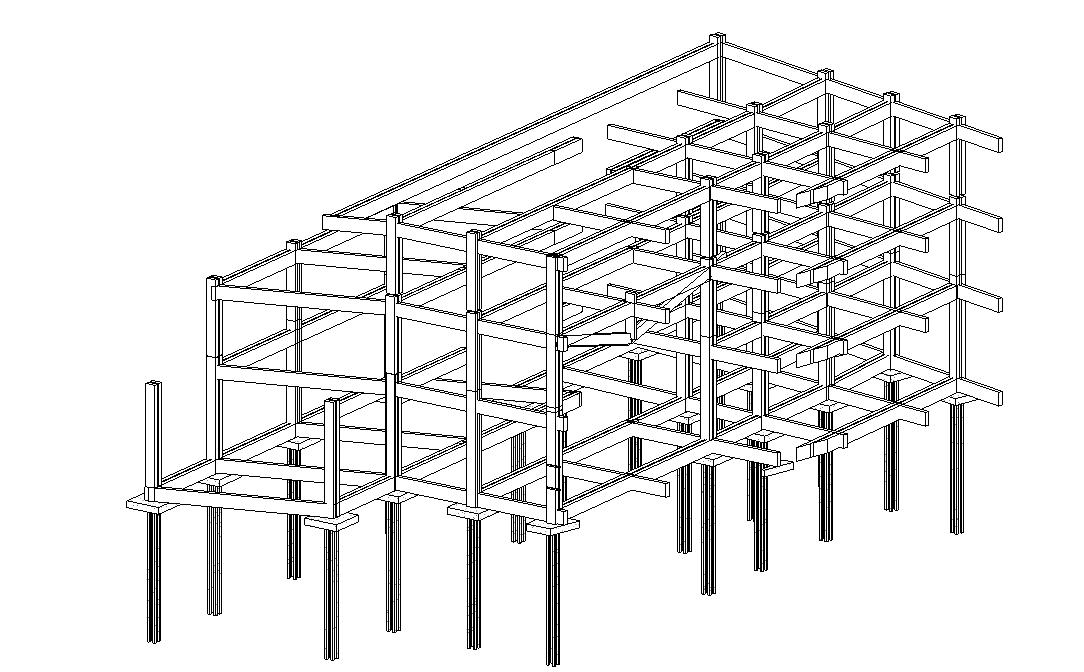

- Glulam clomumns

waterless appliances where possible - waterless green wall system.

3) provide greywater and rainwater recycling - Use of reed beds and an environmentally safe water reuse system.

1) leave site in better regenerative condition -

2)carry out sustainable re mediation of site pollution - green wall system 3) Create a habitat that enhances biodiversity - turn the green wall into a more conscious and diverse wall

1) Create indoors spaces with good lighting and glare control - deep sunken windows to accommodate the southfacing facade. Dedacious trees also used for shading

2)Provide responsive local controls - operable windows and control able havoc systems

3) Design spaces with good acoustic comfort

1)Create spaces for social interaction

2) create secure places with over looking views

3) Create inclusive spaces for community interaction - the human and non human

1) measure added value of occupant health and well being - use of high quality operational systems and natural materials which are proven to have psychological benefits

2) measure added value of sustainable outcomes of buildings.

3) carry out whole life analysis of building materials - naturally biodegradable materials used where possible and all materials can be recycled

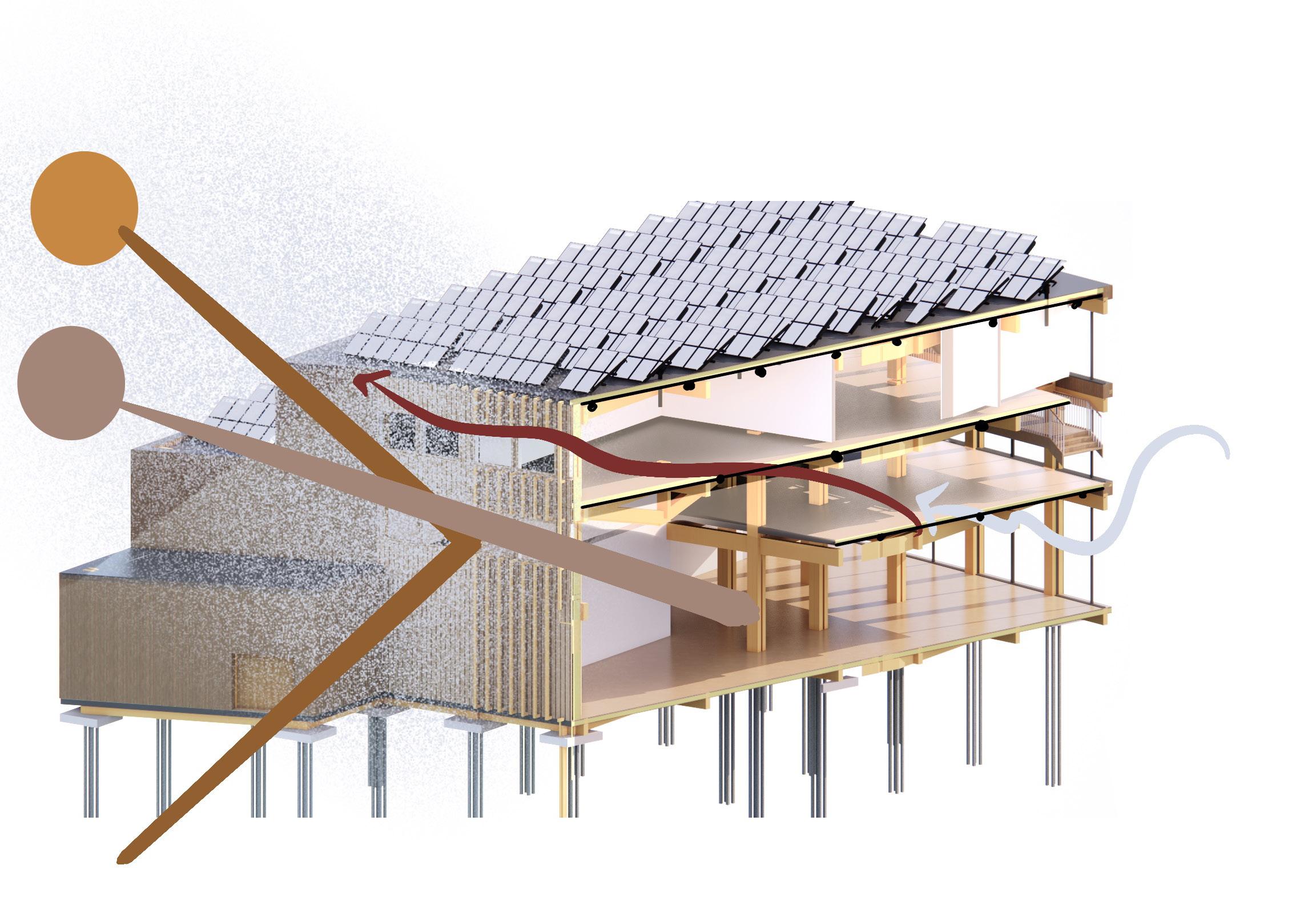

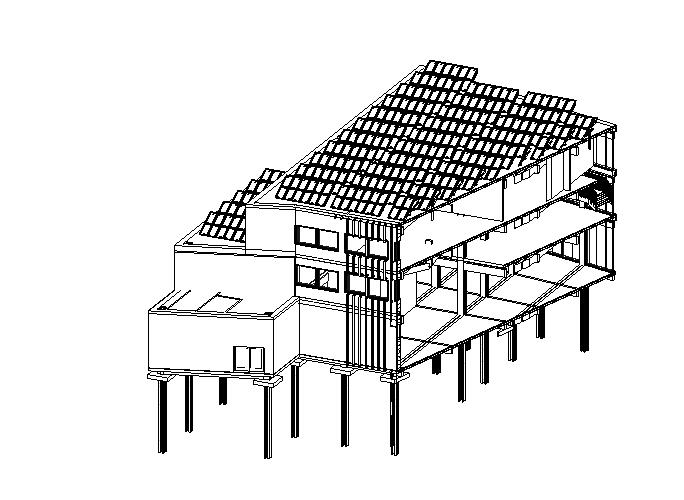

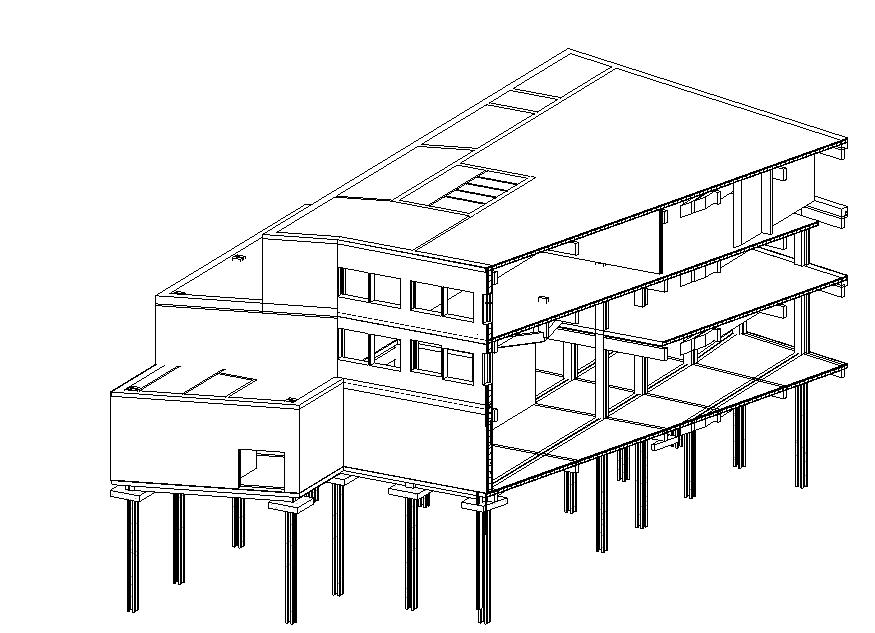

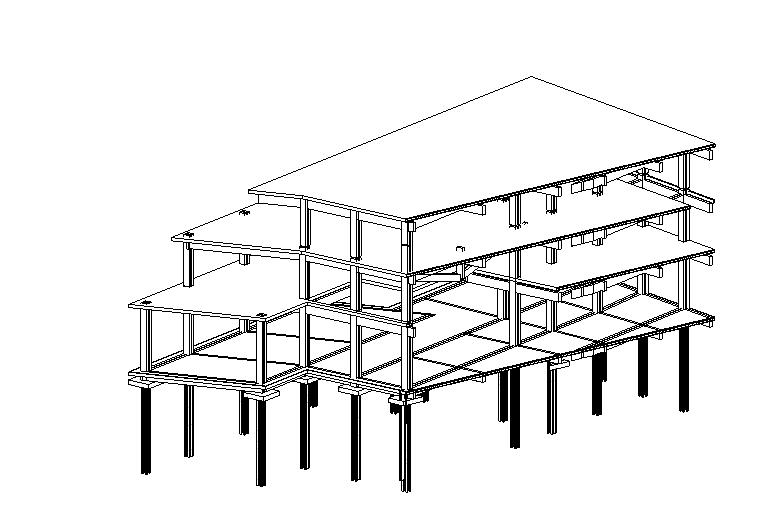

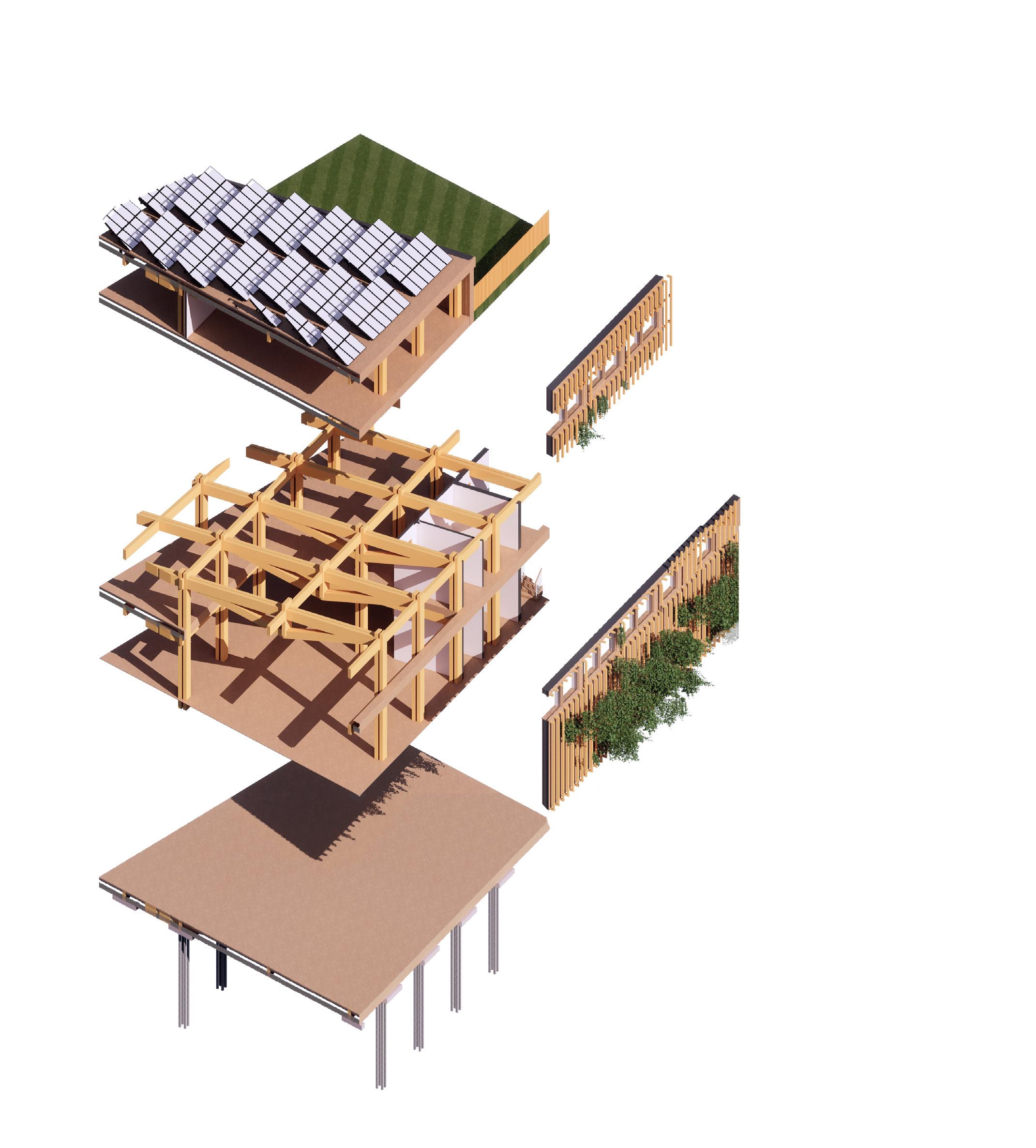

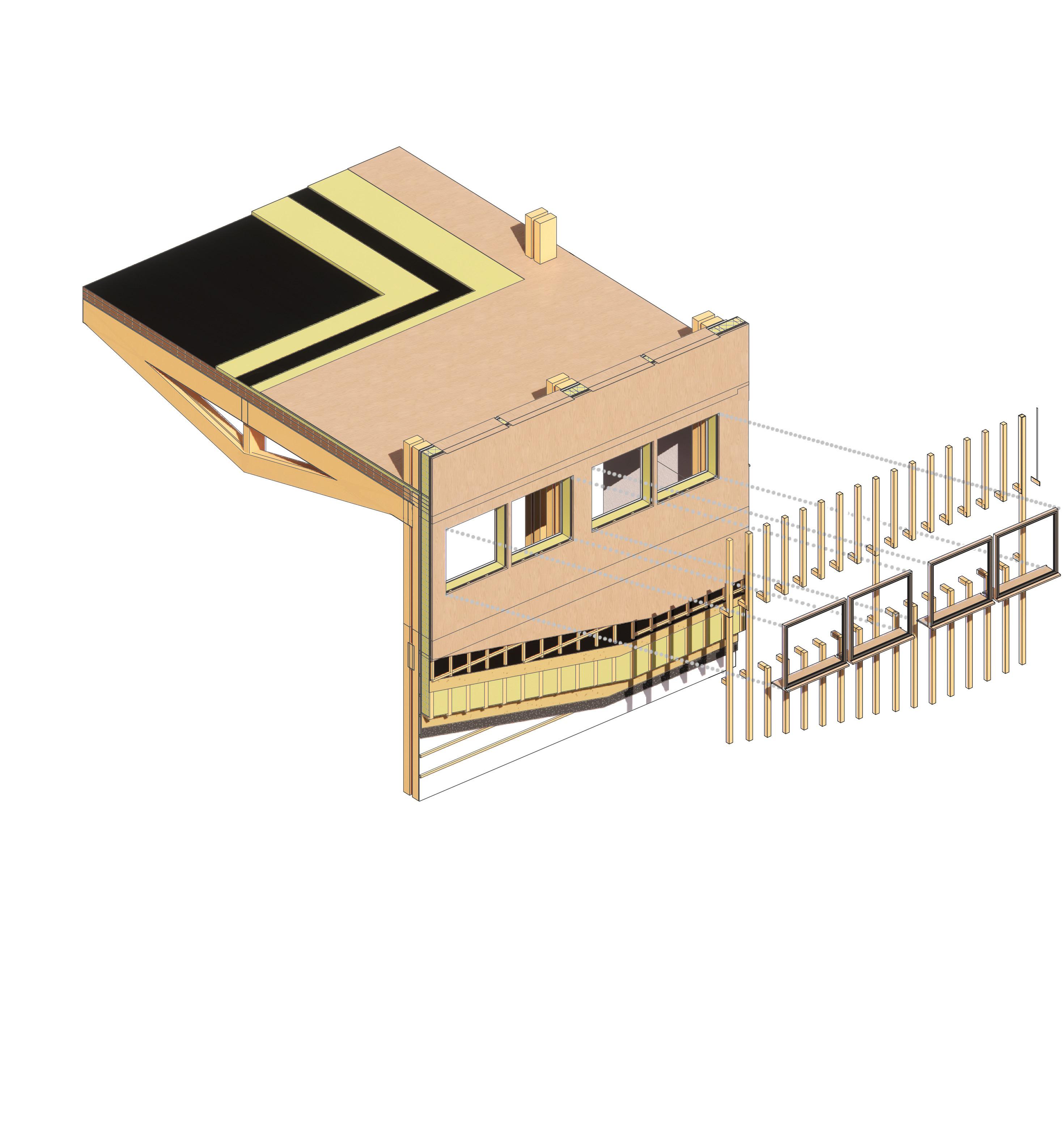

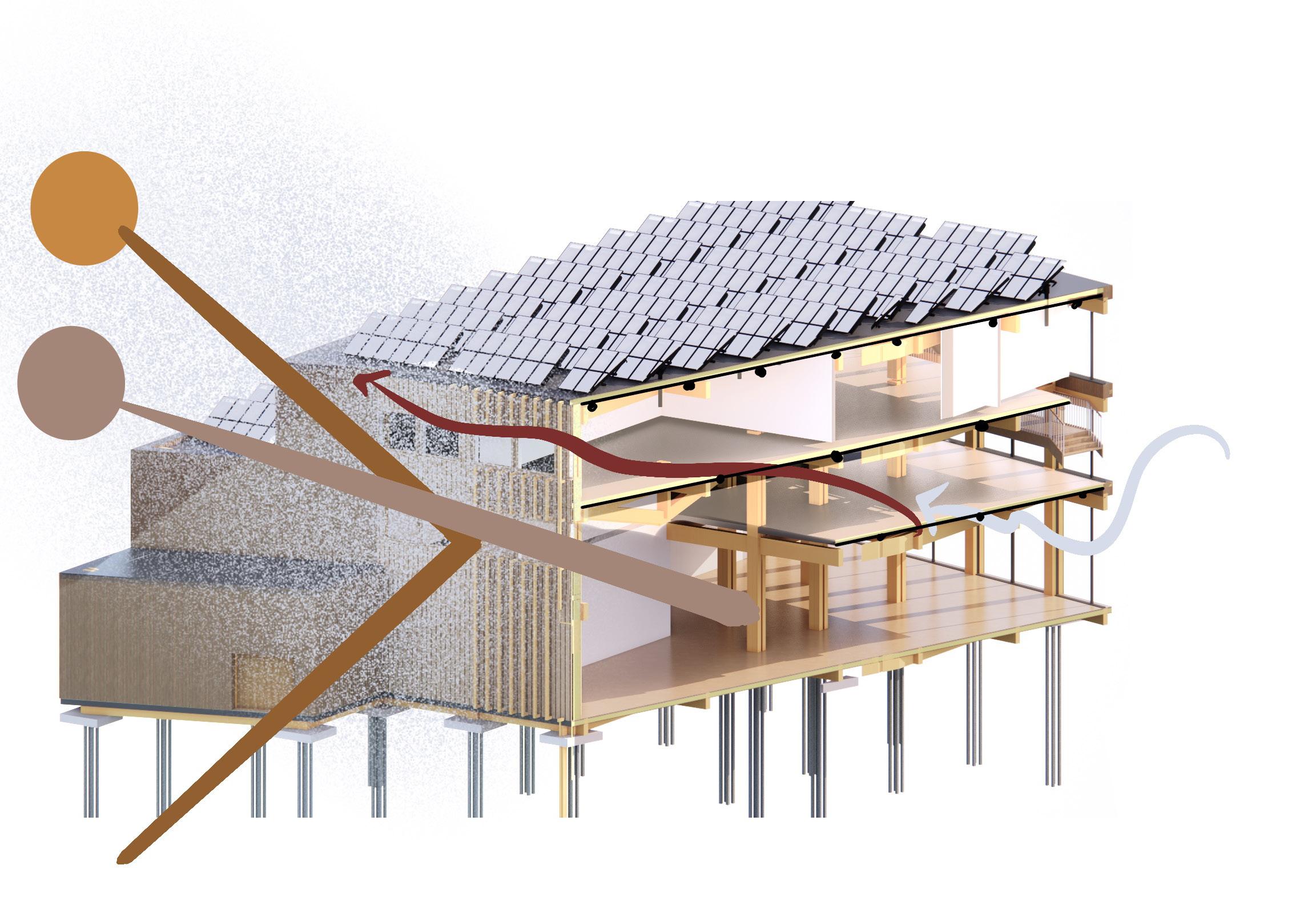

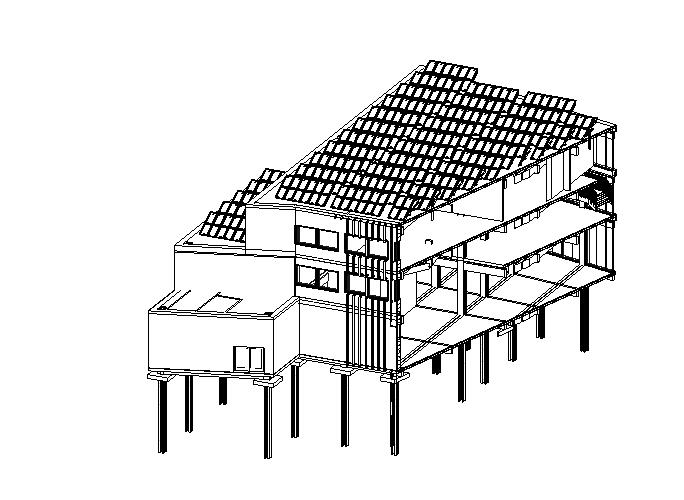

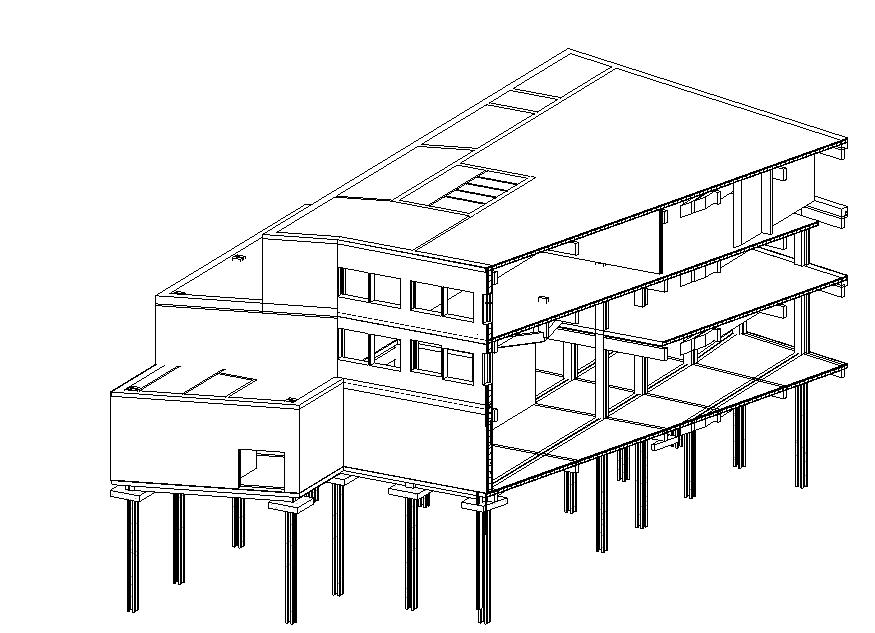

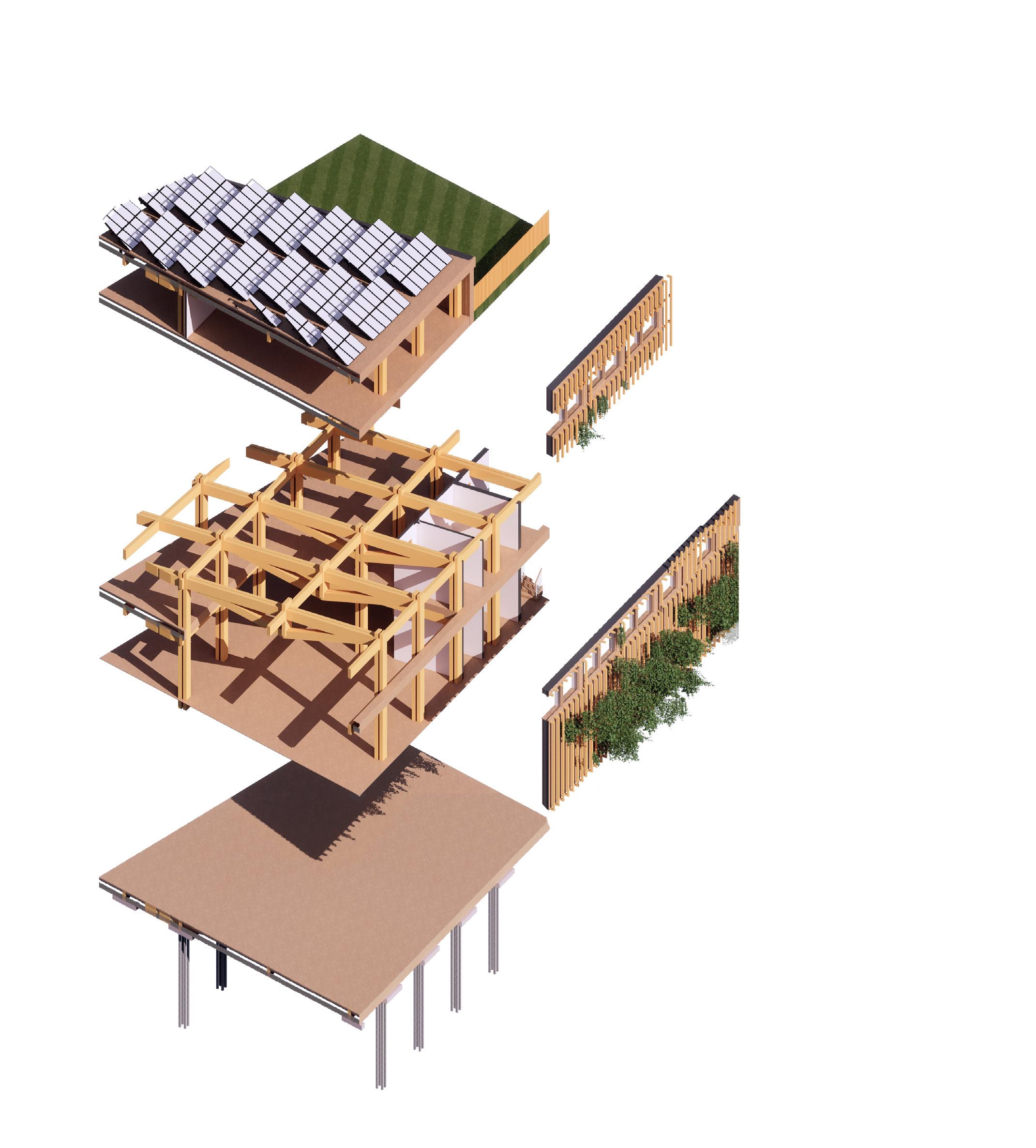

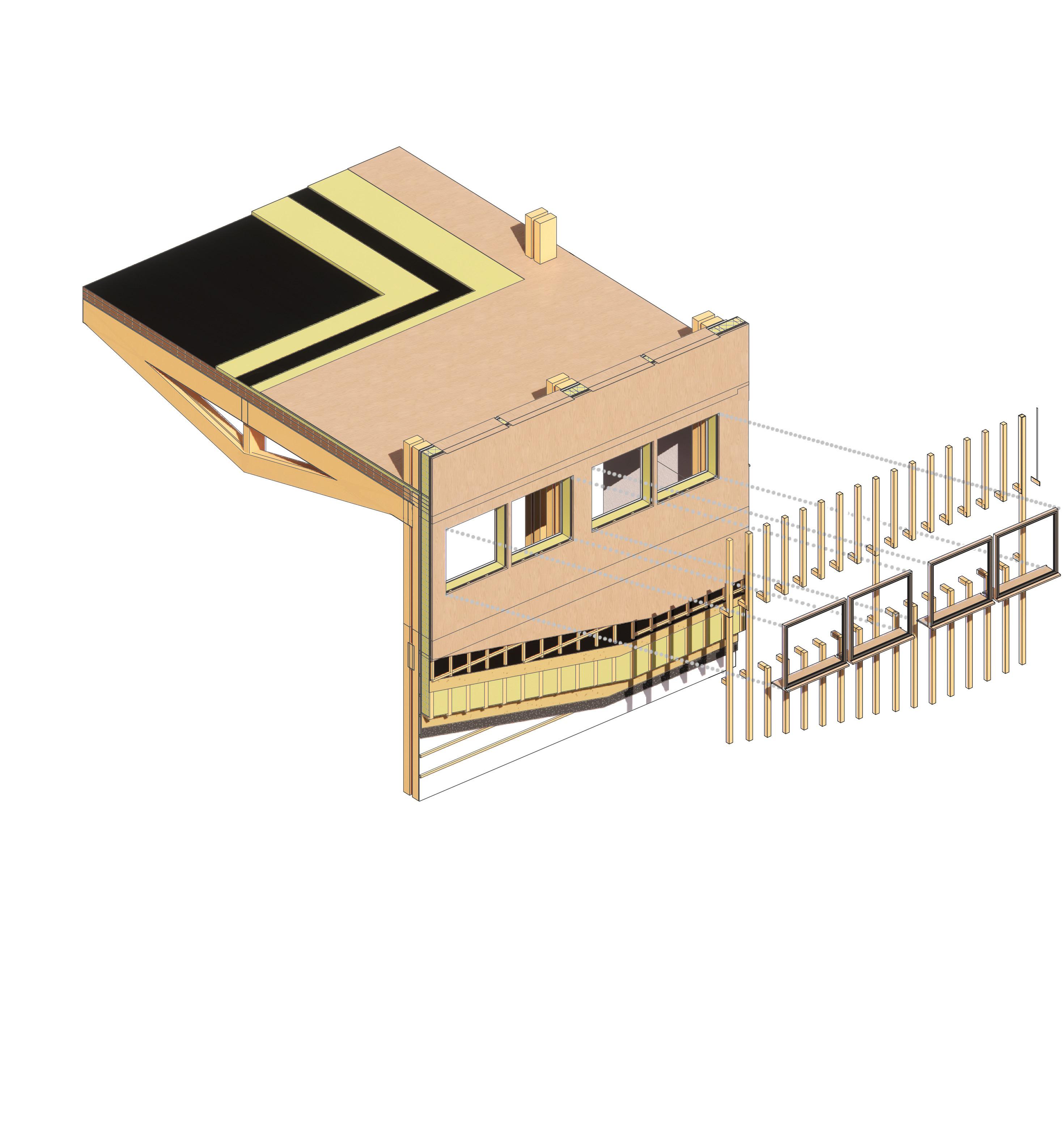

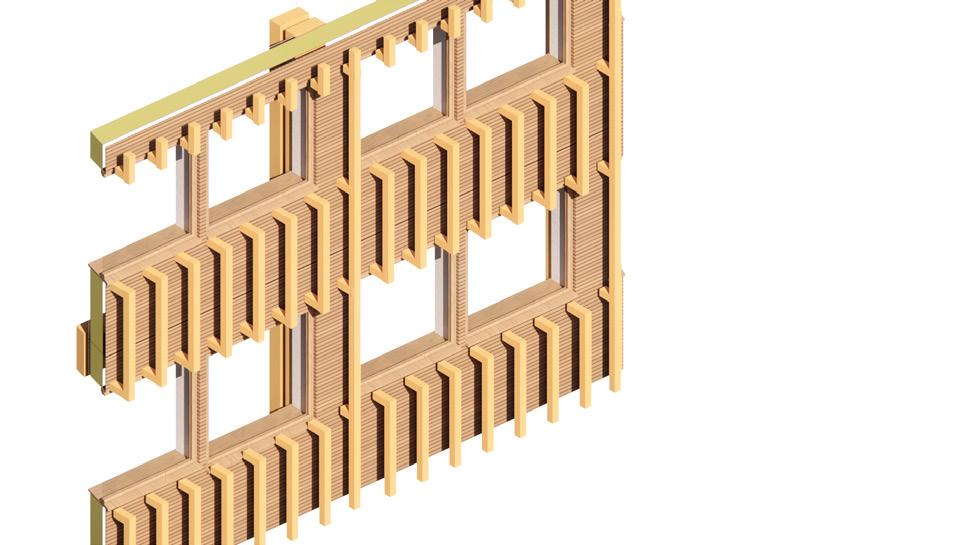

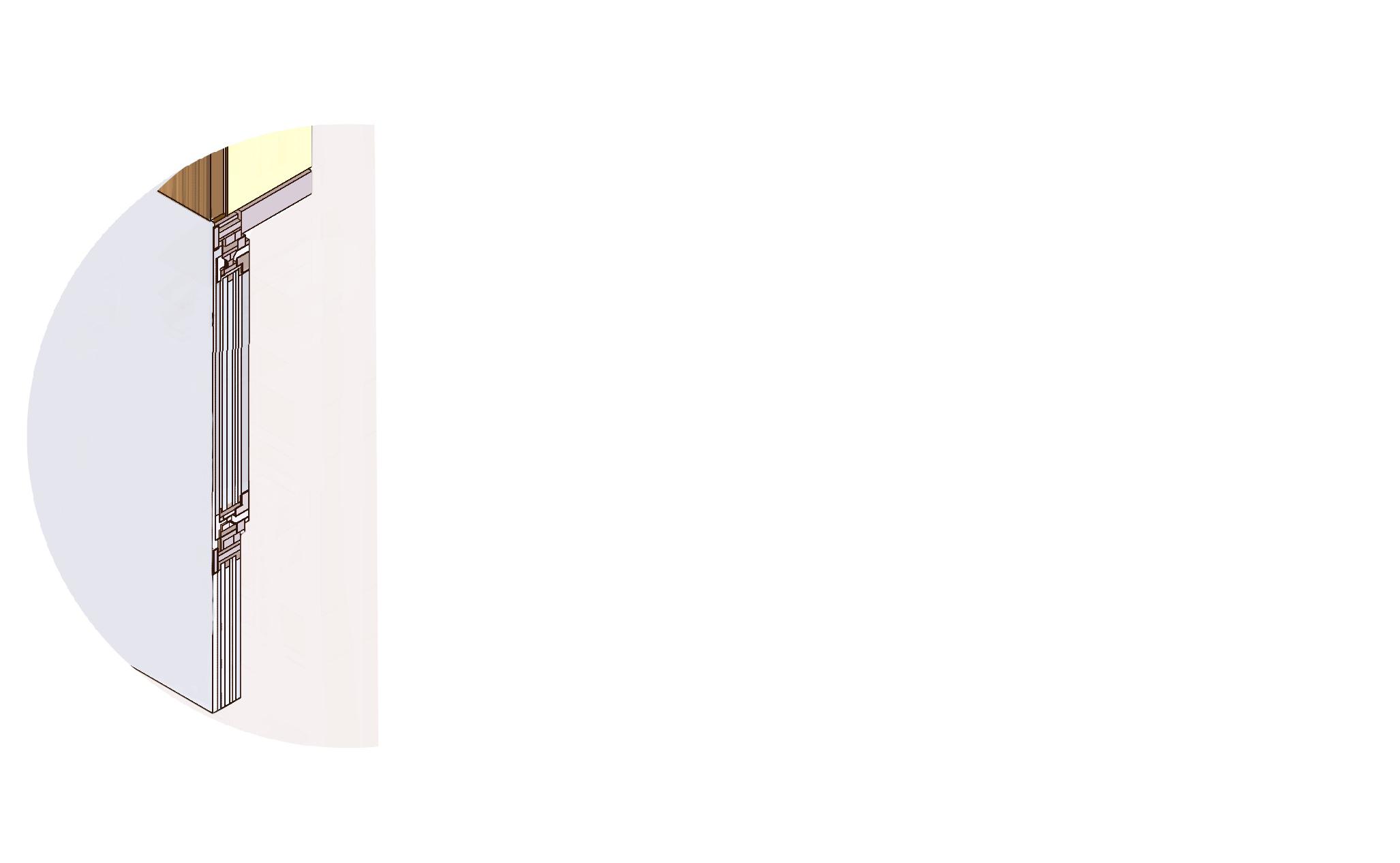

The exploded axonometeric showcases how the fragment sits within the wider scope of the building and how it forms a pivotal connection point on the building.

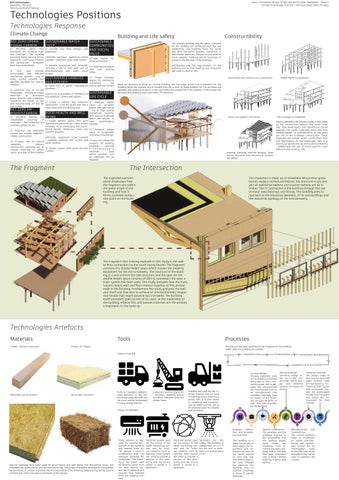

The primary building and life safety concerns for the building are attributed with fire and weathering. The building faces the south and with the harsh weather conditions in manchester there are chances for the wood to rot or weather. Coatings will be nessesary to preserve the life span of the building.

fire requirements of the building are L5. The cladding and insulation will need to cater to this

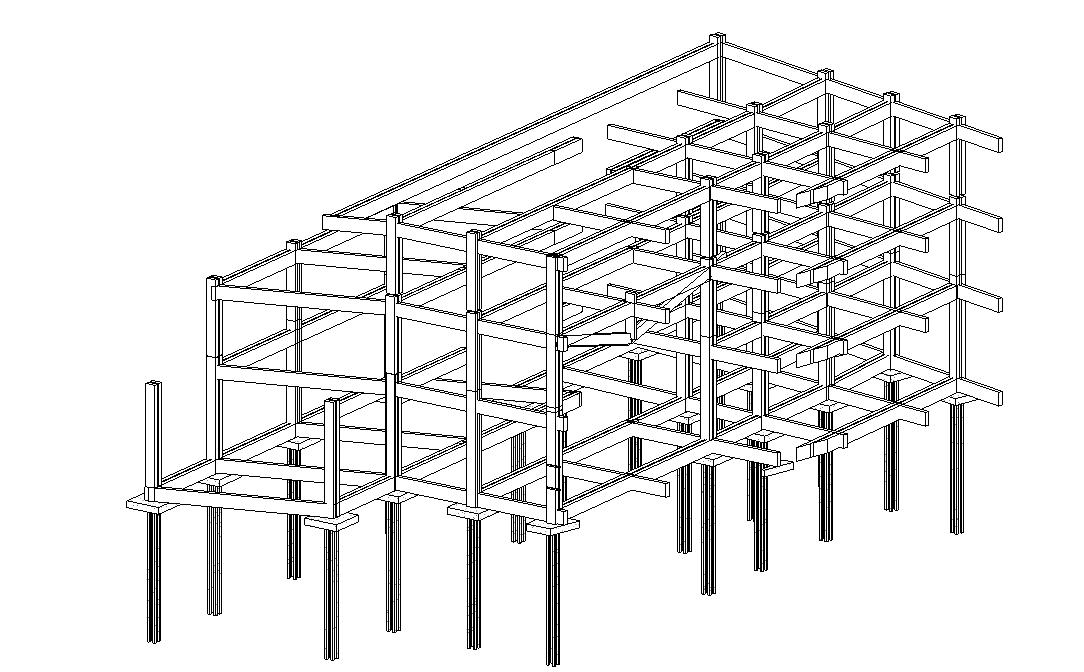

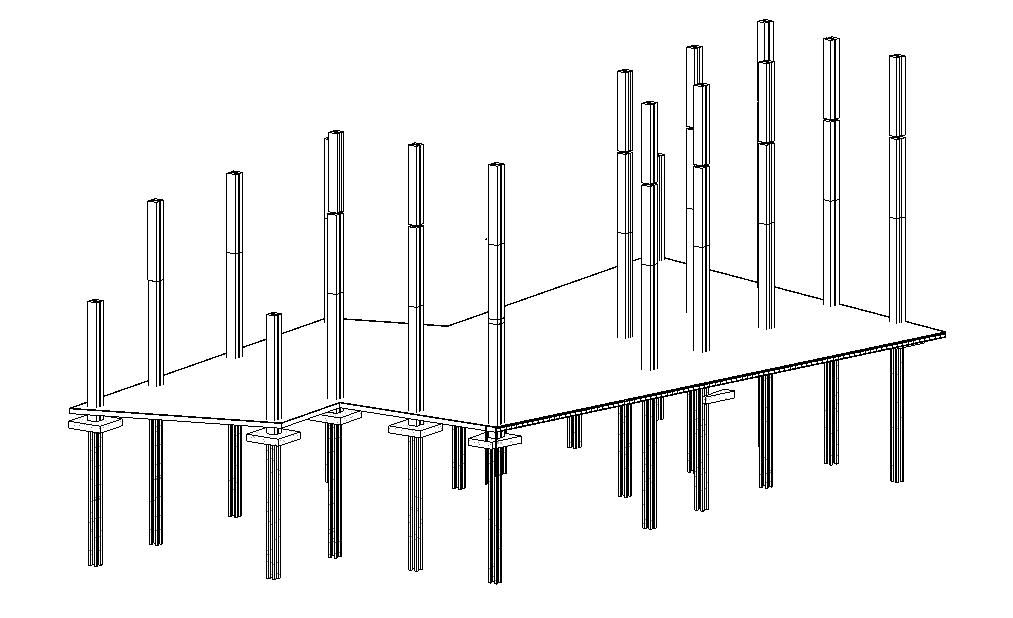

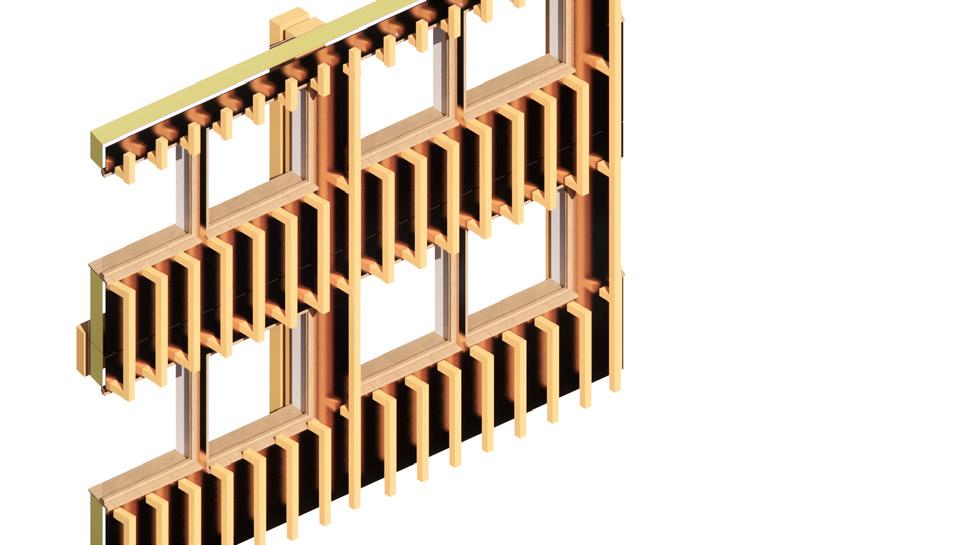

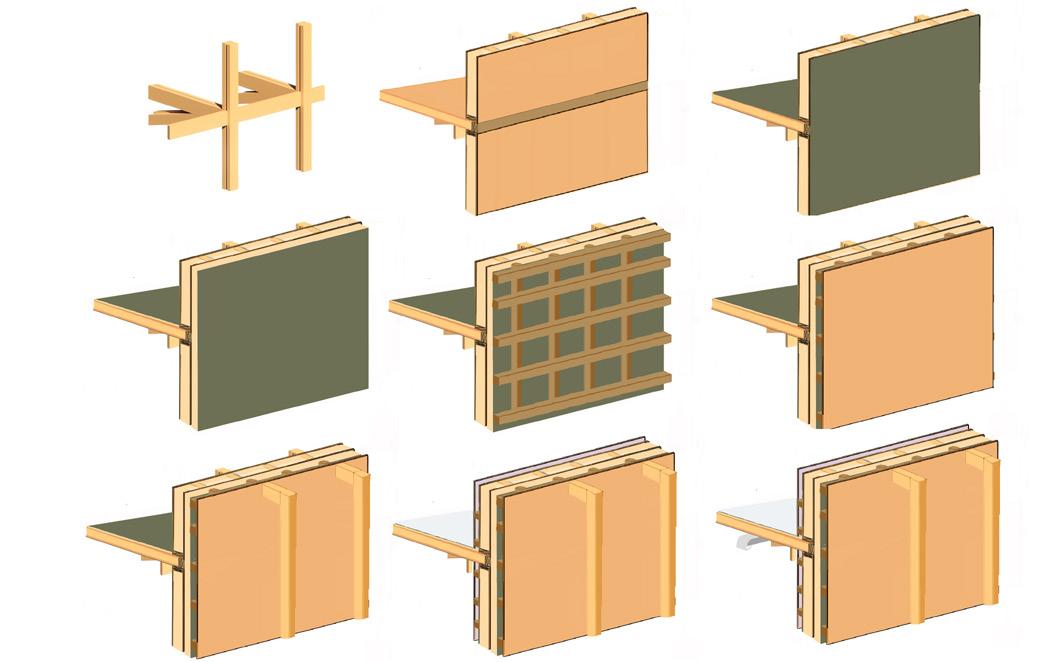

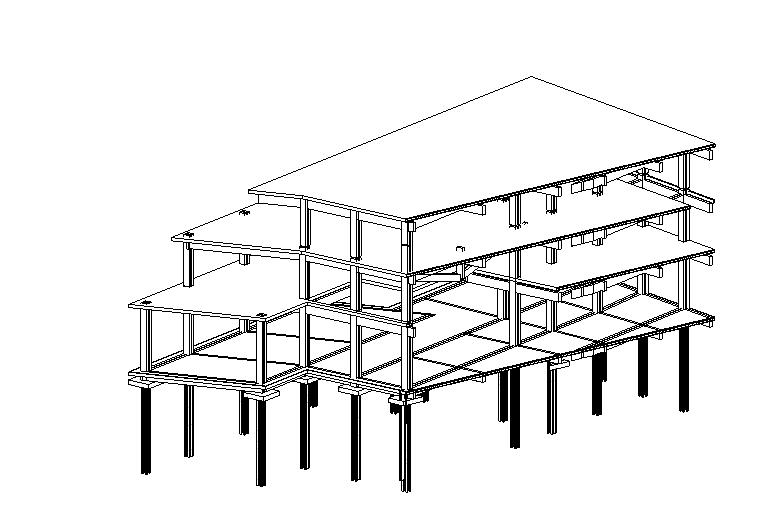

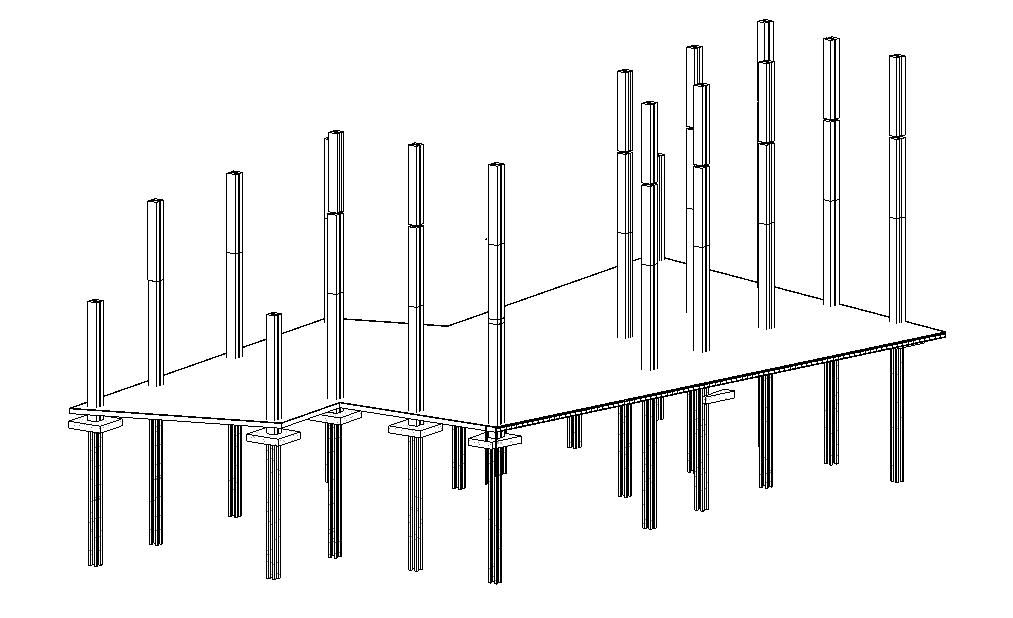

Having identified the primary aspects that make up the construction aspects this study looks into how these layers and connections can be realised. The study especially looks into how modularisation or prefabrication of the units can aid in the buildings construction. These measures can reduse onsite construction time and disturbance to the landscape. This is a priority as seen by the use of the pile foundations . Additionally the use of these systems could reduce human error on site

The insulation is made up of strawbale. Miscanthus grass boards replace normal osb boards, the sturcture is glu lam and all additional battens and counter battens are all in timber. This is contrasted in the building through the use of metal steel bracings and fixings. The building aims to nod back to the industrial aesthetic of its surroundings and the industrial typology of the microbrewery.

grass boards Straw bale insulation

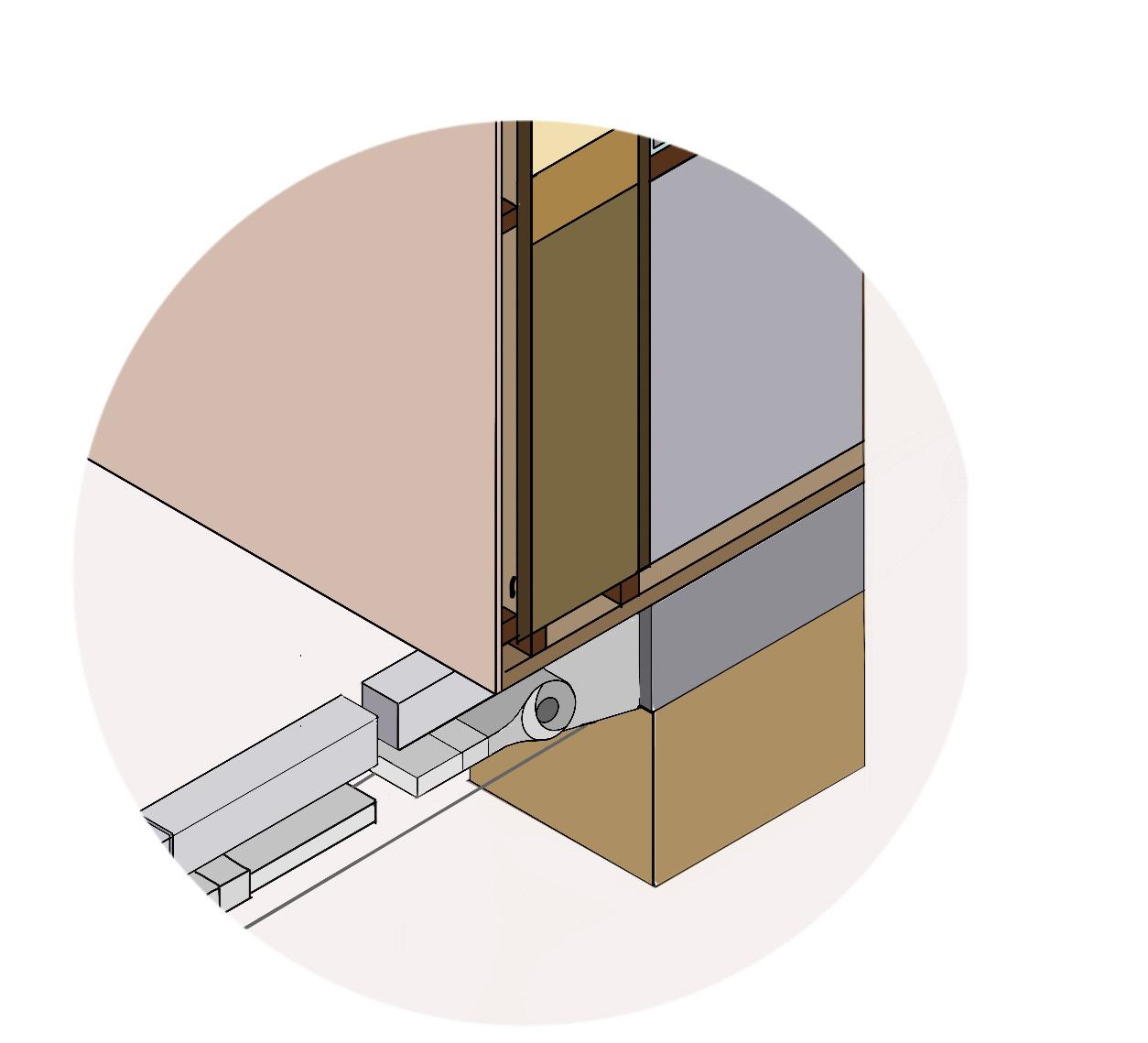

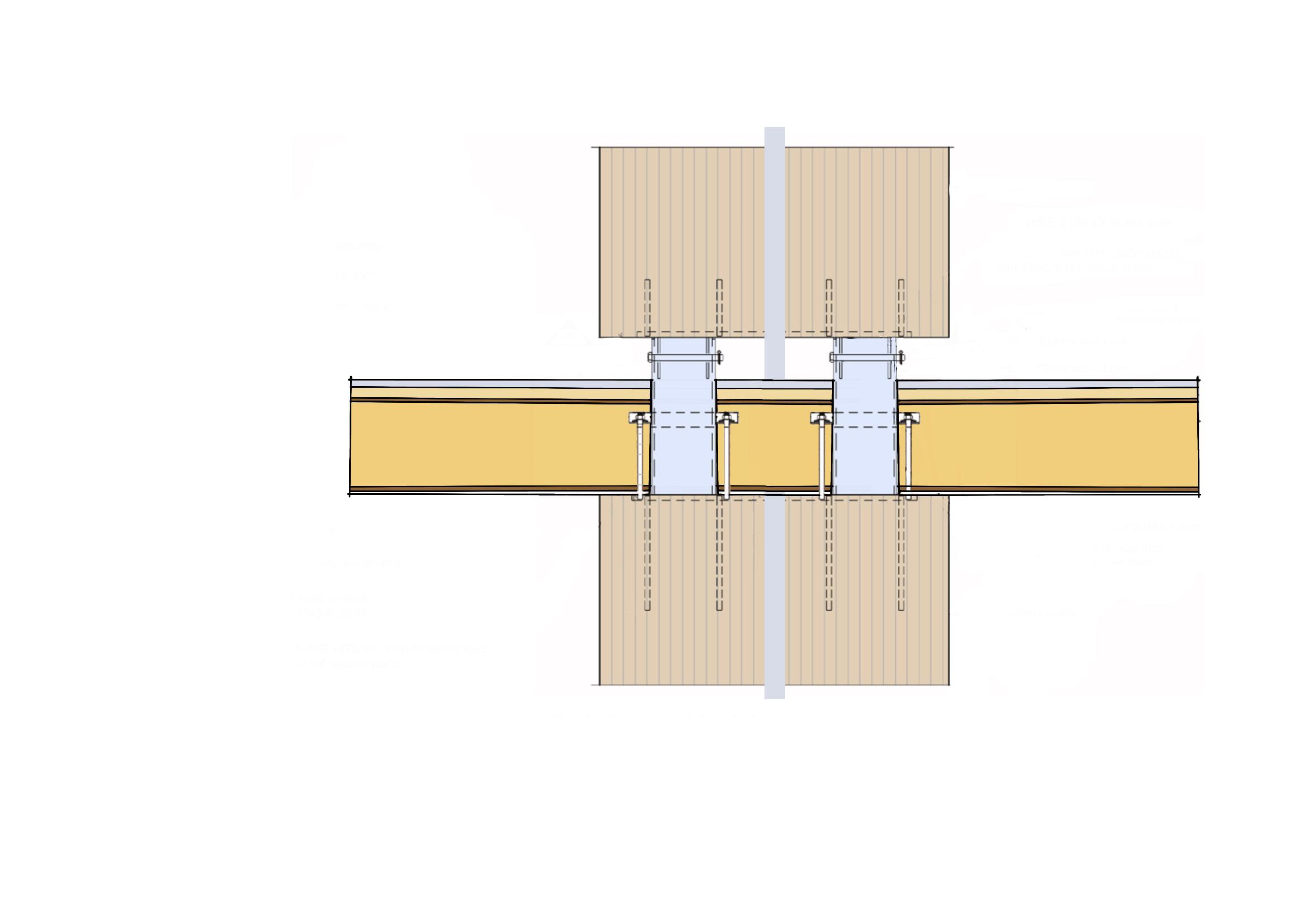

The Fragment that is being explored in this study is the wall to floor connection on the south facing facade. The fragment consists of a double height space which houses the brewing equipment for the micro-brewery. The structure of the building is a non uniform Glu-lam structure and the span for the double height space consists of 18m to counteract the span a truss system has been used. This study analyses how the truss, column, beam, wall and floor interact together at this pivotal node in the building. Furthermore the study analyses the wall unit itself and how best to achieve an environmentally responsive facade that meets passive has standards. The building itself considers grain as one of its users so the materiality of the building reflects this and natural materials are the primary components in the build up

The process has been specified to the fragment of the building rather than the building as a whole

sourcing Manufacturing Transportation Construction and assembley Adaptive reuse and retrofit Dissasembley reuse

concept design

Primary materials used in the building envelope are grown on site ( miscantus grass and strawbale). The raw materials are then handed over to be manufactured into envelope materials. thus all repairs of the building can also be done on site. The site provides for the building

Strategic defenition and preperation and brief.

The building is a place for people to learn about the importance and unknown functions of the world around us and the role that nature plays in out lives. Through the structure the building aims to redefine buildings in terms of natural materials.

Technical design Technical design relies on Lo-TEK construction which simple and effective systems for maximum results

Spacial coordination

The envelope and the windows respond to the programme the. the brewing equipment keeps the southside from receiving too many windows and so the wall had been converted into a livng habitiat aided by a green wall system

Handover and Use

The project looks to be in use for 50 to 100 years without need for maintanence. Furthermore both human and nonhuman species are encouraged to take over the space and adjust the environment for their comfort

Manufacturing and Construction

The current approach looks to implement an onsite manufacturing and asssembley system but tis investigation looks to identify how ofsite manufacturing can be used to enhance the process

Technologies Positions BA3 Technologies Deekshita Viju Nair SKN (Some Kind of Nature) Part C: TECHNICAL DETAIL STUDY; ARCHITECTURAL FRAGMENT - Sheet 1 Architectural Design Position + Technical Detail Study Purpose Technologies Response Climate Change Technologies Artefacts Building and Life safety Materials Constructibility Tools Processes The Fragment The Intersection NET ZERO OPERATIONAL CARBON NET ZERO EMBODIED CARBON SUSTAINABLE WATER CYCLE SUSTAINABLE LANDUSE AND ECOLOGY GOOD HEALTH AND WELL BEING SUSTAINABLE COMMUNITIES AND SOCIAL VALUE SUSTAINABLE LIFE CYCLE 1) Prioritise fabric first principles for building form and envelope - The building envelope meets passive house standards. continuous thermal and waterproof envelopes have been maintained. 2) Fine tune internal environment with efficient mechanical systems - Use of HVAC, lighing systems and operable windows for interior comfort. 3) prioritise use of on-site renewables - primary envolope materials of miscantus grass boards and strawbale insulation are grown on site and manufactured off site for use on site 1) prioritise ethical and responsible sourcing of materials - Raw materials are primarily grown on site. 2) Prioritise low embodied carbon and healthy materialtimber construction 3) Promote use of natural materials - primary construction elements are all natural materials to reflect ‘grain’ as a user of the building 1) provide low flow fittings and appliances. 2)Provide

Timber

Timber

floors TOOLS TO BUILD TOOLS TO OPERATE HVAC systems to regulate the internal temprature of the building and remove stale air. The system is used in combination with the operable windows for ventilation. The majority of the power used for heating comes from the heat capture system which captures and recycles heat released from the brewing process Truck to transport prefabricated elements to site. elements are designed to fit into the truck and be lightweight for easy transportation Cranes are used on site to lift windows, cladding panels and other elements onto the timber frame Forklifts are used for the internal finishes and for ease in haluling heavy machinery across site. it is also useful in collecting and transporting ray material from site to be manufactures into boards and insulation Electrical system used for the pumps in the water harvesting system and for internal comforts such as lighting. Solar panels are used to provide a portion of this electricity and the excess power is stored in a generator Electrical system used for the pumps in the water harvesting system and for internal comforts such as lighting. Solar panels are used to provide a portion of this electricity and the excess power is

a generator Sprinklers for

building

as a L 5 fire rist and so sprinklers are placed every 7.5 m.

Miscanthus

-CLT

stored in

fire safety. The

is categorised

Additionally the

Deep set windows to allow for natural shading. the low angle winter sun is allowed into the building while the summer sun is shaded from the interor by deep window sill. The windows are operable and raised as to assist in the stack effect for ventilation in the summer. In the winter the windows are closed to trap heat within the building Natural materials have been used for good health and well-being. The Miscanthus Grass and strawbale are produced on site for manufacturing. The project therefore attempts to incooperate the principles of circular economy into the materiality of the building. Steel bracing will be used to contrast and offset the natural elements of the design. Foundation and

are

Timber frame is completed

finishes,

electrical

systems are added.

columns

constructed

Floors are added to the frame The envelope is completed external cladding, internal

Solar panels

and Mechanical

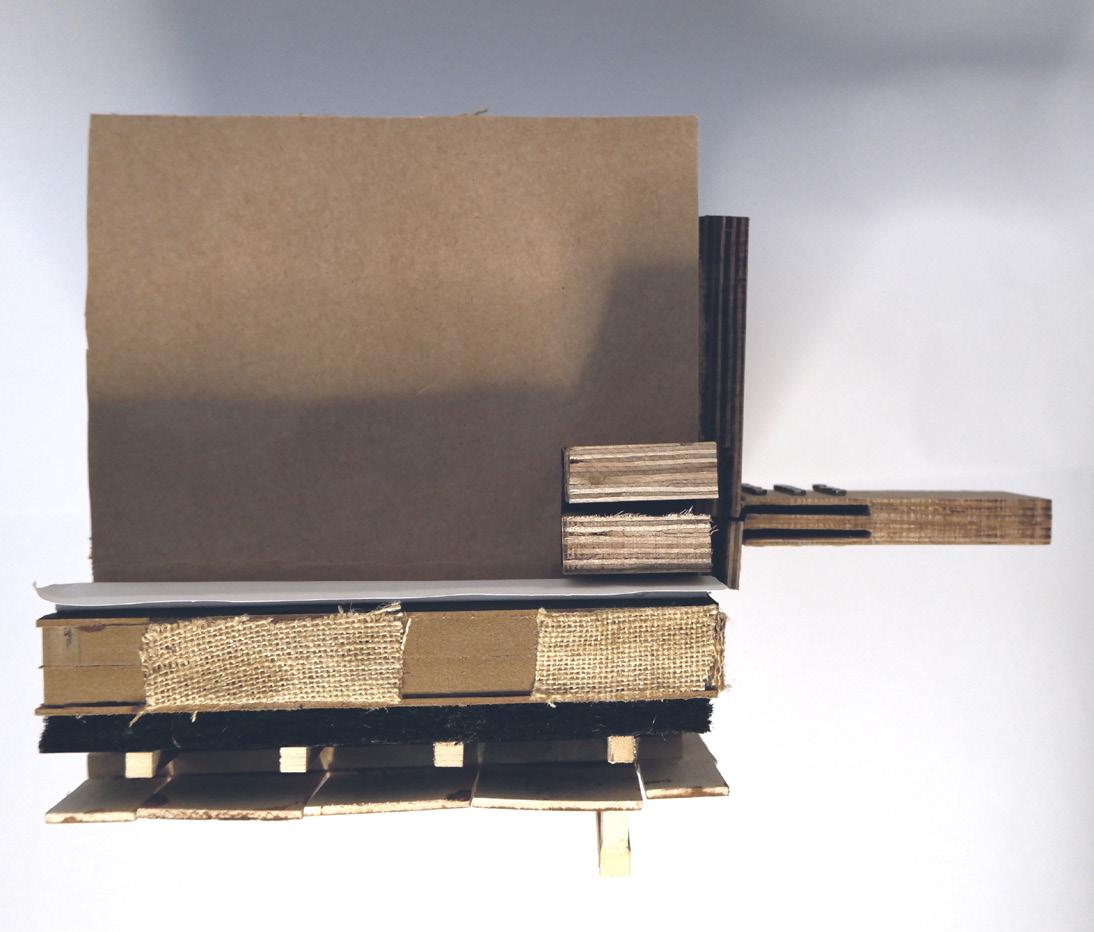

Prototyping

Iterative testing

Iteration series 1

Iteration 1

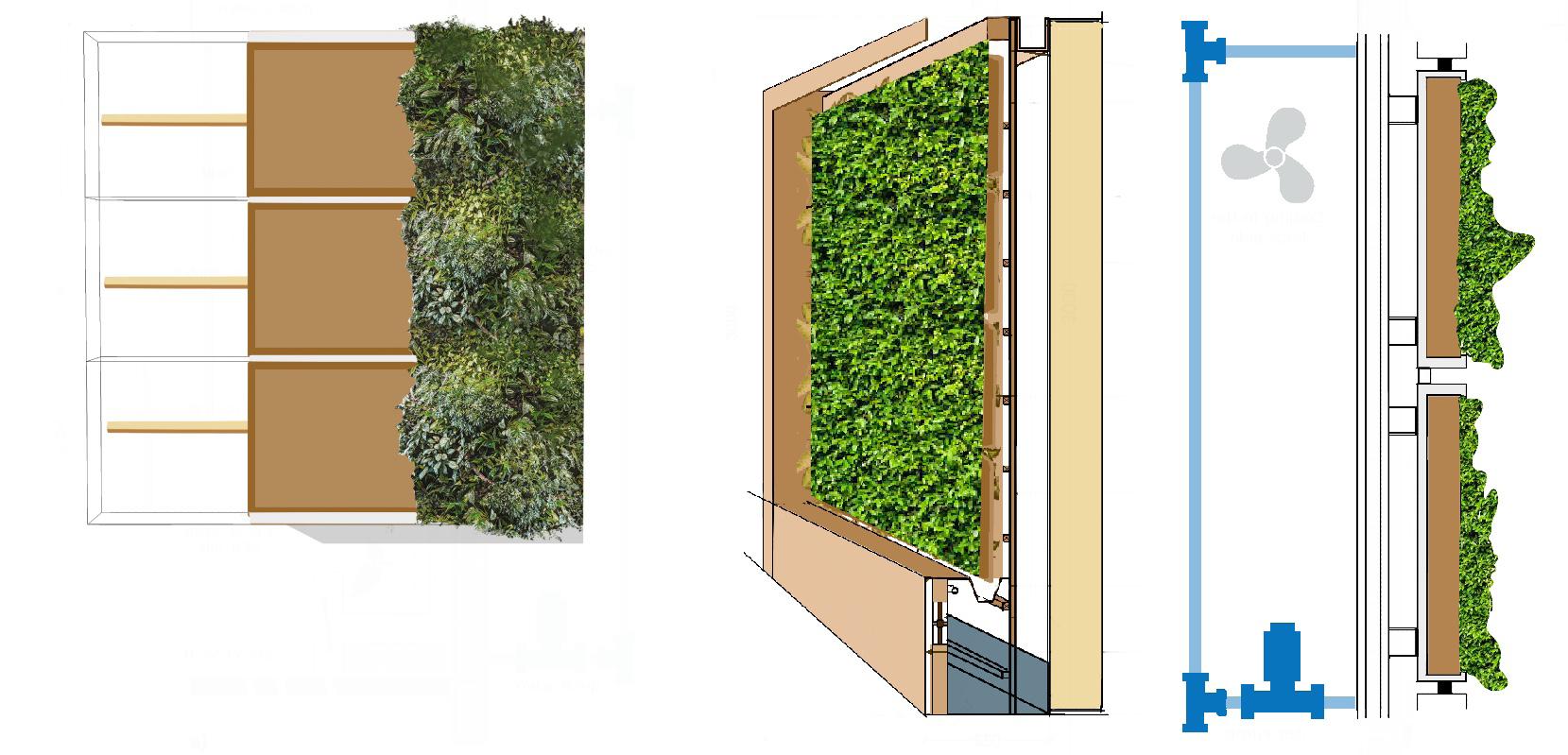

Iteration 1 follows a living wall system based on super soil. potted plants are inserted into the cicular aluminium facade held by vertical battens.

Advantages

-Acoustic insulation against the busy street and the equipment within the micro brewery.

-Environmental benefits - release oxygen and reduce pollution (56% co2 reduction)

-Building preservation - barrier against weathering

- increased bio diversity

Disadvantages

-Misadventurous growth

- energy costs for irrigation system

-High fire hazards (maximum of class B rating)

Iteration 2

This is a modified green wall system that uses climbers instead of potted plants. There is no growing medium on the facade. The plants grow form the ground and creep onto the structure that supports it. Additionally this iteration features insect hotels build into the facade between the climbers supporting structure.

Advantages

-Environmental benefits - release oxygen and reduce pollution

-Building preservation - barrier against weathering

- Structure allows insect hotels to be fixed within the facade which has a greater impact on increasing biodiversity than living wall systems.

- Allows for a primary facade which which can mitigate the fire hazard.

-Easier to control misadventurous growth

Disadvantages - no acoustic advantages

- lesser ingrained biodiversity than living walls

Iteration3

An irrigated living wall system with a separate water system that uses rainwater harvesting to meet water needs Additionally the plants are attatched to a felt sytem.

Advantages

-The gap created between the green wall and the wall surface remains at a constant temperature. This aids in cooling or heating the building by acting as a thermal barrier similar to a double skin facade

-Acoustic insulation

-Water and the living wall system together form a system of evapotranspiration which can counteract the high thermal levels caused by the brewing .

Disadvantages

- Maintanence - falling soil

- high chances of water and damp damage even with protective memberanes and coating.

-Energy costs for irrigation system

-High fire hazards (maximum of class B rating)

Iteration 2 was chosen for primarily the life and building safety factors. This is especially important as the microbrewery ranks as a L5 fire hazard. Additionally it requires no additional irrigation system which is in line with the RIBA goals. It also allows for more natural growth.

Iteration series 3

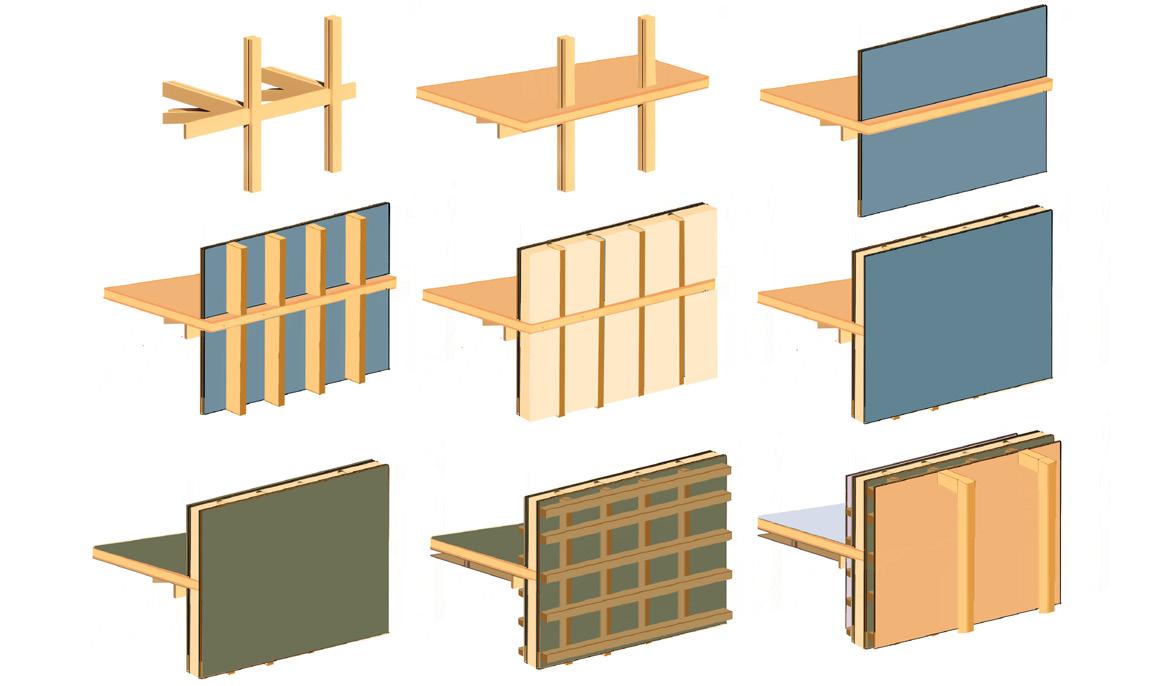

Constructability

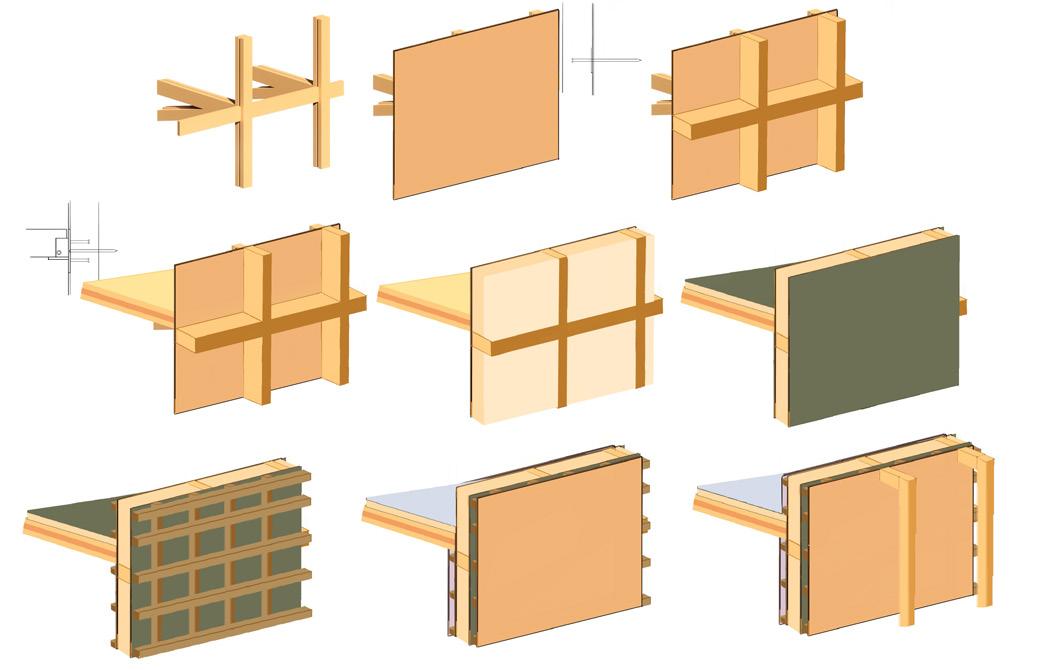

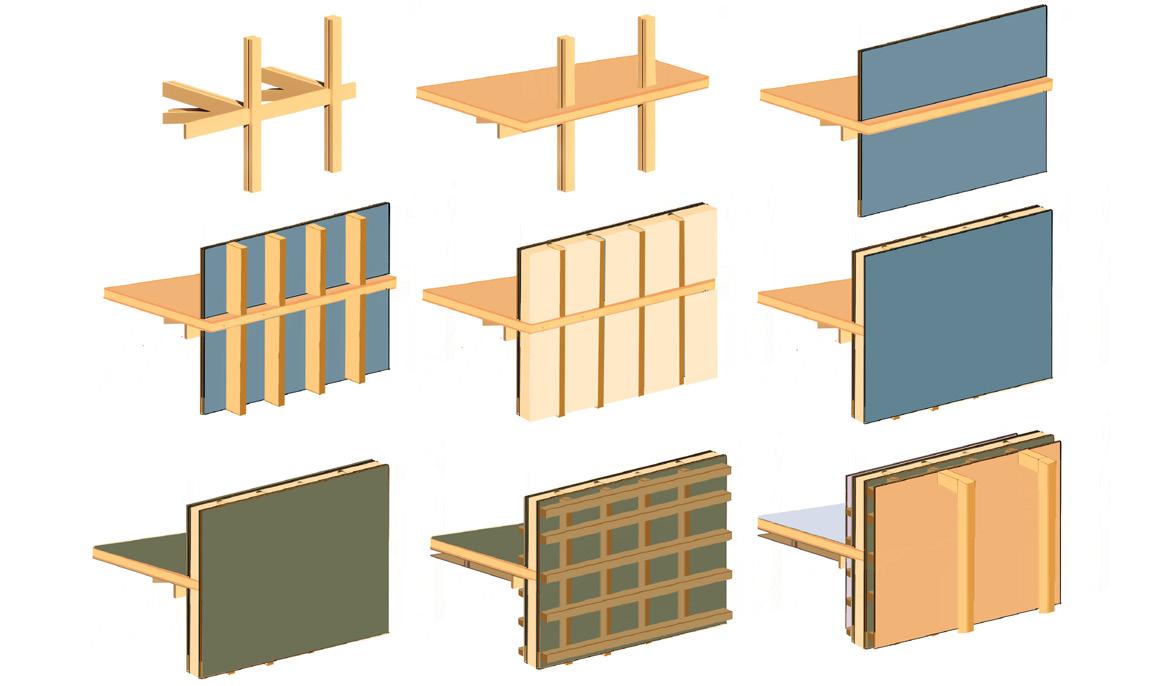

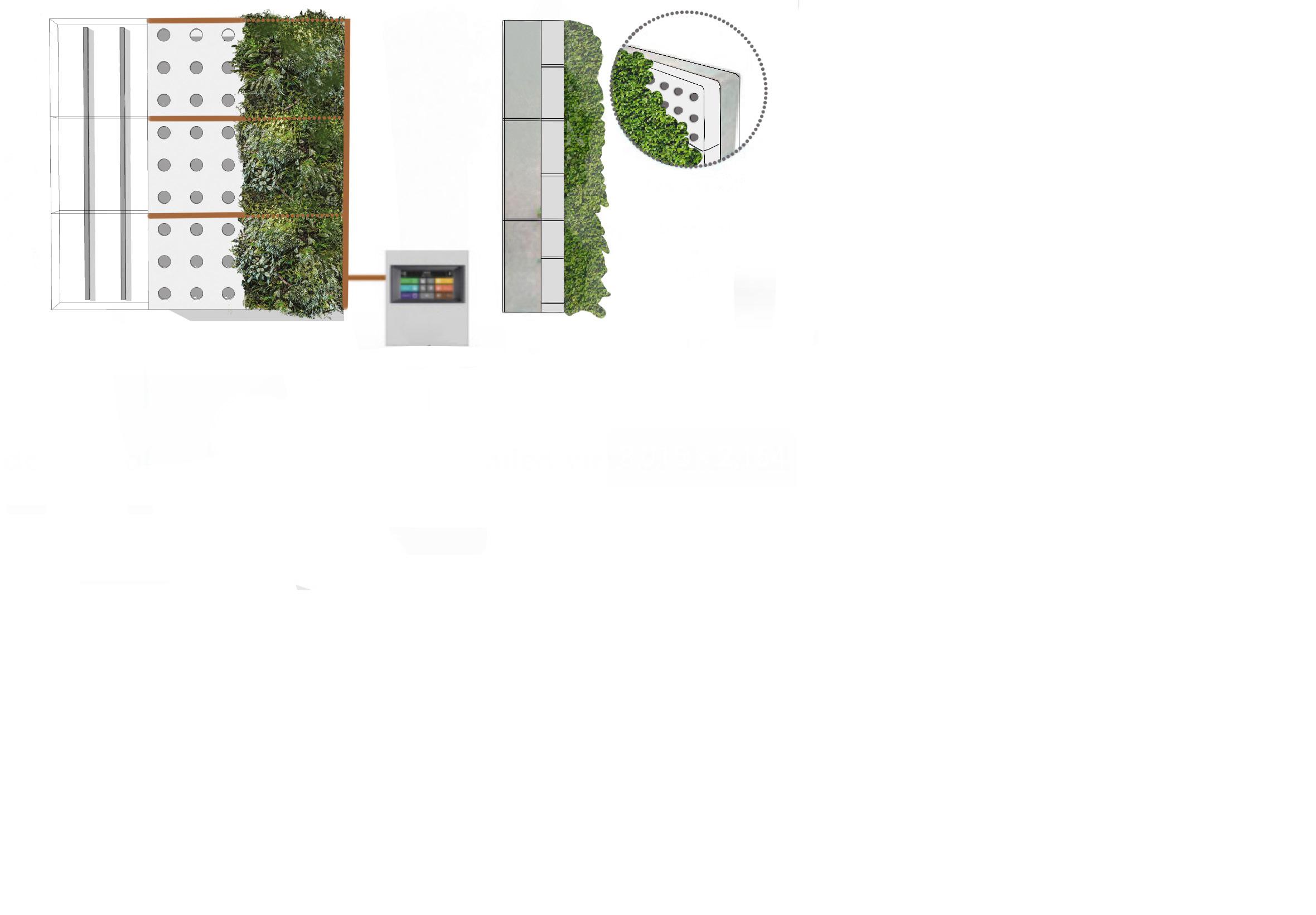

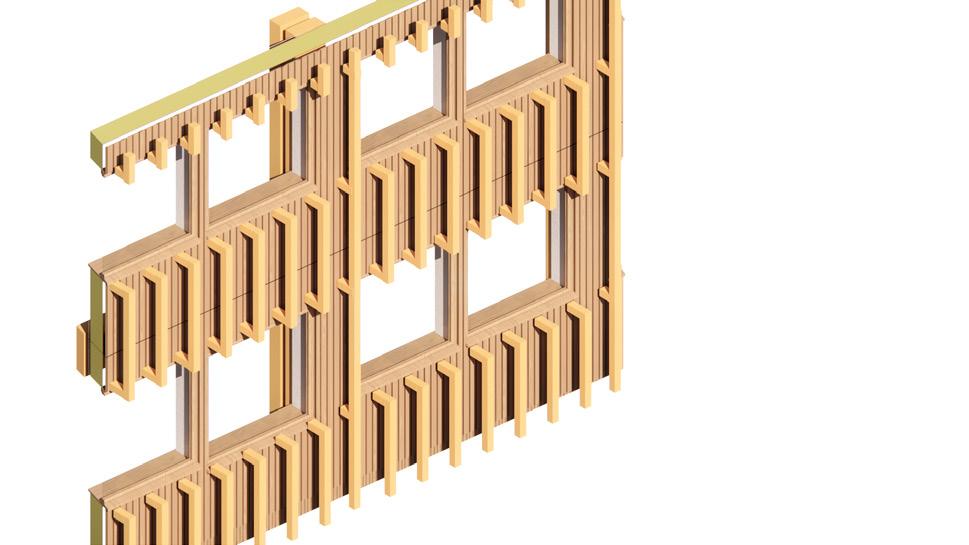

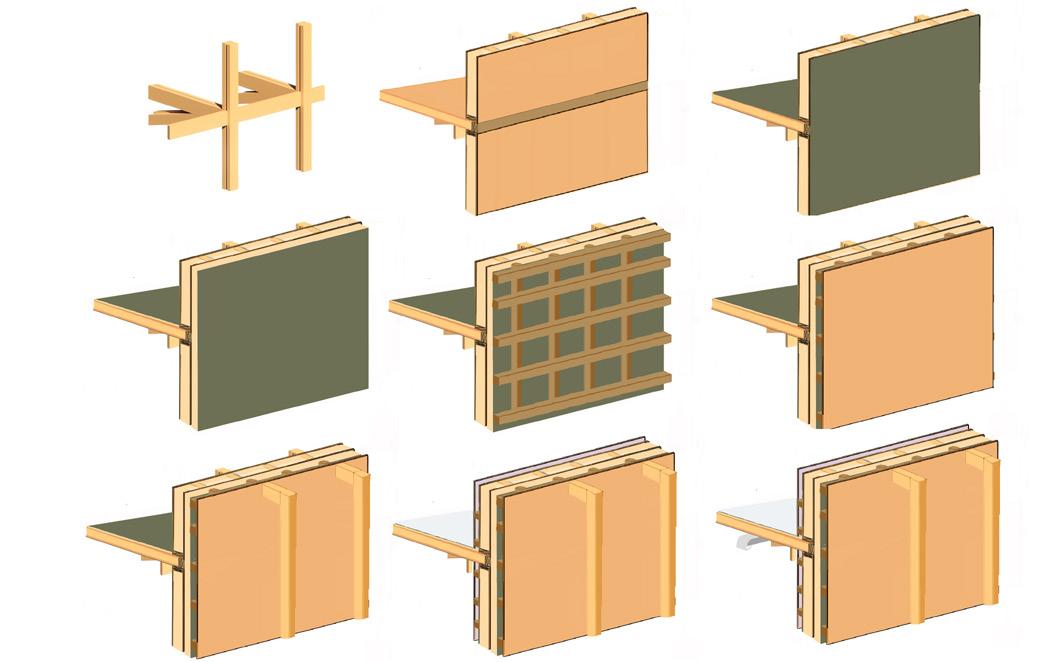

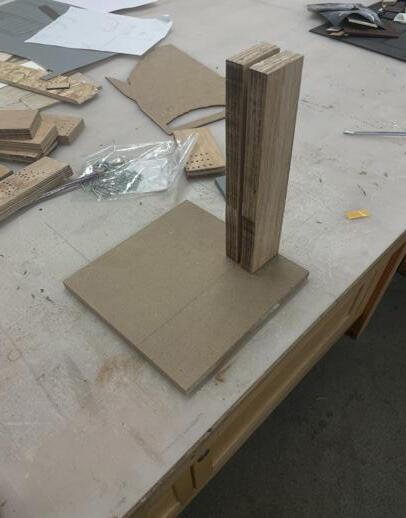

Iteration 1

1.Primary Timber frame is established

4. CLT floor slab is boled through on the other side side

7.Timber crossbattens for the exterior facade and battens for the interior are fixed

8. Internal and external cladding are applied

Iteration 1

Iteration series 2

Materiality

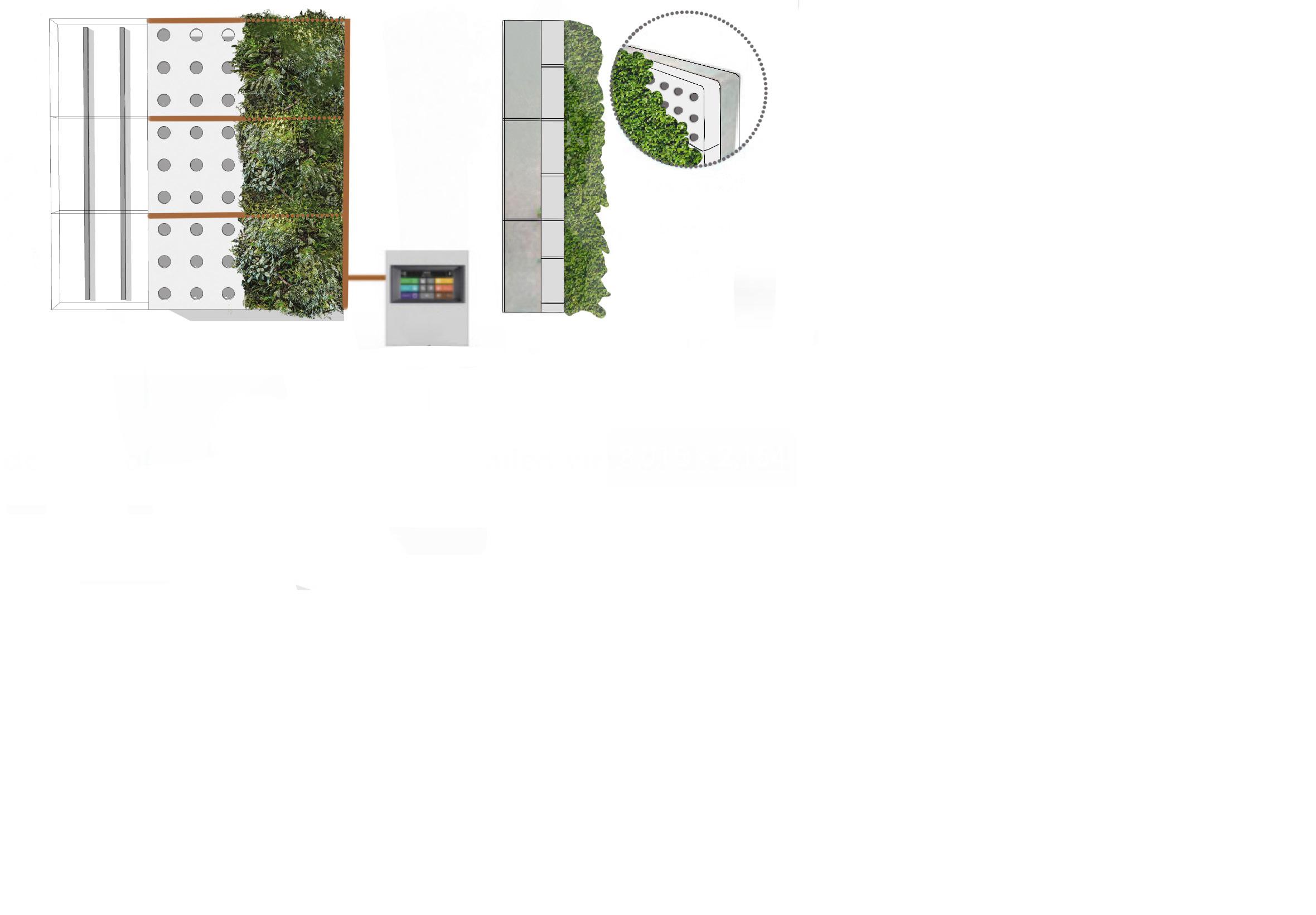

As iteration 2 was chosen the primary facade material becomes a crutial decision

Iteration 1

copper Advantages :

- Grade A1 fire safety with EN 13501-01 standard classification

- high durability and resistance to wind, resistant to corrosion

- natural patina and weathering

-lightweight

Disadvantages

- Copper cannot be around dissimilar metals and can potentially become a problem with steel bracing

- expensive

Iteration 2

Vertical timber boards

Advantages :

-Adds illusion of height

-prefered in areas of high rainfall and naturally more resistant to damp

-natural material and and phycologically healing

Disadvantages:

- low fire resistivity

Iteration 3

Horizontal timber boards

Advantages : -natural material and and phycologically healing

Disadvantages: -contrasts with the timber battens and aesthetically looks too busy - Low fire resistivity

Iteration 4

Vertical Rockpanel cladding

Advantages : -composite material with the appearance of wood and the properties of stone - colour stability and resistant to weathering - crucial as the fragment is part of the south facing facade.

- Grade A fire safety with EN 13501-01 standard classification - installation friendly - no need for pre drilling -transport friendly - lightweight -recyclable with no detriment to quality - allows for a breathable memberane

As fire safety and weathering were the primary concerns rockpanel cladding was chosen.

The iterations build on eachother to improve the existing system

Iteration 2

2.Bolt is positioned to receive gladding and MGB(miscanthus grass boards are bolted on)

Record of process

3. Secondary timber frame is established

5. Insulation is filled into the secondary frame

6.Insulation is placed on the floor slab and the vapour barrier and breather memberanes are attatched

9. Green facade trellis and internal finishes are added

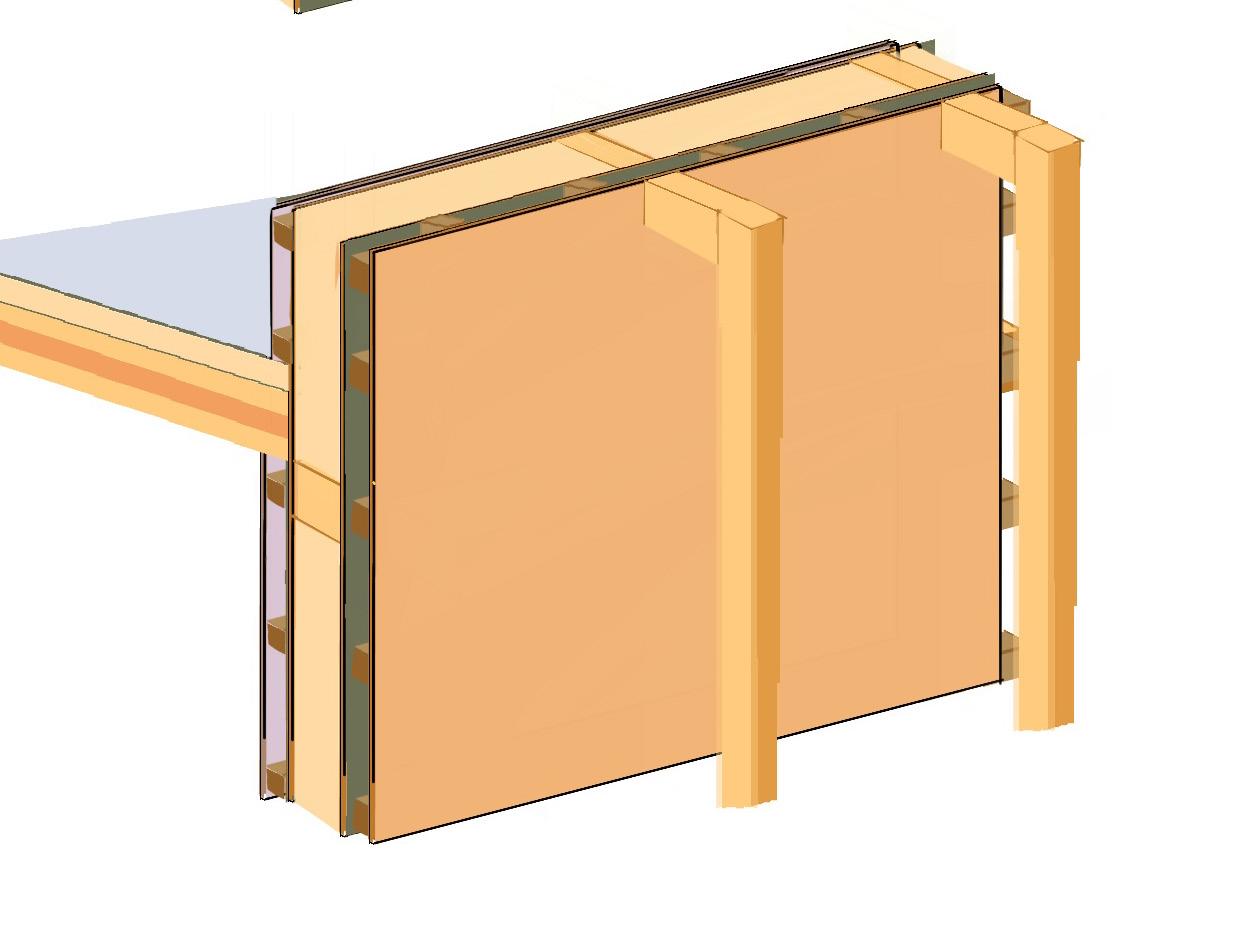

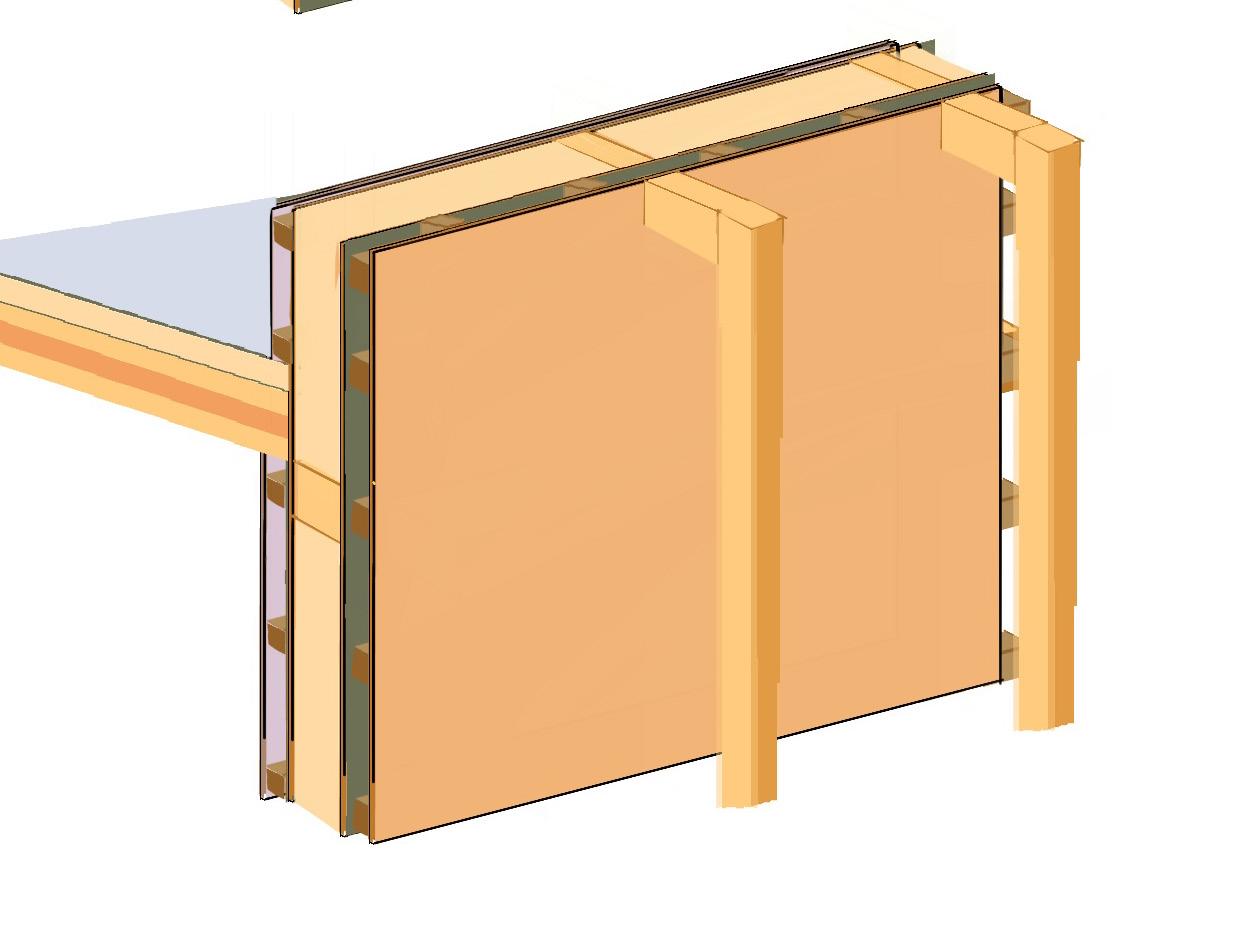

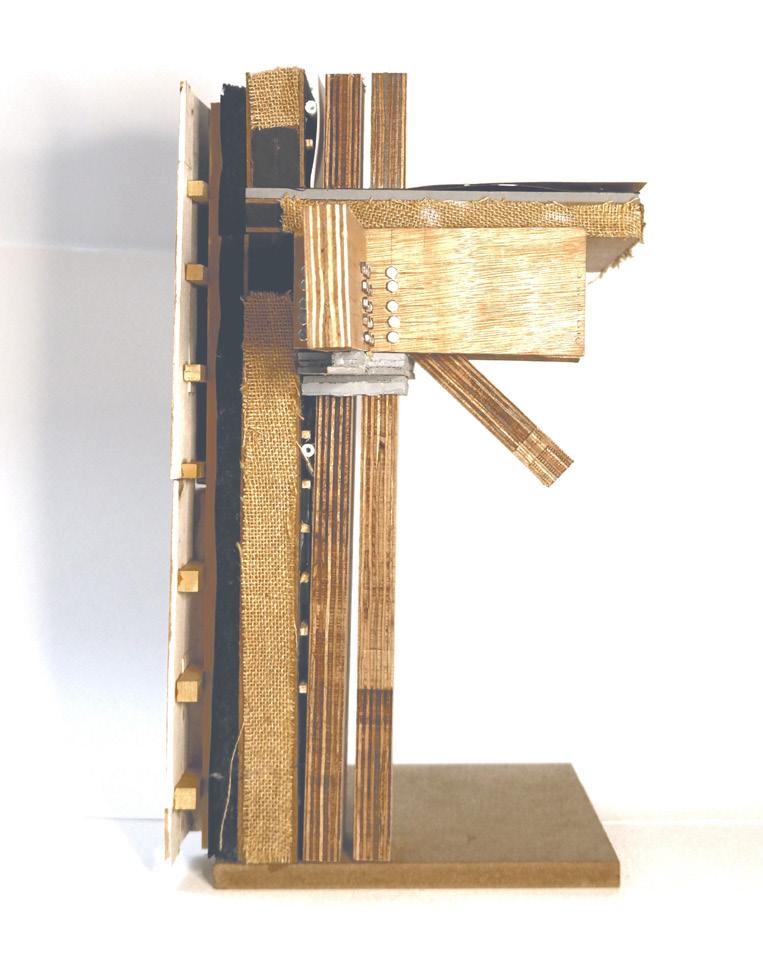

The iteration focuses on having continuous lines of waterproofing and breather membranes. However due to the natural insulation used the U vlaue is too high and does not meet the fabric first approach that I had specified in my technologies position. Moreover the combination of the CLT and OSB construction may not be ideal. Rather than gain the benefits of both construction typologies the result is unsteady.

1.Primary Timber frame is established 2.MGB and insulation creaes RSI panels which are bolted together to make the base of the floor

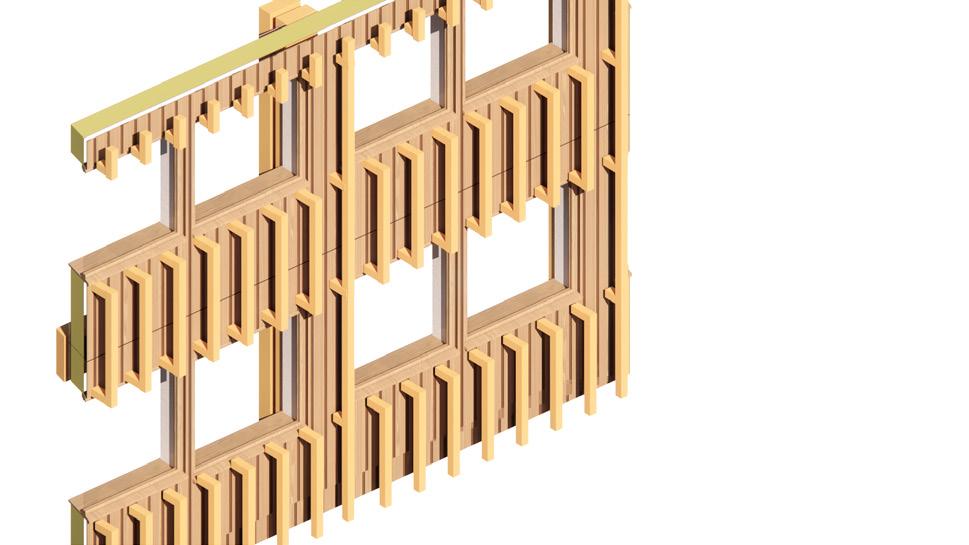

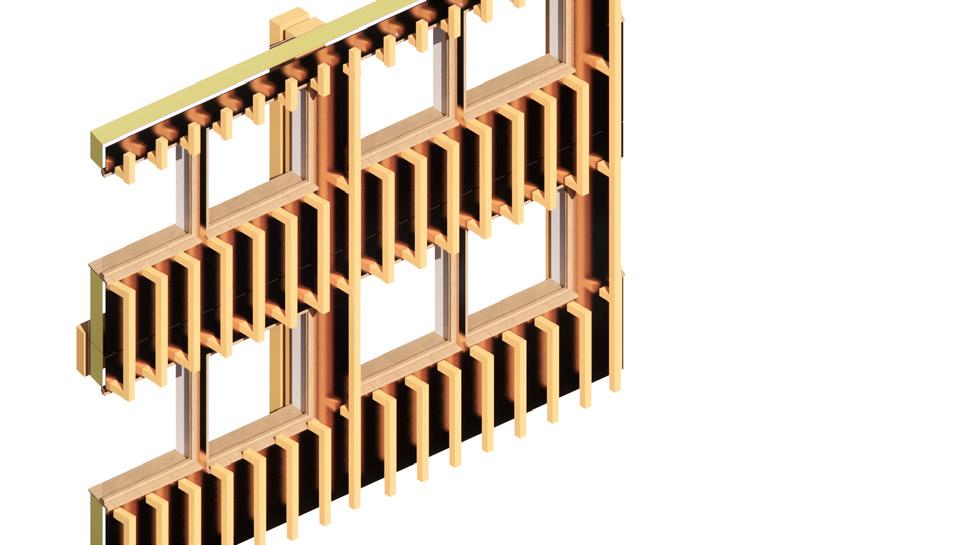

4. Larsen truss is created

5. Insulation is infilled

7. MGB is placed. continuous layers of vapour barrier and breather memberanes are attatched

8.Timber crossbattens for the exterior facade and battens for the interior are fixed

Iteration 2

3. MGB are bolted trhough. PVC fire insulation layers are added

6. pvc panels are used in snadwiching the insulation and creating a fire proof barrier

9. Internal and external cladding are applied. Green facade trellis and internal finishes are added

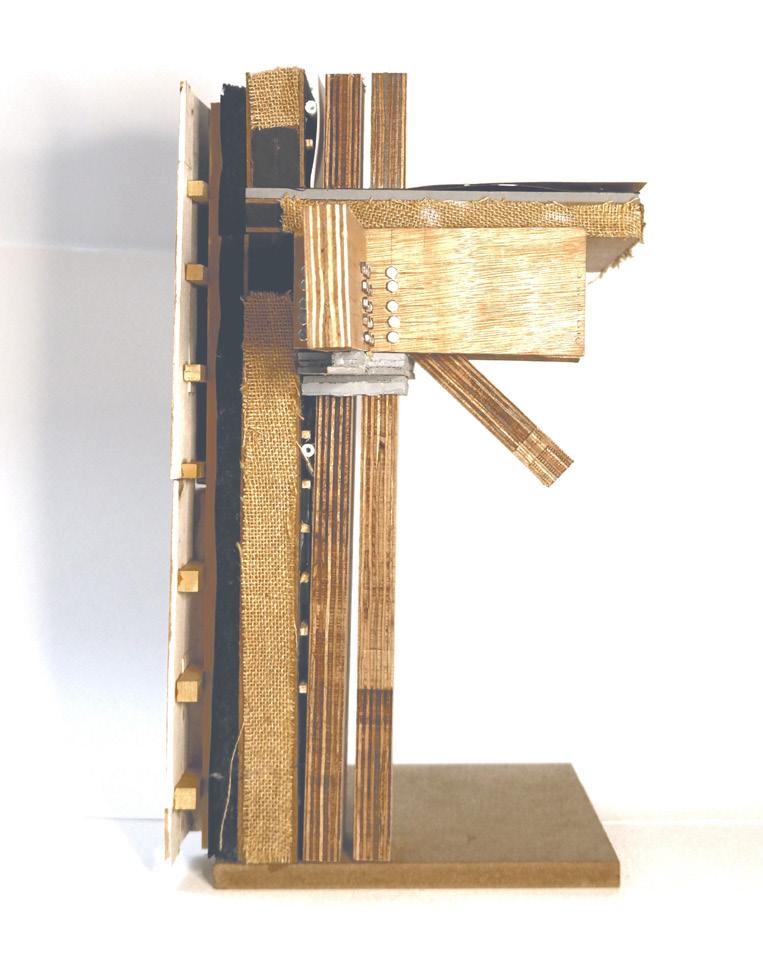

The second iteration builds on the first by introducing the larson truss system. This is a light weight non structural stud wall assembly theat allows for thicker insulation panels and conteracts the problems with the double stud wall construction seen in iteration 1. Furthermore as firesafety is a predominent concern in the building envelope PVC fire resistent sheets have been added to either side of the insulation to enhance it. Additionally the floor layers have acoustic insulation to reduce penetration of noice from the machinery and a false ceiling is introduced to allow for services. Though some of the problems first iteration have been rectified the U value still does not meet passive house standards and the mamranes need to be break free

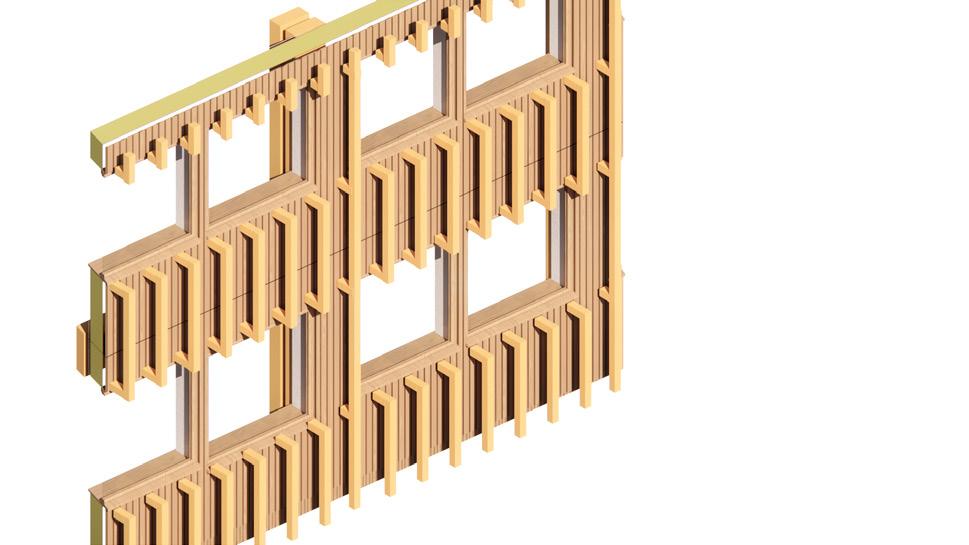

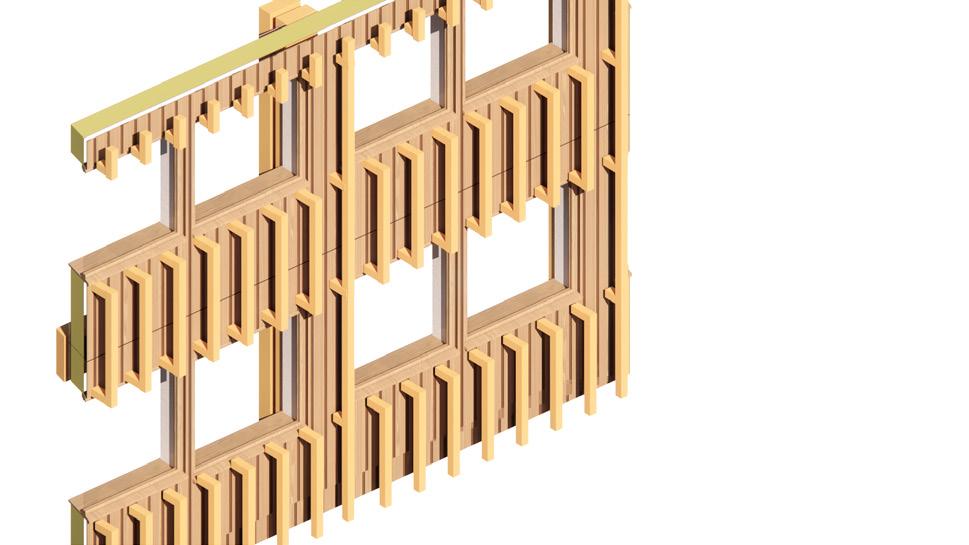

Iteration 3

1.Primary Timber frame is established

4. Second layer of rigid insulation and breathable sanding membrane attached to allow for a breathable facade

5. Timber crossbattens for the exterior facade are fixed

7. Trellis for the green facade are fixed

Iteration 3

2.Modular panels are prefabricated off site Panels are created by sandwiching, insulation supported by timber studs forming a Larsen truss, between two miscanthus grass boards. the panels form the secondary structure

3.continuous layers of vapour barrier and breather memberanes are attatched

6. external cladding is applied

8. Timber battens and interal finishes are applied. pipes are inserted into the servise void created.

9. Mechanical systems are installed

As the second green wall iteration was chosen the wall does not have its acoustic benefits. Additionally the insulation still does not meet passive house standards. The third iteration focuses on maximising insulation and adding a supplementary layer of insulation to meet passive haus standards and to aid with acoustic insulation. Rockwool was chosen as in addition to the above mentioned qualities it also offers fire resistance. PVC fire proof layers can be removed. Additionally the false ceiling for services was removed and exposed services was chosen as it enhanced the industrial aesthetic mentioned in the technologies position. an aluminium cap is used to cover wires

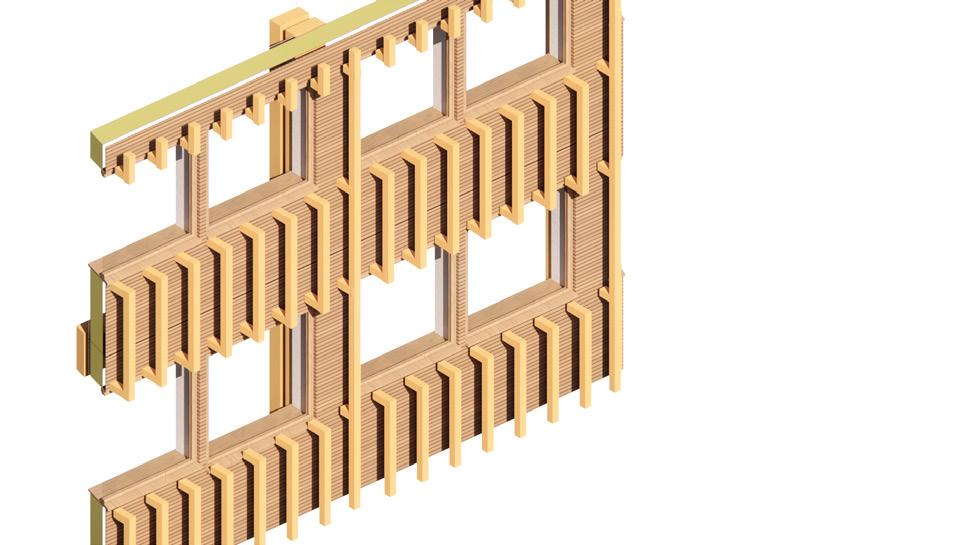

Iteration 3 allows for high levels of prefabrication which mean that the on site construction time is minimised. Additionally it is the iteration which embodies the fabric first approach and meets passive haus standars.

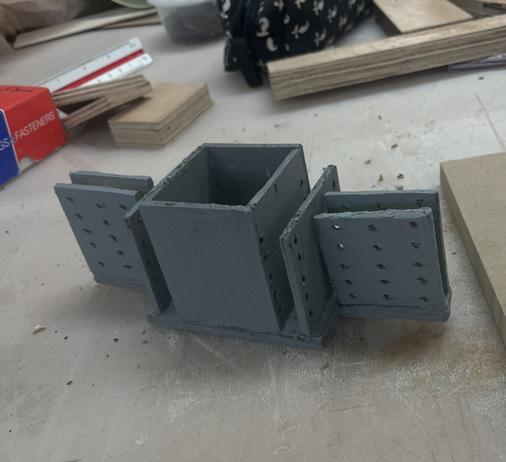

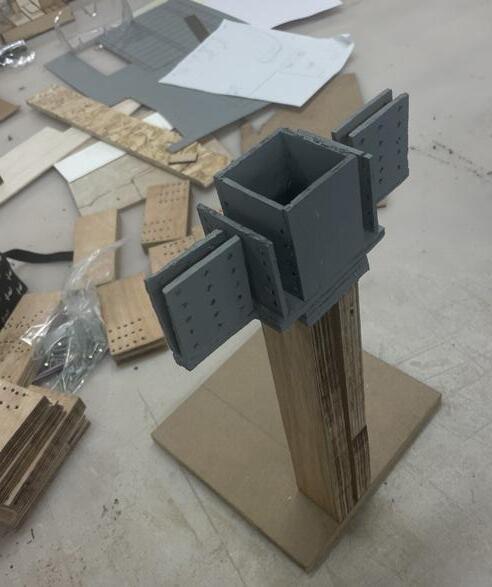

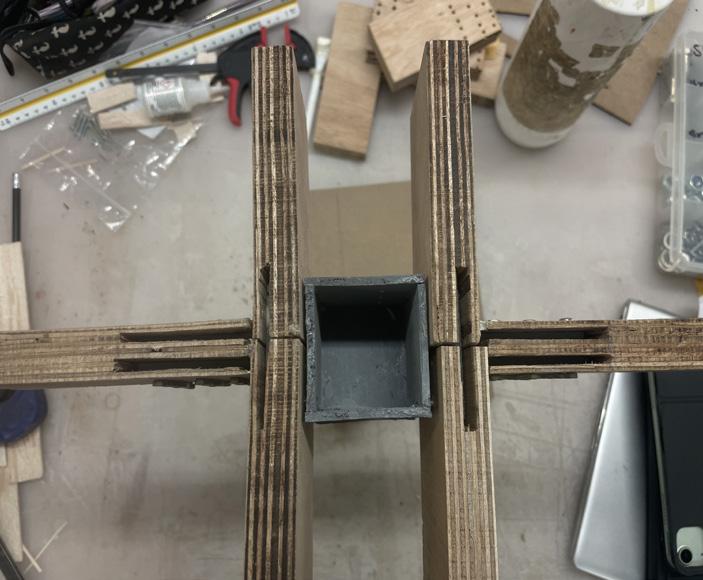

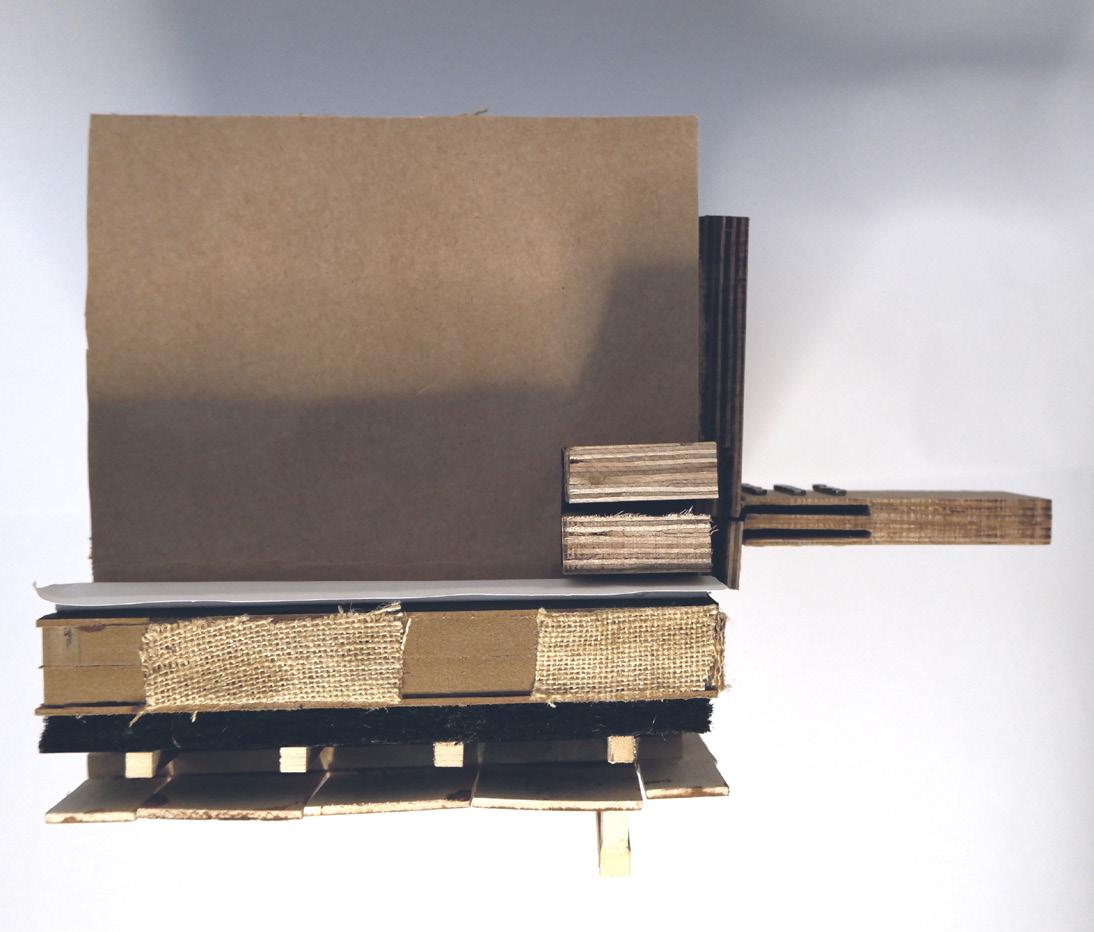

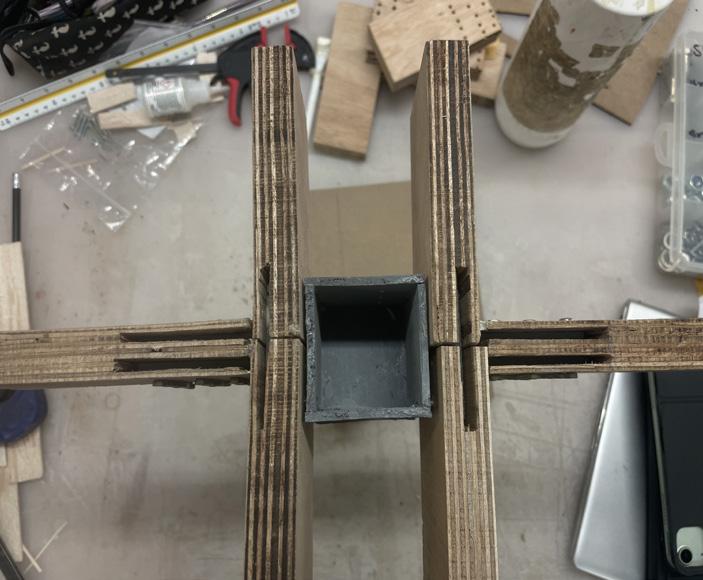

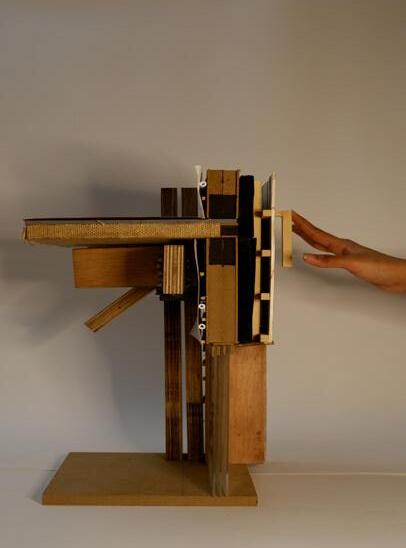

Reflections on constructability

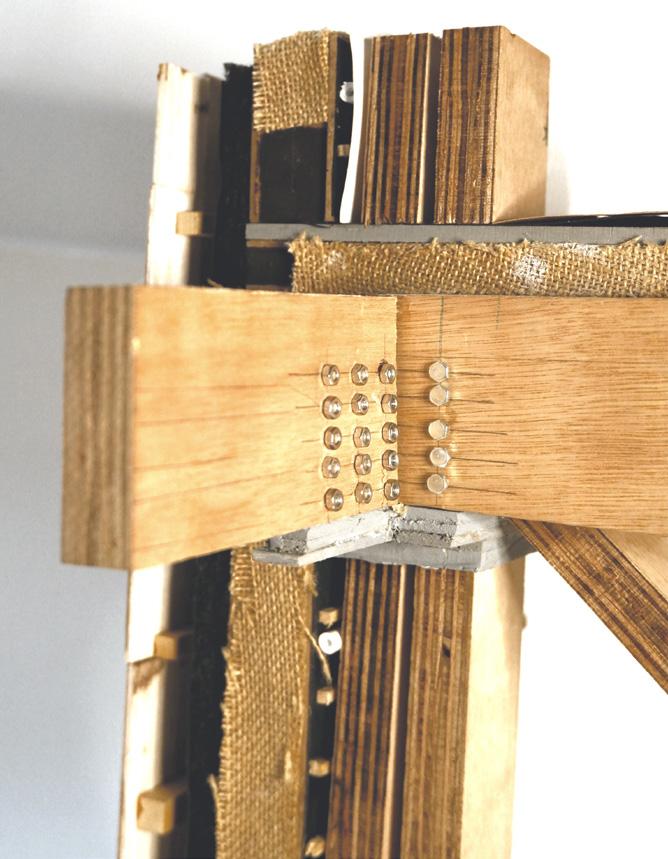

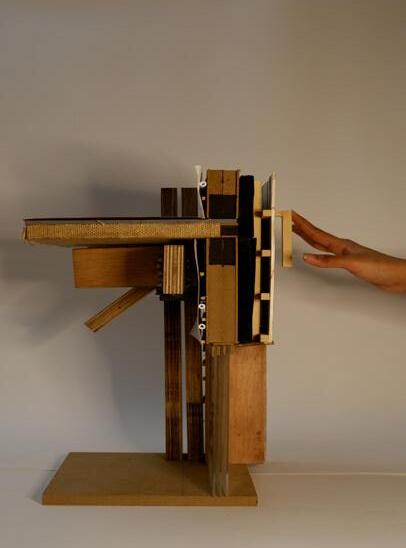

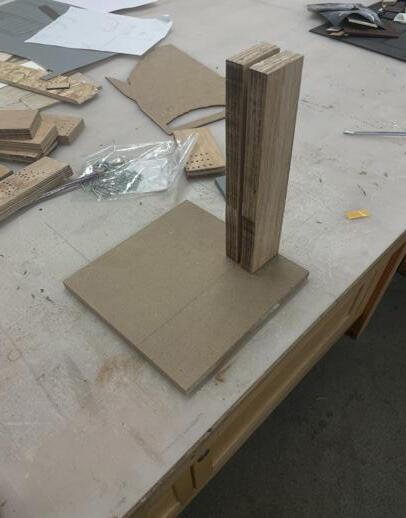

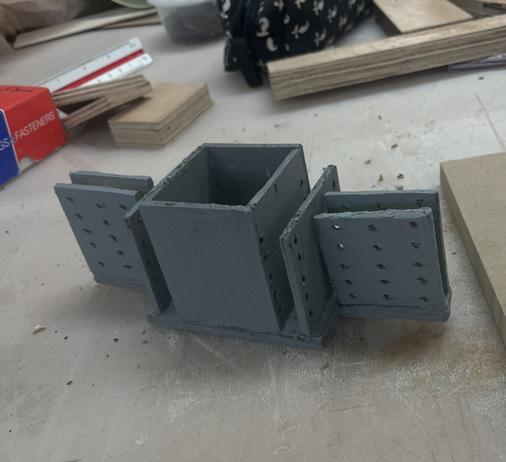

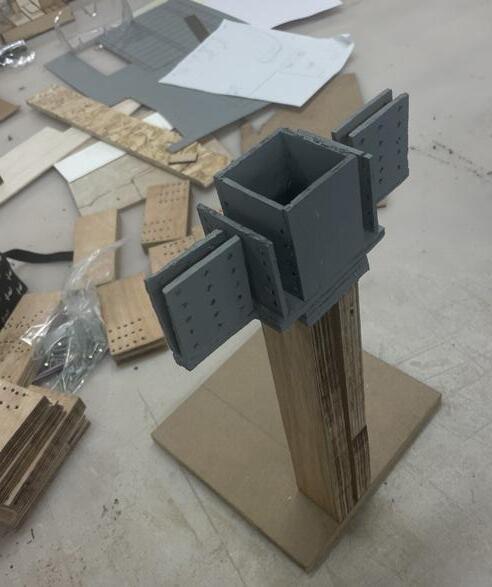

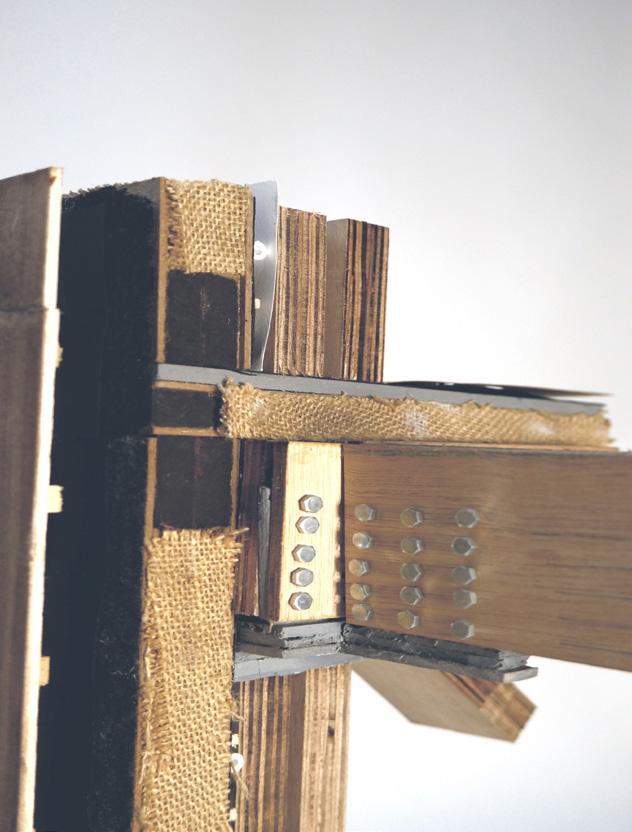

Both the model making process and the iterations on construction order were essencial in understanting how the different elements join and fit together and hurthermore how they interact with one another. understanding how different materials behave when bolted and welded together helped to undersand how to realise such a project rather than simply draw it.

Additionally both those aspects together make it possible understand the role of modularisation ( the insulation panels ) and prefabrication (insulation panels, bracing systems, primary timber structure - columns and beams). It made the disctinction between their uses clear and highlighted the importance of incooperating it within the design process to both allow for ease of construction and to resuce time needed for assembley on site. It would also go a long way in mitigating human error in a complex structure.

Reflections on Building life and safety

As my building houses a microbrewery the alcholol produced makes the building a level 5 fire hazard. This meant that building and life safety was at the forefront of my design considerations. The solutions to this were found in the green wall system coupled with the rockpanel system. The addition of rockwool insulation further strengthened this aspect of my design

heve to be reinforced to provide maximum structural stability. This is where additional steel ties underneath the structure was introduced. Additionally this is where I realised that prefabrication was nessecarry as assembley too 4 mins and 37 seconds but creating the elements and having them sit together took 6 hours.

Additionally thinking about construction in tandem with detail helped to think about how certain ways of detailing can complement certain methods of construction

Additionally the secondary concern regarding the design was focused on the weathering that the building experienced as a result of being in manchesters rainy climate and being a south facing facade. This was resolved by resolving the facade system. The green wall prevents weathering and additinally the rockpanel provides the aesthetic of wood while gaurenteing the anti weathering properties of stone. moreover the addition of the third memberane allowed for the system to be breatheable increasing both the buildings and the occupants health.

BA3 Technologies Deekshita Viju Nair SKN (Some Kind of Nature) Part C: TECHNICAL DETAIL STUDY; ARCHITECTURAL FRAGMENT - Sheet 2 ITERATIVE TESTING + RECORD OF PROCESS

water pump cooling system irrigation panel

The Green Facade

U value Wall: Rso = 0.06km2 Rsi = 0.12km2 R1 Rockpanel wood = 0.02m = 0.055 Km2/W R2 Straw insulation =0.24m = 3.809 Km2/W R3 MGB =0.04m =0.089 Km2/W 0.37W/(Mk) 0.063W/(Mk) 0.45W/(Mk) U value U= 1 0.06 + 0.12 + 0.055 +3.809 +0.089 U= 0.242 W/m2K U value Wall: Rso = 0.06km2 Rsi = 0.12km2 R1 Rockpanel wood = 0.02m = 0.055 Km2/W R2 Straw insulation =0.24m = 3.809 Km2/W R3 MGB =0.04m =0.089 Km2/W R4 PVC plastic coatng = 0.1 m = 0.83 Km2/W 0.12W/(Mk) 0.37W/(Mk) 0.063W/(Mk) 0.45W/(Mk) U value U= 1 0.06 + 0.12 + 0.055 +3.809 +0.089 + 0.83 U= 0.201 W/m2K U value Wall: Rso = 0.06km2 Rsi = 0.12km2 R1 Rockpanel wood = 0.02m = 0.055 Km2/W R2 Straw insulation =0.3m = 4.8 Km2/W R3 MGB =0.04m =0.089 Km2/W R4 rockwool insulation = 0.12 m = 3.43Km2/W 0.035W/(Mk) 0.37W/(Mk) 0.063W/(Mk) 0.45W/(Mk) U value U= 1 0.06 + 0.12 + 0.055 +4.8 +0.089 + 3..43 U= 0.117 W/m2K

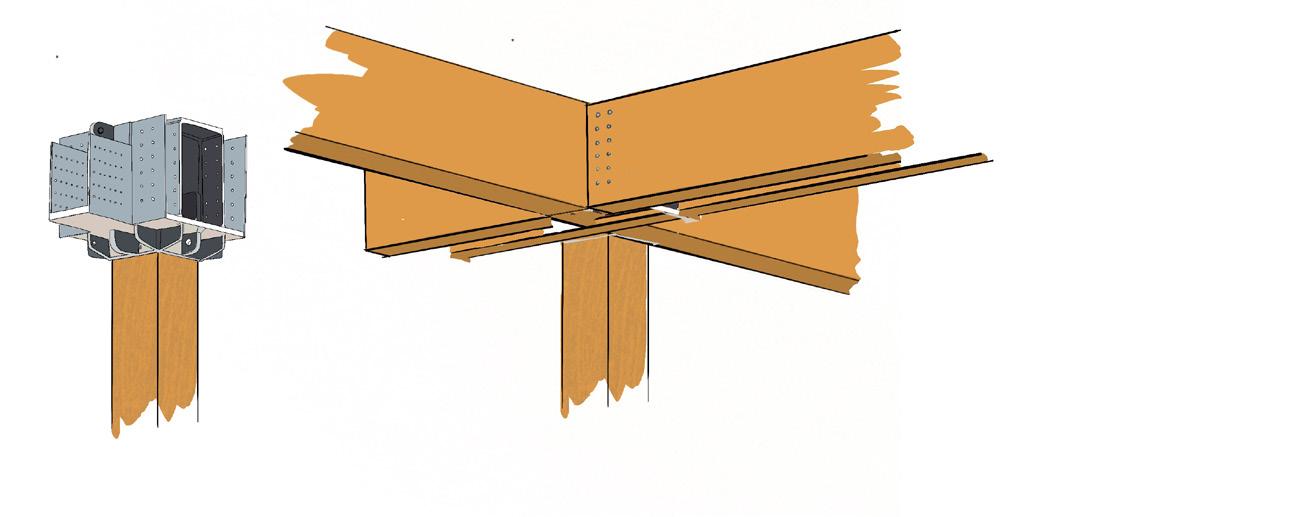

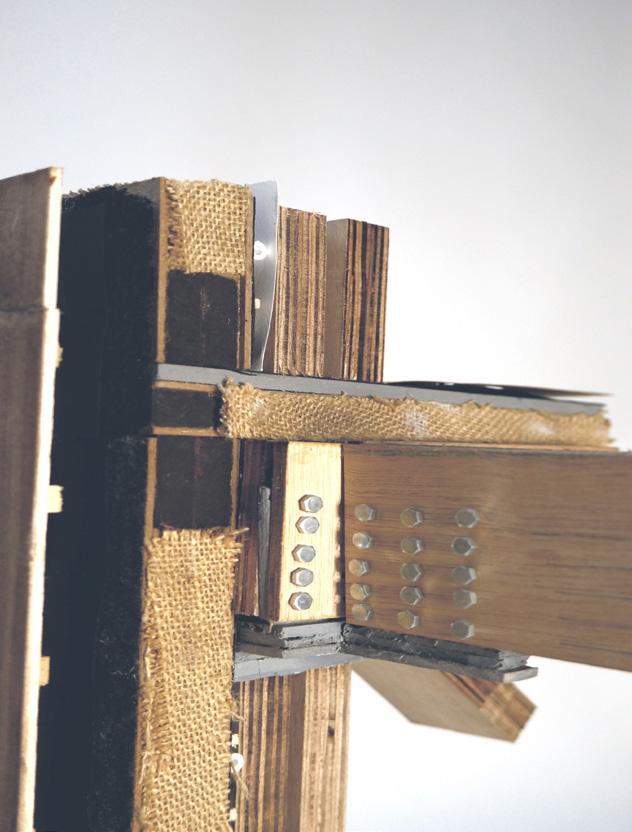

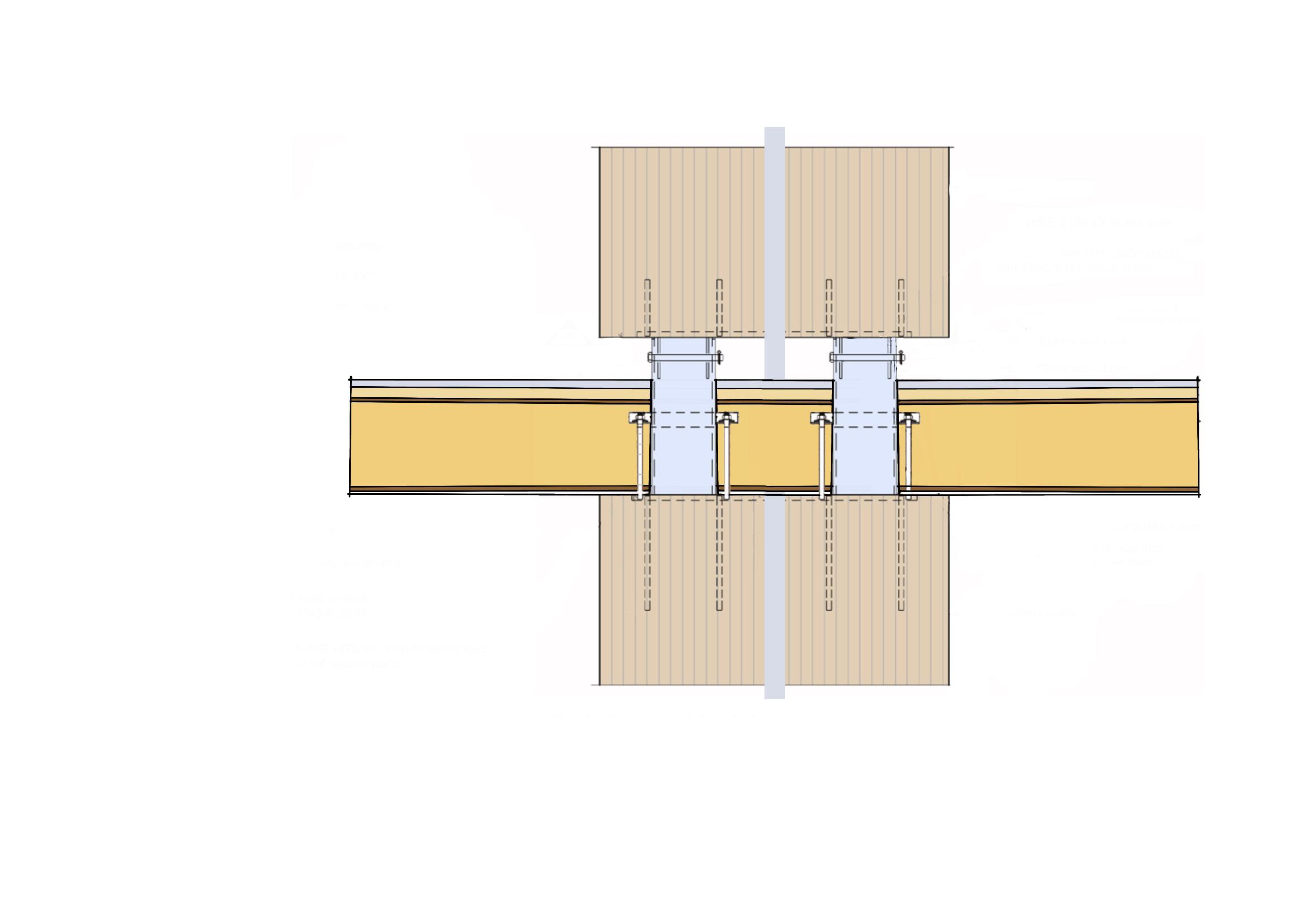

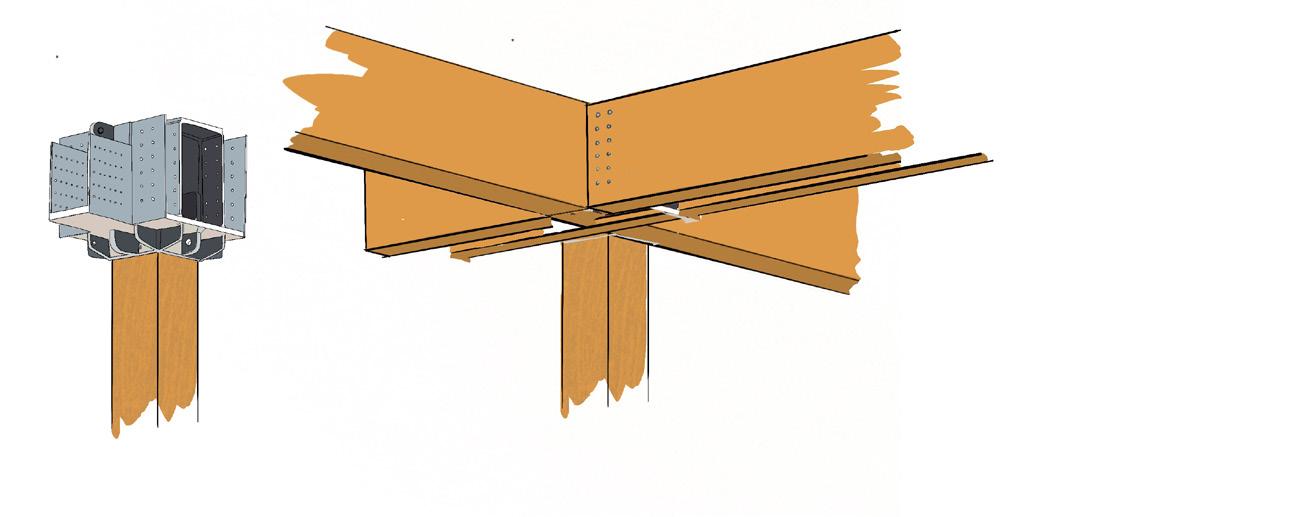

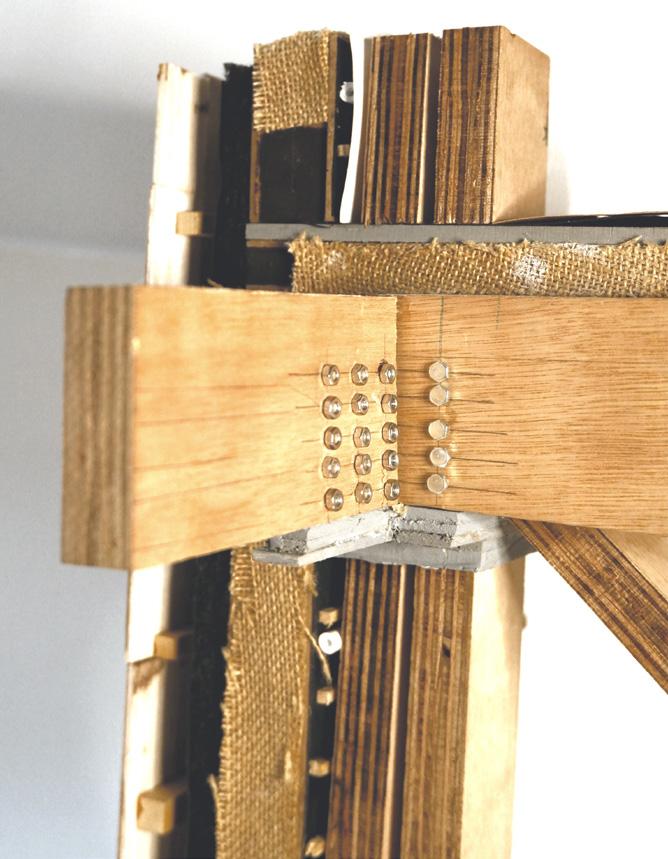

The structure of the building forms a non uniform grid and the large double height span combined with this meant a heavy timber frame. For transportation ease and ease of sourcing a double beam and column system was suggested by the structural engineer. However to have the assembly act as a single unified system rather than two separate systems additional bracing systems were required. I wanted a hidden bracing so the space looked cleaner and the flow of the wood was not interrupted providing a seamless and aesthetic interior. Therefore I experimented with a steel plate and dove tail joint system where the plates sit within prefabricated timber slots and only the bolts are visible externally. This was then intuitively tested and modelled. The bracing system will be used throughout the building and can be prefabricated to correspond to the angles of the building reducing the onsite assembly time. While modelling I learned that the structure would need ample metal bracing to work and the bracing structure itself would

The Materiality The materiality focuses on using locally grown and sourced materials. This makes the construction indeginous to manchester and creates a sence of identity between the site and the building. The idea of building local also provides a sense of place making Furthermore it reduces embodied energy and transportation. Furthermore as all the materials are natural and naturally sourced it makes the building a sustainable alternative to other forms of construction. Choosing materials with a low embodied energy to were also at the forefront of my design intentions. Aditionally triple glazed windows of u value 0.14 were used.

The insulation

A total of 420mm of insulation was used to make the building meet passive house standards while still using natural materials in the envelope. The fabric first approach was realised through this decision

The glulam used for the primary structure falls within strength class GL32 or GL36, as stipulated in the EN 14080 and in accordance with DIN 1052

Services Integrated HVAC, electrical and water systems. The Pipes run-through the exposed ceiling while the wires are concealed within the aluminium cap. All water and electrical wires are insulated to minimise heat loss via convection. The wires and pipes run down the service wall into the taps and power outlets. Exposed HVAC systems adds elements of metal in the building adding to the industrial feel of the building and mimicking the industrial past of the site

Life cycle

The building is designed to last for 100 years with basic repairs and maintenance. exposed services also increase the ease of servicing and allow systems to be replaced with minimal fuss. A carbon monitoring system could be implemented to track how the building performs over time.

The Wall build up The double layers of weatherproofing across the ventilated cavity prevents the formation of mold or rot on the inside of the cladding and this is especially crucial due to the green wall system. The insulation is build up around the larsen truss system. This allows for thick layers of insulation to be erected while maintaining no thermal breaks . The MGBs act as bracing on either side of the insulation and aid in transportation.

Reflections

The study was crucial in understanding how things go together ands how to make them go together better. Through the iteration process and by approaching the tasks in a critical manner the understanding of the individual elements of the fragment become clear. This process of questioning design decisions at a smaller scale will be taken forward into my studio work. Here the construcabilty influenced aesthetic and inturn materiality. More over it was crucial to understand for the climate emergency, building life and safety and constructability all influence eachother most prominently seen in my third iteration series . Model making will also be more of a feature in my furute work as it provides a tangible understanding of what works and what may need a better solution or different order of working.

Orthographic Projections

Bracing between columns for additional stability

Construction sequence

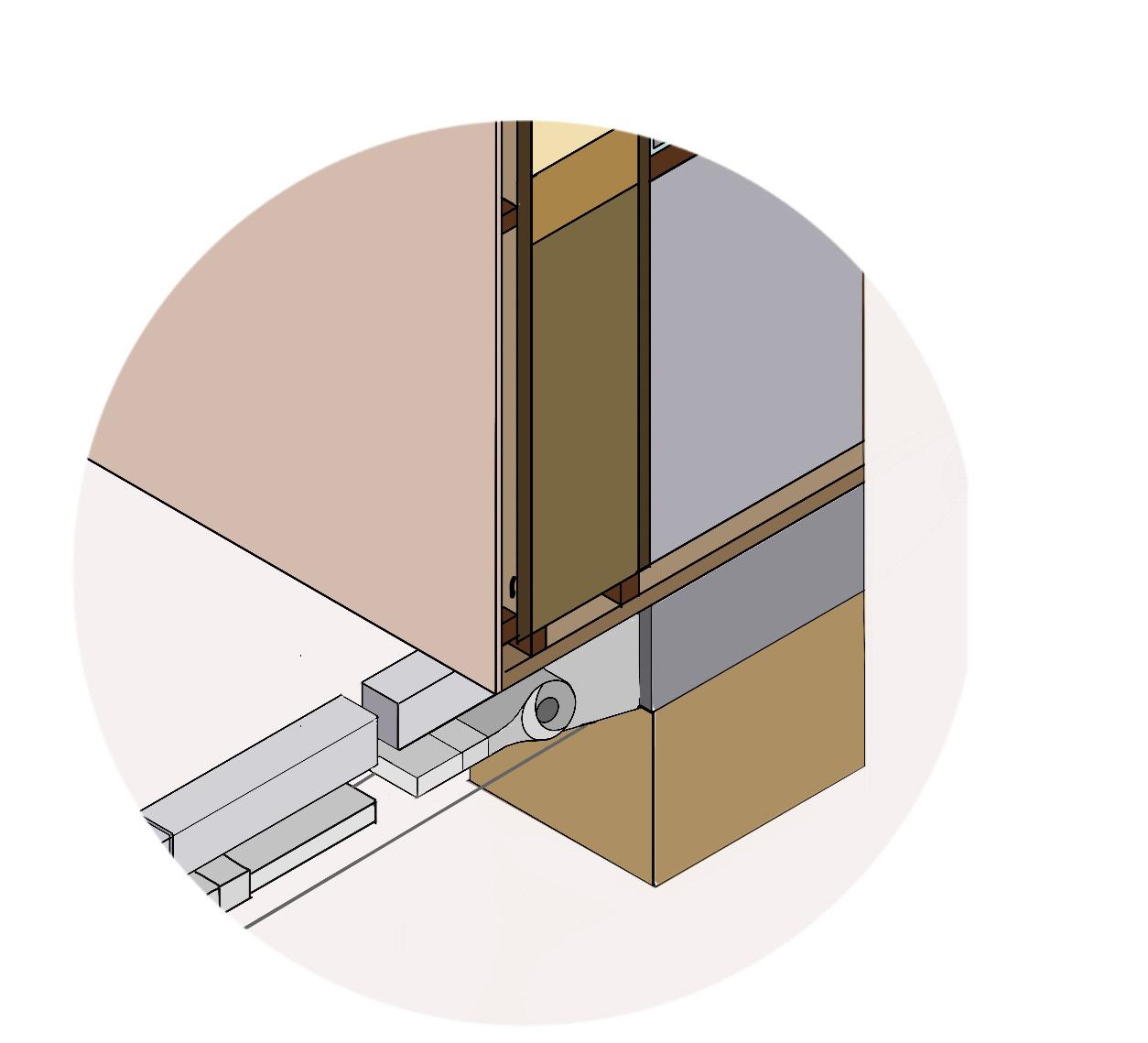

Floor to column bracing detail

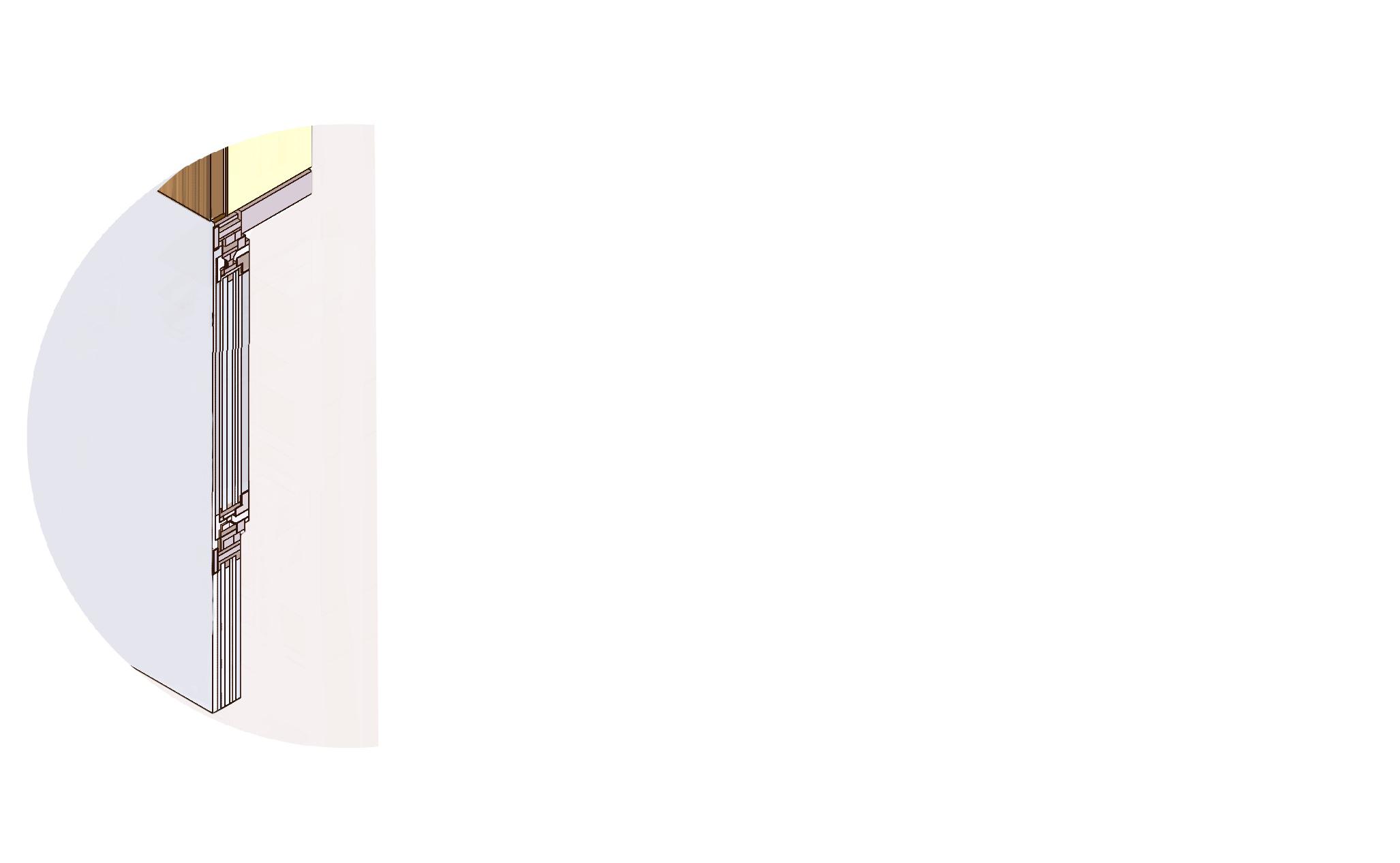

Axonometeric Projections Understanding the interior and exterior spacial qualities The Fragment

BA3 Technologies Deekshita Viju Nair SKN (Some Kind of Nature) Part C: TECHNICAL DETAIL STUDY; ARCHITECTURAL FRAGMENT - Sheet 3 INTEGRATIVE SYSTEMS + DESIGN CONCLUSIONS Technologies Detail Integrative systems / Design Conclusions Bracing system 1) Floor build up 12mm oak parapet flooring water proof membrane 40mm acoustic insulation (impact sound mat) 20mm Miscanthus Grass OSB boards 180mm Straw bale insulation 20mm Miscanthus Grass OSB boards Vapour control barrier Plaster ceiling finish. Beams heald together by 30mm hex head bolts 1 2 2) Wall build up Wooden Trellis structure 20mm Rock Panel Wooden cladding 50 x 50 battens and counter battens forming ventilated cavity Kingspan nilvent breathable sanding membrane 120 mm rockwool insulation Breathable membrane 20mm Miscanthus Grass OSB boards 300mm Straw bale insulation 20mm Miscanthus Grass OSB boards Vapour control barrier 25 x 25 battens forming service void Plaster boards with blanchon extrawhite wax oil finish

Elements are prefabricated off site Columns are erected Bracing structure fixed to column Beams bolted to bracing structure Prefabricated panels are attached to the primary frame Breathable membrane and secondary insulation are attached continuous vapour barrier membrane and breathable sanding membrane are attached Timber crossbattens for the exterior facade are fixed Rockpanel cladding is attached internal battens are fixed and pipes are installed window is inserted and window sill is placed internal wall and floor finish along with trellis structure are attached

Operable window detail