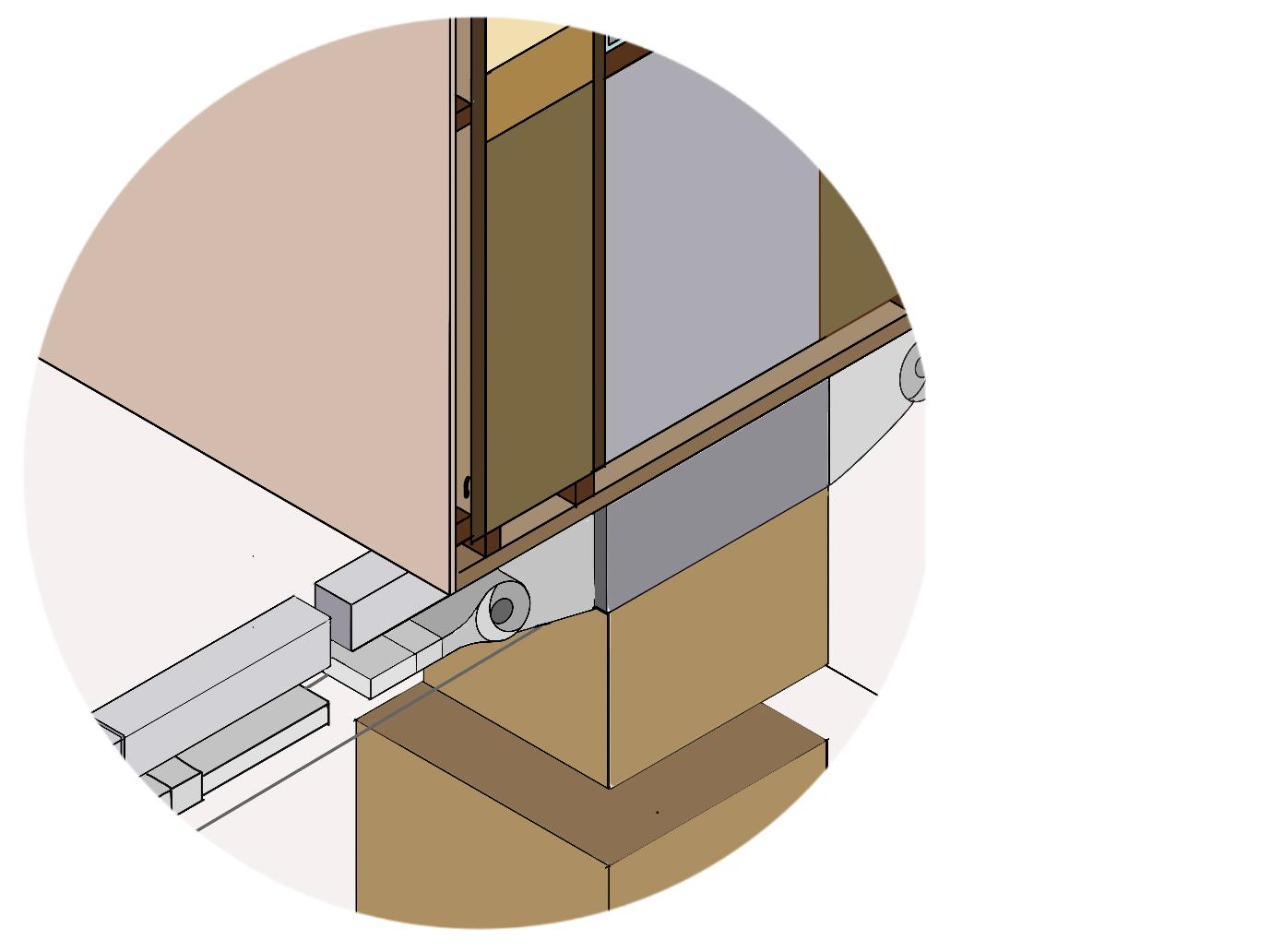

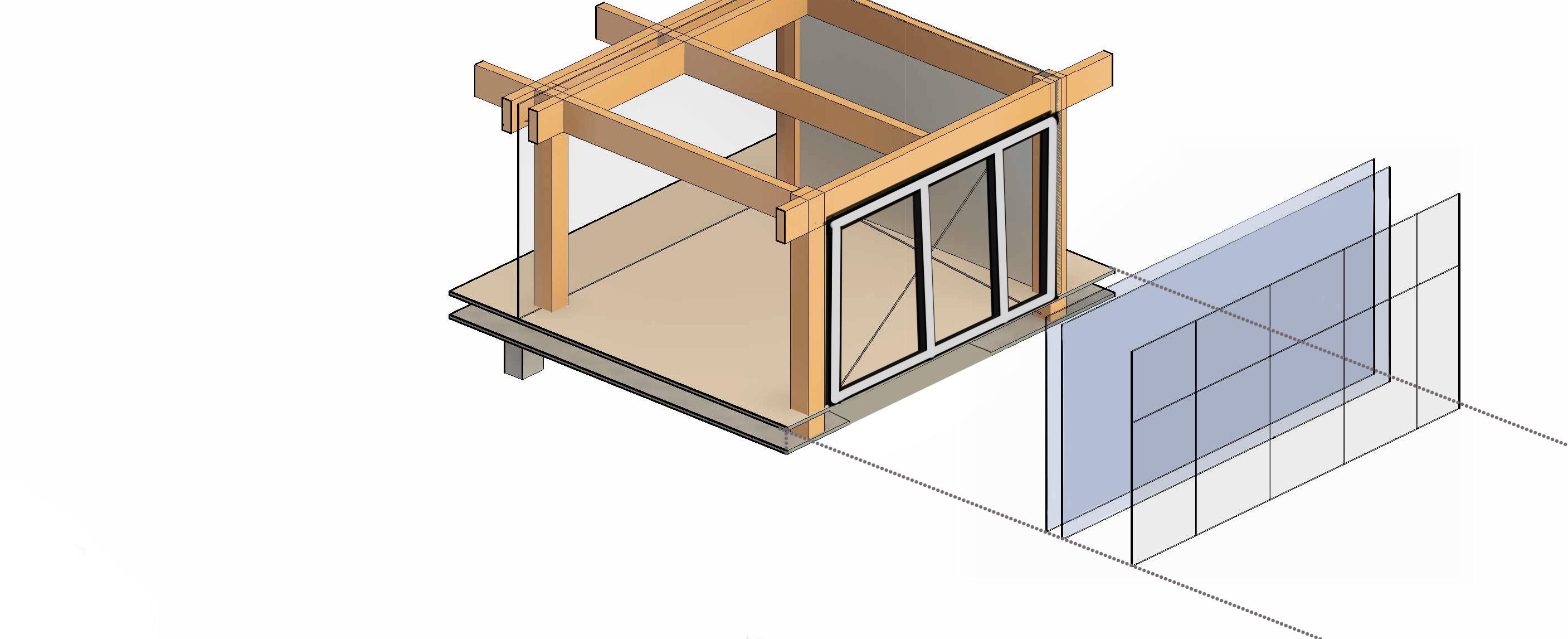

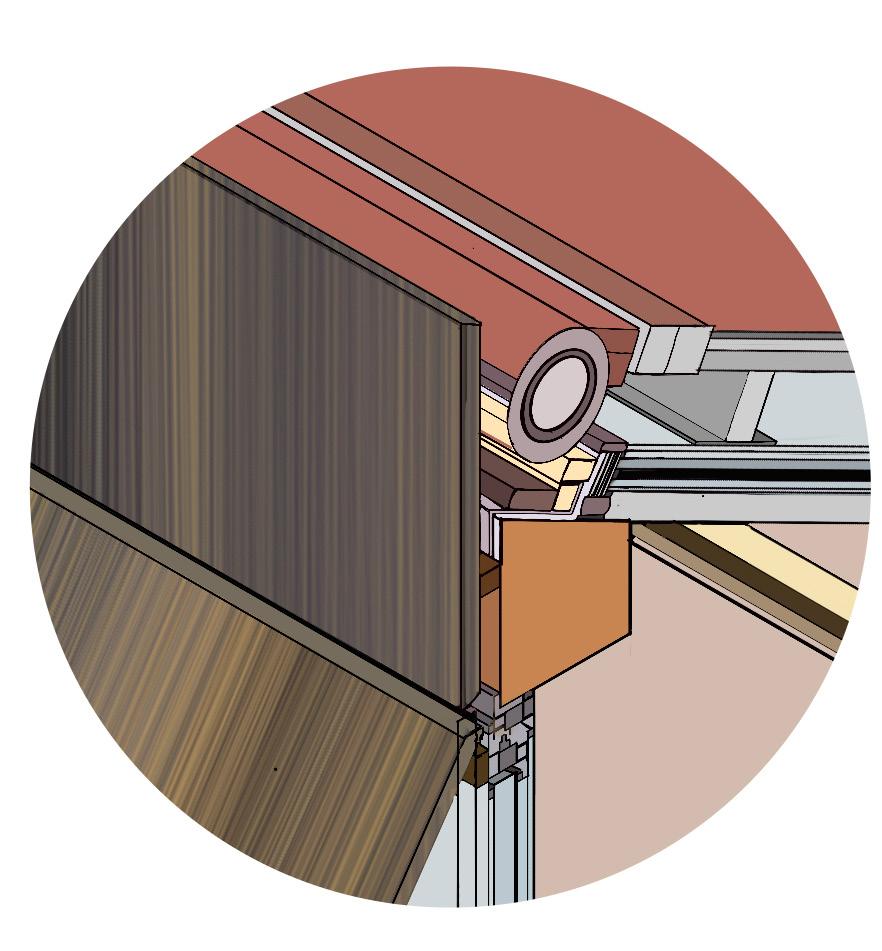

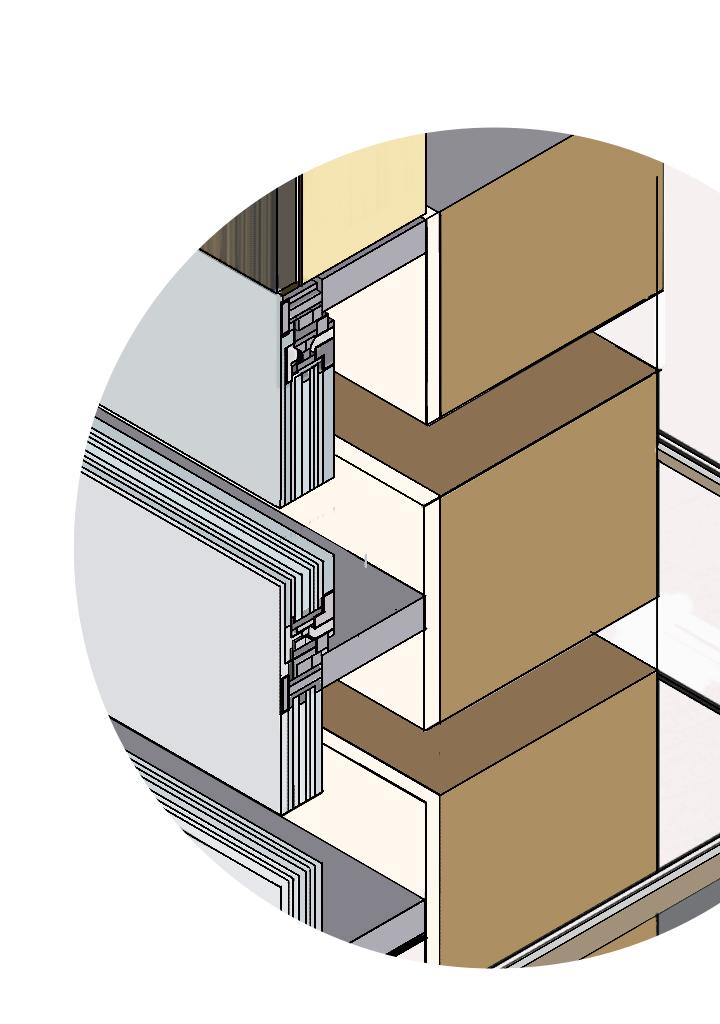

Detailed assembly Building Fabric

The office building in Ferrara Uses a fairly simple and uncomplicated facade system to repond to the environmental needs of the location. High levels of insulation that match passive house standards have been used. The load-bearing glu-lam structure consists of straight rectangular cross-section structural elements made using spruce wood boards in accordance with the EN 14080 and DIN 1052 standards

The spruce glulam used for the posts and secondary deck falls within strength class GL32 or GL36, as stipulated in the EN 14080 standard. All metalwork is suitably protected against corrosion. The building could have benefited from a unitized glazing system over a stick type to have reduced construction time on site and would have added an additional layer of protection against heat loss.

The building has done an exemplary job of using different construction methods, prefabricated secondary facade and standardised glazing units to respond to the needs at the time of construction.

Intergrated 3D envelope study

skylight: operable glazing double glazing

12 mm tempered glass + 16 mm

cavity + 2× 6 mm

compound safety

glass in aluminium

frame

Junction Details

50/30 mm thermally treated fir battens

30/30 mm thermally treated fir counter battens

diffusion- open membrane

22 mm OSB board

200 mm mineralwool thermalinsulation

22 mm OSB board with sealed joints

30/30 mm battens

12 mm OSB boardwith white dye

double glazing

10 mm tempered glass

16 mm cavity

Under the 2012 regulations of Ferrara an easy to re purpose and adapt building scheme was necessary. The 6x6 grid makes the building easy to adapt. Additionally no internal walls are load bearing which makes them easy to remove and re purpose. Using a large number of small parts makes it easy to replace building elements and keep up maintenance. Timber and the small amount of concrete used can be reused.

Secondary Facade

The office building in Ferrara uses existing technology in a highly efficient manner. This comes at no additional cost and utilises computer based technological design in a less technocentric manner by adding to the environmental capabilities of the building not taking away from it. There needs to be more research and development into analysis and simulation to create a truly high performing building that responds to its ecology. This is especially crucial giver the climate crisis that we are in.

Primary Facade

Prefabricated units of the facade are transported onto the site held between an OSB board package.

Timber battens are fixed to both sides of the package then timber firbattens are fized on to add movemnt to the frame.

Wall to Roof Interface Winow Opening Detail

50–60 mm gravel plastic sealing membrane 250 mm EPS thermal insulation vapour barrier ca. 100 mm lightweight concrete to falls separation layer 40 mm timber boards

2× 5 mm compound safety glas in aluminium stick-type facade system

External wall to Ground Slab Detail

mm calciumsulphate raised

Envelope Assembly